Omron NX1P2-11 Series, NX701-16 Series, NX1P2-10 Series, NJ501-*5 Series, NJ501-*4 Series User Manual

...Page 1

Machine Automation Controller

NJ/NX-series

CPU Unit Built-in EtherCAT® Port

User’s Manual

NX701-17

NX701-16

NX1P2-11

NX1P2-10

NX1P2-90

NJ501-5

NJ501-4

NJ501-3

NJ301-12

NJ301-11

NJ101-10

NJ101-90

CPU Unit

W505-E1-15

Page 2

NOTE

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of the information contained in this publication.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan and other

countries for OMRON factory automation products.

• Microsoft, Windows, Windows Vista, Excel, and Visual Basic are either registered trademarks or trademarks of

Microsoft Corporation in the United States and other countries.

• EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

• ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

• The SD and SDHC logos are trademarks of SD-3C, LLC.

Other company names and product names in this document are the trademarks or registered trademarks of their

respective companies.

Copyrights

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Page 3

Introduction

Thank you for purchasing an NJ/NX-series CPU Unit.

This manual contains information that is necessary to use the NJ/NX-series CPU Unit. Please read this

manual and make sure you understand the functionality and performance of the NJ/NX-series CPU

Unit before you attempt to use it in a control system.

Keep this manual in a safe place where it will be available for reference during operation.

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and maintaining FA systems.

• Personnel in charge of managing FA systems and facilities.

Introduction

For programming, this manual is intended for personnel who understand the programming language

specifications in international standard IEC 61131-3 or Japanese standard JIS B 3503.

Applicable Products

This manual covers the following products.

• NX-series CPU Units

•NX701-17

•NX701-16

• NX1P2-11

• NX1P2-111

• NX1P2-10

• NX1P2-101

• NX1P2-90

• NX1P2-901

• NJ-series CPU Units

• NJ501-5

• NJ501-4

• NJ501-3

• NJ301-12

• NJ301-11

• NJ101-10

• NJ101-90

Part of the specifications and restrictions for the CPU Units are given in other manuals. Refer to Rele-

vant Manuals on page 2 and Related Manuals on page 22.

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

1

Page 4

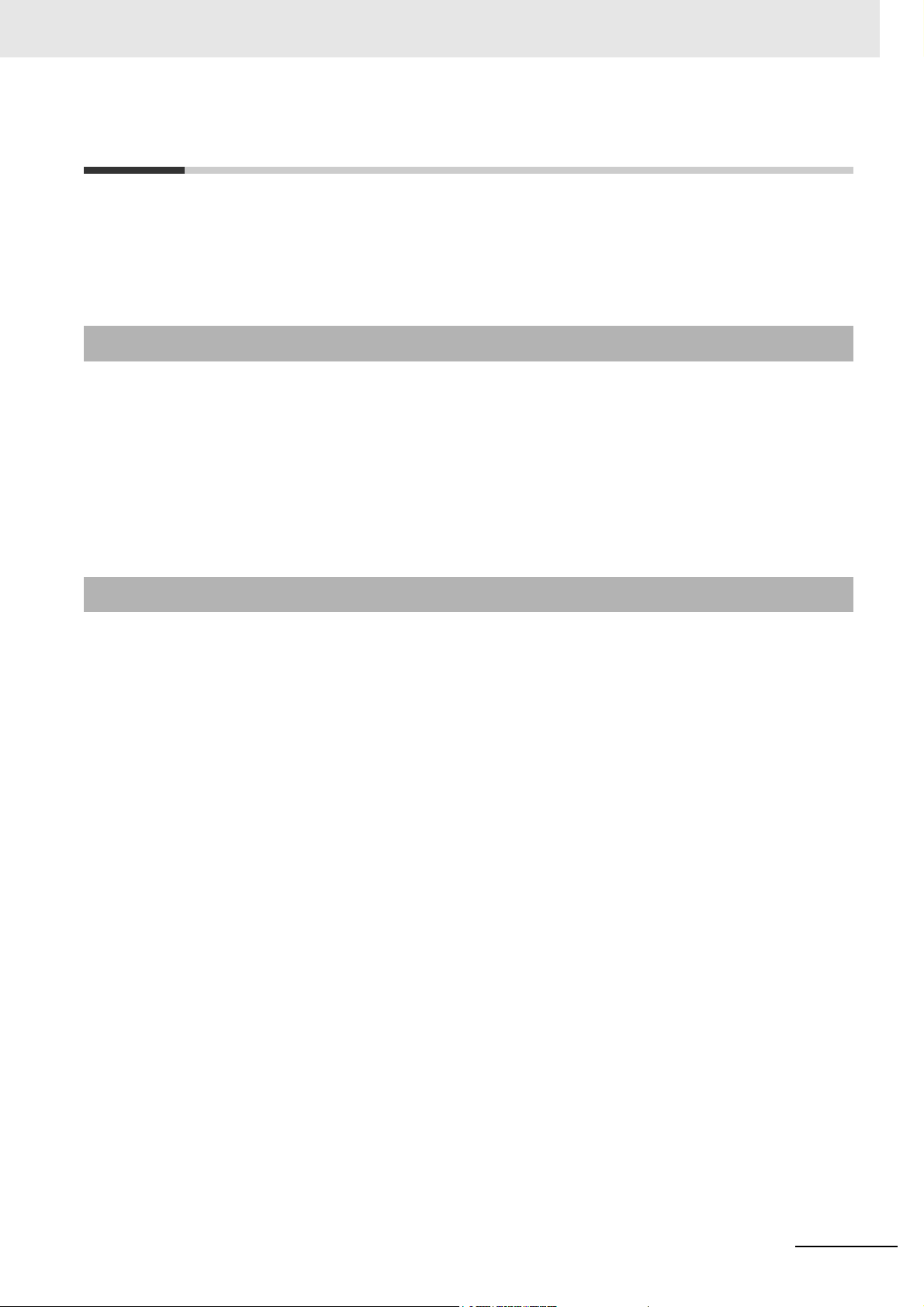

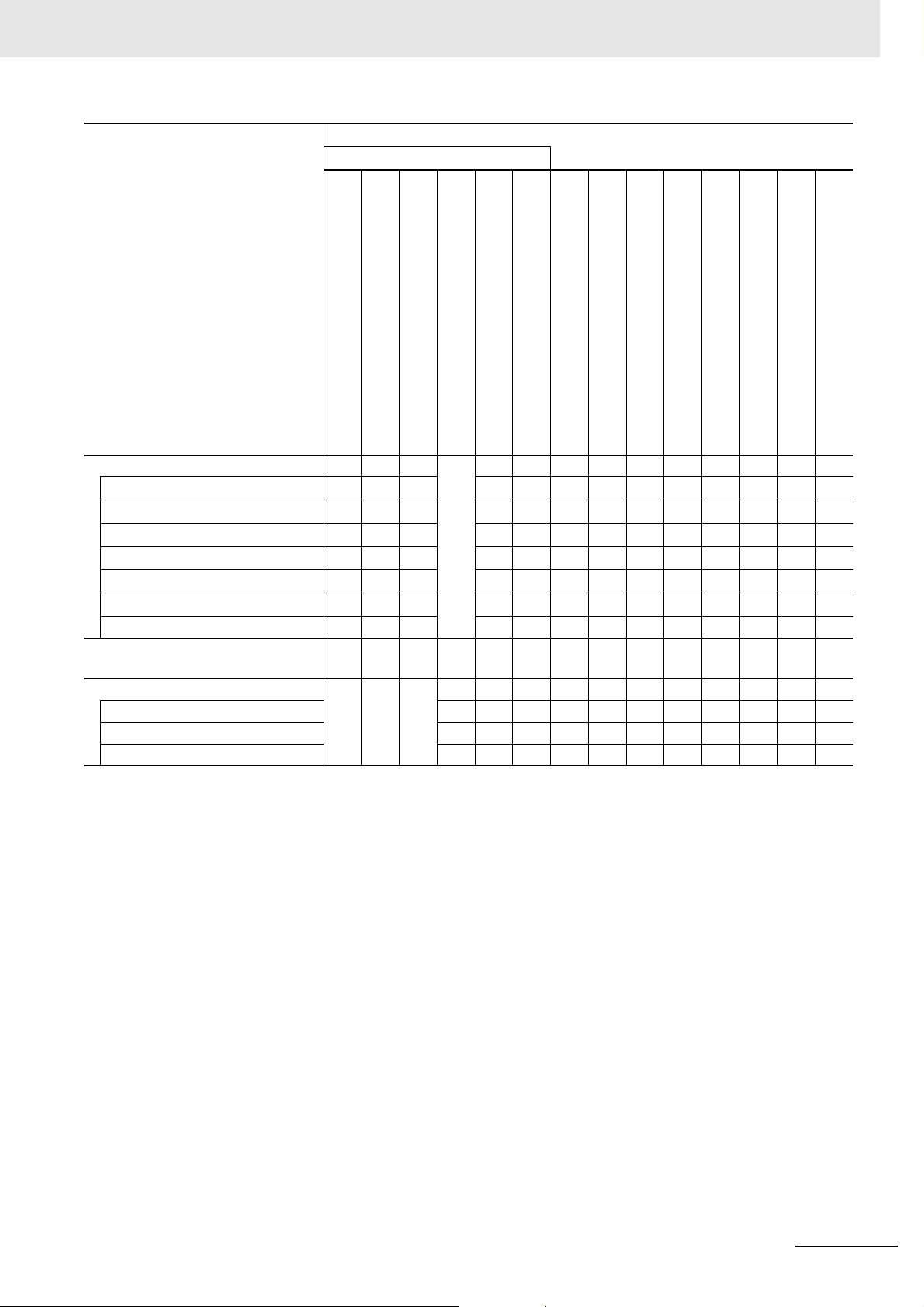

Relevant Manuals

Relevant Manuals

The following table provides the relevant manuals for the NJ/NX-series CPU Units.

Read all of the manuals that are relevant to your system configuration and application before you use

the NJ/NX-series CPU Unit.

Most operations are performed from the Sysmac Studio Automation Software. Refer to the Sysmac Stu-

dio Version 1 Operation Manual (Cat. No. W504) for information on the Sysmac Studio.

Basic information

NX-series CPU Unit

Hardware User’s Manual

NX-series NX1P2 CPU Unit

Hardware User's Manual

Manual

NJ-series CPU Unit

Hardware User’s Manual

NJ/NX-series CPU Unit

Software User’s Manual

Built-in I/O and Option Board User's Manual

NX-series NX1P2 CPU Unit

NJ/NX-series

Instructions Reference Manual

NJ/NX-series CPU Unit

Motion Control User’s Manual

Motion Control Instructions Reference Manual

NJ/NX-series

Built-in EtherCAT Port User’s Manual

NJ/NX-series CPU Unit

NJ/NX-series CPU Unit

Built-in EtherNet/IP Port User’s Manual

User’s Manual

NJ-series Database Connection CPU Units

NJ-series SECS/GEM CPU Units

User’s Manual

NJ-series NJ Robotics

CPU Unit User’s Manual

Troubleshooting Manual

NJ/NX-series

Purpose of use

Introduction to the NX701 Controller

Introduction to the NX1P2 Controller

Introduction to NJ-series Controllers

Setting devices and hardware

Using motion control

Using EtherCAT

Using EtherNet/IP

Software settings

Using motion control

Using EtherCAT

Using EtherNet/IP

Using the database connection service

Using the GEM Services

Controlling robots

Using the NX1P2 Controller

Writing the user program

Using motion control

Using EtherCAT

Using EtherNet/IP

Using the database connection service

Using the GEM Services

Controlling robots

Programming error processing

Using the NX1P2 Controller

2

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

Page 5

Manual

Basic information

NX-series CPU Unit

Hardware User’s Manual

NX-series NX1P2 CPU Unit

Hardware User's Manual

NJ-series CPU Unit

Hardware User’s Manual

NJ/NX-series CPU Unit

Software User’s Manual

NX-series NX1P2 CPU Unit

Built-in I/O and Option Board User's Manual

NJ/NX-series

Instructions Reference Manual

NJ/NX-series CPU Unit

Motion Control User’s Manual

NJ/NX-series

Motion Control Instructions Reference Manual

Built-in EtherCAT Port User’s Manual

Purpose of use

Testing operation and debugging

Using motion control

Using EtherCAT

Using EtherNet/IP

Using the database connection service

Using the GEM Services

Controlling robots

Using the NX1P2 Controller

Learning about error management and

corrections

Maintenance

Using motion control

Using EtherCAT

Using EtherNet/IP

*1

Relevant Manuals

NJ/NX-series CPU Unit

NJ/NX-series CPU Unit

Built-in EtherNet/IP Port User’s Manual

NJ-series Database Connection CPU Units

User’s Manual

NJ-series SECS/GEM CPU Units

User’s Manual

NJ-series NJ Robotics

CPU Unit User’s Manual

NJ/NX-series

Troubleshooting Manual

*1 Refer to the NJ/NX-series Troubleshooting Manual (Cat. No. W503) for the error management concepts and an overview

of the error items. Refer to the manuals that are indicated with triangles for details on errors.

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

3

Page 6

Manual Structure

4-9

4 Installation and Wiring

NJ-series CPU Unit Hardware User’s Manual (W500)

stinU gnitnuoM 3-4

4

stnenopmoC rellortnoC gnitcennoC 1-3-4

4-3 Mounting Units

The Units that make up an NJ-series Controller can be connected simply by pressing the Units together

and locking the sliders by moving them toward the back of the Units. The End Cover is connected in the

same way to the Unit on the far right side of the Controller.

1 Join the Units so that the connectors fit exactly.

2 The yellow sliders at the top and bottom of each Unit lock the Units together. Move the sliders

toward the back of the Units as shown below until they click into place.

Precautions for Correct UsePrecautions for Correct Use

4-3-1 Connecting Controller Components

Connector

Hook

Hook holes

Slider

Lock

Release

Move the sliders toward the back

until they lock into place.

Level 1 heading

Level 2 heading

Level 3 heading

Level 2 heading

A step in a procedure

Manual name

Special information

Level 3 heading

Page tab

Gives the current

headings.

Indicates a procedure.

Icons indicate

precautions, additional

information, or reference

information.

Gives the number

of the main section.

This illustration is provided only as a sample. It may not literally appear in this manual.

The sliders on the tops and bottoms of the Power Supply Unit, CPU Unit, I/O Units, Special I/O

Units, and CPU Bus Units must be completely locked (until they click into place) after connecting

the adjacent Unit connectors.

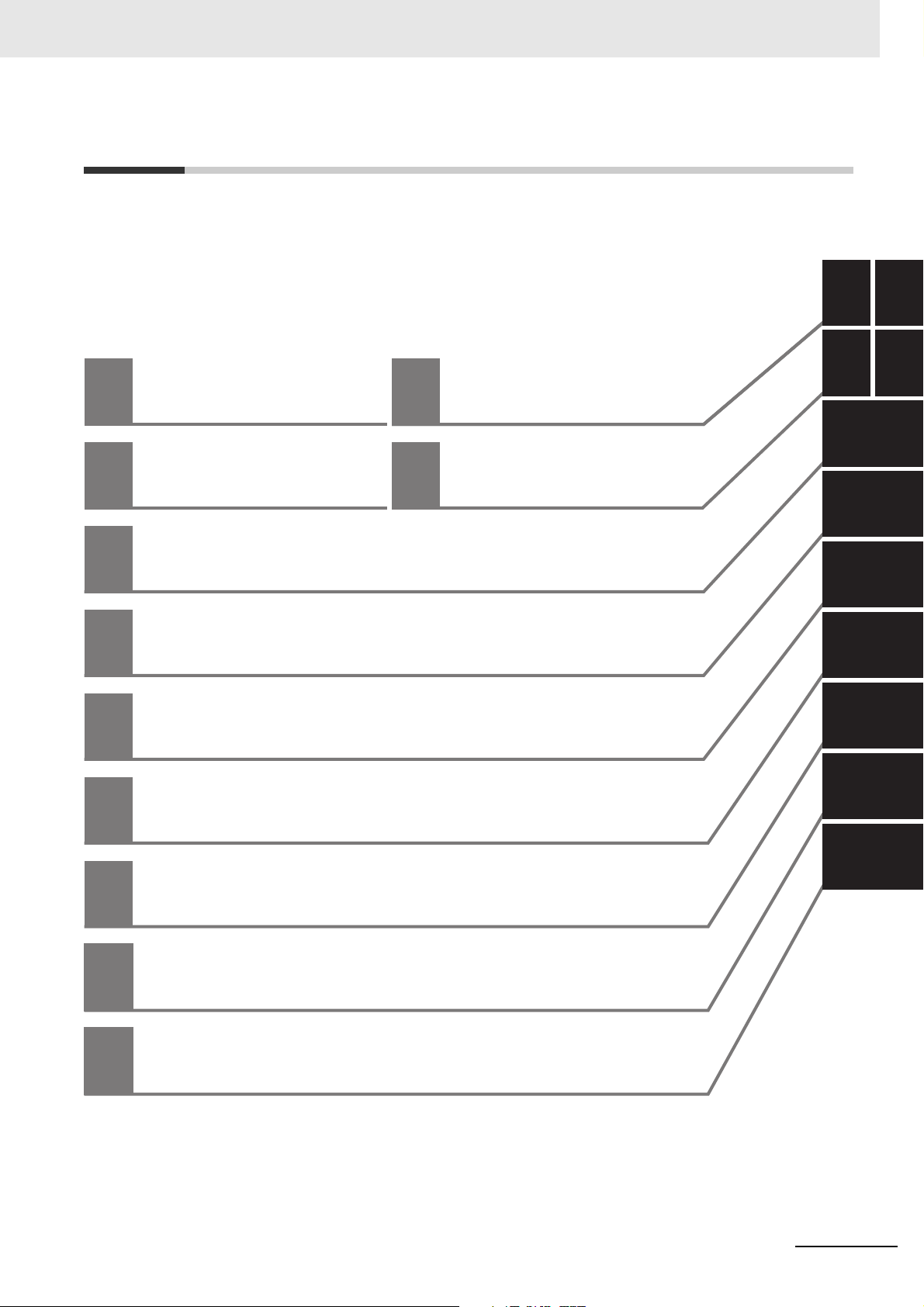

Manual Structure

Page Structure

The following page structure is used in this manual.

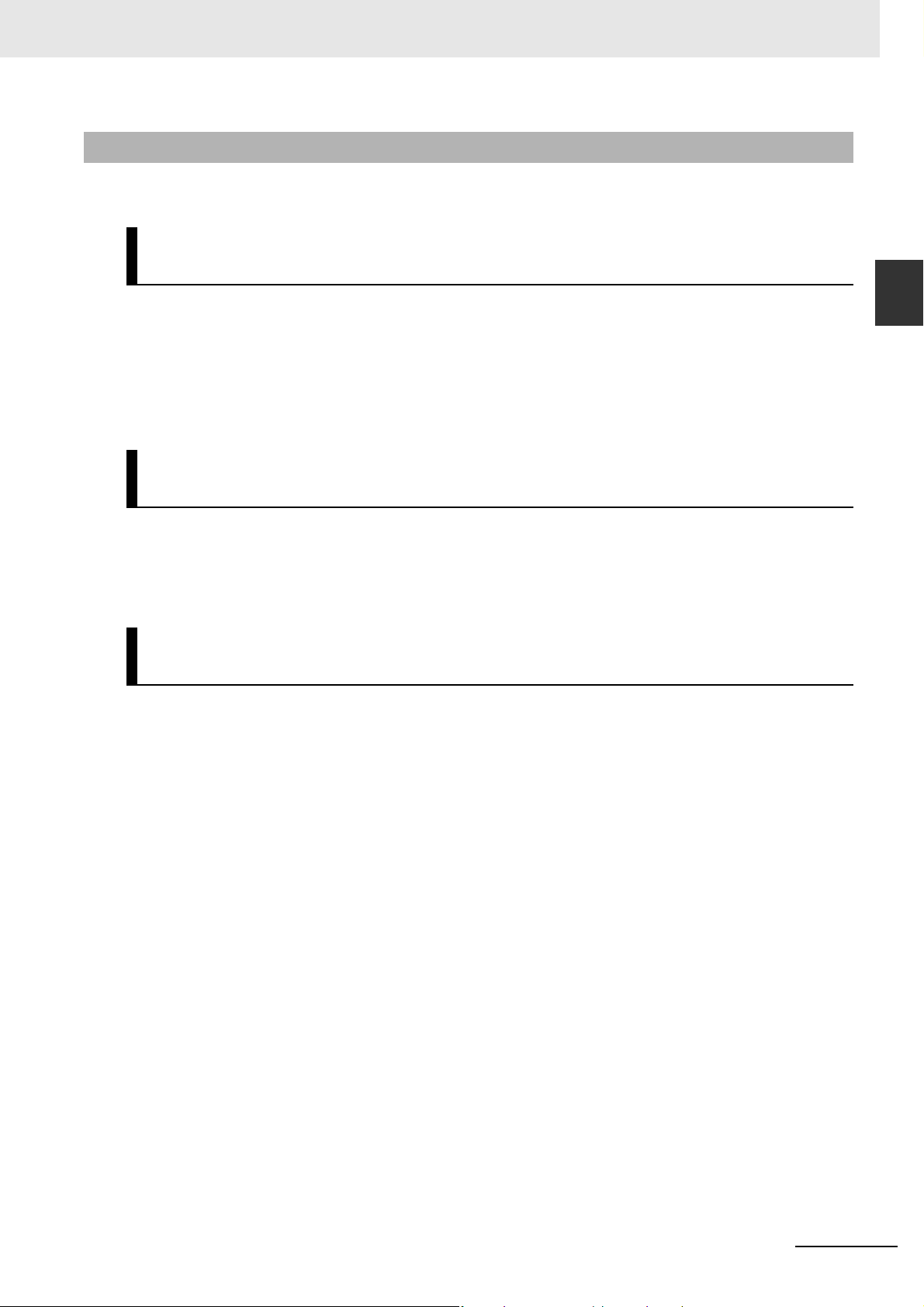

Special Information

Special information in this manual is classified as follows:

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

4

Note References are provided to more detailed or related information.

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

Page 7

Precaution on Terminology

In this manual, “download” refers to transferring data from the Sysmac Studio to the physical Controller

and “upload” refers to transferring data from the physical Controller to the Sysmac Studio.

For the Sysmac Studio, synchronization is used to both upload and download data. Here, “synchronize”

means to automatically compare the data for the Sysmac Studio on the computer with the data in the

physical Controller and transfer the data in the direction that is specified by the user.

Manual Structure

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

5

Page 8

Manual Structure

6

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

Page 9

Sections in this Manual

1A

2I

3

4

5

6

7

8

9

1A

2I

3

4

5

6

7

8

9

Introduction Appendices

Part Names and

Slave Settings

Index

EtherCAT Communications

EtherCAT Network Wiring

Setting Up EtherCAT Communications

with the Sysmac Studio

Process Data Communications

and SDO Communications

System-defined Variables That Are Related

to the Built-in EtherCAT Port

Example of Operations for EtherCAT Communications

Troubleshooting

Sections in this Manual

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

7

Page 10

CONTENTS

CONTENTS

Introduction ...............................................................................................................1

Intended Audience ........................................................................................................................................ 1

Applicable Products ...................................................................................................................................... 1

Relevant Manuals......................................................................................................2

Manual Structure.......................................................................................................4

Page Structure .............................................................................................................................................. 4

Special Information ....................................................................................................................................... 4

Precaution on Terminology ........................................................................................................................... 5

Sections in this Manual ............................................................................................7

Terms and Conditions Agreement .........................................................................12

Warranty, Limitations of Liability ................................................................................................................. 12

Application Considerations ......................................................................................................................... 13

Disclaimers ................................................................................................................................................. 13

Safety Precautions.................................................................................................. 14

Precautions for Safe Use........................................................................................15

Precautions for Correct Use...................................................................................16

Regulations and Standards....................................................................................17

Conformance to EU Directives .................................................................................................................... 17

Conformance to KC Standards ................................................................................................................... 18

Conformance to Shipbuilding Standards .................................................................................................... 18

Software Licenses and Copyrights ............................................................................................................. 18

Versions ...................................................................................................................19

Checking Versions ...................................................................................................................................... 19

Unit Versions of CPU Units and Sysmac Studio Versions ..........................................................................21

Related Manuals......................................................................................................22

Revision History......................................................................................................24

Section 1 Introduction

1-1 Introduction to EtherCAT ........................................................................................................ 1-2

1-1-1 EtherCAT Features ..................................................................................................................... 1-2

1-1-2 EtherCAT Communications......................................................................................................... 1-2

1-1-3 EtherCAT Features for NJ/NX-series CPU Units ........................................................................1-3

1-2 System Configuration and Configuration Devices............................................................... 1-4

1-2-1 System Configuration..................................................................................................................1-4

1-2-2 Determining the Network Configuration ......................................................................................1-8

1-3 Specifications of Built-in EtherCAT Port ............................................................................... 1-9

1-3-1 Performance Specifications ........................................................................................................ 1-9

1-4 Introduction of Communications ......................................................................................... 1-11

1-4-1 Process Data Communications and SDO Communications ..................................................... 1-11

1-4-2 Other Functions......................................................................................................................... 1-11

1-5 EtherCAT Communications Procedure ............................................................................... 1-13

1-5-1 Overview ...................................................................................................................................1-13

8

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

Page 11

CONTENTS

1-5-2 Details....................................................................................................................................... 1-14

Section 2 Part Names and Slave Settings

2-1 Part Names and Functions .....................................................................................................2-2

2-1-1 Built-in EtherCAT Port Indicators ................................................................................................ 2-2

2-1-2 Windows Used in Sysmac Studio ............................................................................................... 2-4

2-1-3 Connecting the Sysmac Studio................................................................................................... 2-7

2-2 Setting the Node Addresses of the EtherCAT Slaves .......................................................... 2-9

2-3 Features of Sysmac Devices ................................................................................................ 2-12

2-3-1 Sysmac Devices ....................................................................................................................... 2-12

2-3-2 Sysmac Device Features.......................................................................................................... 2-12

2-3-3 List of Sysmac Devices............................................................................................................. 2-15

2-3-4 Sysmac Device Features and EtherCAT Masters .................................................................... 2-16

Section 3 EtherCAT Communications

3-1 EtherCAT Communications Types and Settings .................................................................. 3-2

3-1-1 CoE (CAN Application Protocol over EtherCAT) ........................................................................ 3-2

3-1-2 Types of Communications .......................................................................................................... 3-5

3-1-3 Types of EtherCAT Variables...................................................................................................... 3-6

3-1-4 Settings Required for EtherCAT Communications...................................................................... 3-7

3-2 Programming EtherCAT Communications............................................................................ 3-8

3-3 State Transitions for EtherCAT Communications ................................................................ 3-9

3-3-1 Self Diagnosis at Startup ............................................................................................................ 3-9

3-3-2 Control States for EtherCAT Communications............................................................................ 3-9

3-3-3 CPU Unit Status in Relation to EtherCAT ..................................................................................3-11

Section 4 EtherCAT Network Wiring

4-1 Laying the EtherCAT Network ................................................................................................ 4-2

4-1-1 Supported Network Topologies................................................................................................... 4-2

4-1-2 Installation Precautions............................................................................................................... 4-4

4-1-3 Installing EtherCAT Communications Cables ............................................................................. 4-4

4-1-4 Connecting Communications Cables.......................................................................................... 4-8

4-1-5 Cable Connection Procedure...................................................................................................... 4-9

Section 5 Setting Up EtherCAT Communications with

the Sysmac Studio

5-1 Overview of Network Configuration Information.................................................................. 5-2

5-2 Creating the EtherCAT Network Configuration..................................................................... 5-3

5-3 Setting EtherCAT Slave Variables and Axes ......................................................................... 5-6

5-3-1 Registering Device Variables for All EtherCAT Slaves ............................................................... 5-6

5-3-2 Axis Settings for Servo Drives and Encoder Input Slaves ........................................................ 5-10

5-4 EtherCAT Master and Slave Parameter Settings ................................................................ 5-11

5-4-1 Setting EtherCAT Master ...........................................................................................................5-11

5-4-2 Setting EtherCAT Slaves .......................................................................................................... 5-16

5-5 Comparing and Merging EtherCAT Network Configurations ............................................ 5-24

5-5-1 Comparing and Merging with the Actual Network Configuration from the Sysmac Studio ....... 5-24

5-5-2 Automatically Creating the Network Configuration ................................................................... 5-28

5-5-3 Using the Sysmac Studio to Obtain Serial Numbers from the Actual

Network Configuration5-31

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

9

Page 12

CONTENTS

5-6 Downloading the Network Configuration Information ....................................................... 5-33

5-6-1 Downloading the Network Configuration Information from the Sysmac Studio......................... 5-33

5-7 Confirming Communications after Completing

EtherCAT Configuration and Settings5-35

Section 6 Process Data Communications and SDO

Communications

6-1 Process Data Communications (PDO Communications) .................................................... 6-2

6-1-1 Allocated Variables for Process Data Communications.............................................................. 6-2

6-1-2 Process Data Communications Refresh Timing..........................................................................6-4

6-1-3 Checking the Validity of the Process Data ..................................................................................6-7

6-1-4 System Response Time in Process Data Communications...................................................... 6-12

6-1-5 I/O Operations for Major Fault Level Controller Errors and I/O Refreshing with

Specified Values6-17

6-2 SDO Communications...........................................................................................................6-21

6-2-1 EtherCAT Instructions ...............................................................................................................6-21

6-2-2 Sample Programming ............................................................................................................... 6-22

6-2-3 Execution Timing of SDO Communications ..............................................................................6-23

6-2-4 Minimum Message Response Time for SDO Communications................................................6-24

6-3 Instructions Used in EtherCAT Communications............................................................... 6-28

6-3-1 EtherCAT Instructions ...............................................................................................................6-28

Section 7 System-defined Variables That Are Related to

the Built-in EtherCAT Port

7-1 System-defined Variables That Are Related to the Built-in EtherCAT Port........................ 7-2

7-1-1 What Are System-defined Variables? .........................................................................................7-2

7-1-2 System-defined Variables ........................................................................................................... 7-3

7-1-3 EtherCAT Master Function Module, Category Name: _EC.........................................................7-9

Section 8 Example of Operations for EtherCAT Communications

8-1 Example of Operations for EtherCAT Communications ...................................................... 8-2

8-1-1 System Configuration Example...................................................................................................8-2

8-1-2 Wiring and Settings.....................................................................................................................8-2

8-1-3 Setting the EtherCAT Network Configuration..............................................................................8-3

8-1-4 Programming...............................................................................................................................8-5

8-1-5 Offline Debugging .......................................................................................................................8-5

8-1-6 Turning the Power ON ................................................................................................................ 8-5

8-1-7 Online Debugging .......................................................................................................................8-5

8-1-8 Downloading the Network Configuration Information and the User Program .............................8-5

8-1-9 Confirming the Start of Communications.....................................................................................8-6

Section 9 Troubleshooting

10

9-1 Overview of Errors .................................................................................................................. 9-2

9-1-1 How to Check for Errors..............................................................................................................9-3

9-1-2 Errors Related to the EtherCAT Master Function Module........................................................... 9-7

9-2 Troubleshooting .................................................................................................................... 9-10

9-2-1 Error Table................................................................................................................................. 9-10

9-2-2 Error Descriptions ..................................................................................................................... 9-16

9-2-3 Resetting Errors ........................................................................................................................ 9-48

9-2-4 Diagnostic and Statistical Information ....................................................................................... 9-50

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

Page 13

CONTENTS

9-3 Precautions When Connecting or Disconnecting Slaves during Communications ....... 9-67

9-3-1 Procedure for Connecting and Disconnecting Slaves during Communications........................ 9-67

9-3-2 Prohibition to Physically Disconnecting a Slave and Resetting an Error or

9-4 Replacing Slaves during Communications......................................................................... 9-68

9-4-1 Introduction............................................................................................................................... 9-68

9-4-2 Slave Replacement Methods.................................................................................................... 9-69

9-4-3 Backing Up Settings ................................................................................................................. 9-70

9-4-4 Restoring Settings .................................................................................................................... 9-71

9-4-5 Replacement Procedure........................................................................................................... 9-73

Appendices

A-1 EtherCAT Status in Relation to CPU Unit Status ..................................................................A-2

A-1-1 When the Power Supply Is Turned ON.......................................................................................A-2

A-1-2 CPU Unit Operating Modes........................................................................................................ A-3

A-1-3 Controller Errors Other Than Errors in the Built-in EtherCAT Master .........................................A-5

A-1-4 Others.........................................................................................................................................A-6

A-1-5 When the Power Supply Is Turned OFF.....................................................................................A-7

A-2 Monitoring Packets..................................................................................................................A-8

A-3 Multi-vendor Environments ..................................................................................................A-17

A-3-1 EtherCAT Slave Information File (ESI Files).............................................................................A-17

A-3-2 Connecting Slaves from Other Manufacturers to an OMRON Master......................................A-19

A-3-3 Installing ESI Files .................................................................................................................... A-19

A-3-4 Editing PDO Entry Tables ......................................................................................................... A-25

A-3-5 Settings for MDP-compatible Slaves from Other Manufacturers.............................................. A-28

A-4 Glossary .................................................................................................................................A-31

A-5 Version Information...............................................................................................................A-33

Connecting a Slave at the Same Time9-67

Index

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

11

Page 14

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship for a period of twelve months from the date of sale by Omron (or such other period expressed in

writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be

responsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of

any Products by Buyer must be approved in writing by Omron before shipment. Omron Companies

shall not be liable for the suitability or unsuitability or the results from the use of Products in combination with any electrical or electronic components, circuits, system assemblies or any other materials or substances or environments. Any advice, recommendations or information given orally or in

writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

12

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

Page 15

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings

and limitations of use which apply to the Product. This information by itself is not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine, system, or other application or use. Buyer shall be solely responsible for determining appropriateness of

the particular Product with respect to Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Terms and Conditions Agreement

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or

any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual performance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and other

reasons. It is our practice to change part numbers when published ratings or features are changed, or

when significant construction changes are made. However, some specifications of the Product may be

changed without any notice. When in doubt, special part numbers may be assigned to fix or establish

key specifications for your application. Please consult with your Omron’s representative at any time to

confirm actual specifications of purchased Product.

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

13

Page 16

Safety Precautions

Safety Precautions

Refer to the following manuals for safety precautions.

• NX-series CPU Unit Hardware User’s Manual (Cat No. W535)

• NX-series NX1P2 CPU Unit Hardware User’s Manual (Cat. No. W578)

• NJ-series CPU Unit Hardware User’s Manual (Cat No. W500)

14

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

Page 17

Precautions for Safe Use

Refer to the following manuals for precautions for safe use.

• NX-series CPU Unit Hardware User’s Manual (Cat No. W535)

• NX-series NX1P2 CPU Unit Hardware User’s Manual (Cat. No. W578)

• NJ-series CPU Unit Hardware User’s Manual (Cat No. W500)

Precautions for Safe Use

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

15

Page 18

Precautions for Correct Use

Precautions for Correct Use

Refer to the following manuals for precautions for correct use.

• NX-series CPU Unit Hardware User’s Manual (Cat No. W535)

• NX-series NX1P2 CPU Unit Hardware User’s Manual (Cat. No. W578)

• NJ-series CPU Unit Hardware User’s Manual (Cat No. W500)

16

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

Page 19

Regulations and Standards

Conformance to EU Directives

Applicable Directives

• EMC Directives

• Low Voltage Directive

Concepts

EMC Directive

OMRON devices that comply with EU Directives also conform to the related EMC standards so that

they can be more easily built into other devices or the overall machine. The actual products have

been checked for conformity to EMC standards.*

Whether the products conform to the standards in the system used by the customer, however, must

be checked by the customer. EMC-related performance of the OMRON devices that comply with EU

Directives will vary depending on the configuration, wiring, and other conditions of the equipment or

control panel on which the OMRON devices are installed. The customer must, therefore, perform

the final check to confirm that devices and the overall machine conform to EMC standards.

* Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN 61131-2

EMI (Electromagnetic Interference): EN 61131-2 (Radiated emission: 10-m regulations)

Regulations and Standards

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 VAC and 75 to 1,500 VDC meet the

required safety standards. The applicable directive is EN 61010-2-201.

Conformance to EU Directives

The NJ/NX-series Controllers comply with EU Directives. To ensure that the machine or device in

which the NJ/NX-series Controller is used complies with EU Directives, the Controller must be

installed as follows:

• The NJ/NX-series Controller must be installed within a control panel.

• You must use the power supply in SELV specifications for the DC power supplies connected to

DC Power Supply Units and I/O Units.

• NJ/NX-series Controllers that comply with EU Directives also conform to the Common Emission

Standard (EN 61000-6-4). Radiated emission characteristics (10-m regulations) may vary

depending on the configuration of the control panel used, other devices connected to the control

panel, wiring, and other conditions.

You must therefore confirm that the overall machine or equipment complies with EU Directives.

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

17

Page 20

Regulations and Standards

Conformance to KC Standards

Observe the following precaution if you use NX-series Units in Korea.

Class A Device (Broadcasting Communications Device for Office Use)

This device obtained EMC registration for office use (Class A), and it is intended to be used in places

other than homes.

Sellers and/or users need to take note of this.

Conformance to Shipbuilding Standards

The NJ/NX-series Controllers comply with the following shipbuilding standards. Applicability to the

shipbuilding standards is based on certain usage conditions. It may not be possible to use the product in some locations. Contact your OMRON representative before attempting to use a Controller on

a ship.

Usage Conditions for NK and LR Shipbuilding Standards

• The NJ/NX-series Controller must be installed within a control panel.

• Gaps in the door to the control panel must be completely filled or covered with gaskets or other

material.

• The following noise filter must be connected to the power supply line.

Noise Filter

Manufacturer Model

Cosel Co., Ltd. TAH-06-683

Software Licenses and Copyrights

This product incorporates certain third party software. The license and copyright information associated with this software is available at http://www.fa.omron.co.jp/nj_info_e/.

18

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

Page 21

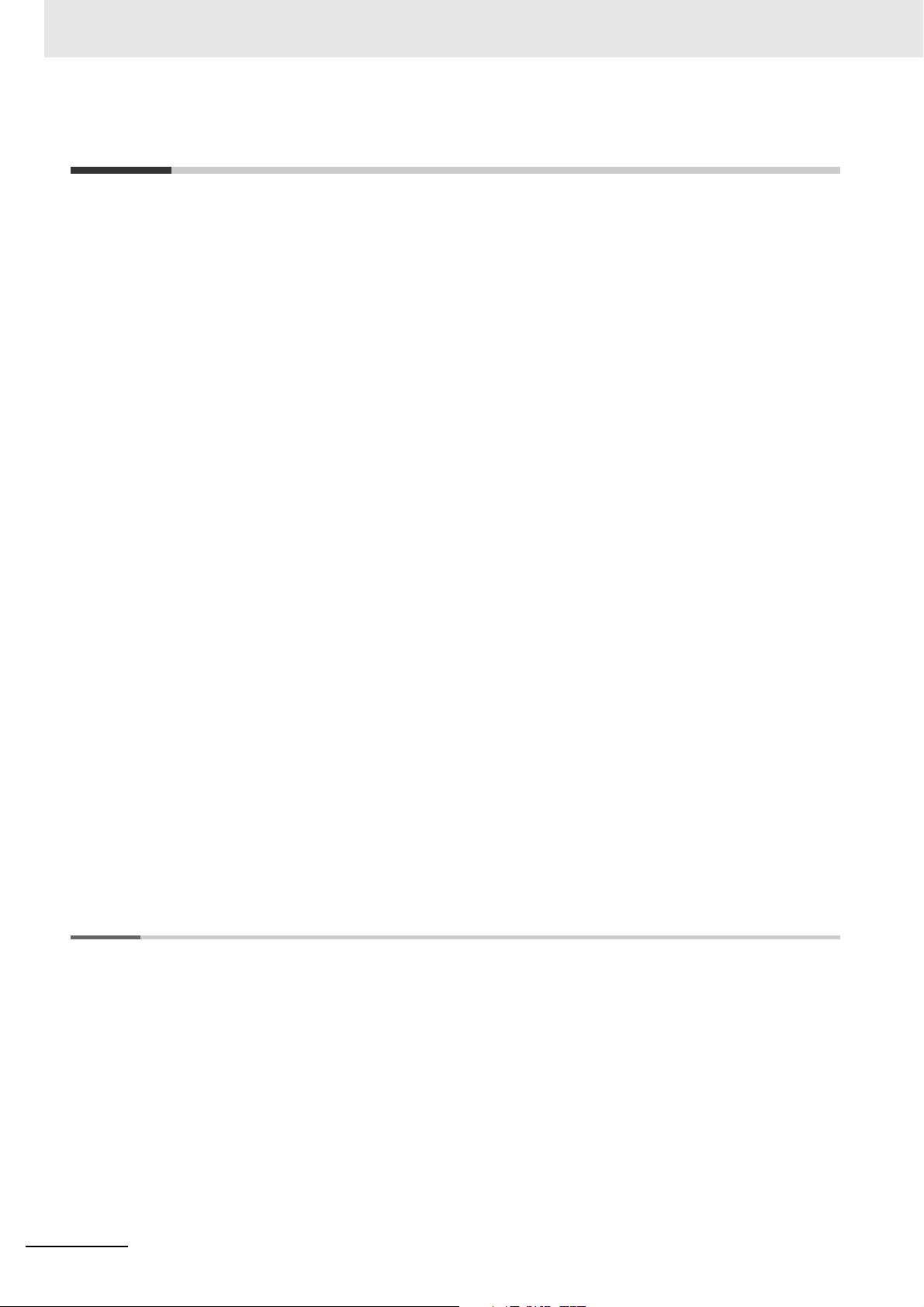

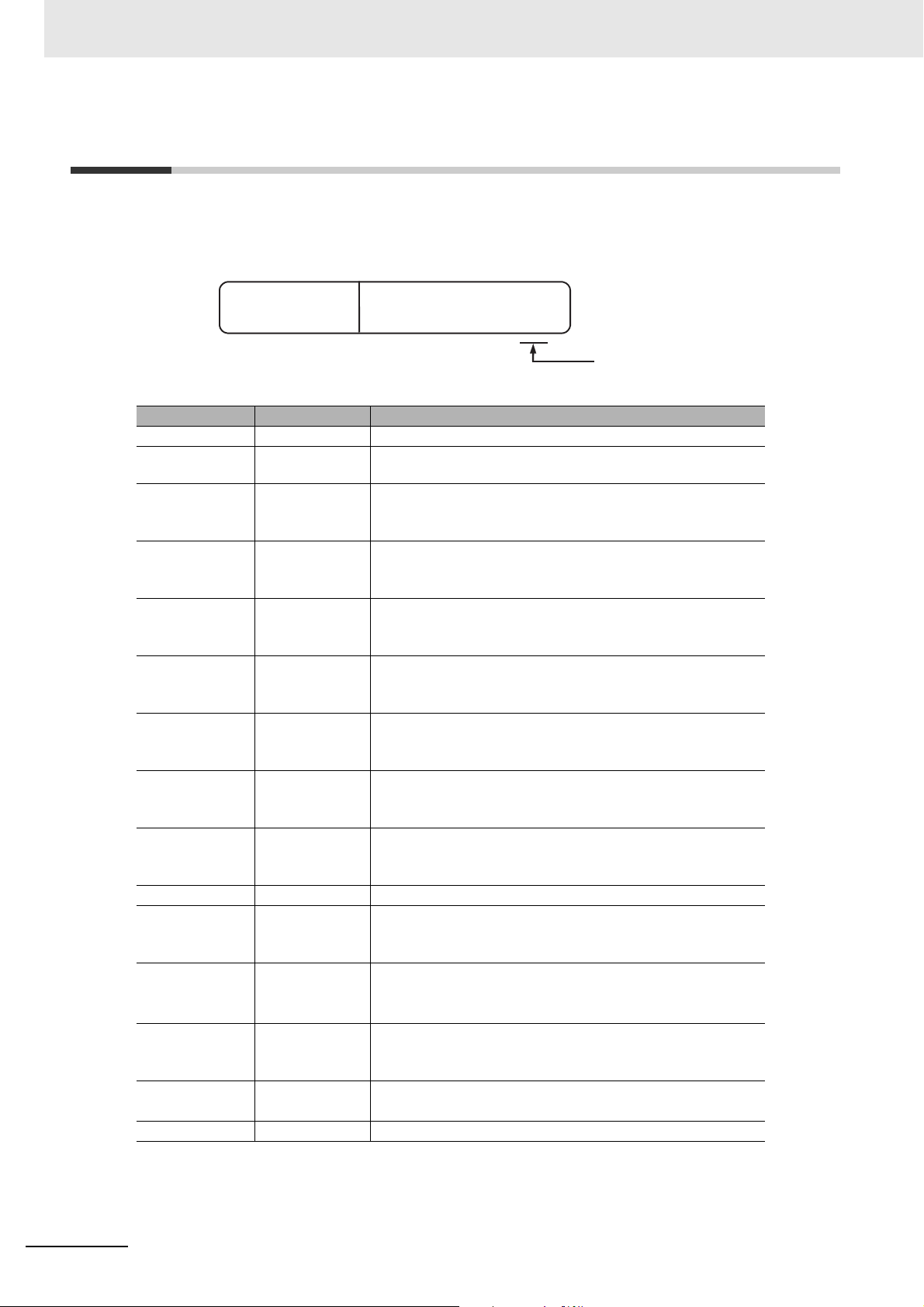

Versions

ID information indication

Lot number Serial number Unit version

MAC address Hardware revision

LOT No. DDMYY xxxx Ver.1.

PORT1 : HW Rev.

PORT2 :

ID information indication

Lot number Serial number

Unit version

PORT1 :

PORT2 :

Ver.1. HW Rev.

LOT No. DDMYY xxxx

MAC address

Hardware

revision

Hardware revisions and unit versions are used to manage the hardware and software in NJ/NX-series

Units and EtherCAT slaves. The hardware revision or unit version is updated each time there is a

change in hardware or software specifications. Even when two Units or EtherCAT slaves have the

same model number, they will have functional or performance differences if they have different hardware revisions or unit versions.

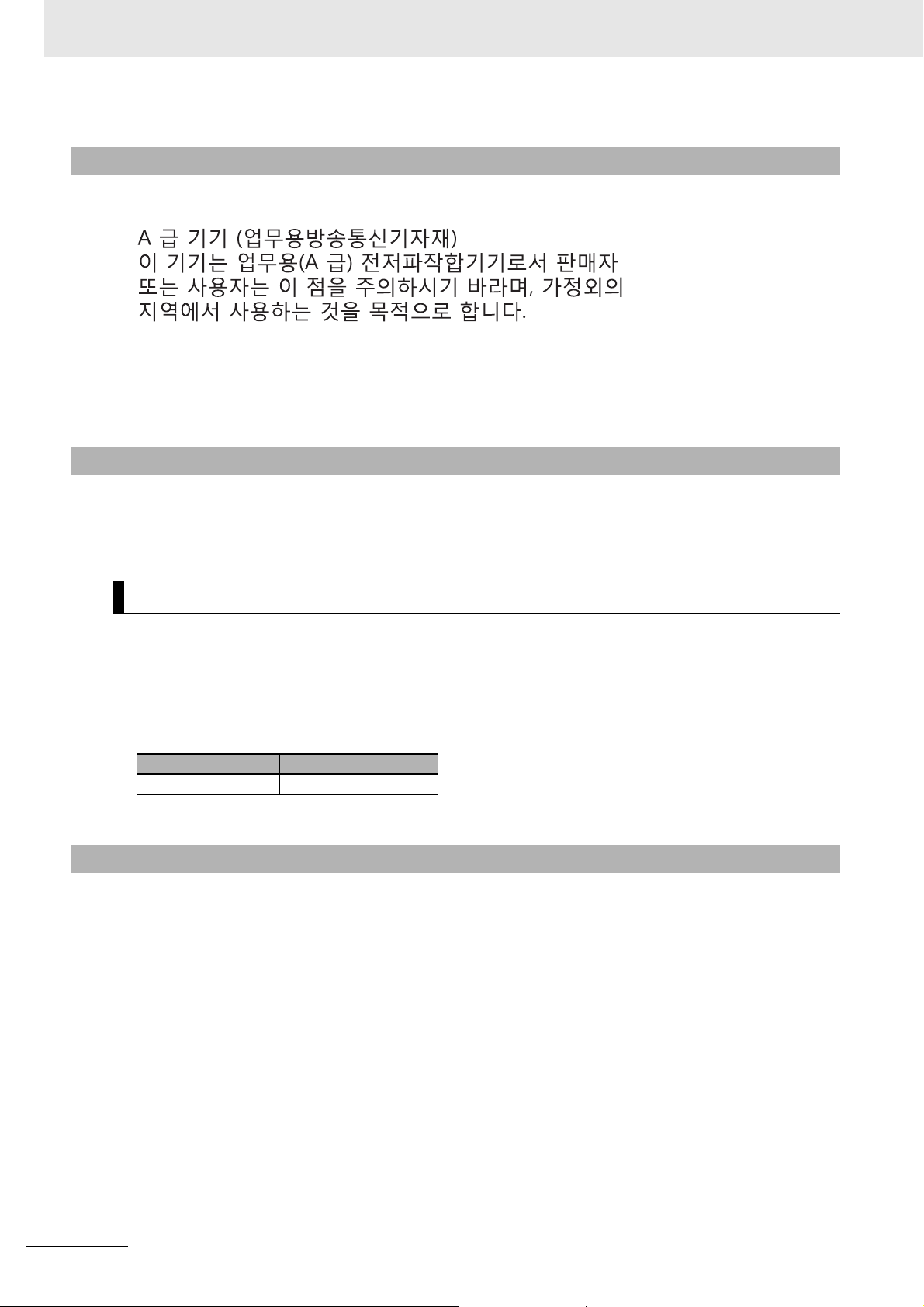

Checking Versions

You can check versions on the ID information indications or with the Sysmac Studio.

Checking Unit Versions on ID Information Indications

The unit version is given on the ID information indication on the side of the product.

Versions

The ID information on an NX-series NX701- CPU Unit is shown below.

Note The hardware revision is not displayed for the Unit that the hardware revision is in blank.

The ID information on an NX-series NX1P2- CPU Unit is shown below.

Note The hardware revision is not displayed for the Unit that the hardware revision is in blank.

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

19

Page 22

Versions

The ID information on an NJ-series NJ501- CPU Unit is shown below.

ID information indication

Unit model

NJ501

PORT1 MAC ADDRESS:

PORT2 MAC ADDRESS:

Lot No. DDMYY

Note The hardware revision is not displayed for the Unit that the hardware revision is in blank.

-

Lot number Serial number MAC address

Unit version Hardware revision

Ver.1.

xxxx

HW Rev.

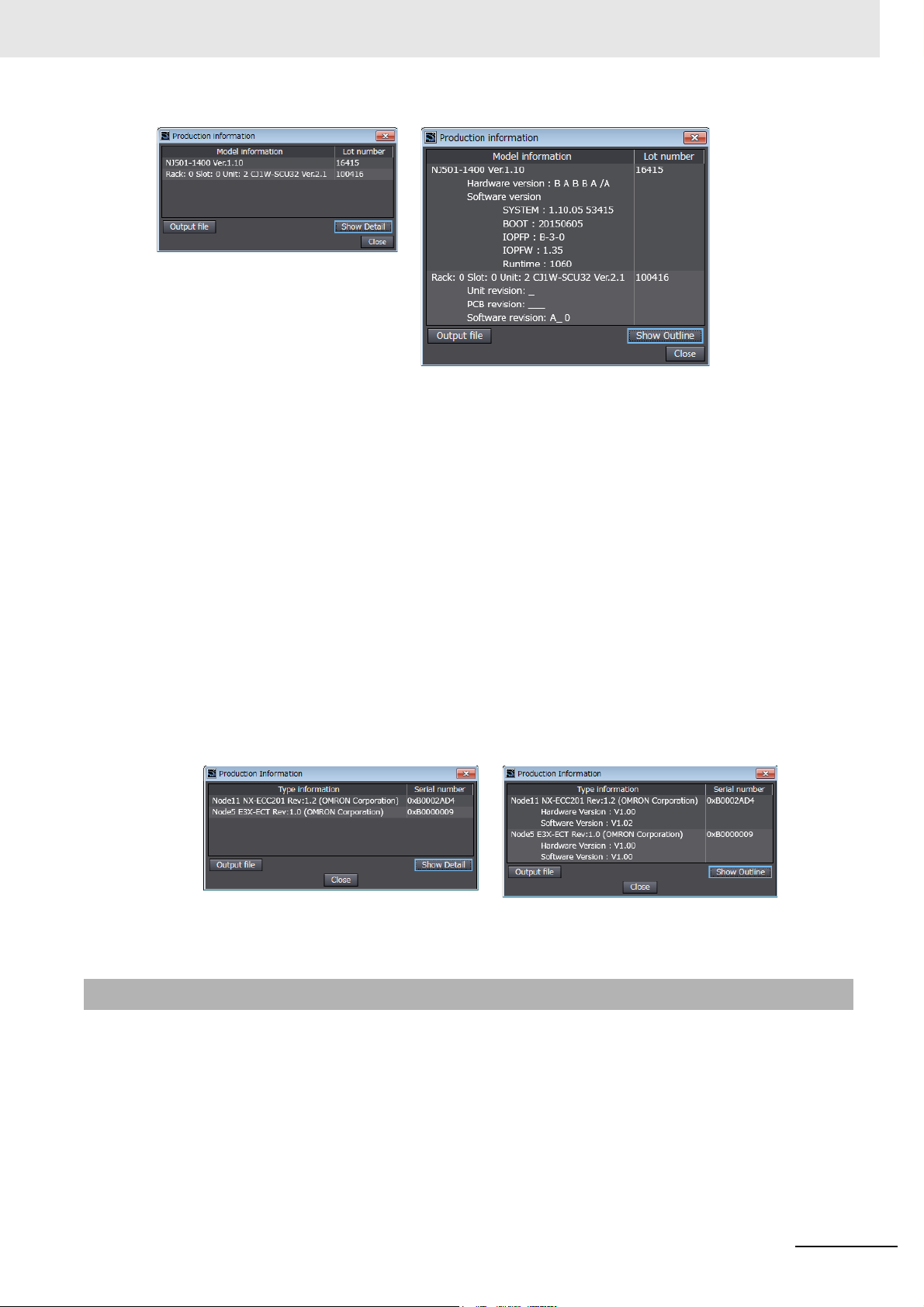

Checking Unit Versions with the Sysmac Studio

You can use the Sysmac Studio to check unit versions. The procedure is different for Units and for EtherCAT slaves.

Checking the Unit Version of an NX-series CPU Unit

You can use the Production Information while the Sysmac Studio is online to check the unit version

of a Unit. You can do this for the CPU Unit. For an NX1P2 CPU Unit, you can also check the unit

versions of the NX Units on the CPU Rack and Option Boards.

1

Right-click CPU Rack under Configurations and Setup - CPU/Expansion Racks in the Multiview Explorer and select Production Information.

The Production Information Dialog Box is displayed.

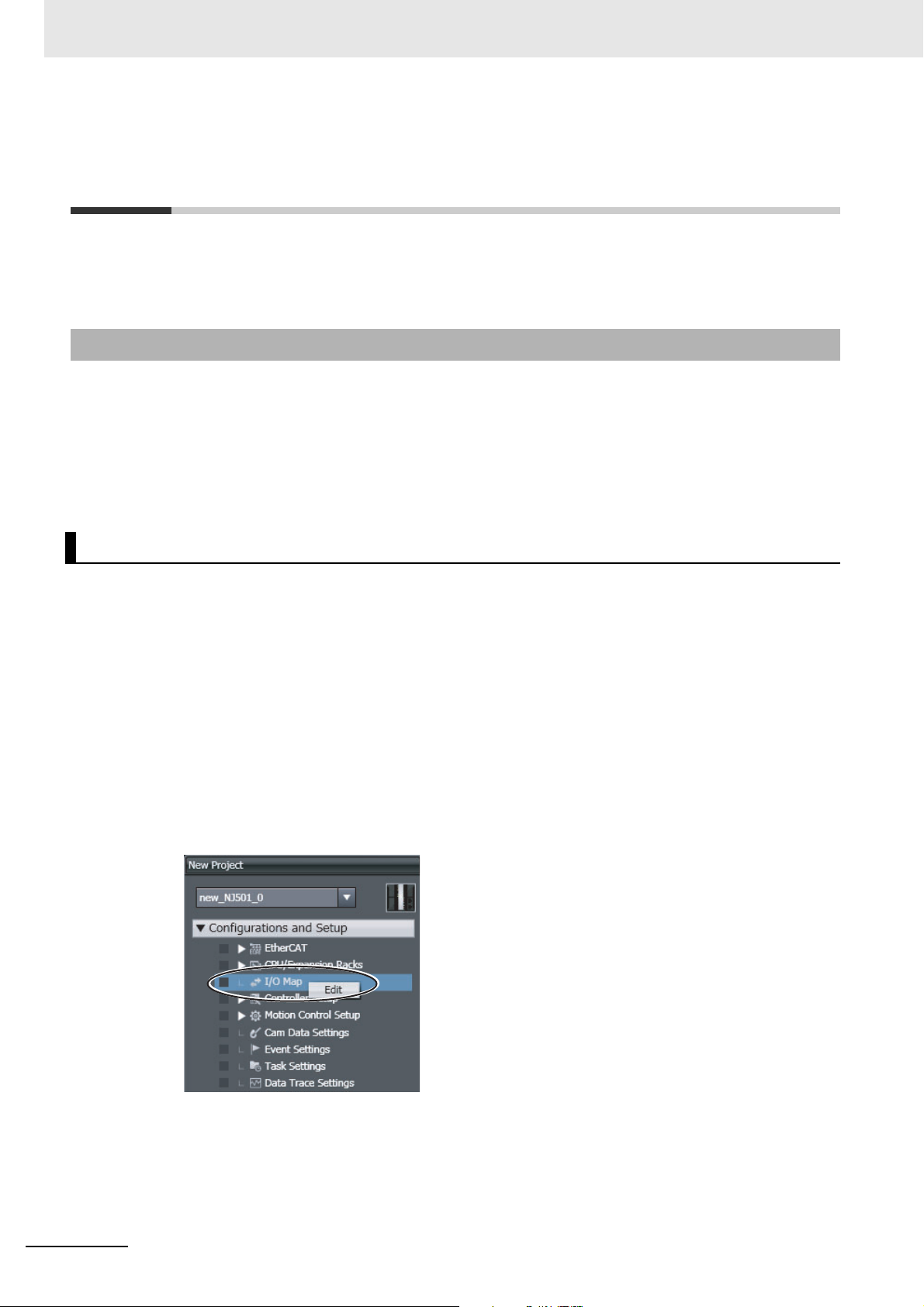

Checking the Unit Version of an NJ-series CPU Unit

You can use the Production Information while the Sysmac Studio is online to check the unit version

of a Unit. You can do this for the CPU Unit, CJ-series Special I/O Units, and CJ-series CPU Bus

Units. You cannot check the unit versions of CJ-series Basic I/O Units with the Sysmac Studio.

Use the following procedure to check the unit version.

1

Double-click CPU/Expansion Racks under Configurations and Setup in the Multiview

Explorer. Or, right-click CPU/Expansion Racks under Configurations and Setup and select

Edit from the menu.

The Unit Editor is displayed.

2

Right-click any open space in the Unit Editor and select Production Information.

The Production Information Dialog Box is displayed.

Changing Information Displayed in Production Information Dialog Box

1

Click the Show Detail or Show Outline Button at the lower right of the Production Information

Dialog Box.

The view will change between the production information details and outline.

20

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

Page 23

Versions

Outline View Detail View

The information that is displayed is different for the Outline View and Detail View. The Detail View

displays the unit version, hardware version, and software versions. The Outline View displays only

the unit version.

Note The hardware revision is separated by “/” and displayed on the right of the hardware version. The hardware

revision is not displayed for the Unit that the hardware revision is in blank.

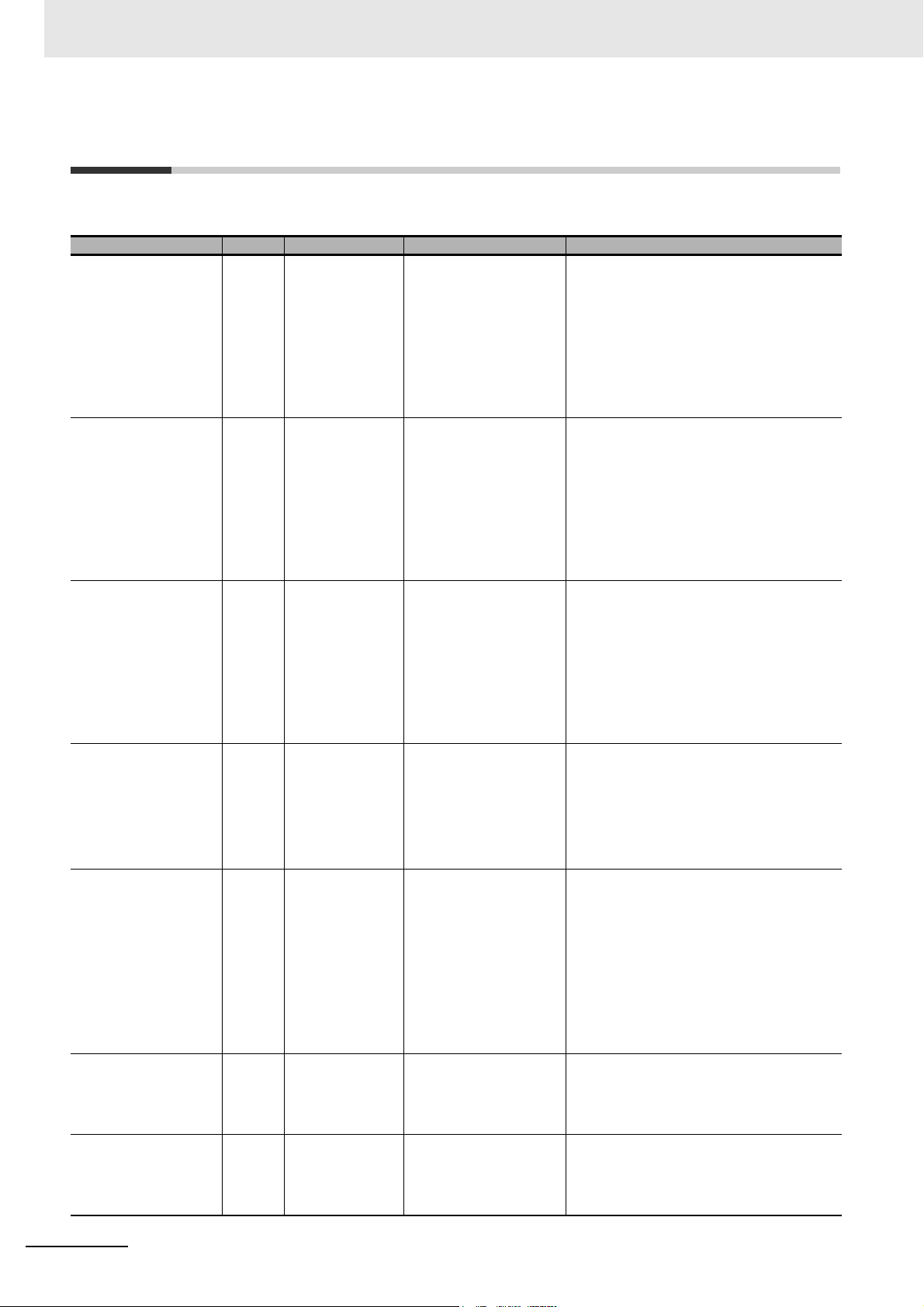

Checking the Unit Version of an EtherCAT Slave

You can use the Production Information while the Sysmac Studio is online to check the unit version

of an EtherCAT slave. Use the following procedure to check the unit version.

1

Double-click EtherCAT under Configurations and Setup in the Multiview Explorer. Or, rightclick EtherCAT under Configurations and Setup and select Edit from the menu.

The EtherCAT Tab Page is displayed.

2

Right-click the master on the EtherCAT Tab Page and select Display Production Information.

The Production Information Dialog Box is displayed.

The unit version is displayed after “Rev.”

Outline View Detail View

Unit Versions of CPU Units and Sysmac Studio Versions

The functions that are supported depend on the unit version of the NJ/NX-series CPU Unit. The version

of Sysmac Studio that supports the functions that were added for an upgrade is also required to use

those functions.

Refer to the NJ/NX-series CPU Unit Software User’s Manual (Cat. No. W501-E1-02 or later) for the

relationship between the unit versions of the CPU Units and the Sysmac Studio versions, and for the

functions that are supported by each unit version.

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

21

Page 24

Related Manuals

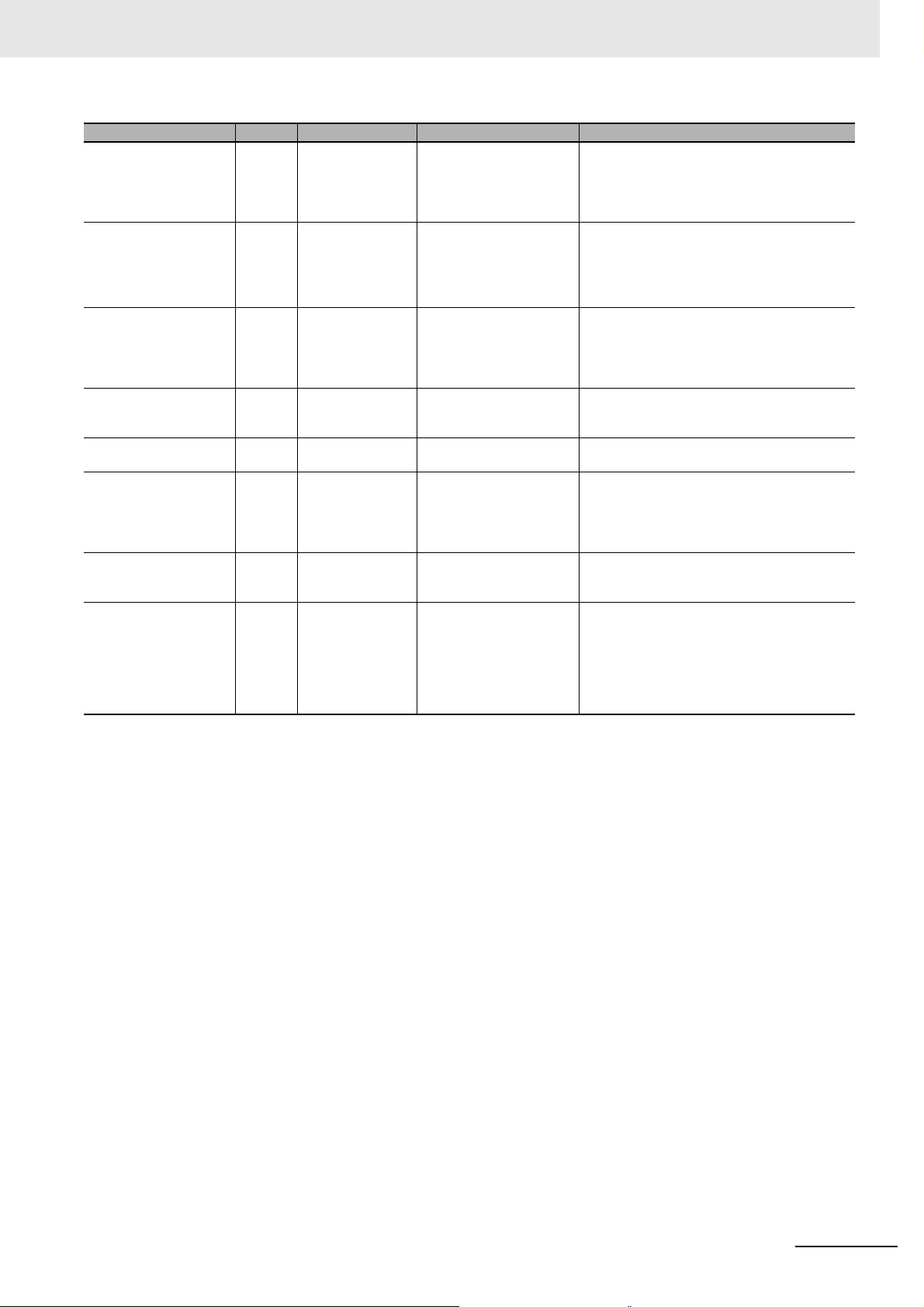

Related Manuals

The followings are the manuals related to this manual. Use these manuals for reference.

Manual name Cat. No. Model numbers Application Description

NX-series CPU Unit

Hardware User’s Manual

NX-series NX1P2 CPU

Unit Hardware User's

Manual

NJ-series CPU Unit

Hardware User’s Manual

NJ/NX-series CPU Unit

Software User’s Manual

NX-series NX1P2 CPU

Unit Built-in I/O and

Option Board User's

Manual

NJ/NX-series Instructions

Reference Manual

NJ/NX-series CPU Unit

Motion Control User’s

Manual

W535 NX701- Learning the basic specifi-

cations of the NX701 CPU

Units, including introductory information, designing,

installation, and maintenance.

Mainly hardware information is provided.

W578 NX1P2- Learning the basic specifi-

cations of the NX1P2 CPU

Units, including introductory information, designing,

installation, and maintenance.

Mainly hardware information is provided.

W500 NJ501-

NJ301-

NJ101-

W501 NX701-

NX1P2-

NJ501-

NJ301-

NJ101-

W579 NX1P2- Learning about the details

W502 NX701-

NX1P2-

NJ501-

NJ301-

NJ101-

W507 NX701-

NX1P2-

NJ501-

NJ301-

NJ101-

Learning the basic specifications of the NJ-series

CPU Units, including introductory information,

designing, installation, and

maintenance.

Mainly hardware information is provided.

Learning how to program

and set up an NJ/NXseries CPU Unit.

Mainly software information is provided.

of functions only for an NXseries NX1P2 CPU Unit

and an introduction of functions for an NJ/NX-series

CPU Unit.

Learning detailed specifications on the basic

instructions of an NJ/NXseries CPU Unit.

Learning about motion

control settings and programming concepts.

An introduction to the entire NX701 system is

provided along with the following information on

the CPU Unit.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

An introduction to the entire NX1P2 system is

provided along with the following information on

the CPU Unit.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

An introduction to the entire NJ-series system is

provided along with the following information on

the CPU Unit.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

The following information is provided on a Controller built with an NJ/NX-series CPU Unit.

• CPU Unit operation

• CPU Unit features

• Initial settings

gramming based on IEC 61131-3 lan-

• Pro

e specifications

guag

Of the functions for an NX1P2 CPU Unit, the following information is provided.

• Built-in I/O

• Serial Communications Option Boards

• Analog I/O Option Boards

An introduction of following functions for an

NJ/NX-series CPU Unit is also provided.

• Motion control functions

• EtherNet/IP communications functions

• EtherCAT communications functions

The instructions in the instruction set (IEC

61131-3 specifications) are described.

The settings and operation of the CPU Unit and

programming concepts for motion control are

described.

22

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

Page 25

Manual name Cat. No. Model numbers Application Description

NJ/NX-series

Motion Control Instructions Reference Manual

NJ/NX-series

CPU Unit

Built-in EtherCAT Port

User’s Manual

NJ/NX-series

CPU Unit

Built-in EtherNet/IP

User’s Manual

NJ-series

SECS/GEM CPU Units

User’s Manual

NJ-series NJ Robotics

CPU Unit User’s Manual

NJ/NX-series

Troubleshooting Manual

Sysmac Studio Version 1

Operation Manual

NX-series

EtherCAT Coupler Unit

User’s Manual

W508 NX701-

NX1P2-

NJ501-

NJ301-

NJ101-

W505 NX701-

NX1P2-

NJ501-

NJ301-

NJ101-

W506 NX701-

Port

W528 NJ501-1340 Using the GEM Services

W539 NJ501-4 Controlling robots with NJ-

W503 NX701-

W504 SYSMAC

W519 NX-ECC Learning how to use an

NX1P2-

NJ501-

NJ301-

NJ101-

NX1P2-

NJ501-

NJ301-

NJ101-

-SE2

Learning about the specifications of the motion control instructions.

Using the built-in EtherCAT

port on an NJ/NX-series

CPU Unit.

Using the built-in EtherNet/IP port on an NJ/NXseries CPU Unit.

with NJ-series Controllers.

series CPU Units.

Learning about the errors

that may be detected in an

NJ/NX-series Controller.

Learning about the operating procedures and functions of the Sysmac Studio.

NX-series EtherCAT Coupler Unit and EtherCAT

Slave Terminals.

The motion control instructions are described.

Information on the built-in EtherCAT port is provided.

This manual provides an introduction and provides information on the configuration, features,

and setup.

Information on the built-in EtherNet/IP port is

provided.

Information is provided on the basic setup, tag

data links, and other features.

Provides information on the GEM Services.

Describes the functionality to control robots.

Concepts on managing errors that may be

detected in an NJ/NX-series Controller and

information on individual errors are described.

Describes the operating procedures of the Sysmac Studio.

The following items are described: the overall

system and configuration methods of an EtherCAT Slave Terminal (which consists of an NXseries EtherCAT Coupler Unit and NX Units),

and information on hardware, setup, and functions to set up, control, and monitor NX Units

through EtherCAT.

Related Manuals

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

23

Page 26

Revision History

W505-E1-15

Revision code

Cat. No.

Revision History

A manual revision code appears as a suffix to the catalog number on the front and back covers of the

manual.

Revision code Date Revised content

01 July 2011 Original production

02 March 2012 Added information on the NJ301-

03 May 2012 • Added information on functional support for unit version

04 August 2012 • Added information on functional support for unit version

05 February 2013 • Added information on functional support for unit version

06 April 2013 • Added information on functional support for unit version

07 June 2013 • Added information on functional support for unit version

08 September 2013 • Added information on functional support for unit version

09 December 2013 • Added information on functional support for unit version

10 July 2014 • Corrected mistakes.

11 January 2015 • Added information on functional support for unit version

12 April 2015 • Added information on the NX701-

13 April 2016 • Added information on functional support for unit version 1.11

14 October 2016 • Added information on the NX1P2-

15 April 2017 • Corrected mistakes.

and corrected mis-

takes.

1.02 of the CPU Units.

• Corrected mistakes.

1.03 of the CPU Units.

• Corrected mistakes.

1.04 of the CPU Units.

• Corrected mistakes.

1.05 of the CPU Units.

• Corrected mistakes.

1.06 of the CPU Units.

• Corrected mistakes.

1.07 of the CPU Units.

• Corrected mistakes.

1.08 of the CPU Units.

• Corrected mistakes.

1.10 of the CPU Units.

• Corrected mistakes.

• Added information on the NJ101-

• Corrected mistakes.

of the CPU Units.

• Corrected mistakes.

• Corrected mistakes.

.

.

.

24

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

Page 27

Introduction

This section provides an overview of EtherCAT communications, describes the system

configuration and specifications, and provides operating procedures.

1-1 Introduction to EtherCAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-1-1 EtherCAT Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-1-2 EtherCAT Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-1-3 EtherCAT Features for NJ/NX-series CPU Units . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-2 System Configuration and Configuration Devices . . . . . . . . . . . . . . . . . . . 1-4

1-2-1 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-2-2 Determining the Network Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1-3 Specifications of Built-in EtherCAT Port . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1-3-1 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1-4 Introduction of Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1-4-1 Process Data Communications and SDO Communications . . . . . . . . . . . . . .1-11

1-4-2 Other Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

1-5 EtherCAT Communications Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

1-5-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

1-5-2 Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

1

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

1-1

Page 28

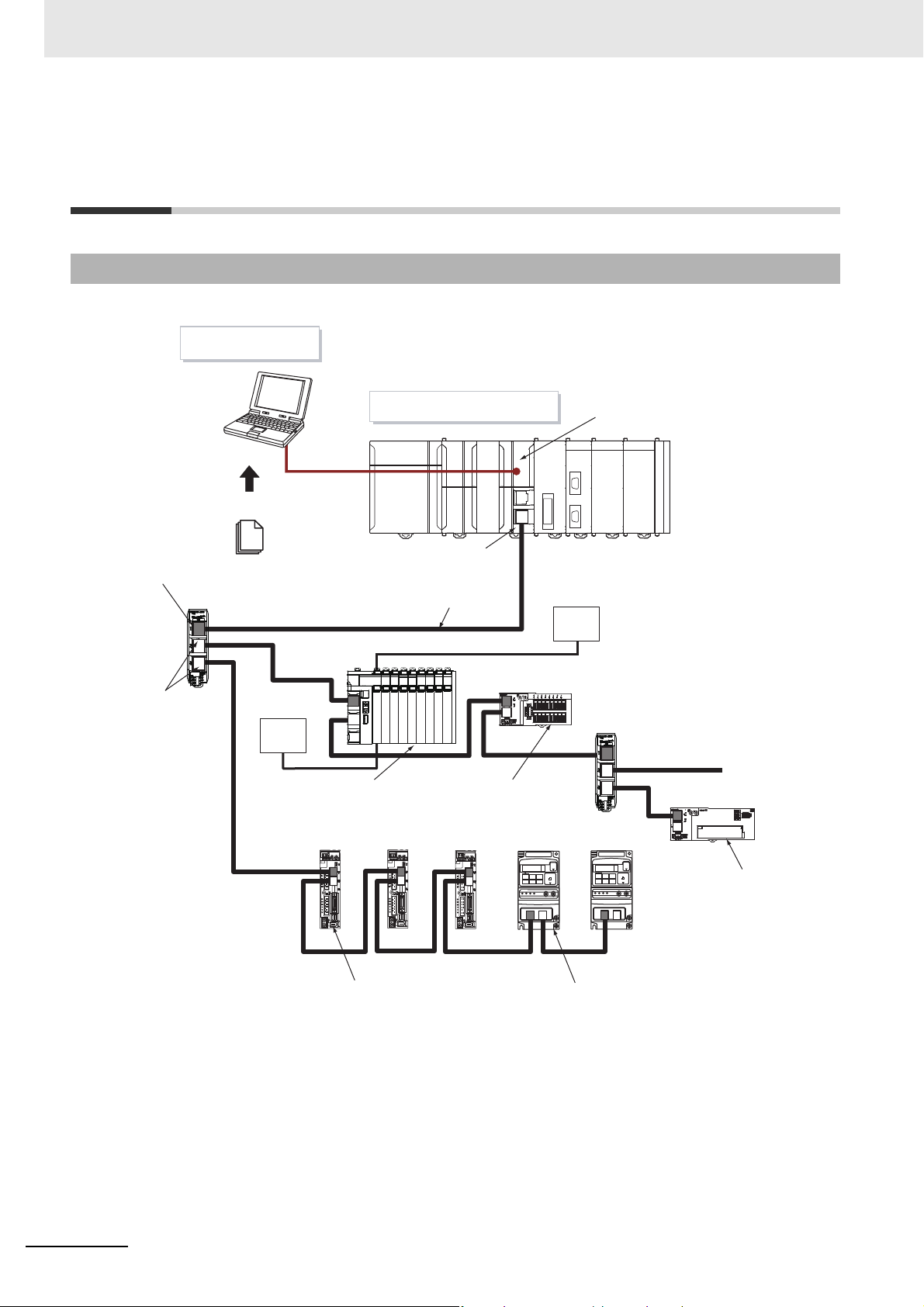

1 Introduction

IN

OUT

Slave

• Output data addressed to the local node is read.

• Input data is written.

Ethernet frames

EtherCAT master

Slave

data

Slave

1-1 Introduction to EtherCAT

EtherCAT (Ethernet Control Automation Technology) is a high-performance industrial network system

that enables faster and more efficient communications based on Ethernet. Each node achieves a short

communications cycle time by transmitting Ethernet frames at high speed. Furthermore, even though

EtherCAT is a unique protocol, it offers excellent general-purpose applicability. For example, you can

use Ethernet cables because EtherCAT utilizes standard Ethernet technology for the physical layer.

And the effectiveness of EtherCAT can be fully utilized not only in large control systems that require

high processing speeds and system integrity, but also in small and medium control systems.

1-1-1 EtherCAT Features

EtherCAT provides the following features.

High-speed Communications at 100 Mbps

The I/O response time from signal input to signal output has been significantly reduced. By fully utilizing

the optimized Ethernet frame bandwidth to transmit data using a high-speed repeat method, it is possible to efficiently transmit a wide variety of data.

1-1-2 EtherCAT Communications

EtherCAT does not send data to individual slave nodes on the network, instead, it passes Ethernet

frames through all of the slave nodes.

When frame passes through a slave node, the slave node reads and writes data in the areas allocated

to it in the frames in a few nanoseconds.

The Ethernet frames transmitted by the EtherCAT master pass through all EtherCAT slaves without

stopping. The last slave returns all of the frames, which again pass through all of the slaves before

returning to the EtherCAT master.

This mechanism ensures high speed and realtime data transmission.

1-2

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

Page 29

1-1-3 EtherCAT Features for NJ/NX-series CPU Units

EtherCAT in the NJ/NX-series CPU Units has the following features.

Synchronization of the CPU Unit Processing Period and the

EtherCAT Communications Cycle

The period of sequence processing and motion processing in the CPU Unit matches the process data

communications cycle of EtherCAT.

This enables high-precision sequence control and motion control with a stable fixed period.

Also, with the NX701 CPU Unit, slaves to be synchronized can be divided into two groups with different

process data communications cycles. This means that slaves are separately processed in one group

that needs high-speed communications and the other that needs not.

Accessing Data with Device Variables without Considering

Addresses

1 Introduction

1-1 Introduction to EtherCAT

1

1-1-3 EtherCAT Features for NJ/NX-series CPU Units

EtherCAT slaves are accessed using device variables that are assigned to the I/O ports of the EtherCAT slaves. Various types of data in Servo Drive and the encoder input slaves are accessed using

structure-type Axis Variables prepared in advance.

This enables access to slaves on EtherCAT without regard to addresses.

Optimum Functionality and Ease of Operation Based on Unified

Specifications

You can use the NJ/NX-series Machine Automation Controllers together with Sysmac devices* and the

Sysmac Studio Automation Software to achieve optimum functionality and ease of operation.

* “Sysmac devices” is a generic name for EtherCAT slaves and other OMRON control components that were

designed with the same communications and user interface specifications.

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

1-3

Page 30

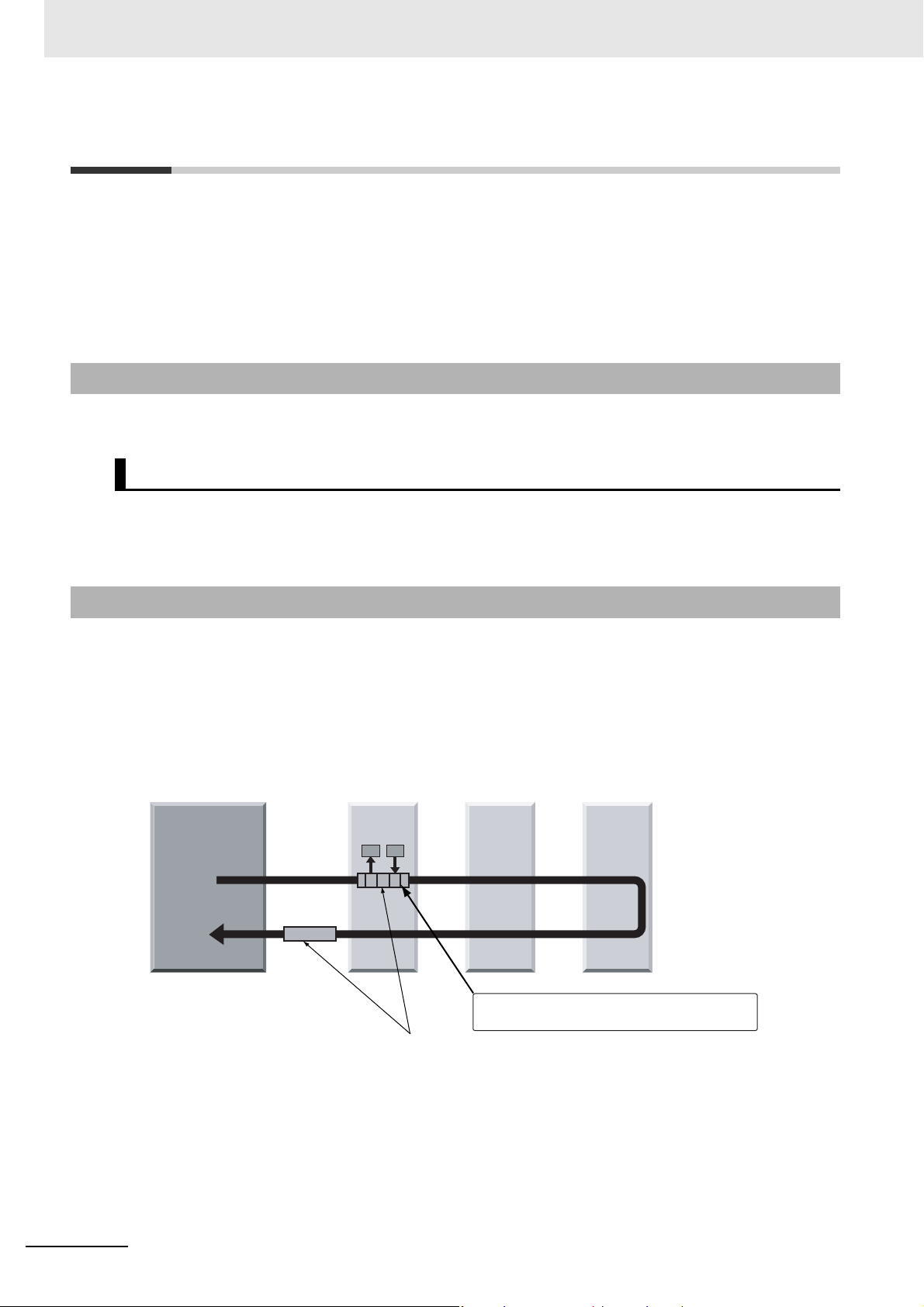

1 Introduction

1-2 System Configuration and

Configuration Devices

1-2-1 System Configuration

The EtherCAT network configuration and configuration devices are shown below.

Sysmac Studio

Input port

EtherCAT Junction Slave

Output ports

ESI files

.xml

I/O power supply

NJ/NX-series CPU Unit

Built-in EtherCAT port

Communications cable

EtherCAT Slave

Terminal

(EtherCAT slave)

ADR

ADR

EtherCAT master

Unit power supply

EtherCAT Junction Slave

Digital I/O Slave

(EtherCAT Slave)

ADR

1-4

Analog I/O Slave

(EtherCAT slave)

Servo Drive (EtherCAT slave) Inverter (EtherCAT slave)

Outlines of the configuration devices are given below.

EtherCAT Master

The EtherCAT master manages the network, monitors the status of slaves, and exchanges I/O data

with slaves. There is one output port.

Output Port

The output port transmits EtherCAT communications data to other devices. When you connect the

output port to another device, always connect it to the input port on the other device. Normal communications will not be possible if you connect to the output port on another device.

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

Page 31

1 Introduction

Input Port

This port is used to input EtherCAT communications data. Always connect it to the output port on

another device. Normal communications will not be possible if you connect to the input port on

another device.

EtherCAT Slaves

Each EtherCAT slave outputs the output data that it received from the EtherCAT master through the

EtherCAT network. It also sends input data to the EtherCAT master through the EtherCAT network.

• Each slave has one input port and at least one output port.

• In the EtherCAT network, you can use the salves and Junction Slaves that are listed below in total

up to the maximum number of slaves.

• Assign node addresses to the slaves and Junction Slaves. The node address can be any value

within the settable node address range, and can be assigned without any distinction between the

slaves and Junction Slaves. But any node address should not be used more than once.

• The EtherCAT slaves can be classified into two: whether they support synchronization based on

a distributed clock (DC) or not.

a) Non-synced Slaves

These slaves perform sequence control that does not require synchronization between them.

Digital I/O Slaves and Analog I/O Slaves are among this type. They do not support a distributed clock (DC).

b) Synced Slaves

These slaves are synchronized based on the distributed clock (DC). Servo Drives and

encoder input slaves are among this type.

1-2 System Configuration and

Configuration Devices

1

1-2-1 System Configuration

Note 1 Refer to 1-3-1 Performance Specifications for details on the maximum number of slaves

and the settable node address range.

2 The slaves are synchronized even when multiple non-synced slaves and Junction Slaves

are connected.

The following tables lists some of the OMRON EtherCAT slaves that are available.

Name Typ e Model

Digital I/O Slaves Slaves with screw

terminals and 2-tier

terminal block

Slaves with screw

terminals and 3-tier

terminal block

Slaves with e-CON

connectors

Analog I/O

Slaves

NX-series EtherCAT Coupler Unit

Multifunctional,

Compact Inverters

Advanced Generalpurpose Inverters

Slaves with screw

terminals and 2-tier

terminal block

NX Series

MX2 Series 3G3MX2 with

RX Series 3G3RX-V1 with

GX-D161/OC1601 Non-synced

GX-ID162/OD162/MD162 Non-synced

GX-D168/D328 Non-synced

GX-AD0471/DA0271 Non-synced

NX-ECC201

NX-ECC202

NX-ECC203

EtherCAT Communications Unit

3G3AX-MX2-ECT

EtherCAT Communications Unit

3G3AX-RX-ECT

Synced/

Non-synced

Slaves

Slaves

Slaves

Slaves

Slaves

*2

*3

*4

Synced

Slaves

Non-synced

Slaves

Non-synced

Slaves

Reference

Clock*

Exist Not

Exist Not

Exist Not

Exist Not

Exist Not possible

Exist Not

Exist Not possible

Assigning

1

possible

possible

possible

possible

(Some of the

connected

NX Units can

be assigned

to an axis.)

possible

an axis

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

1-5

Page 32

1 Introduction

Precautions for Safe Use

Name Type Model

AC Servo Drive G5-series Servo

Drive with EtherCAT

communications

Linear Servo Drives G5-series Linear

Servo Drives with

EtherCAT communications

Encoder Input

Slaves

Vision Sensors FH Series FH-1

Specialized Vision

Sensors for Positioning

Digital Sensor Communications Unit

Fiber Sensor Communications Unit

Confocal Fiber Type

Displacement Sensors

Slave with 3-tier terminal block

FQ-M-series Sensors

with EtherCAT Communications

FZM1-series Vision

Sensors

E3NW Series E3NW-ECT Synced

E3X Series E3X-ECT Synced

ZW Series ZW-CE1 Synced

R88M-K/R88D-KN-ECT Synced

R88L-EC/R88D-KN-ECT-L Synced

GX-EC0211/EC0241 Synced

FH-3

FQ-MS12(-)-ECT Synced

FZM1-35-ECT Synced

Synced/

Non-synced

Slaves

Slaves

Slaves

Slaves

Synced

Slaves

Slaves

Slaves

Slaves

Slaves

Slaves

Reference

Clock*

Exist Possible

Exist Possible

Exist Possible

Exist Not possible

Exist Not possible

Exist Not possible

Exist Not possible

Exist Not possible

Exist Not possible

1

Assigning

an axis

*1 Shows whether or not the slave provides a reference clock. A slave or a master that provides a reference clock is

required for a system configuration that enables synchronization between slaves based on a distributed clock (DC). When

you connect a slave that supports the reference clock, you must meet some conditions. Refer to 4-1-1 Supported Network

Topologies for detail on the conditions.

*2 A CPU Unit with unit version 1.05 or later and Sysmac Studio version 1.06 or higher are required.

*3 A CPU Unit with unit version 1.07 or later and Sysmac Studio version 1.08 or higher are required.

*4 A CPU Unit with unit version 1.07 or later and Sysmac Studio version 1.11 or higher are required.

EtherCAT Junction Slave

This is a special Unit for branching EtherCAT network wiring. Cascade connections are possible

within the range of node addresses that the EtherCAT master can handle.

Each Junction Slave has one input port and more than one output port. The output ports on each

Junction Slave can be connected to another Junction Slave or other EtherCAT slaves.

The Junction Slave supports the reference clock that is required for a system configuration that

enables synchronization between slaves based on a distributed clock (DC).

The following models are examples of some of the OMRON EtherCAT slaves.

Slave type/name Number of ports Model

EtherCAT Junction Slave 3 ports GX-JC03

6 ports

GX-JC06

You cannot use standard Ethernet hubs or repeater hubs with EtherCAT communications. If you

use one of these, a major fault level error or other error may occur.

1-6

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

Page 33

1 Introduction

Precautions for Correct UsePrecautions for Correct Use

Additional Information

• GX-JC03 and GX-JC06 EtherCAT Junction Slaves do not have hardware switches for node

address setting. The Sysmac Studio is required to set the node addresses for these slaves.

The node addresses are set to 0 by default. If you use these slaves with the default node

address, a Network Configuration Verification Error will occur.

• A GX-JC03 EtherCAT Junction Slave needs only one node address. A GX-JC06 EtherCAT

Junction Slave needs two node addresses.

A GX-JC06 EtherCAT Junction Slave which appears to be one Unit is actually composed of two

slaves. The two slaves appear as “Main device” and “Sub-device” in the Sysmac Studio, respectively, as shown in the figure below. The In port of Sub-device appears as “Internal Port” in the

Sysmac Studio and it is internally connected to the Main device.

1-2 System Configuration and

Configuration Devices

1

1-2-1 System Configuration

Sysmac Studio

The Sysmac Studio runs on a personal computer and it is used to configure EtherCAT networks and

slaves, and to program, monitor, and debug the Controller.

Communications Cables

Use a straight, shielded twisted-pair cable (double shielding with aluminum tape and braiding) of

Ethernet category 5 (100BASE-TX) or higher.

ESI (EtherCAT Slave Information) File

The ESI files contain information unique to the EtherCAT slaves in XML format. You can load an ESI

file into the Sysmac Studio, to easily allocate slave process data and make other settings.

Unit Power Supplies

This power supply is for slave communications and internal operation.

I/O Power Supply

This power supply is for I/O operations of external devices connected to the slaves.

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

1-7

Page 34

1 Introduction

Additional Information

Precautions for Safe Use

Review the network

configuration.

Review the slave

positions.

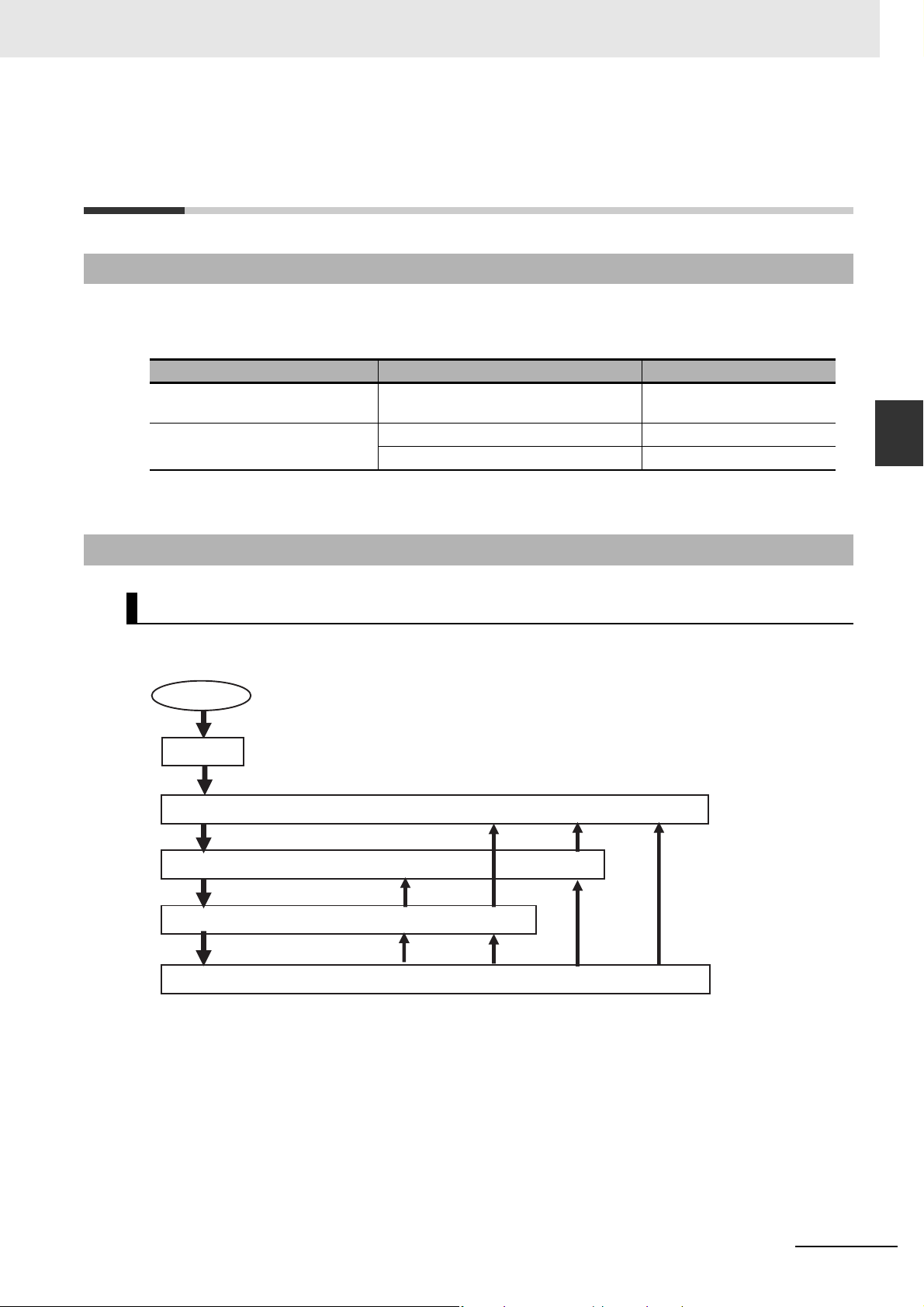

Total number of slaves

is equal to or less than the

maximum number of slaves?

(see Note)

Length of cable

connecting slaves

100 m or less?

Design the network configuration.

Design slave positions.

Start

End

No

No

Yes

Yes

With a CPU Unit with unit version 1.06 or later and Sysmac Studio version 1.07 or higher, you

can add NX-series Safety Control Units to the EtherCAT network.

You can use NX-series Safety Control Units on EtherCAT Slave Terminals to build a safety control system on EtherCAT.

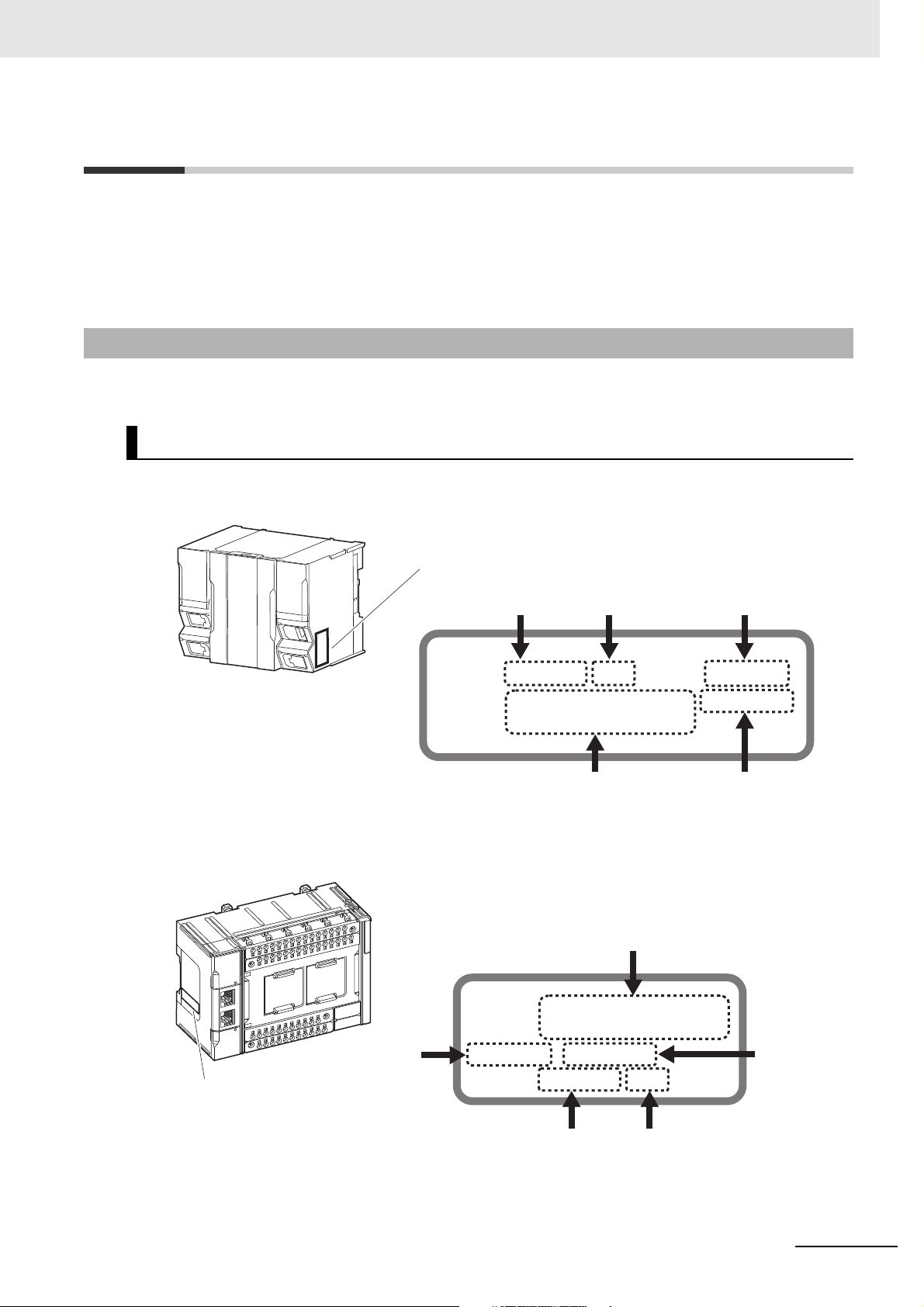

1-2-2 Determining the Network Configuration

Determine the type, total number, and positions of slaves in the network. Check the total number of

slaves and the cable length between slaves based on the following workflow.

Note Refer to 1-3-1 Performance Specifications for details on the maximum number of slaves.

• You cannot use standard Ethernet hubs or repeater hubs with EtherCAT communications.

If you use one of these, a major fault level error or other error may occur.

• Make sure that the communications distance, number of devices connected, and method of

connection for EtherCAT are within specifications.

1-8

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

Page 35

1 Introduction

1-3 Specifications of Built-in

1-3 Specifications of Built-in EtherCAT

Port

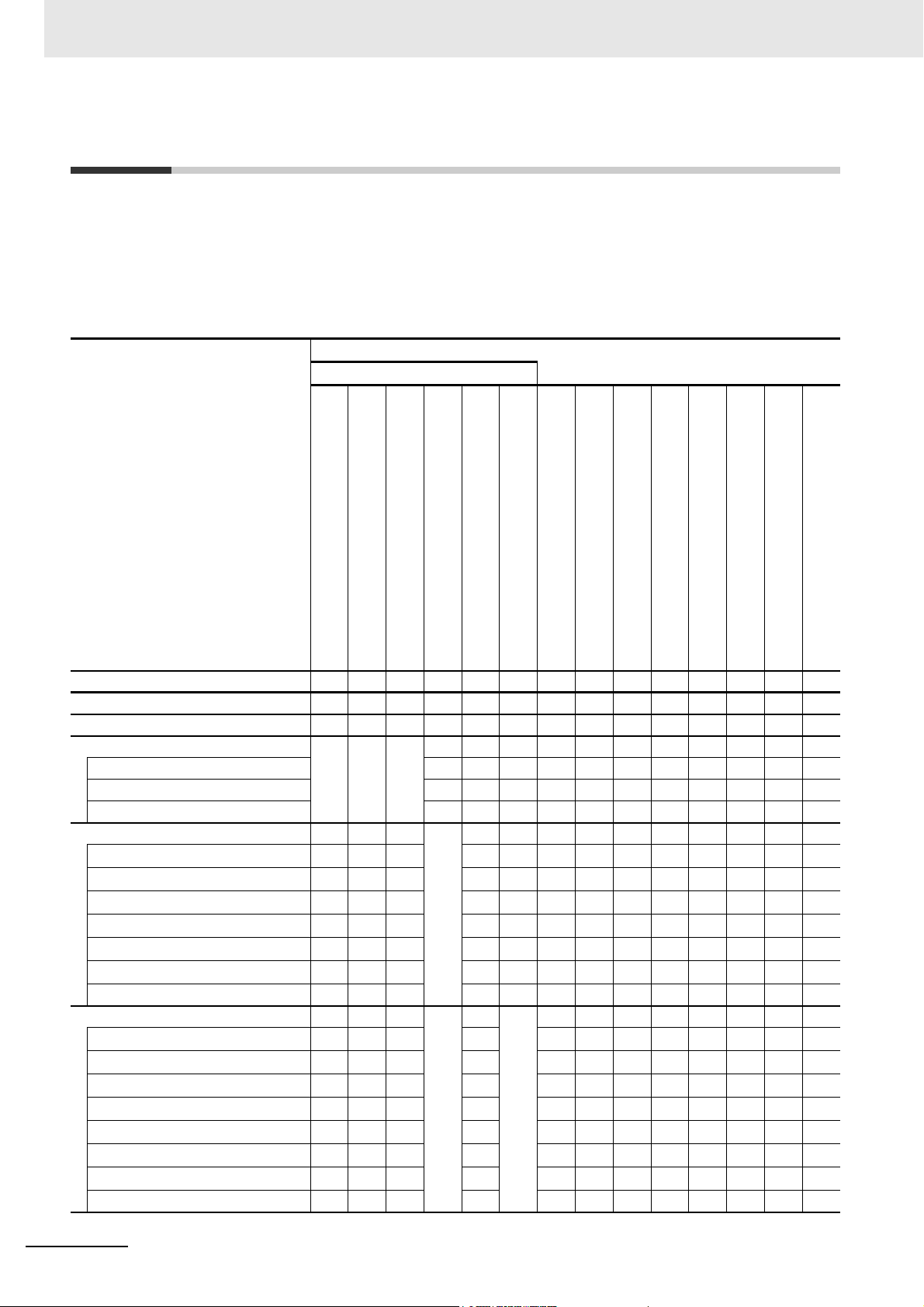

1-3-1 Performance Specifications

Specification

Item

Communications

protocol

Supported services

Synchronization DC (Distributed Clock)

Physical layer 100BASE-TX

Modulation Baseband

Baud rate 100 Mbit/s (100BASE-TX)

Duplex mode

Topology

Transmission

media

Maximum transmission distance

between nodes

Maximum number

of slaves

Settable node

address range

Maximum process

data size

Maximum size per

slave

Maximum message

size

Communications

cycle

Sync jitter 1 μs max.

*2

*3

NX701-

EtherCAT protocol

CoE (Process data communications and SDO communications)

Auto

Line, daisy chain, and branching

Twisted-pair cable of category 5 or higher

(Recommended cable: straight, double-shielded cable with aluminum tape and braiding)

100 m

512 16 192 64

1 to 512 1 to 192

Input: 11,472 bytes

Output: 11,472 bytes

However, the data must

not exceed 8 frames (the

maximum number of process data frames).

Input: 1,434 bytes

Output: 1,434 bytes

2,048 bytes

• Primary periodic task

125 μs, 250 μs to 8 ms

(in 250-μs increments)

• Priority-5 periodic task

125 μs, 250 μs to

100 ms (in 250-μs

increments)

*4

Input: 1,434 bytes

Output: 1,434 bytes

However, the data must

not exceed 1 frames (the

maximum number of process data frames).

2,000 to 8,000 μs

(in 250-μs increments)

NX1P2-

NJ501-/

NJ301-

*1

Input: 5,736 bytes

Output: 5,736 bytes

However, the data must not

exceed 4 frames (the maximum

number of process data frames).

500 μs*5, 1,000

μs, 2,000 μs, or

4,000 μs

NJ101-

1,000 μs, 2,000

μs, or 4,000 μs

EtherCAT Port

1

1-3-1 Performance Specifications

*1 Refer to 3-1-1 CoE (CAN Application Protocol over EtherCAT) for details on CoE.

*2 Connection is possible only in full duplex mode. Half-duplex connections will result in link OFF status.

*3 Wiring in a ring configuration is not possible.

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)

1-9

Page 36

1 Introduction

*4 Setting is available only for integer multiples of the task period of the primary periodic task.

*5 Unit version 1.03 or later of the CPU Unit is required to use this setting on the NJ301-.

List of Supported Functions

Function name Description

Process data communications

DC (distributed clock) Clock synchronization

SDO communications

Configuration

RAS functions

Operations during errors

Slave information

PDO mapping using CoE

Fail-soft operation for slave communications errors

Stop operation for slave communications errors

CoE

• Emergency message server (receptions from slaves)

• SDO requests and responses

• Communications between slaves

Automatic setting of device variable names, etc.

Setting node address using hardware switches on the slaves

Setting node address using the Sysmac Studio

Network scan (collection of information on devices connected to the network)

Display of network configuration information (display of supported topology)

Slave configuration check when starting network

Reading of error information (emergency error history, subscription information,

etc.)

Packet monitoring

Troubleshooting information

Diagnosis/statistics log*2

When error occurs (stop communications or change to fail-soft operation)

Restoring communications when errors are cleared (Moves to operational state.)

Enabling/disabling slaves

Disconnecting/reconnecting slaves

*1

*1 For the NJ301- and NJ101- CPU Units, unit version 1.10 or later and Sysmac Studio version

1.12 or higher are required to use the packet monitoring function.

*2 A CPU Unit with unit version 1.11 is required to use the diagnosis/statistics log.

1-10

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (W505)