Omron NS12-TS01*-V1, NS15-TX01*-V2, NS12-TS01*-V2, NS10-TV00*-V1, NS10-TV00*-V2 Setup Manual

...Page 1

Programmable Terminals

NS-Series

NS15-TX01@-V2

NS12-TS00@-V1/-V2, NS12-TS01@-V1/-V2

NS10-TV00@-V1/-V2, NS10-TV01@ -V1/-V2

NS8-TV00@-V1/-V2, NS8-TV01@-V1/-V2

NS8-TV10@-V1, NS8-TV11@-V1

NS5-SQ00@-V1/-V2, NS5-SQ01@-V1/-V2

NS5-TQ00@-V2, NS5-TQ01@-V2

NS5-MQ00@-V2, NS5-MQ01@-V2

NS5-SQ10@-V2, NS5-SQ11@-V2

NS5-TQ10@-V2, NS5-TQ11@-V2

NS5-MQ10@-V2, NS5-MQ11@-V2

SETUP MANUAL

Cat. No. V083-E1-12

Page 2

Page 3

1

Notice

OMRON products are manufactured for use according to proper procedures by a

qualified operator and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual.

Always heed the information provided with them. Failure to heed precautions can result

in injury to people or damage to property.

! DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

! WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

! Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word "Unit" is also capitalized when it

refers to an OMRON product, regardless of whether or not it appears in the proper name of

the product.

The abbreviation "Ch," which appears in some displays and on some OMRON products, often

means "word" and is abbreviated "Wd" in documentation in this sense.

The abbreviation "PLC" means Programmable Controller.

The abbreviation "host" means a controller, such as an IBM PC/AT or compatible computer,

that controls a PT (Programmable Terminal).

Visual Aids

The following headings appear in the left column of the manual to help you locate different

types of information.

Precautions

for Safe Use

Indicates precautions on handling the product to ensure that the product is

used safely.

Precautions

for Correct Use

Indicates precautions to ensure that product functions and performances are

realized, to ensure that the reliability of the product is maintained, and to ensure

that the product is otherwise used correctly.

Note

Indicates information of particular interest for efficient and convenient operation

of the product.

Reference

Indicates supplementary information on procedures, descriptions, and settings.

1, 2, 3...

1. Indicates lists of one sort or another, such as procedures, checklists, etc.

CS1G-CPU@@-V1

Boxes in model numbers indicate variable characters. For example,

"CS1G-CPU@@-EV1" indicates the following models: CS1G-CPU42-EV1,

CS1G-CPU43-EV1, CS1G-CPU44-EV1, and CS1G-CPU45-EV1.

OMRON, 2003

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Page 4

2

Contents

Notice .............................................................................................................................................1

About this Manual...............................................................................................................................7

Related Manuals ..................................................................................................................................8

Terminology ........................................................................................................................................9

Introduction .......................................................................................................................................10

Section 1 Overview ................................................................................................. 1-1

1-1 NS-series PT Functions and Operation............................................................................................1-2

1-1-1 PT Functions for FA Manufacturing Sites ........................................................................... 1-2

1-1-2 NS-series PT Operating System........................................................................................... 1-3

1-2 Communications with the Host ....................................................................................................... 1-5

1-2-1 What is an NT Link?............................................................................................................ 1-6

1-2-2 Ethernet ................................................................................................................................ 1-6

1-2-3 Controller Link..................................................................................................................... 1-6

1-2-4 Host Link ............................................................................................................................. 1-6

1-2-5 Connecting to a Temperature Controller.............................................................................. 1-6

1-2-6 Memory Link Connections .................................................................................................. 1-7

1-2-7 Communicating with Other Devices.................................................................................... 1-7

1-2-8 EtherNet/IP .......................................................................................................................... 1-7

1-3 System Configuration...................................................................................................................... 1-8

1-3-1 Supported Peripheral Devices.............................................................................................. 1-8

1-4 Procedure for Running NS-series PTs........................................................................................... 1-10

Section 2 Before Connecting ................................................................................... 2-1

2-1 Connecting the Host ........................................................................................................................ 2-2

2-1-1 Communications Types and Connection Methods............................................................... 2-2

2-2 Part Names and Functions ............................................................................................................... 2-8

Section 3 Installing the PT and Connecting Peripheral Devices......................... 3-1

3-1 Installing the PT .............................................................................................................................. 3-3

3-1-1 Installation Environment...................................................................................................... 3-3

3-1-2 Installing RS-232C/RS-422A Converters ............................................................................ 3-4

3-1-3 Mounting the PT to the Control Panel ................................................................................. 3-4

3-1-4 Connecting the Power Supply.............................................................................................. 3-6

3-1-5 Wiring the Ground Wire ...................................................................................................... 3-7

3-1-6 Peripheral Device Connection Limitations .......................................................................... 3-7

3-2 Starting the PT ................................................................................................................................. 3-8

3-2-1 Operation at Startup ............................................................................................................. 3-8

3-2-2 Starting the PT for the First Time ...................................................................................... 3-10

3-3 Connecting the CX-Designer......................................................................................................... 3-12

3-3-1 Connecting via RS-232C or Ethernet................................................................................. 3-12

3-3-2 Connecting via USB........................................................................................................... 3-12

3-3-3 Connecting via a Modem ................................................................................................... 3-14

3-4 Connecting to Bar Code Readers................................................................................................... 3-15

3-4-1 Connection Methods .......................................................................................................... 3-15

3-4-2 Setting Bar Code Readers .................................................................................................. 3-16

Page 5

3

3-4-3 Data Format ....................................................................................................................... 3-17

3-4-4 Bar Code Input................................................................................................................... 3-17

3-5 Connecting to Printers ................................................................................................................... 3-18

3-5-1 Connecting to a Printer Compatible with ESC/P Raster and BJ Raster ............................. 3-18

3-5-2 Connecting a PictBridge-compatible Printer...................................................................... 3-19

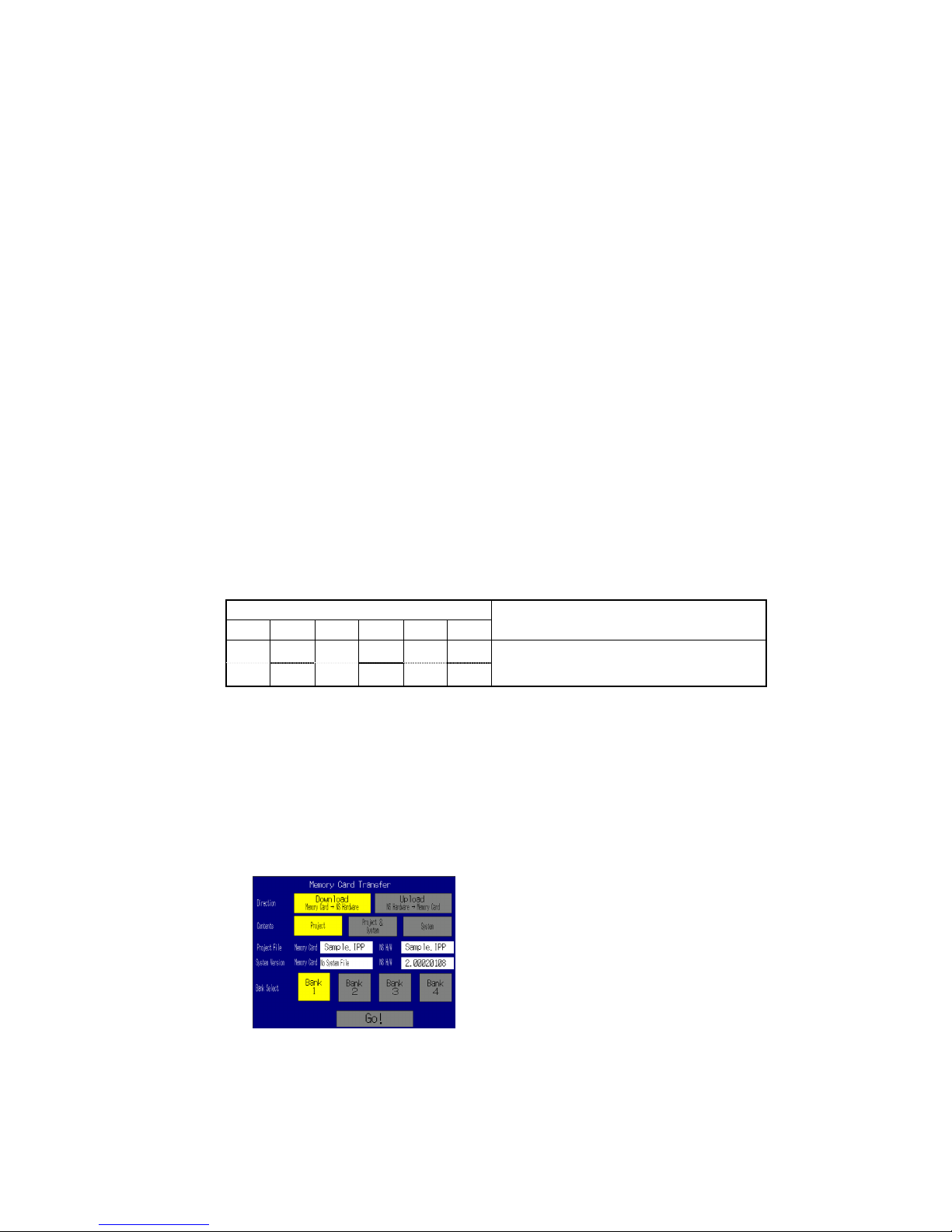

3-6 Using Memory Cards..................................................................................................................... 3-21

3-6-1 Installation.......................................................................................................................... 3-22

3-6-2 Replacing the System Program .......................................................................................... 3-23

3-6-3 Transferring Data with Memory Cards .............................................................................. 3-24

3-7 Installing the Video Input Unit ...................................................................................................... 3-30

3-7-1 Video Input Unit Components ........................................................................................... 3-30

3-7-2 Nomenclature and Functions.............................................................................................. 3-31

3-7-3 Installation Method for Video Input Unit .......................................................................... 3-32

3-7-4 Connecting to Video Input Connectors.............................................................................. 3-37

3-8 Installing the Controller Link Interface Unit ................................................................................. 3-42

3-8-1 Controller Link Interface Unit Components ...................................................................... 3-42

3-8-2 Nomenclature and Functions.............................................................................................. 3-43

3-8-3 Installation Method for Controller Link Interface Unit...................................................... 3-46

3-8-4 Wiring ................................................................................................................................ 3-53

3-9 Connecting a Monitor.................................................................................................................... 3-59

3-10 External Brightness Adjustment.................................................................................................... 3-60

3-11 RS-232C/RS-422A Selector DIP Switch....................................................................................... 3-61

Section 4 Connecting the Host to Serial Port........................................................ 4-1

4-1 1:1 Host Connection ........................................................................................................................ 4-2

4-1-1 Connection Methods ............................................................................................................ 4-2

4-1-2 Unit Setting Methods ........................................................................................................... 4-4

4-2 1:N Host Connection ....................................................................................................................... 4-7

4-2-1 Connection Methods ............................................................................................................ 4-7

4-2-2 Unit Setting Methods ........................................................................................................... 4-7

4-3 High-speed 1:N NT Link ............................................................................................................... 4-18

4-3-1 Unit Setting Methods ......................................................................................................... 4-19

4-4 Recommended Connector Cables.................................................................................................. 4-27

Section 5 Connecting to Host via Ethernet or Controller Link........................... 5-1

5-1 Connecting to Host Via Ethernet..................................................................................................... 5-2

5-1-1 Host Types and Settings....................................................................................................... 5-3

5-2 Connecting to the Host Using Controller Link.............................................................................. 5-17

5-2-1 What Is a Controller Link Network?.................................................................................. 5-17

5-2-2 Data Links.......................................................................................................................... 5-18

5-2-3 Troubleshooting Using Indicators...................................................................................... 5-23

5-3 Connecting to Host via EtherNet/IP ..............................................................................................5-26

5-3-1 What is EtherNet/IP? ......................................................................................................... 5-26

5-3-2 Setting Individual Units ..................................................................................................... 5-27

Section 6 System Menu Operations ....................................................................... 6-1

6-1 Operating Modes and System Menu................................................................................................ 6-3

6-1-1 Mode Configuration............................................................................................................. 6-3

Page 6

4

6-1-2 System Menu Configuration ................................................................................................ 6-3

6-1-3 Overview of Menu Items ..................................................................................................... 6-4

6-1-4 Using the System Menu ....................................................................................................... 6-7

6-2 Initializing and Saving Data and Removing the Memory Card..................................................... 6-10

6-2-1 Screen Data Area Format ................................................................................................... 6-11

6-2-2 Initializing or Saving the Alarm/Event History ................................................................. 6-12

6-2-3 Initializing and Saving Data Log ....................................................................................... 6-14

6-2-4 Initializing and Saving the Operation Log ......................................................................... 6-15

6-2-5 Initializing and Saving the Error Log................................................................................. 6-17

6-2-6 Language Selection ............................................................................................................ 6-18

6-2-7 Removing the Memory Card.............................................................................................. 6-19

6-2-8 Initializing Internal Holding Memories ($HB/$HW)......................................................... 6-20

6-3 PT Settings .................................................................................................................................... 6-21

6-3-1 Start-up Wait Time............................................................................................................. 6-23

6-3-2 Screen Saver....................................................................................................................... 6-24

6-3-3 Key Press Sound ................................................................................................................ 6-25

6-3-4 Buzzer Sound ..................................................................................................................... 6-25

6-3-5 Backlight Brightness .......................................................................................................... 6-26

6-3-6 Calendar Check ..................................................................................................................6-27

6-3-7 Printer Type ....................................................................................................................... 6-28

6-3-8 Printing Mode .................................................................................................................... 6-28

6-3-9 Orientation ......................................................................................................................... 6-29

6-3-10 Changing Values in Device Monitor Setting ..................................................................... 6-29

6-3-11 Contrast (NS5-SQ@@/NS5-MQ@@ Only) ....................................................................... 6-29

6-3-12 CJK Han Unification Priority............................................................................................. 6-30

6-3-13 Alarm Monitor Registration Procedure.............................................................................. 6-30

6-3-14 Starting the Ladder Monitor from Alarm/Event Summary and History

(NS15/12/10/8 Only) ......................................................................................................... 6-30

6-3-15 Setting the Tag Update Notification Message.................................................................... 6-31

6-3-16 Time to Switch to System Menu (NS12, NS10, NS8, or NS5).......................................... 6-31

6-3-17 Double-touch Interval (NS15 Only)................................................................................... 6-32

6-3-18 Analog RGB Output (NS15 only)...................................................................................... 6-32

6-4 Project Settings .............................................................................................................................. 6-33

6-4-1 Project Title........................................................................................................................ 6-33

6-4-2 Number of Labels............................................................................................................... 6-34

6-4-3 Initial Screen ...................................................................................................................... 6-34

6-4-4 Initial Label........................................................................................................................ 6-34

6-4-5 Alarm/Event History Recording Method ........................................................................... 6-34

6-4-6 Data Log Recording Method.............................................................................................. 6-34

6-4-7 Operation Log Recording Method ..................................................................................... 6-35

6-4-8 Error Log Recording Method............................................................................................. 6-35

6-4-9 System Memory ................................................................................................................. 6-35

6-5 Setting Passwords .......................................................................................................................... 6-36

6-5-1 Changing the Password...................................................................................................... 6-36

6-5-2 Setting the Password Function ........................................................................................... 6-37

Page 7

5

6-6 Communications Settings .............................................................................................................. 6-39

6-6-1 Communications Conditions.............................................................................................. 6-39

6-6-2 Setting 1:1 NT Link ........................................................................................................... 6-41

6-6-3 Setting High-speed 1:N NT Links (Standard, High-speed)................................................ 6-42

6-6-4 Setting Ethernet.................................................................................................................. 6-42

6-6-5 Setting the Controller Link Network.................................................................................. 6-45

6-6-6 Setting Bar Code Readers .................................................................................................. 6-46

6-6-7 Modem Settings ................................................................................................................. 6-47

6-7 Screen Data Check ........................................................................................................................ 6-48

6-8 Special Screens .............................................................................................................................. 6-49

6-8-1 Alarm History .................................................................................................................... 6-50

6-8-2 Operation Log .................................................................................................................... 6-51

6-8-3 Error Log............................................................................................................................ 6-52

6-8-4 Device Monitor ..................................................................................................................6-53

6-8-5 Communication Test .......................................................................................................... 6-55

6-8-6 Video Configuration .......................................................................................................... 6-57

6-8-7 USB Device List ................................................................................................................ 6-59

6-8-8 Display Capture Data ......................................................................................................... 6-60

6-8-9 Memory Card Transfers ..................................................................................................... 6-61

6-8-10 External Application Startup.............................................................................................. 6-63

6-8-11 Version Display .................................................................................................................6-64

6-8-12 PLC Data Trace (NS15, NS12, NS10, and NS8 Only) ...................................................... 6-64

6-9 Hardware Check ............................................................................................................................ 6-66

6-9-1 LCD Check ........................................................................................................................ 6-66

6-9-2 Touch Switch Check .......................................................................................................... 6-67

6-9-3 Touch Panel Calibration (NS15 Only) ............................................................................... 6-67

6-10 Starting Operations........................................................................................................................ 6-68

6-11 Verifying Tags............................................................................................................................... 6-70

Section 7 Maintenance and Troubleshooting........................................................ 7-1

7-1 Maintenance .................................................................................................................................... 7-2

7-1-1 Replacing the Battery...........................................................................................................7-2

7-2 Inspection and Cleaning .................................................................................................................. 7-4

7-3 Troubleshooting and Maintenance .................................................................................................. 7-6

7-4 Requesting a Replacement PT ....................................................................................................... 7-14

Appendices .................................................................................................................. A-1

Appendix 1 Specifications .......................................................................................................................A-3

A-1-1 General Specifications .........................................................................................................A-3

A-1-2 Characteristics......................................................................................................................A-5

A-1-3 Communications Specifications...........................................................................................A-8

Appendix 2 Dimensions ........................................................................................................................A-11

Appendix 3 Using NS-AL002 Converters.............................................................................................A-20

A-3-1 Dimensions ........................................................................................................................A-20

A-3-2 Mounting and Removing ...................................................................................................A-21

A-3-3 Specifications.....................................................................................................................A-21

A-3-4 DIP Switch Settings ...........................................................................................................A-22

Page 8

6

A-3-5 Pin Arrangement ................................................................................................................A-23

A-3-6 Handling the Shield on RS-422A/485 Cables....................................................................A-24

A-3-7 Connection Example ..........................................................................................................A-27

Appendix 4 Using NT-AL001 Converters.............................................................................................A-28

A-4-1 Dimensions ........................................................................................................................A-28

A-4-2 Methods for Mounting and Removal .................................................................................A-28

A-4-3 Specifications.....................................................................................................................A-30

A-4-4 DIP Switch Settings ...........................................................................................................A-31

A-4-5 Pin Arrangement ................................................................................................................A-32

A-4-6 Block Diagram...................................................................................................................A-33

Appendix 5 Preparing Connecting Cables .............................................................................................A-34

A-5-1 Cable Preparation...............................................................................................................A-34

A-5-2 Soldering............................................................................................................................A-35

A-5-3 Hood Assembly..................................................................................................................A-35

A-5-4 Preparing Connecting Cables for Host Connection ...........................................................A-36

Appendix 6 Preparing Cables for Computer Connection ......................................................................A-40

A-6-1 Connecting Cable Assembly..............................................................................................A-40

Appendix 7 Preparing Connecting Cables for Bar Code Readers .........................................................A-42

Appendix 8 Standard Models ................................................................................................................A-43

Appendix 9 List of Optional Products ...................................................................................................A-58

A-9-1 Anti-reflection Sheets: NS15-KBA04, NS12-KBA04, NS7-KBA04, NT30-KBA04 .......A-58

A-9-2 Protective Covers: NS12-KBA05(N), NS7-KBA05(N), NT31C-KBA05(N) ...................A-59

A-9-3 NT30-KBA01 Chemical-resistant Cover ...........................................................................A-60

A-9-4 Replacement Battery: CJ1W-BAT01.................................................................................A-60

A-9-5 Recommended Memory Cards...........................................................................................A-61

A-9-6 NS-CLK21 Controller Link Interface Unit ........................................................................A-61

A-9-7 NS-CA001/CA002 Video Input Unit.................................................................................A-61

A-9-8 Attachments: NS12-ATT01(B)/NS12-ATT02/NS8-ATT01/NS8-ATT02 ........................A-61

A-9-9 NS-USBEXT-1M USB Relay Cable..................................................................................A-62

Appendix 10

System Memory List ......................................................................................................A-63

Appendix 11 Differences between "-V1"/"-V2" Models and Other Models .......................................A-66

Appendix 12 NS5 System Menu..........................................................................................................A-68

Page 9

7

About this Manual

Section 1 Overview

This section provides an overview of the NS-series PTs, including functions, features, connection types, and

communications methods.

Section 2 Before Connecting

This section provides information on methods for connecting NS-series PTs that must be understood before connecting

the host and peripheral devices.

Section 3 Installing the PT and Connecting Peripheral Devices

This section describes the methods used to install the PT and connect peripheral devices.

Section 4 Connecting Host to Serial Port

This section describes the methods for connecting the host to the serial port of the PT.

Section 5 Connecting to Host via Ethernet or Controller Link

This section describes the methods for connecting the PT to the host using the PT’s Ethernet interface and the

Controller Link Interface Unit.

Section 6 System Menu Operations

This section describes the methods for operating the System Menu. It also provides details on functions that are useful

for NS-series PT applications and for system maintenance.

Section 7 Maintenance and Troubleshooting

This section describes the maintenance and inspection methods for preventing errors occurring, and troubleshooting

measures when errors occur in the PT.

Appendices

Describe hardware specifications and methods for preparing connections cables, and provide lists of standard

products.

WARNING

Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section in its entirety and be sure you understand the information provided in the section

and related sections before attempting any of the procedures or operations given.

Page 10

8

Related Manuals

The following manuals are used for NS-series PTs. (The boxes at the end of the catalog

numbers indicate the revision code.)

NS Series -V1/-V2 Setup Manual ...............................................V083-E1-@

Provides information on NS Series V1 and V2 PTs (i.e., NS15-V2, NS12-V@, NS10-V@,

NS8-V

@, and NS5-V@).

Describes how to connect the PT to the host and peripheral devices, methods to setup

communications and operation, and procedures for maintenance.

Refer to the NS Series Programming Manual (V073-E1-

@) for information on PT

functions and specific operating procedures.

NS Series Setup Manual ............................................................V072-E1-@

Provides information on NS Series PTs prior to V1 (i.e., NS12, NS10, and NS7).

Describes how to connect the PT to the host and peripheral devices, methods to setup

communications and operation, and procedures for maintenance.

Refer to the NS Series Programming Manual (V073-E1-

@) for information on PT

functions and specific operating procedures.

NS Series Programming Manual ................................................V073-E1-@

Describes the screen configurations, object functions, and host communications for the

PT.

CX-Designer User’s Manual .......................................................V099-E1-@

The screens displayed on the PT can be created in the CX-Designer and transferred

between the CX-Designer and PT. This manual describes the installation and features

of the CX-Designer. For details on CX-Designer operations, refer to the CX-Designer’s

Online Help.

This

manual

Page 11

9

Terminology

The following terminology is used in this manual.

PT In this manual, indicates an NS-series Programmable Terminal.

NS Series

Indicates products in the OMRON NS@@ Series of Programmable Terminals.

PLC Indicates a Programmable Controller in the OMRON SYSMAC CS/CJ, C, or

CVM1/CV Series of Programmable Controllers.

CS/CJ Series Indicates Programmable Controllers in the OMRON SYSMAC CS/CJ Series of

Programmable Controllers: CS1G, CS1H, CS1G-H, CS1H-H, CJ1G, CJ1G-H,

CJ1H-H, CJ1M, CP1H, CP1L, CJ2H.

In this manual, “CJ1H-H” indicates the CJ1H-CPU@@H-R and CJ1H-CPU@@H

CPU Units. “CJ1H-H-R” is used to indicate only the CJ1H-CPU @@H-R CPU Units.

The “CP Series” is used to indicate only the CP1H and CP1L.

C Series Indicates products in the OMRON SYSMAC C Series of Programmable Controllers:

C200HS, C200HX(-Z), C200HG(-Z), C200HE(-Z), CQM1, CQM1H, CPM1A,

CPM2A, CPM2C.

CVM1/CV Series Indicates products in the OMRON SYSMAC CVM1/ CV Series of Programmable

Controllers: CV500, CV1000, CV2000, CVM1

Serial Communications Unit Indicates a Serial Communications Unit for an OMRON CS/CJ-series PLC.

Serial Communications Board Indicates a Serial Communications Board for an OMRON CS-series or CQM1H

PLC.

Communications Board Indicates a Communications Board for an OMRON C200HX/HG/HE(-Z) PLC.

CPU Unit Indicates a CPU Unit in the OMRON SYSMAC CS/CJ, C, or CVM1/CV Series of

Programmable Controllers.

CX-Designer

Indicates the OMRON CX-Designer (NS-CXDC1-V@).

Host Indicates the PLC, IBM PC/AT or compatible computer, or personal computer

functioning as the control device and interfaced with the NS-series PT.

Programming Manual

Indicates the NS Series Programming Manual (V073-E1-@).

Page 12

10

Introduction

• Intended Audience

This manual is intended for the following personnel, who must also have knowledge of

electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems into production facilities.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and connecting FA systems.

• Personnel in charge of managing FA systems and facilities.

• General Precautions

• The user must operate the product according to the performance specifications

described in the operation manuals.

• Do not use the PT touch switch input functions for applications where danger to human

life or serious property damage is possible, or for emergency switch applications.

• Before using the product under conditions which are not described in the manual or

applying the product to nuclear control systems, railroad systems, aviation systems,

vehicles, combustion systems, medical equipment, amusement machines, safety

equipment, and other systems, machines and equipment that may have a serious

influence on lives and property if used improperly, consult your OMRON representative.

• Make sure that the ratings and performance characteristics of the product are sufficient

for the systems, machines, and equipment, and be sure to provide the systems,

machines, and equipment with double safety mechanisms.

• This manual provides information for connecting and setting up an NS-series PT. Be

sure to read this manual before attempting to use the PT and keep this manual close at

hand for reference during installation and operation.

Page 13

11

Safety Precautions

Notation Used for Safety Information

The following notation is used in this manual to provide precautions required to ensure safe

usage of the product.

The safety precautions that are provided are extremely important to safety.

Always read and heed the information provided in all safety precautions.

The following notation is used.

! WARNING

Indicates a potentially hazardous situation which, if not avoided,

will result in minor or moderate injury, or may result in serious injury

or death. Additionally there may be significant property damage.

Symbols

Prohibition

Indicates a general prohibition

Caution

Indicates general cautionary, warning, or

danger level information

Always ensure that the personnel in charge confirm

that installation, inspection, and maintenance were

properly performed for the PT. “Personnel in charge”

refers to individuals qualified and responsible for

ensuring safety during machine design, installation,

operation, maintenance, and disposal.

Ensure that installation and post-installation checks

are performed by personnel in charge who possess

a thorough understanding of the machinery to be

installed.

Do not use the input functions of the PT, such as the

function switches or switches on the touch panel, in

applications that involve human life, in applications

that may result in serious injury, or for emergency

stop switches.

Do not attempt to disassemble, repair, or modify the

PT. Doing so may impair the safety functions.

Do not attempt to take the Unit apart and do not

touch any internal parts while the power is being

supplied. Doing either of these may result in

electrical shock.

The NS15-TX01@-V2 uses an analog touch panel.

Never press more than two points on the panel at a

time. Otherwise, it may activate a switch somewhere

between the two points.

Page 14

12

Precautions for Safe Use

1. When unpacking the Units, check carefully for any external scratches or other damage.

Also, shake the Units gently and check for any abnormal sound.

2. The PT must be installed in a control panel.

3. The mounting panel must be between 1.6 and 4.8 mm thick. Tighten the Mounting

Brackets evenly to a torque of between 0.5 and 0.6 N⋅m to maintain water and dust

resistance. Make sure the panel is not dirty or warped and that it is strong enough to hold

the Units.

4. Do not let metal particles enter the Units when preparing the panel.

5. Do not connect an AC power supply to the DC power input terminals.

6. Use a DC power supply with minimal voltage fluctuation that provides a stable output even

if the power supply input is interrupted for 10 ms. The DC power supply must also have

reinforced or double insulation.

Rated power supply voltage: 24 VDC (Allowable range: 20.4 to 27.6 VDC)

Capacity: NS15: 45 W min.

NS12, NS10, or NS8: 25 W min.

NS5: 15 W min.

7. Do not perform a dielectric voltage test.

8. Use a twisted-pair cable with a cross-sectional area of at least 2 mm

2

to connect to the

power terminals and always use M3.5 crimp terminals. Tighten the terminal screws to a

torque of 0.8 N⋅m. Make sure the screws are properly tightened.

9. Ground the Unit correctly to prevent operational errors caused by noise.

10. Do not touch the surface of the circuit board or the components mounted on it with your

bare hands. Discharge any static electricity from your body before handling the board.

11. Confirm that the current capacity of the connected device is 250 mA or less before using

the 5-V power supply from pin 6 of the RS-232C connector. The 5-V output from the PT is

250 mA max. at 5 V ±5%.

12. Turn OFF the power supply before connecting or disconnecting cables.

13. Always tighten the connector screws after connecting communications cables.

14. The maximum tensile load for cables is 30 N. Do not apply loads greater than this.

15. Confirm the safety of the system before turning ON or OFF the power supply or before

pressing the reset button.

16. The whole system may stop depending on how the power supply is turned ON or OFF. Turn

ON or OFF the power supply according to the specified procedure.

17. After changing the settings of the DIP switch, always turn the power supply OFF and ON or

reset the PT.

18. Do not perform the following operations while the Memory Card is being accessed:

• Turning OFF the power supply to the PT

• Pressing the PT’s reset switch

• Removing the Memory Card

19. To ensure system safety, incorporate a program that periodically calls PT operation bits

from the host side to check that the PT is properly operating.

20. Start actual system application only after sufficiently checking screen data, macros, and

the operation of the program in the host.

21. Do not press a touch switch with a force greater than 30 N.

22. Do not operate a touch switch using a screwdriver or other tool.

23. Confirm the safety of the system before pressing a touch switch.

24. Do not press touch switches consecutively without pausing in between. If touch switches

are pressed consecutively at high speed, the PT may not be able to detect the inputs.

Confirm that the PT has detected the input of a touch switch before pressing any other

touch switch.

25. Do not accidentally press touch switches when the backlight is not lit or when the display

does not appear. Confirm the safety of the system before pressing touch switches.

26. To ensure safety when using numeral input functions, set the upper and lower limits for the

input value.

Page 15

13

27. Before initializing screen data, confirm that existing data is backed up at the CX-Designer.

28. W hen changing the password with the system menu, do not reset or turn OFF the power

supply until writing is finished.

29. W hen using the device monitor, confirm the safety of the system before performing the

following operations.

• Changing monitor data

• Changing operation modes

• Forced setting or resetting

• Changing present values or set values

30. Dispose of any battery that has been dropped on the floor or otherwise subjected to

excessive shock.

31. Do not connect an USB connector to any device that is not applicable.

32. Before connecting an USB connector to a device, make sure that the device is free of

damage.

33. Commercially available USB hubs and the recommended USB hub do not necessarily

have the same general specifications as the PT, and may not function properly if used in

environments subject to static electricity or other forms of noise. W hen using a USB hub,

take sufficient measures to prevent static electricity and other forms of noise, or do not

install the PT in an environment subject to such noise.

34. Do not perform the following operations while downloading or uploading screen data or

system program. Doing so may corrupt the screen data or system program.

• Turning OFF the power supply to the PT

• Pressing the PT’s reset switch

35. W hen mounting the Battery, be sure to use the correct Battery and mount it correctly.

36. Do not disassemble or short-circuit the battery.

37. Dispose of the Units and batteries according to local ordinances as they apply.

38. Never use volatile solvents, such as benzene or thinners, or chemical dusters to clean the

PT.

39. The backlight in the NS-series PT contains mercury. Do not dispose of the PT together with

waste to be processed at disposal plants. Dispose of the PT according to all local laws,

regulations, and ordinances.

40. The backlight in the PT cannot be replaced by the user. Contact your OMRON

representative for backlight replacement.

41. Periodically check the installation conditions in applications where the PT is subject to

contact with oil or water.

42.

The NS15-TX01@-V2 uses an analog touch panel. Deterioration over time can cause the

touch points to move. If the touch points move too far, calibrate the touch panel.

43. Never connect more than two crimp terminals to one terminal.

44. Water and oil resistance will be lost if the front sheet is torn or is peeling off. Do not use

the PT if the front sheet is torn or is peeling off.

45. The Rubber Packing will deteriorate, shrink, expand, or harden depending on the

operating environment. Inspect and replace the Rubber Packing periodically.

Page 16

14

Precautions for Correct Use

1. Do not install the Unit in the following places:

• Locations subject to severe changes in temperature.

• Locations subject to direct sunlight

• Locations subject to temperatures or humidity outside the range specified in the

specifications

• Locations subject to condensation as the result of high humidity

• Locations subject to corrosive or flammable gases

• Locations subject to shock or vibration

• Outdoor locations directly subject to wind or rain

• Locations subject to strong ultraviolet light

•

Locations subject to excessive dust

•

Locations subject to direct sunlight

2. Take appropriate and sufficient countermeasures when installing systems in the following

locations:

• Locations subject to static electricity or other forms of noise

• Locations subject to strong electromagnetic fields

• Locations close to power supplies

• Locations subject to possible exposure to radioactivity

Page 17

15

Conformance to EC Directives

This product is EMC compliant.

• Concepts

OMRON products are electronic devices that are incorporated in machines and manufacturing

installations. OMRON PTs conform to the related EMC Directives (see note) so that the

devices and machines into which they are built can more easily conform to EMC directives.

However, customers may use a wide variety of equipment and manufacturing installations.

Therefore the customer must check whether the Directives are satisfied for the actual system.

EMC-related performance will vary depending on the configuration, wiring, and other

conditions of the equipment or control panel in which the PT is installed. The customer must,

therefore, perform final checks to confirm that the overall machine or device conforms to EMC

standards.

Note: Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN 61131-2

EMI (Electromagnetic Interference): EN 61131-2

(EN 61131-2 radiated emission: 10-m regulations)

• Conformance to EC Directives

NS-series PTs conform to EC Directives. To ensure that the machine or device in which the

NS-series PT is used complies with EC Directives, the PT must be installed as follows:

• The NS-series PT must be installed in a control panel.

• You must use reinforced insulation or double insulation for the DC power supply and the

DC power supply must have minimal voltage fluctuations and provide a stable output

even if the power supply input is interrupted for 10 ms.

• NS-series PTs complying with EC Directives also conform to the Common Emission

Standard (EN 61131-2). Radiated emission characteristics (10-m regulations) may vary

depending on the configuration of the control panel used, other devices connected to the

control panel, wiring, and other conditions. You must therefore confirm that the overall

machine or equipment complies with EC Directives.

• This is a class A product. It may cause radio interference in residential areas, in which

case the user may be required to take adequate measures to reduce interference.

Page 18

16

Conformance to Shipbuilding Standards

This product conforms to shipbuilding standards with the exception of the NS15. The

shipbuilding standards have conditions that may make them unusable depending on the

location in which the PT is installed. When using a PT on a ship, be sure to contact your

OMRON sales representative.

Shipping Standards (NK, LR, ABS, BV, DNV, KR)

Conditions for Use in Locations Other Than the Bridge or Deck

• The NS-series PT must be installed in a control panel.

• The control panel must be equipped with an air conditioner.

• The entire surface of the NS-series PT must be covered with electromagnetic shielding

that is also grounded using conductive tape (e.g., copper tape).

• Gaps in the door of the control panel must be completely filled or covered with gaskets or

other material.

• Gaps between the PT and the panel cutout must be completely covered with conductive

tape, such as copper tape, and the PT must be secured using mounting brackets.

Conditions for Use on the Bridge (Class NK Certification Only)

• The NS-series PT must be installed in a control panel.

• The control panel must be equipped with an air conditioner.

• The entire surface of the NS-series PT must be covered with electromagnetic shielding

that is also grounded using conductive tape (e.g., copper tape).

• Gaps in the door of the control panel must be completely filled or covered with gaskets or

other material.

• Gaps between the PT and the panel cutout must be completely covered with conductive

tape, such as copper tape, and the PT must be secured using mounting brackets.

• The following noise filter must be connected to the 0 to 24 VDC power line.

Electromagnetic Shielding

Manufacturer SEIWA ELECTRIC MFG, Co., Ltd.

Model E09F-100, E09R13502P

* Electromagnetic shielding reduces the permeability by approximately 50%.

Noise Filter

Manufacturer Cosel

Model TAH-06-683

Page 19

17

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on

which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Page 20

18

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

Page 21

19

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

Page 22

20

Page 23

Section 1

Overview

This section provides an overview of the NS-series PTs, including functions, features, connection

types, and communications methods.

1-1

NS-series PT Functions and Operation............................................................................ 1-2

1-1-1 PT Functions for FA Manufacturing Sites................................................................. 1-2

1-1-2 NS-series PT Operating System ................................................................................ 1-3

1-2 Communications with the Host........................................................................................ 1-5

1-2-1 What is an NT Link? ................................................................................................. 1-6

1-2-2 Ethernet ..................................................................................................................... 1-6

1-2-3 Controller Link .......................................................................................................... 1-6

1-2-4 Host Link................................................................................................................... 1-6

1-2-5 Connecting to a Temperature Controller ................................................................... 1-6

1-2-6 Memory Link Connections........................................................................................ 1-7

1-2-7 Communicating with Other Devices ......................................................................... 1-7

1-2-8 EtherNet/IP................................................................................................................ 1-7

1-3 System Configuration...................................................................................................... 1-8

1-3-1 Supported Peripheral Devices ................................................................................... 1-8

1-4 Procedure for Running NS-series PTs........................................................................... 1-10

Page 24

1-1 NS-series PT Functions and Operation

1-2

1-1 NS-series PT Functions and Operation

The NS Series offers advanced operator interfaces called Programmable Terminals that can

be used to display required information and provide operating capabilities for FA manufacturing sites. This section describes the role and functions of the NS-series PTs for first-time

users of Programmable Terminals.

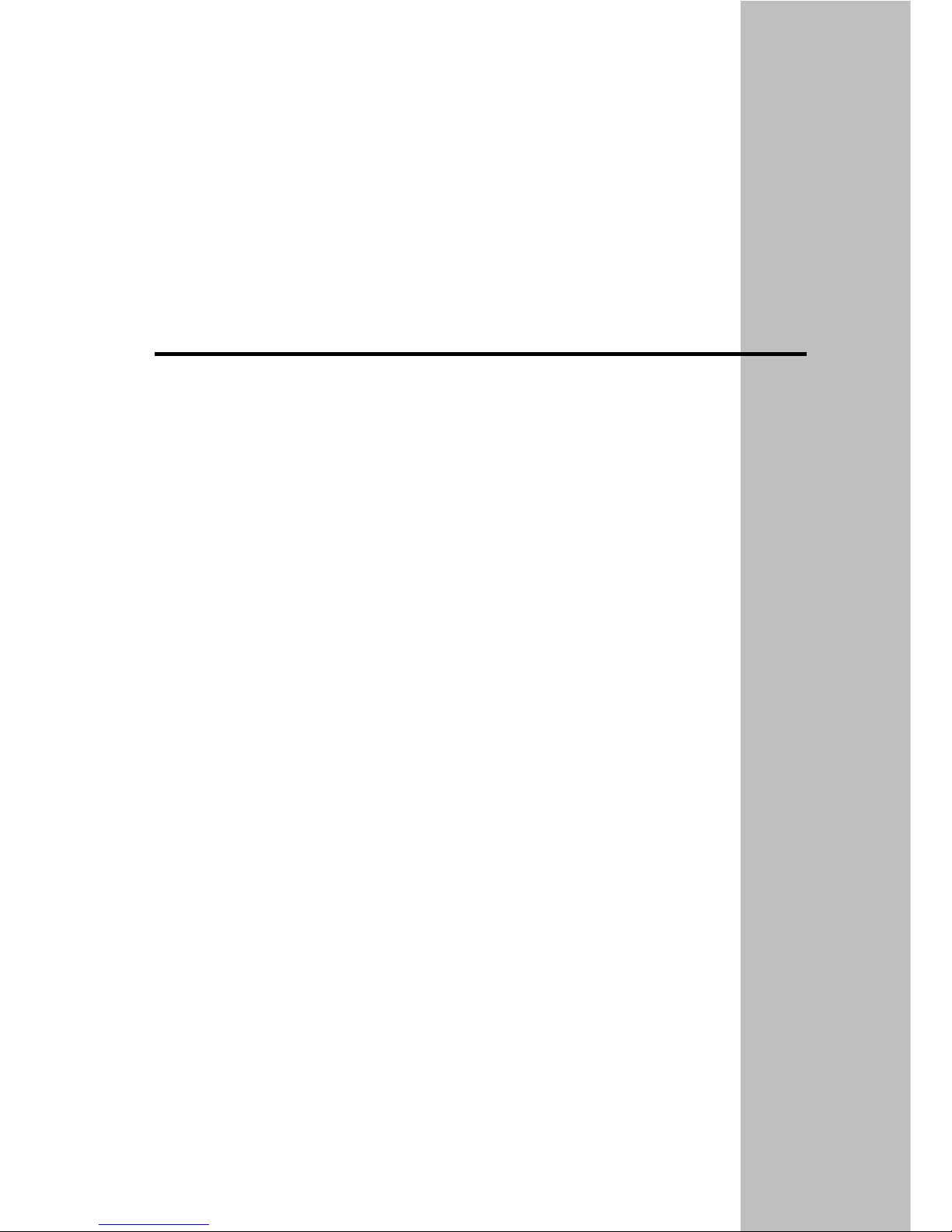

1-1-1 PT Functions for FA Manufacturing Sites

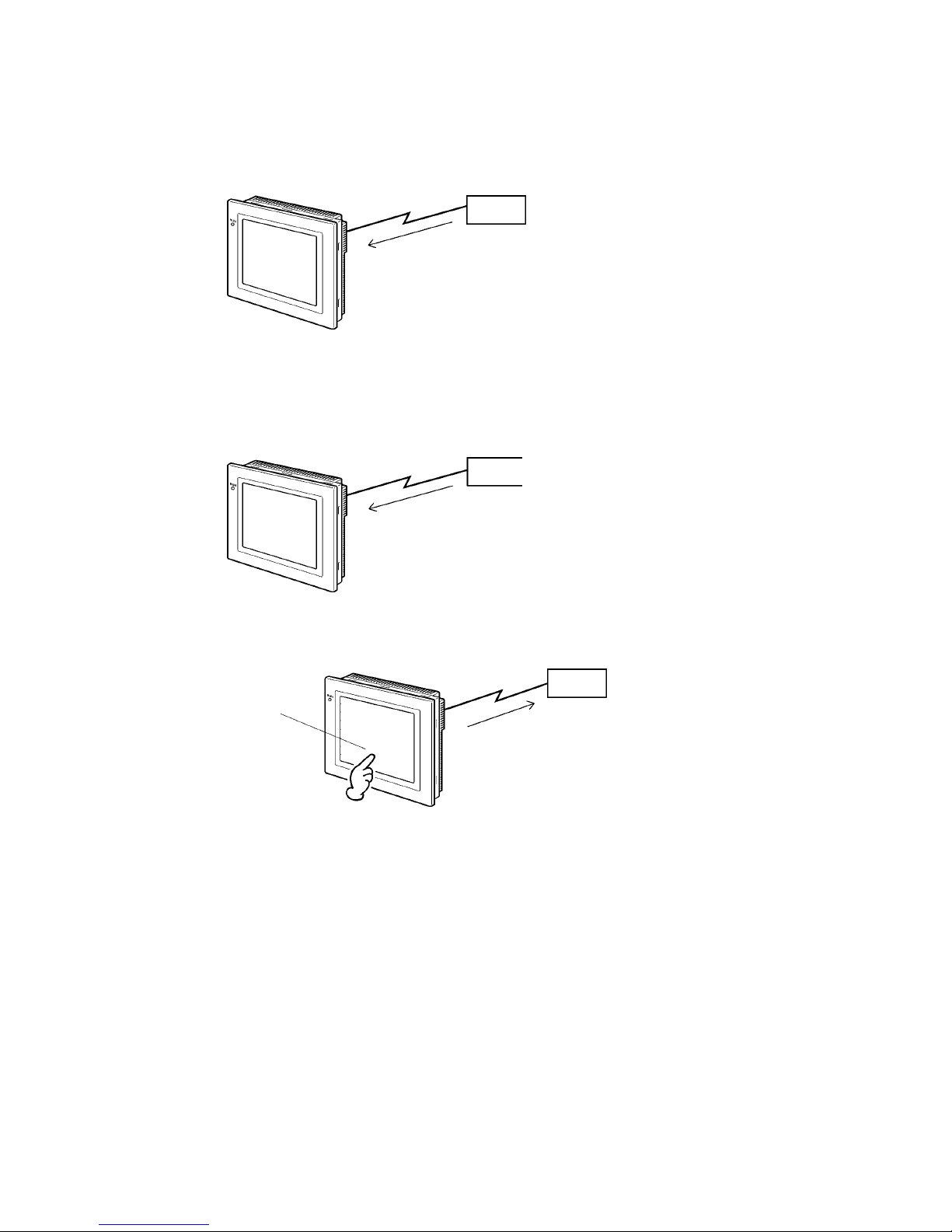

Line Operating Status Monitor Display

NS-series PTs can be used to display information such as the operating status of the system

and the devices. Graphs and other indicators can be used to better represent the information

and make it easy to understand.

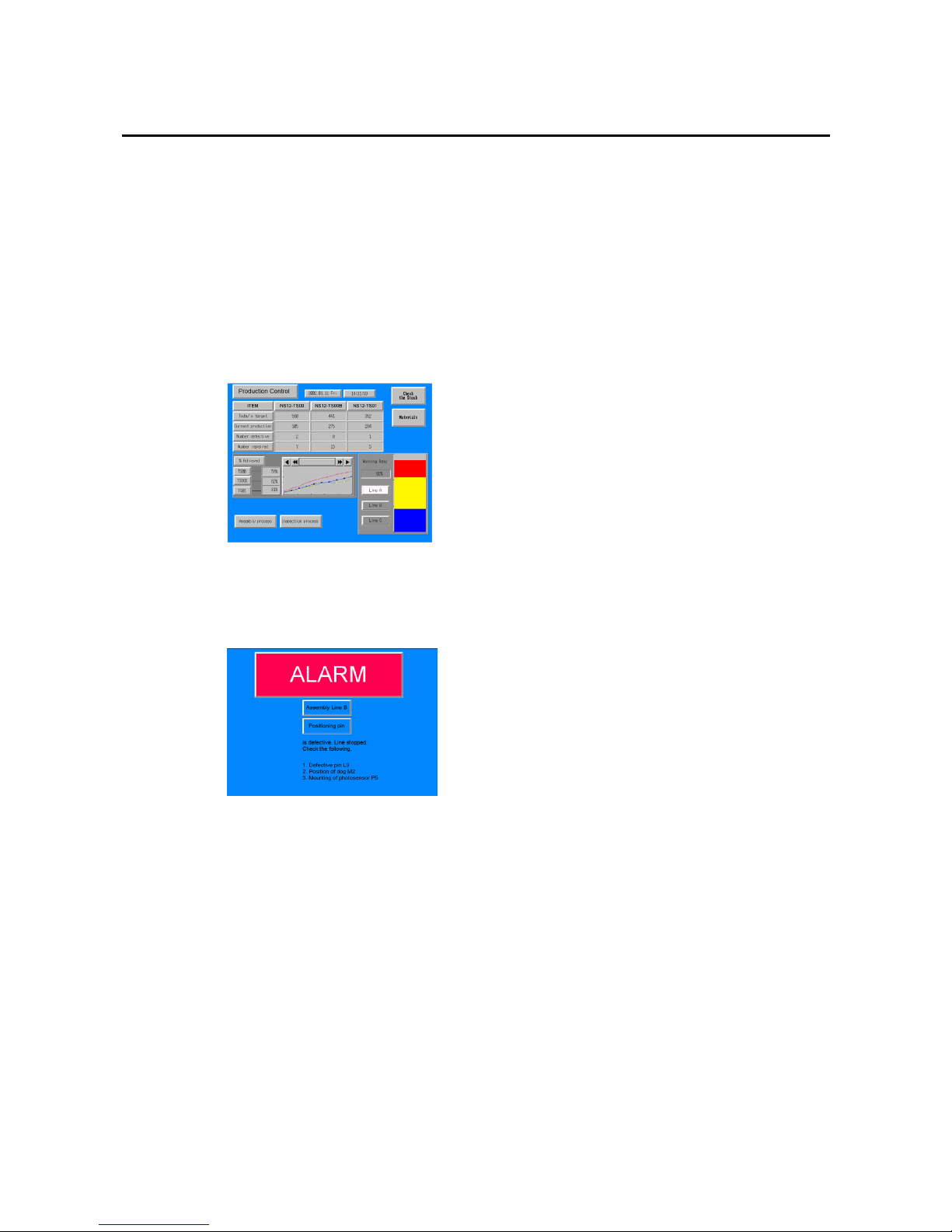

Directions for FA Site Operators

The PTs can be used to inform the operators of system and device errors and assist them in

taking appropriate measures.

Page 25

1-1 NS-series PT Functions and Operation

1-3

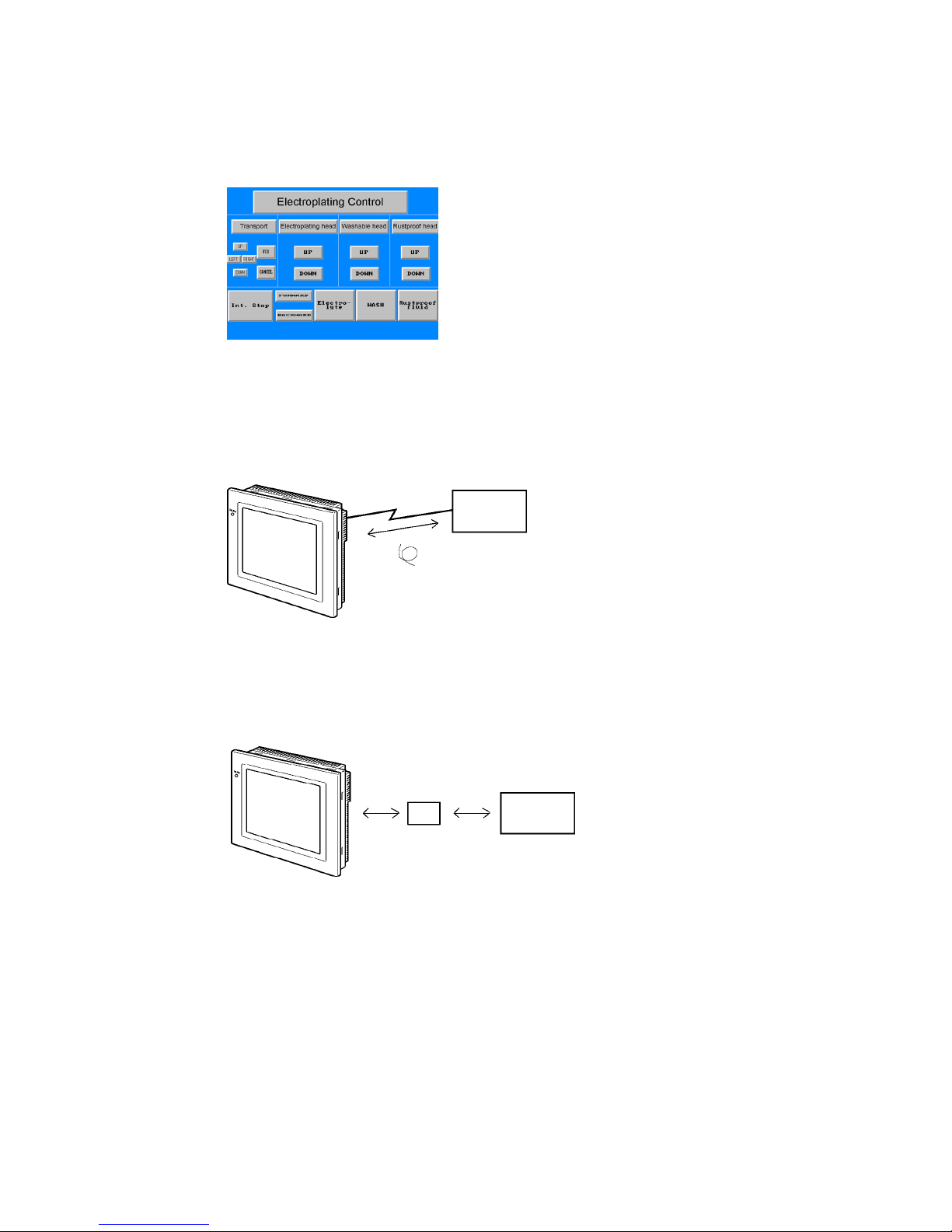

Control Panel Switches

The NS-series PTs allow the user to create various on-screen switches. By using touch

switch inputs, operating results can be sent to the host.

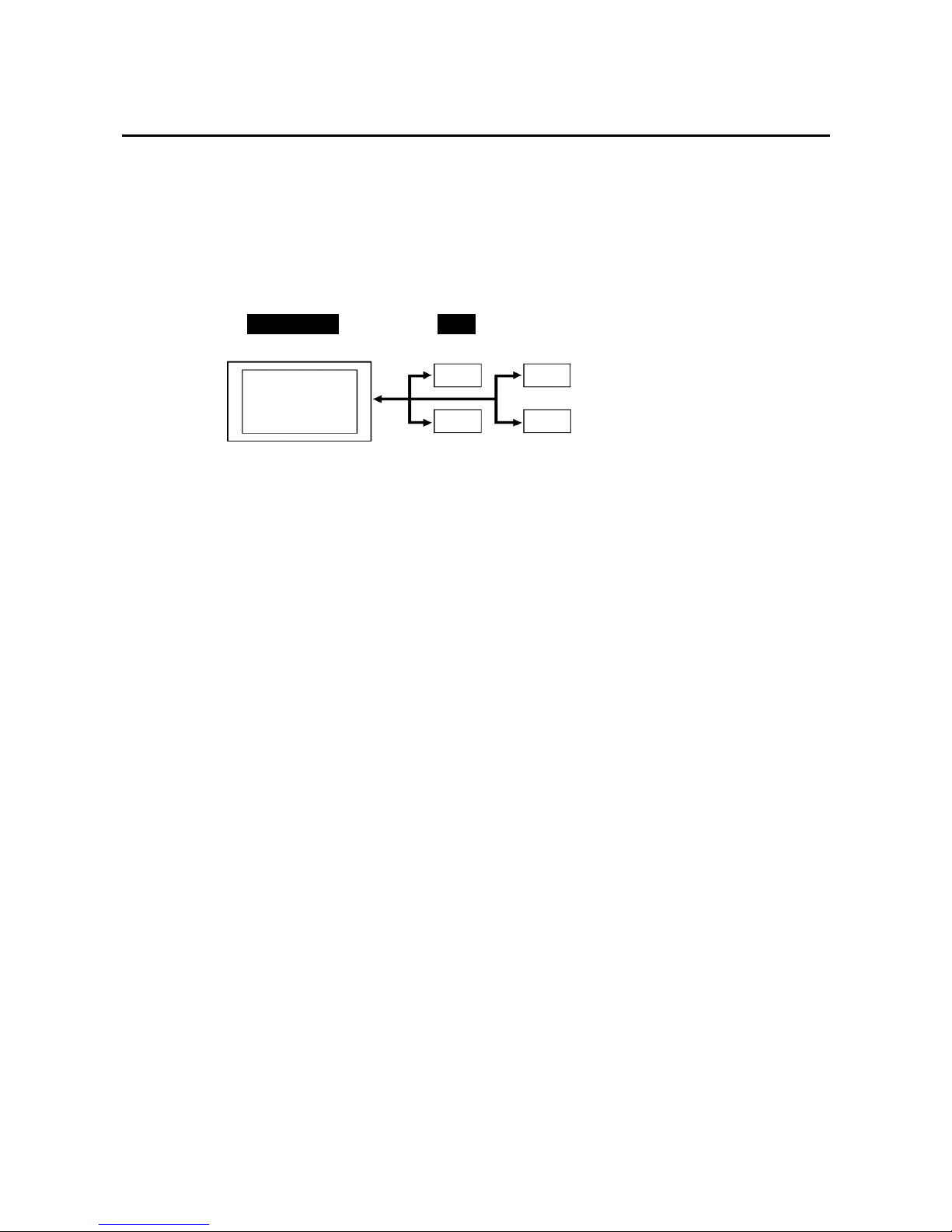

1-1-2 NS-series PT Operating System

Transferring Screen Data

The screen data displayed on NS-series PTs is created using the CX-Designer on a computer and transferred to the PT through RS-232C, Ethernet, or USB communications.

RS-232C, Ethernet,

USB

Screen data

Create screen data.

Connect the computer to the PT only

when transferring screen data to or from

the CX-Designer.

Computer

(CX-Designer)

Note 1: Some models do not support Ethernet.

Note 2: USB data transfer is not supported for some PT lots and system program versions.

Note 3: If the serial port protocol is set to Allen-Bradley DF1, you cannot connect to the CX-Designer

through that port.

Screen data can also be transferred at high speed using a Memory Card.

Memory

Card

Computer

(CX-Designer)

Page 26

1-1 NS-series PT Functions and Operation

1-4

Displaying Screens

The information displayed on the screens is created using the CX-Designer on a computer

and transferred to the PT. The required screens can be displayed by using commands from

the host or touch switch operations.

Host

The required screens can

be displayed by using

commands from the host

or touch switch operations.

Reading Data from the Host

A communications method such as NT Link Ethernet or Controller Link is used to connect the

host, and the required data is automatically read from the host.

Note: Some models do not support Ethernet or Controller Link.

NT Link or Ethernet,

Controller Link

Host

Sending Data to the Host

Data input using touch switches (button ON/OFF status, numerals, and character strings) is

sent to the host.

Touch panel

Host

ON/OFF status,

numeric data, etc.

Page 27

1-2 Communications with the Host

1-5

1-2 Communications with the Host

NS-series PTs allow the user to allocate words and bits in any PLC area for use in accessing

the required display contents and storing input data.

Operations that can be performed include reading and writing allocated word contents and bit

status directly, changing the display status of functional objects on the PT screen, and controlling and notifying PT status.

The NS-series PTs also enable communications with more than one PLC. A host name is

registered for each PLC connected, allowing access to any PLC areas by specifying the host

name and address.

NS - Series PT PLC

Timers/counters

DM Area I/O Area

Auxiliary Area

When using NS-series PTs, the host can be connected using any of the following methods.

• 1:1 NT Link

• 1:N NT Link (normal or high-speed)

• Ethernet

• Controller Link

• Host Link

• Other methods, such as temperature controller protocols

• EtherNet/IP

Page 28

1-2 Communications with the Host

1-6

1-2-1 What is an NT Link?

An NT Link is a method for high-speed communications between an OMRON PLC and an

OMRON Programmable Terminal (PT) using a special protocol. In addition to a 1:1 NT Link,

where a single PT is connected to a single PLC, NS-series PTs also support 1:N NT Links,

allowing up to eight PTs to be connected to a single PLC port.

CS- and CJ-series PLCs can also be connected using high-speed 1:N NT Link communications. For details on the PLCs that support high-speed 1:N NT Link communications, refer to

Appendix 8 Standard Models.

In the rest of this manual, "NT Link" refers to NT Link communications in general, "1:1 NT

Link" refers to an NT Link in a 1:1 configuration only, and "1:N NT Links" refers to NT Links in

a 1:N configuration only. Where necessary, "normal 1:N NT Links" and "high-speed 1:N NT

Links" are used. When "1:N NT Links" is used alone, it refers to both normal and high-speed

communications.

1-2-2 Ethernet

Ethernet Units in PLCs that are supported by the NS-series PTs can be used to read and

write data, word, and bit information simply. The use of FINS (Factory Interface Network Service) message communications, one of OMRON’s standard communications services, enables high-speed communications without the need to be aware of the protocol.

For details on connection methods, refer to Section 5 Connecting

to Host via Ethernet or

Controller Link. For details on the PLCs that can be connected to the Ethernet, refer to Appendix 8 Standard Models.

1-2-3 Controller Link

Controller Link is an FA network that can send and receive large data packets among

OMRON PLCs and FA computers. Controller Link Units for PLCs that are supported by the

NS-series PTs connected to NS-CLK21 Controller Link Interface Units can be used to read

and write data, word, and bit information simply.

The Controller Link supports data links that enable data sharing and a message service that

enables sending and receiving data when required.

For details on connection methods, refer to Section 5 Connecting

to Host via Ethernet or

Controller Link. For details on the PLCs that can be connected using Controller Link, refer to

Appendix 8 Standard Models.

Note: Controller Link Interface Units are compatible only with the NS15, NS12, and NS10.

1-2-4 Host Link

Host Link is a serial communications protocol for connecting an OMRON PT 1:1 to a host (a

PLC) to read and write bits and words from the host. Host Link communications connect a PT

to many different PLCs. Refer to the Host Connection Manual (Host Links) for connection

methods and the PLCs for which Host Links can be used.

1-2-5 Connecting to a Temperature Controller

OMRON Temperature Controllers can be connected with an RS-485 connection.

Attach a CJ1W-CIF11 RS-422A Converter to serial port A or B to convert the communications

protocol to RS-485. For details, refer to the Host Connection Manual (Temp. Control, Mem-

Link).

Page 29

1-2 Communications with the Host

1-7

1-2-6 Memory Link Connections

When the host is a computer instead of a PLC, the Memory Link protocol can be used to

connect with the computer. Use serial port A or B to connect to the host. For details, refer to

the Host Connection Manual (Tem.Control, MemLink).

1-2-7 Communicating with Other Devices

The NS-series PTs can communicate with the following devices.

• OMRON Trajexia Motion Controllers

• Mitsubishi FX-series, A-series, and Q-series PLCs

• Siemens S7-300-series PLCs

• Yaskawa MP-series Machine Controllers

• Yaskawa F7-series Varispeed and VS Mini V7-series Inverters

• Rockwell Automation (Allen-Bradley) SLC50, MicroLogix, PLC-5, CompactLogix,

CompactLogix, and ControlLogix Controllers

• Devices that support Modbus RTU

• Yokogawa Electric FA-M3/FA-M3R-series PLCs

For details on connection methods, refer to the Host Connection Manual (Multivendor Connection).

1-2-8 EtherNet/IP

EtherNet/IP is a multi-vendor industrial network protocol that uses Ethernet. The specification is an open standard managed by the ODVA (Open DeviceNet Vendor Association), as is

DeviceNet, and it is used for a variety of industrial devices.

NS-series PTs can communicate with CS/CJ-series EtherNet/IP Units and

CJ2H-CPU@@-EIP CPU Units, which have a built-in EtherNet/IP port. Also, it is possible to

perform tag message communications if an NS-series PT is connected to a CJ2H PLC. The

CJ2H-CPU@@-EIP has a tag name server in the CJ2H-CPU@@-EIP Unit, so if a tag name

and address table is stored in advance, it is possible to perform access from the NS-series

PT using only the tag name.

Page 30

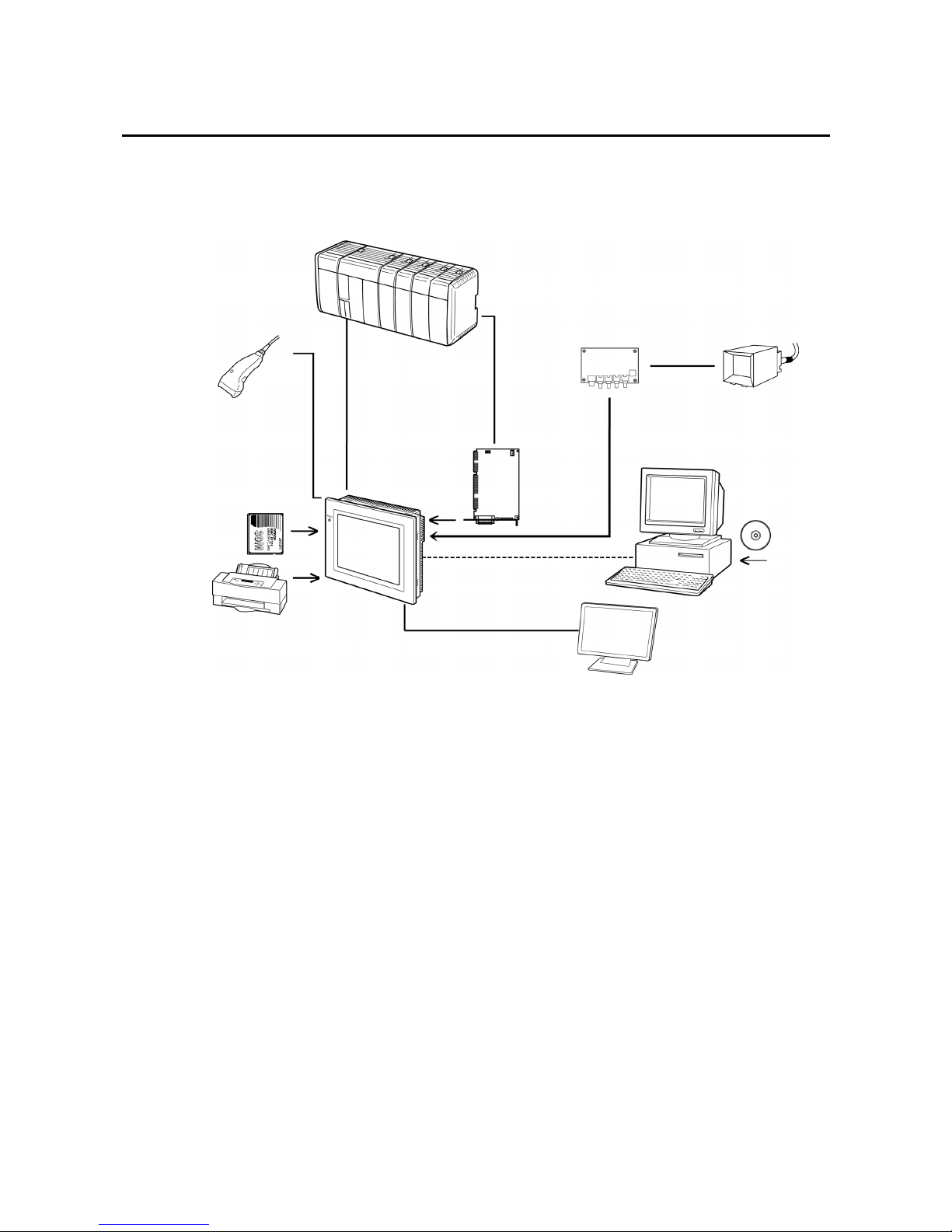

1-3 System Configuration

1-8

1-3 System Configuration

The following information describes the system configuration using NS-series PTs. Refer to

Appendix 8 Standard Models for details on available models.

1-3-1 Supported Peripheral Devices

Printer (See note 4.)

Connecting a general-purpose colo

r

printer to the USB port on an

NS-series PT makes it possible to

print out the current PT display.

RS-232C cable

Ethernet cable

(See note 1.)

USB cable

(See note 5.)

NS-series PT

CX-Designer

Memory Card

Save screen data or

the system program or

automatically read data

at startup.

RS-232C cable (15 m max.)

RS-422A cable (500 m max.)

RS-232C/422A Adapter

Ethernet cable (See note 1.)

Personal computer

Computer running Windows 2000

or XP

Controller Link

Interface Unit

Enables

Controller Link

communications

with a host.

(See note 2.)

NTSC/PAL cable

Host

Twisted-pair cable

Video Input Unit

(See note 3.)

Video camera or

Vision Sensor

Bar Code Reader

Read bar codes as

text string data.

Monitor (See note 6.)

VGA c abl e

Note 1: Only the following models support Ethernet: NS15-TX01@-V2, NS12-TS01(B)-V@,

NS10-TV01(B)-V@, NS8-TV@1(B)-V@, NS5-SQ@1(B)-V@, NS5-TQ@1(B)-V@, and

VS5-MQ@1(B)-V@.

Note 2: Only the following models support the Controller Link Interface Unit: NS15-TX01@-V2,

NS12-TS0@, NS10-TV0@. (The NS8 and NS5 do not support the Controller Link Interface

Unit.)

Note 3: The following models support Video Input Units: NS15-TX01@-V2, NS12-TS0@, NS10-TV0@,

and NS8-TV@@. (The NS15-TX01-V2 does not support the NS-CA001 and it does not support

video input from the NS-CA002. It does support analog RGB input from the NS-CA002.) (The

NS5 does not support Video Input Units.)

Note 4: The NS5-SQ0@(B)-V@, NS5-TQ0@(B)-V@, and NS5-MQ0@(B)-V@ cannot be connected di-

rectly to general-purpose printers.

Note 5: Refer to 3-3-2 Connecting via USB for information on connecting the PT and computer with a

USB cable.

A USB Relay Cable can be used to place a USB slave connector on the front of the control

panel. Refer to 3-1-3 Mounting the PT to the Control Panel.

Note 6: Only the following monitor is supported: NS15-TX01@-V2.

• PTs (Refer to Appendix 8 Standard Models.)

• Recommended Bar Code Reader (Refer to page 3-15.)

OMRON V520-RH21-6

OMRON V400-H111

OMRON V400-H211

Page 31

1-3 System Configuration

1-9

• RS-232C/422A Converters

OMRON NS-AL002 (non-insulated) (Refer to Appendix 3 Using NS-AL002 Converters.)

OMRON NT-AL001 (insulated) (Refer to Appendix 4 Using NT-AL001 Converters.)

OMRON CJ1W-CIF11

• Recommended Memory Cards (Refer to 3-6 Using Memory Cards.)

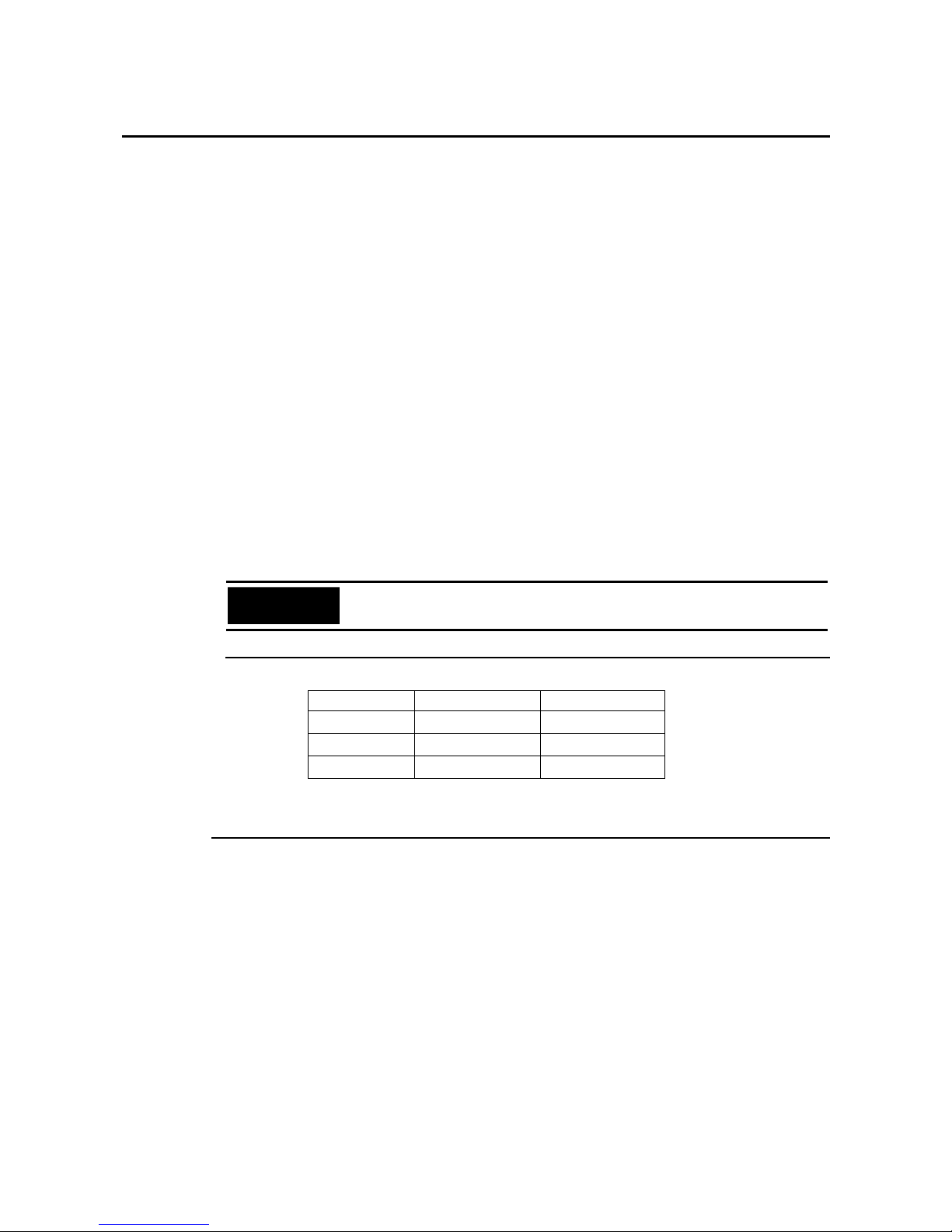

Model Memory capacity Memory type

HMC-EF183 128 MB Flash memory

HMC-EF283 256 MB Flash memory

HMC-EF583 512 MB Flash memory

• CX-Designer (Refer to the CX-Designer Online Help.)

NS-CXDC1-V@ (CD-ROM version)

• Video Input Unit (Refer to 3-7 Installing the Video Input Unit.)

NS-CA001

NS-CA002: Refer to the NS Series RGB and Video Input Unit Operation Manual (Cat. No.

V086).

• Controller Link Interface Unit (Refer to 3-8 Installing the Controller Link Interface

Unit.)

NS-CLK21

• USB-compatible Printers (Refer to 3-5 Connecting to Printers.)

• Attachments (Refer to A-9-8 Attachments: NS12-ATT01(B)/

NS12-ATT02/NS8-ATT01/NS8-ATT02.)

Use an Attachment when replacing NT-series PTs.

NS12-ATT01(B)

NS12-ATT02

NS8-ATT01

NS8-ATT02

• USB Relay Cable (Refer to 3-1-3 Mounting the PT to the Control Panel.)

NS-USBEXT-1M

Reference The following optional products are available. (Refer to Appendix 9 List of Optional

Products.)

Anti-reflection Sheets NS15-KBA04 (For NS15)

(5 sheets) NS12-KBA04 (For NS12 and NS10)

NS7-KBA04 (For NS8)

NT30-KBA04 (For NS5)

Protective Covers NS12-KBA05 (For NS12 and NS10)

(anti-reflection coating) NS7-KBA05 (For NS8)

(5 covers) NT31C-KBA05 (For NS5)

Transparent Protective Covers NS12-KBA05N (For NS12 and NS10)

(5 covers) NS7-KBA05N (For NS8)

NT31C-KBA05N (For NS5)

Chemical-resistant Cover NT30-KBA01 (For NS5)

(1 cover)

Replacement Battery CJ1W-BAT01 (For NS15, NS12, NS10, NS8

and NS5)

Page 32

1-4 Procedure for Running NS-series PTs

1-10

1-4 Procedure for Running NS-series PTs

Use the following procedure to start up the NS-series system.

Host connections

Settings/com check

Operation

System maintenance

PT connections

Programming

RS-232C: Section 4

Ethernet: Section 5

Controller Link: Section 5

EtherNet/IP: Section 5

Host

PT

CX-Designer

See note 5.

Refer to Section 6-1 Operating

Modes and System Menu.

System menu settings

See note 4.

Screen transfer

Refer to

3-6

-

3 Transferring Datawith Memory Cards.

Screen creation

Refer to NS-series PT

Programming Manual

and the CX-Designer

User’s Manual.

Refer to 6-2-1 Screen

Data Area Format.

Data initialization

See

note

3.

See

note

2.

System program

installation

See

note

1.

Power ON

Refer to Page 3-6.

Power connections

Peripheral connections

Refer to Page

3-4

.

Panel installation

Refer to the CX-Designer

User’s Manual.

Installation on the

computer

Host settings

Refer to following pages.

1:1 NT Link: 4-2 and A-8

1:N NT Link: 4-7 and A-9

High-speed 1:N NT Link:

4-15 and A-9

Ethernet: Section 5

EtherNet/IP: Section 5

Controller Link: Section 5

Host Link:

Refer to the Host Connection

Manual (Host Links).

Temperature Controllers:

Refer to the Host

Connection Manual

(Temp. Control, MemLink).

Memory Links:

Refer to the Host

Connection Manual:

(Temp. Control, MemLink).

Other Devices:

Refer to the Host

Connection Manual

(Multivendor Connection).

Connecting to Other Devices

Note 1. RUN mode is entered automatically if screen data already exists.

An error message is displayed if screen data does not exist. Transfer screen data from either

the CX-Designer or a Memory Card.

2. The system program is installed in special situations only, such as when the system program

is being changed or recovered.

3. The system menu can be operated as required to initialize data saved in the PT.

4. For the NS15, the System Menu can be displayed by pressing one of the four corners of the

touch panel twice in a row. For the NS5, NS8, NS10, and NS12, the system menu can be displayed by simultaneously pressing two of the four corners of the touch panel.

5. When errors occur during operation, check I/O and setting statuses as required.

Page 33

1-4 Procedure for Running NS-series PTs

1-11

The following table lists the device and software manuals used for reference.

Device/Software Manual name Catalog No.

Setup Manual

(Provides information on existing NS-series models, i.e.,

NS12, NS10, and NS7.)

V072

Programming Manual V073

NS-series PTs

Macro Reference Provided with

CX-Designer

CX-Designer User’s Manual V099 CX-Designer