Page 1

Machine Automation Controller

NJ-series

NJ Robotics CPU Unit

User’s Manual

NJ501-4500

NJ501-4400

NJ501-4320

NJ501-4310

NJ501-4300

CPU Unit

W539-E1-04

Page 2

NOTE

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of the information contained in this publication.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan and other

countries for OMRON factory automation products.

• Microsoft, Windows, Windows Vista, Excel, and Visual Basic are either registered trademarks or trademarks of

Microsoft Corporation in the USA and other countries.

• EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

• ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

• The SD and SDHC logos are trademarks of SD-3C, LLC.

Other company names and product names in this document are the trademarks or registered trademarks of their

respective companies.

Copyrights

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Page 3

Introduction

Thank you for purchasing an NJ-series NJ Robotics CPU Unit (hereinafter called NJ Robotics CPU

Unit).

This manual contains information that is necessary to use the NJ Robotics CPU Unit. Please read this

manual and make sure you understand the functionality and performance of this product before you

attempt to use it.

When you have finished reading this manual, keep it in a safe location where it will be readily available

for reference during operation.

This manual describes only the functions added to NJ501-4 Units.

Refer to the NJ-series manuals listed in Related Manuals on page 33 for functions which are common

in NJ501- Units including NJ501-1 Units.

Intended Audience

Introduction

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and connecting FA systems.

• Personnel in charge of managing FA systems and facilities.

For programming, this manual is intended for personnel who understand the programming language

specifications in international standard IEC 61131-3 or Japanese standard JIS B 3503.

Applicable Products

This manual covers the following products.

• NJ-series NJ Robotics CPU Unit

NJ501-4500

NJ501-4400

NJ501-4320

NJ501-4310

NJ501-4300

(Robot Version 1.02 or later)

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

1

Page 4

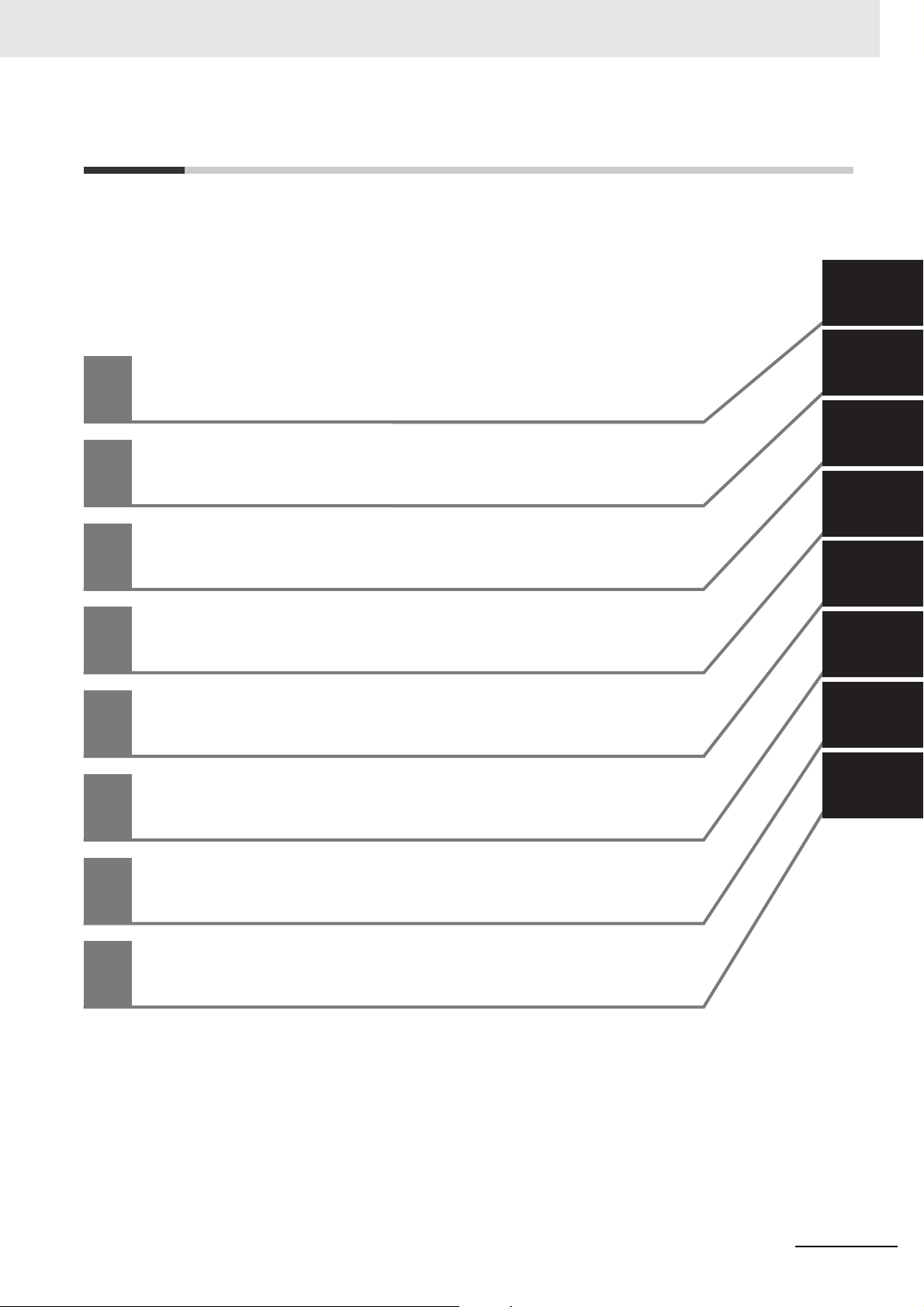

Relevant Manuals

Relevant Manuals

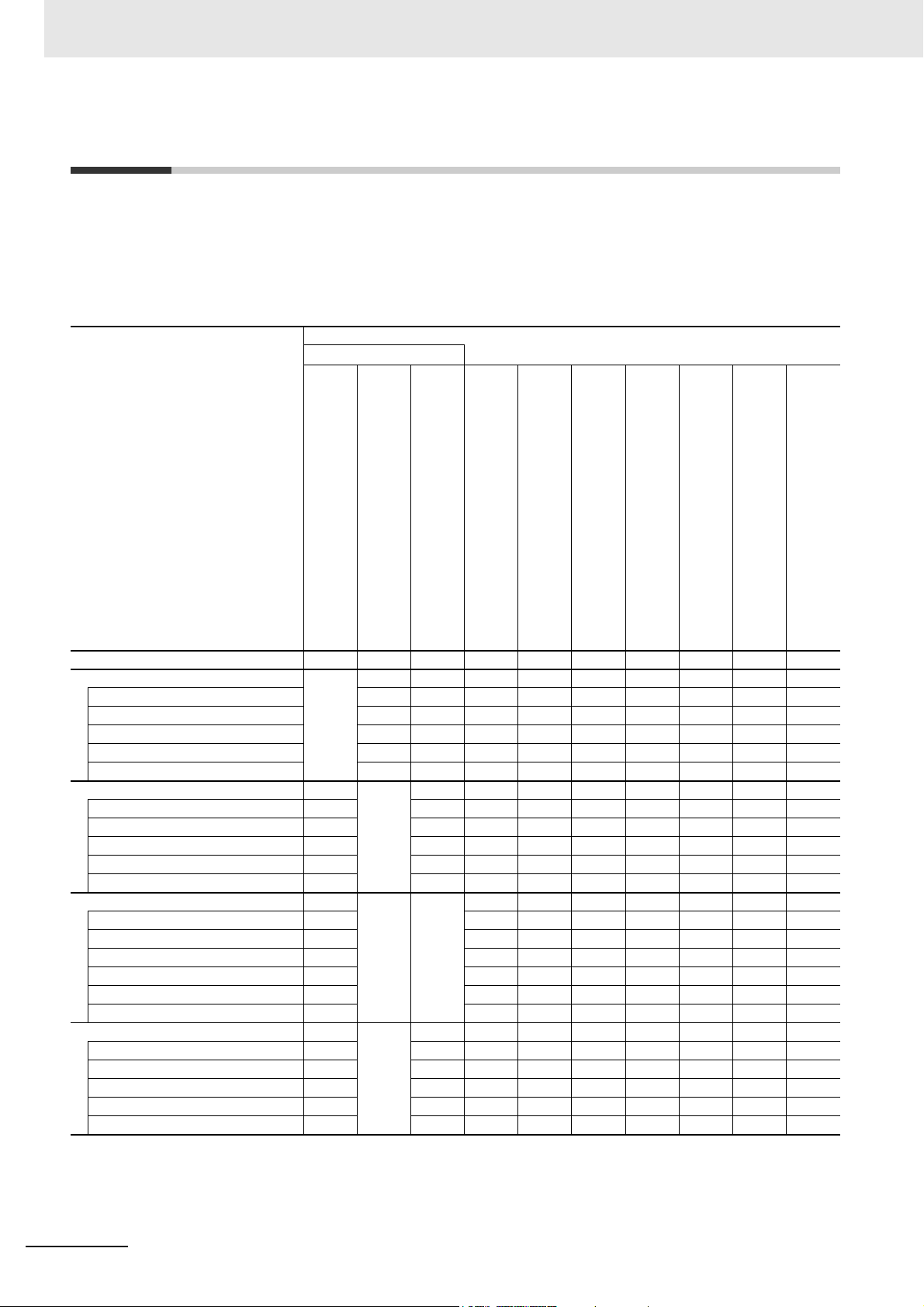

The following table provides the relevant manuals for this product. Read all of the manuals that are relevant to your system configuration and application to make the most of this product.

Most operations are performed from the Sysmac Studio Automation Software.

Refer to the Sysmac Studio Version 1 Operation Manual (Cat. No. W504) for information on the Sys-

mac Studio.

Basic information

NJ-series CPU Unit

Hardware User’s Manual

Purpose of use

Manual

NJ/NX-series CPU Unit

Software User’s Manual

NJ/NX-series

Instructions Reference Manual

NJ/NX-series CPU Unit

Motion Control User's Manual

NJ/NX-series

Motion Control Instructions Reference Manual

NJ/NX-series CPU Unit

Built-in EtherCAT® Port User’s Manual

NJ/NX-series CPU Unit

Built-in EtherNet/IP™ Port User’s Manual

NJ-series Database Connection CPU Units

User’s Manual

NJ-series NJ Robotics CPU Unit

User's Manual

NJ/NX-series

Troubleshooting Manual

Introduction to NJ-series Controllers

Setting devices and hardware

Using motion control

Using EtherCAT

Using EtherNet/IP

Using database connection service

Using robot control

Software settings

Using motion control

Using EtherCAT

Using EtherNet/IP

Using database connection service

Using robot control

Writing the user program

Using motion control

Using EtherCAT

Using EtherNet/IP

Using database connection service

Using robot control

Programming error processing

Testing operation and debugging

Using motion control

Using EtherCAT

Using EtherNet/IP

Using database connection service

Using robot control

2

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

Page 5

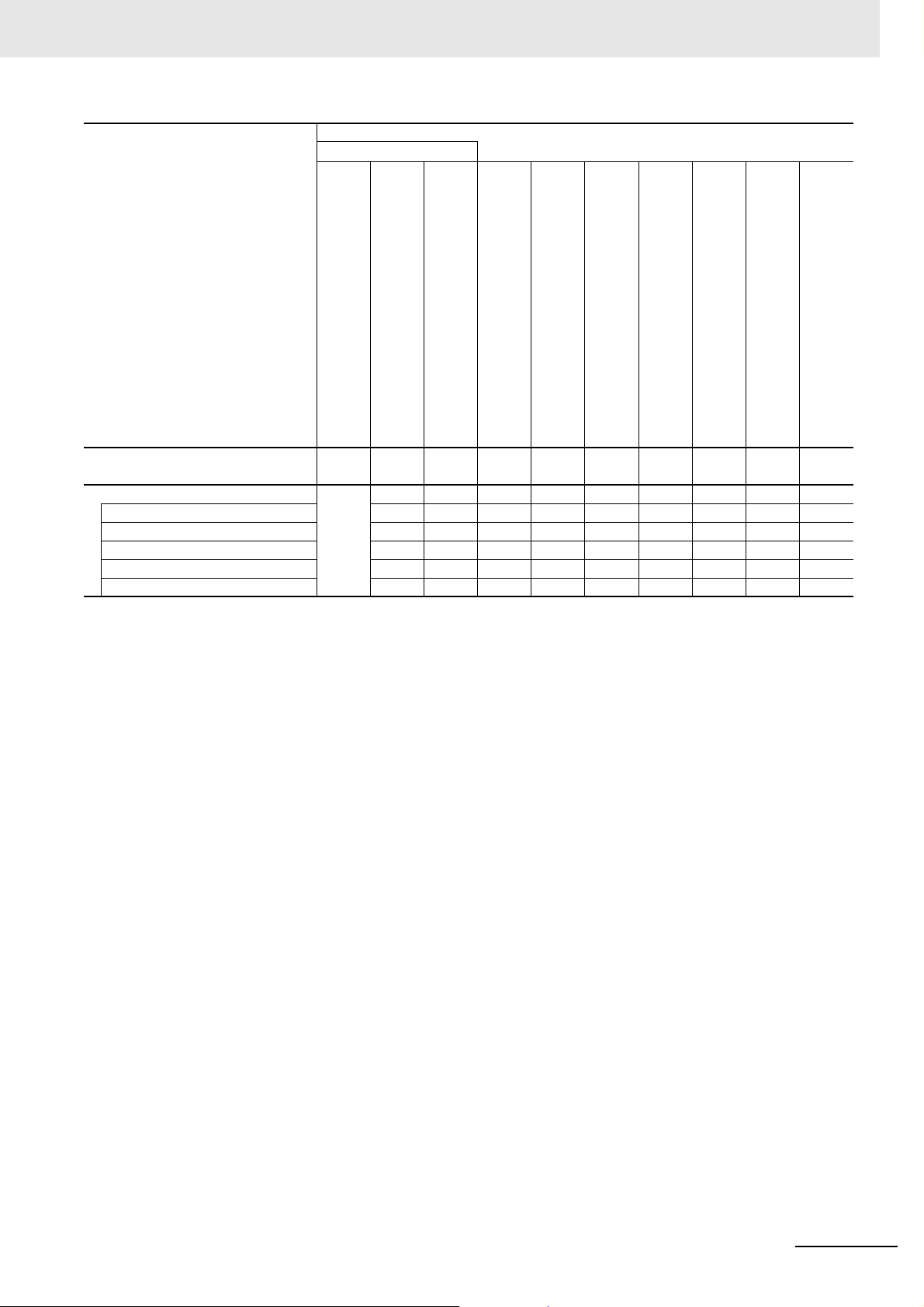

Purpose of use

Basic information

NJ-series CPU Unit

Hardware User’s Manual

NJ/NX-series CPU Unit

Software User’s Manual

NJ/NX-series

Instructions Reference Manual

NJ/NX-series CPU Unit

Motion Control User's Manual

Motion Control Instructions Reference Manual

Manual

NJ/NX-series

Relevant Manuals

NJ/NX-series CPU Unit

Built-in EtherCAT® Port User’s Manual

NJ/NX-series CPU Unit

Built-in EtherNet/IP™ Port User’s Manual

NJ-series Database Connection CPU Units

User’s Manual

NJ-series NJ Robotics CPU Unit

User's Manual

NJ/NX-series

Troubleshooting Manual

Learning about error management and

corrections

Maintenance

Using motion control

Using EtherCAT

Using EtherNet/IP

Using database connection service

Using robot control

*1

*1. Refer to the NJ/NX-series Troubleshooting Manual (Cat. No. W503) for the error management concepts and an overview

of the error items. For details on each error, refer to the relevant manuals indicated with mark.

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

3

Page 6

Manual Structure

4-9

4 Installation and Wiring

NJ-series CPU Unit Hardware User’s Manual (W500)

stinUgnitnuoM3-4

4

stnenopmoCrellortnoCgnitcennoC1-3-4

4-3 Mounting Units

The Units that make up an NJ-series Controller can be connected simply by pressing the Units together

and locking the sliders by moving them toward the back of the Units. The End Cover is connected in the

same way to the Unit on the far right side of the Controller.

1 Join the Units so that the connectors fit exactly.

2 The yellow sliders at the top and bottom of each Unit lock the Units together. Move the sliders

toward the back of the Units as shown below until they click into place.

Precautions for Correct UsePrecautions for Correct Use

4-3-1 Connecting Controller Components

Connector

Hook

Hook holes

Slider

Lock

Release

Move the sliders toward the back

until they lock into place.

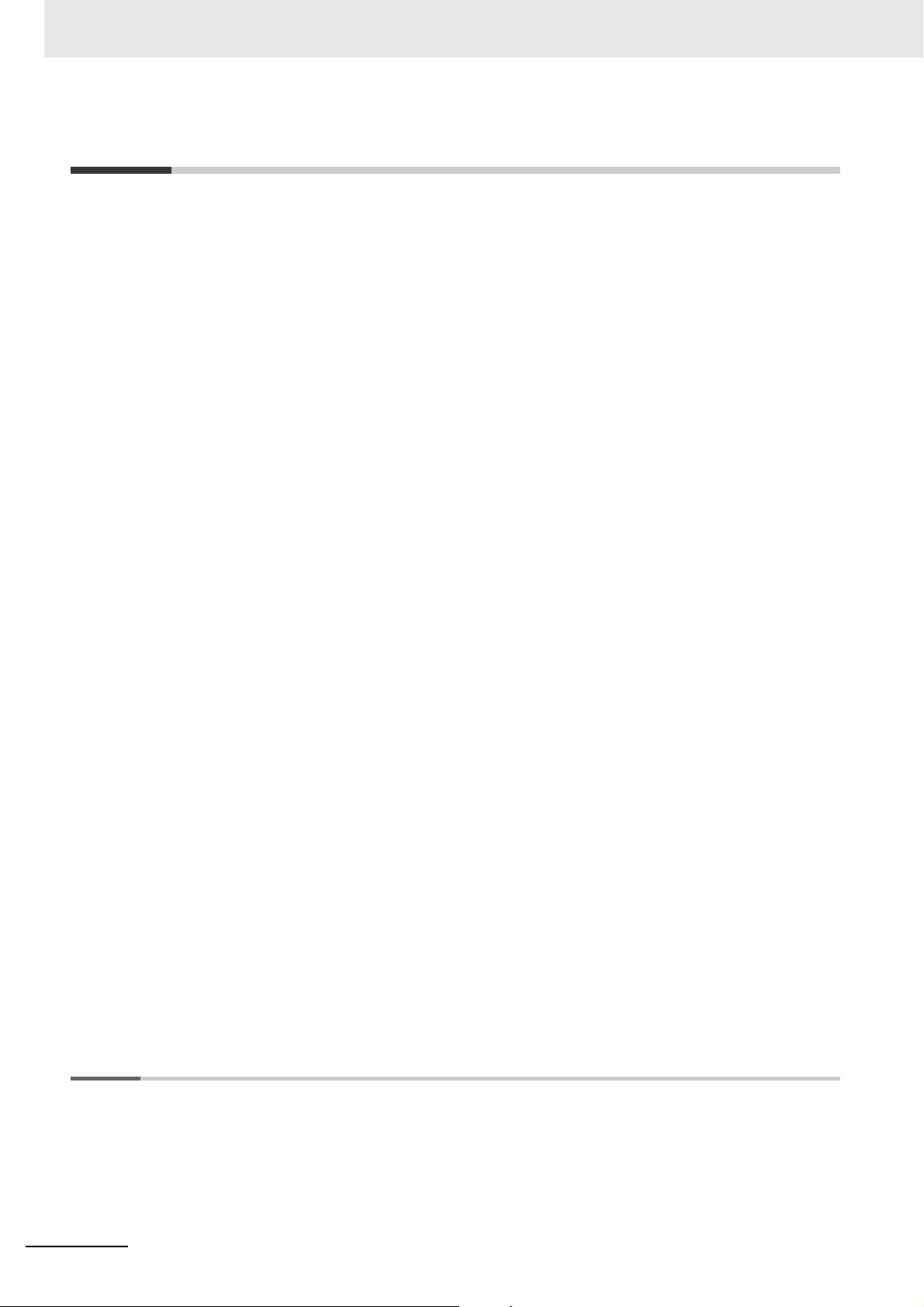

Level 1 heading

Level 2 heading

Level 3 heading

Level 2 heading

A step in a procedure

Manual name

Special information

Level 3 heading

Page tab

Gives the current

headings.

Indicates a procedure.

Icons indicate

precautions, additional

information, or reference

information.

Gives the number

of the main section

The sliders on the tops and bottoms of the Power Supply Unit, CPU Unit, I/O Units, Special I/O

Units, and CPU Bus Units must be completely locked (until they click into place) after connecting

the adjacent Unit connectors.

Manual Structure

Page Structure and Symbols

The following page structure and symbols are used in this user’s manual.

Note This illustration is provided only as a sample. It may not literally appear in this manual.

4

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

Page 7

Precautions for Safe Use

Precautions for Correct Use

Additional Information

Version Information

Special Information

Special information in this user’s manual is classified as follows:

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

Manual Structure

Information on differences in specifications and functionality for CPU Units, Position Interface

Units, and the Sysmac Studio with different versions.

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

5

Page 8

Manual Structure

Precaution on Terminology

• In this user's manual, "download" refers to transferring data from the Sysmac Studio to the physical

Controller and "upload" refers to transferring data from the physical Controller to the Sysmac Studio.

For the Sysmac Studio, synchronization is used to both upload and download data. Here, "synchronize" means to automatically compare the data for the Sysmac Studio on the computer with the data

in the physical Controller and transfer the data in the direction that is specified by the user.

6

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

Page 9

1

2

3

4

A

5

6

3

4

A

5

I

6

I

Overview of NJ Robotics CPU Unit

Features of NJ Robotics CPU Unit

Setting Robot Functions

Robot Instructions

Vision & Robot Integrated Simulation

Troubleshooting

A

I

Appendices

Index

1

2

I

A

Sections in this Manual

Sections in this Manual

3

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

7

Page 10

CONTENTS

CONTENTS

Introduction ..............................................................................................................1

Intended Audience....................................................................................................................................... 1

Applicable Products.....................................................................................................................................1

Relevant Manuals .....................................................................................................2

Manual Structure ......................................................................................................4

Page Structure and Symbols....................................................................................................................... 4

Special Information...................................................................................................................................... 5

Precaution on Terminology .......................................................................................................................... 6

Sections in this Manual ...........................................................................................7

CONTENTS................................................................................................................8

Terms and Conditions Agreement........................................................................12

Warranty, Limitations of Liability ................................................................................................................ 12

Application Considerations ........................................................................................................................ 13

Disclaimers ................................................................................................................................................ 13

Safety Precautions .................................................................................................14

Definition of Precautionary Information...................................................................................................... 14

Symbols..................................................................................................................................................... 14

Warnings.................................................................................................................................................... 15

Cautions..................................................................................................................................................... 17

Precautions for Safe Use....................................................................................... 19

Precautions for Correct Use.................................................................................. 26

Regulations and Standards................................................................................... 28

Using Product Outside Japan.................................................................................................................... 28

Conformance to EC Directives .................................................................................................................. 28

Conformance to Shipbuilding Standards ................................................................................................... 29

Using Controllers in Robot Systems .......................................................................................................... 29

Software Licenses and Copyrights ............................................................................................................ 29

Versions ..................................................................................................................30

Confirming Versions................................................................................................................................... 30

Related Manuals .....................................................................................................33

Terminology ............................................................................................................35

Revision History .....................................................................................................37

Section 1 Overview of NJ Robotics CPU Unit

1-1 Features and System Configuration of Unit ....................................................................... 1-2

1-1-1 Features of NJ Robotics CPU Unit.............................................................................................. 1-2

1-1-2 Introduction to the System Configurations ..................................................................................1-4

1-2 Operation Procedure of Unit ................................................................................................ 1-7

1-3 Specifications of Unit ............................................................................................................ 1-8

1-3-1 Performance Specifications ........................................................................................................1-8

1-3-2 Function Specifications ...............................................................................................................1-8

8

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

Page 11

1-4 Robot Control Configuration.............................................................................................. 1-10

Section 2 Features of NJ Robotics CPU Unit

2-1 Controllable Robot Types .....................................................................................................2-2

2-2 Coordinate System................................................................................................................ 2-5

2-2-1 Overview of Coordinate Systems ............................................................................................... 2-5

2-2-2 Coordinate Systems ................................................................................................................. 2-14

2-3 Robot Functions .................................................................................................................. 2-15

2-3-1 Kinematics Setting.................................................................................................................... 2-15

2-3-2 Workspace Check..................................................................................................................... 2-23

2-3-3 User Coordinate System (UCS)................................................................................................ 2-29

2-3-4 Monitoring................................................................................................................................. 2-30

2-3-5 Time-specified Absolute Positioning......................................................................................... 2-30

2-3-6 Conveyor Synchronization........................................................................................................ 2-31

2-3-7 Inverse Kinematics ................................................................................................................... 2-32

2-3-8 Robot Tool................................................................................................................................. 2-32

2-3-9 Robot Jogging........................................................................................................................... 2-34

2-3-10 Checking Maximum Interpolation Velocity and Maximum Interpolation

Acceleration/Deceleration......................................................................................................... 2-35

2-3-11 Multi-execution of Instructions with Buffered Mode .................................................................. 2-37

2-3-12 Multi-execution of Instructions with Blending Mode.................................................................. 2-37

2-3-13 Trajectory Types for Time-specified Motion .............................................................................. 2-38

CONTENTS

Section 3 Setting Robot Functions

3-1 Setting Group for Robot ....................................................................................................... 3-2

3-1-1 Group Setting Procedures .......................................................................................................... 3-2

3-1-2 Axes Group Settings................................................................................................................... 3-3

3-1-3 Axis Settings............................................................................................................................... 3-4

3-2 Robot Kinematics Settings................................................................................................... 3-9

3-3 Homing ................................................................................................................................. 3-10

3-4 Target Position and Direction Setting Method.................................................................. 3-11

3-4-1 Position Settings........................................................................................................................3-11

3-4-2 Rotational Axis Control ..............................................................................................................3-11

3-5 Checking Wiring from the Sysmac Studio ........................................................................ 3-14

Section 4 Robot Instructions

4-1 Overview of Robot Instructions ........................................................................................... 4-2

4-1-1 List of Robot Instructions ............................................................................................................ 4-2

4-1-2 Axes Group Instructions Enabled/disabled................................................................................. 4-2

4-1-3 Robot Execution and Stop Instructions....................................................................................... 4-3

4-1-4 Unusable Output Variables of Axes Group................................................................................. 4-4

Details on Robot Instructions........................................................................................................ 4-5

MC_SetKinTransform............................................................................................................................... 4-6

MC_DefineCoordSystem........................................................................................................................ 4-15

MC_DefineToolTransform ...................................................................................................................... 4-19

MC_GroupMon....................................................................................................................................... 4-23

MC_MoveTimeAbsolute......................................................................................................................... 4-29

MC_SyncLinearConveyor ...................................................................................................................... 4-38

MC_SyncOut .......................................................................................................................................... 4-59

MC_InverseKin....................................................................................................................................... 4-68

MC_RobotJog ........................................................................................................................................ 4-73

MC_GroupSyncMoveAbsolute............................................................................................................... 4-82

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

9

Page 12

CONTENTS

4-2 Multi-execution of Motion Control Instructions................................................................ 4-84

4-2-1 Multi-execution in Aborting Mode..............................................................................................4-84

4-2-2 Multi-execution in Buffered Mode..............................................................................................4-85

4-2-3 Multi-execution in Blending Mode .............................................................................................4-86

4-3 State Transitions of Robot Instructions ............................................................................ 4-91

4-4 Sample Programming ......................................................................................................... 4-92

Section 5 Vision & Robot Integrated Simulation

5-1 Overview of Simulation......................................................................................................... 5-2

5-2 Models that Support Simulation .......................................................................................... 5-3

5-3 Simulation Procedures ......................................................................................................... 5-5

Section 6 Troubleshooting

6-1 Error Table.............................................................................................................................. 6-2

6-2 Error Description ................................................................................................................. 6-22

6-2-1 Interpreting Error Description....................................................................................................6-22

6-2-2 Error Descriptions .....................................................................................................................6-23

Appendices

A-1 Sysmac Studio Robot Additional Option ............................................................................A-2

A-1-1 Enabling the Sysmac Studio Robot Additional Option ................................................................A-2

A-1-2 Disabling the Sysmac Studio Robot Additional Option................................................................A-4

A-1-3 3D Equipment Model Creation Wizard........................................................................................A-6

A-1-4 3D Machine Models ....................................................................................................................A-8

A-1-5 Calculation of Calibration Parameters.......................................................................................A-19

A-1-6 Display of Images in 3D Motion Monitoring...............................................................................A-20

A-2 Sysmac Studio Robot Options...........................................................................................A-21

A-2-1 Enabling Sysmac Studio Robot Options ...................................................................................A-21

A-2-2 Disabling Sysmac Studio Robot Options ..................................................................................A-23

Index

10

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

Page 13

CONTENTS

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

11

Page 14

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship for a period of twelve months from the date of sale by Omron (or such other period expressed in

writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be

responsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of

any Products by Buyer must be approved in writing by Omron before shipment. Omron Companies

shall not be liable for the suitability or unsuitability or the results from the use of Products in combination with any electrical or electronic components, circuits, system assemblies or any other materials or substances or environments. Any advice, recommendations or information given orally or in

writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

12

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

Page 15

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings

and limitations of use which apply to the Product. This information by itself is not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine, system, or other application or use. Buyer shall be solely responsible for determining appropriateness of

the particular Product with respect to Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Terms and Conditions Agreement

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or

any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual performance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and other

reasons. It is our practice to change part numbers when published ratings or features are changed, or

when significant construction changes are made. However, some specifications of the Product may be

changed without any notice. When in doubt, special part numbers may be assigned to fix or establish

key specifications for your application. Please consult with your Omron’s representative at any time to

confirm actual specifications of purchased Product.

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

13

Page 16

Safety Precautions

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury. Additionally, there may be severe property damage.

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury, or property damage.

Safety Precautions

Definition of Precautionary Information

The following notation is used in this manual to provide precautions required to ensure safe usage of an

NJ Robotics Controller.

The safety precautions that are provided are extremely important to safety. Always read and heed the

information provided in all safety precautions.

The following notation is used.

WARNING

Symbols

Caution

This symbol indicates operations that you must not do.

The specific operation is shown in and explained in text.

This example indicates prohibiting disassembly.

This symbol indicates precautions (including warnings).

The specific operation is shown in and explained in text.

This example indicates a precaution for electric shock.

This symbol indicates precautions (including warnings).

The specific operation is shown in and explained in text.

This example indicates a general precaution.

This symbol indicates operations that you must do.

The specific operation is shown in and explained in text.

This example shows a general precaution for something that you must do.

14

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

Page 17

Warnings

WARNING

During Power Supply

Safety Precautions

Do not touch any of the terminals or terminal blocks while the power is being supplied.

Doing so may result in electric shock.

Do not disassemble any of the Units.

Particularly the power-supplied Units contain parts with high voltages while power is supplied or immediately after power is turned OFF. Touching any of these parts may result in

electric shock. There are sharp parts inside the Units that may cause injury.

Fail-safe Measures

Provide safety measures in external circuits to ensure safety in the system if an abnormality

occurs due to malfunction of the CPU Unit, other Units, or slaves or due to other external

factors affecting operation.

Not doing so may result in serious accidents due to incorrect operation.

Emergency stop circuits, interlock circuits, limit circuits, and similar safety measures must

be provided in external control circuits.

The Controller outputs may remain ON or OFF due to deposition or burning of the output

relays or destruction of the output transistors. As a countermeasure for such problems,

external safety measures must be provided to ensure safe operation of the system.

The CPU Unit will turn OFF all outputs from Basic Output Units in the following cases.

• If an error occurs in the power supply

• If the power supply connection becomes faulty

• If a CPU watchdog timer error or CPU reset occurs

• If a major fault level Controller error occurs

• While the CPU Unit is on standby until RUN mode is entered after the power is turned

ON.

Provide external safety measures so that the system operates safely if all outputs turn OFF

when any of the above conditions occurs.

If external power supplies for slaves or other devices are overloaded or short-circuited, the

voltage will drop, outputs will turn OFF, and the system may be unable to read inputs. Provide external safety measures in controls with monitoring of external power supply voltage

as required so that the system operates safely in such a case.

Unintended outputs may occur when an error occurs in variable memory or in memory used

for CJ-series Units. As a countermeasure for such problems, external safety measures

must be provided to ensure safe operation of the system.

Provide measures in the communications system and user program to ensure safety in the

overall system even if errors or malfunctions occur in data link communications or remote

I/O communications.

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

15

Page 18

Safety Precautions

If there is interference in remote I/O communications or if a major fault level error occurs,

output status will depend on the specifications of the product that is used.

Check the product's specifications and see what operation will occur when there is interference in communications or a major fault level error, and implement safety measures.

Set the slave settings correctly for all EtherCAT slaves.

The NJ-series Controller continues normal operation for a certain period of time even when

a momentary power interruption occurs. This means that the NJ-series Controller may

receive incorrect signals from external devices that are also affected by the power interruption.

Accordingly, take suitable actions, such as external fail-safe measures and interlock conditions, to monitor the power supply voltage of the external devices as required.

You must take fail-safe measures to ensure safety in the event of incorrect, missing, or

abnormal signals caused by broken signal lines, momentary power interruptions, or other

causes.

Not doing so may result in serious accidents due to incorrect operation.

Voltage and Current Inputs

Make sure that the voltages and currents that are input to the Units and slaves are within

the specified ranges.

Inputting voltages or currents that are outside of the specified ranges may cause accidents

or fire.

Downloading

Always confirm safety at the destination before you transfer a user program, configuration

data, setup data, device variables, or values in memory used for CJ-series Units from the

Sysmac Studio.

The devices or machines may perform unexpected operation regardless of the operating

mode of the CPU Unit.

16

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

Page 19

Version Information

Cautions

Caution

Application

Wiring

Safety Precautions

Do not touch any Unit while power is supplied or immediately after the power supply is

turned OFF. Doing so may result in burn injury.

Be sure that all terminal screws and cable connector screws are tightened to the torques

specified in this manual or in the reference manuals. The loose screws may result in fire or

malfunction.

Online Editing

Execute online editing only after confirming that no adverse effects will be caused by deviations in the timing of I/O. If you perform online editing, the task execution time may exceed

the task period, I/O may not be refreshed with external devices, input signals may not be

read, and output timing may change.

Error Message

Precaution on Error Message That Says an Instruction May Cause Unin-

tended Operation

Instructions may results in unexpected operation and affect the system if you clear the

Detect an error when an in-out variable is passed to specific instruction argument Check

Box in the Program Check Area under the Option settings in the Sysmac Studio.

Always confirm that the conditions for use that are given in the NJ/NX-series Instructions

Reference Manual (Cat. No. W502) are met before you clear this check box.

This error message is displayed by and the above option setting is available on Sysmac Studio

version 1.02.

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

17

Page 20

Safety Precautions

Simulation

Although the Sysmac Studio's simulation function simulates the operations of the Controller

and vision sensors, there are differences from the Controller and vision sensors in operation and timing. After you use the simulation function to debug the user program, always

check operation and perform adjustments on the physical Controller and vision sensors

before you use the user program to operate the controlled system. Accidents may occur if

the controlled system performs unexpected operation.

18

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

Page 21

Precautions for Safe Use

Disassembly and Dropping

• Do not attempt to disassemble, repair, or modify any Units. Doing so may result in malfunction or fire.

• Do not drop any Unit or subject it to abnormal vibration or shock. Doing so may result in Unit malfunction or burning.

Mounting

The sliders on the tops and bottoms of the Power Supply Unit, CPU Unit, I/O Units, and other Units

must be completely locked (until they click into place) after connecting the adjacent Unit connectors.

Installation

Precautions for Safe Use

Always connect to a ground of 100 Ω or less when installing the Units. To avoid electric shock, be sure

to install a ground of 100 Ω or less especially when shorting the GR and LG terminals on the Power

Supply Unit.

Wiring

• Follow the instructions in the NJ-series CPU Unit Hardware User's Manual (Cat. No. W500) to correctly perform wiring.

Double-check all wiring and switch settings before turning ON the power supply.

• Use crimp terminals for wiring.

Do not connect bare stranded wires directly to terminals.

• Do not pull on the cables or bend the cables beyond their natural limit.

Do not place heavy objects on top of the cables or other wiring lines. Doing so will damage the cable.

• Mount terminal blocks and connectors only after checking the mounting location carefully.

• Make sure that the terminal blocks, expansion cables, and other items with locking devices are properly locked into place.

• Before you turn ON the power supply, be sure to remove any dustproof labels that are put on the top

of the Units when they are shipped. If the labels are not removed, heat will accumulate and malfunctions may occur.

• Before you connect a computer to the CPU Unit, disconnect the power supply plug of the computer

from the AC outlet. Also, if the computer has an FG terminal, make the connections so that the FG

terminal has the same electrical potential as the GR terminal on the Power Supply Unit.

A difference in electrical potential between the computer and Controller may cause failure or malfunction.

• If the external power supply to an Output Unit or slave has polarity, connect it with the correct polarity.

If the polarity is reversed, current may flow in the reverse direction and damage the connected

devices regardless of the operation of the Controller.

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

19

Page 22

Precautions for Safe Use

Power Supply Design

• Do not exceed the rated supply capacity of the Power Supply Units used in the Controller system.

The rated supply capacities are given in the NJ-series CPU Unit Hardware User's Manual (Cat. No.

W500).

If the capacity is exceeded, operation may stop, malfunctions may occur, or data may not be backed

up normally for power interruptions.

Use only NJ-series Power Supply Units on NJ-series CPU Racks and Expansion Racks.

Operation is not possible if a CJ-series Power Supply Unit is used with an NJ-series CPU Unit or an

NJ-series Power Supply Unit is used with a CJ-series Units.

• Do not apply voltages or connect loads to the Output Units or slaves in excess of the maximum ratings.

• Surge current occurs when the power supply is turned ON. When selecting fuses or breakers for

external circuits, consider the above precaution and allow sufficient margin in shut-off performance.

Refer to the NJ-series CPU Unit Hardware User's Manual (Cat. No. W500) for surge current specifications.

• If the full dielectric strength voltage is applied or turned OFF using the switch on the tester, the generated impulse voltage may damage the Power Supply Unit. Use the adjustment on the tester to gradually increase and decrease the voltage.

• Apply the voltage between the Power Supply Unit's L1 or L2 terminal and the GR terminal when testing insulation and dielectric strength.

• Do not supply AC power from an inverter or other device with a square-wave output. Internal temperature rise may result in smoking or burning. Always input a sinusoidal wave with the frequency

that is given in the NJ-series CPU Unit Hardware User's Manual (Cat. No. W500).

• Install external breakers and take other safety measures against short-circuiting in external wiring.

When Power Is Turned ON

• It takes up to approximately 10 to 20 seconds to enter RUN mode after the power is turned ON.

During that time, outputs will be OFF or will be the values specified in the Unit or slave settings, and

external communications cannot be performed. Use the RUN output on the Power Supply Unit, for

example, to implement fail-safe circuits so that external devices do not operate incorrectly.

• Configure the external circuits so that the power supply to the control system turns ON only after the

power supply to the Controller has turned ON. If the power supply to the Controller is turned ON after

the control power supply, temporary errors may result in incorrect control system signals because the

output terminals on Output Units may momentarily turn ON when power supply is turned ON to the

Controller.

Actual Operation

Check the user program, data, and parameter settings for proper execution before you use them for

actual operation.

Turning OFF the Power Supply

• Do not turn OFF the power supply to the Controller while the BUSY indicator flashes. While the

BUSY indicator is flashing, the user program and settings in the CPU Unit are being backed up in the

built-in non-volatile memory. This data will not be backed up correctly if the power supply is turned

OFF. The next time that the Controller is started, a Controller error in the major fault level will occur

and operation will stop.

20

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

Page 23

Precautions for Safe Use

• Do not turn OFF the power supply or remove the SD Memory Card while SD Memory Card access is

in progress (i.e., while the SD BUSY indicator flashes). Data may become corrupted, and the Controller will not operate correctly if it uses corrupted data. To remove an SD Memory Card from the CPU

Unit when power is supplied to the CPU Unit, press the SD Memory Card power supply switch and

wait for the SD BUSY indicator to turn OFF before you remove the Card.

• Do not disconnect the cable or turn OFF the power supply to the Controller when downloading data

or the user program from the Sysmac Studio.

• Always turn OFF the power supply to the Controller before you attempt any of the following.

a) Mounting or removing I/O Units or the CPU Unit

b) Assembling the Units

c) Setting DIP switches or rotary switches

d) Connecting cables or wiring the system

e) Connecting or disconnecting the connectors

The Power Supply Unit may continue to supply power to the rest of the Controller for a few seconds

after the power supply turns OFF. The PWR indicator is lit during this time. Confirm that the PWR

indicator is not lit before you perform any of the above.

Operation

• Confirm that the controlled system will not be adversely affected before you perform any of the following operations.

a) Changing the operating mode of the CPU Unit (including changing the setting of the Operating

Mode at Startup)

b) Changing the user program or settings

c) Changing set values or present values

d) Forced Refreshing

• Always sufficiently check the safety at the connected devices before you change the settings of an

EtherCAT slave or Special Unit.

• If two different function modules are used together, such as when you use CJ-series Basic Units and

EtherCAT slaves, take suitable measures in the user program and external controls to ensure that

safety is maintained in the controlled system if one of the function modules stops. The relevant outputs will stop if a partial fault level error occurs in one of the function modules.

• Always confirm safety at the connected equipment before you reset Controller errors with an event

level of partial fault or higher for the EtherCAT Master Function Module.

When the error is reset, all slaves that were in any state other than Operational state due to a Controller error with an event level of partial fault or higher (in which outputs are disabled) will go to Operational state and the outputs will be enabled.

Before you reset all errors, confirm that no Controller errors with an event level of partial fault have

occurred for the EtherCAT Master Function Module.

• Always confirm safety at the connected equipment before you reset Controller errors for a CJ-series

Special Unit. When the Controller error is reset, the Unit where the Controller error with an event level

of observation or higher will be restarted.

Before you reset all errors, confirm that no Controller errors with an event level of observation or

higher have occurred for the CJ-series Special Unit. Observation level events do not appear on the

Controller Error Tab Page, so it is possible that you may restart the CJ-series Special Unit without

intending to do so.

You can check the status of the _CJB_UnitErrSta[0,0] to _CJB_UnitErrSta[3,9] error status variables

on a Watch Tab Page to see if an observation level Controller error has occurred.

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

21

Page 24

Precautions for Safe Use

Battery Backup

The user program and initial values for the variables are stored in non-volatile memory in the CPU Unit.

The present values of variables with the Retain attribute and the values of the Holding, DM, and EM

Areas in the memory used for CJ-series Units are backed up by a Battery.

If the Battery is not connected or the Battery is exhausted, the CPU Unit detects a Battery-backup

Memory Check Error.

If that error is detected, variables with a Retain attribute are set to their initial values and the Holding,

DM, and EM Areas in memory used for CJ-series Units are cleared to all zeros.

Perform thorough verifications and provide sufficient measures to ensure that the devices perform safe

operation for the initial values of the variables with Retain attributes and the resulting operation.

Debugging

• Forced refreshing ignores the results of user program execution and refreshes I/O with the specified

values. If forced refreshing is used for inputs for which I/O refreshing is not supported, the inputs will

first take the specified values, but they will then be overwritten by the user program. This operation

differs from the force-set/reset functionality of the CJ-series PLCs.

• You cannot upload or download information for forced refreshing with the Sysmac Studio.

After downloading data that contain the forced refreshing targets, change to RUN mode and then

execute forced refreshing from the Sysmac Studio.

Depending on the difference in the forced status, the control system may operate unexpectedly.

• Do not specify the same address for the AT specification for more than one variable.

Doing so would allow the same entity to be accessed with different variable names, which would

make the user program more difficult to understand and possibly cause programming mistakes.

General Communications

• When you use data link communications, check the error information that is given in _ErrSta (Controller Error Status) to make sure that no error has occurred in the source device. Create a user program

that uses reception data only when there is no error in the source device.

If there is an error in the source device, the data for the data link may contain incorrect values.

• Unexpected operation may result if inappropriate data link tables are set. Even if appropriate data link

tables have been set, confirm that the controlled system will not be adversely affected before you

transfer the data link tables. The data links start automatically after the data link tables are transferred.

• All CPU Bus Units are restarted when routing tables are transferred from Support Software to the

CPU Unit. Confirm that the system will not be adversely affected by restarting before you transfer the

routing tables.

• Tag data links will stop between related nodes while tag data link parameters are transferred during

Controller operation. Confirm that the system will not be adversely affected before you transfer the

tag data link parameters.

22

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

Page 25

Precautions for Safe Use

EtherNet/IP Communications

• All related EtherNet/IP nodes are reset when you transfer settings for the built-in EtherNet/IP port

(including IP addresses and tag data links settings). Confirm that the system will not be adversely

affected by resetting nodes before you transfer the settings.

• If EtherNet/IP tag data links (cyclic communications) are used with a repeating hub, the communications load on the network will increase. This will increase collisions and may prevent stable communications. Do not use repeating hubs on networks where tag data links are used. Use an Ethernet

switch instead.

EtherCAT Communications

• Make sure that the communications distance, number of nodes connected, and method of connection for EtherCAT are within specifications.

Do not connect EtherCAT communications to other types of networks such as EtherNet/IP and a

standard in-house LAN. An overload may cause the network to fail or malfunction.

• Malfunctions or unexpected operation may occur for some combinations of EtherCAT revision numbers of the master and slaves. If you disable the revision check in the network settings, you must use

the Sysmac Studio to check the slave revision numbers in the master settings against the actual

slave revision numbers. Check the functional compatibility by referring to the manuals or other references of the slaves before using. You can check the actual slave revisions from the Sysmac Studio or

on slave nameplates.

• After you transfer the user program, the CPU Unit is restarted and communications with the EtherCAT slaves are cut off. During that period, the slave outputs behave according to the slave settings.

The time that communications are cut off depends on the EtherCAT network configuration. If the EtherCAT network configuration contains only OMRON EtherCAT slaves, communications are cut off for

a maximum of 45 seconds.

Before you transfer the user program, confirm that the Units will not be adversely affected.

• If the Fail-soft Operation Setting parameter is set Stop, process data communications will stop for all

slaves when an EtherCAT communications error is detected in a slave. For this reason, if Servo

Drives are connected, the Servo Drives for all axes will be turned OFF. Make sure that the Fail-soft

Operation Setting results in safe operation when a device error occurs.

• EtherCAT communications are not always established immediately after the power supply is turned

ON. Use the system-defined variables in the user program to confirm that communications are established before attempting control operations.

• If frames sent to EtherCAT slaves are lost due to noise or other causes, slave I/O data is not transmitted, and unexpected operation may occur. If noise countermeasures are required, use the _EC_In-

DataInvalid (Input Data Disable) system-defined variable as an interlock condition in the user

program.

Refer to the NJ/NX-series CPU Unit Built-in EtherCAT Port User's Manual (Cat. No. W505) for

details.

The slave outputs behave according to the slave settings. Refer to the manuals for the slaves for

details.

• When an EtherCAT slave is disconnected, communications will stop and control of the outputs will be

lost not only for the disconnected slave, but for all slaves connected after it. Confirm that the system

will not be adversely affected before you disconnect a slave.

• If you disconnect the cable from an EtherCAT slave to disconnect it from the network, any current

communications frames may be lost. If frames are lost, slave I/O data is not transmitted, and unexpected operation may occur. Perform the following processing for a slave that needs to be replaced.

a) Create the program using the _EC_InDataInvalid (Input Data Disable) system-defined variable

as an interlock condition.

b) Set the PDO communications timeout detection count to at least 2 in the EtherCAT master set-

tings pane.

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

23

Page 26

Precautions for Safe Use

Refer to the NJ/NX-series CPU Unit Built-in EtherCAT Port User's Manual (Cat. No. W505) for

details.

Motion Control

• Confirm the axis number carefully before you perform an MC Test Run.

• The motor is stopped if communications are interrupted between the Sysmac Studio and the CPU

Unit during an MC Test Run. Connect the communications cable between the computer and CPU

Unit securely and confirm that the system will not be adversely affected before you perform an MC

Tes t Ru n.

• Always execute the Save Cam Table instruction if you change any of the cam data from the user program in the CPU Unit or from the Sysmac Studio. If the cam data is not saved, the previous condition

will be restored when the power is turned ON again, possibly causing unexpected machine operation.

• The positive drive prohibit input (POT), negative drive prohibit input (NOT), and home proximity input

(DEC) of the Servo Drive are used by the MC Function Module as the positive limit input, negative

limit input, and home proximity input. Make sure that the signal widths for all of these input signals

are longer than the control period of the MC Function Module. If the input signal widths are shorter

than the control period, the MC Function Module may not be able to detect the input signals, resulting

in incorrect operation.

• During setting, ensure a correct relationship between the direction of commands issued by the Controller and the motor rotation direction of the Servo Drive. Otherwise, a robot may operate unexpectedly.

• Select a correct combination of the kinematics type and workspace type for the MC_SetKinTransform

(Set Kinematics Transformation) instruction to ensure proper workspace check. Check that the workspace check function is performed as intended.

• Adjust the home of the robot before you start robot operation.

• Do not operate the robot outside the workspace while the workspace check function is disabled. If

you do so, the robot may be damaged.

• Use the MC_SyncOut (End Synchronization) instruction to stop the operation caused by the

MC_SyncLinearConveyor (Start Conveyor Synchronization) instruction.

• If you set 0 for the MaxVelocity (Velocity Error Detection Value) or MaxAcceleration (Acceleration

Error Detection Value) parameter for input variables, or if you use the default (0) of these variables,

the velocity error check or acceleration error check is not performed. Properly set the MaxVelocity

(Velocity Error Detection Value) and MaxAcceleration (Acceleration Error Detection Value) to avoid

an unexpected velocity and acceleration.

• If a robot tool (ToolID: 1 to 16) other than TCP0 is selected, the system does not perform the

pre-check of the MaxVelocity (Velocity Error Detection Value) and MaxAcceleration (Acceleration

ErrorDetection Value) parameters in the robotics instruction.

• When using Cartesian 2D kinematics, configure Plane correctly. Otherwise, a robot may operate

unexpectedly.

• When Synchronized stop with Deceleration is selected in MC_SyncOut (End Synchronization)

instruction and Deceleration target time T5 is set to long time, it is possible to reach out of the workspace during deceleration. Do not disable workspace check.

•Select Immediate stop or Immediate stop and Servo OFF when using Delta 3, Delta 3R, Delta 2, Car-

tesian 2D Gantry or Cartesian 3D Gantry robot.

• Set 0 for Maximum Deceleration which are linked mechanically, when using Delta 3, Delta 3R, Delta

2, Cartesian 2D Gantry or Cartesian 3D Gantry robot.

24

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

Page 27

Precautions for Safe Use

Battery Replacement

• The Battery may leak, rupture, heat, or ignite. Never short-circuit, charge, disassemble, heat, or

incinerate the Battery or subject it to strong shock.

• Dispose of any Battery that has been dropped on the floor or otherwise subjected to excessive

shock. Batteries that have been subjected to shock may leak if they are used.

• UL standards require that batteries be replaced by experienced technicians. Make sure that an experienced engineer is in charge of Battery replacement.

• Apply power for at least five minutes before you change the Battery. Install a new Battery within five

minutes (at temperature of 25°C) after you turn OFF the power supply. If power is not supplied for at

least 5 minutes, the saved data may be lost.

Unit Replacement

• We recommend replacing the Battery with the power turned OFF to prevent the CPU Unit's sensitive

internal components from being damaged by static electricity and to prevent malfunctions. The battery can be replaced without turning OFF the power supply. To do so, always touch a grounded piece

of metal to discharge static electricity from your body before starting the procedure.

After you replace the Battery, connect the Sysmac Studio and clear the Low Battery Voltage error.

• Make sure that the required data, including the user program, configurations/setup data, variables,

and memory used for CJ-series Units, is transferred to the new CPU Unit and externally-connected

devices before you restart operation. Be sure to include the routing tables, network parameters, and

other CPU Bus Unit data, which are stored in the CPU Unit.

Disposal

• The disposal of the product and Batteries may be subject to local government regulations. Dispose of

the product and Batteries according to local ordinances as they apply.

• The following information must be displayed for all products that contain primary lithium batteries with

a perchlorate content of 6 ppb or higher when shipped to or transported through the State of California, USA.

Perchlorate Material - special handling may apply.

See www.dtsc.ca.gov/hazardouswaste/perchlorate

• The CPU Unit contains a primary lithium battery with a perchlorate content of 6 ppb or higher. Place

the above information on the individual boxes and shipping boxes when shipping finished products

that contain a CPU Unit to the State of California, USA.

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

25

Page 28

Precautions for Correct Use

Precautions for Correct Use

• Do not install or store the Controller in the following locations. Operation may stop or malfunctions

may occur.

a) Locations subject to direct sunlight

b) Locations subject to temperatures or humidity outside the range specified in the specifications

c) Locations subject to condensation as the result of severe changes in temperature

d) Locations subject to corrosive or flammable gases

e) Locations subject to dust (especially iron dust) or salts

f) Locations subject to exposure to water, oil, or chemicals

g) Locations subject to shock or vibration

• Take appropriate and sufficient countermeasures when installing the Controller in the following locations.

a) Locations subject to strong, high-frequency noise

b) Locations subject to static electricity or other forms of noise

c) Locations subject to strong electromagnetic fields

d) Locations subject to possible exposure to radioactivity

e) Locations close to power supplies

• Before touching a Unit, be sure to first touch a grounded metallic object in order to discharge any

static build-up.

• Install the Controller away from sources of heat and ensure proper ventilation. Not doing so may

result in malfunction, in operation stopping, or in burning.

• An I/O bus check error will occur and the Controller will stop if an I/O Connecting Cable's connector is

disconnected from the Rack. Be sure that the connectors are secure.

• Do not allow foreign matter to enter the openings in the Unit. Doing so may result in Unit burning,

electric shock, or failure.

• Do not allow wire clippings, shavings, or other foreign material to enter any Unit. Otherwise, Unit

burning, failure, or malfunction may occur. Cover the Units or take other suitable countermeasures,

especially during wiring work.

• For EtherCAT and EtherNet/IP, use the connection methods and cables that are specified in the

NJ/NX-series CPU Unit Built-in EtherCAT Port User's Manual (Cat. No. W505) and the NJ/NX-series

CPU Unit Built-in EtherNet/IP Port User's Manual (Cat. No. W506). Otherwise, communications may

be faulty.

• Use the rated power supply voltage for the Power Supply Units. Take appropriate measures to

ensure that the specified power with the rated voltage and frequency is supplied in places where the

power supply is unstable.

• Make sure that the current capacity of the wire is sufficient. Otherwise, excessive heat may be generated. When cross-wiring terminals, the total current for all the terminals will flow in the wire. When

wiring cross-overs, make sure that the current capacity of each of the wires is not exceeded.

• Do not touch the terminals on the Power Supply Unit immediately after turning OFF the power supply.

Residual voltage may cause electrical shock.

• If you use reed switches for the input contacts for AC Input Units, use switches with a current capacity of 1 A or greater.

If the capacity of the reed switches is too low, surge current may fuse the contacts.

26

Error Processing

When you create programs for applications that use the results of instructions that read the error status,

consider how the detected error affects the system. For example, if a minor error is detected during Battery replacement, it can affect the system operation depending on the processing of the user program.

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

Page 29

Precautions for Correct Use

Unit Replacement

• Refer to the CPU Bus Unit and Special I/O Unit operation manuals for details on the data required by

each Unit.

• The absolute encoder home offset is backed up with a Battery in the CPU Unit.

When you change the combination of the CPU Unit and Servomotor, e.g., when you add or replace a

Servomotor, define home again.

To restore the information without changing the CPU Unit-Servomotor combination, remove the

absolute encoder home offset from the data to restore.

Task Setup

If a Task Period Exceeded error occurs, shorten the programs to fit in the task period or increase the

setting of the task period.

Motion Control

• Use the system-defined variable in the user program to confirm that EtherCAT communications are

established before you attempt to execute motion control instructions. Motion control instructions are

not executed normally if EtherCAT communications are not established.

• Use the system-defined variables to monitor for errors in communications with the slaves that are

controlled by the motion control function module. Motion control instructions are not executed normally if an error occur in slave communications.

• Before you start an MC Test Run, make sure that the operation parameters are set correctly.

• Do not download motion control settings during an MC Test Run.

EtherCAT Communications

• Do not disconnect the EtherCAT slave cables during operation. The outputs will become unstable.

• Set the Servo Drives to stop operation if an error occurs in EtherCAT communications between the

Controller and a Servo Drive.

Battery Replacement

• Be sure to install a replacement Battery within two years of the production date shown on the Battery

label.

• Turn ON the power after replacing the Battery for a CPU Unit that has been unused for a long time.

Leaving the CPU Unit unused again without turning ON the power even once after the battery is

replaced may result in a shorter battery life.

• When you replace the Battery, use the CJ1W-BAT01 Battery Set.

SD Memory Card

• Insert the SD Memory Card all the way.

• Do not turn OFF the power supply to the Controller during SD Memory Card access. The files may be

corrupted.

If there is a corrupted file in the SD Memory Card, the file is automatically deleted by the restoration

function when the power supply is turned ON.

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

27

Page 30

Regulations and Standards

Regulations and Standards

Using Product Outside Japan

If you export (or provide a non-resident with) this product or a part of this product that falls under the

category of goods (or technologies) specified by the Foreign Exchange and Foreign Trade Control Law

as those which require permission or approval for export, you must obtain permission or approval (or

service transaction permission) pursuant to the law.

Conformance to EC Directives

Applicable Directives

• EMC Directives

• Low Voltage Directive

Concepts

EMC Directives

OMRON devices that comply with EC Directives also conform to the related EMC standards so that

they can be more easily built into other devices or the overall machine. The actual products have

been checked for conformity to EMC standards.

Whether the products conform to the standards in the system used by the customer, however, must

be checked by the customer. EMC-related performance of the OMRON devices that comply with EC

Directives will vary depending on the configuration, wiring, and other conditions of the equipment or

control panel on which the OMRON devices are installed. The customer must, therefore, perform

the final check to confirm that devices and the overall machine conform to EMC standards.

*1. Applicable EMC (Electromagnetic Compatibility) standards are as follows: EN 61131-2 and EN 61000-6-2 for EMS

(Electromagnetic Susceptibility), and EN 61131-2 and EN 61000-6-4 for EMI (Electromagnetic Interference).

EN 61000-6-4 (Radiated emission) is conformed based on 10-m regulations.

Low Voltage Directive

Devices operating at voltages of 50 to 1,000 VAC and 75 to 1,500 VDC must meet the required

safety standards. The applicable directive is EN 61131-2.

Conformance to EC Directives

*1

28

The NJ/NX-series Controllers comply with EC Directives. To ensure that the machine or device in

which the NJ/NX-series Controller is used complies with EC Directives, the Controller must be

installed as follows:

• The NJ/NX-series Controller must be installed within a control panel.

• You must use reinforced insulation or double insulation for the DC power supplies connected to

DC Power Supply Units and I/O Units.

• NJ/NX-series Controllers that comply with EC Directives also conform to the Common Emission

Standard (EN 61000-6-4). Radiated emission characteristics (10-m regulations) may vary

depending on the configuration of the control panel used, other devices connected, wiring, and

other conditions.

You must therefore confirm that the overall machine or equipment complies with EC Directives.

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

Page 31

Conformance to Shipbuilding Standards

This product complies with the different shipbuilding standards. Applicability to the shipbuilding

standards is based on certain usage conditions. It may not be possible to use the product in some

locations. Contact your OMRON representative before attempting to use a Controller on a ship.

Usage Conditions for NK and LR Shipbuilding Standards

• The NJ-series Controller must be installed within a control panel.

• Gaps in the door to the control panel must be completely filled or covered with gaskets or other material.

• The following noise filter must be connected to the power supply line.

Name Manufacturer Model

Noise Filter Cosel Co., Ltd. TAH-06-683

Regulations and Standards

Using Controllers in Robot Systems

The NJ501-4300/-4310/-4320/-4400/-4500 Controllers do not conform to laws and regulations relating

to the safety of industrial robot application.

When you use the NJ501-4300/-4310/-4320/-4400/-4500 Controllers in robot systems that uses industrial robots, be sure to verify the conformance to laws and regulations relating to the safety of industrial

robot application. Take measures to ensure safety as required.

Software Licenses and Copyrights

This product incorporates certain third party software. The license and copyright information associated

with this software is given in the web pages relating to the NJ501-1300/-1400/-1500 Controllers at

http://www.fa.omron.co.jp/nj_info_e/.

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

29

Page 32

Versions

Versions

Hardware and software upgrades relating to the NJ-series Units and EtherCAT slaves are managed

with the number called "unit version". If any change is made in specifications of hardware or software,

the unit version number is replaced. Even when Units or EtherCAT slaves have the same model

number, they will have differences in functions and performance if they have different unit versions.

Confirming Versions

You can confirm versions in the ID information indications on the product or with the Sysmac Studio.

Confirming Versions with ID Information Indications

The version is given on the ID information indication of the products.

The following figure shows the design of the ID information for NJ Robotics NJ501-4500 CPU Units.

Robot Version

ID information indication

Unit model Unit version

NJ501 - 4500

Ver.1.

Robot Ver.1.02

PORT1 MAC ADDRESS:

PORT2 MAC ADDRESS:

Lot No. DDMYY xxxx

MAC addressesLot number and serial number

30

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

Page 33

Versions

Confirming Versions with Sysmac Studio

You can use the Sysmac Studio to check the version. The procedure to check the versions differs

between a Unit and an EtherCAT slave.

Version of Units

The version of Units are given in the Production Information when the Sysmac Studio is online. You

can check the versions of the following Units: CPU Unit, CJ-series Special I/O Units, and CJ-series

CPU Bus Units. You cannot check the versions of CJ-series Basic I/O Units from the Sysmac Studio.

Use the following procedure.

1 Double-click CPU/Expansion Racks under Configurations and Setup in the Multiview

Explorer. Or, right-click CPU/Expansion Racks under Configurations and Setup and select

Edit from the menu.

The Unit Editor is displayed.

2 Right-click any open space in the Unit Editor and select Display Production Information.

The Production Information Dialog Box is displayed.

Changing Information Displayed in Production Information Dialog Box

1 Select either Show Outline or Show Detail on the lower right corner of the Production Informa-

tion Dialog Box.

The displayed information in the Production Information Dialog Box is switched between the

outline and detail.

Simple Display Detailed Display

The displayed items differ between the simple display and detailed display. The detailed display

gives the unit version, hardware version and software version. The simple display gives the unit version only.

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

31

Page 34

Versions

Version of EtherCAT Slaves

The version of EtherCAT slaves are given in the Production Information Dialog Box when the Sysmac Studio is online. Use the following procedure.

1 Double-click EtherCAT under Configurations and Setup in the Multiview Explorer. Or,

right-click EtherCAT under Configurations and Setup and select Edit from the menu.

The EtherCAT Tab Page is displayed.

2 Right-click the master in the EtherCAT Tab Page and select Display Production Information.

The Production Information Dialog Box is displayed.

The unit version is shown after "Rev".

32

NJ-series NJ Robotics CPU Unit User’s Manual (W539)

Page 35

Related Manuals

Related Manuals

The following manuals are related. Use these manuals for reference.

Manual name Cat. No. Model numbers Application Description

NJ-series CPU Unit Hardware User’s Manual

NJ/NX-series CPU Unit

Software User’s Manual

NJ/NX-series Instructions

Reference Manual

NJ/NX-series CPU Unit

Motion Control User’s Manual

NJ/NX-series Motion Control Instructions Reference

Manual

NJ/NX-series CPU Unit

Built-in EtherCAT® Port

User’s Manual

W500 NJ501-

NJ301-

NJ101-

W501 NX701-

NJ501-

NJ301-

NJ101-

W502 NX701-

NJ501-

NJ301-

NJ101-

W507 NX701-

NJ501-

NJ301-

NJ101-