Page 1

Machine Automation Controller

NJ-series

Robot Integrated CPU Unit

User’s Manual

NJ501-R500

NJ501-R400

NJ501-R300

CPU Unit

O037-E1-01

Page 2

NOTE

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of the information contained in this publication.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan and other

countries for OMRON factory automation products.

• Microsoft, Windows, Excel, and Visual Basic are either registered trademarks or trademarks of Microsoft Corporation in the United States and other countries.

• EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

• ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

• The SD and SDHC logos are trademarks of SD-3C, LLC.

Other company names and product names in this document are the trademarks or registered trademarks of their

respective companies.

Copyrights

• Microsoft product screen shots reprinted with permission from Microsoft Corporation.

• This product incorporates certain third party software. The license and copyright information associated with this

software is available at http://www.fa.omron.co.jp/nj_info_e/.

Page 3

Introduction

Thank you for purchasing an NJ-series Robot Integrated CPU Unit.

This manual contains information that is necessary to use the robot control function of the NJ-series

CPU Unit. Please read this manual and make sure you understand the functionality and performance

of the NJ-series CPU Unit before you attempt to use it in a control system.

Keep this manual in a safe place where it will be available for reference during operation.

This manual describes the functions added to the NJ501-R£££ CPU Unit.

Refer to the NJ/NX-series CPU Unit Software User’s Manual (Cat. No. W501) for information on the

common functions for the NJ501-££££ CPU Unit.

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical sys-

tems (an electrical engineer or the equivalent).

Personnel in charge of introducing F

•

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and maintaining FA systems.

• Personnel in charge of managing FA systems and facilities.

Also, this manual is intended for the personnel, who understand the following contents.

• Personnel who understand the programming language specifications in international standard IEC

61131-3 or Japanese standard JIS B 3503, for programming.

• Personnel in charge of working with a robot and well knowing how to handle the robot.

Introduction

A systems.

Applicable Products

This manual covers the following products.

NJ-series Robot Integrated CPU Unit

•

NJ501-R500

NJ501-R400

NJ501-R300

NJ-series Robot Integrated CPU Unit User's Manual (O037)

1

Page 4

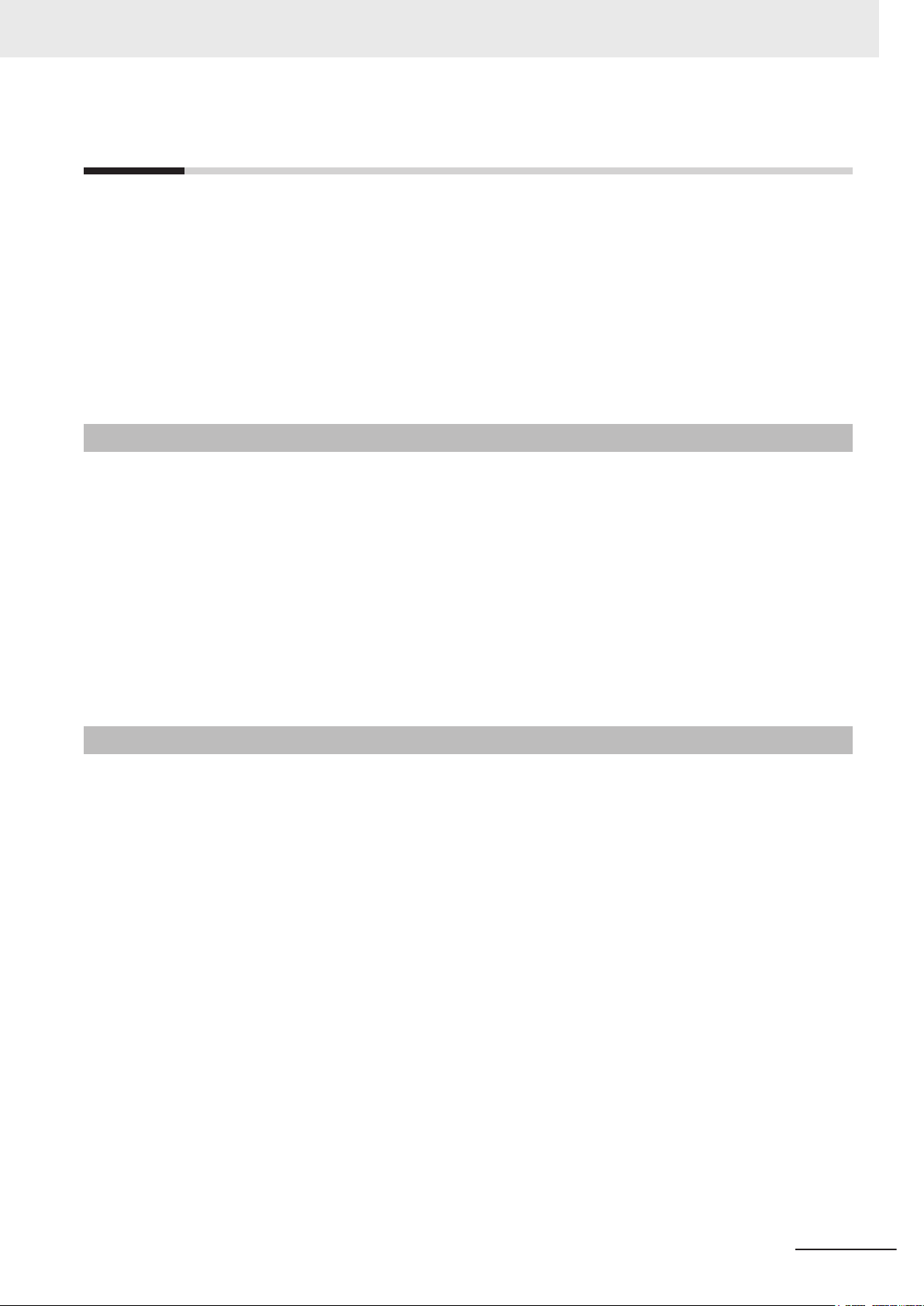

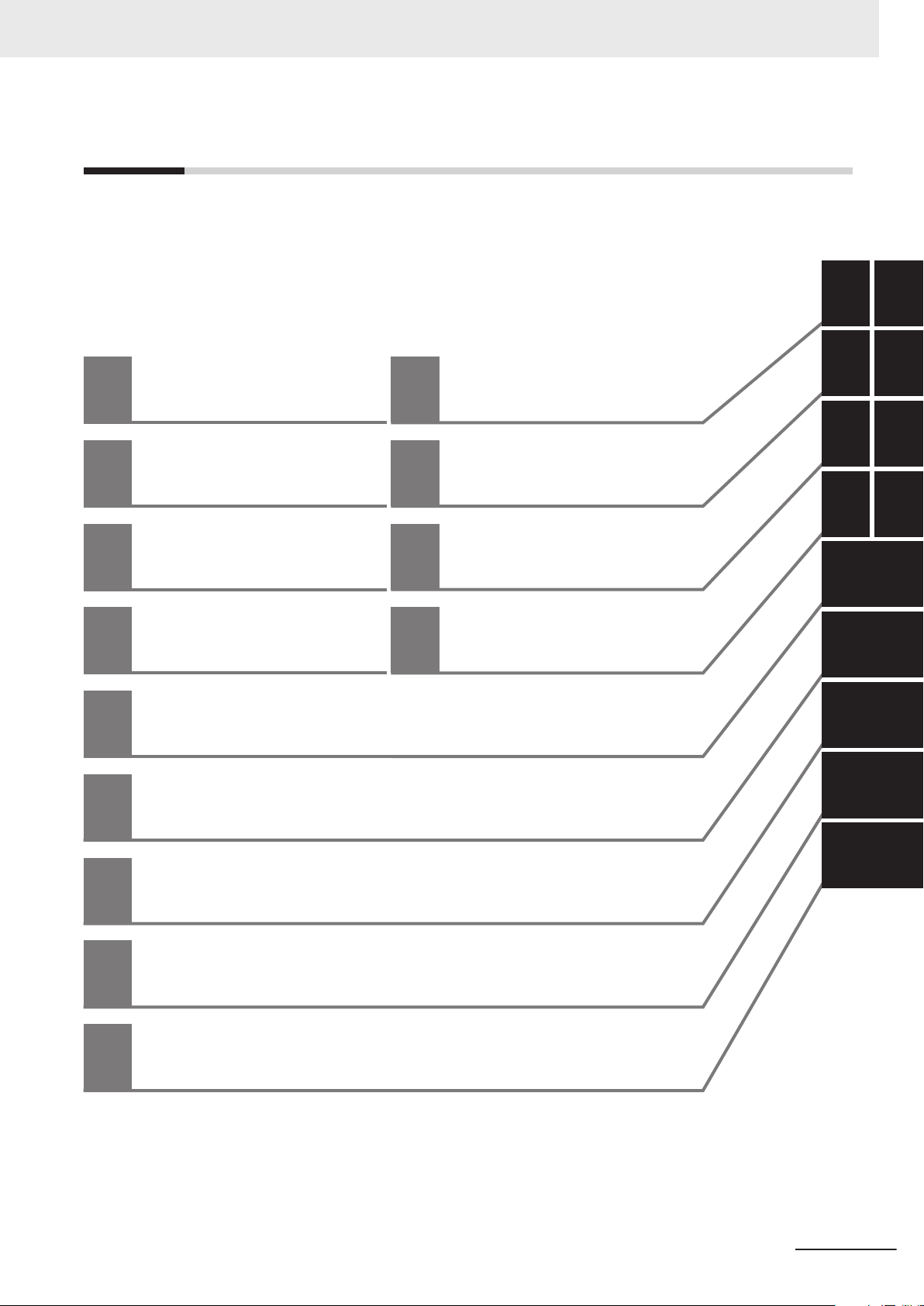

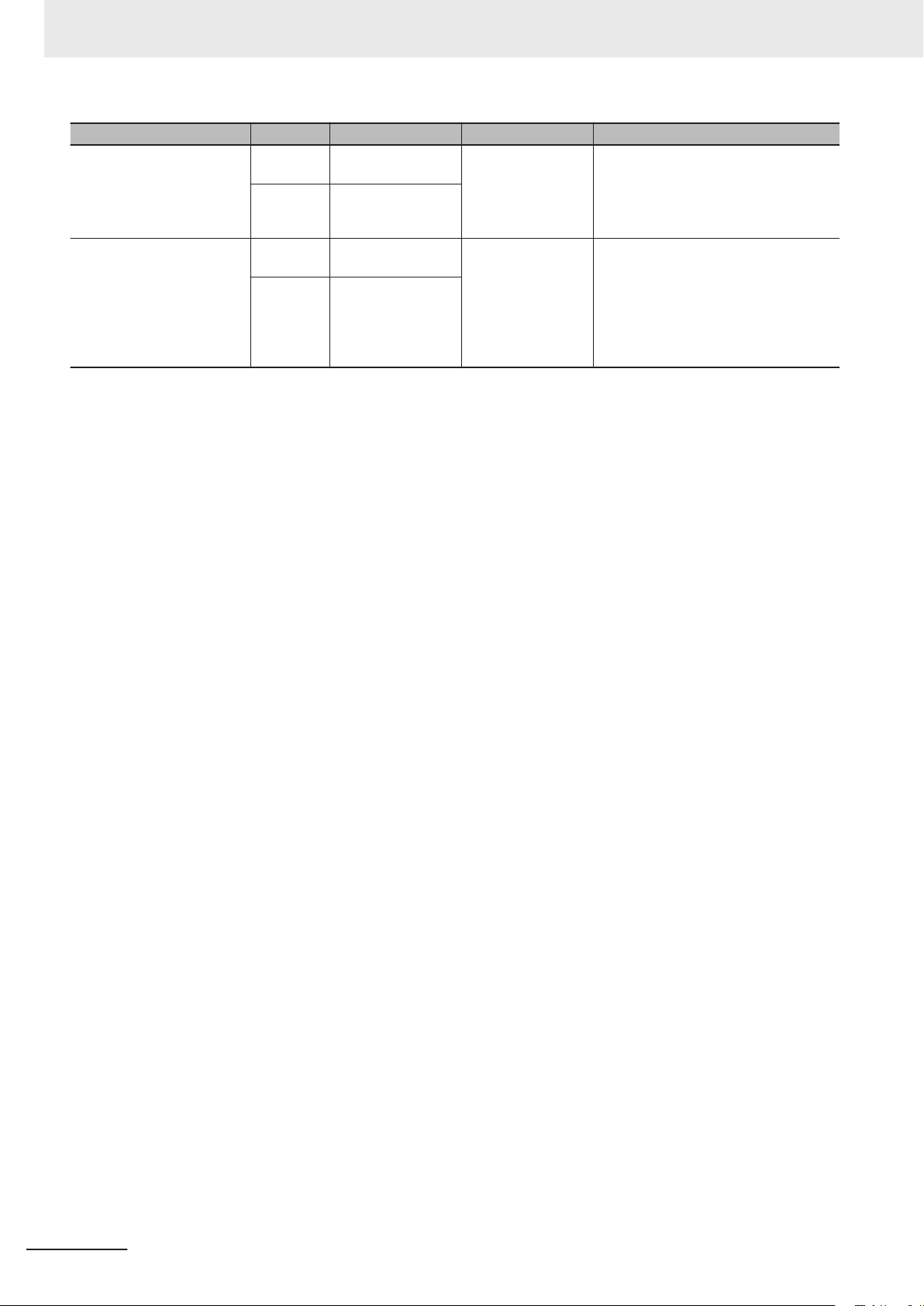

Relevant Manuals

Relevant Manuals

The following table provides the relevant manuals for the NJ-series CPU Units. Read all of the man-

uals that are relevant to your system configuration and application before you use the NJ-series CPU

Unit.

Most operations are performed from the Sysmac Studio Automation Software. Refer to the Sysmac

Studio Version 1 Operation Manual (Cat. No. W504) and the Sysmac Studio Robot Integrated System

Building Function with Robot Integrated CPU Unit Operation Manual (Cat. No. W595) for information

on the Sysmac Studio.

Basic information

NJ-series CPU Unit

Hardware User’s Manual

NJ/NX-series CPU Unit

Software User

Instructions Reference Manual

NJ/NX-series

NJ/NX-series CPU Unit

Motion Control User

NJ/NX-series

Motion Control Instructions Reference Manual

Manual

NJ/NX-series CPU Unit

Built-in EtherNet/IP Port User’

NJ/NX-series CPU Unit

Built-in EtherCA

NJ-series Robot Integrated CPU Unit

User

eV+3 User’s Manual

eV+3 Keyword Reference Manual

NJ-series NJ Robotics CPU Unit

User

NJ/NX-series

Troubleshooting Manual

Purpose of use

Introduction to NJ-series Controllers

Setting devices and hardware

Using motion control

Using EtherCAT

Using EtherNet/IP

Using robot control for OMRON robots

Software settings

Using motion control

Using EtherCAT

Using EtherNet/IP

Using robot control for OMRON robots

Using robot control with NJ Robotics function

Writing the user program

Using motion control

Using EtherCAT

Using EtherNet/IP

Using robot control for OMRON robots

Using robot control with NJ Robotics function

Programming error processing

Testing operation and debugging

Using motion control

Using EtherCAT

Using EtherNet/IP

Using robot control for OMRON robots

Using robot control with NJ Robotics function

¡

¡

’

s Manual

¡

¡ ¡

¡

’s Manual

¡

¡

¡ ¡

¡

T Port User

’s Manual

s Manual

¡

¡

¡

¡

¡

¡

¡

¡

’

s Manual

¡

¡ ¡ ¡

¡ ¡ ¡

¡ ¡ ¡ ¡

¡ ¡ ¡

’

s Manual

¡

¡

¡

2

NJ-series Robot Integrated CPU Unit User's Manual (O037)

Page 5

Purpose of use

Basic information

NJ-series CPU Unit

Hardware User’s Manual

NJ/NX-series CPU Unit

Software User

Instructions Reference Manual

’

s Manual

NJ/NX-series

NJ/NX-series CPU Unit

Motion Control User

’

s Manual

NJ/NX-series

Motion Control Instructions Reference Manual

Relevant Manuals

Manual

NJ/NX-series CPU Unit

Built-in EtherCA

T Port User

’s Manual

NJ/NX-series CPU Unit

Built-in EtherNet/IP Port User

’

s Manual

NJ-series Robot Integrated CPU Unit

User’

s Manual

eV+3 User’s Manual

eV+3 Keyword Reference Manual

NJ-series NJ Robotics CPU Unit

User

’

s Manual

NJ/NX-series

T

roubleshooting Manual

Learning about error management functions and

corrections

Maintenance

*1. Refer to the NJ/NX-series Troubleshooting Manual (Cat. No. W503) for the error management concepts and the error items. However

*1

Using motion control

Using EtherCAT

Using EtherNet/IP

refer to the manuals that are indicated with triangles for details on errors corresponding to the products with the manuals that are indicated with triangles.

¡

¡

¡

r r r r ¡

¡

,

NJ-series Robot Integrated CPU Unit User's Manual (O037)

3

Page 6

4-9

4

Installation and Wiring

NJ-series CPU Unit Hardware User’s Manual (W500)

s

t

i

n

U

gnitn

u

oM

3-4

4

s

t

ne

no

p

m

o

C

rel

l

o

r

t

n

oC

g

n

i

tc

e

n

noC

1

-

3-

4

4-3 Mounting Units

The Units that make up an NJ-series Controller can be connected simply by pressing the Units together

and locking the sliders by moving them toward the back of the Units. The End Cover is connected in the

same way to the Unit on the far right side of the Controller.

1 Join the Units so that the connectors fit exactly.

2 The yellow sliders at the top and bottom of each Unit lock the Units together. Move the sliders

toward the back of the Units as shown below until they click into place.

Precautions for Correct UsePrecautions for Correct Use

4-3-1 Connecting Controller Components

Connector

Hook

Hook holes

Slider

Lock

Release

Move the sliders toward the back

until they lock into place.

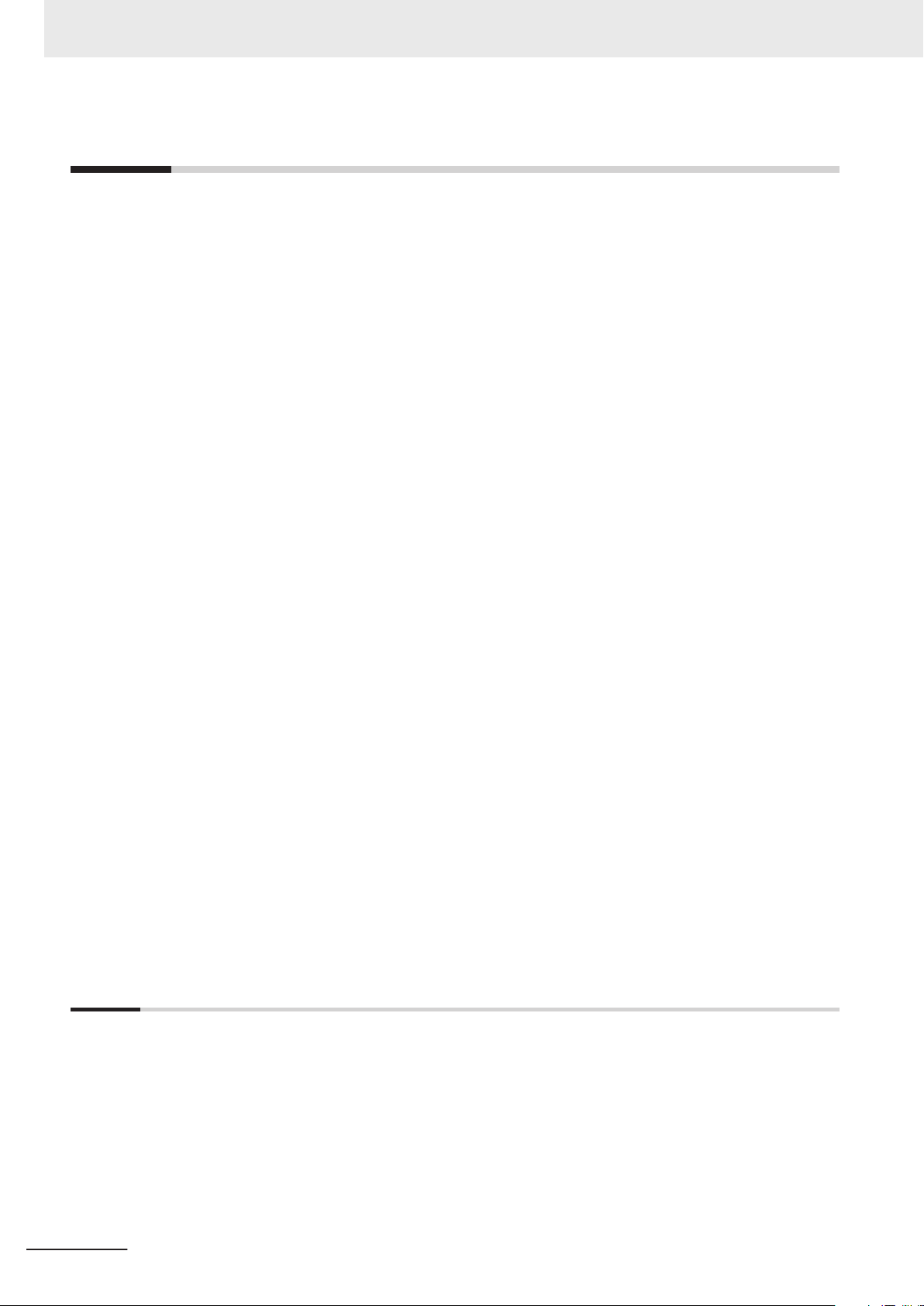

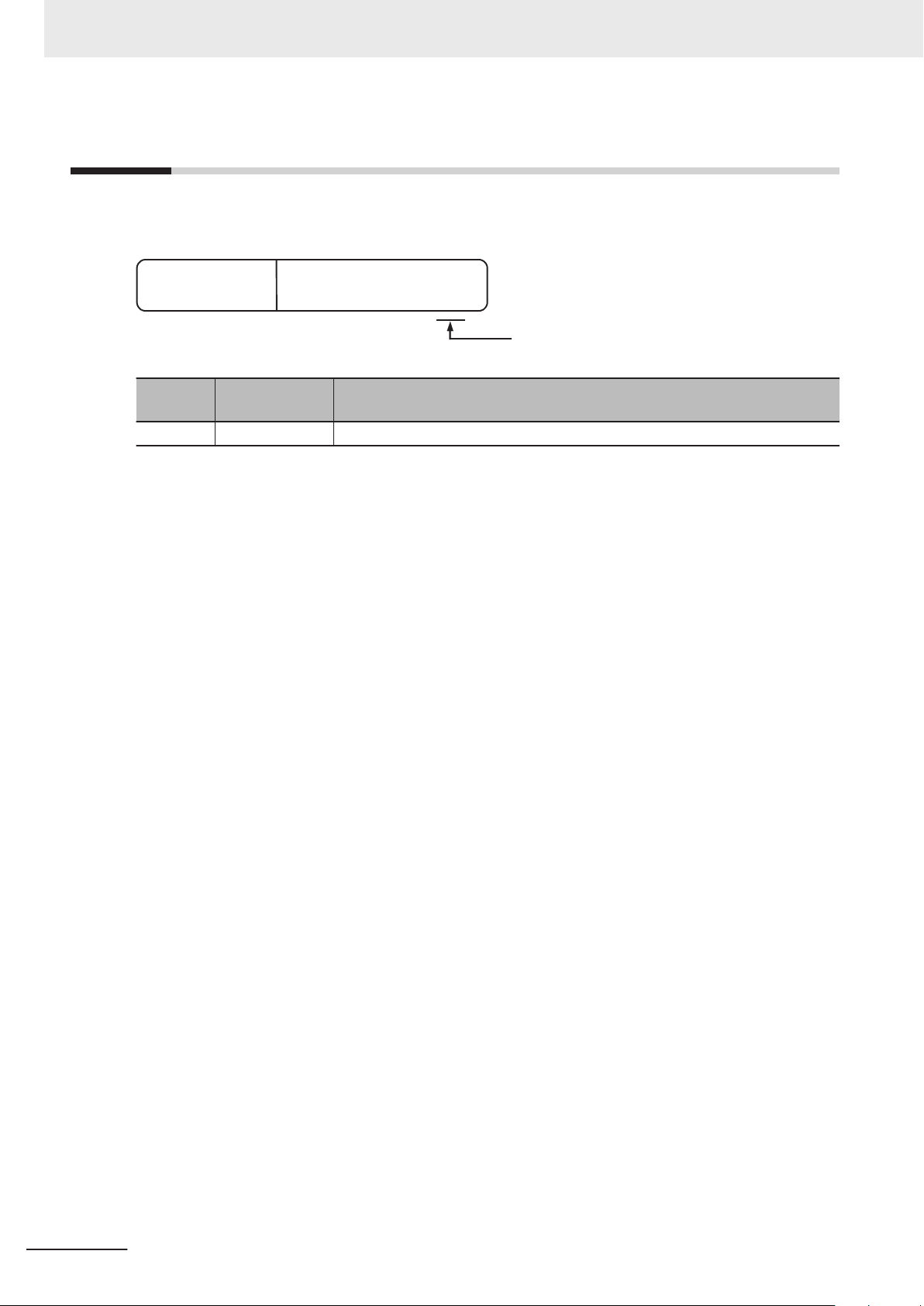

Level 1 heading

Level 2 heading

Level 3 heading

Level 2 heading

A step in a procedure

Manual name

Special information

Level 3 heading

Page tab

Gives the current

headings.

Indicates a procedure.

Icons indicate

precautions, additional

information, or reference

information.

Gives the number

of the main section.

This illustration is provided only as a sample. It may not literally appear in this manual.

Th

e sliders on the tops and bottoms of the Power Supply Unit, CPU Unit, I/O Units, Special I/O

Units, and CPU Bus Units must be completely locked (until they click into place) after connecting

the adjacent Unit connectors.

Manual Structure

Manual Structure

Page Structure

The following page structure is used in this manual.

4

NJ-series Robot Integrated CPU Unit User's Manual (O037)

Page 7

Special Information

Special information in this manual is classified as follows:

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

Manual Structure

Version Information

Information on dif

and for dif

ferent versions of the Sysmac Studio is given.

ferences in specifications and functionality for Controller with different unit versions

Precaution on Terminology

In this manual, "download" refers to transferring data from the Sysmac Studio to the physical Control-

ler and "upload

For the Sysmac Studio, "synchronization

"synchronize" means to automatically compare the data for the Sysmac Studio on the computer with

the data in the physical Controller and transfer the data in the direction that is specified by the user.

" refers to transferring data from the physical Controller to the Sysmac Studio.

" is used to both "upload" and "download" data. Here,

NJ-series Robot Integrated CPU Unit User's Manual (O037)

5

Page 8

Manual Structure

6

NJ-series Robot Integrated CPU Unit User's Manual (O037)

Page 9

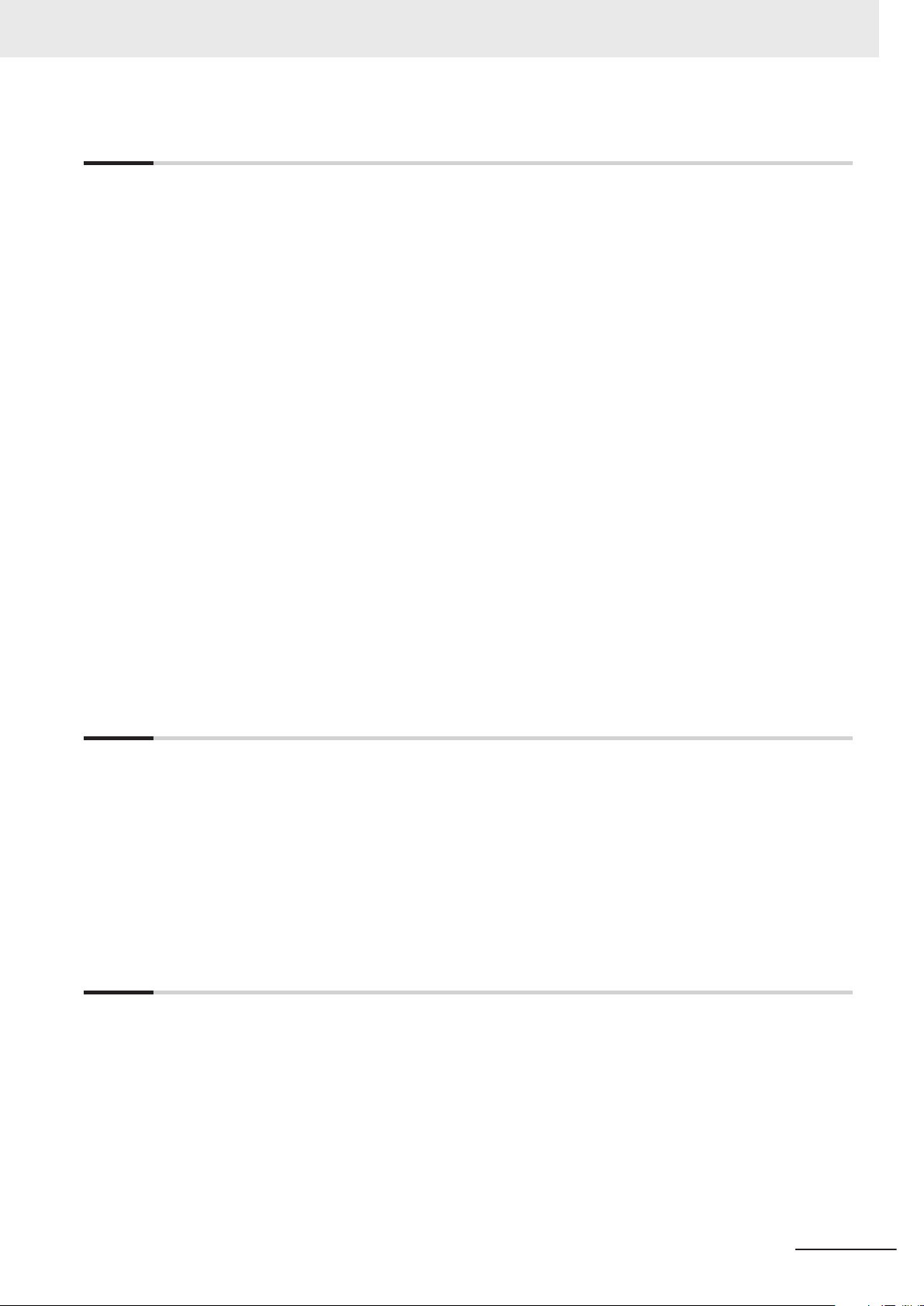

Sections in this Manual

1

10

2

11

3

4

5

6

7

8

9

1

10

2

11

3 A

I

4

5

6

7

8

9

Introduction to Robot

Integrated CPU Unit

Robot Control System

Configuration and Functions

Robot Control Parameters

Program Design of

Robot Control

A

Robot Control Instructions

Robot Control Function

Common Command Instructions

Variables and Instructions

Robot Command Instructions

13

System Control

Instructions

Troubleshooting

Appendices

I

Index

Sections in this Manual

NJ-series Robot Integrated CPU Unit User's Manual (O037)

7

Page 10

CONTENTS

CONTENTS

Introduction .............................................................................................................. 1

Intended Audience...........................................................................................................................................1

Applicable Products

Relevant Manuals..................................................................................................... 2

Manual Structure...................................................................................................... 4

Page Structure.................................................................................................................................................4

Special Information .......................................................................................................................................... 5

Precaution on Terminology ..............................................................................................................................5

Sections in this Manual ........................................................................................... 7

Terms and Conditions Agreement........................................................................ 13

Warranty, Limitations of Liability ....................................................................................................................13

Application Considerations ............................................................................................................................14

Disclaimers ....................................................................................................................................................14

.........................................................................................................................................1

Safety Precautions................................................................................................. 16

Definition of Precautionary Information.......................................................................................................... 16

Symbols ......................................................................................................................................................... 16

WARNING......................................................................................................................................................17

Cautions......................................................................................................................................................... 17

Precautions for Safe Use ...................................................................................... 19

Precautions for Correct Use ................................................................................. 20

Regulations and Standards .................................................................................. 21

Versions.................................................................................................................. 22

Checking Versions.........................................................................................................................................22

Related Manuals..................................................................................................... 24

Terminology............................................................................................................ 27

Revision History..................................................................................................... 28

Section 1 Introduction to Robot Integrated CPU Unit

1-1 Features ..................................................................................................................................1-2

1-2 System Configuration

1-3 Specifications.........................................................................................................................1-6

1-3-1 General Specifications ................................................................................................................1-6

1-3-2 Performance Specifications ........................................................................................................1-6

1-3-3 Function Specifications ...............................................................................................................1-6

1-3-4 V+ Program Specifications..........................................................................................................1-8

1-4 Basic Procedure of Operation ..............................................................................................1-9

8

............................................................................................................1-4

NJ-series Robot Integrated CPU Unit User's Manual (O037)

Page 11

CONTENTS

Section 2 Robot Control System Configuration and Functions

2-1 Internal Configuration for the Robot Integrated CPU Unit.................................................2-2

2-2 Relationship between

2-3 Relationship between Robot Integrated CPU Unit and IPC Application Controller ........2-6

2-4 System-defined Variables for Robot Control ......................................................................2-8

2-4-1 Overview of System-defined Variables for Robot Control ...........................................................2-8

2-4-2 System of System-defined Variables for Robot Control ..............................................................2-8

2-4-3 Attributes of System-defined Variables for Robot Control ......................................................... 2-11

2-5 Tasks ..................................................................................................................................... 2-12

2-5-1 Tasks and Services for Robot Integrated CPU Unit ..................................................................2-12

2-5-2 Basic Operation of Tasks ..........................................................................................................2-12

2-5-3 Relationship between V+ Task and I/O Refreshing...................................................................2-14

2-6 EtherCAT Communications and Robot Control................................................................2-15

2-7 SD Memory Card Operations .............................................................................................. 2-17

2-7-1 Included SD Memory Card Functions .......................................................................................2-18

2-7-2 Exclusive Control of File Access in the SD Memory Card ........................................................2-20

2-8 Memory Management ..........................................................................................................2-22

2-8-1 Data and File Locations ............................................................................................................2-22

2-8-2 Clear All Memory.......................................................................................................................2-22

2-9 Backup and Restore Operations ........................................................................................2-24

2-9-1 Backup and Restore Operations for Robot Integrated CPU Unit ..............................................2-24

2-9-2 Backup and Restore Operations for OMRON Robot ................................................................2-27

2-10 Security.................................................................................................................................2-29

2-10-1 Robot System Operation Authority............................................................................................2-29

2-10-2 CPU Unit Write Protection.........................................................................................................2-29

Robot Integrated CPU Unit and Robot...........................................2-3

Section 3 Robot Control Parameters

3-1 Introduction to Robot Control Parameters..........................................................................3-2

3-1-1 Data Flow for Robot Control Parameters

3-1-2 Relationship between V+ Program and Robot Control Parameters............................................3-3

....................................................................................3-2

3-2 Robot Common Parameters .................................................................................................3-4

3-2-1 Robot Common Parameters .......................................................................................................3-4

3-2-2 I/O Control Settings.....................................................................................................................3-4

3-3 Robot Setting Parameters.....................................................................................................3-7

3-3-1 Robot Setting Parameters...........................................................................................................3-7

3-3-2 Robot Basic Settings...................................................................................................................3-7

Section 4 Program Design of Robot Control

4-1 Introduction ............................................................................................................................4-2

4-2 Sequence Control Program ..................................................................................................4-3

4-2-1 Robot Control Instructions...........................................................................................................4-3

4-2-2 Timing Charts for Robot Control Instructions ..............................................................................4-3

4-2-3 System-defined Variables for Robot Control ...............................................................................4-6

4-2-4 Execution Control for V+ Program ..............................................................................................4-6

4-2-5 Shared Variables with V+ Program .............................................................................................4-7

4-2-6 Using Shared Variables with V+ Programs ...............................................................................4-11

4-3 V+ Program...........................................................................................................................4-14

4-3-1 Overview of V+ Programs .........................................................................................................4-14

4-3-2 Control of V+ Tasks...................................................................................................................4-14

4-3-3 I/O Control Settings for V+ Program .........................................................................................4-14

NJ-series Robot Integrated CPU Unit User's Manual (O037)

9

Page 12

CONTENTS

4-4 Debugging Program ............................................................................................................4-16

4-4-1 Of

4-4-2 Transferring Settings and Programs .........................................................................................4-17

4-4-3 Online Debugging .....................................................................................................................4-17

fline Debugging......................................................................................................................4-16

4-5 States and State Transition.................................................................................................4-19

4-5-1 States of the Robot Integrated CPU Unit ..................................................................................4-19

4-5-2 States of the OMRON Robots...................................................................................................4-20

4-5-3 Changing the Operating Mode ..................................................................................................4-23

4-5-4 Operation of Events ..................................................................................................................4-24

Section 5 Robot Control Function

5-1 Robot Control Common Function ........................................................................................ 5-2

5-2 Latching

5-2-1 Robot Position Latching ..............................................................................................................5-5

5-2-2 Robot Built-in Encoder Latching..................................................................................................5-6

5-3 Coordinate System Integration with NJ Robotics Function .............................................5-8

5-4 Changing Recipe..................................................................................................................5-10

..................................................................................................................................5-5

Section 6 Robot Control Instructions

6-1 Overview of Robot Control Instructions..............................................................................6-2

6-1-1 T

6-1-2 Execution and Status of Robot Control Instructions....................................................................6-2

6-1-3 Error Processing .........................................................................................................................6-2

6-1-4 Changing Input Variables during Execution of Robot Control Instructions (Instruction

6-1-5 Multi-execution of Instructions with BufferMode..........................................................................6-3

ypes of Robot Control Instructions ............................................................................................6-2

Re-execution)..............................................................................................................................6-3

6-2 Basic Understanding of Robot Control Instructions..........................................................6-6

6-2-1 Names of Robot Control Instructions ..........................................................................................6-6

6-2-2 Languages of Robot Control Instructions ...................................................................................6-6

6-2-3 Locations of Robot Control Instructions ......................................................................................6-6

6-2-4 OMRON Robot Specification Method in Sequence Control Program .......................................6-10

6-2-5 Multi-execution of Robot Control Instructions ...........................................................................6-10

6-2-6 Executing Robot Control Instructions to Uncreated Robots...................................................... 6-11

Section 7 Variables and Instructions

7-1 System-defined variables for Robot Control.......................................................................7-2

7-1-1 Robot Control Common Variable.................................................................................................7-2

7-1-2 Robot Variables ...........................................................................................................................7-3

7-1-3 Robot I/O Variables .....................................................................................................................7-7

7-2 Instructions ............................................................................................................................7-9

7-2-1 Common Commands ..................................................................................................................7-9

7-2-2 Robot Commands .......................................................................................................................7-9

7-2-3 System Control Instructions ......................................................................................................7-10

Section 8 Common Command Instructions

RC_ExecVpPrgTask ......................................................................................................................... 8-2

Variables

Function ........................................................................................................................................................8-3

RC_AbortVpPrgTask........................................................................................................................8-6

Variables.......................................................................................................................................................8-6

10

.......................................................................................................................................................8-2

NJ-series Robot Integrated CPU Unit User's Manual (O037)

Page 13

Function ........................................................................................................................................................8-7

RC_GetVpPrgTaskStatus

Variables .......................................................................................................................................................8-8

Function ........................................................................................................................................................8-9

................................................................................................................8-8

RC_ConvertCoordSystem ............................................................................................................. 8-11

Variables .....................................................................................................................................................8-11

Function ......................................................................................................................................................8-12

Section 9 Robot Command Instructions

RC_EnablePower .............................................................................................................................9-2

Variables

Function ........................................................................................................................................................9-3

RC_DisablePower ............................................................................................................................9-5

Variables.......................................................................................................................................................9-5

Function ........................................................................................................................................................9-6

RC_Calibrate.....................................................................................................................................9-8

Variables.......................................................................................................................................................9-8

Function ........................................................................................................................................................9-9

RC_AttachRobot ............................................................................................................................9-10

Variables.....................................................................................................................................................9-10

Function ...................................................................................................................................................... 9-11

Precautions for Correct Use .......................................................................................................................9-12

RC_DetachRobot............................................................................................................................9-13

Variables.....................................................................................................................................................9-13

Function ......................................................................................................................................................9-14

RC_SetToolTransform ...................................................................................................................9-15

Variables.....................................................................................................................................................9-15

Function ......................................................................................................................................................9-16

Precautions for Correct Use .......................................................................................................................9-18

RC_MoveDirect...............................................................................................................................9-20

Variables.....................................................................................................................................................9-20

Function ......................................................................................................................................................9-23

RC_MoveLinear ..............................................................................................................................9-27

Variables.....................................................................................................................................................9-27

Function ......................................................................................................................................................9-30

RC_Stop ..........................................................................................................................................9-33

Variables.....................................................................................................................................................9-33

Function ......................................................................................................................................................9-34

RC_Reset ........................................................................................................................................9-36

Variables.....................................................................................................................................................9-36

Function ......................................................................................................................................................9-37

.......................................................................................................................................................9-2

CONTENTS

Section 10 System Control Instructions

ResetRCError .................................................................................................................................10-2

Variables

Function ......................................................................................................................................................10-3

GetRCError .....................................................................................................................................10-4

Variables.....................................................................................................................................................10-4

Function ......................................................................................................................................................10-4

NJ-series Robot Integrated CPU Unit User's Manual (O037)

.....................................................................................................................................................10-2

11

Page 14

CONTENTS

Section 11 Troubleshooting

11-1 Errors .................................................................................................................................... 11-2

11-1-1

11-1-2 Error Sources ........................................................................................................................... 11-2

11-1-3 Error Levels...............................................................................................................................11-3

11-1-4 Robot Control Function Module Errors by Source ....................................................................11-3

11-1-5 Errors Related to EtherCAT Communications and EtherCAT Slaves .......................................11-5

11-1-6 OMRON Robot Events .............................................................................................................11-5

11-2 Identifying and Resetting Errors ........................................................................................ 11-7

11-2-1 How to Check for Errors............................................................................................................ 11-7

11-2-2 How to Reset Errors..................................................................................................................11-8

11-3 Error Table ............................................................................................................................ 11-9

11-3-1 How to Read Error Tables ......................................................................................................... 11-9

11-3-2 Error Tables............................................................................................................................... 11-9

11-4 Error Descriptions .............................................................................................................11-21

11-4-1 How to Read Error Descriptions.............................................................................................. 11-21

11-4-2 Error Descriptions ...................................................................................................................11-22

Sources of Errors Related to the Robot Control Function Module ............................................ 11-2

Appendices

A-1 Differences in Functions between Robot Integrated CPU Unit and NJ-series CPU UnitA-2

A-2 Guideline for System Service Execution T

Index

ime Ratio......................................................... A-3

12

NJ-series Robot Integrated CPU Unit User's Manual (O037)

Page 15

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and work-

manship for a period of twelve months from the date of sale by Omron (or such other period ex-

pressed in writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-com-

plying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be re-

sponsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return

of any Products by Buyer must be approved in writing by Omron before shipment. Omron Compa-

nies shall not be liable for the suitability or unsuitability or the results from the use of Products in

combination with any electrical or electronic components, circuits, system assemblies or any other

materials or substances or environments. Any advice, recommendations or information given orally

or in writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CON-

SEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

NJ-series Robot Integrated CPU Unit User's Manual (O037)

13

Page 16

Terms and Conditions Agreement

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

, NEGLIGENCE OR STRICT LIABILITY.

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’

er’s request, Omron will provide applicable third party certification documents identifying ratings and

limitations of use which apply to the Product. This information by itself is not sufficient for a complete

determination of the suitability of the Product in combination with the end product, machine, system, or

other application or use. Buyer shall be solely responsible for determining appropriateness of the par-

ticular Product with respect to Buyer’s application, product or system. Buyer shall take application re-

sponsibility in all cases.

s application or use of the Product. At Buy-

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY OR IN LARGE QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE

HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIP-

MENT OR SYSTEM.

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or

any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’

formance is subject to the Omron’s Warranty and Limitations of Liability.

s test conditions, and the user must correlate it to actual application requirements. Actual per-

14

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and oth-

er reasons. It is our practice to change part numbers when published ratings or features are changed,

or when significant construction changes are made. However, some specifications of the Product may

NJ-series Robot Integrated CPU Unit User's Manual (O037)

Page 17

Terms and Conditions Agreement

be changed without any notice. When in doubt, special part numbers may be assigned to fix or estab-

lish key specifications for your application. Please consult with your Omron’s representative at any

time to confirm actual specifications of purchased Product.

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; how-

ever, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

NJ-series Robot Integrated CPU Unit User's Manual (O037)

15

Page 18

Indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

Additionally, there may be severe property

damage.

Indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate

injury, or property damage.

WARNING

C

aution

Safety Precautions

Safety Precautions

Definition of Precautionary Information

The following notation is used in this manual to provide precautions required to ensure safe usage of

the NJ-series Robot Integrated CPU Unit.

The safety precautions that are provided are extremely important for safety. Always read and heed the

information provided in all safety precautions.

The following notation is used.

Symbols

The circle and slash symbol indicates operations that you must not do.

The specific operation is shown in the circle and explained in text.

This example indicates that disassembly is prohibited.

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the triangle and explained in text.

This example indicates a precaution for electric shock.

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the triangle and explained in text.

This example indicates a general precaution.

The filled circle symbol indicates operations that you must do.

The specific operation is shown in the circle and explained in text.

This example shows a general precaution for something that you must do.

16

NJ-series Robot Integrated CPU Unit User's Manual (O037)

Page 19

WARNING

WARNING

Caution

Refer to the following manuals for warnings.

• NJ-series CPU Unit Hardware User’

Designing Systems

When you build a robot system including this CPU Unit and OMRON robots, be sure to comply with

laws and regulations relating to the safety of industrial robot application in a country or region where

the robots are used to design and operate the system.

Refer to the Robot Safety Guide (Cat. No. I590) for details.

Safety Precautions

s Manual (Cat. No. W500)

Operation

If you change the operating mode of this CPU Unit from RUN Mode to PROGRAM Mode, the sequence control program stops, but the current V+ program continues. If necessary, monitor the operating mode of the CPU Unit from the V+ program and stop the V+ program.

Always confirm safety when you change the operating mode of the CPU Unit during execution of the

V+ program. If you cannot confirm safety, stop the V+ program and then change the operating mode.

Cautions

Refer to the following manuals for cautions.

• NJ-series CPU Unit Hardware User’

• NJ-series NJ Robotics CPU Unit User's Manual (Cat. No. W539)

Designing Programs

There are different methods to attach a robot from the sequence control program and the V+

program. In addition, when a robot is attached from a program, the robot cannot be attached

from another program without detaching the robot.

If the same OMRON robot is controlled by switching the sequence control program or the V+

program respectively, make sure to detach the robot from the program that the robot is attached,

and then change the control program to attach the robot.

s Manual (Cat. No. W500)

NJ-series Robot Integrated CPU Unit User's Manual (O037)

17

Page 20

Safety Precautions

Operation

Do not remove the SD Memory Card during operation when you use the robot control function

with this product.

Doing so causes the robot control function to stop due to an error.

The V+ program files and the robot setting files in the SD Memory Card are required for the operation of the Robot Control Function Module. Do not edit or delete the files if you are not sure

that the operation is not affected even when the files are edited and deleted.

Always confirm how the file operations af

SD Memory Card.

fect the control before you perform file operations in the

18

NJ-series Robot Integrated CPU Unit User's Manual (O037)

Page 21

Precautions for Safe Use

Refer to the following manuals for precautions for safe use.

• NJ-series CPU Unit Hardware User’s Manual (Cat. No. W500)

Motion Control

• The coordinate system used by the Robot Control Function Module have different specifications

from the coordinate system used by the NJ Robotics function.

If you use both functions simultaneously, use the RC_ConvertCoordSystem instruction to set the

same coordinate system before performing the robot control.

Precautions for Safe Use

NJ-series Robot Integrated CPU Unit User's Manual (O037)

19

Page 22

Precautions for Correct Use

Precautions for Correct Use

Refer to the following manuals for precautions for correct use.

• NJ-series CPU Unit Hardware User’s Manual (Cat. No. W500)

Designing Programs

• If you create the program to use with the sequence control program and the V+ program, design the

interlocks between the programs with shared variables.

20

NJ-series Robot Integrated CPU Unit User's Manual (O037)

Page 23

Regulations and Standards

Refer to the following manuals for regulations and standards.

• NJ-series CPU Unit Hardware User’s Manual (Cat. No. W500)

Additional Information

The Robot Integrated CPU Unit is not a robot control device that is defined in ISO 10208-1.

Therefore, the Robot Integrated CPU Unit does not comply with the robot regulations and

standards.

Refer to the OMRON robot manuals for information on the OMRON robot itself.

Regulations and Standards

NJ-series Robot Integrated CPU Unit User's Manual (O037)

21

Page 24

ID information indication

NJ501

- Ver.1.

££

PORT1 MAC ADDRESS:

££££££££££££

PORT2 MAC ADDRESS:

££££££££££££

Lot No. DDMYY

£

xxxx

Unit model

Lot number Serial number MAC address

Unit version

HW Rev.

£

RC Ver.1.

££

Hardware revision

R300

Robot Control Function

Module version

Versions

Versions

Hardware revisions and unit versions are used to manage the hardware and software in NJ-series

Units and EtherCAT slaves. The hardware revision or unit version is updated each time there is a

change in hardware or software specifications. Even when two Units or EtherCAT slaves have the

same model number, they will have functional or performance differences if they have different hard-

ware revisions or unit versions.

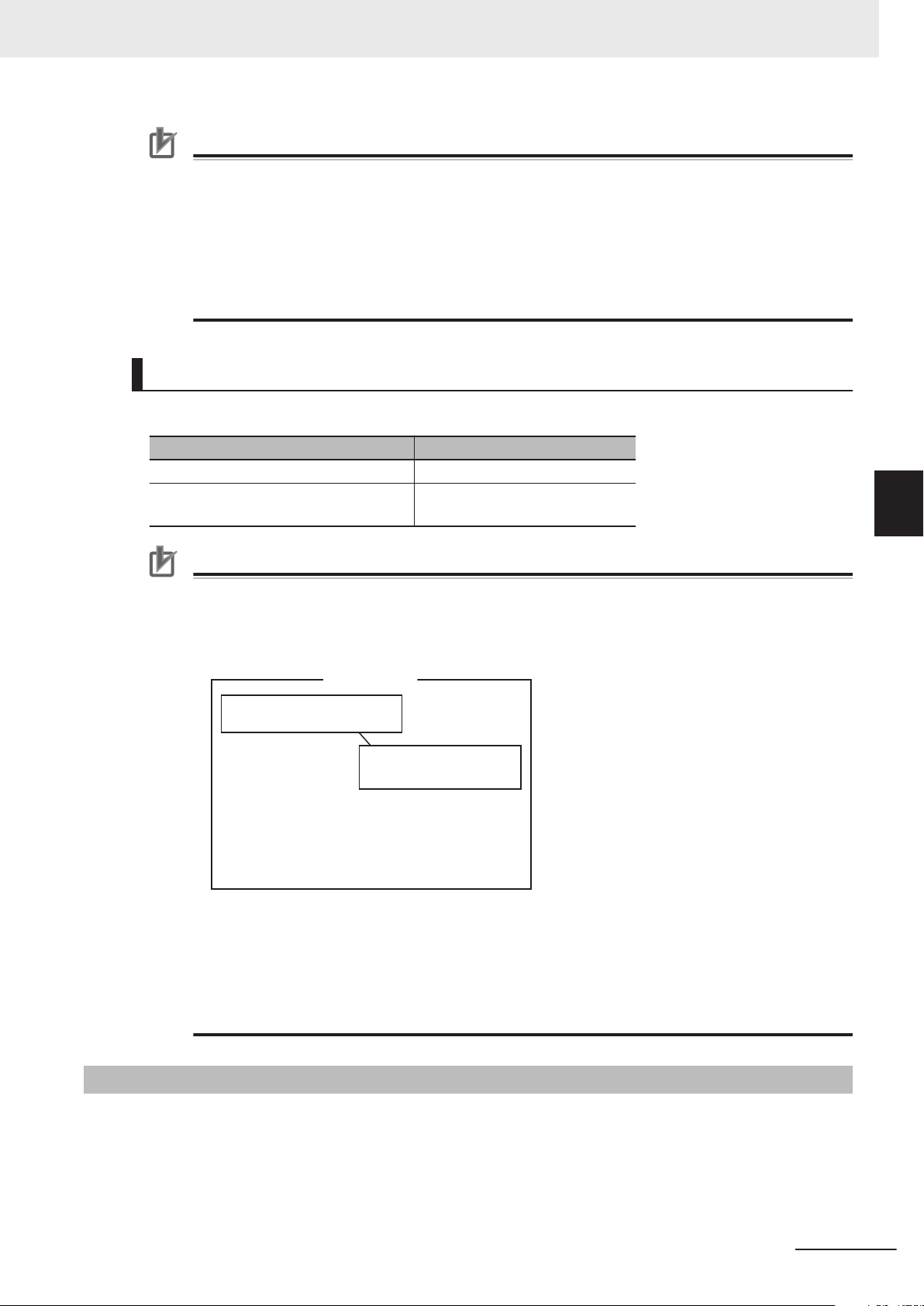

Checking Versions

You can check versions on the ID information indications or with the Sysmac Studio.

Checking Unit Versions on ID Information Indications

The unit version is given on the ID information indication on the side of the product.

NJ501-R£00

The ID information on the NJ-series NJ501-R300 CPU Unit is shown below.

Note

The hardware revision is not displayed for the Unit that the hardware revision is in blank.

22

NJ-series Robot Integrated CPU Unit User's Manual (O037)

Page 25

Versions

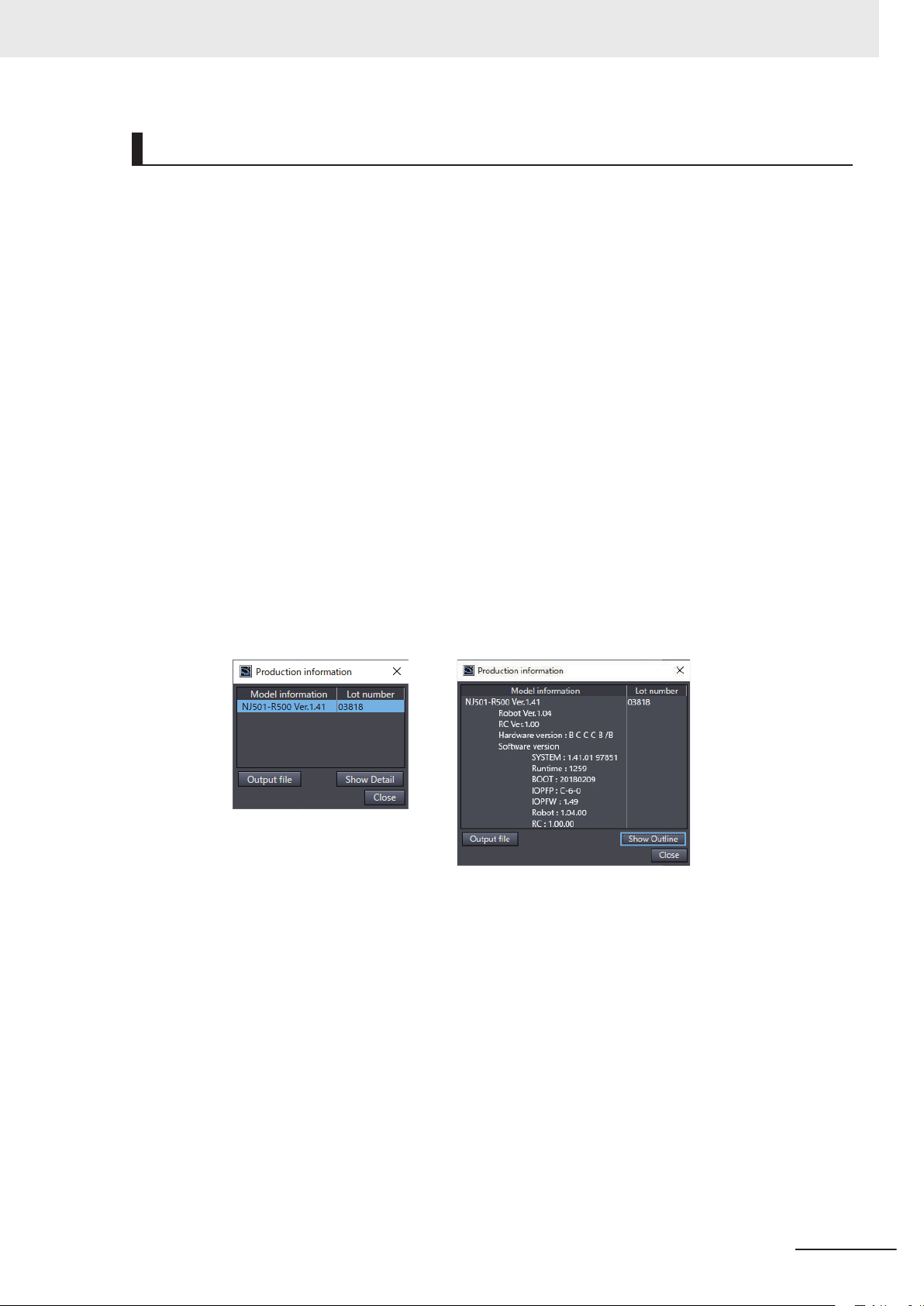

Checking Unit Versions with the Sysmac Studio

You can use the Sysmac Studio to check unit versions.

Checking the Unit Version of an NJ-series CPU Unit

You can use the Production Information while the Sysmac Studio is online to check the unit version

of a Unit. You can do this for the CPU Unit, CJ-series Special I/O Units, and CJ-series CPU Bus

Units. Y

ou cannot check the unit versions of CJ-series Basic I/O Units with the Sysmac Studio.

1 Double-click CPU Rack under Configurations and Setup - CPU/Expansion Racks

Multiview Explorer. Or, right-click CPU Rack under Configurations and Setup - CPU/

Expansion Racks in the Multiview Explorer and select Edit from the menu.

The Unit Editor is displayed.

2 Right-click any open space in the Unit Editor and select Production Information.

The Production Information Dialog Box is displayed.

Changing Information Displayed in Production Information Dialog Box

1 Click the Show Detail or Show Outline Button at the lower right of the Production

Information Dialog Box.

The view will change between the production information details and outline.

in the

Outline View Detailed View

The information that is displayed is different for the Outline View and Detail View. The Detail

V

iew displays the unit version, hardware revision, and various versions. The Outline View dis-

plays only the unit version.

Note

The hardware revision is separated by “/” and displayed on the right of the hardware version. The

hardware revision is not displayed for the Unit that the hardware revision is in blank.

NJ-series Robot Integrated CPU Unit User's Manual (O037)

23

Page 26

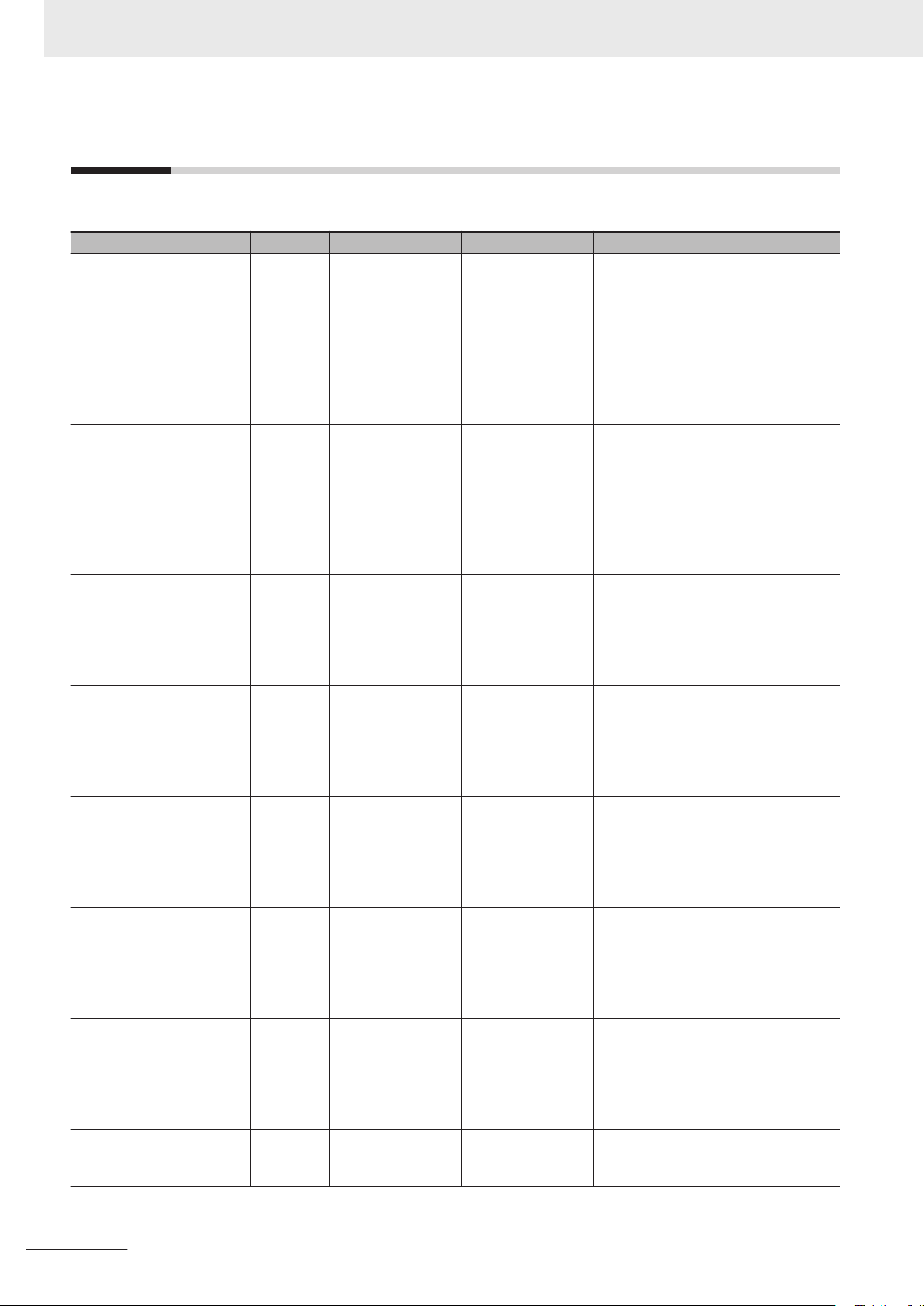

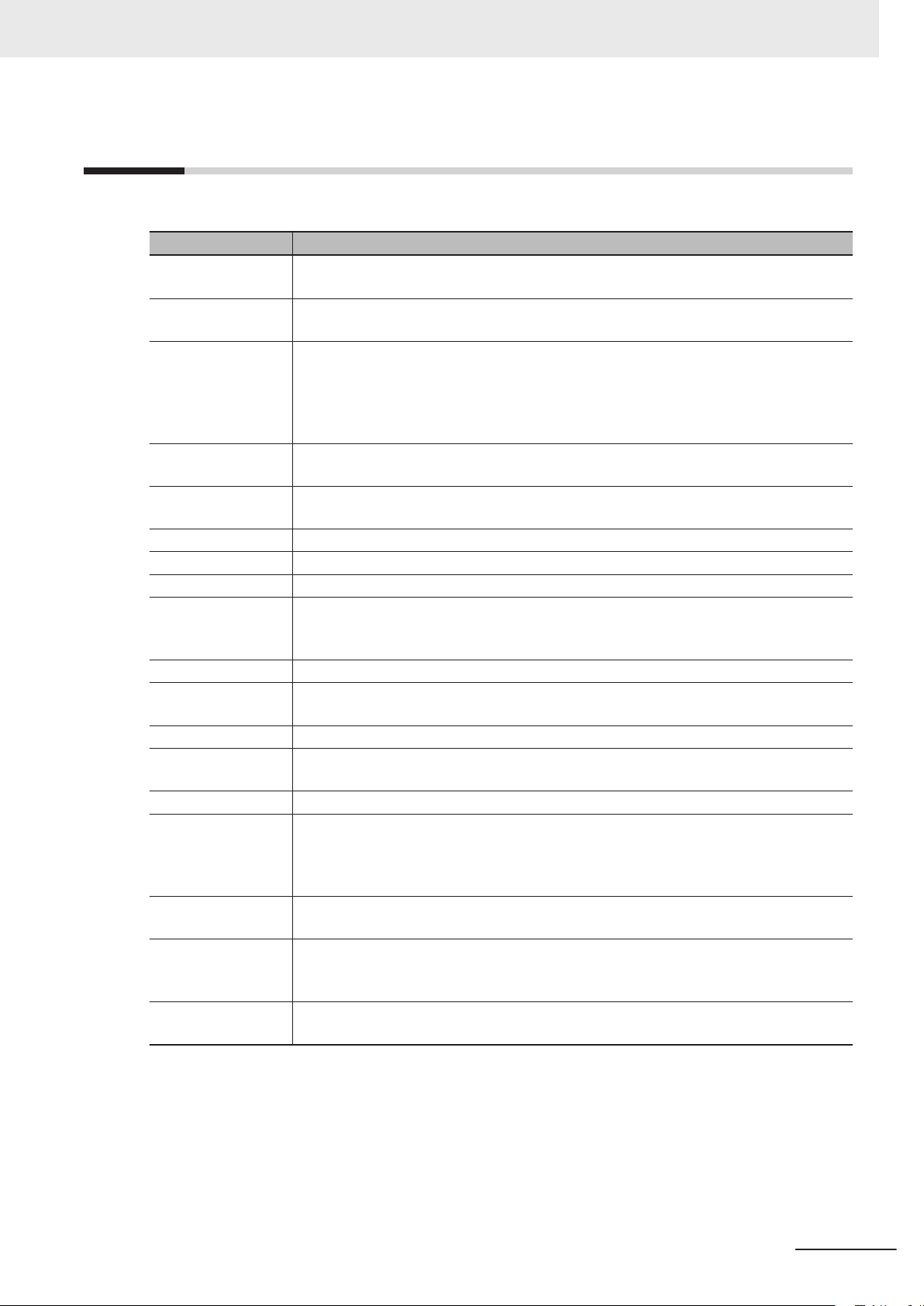

Related Manuals

Related Manuals

The following are the manuals related to this manual. Use these manuals for reference.

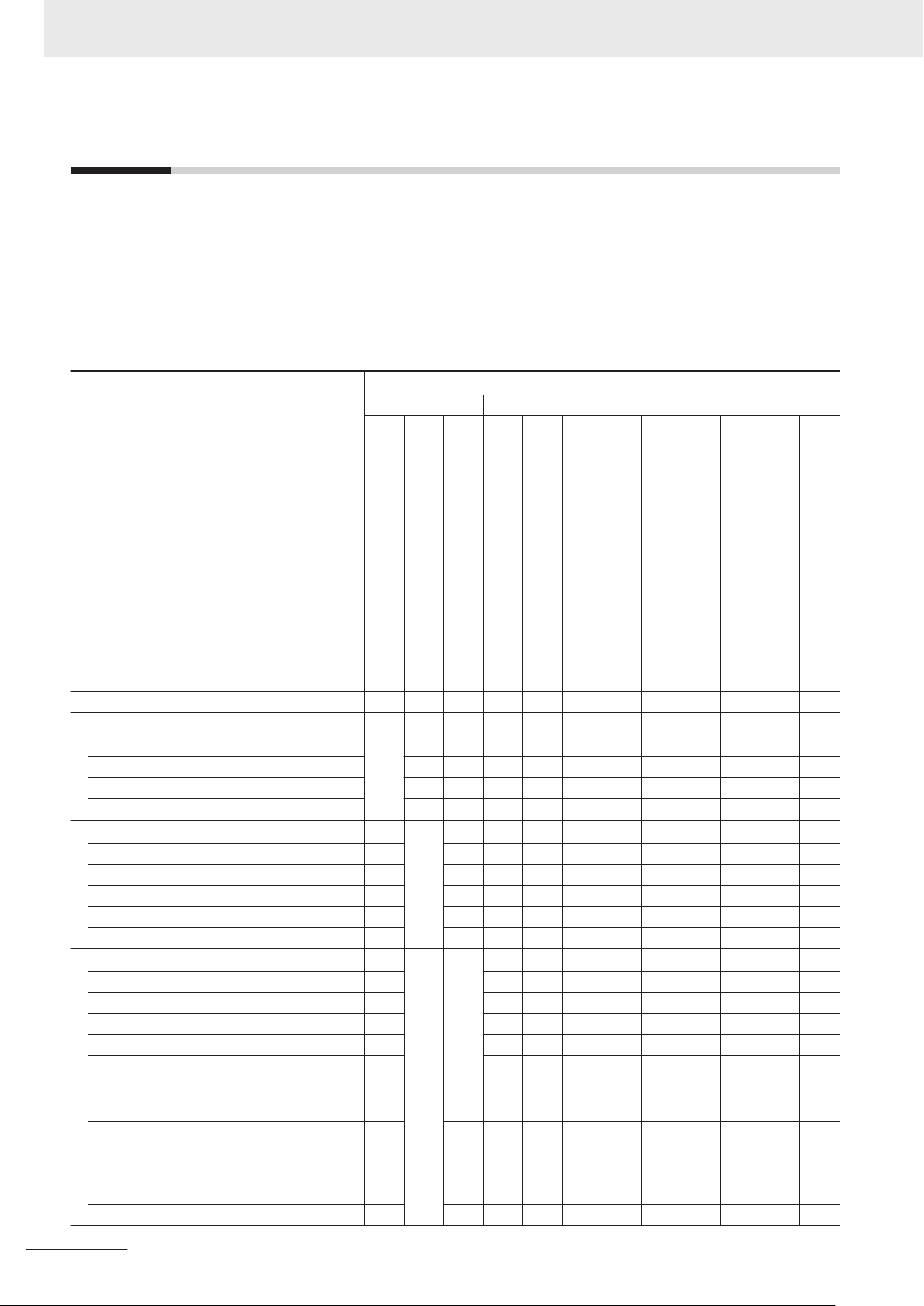

Manual name Cat. No. Model numbers Application Description

NJ-series CPU Unit

Hardware User's Manual

NJ/NX-series CPU Unit

Software User’

NJ/NX-series Instructions

Reference Manual

NJ/NX-series CPU Unit

Motion Control User’

NJ/NX-series

Motion Control Instructions

Reference Manual

NJ/NX-series

CPU Unit

Built-in EtherCA

User

’s Manual

NJ/NX-series

CPU Unit

Built-in EtherNet/IP™ Port

s Manual

User’

NJ-series

Robot Integrated CPU Unit

s Manual

’

User

s Manual

s Manual

T® Port

W500

W501

W502

W507

W508

W505

W506

O037

NJ501-££££

NJ301-££££

NJ101-££££

NX701-££££

NX102-££££

NX1P2-££££

NJ501-££££

NJ301-££££

NJ101-££££

NX701-££££

NX102-££££

NX1P2-££££

NJ501-££££

NJ301-££££

NJ101-££££

NX701-££££

NX102-££££

NX1P2-££££

NJ501-££££

NJ301-££££

NJ101-££££

NX701-££££

NX102-££££

NX1P2-££££

NJ501-££££

NJ301-££££

NJ101-££££

NX701-££££

NX102-££££

NX1P2-££££

NJ501-££££

NJ301-££££

NJ101-££££

NX701-££££

NX102-££££

NX1P2-££££

NJ501-££££

NJ301-££££

NJ101-££££

NJ501-R£££

Learning the basic

specifications of the

NJ-series CPU Units,

including introductory

information, designing, installation, and

maintenance.

Mainly hardware information is provided.

Learning how to program and set up an

NJ/NX-series CPU

Unit.

Mainly software information is provided.

Learning detailed

specifications on the

basic instructions of

an NJ/NX-series

CPU Unit.

Learning about motion control settings

and programming

concepts.

Learning about the

specifications of the

motion control instructions.

Using the built-in

T port on an

EtherCA

NJ/NX-series CPU

Unit.

Using the built-in

EtherNet/IP port on

an NJ/NX-series

CPU Unit.

Using the NJ-series

Robot Integrated

CPU Unit.

An introduction to the entire NJ-series

system is provided along with the following information on the CPU Unit.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

The following information is provided on a

Controller built with an NJ/NX-series CPU

Unit.

• CPU Unit operation

• CPU Unit features

• Initial settings

• Programming based on IEC 61131-3

language specifications

The instructions in the instruction set (IEC

131-3 specifications) are described.

61

The settings and operation of the CPU

Unit and programming concepts for motion control are described.

The motion control instructions are described.

Information on the built-in EtherCAT port

is provided.

This manual provides an introduction and

provides information on the configuration,

features, and setup.

Information on the built-in EtherNet/IP port

is provided.

Information is provided on the basic setup,

tag data links, and other features.

Describes the settings and operation of

the CPU Unit and programming concepts

for OMRON robot control.

24

NJ-series Robot Integrated CPU Unit User's Manual (O037)

Page 27

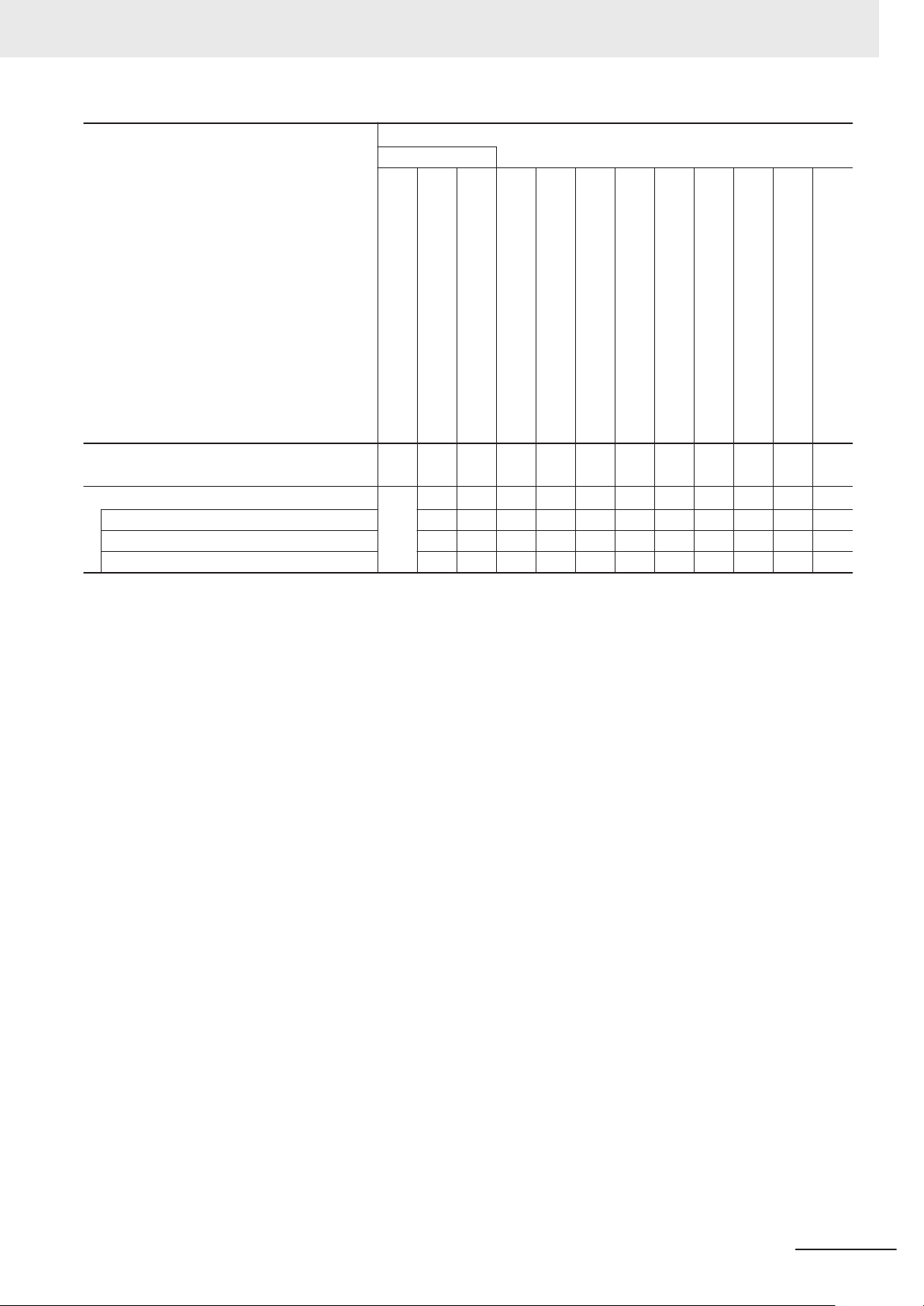

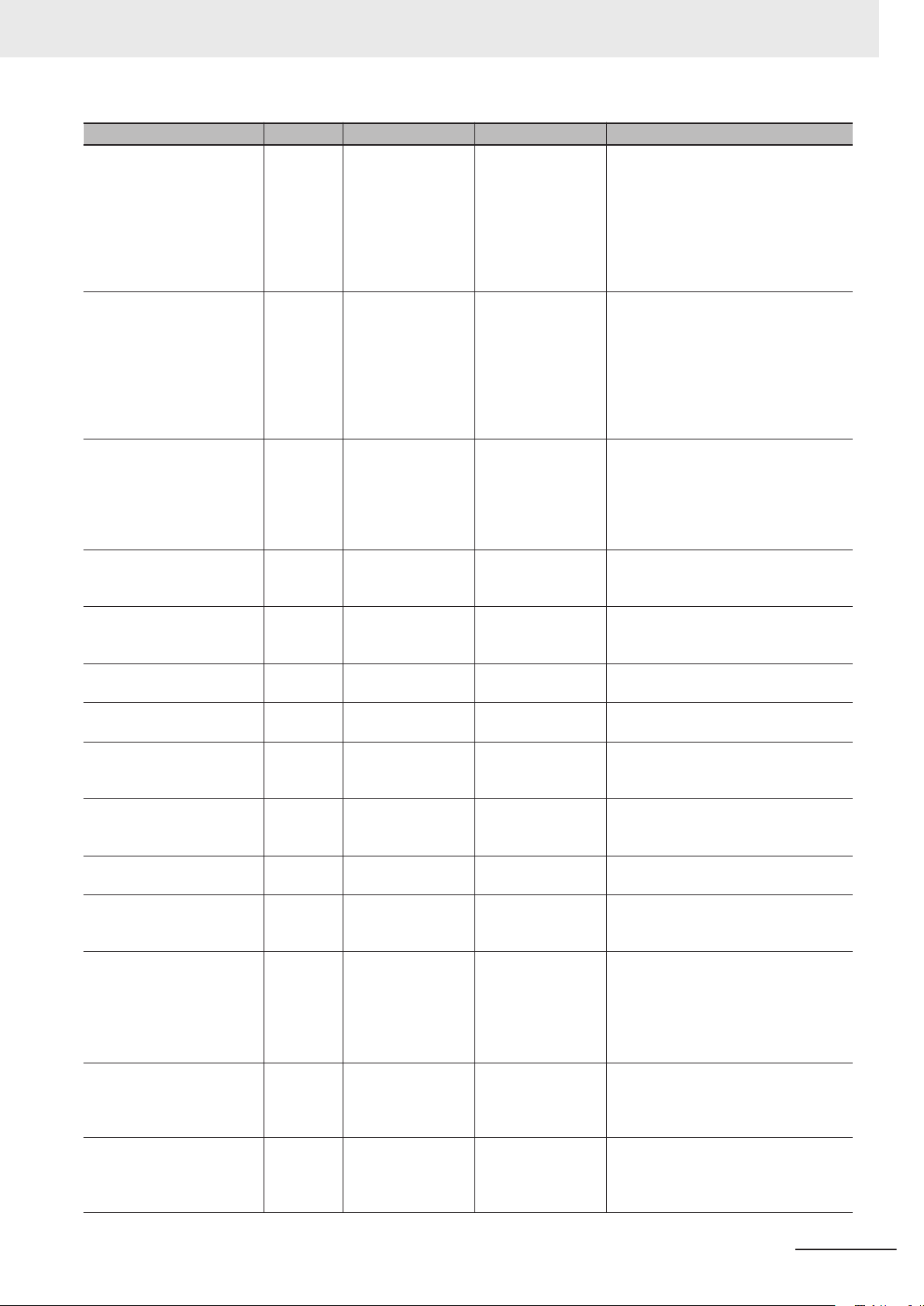

Manual name Cat. No. Model numbers Application Description

Sysmac Studio

Robot Integrated System

Building Function with Robot

Integrated CPU Unit Operation Manual

Sysmac Studio

Robot Integrated System

Building Function with IPC

Application Controller Operation Manual

Sysmac Studio

3D Simulation Function Operation Manual

eV+3

s Manual

’

User

eV+3

Keyword Reference Manual

eCobra 600 and 800 Robot

with EtherCAT User

Viper 650 and 850 Robot with

EtherCAT User

Robot Safety Guide I590

eaching Pendant

T

T20

s Manual

User’

IPC Application Controller

s Manual

User’

NJ-series

NJ Robotics CPU Unit

s Manual

User’

NJ/NX-series

Troubleshooting Manual

Sysmac Studio Version 1

Operation Manual

NX-series

Position Interface Units

s Manual

User’

’s Guide

’s Guide

W595

W621

W618

I651

I652

I653

I654

I601 10046-010 Operating the OM-

I632 AC1-152000 Using the IPC Appli-

W539

W503

W504 SYSMAC

W524

SYSMAC-SE2£££

SYSMACSE200D-64

SYSMAC-SE2£££

SYSMACSE200D-64

SYSMAC-SE2

SYSMAC-SA4££

£-64

NJ501-R£££

NJ501-R£££

RL4-£££££££

RL6-£££££££

RL4-£££££££

RL6-£££££££

NJ501-4£££

NJ501-R£££

NX701-££££

NX102-££££

NX1P2NJ501-££££

NJ301-££££

NJ101-££££

-SE2£££

NX-EC0£££

NX-ECS£££

NX-PG0£££

£££

££££

Learning about the

operating procedures

and functions of the

Sysmac Studio to

configure Robot Integrated System using

Robot Integrated

CPU Unit.

Learning about the

operating procedures

and functions of the

Sysmac Studio to

configure Robot Integrated System using

IPC Application Con-

.

troller

Learning about an

outline of the 3D simulation function of the

Sysmac Studio and

how to use the function.

Operating the OMRON robot with the V

+ program.

Operating the OMRON robot with the V

+ program.

Using the eCobra. Describes the eCobra.

Using the Viper. Describes the Viper.

Learning how to use

the OMRON robot

safely.

RON robot with a

teaching pendant.

cation Controller.

Controlling robots

with NJ-series CPU

Units.

Learning about the

errors that may be

detected in an

NJ/NX-series Con-

.

troller

Learning about the

operating procedures

and functions of the

Sysmac Studio.

Learning how to use

NX-series Position

Interface Units.

Describes the operating procedures of the

Sysmac Studio for Robot Integrated CPU

Unit.

Describes the operating procedures of the

Sysmac Studio for IPC Application Controller.

Describes an outline, execution procedures, and operating procedures for the

3D simulation function of the Sysmac Studio.

Describes the V+ language to control the

OMRON robots.

Describes V+ keywords that are used in

the V+ language.

Describes how to use the OMRON robot

safely.

Describes the setup, operation, and user

maintenance for the Teaching Pendant

T20.

Describes the IPC Application Controller.

Describes the functionality to control robots.

Concepts on managing errors that may be

detected in an NJ/NX-series Controller

and information on individual errors are

described.

Describes the operating procedures of the

Sysmac Studio.

The hardware, setup, and functions for the

NX-series Incremental Encoder Input

Units, SSI Input Units, and Pulse Output

Unit are described.

Related Manuals

NJ-series Robot Integrated CPU Unit User's Manual (O037)

25

Page 28

Related Manuals

Manual name Cat. No. Model numbers Application Description

AC Servomotors/Servo Drives

1S-series with

Built-in EtherCA

cations User's Manual

AC Servomotors/Servo Drives

G5 Series with

Built-in EtherCAT® Communications User's Manual

T® Communi-

I586

I621

I576

I577

R88M-1£

R88D-1SN£

R88M-1AL£/ -1AM£

R88D-1SAN£-ECT

R88M-K

R88D-KN£-ECT

R88L-EC-£

R88D-KN£-ECT-L

-ECT

£

Learning how to use

the Servomotors/

Servo Drives with

built-in EtherCAT

Communications.

Learning how to use

the AC Servomotors/

Servo Drives with

built-in EtherCAT

Communications.

Describes the hardware, setup methods

and functions of the Servomotors/Servo

Drives with built-in EtherCAT Communications.

Describes the hardware, setup methods

and functions of the AC Servomotors/

Servo Drives with built-in EtherCAT Communications.

The Linear Motor Type models and dedicated models for position control are available in G5-series.

26

NJ-series Robot Integrated CPU Unit User's Manual (O037)

Page 29

Terminology

This section describes the terms that are used in this manual.

Term Description

continuous-path motion

IEC 61131-3 language

robots controllable

by NJ Robotics function

TCP A tip (Tool Center Point) defined in each OMRON robot.

V+ keyword A generic term for instructions that are used during a V+ program and monitoring com-

V+ language

V+ task A task that can execute a V+ program.

V+ program A control program written in the V+ language.

OMRON robot Specifies the OMRON robot controllable from the Robot Integrated CPU Unit.

shared variable

sequence control

program

hardware servo A servo system built into the robot amplifier.

user program A generic term for the collection of programs written in the ladder diagram, ST, and V+

recipe A set of product type data in the customer’s system.

recipe change Specifies that the product data and information (recipe) related to the production process

Robot Control Function Module

robot control instructions

Robot Integrated

CPU Unit

Terminology

A motion to move continuous operations smoothly without stopping motion of the OMRON robot.

A programming language to write a sequence control program.

Specify the controllable robots by the data processing for robot in the Motion Control

Function Module of the NJ-series CPU Unit.

The controllable robot consists of the 1S-series or G5-series Servomotor/Servo Drive

with built-in EtherCA

tomer.

The target position or path can be specified based on the TCP.

mand.

A programming language for OMRON robot control.

The robot consists of the robot amplifier and the robot arm connected to the robot ampli-

.

fier

A variable that can be shared between the sequence control program and V+ program.

A control program written in IEC 61131-3 language including the motion control.

languages.

are changed.

The target recipe for the Robot Integrated CPU Unit is a property from the present values of variables and a vision sensor

A software to perform robot control that is installed in the Robot Integrated CPU Unit.

FB instructions written in the sequence control program to control the OMRON robots.

They include an instruction to directly control the OMRON robots and an instruction to

execute or abort V+ programs assigned to the V+ tasks.

A CPU Unit that supports control function for the OMRON robot with the NJ-series CPU

Unit.

T communications and the robot arm that is prepared by the cus-

.

NJ-series Robot Integrated CPU Unit User's Manual (O037)

27

Page 30

O037-E1-01

R

evision code

Cat. No.

Revision History

Revision History

A manual revision code appears as a suffix to the catalog number on the front and back covers of the

manual.

Revision

code

01 August 2020 Original production

Date Revised content

28

NJ-series Robot Integrated CPU Unit User's Manual (O037)

Page 31

1

Introduction to Robot Integrated

CPU Unit

This section describes the features, basic system configuration, specifications, and

overall operating procedure of an NJ-series Robot Integrated CPU Unit

1-1 Features ..........................................................................................................1-2

1-2 System Configuration.................................................................................... 1-4

1-3 Specifications................................................................................................. 1-6

1-3-1 General Specifications .................................................................................... 1-6

1-3-2 Performance Specifications............................................................................. 1-6

1-3-3 Function Specifications ................................................................................... 1-6

1-3-4 V+ Program Specifications.............................................................................. 1-8

1-4 Basic Procedure of Operation ...................................................................... 1-9

.

1

NJ-series Robot Integrated CPU Unit User's Manual (O037)

1-1

Page 32

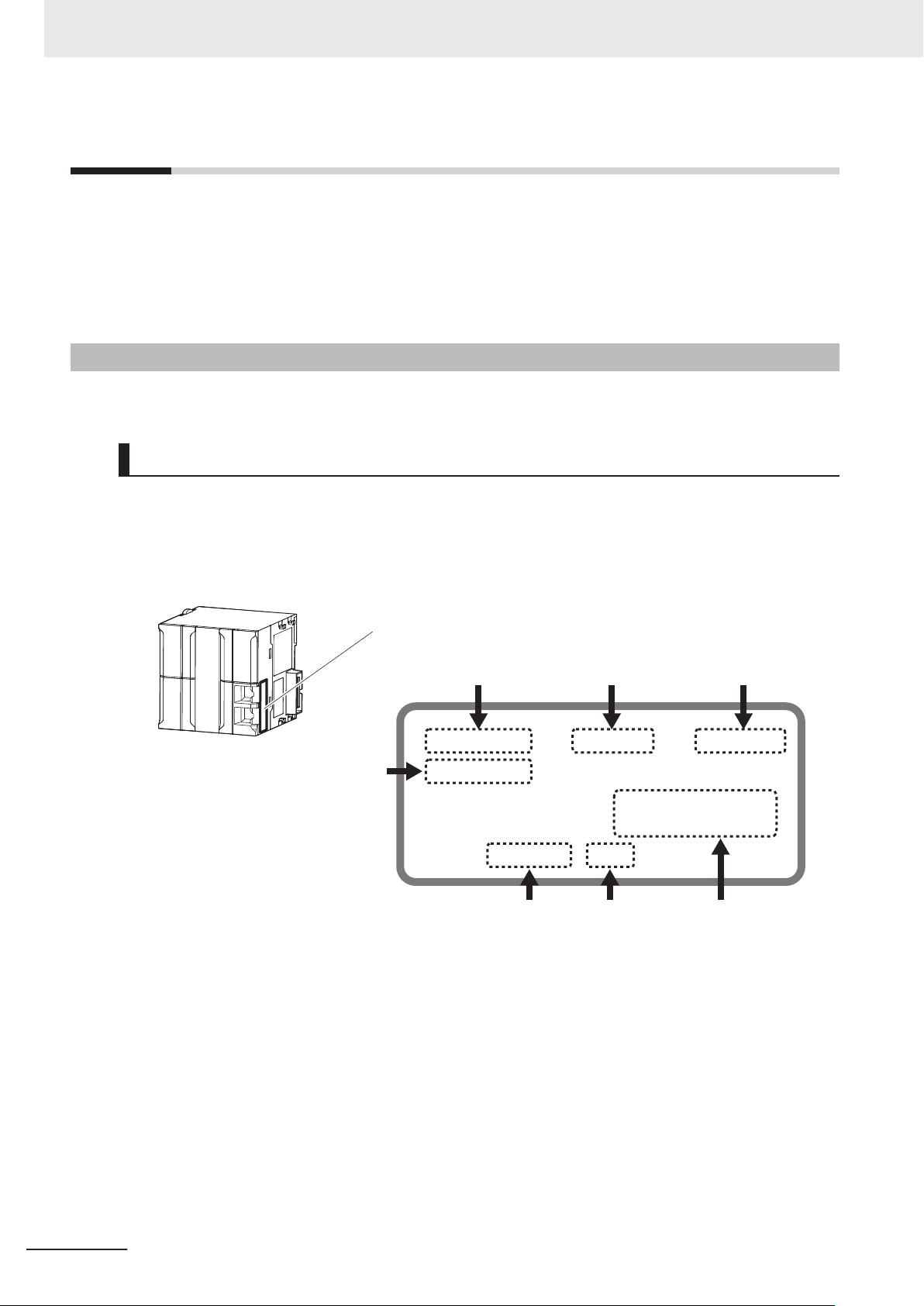

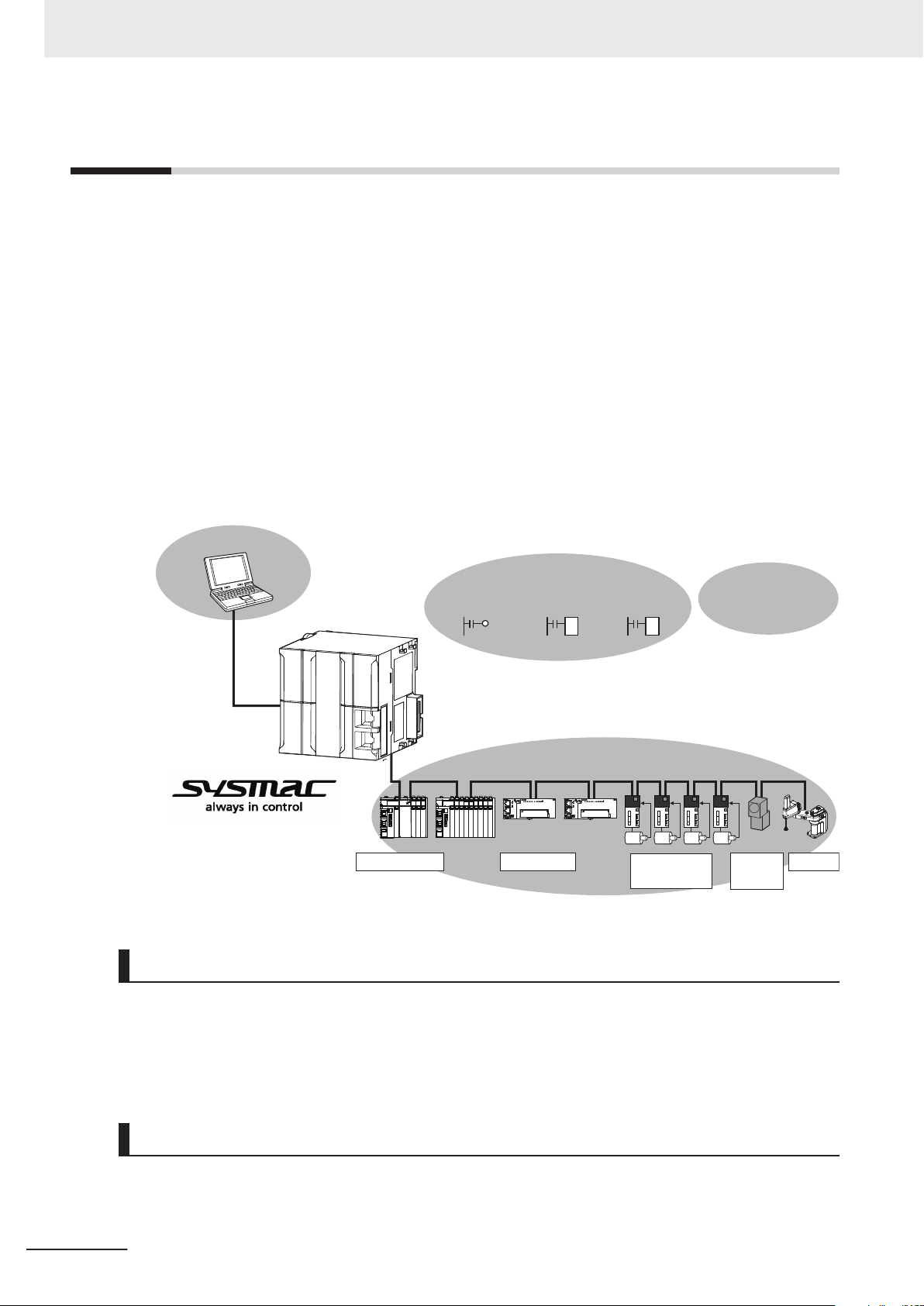

Motion controlSequence control

NJ-series

Robot Integrated

CPU Unit

IEC programming

Safety devices

Machine

vision

Servo Drives

and Inverters

I/O controls

EtherCAT control network

Sysmac Studio

Automation Software

Robots

V+ program

Robot control V+ language

1 Introduction to Robot Integrated CPU Unit

1-1

Features

The NJ-series Robot Integrated CPU Units are next-generation machine automation controllers that

provide the functionality and high-speed performance that are required for machine control. They pro-

vide the safety, reliability, and maintainability that are required of industrial controllers. The NJ-series

Controllers provide the functionality of previous OMRON PLCs, and they also provide the functionality

that is required for robot control. Synchronized control of I/O devices on high-speed EtherCAT can be

applied to robots, safety devices, vision systems, motion equipment, discrete I/O, and more.

OMRON offers the new Sysmac Series of control devices designed with unified communications spec-

ifications and user interface specifications.

The NJ-series Robot Integrated CPU Units are part of the Sysmac Series. You can use them together

with EtherCAT slaves, other Sysmac products, and the Sysmac Studio Automation Software to ach-

ieve optimum functionality and ease of operation. With a system that is created from Sysmac products,

you can connect components and commission the system through unified concepts and usability.

The Robot Control Function Module (sometimes abbreviated to “RC Function Module”) is a software

function module that is built into the Robot Integrated CPU Unit

The RC Function Module can perform robot control for up to 8 OMRON robots through the built-in

EtherCAT port on the Robot Integrated CPU Unit.

The OMRON robots are controlled with robot control instructions in the sequence control program.

1-2

Robot Control Function Module

Sequence Control Program

NJ-series Robot Integrated CPU Unit User's Manual (O037)

.

Page 33

1 Introduction to Robot Integrated CPU Unit

The sequence control program includes function blocks that are operated directly to the OMRON ro-

bots such as the robot joint interpolation, robot linear interpolation, stopping a robot, and other opera-

tions. The program also includes function blocks that controls V+ programs such as executing V+

tasks, aborting V+ tasks, and other operations.

V+ Program

The OMRON robots are controlled using V+ programs. The V+ programs are written in the V+ lan-

guage that is a special language for the robot control. You can easily realize various operation of the

OMRON robot using V+ programs.

In addition, the V+ program can use the interlock with a sequence control program (ladder diagram

and ST language) using shared variables.

Integrated Sequence Control and Motion Control

1-1 Features

1

A CPU Unit can perform both sequence control and motion control. You can simultaneously achieve

both sequence control and multi-axes synchronized control. Sequence control, motion control, and I/O

refreshing are all executed in the same control period.

The same control period is also used for the process data communications cycle for EtherCAT

enables precise sequence and motion control in a fixed period with very little deviation.

. This

Programming Languages Based on the IEC 61131-3 International

Standard

The Controllers support language specifications that are based on IEC 61131-3. To these, OMRON

has added our own improvements. Motion control instructions that are based on PLCopen® standards

and an instruction set (POUs) that follows IEC rules are provided.

Kinematics Function Supported

The kinematics function (NJ Robotics function) can perform data processing for robot in the Motion

Control Function Module (sometimes abbreviated to “MC Function Module”) to control robots that use

parallel link mechanism, Cartesian robots, and SCARA robots that are prepared by the customer.

Refer to the

matics function.

Note that the "kinematics function" is written as the "NJ Robotics function" in this manual.

NJ-series NJ Robotics CPU Unit User's Manual (Cat. No. W539) for details on the kine-

Data Transmission Using EtherCAT Communications

The OMRON robots are connected with EtherCAT communications to enable exchange of all control

information with high-speed data communications.

In addition, cyclic communications are performed with OMRON robots, Servo Drives and other devices

with EtherCAT communications, and the performance for the entire equipment is maximized

NJ-series Robot Integrated CPU Unit User's Manual (O037)

1-3

Page 34

Robots controllable by NJ Robotics function

FH-series Vision

Systems

Camera

Safety

devices

EtherNet/IP

EtherCAT

Sysmac Studio

NA-series

PT

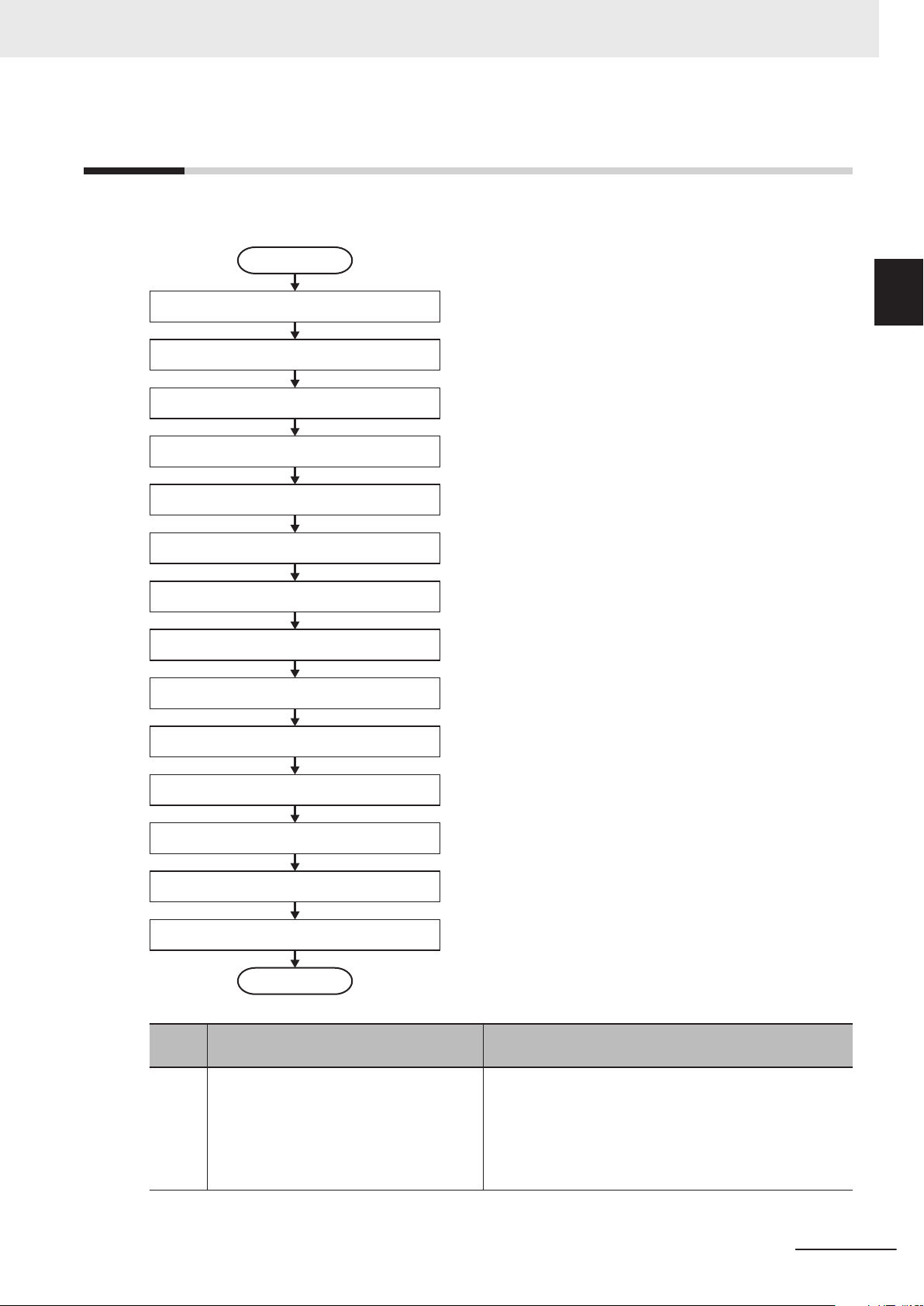

T20 Pendant

(with built-in EtherCAT

communications)

Slave

Terminal

IPC Application

Controller

Vision sensor

OMRON

robot

Robot Integrated CPU Unit

NJ501-R£££

Encoder,

digital I/O

Front

panel

I/O control

external devices

1S-series Servo Drives

G5-series Servo Drives

USB

1 Introduction to Robot Integrated CPU Unit

1-2

System Configuration

This section describes the system configuration and components related to the Robot Integrated CPU

Unit.

1-4

The function of each component in the system is given below.

Component Function in the system

EtherCAT Controls for Servo Drives and OMRON robots through the EtherCAT master port that is

built into the Robot Integrated CPU Unit. It enables precise control in a fixed period with

very little deviation.

OMRON robot

T20 Pendant

Sysmac Studio An integrated development software for use with the Robot Integrated CPU Unit that al-

NA-series PT Displays various information and performs operation as required.

IPC Application

Controller

1S-series Servo

Drives

G5-series Servo

Drives

Robots controllable by NJ Robotics

function

Consists of the robot amplifier and the robot arm connected to the robot amplifier.

It connects with a Robot Integrated CPU Unit through EtherCA

It has digital I/O ports to enable control for the external devices.

*1

A teaching pendant for the OMRON robot. It connects to the OMRON robot and performs

a test run for the OMRON robot or teaching.

lows you to create programming and make device settings.

It is used when you instruct a recipe change to the

A Controller to manage a recipe and more than one OMRON robot controlled by the Robot

Integrated CPU Unit. It can perform image processing by connecting a vision sensor

Servo Drives with built-in EtherCAT communications.

Robots that can be controlled from the Robot Integrated CPU Unit that controls Servomotors/Servo Drives with built-in EtherCAT communications.

NJ-series Robot Integrated CPU Unit User's Manual (O037)

Robot Integrated CPU Unit

T communications.

.

.

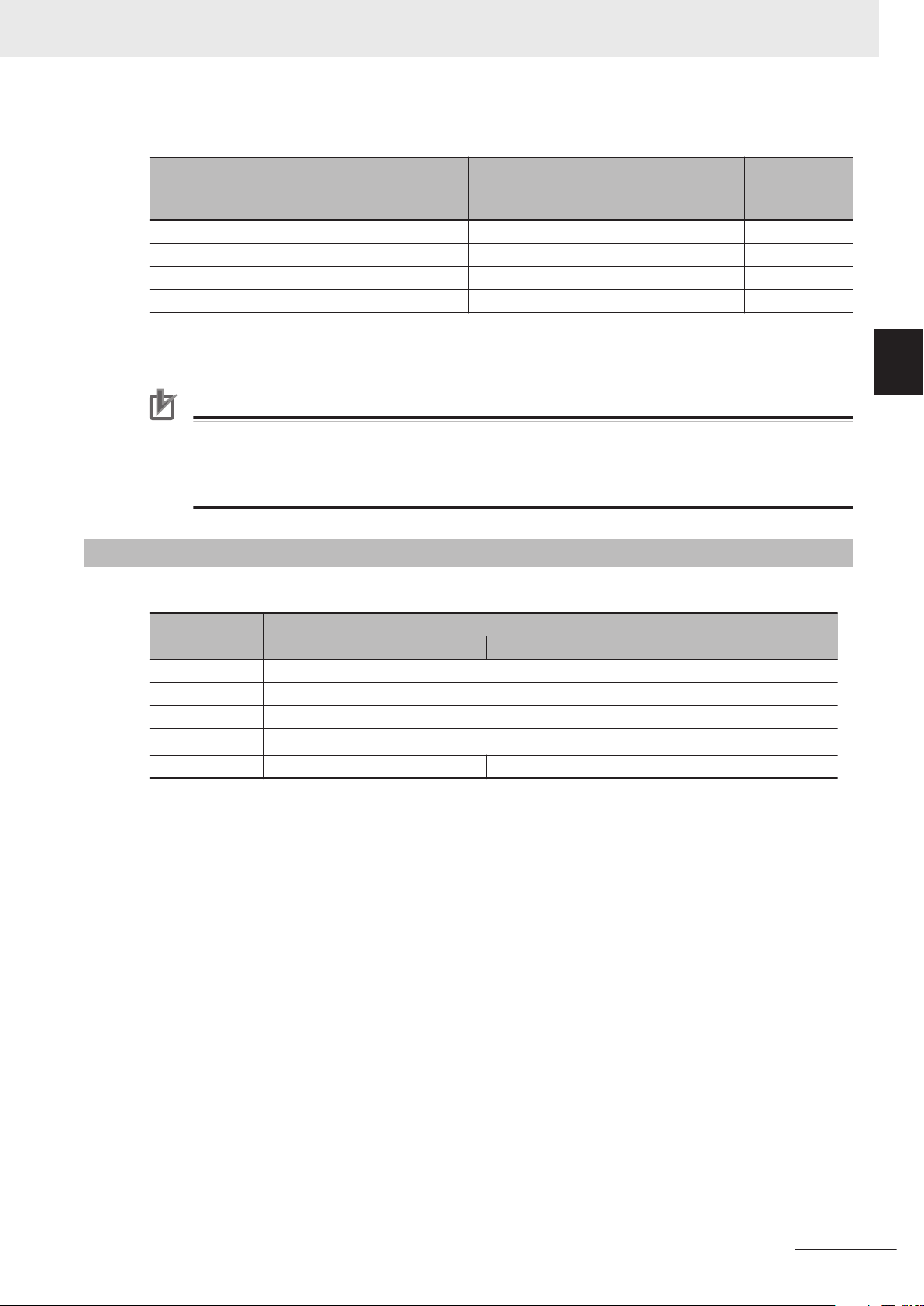

Page 35

1 Introduction to Robot Integrated CPU Unit

Component Function in the system

Slave Terminal

FH-series Vision

Systems

Front panel Changes the operating mode of OMRON robot and executes a emergency stop.

I/O control external devices

Safety devices Safety devices such as a Safety Controller, safety sensor, and safety relay.

*1. Refer to the T20 Pendant User’

Precautions for Correct Use

• Always insert the included SD Memory Card when you use the robot control function with the

Robot Integrated CPU Unit.

Do not remove the SD Memory Card while power is supplied when you use the robot control

•

function with the Robot Integrated CPU Unit.

Doing so causes the robot control function to stop due to an error.

• The robot setting files and V+ program files in the SD Memory Card are required for the operation of the Robot Control Function Module.

Be careful not to overwrite or delete the robot setting files and V+ program files.

Consists of the NX-ECC20£ Communications Coupler Unit and NX Units that are connected to EtherCA

Unit through EtherCA

Various Units such as digital I/O, analog I/O are covered, therefore, you can use the NX

Units depending on the system demand.

Vision systems connected to the EtherCAT communications.

External devices to control from I/O ports of the NX Units or the robot.

They include a photoelectric sensor

T communications. It exchanges I/O data with a Robot Integrated CPU

T communications.

, an air cylinder

s Guide (Cat. No. I601) for details.

, a robot hand, and other devices.

1-2 System Configuration

1

NJ-series Robot Integrated CPU Unit User's Manual (O037)

1-5

Page 36

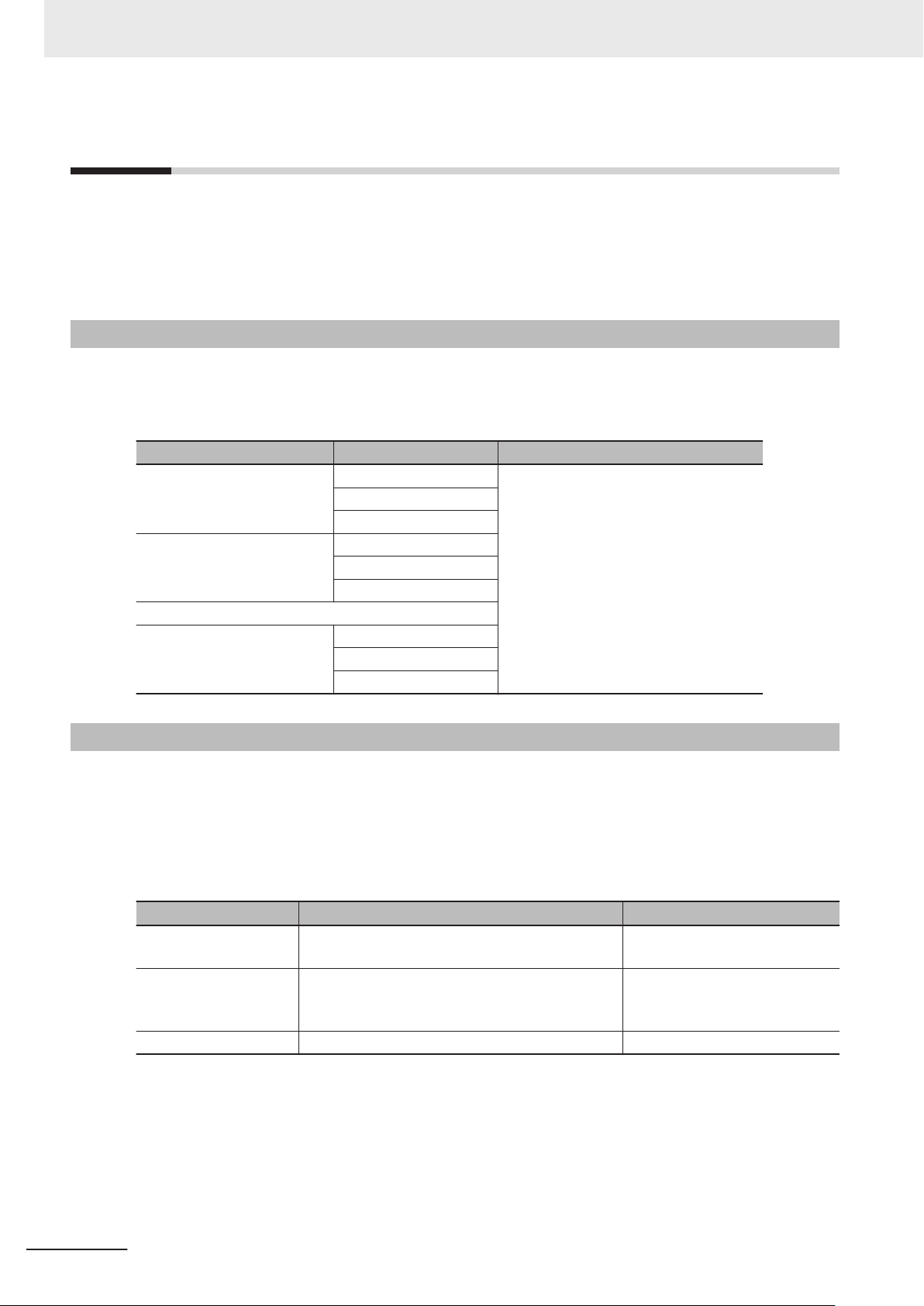

1 Introduction to Robot Integrated CPU Unit

1-3

1-3-1

1-3-2

Specifications

This section describes the general specifications, performance specifications, and function specifica-

tions for the Robot Integrated CPU Unit.

General Specifications

General specifications conform to the general specifications of the CPU Unit.

Refer to the NJ-series CPU Unit Hardware User’s Manual (Cat. No. W500) for details.

Performance Specifications

Performance specifications conform to the performance specifications of the NJ-series Controllers.

Refer to the NJ-series CPU Unit Hardware User’s Manual (Cat. No. W500) for details.