Page 1

Intelligent Flag I/II

V600-HA

Innovative RFID Electronic Flags to

Replace Mechanical Flag and Kanban

Systems

• Doesn't need a program and can be used like a sensor.

• Advanced line construction at minimal cost.

• Saves space.

• Precise installation not required (Transmission distance:

100 mm max.).

• A verification function provided on multi-functional type.

• Addition of 16-bit models to the series responds to applications from Kanban to quality control.

• Equipped with a wiring reduction mode and communications

parity check function (16-bit models).

• Both NPN and PNP output available.

• FCC certified.

Ordering Information/Specifications

■ Amplifier

Type Read-only (8-bit) Multi-functional (8-bit) Read-only (16-bit)

Item Model V600-HAR91 V600-HAR81 V600-HAM91 V600-HAM81 V600-HAR92

Power supply 24 VDC ±10%, ripple (p-p): 10%

Current consumption 130 mA max.

Input Transistor output or contact output

Output

Diagnostic functions Checks for CPU errors and transmission errors

Insulation resistance 50 MΩ max. (at 500 VDC) between cable terminals and case

Dielectric strength 500 VAC, 50/60 Hz for 1 min between cable terminals and case (leakage current: 1 mA max.)

Short-circuit current: 3 mA (typical) (IN terminal and 0-V short-circuit)

OFF voltage: 15 to 30 VDC

ON voltage: 0 to 5 VDC

Input impedance: 8.2 kΩ

Applied voltage: 30 VDC max.

NPN open collector

output, 20 mA max. at

30 VDC, residual voltage: 2 V max.

PNP open collector

output, 20 mA max.

at 30 VDC, residual

voltage: 2 V max.

NPN open collector

output, 20 mA max. at

30 VDC, residual voltage: 2 V max.

PNP open collector output, 20 mA max. at 30

VDC, residual voltage: 2 V

max.

Transistor output

OFF voltage:

15 to 30 VDC

Input impedance:

8.2 kΩ

Short-circuit current:

3 mA (typical) (for 0-V short-circuit of

INHIBIT/TRG)

ON voltage:

0 to 5 VDC

Applied voltage:

30 VDC max.

NPN open collector output, 20 mA

max. at 30 VDC, residual voltage: 2 V

max.

2 Intelligent Flag I/II V600-HA

Page 2

Type Read-only (8-bit) Multi-functional (8-bit) Read-only (16-bit)

Item Model V600-HAR91 V600-HAR81 V600-HAM91 V600-HAM81 V600-HAR92

Vibration resistance Destruction: 10 to 150 Hz, 0.3-mm double amplitude, with 4 sweeps of 8 min each in

Shock resistance

Ambient temperature −10 to 55°C (with no icing)

Ambient humidity 35% to 85% (with no condensation)

Storage temperature −25 to 65°C

Degree of protection IEC60529: IP40

Ground Ground to 100 Ω or less.

Material ABS resin (case)

Cable length Standard, 0.5 m with a dedicated connector (See note.)

Weight Approx. 170 g Approx. 180 g

Note: The connector is not waterproof. If there is a possibility that the connector may be exposed to water, keep it inside the control box. Be sure

to use the connector together with the separately sold interface cable.

3 directions

Destruction: 294 m/s

2

, 3 times each in 6 directions

Destruction: 10 to 150 Hz, 1.5-mm

double amplitude, with 4 sweeps

of 8 min each in 3 directions

■ Functions

V600-HAR91/-HAR81 (Read-only type)

Reads the 8-bit data (1 byte) of the set address and outputs to the 8

data output lines.

V600-HAM91/-HAM81 (Multi-functional type)

The amplifier has the following three basic functions.

Read

Reads the 8-bit (1 byte) data of the set address and outputs to the 8

data output lines.

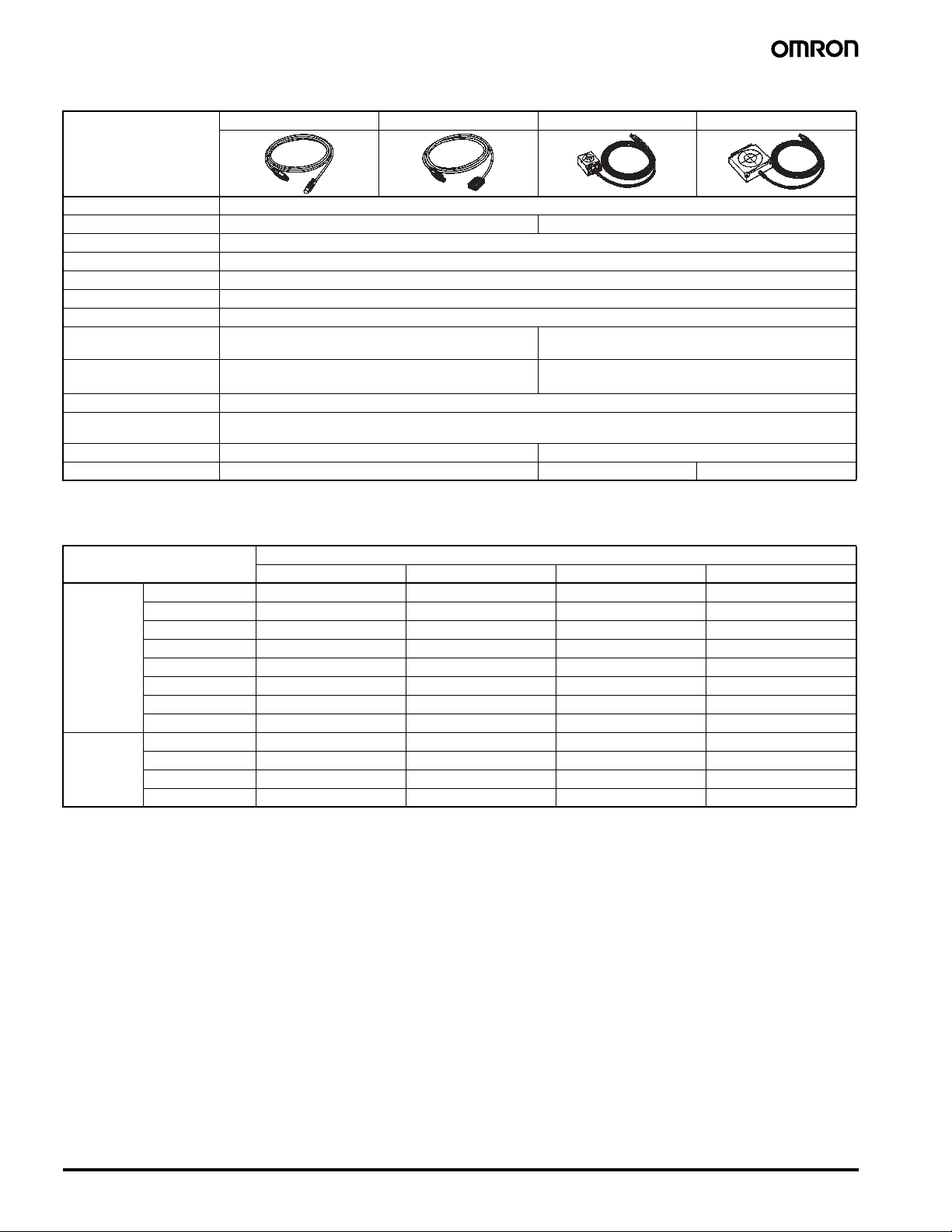

■ Interface Cable

Amplifier Cable length Interface Cable

V600-HAR91/81

(Connector: 20 pin)

V600-HAM91/81

V600-HAR92

(Connector: 26 pin)

Note: The interface cable connector is not waterproof. If there is a

possibility that the connector may be exposed to water, keep it

inside the control box. The maximum cable length is 10 m.

2 m V600-A60R

5 m V600-A61R

10 m V600-A62R

2 m V600-A60M

5 m V600-A61M

10 m V600-A62M

Write

Writes on the set address the 8-bit (1 byte) data designated via the 8

data input lines.

Verify

Reads the 8-bit data (1 byte) of the set address, compares with the 8bit (1 byte) data input via the 8 verification data input lines, and outputs the verification result.

V600-HAR92 (Read-only type)

Reads the 16-bit data (2 bytes) of the set address and outputs to the

16 data output lines.

Intelligent Flag I/II V600-HA 3

Page 3

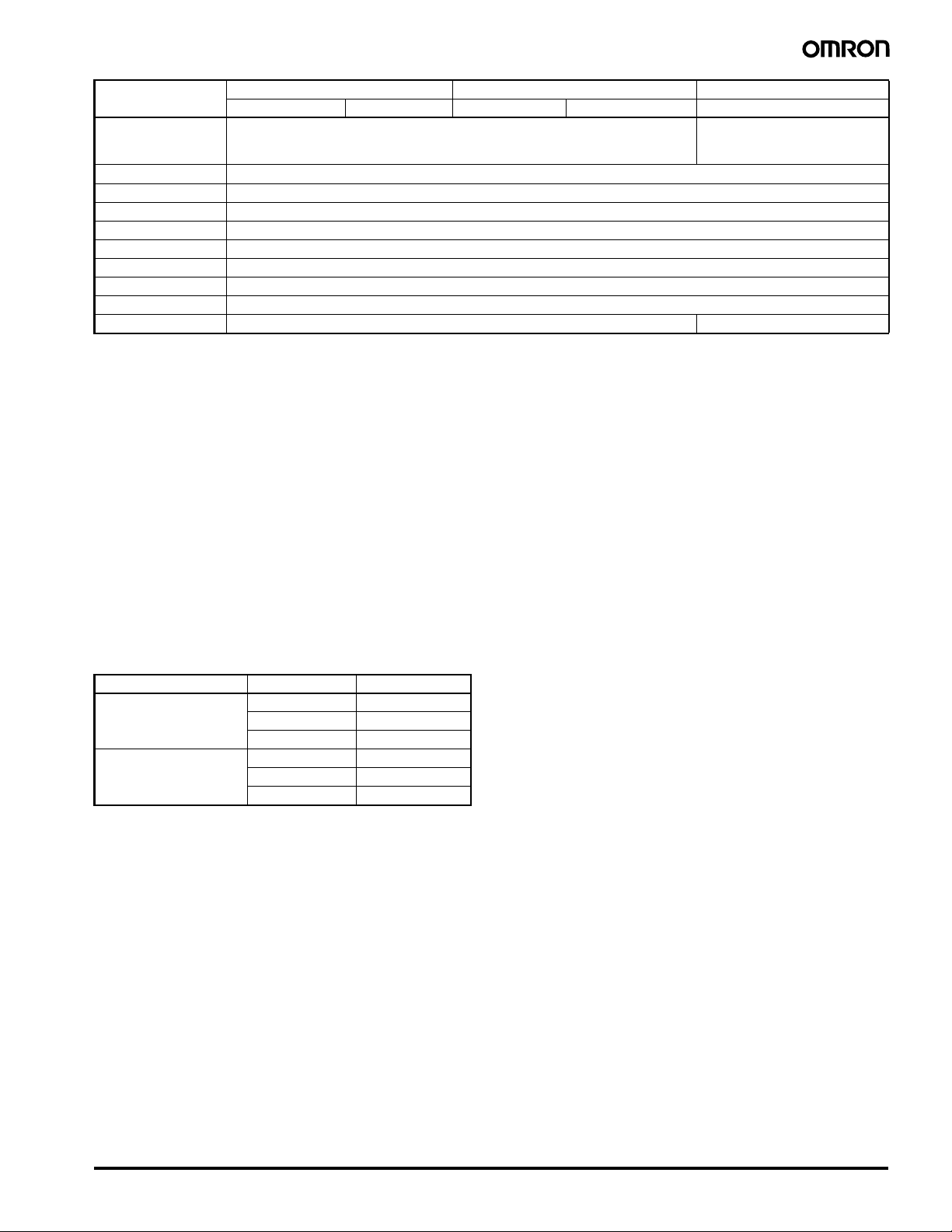

■ Sensor

Model V600-HS51 V600-HS61 V600-HS63 V600-HS67

Shape

Item

Transmission frequency 530 kHz

Ambient temperature −10 to 60°C −10 to 70°C

Storage temperature −25 to 75°C

Ambient humidity 35% to 95%

Insulation resistance 50 MΩ (at 500 VDC) between cable terminal and case

Dielectric strength 1,000 VAC, 50/60 Hz for 1 min between cable terminal and case (leakage current: 1 mA max.)

Degree of protection IEC60529: IP67

Vibration resistance Destruction: 10 to 2,000 Hz, 3-mm double amplitude, with

Shock resistance

Cable length 2 m (fixed)

Wireless transmission

error direction

Indicator --- Power: green

Weight Approx. 70 g Approx. 190 g Approx. 540 g

2 sweeps of 15 min each in 3 directions

2

Destruction: 981 m/s

times total)

16-bit CRC (Cyclic Redundancy Check) in both directions

, 3 times each in 3 directions (18

Destruction: 10 to 500 Hz, 2-mm double amplitude, with 3

sweeps of 11 min each in 3 directions

Destruction: 490 m/s2, 3 times each in 3 directions (18

times total)

■ Transmission Distance Specifications

Recommended Combinations

Amplifier V600-HAR91/-HAR81/-HAM91/-HAM81/-HAR92

Data Carrier

Memory

EEPROM

(Batteryless type)

Memory

SRAM

(Built-inbattery

type)

Note: 1. The specifications take fluctuations in ambient temperature and slight differences between products into account.

2. The read distance and write distance are the same.

3. Sensor Installation Conditions

• V600-HS51:When flush-mounted in iron

Axial offset from the Data Carrier: ±2.0 mm

4. Data Carrier Installation Conditions

5. The transmission distance specified in the specifications is also applicable when the Data Carrier is mounted on non-metallic surfaces.

6. The Data Carrier is stationary.

V600-D23P53 0.5 to 3.0 mm 0.5 to 3.0 mm --- --V600-D23P54 0.5 to 5.0 mm 0.5 to 5.5 mm --- --V600-D23P55 0.5 to 7.0 mm 0.5 to 7.0 mm 0.5 to 9.5 mm --V600-D23P61 0.5 to 8.0 mm 0.5 to 9.0 mm 2 to 16 mm --V600-D23P66N --- --- 5 to 30 mm 5 to 35 mm

V600-D23P66SP --- --- 5 to 25 mm 5 to 30 mm

V600-D23P71 --- --- 5 to 35 mm 10 to 70 mm

V600-D23P72 --- 0.5 to 18 mm 5 to 35 mm 10 to 50 mm

V600-D8KR12 5 to 15 mm 5 to 18 mm 5 to 45 mm 10 to 60 mm

V600-D8KR13 --- --- 10 to 30 mm 10 to 40 mm

V600-D8KR04 --- --- 10 to 65 mm 10 to 100 mm

V600-D2KR16 --- --- 2 to 15 mm ---

• V600-HS61: When surface-mounted on metal (ferrous)

• V600-HS63: When surface-mounted on metal (ferrous)

• V600-HS67: When surface-mounted on metal (ferrous)

• V600-D23P53/-P54: When flush-mounted in iron

• V600-D23P55/-P66N/-P66SP/-P71/-P72: When surface-mounted on resin (no metal on the backside)

• V600-D23P61: When surface-mounted on metal (ferrous)

• V600-D8KR12/-13/-04: When surface-mounted on metal (ferrous)

• V600-D2KR16: When the Data Carrier attached to the holder is mounted on a metal (ferrous) surface

Sensor V600-HS51 V600-HS61 V600-HS63 V600-HS67

Axial offset from the Data Carrier: ±2.0 mm

Axial offset from the Data Carrier: ±10.0 mm

Axial offset from the Data Carrier: ±10.0 mm

4 Intelligent Flag I/II V600-HA

Page 4

System Configuration

Sensor

(Cable length: fixed to 2 m)

Amplifier (Cable length:

fixed to 0.5 m, with connector)

interface

Interface cable available in

three lengths: 2 m,

5 m, and 10 m (10 m max.)

Connector

connection

Host

Programmable Controller, I/O terminal, B7A, CompoBus/S, etc. Sensor Controller

Terminal block wiring

Interface cable

V600-A6R V600-A6M

Connector pins: 20

Cable lengths: 2 m, 5 m,

10 m

Connector

Amplifier

Power

supply

24 VDC

Connector

connection

connection

V600

-HAR91/

HAR81

Sensor

V600-HS51 V600-HS61 V600-HS63 V600-HS67

Power

supply

24 VDC

Connector connection Connector connection

Connector pins: 26

Cable lengths: 2 m, 5 m,

10 m

Connector

connection

V600

-HAM91/

HAM81

Connector

connection

Power

supply

24 VDC

V600

-HAR92

V600

-D23P53

Wireless

transmission

V600

-D23P54

V600

-D23P55

V600

-D23P61

Data Carrier

V600

V600

-D23P66N

-D23P66SP

V600

-D23P71

V600

-D23P72

V600

-D8KR12

Wireless

transmission

V600

-D8KR04

V600

-D2KR16

Intelligent Flag I/II V600-HA 5

Page 5

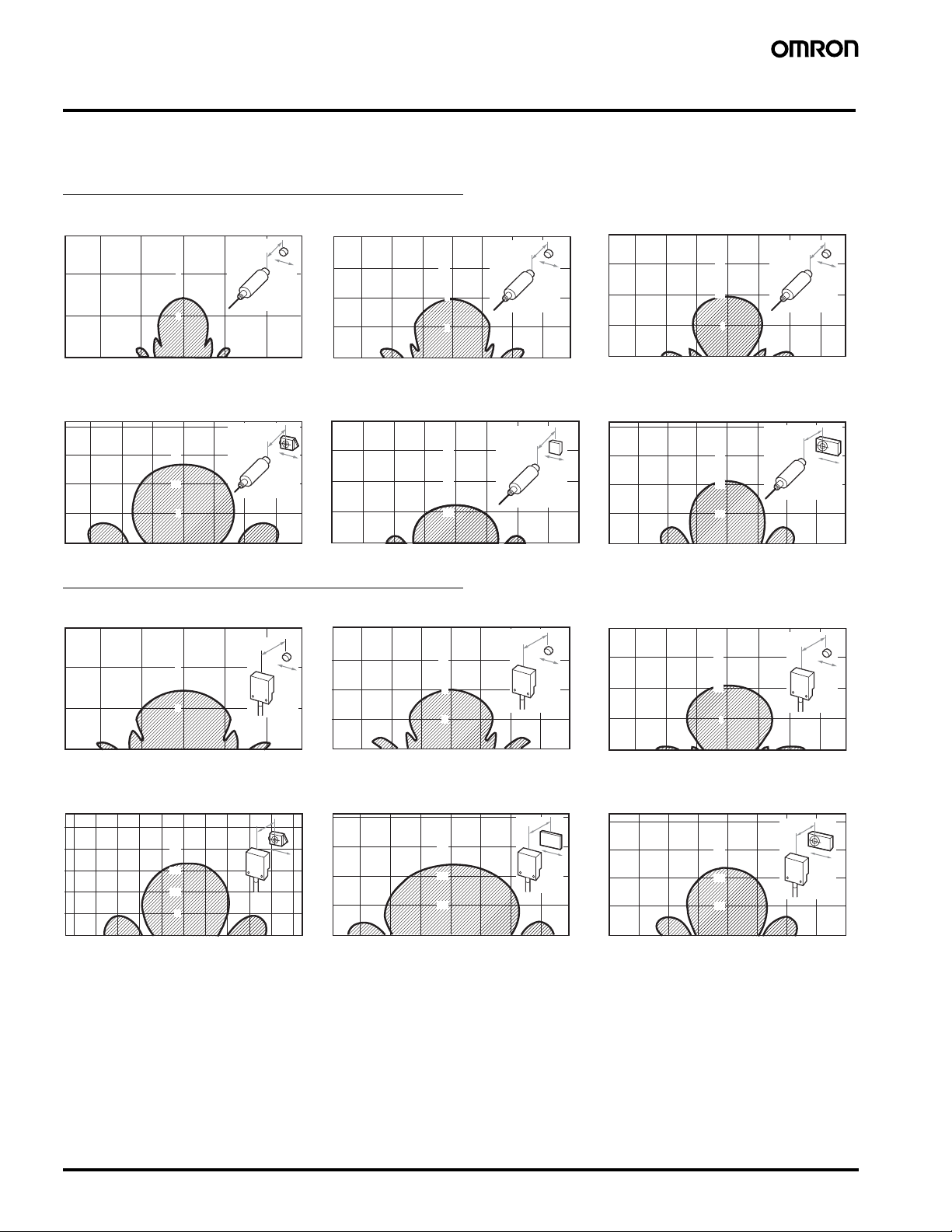

Characteristic Data (Typical)

■ Transmission Range

Combinations with the V600-HS51 Sensor

V600-HS51 & V600-D23P53 V600-HS51 & V600-D23P54 V600-HS51 & V600-D23P55

Y

8

4

Y

X

Y

12

8

4

Y

X

Y

15

10

5

Y

X

0–4–8 4 8

X

0–4–8–12 4

812

X

0–5–10–15 5

V600-HS51 & V600-D23P61 V600-HS51 & V600-D23P66N V600-HS51 & V600-D8KR12

Y

15

10

5

0–5–10–15 5 10 15

Y

X

X

Y

30

20

10

0–10–20–30 10

20 30

Y

X

X

Y

30

20

10

0–10–20–30 10 20 30

Combinations with the V600-HS61 Sensor

V600-HS61 & V600-D23P53 V600-HS61 & V600-D23P54 V600-HS61 & V600-D23P55

Y

8

4

0–4–8 4 8

Y

X

X

Y

12

8

4

0–4–8–12 4 8 12

Y

X

X

V600-HS61 & V600-D23P61 V600-HS61 & V600-D23P72 V600-HS61 & V600-D8KR12

Y

20

15

10

5

Y

X

Y

30

20

10

Y

X

Y

15

10

5

0–5–10–15 5

Y

30

20

10

10 15

Y

Y

10 15

Y

X

X

X

X

X

X

0–5–10–15–20–25 5 10 15 20 25

X

6 Intelligent Flag I/II V600-HA

0–10–20–30 10 20 30

X

0–10–20–30 10 20 30

X

Page 6

Combinations with the V600-HS63 Sensor

V600-HS63 & V600-D23P55 V600-HS63 & V600-D23P61 V600-HS63 & V600-D23P66N

Y

Y

30

X

20

10

Y

30

20

10

Y

X

Y

50

40

30

20

10

Y

X

20 30

X0–10–20–30 10

0–10–20–30–40 10 20 30 40

X

0–10–20–30–40–50 10 20 30 5040

V600-HS63 & V600-D23P66SP V600-HS63 & V600-D23P71 V600-HS63 & V600-D23P72

Y

50

40

30

20

10

0–10–20–30–40–50 10 20 30 5040

Y

X

X

Y

60

Y

X

40

20

X

0–20–40–60 20 40 60

X

Y

60

40

20

0–20–40–60 20 40 60

V600-HS63 & V600-D8KR12 V600-HS63 & V600-D8KR04 V600-HS63 & V600-D2KR16

Y

60

40

20

0–20–40–60 20 40 60

Y

X

Y

80

60

40

20

X

0–20–40–60–80 20 40 60 80

Y

X

Y

60

40

20

X

0–20–40–60–80 20 40 60 80

X

Y

X

X

Y

X

X

Intelligent Flag I/II V600-HA 7

Page 7

Combinations with the V600-HS67 Sensor

–

V600-HS67 & V600-D23P66N V600-HS67 & V600-D23P66SP V600-HS67 & V600-D23P71

Y

80

60

40

20

Y

X

Y

80

60

40

20

Y

XX

Y

100

80

60

40

20

Y

X

X020406080–20–40–60–80

0–20–40–60–80 20 40 60 80

X

0–20–40–60–80–100 20 40 60 80 100

V600-HS67 & V600-D23P72 V600-HS67 & V600-D8KR12 V600-HS67 & V600-D8KR13

Y

100

80

60

40

20

100 20 40 60 80 100

0–20–40–60–80

Y

X

Y

80

60

40

20

X

0–20–40–60–80 20406080

Y

X

X

Y

80

60

40

20

0–20–40–60–80 20406080

Y

X

V600-HS67 & V600-D8KR04

Y

120

80

40

0–40–80–120 40 80 120

Y

X

X

■ Transmission Time

The transmission time refers to the time required for communications between the Sensor and the Data Carrier. It is used for calculating the travel

speed of the auto command.

X

X

DC speed

(conveyor

speed)

Distance travelled in the transmission range

=

Transmission time

Model V600-HAR91/-HAR81/-HAM91/-HAM81 V600-HAR92

Read Write Read

Mode type DATA READ mode,

VERIFY READ mode

BYTE mode BIT SET mode, BIT

CLEAR mode

DATA READ mode

Data Carrier type EEPROM 75 ms 138 ms 150 ms 77 ms

SRAM 60 ms 95 ms 107 ms 62 ms

Example: Combinations with the V600-HAR91, V600-HS63, and V600-D8KR04 Sensors.

Y

80

60

DC speed

(conveyor

speed)

40

20

0–20–40–60–80 20 40 60 80

75 (mm)

=

60 (ms)

=

Y

75 × 10

60 × 10

X

X

-3

(m)

-3

× 1/60 (min)

= 75 (m/min)

Note: 1. The DC speed varies depending on transmission distance Y

and the axial offset. It is recommended that you refer to the

transmission range graphs and use the product where the

range is the largest.

2. This calculation is intended as a guideline only. Perform a

test with the actual product prior to use.

3. This equation does not include transmission error processing.

8 Intelligent Flag I/II V600-HA

Page 8

Circuit Configuration

T

g

V600-HAR91

V600-HAM91

Input Circuit

24 V

Ω

0 V

8.2 k

IN

ON/

OFF

Tr

Output Circuit

Main circuit

V600-HAR92

Input Circuit

24 V

Ω

ON/

OFF

Tr

Output Circuit

Main circuit

8.2 k

IN

0 V

Main circuit

OUT

0 V

Main circuit

OUT

V600-HAR81

V600-HAM81

Input Circuit

+DC

Tr

IN

8.2 kΩ

0 V

Output Circuit

Main circuit

Main circuit

+DC

OU

0 V

0 V

Precautions

■ Cautions

!Caution

Be sure to house the V600-HA@91/-HA@81/-HA@92 together with

their connectors and cable in control boxes when using them and

do not expose them to water, oil, dust, metal powder, corrosive

gas, or organic solvent, otherwise they may malfunction, suffer

damage, or burn.

!Caution

The connectors of the V600-HA@91/-HA@81/-HA@92 can be

mounted to metal plates, provided that there is an insulation plate

with a thickness of 1.5 mm minimum between each of the connectors and metal plates.

Input/Output

The Data Input and Data Output lines are set to “1" when the transistor turns ON and to “0" when it turns OFF.

Do not use a solid-state output with the following ratings with the

V600-HAM91/-HAM81, otherwise an external input error may result.

1. Maximum switching current: 1 A min.

2. Minimum switching current: 10 mA min.

3. Response time (ON to OFF): 3 ms min.

The following OMRON products cannot be connected to this product.

• CVM1-OD219, C20H, C28H, C40H, or C60H Programmable

Controllers

• Sensor Controllers other than from the S3D2 Series

When using a contact output, pay careful attention to chattering and

to the minimum switching current. Also note that the minimum switching current may be specified for some solid-state outputs.

When connecting an inductive load or an electrical device that tends

to generate noise to the output, connect a diode in parallel with the

load. Connect the cathode side of the diode to the positive side of the

power source.

L

Open collector output

Diode

Diode

Peak inverse voltage

Minimum of three times of the load voltage

e rectified current: 1 A

Avera

DC

power supply

Intelligent Flag I/II V600-HA 9

Page 9

Power Supply Voltage

Do not impose any voltage exceeding the rated voltage range. Doing

so, or applying alternating current (100 VAC) may cause the product

to explode or burn.

Load Short-circuiting

Do not short-circuit the load connected to the product or connect to

the power supply. Doing so may cause the product to explode or

burn.

Wiring

Avoid wiring mistakes such as incorrect polarity in the power supply.

Wiring mistakes may cause the product to explode or burn.

■ Correct Use

Grounding

The FG line is provided for grounding to the earth. When using the

Amplifier in an environment where it is exposed to large amounts of

noise or if the V600-HA@91/-HA@81/-HA@92 Amplifier malfunctions,

provide a Class-3 ground (ground resistance of 100 Ω or less). Note

that sharing the grounding wire with other equipment or grounding to

the beam of a building will adversely affect the grounding effect.

I/O Interface Requirements

1. The TRG input must be 10 ms min.

2. The INHIBIT input must be 20 ms min.

3. Minimum of 5 ms is required as the transfer time of the Read/

Write Selection Input (W/R).

4. The read data output must be read after the Normal End Output is

set to ON.

Connecting the Sensor

Hold the black part of the connector, line up the notch and push it in

until it clicks.

V600-HA91/81/92 Other equipment

OK

FG

V600-HA91/81/92 Other equipment

Less than 100 Ω

NG

FG

Less than 100

Ω

Mounting

Amplifier Spacing

When installing V600-HA@91/V600-HA@81/V600-HA@92 Amplifiers in a row, provide a minimum space of 10 mm between Amplifiers

in order to prevent them from being affected by the heat produced by

each Amplifier.

10 mm min.

Compatibility with the SRAM Memory

Type Data Carrier

1. If the Data Carrier is stationary in the transmission area for a long

time when using the V600-HA@91/81 in the AUTO mode, or when

using the V600-HAR92, it will drastically reduce the battery life.

Therefore, stop the oscillation in the sensor either by turning off

the power of the V600-HA@91/81/92 Amplifier or by setting the

Inhibit input to ON.

2. Use a Data Carrier that has the oscillation frequency of 530 kHz.

Note that the following models manufactured before February

1991 cannot be used.

• V600-D2KR01

• V600-D2KR02

Precautions When Using the AUTO

Mode

If transmitting to the Data Carrier while it is traveling under the AUTO

mode, conduct tests to make sure that the travel speed and installation conditions are fully satisfied.

V600-HA91/81/92

When housing the Amplifiers in a box, provide a fan or ventilation

opening for radiating the heat.

When wiring power cables, which carry large current such as motor

drive cables, near the V600-HA@91/81/92 Amplifiers, conduct necessary tests to make sure that the installation conditions are fully satisfied.

10 Intelligent Flag I/II V600-HA

Page 10

Dimensions

Note: All units are in millimeters unless otherwise indicated.

Amplifier

V600-HAR91/-HAR81

* Enlarged Section of Mounting Hole

25

4.4

30

Two, mounting

holes

*

89

98

Mounting Hole Dimensions

2-M4

89±0.2

21±0.2

17.5

5.5

28.3

30û

36.3

61.8

68.5

Vinyl-insulated round cord 5.8-mm dia.,

13-conductor cable, standard length: 0.5 m

XG4E-2031

55

6

80

44.7

35.2

500 mm

28.1

25

30

21

8.2

Intelligent Flag I/II V600-HA 11

Page 11

V600-HAM91/-HAM81

* Enlarged Section of Mounting Hole

4.4

25

30

Two mounting

holes *

89

98

Mounting Hole Dimensions

2-M4

89±0.2

21±0.2

17.5

5.5

28.3

30˚

36.3

44.3

52.3

61.8

68.5

75

Vinyl-insulated round cord 5.8-mm dia.,

23-conductor cable, standard length: 0.5 m

XG4E-2631

55

6

80

52.3

35.2

500 mm

28.1

25

30

21

8.2

12 Intelligent Flag I/II V600-HA

Page 12

V600-HAR92

* Enlarged Section of Mounting Hole

4.4

25

30

Two, mounting

holes *

89

98

Mounting Hole Dimensions

2-M4

89±0.2

21±0.2

17.5

5.5

28.3

30˚

36.3

44.3

61.8

68.5

75

80

Vinyl-insulated round cord 5.8-mm dia.,

23-conductor cable, standard length: 0.5 m

XG4E-2631

55

52.3

6

35.2

500 mm

28.1

25

30

21

8.2

Sensor

V600-HS51

V600-HS61

M12X1

9.6 dia.

18

Detection surface

10

2 lock washers

2 lock nuts

7

33

35

30.5

4.5

18

12±0.2

8.5

2-3.5X5

(mounting holes)

Vinyl-insulated round cord (4-mm dia.)

Connector

49.5

49.5

Connector

Vinyl-insulated round cord (4-mm dia.)

6.5

13.7 dia.

13.7 dia.

Case: Brass

Transmission window: ABS resin

Filter: Epoxy resin

Cable: PVC (oil-resistant)

Case: ABS resin

Filter: Epoxy resin

Cable: PVC (oil-resistant)

Intelligent Flag I/II V600-HA 13

Page 13

V600-HS63

40 28

4-R1

Two, 4.5-dia. mounting holes

2-R5

10

Bushing

Vinyl-insulated round cord 6-mm dia

(7/0.18-mm dia.), 8-conductor cable,

standard length: 2 m

Connector

13.8 dia.

V600-HS67

Power indicator (green)

Power indicator

(green)

5

5

23

11

5

5

50

100

0.2

±

90

14

27 6

50

90

100

2053

Case: ABS resin

Filter: Epoxy resin

Cable: PVC (oil-resistant)

Four, 4.5-dia.

0.2

±

mounting holes

25

Bushing

Vinyl-insulated round cord (6-mm dia.)

10

10

51.5

Connector

51.5

Case: ABS resin

Filter: Epoxy resin

Cable: PVC (oil-resistant)

135

18

13.8 dia.

Interface Cable

V600-A6@R (for V600-HAR91/-HAR81))

30

20

330

0

+5

±5

±5

20

20

+100

L

0

Vinyl-insulated round cord 9-mm dia

(7/0.2-mm dia.), 13-conductor cable,

standard length: 2 m

±5

20

11

10.6

±5

30

30

37.6

XG5M-2032-N Connector

7.6

14 Intelligent Flag I/II V600-HA

Page 14

V600-A6@M (for V600-HAM91/-HAM81/-HAR92)

330

0

Model L (m)

V600-A60R/60M 2

V600-A61R/61M 5

V600-A62R/62M 10

+5

±5

±5

20

20

Vinyl-insulated round cord 9-mm dia (7/0.2-mm dia.),

23-conductor cable, standard length: 2 m

L

0

+100

±5

±5

20

30

30

XG5M-2632-N Connector

10.6

7.6

37.6

Intelligent Flag I/II V600-HA 15

Page 15

Terms and Conditions

WARRANTY, LIMITATIONS OF

LIABILITY

WARRANTY OMRON’s exclusive warranty is that the products are

free from defects in materials and workmanship for a period of one

year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION,

EXPRESS OR IMPLIED, REGARDING NON-INFRINGEMENT,

MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSE

OF THE PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES

THAT IT ALONE HAS DETERMINED THAT THE PRODUCTS WILL

SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED

USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS

BASED ON CONTRACT, WARRANTY, NEGLIGENCE OR STRICT

LIABILITY.

In no event shall responsibility of OMRON for any act exceed the individual price of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR OR OTHER CLAIMS REGARDING THE PRODUCTS UNLESS OMRON’S ANALYSIS CONFIRMS THAT THE

PRODUCTS WERE PROPERLY HANDLED, STORED, INSTALLED

AND MAINTAINED AND NOT SUBJECT TO CONTAMINATION,

ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR

REPAIR.

APPLICATION CONSIDERATIONS

SUITABILITY FOR USE OMRON shall not be responsible for confor-

mity with any standards, codes or regulations which apply to the

combination of the product in the customer's application or use of the

product.

At the customer's request, OMRON will provide applicable third party

certification documents identifying ratings and limitations of use

which apply to the product. This information by itself is not sufficient

for a complete determination of the suitability of the product in combination with the end product, machine, system, or other application or

use.

The following are some examples of applications for which particular

attention must be given. This is not intended to be an exhaustive list

of all possible uses of this product, nor is it intended to imply that the

uses listed may be suitable for this product:

• Outdoor use, uses involving potential chemical contamination or

electrical interference, or conditions or uses not described in this

catalog.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical equipment, amusement machines,

vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines and equipment that could present a risk to life

or property.

Please know and observe all prohibitions of use applicable to this

product.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING

SERIOUS RISK TO LIFE OR PROPERTY WITHOUT ENSURING

THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT IS

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE

WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS OMRON shall not be responsible

for the user’s programming of a programmable product, or any consequence thereof.

DISCLAIMERS

PERFORMANCE DATA Performance data given in this catalog is

provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON’s

test conditions, and the user must correlate it to actual application

requirements. Actual performance is subject to the OMRON Warranty and Limitations of Liability.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons. It is our practice to change part numbers when published

ratings or features are changed, or when significant construction

changes are made. However, some specifications of the product may

be changed without any notice. When in doubt, special part numbers

may be assigned to fix or establish key specifications for your application. Please consult with your OMRON representative at any time

to confirm actual specifications of purchased product.

ERRORS AND OMISSIONS

The information in this catalog has

been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical or proofreading

errors, or omissions.

OMRON ON-LINE

Global - http://www.omron.com

USA - http://www.omron.com/oei

Canada - http://www.omron.ca

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS. To convert millimeters into inches, divide by 25.4

Cat. No. GC RFID 4

Printed in USA

OMRON CANADA, INC.

885 Milner Avenue

Toronto, Ontario M1B 5V8

416-286-6465

OMRON ELECTRONICS LLC

One Commerce Drive

Schaumburg, IL 60173

847-843-7900

For US technical support or other inquiries:

800-556-6766

5/03 Specifications subject to change without notice

Complete terms and conditions for product purchase and use are on Omron’s website at

www.omron.com/oei – under the “About Us” tab, in the Legal Matters section.

16 Intelligent Flag I/II V600-HA

Loading...

Loading...