Page 1

Cat. No. I203-E2-02

R88A-MCW151-E

R88A-MCW151-DRT-E

Motion Control Option

Board

OPERATION MANUAL

Page 2

MCW151 Series

Motion Control Option Board

Models: R88A-MCW151-E

R88A-MCW151-DRT-E

Operation Manual

Produced March 2003

Page 3

Page 4

Notice:

OMRON products are manufactured for use according to proper procedu res by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injur y to p eople or damage to property.

!DANGER

!WARNING

!Caution

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch”, which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used a s an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Note In dicates information of par ticular interest for efficient and convenient opera-

tion of the product.

1,2,3... Indicates lists of one sort or another, such as procedures, checklists, etc.

Trademarks and Copyrights

DeviceNet is a registered trademark of the Open DeviceNet Vendor Association, Inc.

OMRON, 2003

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of the information conta ined in this publication.

v

Page 5

vi

Page 6

About this Manual:

This manual descri bes the installation and operation o f the R88A-MCW151-E an d R88A-MCW151DRT-E Motion Control Option Boards (MC Units) and includes the sections described below.

Please read this manual and the related manuals listed in the following table carefully and be sure you

understand the information provided before attempting to install or operate the MC Unit. Be sure to

read the precautions provided in the following section.

Name Cat. No. Contents

MCW151 Series

R88A-MCW151-E

R88A-MCW151-DRT-E

Operation Manual

OMNUC W-series

R88M-W

R88D-W

User’s manual

DeviceNet Operation Manual W267 Describes the conf iguration and construct ion of a DeviceNet net-

DeviceNet Conf igurator Operation Manual

❏ (AC Servomotors)

❏ (AC Servo Drivers)

I203 Describes the instal lation and operation of the R88A-MCW151-E

and MCW151-DRT-E Motion Control Units.

(This manua l)

I531 Describes the inst al lation a nd oper ati on of t he W -seri es Servo Dri ver

and Servomotor.

work, including installation procedures and specifications for cables,

connectors, and other connection devices, as well as information on

the communic ations power supply.

W328 Describes the operation of the DeviceNet Configurator to allocate

remote I/O areas according to application needs, as well as procedures to set up a DeviceNet network with more than one master.

Precautions provides general precautions for using the MC Unit and related devices.

Section 1

describes the features and system configuration of the R88A-MCW151-E and R88A-

MCW151-DRT-E Motion Control Units and concepts related to their operation.

Section 2

Section 3

describes the MC Unit components and provides the information for installing the MC Unit.

describes the different Motion Control features of the MCW151. Also the functiona lity of the

Servo Driver related commands are explained.

Section 4

describes the com munication componen ts of the MCW 151-E and MCW151-DRT-E. The

functionality of the serial communication protocols and the DeviceNet interface are explained.

Section 5

provides an overview of the fundamentals of multitasking BASIC progr a ms and the methods

by which programs are managed in the MC Unit.

Section 6

describes all commands, functions and parameters required for programing the motion con-

trol application using the MC Unit.

Section 7

describes the operation of the Motion Perfect programming software package. Motion Per-

fect provides the user a tool to program, monitor and debug motion based applications for the MC Unit.

Section 8

describes error processing and troubleshooting procedures needed to keep the system

operating properly.

Section 9

explains the maintenance and inspec tion procedures that must b e followed to keep the M C

Unit operating in optimum condition. It also includes proper procedures when replacing an MC Unit.

The Appendices provide the required p arameter settings for the Ser vo Driver, the DeviceNet protocol

specification and some general programming examples.

!WARNING

Failure to read and understand the information pro vided in this manual may result in personal injury or death, damage to t he product, or product failure. Pleas e read each section

in its entirety and be sure you unders tand the information provided in the section and

related sections before attempting any of the procedures or operations given.

vii

Page 7

Page 8

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

3 General Warnings and Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

4 Storage and Transportation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

5 Installation and Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

6 Operation and Adjustment Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

7 Maintenance and Inspection Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

8 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

SECTION 1

Features and System Configuration . . . . . . . . . . . . . . . . 1

1-1 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-3 Motion Control Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-4 Control System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1-5 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1-6 Comparison between Firmware Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

SECTION 2

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2-1 Components and Unit Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2-2 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2-3 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2-4 Servo System Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2-5 Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

SECTION 3

Motion Control Functions . . . . . . . . . . . . . . . . . . . . . . . . 43

3-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3-2 System Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3-3 System Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

SECTION 4

Communication Interfaces. . . . . . . . . . . . . . . . . . . . . . . . 59

4-1 Serial Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4-2 DeviceNe t (MCW151-DRT -E only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

ix

Page 9

TABLE OF CONTENTS

SECTION 5

Multitasking BASIC Programming . . . . . . . . . . . . . . . . . 85

5-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

5-2 BASIC Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

5-3 Motion Execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

5-4 Command Line Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

5-5 BASIC Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

5-6 Task Operation Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

5-7 Error Processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

SECTION 6

BASIC Motion Control Programm ing Langua ge . . . . . 97

6-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

6-2 Command Reference List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

6-3 Command, function and parameter description. . . . . . . . . . . . . . . . . . . . . . . . . . . 111

SECTION 7

Motion Perfect Software Package . . . . . . . . . . . . . . . . . . 197

7-1 Features and Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

7-2 Connecting to the MC Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

7-3 Motion Perfect Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

7-4 Desktop Appearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

7-5 Motion Perfect Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

7-6 Suggestions and Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

SECTION 8

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

8-1 Error Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

8-2 Error Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

8-3 Problems and Countermeasures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

SECTION 9

Maintenance and Inspection. . . . . . . . . . . . . . . . . . . . . . . 233

9-1 Routine Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

9-2 Replacing a MC Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Appendices

Appendix A Servo Driver Parameter List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Appendix B Device Protocol (MCW151-DRT-E only). . . . . . . . . . . . . . . . . . . . . . . 239

Appendix C Programming Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

x

Page 10

PRECAUTIONS

This section provides general precautions for using the Motion Control Unit and related devices.

The information contained in this section is important for the safe and reliable application of the Motio n Control

Unit. You must read this section and u nderstand the information contained before attempting to set up or o perate

a Motion Control Unit and Servo Dri ver.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

3 General Warnings and Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

4 Storage and Transportation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

5 Installation and Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

6 Operation and Adjustment Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

7 Maintenance and Inspection Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

8 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

8-1 Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

8-1-1 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

xi

Page 11

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must a lso have knowledge of el ectr ical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate t he product accordi ng to the perfor mance specifications described in

the operation manuals. You should assume t hat anything not des cribed in this manual is not

possible.

Before using the product under the following conditions, consult your OMRON representative,

make sure the ratings and performance characteristics of the products are good enough for

the systems, machines, or equipment, and be sure to provide the systems, machines, or

equipment with double safety mechanisms.

1. Conditions not described in the manual.

2. The application of the product to nuclear control systems, railroad systems, aviation systems, vehicles, combustion systems, medical equipment, amusement machines, or safety

equipment.

3. The application of the product to systems, machines, or equipment that may have a serious

influence on human life and property if they are used improperly.

!WARNING

It is extremely important that Mot ion Control Units and related devices be used for the

specified purpose and under the specif ied conditions, especially in applications that can

directly or indirectly affect human life. You must consult with your OMRON representative

before applying Motion Control Units an d related devices to the above mentione d applications.

3 General Warnings and Safety Precautions

Observe the following warnings when using the MC Unit and all pheripheral devices.

Consult your OMRON representative when using the product after a long period of storage.

!WARNING

!WARNING

!WARNING

!WARNING

!WARNING

Always connect the frame ground terminals of the S ervo Dr iver and the Servomotor to a

class-3 ground (to 100 Ω or less). Not connecting to a class-3 ground may result in electric shock.

The product contains dangerous high voltage inside. Tur n OF F the power and wait for at

least five minutes to allow power to discharge before handling or working with the product.

Do not touch the inside of the Servo Driver. Doing so may result in electric shock.

Do not remove the front cover, terminal covers, cables, Parameter Units, or optional

items while the power is being supplied. Doing so may result in electric shock.

Installation, operation, maintenance, or inspection must be performed by authorized per-

sonnel. Not doing so may result in electric shock or injury.

!WARNING

!WARNING

xii

Wiring or inspection must not be performed for at least five minutes after turning OFF the

power supply. Doing so may result in electric shock.

Do not damage, press, or put excessive stress or heavy objects on the cables. Doing so

may result in electric shock, stopping operation of the product, or burning.

Page 12

General Warnings and Safety Precautions 3

!WARNING

!WARNING

!WARNING

!WARNING

Do not touch the rotating par ts of the Servomotor in operation. Doing so m ay result in

injury.

Do not modify the product. Doing so may result in injury or damage to the product.

Provide safety measures in external control circuits (i.e., not in the MC Unit) to ensure

safety in the system if an abnormality occurs due to malfunction of the MC Unit, incorrect

or unintended configuration and programming of the MC Unit or external factors affecting

the operation of the MC Unit. Not providing sufficient safety measures may result in serious accidents, or property damage.

• The MC Unit ou tputs m ay remain ON or OFF due to deposits on or burning of th e out put relays, or destruction of the output transistors. As a counter-measure for such problems, external safety measures must be provided to ensure safety in the system.

• Provide an external em ergency stopping device that allows an i nstantaneous stop of

operation and power interruption. Not doing so may result in injury.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety measures

must be provided in external control circuits.

• When the 24 -VDC output (service power supply to the Unit) is overloaded or short-circuited, the voltage may drop and result in the output s being turned OFF. As a countermeasure for such problems, external safety measures must be provided to ensure

safety in the system.

It is the nature of high speed motion control and mot ion control language programming

and multi-tasking systems, that it is not always possible for the system to validate the

inputs to the functions or to validate the combination of functions.

!WARNING

!Caution

!Caution

!Caution

!Caution

It is t he responsibi li ty of the prog rammer to e n s u re that the various BASIC statements are

invoked correctly with the correct number of parameters and inputs, that the values are

correctly validated prior to the actual calling of the functions, and that the BASIC program(s) provide the desired functionality for the application. Failure to do so may result in

unexpected behaviour, loss or damage to the machinery.

When the SERVO_PERIOD parameter has been s et t o change the ser vo cycle pe riod of

the MC Unit, a power down or software reset (using DRV_RESET) must be performed for

the complete system. Not doing so may result in undefined behaviour.

Use the Servomotors and Servo Drivers in a specified combination. Using them incorrectly may result in fire or damage to the product.

Do not operate the control system in the following locations:

• Locations subject to direct sunlight.

• Locations subject to temperat ures or hum idity out side the ra nge spec ified in th e spec i-

fications.

• Locations subject to condensation due to radical temperature changes.

• Locations subject to corrosive or inflammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to vibration or shock.

• Locations subject to exposure to water, oil or chemicals.

Do not touch the Servo Driver radiator, Regeneration Resistor, or Servomotor while the

power is being supplied or soon after power is turned OFF. Doing so may result in a skin

burn due to the hot surface.

xiii

Page 13

Storage and Transportation Precau tions 4

4 Storage and Tran sportation Precautions

!Caution

!Caution

!Caution

Do not hold the product by the cables or motor shaft while transporting it. Doing so may

result in injury or malfunction.

Do not place any load exceeding the figure indicated on the product. Doing so may result

in injury or malfunction.

Use the motor eye-bolts only for transporting the M otor. Using them for transporting the

machine ry may resu lt in in j u ry or malf u nc ti o n .

5 Installation and Wiring Precautions

!Caution

!Caution

!Caution

!Caution

!Caution

!Caution

!Caution

Do not step or place a heavy object on the product. Doing so may result in injury.

Do not cover the inlet or outlet ports and prevent any foreign objects from entering the

product. Doing so may result in fire.

Be sure to install the product in the right direction. Not doing so may result in malfunction.

Provide the specified clearance between the Servo Driver and the control panel or with

other devices. Not doing so may result in fire or malfunction.

Do not apply any strong impact. Doing so may result in malfunction.

Be sure to wire correc tly and sec urely. Not doing so may result in motor r unaway, injury,

or malfunction.

Be sure that all mounting screws, term inal sc rews, and cable connector screws are tight-

ened securely. Incorrect tightening may result in malfunction.

!Caution

!Caution

!Caution

!Caution

!Caution

!Caution

!Caution

Use crimp ter minals for wiring. Do not connect b are stranded wires directly to ter minals.

Connection of bare stranded wires may result in fire.

Always use the power supply voltages specified in the manual. An incorrect voltage may

result in malfunction or burning.

Take appropr iate m eas ures t o en su re that the spec ified power with the rated voltage a nd

frequency is supplied. Be par ticularly careful in places wh ere the power suppl y is unstable. An incorrect power supply may result in malfunction.

Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may result in burning.

Take appropriate and sufficient countermeasures when installing systems in the following

locations. Not doing so may result in damage to the product.

• Locations subject to static electricity or other sources of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radiation.

• Locations near power supply lines.

Do not reverse the polarity of the battery when connect ing it. Reversing the polarity may

damage the battery or cause it to explode.

Before touching a Unit, be sure to first touch a grounded metallic objec t in order to discharge any static build-up. Not doing so may result in malfunction or damage.

xiv

Page 14

Operation and Adjustment Precautions 6

6 Opera tion an d A djustment Pre c autio ns

!Caution

!Caution

!Caution

!Caution

!Caution

!Caution

!Caution

!Caution

Confirm that no adverse effects will occur in the system before performing the test operation. Not doing so may result in damage to the product.

Check the modified user programs, newly set parameters and switches for proper execution before actually running them. Not doing so may result in damage to the product.

Do not make any extreme adjustment s or s ett ing ch anges. Do ing so m ay result in uns table operation and injury.

Separate the Servomotor from the ma chine, check for proper operation, and then connect to the machine. Not doing so may cause injury.

When an a larm occurs, remove the cau se, reset the alarm after confirming safety, a nd

then resume operation. Not doing so may result in injury.

Do not come close to the machine immediately after resetting momentary power interruption to avoid an unexpected restart. (Take appropriate measures to secure safety against

an unexpected restart.) Doing so may result in injury.

Confirm that no adverse effect will occur in the system before attempting any of the following. Not doing so may result in an unexpected operation or damage to the product.

• Changing the present values or set values.

• Changing the parameters.

• Modifying (one of) the application programs.

Do not save data into the flash memory duri ng memory operation or while the motor is

running. Otherwise, unexpected operation may be caused.

!Caution

!Caution

!Caution

Do not turn OFF the power supply to the Unit while data is being written to flash memory.

Doing so may cause problems with the flash memory.

Do not turn OFF the power supply to the Unit while data is being t ransferred. Doing so

may result in malfunction or damage to the product.

Do not download any firmware to the MC Unit that has not been distributed by OMRON or

that has not been authorized and approved by OMRON for downloading into the

MCW151 series. Failure to do so may result in permanent or temporar y malfunction of

the Unit or unexpected behaviour .

7 Maintenance and Inspection Precautions

!WARNING

!Caution

Do not attempt to disassemble, repair, or modify any Units. Any attempt to do so may

result in malfunction, fire, electric shock, or injury.

Resume operation only after transferring to the new Unit the contents of the data required

for operation. Not doing so may result in an unexpected operation or damage to the product.

8 Conformance to EC Directives

Applicable Directives

• EMC Directives

• Low Voltage Directive

xv

Page 15

Conformance to EC Directives 8

8-1 Concepts

EMC Directives

OMRON devices that comply with EC Directives also conform to the related E MC standards

so that they can be more easil y built into other devices or ma-chines. The actua l products

have been checked for conformity to EMC standards (see the following note). Whether the

products conform to the standards in the system used by the customer, however, must be

checked by the customer. EMC-related performance of th e OMRON devices that comply with

EC Directives will vary depending on the configuration, wiring, and other conditions of the

equipment or con trol panel in which the OMRON devices are installed. The customer must,

therefore, perform final checks to confirm that devices and the over-all machine conform to

EMC standards.

Note Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN61000-6-2, EN50082-2

EMI (Electromagnetic Interference): E N55011 Class A Group 1

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 VAC or 75 to 1,500 VDC meet

the required safety standards.

8-1-1 Conformance to EC Directives

The W-series Servo Driver complies with EC Directives. To ensure that the machine or device

in which a Ser vo Dr iver and MC Unit are used complies with EC directives, the Servo System

must be installed as follows (refer to OMNUC W-series User’s manual (I531)):

1,2,3... 1. The Servo Driver must be mounted in a metal case (control box). (It is not necessary to

mount the Servomotor in a metal box.)

2. Noise filters and surge absorbers must be inserted in power supply lines.

3. Shielded cable must be used for I/O signal cables and encoder cables. (Use soft steel wire.)

4. Cables leading out from the control box must be enclosed within metal ducts or conduits

with blades.

5. Ferrite cores must be installed for cables with braided shields, an d the shield must be directly grounded to a ground plate.

xvi

Page 16

SECTION 1

Features and System Configuration

This section describes the features and system configuration of the R88A-MCW151-E and R88A-MCW151-DRT-E

Motion Control Units and concepts related to their operation.

1-1 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-2 Description of Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-3 Motion Control Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-3-1 PTP-control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-3-2 CP-control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1-3-3 EG-Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-3-4 Other Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1-4 Control System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1-4-1 Servo System Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1-4-2 Encoder Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1-5 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1-5-1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1-5-2 Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1-5-3 DeviceNet Specifications (MCW151-DRT-E only) . . . . . . . . . . . . . 21

1-6 Comparison between Firmware Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1

Page 17

Features Section 1-1

1-1 Features

MCW151-E MCW151-DRT-E

1-1-1 Overview

MCW151

RUN STS

SD RD

1

25

PORT0 ,1

PORT2

2

I/O

26

+24V

0V

MCW151-DRT

RUNMSSTS

1

25

NS

PORT0,1

2

I/O

26

+24V

0V

The R88A-MCW151 is a 1.5-axis Motion Control (MC) Unit which is connected to the W-series Servo Driver. The MC Unit provides direct control of

the Servo Driver, enables both speed and torque control and has ac cess to

detailed Servo Driver data. To support a multi-axis control application, the MC

Unit features both an encoder input and output connection.

There are two types of the MCW151 Motion Controllers, according to the

communication interface which is integrated into the Unit.

Communication Interface Model

RS-422A/485 Serial Communication R88A-MCW151-E

DeviceNet R88A-MCW151-DRT-E

The multi-tasking BASIC motion control language provides an easy to use

tool for programming advanced motion control applications.

Three types of motion control are possible: point-to-point, continuous path

and electronic gearing.

Point-to-point Control Point-to-point (PTP) control enables positioning independently for each axis.

Axis specific parameters and c ommands are us ed to determi ne the p aths for

the axes.

Continuous Path Control Continuous path (CP) control enables the user not only to control the start and

end positions, but also the path between those points. Possible multi-axis

paths are linear interpolation and circular interpolation. Also user defined

paths can be realized with the CAM control.

Electronic Gearing Electronic gearing (EG ) enables controlling an axis as a direct li nk to another

axis. The MC Units supports electronic gear boxing, linked moves and CAM

movements and adding all movements of one axis to another.

2

Page 18

Features Section 1-1

1-1-2 Descr iption of Features

The MC Unit provides the following features.

Motion Control The direct connection to the Servo Driver provides a high performance / high

precision control system. Operation will be processed in optimal synchronization.

• Suppor t s both speed and torque co ntrol modes of the Servo Dr iver.

• Supports switching between the modes during operation.

• Suppor t s speed limit during torque con trol using the speed reference.

• Selectable MC Unit servo period cy cle which can be set to either 0.5 ms

or 1.0 m s.

Servo Driver Access Apart from the motion control operation with the Servo Driver, the MC Unit

provides the following features:

• Monitor the detailed Servo Driver alarm status.

• Monitor various monitor signals (rotation speed, command torque).

• Monitor the Servo Driver digital inputs and a nalog input to i nclude in the

application.

• Read and write of the Servo Driver Parameters.

• Execution of several Driver functions from the MC Unit. Examples are

Print Registration, Origin Search, Driver Alarm Reset and Driver Reset.

Easy Programming with

BASIC Motion Control

Language

Encoder Input and Output To achieve a solution for multi-axis applications, the M C Unit is provided wi th

DeviceNet Interface

(MCW151-DRT-E only)

Serial Communications The MC Unit has three (MCW151-E ) or two (MCW151-DRT-E ) seri al ports for

The multi-task BASIC motion control language is used to program the MC

Unit. A total of 14 programs can be held in the Unit and up to 3 tasks can be

run simultaneously. The MC Unit is programmed using a Windows-based

application called

programming and debugging.

an encoder axis. This axis provides either to have an encoder input for external encoders or to have an encoder output to cascade position data to

another MC Unit.

The MCW151-DRT-E can be connected easily in an existing DeviceNet network. The DeviceNet network has a maximum communication distance of

500 m, so an MC Unit in a remote location can be controlled from the Master.

The MC Unit supports both remote I/O and explicit message communications.

• Remote I/O communications

Remote I/O communications can exchange data (4 input words and 4 output words max.) with the MC Unit at high speed and without programming, just like regular I/O.

• Explicit message commun ications

Large data transfers to a nd from t he M C Unit m emor y can be perform ed

by sending explicit messages from the Master when required.

communication to several external devices. Next to the connection to th e Personal Computer for configuring, the MC Unit can be connected with PCs, Programming Ter minals (PTs) and other MC Units. The serial ports suppor t the

Host Link Master and Slave protocols.

1

Motion Perfect. Motion Perfect allows extremely flexible

Absolute Encoder

Support

By using a S ervomotor with absol ute encoder, the motor position is updat ed

automatically in the MC Unit at start-up of the system. No origin search

sequence will be necessary in the system initiation phase.

1.Motion Perfect is a product of Trio Motion Technology Limited.

3

Page 19

Features Section 1-1

Virtual Axes The MC Unit contains a total of 3 axes, of which two can be configured as vir-

tual axis. The virtual axes are internal axes and are used for computational

purposes. They act as perfect servo axes and are very useful for creating profiles. They can be linked directly to the servo axes.

Hardware-based

Registration Inputs

There is a high-speed registration input for the encoder inp ut and out put axis.

On the rising or falling edge of a regi stration input, th e MC Unit will store the

current position in a register. The registered position can then be used by the

BASIC program as required. T he registered positions are captured in hardware.

General-purpose Input

and Output Signals

Starting, st opping, limit switching, origin sea rches and many other f unctions

can be controlled by the MC Unit. The general I/O can have specific functions

(such as the registration, limit switches), but also can be freely used.

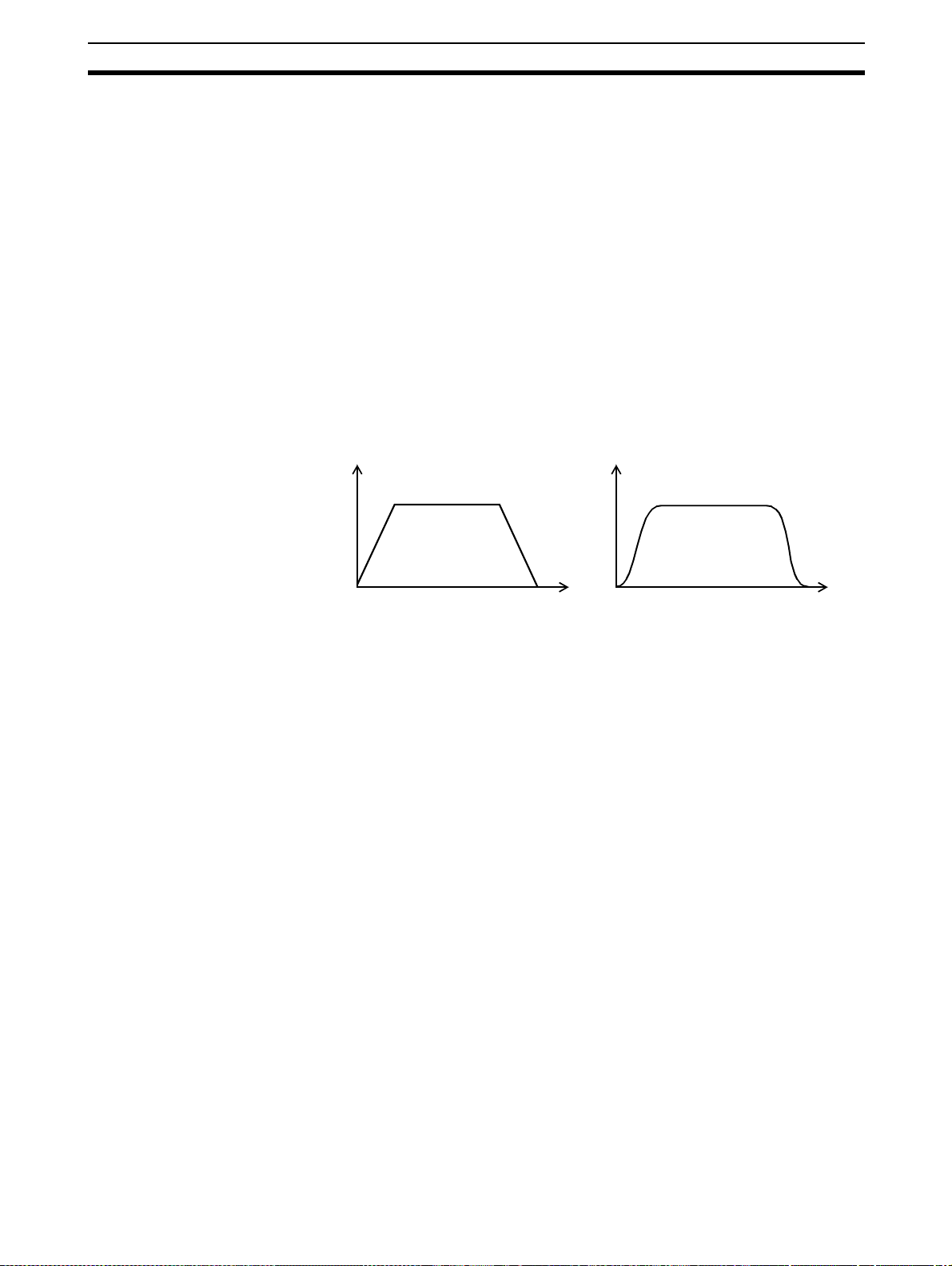

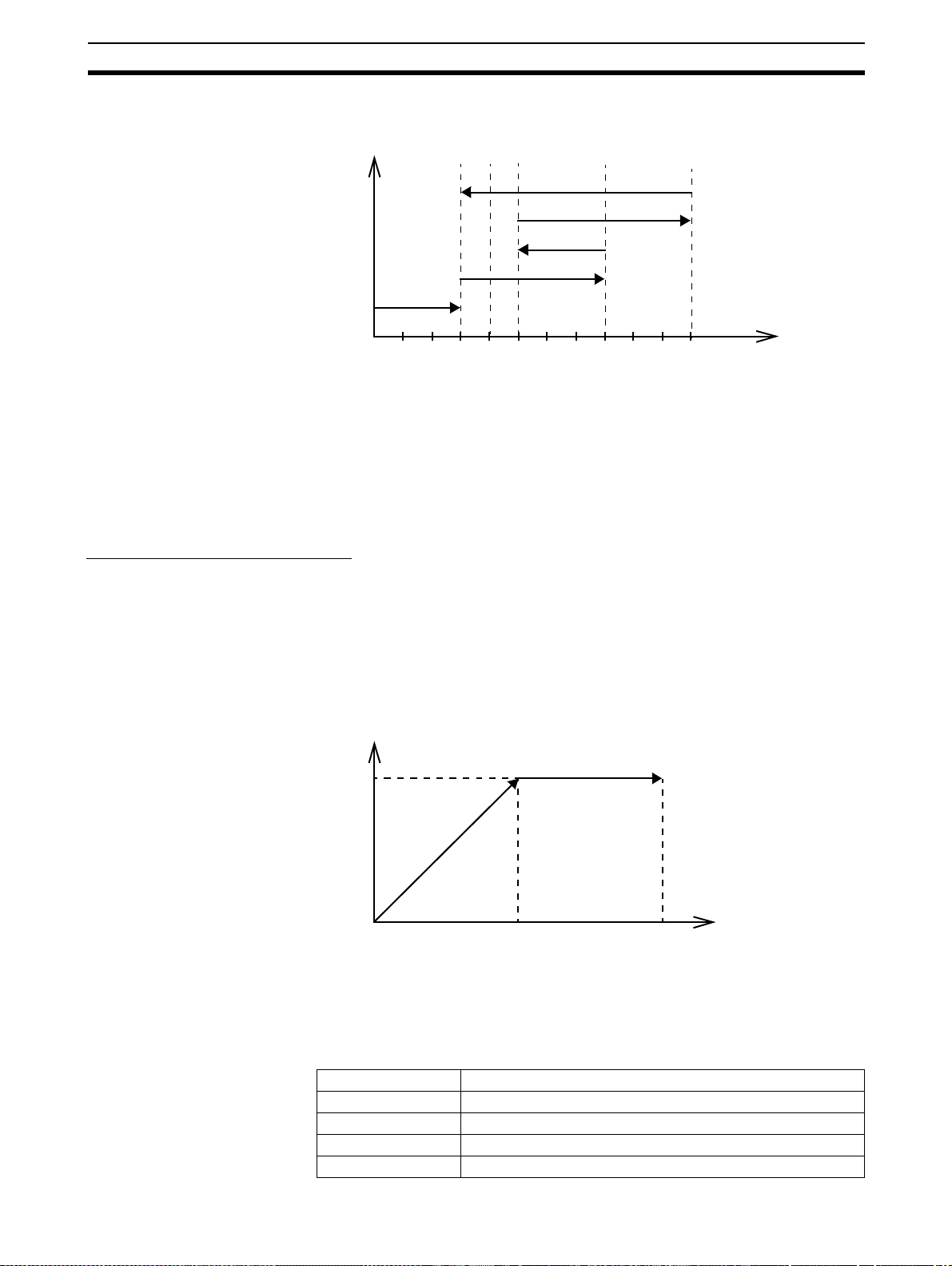

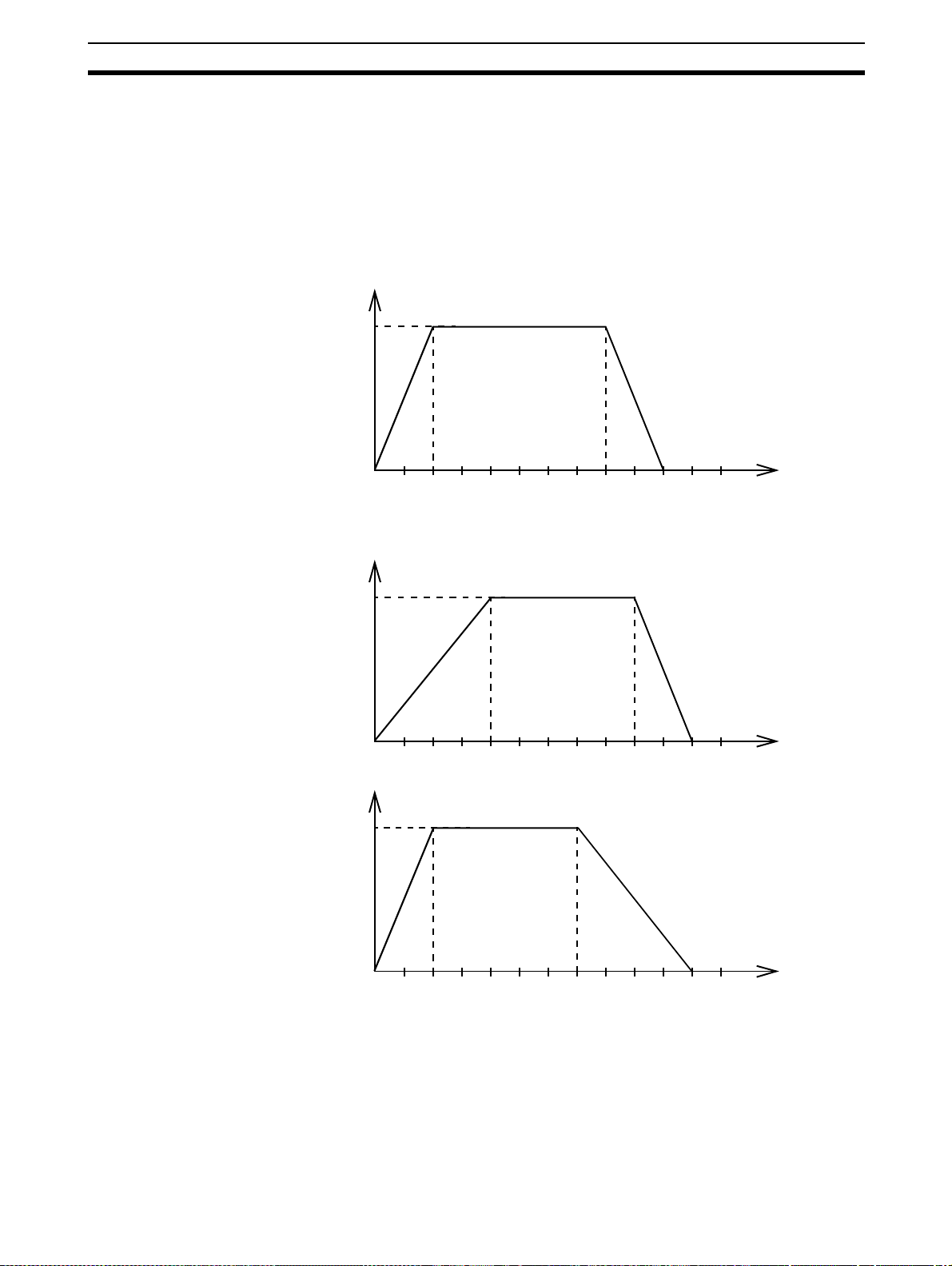

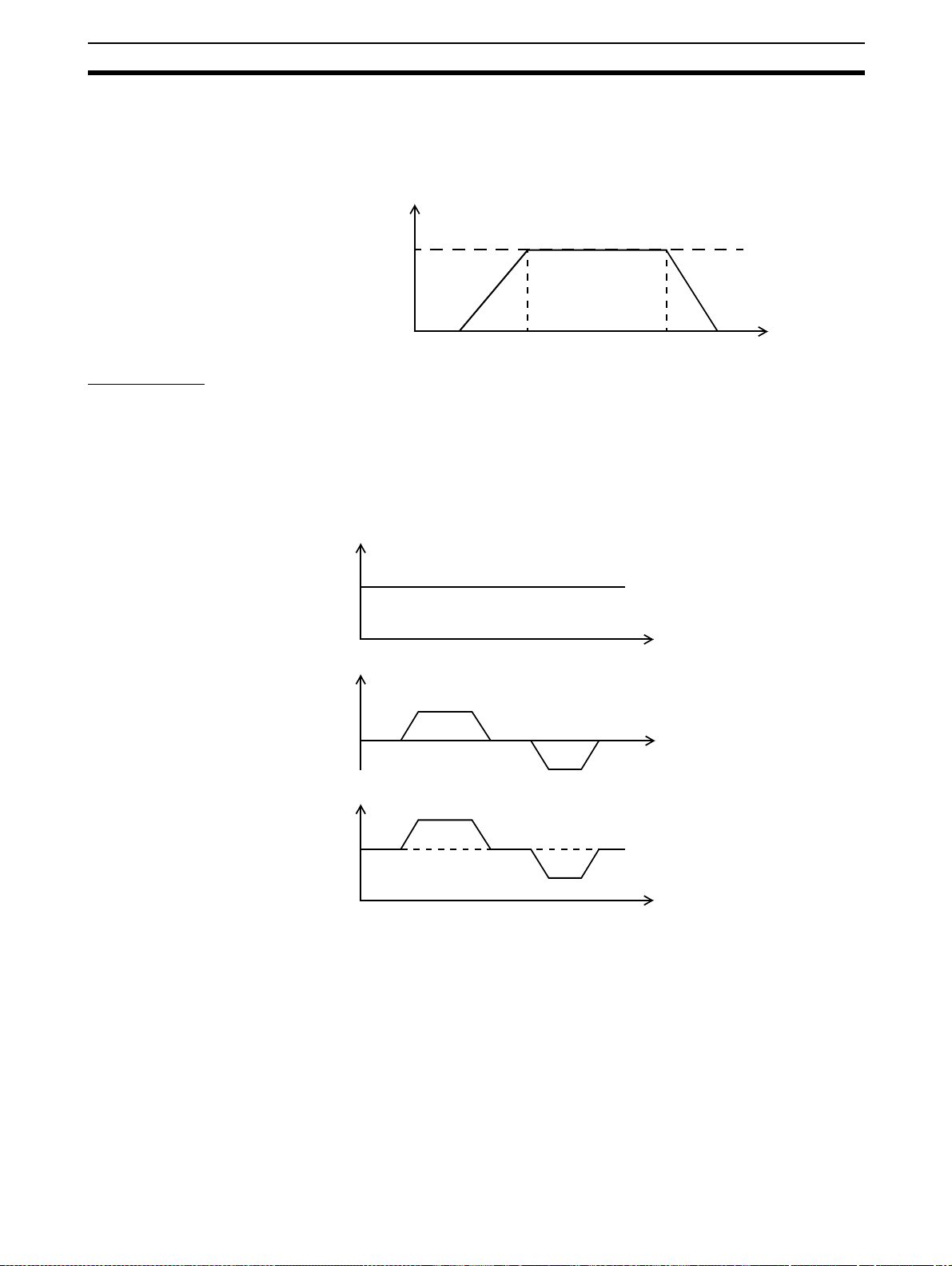

Reduced Machine Wear The traditional trap ezoidal speed prof ile is provided t o ge nerate sm oot h st art-

ing and stopping. The trapezoidal corners can be rounded off to S-curves.

Trapezoidal Speed Profile with

Square Corners

Time

Trapezoidal Speed Profile with

S-curveCorners

SpeedSpeed

Time

4

Page 20

System Configuration Section 1-2

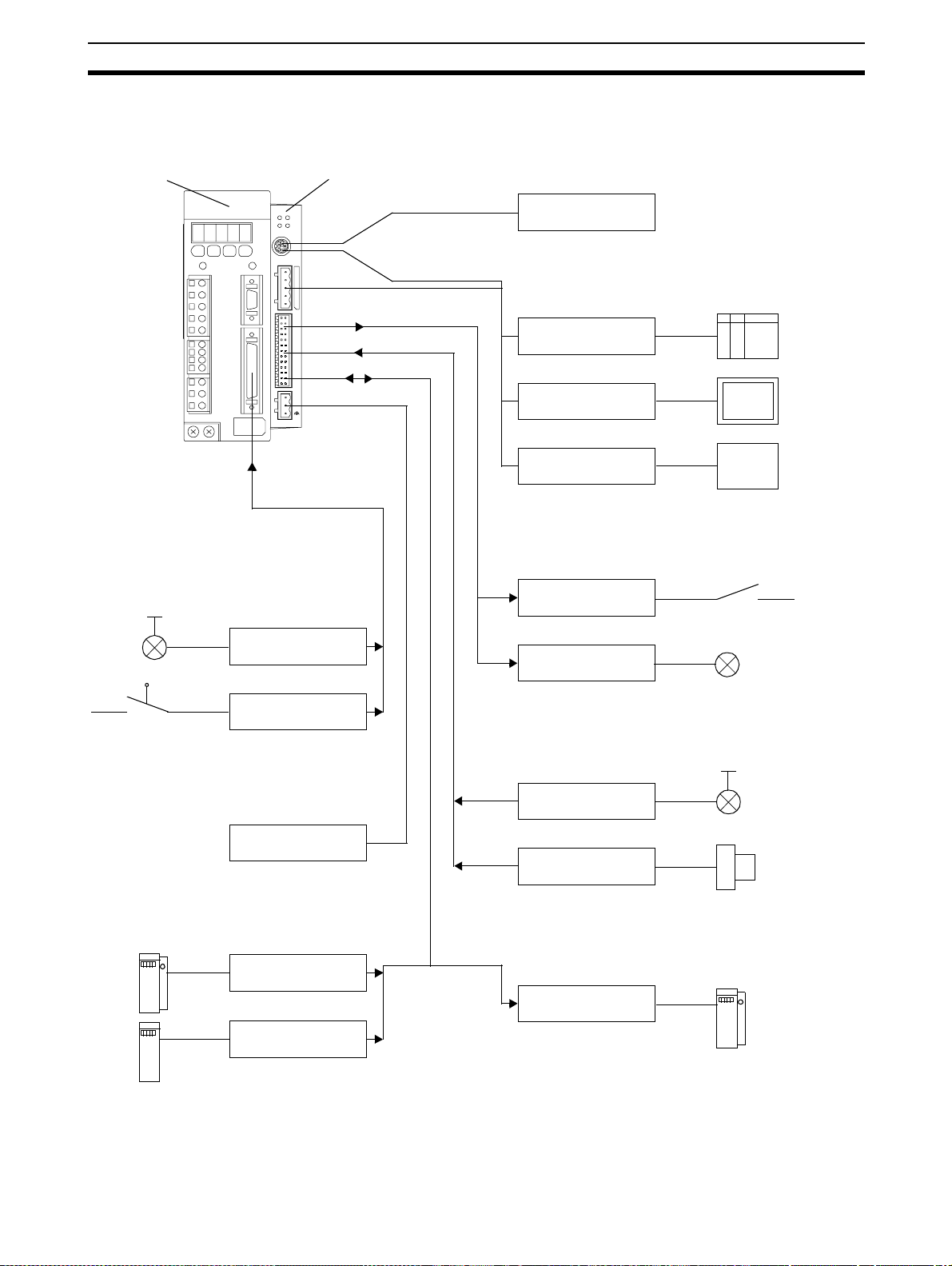

1-2 System Configuration

Basic Configuration

W-series Servo Driver MCW151

Personal Computer running Motion Perfect

MCW151

STS

RUN

SD

RD

PORT2 PO RT0 ,1

1

2

I/O

25

26

+24V

0V

Typical applicable Sensors for Servo

Driver Digital I nputs

Print Registration

Personal

Computer

1

Typicalapplicable Units for Serial Comm. Ports

PC

2

Programmable

Terminal (PT)

General-purpose

device

Typical applicable Actuators for Digital O utputs

Relais

Lamp

Limit Switches

Power Supply connection

24 V Power supply

Typicalapplicable Pulse Generators for

Encoder Input

MCW151 Unit

Servo Driver

Note 1. The RS-422A/485 Serial Port 2 is only available on the MCW151-E Unit.

2. The MC Unit has one encoder axis. Either the encoder input or the encoder

Typical applicable Sensors for Digital Inputs

Print Registration

Proximity Sensor

Typical applicable Units f or Encoder Output

MCW151 Unit

output can be used.

5

Page 21

System Configuration Section 1-2

The equipment and models which can be used in the system configuration

are shown in the following table.

Device Model

Motion Control Unit R88A-MCW151-E

R88A-MCW151-DRT-E

Servo Driver (see note) R88D-WT

Servomotor

Control De vices (using

Host Link)

Personal Computer (for

Motion Perfect)

Motion Perfect Version 2.0 or later

R88M-W

Prog ramma bl e Terminals

CPU Units

IBM Pers onal Computer or 100% compatible

Note The MC Unit must be used with a Servo Driver with software version 14 or

later. The MC Unit cannot be used with software version 8.

❏

❏

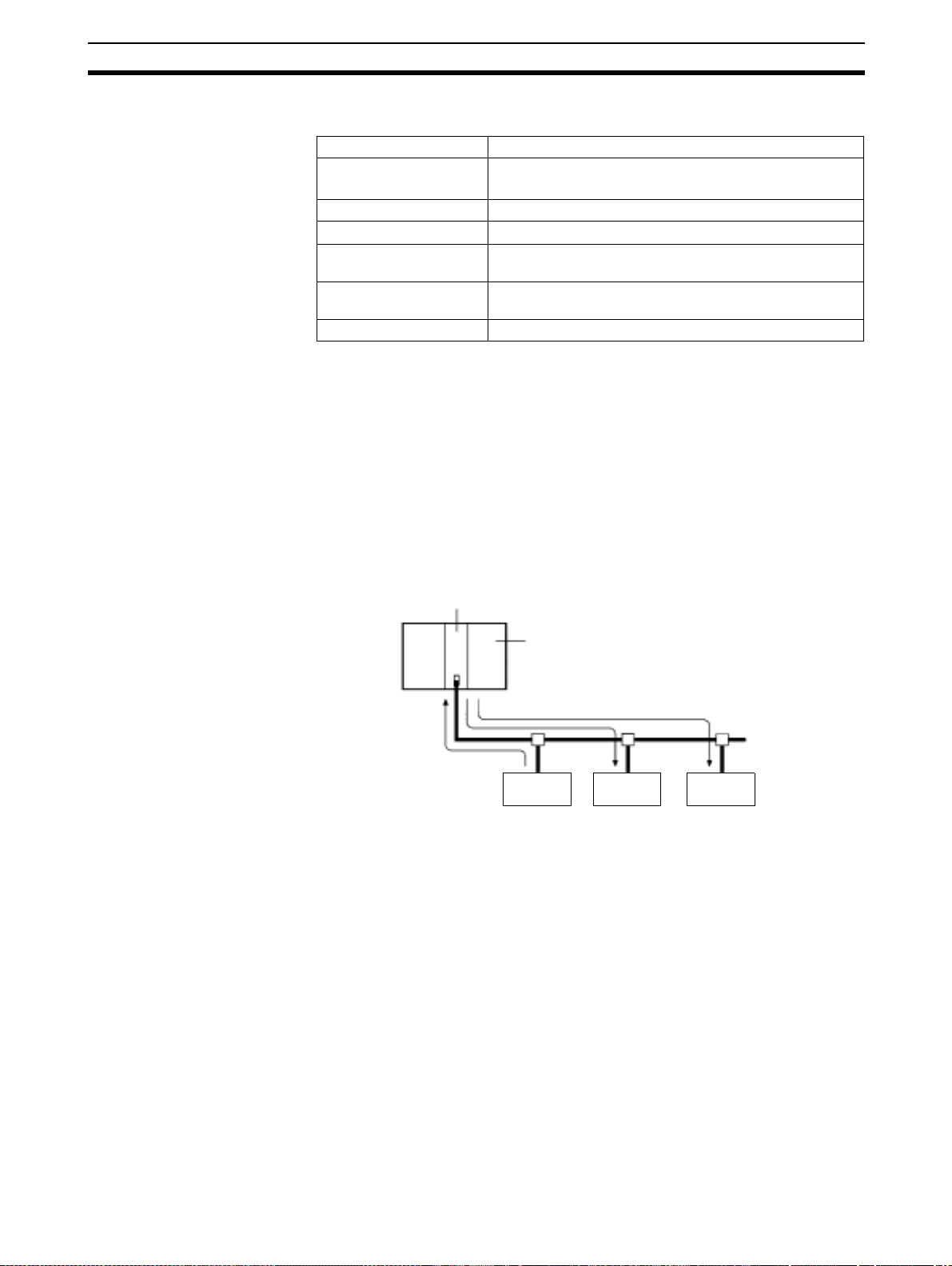

DeviceNet Configuration

(MCW151-DRT-E only)

A DeviceNet system can be constructed in two ways: fixed allocation or free

allocation.

Fixed Allocation

A DeviceNet system can be constructed easily without the Configurator. With

fixed allocation, predetermined words are allocated to each node for the

Slave’s I/O.

An OMRON Master must be used in order to perform fixed allocation. Moreover, with fixed allocation only one M aster Unit can be u sed in a DeviceNet

network and only one Master Unit may be mounted to a PC.

Master Unit

CPU Unit

Remote I/O communications

Slave Slave MC Unit

Free Allocatio n

The Configurator can be used to freely allocate the words used by each

Slave. With free allocation, more than one Master Unit can be connected in a

DeviceNet network and each Master’s Slave I/O can be set independently.

More than one Master Unit may be mounted to each PC and those Masters

can be used independently. Furthermore, other compan ies’ Masters can be

6

Page 22

Motion Control Concepts Section 1-3

used. For details, refer to the DeviceNet Configurator Operation Manual

(W328).

Master Unit Master Unit

CPU Unit

Remote I/O communications

MC Unit

Slave

Master Unit

Message

communications

Slave

MC Unit

The following OMRON Master Units can be used.

Appli c able P C Ma s te r Un it mo d e l

number

CS1 Series CS1-DRM21 CPU Rack or Expansion I/O Rack

(Classified as Special I/O Units)

C200HZ/HX/HG/HE C200HW-DRM21-V1 CPU Rack or Expansion I/O Rack

(Classified as Special I/O Units)

Mounting position Max. number of Units

Note S om e CPUs can control 16 Master Units and other CPUs can control 10.

With

Configurator

16 1

10 or 16 (see

note)

Configurator

ISA Board

Without

Configurator

1

1-3 Motion Control Concepts

The MC Unit offers the following types positioning control operations.

1. Point-to-point control

2. Continuous Path control

3. Electronic Gearing

This section will introduce some of the commands and parameters as used in

the BASIC programming of the motion control application. Refer to

SECTION 6 BASIC Motion Control Programming Language for details.

Coordinate S ys te m Positioning operations performed by the MC Unit are based on an axis coordi-

nate system. The MC Unit converts the position data from either the connected Servo Driver or the connected encoder into an internal absolute

coordinate system.

The engineering unit which specif ies the distances of travelling can be freely

defined for each axis separately. The conversion is performed through the

use of the unit conversion factor, which is defined by the UNITS axis parameter. The origin point of the coordinate system can be det ermined using the

DEFPOS command. Thi s command re-de fines the current position to zero or

any other value.

A move is defined in either absolute or relative terms. An absolute move takes

the axis to a specific predefined position with respect to the origin point. A relative move takes the axis from the current position to a position that is defined

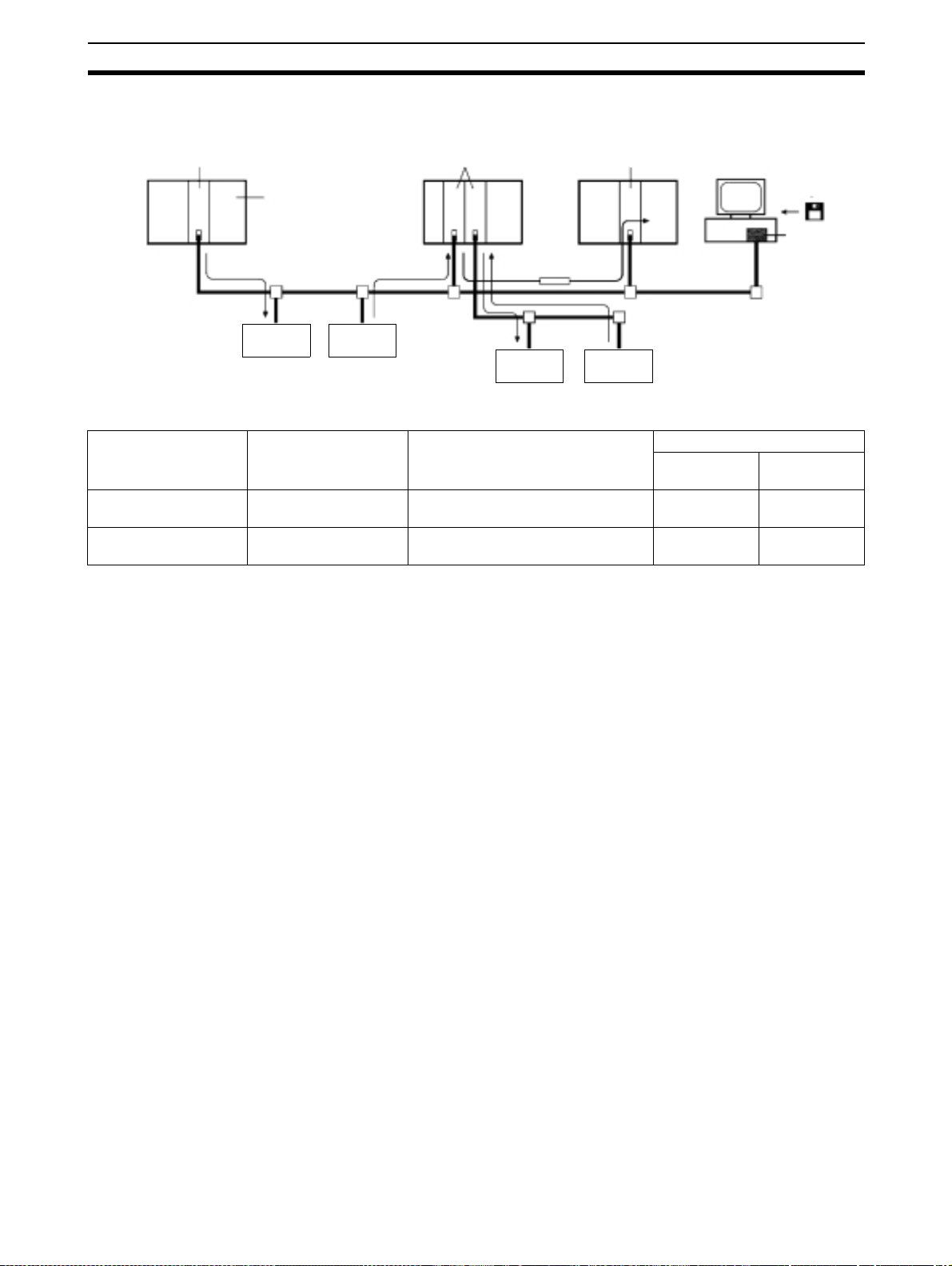

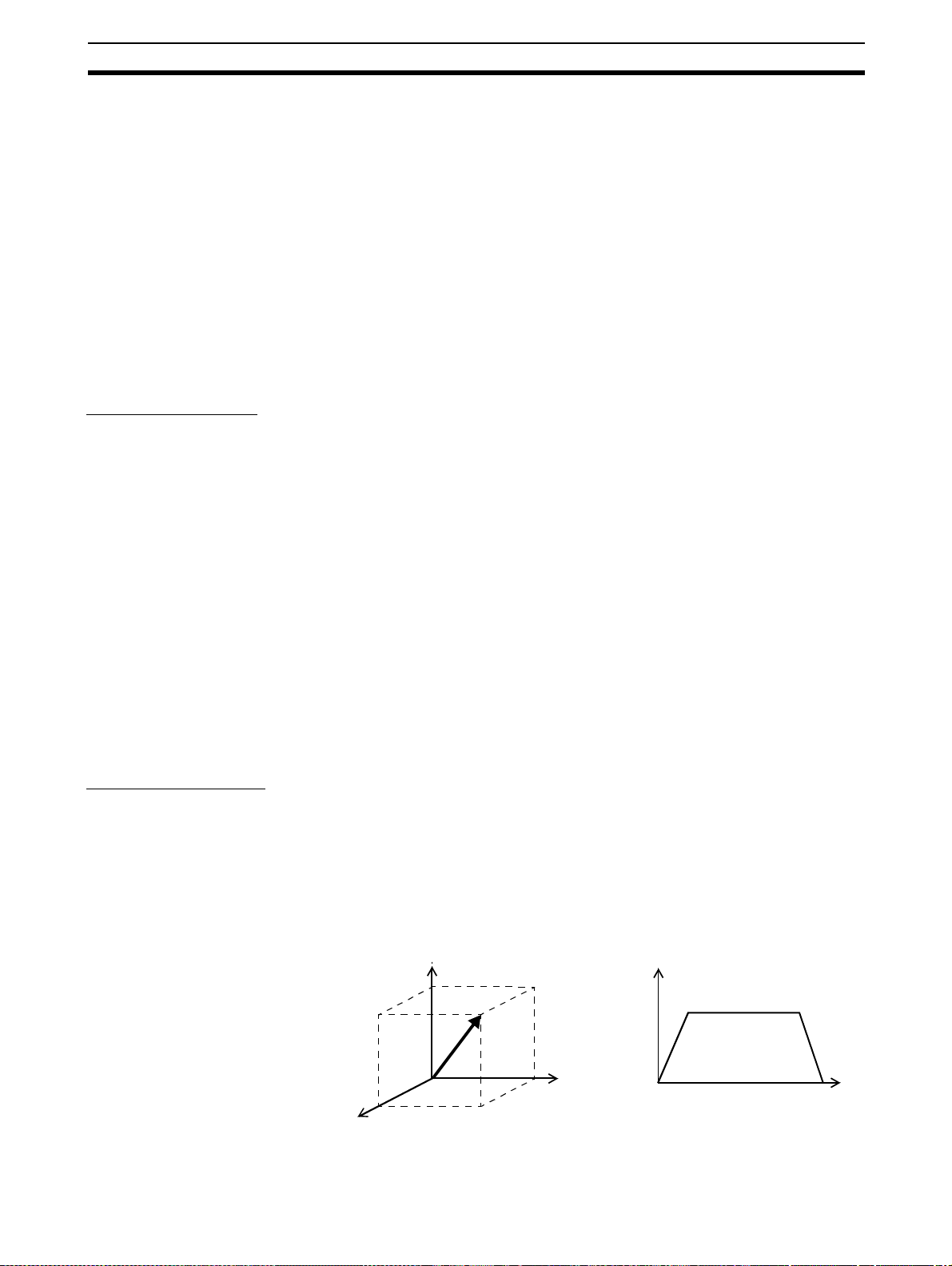

relative to this current position. The following diagram shows gives an exam-

7

Page 23

Motion Control Concepts Section 1-3

ple of relative (command MOVE) and absolute (command M OVEABS) linear

moves.

MOVEABS(30)

MOVE(60)

MOVEABS(50)

MOVE(50)

MOVE(30)

1-3-1 PTP-control

In point-to-point positioning, each axi s is moved independently of the other

axis. The MC Unit supports the following operations.

• Relative m o ve

• Absolute move

• Continuous move forward

• Continuous move reverse

Relative and Absolute Moves

To move a single axis either t he command MOVE for a relative move or the

command MOVEABS for an absolute move is used. Each axis has its own

move characteristics, which are defined by the axis parameters.

Suppose a control program is executed to move from the origin to an axis

no. 0 coordinate of 100 and axis no. 1 coordinate of 50. If the speed parameter is set to be the s ame for both axes and the acceleration and dec eleration

rate are set sufficiently high, the m ovements for axis 0 and axis 1 will be as

illustrated below.

Axis 1

0

50

50 100

MOVEABS(100) AXI S(0)

MOVEABS(50) AXIS(1)

Axis position

0

50

100

Axis 0

At start, both the axis 0 and axis 1 will move to a coordinate of 50 over the

same duration of time. At this point, axis 1 will stop and the axis 0 will continue to move to a coordinate of 100.

Relevant Axis Parameters As mentioned before the move of a certain axis is determined by the axis

parameters. Some relevant parameters are given in the next table.

Parameter Description

UNITS Unit conver sion factor

ACCEL Acceleration rate of an axis in units/s

DECEL Deceleration rate of an axis in units/s

SPEED Demand speed of an axis in units/s

2

2

8

Page 24

Motion Control Concepts Section 1-3

D

d

Defining moves The speed profile below shows a simple MOVE operation. The UNITS param-

eter for this axis has been defined for example as meters. The required maximum speed has been set to 10 m/s. In order to reach this speed in one

second and also t o decelerate to zero speed again i n one second, both the

acceleration as the deceleration rate have been set to 10 m/s

tance travelled is the sum of distances travelled during the acceleration, constant speed and decel eration segm ents. Suppose the di stance moved by the

MOVE command is 40 m, the speed profile will be given by the following

graph.

Speed

10

2

. The total dis-

ACCEL=10

DECEL=10

SPEED=10

MOVE(40)

0

12345

6

Time

The following two speed profiles show the same movement with an acceleration time respectively a deceleration time of 2 seconds.

Speed

ACCEL=5

6

DECEL=10

SPEED=10

MOVE(40)

Time

ACCEL=10

DECEL=5

SPEED=10

MOVE(40)

10

Speed

10

0

12345

0

12345

6

Time

Move Calculations The following equations are used to calculate the total time for the motion of

the axes. Consider the moved distance for the MOVE command as , the

demand speed as , the acceleration rate and deceleration rate .

V

a

9

Page 25

Motion Control Concepts Section 1-3

Continuous Moves

Acceleration time

V

---=

a

2

Acceleration dist a nc e

V

------=

2a

Deceleratio n time

V

---=

d

2

Deceleration distance

V

------=

2d

Constant speed distance

V2ad+()

D=

-----------------------–

2ad

D

Total time

The FORWARD and REVERSE commands can be used to start a continuous

movement with constant speed on a cert ain axis. The FORWARD command

will move the axis in positive direction and the REVERSE comman d in negative direction. For these commands also the axis parameters ACCEL and

SPEED apply to specify the acceleration rate and demand speed.

Both movements can be canceled by using either the CANCEL or RAPIDSTOP command. The CANCEL command will cancel the m ove for one axis

and RAPIDSTOP will cancel m oves on all axes. The de celeration rate is set

by DECEL.

Va d+()

--- -=

-------------------- -+

V

2ad

1-3-2 CP-control

Linear Interpolation

Continuous Path control enables to control a specif ied p ath bet ween t he st art

and end position of a movement for one or multiple axes. The MC Unit supports the following operations.

• Linear interpolation

• Circular interpolation

• CAM control

In applications it can be required for a set of motors to perform a move operation from one position to another in a straight line. Linearly interpolated moves

can take place among several axes. The commands MOVE and MOVEABS

are also used for the linear int erpola ti on . I n t h is c as e t h e c o m ma nds will h ave

multiple arguments to specify the relative or absolute move for each axis.

Consider the following three axis move in a 3-dimensional plane.

MOVE(50,50,50)

Axis 2

Axis 1

Speed

Time

10

Axis 0

Page 26

Motion Control Concepts Section 1-3

The speed profile of the motion along the path is given in the diagram. The

three parameters SPEED, ACCEL and DECEL which determine the multi axis

movement are taken from the corresponding parameters of the base axis.

The MOVE command computes the various components of speed demand

per axis.

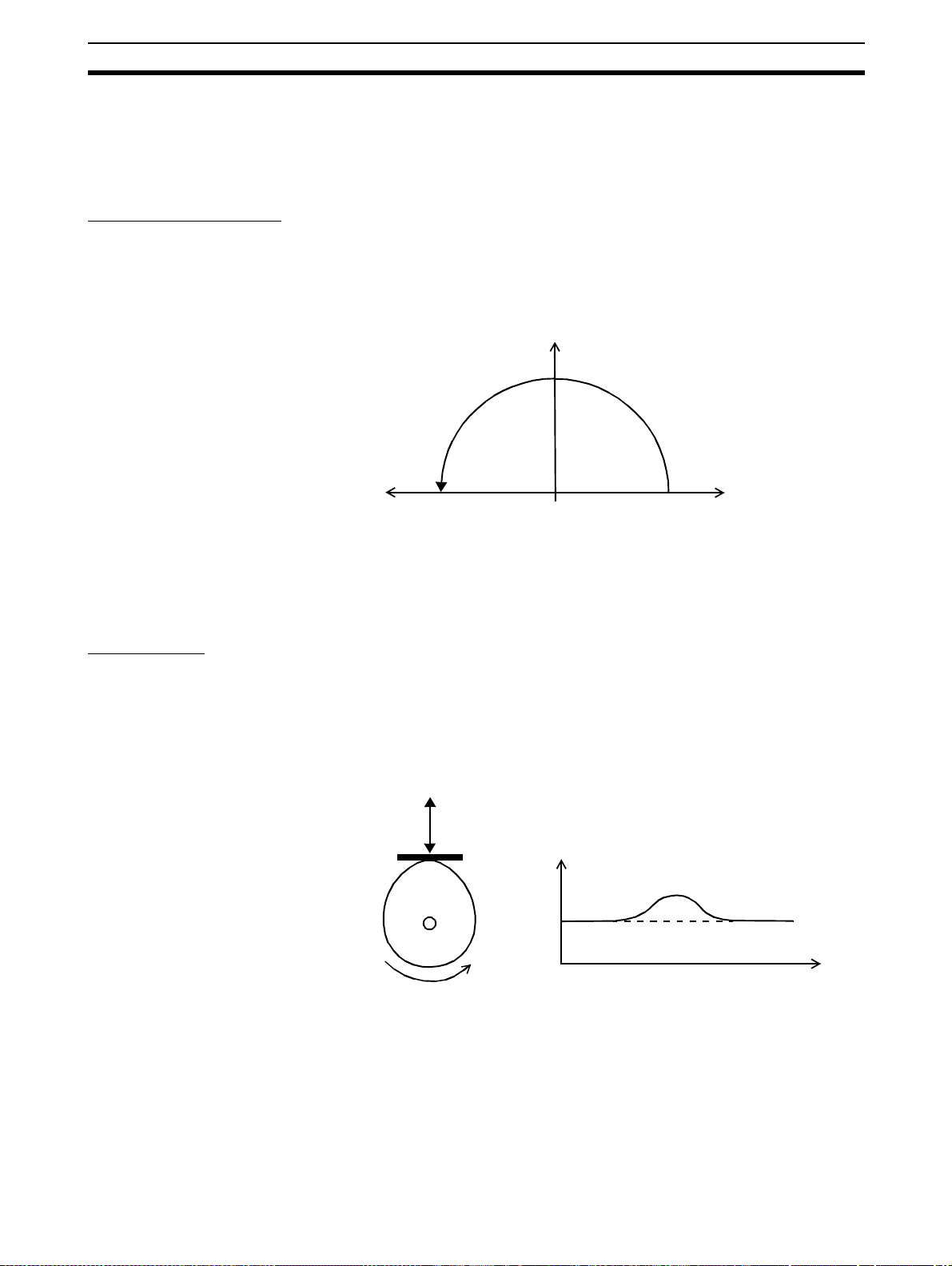

Circular Interpolation

It may be required that a tool travels from the starting point to the end point in

an arc of a circle. In this instance the motion of two axes is related via a circular interpolated move using the MOVECIRC command. Consider the following

diagram.

CAM Control

MOVECIRC(-100,0,-50,0,0)

-50

The centre point and desired en d point of the trajectory relative to the start

point and the direction of movement are specified. The MOVECIRC command

computes the radius and the angle of rotation . Like the linearly inter polated

MOVE command, the ACCEL, DECEL and SPEED variables associated with

the base axis determine the speed profile along the circular move.

Additional to the standard move profiles the MC Unit also provides a way to

define a position profile for the axis to move. The CAM command will move an

axis according to position values stored in the MC Unit Table array. The

speed of travelling through the profile is determined by the axis parameters of

the axis.

CAM(0,99,100,20)

Axis 1

0

50

50

Axis 0

1-3-3 EG-Control

Position

Time

Electronic Gearing control allows you to create a direct gearbox link or a

linked move between two axes. The MC Unit supports the following operations.

1. Electronic gearbox

2. Linked CAM

3. Linked move

4. Adding axes

11

Page 27

Motion Control Concepts Section 1-3

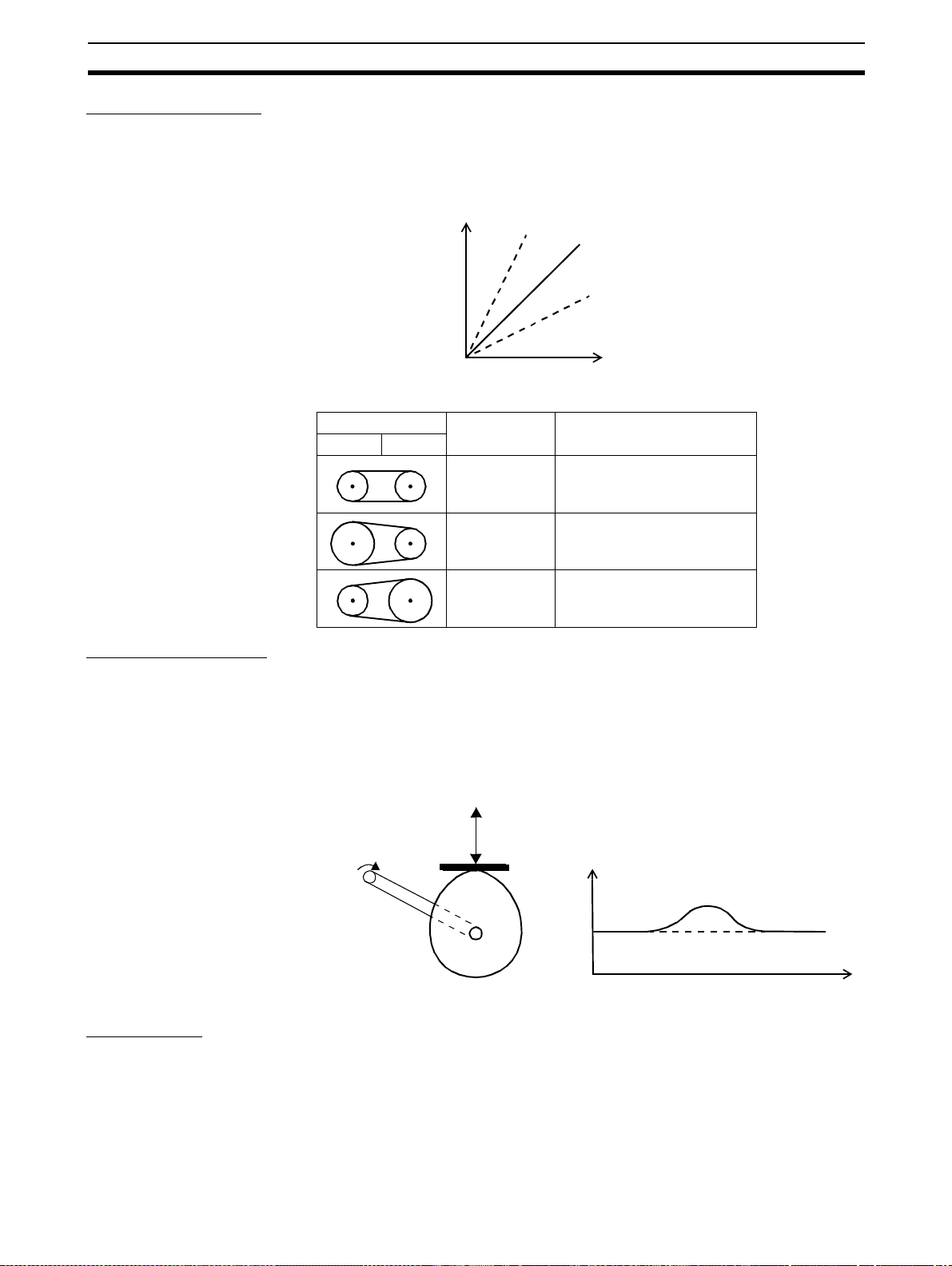

Electronic Gearbox

The MC Unit is able to have a gearbox link from one axis to another as if there

is a physical gearbox connecting them. This can be done using the C ONNECT command in the program. In the command the ratio and the axis to link

to are specified.

CONNECT Axis

2:1

Axes Ratio CONNECT command

01

1:1 CONNECT(1,0) AXIS(1)

2:1 CONNECT(2,0) AXIS(1)

1:1

1:2

Master Axis

Linked CAM control

Linked Move

1:2 CONNECT(0.5,0) AXIS(1)

Next to the standard CAM profiling tool the MC Unit also provides a tool to link

the CAM profile to another axis. The command to create the link is called

CAMBOX. The travelling speed through the profile is not deter mined by the

axis parameters of the a xis but by the position of t he linked axis. This is like

connecting two axes through a cam.

CAMBOX(0,99,100,20,0) AXI S(1)

CAMBOX Axis (1) Position

Master Axis (0) Position

The MOVELINK command provides a way to link a specified move to a master axis. The move is divided into an acceleration, dece leration and constant

12

Page 28

Motion Control Concepts Section 1-3

speed part and they are specified in master link distances. This can be particularly useful for synchronizing two axes for a fixed period.

MOVELINK(50,60,10,10,1) AXIS(0)

Speed

Master Ax is (1)

Synchronized

MOVELINK Axis (0)

Time

Adding Axes

It is very useful to be able to add all movements of one axis to another. One

possible application is for instance changing the offset between two axes

linked by an electronic gearbox. The MC Unit provides this possibility by using

the ADDAX command. The movements of the linked ax is will consists of all

movements of the actual axis plus the a dditional movements of the master

axis.

Speed axis 0*

BASE(0)

ADDAX(2)

FORWARD

MOVE(100) AXIS(2)

MOVE(-60) AXIS(2)

Speed axis 2

Time

+

Speed axis 0

Time

=

Time

1-3-4 Other Operations

Canceling Moves In normal operation or in case of emergency it can be necessary to cancel the

current movement from the buffers. When the CANCEL or RAPIDSTOP commands are given, the selected axis respectively all axes will cancel their current move.

Orig in Sea rch The encoder feedback for controlling the position of the motor is incremental.

This means that all movement must be defined with respect to an origin point.

The DATUM comm and is used to set up a procedure whereby the MC Unit

goes through a sequence and searche s for the origin based on digital inputs

and/or Z-marker from the encoder signal.

13

Page 29

Control System Configuration Section 1-4

Print Registration The MC Unit can capture t he position of an axis in a regi ster when an event

occurs. The event is referred to as the print registration input. On the risin g or

falling edge of an input signal, which is either the Z-marker or an input, the MC

Unit captures the position of an axis in hardware. This position can then be

used to correct possible error between the actual position and the desired

position. The print registration is set up by using the REGIST command.

The position is captured in hardware, and therefore there is no software overhead and no interrupt service routines, eliminating the nee d to deal with the

associated timing issues.

Merging Move s If the MERGE axis parameter is set to 1, a movement will always be followed

by a subsequent movement without stopping. The following illustrations will

show the transitions of two moves with MERGE value 0 and value 1.

Speed

MERGE=0

Time

Speed

MERGE=1

Time

Jogging Jogging moves the axes at a constant speed forward or reverse by manual

operation of the digital in puts. Different speeds are also selectable by input.

Refer to the FWD_JOG, REV_JOG and FA ST_JOG axis parameters.

1-4 Control System Configuration

1-4-1 Servo System Principles

The servo system used by and the internal operation of the MC Unit are

briefly described in this section. Refer to 2-4 Servo System Precautions fo r

precautions related to servo system operation.

Semi-closed Loop System The servo system of the MC Unit uses a semi-closed or inferred closed loop

system. This system detects actua l m ac hin e movements b y th e ro tation of the

motor in relation to a t arget value. It calculates the error between the target

value and actual movement, and reduces the error through feedback.

14

Page 30

Control System Configuration Section 1-4

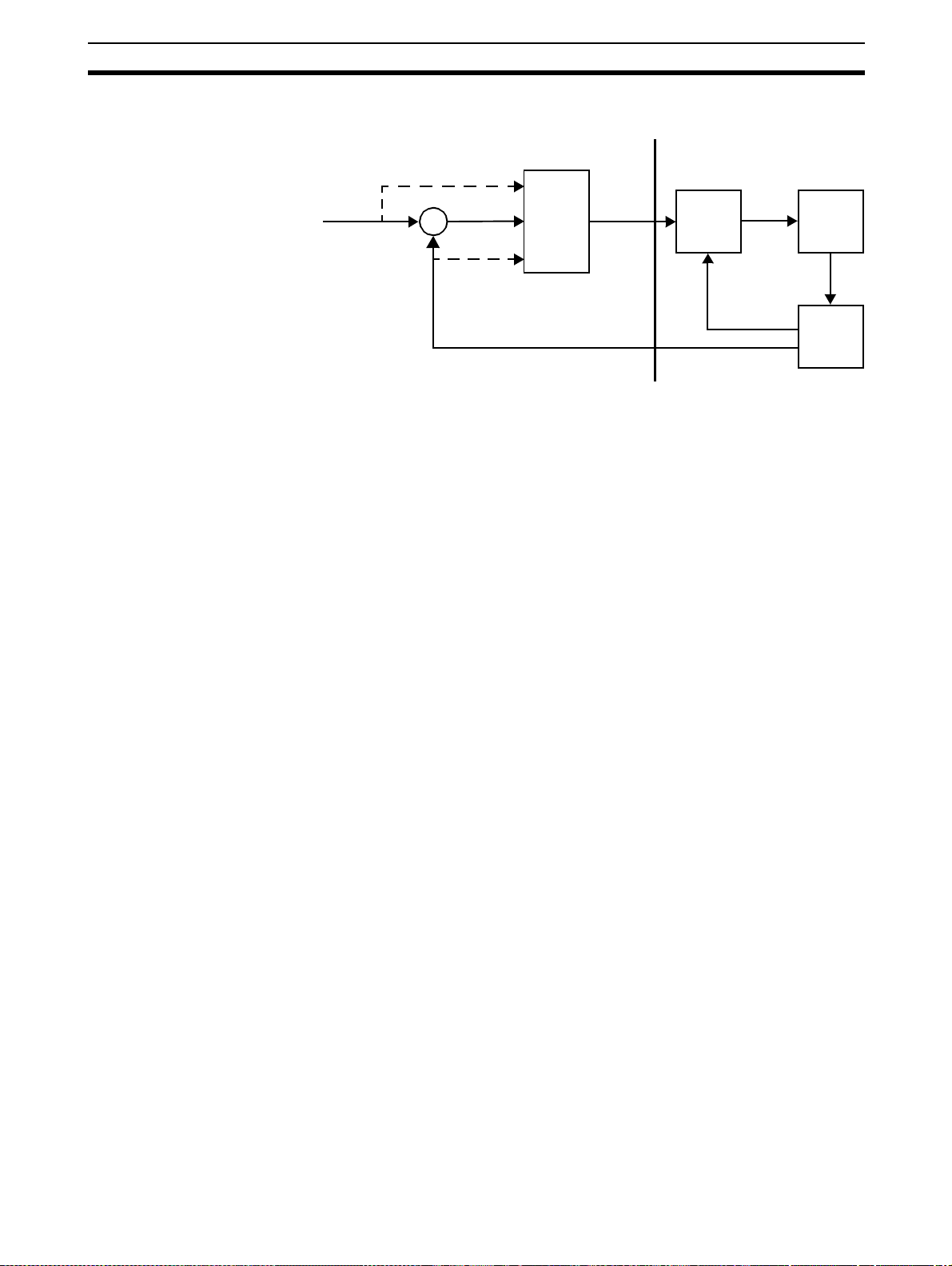

Internal Operation of the

MC Unit

1,2,3... 1. The MC Unit performs actual position c ontrol. The main inpu t of the con-

MC Unit

Servo System

2

3

Demand

position

1

+

-

Position

Control

Speed

reference

Speed

Control

Motor

4

Measured

speed

Encoder

Measured

position

Inferred closed loop systems occupy the mainstream in modern servo systems applied to positioning devices for industrial applications. The following

graph shows the basic principle of the Servo System as used in the MC Unit.

troller is the following error, which is the calculated difference between the

demand position and the actual measured position.

2. The Position Controller calculates the required speed reference output determined by the following error and possibly the dema nded position and

the measured position. The speed reference is provided to the Servo Driver.

3. The Servo Driver controls the rotational speed of the Servomotor corresponding to the speed reference. The rotational speed is proportional to

the speed reference.

4. The rotary encoder wil l generate the feedback pulses for both the speed

feedback within the Servo Driver speed loop and the position feedback

within the MC Unit position loop.

Motion Control Algorithm The servo system controls the m otor by continuously ad justing t he s pee d ref -

erence to the Servo Driver. The speed reference is calculated by the MC

Unit’s Motion Control algorithm, which is explained in this section.

The Motion Control algorithm uses th e demand position, the measured posi tion and the following error to determine the speed reference. The following

error is the difference between the d emanded and measured position. The

demand position, me asured position and following error are represented by

axis parameters MPOS, DPOS and FE. Five gain values have been implemented for the user to be able to configure the correct control operation for

each application.

15

Page 31

Control System Configuration Section 1-4

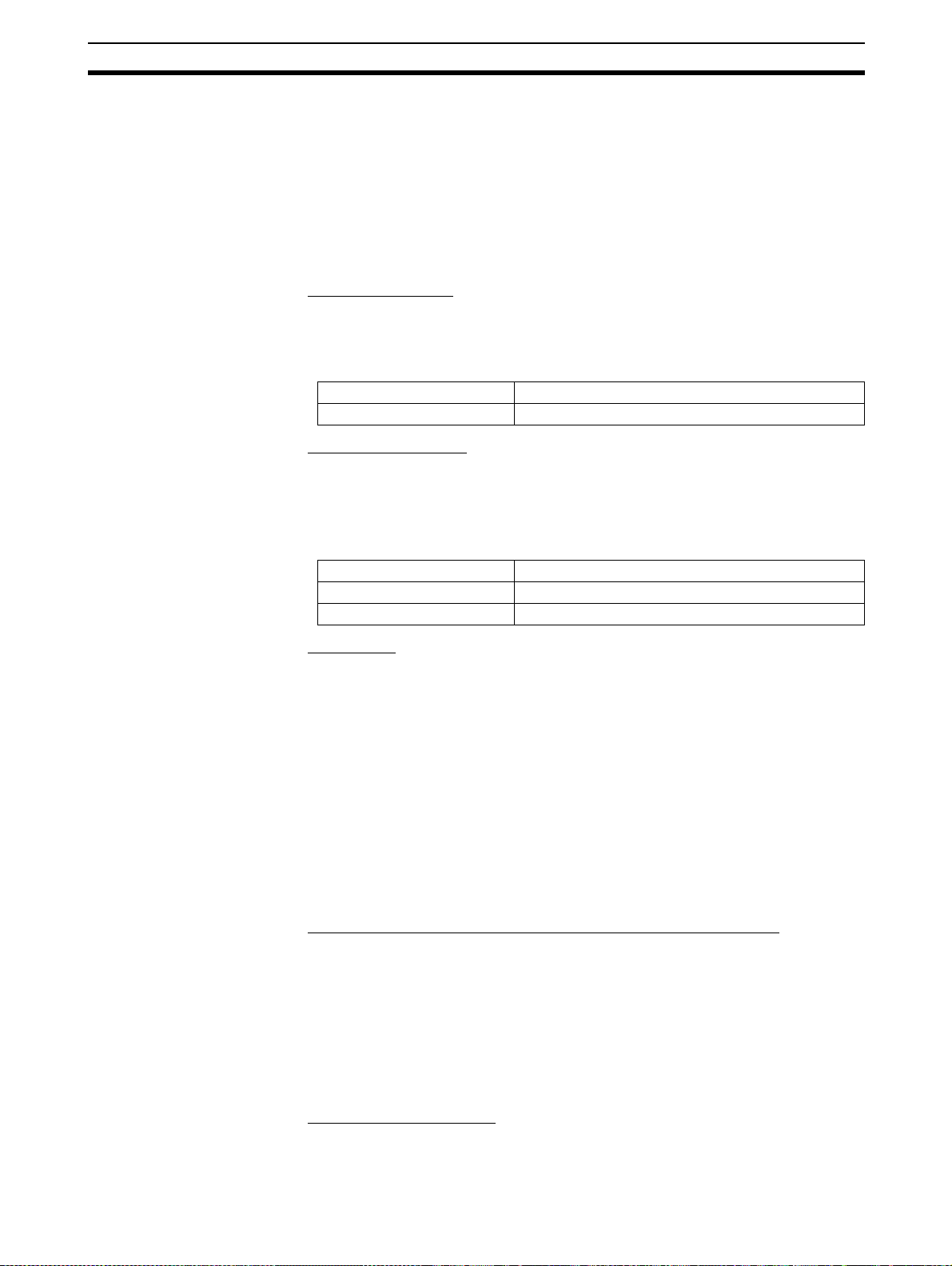

The Motion Control algorithm of the MC Unit is shown in the diagram below.

K

∆

vff

K

p

K

ov

Output

signal

∆

Measured

position

Demand

position

Proportional Gain The proportional gain creates an output that is proportional to the

foll owing er ror .

O

All practical systems use proportional gain. For many just using this gain

parameter alone is sufficient. The proportional gain axis parameter is called

P_GAIN.

Integral Gain The integral gain creates an output that is proportional to the sum of

the following errors that have occurred during the system operation.

O

Integral gain can cause overshoot and so is usually used only on systems

working at constant speed o r with slow accelerations. The integral gain axis

parameter is called I_GAIN.

KpE⋅=

p

K

i

Following

error

+

K

Σ

K

i

∆

d

-

K

p

++

O

p

E

K

i

O

i

E

E

⋅=

i

å

Derivative Gain The derivative gain produces an output that is proportional to the

change in the following error and speeds up the response to changes in

error while maintaining the same relative stability.

d

ov

vff

K

K

K

d

ov

vff

O

Derivative gain may create a smoother response. High values may lead to

oscillation. The derivative gain axis parameter is called D_GAIN.

Output Speed Gain The output speed gain produce s an output that is proportional to

the change in the measured position and increases system damping.

O

The output speed gain can be us eful for smoothing motions but will gene rate

high following errors. The output speed gain axis parameter is called

OV_GAIN.

Speed Feedforward Gain The speed feedforward gain produces an output that is propor-

tional to the change in dem and position and minimizes the following error

at high speed.

O

The parameter can be set to minimise the following error at a constant

machine speed after ot her gai ns have been set. Th e speed feed forward gain

axis parameter is called VFF_GAIN.

K

d

O

d

E

E∆⋅=

K

ov

P

m

O

ov

Pm∆⋅=

K

vff

P

d

O

vff

Pd∆⋅=

16

Page 32

Control System Configuration Section 1-4

De faul t Val u es The default settings are given below along with the resulting profiles. Frac-

tional values are allowed for gain settings.

Gain Default

Proportional Gain 0.1

Integral Gain 0.0

Derivative Gain 0.0

Output Speed Gain 0.0

Speed Feedforward Gain 0.0

1-4-2 Encoder Signals

Standard OMRON equipment is designed for an advanced phase-A for forward rotation and an advanced phase-B for reverse rotation. For the encoder

input and output signals, the MC Unit is designe d to comply with this phase

definition, allowing the M C Unit to be connect ed to other equipment without

problems.

With this arrangement, the direction of rotation can be easily detected by

monitoring the relative phase of both signals. If channel A leads channel B,

indicating clockwis e (CW ) movement, th e counter w ill increm ent. Co nversely,

if channel B leads channel A, indicating counterclockwise (CCW) movement,

the counter will decrement.

Typically, rotar y en coders also provide an addi tional Z-marker as a reference

pulse within each revolution. By properly decoding and counting these

encoder signals, the direction of motion, speed, and relative position can be

determine d.

Encoder input For the MC Unit encoder input, the pulse ratio is 4. Ev ery encoder edge (pulse

edge for either A or B phase) is one internal count.

Forward rotation (CW) Reverse rotation (CCW)

Phase A

Phase B

01 423 567 76 354 210

Counts (x4)

The signals A, B and Z appear physically as A+ and A-, B+ and B- and Z+ and

Z-. These appear as differential signals on twisted-pair wire inputs, ensuring

that common m odes are rejected and that the noise level is kept to a minimum.

When using encoders by other makers, check carefully the encoder specification for phase advancement. If the definition differs from the ones given

above, reverse the B-phase wiring between the MC Unit and the Servo Driver.

In most case, this should resolve the problem.

17

Page 33

Control System Configuration Section 1-4

Encoder ou tput For encoder output, the pulse ratio is 64. For every 16 inter nal counts one

encoder edge for one of the two phases will be produced.

Phase A

Phase B

Phase Z

016 6432 48 80 96

Internal Counts

The Z-phase signal has the following specification:

• The Z-marker has a period of 4096 generated edges.

• The pulse has a width of a quarter pulse period length (when both phase

A and B are low).

• The Z-phase signal is active after power-on.

The generated frequency is limited to the maximum allowable frequency. If

the internal speed would result in a frequenc y above this maximum, an axis

status flag will be set. See 8-2-1 MC Unit Error Handling for details.

18

Page 34

Specifications Section 1-5

1-5 Specifications

1-5-1 General Specifications

The MC Unit provides the following general specifications.

Item Contents

Applicable Servo Driver R88D-W Series (software version 14 or later, see note)

Servomotors Type R88M-W Series

Encode r Incremental / Absolute

Installati on M ethod Mounted on the CN10 connector on the Servo Driver

side.

Basic Specificat ions Power Supply Method 5 VDC (supplied from the control power supply of the

Servo Driver)

24 VDC (supplied from ext ernal power supply)

Total Power Consumption 4.0 W

External Dimensions 20 x 142 x 128 mm (H x W x D)

Approx. Mass 200 g

Current Consumption 170 mA for 24 VDC

Output Power Supply 5 VDC, maximum 160 mA (to external encoder)

Environment Ambient Operating Tem-

perature

Ambient Operating

Humidity

Ambient Atmosphere Free from corrosive gasses

Ambient Storage Temper-

ature

Ambient Storage Humi dity 90 % RH or less (non-condensing)

Vibration Resistance 4.9 m/s

Impact Resistance Acceleration 19.6 m/s2 or less (when the impact is

0 to 55

°C

90 % RH or less (non-condensing)

-20 to 75

applied three times in each X, Y, Z direction )

°C

2

Note T he MC Unit cannot be used with software version 8.

1-5-2 Functional Specifications

The MC Unit provides the following functional specifications.

Item Contents

Type of Unit Optional board for W-series Servo Driv er

Motion Control Speed Control Inferred closed loop with PID , out put speed and speed

Torque Control Torque referen ce

Control Switch Speed / Torque control switching during operation

Configuration Maximum No. of axes 3

No. of contr olled servo

axes

Maximum No. of encoder

in- or output axes

Maximum No. of virtual

axes

Servo Loop Cycle Selectable to 0.5 ms or 1.0 ms.

Measurement Units User definabl e

feed forward gains

Speed reference (open loop)

Possi ble torque limit oper ation

Possi ble speed limit operation

1

1

2

19

Page 35

Specifications S ecti on 1-5

Item Contents

Positioning operations Linear interpolation Linear interpolation for any num ber of axes

Circular interpolation Circular interpolation for any two axes

CAM profile CAM profile movement for any axis

Electronic gearbox Electronic gearbox link between any two axes

Linked CAM Linked CAM profile movement for any two axes

Linked mo ve Linked move for any two ax es

Adding axes Adding any two axes

Acceleration/decelerati on curves Trapezoidal or S-curve

Servo Driver Access Motion Control Speed Control

Torque Control

Pos ition Feed-back

Driver Enable

Driver Print Registration

Monitoring Driver Alarm and Warning Status

General Driver Status

Driver Digital Input

Driver Analogue Input

Driver Limit Switches

General C o ntrol D r ive r A larm Reset

Driver Reset

Par am eter Access Read and Write Pn-paramet ers

Read U n p arameters

External connected devices Personal Computer with Motion Perfect Programming

Software

Serial Communications RS-232C Port 0:

Connection to PC (Motion Perfect Software)

Port 1:

Host Link Master pr otocol

Host Link Slave protocol

General-purpose

RS-422A/485 (MCW151E only)

External

I/O

Switch setting DeviceNet settings (MCW151-DRT-E only)

Power supply for general and axis I/O Provided externally

Encoder Input Line receiver input; maximum response frequency:

Encoder Output Line recei ve output; maximum frequency:

Digital Input s Total of 8 digital inputs can be wired and used for

Digital Outputs Total of 6 digital outputs can be wired and used for

Registrat ion inputs Two registration input s can be used (s imu ltaneo usly) t o

Port 2:

Host Link Master pr otocol

Host Link Slave protocol

General-purpose

1500 kHz pulses (before multip li cation)

Pulse multip l ic at io n :

x4

500 kHz pulses

Internal counts to output pulse ratio:

64 : 1

instance for limit switches, emergency stop and proximity inputs. Two inputs can be used for registration of

the encoder input /output axis.

position dependent switching or other general purposes.

capture the position in hardware .

General purpose (MCW151-E onl y)

20

Page 36

Comparison between Firmware Versions Section 1-6

Item Contents

Task program management

Saving program data MC Unit Random Access Memory (RAM) and Flash memory

Self diagnostic functions Detection of memory corruption via checksum

Programming language BASIC

Number of tasks Up to 3 tasks running simultaneously plus the Com-

mand Line task

Max. number of programs 14

Data storage capac it y 251 (VR) + 8000 (Table) max.

backup. (See note)

Personal Computer Motion Perfect software manages a backup on the

hard disk of the personal computer.

Detection of error counter overrun

Note The service life for the flash memory is 100,000 writing operations.

1-5-3 DeviceNet Specifications (MCW151-DRT-E only)

The MC Unit provides the following DeviceNet specifications.

Item Contents

Communications protocol DeviceNet

Supported connections (comm unications) Master-Slave: Remote I/O and explicit messages

Both conform to DeviceNet specifications

Connection forms (see note) Combination of multi-drop and T-branch connections

(for trunk or drop lines)

Baud rate 500 kbps, 250 kbps, 125 kbps (switchable)

Communications media Special 5-wire cables (2 signal lines, 2 power lines, 1

shield line)

Communications distances

Communications power supply 11 to 25 VDC (Supplied from the communications con-

500 kbps Network l ength: 100 m max. (100 m max.)

Drop line length: 6 m max.

Total drop li ne length: 39 m max.

250 kbps Network l ength: 250 m max. (100 m max.)

Drop line length: 6 m max.

Total drop li ne length: 78 m max.

125 kbps Network l ength: 500 m max. (100 m max.)

Drop line length: 6 m max.

Total drop li ne length: 156 m max.

Parentheses indicate the length when Thin Cables are used.

nector)

Note Terminating resistors are required at both ends of trunk line.

Refer to the DeviceNet Operation Manual (W267) for other communication

specifications, such as communication cycle times.

1-6 Comparison between Firmware Versions

The following table shows a comparison between the two current versions of

the R88A-MCW151-E and R88A-MCW151-DRT-E Motion Control Units. The

changes are only related to firmware (not hardware) and the firmware is common for both types. Verify the current version of the MC Unit using the VERSION parameter.

21

Page 37

Comparison between Firmware Versions Section 1-6

!Caution

Commands and

instructions

DeviceNet

(MCW151-DRT-E

only)

The R88A-MCW151-E FW 1.62 is fully backward compatible with the previous version FW 1.61. For the R88A-MCW151-DRT-E FW 1.62 many

DeviceNet implementation changes have been done. For both Units caution

must be taken when upgrading.

Item FW 1.61 FW 1.62

ADD_DAC No. Yes.

Command to enable dual feedback control.

Softwa re reset of

MC Unit

Explicit message s

(read and write)

Device object s - Update of Device objects.

Possible by either bit in

Remote I/O O u tp u t word 1 or

Explicit Message command

RESET.

Different maximum transfer

amount for re ad and writ e.

Po ssibl y o n ly by Ex p licit Message command RESET.

Maximum amount of el em ents

to transfer (read/write) is 39

(three-word format) and 119

(one-word format).

See 4-2-2 Explicit DeviceNet

Messages.

See Appendix B Devi ce Proto-

col (MCW151-DRT-E only).

22

Page 38

SECTION 2

Installation

This sectio n des cribes the MC Unit componen ts and provides the information required for installing the MC Unit.

2-1 Components and Unit Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2-2 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2-2-1 Installation Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2-2-2 Installation Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2-2-3 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2-3 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2-3-1 Control Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2-3-2 Serial Port Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2-3-3 DeviceNet Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2-3-4 I/O Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2-3-5 Connection examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2-4 Servo System Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2-5 Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

23

Page 39

Components and Unit Settings Secti on 2-1

2-1 Compone nts and Unit Sett ings

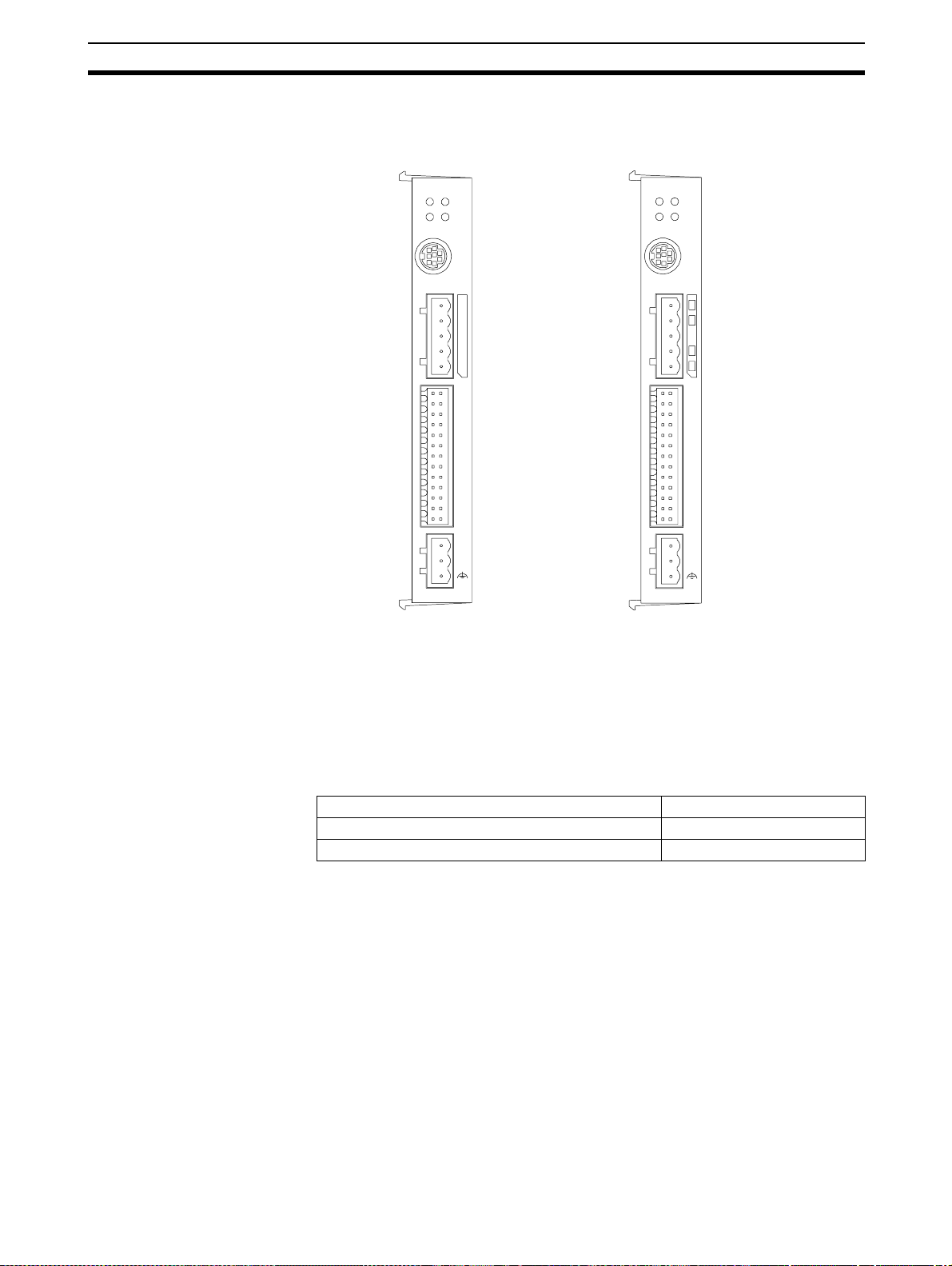

The following diagram shows the main components of the MC Unit.

Indicators

MCW151

RUN ST S

SD RD

Indicators

MCW 15 1 -DRT

RUNMSSTS

NS

RS-232C Ports

PORT 0 , 1

Connector

PORT 0 , 1

RS-422A/485 Port

Connector

25126

PORT2

2

I/O

+ 24V

0V

DeviceNet

Connector

I/O Connector

Power Connector

25126

2

I/O

+ 24V

0V

The following table describes the indicators on the front of the MC Unit.

■ Motion Control

Indicator Color Status Meaning

RUN Green ON The MC Unit is operating normally.

OFF The M C Unit did not s tart properly or is not pow-

ered on.

Flashing with

STS

STS Red ON The axis has been disabled. The Servo Enable

OFF The axis is enabled.

Flashing alone A motion error has occurred. The Servo Driver

Flashing with

RUN

An error occ urred in th e commu nicati on wit h the

Servo Driver.

is not ON.

has been disabled.

An error occ urred in th e commu nicati on wit h the

Servo Driver.

24

■ RS-422A/485 (MCW 151-E only)

Indicator Color Status Meaning

SD Green ON Transmitting data.

OFF No co mmunication.

RD Green ON Receiving data.

OFF No co mmunication.

Page 40

Components and Unit Settings Section 2-1

■ D eviceNet (MCW151-DRT-E only)

Indi

Color Status Definition Meaning

cator

MS Green ON Device

Operational

Flashing Device in

Standby

Red ON Unrecover-

able Fault

Flashing Minor Fault Switch settings incor rect.

--- OFF No Unit

Power

NS Green ON Link OK.

Online, Connected.

Flashing Online, Not

connected

Red ON Cr itical Link

Failure

Flashing Connection

Timeout

--- OFF No Fieldbus

Power / Not

Online

Normal operating status.

Reading switch settings.

Unit hardware error: Watchdog timer error.

Unit power is not supplied, waiting for initial

processing to st art, or the Unit is being reset.

Network is operating normally (communications established).

Network is operating normally, but communi cations have not yet been established.

A fatal communications error has occurred.

Network communications are not possible.

Communications timeout.

Checking for node address duplication on the

Master, switch sett ings are incorrect, or fieldbus powe r is not supplied.

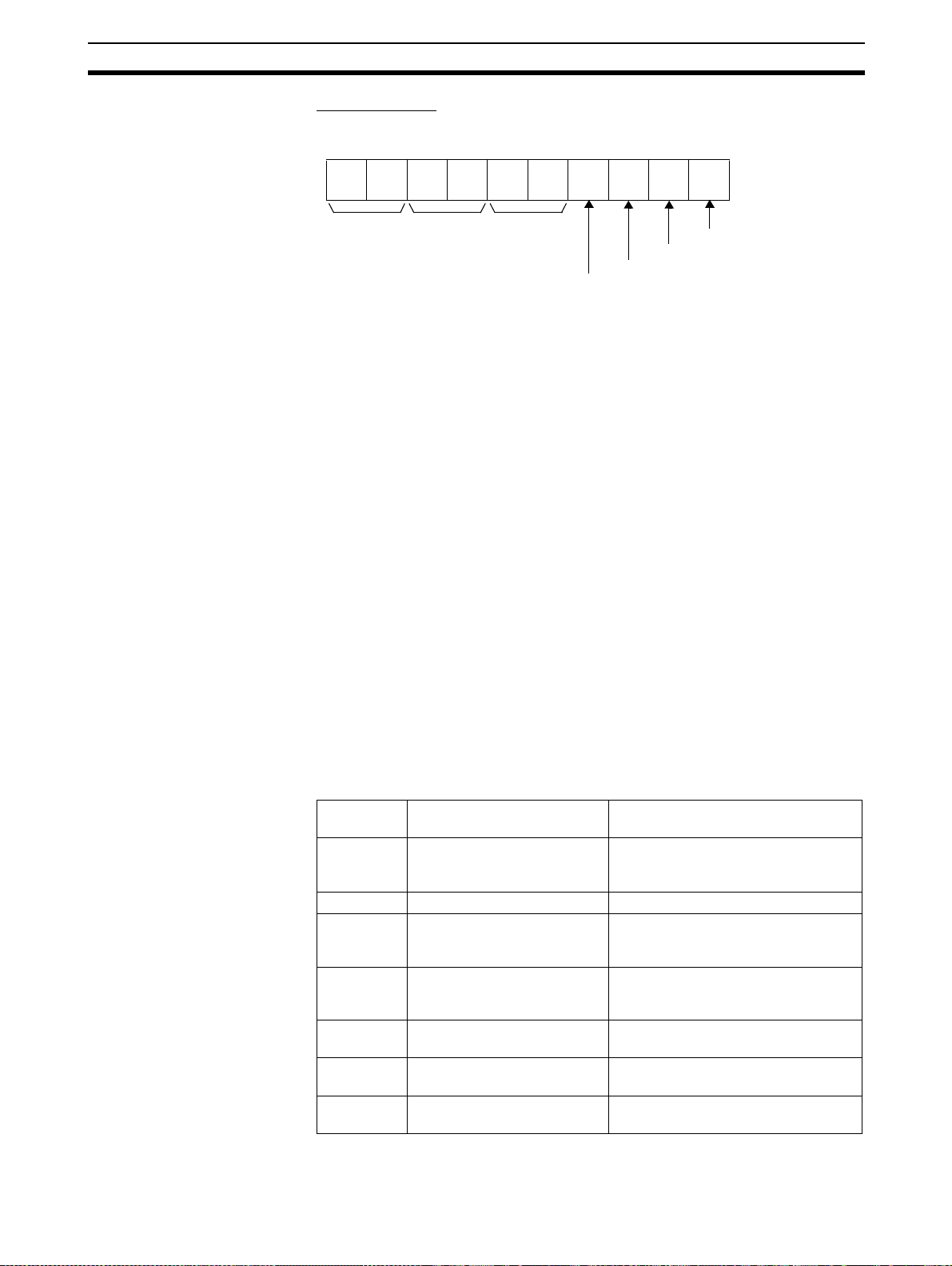

Switch Settings

The MCW151 Units are equipped with the following DIP-switches.

■ D eviceNet Switch Settings (MCW151-DRT-E only)

The external switch settings will set the Slaves’ node address setting and

baud rate setting.

ON

1 2

1 NA0

NA1

2

3

NA2

NA3

4

NA4

5

NA5

6

MD0

7

NC

8

DR0

9

DR1

10

ON

3

4

56

7

8910

Node address

The node addres s of the slave is set with pins 1 through 6 o f the DIP switch.

Any node address within the setting range can be used as long as it is not

already set on another node.

25

Page 41

Components and Unit Settings Section 2-1

DIP sw itch settin g Nod e ad dress

Pin 6 Pin 5 Pin 4 Pin 3 Pin 2 Pin 1

0000000 (default)

0000011

0000102

... ...

11110161

11111062

11111163

0: OFF, 1: ON

Baud rate

Pins 9 and 10 are used to set the baud rate as shown in the following table.

Pin 10 Pin 9 Baud rate

OFF OFF 125 kbps (default)

OFF ON 250 kbps

ON OFF 500 kbps

ON ON Not allowed

Note 1. Always turn OFF the MC Unit’s power supply (including the commu nica-

tions power supply) before changing the baud rate setting.

2. Set the same baud rate on all of the nodes (master and slaves) in t he Network.

Other settings