Page 1

Model

Model

V640-HAM11-V4

V640-HAM11-L-V2

Amplifier Unit

INSTRUCTION SHEET

Thank you for selecting OMRON product. This sheet primarily describes precautions required in installing and

operating the product.

Before operating the product, read the sheet thoroughly to

acquire sufficient knowledge of the product. For your convenience, keep the sheet at your disposal.

TRACEABILITY INFORMATION:

Representative in EU:

Omron Europe B.V.

Wegalaan 67-69

2132 JD Hoofddorp,

The Netherlands

OMRON Corporation All Rights Reserved.

©

PRECAUTION FOR SAFE USE

1.Ensure safety, be absolutely sure to follow the instructions below:

(1) Never use the product in an environment where combustible or explosive

gas is present.

(2) Please separate from a high-pressure equipment and the power

equipment to secure the safety of the operation and maintenance.

(3)

In the installation, please tighten the screw surely. (Recommended 1.2N・m)

(4) Please do not insert foreign bodies such as water and the wires from the

space of the case.

(5) Please do not dismantle, repair or modify this product.

(6) Please process as industrial waste when you abandon this product.

(7) When you work on wiring and put on and take off cables, CIDRW head,

please perform it after switching off this product.

(8) Provide enough space around this product for ventilation.

(9) Please avoid installing this product near the machinery (a heater, a

transformer, large-capacity resistance) that has high the calorific value.

(10) Please talk to our office by any chance after you cancel use immediately

when you felt abnormality to this product, and having switched it off.

PRECAUTION FOR CORRECT USE

1.About installation site

Do not install this product in the locations subject to the following conditions.

(1)Place where direct sunshine strikes

(2)Place with corroded gas, dust, metallic powder, and salinity

(3)Place with condensation due to rapid temperature fluctuations.

(4)Place with condensation due to high humidity.

(5)Place where vibration and impact more than being provided by

specification are transmitted directly to main body.

(6)Place with spray of water, oil, and chemical medicine.

(7)

The working temperature is within the range stipulated in the specifications.

2.About depository site

(1)

Please follow the save ambient temperature / humidity, and keep this product.

3.About wiring

(1)Use the power supply voltage specified in this cocument.

(2)

Ensure correct polarity when connecting to the +/- power supply terminals.

(3)Do not run high-voltage lines and power lines though the same conduit.

(4)To avoid static-induced failure, wear a wrist band or equivalent means

to release a static charge before touching a terminal or a signal line

within a connector.

(5)When you put on and take off a CIDRW head, please do not add

excessive power to a connector.

(6)Please connect the correct CIDRW head to the amplifier unit.

Manufacturer:

Omron Corporation,

Shiokoji Horikawa, Shimogyo-ku,

Kyoto 600-8530 JAPAN

Ayabe Factory

3-2 Narutani, Nakayama-cho,

Ayabe-shi, Kyoto 623-0105 JAPAN

2015

4.About cleaning

(1)Use alcohol to clean this product.

(2)NEVER use an organic solvent such as thinner, benzene, acetone or

kerosene, as it will attack resin components or case coating.

5.Power and Graound Cables

(1)Use an appropriate ground. An insufficient ground can affect this

product operation or result in damage to this product.

6.About the communication range and time

(1)Do the communication test with Transponder in the installation

environment because the metal, noise and ambient temperature around

CIDRW head damage to the communication range and time.

(2)Install CIDRW head and ID tag in the appropriate distance because the

communication range can change by the difference of ID tag

specifications.

7.About mounting

(1)This product communicates with ID Tags using the 134 kHz frequency

band. Some transceivers, motors, monitoring equipment, and power

supplies (power supply ICs) generate electrical waves (noise) that

interfere with communications with ID Tags, If you are using the

product in the vicinity of any of these devices, check the effect on

communications in advance.

(2)In order to minimize the effects of noise, ground nearby metal bodies

with a grounding resistance not exceeding 100 ohms.

(3)When multiple CIDRW Heads are mounted next to each other,

communications performance could be impaired by mutual

interference. Read and follow the information in this manual on mutual

interference when installing multiple heads.

(4)When mounting CIDRW Heads, tighten the screws tightly.

(Recommended 0.6N・m)

8.Screw Locking Adhesive

(1)Screw locking adhesive (screw lock) may cause deterioration and

cracking of resin parts; do not use it for screws in resin parts or

anywhere where resin washers are used.

9.Communications with the Host Device

(1)Communicate with the host device only after confirming that the

CIDRW Controller has started. Also, unstable signals may occur at the

host interface when the CIDRW Controller is started. When initializing

operation, clear the reception buffer at the host device or take other

suitable methods to clear unwanted signals.

10.Startup precaution

(1)Never turn OFF the power supply while the CIDRW Controller is

starting, including when power is turned ON, when the mode is

changed, or when the CIDRW Controller is being reset. Doing so may

damage the CISRW Controller.

11.About Transponder and RF module made by Texas Instruments Co.

(1)We can’t warrant the specifications of the communication with

Transponder and RF module.

(2) When the RF module is at fault, we can’t analyze the RF module.

12.The characteristics of the V640-HAM11-V3 / V640-HAM11-V4

(1)It is a circuit, designed to communicate characteristics match, but

because it is intended to carry out the communication with RF module

and the transponder, can not be guaranteed.

■General specifications

Characteristic

Supply voltage

Current consumption

Protection rating

Ambient

temperature

Ambient

humidity

Insulation

resistance

Dielectric

Vibration

resistance

Shock resistance

Environmental

pollution degree

Over voltage category

Mounting system

CIDRW head

Applied standards

V640-HAM11-V4

24 VDC, +10%, -15%

150 mA max

IP20 (IEC 60529)

Operating: 0℃ to +40℃ Storage: -15℃ to +65℃

(No freezing, No dew condensation)

Operating/ Storage: 35% to 85%

(No freezing, No dew condensation)

20MΩ min. (100V DC for appliance)

(between power supply terminal and

frame grounding terminal)

1000V AC (50/60Hz, for 1 min.)

leak current consumption 5mA max.

(between power supply terminal and

frame grounding terminal)

10 to 150Hz, 0.20mm double amplitude,

acceleration 15m/s2, with 10 sweeps of

8min each in 3 directions

150m/s

Degree 2

CategoryⅠ

Secured with four M4 screws.

(tightening torque:1.2 N・m)

V640-HS61

USA / Europe / Japan / Canada

Specification

V640-HAM11-L-V2

400 mA max

2

, 3 times each in 6 directions

V640-HS62

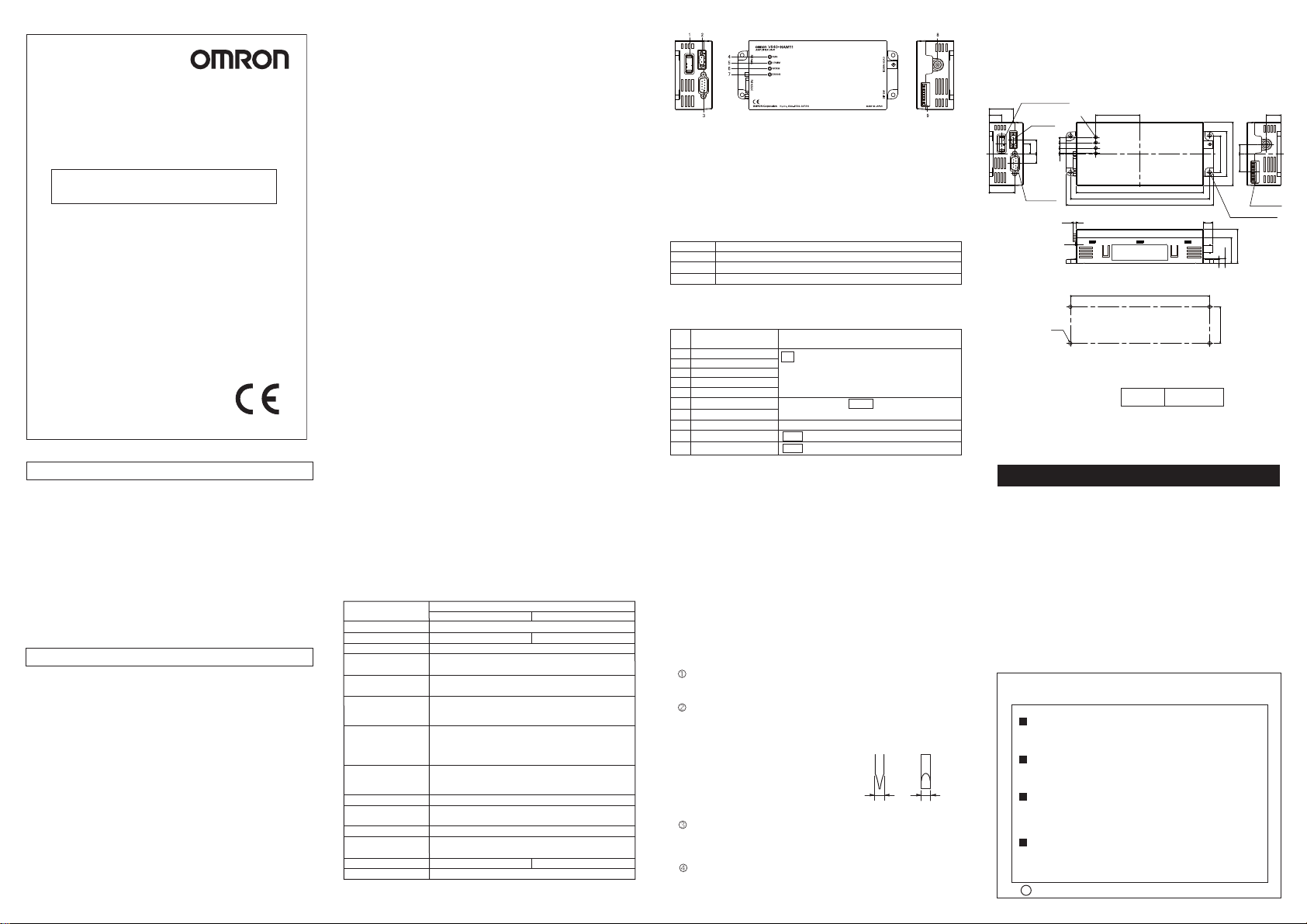

■Names and functions

●RS-232C port (3)

This port is for connection to the host or the CIDRW controller: V700-L22

according to RS-232C interface standard.

●RS-485 port (2)

If two or more Amplifier units are connected to one RS-232C port of a

host or a CIDRW controller: model V700-L22, this RS-485 port is

connected to a RS-485 port on another amplifier unit. An RS-485 port (if

any) on the host can be connected to this port. However the RS-232C port

and the RS-485 port are unable to be used at the same time.

●CIDRW head connection port (8)

A port dedicated to connection of a CIDRW head.

●Status indicators (4 -7)

Four indicator lamps (RUN, COMM, NORM, ERROR) indicate the

current operating status of the amplifier unit.

RUN

Remains stably lit as long as the link unit is operating normally.

COMM

Remains lit during the communication with a host or an ID tag.

Lights when the communications with an ID tag are successful.

NORM

Lights when the communications with an host or an ID tag are failed.

ERROR

●Setup DIP-SW (9)

This switch array allows the operator to assign ID No. to amplifier unit

and define various operating conditions.

DIP-SW settings: factory-setting is all OFF

No. Description

1

Node No.1

Node No.2

2

3

Node No.3

4

Node No.4

Node No.5

5

6

Baud rate setting 1

7

Baud rate setting 2

Reserved

8

Test mode

9

10

RS-485 terminator

・Set the RS-485 terminator setting to ON for the amplifier units on both

ends of multidrop, and to OFF for other units.

If only one amplifier unit is operated, set the terminator setting to ON.

●24VDC power terminals (1)

・Recommended cable : AWG20 - 24

・Recommeded connector : Model 1-178288-3 (Tyco Electronics Co.)

・Recommended compression ring : Model 175217-3

(Tyco Electronics Co.)

(These connector and compression ring are supplied with model V640-A90.)

・Recommended 24 V power supply : Model S8VS-01524(OMRON)

*Use the product below as a crimping tool for crimping the compression ring.

Model 919601-1 (Tyco Electronics Co.)

■Cables for RS-485 port

・Recommended cable : Model MVVS 2CX0.5SQ

(Tachii Densen Co.)

・Recommended compression ring : Molde AI0.5-8WH (Phoenix Contact Co.)

*The following product is recommended as a compression ring for

connecting two cables to one terminal. Model AI-TWIN2 ~0.5-8WH

(Phoenix Contact Co.)

Use the product below as a crimping tool for crimping the compression ring.

*

Model CRIMPFOX UD6 (Phoenix Contact Co.)

■How to connect cables

Fit a compression ring to the stripped section of each cable.

Next, being sure of the connector orientation, insert each

cable into a corresponding hole on the connector.

Securely fasten each cable using the cable locking screw on the

connector.

An ordinary screwdriver whose shank is tapered at the tip does not go all

the way into the hole. Use a miniature flat-blade screwdriver with a

straight shank. Tighten the cable locking screws at an appropriated

tightening torque (approx. 0.3 N・m).

The following purpose-built screwdriver is available:

OMRON: Model XW4Z-00C

Connect the connector to the amplifier unit together with the cables.

Match the orientation of amplifier unit side connector with that of cable side

connector, insert the cable side connector all the way, and then tighten the

connector lock screws.

When removing the connector, fully loosen the two lock screws and draw out it

straight by holding the protrusions on connector.

If the connector does not easily come loose, draw it out while holding down the

link unit proper.

Meaning (Content within a box

represents factory-setting)

01〜31 No. 1 is LSB, and No. 5 is MSB.

When all switches are ON,this amplifier

unit selects 1:1 protocol.

38400/19200/ 9600 / 4800bps

[ON,ON][ON,OFF][OFF,OFF][OFF,ON] : [No7,No6]

Please turn off this SW.

OFF / ON

OFF / ON

Side view

From of drip:

Front view

0.6mm 3.5mm

■Dimensions

24VDC power terminals

(30.2)

(15.8)

(32.5)

*

Be sure to limit the tightening torque for the M4 screws as 1.2 N・m.

RS-485 port

(13)

(17.75)(12)

RS-232C port

6.8

6.8

6.8

0.6

4-M4

OPERATING

INDICATOR

(4.2)

(1)

55.5

160

175

185

175

±0.5

MOUNTING SCREW HOLES

material PC+ABS

(11.5)

(12)

465680

(22.5)

4-φ4.5 dia.

(MOUNTING HOLES)

43

7)

(32.5)

(5.

5

46±0.5

(Unit: mm)

Suitability for Use

Omron Companies shall not be responsible for conformity with any standards,

codes or regulations which apply to the combination of the Product in the

Buyer’s application or use of the Product. At Buyer’s request, Omron will

provide applicable third party certification documents identifying ratings and

limitations of use which apply to the Product. This information by itself is not

sufficient for a complete determination of the suitability of the Product in

combination with the end product, machine, system, or other application or

use. Buyer shall be solely responsible for determining appropriateness of the

particular Product with respect to Buyer’s application, product or system.

Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS

RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE SYSTEM

AS A WHOLE HAS BEE

THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR

SYSTEM.

See also Product catalog for Warranty and Limitation of Liability.

OMRON Corporation

Tokyo, JAPAN

Regional Headquarters

OMRON EUROPE B.V.

Sensor Business Unit

Carl-Benz-Str. 4, D-71154 Nufringen, Germany

Tel: (49) 7032-811-0/Fax: (49) 7032-811-199

OMRON ELECTRONICS LLC

2895 Greenspoint Parkway, Suite 200

Hoffman Estates, IL 60169 U.S.A.

Tel: (1) 847-843-7900/Fax: (1) 847-843-7787

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08 (Lobb y 2),

Alexandra Technopark,

Singapore 119967

Tel: (65) 6835-3011/Fax: (65) 6835-2711

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120, China

Tel: (86) 21-5037-2222/Fax: (86) 21-5037-2200

s

Oct, 2014

D

N DESIGNED TO ADDRESS THE RISKS, AND

Industrial Automation Company

Contact: www.ia.omron.com

(18.2)

DIP SWITCH

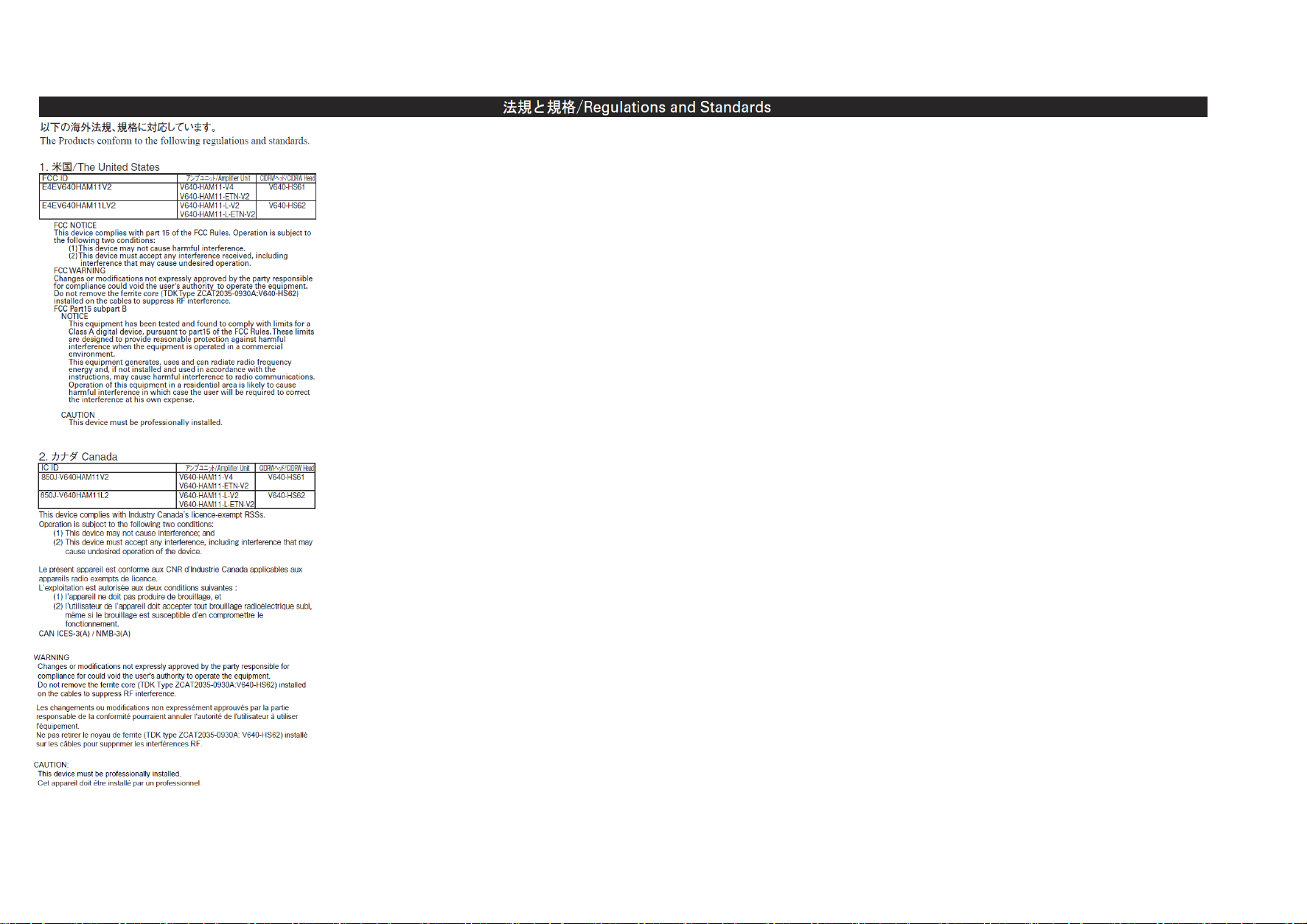

Page 2

Loading...

Loading...