Page 1

Cat. No. W404-E1-07

DRT2 Series

DeviceNet Slaves

OPERATION MANUAL

Page 2

DRT2 Series DeviceNet Slaves

Operation Manual

Revised April 2008

Page 3

iv

Page 4

Notice:

r

f

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 2002

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 5

vi

Page 6

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

1 Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

5 Application Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xx

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

SECTION 1

Smart Slaves and Features . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 DRT2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 DRT2 Slaves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SECTION 2

Example System Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2-1 Basic Procedures and Configuration Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2-2 Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2-3 Setting and Wiring Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2-4 Starting Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

2-5 Checking Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

SECTION 3

Common Slave Specifications . . . . . . . . . . . . . . . . . . . . . . . . 31

3-1 Common Slave Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3-2 DeviceNet Remote I/O Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

SECTION 4

Functions of All Slaves, General-purpose Slaves,

and Environment-resistive Slaves . . . . . . . . . . . . . . . . . . . . . 47

4-1 Maintenance Mode Window and Main Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4-2 Common Slave Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4-3 Functions of General-purpose Slaves and Environment-resistive Slaves . . . . . . . . . . . . . . . 61

SECTION 5

General-purpose Slaves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

5-1 Common Specifications for General-purpose Slaves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

5-2 Connecting Communications Cables to General-purpose Slaves . . . . . . . . . . . . . . . . . . . . . 87

5-3 Mounting Terminating Resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

5-4 Maintenance Information Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

5-5 Remote I/O Terminals with Transistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

5-6 Connector Terminals with Transistors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

5-7 Screw-less Clamp Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

vii

Page 7

TABLE OF CONTENTS

SECTION 6

Environment-resistive Slaves. . . . . . . . . . . . . . . . . . . . . . . . . 233

6-1 Common Specifications for Environment-resistive Slaves . . . . . . . . . . . . . . . . . . . . . . . . . . 234

6-2 Connecting Communications Cables to Environment-resistive Slaves . . . . . . . . . . . . . . . . . 236

6-3 Maintenance Information Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

6-4 Advanced Environment-resistive Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

6-5 Standard Environment-resistive Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

6-6 Mounting and Wiring Environment-resistive Slaves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

SECTION 7

Analog Slaves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

7-1 Overview of Analog Slaves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

7-2 Common Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

7-3 Maintenance Information Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

7-4 Analog Input Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

7-5 Analog Output Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .359

7-6 Temperature Input Terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 377

SECTION 8

Communications Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 443

8-1 Remote I/O Communications Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 444

8-2 Message Communications Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 453

SECTION 9

Troubleshooting and Maintenance . . . . . . . . . . . . . . . . . . . . 455

9-1 Indicators and Error Processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 456

9-2 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 457

9-3 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 466

Appendices

A DeviceNet Explicit Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 469

B Using Another Company's Master Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 493

C Restrictions on Reading Total ON Time/Contact Operation Counter

for All Slaves at Once . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 539

D Connectable Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .553

E Current Consumption Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 563

F Precautions with Connecting Two-wire DC Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 567

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 569

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 575

viii

Page 8

About this Manual:

This manual describes the installation and operation of an DeviceNet Smart Slave Units and includes

the sections described below.

Please read this manual carefully and be sure you understand the information provided before

attempting to install or operate the DeviceNet Smart Slave Units. Be sure to read the precautions

provided in the following section.

The following manuals also cover information related to DeviceNet applications. Use the DeviceNet

Operation Manual together with other required manuals.

Manual Contents Cat. No.

DeviceNet

Operation Manual

DeviceNet Masters

Operation Manual

DeviceNet CS/CJ Series Units

Operation Manual

DeviceNet DRT2 Series

Slaves Operation Manual (this

manual)

DeviceNet DRT1 Series

Slaves Operation Manual

DeviceNet Configurator Ver.

2.@ Operation Manual

DeviceNet MULTIPLE I/O

TERMINAL Operation Manual

Describes the configuration and construction of a DeviceNet network,

including installation procedures and specifications for cables, connectors, and other connection devices, as well as information on functions,

operating procedures, and applications.

Describes the models, specifications, functions, operating procedures,

and applications of C200HX/HG/HE, CVM1, and CV-series DeviceNet

Master Units.

Describes the models, specifications, functions, operating procedures,

and applications of CS-series and CJ-series DeviceNet Master Units.

Describes the models, specifications, functions, operating procedures,

and applications of DRT2-series Smart Slave Units.

Describes the models, specifications, functions, operating procedures,

and applications of DRT1-series Smart Slave Units.

Describes the operating procedures of the DeviceNet Configurator. W382

Describes the models, specifications, functions, operating procedures,

and applications of the DeviceNet MULTIPLE I/O TERMINALs.

W267

W379

W380

W404

W347

W348

Precautions provides general precautions for planning, installing, and operating the DeviceNet DRT2series Smart Slaves and related devices.

Section 1 provides an overview of the DeviceNet DRT2-series Smart Slaves, including lists of models,

and information on features that were not included in the DRT1-series Slaves.

Section 2 provides information on hardware aspects of Masters and Slaves connected to a DeviceNet

Network to ensure the proper operation of the system. Included are system configuration examples,

basic procedures for wiring, details on mounting and setting Master and Slave Units, procedures for

connecting cables and power supplies, creating I/O tables, creating and registering scan lists, and

checking operation of the system.

Section 3 provides specifications and indicator displays that are common to all Slaves. The allocation

of remote I/O memory for Smart Slaves is also described here.

Section 4 describes the functions of DRT2-series Smart Slaves and their applications, including operation procedures using a DeviceNet Configurator.

Section 5 provides the specifications and describes the components, terminal arrangements, basic

procedures for wiring, and methods for connecting cables of General-purpose Slaves. Information on

Slave settings, mounting and wiring methods are also provided separately for each Slave type.

Section 6 provides the specifications and describes the components, terminal arrangements, basic

procedures for wiring, and methods for connecting cables of Environment-resistive Slaves (conforming

to IP67). Information on Slave settings, mounting and wiring methods are also provided separately for

each Slave type.

ix

Page 9

About this Manual, Continued

Section 7 provides the specifications, terminal arrangements, mounting procedures, and connection

methods of Analog I/O Terminals. Information is included on types of I/O data that can be allocated,

allocation methods and procedures, and math operation processing. Setting methods using the Configurator are also described.

Section 8 provides information on the time required for a complete communications cycle, for an output response to be made to an input, to start the system, and to send messages.

Section 9 describes error processing, periodic maintenance operations, and troubleshooting procedures needed to keep the DeviceNet Network operating properly. We recommend reading through the

error processing procedures in both this manual and the operation manual for the master being used

before operation so that operating errors can be identified and corrected more quickly.

Appendix A provides lists of DeviceNet explicit messages and their basic format.

Appendix B provides information on using masters from other companies and Slave device profiles

necessary for multi-vendor applications, including information on installing EDS files.

Appendix C describes restrictions on reading the total ON time and contact operation counter for all

Slaves at once.

Appendix D provides lists of standard models of DRT2-series Smart Slaves and connectable devices.

Appendix E shows the current consumptions of DRT2-series Smart Slaves.

Appendix F provides precautions for connecting two-wire DC sensors.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

x

Page 10

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xi

Page 11

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xii

Page 12

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xiii

Page 13

xiv

Page 14

PRECAUTIONS

This section provides general precautions for installing and using the DeviceNet Smart Slave and related devices.

The information contained in this section is important for the safe and reliable application of the DeviceNet Smart

Slave. You must read this section and understand the information contained before attempting to set up or operate

a DeviceNet network using DeviceNet Smart Slaves.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

6-1 Applicable Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

6-2 Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

6-3 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

xv

Page 15

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of purchasing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and connecting FA systems.

• Personnel in charge of managing FA systems and facilities.

xvi

Page 16

General Precautions 2

2 General Precautions

The user must operate the product according to the specifications described

in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with redundant safety mechanisms.

This manual provides information for installing and operating OMRON

DeviceNet products. Be sure to read this manual before operation and keep

this manual close at hand for reference during operation.

!WARNING It is extremely important that a PLC and all PLC Units be used for the speci-

fied purpose and under the specified conditions, especially in applications that

can directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PLC system to the above mentioned applications.

xvii

Page 17

Safety Precautions 3

3 Safety Precautions

!WARNING Never attempt to disassemble any Units while power is being supplied. Doing

so may result in serious electrical shock or electrocution.

!WARNING Provide safety measures in external circuits (i.e., not in the Programmable

Controller), including the following items, to ensure safety in the system if an

abnormality occurs due to malfunction of the PLC or another external factor

affecting the PLC operation. Not doing so may result in serious accidents.

!WARNING Input only the specified range of voltage or current to a Unit. A current or volt-

age exceeding the specified range may cause malfunction or fire.

!WARNING Provide safety measures in external circuits (i.e., not in the Programmable

Controller), including the following items, to ensure safety in the system if an

abnormality occurs due to malfunction of the PLC or another external factor

affecting the PLC operation. Not doing so may result in serious accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PLC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instruction is executed.

As a countermeasure for such errors, external safety measures must be

provided to ensure safety in the system.

• The PLC outputs may remain ON or OFF due to deposits on or burning of

the output relays, or destruction of the output transistors. As a countermeasure for such problems, external safety measures must be provided

to ensure safety in the system.

• When the 24-V DC output (service power supply to the PLC) is overloaded or short-circuited, the voltage may drop and result in the outputs

being turned OFF. As a countermeasure for such problems, external

safety measures must be provided to ensure safety in the system.

xviii

!WARNING The CPU Unit refreshes I/O even when the program is stopped (i.e., even in

PROGRAM mode). Confirm safety thoroughly in advance before changing the

status of any part of memory allocated to Output Units, Special I/O Units, or

CPU Bus Units. Any changes to the data allocated to any Unit may result in

unexpected operation of the loads connected to the Unit. Any of the following

operations may result in changes to memory status.

• Transferring I/O memory data to the CPU Unit from a Programming

Device

• Changing present values in memory from a Programming Device

• Force-setting/-resetting bits from a Programming Device

• Transferring I/O memory files from a Memory Card or EM file memory to

the CPU Unit

• Transferring I/O memory from a host computer or from another PLC on a

network

Page 18

Operating Environment Precautions 4

4 Operating Environment Precautions

Install the system properly according to the directions in this manual.

Do not operate the control system in the following places.

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to water, oil, or chemicals (General-purpose Slaves)

• Locations subject to acid or chemicals (Environment-resistive Slaves).

• Locations subject to shock or vibration.

Take appropriate and sufficient countermeasures when installing systems in

the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

!Caution The operating environment of the PLC System can have a large effect on the

longevity and reliability of the system. Improper operating environments can

lead to malfunction, failure, and other unforeseeable problems with the PLC

System. Be sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life

of the system.

xix

Page 19

Application Precautions 5

5 Application Precautions

Observe the following precautions when using the DeviceNet Smart Slave.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal

lines, momentary power interruptions, or other causes.

• Provide external interlock circuits, limit circuits, and other safety circuits in

addition to any provided within the PLC to ensure safety.

• Mount the Unit to a DIN Track or mount it with screws.

• If the system is installed at a site with poor power supply conditions, take

appropriate measures to ensure that the power supply remains within the

rated voltage and frequency specifications.

• Provide circuit breakers and other safety measures to provide protection

against shorts in external wiring.

• Always ground the system to 100

protect against electrical shock.

• Always turn OFF the communications power supply and the power supplies to the PLC and Slaves before attempting any of the following.

• Mounting or removing a Unit such as an I/O Unit, CPU Unit, Memory

Cassette, or Master Unit.

• Mounting or removing Remote I/O Terminal circuit sections.

• Assembling any devices or racks.

• Setting rotary switches.

• Connecting or wiring cables.

• Connecting or disconnecting connectors.

• Do not attempt to disassemble, repair, or modify any Units.

• Be sure that all the terminal screws are tightened to the torque specified

in the relevant manuals. Loose screws may cause fire, malfunction, or

damage the Unit.

• Be sure that all the mounting screws and cable connector screws are

tightened to the torque specified in the relevant manuals.

• Do not remove the label from a Unit before wiring. Always remove the

label after completing wiring, however, to ensure proper heat dispersion.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals.

• Double-check all switch settings and wiring before turning ON the power

supply.

• Always follow the electrical specifications for terminal polarity, communications path wiring, power supply wiring, and I/O jumpers. Incorrect wiring

can cause failures.

• Be sure to wire the Unit correctly.

• Be sure to wire terminals with the correct polarity.

• Be sure that the communications cable connectors and other items with

locking devices are properly locked into place.

• Do not drop the Unit or subject the Unit to excessive vibration or shock.

Doing so may cause malfunction or damage to the Unit.

• Use the special packing box when transporting the Unit. Ensure that the

product is handled carefully so that no excessive vibration or impact is

applied to the product during transportation.

Ω or less when installing the system to

xx

Page 20

Application Precautions 5

• Do not apply voltages or connect loads to the Output Units in excess of

the maximum switching capacity.

• Do not apply voltages to the Input Units in excess of the rated value.

• After replacing a CPU Unit or Special I/O Unit, resume operation only

after transferring to the new CPU Unit or Special I/O Unit the contents of

the DM Area, HR Area, and other data required for resuming operation.

• Check the user program for proper execution before actually running it

with the system.

• Observe the following precautions when wiring the communications

cables.

• Wire the communications cables separately from the power lines or

high-tension lines.

• Do not bend the communications cables excessively.

• Do not pull on the communications cables excessively.

• Do not place objects on top of the communications cables.

• Route communications cables inside ducts.

• Confirm that the system will not be adversely affected before performing

the following operations.

• Changing the operating mode of the PLC

• Setting/resetting any bit in memory

• Changing the present value of any word or any set value in memory

• Before touching a Unit, be sure to first touch a grounded metallic object in

order to discharge any static build-up.

• When replacing parts, such as a relay, make sure the replacement part

has the correct specifications.

• Be sure that metal filings do not enter the Unit when wiring or installing.

• Use correct parts for wiring.

• Use the specified communications cables and connectors.

• Always enable the scan list before operation.

• Before clearing the scan list of a Unit that has user-allocated remote I/O,

always confirm that no errors occur after the I/O Area setting is changed

to fixed allocation.

• When adding a new node to the network, check that the new node’s baud

rate is the same as the baud rate set on the other nodes.

• Do not extend connection distances beyond the ranges given in the specifications.

• Although the Environment-resistive Slaves have IP67 enclosure ratings,

do not used them in applications where the Slave is always submerged in

water.

xxi

Page 21

Conformance to EC Directives 6

6 Conformance to EC Directives

6-1 Applicable Directives

•EMC Directives

• Low Voltage Directive

6-2 Concepts

EMC Directives

OMRON devices are designed so that they comply with the related EMC

Directives so that they can be more easily built into other devices or the overall machine. The actual products have been checked for conformity to EMC

Directives (see the following note). Whether the products conform to the standards in the system used by the customer, however, must be checked by the

customer.

EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions of

the equipment or control panel on which the OMRON devices are installed.

The customer must, therefore, perform the final check to confirm that devices

and the overall machine conform to EMC standards.

Note Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN 61000-6-2

EMI (Electromagnetic Interference): EN 61000-6-4

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 V AC and 75

to 1,500 V DC meet the required safety standards for EN 61131-2.

6-3 Conformance to EC Directives

The CompoNet Master Units comply with EC Directives. To ensure that the

machine or device in which a CompoNet Master Unit is used complies with

EC Directives, the CompoNet Master Unit must be installed as follows:

1,2,3... 1. The CompoNet Master Unit must be installed within a control panel.

2. You must use reinforced insulation or double insulation for the DC power

supplies used for the communications power supply and I/O power supplies.

3. CompoNet Master Units complying with EC Directives also comply with the

Common Emission Standard (EN 61000-6-4). Radiated emission characteristics (10-m regulations) may vary depending on the configuration of the

control panel used, other devices connected to the control panel, wiring,

and other conditions. You must therefore confirm that the overall machine

or equipment complies with EC Directives.

(Radiated emission: 10-m regulations)

xxii

Page 22

SECTION 1

Smart Slaves and Features

This section provides an overview of the DeviceNet DRT2-series Smart Slaves, including lists of models, and information

on features that were not included in the DRT1-series Slaves.

1-1 DRT2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-2 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 DRT2 Slaves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-2-1 General-purpose Slaves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-2-2 Environment-resistive Slaves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-2-3 Analog Slaves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1-2-4 Smart Slave Feature Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-2-5 Installing and Connecting Slaves . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1

Page 23

DRT2 Features Section 1-1

1-1 DRT2 Features

1-1-1 Overview

The DRT2-series Smart Slaves can be used to collect various information that

improves the operating rate of the equipment, in addition to performing basic

input and output of ON/OFF signals.

A maintenance system can be configured separately from the control system.

This enables a balance between control and maintenance using an existing

DeviceNet network, contributing to reduced startup time, shorter recovery

time when problems occur, and preventative maintenance of the equipment.

• Control System

The default settings for remote I/O communications with the PLC are the

same as for previous Slaves, whereby real I/O is allocated for each node

address. One difference with previous Slaves is that an area for Smart

Slave status information can be allocated to the Smart Slaves within the

IN Area of the Master. This is in addition to real I/O. (Settings are performed using the Configurator or explicit messages.)

• Maintenance System

The Configurator is used to read and write various types of equipment

information stored in the DRT2 Slave. The same equipment information

can also be read and written by sending explicit messages to the DRT2

Slave from the Master (such as a PLC or a DeviceNet Master Board

mounted in a personal computer).

1-1-2 Features

Common Features

Node Addresses Set

Using Rotary Switches

Automatically Detected

Baud Rate

Remote I/O

Communications

Network Power Supply

Volt a g e M onito r

DRT2-series Slaves have the following features.

Node addresses are set using rotary switches, which are clearer than the previous DIP switch settings. Node addresses can also be set from the Configurator.

Previous models required the baud rate to be set using the Slave's DIP

switch, but Smart Slaves do not require the baud rate to be set. The Smart

Slave automatically operates at the baud rate of the Master Unit.

When using default remote I/O communications from the PLC for DRT2

Slaves, only real I/O is allocated. This is the same method used by the previous DRT1 Slaves.

The following status information can be allocated in addition to real I/O, in the

IN Area of the Master by using the Configurator or explicit messages to make

user settings (default connection path settings):

Generic Status Flags, Top/Valley Detection Timing Flags, Analog Status Flags

As part of the remote I/O function, Network power supply voltages (present,

peak, and bottom values) can be recorded in the Slave. The Configurator can

be used to read the information. The Slave also maintains a set value for monitoring the voltage, and will provide notification in the Status Area if the voltage

drops below the set level.

Unit Conduction Time

Monitor

2

The time that the Slave's internal circuit power is ON can be totaled and

recorded. The Configurator or explicit messages can be used to read the

information. The Slave also maintains a set value for monitoring the Unit's ON

time, and will provide notification in the Status Area if the set time is reached.

Page 24

DRT2 Features Section 1-1

Slave Comments User-set names can be assigned and saved in the Slave for each Unit.

I/O Comments User-set names can be assigned and saved in the Slave for each of the I/O

contacts, such as sensors or valves, that are connected to the Slave.

Communications Error

History Monitor

Last Maintenance Date The dates on which maintenance is performed can be written to the Unit using

The error statuses (communications error cause code and communications

power supply voltage when error occurred) for the last four communications

errors that occurred can be recorded in the Slave. The Configurator can be

used to read the information.

the Configurator.

Features of General-purpose Slaves and Environment-resistive Slaves

No Internal Circuit Power

Supply Wiring for Slaves

I/O Power Status Monitor The I/O Power Status Monitor is used to detect whether the I/O power supply

Input Filter The input filter is used to read the input value several times during the set

Power ON Delay The I/O power supply can be monitored to stop any input when the I/O power

Contact Operation

Counter

The communications power supply is used for the internal circuit power for the

Unit. This eliminates the need to wire the Unit's internal circuit power supply.

is connected and provide notification in the Status Area. The Configurator or

explicit messages can be used to read the information.

interval and remove irregular data caused by noise and switch chattering.

This function can also be used to create ON/OFF delays.

is OFF and for 100 ms after it is turned ON. This function prevents incorrect

inputs caused by inrush current at startup after the I/O power is turned ON.

The number of times each input or output contact changes from OFF to ON

can be counted (maximum resolution: 50 Hz). The Configurator or explicit

messages can be used to read the information. The Slave also maintains a

set value for monitoring the number of contact operations, and will provide

notification in the Status Area if the set value is reached.

Note The Contact Operation Counter and Total ON Time Monitor cannot be used at

the same time for a single contact.

Total ON Time Monitor This function is used to total and record in the Slave the time that devices,

such as sensors and relays, that are connected to the Slave are ON. The

Configurator or explicit messages can be used to read the information. The

Slave also maintains a set value for monitoring the total ON time, and will provide notification in the Status Area if the set value is reached.

Note The Total ON Time Monitor and Contact Operation Counter cannot be used at

the same time for a single contact.

Detection of Sensor Power

Short-circuit

The I/O power supply current is monitored and if the current exceeds the rated

current, it is judged to be a sensor power short-circuit and the sensor power

output is forced OFF.

Environment-resistive Slaves, Advanced Models: The number of the shorted

contact can be checked from the I/O status indicators. The Configurator or

explicit message communications can also be used to read which connector

or sensor has shorted. The Slave will automatically reset when the cause of

the short-circuit has been removed.

Sensor Connector Terminals: When a short-circuit is detected in any of the

contacts, the I/O power for the Unit is turned OFF. A short-circuit detection

error can be confirmed using the SHTO indicator. The Configurator or explicit

messages can also be used to read the error status.

3

Page 25

DRT2 Features Section 1-1

Screw-less Clamp Terminals (DRT2-@D32SLH-1): The number of the shorted

contact can be checked using the I/O status indicators. The Configurator or

explicit message communications can also be used to read which terminal

sensor has shorted. The Slave will automatically reset when the cause of the

short-circuit has been removed.

External Load Shortcircuit Detection

Sensor Disconnected

Detection

External Load Short-circuit Detection monitors the output load current and if

the Output Unit's current exceeds the set value, it is judged to be an external

load short-circuit and the output is forced OFF to prevent damage to the Unit's

output circuit. When an external load short-circuit is detected, the External

Load Short-circuit Detection Flag turns ON. The External Load Short-circuit

Detection Flag can be read by either the Configurator or explicit messages.

The I/O power supply current is monitored and it is determined whether a sensor is disconnected. The Configurator or explicit messages can be used to

read which sensor is not connected.

Features of Remote I/O Terminals (General-purpose Slaves)

Detachable Terminal

Block

Expansion Units A Basic Unit can be combined with an Expansion Unit. The various I/O combi-

Operation Time Monitor

The terminal block can be detached.

nations that are possible, such as 16 inputs and 8 outputs, or 24 inputs (16

inputs plus 8 inputs), increase the system configuration possibilities.

■ Basic I/O Unit + Expansion Unit

The time that lapses from when the output turns ON to when the input turns

ON can be measured at high speed from the Slave (without relying on the ladder program). The Slave also maintains a set value for monitoring the operation time, and will provide notification the Status Area if the set time is

exceeded. The Configurator or explicit messages can be used to read the

information.

The DRT2-MD16(-1) cannot be expanded with an Expansion Unit, but its

operation time can be monitored.

■ Three-tier Terminal Block

In contrast to the existing Units, which could only measure I/O (OUT-IN), these

Units can also measure operating times for IN-IN and OUT-OUT combinations. In addition, the trigger edge (ON to OFF or OFF to ON) can be selected

and input and output numbers can be freely combined for flexible settings.

Features of Connector Terminals (General-purpose Slaves)

Wired with Industry

Standard Sensor

Connectors (Sensor

Connector Terminals)

Operation Time Monitor

Industry standard sensor connectors are provided to standardize the I/O wiring, thereby making wiring simpler and less labor intensive.

■ Sensor Connector Terminals

The time that lapses from when the output turns ON to when the input turns

ON can be measured at high speed from the Slave (without relying on the ladder program). The Slave also maintains a set value for monitoring the operation time, and will provide notification the Status Area if the set time is

exceeded. The Configurator or explicit messages can be used to read the

information.

4

Page 26

DRT2 Features Section 1-1

■ MIL Connector Terminals/Board Terminals

In contrast to the existing Units, which could only measure I/O (OUT-IN), these

Units can also measure operating times for IN-IN and OUT-OUT combinations. In addition, the trigger edge (ON to OFF or OFF to ON) can be selected

and input and output numbers can be freely combined for flexible settings.

Features of Screw-less Clamp Terminals (General-purpose Slaves)

Labor-saving Clamp

Termina l Block

Detection Functions

(Standard Feature, DRT2@D@@SLH(-1) Only)

Operation Time Monitor In contrast to the existing Units, which could only measure I/O (OUT-IN), these

For I/O wiring, a screw-less clamp terminal block is provided. Wiring is

reduced by the use of post terminals that can be easily inserted and then later

removed by simply pressing a release button.

Detection results can be read by using the Configurator or explicit messages if

the sensor short-circuit/disconnected and external load short-circuit/disconnected detection functions are used. The error location can be rapidly specified and restored.

Units can also measure operating times for IN-IN and OUT-OUT combinations. In addition, the trigger edge (ON to OFF or OFF to ON) can be selected

and input and output numbers can be freely combined for flexible settings.

Features of Environment-resistive Terminals

Dust-proof and

Waterproof Construction

(IP67) for High Resistance

to Environment

No Power Supply Wiring

for Input Devices

(Advanced Models Only)

Connect High-load

Devices (1.5 A Max.,

Advanced Models Only)

The environment-resistive construction enables usage in locations subject to

oil and water splashes (IP67). An environment-resistive box is not required,

enabling greater downsizing and reducing wiring labor.

Power for communications, internal circuits, and input devices is shared, making wiring necessary only for the communications power supply. With standard models, a power supply must be wired to I/O devices.

The rated output current is 1.5 A, allowing the direct connection of output

devices with high loads.

Operation Time Monitor

(DRT2-MD16CL(-1) and

DRT2-@D04CL Only)

The time that lapses from when the output turns ON to when the input turns

ON can be measured at high speed from the Slave (without relying on the ladder program). The Slave also maintains a set value for monitoring the operation time, and will provide notification the Status Area if the set time is

exceeded. The Configurator or explicit messages can be used to read the

information.

Analog Slave Features

Setting the Number of AD

Conversion Points (DRT2AD04 Only)

Moving Average (Input

Units Only)

Scaling Scaling allows values to be converted according to the industry unit required

Peak/Bottom Hold (Input

Units Only)

The conversion cycle when all 4 analog input points are used is 4 ms max.

The AD conversion cycle can be shortened by reducing the number of points

used (i.e., the number of AD conversion points).

Analog Input Terminals and Temperature Input Terminals can calculate the

average of the past eight analog input values to produce a stable input value

even when the input value is unsteady.

by the user. It reduces the number of operations requiring ladder programming in the Master CPU Unit. Scaling also supports an offset function for compensating for errors in scaled values.

The maximum (peak) and minimum (bottom) values input to Analog Input Terminals and Temperature Input Terminals can be held. These values can then

5

Page 27

DRT2 Features Section 1-1

be compared with alarm set values, and flags turned ON as appropriate to

indicate the status (comparator function).

Top/Valley Hold (Input

Units Only)

Rate of Change (Input

Units Only)

Comparator (Input Units

Only)

Off-wire Detection (Input

Units Only)

User Adjustment Input (or output) can be adjusted to compensate for errors in the input (or out-

The top and valley values for values input to Analog Input Terminals and Temperature Input Terminals can be held. The timing of tops and valleys can be

monitored with the Top/Valley Detection Timing Flags. The top and valley values can be compared with alarm set values, and flags turned ON as appropriate to indicate the status (comparator function).

The rate of change for values input to Analog Input Terminals and Temperature Input Terminals can be obtained for each sampling cycle.

Values input to Analog Input Terminals and Temperature Input Terminals or

values after math processing can be compared to the alarm set values (HH,

H, L, and LL), and the result indicated with the Analog Status Flags. If the

result is outside the set range, the Normal Flag (pass signal) is turned ON.

With Analog Input Terminals, disconnections can be detected in wiring for

analog (voltage or current) inputs that are enabled as AD conversion points.

The status can be checked at the Master using the Off-wire Detection Flag.

This function is valid only for the input ranges 4 to 20 mA and 1 to 5 V.

With Temperature Input Terminals, disconnections can be detected for each

sensor input. The status can be checked at the Master using the Off-wire

Detection Flag.

put) voltage or current resulting from the characteristics or connection methods of the input (or output) device. Compensation is performed by applying

linear conversion based on the points corresponding to 0% and 100%.

Cumulative Counter A cumulated value that approximates the integral of analog input (or output)

values or a temperature input value over time can be calculated and read.

Monitor values can also be set in the Unit. When the cumulated count value

exceeds the set monitor value, the Cumulative Counter Flag in the area for

Generic Status Flags turns ON.

Communications Error

Output (Output Units

Only)

Top/Valley Count Function The number of times the top or valley value is reached can be counted for an

Temperature Range

Timing Function

Input Temperature

Variation Detection

Function

The values output by Output Units when errors occur can be set for each output.

application that has fixed cycles of temperature changes. Explicit messages

can be used to see if the number of times that is counted has exceeded a

monitoring set value.

The length of time that the system is at a user-set temperature or within a

user-set temperature range can be measured in seconds. Explicit messages

can be used to see if the measured time has exceeded a monitoring set value.

A relative comparison can be made between two inputs (0 to 3) and to detect

temperature differences between two inputs or with a monitoring set value.

Explicit messages can be used to see if the temperature difference has

exceeded a monitoring set value.

6

Page 28

DRT2 Slaves Section 1-2

1-2 DRT2 Slaves

The DRT2-series Smart Slaves are classified into the following categories.

• General-purpose Slaves

Slaves with digital I/O functions using standard connectors for communications cables.

• Environment-resistive Slaves

Slaves with I/O functions using round waterproof connectors for communications cables.

• Analog Slaves

Slaves with analog I/O functions using standard connectors for communications cables.

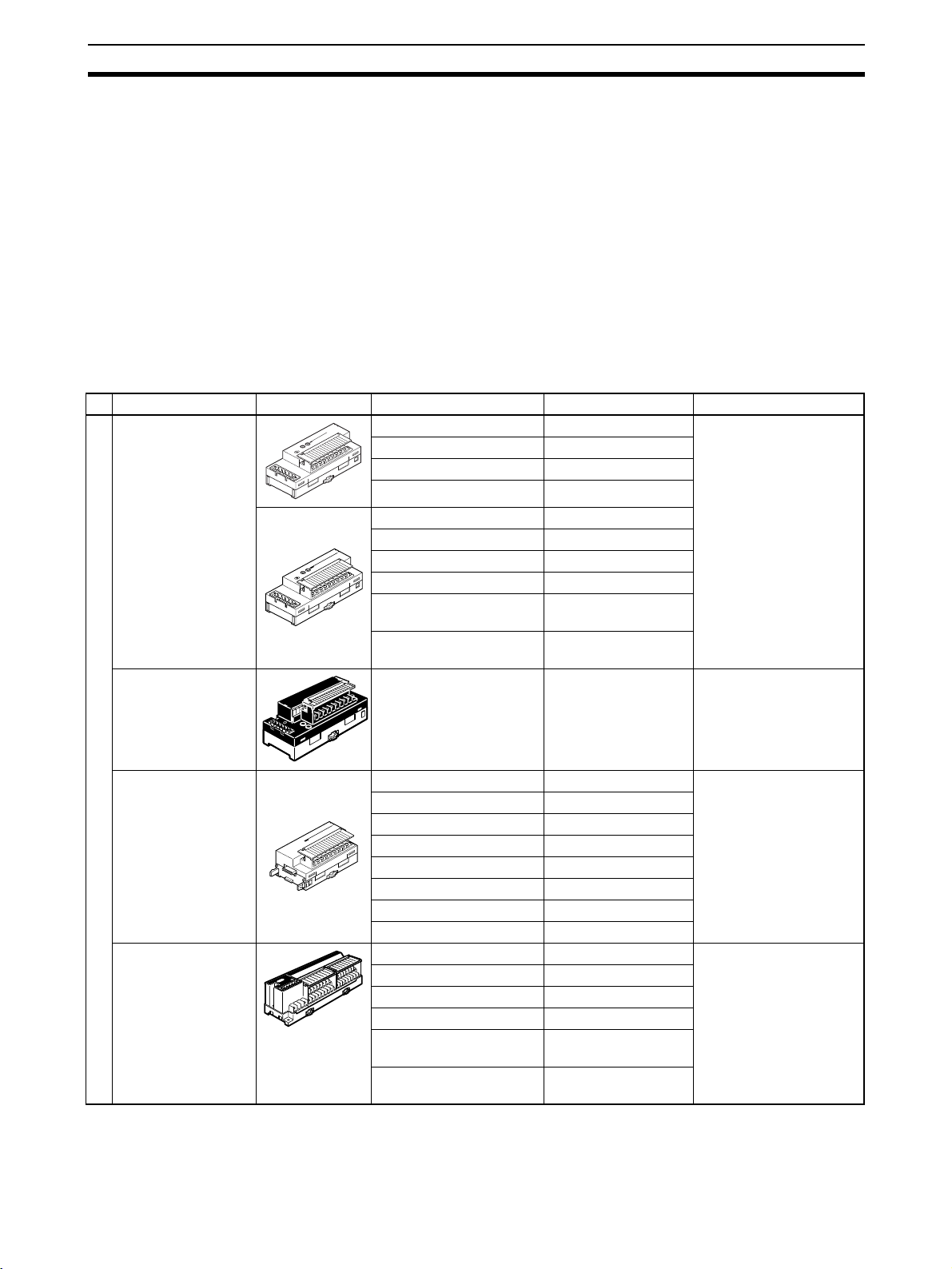

1-2-1 General-purpose Slaves

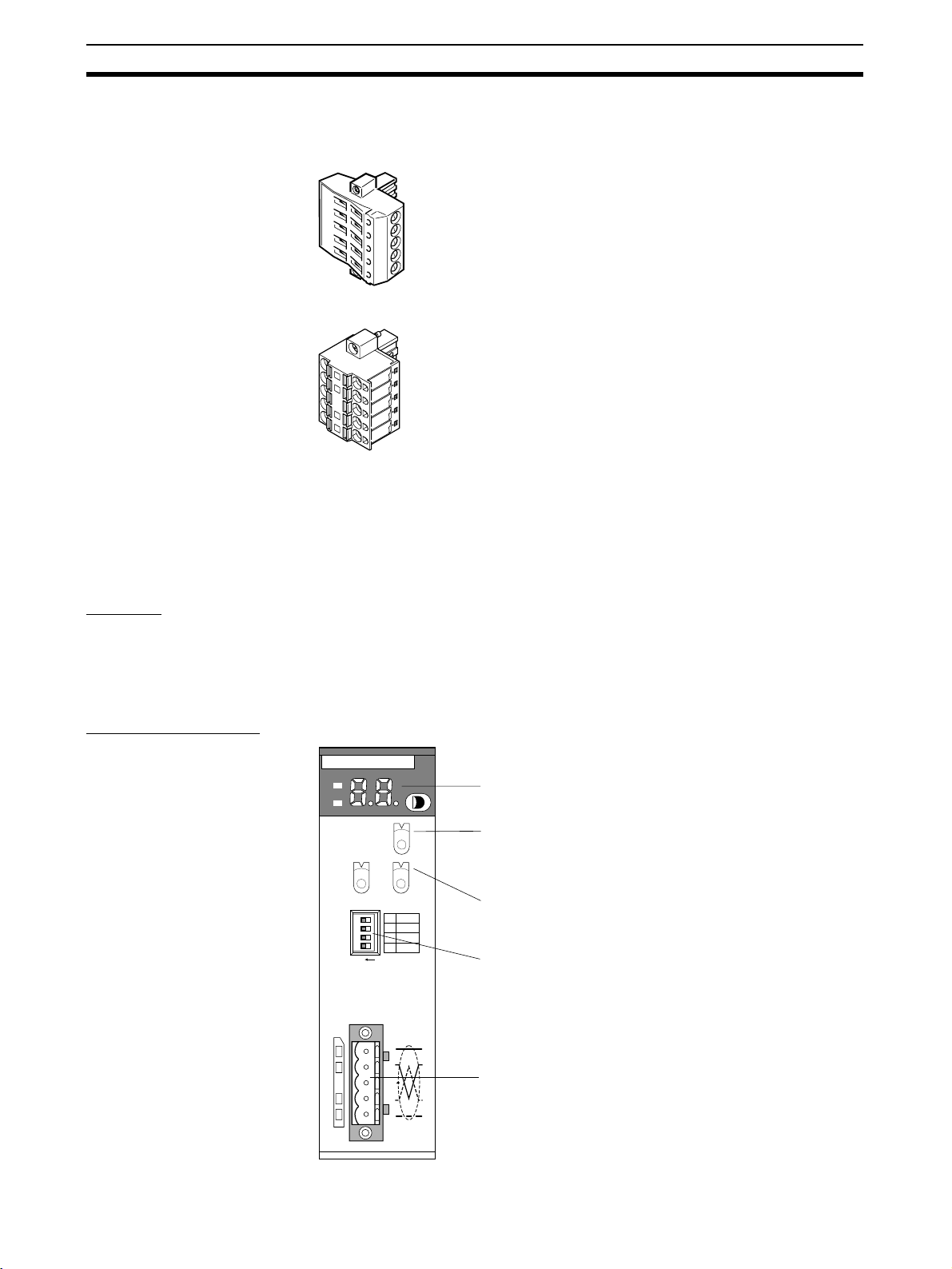

Name Appearance I/O points Model number Remarks

Remote I/O Terminals with Transistors

Remote I/O Terminal with Relay Outputs

8 input points (NPN) DRT2-ID08 Terminal block mounted/

8 input points (PNP) DRT2-ID08-1

8 output points (NPN) DRT2-OD08

8 output points (PNP) DRT2-OD08-1

16 input points (NPN) DRT2-ID16

16 input points (PNP) DRT2-ID16-1

16 output points (NPN) DRT2-OD16

16 output points (PNP) DRT2-OD16-1

8 input points/8 output

points (NPN)

8 input points/8 output

points (PNP)

16 output points DRT2-ROS16 Relay outputs

DRT2-MD16

DRT2-MD16-1

removed using screws.

Remote I/O Terminal Expansion Units

with Transistors

Remote I/O Terminals

Remote I/O Terminals with 3-tier Terminal Blocks and

Transistors

16 input points (NPN) XWT-ID16 Expansion Unit for

16 input points (PNP) XWT-ID16-1

16 output points (NPN) XWT-OD16

16 output points (PNP) XWT-OD16-1

8 input points (NPN) XWT-ID08

8 input points (PNP) XWT-ID08-1

8 output points (NPN) XWT-OD08

8 output points (PNP) XWT-OD08-1

16 input points (NPN) DRT2-ID16TA Wiring locations easy to

16 input points (PNP) DRT2-ID16TA-1

16 output points (NPN) DRT2-OD16TA

16 output points (PNP) DRT2-OD16TA-1

8 input points/8 output

points (NPN)

8 input points/8 output

points (PNP)

DRT2-MD16TA

DRT2-MD16TA-1

increasing inputs or outputs of the Basic Unit.

find (wiring to the same

terminal not required).

Cannot be expanded

with an Expansion Unit.

7

Page 29

DRT2 Slaves Section 1-2

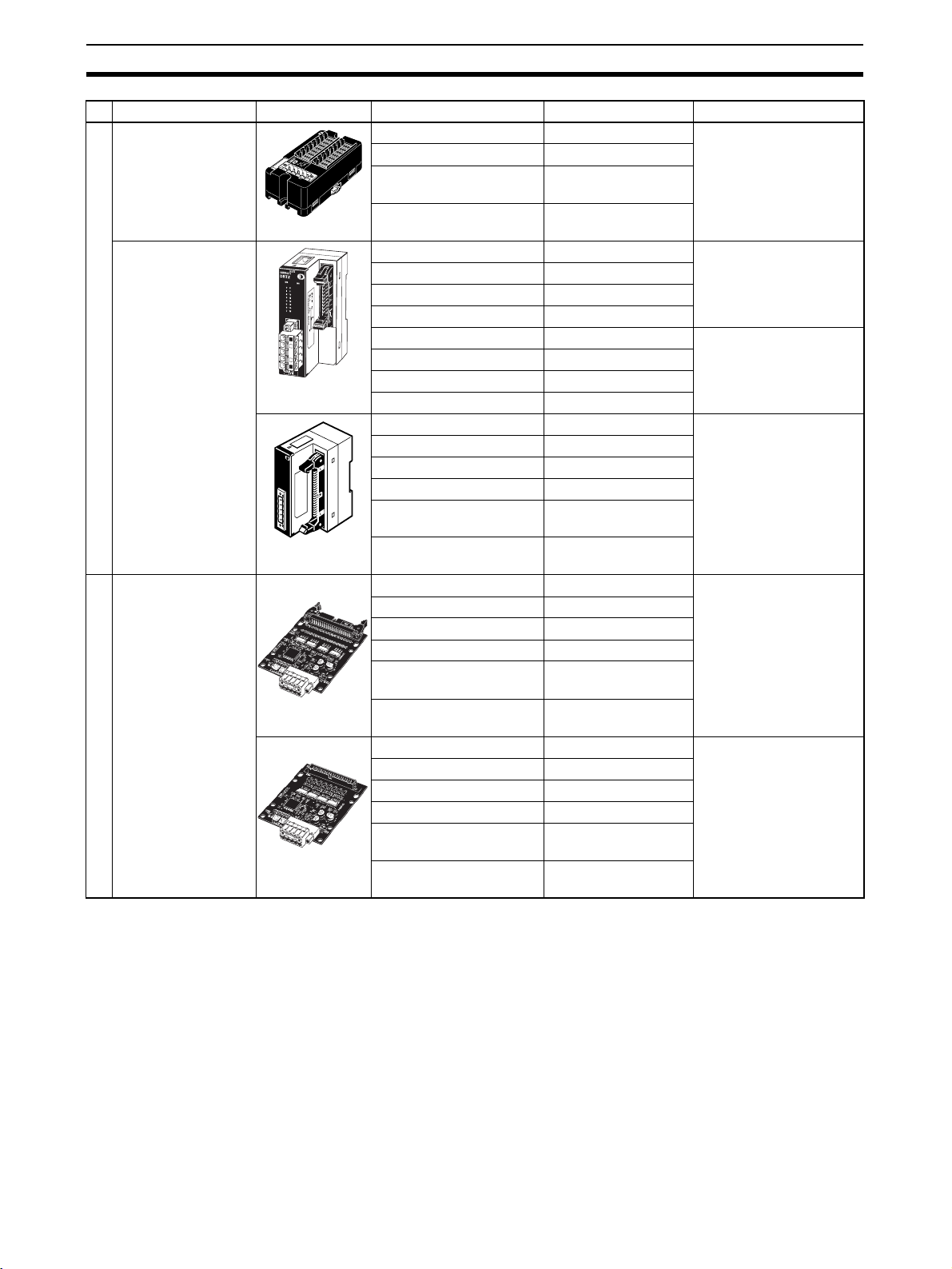

Name Appearance I/O points Model number Remarks

Sensor Connector

Terminals with Transistors

MIL Connector Terminals with Transistors

Connector Terminals

Board MIL Connector Terminals with

Transistors

Connector Terminals

16 input points (NPN) DRT2-ID16S Use industry standard

16 input points (PNP) DRT2-ID16S-1

8 input points/8 output

DRT2-MD16S

sensor connectors.

points (NPN)

8 input points/8 output

DRT2-MD16S-1

points (PNP)

16 input points (NPN) DRT2-ID16ML Connects to relay termi-

16 input points (PNP) DRT2-ID16ML-1

nal using MIL cable.

16 output points (NPN) DRT2-OD16ML

16 output points (PNP) DRT2-OD16ML-1

16 input points (NPN) DRT2-ID16MLX A connecting cable (10

16 input points (PNP) DRT2-ID16MXL-1

cm) is included.

16 output points (NPN) DRT2-OD16MLX

16 output points (PNP) DRT2-OD16MXL-1

32 input points (NPN) DRT2-ID32ML Connects to relay termi-

32 input points (PNP) DRT2-ID32ML-1

nal using MIL cable.

32 output points (NPN) DRT2-OD32ML

32 output points (PNP) DRT2-OD32ML-1

16 input points/16 output

DRT2-MD32ML

points (NPN)

16 input points/16 output

DRT2-MD32ML-1

points (PNP)

32 input points (NPN) DRT2-ID32B MIL connectors mounted

32 input points (PNP) DRT2-ID32B-1

parallel to board

32 output points (NPN) DRT2-OD32B

L

A

32 output points (PNP) DRT2-OD32B-1

N

I

M

n

R

o

V

i

t

4

E

a

2

T

r

o

:

E

p

r

E

T

o

C

O

C

R

M

U

E

n

o

O

R

r

S

m

O

16 input points/16 output

DRT2-MD32B

points (NPN)

16 input points/16 output

DRT2-MD32B-1

points (PNP)

32 input points (NPN) DRT2-ID32BV MIL connectors mounted

32 input points (PNP) DRT2-ID32BV-1

32 output points (NPN) DRT2-OD32BV

L

A

N

I

M

n

R

V

o

i

4

E

t

2

a

T

r

:

o

E

p

E

T

r

o

C

O

C

R

M

U

E

n

O

o

R

r

S

m

32 output points (PNP) DRT2-OD32BV-1

O

16 input points/16 output

DRT2-MD32BV

perpendicular to board

points (NPN)

16 input points/16 output

DRT2-MD32BV-1

points (PNP)

8

Page 30

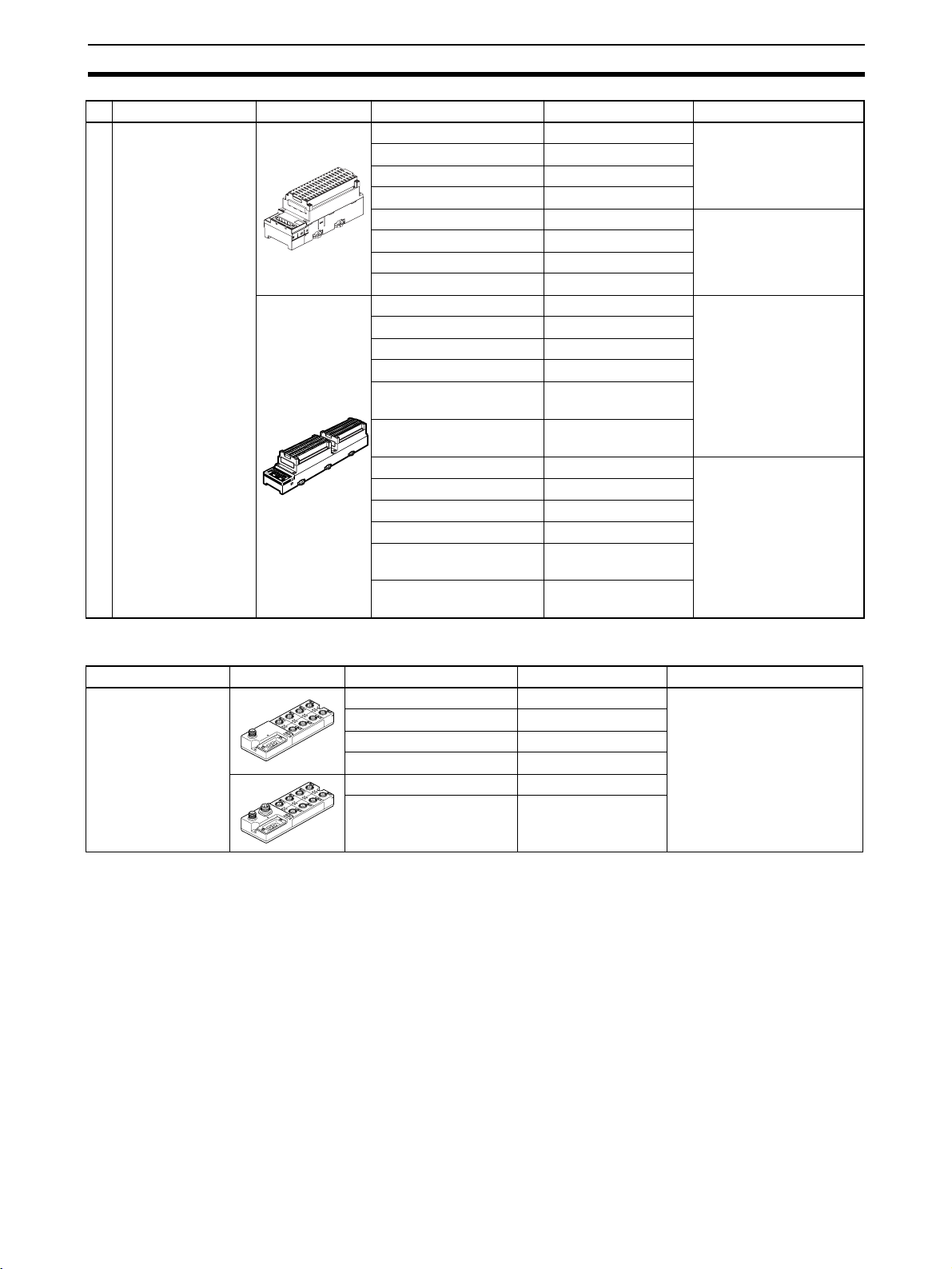

DRT2 Slaves Section 1-2

Name Appearance I/O points Model number Remarks

Screw-less Clamp

Terminal with Transistors

Screw-less Clamp Terminals

16 input points (NPN) DRT2-ID16SL Without detection func-

16 input points (PNP) DRT2-ID16SL-1

16 output points (NPN) DRT2-OD16SL

16 output points (PNP) DRT2-OD16SL-1

16 input points (NPN) DRT2-ID16SLH With detection function

16 input points (PNP) DRT2-ID16SLH-1

16 output points (NPN) DRT2-OD16SLH

16 output points (PNP) DRT2-OD16SLH-1

32 input points (NPN) DRT2-ID32SL Without detection func-

32 input points (PNP) DRT2-ID32SL-1

32 output points (NPN) DRT2-OD32SL

32 output points (PNP) DRT2-OD32SL-1

16 input points/16 output

points (NPN)

16 input points/16 output

points (PNP)

32 input points (NPN) DRT2-ID32SLH With detection function

32 input points (PNP) DRT2-ID32SLH-1

32 output points (NPN) DRT2-OD32SLH

32 output points (PNP) DRT2-OD32SLH-1

16 input points/16 output

points (NPN)

16 input points/16 output

points (PNP)

DRT2-MD32SL

DRT2-MD32SL-1

DRT2-MD32SLH

DRT2-MD32SLH-1

tion

tion

1-2-2 Environment-resistive Slaves

Name Appearance I/O points Model number Remarks

Environment-resistive Terminals,

Advanced Models

8 input points (NPN) DRT2-ID08C Waterproof, oil-proof, and

8 input points (PNP) DRT2-ID08C-1

16 input points (NPN) DRT2-HD16C

16 input points (PNP) DRT2-HD16C-1

8 output points (NPN) DRT2-OD08C

8 output points (PNP) DRT2-OD08C-1

spatter-proof construction

(IP67).

Equipped with detection

functions.

9

Page 31

DRT2 Slaves Section 1-2

Name Appearance I/O points Model number Remarks

Environment-resistive Terminals, Standard Models

4 input points (NPN) DRT2-ID04CL Waterproof, oil-proof, and

4 input points (PNP) DRT2-ID04CL-1

4 output points (NPN) DRT2-OD04CL

4 output points (PNP) DRT2-OD04CL-1

8 input points (NPN) DRT2-ID08CL

8 input points (PNP) DRT2-ID08CL-1

16 input points (NPN) DRT2-HD16CL

16 input points (PNP) DRT2-HD16CL-1

8 output points (NPN) DRT2-OD08CL

8 output points (PNP) DRT2-OD08CL-1

16 output points (NPN) DRT2-WD16CL

16 output points (PNP) DRT2-WD16CL-1

8 input points/8 output

points (NPN)

8 input points/8 output

points (PNP)

DRT2-MD16CL

DRT2-MD16CL-1

spatter-proof construction

(IP67).

Not equipped with detection

functions.

1-2-3 Analog Slaves

Name Appearance I/O points Model number Remarks

Analog Terminals 4 input points

(0 to 5 V, 1 to 5 V, 0 to

10 V, −10 to 10 V, 0 to

20 mA, 4 to 20 mA)

4 input points

(0 to 5 V, 1 to 5 V, 0 to

10 V, 0 to 20 mA, 4 to

20 mA)

DRT2-AD04 Terminal block mounted/

removed using screws.

The DRT2-AD04H is a High-

resolution Terminal (1/30,000

FS).

DRT2-AD04H

Temperature Input

Te r mi n al s

2 output points

(0 to 5 V, 1 to 5 V, 0 to

10 V, −10 to 10 V, 0 to

20 mA, 4 to 20 mA)

4 input points

(Switchable between R,

S, K1, K2, J1, J1, T, E, B,

N, L1, L2, U, W, and

PL2.)

4 input points

(Switchable between PT,

JPT, PT2, and JPT2.)

DRT2-DA02

DRT2-TS04T Thermocouple input

DRT2-TS04P Platinum resistance ther-

mometer input

10

Page 32

DRT2 Slaves Section 1-2

1-2-4 Smart Slave Feature Support

Yes: Supported.; No: Not supported.

Type General-purpose Slaves

Remote I/O Terminals

Standard Relay

Feature Input Output Mix Output Input Output Mix

Operation Time Monitor Yes (for inputs + outputs only) (See note

Contact Operation Counter Yes

Unit ON Time Monitor Yes

Total ON Time Monitor Yes

Naming Units Yes

Naming connected devices Yes

Network Power Voltage Monitor Yes

I/O Power Status Monitor Yes No Yes

Communications Error History Monitor Yes

Input filter Yes No Yes No Yes No Yes

Preventing malfunctions caused by inrush

current at startup

Sensor power short-circuit detection No

Sensor disconnected detection No

External load short-circuit detection No

External load disconnected detection No

Detachable terminal block construction Yes

Automatic baud rate detection Yes

Power supply wiring not required for Units Yes

Power supply wiring not required for input

devices

Expansion using Expansion Units Yes (See note 2.) No No No

Scaling No

User adjustment No

Last maintenance date Yes

Cumulative counter No

Moving average No

Setting the number of AD conversion points No

Peak/bottom hold No

Top / va ll e y ho l d No

Rate of change No

Comparator No

Communications error output No

1.)

Ye s N o Ye s N o Ye s N o Ye s

No Yes No No No

outputs

3-tier terminal block

Ye s

Note 1. The Operation Time Monitor cannot be used with the DRT2-@D08(-1).

2. The DRT2-@D08(-1) and DRT2-MD16(-1) cannot be expanded with an Ex-

pansion Unit.

3. The Contact Operation Counter and Total ON Time Monitor cannot be

used at the same time for the same contact.

11

Page 33

DRT2 Slaves Section 1-2

Yes: Supported.; No: Not supported.

Type General-purpose Slaves

Sensor Connector Terminals

Sensor connectors MIL connectors

(Board Terminals)

Feature Input Mix Input Output Mix

Operation Time Monitor No Yes Yes

Contact Operation Counter Yes

Unit ON Time Monitor Yes

Total ON Time Monitor Yes

Naming Units Yes

Naming connected devices Yes

Network Power Voltage Monitor Yes

I/O Power Status Monitor No Yes

Communications Error History Monitor Yes

Input filter Yes Yes No Yes

Preventing malfunctions caused by inrush current at

startup

Sensor power short-circuit detection Yes No

Sensor disconnected detection No

External load short-circuit detection No Yes No

External load disconnected detection No

Detachable terminal block construction No

Automatic baud rate detection Yes

Power supply wiring not required for Units Yes

Power supply wiring not required for input devices Yes No

Expansion using Expansion Units No

Scaling No

User adjustment No

Last maintenance date Yes

Cumulative counter No

Moving average No

Setting the number of AD conversion points No

Peak/bottom hold No

Top / va ll e y ho l d No

Rate of change No

Comparator No

Communications error output No

Ye s Ye s N o Ye s

12

Note The Contact Operation Counter and Total ON Time Monitor cannot be used at

the same time for the same contact.

Page 34

DRT2 Slaves Section 1-2

Yes: Supported.; No: Not supported.

Type General-purpose Slaves

Screw-less Clamp Terminals

DRT2-

@D16SLH (With

detection function)

Feature Input Output Input Output

Operation Time Monitor Yes

Contact Operation Counter Yes

Unit ON Time Monitor Yes

Total ON Time Monitor Yes

Naming Units Yes

Naming connected devices Yes

Network Power Voltage Monitor Yes

I/O Power Status Monitor Yes

Communications Error History Monitor Yes

Input filter Yes No Yes No

Preventing malfunctions caused by inrush current at

startup

Sensor power short-circuit detection Yes No No

Sensor disconnected detection Yes No No

External load short-circuit detection No Yes No

External load disconnected detection No Yes No

Detachable terminal block construction Yes

Automatic baud rate detection Yes

Power supply wiring not required for Units Yes

Power supply wiring not required for input devices No

Expansion using Expansion Units No

Scaling No

User adjustment No

Last maintenance date Yes

Cumulative counter No

Moving average No

Setting the number of AD conversion points No

Peak/bottom hold No

Top / va ll e y ho l d No

Rate of change No

Comparator No

Communications error output No

Ye s N o Ye s N o

DRT2-@D16SL (Without

detection function)

The Contact Operation Counter and Total ON Time Monitor cannot be used at

the same time for the same contact.

13

Page 35

DRT2 Slaves Section 1-2

Yes: Supported.; No: Not supported.

Type General-purpose Slaves

Screw-less Clamp Terminals

DRT2-@D32SLH (With detection

Feature Input Output Mix Input Output Mix

Operation Time Monitor Yes Yes

Contact Operation Counter Yes

Unit ON Time Monitor Yes

Total ON Time Monitor Yes

Naming Units Yes

Naming connected devices Yes

Network Power Voltage Monitor Yes

I/O Power Status Monitor Yes

Communications Error History Monitor Yes

Input filter Yes No Yes Yes No Yes

Preventing malfunctions caused by inrush

current at startup

Sensor power short-circuit detection Yes No Yes No

Sensor disconnected detection Yes No Yes No

External load short-circuit detection No

External load disconnected detection No Yes Yes No

Detachable terminal block construction Yes

Automatic baud rate detection Yes

Power supply wiring not required for Units Yes

Power supply wiring not required for input

devices

Expansion using Expansion Units No

Scaling No

User adjustment No

Last maintenance date Yes

Cumulative counter No

Moving average No

Setting the number of AD conversion points No

Peak/bottom hold No

Top / va ll e y ho l d No

Rate of change No

Comparator No

Communications error output No

Ye s N o Ye s Ye s N o Ye s

No

function)

DRT2-@D32SL (Without detection

function)

14

Note The Contact Operation Counter and Total ON Time Monitor cannot be used at

the same time for the same contact.

Page 36

DRT2 Slaves Section 1-2

Yes: Supported.; No: Not supported.

Type Environment-resistive Terminals

Advanced models Standard models

Feature Input Output Input Output Mix

Operation Time Monitor No No No (See note.) Yes

Contact Operation Counter Yes Yes Yes Yes Yes

Unit ON Time Monitor Yes Yes Yes Yes Yes

Total ON Time Monitor Yes Yes Yes Yes Yes

Naming Units Yes Yes Yes Yes Yes

Naming connected devices Yes Yes Yes Yes Yes

Network Power Voltage Monitor Yes Yes Yes Yes Yes

I/O Power Status Monitor No Yes Yes Yes Yes

Communications Error History Monitor Yes Yes Yes Yes Yes

Input filter Yes No Yes No Yes

Preventing malfunctions caused by inrush current at

startup

Sensor power short-circuit detection Yes No No No No

Sensor disconnected detection Yes No No No No

External load short-circuit detection No Yes No No No

External load disconnected detection No No No No No

Detachable terminal block construction No No No No No

Automatic baud rate detection Yes Yes Yes Yes Yes

Power supply wiring not required for Units Yes Yes Yes Yes Yes

Power supply wiring not required for input devices Yes No No No No

Expansion using Expansion Units No No No No No

Scaling NoNoNoNoNo

User adjustment No No No No No

Last maintenance date Yes Yes Yes Yes Yes

Cumulative counter NoNoNoNoNo

Moving average No No No No No

Setting the number of AD conversion points No No No No No

Peak/bottom hold NoNoNoNoNo

Top/valley hold No No No No No

Rate of change No No No No No

Comparator No No No No No

Communications error output No No No No No

Top/valley count function No No No No No

Temperature range timing function No No No No No

Input temperature variation detection function No No No No No

Ye s N o Ye s N o Ye s

Note (1) The Operation Time Monitor can be used with the DRT2-@D04CL(-1).

(2) The Contact Operation Counter and Total ON Time Monitor cannot be

used at the same time for the same contact.

15

Page 37

DRT2 Slaves Section 1-2

Yes: Supported.; No: Not supported.

Type Analog Slaves

Analog Terminals Temperature

DRT2-AD04 DRT2-AD04H DRT2-DA02

Feature Input Output Input

Operation Time Monitor No No No No

Contact Operation Counter No No No No

Unit ON Time Monitor Yes Yes Yes Yes

Total ON Time Monitor No No No No

Naming Units Yes Yes Yes Yes

Naming connected devices Yes Yes Yes Yes

Network Power Voltage Monitor Yes Yes Yes Yes

I/O Power Status Monitor No No No No

Communications Error History Monitor Yes Yes Yes Yes

Input filter No No No No

Preventing malfunctions caused by inrush current at startup No No No No

Sensor power short-circuit detection No No No No

Sensor disconnected detection No No No No

External load short-circuit detection No No No No

External load disconnected detection No No No No

Detachable terminal block construction Yes Yes Yes Yes

Automatic baud rate detection Yes Yes Yes Yes

Power supply wiring not required for Units Yes Yes Yes Yes

Power supply wiring not required for input devices No No No No

Expansion using Expansion Units No No No No

Scaling Yes Yes Yes Yes

User adjustment Yes Yes Yes Yes

Last maintenance date Yes Yes Yes Yes

Cumulative counter Yes Yes Yes Yes

Moving average Yes Yes No Yes

Setting the number of AD conversion points Yes No No No

Peak/bottom hold Yes Yes No Yes

Top/valley hold Yes Yes No Yes

Rate of change Yes Yes No Yes

Comparator Yes Yes No Yes

Communications error output No No Yes No

Top/valley count function No No No Yes

Temperature range timing function No No No Yes

Input temperature variation detection function No No No Yes

Input

Ter mina l

16

Note The Contact Operation Counter and Total ON Time Monitor cannot be used at

the same time for the same contact.

Page 38

DRT2 Slaves Section 1-2

1-2-5 Installing and Connecting Slaves

Slave type Communi-

cations

cables

General-purpose Slaves

Standard

rectangular

connector

Name Model Slave

Remote I/O

Te r m i n a ls

with Transistors

Remote I/O

Te r m i n a ls

with 3-tier Terminal Blocks

and Transistors

Remote I/O

Te r m i n a l

Expansion

Units with

Transistors

Remote I/O

Te r mi na l w it h

Relay Outputs

Sensor Connector Terminals with

Transistors

MIL Connector Terminals

with Transistors

DRT2-ID08 DIN Track M3 termi-

DRT2-ID08-1

DRT2-OD08

DRT2-OD08-1

DRT2-ID16

DRT2-ID16-1

DRT2-OD16

DRT2-OD16-1

DRT2-MD16

DRT2-MD16-1

DRT2-ID16TA DIN Track

DRT2-ID16TA-1

DRT2-OD16TA

DRT2-OD16TA-1

DRT2-MD16TA

DRT2-MD16TA-1

XWT-ID16 DIN Track See note.

XWT-ID16-1

XWT-OD16

XWT-OD16-1

XWT-ID08

XWT-ID08-1

XWT-OD08

XWT-OD08-1

DRT2-ROS16 Relay Shares

DRT2-ID16S DIN Track

DRT2-ID16S-1

DRT2-MD16S

DRT2-MD16S-1

DRT2-ID16ML DIN Track

DRT2-ID16ML-1

DRT2-OD16ML

DRT2-OD16ML-1

DRT2-ID16MLX

DRT2-ID16MLX-1

DRT2-OD16MLX

DRT2-OD16MLX-1

installation

or screws

or screws

or screws

with Mounting Bracket

I/O con-

nection

method

nal block

(detachable)

Industry

standard

connector

MIL connector

Internal

power sup-

ply

Shares

communications

power supply.

Shares

communications

power supply.

I/O power

supply

Requires

external

power supply.

communications

power supply. An

external

power supply is

required,

however, for

MD16S-1

outputs.

Requires

external

power supply.

17

Page 39

DRT2 Slaves Section 1-2

Slave type Communi-

General-purpose Slaves

cations

cables

Standard

rectangular

connector

Name Model Slave

MIL Connector Terminals

with Transistors

Board MIL

Connector

Te r m i n a ls

with Transistors

Screw-less

Clamp Terminal with Transistors

DRT2-ID32ML DIN Track

DRT2-ID32ML-1

DRT2-OD32ML

DRT2-OD32ML-1

DRT2-MD32ML

DRT2-MD32ML-1

DRT2-ID32B Screws

DRT2-ID32B-1

DRT2-OD32B

DRT2-OD32B-1

DRT2-MD32B

DRT2-MD32B-1

DRT2-ID32BV

DRT2-ID32BV-1

DRT2-OD32BV

DRT2-OD32BV-1

DRT2-MD32BV

DRT2-MD32BV-1

DRT2-ID16SL DIN Track Screw-less

DRT2-ID16SL-1

DRT2-OD16SL

DRT2-OD16SL-1

DRT2-ID32SL

DRT2-ID32SL-1

DRT2-OD32SL

DRT2-OD32SL-1

DRT2-MD32SL

DRT2MD32SL-1

DRT2-ID16SLH

DRT2-ID16SLH-1