Page 1

Switch Mode Power Supply

S82K (3/7.5/15/30/50/90/100-W Models)

Ultimate DIN-rail-mounting Power Supply

with a Power Range of 3 to 100 W

• EMI: EN 61204-3 class B

• Input: 85 to 264 VAC (except 90-W and 100-W models)

• Safety standards: UL 60950-1/508, cUL: C22.2, cUR: No.

60950-1/14, Class 2 (UL, CSA), EN 60950-1 (=VDE 0805, Teil 1)

• Undervoltage alarm indication available for standard models.

Note: Refer to “Safety Precautions” on page 13.

Model Number Structure

■ Model Number Legend

Note: Not all combinations are possible. Please refer to the list of models in “Ordering Information” on page 1.

S82K -

1 2 3

1. Power Factor Correction

None: No

P: Yes

2. Power Ratings

003: 3 W

007: 7.5 W

015: 15 W

030: 30 W

050: 50 W

090: 90 W

100: 100 W

3. Output Voltage

05: +5 VDC

12: +12 VDC

15: +15 VDC

24: +24 VDC

27: ±12 VDC

28: ±15 VDC

Ordering Information

■ List of Models

Note: For details on normal stock models, contact your nearest OMRON representative.

Power ratings Output voltage Output current Function Configuration Models

3 W 5 V 0.6 A Single output Yes No S82K-00305

7.5 W 5 V 1.5 A S82K-00705

15 W 5 V 2.5 A Single output S82K-01505

30 W 5 V 5.0 A S82K-03005 (See note 1.)

50 W 24 V 2.1 A S82K-05024

90 W 24 V 3.75 A No S82K-09024

100 W 24 V 4.2 A (See note 2.) No S82K-10024

Note:1. The output capacity of the S82K-03005 is 25 W.

2. The output current during parallel operation is 3.78 A.

12 V 0.25 A S82K-00312

15 V 0.2 A S82K-00315

24 V 0.13 A S82K-00324

12 V 0.6 A S82K-00712

15 V 0.5 A S82K-00715

24 V 0.3 A S82K-00724

±12 V 0.3 A/0.2 A Dual output S82K-00727

±15 V 0.2 A/0.2 A S82K-00728

12 V 1.2 A S82K-01512

24 V 0.6 A S82K-01524

12 V 2.5 A S82K-03012

24 V 1.3 A S82K-03024

Output Undervoltage alarm indicator/output PFC

Yes S82K-P09024

Yes S82K-P10024

Switch Mode Power Supply S82K 1

Page 2

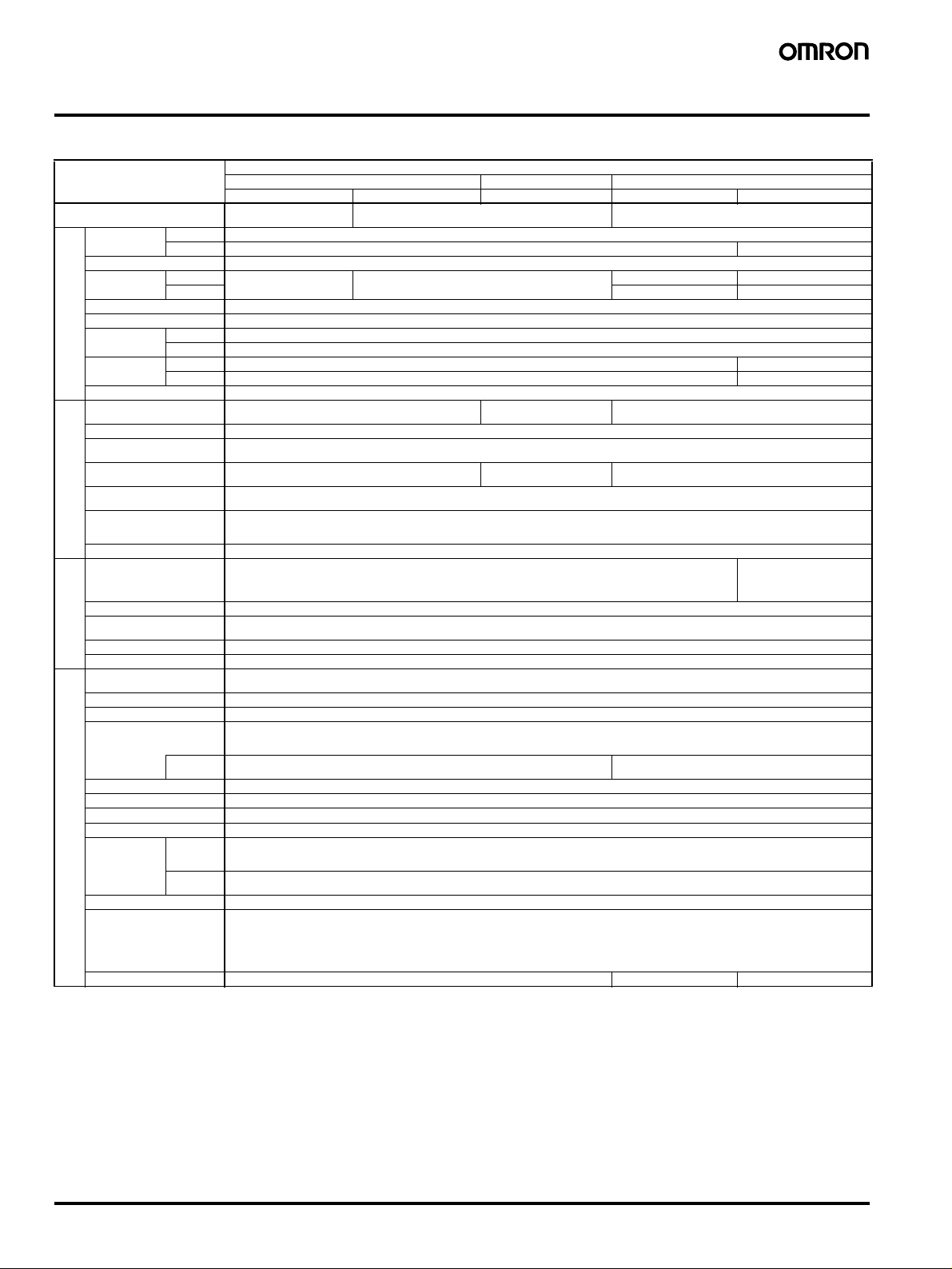

Specifications

■ Ratings/Characteristics

Power r atin gs

(See note 1.)

Item 3 W 7.5 W 7.5 W 15 W 30 W

Efficiency (typical) 60% min. (Varies depending

Input Voltage

(See note 2.)

Frequency 50/60 Hz (47 to 450 Hz)

Current

(See note 3.)

Power Factor ---

Harmonic current emissions ---

Leakage current

(See note 3.)

Inrush current

(See note 3.)

Noise filter Ye s

Out-

Voltage Adjustment Range ±10% (with V. ADJ) (See note 5.) Not possible (See note 6.) ±10% (with V. ADJ) (−10% to 15% for S82K-03012/-03024)

put

(See

Ripple (See note 3.) 2% (p-p) max.

note

4.)

Input variation influence 0.5% max. (at 85 to 264 VAC input, 100% load)

Load variation influence

(rated input voltage)

Temperature variation influ-

ence (See note 3.)

Start up time 100 ms max. (up to 90% of output voltage at rated input and output)

Hold time (See note 3.) 20 ms min.

Addi-

Overload protection

tion-

(See note 7.)

al

functions

Overvoltage protection No

Undervoltage alarm indica-

tion

Undervoltage alarm output No

Parallel operation No

Oth-erOperating ambient tempera-

ture

Storage temperature −25 to 65°C (with no icing or condensation)

Operating ambient humidity 25°C to 85% (Storage humidity: 25% to 90%)

Dielectric strength 3.0 kVAC for 1 min. (between all inputs and all outputs)

Insulation resistance 100 MΩ min. (between all outputs and all inputs, PE terminals) at 500 VDC

Vibration resistance 10 to 55 Hz, 0.375-mm single amplitude for 2 h each in X, Y, and Z directions

Shock resistance

Output indicator Yes (color: green)

EMI Conducted

EMS Conforms to EN61204-3 High severity levels

Approved standards UL: UL508 (Listing), 60950-1 Class 2 (excluding Dual output models)

AC 100 to 240 VAC (85 to 264 VAC)

DC 90 to 350 VDC Not possible

100-V input 0.15 A max. 0.25 A max. 0.45 A max. 0.9 A max.

200-V input 0.25 A max. 0.6 A max.

100-V input 0.5 mA max.

200-V input 1 mA max.

100-V input 15 A max. (for cold start at 25°C)

200-V input 30 A max. (for cold start at 25°C)

Detection

current

Emissions

Radiated

Emissions

on specifications)

1.5% max. (0 to 100% load) +V: 1.5% max.

0.05%/°C max.

105% to 160% of rated load current (105% to 250% of rated load current for dual output models), gradual current/voltage

drop, automatic reset (See note 8.)

Yes (color: red)

Refer to the derating curve in Engineering Data. (with no icing or condensation)

2.0 kVAC for 1 min. (between all inputs and PE terminals)

1.0 kVAC for 1 min. (between all outputs and PE terminals)

10 mA 20 mA

2

, 3 times each in ±X, ±Y, ±Z directions

300 m/s

Conforms to EN61204-3 EN55011 Class B and based on FCC Class B

Conforms to EN61204-3 EN55011 Class B

CSA: cUL: C22.2 No.14, cUR: No. 60950-1 Class 2 (excluding Dual output models)

EN/VDE: EN50178 (VDE=0160), EN60950-1 (=VDE0805 Teil 1)

Based on VE0106/P100

Single output Dual output Single output

64% min. (Varies depending on specifications) 66% min. (Varies depending on specifications)

−V: 3% max. (0 to 100% load)

S82K

(See note 5.)

1.5% max. (0 to 100% load)

25 A max. (for cold start at 25°C)

50 A max. (for cold start at 25°C)

105% to 160% of rated load

current, gradual current increase, voltage drop intermittent operation, automatic reset

Weig ht 150 g max. 260 g max. 380 g max.

Note:1. When a load is connected that has a built-in DC-DC converter, the overload protection may operate at startup and the power supply may not start.

Refer to the Overload Protection section on page 8 for details.

2. Use with DC voltage input is beyond the conditions of approval or conformance to applicable safety standards. (DC input possible with 15 W max.

Use the 7.5-W single-output models under the load of 90% max. if the voltage range is between 90 and 110 VDC.

Do not use the Inverter output for the Power supply. Inverters with an output frequency of 50/60 Hz are available, but the rise in the internal temperature of the

Power Supply may result in ignition or burning.

3. Defined with a 100% load and the rated input voltage (100 or 200 VAC.)

4. The output specification is defined at the power supply output terminals.

5. If the V. ADJ adjuster is turned, the voltage will increase by more than +10% of the voltage adjustment range. (+15% for S82K-03012/-03024)

When adjusting the output voltage, confirm the actual output voltage from the Power Supply and be sure that the load is not damaged.

6. The settings for the output voltage must be within the following range:

+V: ±1% of the rated value

−V: ±5% of the rated value

7. Refer to the Overload Protection section on page 8 for details.

8. When using the 7.5-W single-output models within the input voltage range between 90 and 110 VDC, the protection function will operate at a current of 95% to

160% of the rated load current.

2 Switch Mode Power Supply S82K

Page 3

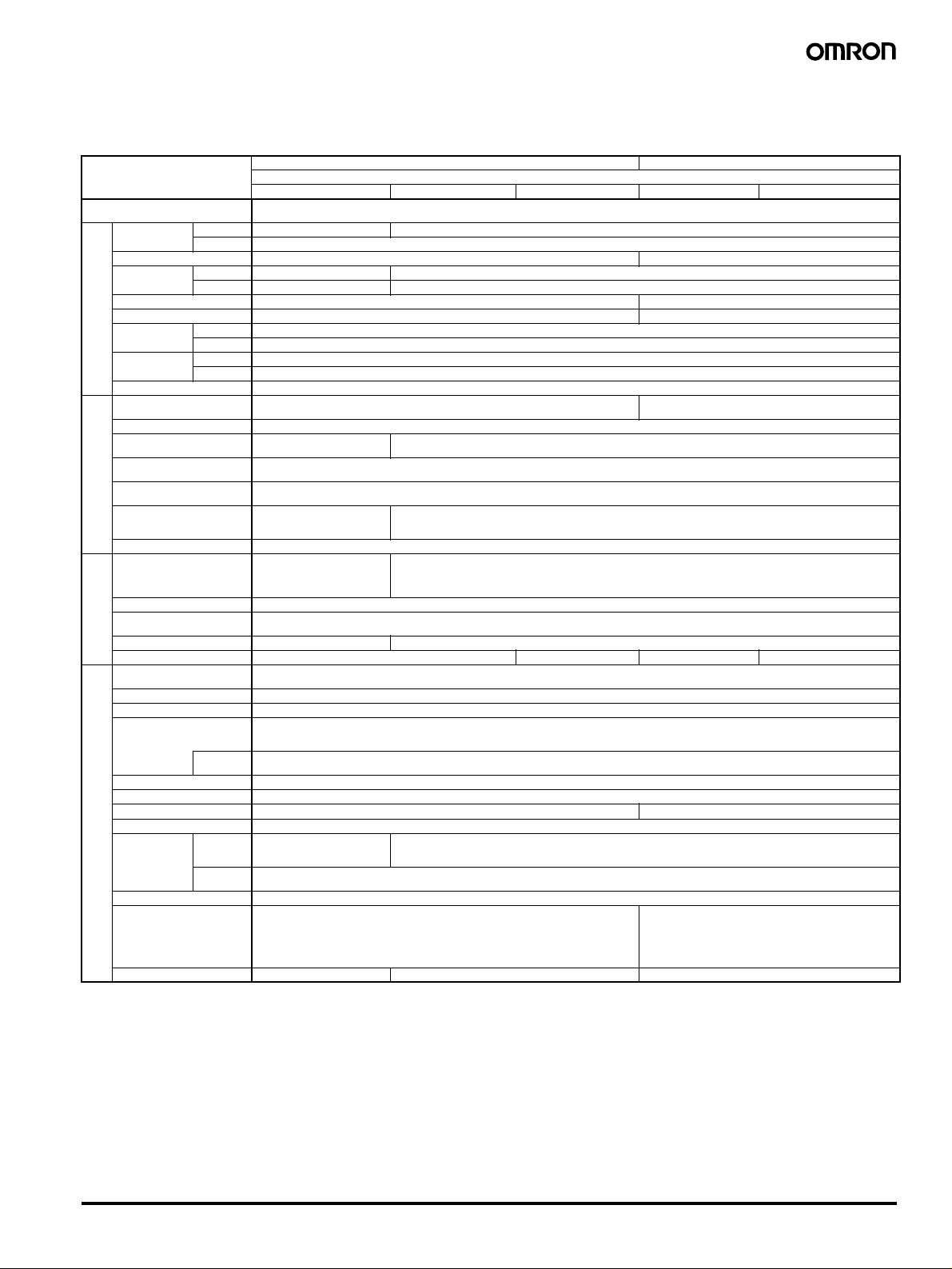

Power ratings

(See note 1.)

Item 50 W 90 W 100 W 90 W 100 W

Efficiency (typical) 80% min. (Varies depending on specifications)

Input Voltage

(See note 2.)

Frequency 50/60 Hz (47 to 450 Hz) 50/60 Hz (47 to 63 Hz)

Current

(See note 3.)

Power Factor --- 0.7 min. (at 200 VAC input, at rated output), 100 V: unlimited

Harmonic current emissions --- Conforms to EN6100-3-2 (200-V only)

Leakage current

(See note 3.)

Inrush current

(See note 3.)

Noise filter Ye s

Out-

Voltage Adjustment Range ±10% (with V. ADJ) (−10% to 15% for S82K-05024) (See Note 5.) ±10% (with V. ADJ) (See note 5.)

put

(See

Ripple (See note 3.) 2% (p-p) max.

note

4.)

Input variation influence 0.5% max. (at 85 to 264 VAC in-

Load variation influence

(rated input voltage)

Temperature variation influ-

ence (See note 3.)

Start up time 100 ms max. (up to 90% of out-

Hold time (See note 3.) 20 ms min.

Addi-

Overload protection

tion-

(See note 6.)

al

functions

Overvoltage protection No

Undervoltage alarm indica-

tion

Undervoltage alarm output No Yes

Parallel operation No Yes (up to 2 units.) No Yes (up to 2 units.) (See note 8.)

Oth-erOperating ambient tempera-

ture

Storage temperature −25 to 65°C (with no icing or condensation)

Operating ambient humidity 25°C to 85% (Storage humidity: 25% to 90%)

Dielectric strength 3.0 kVAC for 1 min. (between all inputs and all outputs)

Insulation resistance 100 MΩ min. (between all outputs and all inputs, PE terminals) at 500 VDC

Vibration resistance 10 to 55 Hz, 0.375-mm single amplitude for 2 h each in X, Y, and Z directions

Shock resistance

Output indicator Yes (color: green)

EMI Conducted

EMS Conforms to EN61204-3 High severity levels

Approved standards UL: UL508 (Listing), 60950-1 Class 2 (excluding Dual output models) (See note 9.)

Weig ht 400 g max. 600 g max. 1000g max.

Note: 1. When a load is connected that has a built-in DC-DC converter, the overload protection may operate at startup and the power supply may not start.

Refer to the Overload Protection section on page 8 for details.

2. Use with DC voltage input is beyond the conditions of approval or conformance to applicable safety standards. (DC input possible with 15 W max.

Use the 7.5-W single-output models under the load of 90% max. if the voltage range is between 90 and 110 VDC.

Do not use the Inverter output for the Power supply. Inverters with an output frequency of 50/60 Hz are available, but the rise in the internal temperature of

the Power Supply may result in ignition or burning.

3. Defined with a 100% load and the rated input voltage (100 or 200 VAC.)

AC 100 to 240 VAC (85 to 264 VAC) 100 V (85 to 132 VAC)/200 V (170 to 264 VAC) Selectable

DC Not possible

100-V input 1.3 A max. 2.5 A max.

200-V input 0.8 A max. 1.5 A max.

100-V input 0.5 mA max.

200-V input 1 mA max.

100-V input 25 A max. (for cold start at 25°C)

200-V input 50 A max. (for cold start at 25°C)

put, 100% load)

1.5% max. (0 to 100% load)

0.05%/°C max.

put voltage at rated input and

output)

105% to 160% of rated load

current, gradual current increase, voltage drop intermittent operation, automatic reset

Yes (color: red)

Refer to the derating curve in Engineering Data. (with no icing or condensation)

2.0 kVAC for 1 min. (between all inputs and PE terminals)

Detection

current

Emissions

Radiated

Emissions

1.0 kVAC for 1 min. (between all outputs and PE terminals)

20 mA

300 m/s2, 3 times each in ±X, ±Y, ±Z directions 150 m/s2, 3 times each in ±X, ±Y, ±Z directions

Conforms to EN61204-3

EN55011 Class B and based

on FCC Class B

Conforms to EN61204-3 EN55011 Class B

CSA: cUL: C22.2 No.14, cUR: No. 60950-1 Class 2 (excluding Dual output models) (See

note 9.)

EN/VDE: EN50178 (VDE=0160), EN60950-1 (=VDE0805 Teil 1) Based on VE0106/P100

S82K S82K-P

0.5% max. (at 85 to 132 VAC input /170 to 264 VAC input, 100% load)

200 ms max.

105% to 160% of rated load current, inverted L drop, automatic reset (See note 7.)

Conforms to EN61204-3 EN55011 Class B and based on FCC Class A

Single output

UL: UL508 (Listing), Class 2 (per UL 1310) 60950-1 (See

note 9.)

CSA: cUL: C22.2 No.14, cUR: No. 60950-1 Class 2 (See note

9.)

EN/VDE: EN50178 (VDE=0160), EN60950-1 (=VDE0805

Teil 1) According to VDE0106/P100"

4. The output specification is defined at the power supply output terminals.

5. If the V. ADJ adjuster is turned, the voltage will increase by more than +10% of the voltage adjustment range. (+15% for S82K-03012/-03024)

When adjusting the output voltage, confirm the actual output voltage from the Power Supply and be sure that the load is not damaged.

6. Refer to the Overload Protection section on page 8 for details.

7. When using the 90-W model at an ambient temperature of 25×C or less, the overload protection function will operate at currents from 101% to 111% of the

rated output current. When using the 90-W model at an ambient temperature exceeding 25×C, the overload protection function will operate at currents from

92% to 111% of the rated output current.

8. Parallel operation is set with the Parallel/Single Operation Selector Switch.

9. To meet Class-2 requirements with the 100-W, either a fuse or circuit breaker that is UL listed or CSA certified, and rated at 4.2 A max. should be wired in

series with the load to be connected to the Power Supply. Only then can the Power Supply output be considered as meeting Class 2.

Switch Mode Power Supply S82K 3

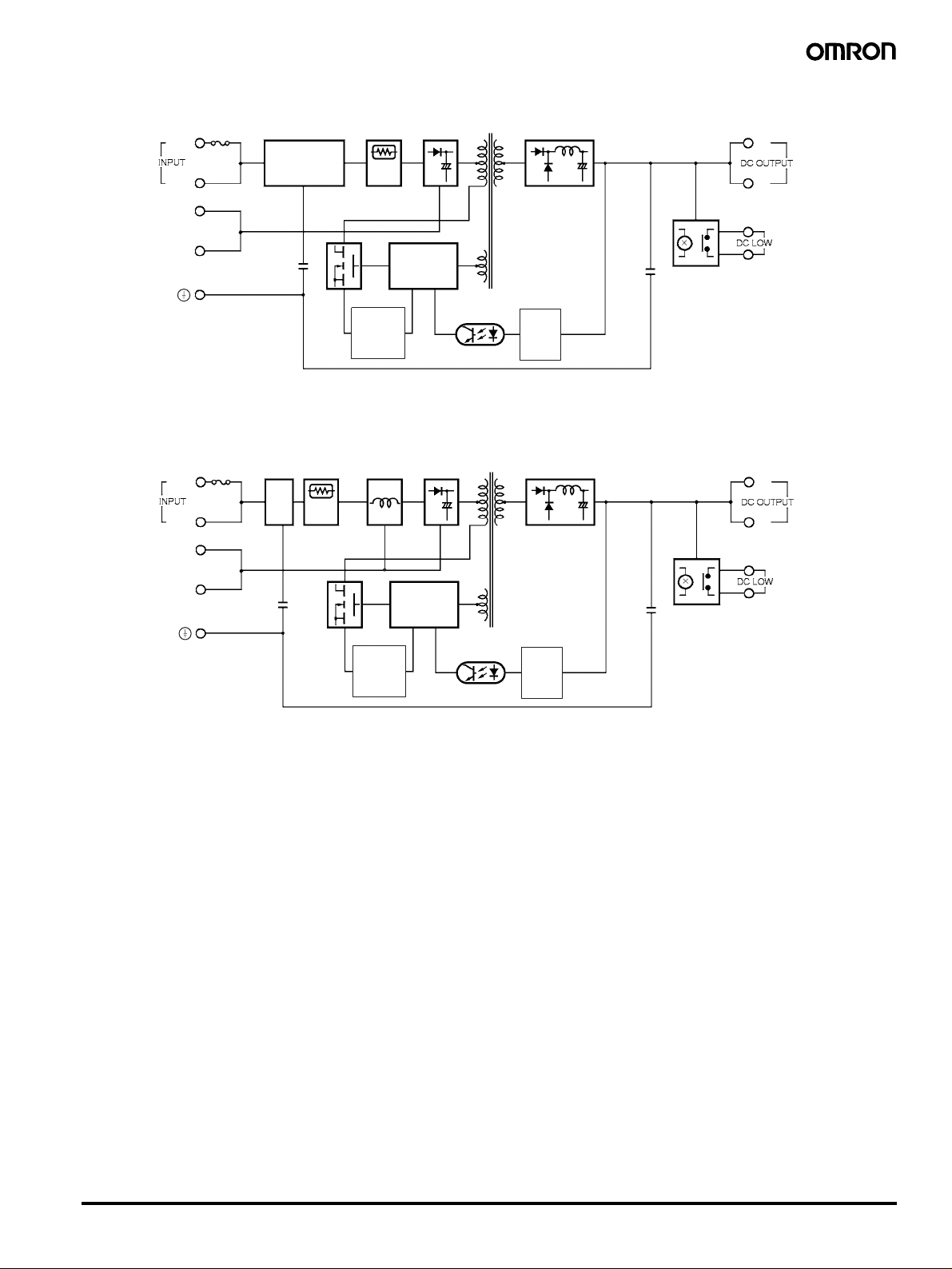

Page 4

Connections

■ Block Diagrams

S82K-003@@ (3 W)

S82K-007@@ (7.5 W, Single Output)

Fuse (1 A)

AC (L)

Noise filter

AC (N)

Inrush current

protection

circuit

Rectifier/

smoothing

circuit

Rectifier/

smoothing

circuit

+ V

− V

S82K-007@@ (7.5 W, Dual Outputs)

Fuse (1 A)

AC (L)

Noise filter

AC (N)

S82K-015@@ (15 W)

S82K-030@@ (30 W)

S82K-05024 (50 W)

Drive control

circuit

Overload

detection

circuit

Inrush current

protection

circuit

Drive control

circuit

Overload

detection

circuit

Rectifier/

smoothing

circuit

Photocoupler

Photocoupler

Detector

Rectifier/

smoothing

circuit

Rectifier/smoothing circuit

Detector

3-terminal

REG

Undervoltage

alarm

indicator

Undervoltage

alarm

indicator

− V

+ V

Fuse (3 A)

AC (L)

Noise filter

AC (N)

Inrush current

protection

circuit

Overload

detection

circuit

Rectifier/

smoothing

circuit

Drive control

circuit

4 Switch Mode Power Supply S82K

Photocoupler

Rectifier/

smoothing

circuit

Detector

Undervoltage

alarm

indicator

+ V

− V

Page 5

S82K-09024 (90 W)

S82K-10024 (100 W)

Fuse (5 A)

AC (L)

AC (N)

100 or 200 V

Selectable

terminals

(See note.)

Noise filter

Inrush current

protection

circuit

Drive control

circuit

Rectifier/

smoothing

circuit

Rectifier/

smoothing

circuit

Undervoltage

alarm indicator

+ V

− V

S82K-P09024 (90 W)

S82K-P10024 (100 W)

Fuse (5 A)

AC (L)

AC (N)

100 or 200 V

Selectable

terminals

(See note.)

Noise

filter

Overload

detection

circuit

Photocoupler

Detector

Note: Use the short bar to short-circuit terminals 7 and 8 to select 100 to 120 VAC and

remove the short bar to select 200 to 240 VAC.

Harmonic current

emission control

(200-V input only)

Inrush current

protection

circuit

Overload

detection

circuit

Rectifier/

smoothing

circuit

Drive control

circuit

Photocoupler

Rectifier/

smoothing

circuit

Detector

Undervoltage

alarm indicator

+ V

− V

Note: Use the short bar to short-circuit terminals 7 and 8 to select 100 to 120 VAC and

remove the short bar to select 200 to 240 VAC.

Switch Mode Power Supply S82K 5

Page 6

Construction and Nomenclature

■ Nomenclature

S82K-003@@/S82K-007@@

(Single Output)

1

5

7

6

23

S82K-030@@/S82K-05024

1

5

7

6

S82K-007@@ (Dual outputs)

11

5

7

23

S82K-@09024/S82K-@10024

8

5

7

6

S82K-015@@

1

5

7

6

23

1

23

234

1. DC Output Terminals: Connect the load lines to these terminals.

2. Input Terminals: Connect the input lines to these terminals.

3. Protective Earthing Terminals (PE): Connect a ground line to these terminals.

4. Input Voltage Selector Terminals (VOLTAGE SELECT): Selects a 100 V or 200 V

input voltage.

5. Output Indicator (DC ON: green): Lights while a Direct Current (DC) output is ON.

6. Output Voltage Adjuster(V.ADJ): Use to adjust the voltage.

7. Undervoltage Alarm Indicator Terminal (DC LOW: red): Lights when there is a

drop in the output voltage.

8. Undervoltage Alarm Output Terminals (DC LOW): S82K-@09024/-@10024 only.

9. Parallel/Single Operation Selector: Set to "PARALLEL" for parallel operation.

Parallel/Single

Operation Selector

(Only for S82KP10024)

9

6 Switch Mode Power Supply S82K

Page 7

Engineering Data

■ Derating Curve (A: Standard mounting, B: Face-up mounting)

3-/7.5-/15-/30-/50-/100-W

Models

Single-Unit Operation

Installation A

Load (%)

65

Note: When using the 7.5-W single-output

models within the input voltage range

between 90 and 110 VDC, the load

rate will become 90% or less.

Installation B

S82K-P10024:

85-VAC input

S82K-03005

Installation A

Ambient temperature (°C)

90-W Models

Single-Unit Operation

100-W Models without PFC

(S82K-10024)

Parallel-Unit Operation

Load (%)

Installation A

Installation B

Ambient temperature (°C)

100-W Models with PFC

(S82K-P10024)

Parallel-Unit Operation

90

Load (%)

65

S82K-P10024:

85-VAC input

Installation B

Ambient temperature (°C)

Installation A

Load (%)

65

Note: 1. Note that the derating curve may vary depending on the installation conditions.

2. Multiple units cannot be installed in a configuration where they are lined up vertically.

3. Use the 7.5-W single-output models under the load of 90% max. if the voltage range is between 90 and 110 VDC.

4. The cold-start time will be longer when using S82K-P09024 or S82K-P10024 with 85-VAC input.

S82K-P09024:

85-VAC input

Installation A

Installation B

Ambient temperature (°C)

■ Mounting

Top Top

Note: Installations other than (A) and (B) are not possible.

(A) Standard mounting (B) Face-up mounting

Switch Mode Power Supply S82K 7

Page 8

■ Overload Protection

)

p

)

p

)

The Power Supply is provided with an overload protection function that protects the Power Supply from possible damage by overcurrent. When the

output current rises above 105% min. of the rated current, the protection function is triggered, automatically decreasing the output voltage. When

the output current falls within the rated range, the overload protection function is automatically cleared.

3-/7.5/15 W Models

Output voltage (V)

0 10050

Output current (%

Note: 1. When connecting a load that has a built-in DC-DC converter, the overcurrent protection function may operate during start-up, thus pre-

venting the Power Supply from starting.

2. Internal parts may occasionally deteriorate or be damaged if a short-circuited or other overcurrent state continues during operation.

3. When using the 7.5-W single-output models within the input voltage range between 90 and 110 VDC, the overload protection function

will operate at currents from 95% to 160% of the rated output current.

4. When using the 90-W model at an ambient temperature of 25

101% to 111% of the rated output current. When using the 90-W model at an ambient temperature exceeding 25

tion function will operate at currents from 92% to 111% of the rated output current.

5. When using the 100-W model with PFC in parallel operation, operation is limited to a load ratio of 90% to 100% of the rated output current

at 4.2 A.

30-/50 W Models

Output voltage (V)

Intermittent operation

0 100

50

Out

ut current (%

°C or less, the overload protection function will operate at currents from

90-/100 W Models

Output voltage (V)

0 10050

Out

°C, the overload protec-

ut current (%

When Using ± Output Models

The +V output detects the total output power (+V output and −V output) to trigger the short-circuit protection against overcurrent. This protection

varies depending on the

−V output state. The −V output independently triggers the short-circuit protection.

■ Undervoltage Alarm Indicator and Output Function

If the output voltage at the output terminal drops to 75% to 90% of the rated voltage, the red indicator of the S82K (DC LOW indicator) will be lit.

In the case of the S82K-@09024/@10024, a voltage drop alarm will be output via the relay available in the models (DC LOW output).

Note: This function detects the voltage at the output terminal of the Power Supply. To check the precise output voltage, measure the voltage at the

terminal of the load.

Indicator Voltage Operation of @09024/@10024’s

Green: DC ON

Red: DC LOW

Green: DC ON

Red: DC LOW

Green: DC ON

(See note 1.)

If the voltage at the output terminal is more than 82% of

the rated voltage and operation is normal, the green indicator will be lit and the red indicator will not be lit.

If the voltage at the output terminal drops to below 82%

of the rated voltage, the red indicator will be lit. (See

note 3.)

If the voltage at the output terminal approaches 0 V,

both the green and red indicators will not be lit.

Red: DC LOW

Note: 1. The more the voltage at the output terminal drops, the darker both the green and red indicators will be.

2. The relay contacts have a capacity of 0.1 A at 24 VDC.

3. The red indicator will actually first light at a voltage between 75% and 90% of the rated voltage.

output (DC LOW output)

(See note 2.)

8 Switch Mode Power Supply S82K

Page 9

■ Inrush Current, Startup Time, Hold Time

Input OFF

Hold time

(20 ms min.)

AC input voltage

AC input current

Output voltage

Input ON

Inrush current on input application

Startup time: 100 to 1000 ms

max. depending on the model.

90% 96.5%

■ Reference Value

Item Value Definition

Reliability (MTBF) 135,000 hrs min. MTBF stands for Mean Time Between Failures, which is calculated according to the prob-

Life expectancy 8 yrs. min. The life expectancy indicates average operating hours under the ambient temperature of

ability of accidental device failures, and indicates reliability of devices. Therefore, it does

not necessarily represent a life of the product.

40

°C and a load rate of 50%. Normally this is determined by the life expectancy of the built-

in aluminum electrolytic capacitor.

Switch Mode Power Supply S82K 9

Page 10

Dimensions

Note: All units are in millimeters unless otherwise indicated.

S82K-003@@ (3 W)

S82K-007@@ (7.5 W)

Mounting Brackets (Included)

(Supplied with the Switching Power Supply)

Used when not mounting the Power Supply directly

on the DIN rail.

Two, 4. 5 ±0.1 dia.

S82K-015@@ (15 W)

M3.5 with square washer

(sliding

7 max.)

Mounting Holes

75 58.1

9.8

45

8.3

Attached

Mounting

Bracket

M4 or 4.5-dia.

hole

45

35±0.15

37.5±0.1

25±0.15

27±0.1

Note: If more than one Power Supply is installed in a

row, keep a distance of 20 mm min. (L = 20 mm

min.) between each adjacent Power Supply.

7.5

35

4.6

(sliding 7 max.)

M3.5 with square

washer

Mounting Holes

Two, M4 or 4.5-dia. mounting holes

60

L

35

10 Switch Mode Power Supply S82K

91

5

Note: If more than one Power Supply is installed in a row,

keep a distance of 20 mm min. (L = 20 mm min.)

between each adjacent Power Supply.

Page 11

S82K-030@@ (30 W)

S82K-05024 (50 W)

Four, 4.5 dia.

35

S82K-@09024 (90 W)

S82K-@10024 (100 W)

4

(sliding 7 max.)

M3.5 with square washer

Mounting Holes

Four, M4 or 4.5-dia. mounting holes

L

58.1

75

80

8.39.8

60

145

135±0.2

Note: If more than one Power Supply is

installed in a row, keep a distance of

20 mm min. (L = 20 mm min.) between

each adjacent Power Supply.

Four, 4.5 dia.

45

60±0.2

7.5

35

4

(sliding 7 max.)

M3.5 with square washer

Mounting Holes

Four, M4 or 4.5-dia. mounting holes

L

135

M3.5 terminal screw

Short bar

91

Note: If more than one Power Supply is

60

installed in a row, keep a distance of

20 mm min. (L = 20 mm min.) between

each adjacent Power Supply.

Switch Mode Power Supply S82K 11

5

Page 12

■ Accessories

DIN Rail (Order Separately)

PFP-100N/PFP-50N

PFP-100N2

4.5

15 25 25 25 25

10 10

1,000 (500)

(See note.)

7.3±0.15

15 (5)

(See note.)

Note: The values shown in parentheses are for the

PFP-50N.

Noise Filter (Order Separately)

S82Y-JF3-N for 3- to 50-W Models

S82Y-JF6-N for 90- and 100-W Models

4

39±0.5

4

35±0.3

16 max.

6.5

27±0.15

1

4.5

15 25 25 25 25 15

10 10

1,000

A max.

B±1

Nameplate

C±0.5

16 max.

6.5

35±0.3

Two, 4.8 dia.

(Mounting

holes)

Six, M4

16

27 24

11.5

D±1

29.2

47±1

12 Switch Mode Power Supply S82K

Page 13

Safety Precautions

!CAUTION

Minor electric shock, fire, or Product failure may

occasionally occur. Do not disassemble, modify, or repair

the Product or touch the interior of the Product.

Minor burns may occasionally occur. Do not touch the

Product while power is being supplied or immediately

after power is turned OFF.

Fire may occasionally occur. Tighten terminal screws to

the specified torque of 0.98 N·m.

Minor injury due to electric shock may occasionally occur.

Do not touch the terminals while power is being supplied.

Always close the terminal cover after wiring.

Minor electric shock, fire, or Product failure may

occasionally occur. Do not allow any pieces of metal or

conductors or any clippings or cuttings resulting from

installation work to enter the Product.

■ Precautions for Safe Use

Mounting

Take adequate measures to ensure proper heat dissipation to

increase the long-term reliability of the product.

The Power Supply is designed to radiate heat by means of natural

air-flow. Therefore, mount the Power Supply so that air flow takes

place around the Power Supply.

To dismount the Power Supply, pull down portion (C) with a flat-blade

screwdriver and pull out the Power Supply.

(C)

When tightening the terminals, do not tighten the terminal block to a

torque greater than 75 N.

30 mm min.

Rail stopper

Selection of 100 or 200 VAC Input

Voltag e

(S82K-@09024/-@10024)

Select a 100 V or 200 V input by shorting or opening the Input Voltage Selector Terminals, as shown in the following diagram.

(The default setting is 200 V.)

100 V Input

Air

When mounting two or more Power Supplies side-by-side, allow at

least 10 mm spacing between them, as shown in the following

illustration.

Forced air-cooling is recommended.

10 mm min.

Short bar

To mount the Power Supply on a DIN rail, hook portion (A) of the

Power Supply to the rail and press the Power Supply toward direction

(B).

(A)

(B)

Use the short bar to short-circuit

terminals 7 and 8.

200 V Input

Remove the short bar.

Generating Output Voltage (±)

An output of ± can be generated by using two Power Supplies as

shown below, because the Power Supply produces a floating output.

Correct

INPUT

INPUT

When connecting the Power Supplies in series with an operation

amplifier, connect diodes to the output terminals as shown by the

dotted lines in the figure. No diodes are required with S82K 90-W/

100-W models.

+V

−V

+V

−V

Switch Mode Power Supply S82K 13

Page 14

Charging the Battery

If a battery is to be connected as the load, install an overcurrent limiting circuit and an overvoltage protection circuit.

Series Operation

S82K 90-W/100-W models can be operated in series.

It must be noted that the + output of the 7.5-W dual output model

cannot be connected in series to its – output.

Correct

90-, 100-W Models

Parallel Operation

S82K 100-W models can be operated in parallel.

Perform parallel operation with power supplies satisfying the same

specifications.

Correct

100-W Models

+V

INPUT

−V

Incorrect

INPUT

+V

−V

+V

INPUT

−V

3-, 7.5-, 15-, 30-, 50-W Models

+V

INPUT

−V

+V

INPUT

−V

INPUT

+V

−V

Note: When operating the S82K-P10024 in parallel operation, set the

switch to “PARALLEL. In this case, the rated current per S82KP10024 is 3.78 A.

Incorrect

3-, 7.5-, 15-, 30-, 50- and 90-W Models

+V

INPUT

−V

+V

INPUT

−V

Parallel Operation Precautions

The length and thickness of each wire connected to the load must be

the same so that there is no difference in voltage drop value between

the load and the output terminals of each Power Supply.

Adjust the output voltage of each Power Supply so that there will be

no difference in output voltage between each Power Supply.

14 Switch Mode Power Supply S82K

Wiring

Do not apply more than 75-N force to the terminal block when

tightening it.

Ensure that input and output terminals are wired correctly.

Minimum Output Current

(S82K-00727/S82K-00728)

The minimum output current of the S82K-00727 and S82K-00728 is

restricted by the output voltage and control method.

Note: All the outputs of the S82K-00727 and S82K-00728 are

controlled by the +V output. If the +V output current falls to 10%

or less of the rated output, the –V output voltage may drop.

Page 15

Switch Mode Power Supply S82K 15

Page 16

Warranty and Application Considerations

Read and Understand this Catalog

Please read and understand this catalog before purchasing the products. Please consult your OMRON representative if you

have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a period of one year (or

other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NON-INFRINGEMENT,

MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR USER

ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET

THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS,

OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON

CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE

PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORED,

INSTALLED, AND MAINTAINED AND NOT SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE

MODIFICATION OR REPAIR.

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the combination of

products in the customer's application or use of the products.

Take all necessary steps to determine the suitability of the product for the systems, machines, and equipment with which it will

be used.

Know and observe all prohibitions of use applicable to this product.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY WITHOUT

ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON

PRODUCTS ARE PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR

SYSTEM.

Disclaimers

PERFORMANCE DATA

Performance data given in this catalog is provided as a guide for the user in determining suitability and does not constitute a

warranty. It may represent the result of OMRON's test conditions, and the users must correlate it to actual application

requirements. Actual performance is subject to the OMRON Warranty and Limitations of Liability.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other reasons. Consult with

your OMRON representative at any time to confirm actual specifications of purchased product.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. T035-E1-01

In the interest of product improvement, specifications are subject to change without notice.

OMRON Corporation

Industrial Automation Company

Control Devices Division H.Q.

Power Electronics Department

Shiokoji Horikawa, Shimogyo-ku,

Kyoto, 600-8530 Japan

Tel: (81)75-344-7108/Fax: (81)75-344-7189

Printed in Japan

1105-1.5M (1105) (O)

Loading...

Loading...