Page 1

Cat. No. V07-EN-01

NQ3-TQ0B

NQ3-MQ0B

NQ5-SQ0B

NQ5-MQ0B

NQ-Series HMI

GETTING STARTED GUIDE

Page 2

Page 3

Notice

OMRON products are manufactured for use by a trained operator and only for

the purposes described in this manual.

The following conventions are used to classify and explain the precautions in

this manual. Always heed the information provided with them.

!WARNING Indicates information that, if not heeded, could possibly result in serious injury or loss of

life.

!Caution Indicates information that, if not heeded, could possibly result in minor or relatively

serious injury, damage to the product or faulty operation.

OMRON product references

In this manual the first letter of the name of each OMRON product is

capitalized.

Visual aids

The following heading appears in the left column of the manual to help you

locate different types of information.

Note Indicates information of particular interest for efficient and convenient

operation of the product.

1,2,3... Indicates various lists such as procedures, checklists etc.

Trademarks and copyrights

All product names, company names, logos or other designations mentioned

herein are trademarks of their respective owners.

Copyright

Copyright © 2009 OMRON

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system, or transmitted, in any form, or by any means, mechanical,

electronic, photocopying, recording, or otherwise, without the prior written

permission of OMRON.

No patent liability is assumed with respect to the use of the information

contained herein. Moreover, because OMRON is constantly striving to improve

its high-quality products, the information contained in this manual is subject to

change without notice. Every precaution has been taken in the preparation of

this manual. Nevertheless, OMRON assumes no responsibility for errors or

omissions. Neither is any liability assumed for damages resulting from the use

of the information contained in this publication.

Page 4

SECTION 1

Precautions vi

1-1 Intended audience...................................................................................................................................vii

1-2 General precautions ................................................................................................................................vii

1-3 Safety precautions..................................................................................................................................viii

1-4 Operating environment precautions ........................................................................................................ ix

1-5 Application precautions ............................................................................................................................ x

1-6 Handling, storage and disposal ...............................................................................................................xii

1-7 Conformance to EC Directives................................................................................................................xii

SECTION 2

Introduction 1

2-1 About this manual..................................................................................................................................... 2

2-2 NQ-Series models .................................................................................................................................... 2

2-3 Specifications for all models..................................................................................................................... 3

2-4 Specifications per model .......................................................................................................................... 5

SECTION 3

Installation and wiring 7

3-1 Installation notes ...................................................................................................................................... 8

3-2 Mounting................................................................................................................................................... 9

3-3 Wiring ..................................................................................................................................................... 12

3-4 Multi-drop networks ................................................................................................................................ 15

SECTION 4

Creating applications 17

4-1 Preparing for programming .................................................................................................................... 18

4-2 Using NQ-Designer ................................................................................................................................ 21

4-3 Example application ............................................................................................................................... 33

SECTION 5

Transferring programs 49

5-1 Downloading........................................................................................................................................... 50

5-2 Uploading ............................................................................................................................................... 52

5-3 USB host functionality ............................................................................................................................ 55

SECTION 6

Simulation and debugging 61

6-1 Simulation............................................................................................................................................... 62

6-2 Debugging .............................................................................................................................................. 63

Page 5

Section

SECTION 7

Maintenance 65

7-1 Erasing keys .......................................................................................................................................... 66

7-2 Touch screen calibration........................................................................................................................ 67

7-3 Troubleshooting ..................................................................................................................................... 68

7-4 NQ-Series diagnostics ........................................................................................................................... 69

Appendix A 75

A-1 OMRON to NQ-Series configurations .................................................................................................... 75

A-2 OMRON communication cables............................................................................................................. 82

A-3 Non-Omron devices to NQ-Series configurations .................................................................................. 88

A-4 Non-Omron devices communication cables ........................................................................................ 120

Revision history 131

Page 6

Page 7

Section

SECTION 1

Precautions

This section provides general precautions for using the NQ-Series Operator

Interfaces (OIs), Programmable Logic Controllers (PLCs) and related devices.

The information contained in this section is important for the safe and

reliable operation of the NQ-Series terminal. You must read this section

and understand the information contained before attempting to set up or

operate an NQ-Series terminal.

SECTION 1

Precautions vi

1-1 Intended audience...... .... ...................................... .... ... .....................vii

1-2 General precautions.........................................................................vii

1-3 Safety precautions............................. ... ... .... ... ... ... ............................viii

1-4 Operating environment precautions.................. ... .... ... ... ... ...............ix

1-5 Application precautions....................................................................x

1-6 Handling, storage and disposal........................................................xii

1-7 Conformance to EC Directives.........................................................xii

vi

Page 8

Intended audience Section 1-1

1-1 Intended audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

1-2 General precautions

The user must operate the product according to the performance

specifications described in the operation manual.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment,

amusement machines, safety equipment, and other systems, machines, and

equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for installing and operating the OMRON NQSeries HMI (referred to as “HMI”). Be sure to read this manual before

attempting to use the HMI and keep this manual close at hand for reference

during operation.

• The HMI is a general purpose product. It is a system component and is used in conjunction with other items of industrial equipment such as PLC's. Loop Controllers,

Adjustable Speed Drives, etc.

• A detailed system analysis and job safety analysis should be performed by the system designer or system integrator before including the HMI unit in any new or existing system. Consult your OMRON representative for options availability and for

application specific system integration information if required.

• The product may be used to control an adjustable speed drive connected to high

voltage sources and rotating machinery that is inherently dangerous if not operated

safely. Interlock all energy sources, hazardous locations, and guards in order to

restrict the exposure of personnel to hazards. The adjustable speed drive may start

the motor without warning. Signs on the equipment installation must be posted to

this effect. A familiarity with auto-restart settings is a requirement when controlling

adjustable speed drives. Failure of external or ancillary components may cause

intermittent system operation, i.e., the system may start the motor without warning

or may not stop on command. Improperly designed or improperly installed system

interlocks and permissives may render a motor unable to start or stop on command.

vii

Page 9

Safety precautions Section 1-3

1-3 Safety precautions

!WARNING Do not attempt to take any HMI apart or touch any internal parts while the

power is being supplied. Doing so may result in electric shock.

!WARNING Do not attempt to disassemble, repair, or modify any HMI. Any attempt to do so may

result in malfunction, fire, or electric shock.

!WARNING Provide safety measures in external circuits, i.e., not in the HMI, in order to ensure

safety in the system if an abnormality occurs due to malfunction of the HMI or another

external factor affecting the HMI operation. Not doing so may result in serious

accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety measures

must be provided in external control circuits.

!WARNING Never short-circuit the positive and negative terminals of the batteries, charge

the batteries, disassemble them , deform them by applying pressu re, or throw

them into a fire. The batteries may explode, combust or leak liquid.

!WARNING Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal lines,

momentary power interruptions, or other causes. Not doing so may result in

serious accidents.

!WARNING The HMI will turn OFF when its self-diagnosis function detects any error. As a

countermeasure for such errors, external sa fety measures must be provided to

ensure safety in the system.

!WARNING Do not touch any of the terminals or terminal blocks while the power is b eing supplied.

Doing so may result in electric shock.

!Caution Pay careful attention to the p olarities (+/-) when wiring the DC powe r supply. A wrong

connection may cause malfunction of the system.

!Caution Confirm safety at the destination HMI before transferring a program or settings to

another HMI. Doing this without confirming safety may result in injury.

!Caution Tighten the screws on the terminal block of the Power Supply connector to the torque

specified in the operation manual. The loose screws may result in burning or

malfunction.

viii

Page 10

Operating environment precautions Section 1-4

1-4 Operating environment precautions

!Caution Do not operate the control system in the following locations. Doing so may result in

malfunction, electric shock or burning:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humiditi es outside the range specified in the

specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

!Caution

Take appropriate and sufficient countermeasures when installing systems in the

following locations. Doing so may result in malfunction:

• Locations subject to static electricity or other forms of electric noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

!Caution The operating environment of the HMI System can have a large effect on the longevity

and reliability of the system. Improper operating environments can lead to malfunction,

failure and other unforeseeable problems with the system. Make sure that the operating

environment is within the specified conditions at installation and remains within the

specified conditions during the life of the system. Follow all installation instructions and

precautions provided in this operation manual.

ix

Page 11

Application precautions Section 1-5

1-5 Application precautions

!WARNING Failure to abide by the following precautions could lead to serious or possibly fatal

injury. Always read these precautions.

• Always connect to a ground of 100 Ohm or less when installing the HMI.

Not doing so may result in electric shock. Always connect to a ground of

100 Ohm or less when short-circuiting the functional ground and line

ground terminals of the Power Supply Unit, in particular.

• Always turn OFF the power supply to the HMI before attempting any of the

following. Not turning OFF the power supply may result in malfunction or

electric shock.

- Mounting or dismounting Power Supply units and Control Units

- Assembling option boards on HMI

- Replace the battery

- Setting switches

- Connecting or wiring the cables

- Connecting or disconnecting the connectors

• Check the user program for proper execution before actually running it on

the HMI. Not checking the program may result in an unexpected operation.

!Caution

Failure to abide by the following precautions could lead to faulty operation of the HMI or

the system, or could damage the HMI. Always read these precautions.

• Install external breakers and take other safety measures against shortcircuiting in external wiring. Not observing this may result in burning.

• Be sure that all the terminal screws and cable connector screws are

tightened to the torque specified in the relevant manuals. Incorrect

tightening torque may result in malfunction.

• Mount the HMI only after checking the connectors and terminal blocks

completely.

• Before touching the HMI, be sure to first touch a grounded metallic object in

order to discharge any static built-up. Not doing so may result in

malfunction or damage.

• Be sure that the terminal blocks, conn ectors, and other items with locking

devices are properly locked into place. Improper locking may result in

malfunction.

• Wire correctly according to the specified procedures.

• Always use the power supply voltage specified in the operation manuals.

An Incorrect voltage may result in malfunction or burning.

• Do not connect an AC power supply to the NQ-ser ies HMI power ter minals,

an incorrect power supply may result in burning.

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied. Be particularly careful in places

where the power supply is unstable. An incorrect power supply may result

in malfunction.

• Use crimp terminals for wiring. Do not connect bare stranded wires directly

to terminals. Connection of bare stranded wires may result in burning.

• Disconnect the functional ground terminal when performing withstand

voltage tests. Not disconnecting the functional ground terminal may result

in burning.

• Wire correctly and double-check all the wiring or the setting switches

before turning ON the power supply. Incorrect wiring may result in burning.

• Check that the switches and settings are properly set before starting

operation.

x

Page 12

Application precautions Section 1-5

• Resume operation only after transferring to the new HMI the contents of

the all settings, programs, parameters, and data required for resuming

operation. Not doing so may result in an unexpected operation.

• Do not pull on the cables or bend the cables beyond their natural limit.

Doing either of these may break the cables.

• Do not place objects on top of the cables. Doing so may break the cables.

• Use the dedicated connecting cables specified in operation manuals to

connect the HMI. Using commercially available RS-232C computer cables

may cause failures in external devices or the NQ-series HMI.

• When replacing parts, be sure to confirm that the rating of a new part is

correct. Not doing so may result in malfunction or burning.

• When transporting or storing the product, cover the PCBs with electrically

conductive materials to prevent LSls and ICs from being dama ged b y static

electricity, and also keep the product within the specified storage

temperature range.

• Do not touch the mounted parts or the rear surface of PCBs because PCBs

have sharp edges such as electrical leads .

• Make sure that parameters are se t correctly. Incorrect parameter settings

may result in unexpected operations. Make sure that equipment will not be

adversely affected by the parameter setti ngs before st ar ting or stopping the

HMI.

• Do not press the touch switch with a sharp pointer or pencil, doing so may

result in malfunction or damage.

• Do not press the touch switch with a force greater than 30N, doing so may

result in malfunction or damage.

• Always following the specified procedure when removing the USB-stick.

Removing the USB-stick while it is being accessed may render the USBstick unusable.

• Please make sure to have a backup of the data already present on the

USB-stick before connecting it with NQ-series HMI. Not doing so may

result in lost of data.

• Do not let metal particles enter the HMI when preparing the panel.

• Do not use benzene, paint thinner, or other volatile solvents and do not use

chemically treated cloths.

• Carefully unpack the equipment and check for parts that were damaged

from shipping, missing parts, or concealed damage. If any discrepancies

are discovered, it should be noted with the carrier prior to accepting the

shipment, if possible. File a claim with the carrier if necessary and

immediately notify your OMRON representative.

• Do not install or energize equipment that has been damaged. Damaged

equipment may fail during operation resulting in further equipment damage

or personal injury.

xi

Page 13

Handling, storage and disposal Section 1-6

1-6 Handling, storage and disposal

• Use proper lifting techniques when moving the HMI; including properly

sizing up the load, and getting assistance if required.

• Store in a well-ventilated covered location and preferably in the original

packaging if the HMI will not be used upon receipt.

• Store in a cool, clean, and dry location. Avoid storage locations with

extreme temperatures, rapid temperature changes, high humidity,

moisture, dust, corrosive gases, or metal particles.

• Do not store the HMI in places that are exposed to outside weather

conditions (i.e., wind, rain, snow, etc.).

• Never dispose electrical components via incineration. Contact your state

environmental agency for details on disposal of electrical components,

batteries and packaging in your area.

1-7 Conformance to EC Directives

1-7-1 Applicable directives

• EMC (ElectroMagnetic Compatibility) Directives

• Low-voltage directive

1-7-2 Concepts

OMRON units complying with EC Directives also conform to related product

standards making them easier to incorporate in other units or machines. The

actual products have been checked for conformity to product standards.

Whether the products conform to the standards in the system used by the

customer, however, must be checked by the customer.

Product related performance of OMRON units complying with EC Directives

will vary depending on the configuration, wiring, and other conditions of the

equipment or control panel in which OMRON devices are installed. The

customer must, therefore, pe rform final checks to confirm that units and the

overall system conforms to product standards.

A Declaration of Conformity for the NQ-Series can be requested at your

nearest OMRON representative.

1-7-3 Conformance to EC Directives

NQ-Series should be installed as follows, for the complete configuration to

meet the EC directives:

1 The units are designed for installation in panels. All units must be installed

in control panels.

2 Use reinforced insulation or double insulation for the DC power supplies

used for the communication power supply, internal circuit power supply,

and the I/O power supplies.

3 The NQ-Series meets the generic emission standard. However as EMC

performance can vary in the final installation, additional measures may be

required to meet the standards. It should therefore be verified that the

overall machine or device also meets the relevant standards. You must

therefore confirm that EC directives are met for the overall machine or

device, particularly for the radiated emission requirement (10 m).

4 This is a class A product. It may cause radio interference in residential

areas, in which case the user m ay be re quired to take adequ ate meas ures

to reduce interference.

xii

Page 14

Conformance to EC Directives Section 1-7

xiii

Page 15

Section

SECTION 2

Introduction

This section introduces the NQ-Series models and the specifications of the

models.

SECTION 2

Introduction 1

2-1 About this manual................................. ... .... ... ... ...............................2

2-2 NQ-Series models...... .... ...................................... .... ... .....................2

2-3 Specifications for all models.............................. ... .... ... ... ... ...............3

2-4 Specifications per model..................................................................5

1

Page 16

About this manual Section 2-1

2-1 About this manual

This manual describes the installation and operation of the NQ-Series. The

NQ-Series products are versatile Human Machine Interfaces (HMI) .

Please read this manual carefully and be sure to understand the information

provided before installing or operating the NQ-Series.

The program provided in this manual is given strictly as an example. When

implementing an actual system, check the specifications, performance and

safety instructions.

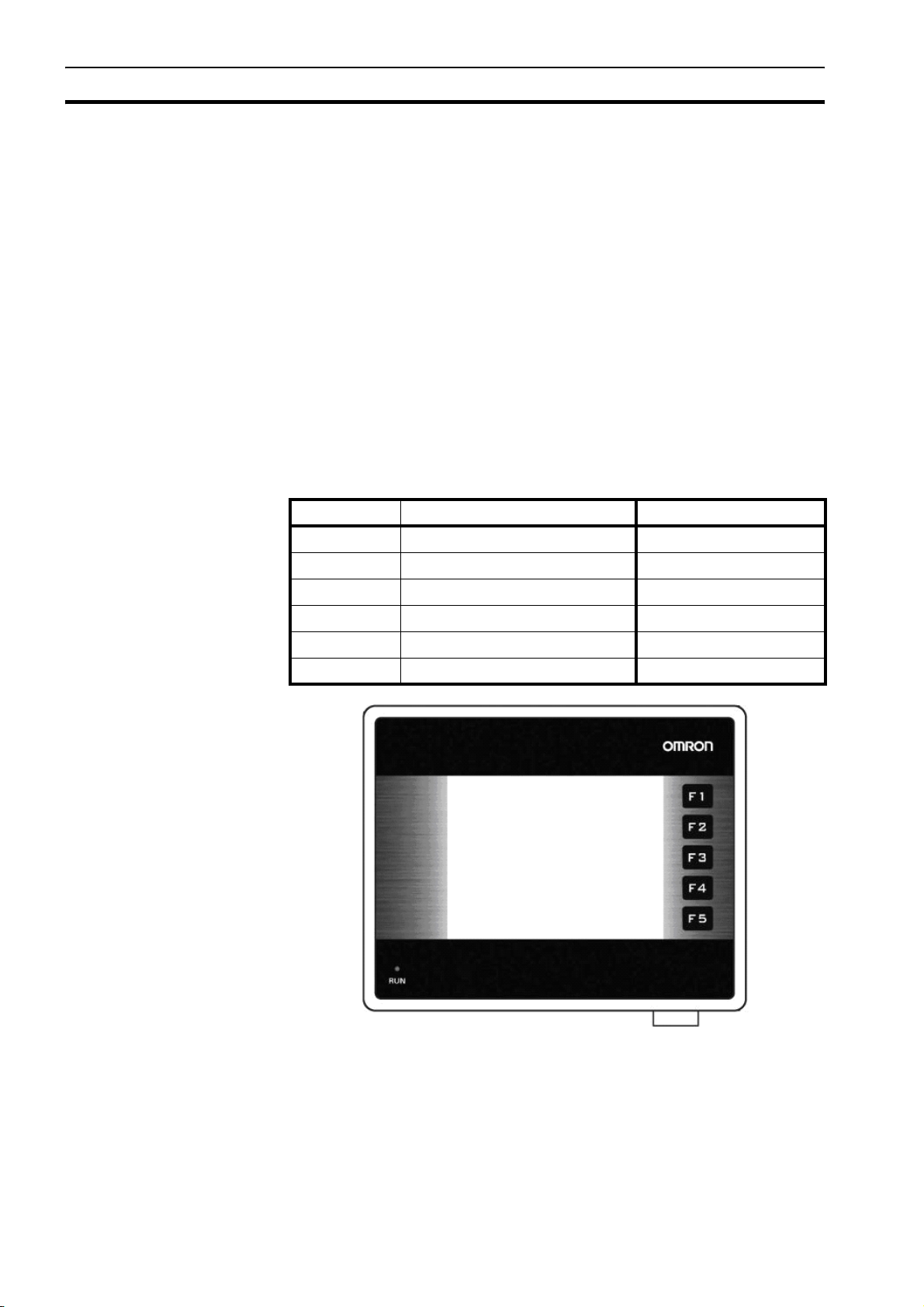

2-2 NQ-Series models

The NQ-Series are Human Machine Interfaces (HMIs) in three different

display sizes and two orientation models. Models included in the NQ-Series

are shown in Table 2.1: NQ-Series models. All models need +24 V

from an external power supply.

/i

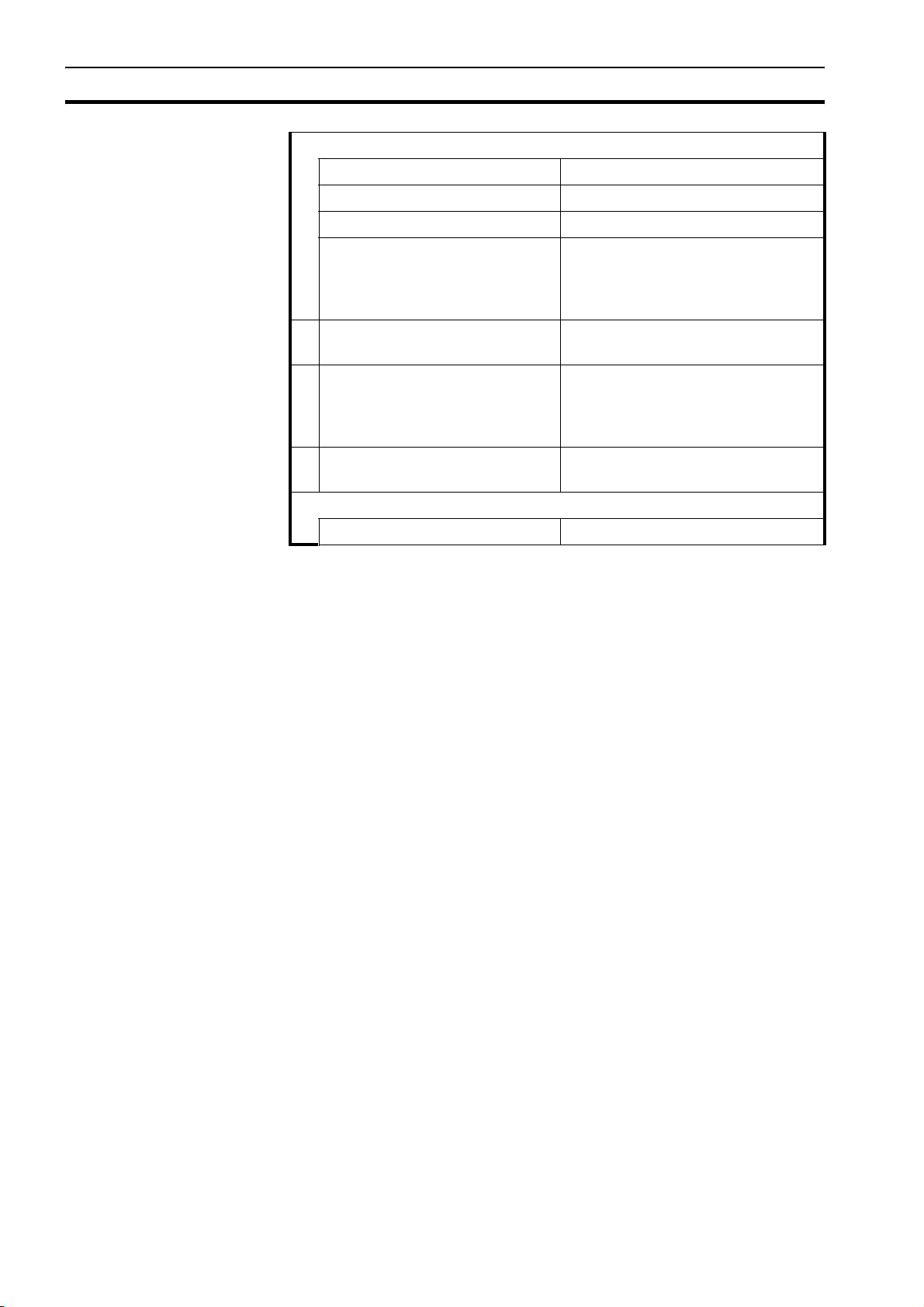

Table 2.1: NQ-Series models

Model Description Orientation

NQ5-MQ000B 5.7” Monochrome STN blue mode Landscape

NQ5-MQ001B 5.7” Monochrome STN blue mode Portrait

DC

power

NQ5-SQ000B 5.7” STN Colour Landscape

NQ5-SQ001B 5.7” STN Colour Portrait

NQ3-TQ000B 3.5” TFT Colour Landscape

NQ3-MQ000B 3.8” Monochrome STN blue mode Landscape

Figure 2.1: Front view of a NQ-Series with 5 function keys

2

Page 17

Specifications for all models Section 2-3

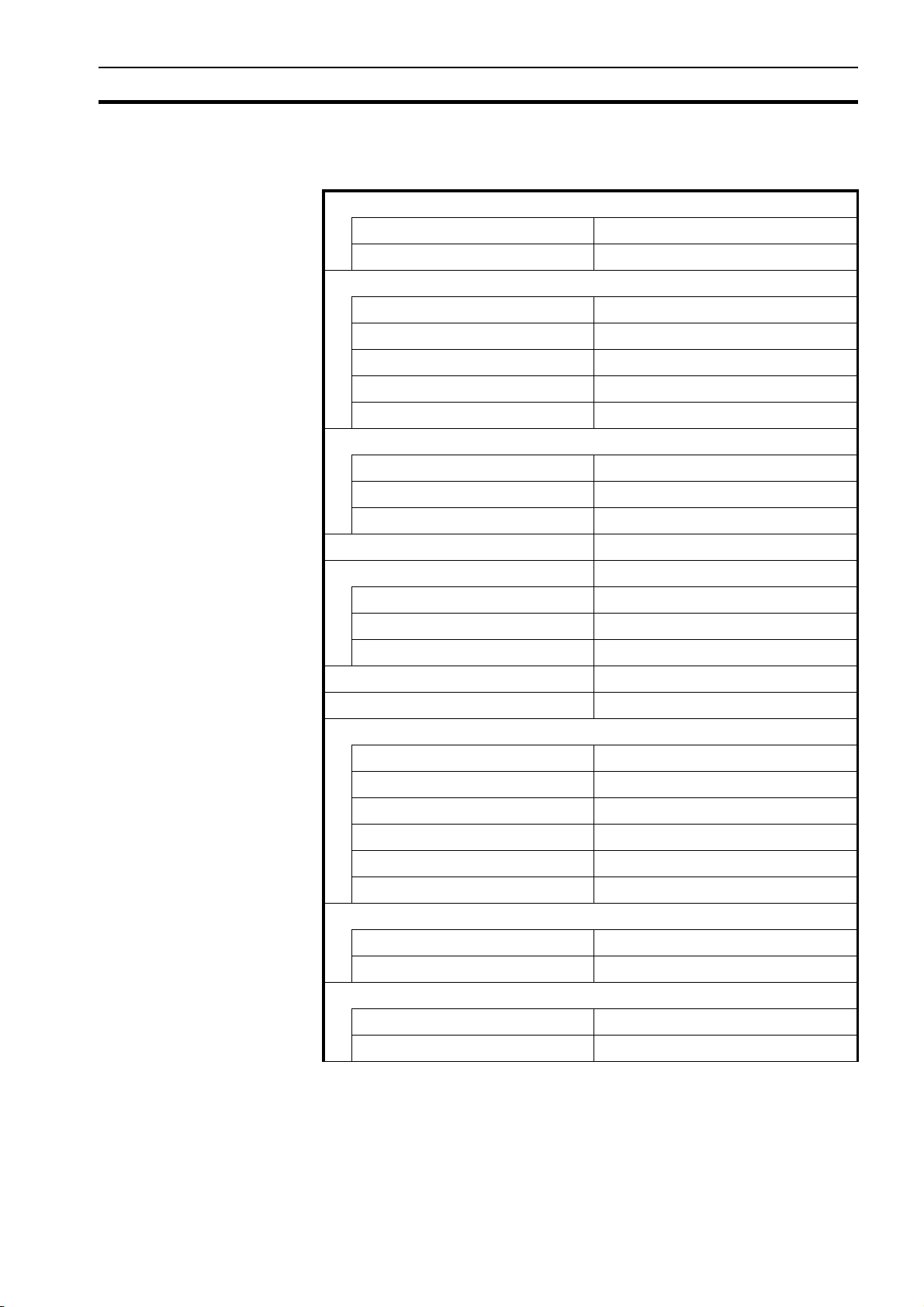

2-3 Specifications for all models

/i

Table 2.2: Common specifications for NQ-Series

Power supply

Input voltage 24 V

Tolerance on input voltage +/− 15%

Display

Resolution (H * V) landscape models 320 * 240 pixels

Resolution (H * V) portrait models 240 * 320 pixels

Backlight life Min. 50000 hours at 25°C

Backlight saver Yes

Backlight dimming (NQ3) Using touch screen / Function Keys

Touch screen

Type 4-wire analogue resistive

Light transparency Min. 80%

Life Min. 5 million touches

Number of LEDs 1

Communication interfaces

RS-232/422/485 Yes

USB device Yes

DC

USB host Yes

Processor 32-bit RISC (ARM)

Real-Time Clock (RTC) Yes (date and time)

Memory

Data register 1000

Retentive register 1400

System register 128

System coil 100

Internal coil 5000

Internal register 313

Battery

Type 3 V coin battery, with holder

Battery back-up Min. 5 years for RTC

Mounting

Method Panel mounting

Enclosure rating Front panel: IP65

3

Page 18

Specifications for all models Section 2-3

Environment

Ambient operating temperature 0 °C to 50 °C

Operating environment No corrosive gasses

Storage temperature -20 °C to 60 °C

1

Humidity 10% to 90%

(Noncondensing)

10% to 85%

(Noncondensing)

Noise immunity Conforms to IEC61000-4-4,

2 KV (power lines)

relative humidity

2

relative humidity

Vibration resistance (during operation) 5 to 8.4 Hz with 3.5 mm single amplitude

and 8.4 to 150 HZ with 9.8 m/s

tion 10 times in each of X, Y and Z directions

Shock resistance (during operation) 147 m/s

directions

International standards

Directives CE, cULus

2

3 times in each of X, Y and Z

2

accelera-

1. At 25 °C ambient temperature.

2. 85% at 40 °C ambient temperature. Above 40 °C the equivalent absolute humidity is less than 85%.

4

Page 19

Specifications per model Section 2-4

2-4 Specifications per model

/i

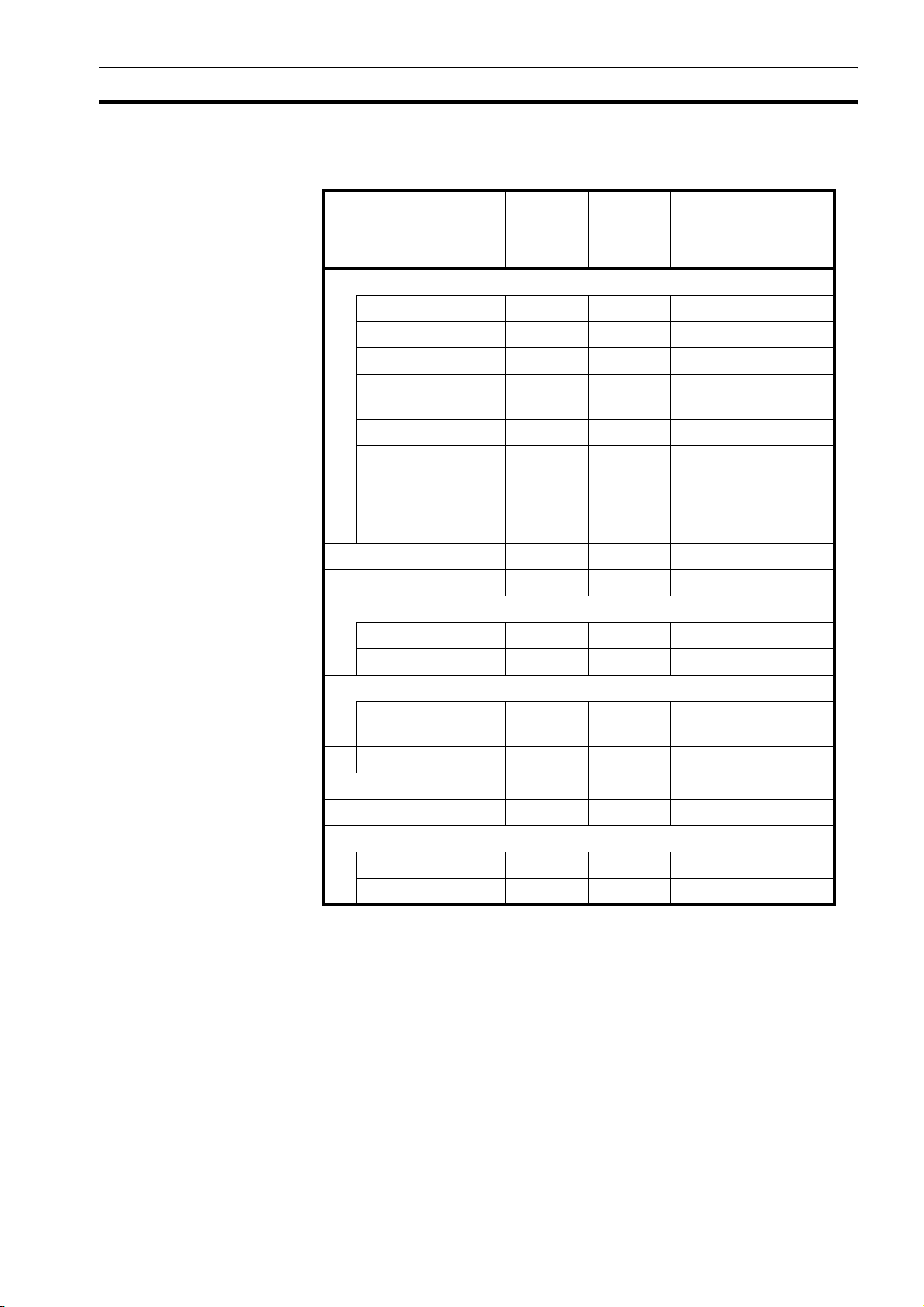

Table 2.3: Specifications per NQ-Series model

Model NQ5-

Display

Display size 5.7 “ 5.7 “ 3.5 “ 3.8 “

Display type STN STN TFT STN

Monochrome/colour Mono Colour Colour Mono

Colours supported 16

Brightness (Cd/m2) Min. 200 Min. 200 Min. 200 Min. 160

Contrast ratio 4 55 300 3

Contrast adjustment

using touch screen

Backlight types CCFL CCFL LED LED

Touch screen size 5.7 “ 5.7 “ 3.5 “ 3.8 “

Function keys 6655

Memory

Total (MB) 8884

NQ5-

MQ000B/

NQ5MQ001B

gradations

Yes Yes No Yes

SQ000B/

NQ5SQ001B

256

colours

1

NQ3TQ000B

256

colours

2

NQ3MQ000B

16

gradations

Program (MB) 6.7 6.7 6.7 2.6

Communication interfaces

RS-232/485/422 port

(Com 1)

RS-232 port (Com 2) Yes Yes NA NA

Power rating (W) 10101010

Weight 0.7 kg max. 0.7 kg max. 0.3 kg max. 0.3 kg max.

External dimensions

Width * Height (mm) 195 * 142 195 * 142 128 * 102 128 * 102

Thickness (mm) 50 50 44.5 44.5

Yes Yes Yes Yes

1. 4096 colours for bitmaps

2. 32000 colours for bitmaps

5

Page 20

Specifications per model Section 2-4

6

Page 21

Section

SECTION 3

Installation and wiring

This section describes how to install the NQ-Series and how to wire the HMI.

SECTION 3

Installation and wiring 7

3-1 Installation notes .............................................................................. 8

3-2 Mounting .......................................................................................... 9

3-3 Wiring ............................................................................................... 12

3-4 Multi-drop networks .......................................................................... 15

7

Page 22

Installation notes Section 3-1

3-1 Installation notes

For improved reliability and maximized functionality, take the following

information into consideration when installing a NQ-Series HMI.

3-1-1 Location

Do not install the NQ-Series in the following locations:

• Areas subject to explosion hazards due to flammable gasses, vapours and

dusts.

• Areas subject to dramatic temperature changes. Temperature changes can

cause condensation of water in the device.

• Areas with an ambient temperature lower than 0 °C or higher than 50 °C.

• Areas subject to shock or vibration.

3-1-2 Temperature control

• Provide adequate space for air flow.

• Do not install the NQ-Series above equipment that generates significant

heat.

• If the ambient temperature exceeds 50 °C, install a cooling fan or air

conditioner.

3-1-3 Accessibility

3-1-4 Panel cut-out

• For safety during operation and maintenance, mount the NQ-Series as far

as possible from high-voltage equipment and power machinery.

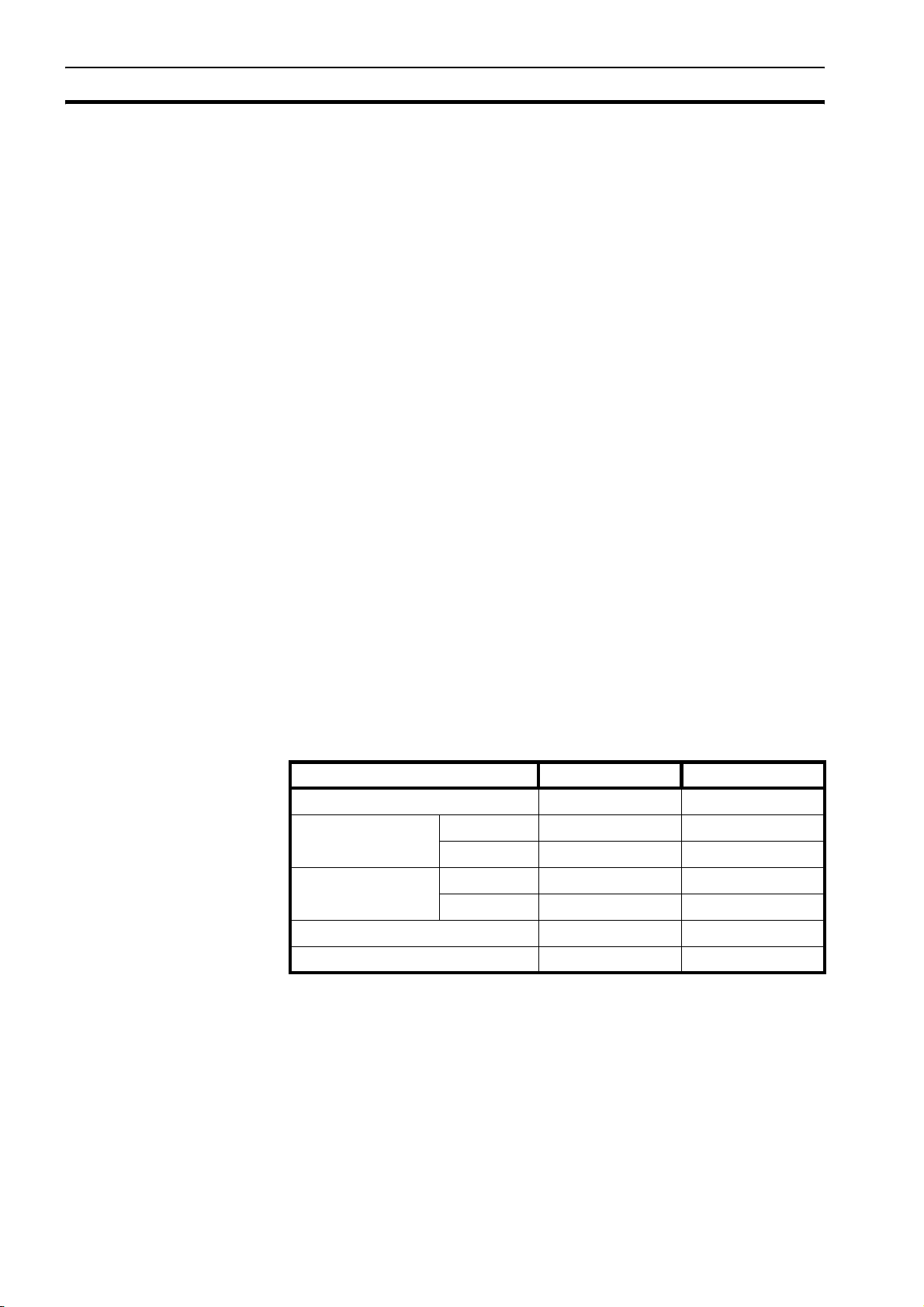

Before the NQ-Series can be mounted, a rectangular cut-out must be made in

the panel in which the NQ-Series will be mounted. Table 3.1: Dimensions of

NQ-Series and required panel cut-out shows the dimensions and tolerances of

the NQ-Series, the panel and the required cut-out.

/i

Table 3.1: Dimensions of NQ-Series and required panel cut-out

NQ5- NQ3-

Display size 5.7 “ 3.5 “ and 3.8 “

External dimensions: W

Panel cut-out: W

Panel cut-out tolerance +0.50 mm +0.50 mm

Panel thickness Max. 6.0 mm Max. 6.0 mm

H

ext

H

cut-out

ext

cut-out

195 mm 128 mm

142 mm 102 mm

184.00 mm 119.00 mm

131.00 mm 93.00 mm

Above external dimensions and cut-outs are for landscape models.

For portrait models exchange the W and H sizes. For portrait models the

cables will be mounted to the left side of the NQ-Series (view from front).

8

Page 23

Mounting Section 3-2

W

ext

W

cut-out

ext

H

cut-out

H

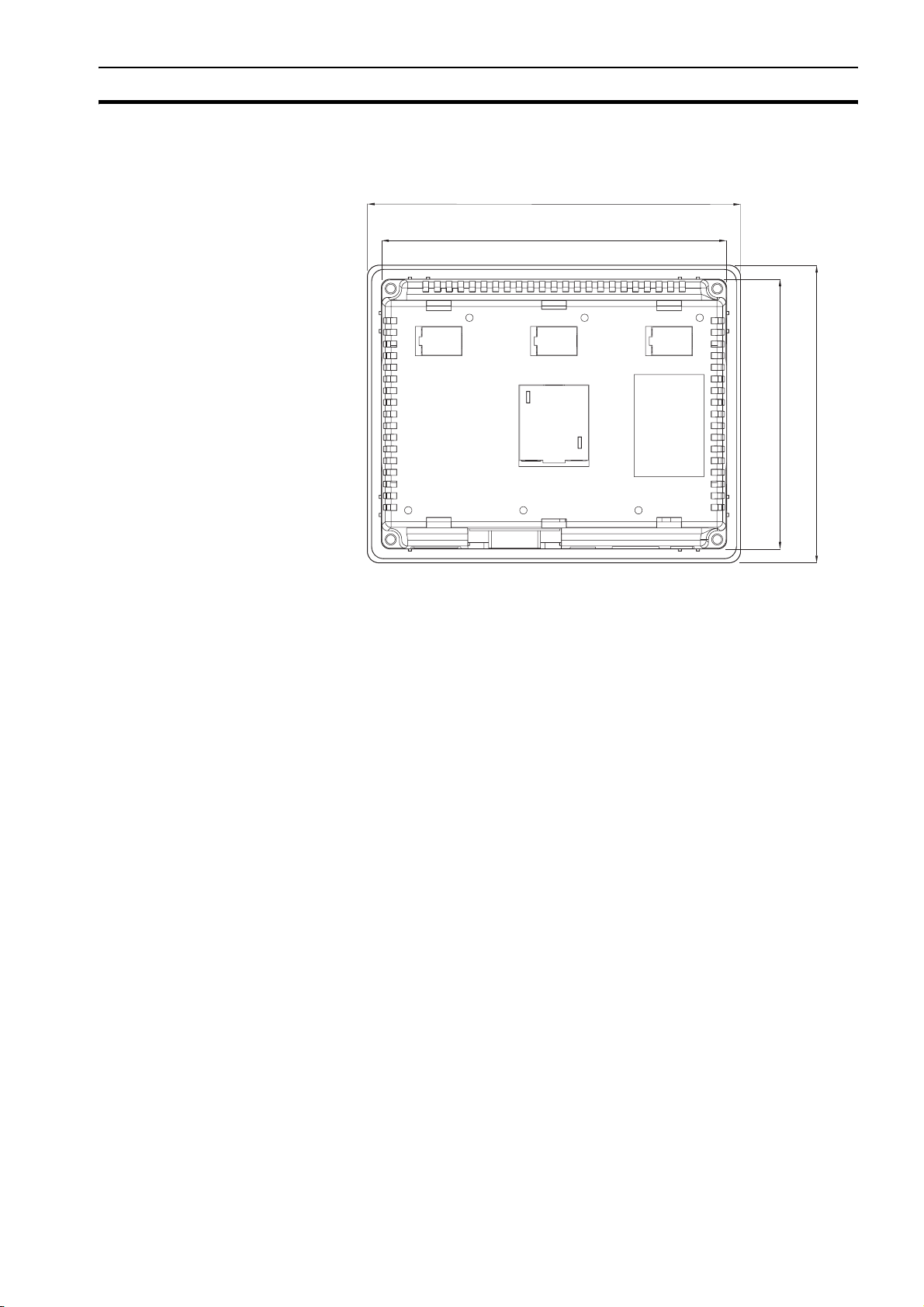

3-2 Mounting

Figure 3.1: Dimensions of NQ-Series and required panel cut-out (landscape).

The NQ-Series has been developed for panel mounting.

Delivered mounting set with each NQ-Series contains:

• 4 mounting clamps

• A green power connector

• A sealing gasket (already mounted on the NQ)

Use the delivered mounting set for proper installation. After the preparation of

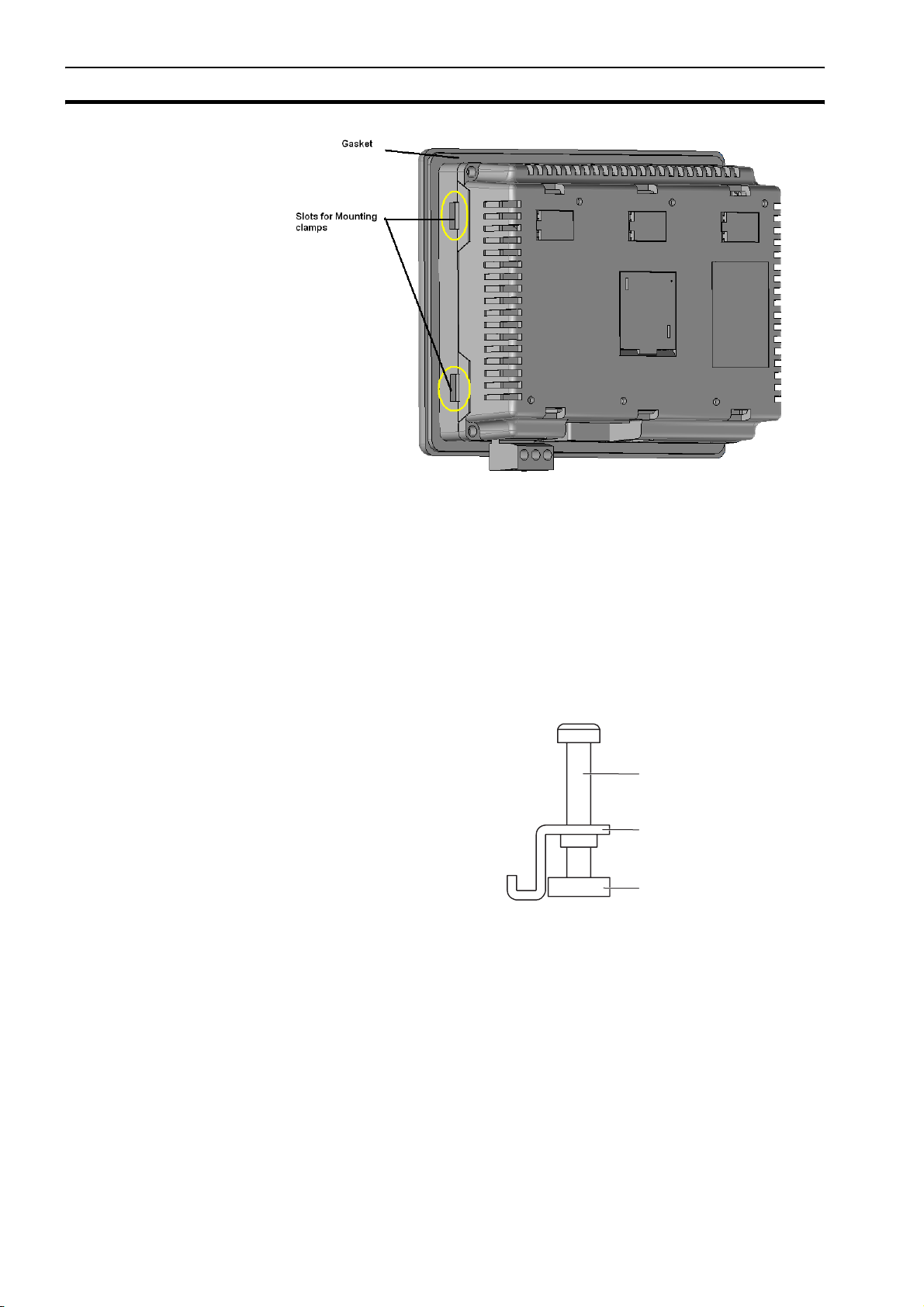

the panel, the NQ-Series can be mounted using the supplied clamps. The NQSeries comes with a gasket pre-installed behind the bezel, as shown in Figure

3.2: NQ-Series with gasket and mounting clamp slots.

9

Page 24

Mounting Section 3-2

Figure 3.2: NQ-Series with gasket and mounting clamp slots

Mount the NQ-Series as follows.

1 Locate the four mounting clamp slots in the case of the NQ-Series. The

NQ3 models have their slots located at the side surfaces of the case (as

shown in Figure 3.2: NQ-Series with gasket and mounting clamp slots. The

slots of the NQ5 models are located at the top and bottom surfaces of the

case.

2 Keep the four mounting sets at hand. Each set consists of a screw (1), a

clamp (2) and a cap (3) as shown in Figure 3.3: Mounting hardware set.

1

2

3

Figure 3.3: Mounting hardware set

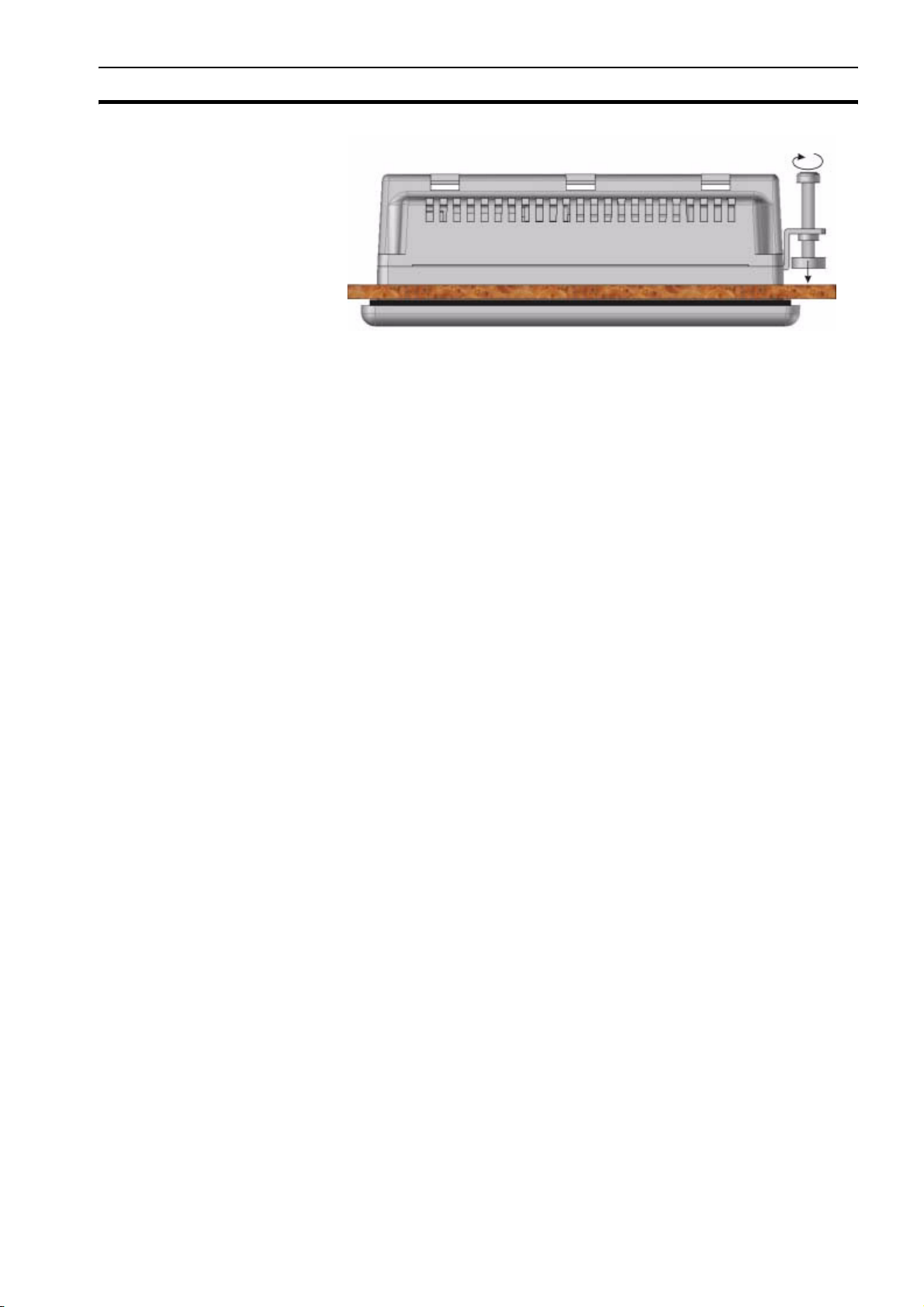

3 Insert the case into the cut-out in the panel, from the front side of the panel.

4 Insert a clamp into a mounting clamp slot on the case and tighten the screw

slightly as shown in Figure 3.4: Case being fixed in panel.

10

Page 25

Mounting Section 3-2

Figure 3.4: Case being fixed in panel

5 Repeat previous step for the other three clamps.

6 Hold the NQ-Series straight and tighten all four screws evenly to a torque

between 0.5 Nm and 0.6 Nm.

11

Page 26

Wiring Section 3-3

3-3 Wiring

NQ-Series models have, besides one power connector, a number of

communication ports. Please refer to Table 2.2: Common specifications for

NQ-Series and Table 2.3: Specifications per NQ-Series model for the

availability of these ports on each of the NQ-Series models.

!Caution

If wiring is to be exposed to lightning or surges, use appropriate surge suppression

devices. Keep AC, high energy and rapidly switching DC wiring separate from signal

wires.

!WARNING Connecting high voltages or AC power mains to the DC input will make the NQ Series

unusable and may create an electrical shock hazard to personnel. Such a failure or

shock could result in serious personal injury, loss of life and/or equipment damage. DC

voltage sources should provide proper isolation from main AC power and similar

hazards.

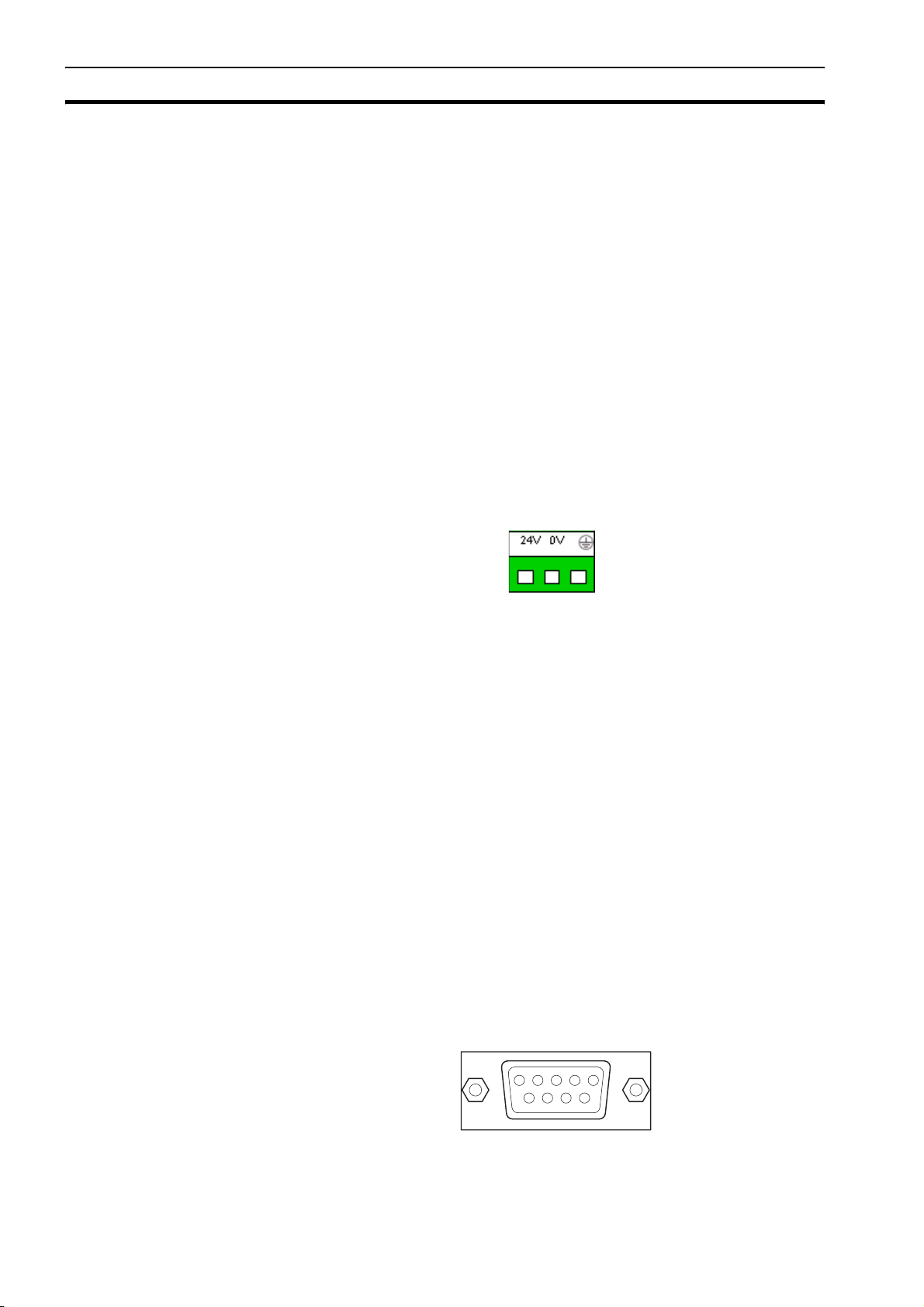

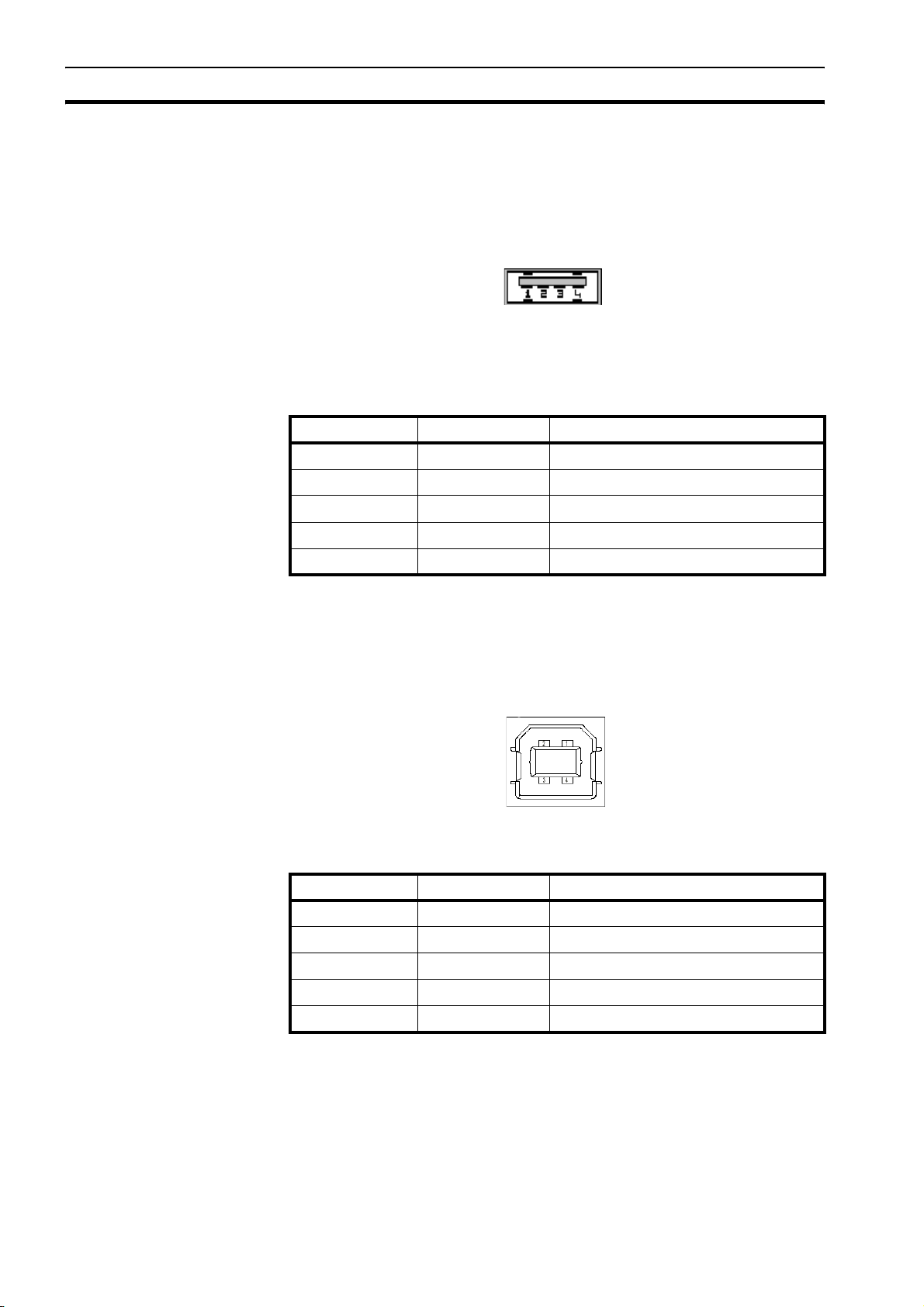

3-3-1 Power connector

All NQ-Series models have a 3-pin, Green coloured, power connector with pin

layout as shown in Figure 3.5: Power connector. Wire the inputs of the power

connector according to the pin layout, from left to right: +24 V

(DC−) and Earth.

3-3-2 Communication ports

The serial communication ports have two functions:

1 To connect to programming devices during configuration.

2 To communicate with a PLC and other devices in operating mode.

Figure 3.5: Power connector

(DC+), 0 V

DC

3-3-2-1 COM1 port

NQ-Series communication ports support various types of (serial)

communication.

COM1 is an integrated RS-232 and RS-485/RS-422 communication port. It

communicates with external peripherals devices at baud rates of 4800 kbps to

187.5 kbps with none, even or odd parity.

RS-485/RS-422 can be used in multi-drop (networks with more than one NQSeries or PLC) communication networks.

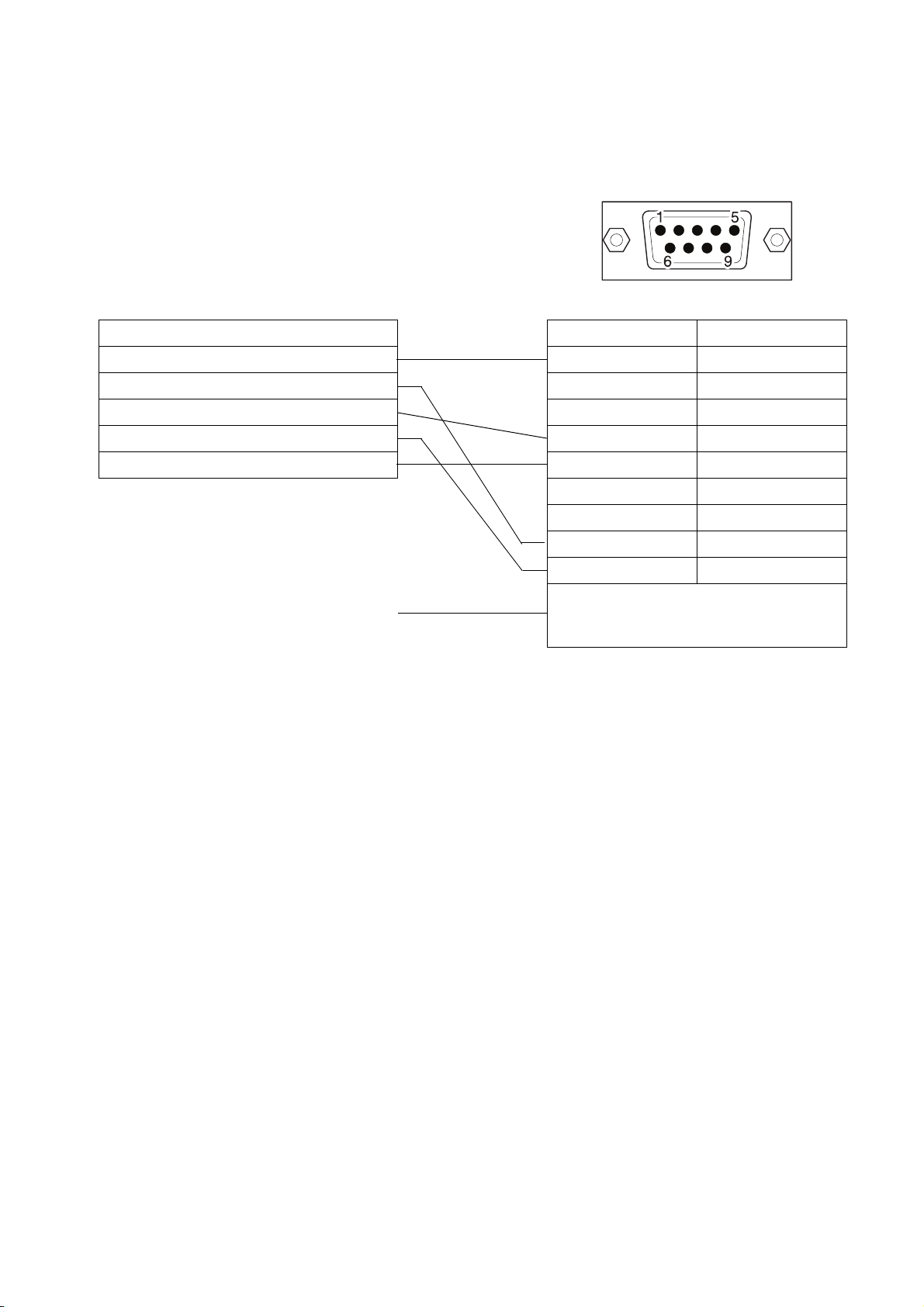

The connector is a standard D-type 9-pin female connector (see Figure 3.6: 9pin sub-D connector) with pin layout as shown in Table 3.2: Pin layout of port

COM1.

Figure 3.6: 9-pin sub-D connector

/i

12

Page 27

Wiring Section 3-3

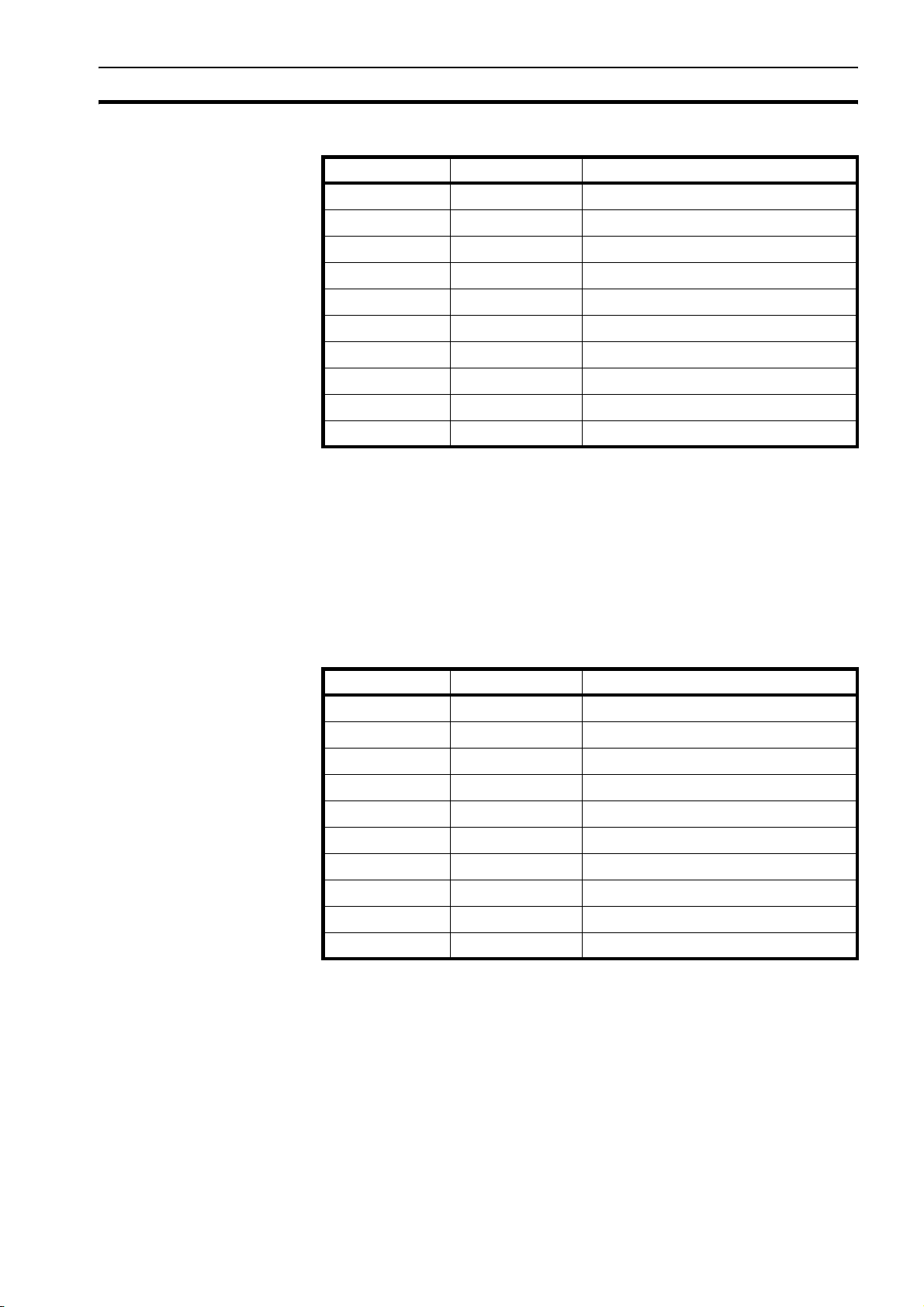

Table 3.2: Pin layout of port COM1

Pin number Pin name Description

1 TX+ RS-422 transmit +

2 TXD RS-232 transmit

3 RXD RS-232 receive

4 RX+ RS-422 receive +

5 GND Signal Ground

6 NC Not connected

7 NC Not connected

8 TX− RS-422 transmit -

9 RX− RS-422 receive -

shell shield

3-3-2-2 COM2 port

COM2 is a RS-232 communication port. It communicates with external

peripherals at baud rates of 4800 kbps to 115.2 kbps with None, Even or Odd

parity.

The connector is a standard D-type 9-pin female connector (see Figure 3.6: 9pin sub-D connector) with pin layout as shown in Table 3.3: Pin layout of port

COM2.

/i

Table 3.3: Pin layout of port COM2

Pin number Pin name Description

1 NC Not connected

2 TXD RS-232 transmit

3 RXD RS-232 receive

4 NC Not connected

5 GND Signal Ground

6 NC Not connected

7 NC Not connected

8 NC Not connected

9 NC Not connected

shell shield

13

Page 28

Wiring Section 3-3

3-3-2-3 USB host port

The USB host port is compliant with the USB 2.0 specification. The USB host

port supports USB memory stick devices. The USB sticks can be used for data

logging and program upload/download, and carrying print files in CSV format.

The connector is a standard USB type A female connector as shown in Figure

3.7: USB host connector.

Figure 3.7: USB host connector

Pinning of the USB host port is described in the table below.

/i

Table 3.4: Pin layout of USB host port

Pin number Pin name Description

1 VBUS +5V

2 D- Data -

3 D+ Data +

4 GND Signal ground

3-3-2-4 USB device port

shell shield

The USB device port is compliant with the USB 2.0 specification for selfpowered devices.

The connector is a standard USB type B female connector as shown in Figure

3.8: USB device connector.

Figure 3.8: USB device connector

/i

Table 3.5: Pin layout of USB device port

Pin number Pin name Description

1 VBUS +5V

2 D- Data -

3 D+ Data +

4 GND Circuit ground

14

shell shield

Page 29

Multi-drop networks Section 3-4

3-4 Multi-drop networks

Several NQ-Series can be set up in a network. The following wiring diagrams

show the correct connections:

• RS-422 interface

• RS-485 interface

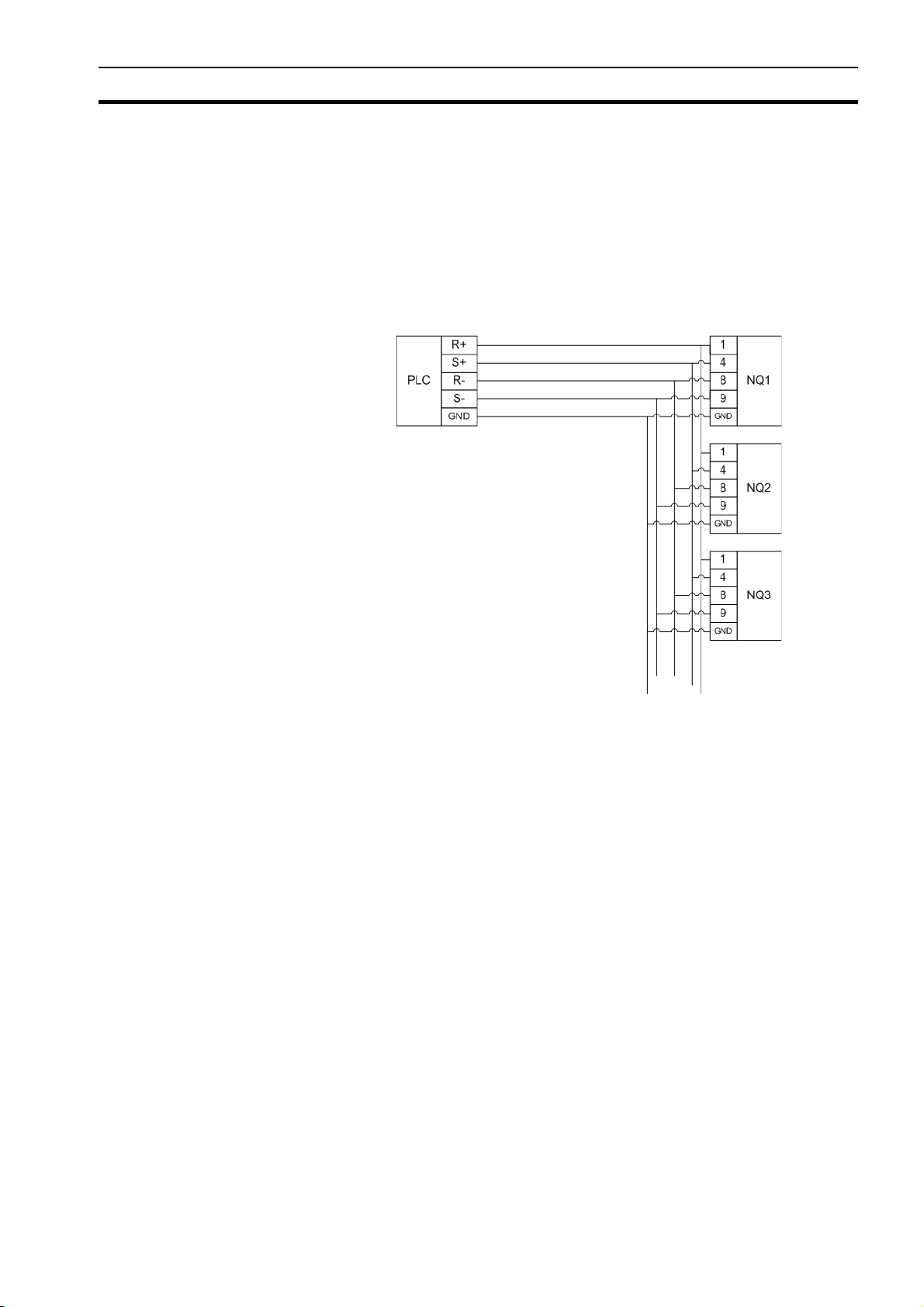

3-4-1 RS-422 network

The following wiring diagram is applicable for a RS-422 network (4-wire).

Figure 3.9: RS-422 network

15

Page 30

Multi-drop networks Section 3-4

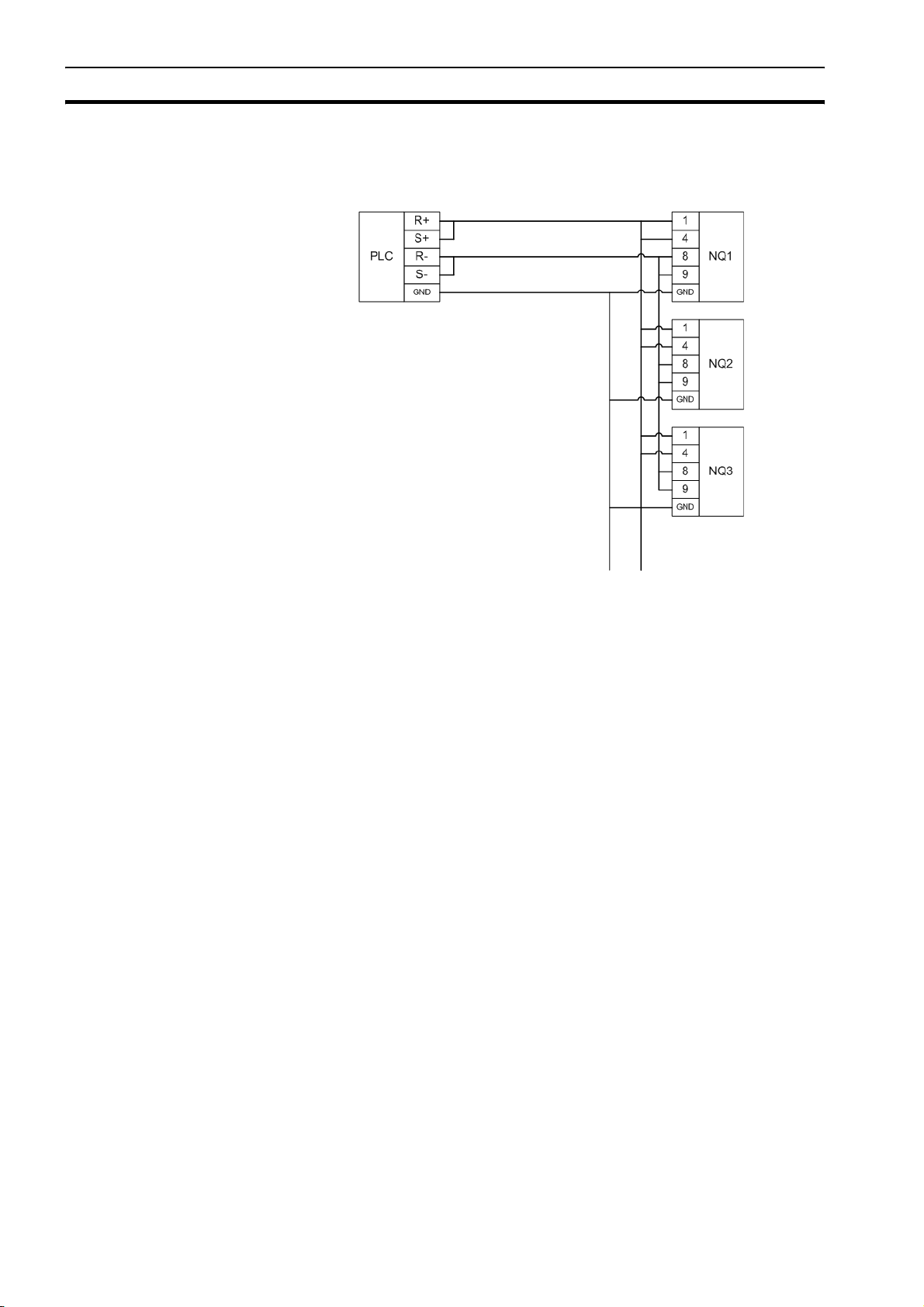

3-4-2 RS-485 network

The following wiring diagram is applicable for a RS-485 network (2-wire).

3-4-3 Network termination

The two ends of a multi-drop network have to be terminated. For the correct

termination of the last NQ-Series in the network, a resistor (120 Ohm) needs

to be applied between R+ (pin 4) and R- (pin 9) on DSUB9 (Male) cable

connector for correct termination.

Figure 3.10: RS-485 network

16

Page 31

Section

SECTION 4

Creating applications

This section describes how to create programs for the NQ-Series.

SECTION 4

Creating applications 17

4-1 Preparing for programming .............................................................. 18

4-2 Using NQ-Designer .......................................................................... 21

4-3 Example application .........................................................................33

17

Page 32

Preparing for programming Section 4-1

4-1 Preparing for programming

4-1-1 NQ-Designer

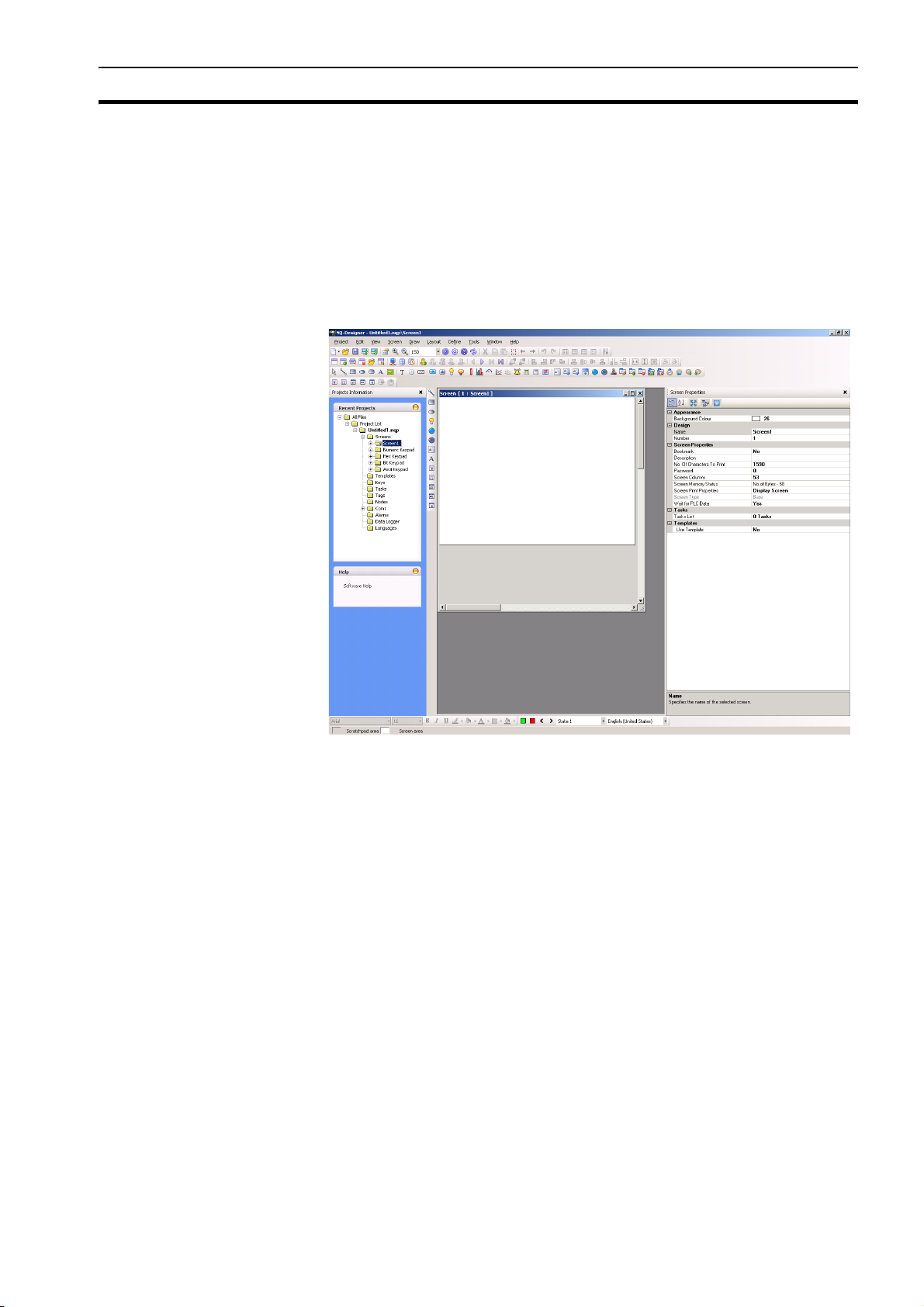

NQ-Designer is used to create and modify user interfaces for the NQ-Series.

The user interface is created in the software and downloaded to the device.

Existing user interfaces can be uploaded to the software and be modified as

required. The software can also be used in a simulation mode to test the

program without downloading the program to the NQ-Series.

Figure 4.1: NQ-Designer

4-1-2 System requirements

The following basic PC hardware configuration is needed to install and use

NQ-Designer.

4-1-2-1 Microsoft® Windows® XP configuration

/i

Table 4.1: Windows XP configuration

Device Recommendations

Processor Minimum: 600 MHz Pentium processor or

equivalent processor

Recommended: 800 MHz Pentium processor or

equivalent processor

Operating System Windows® 2000 with SP4,

Microsoft® Windows® XP Professional

Microsoft® Windows® XP Home Edition with SP2

System RAM Minimum: 128 MB

Recommended: 256 MB/512 MB

Hard Disk Space 800 MB

(including 200 MB for the .NET Framework Redistributable)

18

Page 33

Preparing for programming Section 4-1

Device Recommendations

Display Minimum: 800 x 600 with 256 colours

Recommended: 1024 x 768 with 16 bit colour quality

Serial Port Serial port or USB port

Mouse Microsoft® Mouse or compatible pointing device

Keyboard Required

4-1-2-2 Microsoft® Windows® Vista configuration

/i

Table 4.2: Windows Vista configuration

Device Recommendations

Processor Minimum: 800 MHz Pentium processor or

equivalent processor

Recommended: 1 GHz Pentium processor or

equivalent processor

Operating System Microsoft® Windows® Vista Home

Microsoft® Windows® Vista Business Edition

System RAM Minimum: 512 MB

Recommended: 1 GB

Hard Disk Space 800 MB

(including 200 MB for the .NET Framework Redistributable)

Display Minimum: 800 x 600 with 256 colours

Recommended: 1024 x 768 with 16 bit colour quality

Serial Port Serial port or USB port

Mouse Microsoft® Mouse or compatible pointing device

Keyboard Required

4-1-3 Installing the software

To install NQ-Designer run setup.exe from the installation disc and follow the

installation instructions.

4-1-4 Connecting the NQ-Series power supply

Connect a 24 VDC power supply to the NQ-Series.

4-1-5 Connecting the NQ-Series to a PC

The NQ-Series can be connected to a PC with the following programming

cables:

• Serial cable (NT2S-CN002)

• USB cable (CP1W-CN221)

Refer to Appendix A-2 and A-4 for more information on cables.

4-1-5-1 Serial cable

The serial cable can be used directly after connecting the cable.

19

Page 34

Preparing for programming Section 4-1

4-1-5-2 USB cable

In order to use a USB cable the USB driver needs to be installed on the PC

operating system. Perform the following steps to install the USB driver.

1 Connect the USB cable to the PC and NQ-Series.

2 When the PC detects the NQ-Series the following message is displayed:

Found New Hardware: HMI USB Device.

On the dialog select Found New Hardware Wizard, No, not this time

and click Next (It depends on the environment whether the message is

displayed or not.).

3Select Install from a list of specific location and click Next.

4 Ensure that Include this location in the search is checked and browse to

the following location:

C:\Program Files\OMRON\NQ-Designer\USBDrivers\

5Click Next to install the USB driver.

6 If the Hardware Installation dialog is displayed, click Continue Anyway.

7Click Finish to complete the installation.

A correct installed driver will show a message on the NQ-Series’ screen: USB

device status: Connected (This message is only shown when no firmware is

downloaded in the NQ).

20

Page 35

Using NQ-Designer Section 4-2

4-2 Using NQ-Designer

4-2-1 Starting NQ-Designer

Select Start, Programs or All Programs, Omron and click on NQ-Designer

to start the program.

4-2-2 NQ-Designer program window

Opening a project or creating a new project will show the below programming

window on your Personal Computer.

4-2-2-1 Title bar

4-2-2-2 Menu bar

4-2-2-3 Toolbars

4-2-2-4 Project panel

Figure 4.2: NQ-Designer program window

The title bar displays the name of the program and the selected part of the

project.

The menu bar contains the program commands.

The toolbars contain shortcuts to all program functions.

To display the tool tips hover over the icons in the toolbars.

On the View menu click Toolbars to hide or show a toolbar. The toolbars

supporting drag and drop functionality.

The project panel shows the structure of the program. From the project

structure the project is managed and the project parts are set and configured.

On the View menu click Projects Information to hide or show the project

panel.

21

Page 36

Using NQ-Designer Section 4-2

Project list

The Project list contains all saved projects. The project file extension is .NQP.

Creating or opening a project will show the root folders described below.

Screens

The Screens folder contains one base screen and four predefined keypad

screens that can be used in the project. For every screen the following parts

can be configured:

• Layout: graphical representation of the screen

• Keys: function keys used in this screen

• Tasks: assigned tasks to the screen

• Password: a password can be assigned to pages that must be entered

before the page can be accessed.

Keypad screens and screens numbered 65000 and higher are assigned as

pop up screens. If a new popup screen is added to the project the screen will

be located here.

Functions that can not be assigned to pop up screens are:

• Goto next screen

• Goto previous screen

• Open popup screen (it is not allowed to chain pop up screens)

• Data entry objects

• All objects configured to PLC tags

• Password protection

Templates

The Tem p l a tes folder contains the created template screens. Template

screens are screens that can be added to a base screen. Template screens

are always placed behind the base screen. These screens usually contain

keys, buttons or background images that are used frequently in the project.

Following objects can not be assigned or are conditional to template screens:

• Data Entry on PLC tags

• Keypads placed on template screens act on numerical input of the base

screen

• Screen tasks ( Before showing, while showing, after hiding tasks)

• Key specific tasks

• Objects related to PLC tags

• Passwords

22

Using templates will also positively influence the usage of the memory and

reduce the programming time. (You re-use screens that you have

programmed before and assign them to different base screens).

To add a template proceed as follows:

• Click on ADD Templates ( ).

Page 37

Using NQ-Designer Section 4-2

Global Keys

The Global Keys folder can be used to assign tasks to global keys. Global

keys are running cyclic for the whole project. The following tasks are available:

• Press Task (tasks executed while pressing the key)

• Pressed Tasks, (tasks executed while holding the key)

• Released Tasks (tasks executed while releasing the key)

Please note that when key tasks are assigned to screen keys the global keys

will not be executed, e.g. global key F1 = add 1 to D000, and screen key F1 =

subtract 1 from D000 then subtract 1 is active for this screen when pressing

F1.

Tasks

On the Tasks dialog the Power On tasks and Global tasks can be configured.

The Power On tasks are executed once the NQ-Series starts up. The Global

tasks are executed every cycle of the program. The task list can contain more

than one command.

Global tasks that most common used are:

• Switch SCREEN from TAG (used when the PLC is responsible for screen

switching).

• Copy RTC to PLC (this copies the NQ-Series’ RTC data to assigned PLC

tags (7 sequential tags)).

If the program contains many global tasks it can influence the performance of

the NQ-Series.

Tags

The folder Tags shows all tags that can be used in the project. The folder

contains the following tags: system tags (default set), internal tags (NQ tags)

and PLC tags created by users.

Tags represent the addresses (bit, byte, word, double word registers) that will

be used in a project.

23

Page 38

Using NQ-Designer Section 4-2

To add a tag proceed as follows.

•Click Tag ( )in the toolbar and click Add....

Figure 4.3: Tag information

• Enter Tag Name.

•Select Register/Coil Type.

•Select Tag Ty p e.

•Select Auto Add to create a number of tags in sequence increasing by

word or by bit depending on tag choice. ( names can be edited afterwards)

•Select 2-Bytes (1-word).

Default system tags

The following tables contain the default system tags. Do not attempt to modify

or delete the system tags. This could affect the functionality of the NQ-Serie.

On the toolbar you find a button ( ) that allows you to display all tags or

user created tags shown in your tag list.

/i

Table 4.3: Default system tags (words)

Register Tag name Read/Write Description

S0001 Language Read/Write Writing a value will change

languages in multi language

supported objects (texts).

S0002 Flash memory status Read Shows percentage used of

logger memory.

S0004 Number of historical

alarms

S0005 Screen trigger register Read/Write Shows active screen.

Read Shows number of alarms

stored in history.

Change screen by writing a

valid screen number in the

register.

24

S0006 Screen saver time Read/Write The screen saver time (Sec)

can be changed during

operation.

Page 39

Using NQ-Designer Section 4-2

Register Tag name Read/Write Description

S0010 RTC day Read RTC day in integer format

S0011 RTC month Read RTC month in integer format

S0012 RTC year Read RTC year in integer format

S0013 RTC hour Read RTC hour in integer format

S0014 RTC min Read RTC minute in integer format

S0015 RTC sec Read RTC second in integer format

S0016 RTC day of the week Read RTC day of week in integer

format

S0017 Scan time register Read Shows time required to

execute screen, screen task

and global task in millisecond.

Use ####.## format for

display.

S0018 Communication recover

time[s] for port1

Read/Write Shows time in seconds to

recover the communication

with failed nodes for port1. The

default value is 60 sec.

S0020 Driver scan time register

for port1

Read Shows time required to

execute screen blocks in

milliseconds. Use ####.##

format for display.

S0023 Popup screen trigger

register

Read/Write Holds the screen number for

the pop-screen that will be

shown when bit s20 bit is set.

S0116 Fact_Appln_1 Read/Write Reserved

S0117 Fact_Appln_2 Read/Write Reserved

S0118 Fact_Appln_3 Read/Write Reserved

S0119 Fact_Appln_4 Read/Write Reserved

S0120 Fact_Appln_5 Read/Write Reserved

S0121 Contrast control

(Retentive register)

Read/Write This retentive register used for

setting the contrast of the NQSeries.

S0122 Brightness control

(Retentive register)

Read/Write This retentive register used for

setting the brightness of the

NQ-Series.

S0123 Fact_Appln_6 Read/Write Reserved

S0124 Fact_Appln_7 Read/Write Reserved

S0125 Fact_Appln_8 Read/Write Reserved

/i

Table 4.4: Default system tags (Bit)

Register Tag name Read/Write Description

S0003_00 Logger memory full status Read 1: full memory

S0003_01 Logger memory clear

status

Read 1: memory clear is

being executed

25

Page 40

Using NQ-Designer Section 4-2

Register Tag name Read/Write Description

S0003_02 RTC fail Read RTC fail (contents of

registers not within

defined ranges e.g.

minutes>60 )

S0003_14 Comm1 status Read 0: communication error

1: communication OK

S0003_15 Comm2 status Read 0: communication error

1: communication OK

s0003 Minute change pulse Read 1 for every change in

minute for one scan

cycle

s0004 Hour change pulse Read 1 for every change in

hour for one scan cycle

s0005 Date change pulse Read 1 for every change in

date for one scan cycle

s0006 Month change pulse Read 1 for every change in

month for one scan

cycle

s0007 Year change pulse Read 1 for every change in

year for one scan cycle

s0008 Screen saver control Read/Write 0: disable screen saver

1: enable screen saver

This bit can be changed

in during operation

s0009 Beeper on/off Read/Write 0: disable beeper

1: enable beeper

This bit can be changed

during operation.

s0010 Battery status Read 0: battery voltage is OK

1: low battery

(below 2.2 V)

s0012 Update the historical trend Read/Write Update the historical

trend window when set

to 1

s0014 Acknowledge all alarms Read 0: all alarms are

acknowledged

1: all alarms are not

acknowledged in the

real and historical

alarms

26

s0016 Valid key beeper Read/Write 0: disable valid Function

key beeper

1: enable valid Function

key beeper

This bit can be changed

during operation

Page 41

Using NQ-Designer Section 4-2

Register Tag name Read/Write Description

s0017 Invalid key beeper Read/Write 0: disable valid screen

beeper

1: enable valid screen

beeper.

When set to 0 the NQSeries will only generate

a beep when an input

area is pressed.

This bit can be changed

during operation

s0019 Invalid date entry Read 0: valid date

1: invalid date (range

not within defined

ranges e.g. month > 12)

s0020 Popup screen control coil Read/Write Triggers the popup

screen number stored in

S0023

s0021 Communication recover

enable bit: port1

Read/Write If this bit is set

communication with the

failed nodes is detected

after scan time S0018

for port1 (on by default)

s0028 Bittask datalogger-logger

group1 bit

s0029 Bittask datalogger-logger

group2 bit

s0030 Bittask datalogger-logger

group3 bit

s0031 Bittask datalogger-logger

group4 bit

Read/Write User can start/stop

logging in bit task mode

for group1 by using this

bit.

1: Start logging

0: Stop logging

Read/Write User can start/stop

logging in bit task mode

for group2 by using this

bit.

1: Start logging

0: Stop logging

Read/Write User can start/stop

logging in bit task mode

for group3 by using this

bit.

1: Start logging

0: Stop logging

Read/Write User can start/stop

logging in bit task mode

for group4 by using this

bit.

1: Start logging

0: Stop logging

s0032 Lock data entry Read/Write User can lock/unlock

the data entry (keypad

entry).

0: data entry unlock

1: data entry lock

27

Page 42

Using NQ-Designer Section 4-2

Register Tag name Read/Write Description

s0033 Start data entry only

through enter key

Read/Write User can choose the

mode of data entry

using this bit.

0: allow data entry

through enter key or

numeric key

1: allow data entry only

by pressing enter key

first

4-2-2-5 Alarms

s0035 Ignore real and historical

alarms

s0036 Run LED on/off Read/Write 0: Run Led is On

s0037 Allow USB host operation Read/Write 0: USB host operation

Read/Write 0: Monitor all alarms

1: Ignore all real and

historical alarms

1: Run Led is Off

not allowed

1: USB host operation

allowed.

Nodes

The Nodes folder contains the information of your network: the name of the

panel and PLCs, node addresses in the network (listed under COM1 or

COM2), protocol used on the COM port. COM1 and COM2 can have different

protocols.

In this folder you can also add a node to your network.

•Click Nodes ( ).

• Right-Click on screen.

• Select add Node.

In the alarm folder alarms can be assigned and configured.

28

For alarms there can be chosen of two formats to configure.

• 16 Random words

For each TAG (word) 16 alarms can be configured / assigned in the alarm

folder.

A total of 16 different words ( = 256 alarms) can be configured / assigned.

• 16 consecutive words

This function is enabled after 16 consecutive Word tags have been created

in the tag database. If this method is chosen all 256 lines will be created in

your alarm screen.

Page 43

Using NQ-Designer Section 4-2

Attached image shows a screenshot of the alarm screen.

Figure 4.4: Alarm project configuration properties

Above image shows the window that is shown when opening the alarm folder.

From top to bottom you see:

• Alarm type: 16 random words (this is the selection made in the alarms tab

starting the project)

• Also action, If alarm memory is full, this is also selected in the alarm tab,

and the action that is performed.

• Acknowledge alarms on selection, this means that for each alarm an

acknowledge bit must be selected.

If any of the selections made above is incorrect, press button Change

properties.

Note that this will erase any alarm assignments already created.

For assigning the alarm register that will be used to trigger alarms a tag has to

be created in tag list.

Example:

HR000 is the alarm register used in the PLC program. Create a tag with

HR000 in your tag list. Select this created tag and assign the alarm register.

Upon assigning you will see that the first 16 lines are now identified as alarms.

Bit HR000.00 as alarm 0 (Motor stopped), bit HR000.01 as alarm 1 (Fuse

blown), etc.

Clicking on alarm 0 first line allows you to enter the alarm text, acknowledge

(Y/N) and which bit should be used to perform ACK, severity, real time alarm

or Historical alarm.

When all of these settings are made you click button ACCEPT. You see now

all text turns blue and alarm sign has changed to YES.

With this method you can assign all alarms used in your project.

29

Page 44

Using NQ-Designer Section 4-2

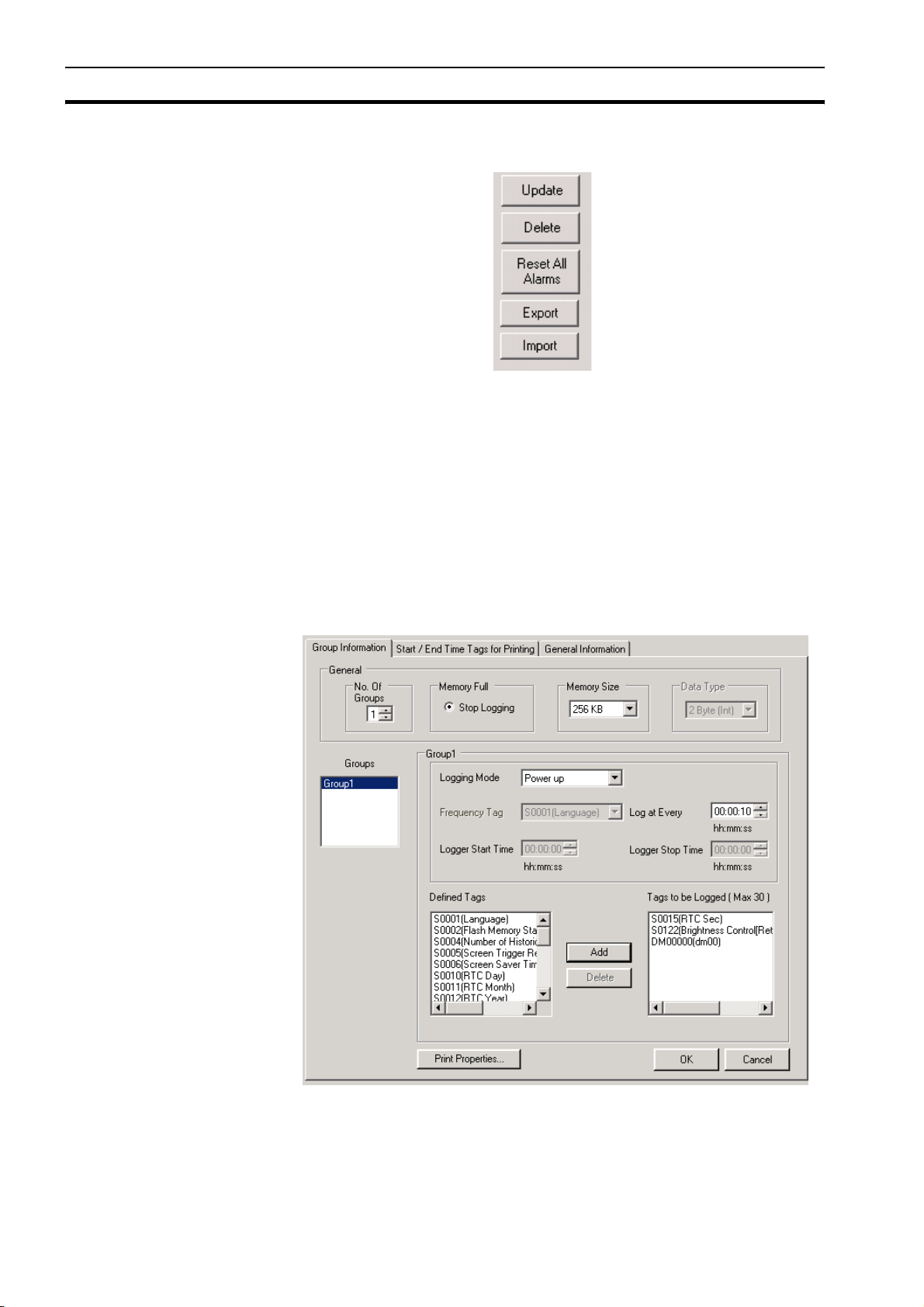

Important buttons are explained below for assigning alarms.

Figure 4.5: Alarm buttons

• Update will update the change you have applied to the alarms

• Delete will delete the alarm line you have selected.

• Reset all alarms will reset all settings in alarms. All will be cleared including

the selected register for alarms

• Export will export all text used in alarms to CSV for creation of

Multilanguage application.

• Import will import the modified CSV file for multilanguage in the project.

4-2-2-6 Data Logger

The data logger allows users to log data (tags) in the NQ-Series over time.

The data logger folder contains the set-up/configuration for data logging and

data logging printing.

30

Figure 4.6: Data logger

Page 45

Using NQ-Designer Section 4-2

The memory size reserved for logging data in the terminal can be selected.

Several ranges can be selected from 256Kb to 2048Kb.

For logging the data type (word / double word) can be selected. Upon this

selection the tags available for logging will then be filtered to what can be

chosen for logging.

The data logger allows a user to define 4 different groups. Each group can

contain of 30 tags that can be logged. For each group a logging mode can be

defined.

The datalogger can handle 6 different logging modes.

• Power up

Each tag defined in this group will be logged when terminal is powered and

application is running. The logging frequency for this group can be set.

• Start / Stop time

User can define on which part of the day the logging must occur. Also with

this option the logging frequency can be programmed for the whole group

when choosing this mode.

•Key task

User can assign keys / buttons to start and stop logging. The commands

can be found under "Keys specific Task" selection.

• Logging with run time frequency

This mode can only be used for group 1 and is intended for datalog printing

only. When selected this option each tag will be logged with a selectable

interval of minimum 30 minutes.

•Bit task

User can use the system bits s28 (group1) to s31 (group4) to start or stop

logging. If system bit is set to 1 logging starts.

•Event based

User can select an internal bit for logging. There are 3 options to select. :

Positive edge, Negative edge, Both edges. When selecting each of these

options the logging will start / stop on the selected conditions.

4-2-2-7 Languages

The Languages dialog shows the supported languages and manages the

languages supported by the project. To support a language the language

needs to be added to the program. NQ-Designer supports a total of 9

languages. The default language of the program is the default language of the

operating system.

Figure 4.7: Languages

To add a language proceed as follows.

• Select the language from the Supported Languages list and click Add.

• Check the checkbox to enable keyboard layout for the selected language.

31

Page 46

Using NQ-Designer Section 4-2

In the language folder you will see S0001 displayed. In front of each added

language a value is shown. If the value in register S0001 is set to the value

shown in front of the added language the project will then be displayed in the

selected language.

First language shown in the language folder is the default language of your

Windows operating system. Languages can be added or removed from this

folder.

If you use the import/export tool for entering multiple languages you do not

need to enable the keyboards in this folder. A keyboard can be enabled if you

add the language to your Windows operating system. Languages can always

be added to the program in a later stage.

Creating a multi language application import / export functionality for

translation you will always have to export and import 2 different files.

Text objects (Import / export text objects in Toolbar) AND Alarm objects (in

alarm folder).

4-2-2-8 Workspace

The workspace is used to create and edit the projects. The properties panel

displays the properties of the settings. The properties can be changed by

clicking the properties’ value.

4-2-2-9 Status bar

The status bar contains additional information regarding scratch pad area and

the screen area coordinates. The scratch pad area is the total screen area

available for programming.

4-2-2-10 Properties window

The properties window shows the properties of the selected object. Properties

that can be changed by user are displayed in bold.

4-2-3 Using the help function

The help function is displayed by clicking Software help or Contents on the

Help menu.

32

Page 47

Example application Section 4-3

4-3 Example application

4-3-1 Project settings

1 Start NQ-Designer.

2 Click Create New Project or click Create New NQ Project on the Project

menu under New.

Figure 4.8: Select model

33

Page 48

Example application Section 4-3

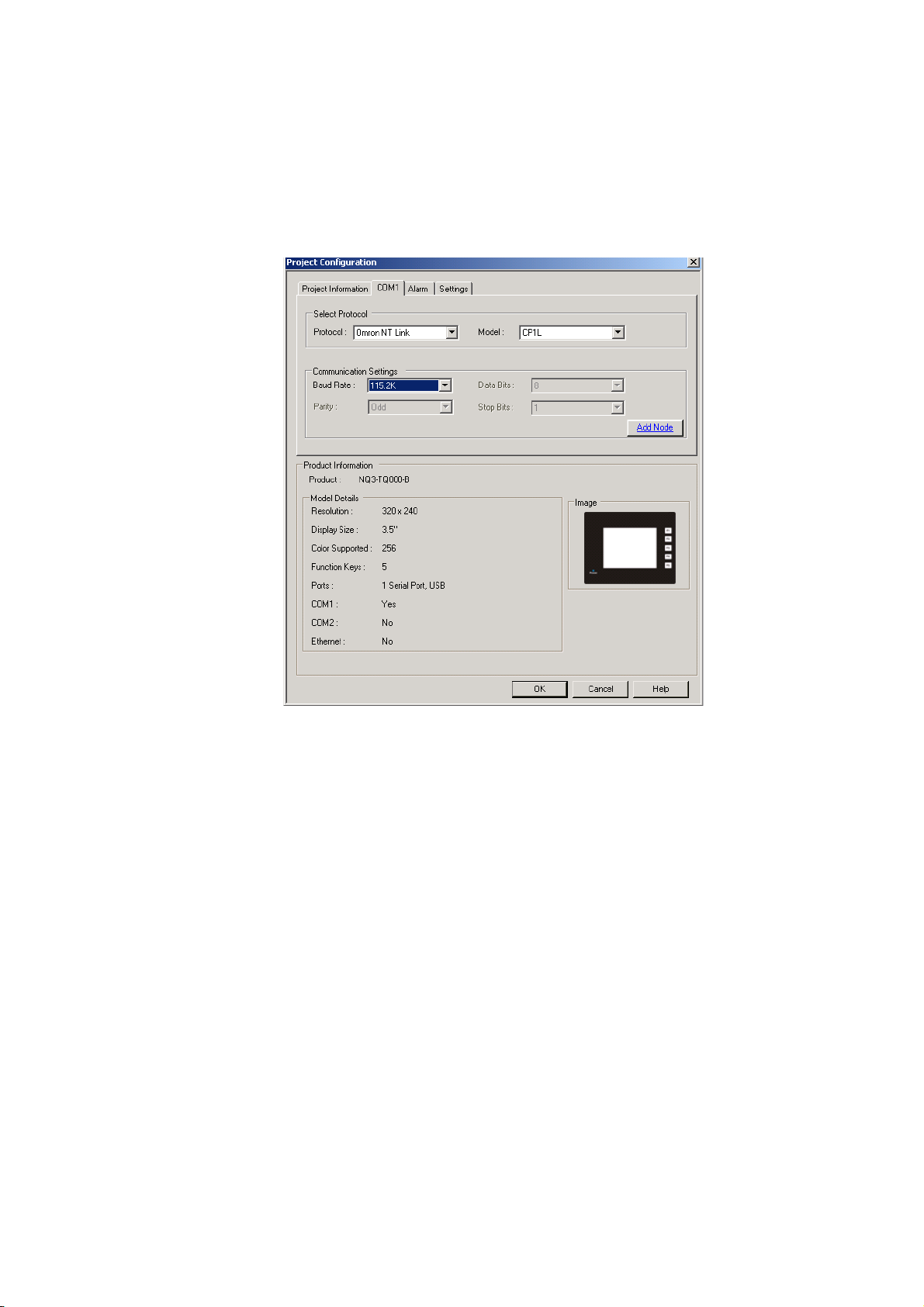

3Select NQ3 in product pulldown list. Select NQ3-TQ000B as model type.

Click OK.

Figure 4.9: Project information

4 Enter the following project data:

• Project title: Example

34

Page 49

Example application Section 4-3

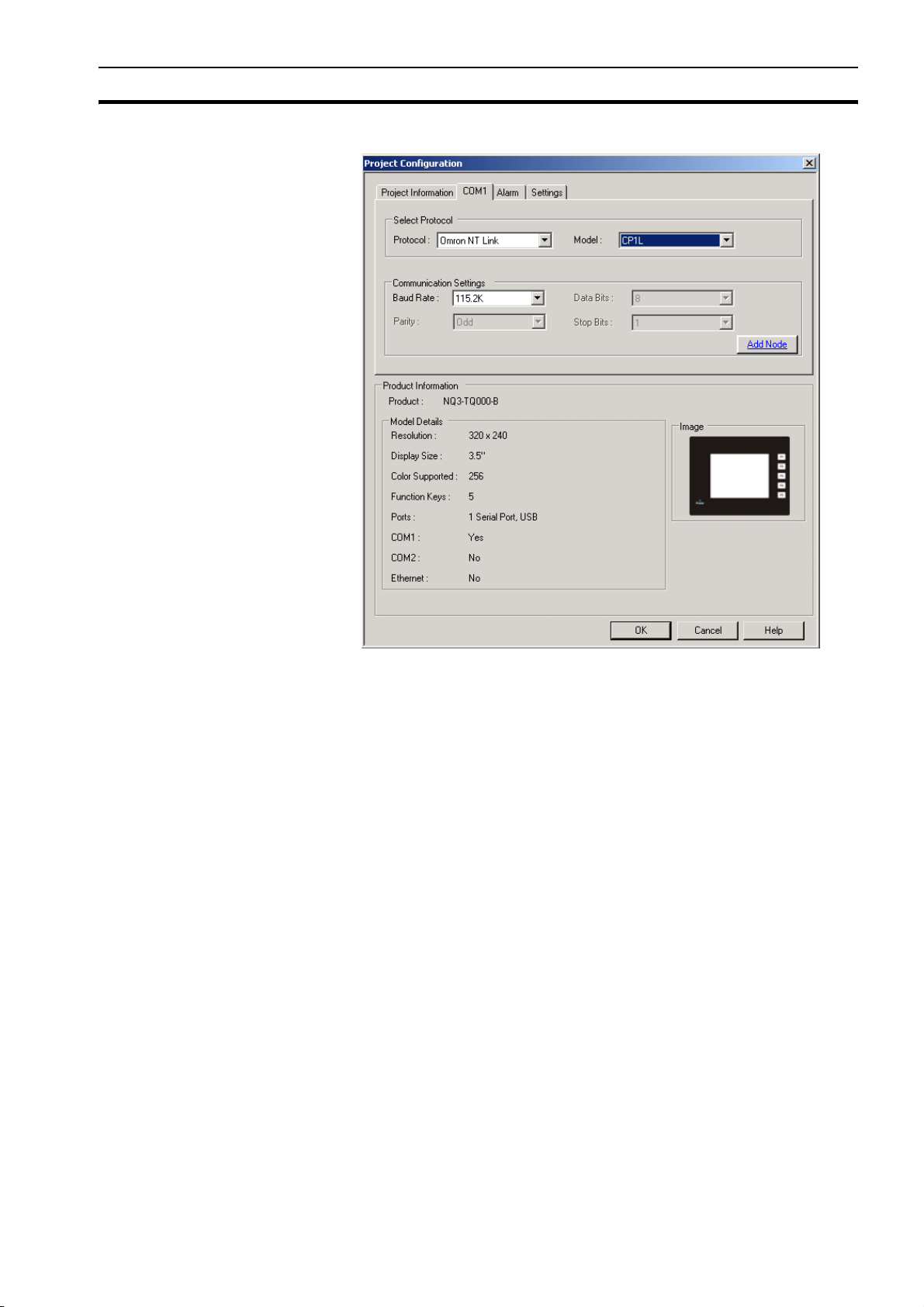

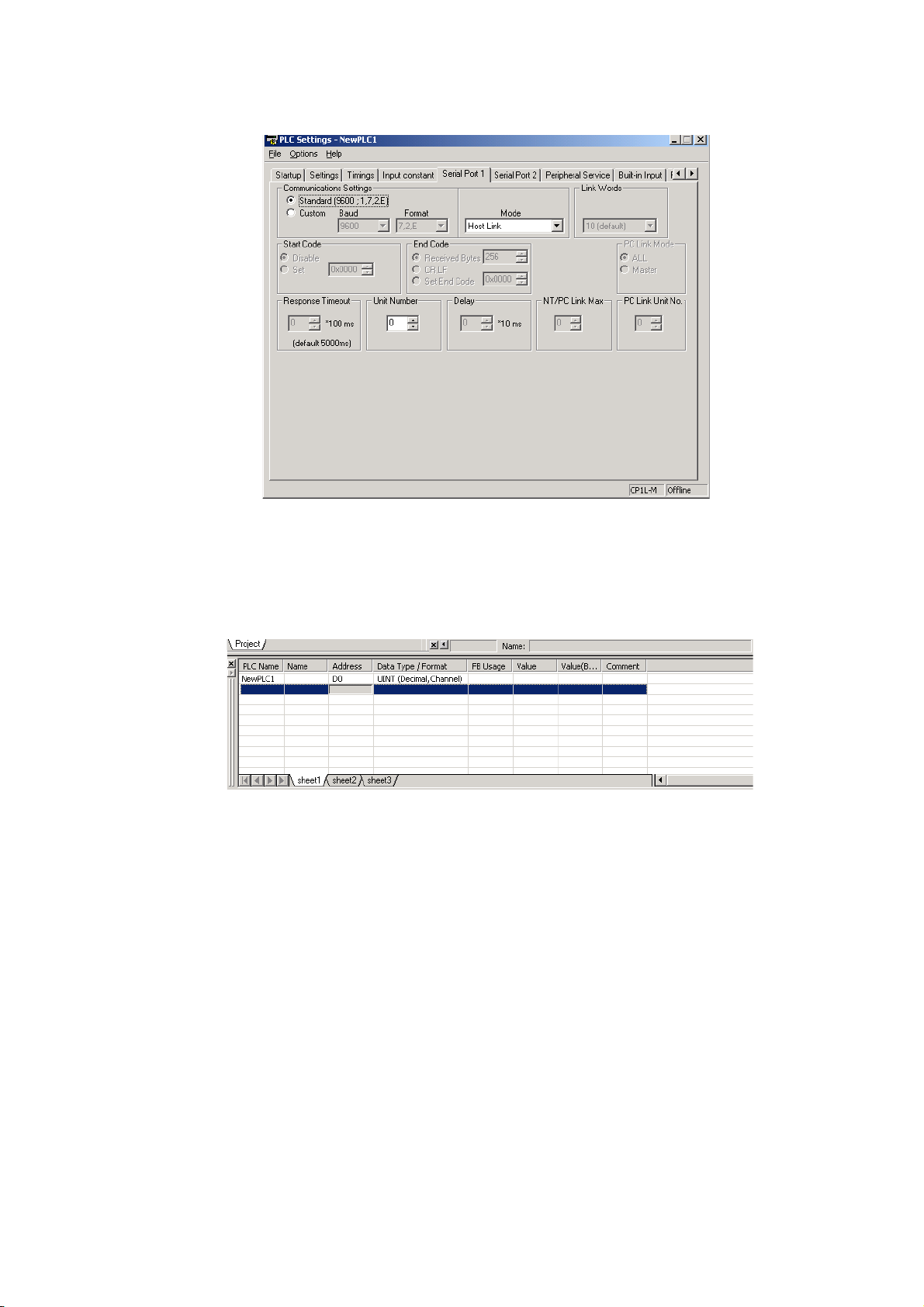

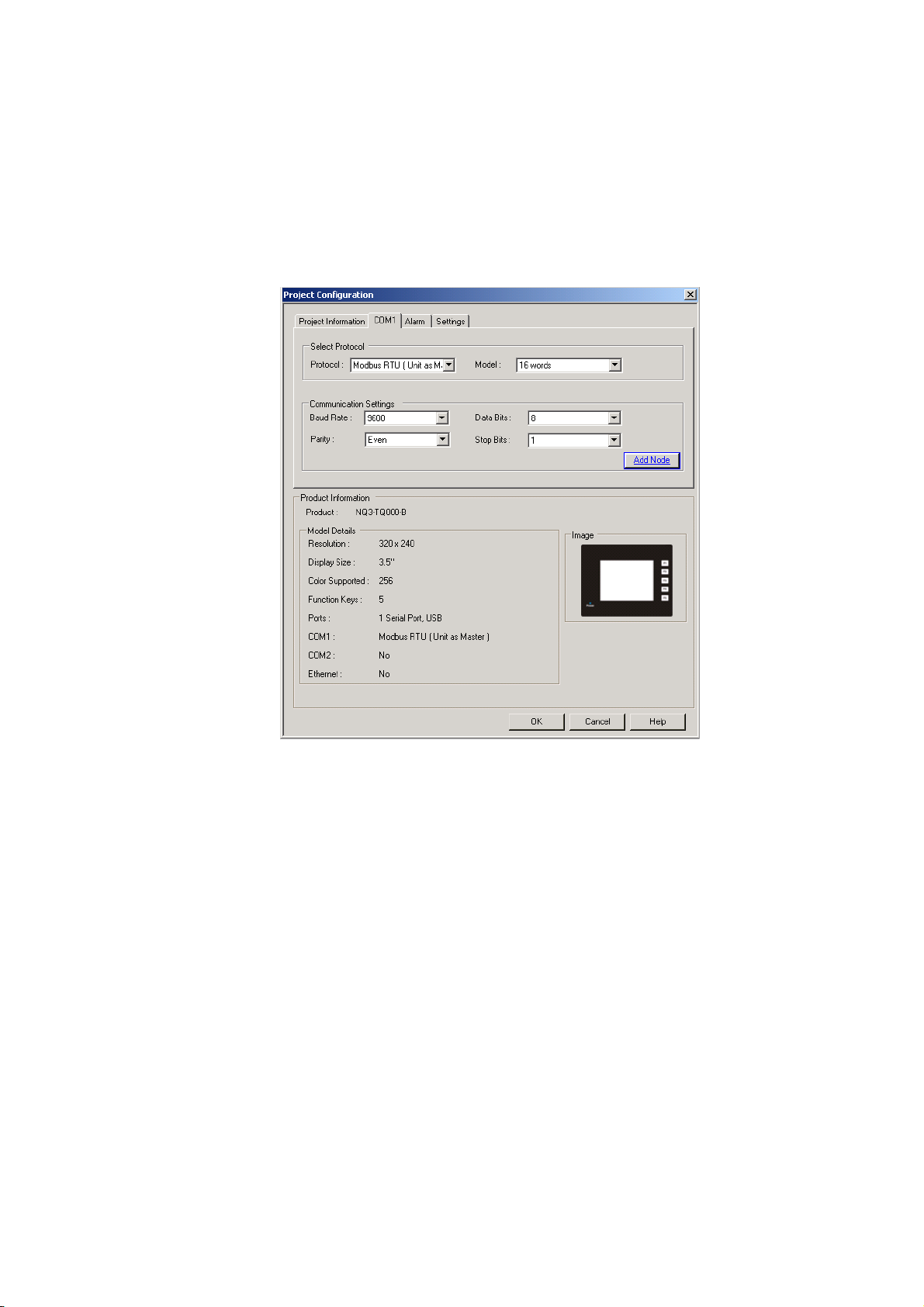

5 Click COM1 tab.

Figure 4.10: COM1

6 Enter the following communication settings:

• Protocol: Omron NT Link

• Model: CP1L

• Baud Rate: 115.2K

•Data Bits: 8

•Parity: Odd

•Stop Bits: 1

7 Click Add Node.

8 Click Alarm tab.

35

Page 50

Example application Section 4-3

Figure 4.11: Alarm

9 Enter the following alarm settings:

• 16 random words: Each bit of each random assigned word is an alarm

36

Page 51

Example application Section 4-3

10 Click Settings tab.

11 Enter the following settings:

• Screen Saver Enabled

12 Click OK.

Figure 4.12: Settings

Figure 4.13: NQ-Designer screen

Refer to 4-2-2-4 Project panel for information on the project panel content.

37

Page 52

Example application Section 4-3

4-3-2 Screen functionality

NQ-Designer automatically generates 5 screens:

• 1 base screen for programming

• 4 predefined keypad screens (pop-up screens)

The properties window can be used to change the properties. Properties

displayed in bold can be changed. The most important properties are as

follows:

• Tasks List

• Use Template

Proceed as follows:

1 Double-click Screens. Click Screen1.

2Click ... from Tasks List in the property panel.

3 Select task from pulldown menu.

For each screen you can define if actions should be made before , during

or after closing the screen

4-3-3 Multilingual text objects

Multilingual text objects are used to display texts. This object should be used

when programming a multilingual application. The most important properties

are as follows:

• Visibility Animation

• Font

•Flash

• Text Colour

38

Page 53

Example application Section 4-3

Proceed as follows:

1 Click Multilingual Text ( ).

2 Draw the multilingual text object on Screen1.

3 Press the space bar. This will open a field in the Status Bar of NQ-

Designer. This will allow you to enter text immediately.

4-3-4 Data entry objects

Data entry objects will use a keypad to change data. In the property box a

popup screen ( keypad screen is automatically assigned with respect to format

used). If the user wants to add a keypad to base screen to change an input,

the setting keypad should be set to NO in the numerical input configuration

Data entry objects are used to enter:

• numerical data

•bit data

The most important properties for numerical data are as follows:

• Tag Address (register)

• Tag Name

• Data Type (unsigned, hex, binary, etc.)

• Format (4,2) total 4 digit of which are 2 behind the delimiter (**,**)

The most important properties for bit data are as follows:

•Off Text

•On Text

•Keypad

Figure 4.14: Multilingual text objects

39

Page 54

Example application Section 4-3

Proceed as follows:

1 Right-click on Screens folder in project panel.

2Click New Base Screen ( ).

3 Click on Screen2.

4Click Numerical Data Entry ( ).

Note Right lower field shows explanation of field selected in property box.

4-3-5 Display data objects

Display data objects are used to display:

• numerical data

• message data

•bit data

The most important properties for numerical data are as follows:

• Tag Address

• Tag Name

• Data Type

The most important properties for message data are as follows:

• Ranges

•On Text

• Tag Address

• Colour/Flash/Visibility Animation

The most important properties for bit data are as follows:

•Off Text

•On Text

• Tag Address

• Colour/Flash/Visibility Animation

Figure 4.15: Data entry objects

40

Page 55

Example application Section 4-3

Proceed as follows:

1 Right-click on Screens folder in project panel.

2 Select New Base Screen ( )

3 Click on Screen3.

4 Click Numerical Data Display ( ).

5 Click on Screen3.

6 Click Message Data Display ( ).

7 Click 1 from Ranges in the property panel.

Figure 4.16: Display data objects

8 Click Add. (ranges can be modified to desired values)

Figure 4.17: Register text range

41

Page 56

Example application Section 4-3

4-3-6 Buttons

Buttons are used to assign tasks. The following buttons are available:

defined buttons (

• Pre

Buttons to which predefined single tasks can be assigned..

• Advanced bit button ( )

Free configurable bit buttons with feedback option. The following behaviour

can be programmed: press (rising edge), pressed (high) and released

(falling edge).

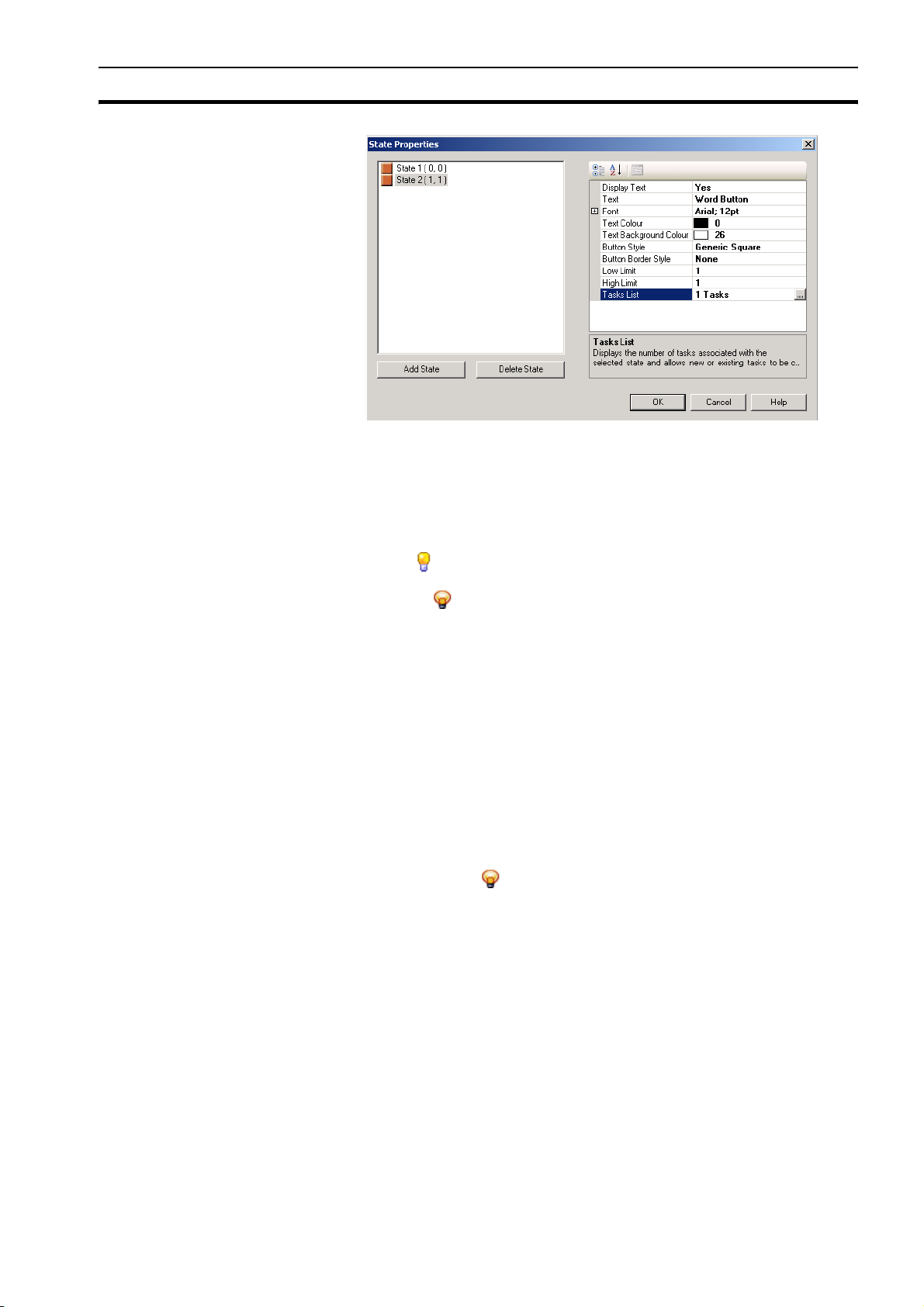

• Word button ( )

Buttons that can be configured on 32 states referenced to the value of the

used tag defined for each state. Different tasks and messages can be

assigned to each state of a word button.

The most important properties for buttons, advanced bit buttons and word

buttons are as follows:

• Button Style

•On Text

•On Text Colour

Proceed as follows:

1 Click on Screen3.

2Click Word Button ( ).

(Pressing the space bar will allow you to enter text directly.)

3Click Collection from State Properties in the property panel.

4Click Add State.

)

42

Figure 4.18: Word button

5Click ... from Tasks List in the property panel.

6Click Add.

Page 57

Example application Section 4-3

Figure 4.19: State properties

7 Click OK.

8 Click OK.

4-3-7 Lamp objects

The following lamp objects can be used:

• Bit lamp ( )

Bit lamp objects are used to display the on and off state of a coil type tag.

• Word lamp ( )

Word lamp objects are used to display multiple states (max. 32) depending

of the value of the assigned address.

The most important properties for bit lamp objects are as follows:

• Tag Address

• Style (generic, images, etc.)

• On Text Colour

The most important properties for word lamp objects are as follows:

• Tag Address

• State Properties

Proceed as follows:

1 Click Screen3.

2 Click Word Lamp ( ).

3 Click on Screen3.

4 Click ... from State Properties in the property panel.

43

Page 58

Example application Section 4-3

5Click Add State.

6Click OK.

4-3-8 Graphical objects

The following graphical objects can be used to draw objects and place pictures

on the screen:

• Line ( )

•Rectangle ( )

• Ellipse ( )

Figure 4.20: Lamp objects

44

Page 59

Example application Section 4-3

• Rounded rectangle ( )

• Advanced picture ( )

All imported pictures are converted to BMP before downloading the

pictures to the NQ-Series. This means that GIF and JPEG pictures will be

converted to BMP resulting in a bigger memory use.

4-3-9 Wizards

4.21: Graphical objects

The following wizards can be used to add functionalities:

• Bar graph ( )

To display a value by means of a bar.

• Multiple bar graph ( )

To display values by means of max. 4 bars in one graphic. Each bar can be

defined with different min. and max. values and assigned to different

addresses. See image attached with multiple bar graph properties

selected.

• Analogue meter ( )

To display a value by means of a meter.

45

Page 60

Example application Section 4-3

• Trend ( )

To display a value over a period of time in a diagram.

• Historical Trend ( )

To display the trend of logged data. This command can only be used if a

tag is logged in data logging. A maximum of 4 logged tags can be shown in

the historical trend.

4-3-10 Alarms

Figure 4.22: Wizards

Alarm windows are created for displaying alarms on screen. The most

important properties for alarms are as follows:

• Alarm Type (real time or historical)

• Select Display Fields ( what is shown and order)

Proceed as follows:

1Click Screen.

2Click Alarm ( ).

To define the alarm see Alarms in 4-2-2-4 Project panel.

3Click Collection from Select Display Fields in the property panel.

4Select On-Time and Off-time and click Add. The order of data shown in

the window can be configured here.

46

Page 61

Example application Section 4-3

4-3-11 Keypad

Figure 4.23: Alarms

5 Click OK.

The tool bar contains four predefined alarm buttons: two buttons for navigation

and two buttons to acknowledge ( ). The acknowledge button

acknowledges the first alarm shown in the alarm window. The navigation

buttons are used to navigate through the alarm window.

Keypads can be used on a popup screen or on the base screen. If used on a

popup screen the keypad will behave exactly the same as the predefined

keypads in NQ-Designer.

If the keypads are placed on a base screen where also an input is placed

(select No keypad in the property box), the keypad will change the data of this

input. If a keypad is placed on a base screen with more input fields it will

change all input fields on that screen one by one. To enable the keypad on a

base screen press ENT or one of the numeric keys. The first numerical input

will start to flicker. Now you can start entering the data.

47

Page 62

Example application Section 4-3

The following keypad can be used:

• Keypad ( )

This keypad is a numeric keypad that provides different styles of displaying

keypads.

• ASCII keypad ( )

This keypad is an ASCII keypad. There are two keypad styles:

ASCII (Style 1) and ASCII numeric (Style 2).

• Custom keypad ( )

This keypad can be selected to create a custom numeric or ASCII keypad.

The format can be freely chosen. This means merging keys, number of

keys. Assignments for keys can be chosen in the property box.

48

Page 63

Section

SECTION 5

Transferring programs

This section describes how to transfer NQ-Designer programs to NQ-Series

models.

SECTION 5

Transferring programs 49

5-1 Downloading..................................................................................... 50

5-2 Uploading ......................................................................................... 52

5-3 USB host functionality ...................................................................... 55

49

Page 64

Downloading Section 5-1

5-1 Downloading

A project can be downloaded from NQ-Designer to the NQ-Series. A project

always consists at least of an Application and Firmware.

5-1-1 Downloading options

The following options can be selected:

• Application

•Firmware

• Font

5-1-1-1 Application option

If this option is selected, only the application will be downloaded to the NQSeries.

5-1-1-2 Firmware option

If this option is selected the firmware will be downloaded to the NQ-Series.

This option is necessary if:

• The firmware is downloaded to the NQ-Series for the first time.

• A PLC is either added or deleted in the network configuration.

• The firmware is updated with a newer version.

• Applications that are created in an older NQ-Designer version are

downloaded to the NQ-Series.

5-1-1-3 Font option

If this option is selected the fonts will be downloaded to the NQ-Series.

This option is necessary if the default fonts have been modified.

50

Page 65

Downloading Section 5-1

5-1-2 Downloading applications

To download an application proceed as follows.

1 Click Download ( ).

2 Select the required options and settings.(USB, application (project), FW,

3 Click Download.

5-1-3 Download errors

The following errors can occur during downloading applications:

• Product mismatch

• NQ-Series is not responding

• Port is either busy or does not exist

A product mismatch error occurs if an application is not compatible with the

NQ-Series attached.