Page 1

New Product

Switch Mode Power Supply

S8JC-Z (15/35/50/100/150/350-W Models)

Economical Power Supply

• Mount to DIN Rails for models with ratings of 15 to

350 W

• Protection against overcurrents and overvoltages.

Note: Refer to Safety Precautions on page 7.

Model Number Structure

Model Number Legend

Note: Not all combinations are possible. Refer to List of Models in Ordering Information on page 1.

S8JC-Z@@@@@@@

123

1. Power Ratings

015: 15 W

035: 35 W

050: 50 W

100: 100 W

150: 150 W

350: 350 W

2. Output Voltage

05: 5 V

12: 12 V

24: 24 V

4

3. Configuration (15/35/50/100/150 W model)

C: Covered

4. Configuration/mounting

None: Bottom-mounting

D: DIN Rail-mounting

Ordering Information

List of Models

Note: For details on normal stock models, contact your nearest OMRON representative.

Configuration Input voltage Power ratings Output voltage (VDC) Output current Model

Covered Power

Supplies

Bottom-mounting

DIN Rail-mounting

200 to 240 VAC

15 W

35 W

50 W 24 V 2.1 A S8JC-Z05024C

100 W 24 V 4.5 A S8JC-Z10024C

150 W 24 V 6.5 A S8JC-Z15024C

350 W 24 V 14.6 A S8JC-Z35024C

15 W

35 W

50 W 24 V 2.1 A S8JC-Z05024CD

100 W 24 V 4.5 A S8JC-Z10024CD

150 W 24 V 6.5 A S8JC-Z15024CD

350 W 24 V 14.6 A S8JC-Z35024CD

5 V 3.0 A S8JC-Z01505C

12 V 1.3 A S8JC-Z01512C

24 V 0.7 A S8JC-Z01524C

5 V 7.0 A S8JC-Z03505C

12 V 3.0 A S8JC-Z03512C

24 V 1.5 A S8JC-Z03524C

5 V 3.0 A S8JC-Z01505CD

12 V 1.3 A S8JC-Z01512CD

24 V 0.7 A S8JC-Z01524CD

5 V 7.0 A S8JC-Z03505CD

12 V 3.0 A S8JC-Z03512CD

24 V 1.5 A S8JC-Z03524CD

1

Page 2

S8JC-Z

Ratings, Characteristics, and Functions

15-/35-/50-W Models

Item Power ratings 15 W 35 W 50 W

Output voltage (VDC) 5 V 12 V 24 V 5 V 12 V 24 V 24 V

Output current 3.0 A 1.3 A 0.7 A

Output

Efficiency (typical) 74%

Input

Additional

functions

Other

Voltage adjustment range (typical)

Ripple (typical)

Startup time (typical) 300 ms

Hold time (typical) 50 ms

Voltage 200 to 240 VAC (185 to 264 VAC)

Frequency 50/60 Hz (47 to 63 Hz)

Current (typical) 0.22 A 0.5 A 0.6 A

Leakage current 1 mA max.

Inrush current (for a cold start at 25°C) (typical) 40 A

Overload protection 105% of rated load current, voltage drop, intermittent, automatic reset

Overvoltage protection Yes

Parallel operation No

Series operation No

Ambient operating temperature Refer to the derating curve in Engineering Data on page 3 (with no icing or condensation)

Dielectric strength

Vibration resistance 10 to 55 Hz, 0.26-mm single amplitude for 2h each in X, Y, and Z directions

Output indicator Yes (Color: Green)

Dimensions (W×H×D)

Weight (typical)

Bottom-mounting model 36×97×80 mm 38×98×129 mm

DIN Rail-mounting model (See

note 3.)

Bottom-mounting model 190 g 280 g

DIN Rail-mounting model 360 g 450 g

−10% to 10%

100 mV 100 mV 150 mV 100 mV

1.5 kVAC for 1 min. (between all inputs and outputs; detection current: 20 mA)

1.5 kVAC for 1 min. (between all inputs and PE terminals; detection current: 20 mA)

0.5 kVAC for 1 min. (between all outputs and PE terminals; detection current: 20 mA)

46×97×106 mm 46×98×155 mm

80%

7.0 A 3.0 A 1.5 A 2.1 A

30 ms

75%

82% 84%

84%

100-/150-/350-W Models

Item Power ratings 100 W 150 W 350 W

Output voltage (VDC) 24 V 24 V 24 V

Output current 4.5 A 6.5 A 14.6 A

Output

Efficiency (typical) 86% 88% 84%

Input

Additional

functions

Other

Note: 1. Unless otherwise specified, all parameters are measured with a 230-VAC input, at the rated load, and at an ambient temperature of 25°C.

Voltage adjustment range (typical) −10% to 10%

Ripple (typical) 100 mV

Startup time (typical) 300 ms

Hold time (typical) 50 ms

Voltage 200 to 240 VAC (185 to 264 VAC)

Frequency 50/60 Hz (47 to 63 Hz)

Current (typical) 1.4 A 2.0 A 4.2 A

Leakage current 1 mA max.

Inrush current (for a cold start at 25°C) (typical) 40 A

Overload protection 105% of rated load current, voltage drop, intermittent, automatic reset

Overvoltage protection Yes

Parallel operation No

Series operation No

Ambient operating temperature Refer to the derating curve in Engineering Data on page 3 (with no icing or condensation)

Dielectric strength

Vibration resistance 10 to 55 Hz, 0.26-mm single amplitude for 2h each in X, Y, and Z directions

Output indicator Yes (Color: Green)

Dimensions (W×H×D)

Weight (typical)

Bottom-mounting model 38×98×159 mm 50×98×159 mm 50×115×195 mm

DIN Rail-mounting model (See

note 3.)

Bottom-mounting model 350 g 450 g 750 g

DIN Rail-mounting model 520 g 620 g 920 g

1.5 kVAC for 1 min. (between all inputs and outputs; detection current: 20 mA)

1.5 kVAC for 1 min. (between all inputs and PE terminals; detection current: 20 mA)

0.5 kVAC for 1 min. (between all outputs and PE terminals; detection current: 20 mA)

46×98×186 mm 52×98×186 mm 52×115×221 mm

150 mV 200 mV

25 ms

2. Ripple and noise are measured at a bandwidth of 20 MHz.

3. Refer to the dimensional diagrams for details on DIN Rail-mounting Models (excluding terminal blocks and DIN Rail products).

2

Page 3

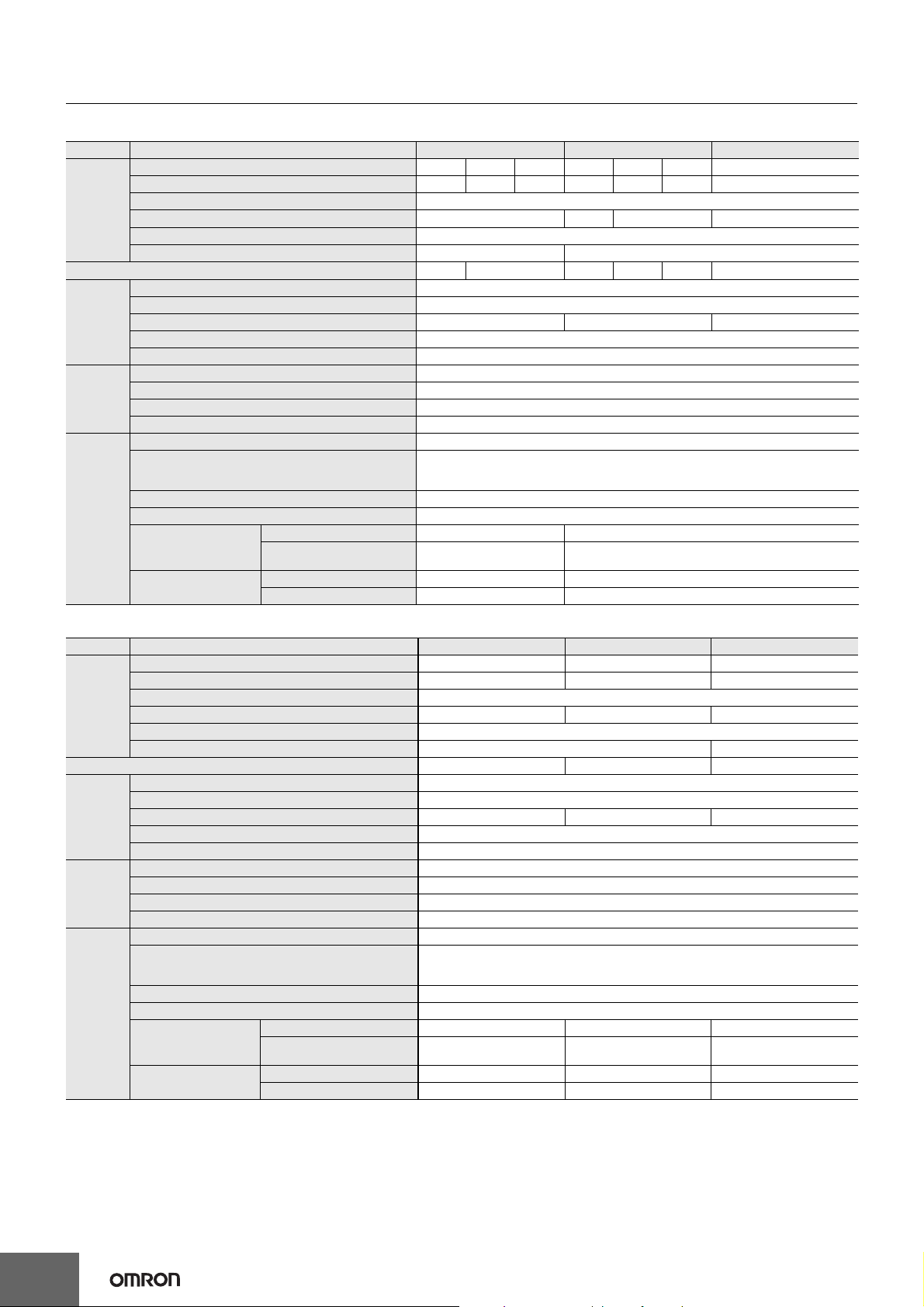

Engineering Data

Derating Curves

120

S8JC-Z

100

Load rate (%)

80

60

40

20

0

-20 -10 0 10 20 30 40 50 60 70

Note: 1. Internal parts may occasionally deteriorate or be damaged. Do not use the Power Supply in areas outside the derating curve (i.e., the

area shown by shading A in the above graph).

2. If there is a derating problem, use forced air-cooling.

Ambient Temperature (°C)

A

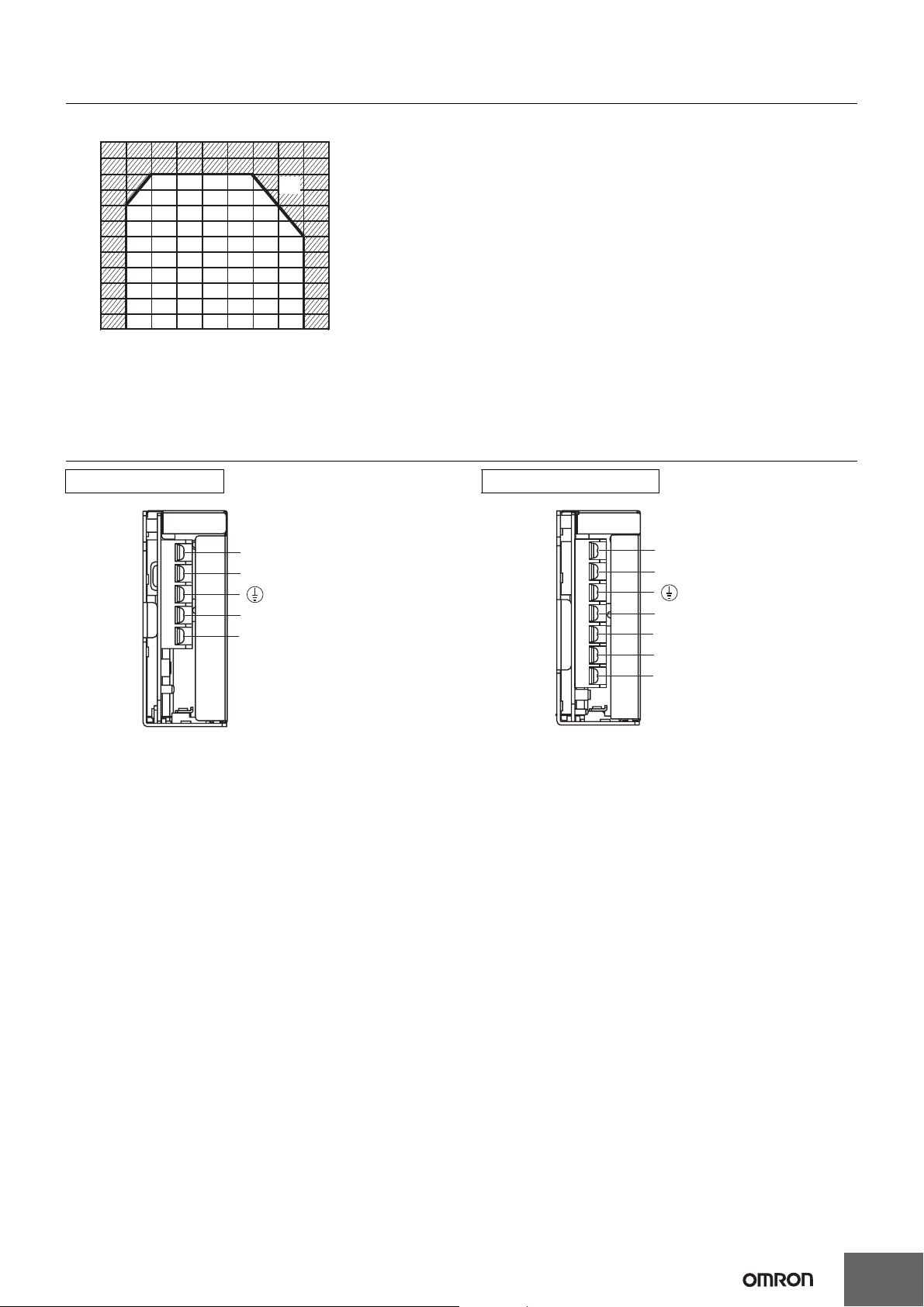

Terminal Arrangement

15-/35-/50-W Models 100-/150-/350-W Models

AC(L)

AC(N)

−V

+V

AC(L)

AC(N)

−V

−V

+V

+V

Note: The S8JC-Z05024C is shown above. Note: The S8JC-Z10024C is shown above.

3

Page 4

S8JC-Z

Dimensions (Unit: mm)

Bottom-mounting Models

S8JC-Z015@@C (15 W)

S8JC-Z035@@C (35 W)

S8JC-Z05024C (50 W)

Panel mounting holes dimensions

Surface screw mounting

Two, M3

Side

Mounting

±0.5

70.5

Bottom

Mounting

Two, M3

70.5

±0.5

±0.5

59.5

±0.5

6.5

36±1

9.5

3.5 dia.

5.5

4.25

4 dia.

30.5

Two , M 3

(Depth 2 mm max.)

3.5

8

20.5

35±0.5

70.5±0.5

79.5±1

4.5

17.5

54±0.5

18

75±1

97±1

65±0.5

45.5

4

24

Note: The screws must not protrude more than 2 mm inside the Power Supply when screw holes provided

on the chassis are used. If the dimensions are not correct, the Power Supply may be damaged.

Panel mounting holes dimensions

98.3±1

33±0.5

Side

Mounting

34

Bottom

13

18±0.5

Mounting

15.5

10.5

Surface screw mounting

Two, M3

±0.5

122.5

Three, M3

±0.5

120

±0.5

85.5

±0.5

13

38±1

9.5

8

4 dia.

5.5

4.5

4 dia.

29

19.5

Three, M3

(Depth 2 mm max.)

129±1

78

32

6.5

77±0.5

S8JC-Z10024C (100 W)

38±1

9.5

8

4 dia.

6

4.5

22 120±0.5

7

4 dia.

31.5

22

22 125±0.5

159±1

149.5±0.5

Three, M3

(Depth 2 mm max.)

Panel mounting holes dimensions

80±0.5

97.6±1

Side

8.7

Mounting

13±0.5

15±0.5

13

16.5

Bottom

Mounting

Surface screw mounting

Two, M3

±0.5

152

±0.5

149.5

Three, M3

±0.5

84

±0.5

15

4

Page 5

S8JC-Z15024C (150 W)

Seven, M3 screws

50±1

4 dia.

S8JC-Z

Four, M3 screws

98

80±0.5

9.5

8

6

4.5

22

120±0.5

159±1

8.7

S8JC-Z35024C (350 W)

7

4 dia.

43.5

29

Three, M3

(Depth 2 mm max.)

22 125±0.5

Panel mounting holes dimensions

Surface screw mounting

Side

Mounting

152

Bottom

Mounting

149.5

±0.5

±0.5

149.5±0.5

Three, M3

Two, M3

26±0.5

13

20

17.5

±0.5

84

±0.5

26

(3)

50±1 (3)

Four, M3

(Depth 2 mm max.)

80±0.5

17.2

115

9.5

8

32.8

25±0.5

13

30

145±0.5

194.8

140±0.5

5

Page 6

S8JC-Z

DIN Rail-mounting Models

S8JC-Z015@@CD (15 W)

S8JC-Z035@@CD (35 W)

S8JC-Z05024CD (50 W)

S8JC-Z10024CD (100 W)

(15.6)

97

5.5

9.5 mm max.

15

98.3

5

9.5 mm max.

9.5

7.8

(3)

46

(3)

46

(10)

9.5

7.8

(10)

79.5

129

97.6

9.5

7.8

46

(3)

(10)

159

(16.1)

5

9.5 mm max.

6

Page 7

S8JC-Z15024CD (150 W)

S8JC-Z35024CD (350 W)

S8JC-Z

97.5

9.5

7.8

(3)

51.5

(10)

159

(16)

5

9.5 mm max.

9.5

7.8

(3)

51.5

(3)

(10)

Safety Precautions

Refer to Safety Precautions for All Power Supplies.

Precautions for Safe Use

• Minor burns may occasionally occur. Do not touch the Product

while power is being supplied or immediately after power is turned

OFF.

• Minor injury due to electric shock may occasionally occur. Do not

touch the terminals while power is being supplied.

• Take adequate measures to ensure proper heat dissipation to

increase the long-term reliability of the Product.

• Connect the ground completely. Electric shock or malfunction may

occur if the ground is not connected completely.

• The service life of the fan is approximately 35,000 hours (at 25°C).

The service life varies, however, depending on the ambient

temperature or other surrounding environmental conditions such

as dust. As a guide two years if it is used at an ambient

temperature of 40°C. (For 350-W Models only.)

• The screws must not protrude more than 2 mm inside the Power

Supply when screw holes provided on the chassis are used.

• Avoid places where the product is subjected to penetration of

liquid, foreign substance, or corrosive gas (in particular, sulfide

gas or ammonia gas).

194.8

(16)

115

5

9 mm max.

7

Page 8

Read and Understand this Catalog

Please read and understand this catalog before purchasing the product. Please consult your OMRON representative if you have any questions

or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a period of one year (or other period

if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NON-INFRINGEMENT,

MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT

THE BUYER OR USER ALONE HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS, OR

COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT,

WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE PRODUCTS

UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORED, INSTALLED, AND

MAINTAINED AND NOT SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the combination of products in the

customer's application or use of the products.

Take all necessary steps to determine the suitability of the product for the systems, machines, and equipment with which it will be used.

Know and observe all prohibitions of use applicable to this product.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT

THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY

RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user’s programming of a programmable product, or any consequence thereof.

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other reasons.

It is our practice to change model numbers when published ratings or features are changed, or when significant construction changes are made.

However, some specifications of the products may be changed without any notice. When in doubt, special model numbers may be assigned to

fix or establish key specifications for your application on your request. Please consult with your OMRON representative at any time to confirm

actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

PERFORMANCE DATA

Performance data given in this catalog is provided as a guide for the user in determining suitability and does not constitute a warranty. It may

represent the result of OMRON’s test conditions, and the users must correlate it to actual application requirements. Actual performance is

subject to the OMRON Warranty and Limitations of Liability.

OMRON Corporation

Industrial Automation Company

Control Devices Division H.Q.

Industrial Component Division

2-2-1 Nishikusatsu, Kusatsu-shi,

Shiga, 525-0035 Japan

Tel: (81) 77-565-5160/Fax: (81) 77-565-5569

Regional Headquarters

OMRON EUROPE B.V.

Wegalaan 67-69-2132 JD Hoofddorp

The Netherlands

Tel: (31)2356-81-300/Fax: (31)2356-81-388

OMRON Industrial Automation Global: www.ia.omron.com

OMRON ELECTRONICS LLC

One Commerce Drive Schaumburg,

IL 60173-5302 U.S.A.

Tel: (1) 847-843-7900/Fax: (1) 847-843-7787

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08 (Lobby 2),

Alexandra Technopark, Singapore 119967

Tel: (65) 6835-3011/Fax: (65) 6835-2711

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120, China

Tel: (86) 21-5037-2222/Fax: (86) 21-5037-2200

Authorized Distributor:

© OMRON Corporation 2009 All Rights Reserved.

In the interest of product improvement,

specifications are subject to change without notice.

Cat. No. T044-E1-01

Printed in Japan

0909

Loading...

Loading...