Page 1

S8AS

Smart Power Supply

USER'S MANUAL

Cat. No. Z269-E1-05

Page 2

Page 3

S8AS Smart Power Supply

User’s Manual

Revised September 2013

Page 4

iv

Page 5

v

About this Manual:

This manual describes the installation and operation of the S8AS Smart Power Supply and includes

the sections described below.

Please read this manual carefully and be sure you understand the information provided before

attempting to install or operate the S8AS Smart Power Supply. Be sure to read the precautions provided in the following section.

Precautions provides general precautions for using the S8AS Smart Power Supply and related

devices.

Section 1 introduces the features and functions of the S8AS Smart Power Supply and concepts

related to its operation.

Section 2 identifies the S8AS Smart Power Supply’s components, provides specifications, and

describes the basic functions.

Section 3 describes how to install and wire the S8AS Smart Powe r Supply.

Section 4 describes how to set the S8AS’s various parameters.

Section 5 describes how to connect the branch outputs and test operation.

Section 6 describes how to use S8AS communications.

Section 7 provides information on troubleshooting problems that may occur with the S8AS Smart

Power Supply.

The appendices provide a glossary of terms related to the S8AS and flowcharts of S8AS key opera-

tions.

! W ARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the Product, or Product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

Page 6

vi

Page 7

vii

TABLE OF CONTENTS

SECTION 1

Features and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Overview of Features and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 S8AS Operating Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1-3 Table of Basic Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-4 S8AS Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

SECTION 2

Specifications and Functions . . . . . . . . . . . . . . . . . . . . . . . . . 15

2-1 Component Names and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-2 Internal Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2-3 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2-4 Basic Function Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2-5 Startup Sequence Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

2-6 Shutdown Sequence Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2-7 External Tripping Input Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

SECTION 3

Installation and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3-1 Installing the S8AS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3-2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3-3 Power Supply and Input/Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3-4 RS-485 Port Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

SECTION 4

Parameter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4-1 Parameter Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4-2 Switching the Operating Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4-3 Changing the Protection Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4-4 Switching to Setting Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

4-5 Individual Branch Output Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4-6 Shared Parameter Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

4-7 Special Settings and Communications Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

SECTION 5

Trial Operation to Actual Operation . . . . . . . . . . . . . . . . . . 77

5-1 Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

5-2 Connection/Disconnection Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5-3 Checking Sequence Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

5-4 Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Page 8

viii

TABLE OF CONTENTS

SECTION 6

Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

6-1 CompoWay/F Communications Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6-2 Frame Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

6-3 Variable Area Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

6-4 Read Controller Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

6-5 Read Controller Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

6-6 Read Controller Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

6-7 Echoback Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

6-8 Operation Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

6-9 Response Code List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

6-10 ASCII List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 10

SECTION 7

Error Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

7-1 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

7-2 Seven-segment Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

7-3 Clearing Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Appendices

A Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

B List of Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Page 9

ix

Terms and Conditions Agreement

Read and understand this Manual

Please read and understand this catalog before purchasing the products. Please consult your OMRON

representative if you have any questions or comments.

Warranty, Limitations of Liability

Warranties

● Exclusive Warranty Omron’s exclusive warranty is that the Products will be free from defects in

materials and workmanship for a period of twelve months from the date of

sale by Omron (or such other period expressed in writing by Omron). Omron

disclaims all other warranties, express or implied.

● Limitations OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR

IMPLIED, ABOUT NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF THE PRODUCTS. BUYER

ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED

USE.

Omron further disclaims all warranties and responsibility of any type for claims

or expenses based on infringement by the Products or otherwise of any intellectual property right.

● Buyer Remedy Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace

(in the form originally shipped with Buyer responsible for labor charges for

removal or replacement thereof) the non-complying Product, (ii) repair the

non-complying Product, or (iii) repay or credit Buyer an amount equal to the

purchase price of the non-complying Product; provided that in no event shall

Omron be responsible for warranty, re pair, indemnity or any other claims or

expenses regarding the Products unless Omron’s analysis confirms that the

Products were properly handled, stored, installed and maintained and not

subject to contamination, abuse, misuse or inappropriate modification. Return

of any Products by Buyer must be approved in writing by Omron before shipment. Omron Companies shall not be liable for the suitability or unsuitability or

the results from the use of Products in combination with any electrical or electronic components, circuits, system assemblies or any other materials or substances or environments. Any advice, recommendations or information given

orally or in writing, are not to be construed as an amendment or addition to

the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for

published information.

Limitation on

Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR

PRODUCTION OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH

THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Page 10

x

Further, in no event shall liability of Omron Companies exceed the individual

price of the Product on which liability is asserted.

Application Considerations

Suitability of Use Omron Companies shall not be responsible for conformity with any standards,

codes or regulations which apply to the combination of the Product in the

Buyer’s application or use of the Product. At Buyer’s request, Omron will provide applicable third party certification documents identifying ratings and limitations of use which apply to the Product. This information by itself is not

sufficient for a complete determination of the suitability of the Product in combination with the end product, machine, system, or other application or use.

Buyer shall be solely responsible for deter mining appropriateness of the particular Product with respect to Buyer’s application, product or system. Buyer

shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS

RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE SYSTEM

AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND

THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Programmable

Products

Omron Companies shall not be responsible for the user’s programming of a

programmable Product, or any consequence thereof.

Disclaimers

Performance Data Data presented in Omron Company websites, catalogs and other materials is

provided as a guide for the user in determining suitability and does not constitute a warranty. It may represent the result of Omron’s test conditions, and the

user must correlate it to actual application requirements. Actual performance

is subject to the Omron’s Warranty and Limitations of Liability.

Change in

Specifications

Product specifications and accessories may be change d at an y time base d on

improvements and other reasons. It is our practice to change part numbers

when published ratings o r features are changed, or when signifi can t cons truction changes are made. However, some specifications of the Product may be

changed without any notice. When in doubt, special part numbers may be

assigned to fix or establish ke y specification s for your application. Please consult with your Omron’s representative at any time to confirm actual specifications of purchased Product.

Errors and Omissions Information presented by Omron Companies has been checked and is

believed to be accurate; however, no responsibility is assumed for clerical,

typographical or proofr eading errors or omissions.

Page 11

xi

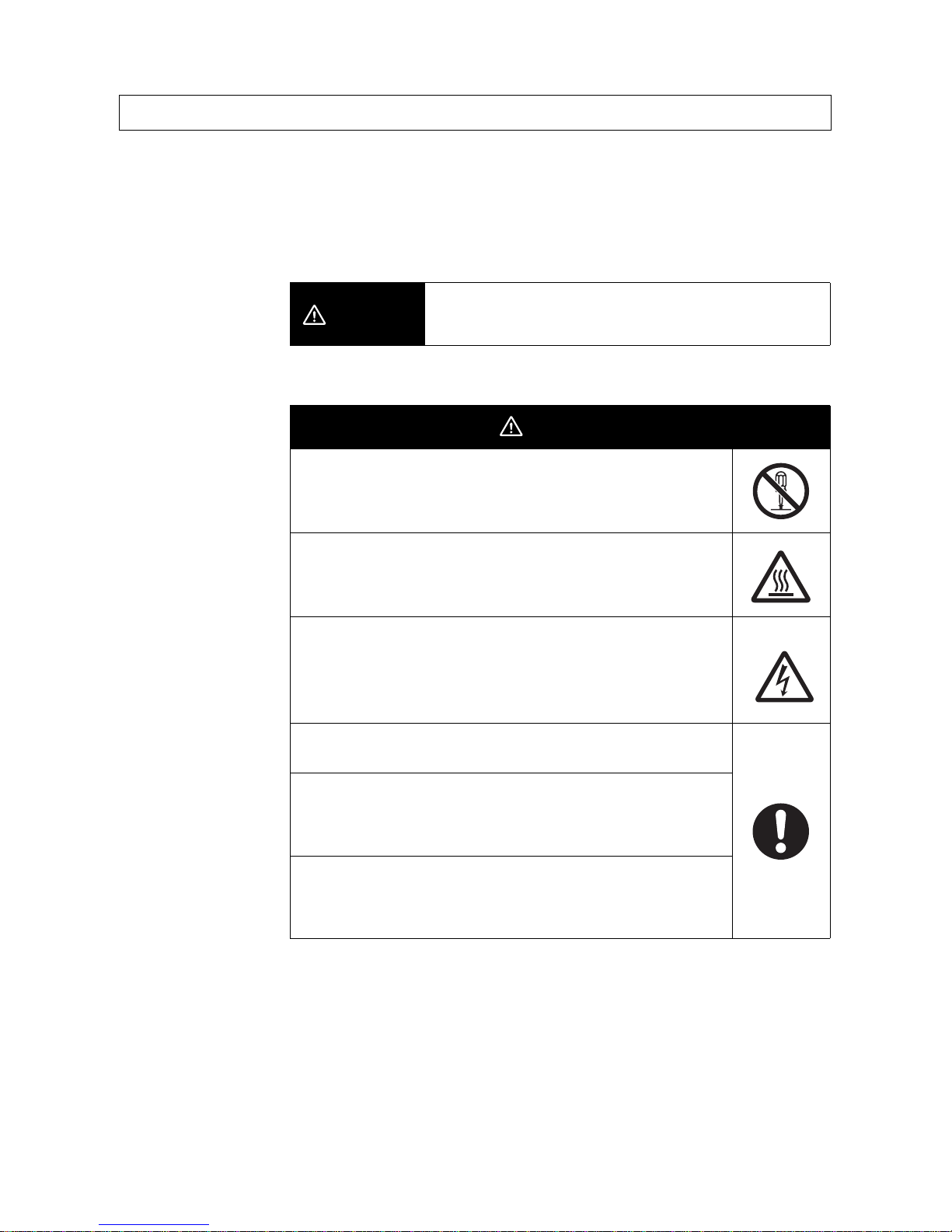

■ Precaution Classifications

The following conventions are used to indicate and classify precautions in this

manual.

Always heed the information provided with them. Failure to heed precautions

can result in injury to people or damage to property.

■ Cautions

Safety Precautions

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury or in

property damage.

CAUTION

Minor electric shock, fire, or Product failure may occasionally

occur. Do not disassemble, modify, or repair the Product or touch

interior of the Product.

Minor burns may occasionally occur. Do not touch the Product

during power is being supplied or immediately after power is

turned OFF.

Minor injury may occasionally occur due to electrical shock. Do

not touch the terminals while power is being supplied. Also, be

sure to close the terminal cover after wiring the terminals.

Fire may occasionally occur. Tighten terminal screws to the

specified torque.

Minor electric shock, fire, or Product failure may occasionally

occur. Do not allow any pieces of metal or conductors or any

clippings or cuttings resulting from installation work to enter the

Product.

A maximum voltage of 370 V may be generated internally when

power is supplied.

This voltage will remain for 30 s even after the power supply has

been turned OFF.

Page 12

xii

The S8AS Smart Power Supply combines the highly reliable S8VS Switch Mode Power Supply with the S8M

Digital Multicircuit Protector into a single unit to reduce both wiring and space requirements. The built-in digital

circuit protector uses semiconductor relays to close and trip circuits, and does not contain any contact

switching mechanisms, as normal circuit protector s do.

Observe the following precautions when introducing the S8AS into or using the S8AS in any system.

■ Installation and Storage Environment

1. Store the Product at an ambient temperature of –25 to 65°C and relative humidity of 25% to 90%.

2. To maintain performance of the maintenance forecast monitor, make sure the following conditions are

satisfied for long-term storage.

• For storage exceeding three months, keep the Product at a temperature of –20°C to 30°C and a

humidity of 25% to 70%.

3. Internal parts may occasionally be deteriorated or damaged. Do not use the Product in conditions

exceeding the derating curve (in portion (1) of the derating curve on pagexiv).

4. Inter nal par ts may possibly be damaged. Do not use a current that exceeds the rated total output current.

If temporary peak currents occur repetitively, design the system so that the peak currents do not ex ceed

the rated total output current.

5. The surrounding air temperature to comply with UL508 and UL60950-1 is 25°C.

6. Use the Product where the relative humidity is 25% to 85%.

7. Do not use the Product where it would be subjected to direct sunlight.

8. Do not use the Product where it would be subjected to the possibility of penetration of liquid, foreign

substance, or corrosive ga s.

9. Do not use the Product where it would be subjected to shock or vibration. A device such as a contact

breaker may be a vibration source. Set the Product as far as possible from possible sources of shock or

vibration. Additionally, install a PFP-M End Plate on each end of the Product after mounting it to a DIN

Rail.

10. Use a DIN Rail made of steel. If an aluminum DIN Rail is used, vibration or shock may cause the

formation of metal dust due to abrasion of the aluminum.

11. Poor heat dissipation may deteriorate or damage internal parts. Do not loosen the screws on the side of

the Product.

12. If the Product is used in an area with excessive electronic noise, be sure to separate the Product as far as

possible from the noise sources.

13. Cutoff p erformance is guaranteed according to the a mbient operating temperature. Use the Product withi n

the derating range. Refer to the Derating Curve on pagexiv.

14. Poor heat dissipation resulting from improper installation conditions may occasionally deteriorate or

damage internal parts and also cause the maintenance forecast monitor function to not operate properly.

Do not use any mounting orientation other than a standard one.

15. Do not conne ct a battery or other backup power supply to the output of the Product.

16. To comply with UL standards, insert a fast-breaking, UL-approved fuse rated at 20 A into each input line.

17. Although some inverters have an output frequency of 50/60 Hz, they may cause internal temperatures to

rise, possibly resulting in burning, if they are connected as the power source for the S8AS. Do not use the

output from an inverter as the power source for the S8AS.

Precautions for Safe Use

Standard Mounting

Face-up Mounting

Page 13

xiii

■ Installation and Wiring

1. Minor electric shock during operation may occasionally occur. Always attach the cover or take other

precautions so that the terminals cannot be touched directly.

Also, connect the ground completely. The ground is a protective earth (PE) terminal specified in safety

standards. If the ground is not connected completely, electric shock or malfunction may occur.

2. Minor fire may possibly occur. Ensure that input and output terminals are wired correctly.

3. Heat generated by wiring materials may cause the temperature of internal parts to increase, which may

result in deterioration of or damage to the internal par ts. Select the wiring ma terials according to the

current that is being used.

4. Using the wiring materials, torque, and wire stripping length specified in 3-3 Power Supply and Input/

Output Wiring is recommended to prevent smoke or fire of the wire material due to an abnormal load.

5. It is conceivable that internal parts may be deteriorated or damaged. Do not repeatedly perform cutoff or

recovery operations more than necessary.

6. Do not push more than 100 N of force to the terminal block when tightening screws.

7. Be sure to tighten the lock screws on the sides of the connector after connecting any output connector.

When removing a connector, be sure the lock screws are completely loose before pulling on the

connector.

8. Be sure to remove the sheet covering the Product during installation before turning ON the power.

■ Output Voltage Adjustment

1. The output voltage adjuster (V.ADJ.) may possib l y become damaged. Do not a pply more than the requ ired

force.

2. Do not exceed the rated output capacity and rated total output current after adjusting the outp ut voltage.

■ Periodic Inspections

Under normal operating conditions, the Product will require several years or even more than ten years until the

maintenance forecast monitor function operates. When using the Product for an extended period of time, perform the following procedure periodically to confirm that the output for the maintenance forecast monitor function (LFE) is operating correctly.

a) Change to Run Mode.

b) Confirm that the (LFE) output is ON (electrical continuity between LFE and COM).

Note For details about terminal names, refer to 2-1 Component Names and Functions.

Page 14

xiv

• When the tripping alarm output operates, always remove the cause of the output first and then reset the

alarm.

• When cycling the input power supply, always remove any problems first and then turn ON the input power

supply.

■ Startup Time

When the input power is turned ON to the S8AS, a hardware check, software check, and initialization processing are performed before the branch outputs are turned ON. Approximately three seconds is required. When

using the S8AS with other control equipment, incorp orate the startup time of the S8AS in the overall system

design.

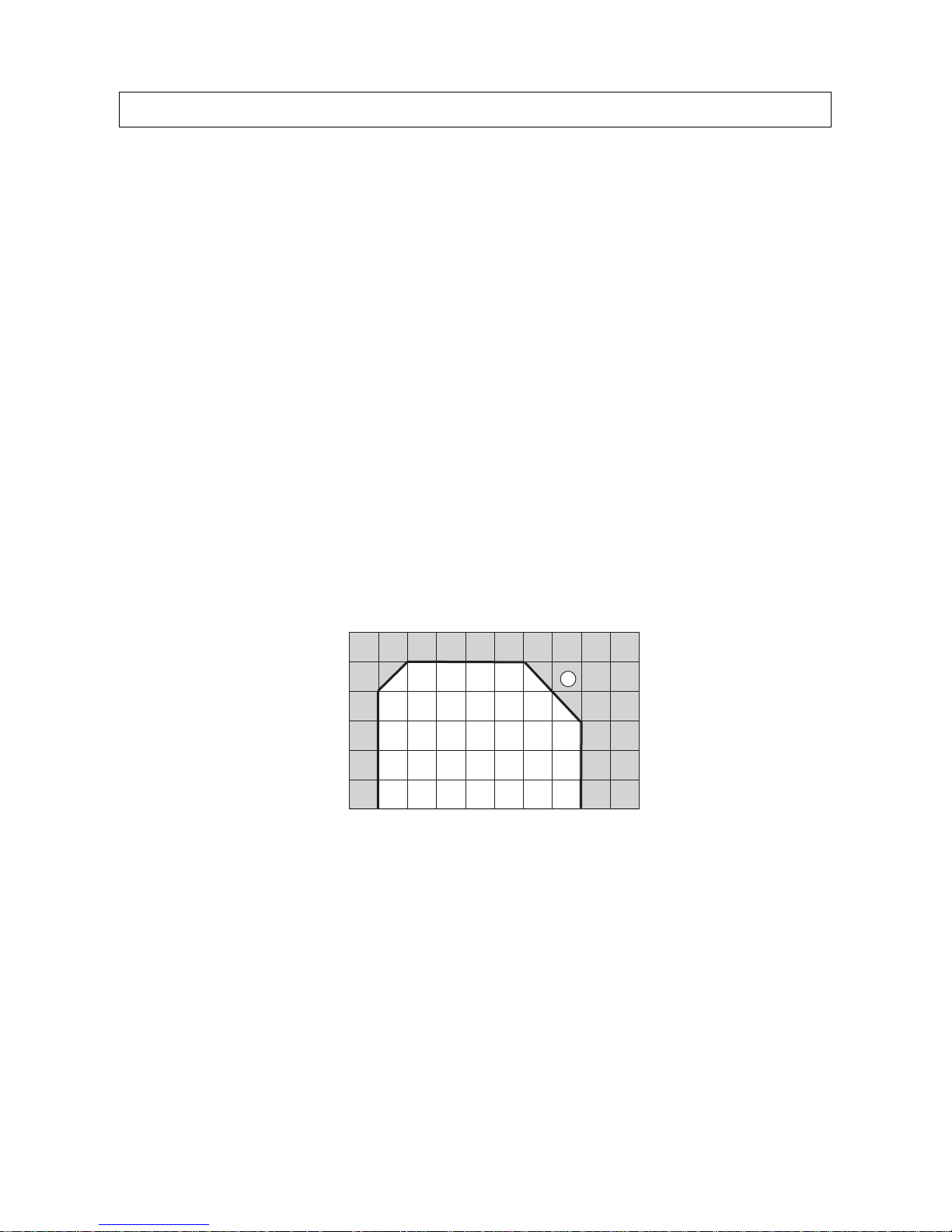

■ Installation

• Mounting Direction

Mount the S8AS to a DIN Rail using the standard mounting direction. Do not mount it in any other direction,

such as face up.

(Refer to 3-1 Installing the S8AS.)

• Mounting Space

The long-term reliability of the S8AS can be increased by installing it properly and sufficiently considering heat

dissipation.

Be sure to install the S8AS so that the air flow circulates around it, because the S8AS is designed to radiate

heat by means of natural air circulation.

■ Derating Curve

The temperature range within which the S8AS can be used is restricted by the maximum current that normally

flows for the total output. This restriction is given as a derating curve.

Note

1. The ambient temperature is measured at a point 50 mm below the S8AS.

2. Use forced cooling if necessary to satisfy the derating curve.

3. For 480-W models , re duce the loa d to 80 % or le ss for long-term use at an input voltage of 95 VAC or less.

■ Abnormal Voltage Tripping

1. The S8AS has an abnormal voltage tripping function. All branch outputs will be cut off if the input voltage

exceeds 28.8 VDC. This function, however, does not protect loads and internal parts from high voltages in

all cases. Be sure the output voltage is within the rated range .

2. Outputs may be cut off by the abnormal voltage protection with loads that generate reverse peak electromotive force.

Precautions for Correct Use

Load rate (%)

Total output current

Ambient temperature (°C)

120

100

80

60

40

20

0

−20 −10 0 10 20 30 40 50 60 70 80

1

Page 15

xv

■ Abnormal Current Tripping

The S8AS has an abnormal current tripping function. A branch output will be cut off if its current exceeds a preset value. Also, all branch outputs will be cut off if their total peak output current exceeds a specified value.

Note

1. Continuing operation with o vercurrent may occa sionally result in deterior ation or destruction of internal ele-

ments.

2. Do not use the S8AS for applications in which load inrush current or overload will frequently occur.

Doing so may result in deterioration or damage to internal components.

■ Maintenance Forecast Monitor Function

The accuracy of the maintenance forecast monitor function will be reduced in applications where the AC input

turns ON and OFF frequently.

■ Tripping Performance

There are three methods that can be used to determine abnormal current trippings: Standard Detection,

Instantaneous Detection, and Extended Detection. (This is not possible for the S8AS-24006N/ 48008N.)

Refer to 2-4-2 Over-current Protection Functions for details of cutoff performance.

Note

1. When the tripping alarm output operates, always remove the cause of the output first and then reset the

alarm.

2. When using a load with a fixed-power operation, the S8AS may cause a cutoff when the power supp ly is

turned OFF.

3. Tolerance of current tripping alarm threshold is ±0.3 A.

4. Use Extended Detection only when using OMRON Remot e I/O Terminal with short-circuit detection.

■ Total Peak Output Current

The S8AS is designed to provide a temporary peak current to provide the overcurrent required to start load

devices.

The total peak output current for all branch outputs combined is given below.

If the total current exceeds any of these values, all branch outputs will be cut off according to the size of the

peak current or application time to ensure safety.

• 240-W Models

Input voltage range: 200 to 240 VAC

Peak current/Peak current pulse width: 17 A max. for 2 s max.

15 A max. for 5 s max.

13 A max. for 10 s max.

12 A max. for 20 s max.

If the total output peak current exceeds even one of these conditions, all branch outputs will be shut off to

ensure safety.

• 480-W Models

Input voltage range: 200 to 240 VAC

Peak current/Peak current pulse width: 27 A max. for 1 s max.

25 A max. for 2 s max.

22.5 A max. for 5 s max.

Note

1. If the input volta ge range is not within the v alues specified abo ve or the total output current e xceeds the max-

imum peak current value, internal operation will become unstable and the branch outputs may be cut off.

2. Maintain the total current f or normal oper ation after the load de vices ha v e started to within the rated r anges.

Page 16

xvi

3. Do not allow a peak current to flo w again for at least 60 seconds after a peak current has e xceeded the rated

current.

■ Startup Delay

The S8AS has a startup delay function that prevents cutoffs caused by inrush current at startup.

The startup delay disables the cutoff operation for 40 ms after the semiconductor relay turns ON.

To protect inter nal circuits, however, the relevant branch outputs will be cut off even during the startup delay

period if a current limit is exceeded within a specific time period.

Note The startup delay will not operate when a relay or other device is used fo r ON /OFF control on the output

side of the S8AS, so a cutoff operation may occasionally occur.

■ Dielectric Strength Test

The S8AS is designed to withstand 3,000 VAC for 1 minute between the AC input terminals collectively and

the branch output, I/O signal, or communications terminals collectively. When testing, set the cutoff current for

the withstand voltage test device to 20 mA.

Note

1. The S8AS may possib ly be damage d f rom th e imp ulse voltage if a testing device switch is used to abruptly

apply or cut off 3000 V A C. Increase the applied voltage grad ually using the voltage adjust ment on the testing

device.

2. When testing terminals together, always short the specified terminals so that the voltage is applied to all of

the terminals at the same time.

■ Insulation Resistance Test

When testing the insulation resistance, use a DC resistance meter at 500 VDC.

Note To prevent damage, always short branch output terminals (+/–), all I/O terminals, and communications

terminals before testing.

■ Output Voltage Adjustment

Default setting: Set as the rated voltage.

Adjustable range: Adjustable from –10% to +10% of the rated output voltage by using the V.ADJ. adjuster on

the front or the Power Supply. Turning the adjuster clockwise increases the output voltage, and turning it

counterclockwise decreases the output voltage.

Note

1. If the output voltage is set to less than 20 V (default setting), the undervoltage detection may be activated.

2. Do not exceed the rated output capacity and rated total output current after adjusting the output voltage.

3. The output voltage may increase beyond the allowable voltage range rated voltage +10% when the V.ADJ

adjuster is used. When adjusting the output voltage, check the output voltage of the power supply to make

sure that the load is not damaged.

■ No Output Voltage

The internal circuit’s overcurrent protection or overvoltage protection may operate. Alternatively, the latch

protection circuit may operate if there is a lightning surge or other large voltage applied to the input.

Contact your OMRON representative if there is still no output voltage after checking the following two points:

• Checking Overcurrent Protection

Check whether the load is in an overcurrent or short-circuited state. Remove the wires to the load before

checking.

• Checking Overvoltage Protection and Latching Protecti on

Turn the power supply OFF and leave it OFF for at least 3 minutes, then turn it ON again.

Page 17

xvii

■ Startup Time

At startup, the S8AS will check hardware and software before starting the operation of branch outputs.

A time of approximately 3 se conds is required for these self-diagnostic functions.

Take this time into account when designing the system.

■ External Tripping Input

Wire the polarity of the external tripping input correctly. After completing wiring, confirm that operation is correct.

■ Tripping Alarm Output, Undervoltage Detection Output, Maintenance

Forecast Monitor Output, and Over-temperature Output

Photoswitch outputs: 30 VDC max., 50 mA max., residual voltage when ON: 2 V max., leakage current when

OFF: 0.1 mA max.

Wire all output signal circuits correctly. Internal current control circuits are not provided internally for output signals. Do not allow the output current to e xceed 50 mA. After completing wiring, confirm that the circuits oper ate

correctly.

■ Displaying the Output Voltage

The voltage detection function displays on the 7-segment display the voltage that is monitored at the internal

circuit after AC/DC conversion. The displayed voltage will be somewhat lower than the value at the output

terminals of the power source due to internal voltage drop. To accurately confirm the output voltage, measure

it at the branch output terminal.

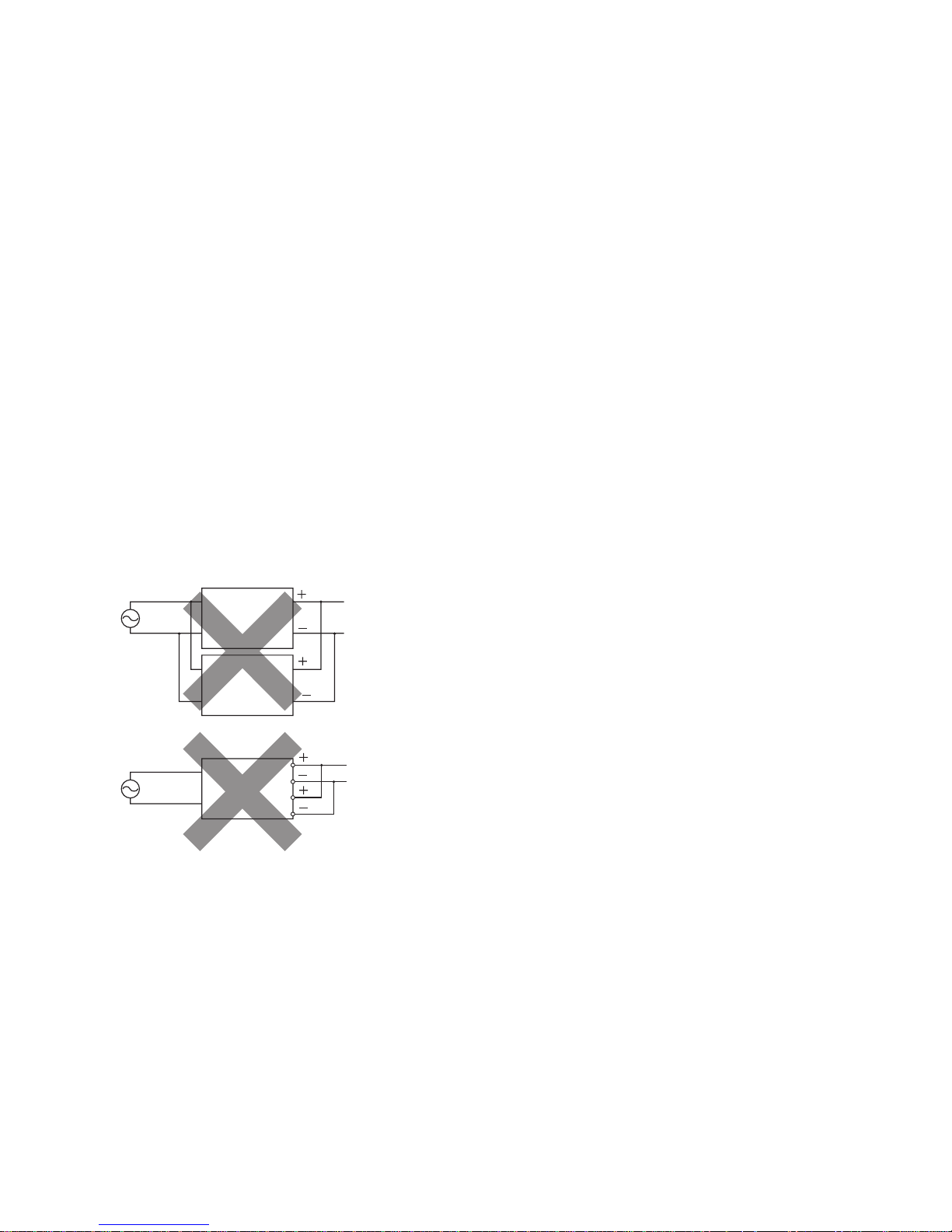

■ Prohibition of Parallel Connection

Do not connect branch outputs from the S8AS in parallel. Also, do not connect the branch outputs in parallel

with branch outputs of other S8AS Power Supplies.

■ Supplementary Information: Conformity to IEC and EN Safety Stan-

dards

Warning: The S8AS is a Class A product. In a residential, commercial, or light industrial environment, it may

cause radio interference. The S8AS is not intended to be installed in a residential environment. In a

commercial or light industrial environment with connection to a commercial power supply, the user may be

required to take adequate measures to reduce interference.

S8AS

S8AS

S8AS

Connections cannot be made in parallel

with other branch output circuits.

Page 18

xviii

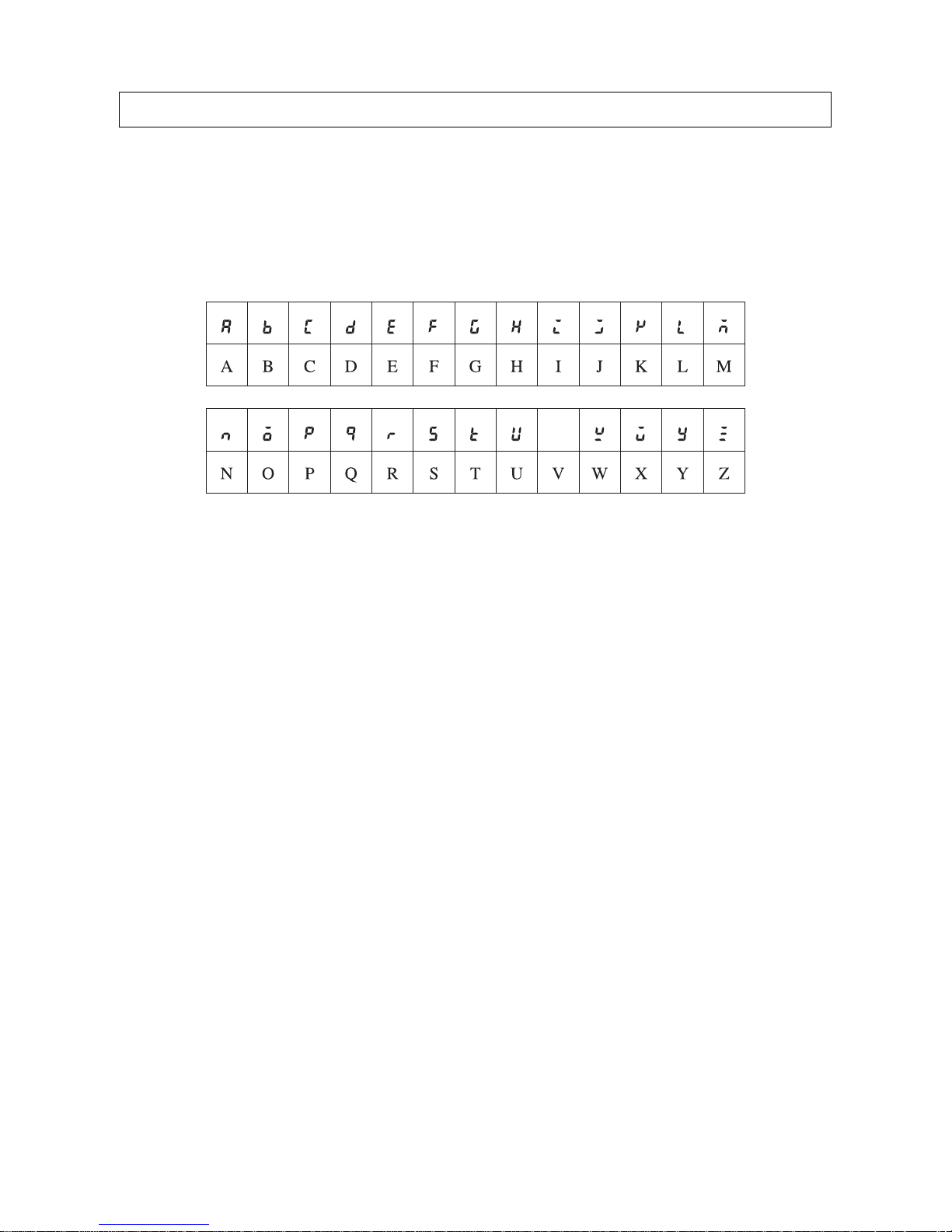

■ Notation in this Manual

In this manual, the S8AS Smart Power Supply is referred to as the S8AS.

■ Notation of Setting Data

Setting data codes and contents are displayed in seven-segment display characters, as shown in the following

diagram.

Using this Manual

V

Page 19

1

SECTION 1

Features and Functions

This section describes the features and functions of the S8AS.

1-1 Overview of Features and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 S8AS Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-3 Table of Basic Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-4 S8AS Operating Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Page 20

2

Overview of Features and Functions Section 1-1

1-1 Overview of Features and Functions

The S8AS Smart Power Supply is a 24-VDC power supply unit with an internal digital circuit protector that incorporates the highly reliable S8VS Switch

Mode Power Supply and the S8M Digital Multicircuit Protector in one unit.

The input power supply to the S8AS is 100 to 240 VAC at 50/60 Hz. Models

are available for 240 W with 6 branch outputs or for 480 W with 8 branch outputs, with and without communications. Models for which parameters cannot

be changed are also available.

The S8AS provides a stable 24-VDC power supply at an output current of 3.8

A maximum.

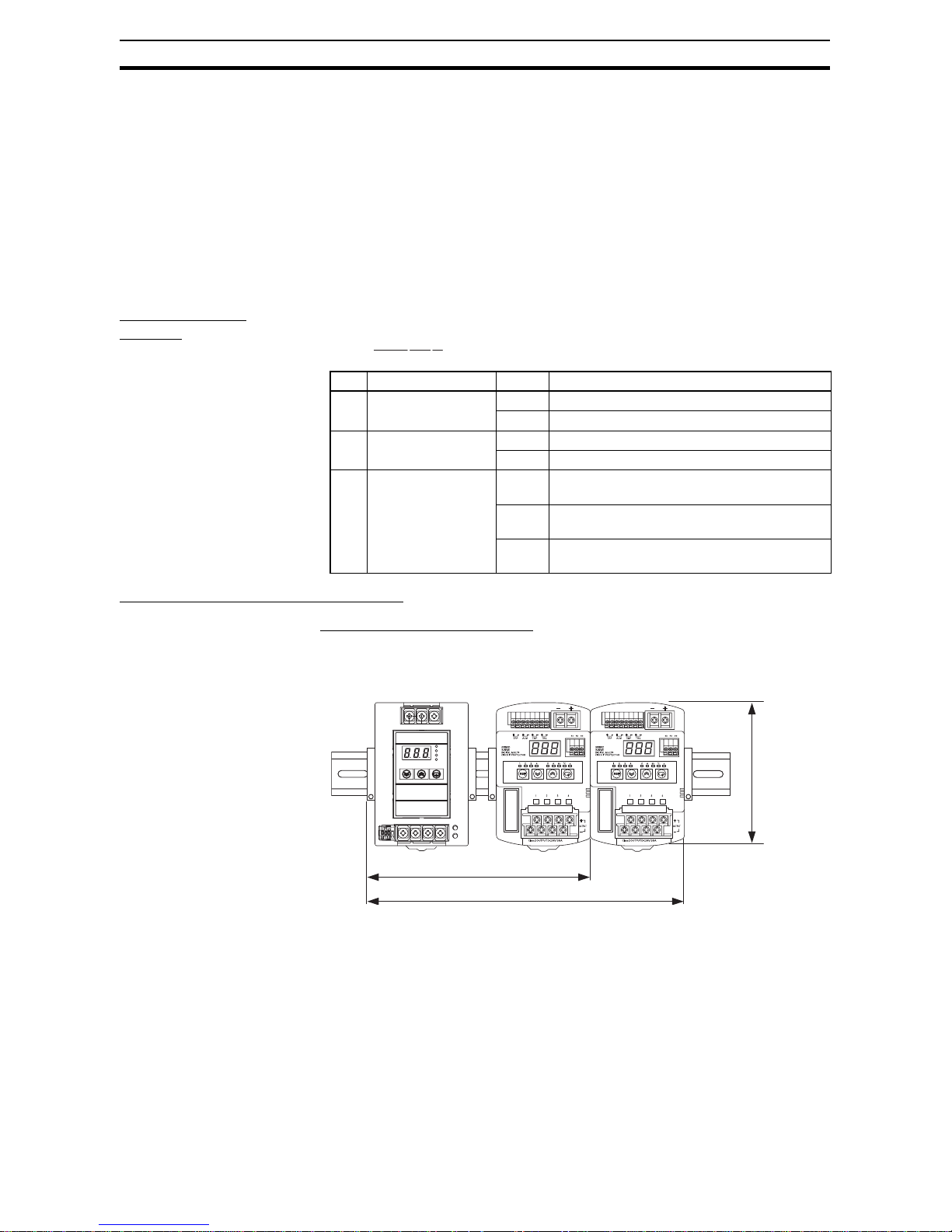

Model Number

Legend

S8AS Model Numbers

Reduced Space, Wiring, and Work

■ Combination of S8VS and S8M

The space required within the control panel and the amount of wiring have

been reduced by integr ating a Digit al Mu lticircuit Protector into a Switch Mode

Power Supply.

No. Item Code Meaning

1 Output capacity 240 240 W

480 480 W

2 Number of output

branches

06 6 branch outputs

08 8 branch outputs

3 Communications /

Additional functions

blank Changeable parameter settings with no com-

munications

N Unchangeable parameter settings with no

communications

R Changeable parameter settings with communi-

cations (RS-485)

S8AS-@@@@@@

1

2

3

115 mm

170 mm for models with 4 branch outputs

245 mm for models with 8 branch outputs

Page 21

3

Overview of Features and Functions Section 1-1

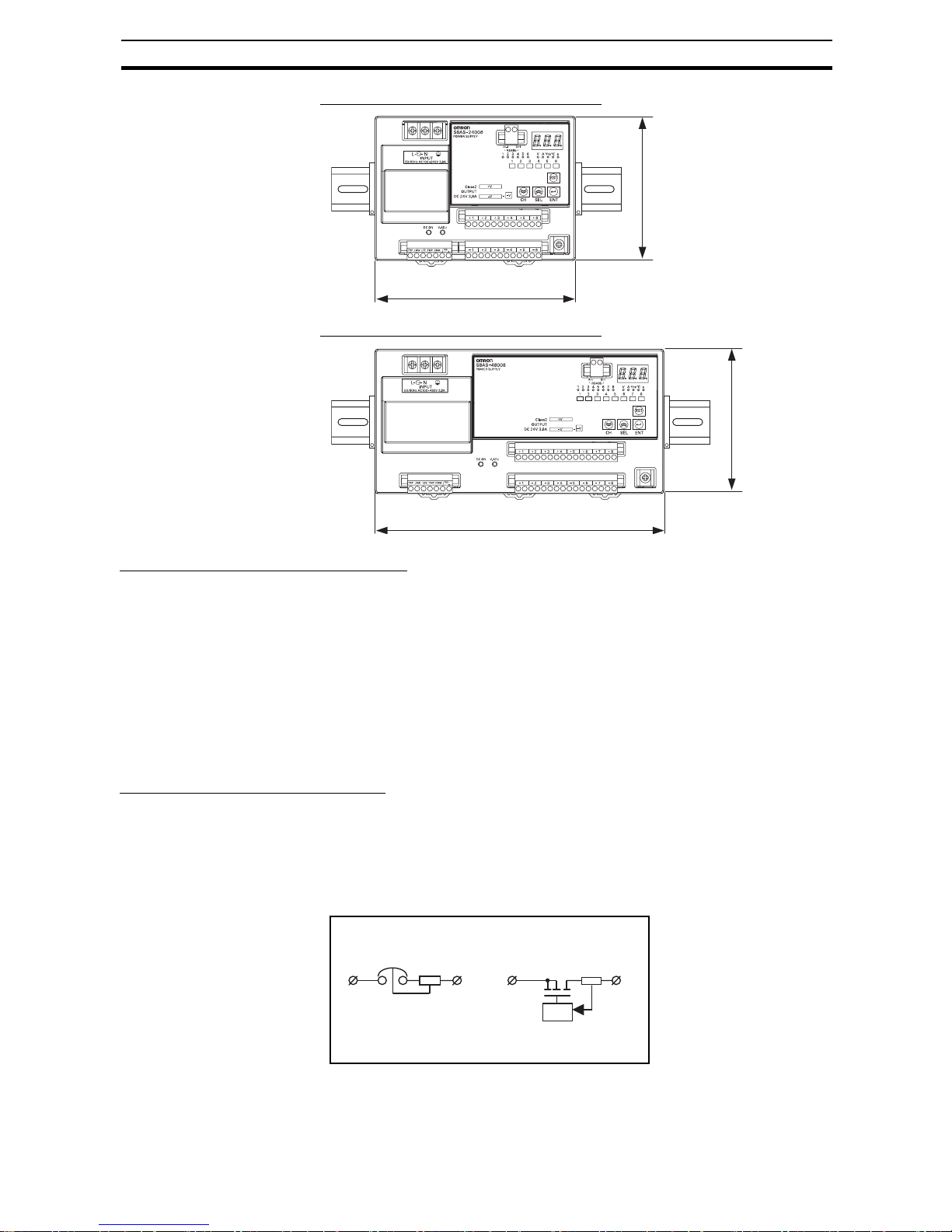

■ S8AS-24006@ (240 W, 6 Branch Outputs)

■ S8AS-48008@ (480 W, 8 Branch Outputs)

Power Supply and Branch Outputs

The power supply section incorporates the highly praised AC-DC conversion

circuit of the S8VS Switch Mode Power Supply in order to produce stable 24VDC power.

The branch output circuits consist of the protection circuits and tripping circuits of the S8M Digital Circuit Protector. They support various safety functions, such as overvoltage protection, overcurrent protection, and short-circuit

protection, as well as maintenance functions, such as monitoring using the

seven-segment display, error indications, and various alarm outputs .

Models that support communications can be monitored from a host computer

using RS-485 communications.

Branch Output Tripping Circuits

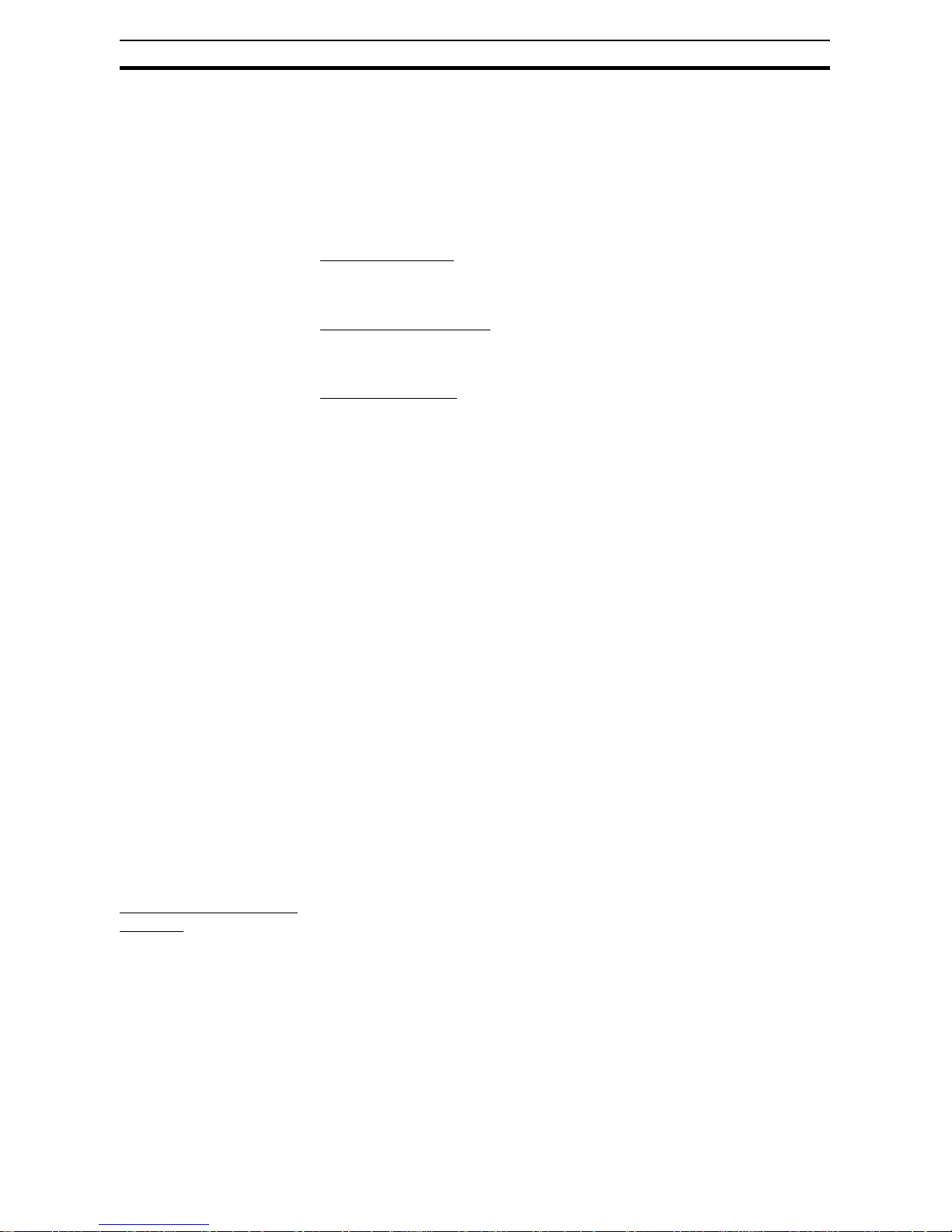

No-contact Switching The S8AS built-in circuit protectors differ from conventional mechanical con-

tact-type circuit protectors in that they use no-contact transistor relay switching. Without the contact life of mechanical cir cuit protectors, semiconductor

relays are able to provide a much longer lifetime. Digital processing also provides other benefits, such as being able to specify de ta ile d overcurrent detec tion conditions.

115 mm

160 mm for models

with 6 branch outputs

230 mm for models with 8 branch outputs

115 mm

Conventional contactstyle circuit protector

S8AS built-in circuit

protector

Overcurrent tripping

mechanism

Overcurrent

detection circuit

Page 22

4

Overview of Features and Functions Section 1-1

Tripping Current Can be

Set for Each Branch

Output

The abnormal tripping current value can be set for each branch output.

Setting range: 0.5 to 3.8 A (in 0.1 A increments).

Tolerance of current tripping threshold: ±0.3 A.

Abnormal Current

Detection and Tripping

Time

The abnormal current tripping characteristics can be set for each branch output. (This is not possible for the S8AS-24006N/48008N.)

There are three methods that can be used t o dete rmine abnormal current trippings. (This is not possible for the S8AS-24006N/48008N.)

■ Standard Detection

When the current exceeds the set value, the branch output is cut off within

100 ms.

■ Instantaneous Detection

When the current exceeds the set value, the branch output is cut off within

20 ms.

■ Extended Detection

When the current exceeds the set value, the branch output is cut off within

1,000 ms.

Error Indication and Alarm

Output for Abnormal

Current Tripping

The following will occur when an abnormal current is detected and the branch

output is cut off:

• The branch output status indicator will light red.

• The seven-segment display will show the error code A11 and the abnormal current value alternately.

• The external output terminal for tripping alarms (TRP) will tur n ON. (The

photoswitch output will turn OFF.)

Always remove the cause of the abnormal current before resetting the alarm.

Tripping for Total Peak

Output Current

When the total branch output current exceeds the set value for a specified

amount of time, all branch outputs will be cut off.

• All branch output status indicators will light red.

• The seven-segment display will flash the error code A12.

• The external output terminal for tripping alarms (TRP) will tur n ON. (The

photoswitch output will turn OFF.)

Abnormal Voltage

Tripping

If the output voltage exceeds 28.8 VDC, all branch outputs will be cut off in

order to protect load devices.

The following will happen when this occurs:

• The seven-segment display will show the error code A10 and the abnormal voltage alternately.

• The external output terminal for tripping alarms (TRP) will tur n ON. (The

photoswitch output will turn OFF.)

Internal Temperature

Monitor

The S8AS has an built-in temperature sensor that constantly measures the

internal temperature. The temperature can be read from the seven-segment

display. The temperature display range is −20 t o 10 0°C. The temperature sensor has one external output (TMP), which can be used to control cooling

equipment for the control panel.

The temperature output setting range is 25 to 90°C.

• The seven-segment displa y wi ll sho w the err or code A30 and tem per atur e

(°C) alternately.

Page 23

5

Overview of Features and Functions Section 1-1

• The external output terminal for over-temperature (TMP) will turn ON.

(The photoswitch output will turn OFF.)

Maintenance Forecast

Monitor Function

This function calculates the condition of the electrolytic capacitor based o n the

power-ON time and internal temperature of the Power Supply to forecast

when the Power Supply needs to be replaced. The monitor value can be set to

between 0.0 and 5.0 years (approximate) in increments of 0.5 years.

The following occurs when the estimated replacement time reaches the set

value:

• The seven-segment display will show the error code A23 and the replacement time (years) alternately.

• The external output terminal for the maintenance forecast monitor (LFE)

will turn ON. (The photoswitch output will turn OFF.)

Safety Functions If an abnor mal voltage or current is detected, the semiconductor relay will cut

off the branch output. In the unlikely event that the semiconductor relay cannot cut off an abnormal current or short-circuit current, the short-circuit protection fuse will cut the circuit to protect the system. If the branch output is cut off

by the fuse, an error indication will not be shown on the seven-segment display and the alarm output (TRP) will not operate.

The overcurrent protection fuse or over-temperature fuse cannot be replaced.

If a fuse burns out, use a different branch output or replace the S8AS.

External Outputs The S8AS has 4 external outputs: the Tripping Alarm Output (TRP), Under-

voltage Detection Output (LOW), Maintenance Forecast Monitor Output

(LFE), and Over-temperature Output (TMP).

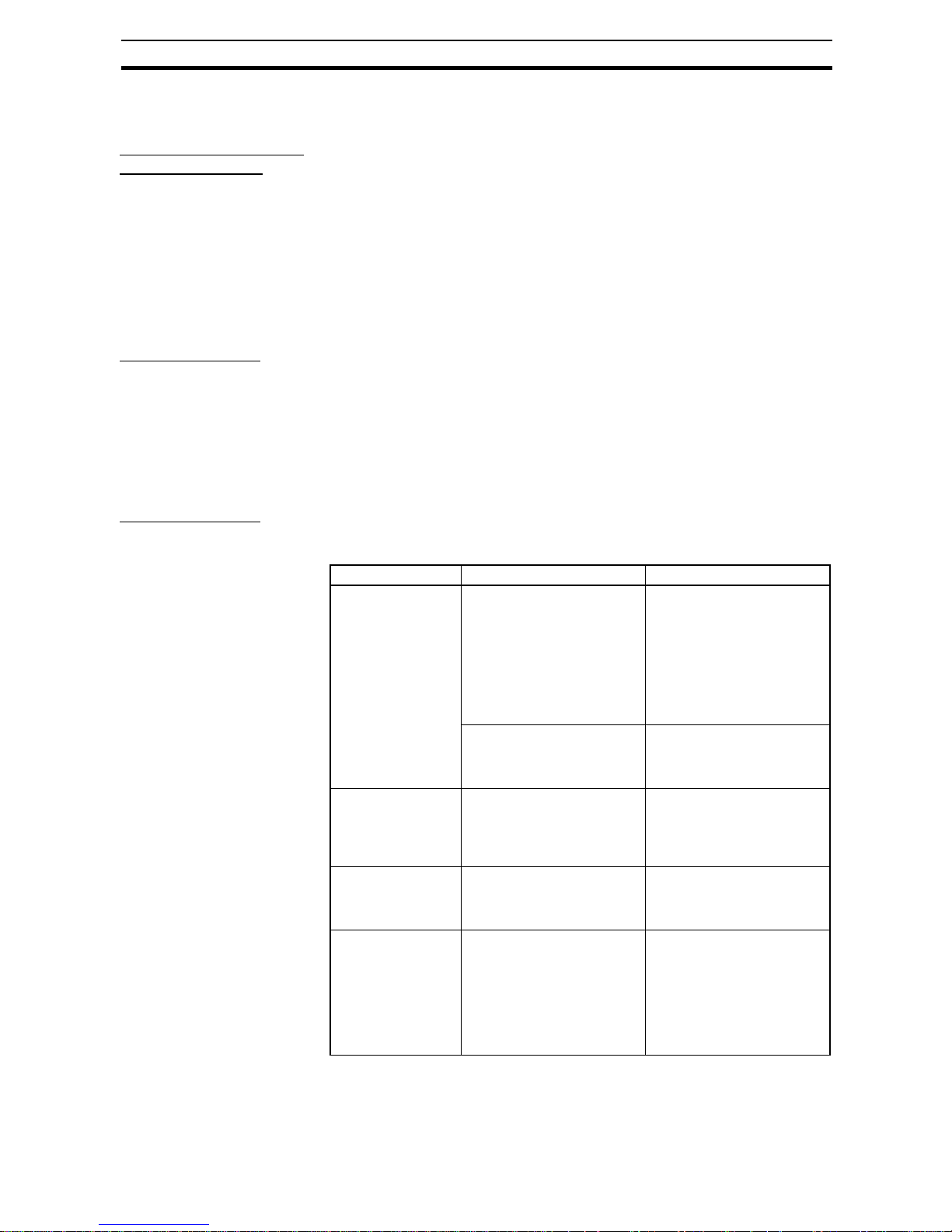

Output Output condition Restoration condition

Tripping Alarm

Output (TRP)

• Abnormal voltage tripping

If the output voltage exceeds

28.8 V , all branch outputs are

cut off.

• Abnormal current tripping

If a current exceeding the set

value is detected, the corresponding branch output is

cut off.

The output status is retained

when power is interrupted but

can reset with the reset operation.

Test Mode only

When even one branch output

is disconnected.

Restore by connecting all

branch outputs, or by switching to any mode other than

Test Mode.

Undervoltage Detection Output (LOW)

Output when the 24 VDC output falls below the undervoltage detection threshold.

This output can be reset with

the reset operation. If the

alarm is cleared when the

power is turned ON, the output will be reset.

Over-temperature

Output (TMP)

Output when a temperature

exceeding the threshold is

detected.

The output is reset automatically when the temperature

falls to 3°C below the overtemperature output threshold.

Maintenance Forecast Monitor Output

(LFE)

•Output when the estimated

replacement time falls below

the set value.

• Output when the replacement time can no longer be

calculated due to rise in temperature of the power supply

section.

•Prepare to replace the

Power Supply.

•Take measures to lower the

internal temperature.

Page 24

6

Overview of Features and Functions Section 1-1

Tripping Functions Using External Signals

Branch outputs can be forcibly cut off by turning ON the External Tripping

Input (TRG).

• Tripping using the External Tripping Input can be enabled or disabled

independently for each branch output. Refer to Tripping Input Trigger Set-

ting: TRG (Trigger) on page 68.

• The Exter nal Tripping Input directly cuts off a b ranch output's DC circuit,

so it acts eve n faster than cutting off the output by turning OFF the normal

AC power supp ly.

• When a shutdown sequence has been set, this function can be used to

set a time lag for the branch output cutoff. (For details, refer to 2-6 Shut-

down Sequence Function.)

• The tripping input type can be set. (Refer to 2-7 External Tripping Input

Function)

• EGE: Output cut off when the tripping input changes from OFF to ON.

• LVL: Output cut off when the tripping input changes from OFF to ON

and connected when tripping input changes from ON to OFF.

Additional Functions

Startup Sequence

Function

A delay can be set for t he connection of the br anch outputs . When y ou w ant to

apply a startup delay to the branch output, it is not necessary to construct an

external sequence circuit. The inrush current can be suppressed by applying

a delay and the Power Supply Unit's load can be reduced. (For details, ref er to

2-5 Startup Sequence Function.)

Shutdown Sequence

Function

The branch outputs' cutoff can be delayed. When you want to apply a shutdown delay to the branch output, it is not necessary to construct an external

sequence circuit. (For details, refer to 2-6 Shutdown Sequence Function.)

Protecting Parameter

Settings (Protection Level

Settings)

The Protection Level can be set to restrict access to the parameters. Three

levels, levels 0, 1, and 2, are available. This function can be used to prevent

parameters from being changed or deleted inadvertently.

The default setting is protection level 1. (For details, refer to 4-3 Changing the

Protection Level.)

Note The read/wr ite access for models that do not support parameter

changes (S8AS-24006N/48008N) cannot be changed regardless

of the protection level.

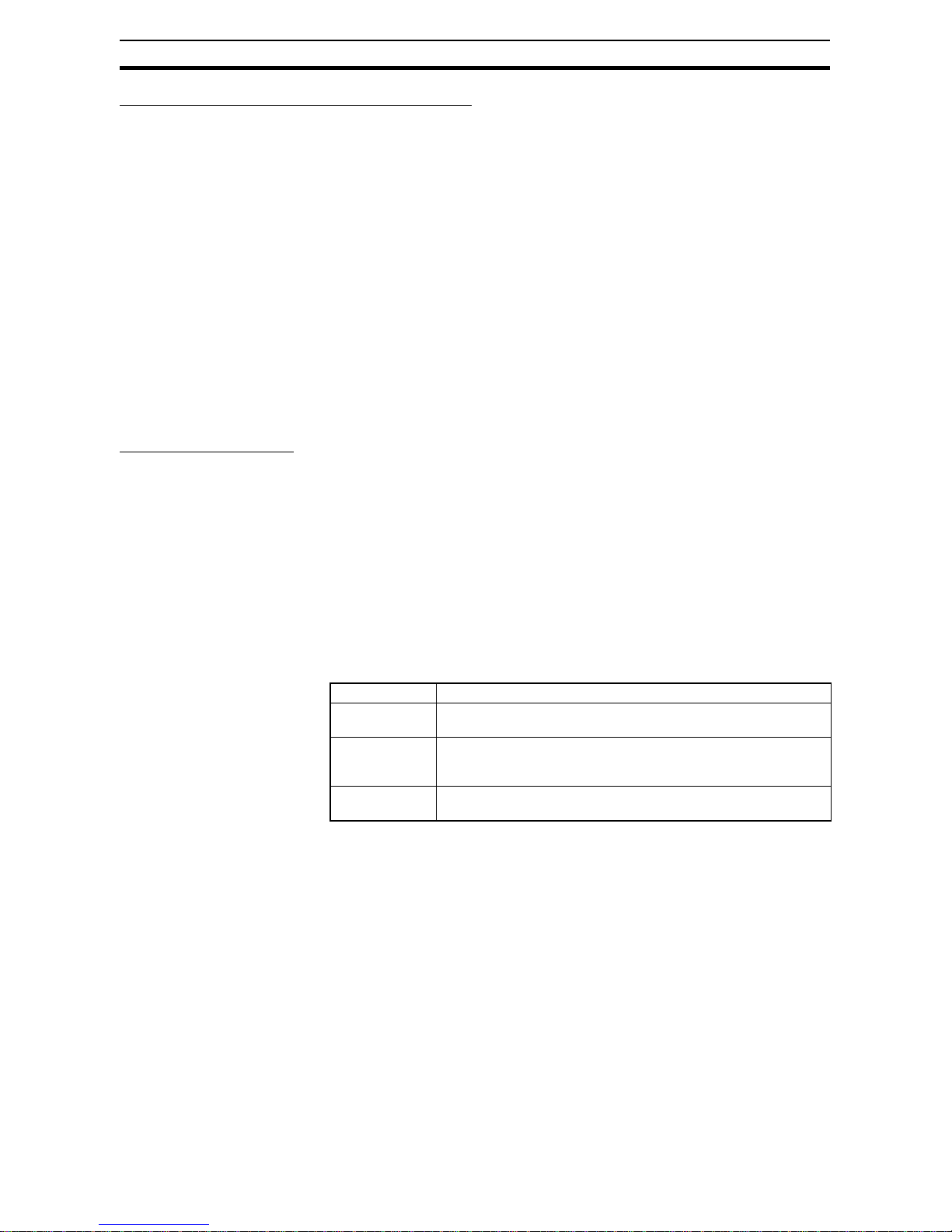

Protection level Restrictions

0 There are no restrictions on reading and changing the parameter

settings.

1 Permits only reading and changing of the output voltage, current,

internal temperature, and maintenance forecast monitor parameters.

2 Permits only reading of the output voltage, current, internal tem-

perature, and maintenance forecast monitor parameters.

Page 25

7

S8AS Operating Modes Section 1-2

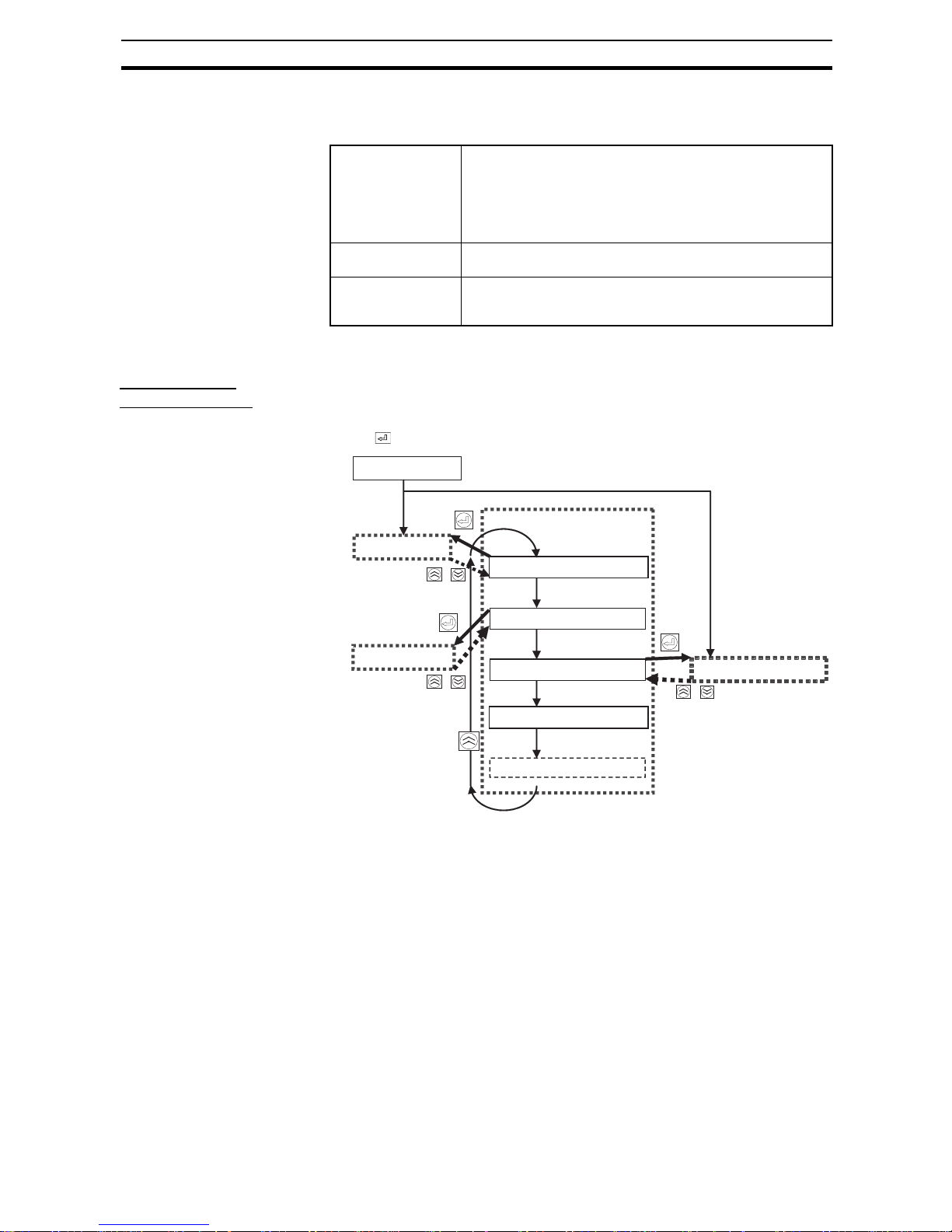

1-2 S8AS Operating Modes

The S8AS has 3 operating modes: Run Mode, Setting Mode, and Test Mode.

Note Test Mode can be entered only in protection level 0 or 1.

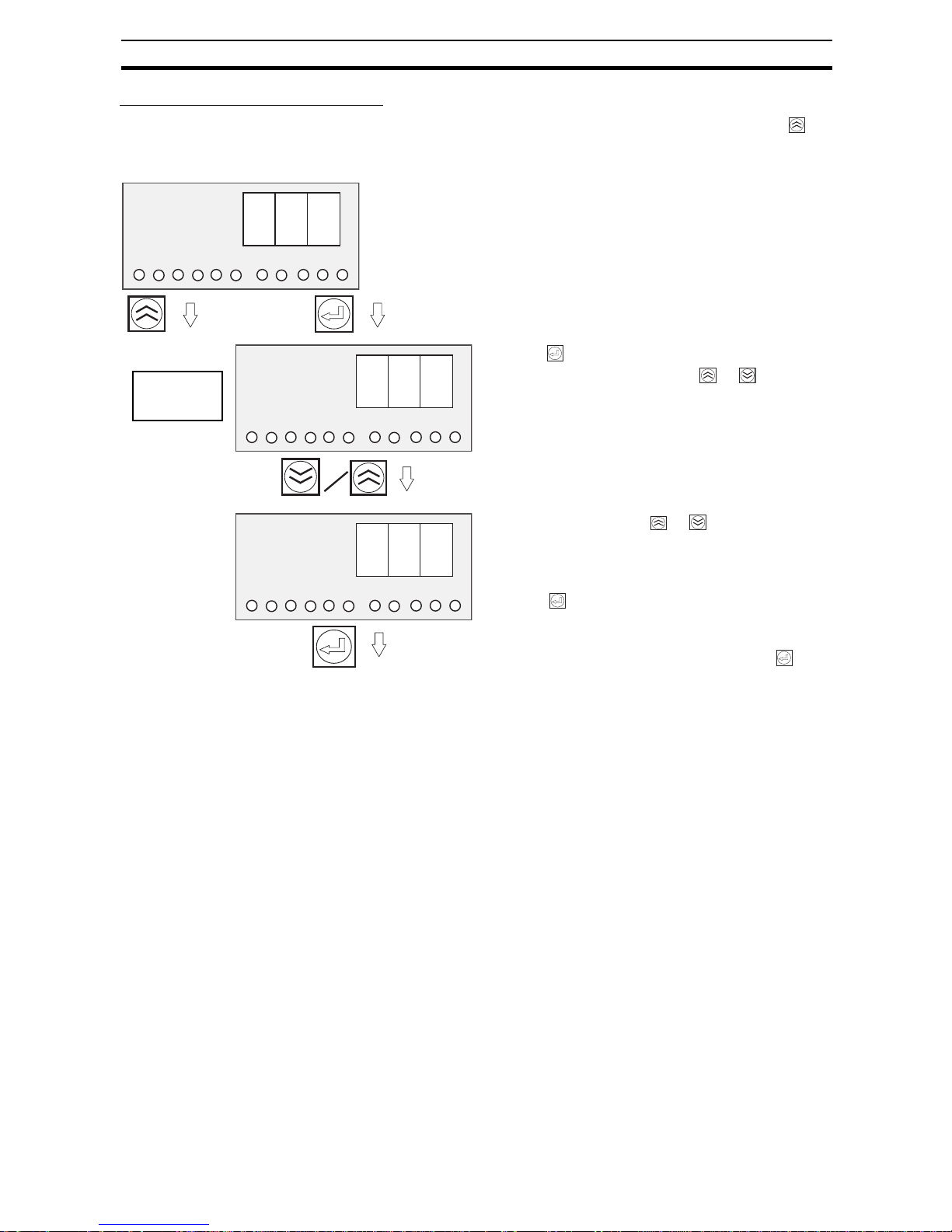

Changing the

Operating Mode

To change the operating mode, press the Up (SEL) (U) and Down (CH) (D)

Keys simultaneously for 3 s. The Mode Selection Menu will be displayed. Use

the Up (SEL) Key to select the desired operating mode and then press the

Enter ( ) Key.

Note (1) The Protection Level function can restrict parameter rea d/write access to

one of three lev els. F or details, ref er to 4-3 Changing the Protection Level.

(2) The Initialize Parameters function restores all of the S8AS's parameter

settings to their default values. For details on default values, refer to 4-1

Parameter Table.

(3) T est Mode can be entered only in protection level 0 or 1.

(4) The Setting Mode, Protection Level, or Parameter Initialization options

cannot be accessed with models such as S8AS-24006N/48008N that d o

not permit changes in parameter settings.

Run Mode The output voltage, output current, internal temperature, and

run time are monitored while supplying 24 VDC to the branch

outputs. The monitored values can be displayed on the sevensegment display.

The S8AS automatically starts in Run Mode when the S8AS is

used for the first time.

Setting Mode This mode is used to set parameters. Branch output connec-

tions are the same as in Run Mode.

Test Mode

(See note.)

This mode is used to test operation. The factory default setting

for all outputs is ON, so any branch outputs that are not being

used must be turned OFF in Test Mode.

+

+

Power ON

• When started for the

first time

• S8AS was not in Test

Mode when power

went OFF.

Run Mode

Setting Mode

Press for 3 s.

Press for 3 s.

Press for 3 s.

Mode Selection Menu

Select Run Mode run (RUN)

Select Setting Mode set (SET)

Select T est Mode tst (TST)

S8AS was in

Test Mode

when power

went OFF.

Select Protection Level prt (PRT)

Initialize Parameters ini (INI)

Test Mode (See note 3.)

The Initialize Parameters

command is displayed in

protection level 0 only.

(See

note 4.)

(See

note 4.)

(See

note 4.)

+

Page 26

8

S8AS Operating Modes Section 1-2

Turning the Power ON for

the First Time

• When a newly purchased S8AS is turned ON for the first time, it will enter

Run Mode with all the branch outputs turned ON. To change parameter

settings, return to the Mode Selection Menu and switch to Setting Mode.

Refer to SECTION 4 Par ameter Settings for details on setting parameters.

• T o start trial operation or to set branch output con nections after setting the

parameters, return to the Mode Se lection Menu and switch to Test Mode.

Refer to SECTION 5 Trial Operation to Actual Operation for details on the

operations in Test Mode.

• When changing to Run Mode after completing trial operation, return to the

Mode Selection Menu and switch to Run Mode. If the power is turned

OFF while the S8AS is in Test Mode, the S8AS will enter T est Mode again

the next time that the power is turned ON. All branch outputs will retain

the connection status they had before the power was turned OFF.

Normal Power-ON

Procedure

If the S8AS has been turned ON already, it will enter Run Mode or Test Mode

the next time that power is turned ON. If the S8AS was in T est Mode when the

power went OFF, it will start in Test Mode. If it was in a mode other than Test

Mode when the power went OFF, it will start in Run Mode.

In addition to selecting the operating mode, the Mode Selection Menu can be

used to select the protection level and initialize the parameters (see note 2).

(These options cannot be selected when using the S8AS-24006N/48008N.)

The Initialize Parameters function restores all of the S8AS's parameter settings to their default values. For details on default values, refer to Turning t he

Power ON for the First Time.

Automatic Operation

after Power ON

When the rated voltage (100 to 240 VAC, 50/60 Hz) is applied to the AC input

terminal block, the S8AS performs self-diagnostics (hardware and software

checks) for approximately 3 seconds. (“AS” will flash on the seven-segment

display during the self-diagnostic process.) If no errors are detected, the

S8AS will immediately start connecting the branch outputs.

Branch outputs will not be connected if they were not set to ON in Test Mode.

Furthermore, if the startup sequence function (refer to 2-5 Startup Sequence

Function) has been set, the branch outputs will be connected according to

their corresponding settings.

Operation in Run

Mode

In Run Mode, the S8AS continuously measures the output voltage, branch

output circuit currents, and internal temperature, and compares these values

to the set values (both user-set par ameters and system set values).

Monitor Operation The monitored output voltage, branch output currents, branch output peak

current, total current, internal temperature, and replacement time can be read

on the S8AS's seven-segment display. The displayed value can be switched

with the Up (SEL) Key (U) and Down (CH) Key (D).

Tripping Operation If the voltage or current is abnormal, the branch output will be cut off to protect

the circuit.

■ Abnormal Voltage Tripping

All branch outputs will be cut off if the output voltage exceeds 28.8 VDC in

order to protect the load devices.

■ Abnormal Current Tripping

A branch output will be cut off if the tripping current threshold (see note) or an

abnormal current is detected using the specified current detection method

(see note). (The tripping current threshold and current detection method cannot be changed for the S8AS-24006N/48008N.)

Page 27

9

Table of Basic Functions Section 1-3

An error code will be displayed, and the tripping alarm output will operate

when a branch output is cut off.

Other Status Monitoring The internal temperature and replacement time status are monitored and

error processing is performed if an error is detected.

Operation in Setting

Mode

Setting Mode can be used to set the v arious paramet ers. The S8AS is in operating status when it is in Setting Mode. Branch outputs are connected in Setting Mode in the same way as in Run Mode. When an error is detected,

branch outputs will be cut off and alarms will be output, just as they are in Run

Mode.

Note If an error occurs in Setting Mode, the error code is not displayed.

Operation in Test

Mode

In Test Mode, each branch output can be set to ON or OFF (connected or d isconnected).

The factory default setting f o r all outputs is ON, so an y branch outp uts that are

not being used must be turned OFF in Test Mode.

In Test Mode, the operation of each branch circuit can be verified as well as

the operation of the startup sequence and shutdown sequence.

Note (a) If the power is tur ned OFF while the S8AS is in Test Mode, the

S8AS will enter Test Mode again the next time that the power is

turned ON.

(b) When an error occurs in Test Mode, branch outputs will be cut off

and external signals will be output, just as they are in Run Mode.

The error code will not be displayed.

(c) Refer to 7-3 Clearing Errors for details on clearing errors.

Note (1) When the S8AS is shipped from the factory, all bra nch outpu ts ar e se t to

ON (connected) and the S8AS will enter Run Mode when the power is

turned ON. After setting the parameters that require changing, switch to

Test Mode, set the switching status of the required branch outputs, and

then switch to Run Mode.

(2) If a branch output is OFF (disconnected) when the mode is changed from

Test Mode to Run Mode, it will not be connected (ON) in Run Mode.

(3) If the power is turned OFF while the S8AS is in Test Mode, the S8AS will

start in Test Mode the next time that the power is turned ON, but all

branch outputs will be OFF.

1-3 Table of Basic Functions

Monitor Functions

Monitored

parameter

Details Indications

Seven-

segment

display

Branch

output

number

indicators

Unit

indicators

Output voltage Displays the output voltage. 16.3 to

30.0

Not lit V

Tota l current Displays the sum of all the

branch output currents.

0.0 to 40.0 All

branches

lit

A

Branch output

current

Displays individual branch

output currents.

0.0 to 20.0 Lit A

Page 28

10

Table of Basic Functions Section 1-3

Setting Functions Refer to SECTION 4 Parameter Settings for details on parameter settings.

(These parameters cannot be changed for the S8AS-24006N/48008N.)

Branch output

peak current

Displays individual branch

output peak currents.

0.0 to 20.0 Lit A

(flashing)

Replacement

time

Displays the estimated number of years left until the

S8AS needs to be replaced.

(Setting: 0.0 to 5.0 years, in

0.5-year increments.)

FUL, HLF

0.0 to 5.0

Not lit Yrs

Internal temperature

Displays the S8AS's internal temperature.

−20 to 100 Not lit °C

Monitored

parameter

Details Indications

Seven-

segment

display

Branch

output

number

indicators

Unit

indicators

Data name Detail Setting

range

Undervoltage

detection threshold

The undervoltage detection output (LOW) is output

when the output voltage of the S8AS falls below this

detection threshold. The detection threshold can be

set in 0.1-V increments. Branch outputs will not be

cut off.

18.0 to

26.4 V

Abnormal current

tripping threshold

The current tripping threshold can be set for each

branch output in 0.1-A increments.

0.5 to

3.8 A

Abnormal current

tripping type

The tripping type can be set for each branch output.

USU: Standard (tripping within 100 ms)

INS: Instantaneous (tripping within 20 ms)

LNG: Extended (tripping within 1,000 ms)

USU/INS/

LNG

Maintenance

forecast monitor

function

Set the expected number of years until the S8AS

needs to be replaced. When the estimated value falls

below the set value, the maintenance forecast monitor output (LFE) will turn ON. (The photoswitch output

will turn OFF.)

0.0 to

5.0 yr

Over-temperature threshold

An excessive temperature rise inside the S8AS will

be detected and the over-temperature output (TMP)

will turn ON. (The photoswitch output will turn OFF.)

This output can be used to control cooling equipment

to reduce the temperature in the control panel.

25 to 90°C

Startup

sequence

The connection of branch outputs may be initiated by

communications or when the power is turned ON,

and a time delay can be set for the connection

sequence. Connecting the branch outputs in

sequence instead of simultaneously can reduce the

inrush current and reduce the load on the Power Supply.

0.0 to

99.9 s

Shutdown

sequence

Branch outputs can be disconnected in sequence initiated by communications or an external tripping input

(TRP), and a time delay can be set for the sequence.

0.0 to

99.9 s

Tripping trigger

input

The external tripping input function (TRG) can be

enabled (ON) or disabled (OFF) for each branch output.

OFF, ON

Tripping trigger

type

The tripping trigger type can be set for all branches

that have the tripping input function enabled.

EGE, LVL

Page 29

11

Table of Basic Functions Section 1-3

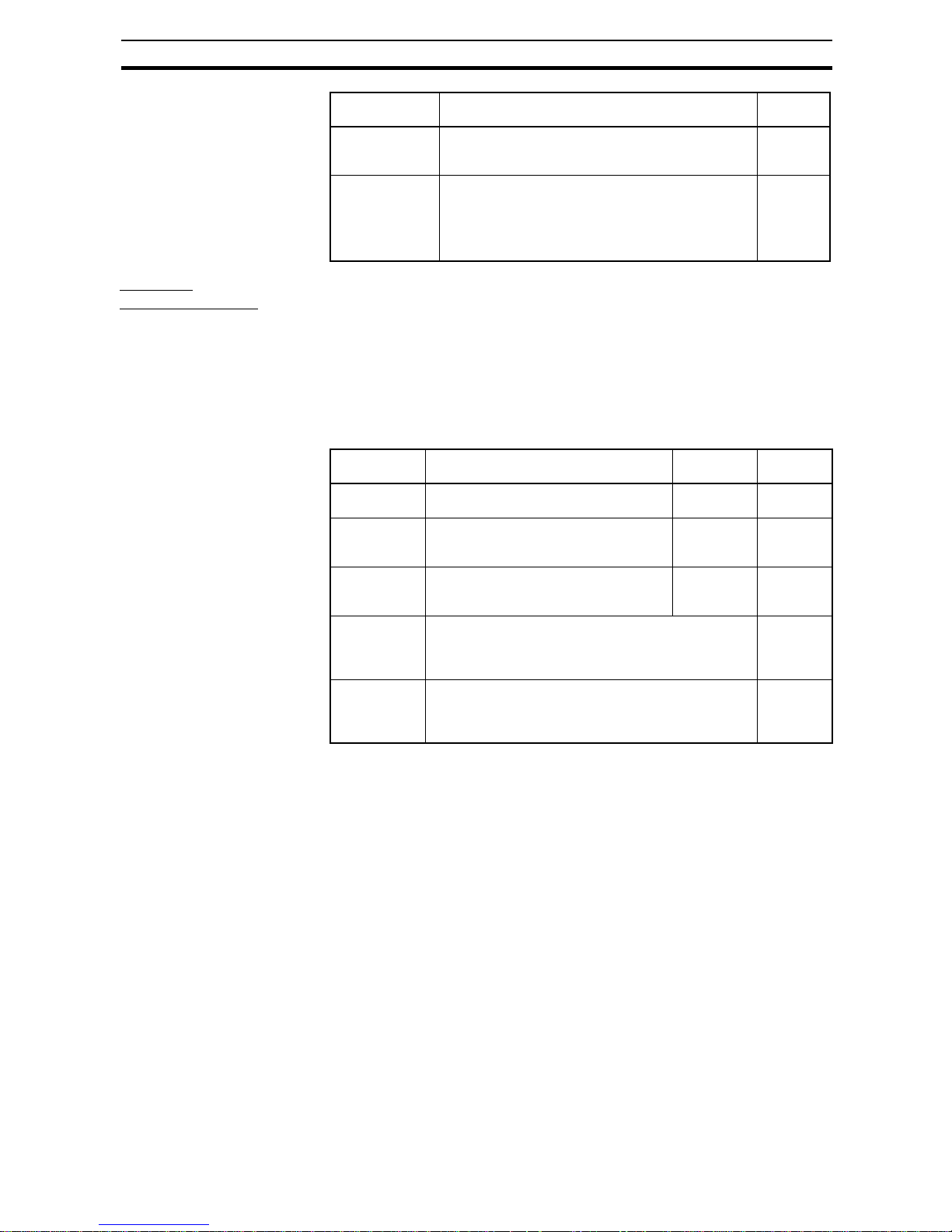

Tripping/

Alarm Functions

There are three ways for the S8AS's tripping function to operate:

• Tripping by user-set parameters

• Tripping by the S8AS's system monitor

• Tripping by external operation

The external signal outputs include the Tripping Alarm Output (TRP), Undervoltage Detection Output (LOW), Maintenance Forecast Monitor Output

(LFE), and Over-temperature Output (TMP).

Tripping Functions

Note (1) The tripping function operates within 100 ms when the S8AS is set to

standard detection, within 20 ms when it is set to instantaneous detection, and within 1,000 ms when it is set to extended detection.

(2) The TRG signal applies only to the branch outputs for which the e xte rnal

tripping input is enabled. For details, refer to 2-7 External Tripping Input

Function.

Protection level The Protection Level function can restrict parameter

read/write access by setting one of three levels. The

default protection level is level 1.

0 to 2

Reset operation The tripping alarm output and alarm output can be

cleared after removing the cause of the alarm by the

following two methods.

•KEY: RST Key only.

• ALL: RST Key or turning power OFF and ON again.

KEY, ALL

Data name Detail Setting

range

Setting Operating range Parameter

settings

Outputs

cut off

Abnormal voltage tripping

Output cut off for voltage over 28.8 VDC. None All branch

outputs

Short-circuit

current

tripping

Output cut off at 16 A for 20 ms max.

Output cut off at 11 A for 60 ms max.

None Individual

branch output

Abnormal total

current tripping

Output cut off when the sum of all branch

output currents exceeds the set value for

a specific length of time.

None All branch

outputs

Abnormal

current

tripping

(See note 1.)

0.5 to 3.8 A (in 0.1-A increments)

Select from standard, instantaneous, and extended

detection methods.

Individual

branch output

External tripping input

•External input signal (TRG) ON

•Tripping by communications.

Specified

output

(See note

2.)

Page 30

12

Table of Basic Functions Section 1-3

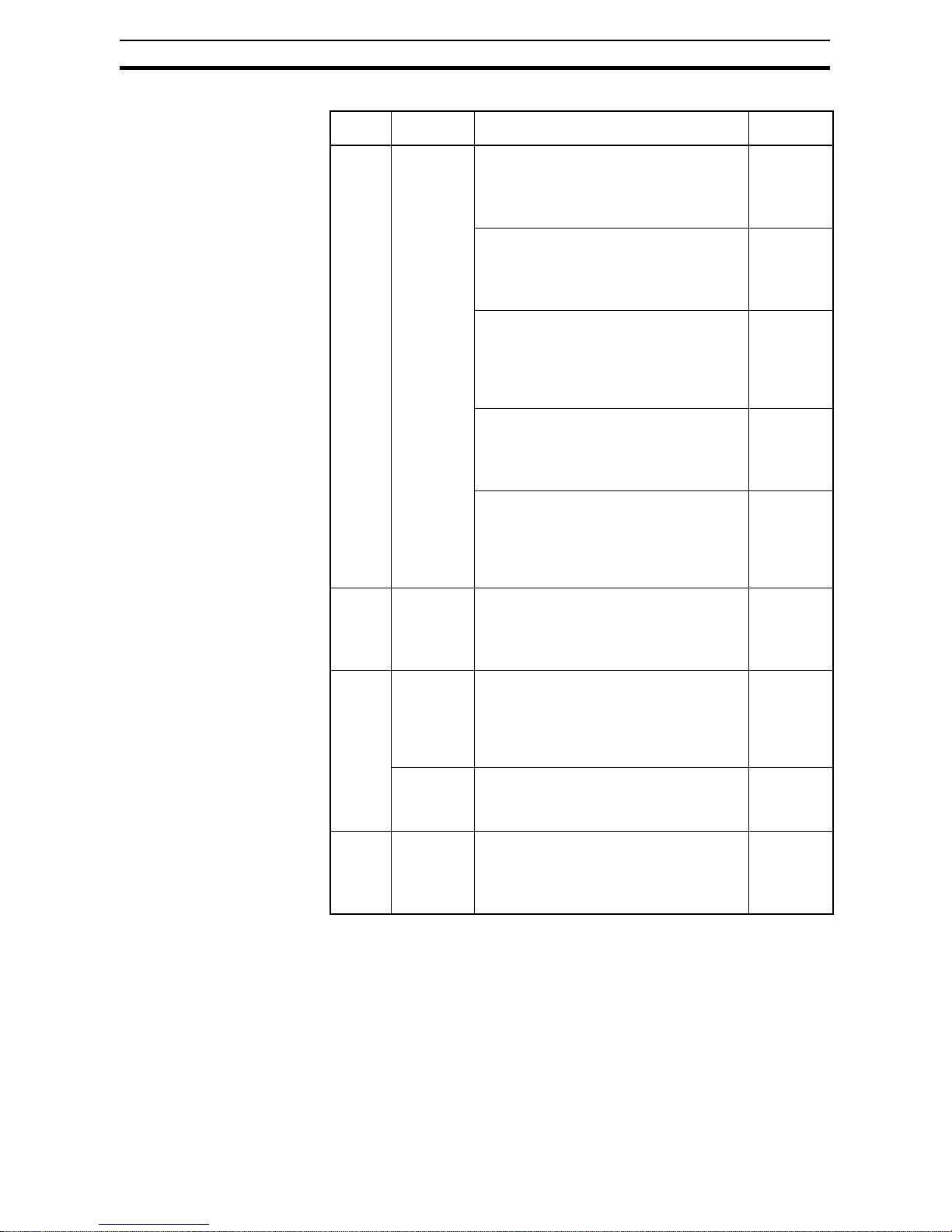

Alarm Output and Error

Display Functions

Note (1) In this manual, the lifetime of the Unit is expressed in years.

(2) If the overheating alarm stays on for more than 3 hours, it can no longer

be cleared.

Symbol Output

name

Operation Error code

displayed

TRP Tripping

alarm output

Abnormal Voltage Tripping Operati on

When the output voltage exceeds 28.8 VDC,

all branch outputs are cut off and the TRP

output is turned ON. (The photoswitch output

is turned OFF.)

A10

Abnormal Current Tripping Operation

When the branch output current exceeds the

set value, the branch output is cut off and the

TRP output is turned ON. (The photoswitch

output is turned OFF.)

A11/Current

(alternating)

Volt-amperage (VA) Tripping Operation

When the voltage times the current (VA)

exceeds the set value for a specified amount

of time, the branch output is cut off and the

TRP output is turned ON. (The photoswitch

output is turned OFF.)

A11/Current

(alternating)

Abnormal Total Current Tripping Operation

When the total output current exceeds the set

value, all branch outputs are cut off and the

TRP output is turned ON. (The photoswitch

output is turned OFF.)

A12

Indicates that there are branch outputs that

are not connected. This error is not output in

any mode other than Test Mode.

When there is a disconnected branch output

in Test Mode, the TRP output is turned ON.

(The photoswitch output is turned OFF.)

---

LOW Undervolt-

age detection output

Setting range: 18.0 to 26.4 VDC (0.1-V increments)

When the output voltage falls below the set

value, the LOW output is turned ON. (The

photoswitch output is turned OFF.)

A21/V oltage

(alternating)

LFE Mainte-

nance forecast monitor

output

Setting range: 0.0 to 5.0 years (0.5-yr increments) (See note 1.)

When the internally calculated replacement

time falls below the set value, the LFE output

is turned ON. (The photoswitch output is

turned OFF.)

A23/

Replacement time

(alternating)

Overheating

alarm (See

note 2.)

LFE output is turned ON (the photoswitch output is turned OFF) when the replacement

time cannot be calculated correctly due to rise

in internal temperature.

A23/HOT

(alternating)

TMP Over-tem-

perature

output

Setting range: 25 to 90°C (1°C increments)

When the temperature falls below the set

value minus 3°C, the TMP output and the

error code shown on the seven-segment display will be automatically cleared.

A30/Temperature (alternating)

Page 31

13

S8AS Operating Procedure Section 1-4

1-4 S8AS Operating Procedure

Using the S8AS

Typical Startup Proc edure

Using the S8AS's Keys

Summary of Application Objectives and Settings

Preparation

Installation and wiring

Power ON

Set parameters

Trial run in Test Mode

Verify operation

Actual operation

See Section 3 Installation and Wiring.

See Section 4 Initial Settings.

(S8AS-24006N/48008N parameters

cannot be changed.)

See Section 5 Trial Run.

Branch outputs that will not be used can be

set to OFF (disconnected.)

Verify proper operation while monitoring status in Run Mode.

Desired objective/

usage

Settings Details

Use as a circuit

breaker with overcurrent tripping.

In Setting Mode, set the abnormal current tripping threshold (C-V) for the branch output being

used and set the abnormal current tripping

detection setting (C-T) to standard detection

(USU).

p. 30,

p. 62

Use as a circuit

breaker for short-circuit current protection.

In Setting Mode, set the abnormal current tripping threshold (C-V) for the branch output being

used and set the abnormal current tripping

detection setting (C-T) to instantaneous detection (INS).

Detect a drop in

power supply voltage.

In Setting Mode, set the undervoltage detection

threshold (V-U). Take the alarm signal from the

Undervoltage Detection Output (LOW) terminal.

When an undervoltage is detected, the sevensegment display will show error code A21 and

the LOW output photoswitch output will go OFF.

p. 29,

p. 50

p. 63

Apply a separate

time lag when connecting each branch

output.

In Setting Mode, set the startup sequence

(UPS).

p. 37,

p. 66

Apply a separate

time lag when cutting

off each branch output.

In Setting Mode, set the shutdown sequence

(DWS) and enable the External Trip ping Input

(TRG).

p. 38,

p. 67

Use the S8AS

replacement time for

better maintenance.

The seven-segment display and the LFE terminal signal output can be used to check the estimated replacement time using the maintenance

forecast monitor function.

p. 34,

p. 64

Page 32

14

S8AS Operating Procedure Section 1-4

Monitor temperature

rise in control panel

and prevent overheating.

In Setting Mode, set the over-temperature output

threshold (TMP). Take the signal from the Overtemperature Output (TMP) terminal and use that

signal to operate a fan or air conditioner.

p. 35,

p. 65

p. 50

Restrict read/write

access of parameters to prevent mistaken operations.

Select the protection level setting (PRT) from the

Mode Selection Menu and set the desired protection level.

p. 54,

p. 59

Desired objective/

usage

Settings Details

Page 33

15

SECTION 2

Specifications and Functions

This section provides the specifications of the S8AS and describes special S8AS functions.

2-1 Component Names and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-2 Internal Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2-3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2-4 Basic Function Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2-4-1 Voltage Monitoring and Protection Functions . . . . . . . . . . . . . . . . . 29

2-4-2 Over-current Protection Functions . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2-4-3 Maintenance Forecast Monitor Function . . . . . . . . . . . . . . . . . . . . . 34

2-4-4 Over-temperature Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2-5 Startup Sequence Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2-6 Shutdown Sequence Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2-7 External Tripping Input Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Page 34

16

Component Names and Functions Section 2-1

2-1 Component Names and Functions

Component Names

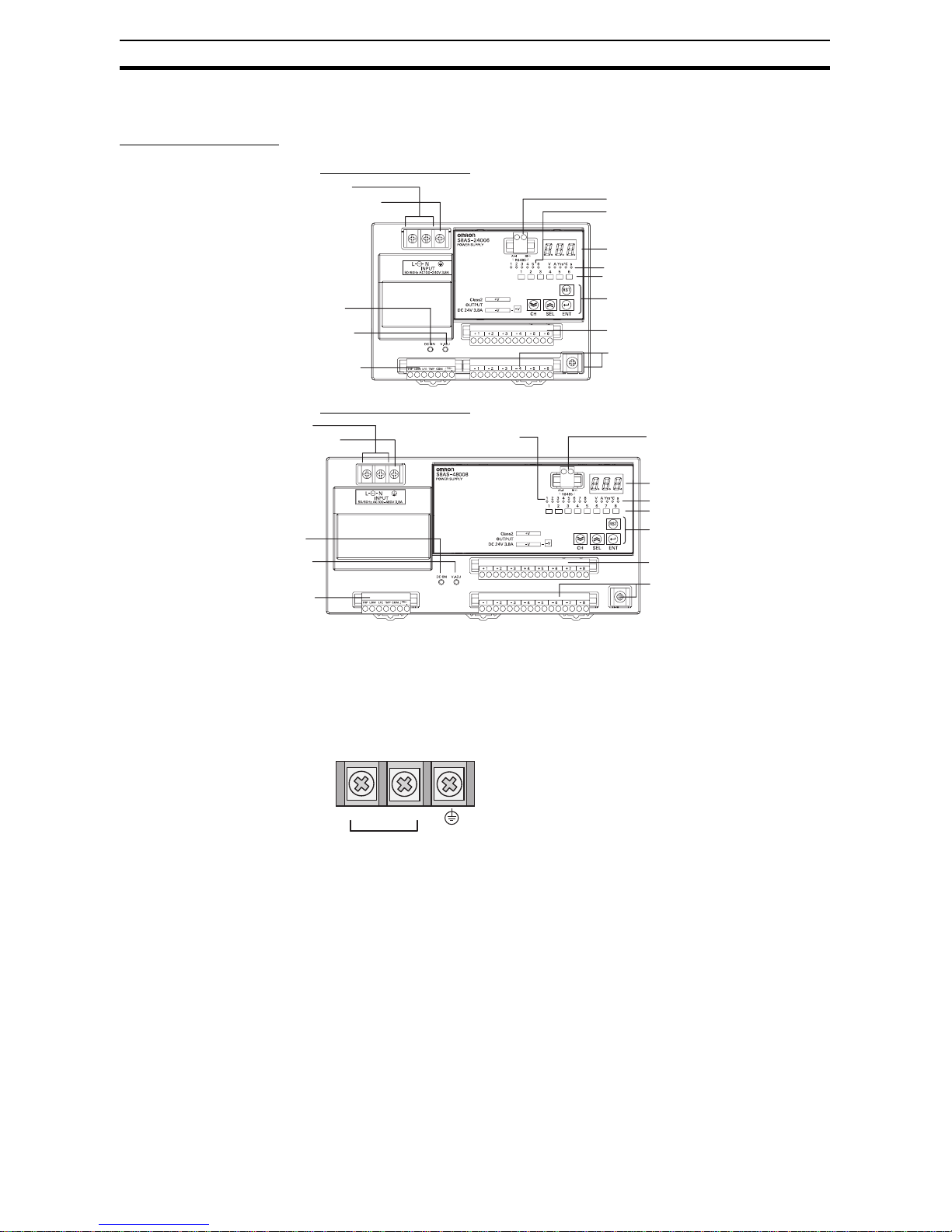

■ 240-W Output Models

■ 480-W Output Models

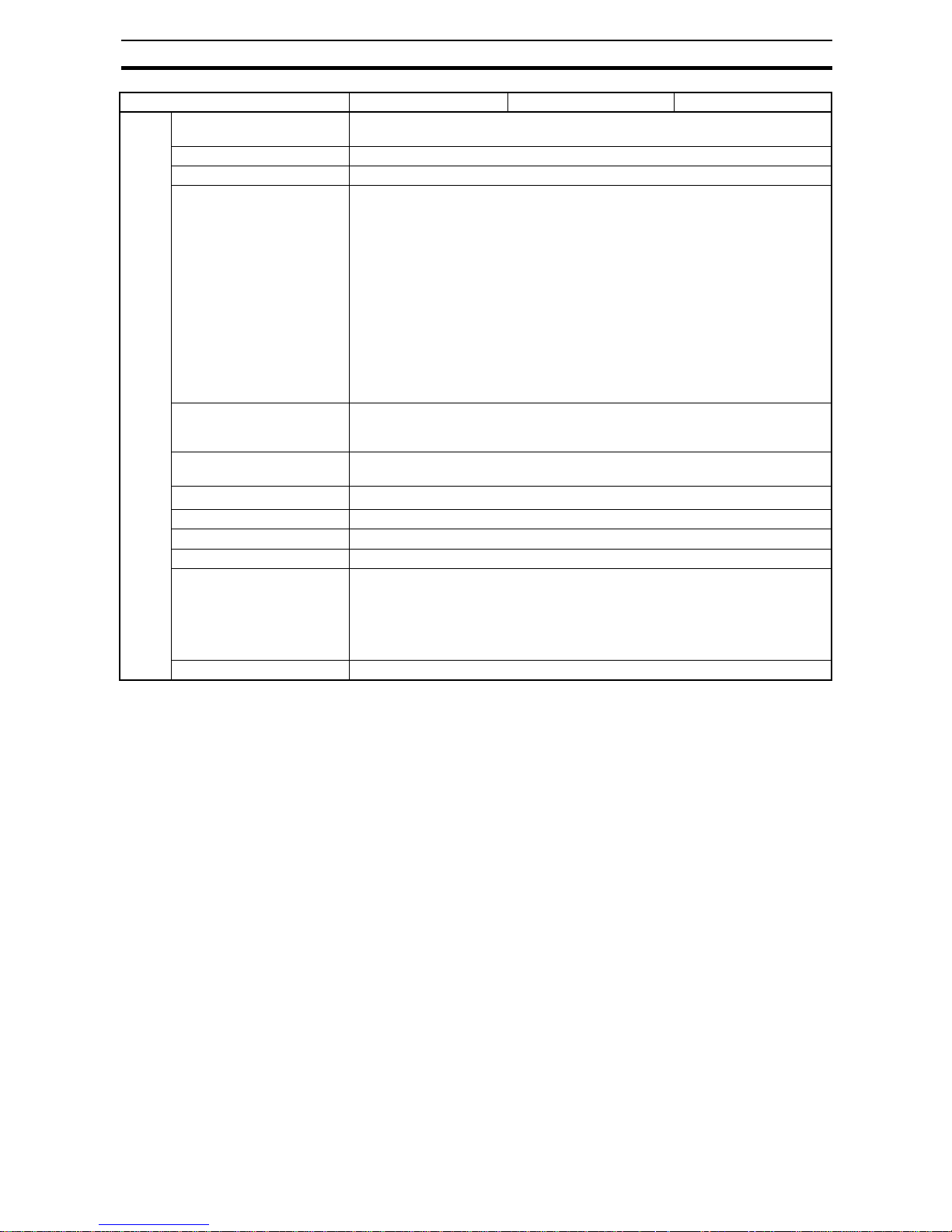

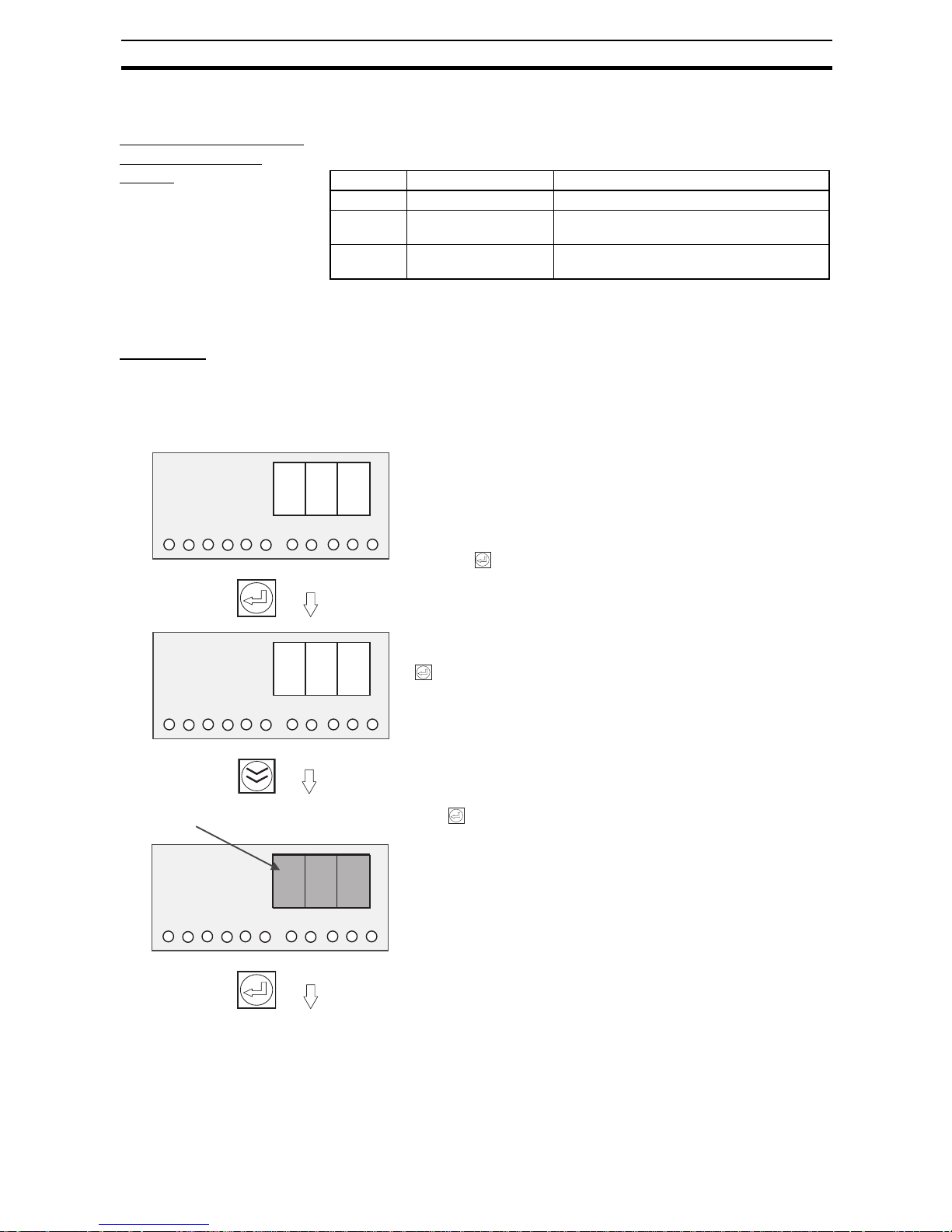

(1) AC Input Terminals (L and N) and (2) Protective Earth (PE) Terminal

Connect the input power supply (100 to 240 VAC, 50/60 Hz) (commercial

power) to the Power Supply.

Do not connect an inverter output as the power supply.

Make sure that the protective earth (PE) terminal is connected to ground to

prevent electric shock or malfunction.

(3) Positive (+) and (4) Negative (−) Branch Output Terminals

Connect to each branch output. Positive and negative branch outputs are connected to separate terminal blocks with two positive and two negative terminals for each branch output.

1. AC input terminals

2. Protective earth (PE) terminal

3. Branch output terminals (+)

4. Branch output terminals (−)

6. Output indicator (DC ON)

7. Output voltage adjuster (V.ADJ)

8. Seven-segment display

5. I/O signal terminals

13. Communications terminal

s

9. Branch output indicators

10. Unit indicators

11. Status indicators

12. Operation keys

1. AC input terminals

2. Protective earth (PE) terminal

6. Output indicator (DC ON)

7. Output voltage adjuster (V.ADJ)

5. I/O signal terminals

3. Branch output terminals (+)

4. Branch output terminals (−)

8. Seven-segment display

13. Communications terminals

9. Branch output indicators

10. Unit indicators

11. Status indicators

12. Operation keys

(The terminal screws are M4.)

L N

100 to 240 VAC,

50/60 Hz

Page 35

17

Component Names and Functions Section 2-1

• 240-W Model Outp ut Terminals

• 480-W Model Outp ut Terminals

(5) I/O Signal Terminals

Connect the external outputs and external tripping inputs.

TRP T ripping Alarm Output Turns ON to indicate when an abnormal voltage

or current was detected and the output was cut

off (The photoswitch output will turn OFF.).

LOW Undervoltage Detec-

tion Output

Turns ON when the 24-VDC output voltage

from the S8AS falls below the threshold.

(The photoswitch output will turn OFF.).

LFE Maintenance Forecast

Monitor Output

Turns ON to indicate when the number of years

to the set replacement time has been reached

(The photoswitch output will turn OFF.).

TMP Over-temperature

Output

Turns ON to indicate that the temperature

exceeded the over-temperature output threshold (The photoswitch output will turn OFF.).

Branch

output 1

+

Branch

output 2

+

Branch

output 3

+

Branch

output 4

+

Branch

output 5

+

Branch

output 6

+

Branch

output 1

−

Branch

output 2

−

Branch

output 3

−

Branch

output 4

−

Branch

output 5

−

Branch

output 6

−

Branch output

common (−)

Branch

output 7

+

Branch

output 1

+

Branch

output 2

+

Branch

output 3

+

Branch

output 4

+

Branch

output 5

+

Branch

output 6

+

Branch

output 1

−

Branch

output 2

−

Branch

output 3

−

Branch

output 4

−

Branch

output 5

−

Branch

output 6

−

Branch

output 8

+

Branch

output 7

−

Branch

output 8

−

Branch output

common (−)

TRP

LOW

LFE

TMP

COM

TRG (+)

TRG (−)

Page 36

18

Component Names and Functions Section 2-1

(6) Output Indicator (DC ON)

The indicator is lit green when the S8AS is in normal operation. It indicates

that the 24 VDC output can be used as a supply voltage.

(7) Output Voltage Adjuster (V.ADJ)

The output voltage is set at a default of the 24-VDC rated voltage.

Use the output voltage adjuster to adjust the output voltage.

Note (1) If the output voltage is set to less than 20.0 V (default setting), the under-

voltage detection may be activated.

(2) Do not exceed the rated output capacity and rated t otal output current af-

ter adjusting the output voltage.

(3) The output voltage may increase be yond the allow able vo ltage range (rat-

ed voltage +10%) when the V.ADJ adjuster is used. When adjusting the

output voltage, ch eck the output v oltage of the po wer supply to mak e sure

that the load is not damaged.

(4) Do not use excessive force to turn the adjuster (V.ADJ). It may be dam-

aged.

(8) Seven-segment Display (Red)

Displays measured values or set values on a 3-digit LED display.

(9) Branch Output Indicators (Orange)

(10) Unit Indicator s (Orange)

Shows the branch output number and the unit for the value shown in the

seven-segment display.

• Six-branch Output Mod e l

COM Common Terminal Common terminal shared by the four alarm out-

puts above .

TRG (+)

TRG (−)

External Tripping Input Can be used to send an input signal from an

external device to cut off a branch output.

The adjustable range is −10% to +10 % of the rated output voltage. Turning the adjuster clockwise increases the output voltage, and turning it

counterclockwise decreases the output voltage.

DC ON

V. ADJ

1 to 6: 240 W

1 to 8: 480 W

Lit or flashing when the display is related to the corresponding

branch output.

V Lit when displaying the output voltage.

A Lit when displaying the output current.

Flashes when displaying the peak output current.

Yrs Lit when the number of years to th e se t repl ace m e n t ti me is

displayed.

8. 8. 8.

1 2 3 4 5 6

V A Yrs°C s

Branch output number indicators

Unit indicators

Page 37

19

Component Names and Functions Section 2-1

(11) Status indicators (Green/Red)

Indicate the connection and cut off status for the branch outputs.

• Six-branch Output Mod e l

(12) Operation Keys

(13) Communications Terminals (A (−), B (+)) (Only for Models That

Support Communications)

°C Lit when displaying the temperature.

s Lit when setting the star tup sequence time or shutdown

sequence time.

Not lit Not

connected

Set to OFF (disconnected) or forcibly

cut off by command.

Green Lit Connected Connected normally.

Flash Not con-

nected

In the startup sequence and waiting for

connection.

Red Lit Cut off Cut off due to an error.

Flash Cut off Cut off by an internal error.

Reset (RST) Key Used to clear the error status when a branch output was cut

off by an error or there was an alarm output.

Enter (ENT) Key Used to switch the display item, enter or execute settings, etc.

Up (SEL) Key Used to change the display item forward or to increase a set

value.

Down (CH) Key Used to switch the branch output or to decrease a set value.

The branch output number that is set remains the same in

other modes.

Used to connect to the RS-485 communications line.

1 2 3 4 5 6

RST

A (−)B (+)

Page 38

20

Internal Configuration Section 2-2

2-2 Internal Configuration

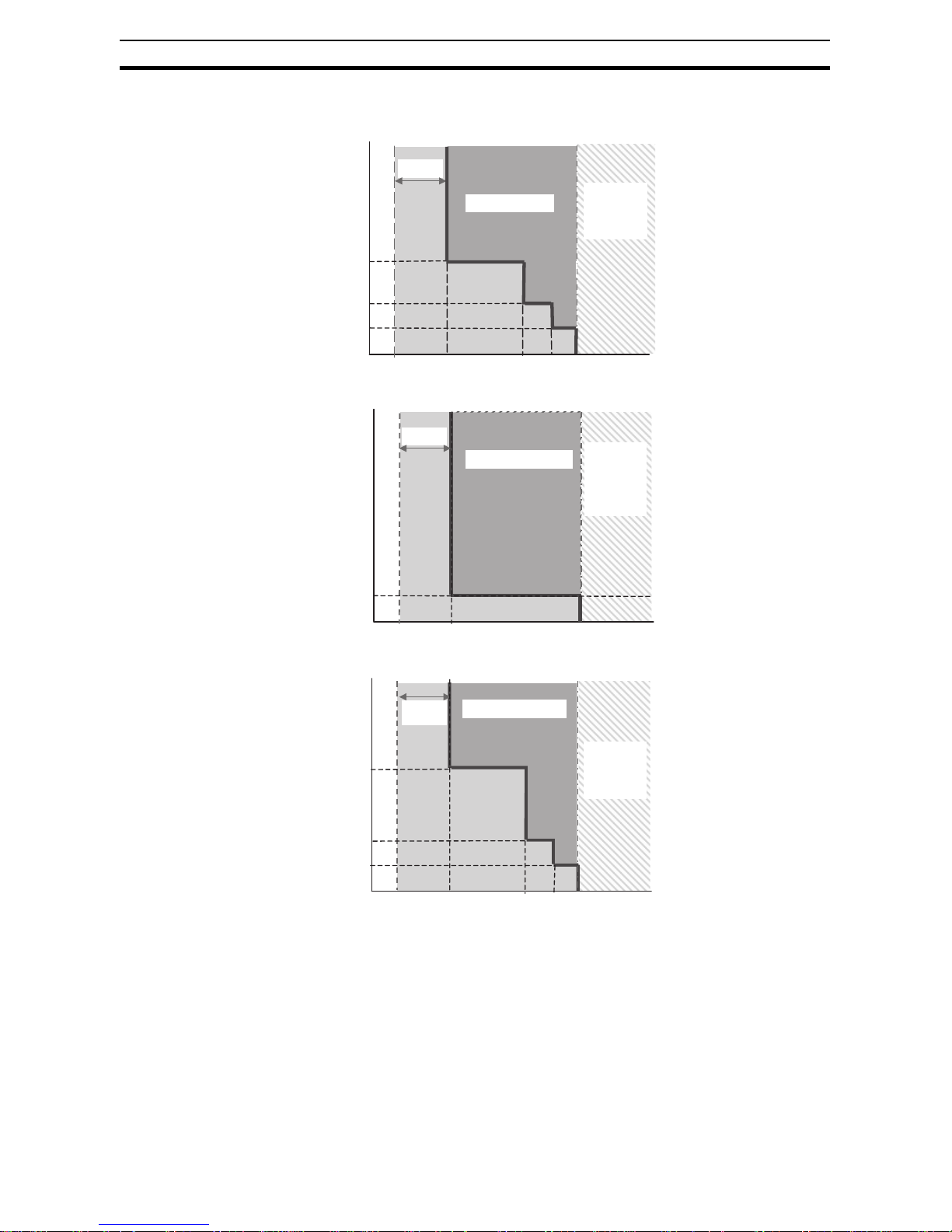

S8AS-24006 (Model with NO Communications and Changeable Parameter Settings)

S8AS-24006N (Model with NO Communications and Unchangeable Parameter Settings)

S8AS-24006R (Model with Communications and Changeable Parameter Settings)

SCREW (M3.5)

INPUT

AC (L)

AC (N)

Fuse:

12 A

Noise

filter

Rectification

Inrush

current

limit

Harmonic

current

control

Smoothing

Drive control

circuit

Photocoupler

Voltage-ON

detection

Rectification

and smoothing

Processing

circuit

(replacement

time)

Thermal

fuse

Current-

detection

resistor

Current-

limiting

circuit

Branch output 1

Branch output 2

Branch output 3

Branch output 4

Branch output 5

Branch output 6

Communications between

processing circuits (RS-232C)

Processing circuit

(main processing)

Voltage

detection

Current

fuse

SCREW (M4)

DC OUTPUT

B (+)

A (−)

−V

Communica-

tions

circuit

(S8AS-24006R only)

RS-485

TRP

LOW

LFE

TMP

COM

TRG+

TRG−

−V

+V

Display

circuit

Switches

Temperature

detection

Current-

detection

resistor

Cutoff

circuit

Cutoff circuit

Power supply

detection

Rectification

and smoothing

Page 39

21

Internal Configuration Section 2-2

S8AS-48008 (Model with NO Communications and Changeable Parameter Settings)

S8AS-48008N (Model with NO Communications and Unchangeable Parameter Settings)

S8AS-48008R (Model with Communications and Changeable Parameter Settings)

• The S8AS compares the measured input voltage, current, and internal

temperature with the preset pa r ameters. These values can be read on the

S8AS's seven-segm ent display.

• When an error is detected, the branch output will be cut off or an alar m

will be output. The error code and PV will be displayed alternately on the

seven-segment display.

• When an abnormal voltage or current is detected, the semiconductor

relay will cut off the branch output. In the unlikely event that the semiconductor relay cannot cut off an abnormal current or sho rt-circuit current, the

redundant protection circuit, and the short-circuit protection fuse (12.0 A

minimum) will operate to protect the system.

• The S8AS has a built-in temperature sensor, which can detect a temperature rise inside the S8AS. When the internal temperature exceeds the

detection threshold, the Over-temperature Output (TMP) photoswitch output will turn OFF.