Omron SCARA YRCX Programming Manual

=;76HULHV

&DW1R,((1$

<5&;5RERW&RQWUROOHU

352*5$00,1*

0$18$/

6&$5$5RERWV

<5&;6HULHV

Introduction

Our sincere thanks for your purchase of this OMRON YRCX robot controller.

This manual describes robot program commands and related information for using OMRON YRCX

robot controllers. Be sure to read this manual carefully as well as related manuals and comply with

their instructions for using the OMRON robot controllers safely and correctly.

For details on how to operate OMRON robot controllers, refer to the separate controller user's

manual that comes with the OMRON robot controller.

Applicable controllers:

YRCX

Safety precautions

Be sure to read before using

Before using the OMRON robot controller, be sure to read this manual and related manuals, and

follow their instructions to use the robot controller safely and correctly.

Warning and caution items listed in this manual relate to OMRON robot controllers.

When this robot controller is used in a robot controller system, please take appropriate safety

measures as required by the user’s individual system.

This manual classifies safety caution items and operating points into the following levels, along with

symbols for signal words “CAUTION” and “NOTE”.

CAUTION

"CAUTION" indicates a potentially hazardous situation which, if not avoided, could

result in minor or moderate injury or damage to the equipment or software.

NOTE

Primarily explains function differences, etc., between software versions.

MEMO

Explains robot operation procedures in a simple and clear manner.

Note that the items classified into “CAUTION” might result in serious injury depending on the

situation or environmental conditions.

Keep this manual carefully so that the operator can refer to it when needed. Also make sure that this

manual reaches the end user.

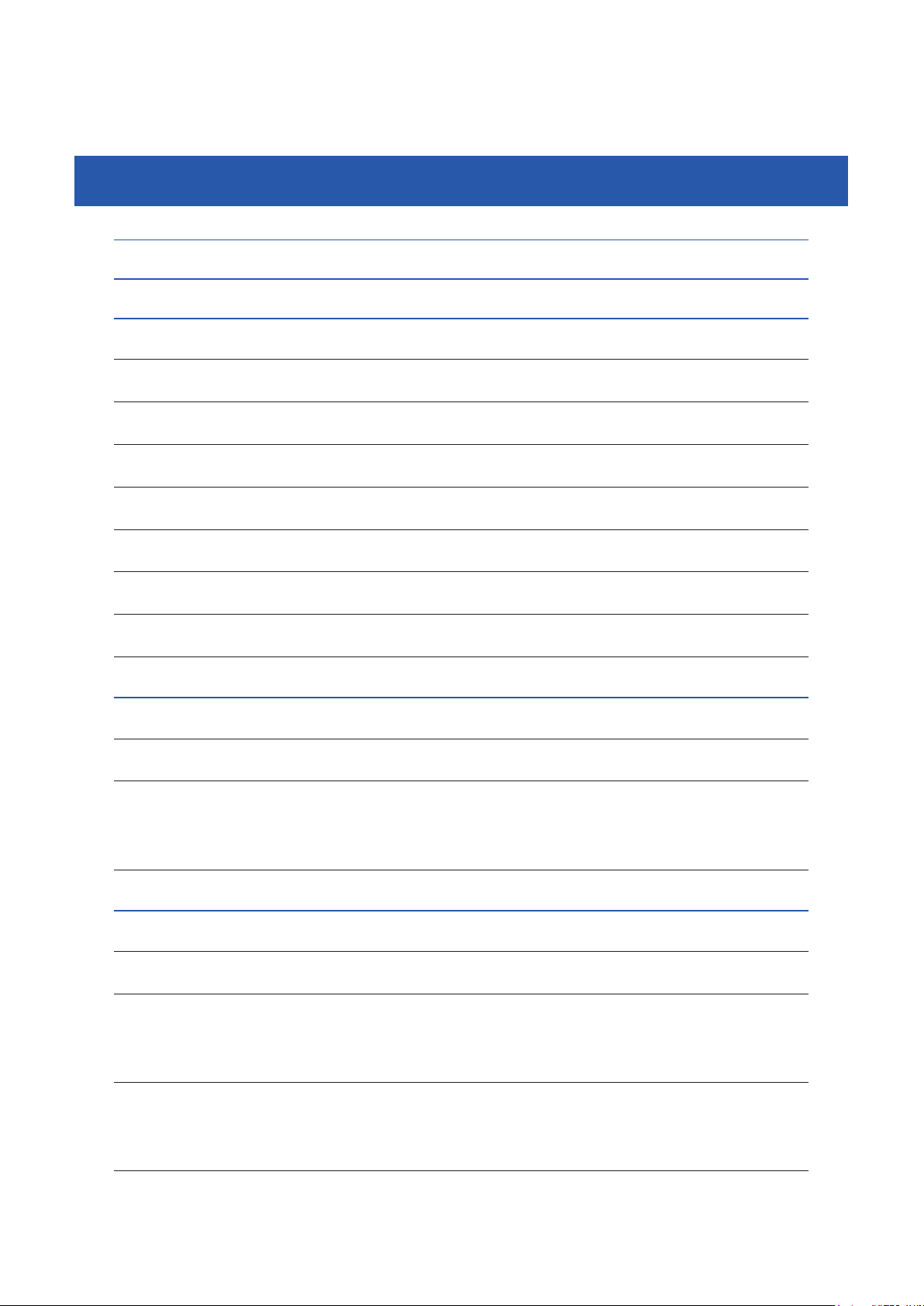

CONTENTS

Programming Manual

Introduction

Safety precautions

Chapter 1 Writing Programs

1 The OMRON Robot Language 1-1

2 Characters 1-1

3 Program Basics 1-1

4 Program Names 1-2

5 Identiers 1-4

6 LABELStatement 1-4

YRCX

7 Comment 1-5

8 Command Statement Format 1-5

Chapter 2 Constants

1 Outline 2-1

2 Numeric constants 2-1

2.1 Integer constants 2-1

2.2 Real constants 2-1

3 Character constants 2-2

Chapter 3 Variables

1 Outline 3-1

2 User Variables & System Variables 3-2

2.1 User Variables 3-2

2.2 System Variables 3-2

3 Variable Names 3-3

3.1 Dynamic Variable Names 3-3

3.2 Static Variable Names 3-3

4 VariableTypes 3-4

T-1

CONTENTS

4.1 Numeric variables 3-4

4.2 Character variables 3-4

5 Array variables 3-5

6 Value Assignments 3-5

7 Type Conversions 3-6

8 Value Pass-Along & Reference Pass-Along 3-6

9 System Variables 3-7

9.1 Point variable 3-7

9.2 Shift variable 3-8

9.3 Parallel input variable 3-8

9.4 Parallel output variable 3-9

9.5 Internal output variable 3-10

9.6 Arm lock output variable 3-11

9.7 Timer output variable 3-12

9.8 Serial input variable 3-13

9.9 Serial output variable 3-14

9.10 Serial word input 3-15

9.11 Serial double word input 3-15

9.12 Serial word output 3-16

9.13 Serial double word output 3-16

Programming Manual

YRCX

T-2

10 Bit Settings 3-17

11 Valid range of variables 3-18

11.1 Valid range of dynamic (array) variables 3-18

11.2 Valid range of static variables 3-18

Clearing variables 3-19

12

12.1 Clearing dynamic variables 3-19

12.2 Clearing static variables 3-19

Chapter4 ExpressionsandOperations

1 Arithmeticoperations 4-1

1.1 Arithmetic operators 4-1

1.2 Relational operators 4-1

1.3 Logic operations 4-2

1.4 Priority of arithmetic operation 4-3

1.5 Data format conversion 4-3

CONTENTS

2 Characterstringoperations 4-4

2.1 Character string connection 4-4

2.2 Character string comparison 4-4

3 Pointdataformat 4-5

4 DI/DOconditionalexpressions 4-6

Programming Manual

Chapter 5 Multiple Robot Control

1 Overview 5-1

2 Command list with a robot setting 5-2

Chapter 6 Multi-tasking

1 Outline 6-1

YRCX

2 Taskdenitionmethod 6-1

3 Task status and transition 6-2

3.1 Starting tasks 6-2

3.2 Task scheduling 6-3

3.3 Condition wait in task 6-4

3.4 Suspending tasks (SUSPEND) 6-5

3.5 Restarting tasks (RESTART) 6-5

3.6 Deleting tasks 6-6

3.7 Stopping tasks 6-7

4 Multi-taskprogramexample 6-8

5 Sharing the data 6-8

6 Cautionary Items 6-9

Chapter 7 Sequence fnction

1 Sequence function 7-1

2 Creating a sequence program 7-1

2.1 Programming method 7-1

2.2 Compiling 7-3

3 Executingasequenceprogram 7-4

3.1 Sequence program STEP execution 7-4

T-3

CONTENTS

4 Programming a sequence program 7-5

4.1 Assignment statements 7-5

4.2 Input/output variables 7-5

4.2.1 Input variables 7-5

4.2.2 Output variables 7-6

4.3 Timerdenitionstatement 7-7

4.4 Logical operators 7-7

4.5 Priority of logic operations 7-8

4.6 Sequenceprogramspecications 7-8

Chapter 8 Robot Language Lists

How to read the robot language table 8-1

Command list in alphabetic order 8-2

Operation-specic 8-7

Programming Manual

YRCX

Functions: in alphabetic order 8-13

Functions:operation-specic 8-16

1 ABS

2 ABSRPOS

3 ACCEL

4 ARCHP1 / ARCHP2

5 ARMCND

6 ARMSEL

7 ARMTYP

8 ASPEED

9 ATN / ATN2

10 AXWGHT

11 CALL

12 CHANGE

13 CHGPRI

14 CHR$

15 CLOSE

16 COS

17 CURTQST

Acquires absolute values 8-18

Acquires the machine reference value (axes: mark method) 8-19

Species/acquires the acceleration coefcient parameter 8-20

Species/acquires the arch position parameter 8-21

Acquires the current arm status 8-23

Sets/acquires the current hand system selection 8-24

Sets/acquires the hand system selection during program reset 8-25

Sets/acquires the AUTO movement speed of a specied robot 8-26

Acquires the arctangent of the specied value 8-27

Sets/acquires the axis tip weight 8-28

Calls a sub-procedure 8-29

Switches the hand 8-30

Changes the priority ranking of a specied task 8-31

Acquires a character with the specied character code 8-32

Closes the specied General Ethernet Port 8-33

Acquires the cosine value of a specied value 8-34

Acquires the current torque value of a specied axis

to the rated torque 8-35

T-4

18 CURTRQ

Acquires the current torque of the specied axis 8-36

CONTENTS

Programming Manual

YRCX

19 CUT

20 DATE$

21 DECEL

22 DEF FN

23 DEGRAD

24 DELAY

25 DI

26 DIM

27 DIST

28 DO

29 DRIVE

30 DRIVEI

31 END SELECT

32 END SUB

33 ERR / ERL

34 ETHSTS

35 EXIT FOR

36 EXIT SUB

Terminates another task which is currently being executed 8-37

Acquires the date 8-38

Species/acquires the deceleration rate parameter 8-39

Denes functions which can be used by the user 8-40

Angle conversion (degree → radian) 8-41

Program execution waits for a specied period of time 8-42

Acquires the input status from the parallel port 8-43

Declares array variable 8-44

Acquires the distance between 2 specied points 8-45

Outputs to parallel port or acquires the output status 8-46

Executes absolute movement of specied axes 8-48

Moves the specied robot axes in a relative manner 8-52

Ends the SELECT CASE statement 8-57

Ends the sub-procedure denition 8-58

Acquires the error code / error line number 8-59

Acquires the Ethernet port status 8-60

Terminates the FOR to NEXT statement loop 8-61

Terminates the sub-procedure dened by the SUB to END SUB

statement 8-62

37 EXIT TASK

38 FOR to NEXT

39 GEPSTS

40 GOSUB to RETURN

41 GOTO

42 HALT

43 HALTALL

44 HAND

44.1 For SCARA Robots 8-70

45 HOLD

46 HOLDALL

47 IF

47.1 Simple IF statement 8-75

47.2 Block IF statement 8-76

48 INPUT

49 INT

Terminates its own task which is in progress 8-63

Performs loop processing until the variable exceeds

the specied value 8-64

Acquires the General Ethernet Port status 8-65

Jumps to a subroutine 8-66

Executes an unconditional jump to the specied line 8-67

Stops the program and performs a reset 8-68

Stops all programs and performs reset 8-69

Denes the hand 8-70

Temporarily stops the program 8-73

Temporality stops all programs 8-74

Evaluates a conditional expression value, and executes

the command in accordance with the conditions 8-75

Assigns a value to a variable specied from the programming box 8-77

Truncates decimal fractions 8-79

T-5

CONTENTS

Programming Manual

YRCX

50 JTOXY

51 LEFT$

52 LEFTY

53 LEN

54 LET

55 LO

56 LOCx

57 LSHIFT

58 MCHREF

59 MID$

60 MO

61 MOTOR

62 MOVE

63 MOVEI

64 MOVET

65 MTRDUTY

66 OFFLINE

67 ON ERROR GOTO

68 ON to GOSUB

69 ON to GOTO

70 ONLINE

71 OPEN

72 ORD

73 ORGORD

74 ORIGIN

75 OUT

76 OUTPOS

77 PATH

78 PATH END

79 PATH SET

80 PATH START

81 PDEF

82 PGMTSK

Performs axis unit system conversions (pulse → mm) 8-80

Extracts character strings from the left end 8-81

Sets the SCARA robot hand system as a left-handed system 8-82

Acquires a character string length 8-83

Assigns values to variables 8-84

Arm lock output or acquires the output status 8-87

Species/acquires point data for a specied axis or shift data

for a specied element 8-89

Left-shifts a bit 8-91

Acquires the machine reference value

(axes: sensor method / stroke-end method) 8-92

Acquires a character string from a specied position 8-93

Outputs a specied value to the MO port

or acquires the output status 8-94

Controls the motor power status 8-96

Performs absolute movement of robot axes 8-97

Performs relative movement of robot axes 8-112

Performs relative movement of all robot axes in tool coordinates 8-122

Acquires the motor load factor of the specied axis 8-132

Sets a specied communication port to the "ofine" mode 8-133

Jumps to a specied label when an error occurs 8-134

Executes the subroutine specied by the <expression> value 8-135

Jumps to the label specied by the <expression> value 8-136

Sets the specied communication port to the "online" mode 8-137

Opens the specied General Ethernet Port 8-138

Acquires a character code 8-139

Species/acquires the robot's return-to-origin sequence 8-140

Performs return-to-origin 8-141

Turns ON the specied port output 8-142

Species/acquires the OUT enable position parameter of the robot

Species the motion path 8-145

Ends the path setting 8-151

Starts the path setting 8-152

Starts the PATH motion 8-155

Denes the pallet 8-159

Acquires the task number

in which a specied program is registered 8-160

8-143

T-6

CONTENTS

Programming Manual

YRCX

83 PGN

84 PMOVE

85 Pn

86 PPNT

87 PRINT

88 PSHFRC

89 PSHJGSP

90 PSHMTD

91 PSHRSLT

92 PSHSPD

93 PSHTIME

94 PUSH

95 RADDEG

96 REM

97 RESET

98 RESTART

99 RESUME

RETURN

100

Acquires the program number from a specied program name 8-161

Executes a pallet movement command for the robot 8-162

Denes points within a program 8-166

Creates pallet point data 8-168

Displays the specied expression value at the programming box 8-169

Species/acquires the pushing force parameter 8-170

Species/acquires the push judge speed parameter 8-171

Species/acquires a pushing type parameter 8-172

Acquires the status when PUSH statement ends 8-173

Species/acquires the push speed parameter 8-174

Species/acquires the push time parameter 8-175

Executes a pushing operation for specied axes 8-176

Performs a unit conversion (radians → degrees) 8-181

Inserts a comment 8-182

Turns OFF the bits of specied ports, or clears variables 8-183

Restarts another task during a temporary stop 8-184

Resumes program execution after error recovery processing 8-185

Processing which was branched by GOSUB, is returned

to the next line after GOSUB 8-186

RIGHT$

101

RIGHTY

102

RSHIFT

103

104

SELECT CASE to END SELECT

SEND

105

SERVO

106

SET

107

SETGEP

108

SGI

109

SGR

110

SHARED

111

SHIFT

112

SI

113

SID

114

SIN

115

Extracts a character string

from the right end of another character string 8-187

Sets the SCARA robot hand system as a right-handed system 8-188

Shifts a bit value to the right 8-189

Executes the specied command block in accordance with the

<expression> value 8-190

Sends readout le data to the write le 8-191

Controls the servo status 8-193

Turns the bit at the specied output port ON 8-194

Sets the General Ethernet Port 8-195

Assigns /acquires the value

to a specied integer type static variable 8-196

Assigns /acquires the value to a specied real type static variable

Enables sub-procedure referencing without passing on the variable

Sets the shift coordinates 8-199

Acquires specied SI status 8-200

Acquires a specied serial input's double-word information 8-201

Acquires the sine value for a specied value 8-202

8-197

8-198

T-7

CONTENTS

Programming Manual

YRCX

SIW

116

Sn

117

SO

118

SOD

119

SOW

120

SPEED

121

SQR

122

START

123

STR$

124

SUB to END SUB

125

SUSPEND

126

SWI

127

TAN

128

TCOUNTER

129

TIME$

130

TIMER

131

TO

132

Acquires a specied serial input's word information 8-203

Denes the shift coordinates in the program 8-204

Outputs a specied value

to serial port or acquires the output status 8-205

Outputs a specied serial output's double-word information

or acquires the output status 8-207

Outputs a specied serial output's word information

or acquires the output status 8-208

Changes the program movement speed 8-209

Acquires the square root of a specied value 8-210

Starts a new task 8-211

Converts a numeric value to a character string 8-212

Denes a sub-procedure 8-213

Temporarily stops another task which is being executed 8-215

Switches the program being executed 8-216

Acquires the tangent value for a specied value 8-217

Timer & counter 8-218

Acquires the current time 8-219

Acquires the current time 8-220

Outputs a specied value to the TO port

or acquires the output status 8-221

TOLE

133

TORQUE

134

TSKPGM

135

VAL

136

WAIT

137

WAIT ARM

138

WEIGHT

139

WEND

140

WHERE

141

WHILE to WEND

142

WHRXY

143

XYTOJ

144

Species/acquires the tolerance parameter 8-222

Species/acquires the maximum torque command value 8-223

Acquires the program number

which is registered in a specied task number 8-225

Converts character strings to numeric values 8-226

Waits until the conditional expression is met 8-227

Waits until the robot axis operation is completed 8-228

Species/acquires the tip weight parameter 8-229

Ends the WHILE statement's command block 8-230

Acquires the arm's current position (pulse coordinates) 8-231

Repeats an operation for as long as a condition is met 8-232

Acquires the arm's current position in Cartesian coordinates 8-233

Converts the Cartesian coordinate data ("mm")

to joint coordinate data ("pulse") 8-234

T-8

CONTENTS

Programming Manual

Chapter 9 PATH Statements

1 Overview 9-1

2 Fe atur e s 9 -1

3 How to use 9-1

4 Cautions when using this function 9-2

Chapter10Dataledescription

1 Overview 10-1

1.1 Dataletypes 10-1

1.2 Cautions 10-2

2 Programle 10-3

YRCX

2.1 All programs 10-3

2.2 One program 10-4

3 Pointle 10-5

3.1 All points 10-5

3.2 One point 10-7

4 Pointcommentle 10-8

4.1 All point comments 10-8

4.2 One point comment 10-9

5 Pointnamele 10-10

5.1 All point names 10-10

5.2 One point name 10-11

6 Parameterle 10-12

6.1 All parameters 10-12

6.2 One parameter 10-14

7 Shiftcoordinatedenitionle 10-16

7.1 All shift data 10-16

7.2 Oneshiftdenition 10-17

8 Handdenitionle 10-18

8.1 All hand data 10-18

8.2 Onehanddenition 10-19

T-9

CONTENTS

9 Palletdenitionle 10-20

9.1 Allpalletdenitions 10-20

9.2 Onepalletdenition 10-22

10 GeneralEthernetportle 10-24

11 Input/outputnamele 10-26

11.1 All input/output name data 10-26

11.2 One input/output type 10-27

11.3 One input/output port 10-28

11.4 One input/output bit 10-29

Areacheckoutputle 10-30

12

12.1 All area check output data 10-30

12.2 Oneareacheckoutputdenition 10-31

13 Allle 10-32

Programming Manual

YRCX

13.1 Allle 10-32

14 Programdirectoryle 10-34

14.1 Entire program directory 10-34

14.2 One program directory 10-35

15 Parameterdirectoryle 10-36

15.1 Entire parameter directory 10-36

16 Machinereferencele 10-37

16.1 Machine reference (axes: sensor method, stroke-end method) 10-37

16.2 Machine reference (axes: mark method) 10-38

17 Systemcongurationinformationle 10-39

18 Versioninformationle 10-40

19 Optionboardle 10-41

20 Selfcheckle 10-42

T-10

21 Alarmhistoryle 10-43

22 Remainingmemorysizele 10-45

23 Variablele 10-46

CONTENTS

Programming Manual

24 Constantle 10-52

24.1 One character string 10-52

25 Arrayvariablele 10-53

25.1 All array variables 10-53

25.2 One array variable 10-54

26 DIle 10-55

26.1 All DI information 10-55

26.2 One DI port 10-56

27 DOle 10-57

27.1 All DO information 10-57

27.2 One DO port 10-58

28 MOle 10-59

28.1 All MO information 10-59

28.2 One MO port 10-60

YRCX

29 LOle 10-61

29.1 All LO information 10-61

29.2 One LO port 10-62

30 TOle 10-63

30.1 All TO information 10-63

30.2 One TO port 10-64

31 SIle 10-65

31.1 All SI information 10-65

31.2 One SI port 10-66

32 SOle 10-67

32.1 All SO information 10-67

32.2 One SO port 10-68

33 SIWle 10-69

33.1 All SIW data 10-69

33.2 One SIW data 10-70

34 SOWle 10-71

34.1 All SOW 10-71

34.2 One SOW data 10-72

T-11

CONTENTS

35 EOFle 10-73

35.1 EOF data 10-73

36 Serialportcommunicationle 10-74

36.1 Serialportcommunicationle 10-74

37 Ethernetportcommunicationle 10-75

37.1 Ethernetportcommunicationle 10-75

Chapter11Userprogramexamples

1 Basic operation 11-1

1.1 Directly writing point data in program 11-1

1.2 Using point numbers 11-2

1.3 Using shift coordinates 11-3

1.4 Palletizing 11-4

1.4.1 Calculating point coordinates 11-4

1.4.2 Utilizing pallet movement 11-6

1.5 DI/DO (digital input and output) operation 11-7

Programming Manual

YRCX

2 Application 11-8

2.1 Pick and place between 2 points 11-8

2.2 Palletizing 11-10

2.3 Pick and place of stacked parts 11-12

2.4 Parts inspection (Multi-tasking example) 11-14

2.5 Sealing 11-17

2.6 Connection to an external device through RS-232C (example 1) 11-18

2.7 Connection to an external device through RS-232C (example 2) 11-19

Chapter 12 Online commands

1 Online Command List 12-1

1.1 Onlinecommandlist:Operation-specic 12-2

1.2 Online command list: In alphabetic order 12-6

2 Operation and setting commands 12-9

2.1 Program operations 12-9

2.2 MANUAL mode operation 12-17

2.3 Alarm reset 12-18

2.4 Clearingoutputmessagebuer 12-19

2.5 Setting input data 12-20

2.6 Change access level 12-21

2.7 Setting input data 12-22

T-12

CONTENTS

Programming Manual

3 Reference commands 12-23

3.1 Acquiring return-to-origin status 12-23

3.2 Acquiring the servo status 12-24

3.3 Acquire motor power status 12-24

3.4 Acquiring the access level 12-25

3.5 Acquiring the break point status 12-25

3.6 Acquiring the mode status 12-26

3.7 Acquiring the communication port status 12-26

3.8 Acquiring the main program number 12-27

3.9 Acquiring the sequence program execution status 12-27

3.10 Acquiring the version information 12-28

3.11 Acquiring the tasks in RUN or SUSPEND status 12-28

3.12 Acquiring the tasks operation status 12-29

3.13 Acquiring the task end condition 12-29

3.14 Acquiring the shift status 12-30

3.15 Acquiring the hand status 12-30

3.16 Acquiring the remaining memory capacity 12-31

3.17 Acquiring the alarm status 12-31

3.18 Acquiring the emergency stop status 12-32

3.19 Acquiring the manual movement speed 12-32

3.20 Acquiring the inching movement amount 12-33

3.21

Acquiring the last reference point number (current point number) 12-33

3.22 Acquiring the output message 12-34

3.23 Acquiring the input data 12-34

3.24 Acquiring various values 12-35

YRCX

4 Operation commands 12-37

4.1 Absolute reset 12-37

4.2 Return-to-origin operation 12-38

4.3 Manual movement: inching 12-39

4.4 Manual movement: jog 12-40

5 Dataleoperationcommands 12-41

5.1 Copy operations 12-41

5.2 Erase 12-42

5.3 Rename program 12-47

5.4 Changing the program attribute 12-47

5.5 Initialization process 12-48

5.6 Data readout processing 12-50

5.7 Data write processing 12-51

T-13

CONTENTS

6 Utility commands 12-52

6.1 Settingthesequenceprogramexecutionag 12-52

6.2 Setting the date 12-52

6.3 Setting the time 12-53

7 Individualexecutionofrobotlanguage 12-54

8 Control codes 12-55

Chapter13Appendix

1 Reserved word list 13-1

2 Changes from conventional models 13-3

1 Program name 13-3

A) FUNCTION 13-3

B) _SELECT 13-3

2 Multiple Robot Control 13-3

3 Multi-tasking 13-4

4 Robot Language 13-4

5 Online commands 13-5

6 Datale 13-5

Programming Manual

YRCX

Index

T-14

Chapter 1

Writing Programs

1 1

The OMRON Robot Language .................

2 2

Characters ................................................

3 3

Program Basics .........................................

4 4

Program Names ........................................

5 5

Identifiers ...................................................

6 6

LABEL Statement .......................................

7 7

Comment ..................................................

8 8

Command Statement Format .................

1-1

1-1

1-1

1-2

1-4

1-4

1-5

1-5

1

The OMRON Robot Language

1

The OMRON robot language is similar to BASIC (Beginner’s All-purpose Symbolic Instruction Code)

and makes even complex robot movements easy to program. This manual explains how to write

robot control programs with the OMRON robot language, including actual examples on how its

commands are used.

2

Characters

2

3

The characters and symbols used in the OMRON robot language are shown below.

Only 1-byte characters can be used.

• Alphabetic characters

A to Z, a to z

• Numbers

0 to 9

• Symbols

( ) [ ] + - * / ^ = < > & | ~ _ % ! # $ : ; , . " ' { }@ ?

• katakana (Japanese phonetic characters

)

4

5

MEMO

3

• For details regarding sub-

• For details regarding user

Program Basics

NOTE

procedure, refer to "11

CALL" and "125 SUB to

END SUB" in Chapter 8.

NOTE

defined functions, refer to

"22 DEF FN" in Chapter 8.

• Katakana (Japanese phonetic characters) cannot be entered from a programming box. Katakana

can be used when communicating with a host computer (if it handles katakana).

• Spaces are also counted as characters (1 space = 1 character).

Programs are written in a "1 line = 1 command" format, and every line must contain a command.

Blank lines (lines with no command) will cause an error when the program is executed. A line-feed

on the program's final line creates a blank line, so be careful not to do so.

To increase the program's efficiency, processes which are repeated within the program should be

written as subroutines or sub-procedures which can be called from the main routine. Moreover,

same processing items which occurs in multiple programs should be written as common routines

within a program named [COMMON], allowing those processing items to be called from multiple

programs.

User functions can be defined for specific calculations. Defined user functions are easily called,

allowing even complex calculations to be easily performed.

6

Multi-task programs can also be used to execute multiple command statements simultaneously in a

parallel processing manner.

Using the above functions allows easy creation of programs which perform complex processing.

The OMRON Robot Language 1-1

1

4

Program Names

Each program to be created in the robot controller must have its own name.

Programs can be named as desired provided that the following conditions are satisfied:

2

3

4

5

6

■

Program names may contain no more than 32 characters, comprising a combination of

alphanumeric characters and underscores (_).

■

Each program must have a unique name (no duplications).

The 2 program names shown below are reserved for system operations, and programs with these

names have a special meaning.

A) SEQUENCE

B) COMMON

The functions of these programs are explained below.

A) SEQUENCE

Functions Unlike standard robot programs, the YRCX Controller allows the execution of high-

speed processing programs (sequence programs) in response to robot inputs and outputs

(DI, DO, MO, LO, TO, SI, SO). Specify a program name of "SEQUENCE" to use this

function, thus creating a pseudo PLC within the controller.

When the controller is in the AUTO or MANUAL mode, a SEQUENCE program can

be executed in fixed cycles (regardless of the program execution status) in response to

dedicated DI10 (sequence control input) input signals, with the cycle being determined

by the program capacity. For details, refer to "4.6 Sequence program specifications" in

Chapter 7.

This allows sensors, push-button switches, and solenoid valves, etc., to be monitored

and operated by input/output signals.

Moreover, because the sequence programs are written in robot language, they can

easily be created without having to use a new and unfamiliar language.

SAMPLE

DO(20)=~DI(20)

DO(25)=DI(21) AND DI(22)

MO(26)=DO(26) OR DO(25)

:

REFERENCE For details, refer to "4.6 Sequence program specifications" in Chapter 7.

1-2 Chapter 1 Writing Programs

B) COMMON

Functions A separate "COMMON" program can be created to perform the same processing in

multiple robot programs. The common processing routine which has been written in the

COMMON program can be called and executed as required from multiple programs.

This enables efficient use of the programming space.

The sample COMMON program shown below contains two processing items (obtaining

the distance between 2 points (SUB *DISTANCE), and obtaining the area (*AREA))

which are written as common routines, and these are called from separate programs

(SAMPLE 1 and SAMPLE 2).

When SAMPLE1 or SAMPLE2 is executed, the SUB *DISTANCE (A!,B!,C!) and the

*AREA routine are executed.

SAMPLE

Program name: SAMPLE1

X!=2.5

Y!=1.2

CALL *DISTANCE(X!,Y!,REF C!)

GOSUB *AREA

PRINT C!,Z!

HALT

Program name: SAMPLE2

X!=5.5

Y!=0.2

CALL *DISTANCE(X!,Y!,REF C!)

GOSUB *AREA

PRINT C!,Z!

HALT

1

2

3

4

5

6

Program name: COMMON ··············· Common routine

SUB *DISTANCE(A!,B!,C!)

C!=SQR(A!^2+B!^2)

END SUB

*AREA:

Z!=X!*Y!

RETURN

REFERENCE For details, refer to the command explanations given in this manual.

Program Names 1-3

1

2

3

4

5

5

Identifiers

"Identifiers" are a combination of characters and numerals used for label names, variable names,

and procedure names. Identifiers can be named as desired provided that the following conditions

are satisfied:

■

Identifiers must consist only of alphanumeric characters and underscores (_). Special symbols

cannot be used, and the identifier must not begin with an underscore (_).

■

The identifier length must not exceed 32 characters (all characters beyond the 32th character are

ignored).

■

The maximum number of usable identifiers varies depending on the length of the identifiers.

When all identifier length is 32 characters, the number is at the maximum. Local variables can be

used up to 128 (in one program task) and global variables can be used up to 512.

■

Variable names must not be the same as a reserved word, or the same as a name defined as

a system variable. Moreover, variable name character strings must begin with an alphabetic

character. For label names, however, the "*" mark may be immediately followed by a numeric

character.

SAMPLE

LOOP, SUBROUTINE, GET_DATA

6

REFERENCE For details regarding reserved words, refer to Chapter 13 "1. Reserved word list",

regarding system variables, refer to Chapter 3 "9 System Variables".

6

LABEL Statement

Defines a label on a program line.

Format

*label:

A label must always begin with an asterisk (*), and it must be located at the beginning of the line.

Although a colon (:) is required at the end of the label when defining it, this mark is not required

when writing a jump destination in a program.

1. A label must begin with an alphabetic or numeric character.

2. Alphanumeric and underscore (_) can be used as the remaining label characters. Special

symbols cannot be used.

3. The label must not exceed 32 characters (all characters beyond the 32th character are ignored).

SAMPLE

*ST: ····················· *ST label is defined.

MOVE P,P0

DO(20) = 1

MOVE P,P1

DO(20) = 0

GOTO *ST ····················· Jumps to *ST.

HALT

1-4 Chapter 1 Writing Programs

7

Comment

1

Characters which follow REM or an apostrophe (') are processed as a comment. Comment

statements are not executed. Moreover, comments may begin at any point in the line.

SAMPLE

REM *** MAIN PROGRAM ***

(Main program)

’*** SUBROUTINE ***

(Subroutine)

HALT ’HALT COMMAND ············ This comment may begin at any point in

the line.

2

3

4

8

Command Statement Format

Format

label: statement operand

One robot language command must be written on a single line and arranged in the format shown

below:

• The shaded section can be omitted.

• The italic items should be written in the specific format.

• Items surrounded by | | are selectable.

• The label can be omitted. When using a label, it must always be preceded by an asterisk (*),

and it must end with a colon (:) (the colon is unnecessary when a label is written as a branching

destination).

5

6

For details regarding labels, refer to "6 LABEL Statement" in this Chapter.

• Operands may be unnecessary for some commands.

• Programs are executed in order from top to bottom unless a branching instruction is given.

1 line may contain no more than 255 characters.

Comment 1-5

Chapter 2

Constants

1 1

Outline .......................................................

2 2

Numeric constants ...................................

3 3

Character constants ................................

2-1

2-1

2-2

1

Outline

1

Constants can be divided into two main categories: "numeric types" and "character types". These

categories are further divided as shown below.

Category Type Details/Range

Numeric

type

Character

type

2

Numeric constants

Integer

type

Real type Single-precision real numbers

Character

string

Decimal constants

-2,147,483,648 to 2,147,483,647

Binary constants

&B0 to &B11111111

Hexadecimal constants

&H80000000 to &H7FFFFFFF

-999,999.9 to +999,999.9

Exponential format single-precision real numbers

-1.0×10

Alphabetic, numeric, special character, or katakana (Japanese)

character string of 255 bytes or less.

38

to +1.0×10

38

2

3

4

5

6

2.1 Integer constants

1. Decimal constants

Integers from -2,147,483,648 to 2,147,483,647 may be used.

2. Binary constants

Unsigned binary numbers of 8 bits or less may be used. The prefix "&B" is attached to the

number to define it as a binary number.

Range: &B0 (decimal: 0) to &B11111111 (decimal: 255)

3. Hexadecimal constants

Signed hexadecimal numbers of 32 bits or less may be used. The prefix "&H" is attached to the

number to define it as a hexadecimal number.

Range: &H80000000 (decimal: -2,147,483,648) to &H7FFFFFFF (decimal: 2,147,483,647)

2.2 Real constants

1. Single-precision real numbers

Real numbers from -999999.9 to +999999.9 may be used.

• 7 digits including integers and decimals. (For example, ".0000001" may be used.)

2. Single-precision real numbers in exponent form

Numbers from -1.0×10

• Mantissas should be 7 digits or less, including integers and decimals.

MEMO

Examples:

3. 14E0

1. E5

• An integer constant range of –1,073,741,824 to 1,073,741,823 is expressed in signed

hexadecimal number as &H80000000 to &H7FFFFFFF.

-1. 23456E-12

38

to +1.0×1038 may be used.

Outline 2-1

1

2

3

4

5

3

Character constants

Character type constants are character string data enclosed in double quotation marks ("). The

character string must not exceed 255 bytes in length, and it may contain upper-case alphabetic

characters, numerals, special characters, or katakana (Japanese) characters.

To include a double quotation mark (") in a string, enter two double quotation marks in succession.

SAMPLE

"OMRON ROBOT"

"EXAMPLE OF""A""" ·················· EXAMPLE OF "A"

PRINT "COMPLETED"

"OMRON ROBOT"

6

2-2 Chapter 2 Constants

Loading...

Loading...