Omron NJ501-*5 Series, NX701-16 Series, NJ501-*4 Series, NJ501-*3 Series, NJ301-12 Series Troubleshooting Manual

...Page 1

Machine Automation Controller

NJ/NX-series

Troubleshooting Manual

NX701-17

NX701-16

NX1P2-11

NX1P2-10

NX1P2-90

NJ501-5

NJ501-4

NJ501-3

NJ301-12

NJ301-11

NJ101-10

NJ101-90

W503-E1-18

Page 2

NOTE

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of the information contained in this publication.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan and other

countries for OMRON factory automation products.

• Microsoft, Windows, Windows Vista, Excel, and Visual Basic are either registered trademarks or trademarks of

Microsoft Corporation in the United States and other countries.

• EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

• ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

• The SD and SDHC logos are trademarks of SD-3C, LLC.

Other company names and product names in this document are the trademarks or registered trademarks of their

respective companies.

Copyrights

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Page 3

Introduction

Thank you for purchasing an NJ/NX-series CPU Unit.

This manual contains information that is necessary to use the NJ/NX-series CPU Unit. Please read this

manual and make sure you understand the functionality and performance of the NJ/NX-series CPU

Unit before you attempt to use it in a control system.

Keep this manual in a safe place where it will be available for reference during operation.

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and maintaining FA systems.

• Personnel in charge of managing FA systems and facilities.

For programming, this manual is intended for personnel who understand the programming language

specifications in international standard IEC 61131-3 or Japanese standard JIS B 3503.

Introduction

Applicable Products

This manual covers the following products.

• NX-series CPU Units

• NX701-17

• NX701-16

• NX1P2-11

• NX1P2-111

• NX1P2-10

• NX1P2-101

• NX1P2-90

• NX1P2-901

• NJ-series CPU Units

• NJ501-5

• NJ501-4

• NJ501-3

• NJ301-12

• NJ301-11

• NJ101-10

• NJ101-90

Part of the specifications and restrictions for the CPU Units are given in other manuals. Refer to Relevant Manuals on page 2 and Related Manuals on p age 21.

NJ/NX-series Troubleshooting Manual (W503)

1

Page 4

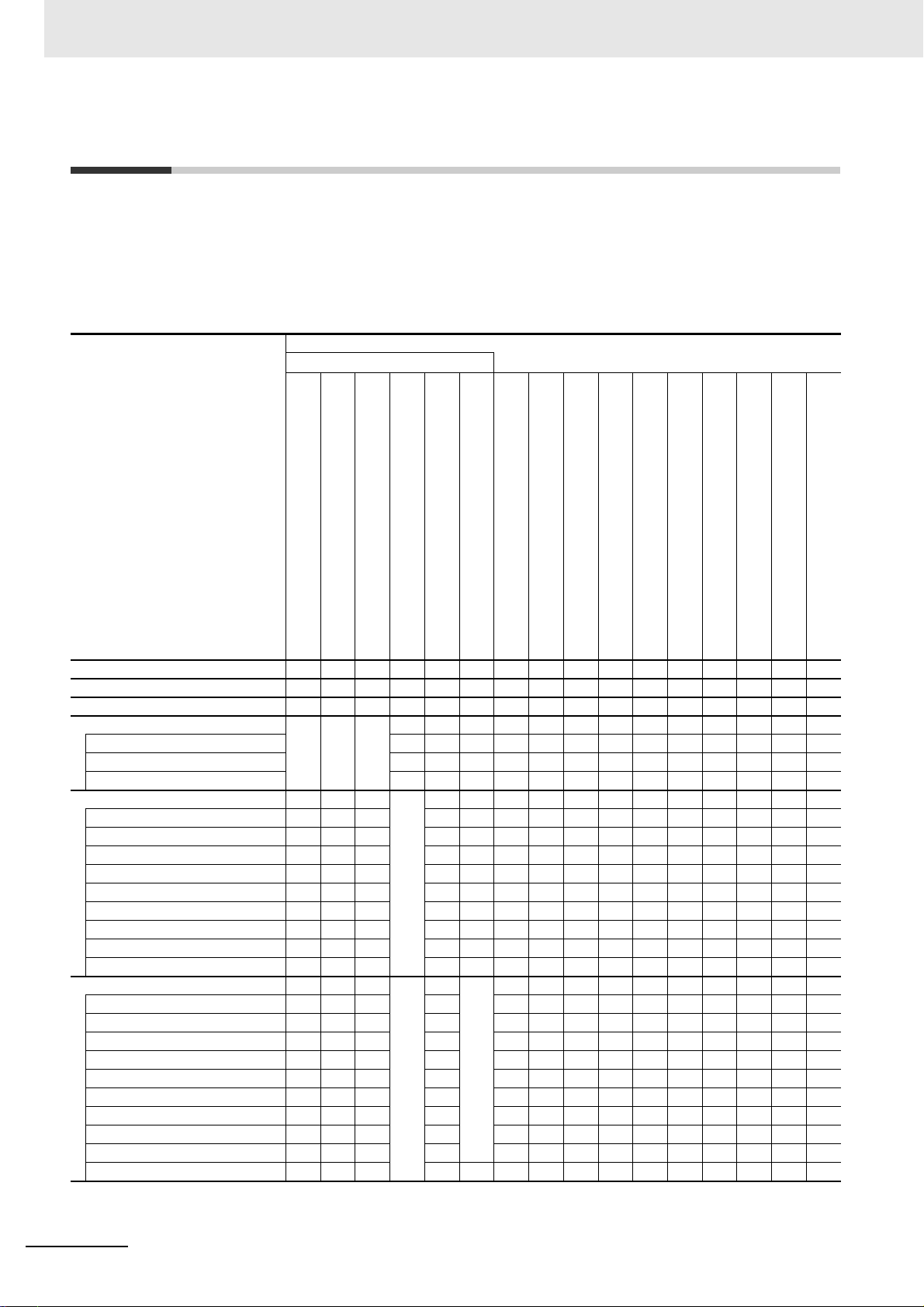

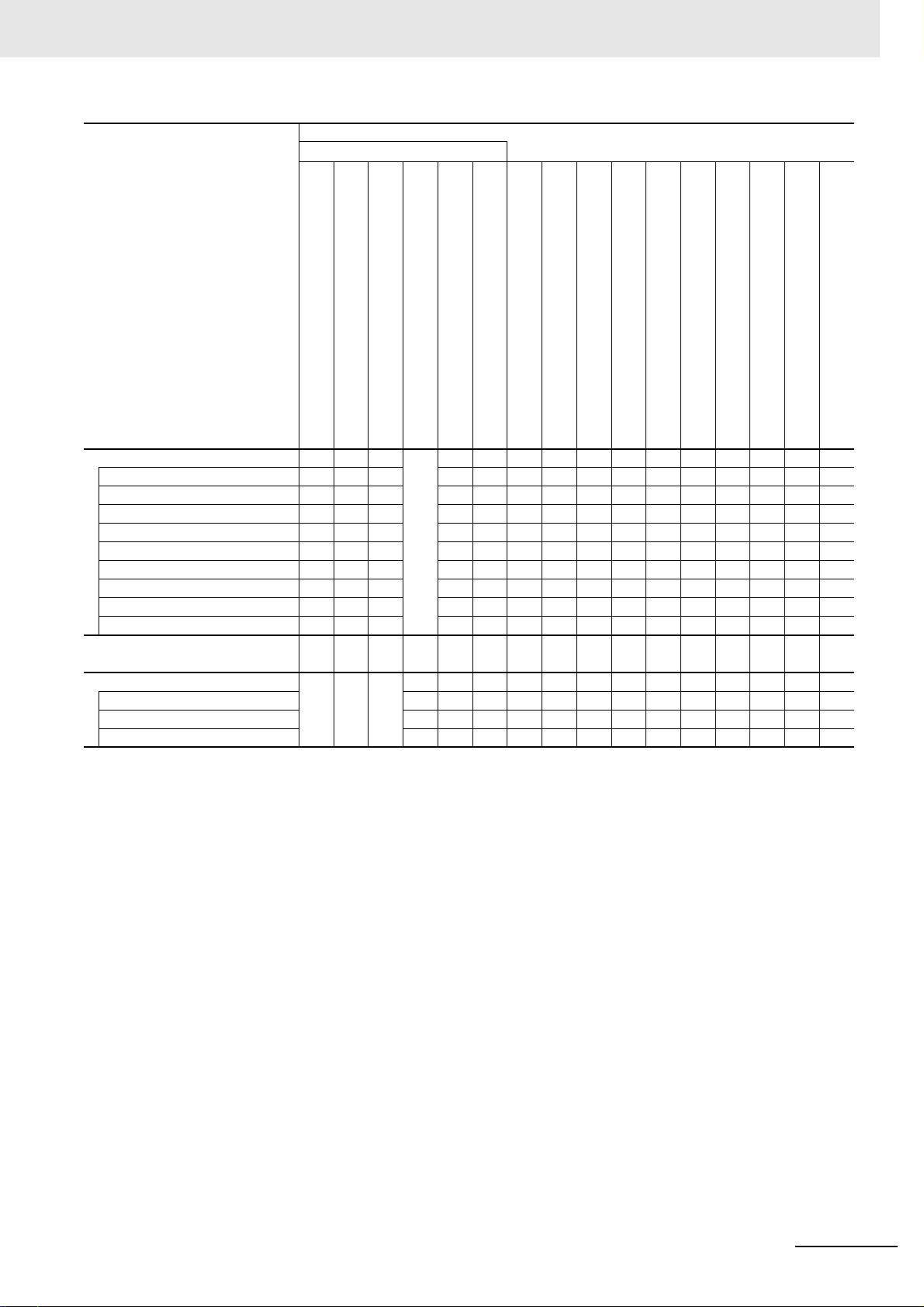

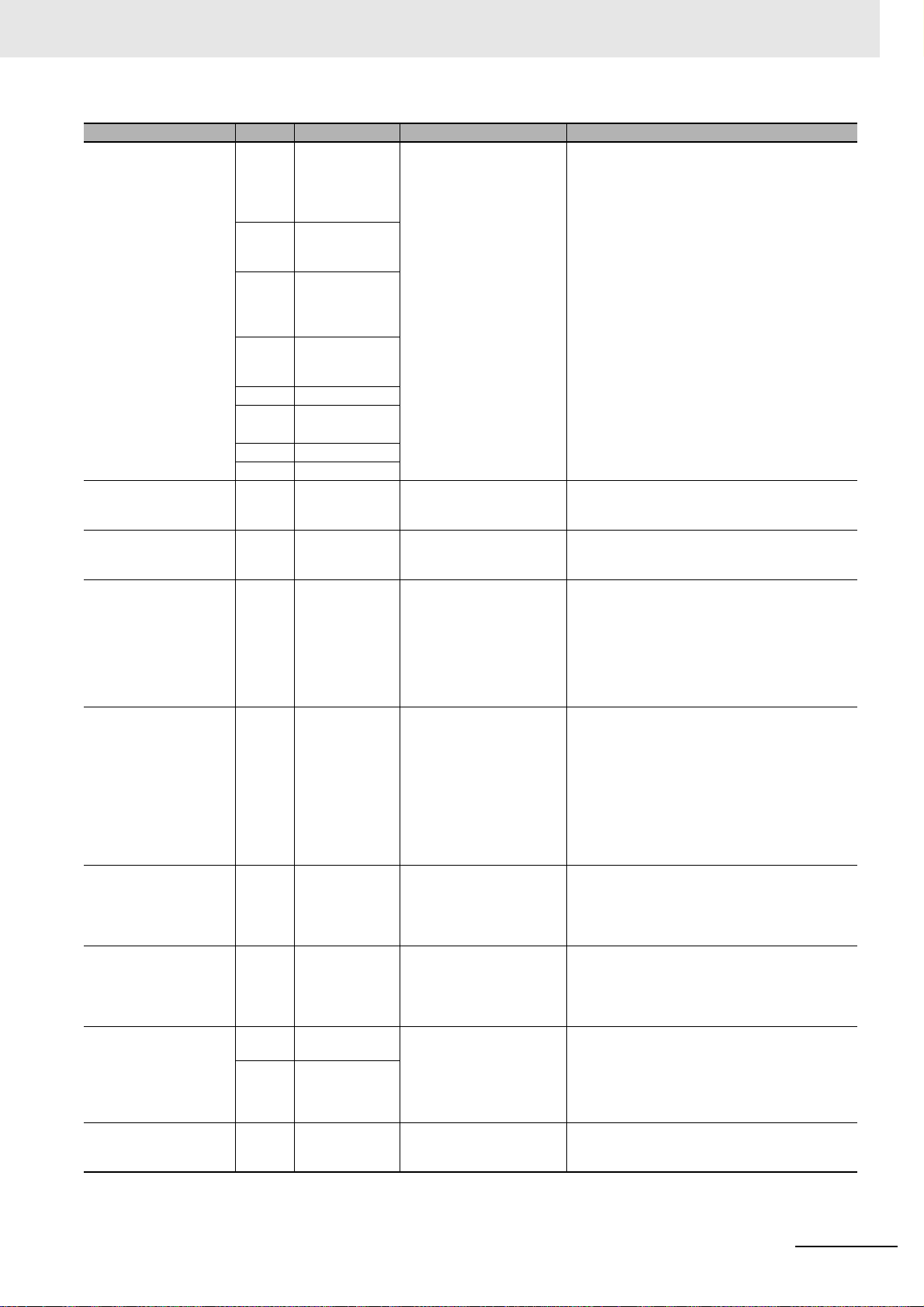

Relevant Manuals

Relevant Manuals

The following table provides the relevant manuals for the NJ/NX-series CPU Units.

Read all of the manuals that are relevant to your system configuration and application before you use

the NJ/NX-series CPU Unit.

Most operations are performed from the Sysmac Studio Automation Soft ware. Refer to the Sysmac Stu-

dio Version 1 Operation Manual (Cat. No. W504) for information on the Sysmac Studio.

Basic information

NX-series CPU Unit

Hardware User’s Manual

NX-series NX1P2 CPU Unit

Hardware User's Manual

Hardware User’s Manual

Manual

NJ-series CPU Unit

NJ/NX-series CPU Unit

Software User’s Manual

NX-series NX1P2 CPU Unit

Built-in I/O and Option Board User's Manual

NJ/NX-series

Instructions Reference Manual

Motion Control User’s Manual

NJ/NX-series CPU Unit

Motion Control Instructions Reference Manual

NJ/NX-series

NJ/NX-series CPU Unit

Built-in EtherCAT Port User’s Manual

Built-in EtherNet/IP Port User’s Manual

NJ/NX-series CPU Unit

NJ-series CPU Unit OPC UA

User’s Manual

NJ/NX-series Database Connection CPU Units

User’s Manual

NJ-series SECS/GEM CPU Units

User’s Manual

NJ-series NJ Robotics

CPU Unit User’s Manual

NJ/NY-series NC Integrated Controller

User’s Manual

NJ/NX-series

Troubleshooting Manual

Purpose of use

Introduction to NX701 CPU Units

Introduction to NX1P2 CPU Units

Introduction to NJ-series Controllers

Setting devices and hardware

Using motion control

Using EtherCAT

Using EtherNet/IP

Software settings

Using motion control

Using EtherCAT

Using EtherNet/IP

Using OPC UA

Using the database connection service

Using the GEM Services

Using robot control

Using numerical control

Using the NX1P2 CPU Unit functions

Writing the user program

Using motion control

Using EtherCAT

Using EtherNet/IP

Using OPC UA

Using the database connection service

Using the GEM Services

Using robot control

Using numerical control

Programming error processing

Using the NX1P2 CPU Unit functions

2

NJ/NX-series Troubleshooting Manual (W503)

Page 5

Relevant Manuals

Manual

Basic information

NX-series CPU Unit

Hardware User’s Manual

Purpose of use

Testing operation and debugging

Using motion control

Using EtherCAT

Using EtherNet/IP

Using OPC UA

Using the database connection service

Using the GEM Services

Using robot control

Using numerical control

Using the NX1P2 CPU Unit functions

Learning about error management

and corrections

Maintenance

Using motion control

Using EtherCAT

Using EtherNet/IP

*1

NX-series NX1P2 CPU Unit

Hardware User's Manual

NJ-series CPU Unit

Hardware User’s Manual

NJ/NX-series CPU Unit

Software User’s Manual

NX-series NX1P2 CPU Unit

Built-in I/O and Option Board User's Manual

NJ/NX-series

Instructions Reference Manual

Motion Control User’s Manual

NJ/NX-series CPU Unit

Motion Control Instructions Reference Manual

NJ/NX-series

NJ/NX-series CPU Unit

Built-in EtherCAT Port User’s Manual

Built-in EtherNet/IP Port User’s Manual

NJ/NX-series CPU Unit

NJ-series CPU Unit OPC UA

User’s Manual

User’s Manual

NJ/NX-series Database Connection CPU Units

NJ-series SECS/GEM CPU Units

User’s Manual

CPU Unit User’s Manual

NJ-series NJ Robotics

User’s Manual

NJ/NY-series NC Integrated Controller

Troubleshooting Manual

NJ/NX-series

*1 Refer to the NJ/NX-series Troubleshooting Manual (Cat. No. W503) for the error management concepts and an overview of the error

items. Refer to the manuals that are indicated with triangles for details on errors for the corresponding Units.

NJ/NX-series Troubleshooting Manual (W503)

3

Page 6

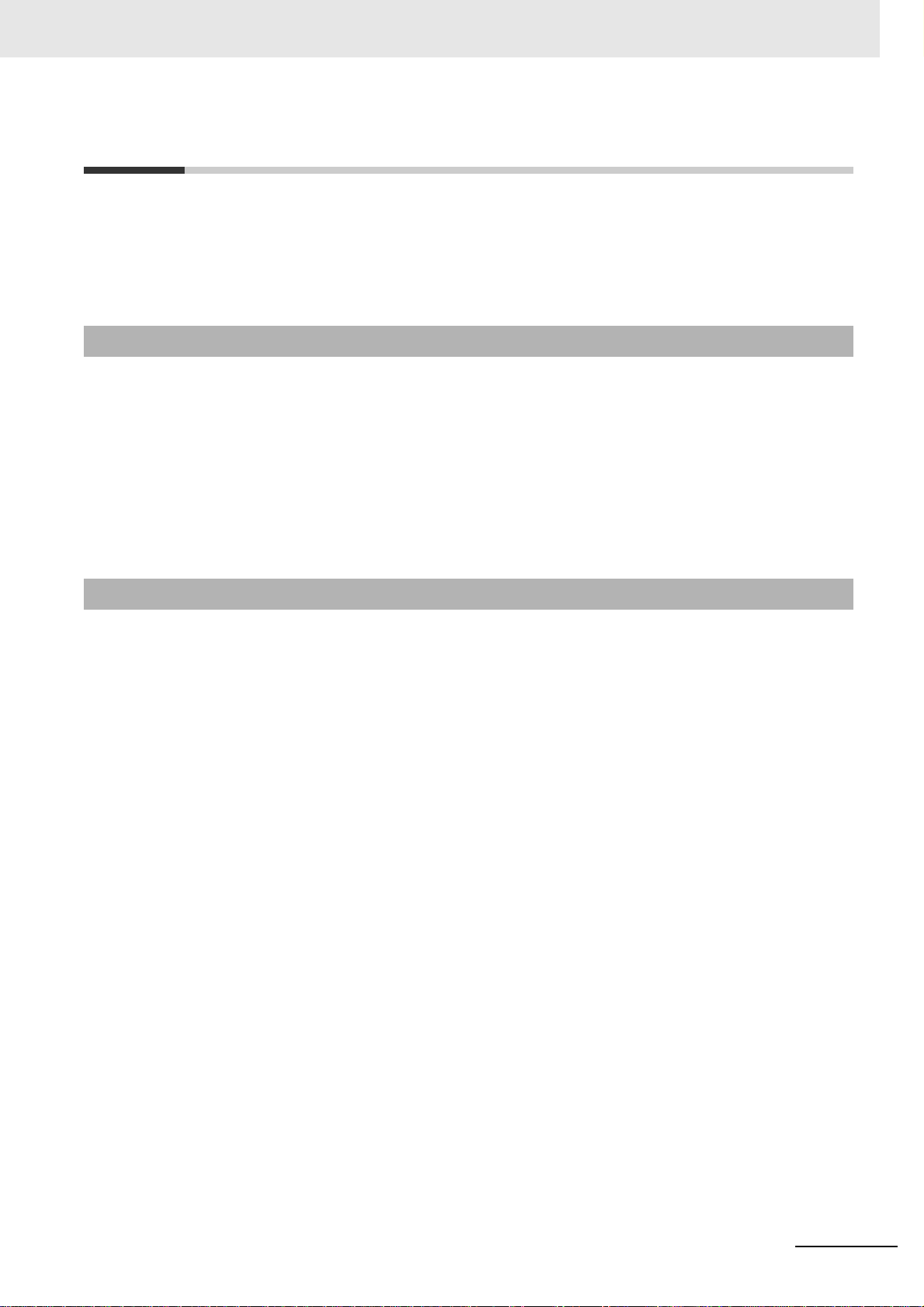

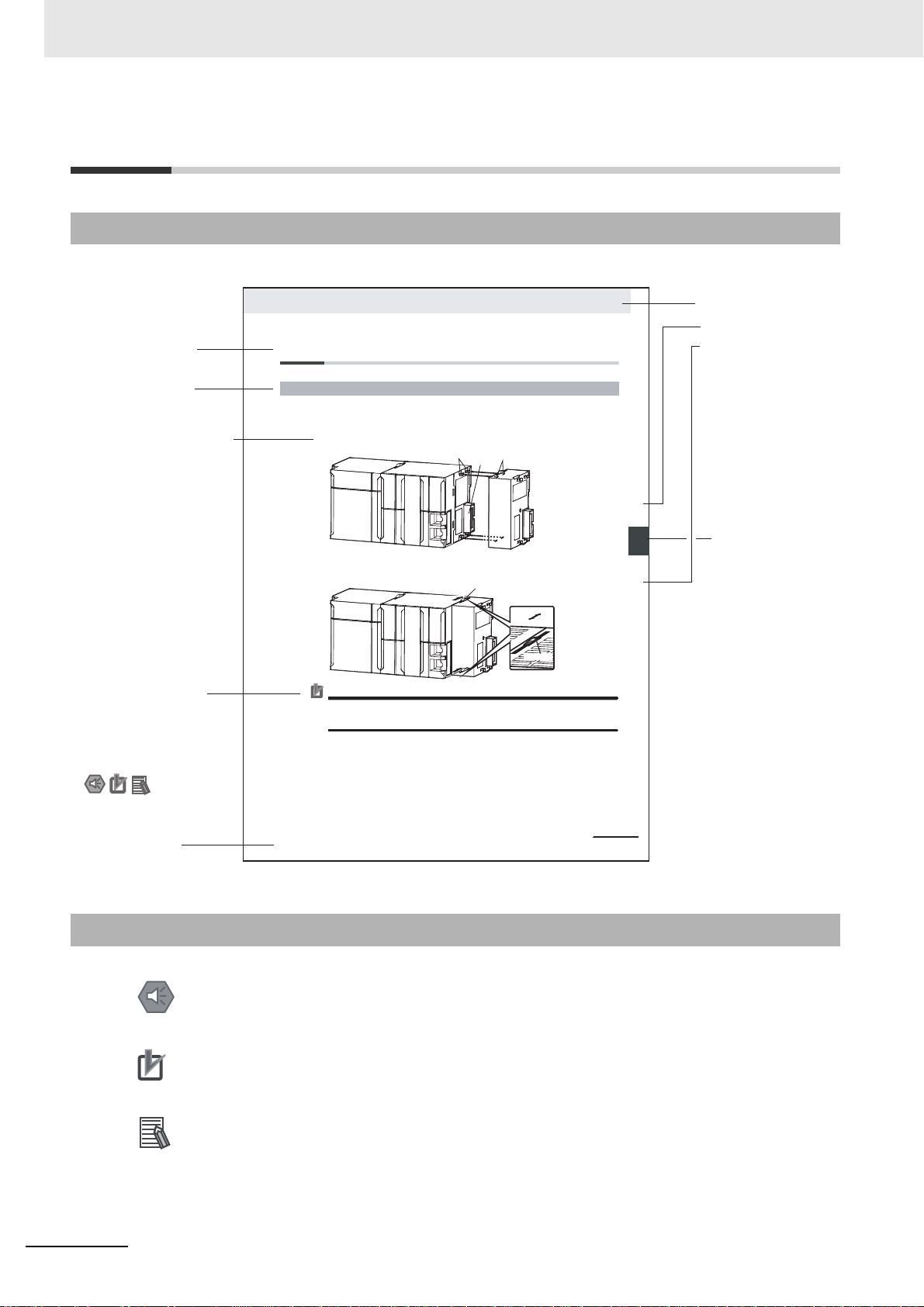

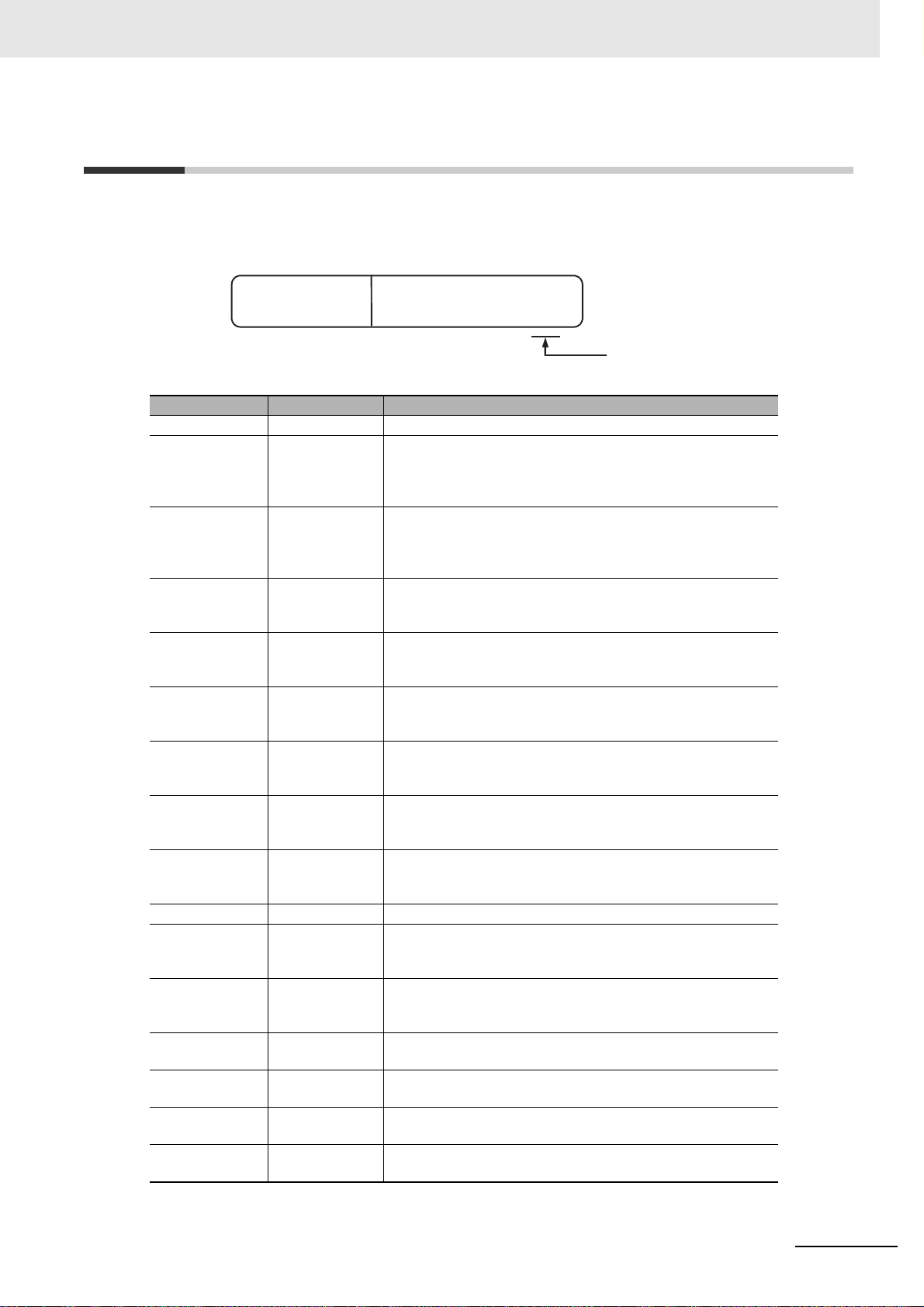

Manual Structure

4-9

4 Installation and Wiring

NJ-series CPU Unit Hardware User’s Manual (W500)

stinU gnitnuoM 3-4

4

stnenopmoC rellortnoC gnitcennoC 1-3-4

4-3 Mounting Units

The Units that make up an NJ-series Controller can b e co nn ec te d si m pl y b y p re s si n g t h e U n i t s t o g e t h e r

and locking the sliders by moving them toward the bac k o f th e U nit s . T he End Co ver is connect ed i n t he

same way to the Unit on the far right side of the Controller.

1 Join the Units so that the connectors fit exactly.

2 The yellow sliders at the top and bottom of each Unit lock the Units together. Move the sliders

toward the back of the Units as shown below until they click into place.

Precautions for Correct UsePrecautions for Correct Use

4-3-1 Connecting Controller Components

Connector

Hook

Hook holes

Slider

Lock

Release

Move the sliders toward the back

until they lock into place.

Level 1 heading

Level 2 heading

Level 3 heading

Level 2 heading

A step in a procedure

Manual name

Special information

Level 3 heading

Page tab

Gives the current

headings.

Indicates a procedure.

Icons indicate

precautions, additional

information, or reference

information.

Gives the number

of the main section.

This illustration is provided only as a sample. It may not literally appear in this manual.

The sliders on the tops and bottoms of the Power Supply Unit, CPU Unit, I/O Units, Special I/O

Units, and CPU Bus Units must be completely locked (until they click into place) after connecting

the adjacent Unit connectors.

Manual Structure

Page Structure

The following page structure is used in this manual.

Special Information

Special information in this manual is classified as follows:

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

4

Note References are provided to more detailed or related information.

NJ/NX-series Troubleshooting Manual (W503)

Page 7

Precaution on Terminology

In this manual, “download” refers to transferring data from the Sysmac Studio to the physical Controller

and “upload” refers to transferring data from the physical Controller to the Sysmac Studio.

For the Sysmac Studio , synchronization is used to both upload and download data . Here, “synchronize”

means to automatically compare the data for the Sysmac Studio on the computer with the data in the

physical Controller and transfer the data in the direction that is specified by the user.

Manual Structure

NJ/NX-series Troubleshooting Manual (W503)

5

Page 8

Manual Structure

6

NJ/NX-series Troubleshooting Manual (W503)

Page 9

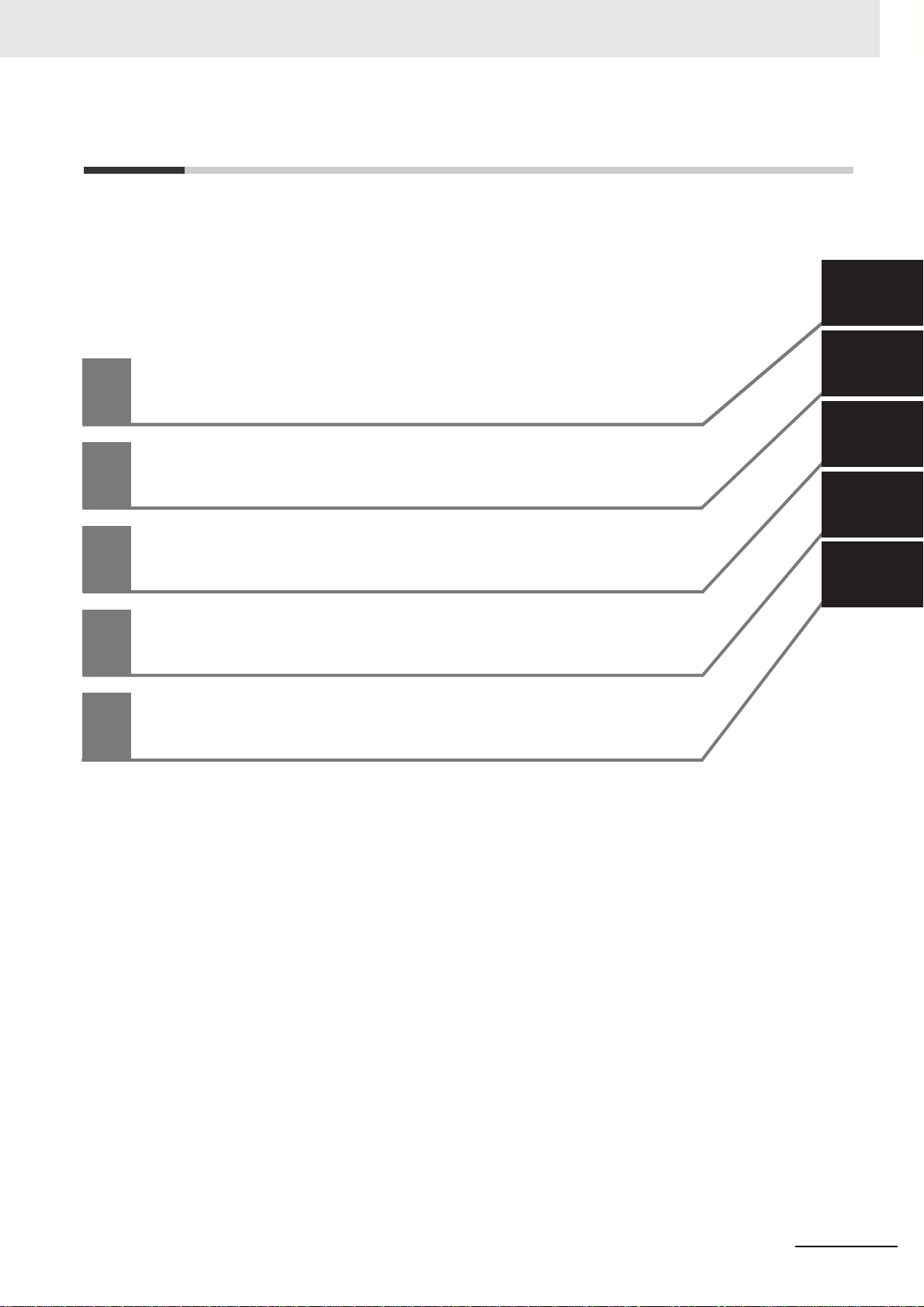

Sections in this Manual

1

2

3

1

2

3

A

Overview of Errors

Error Troubleshooting Methods

Error Tables

Appendix

A

I

Index

I

Sections in this Manual

NJ/NX-series Troubleshooting Manual (W503)

7

Page 10

CONTENTS

CONTENTS

Introduction ...............................................................................................................1

Relevant Manuals......................................................................................................2

Manual Structure.......................................................................................................4

Sections in this Manual ............................................................................................7

Terms and Conditions Agreement.........................................................................10

Safety Precautions..................................................................................................12

Precautions for Safe Use........................................................................................13

Precautions for Correct Use...................................................................................14

Regulations and Standards....................................................................................15

Versions ...................................................................................................................17

Related Manuals......................................................................................................21

Revision History......................................................................................................25

Section 1 Overview of Errors

1-1 Overview of NJ/NX-series Errors ........................................................................................... 1-2

1-1-1 Types of Errors............................................................................................................................1-3

1-1-2 CPU Unit Status..........................................................................................................................1-4

1-2 Fatal Errors...............................................................................................................................1-7

1-2-1 Types of Fatal Errors...................................................................................................................1-7

1-2-2 Checking for Fatal Errors........................... .................................................................................1-8

1-3 Non-fatal Errors .......................................................................................................................1-9

1-3-1 Types of Non-fat al Errors............................................... ... .................................... ......................1-9

1-3-2 Checking for Non-fatal Errors....................................................................................................1-19

1-3-3 Resetting Non-fatal Errors.........................................................................................................1-22

Section 2 Error Troubleshooting Methods

2-1 Troubleshooting Flowcharts...................................................................................................2-2

2-1-1 Checking to See If the CPU Unit Is Operating............................................................................2-2

2-1-2 Troubleshooting Flowchart for Non-fatal Errors ..........................................................................2-4

2-2 Troubleshooting Fatal Errors .................................................................................................2-5

2-3 Troubleshooting Non-fatal Errors.......................................................................................... 2-7

2-3-1 Identifying and Resetting Errors with the Sysmac Studio............................................................2-7

2-3-2 Identifying and Resetting Errors with an HMI............................................................................2-11

2-3-3 Identifying and Resetting Errors from the User Program..........................................................2-14

2-3-4 Checking for Errors with System-defined Variables..................................................................2-16

2-4 Troubleshooting When You Cannot Go Online from the Sysmac Studio ........................2-18

2-4-1 Causes and Correction When You Cannot Go Online from the Sysmac Studio.......................2-18

2-4-2 Troubleshooting for Each Cause...............................................................................................2-20

8

NJ/NX-series Troubleshooting Manual (W503)

Page 11

CONTENTS

Section 3 Error Tables

3-1 Errors by Source ............................................... .... ... .......................................... ... ... ... ............ 3-2

3-1-1 Interpreting Error Descriptions.................................................................................................... 3-2

3-1-2 Errors in the PLC Function Module............................................................................................. 3-2

3-1-3 Errors in the NX Bus Function Module ......... ... ......................................................................... 3-61

3-1-4 Errors in the Motion Control Function Module..........................................................................3-64

3-1-5 Errors in the EtherNet/IP Function Module...............................................................................3-95

3-1-6 Errors in the EtherCAT Master Function Module......................................................................3-99

3-1-7 Errors in OPC UA................................................................................................................... 3-104

3-1-8 Errors in the DB Connection Service Function ....................................................................... 3-108

3-1-9 Errors in GEM Services................................................................. ..........................................3-114

3-1-10 Errors in Robot Control Function.............................................................................................3-119

3-1-11 Errors in CNC Fu nction...........................................................................................................3-134

3-1-12 Errors in Slave Terminals........................................................................................................ 3-150

3-1-13 Errors in EtherCAT Slaves...................................................................................................... 3-190

3-1-14 Errors in CJ-series Units.........................................................................................................3-223

3-2 An Error Log Table for CJ-series Special Units................................................................ 3-243

3-3 Events in Order of Event Codes.........................................................................................3-248

3-3-1 Interpreting Error Descriptions................................................................................................ 3-248

3-3-2 Error Table..............................................................................................................................3-249

3-4 Instruction Error Table......................... .... ... ... ... .... ... ... .......................................... ... ... .... .... 3-296

Appendix

Index

A-1 Applicable Range of the HMI Troubleshooter.......................................................................A-2

A-1-1 Combinations of HMIs and CPU Units That Enable Using the Troubleshooter..........................A-2

A-1-2 System Configuration Elements Supported by the Troubleshooter ............................................A-3

A-2 Correspondence of NX Bus Events between NX1P2 CPU Units and Slave Terminals.....A-4

NJ/NX-series Troubleshooting Manual (W503)

9

Page 12

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship for a period of twelve months from the date of sale by Omro n (or such other period expr essed in

writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron ’s election, to (i) replace (in the form o rig inal ly

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be

responsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of

any Products by Buyer must be approved in writing by Omron before shipment. Omron Companies

shall not be liable for the suitability or unsuitability or the results from the use of Products in combination with any electrical or electronic components, circuits, system assemblies or any other materials or substances or environments. Any advice, recommendations or information given orally or in

writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

10

NJ/NX-series Troubleshooting Manual (W503)

Page 13

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings

and limitations of use which apply to the Product. This information by itself is not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine, system, or other application or use. Buyer shall be solely responsible for determining appropriateness of

the particular Product with respect to Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Terms and Conditions Agreement

Programmable Products

Omron Companies shall not be responsib le for the user’s progr amming of a pr ogra mmab le Pr od uct, o r

any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual performance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and other

reasons. It is our practice to change part numbers when published ratings or features are chan ged, or

when significant construction changes are made. However, some specifications of the Product may be

changed without any notice. When in doubt, special part numbers may be assigned to fix or establish

key specifications for your application. Please consult with your Omron’s representative at any time to

confirm actual specifications of purchased Product.

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

NJ/NX-series Troubleshooting Manual (W503)

11

Page 14

Safety Precautions

Safety Precautions

Refer to the following manuals for safety precautions.

• NX-series CPU Unit Hardware User’s Manual (Cat. No. W535)

• NX-series NX1P2 CPU Unit Hardware User’s Manual (Cat. No. W578)

• NJ-series CPU Unit Hardware User’s Manual (Cat No. W500)

12

NJ/NX-series Troubleshooting Manual (W503)

Page 15

Precautions for Safe Use

Refer to the following manuals for precautio ns for th e sa fe use of the NJ/NX-series Controller.

Installation precautions are also provided for the NJ/NX-series CPU Unit and the NJ/NX-series Controller system.

• NX-series CPU Unit Hardware User’s Manual (Cat. No. W535)

• NX-series NX1P2 CPU Unit Hardware User’s Manual (Cat. No. W578)

• NJ-series CPU Unit Hardware User’s Manual (W500)

Precautions for Safe Use

NJ/NX-series Troubleshooting Manual (W503)

13

Page 16

Precautions for Correct Use

Precautions for Correct Use

Refer to the following manuals for precautions for the correct use of the NJ/NX-series Controller.

Installation precautions are also provided for th e NJ/NX-series CPU Unit and the NJ/NX-series Controller system.

• NX-series CPU Unit Hardware User’s Manual (Cat. No. W535)

• NX-series NX1P2 CPU Unit Hardware User’s Manual (Cat. No. W578)

• NJ-series CPU Unit Hardware User’s Manual (W500)

14

NJ/NX-series Troubleshooting Manual (W503)

Page 17

Regulations and Standards

Conformance to EU Directives

Applicable Directives

• EMC Directives

• Low Voltage Directive

Concepts

EMC Directive

OMRON devices that comply with EU Directives also conform to the related EMC standards so that

they can be more easily built into other devices or the overall machine. The actual products have

been checked for conformity to EMC standards.*

Whether the products conform to the standards in the system used by the customer, however, must

be checked by the customer. EMC-related performance of the OMRON devices th at comply with EU

Directives will vary depending on the configuration, wiring, and other conditions of the equipment or

control panel on which the OMRON devices are installed. The customer mu st, therefore, perform

the final check to confirm that devices and the overall machine conform to EMC standards.

* Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN 61131-2

EMI (Electromagnetic Interference): EN 61131-2 (Radiated emission: 10-m regulations)

Regulations and Standards

Low Voltage Directive

Always ensure that devices operating at voltag es of 50 to 1,00 0 VAC and 75 to 1,500 VDC meet the

required safety standards. The applicable directive is EN 61010-2-201.

Conformance to EU Directives

The NJ/NX-series Controllers comply with EU Directives. To ensure that the machine or device in

which the NJ/NX-series Controller is used complies with EU Directives, the Controller must be

installed as follows:

• The NJ/NX-series Controller must be installed within a control panel.

• You must use the power supply in SELV specifications for the DC power supplies connected to

DC Power Supply Units and I/O Units.

• NJ/NX-series Controllers that comply with EU Directives also conform to the Common Emission

Standard (EN 61000-6-4). Radiated emission characteristics (10-m regulations) may vary

depending on the configuration of the control panel used, other devices connected to the control

panel, wiring, and other conditions.

You must therefore confirm that the overall machine or equipment complies with EU Directives.

NJ/NX-series Troubleshooting Manual (W503)

15

Page 18

Regulations and Standards

Conformance to KC Standards

Observe the following precaution if you use NX-series Units in Korea.

Class A Device (Broadcasting Communications Device for Office Use)

This device obtained EMC registration for office use (Class A), and it is intended to be used in places

other than homes.

Sellers and/or users need to take note of this.

Conformance to Shipbuilding Standards

The NJ/NX-series Controllers comply with the following shipbuilding standards. Applicability to the

shipbuilding standards is based on certain usage conditions. It may not be possible to use the product in some locations. Contact your OMRON represent ative before a ttempting to use a Contro ller on

a ship.

Usage Conditions for NK and LR Shipbuilding Standards

• The NJ/NX-series Controller must be installed within a control panel.

• Gaps in the door to the control panel must be completely filled or covered with gaskets or other

material.

• The following noise filter must be connected to the power supply line.

Noise Filter

Manufacturer Model

Cosel Co., Ltd. TAH-06-683

Software Licenses and Copyrights

This product incorporates certain third party software. The license and copyright information associated with this software is available at http://www.fa.omron.co.jp/nj_info_e/.

16

NJ/NX-series Troubleshooting Manual (W503)

Page 19

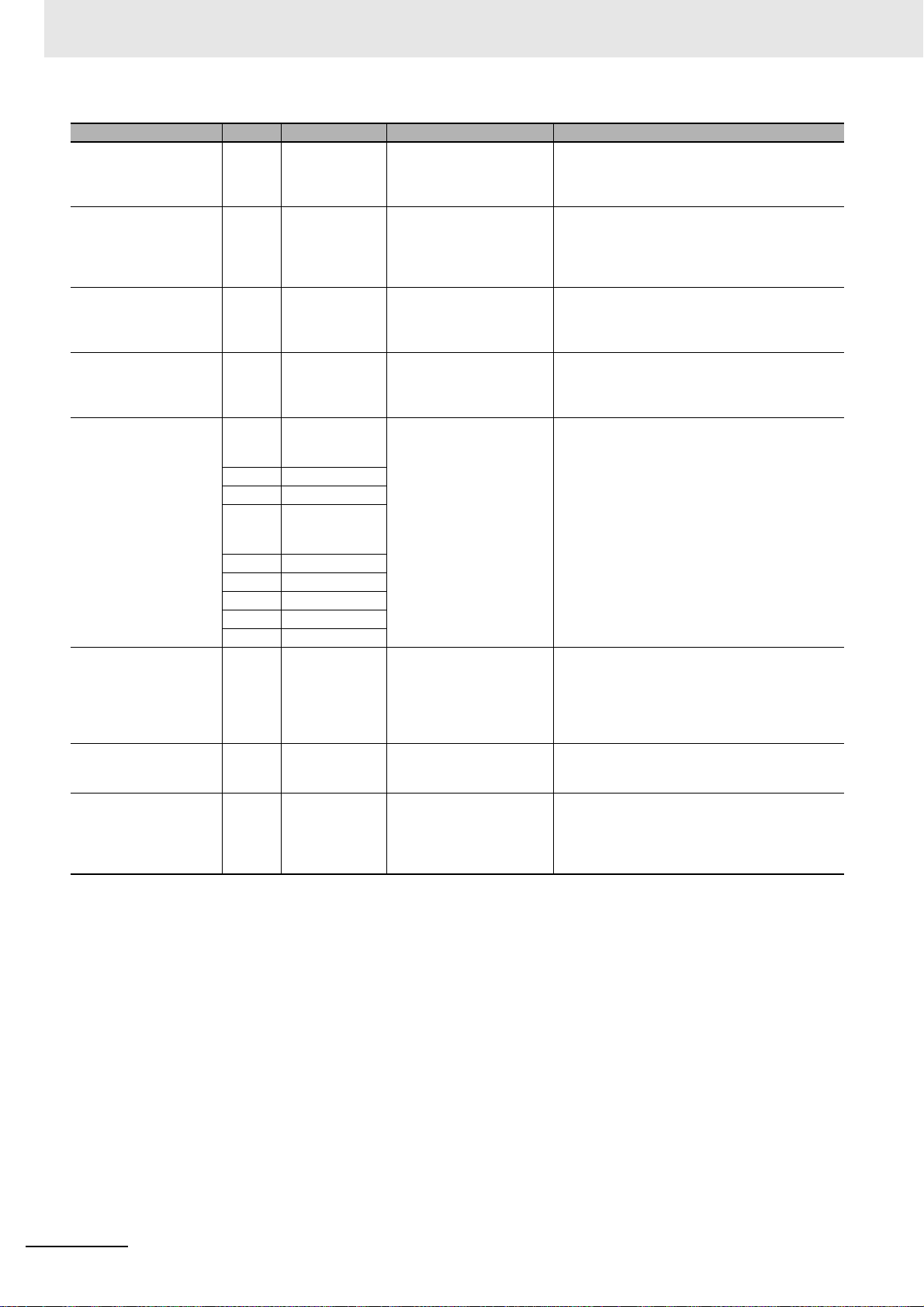

Versions

ID information indication

Lot number Serial number Unit version

MAC address Hardware revision

LOT No. DDMYY xxxx Ver.1.

PORT1 : HW Rev.

PORT2 :

PORT1 :

PORT2 :

Ver.1. HW Rev.

LOT No. DDMYY xxxx

ID information indication

Lot number Serial number

Unit version

MAC address

Hardware

revision

Hardware revisions and unit versions are used to manage the hardware and software in NJ/NX-series

Units and EtherCAT slaves. The hardware revision or unit version is updated each time there is a

change in hardware or software specifications. Even when two Units or EtherCAT slaves have the

same model number, they will have functional or performance differences if they have different hardware revisions or unit versions.

Checking Versions

You can check versions on the ID information indications or with the Sysmac Studio.

Checking Unit Versions on ID Information Indications

The unit version is given on the ID information indication on the side of the product.

The ID information on an NX-series NX701- CPU Unit is shown below.

Versions

Note The hardware revision is not displayed for the Unit that the hardware revision is in blank.

The ID information on an NX-series NX1P2- CPU Unit is shown below.

Note The hardware revision is not displayed for the Unit that the hardware revision is in blank.

NJ/NX-series Troubleshooting Manual (W503)

17

Page 20

Versions

ID information indication

Unit model

Lot number Serial number MAC address

Unit version Hardware revision

NJ501

-

Ver.1.

PORT1 MAC ADDRESS:

PORT2 MAC ADDRESS:

Lot No. DDMYY

xxxx

HW Rev.

The ID information on an NJ-series NJ501- CPU Unit is shown below.

Note The hardware revision is not displayed for the Unit that the hardware revision is in blank.

Checking Unit Versions with the Sysmac Studio

You can use the Sysmac Studio to check unit versions. The procedure is different for Units and for EtherCAT slaves.

Checking the Unit Version of an NX-series CPU Unit

You can use the Production Information while the Sysmac Studio is online to check the unit version

of a Unit. You can do this for the CPU Unit. For an NX1P2 CPU Unit, you can also check the unit

versions of the NX Units on the CPU Rack and Option Boards.

1 Right-click CPU Rack under Configurations and Setup − CPU/Expansion Racks in the

Multiview Explorer and select Production Information.

The Production Information Dialog Box is displayed.

Checking the Unit Version of an NJ-series CPU Unit

You can use the Production Information while the Sysmac Studio is online to check the unit version

of a Unit. You can do this for the CPU Unit, CJ-series Special I/O Units, and CJ-series CPU Bus

Units. You cannot check the unit versions of CJ-series Basic I/O Units with the Sysmac Studio.

Use the following procedure to check the unit version.

18

1 Double-click CPU/Expansion Racks under Configurations and Setup in the Multiview

Explorer. Or, right- click CPU/Expansion Racks under Configurations and Setup and select

Edit from the menu.

The Unit Editor is displayed.

2 Right-click any open space in the Unit Editor and select Production Information.

The Production Information Dialog Box is displayed.

NJ/NX-series Troubleshooting Manual (W503)

Page 21

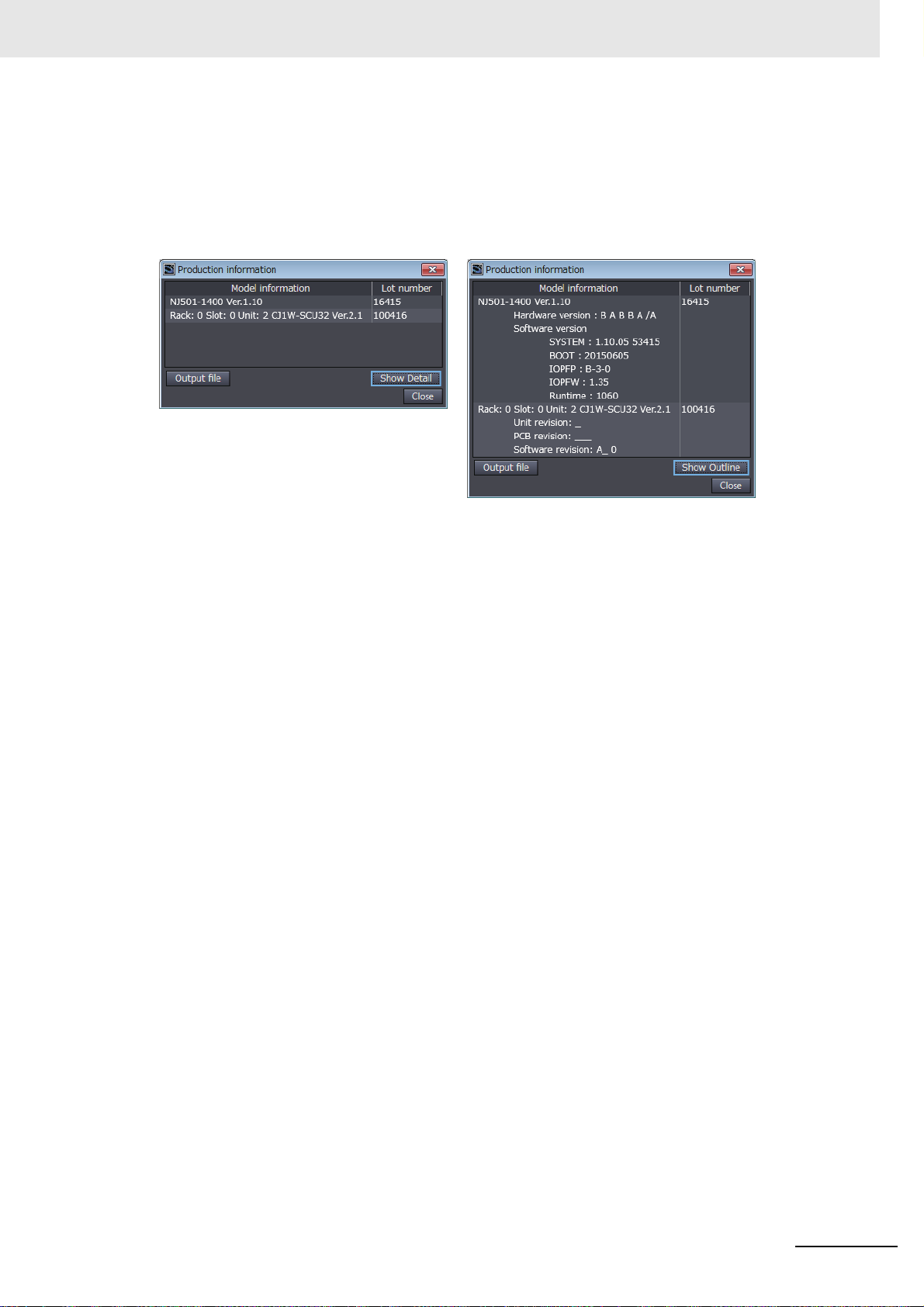

Versions

Changing Information Displayed in Production Information Dialog Box

1 Click the Show Detail or Show Outline Button at the lower right of the Production Information

Dialog Box.

The view will change between the production information details and outline.

Outline View Detail View

The information that is displayed is different for the Outline View and Detail View. The Detail View

displays the unit version, hardware version, and software versions. The Outline View displays only

the unit version.

Note The hardware revision is separated by “/” and displayed on the right of the hardware versio n. The hardware

revision is not displayed for the Unit that the hardware revision is in blank.

Checking the Unit Version of an EtherCAT Slave

You can use the Production Information while the Sysmac Studio is online to check the unit version

of an EtherCAT slave. Use the following procedure to check the unit version.

1 Double-click EtherCAT under Configurations and Setup in the Multiview Explorer. Or, right-

click EtherCAT under Configurations and Setup and select Edit from the menu.

The EtherCAT Tab Page is displa ye d.

2 Right-click the master on the EtherCAT Tab Page and select Display Production Information.

The Production Information Dialog Box is displayed.

The unit version is displayed after “Rev.”

NJ/NX-series Troubleshooting Manual (W503)

19

Page 22

Versions

Changing Information Displayed in Production Information Dialog Box

1 Click the Show Detail or Show Outline Button at the lower right of the Production Information

Dialog Box.

The view will change between the production information details and outline.

Outline View Detail View

Unit Versions of CPU Units and Sysmac Studio Versions

The events that can occur depend on the unit versions of the NJ/NX-series CPU Unit, the EtherCAT

slaves, and the NX Units. You must use the corresponding version of Sysmac Studio to display events

that were added for version upgrades when troubleshooting from the Sysmac Studio or from the Troubleshooter on an HMI. Refer to the product manuals for information on the unit versions of the CPU

Unit, EtherCAT slaves, and NX Units, and for the relationship with the version of the Sysmac Studio.

20

NJ/NX-series Troubleshooting Manual (W503)

Page 23

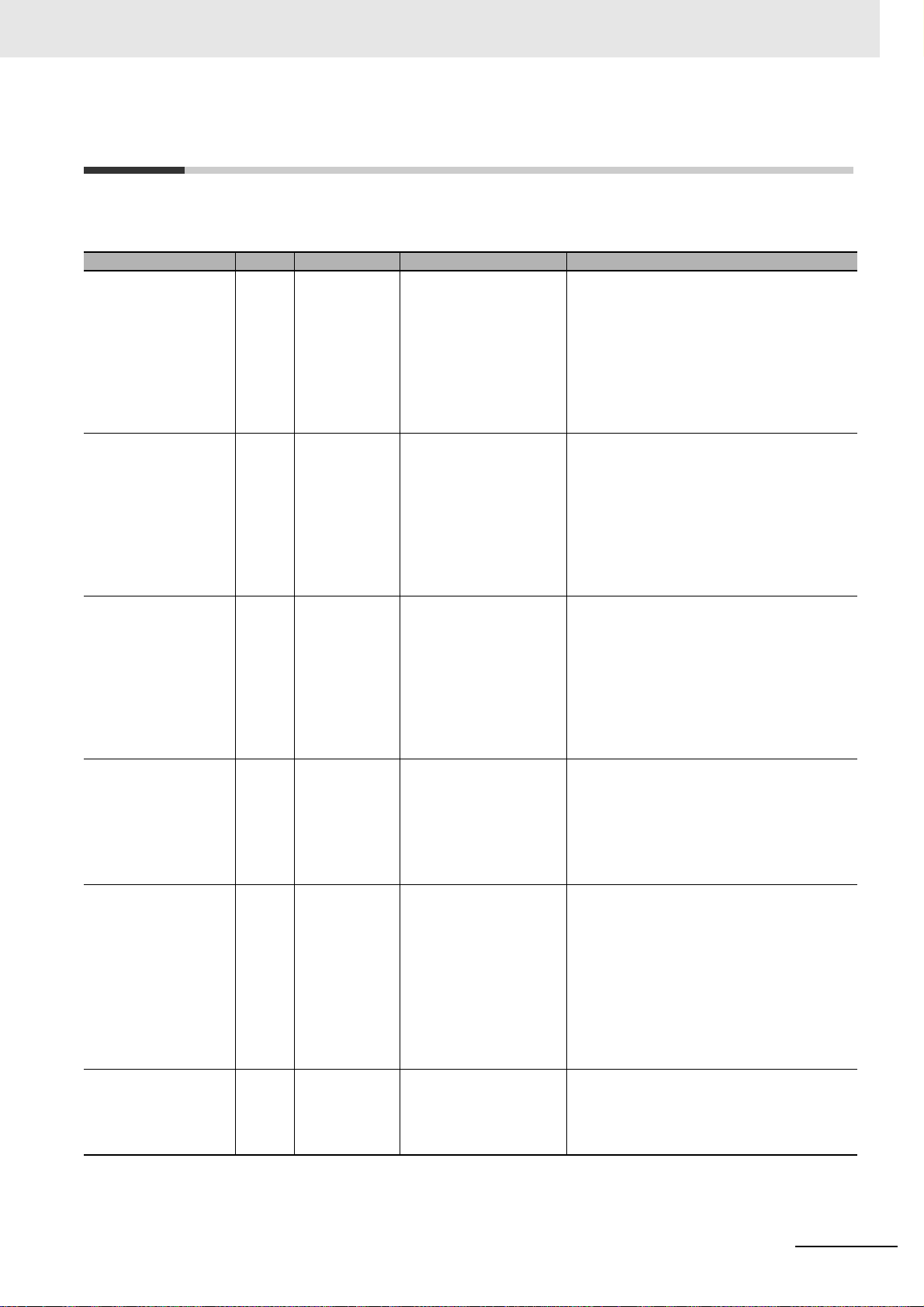

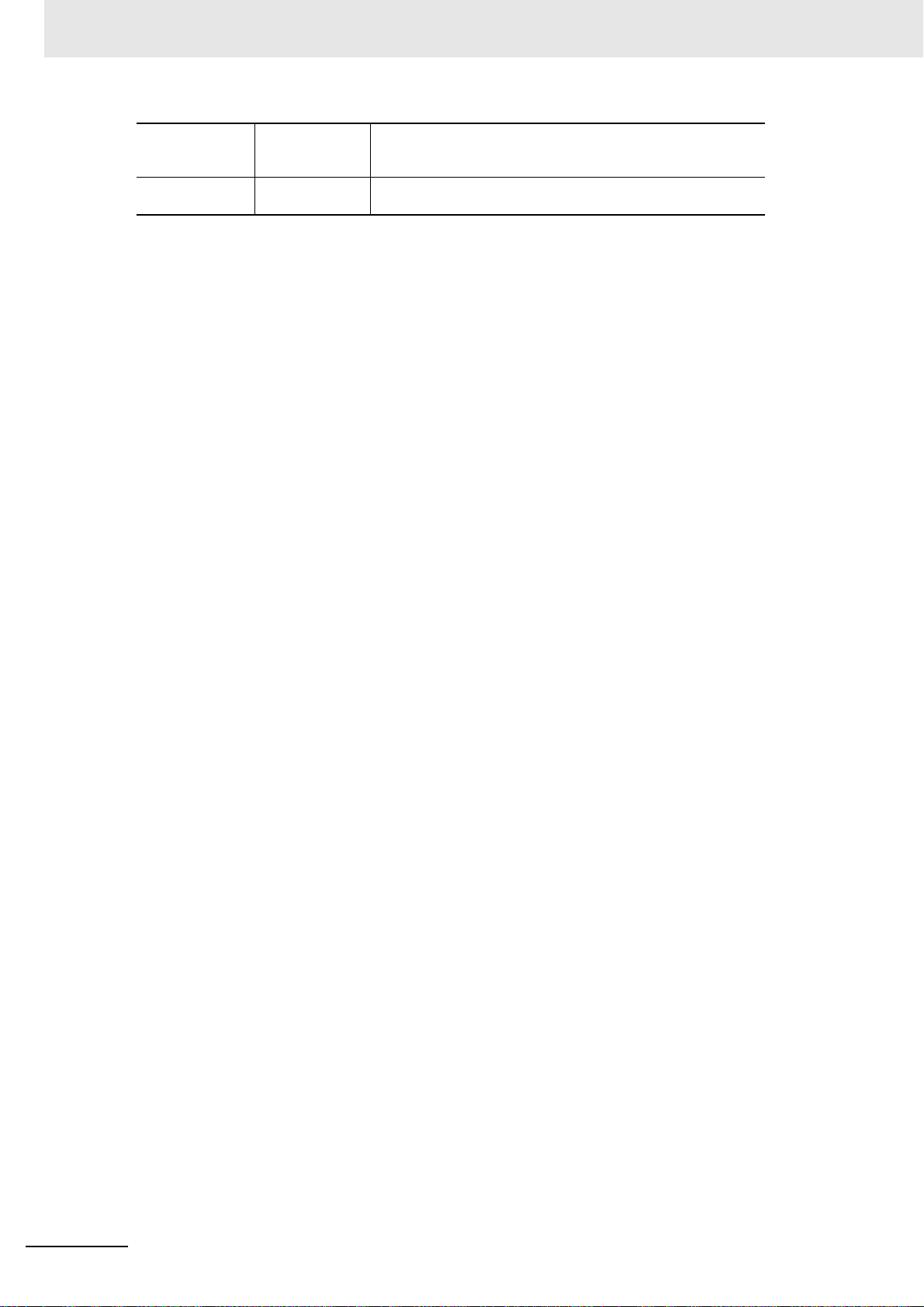

Related Manuals

The followings are the manuals related to this manual. Use these manuals for reference.

Manual name Cat. No. Model numbers Application Description

NX-series CPU Unit

Hardware User's Manual

NX-series

NX1P2 CPU Unit

Hardware

User’s Manual

NJ-series CPU Unit

Hardware User’s Manual

NJ/NX-series CPU Unit

Software User’s Manual

NX-series

NX1P2 CPU Unit

Built-in I/O and

Option Board

User’s Manual

NJ/NX-series Instructions Reference Manual

W535 NX701- Learning the basic specifi-

cations of the NX701 CPU

Units, including introductory

information, designing,

installation, and maintenance. Mainly hardware

information is provided.

W578 NX1P2- Learning the basic specifi-

cations of the NX1P2 CPU

Units, including introductory

information, designing,

installation, and maintenance.

Mainly hardware information is provided.

W500 NJ501-

NJ301-

NJ101-

W501 NX701-

NX1P2-

NJ501-

NJ301-

NJ101-

W579 NX1P2- Learning about the details

W502 NX701-

NX1P2-

NJ501-

NJ301-

NJ101-

Learning the basic specifications of the NJ-series

CPU Units, including introductory information, designing, installation, and

maintenance. Mainly hardware information is provided.

Learning how to program

and set up an NJ/NX-series

CPU Unit. Mainly software

information is provided.

of functions only for an NXseries NX1P2 CPU Unit and

an introduction of functions

for an NJ/NX-series CPU

Unit.

ning detailed specifica-

Lear

tions on the basic instructions of an NJ/NX-series

CPU Unit.

An introduction to the entire NX701 system is provided along with the following information on the

CPU Unit.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

An introduction to the entire NX1P2 system is pro-

vided along with the following information on the

CPU Unit.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

An introduction to the entire NJ-series system is

provided along with the following information on

the CPU Unit.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

The following information is provided on NJ/NX-

series CPU Units.

• CPU Unit operation

• CPU Unit features

• Initial settings

• Programming based on IEC 61131-3 language

specifications

Of the functions for an NX1P2 CPU Unit, the following information is provided.

• Built-in I/O

• Serial Communications Option Boards

• Analog I/O Option Boards

An introduction of following functions for an NJ/NXseries CPU Unit is also provided.

• Motion control functions

• EtherNet/IP communications functions

• EtherCAT communications functions

The instructions in the instruction set (IEC 61131-3

specifications) are described.

Related Manuals

NJ/NX-series Troubleshooting Manual (W503)

21

Page 24

Related Manuals

Manual name Cat. No. Model numbers Application Description

NJ/NX-series CPU Unit

Motion Control User’s

Manual

NJ/NX-series Motion

Control Instructions Reference Manual

NJ/NX-series CPU Unit

Built-in EtherCAT® Port

User’s Manual

NJ/NX-series CPU Unit

Built-in EtherNet/IP

Port User’s Manual

NJ-series

CPU Unit OPC UA

User’s Manual

NJ/NX-series Database

Connection CPU Units

User’s Manual

NJ-series SECS/GEM

CPU Units User’s Manual

NJ-series NJ Robotics

CPU Unit User’s Manual

NJ/NY-series NC Integrated Controller User’s

Manual

NJ/NY-series

G code Instructions Reference Manual

NJ/NX-series Troubleshooting Manual

Sysmac Studio V ersion 1

Operation Manual

CNC Operator

Operation Manual

NX-series EtherCAT®

Coupler Unit User’s Manual

NX-series Data

Reference Manual

W507 NX701-

NX1P2-

NJ501-

NJ301-

NJ101-

W508 NX701-

NX1P2-

NJ501-

NJ301-

NJ101-

W505 NX701-

W506 NX701-

TM

W588 NJ501-100 Using the OPC UA.

W527 NX701-20

W528 NJ501-1340 Using the GEM Services

W539 NJ501-4 Controlling robots with NJ-

O030

O031

W503 NX701-

W504 SYSMAC-

O032

W519 NX-ECC Leaning how to use an NX-

W525 NX- Referencing lists of the data

NX1P2-

NJ501-

NJ301-

NJ101-

NX1P2-

NJ501-

NJ301-

NJ101-

NJ501-20

NJ101-20

NJ501-5300

NY532-5400

NJ501-5300

NY532-5400

NX1P2-

NJ501-

NJ301-

NJ101-

SE2

SYSMAC

-RTNC0

Learning about motion control settings and programming concepts.

Learning about the specifications of the motion control

instructions that are provided by OMRON.

Using the built-in EtherCAT

port on an NJ/NX-series

CPU Unit.

Using the built-in EtherNet/IP port on an NJ/NXseries CPU Unit.

Using the database connection service with NJ/NXseries Controllers

with NJ-series Controllers

series CPU Units.

Performing numerical con-

trol with NJ/NY-series Controllers.

Learning about the specifications of the G code/M

code instructions.

Learning about the errors

that may be detected in an

NJ/NX-series Controller.

Learning about the operating procedures and functions of the Sysmac Studio.

Learning an introduction of

the CNC Operator and how

D

to use it.

series EtherCAT Coupler

Unit and EtherCAT Slave

Terminals

that is required to configure

systems with NX-series

Units.

The settings and operation of the CPU Unit and

programming concepts for motion control are

described.

The motion control instructions are described.

Information on the built-in EtherCAT port is provided. This manual provides an introduction and

provides information on the configuration, features,

and setup.

Information on the built-in EtherNet/IP port is provided. Information is provided on the basic setup,

tag data links, and other features.

Information on the OPC UA is provided.

Describes the database connection service.

Information is provided on the GEM Services.

Describes the functionality to control robots.

Describes the functionality to perform the numerical control.

The G code/M code instructions are described.

Concepts on managing errors that may be

detected in an NJ/NX-series Controller and information on individual errors are described.

Describes the operating procedures of the Sysmac

Studio.

An introduction of the CNC Operator, installation

procedures, basic operations, connection operations, and operating procedures for main functions

are described.

The system and configuration of EtherCAT Slave

T erminals, which consist of an NX-series EtherCA T

Coupler Unit and NX Units, are described along

with the hardware, setup, and functions of the EtherCAT Coupler Unit that are required to configure,

control, and monitor NX Units through EtherCAT.

Lists of the power consumptions, weights, and

other NX Unit data that is required to configure

systems with NX-series Units are provided.

22

NJ/NX-series Troubleshooting Manual (W503)

Page 25

Manual name Cat. No. Model numbers Application Description

NX-series NX Units

User’s Manuals

NX-series Safety Control

Unit User’s Manual

NX-series Safety Control

Unit Instructions Reference Manual

IO-Link System User’s

Manual

GX-series EtherCAT

Slave Units User's Manual

MX2/RX Series Inverter

EtherCAT Communication Unit User’s Manual

AC Servomotors/Servo

Drives 1S-series with

Built-in EtherCAT® Communications User’s Manual

AC Servomotors/Servo

Drives G5-series with

Built-in EtherCAT® Communications User’s Manual

EtherCAT Digital-type

Sensor Communication

Unit Operation Manual

W521 NX-ID

NX-IA

NX-OC

NX-OD

NX-MD

W522 NX-AD

NX-DA

NX-TS

W523 NX-PD1

NX-PF0

NX-PC0

NX-TBX

W524 NX-EC0

NX-ECS

NX-PG0

W540 NX-CIF

W566

W565 NX-RS

W567 NX-ILM

Z930 NX-SL

Z931 NX-SL Learnin g about the specifi-

W570 NX-ILM

W488 GX-ID

I574

I586 R88M-1

I576 R88M-K

I577 R88L-EC-

E413 E3X-ECT Learning how to connect

NX-TS

NX-HB

NX-SI

NX-SO

GX-ILM

GX-OD

GX-OC

GX-MD

GX-AD

GX-DA

GX-EC

XWT-ID

XWT-OD

GX-ILM

3G3AX-MX2-ECT

3G3AX-RX-ECT

R88D-1SN-ECT

R88D-KN-ECT

R88D-KN-ECT-L

Learning how to use NX

Units

*1

Learning how to use NXseries Safety Control Units

cations of instructions for

the Safety CPU Unit.

Learning everything from an

introduction to details about

IO-Link Systems, including

mainly software information

common to all IO-Link masters, Support Software operating methods, and

troubleshooting.

Learning how to use the

EtherCAT remote I/O

terminals.

Learning how to connect a

3G3AX-MX2-ECT or

3G3AX-RX-ECT EtherCAT

Communications Unit for

MX2/RX-series Inverters.

Learning how to use the 1Sseries AC Servomotors/Servo Drives with builtin EtherCAT Communications.

Learning how to use the AC

Servomotors/Servo Drives

with built-in EtherCAT Communications.

E3X-series EtherCAT Slave

Units.

Describes the hardware, setup methods, and functions of the NX Units.

Manuals are available for the following Units.

Digital I/O Units, Analog I/O Units, System Units,

Position Interface Units, Communications Interface

Units, Load Cell Input Units, and IO-Link Master

Units.

Describes the hardware, setup methods, and functions of the NX-series Safety Control Units.

Describes the instructions for the Safety CPU Unit.

Introduces IO-Link Systems and describes system

configurations, communications specifications,

communications methods, I/O data, parameters,

functions, Support Software, and troubleshooting.

Describes the hardware, setup methods and functions of the EtherCAT remote I/O terminals.

Describes the following information for the 3G3AXMX2-ECT and 3G3AX-RX-ECT EtherCAT Communications Unit for MX2/RX-series Inverters:

installation, parameter settings required for operation, troubleshooting, and inspection methods.

Describes the hardware, setup methods and functions of the AC Servomotors/Servo Drives with

built-in EtherCAT Communications.

Describes the hardware, setup methods and functions of the AC Servomotors/Servo Drives with

built-in EtherCAT Communications.

The linear motor type model and the model dedicated for position controls are available in

G5-series.

Provides the specifications of and describes application methods for E3X-series EtherCAT Slave

Units.

Related Manuals

NJ/NX-series Troubleshooting Manual (W503)

23

Page 26

Related Manuals

Manual name Cat. No. Model numbers Application Description

E3NW-ECT EtherCAT

Digital Sensor Communications Unit Operation

Manual

FQ-M-series Specialized

Vision Sensor for Positioning User’s Manual

FH/FZ5 Vision System

FH/FZ5 Series User’s

Manual for Communications Settings

ZW-CE1

Fiber Type Displacement Sensor User's Manual

CJ-series Special Unit

Manuals for NJ-series

CPU Unit

NA-series Programmable

Terminal Hardware

User’s Manual

NA-series Programmable

T erminal Software User’s

Manual

NS-series Programmable Terminals Programming Manual

T Confocal

*1 Temperature Input Units are introduced in Cat. No. W522 before Cat. No. W566 is released.

E429 E3NW-ECT Learning how to connect

E3NW EtherCAT Slave

Units.

Z314 FQ-MS12 Learning how to connect

FQ-M-series Specialized

Vision Sensor for Positioning.

Z342 FH-3

FH-1

Z332 ZW-CE1

W490 CJ1W-AD

CJ1W-DA

CJ1W-MAD42

W491 CJ1W-TC

W492 CJ1W-CT021

W498 CJ1W-PDC15

CJ1W-PH41U

CJ1W-AD04U

W493 CJ1W-CRM21

W494 CJ1W-SCU

W495 CJ1W-EIP21

W497 CJ1W-DRM21

Z317

V117

V118

V073 NS15-

CJ1W-V680

NA5-W

NA5-W

NS12-

NS10-

NS8-

NS5-

T Learning how to connect

Learning how to connect

FH/FZ5-series Vision Systems

ZW-CE1

Slave Units.

Learning how to use CJseries Units with an NJseries CPU Unit.

Learning the specifications

and settings required to

install an NA-series Programmable Terminals and

connect peripheral devices.

Learning about NA-series

Programmable Terminal

pages and object functions.

Learning how to use the

NS-series Programmable

Terminals.

T EtherCAT

Provides the specifications of and describes application methods for E3NW EtherCAT Slave Units.

Describes the following information for the FQ-Mseries Specialized Vision Sensor for Positioning:

installation, wiring methods, parameter settings

required for operation, troubleshooting, and

inspection methods.

The functions, settings, and communications

methods to communicate with FH/FZ5-series

Vision Systems from a PLC or other external

device are described.

Provides the specifications of and describes application methods for ZW-CE1T EtherCAT Slave

Units.

The methods and precautions for using CJ-series

Units with an NJ501 CPU Unit are described,

including access methods and programming interfaces.

Manuals are available for the following Units.

Analog I/O Units, Insulated-type Analog I/O Units,

Temperature Control Units, ID Sensor Units, Highspeed Counter Units, Serial Communications

Units, DeviceNet Units, EtherNet/IP Units, and

CompoNet Master Units.

Information is provided on NA-series Programmable T erminal specifications, part names, installation

procedures, and procedures to connect an NA Unit

to peripheral devices. Information is also provided

on maintenance after operation and troubleshooting.

NA-series Programmable Terminal pages and

object functions are described.

Describes the setup methods, functions, etc. of the

NS-series Programmable Terminals.

24

NJ/NX-series Troubleshooting Manual (W503)

Page 27

Revision History

W503-E1-18

Revision code

Cat. No.

A manual revision code appears as a suffix to the catalog number on the front and back covers of the

manual.

Revision code Date Revised content

01 July 2011 Original production

02 March 2012 Added information related to the upgrade to CPU unit version

03 May 2012 Added information related to the upgrade to CPU unit version

04 August 2012 Made additions to events and changes to the contents related

05 February 2013 Made additions to events and changes to the contents related

06 April 2013 Made additions to events and changes to the contents related

07 June 2013 Made additions to events and changes to the contents related

08 September 2013 Made additions to events and changes to the contents related

09 December 2013 Made additions to events and changes to the contents related

10 July 2014 Corrected mistakes.

1 1 January 2015 Made additions to events and changes to the contents related

12 April 2015 Made additions to events and changes to the contents related

13 April 2016 Made changes to the contents related to the upgrade to CPU

14 July 2016 Made changes to the contents related to the upgrade to CPU

15 October 2016 Made changes to the contents related to the upgrade to CPU

16 April 2017 Made changes to the contents related to the upgrade to CPU

Revision History

1.01, made additions and changes to events related to the

addition of devices that can be connected, and corrected mistakes.

1.02, made additions and changes to events related to the

addition of devices that can be connected, and corrected mistakes.

to the upgrade to CPU unit version 1.03, and corrected mistakes.

to the upgrade to CPU unit version 1.04, and corrected mistakes.

to the upgrade to CPU unit version 1.05, and corrected mistakes.

to the upgrade to CPU unit version 1.06, and corrected mistakes.

to the upgrade to CPU unit version 1.07, and corrected mistakes.

to the upgrade to CPU unit version 1.08, and corrected mistakes.

to the upgrade to CPU unit version 1.10, and corrected mistakes.

to the addition of the NX701corrected mistakes.

unit version 1.11, and corrected mistakes.

unit version 1.12, and corrected mistakes.

unit version 1.13, and corrected mistakes.

unit version 1.14, and corrected mistakes.

and NJ101-

, and

NJ/NX-series Troubleshooting Manual (W503)

25

Page 28

Revision History

17 October 2017 Made changes to th e contents related to the upgrade to CPU

18 January 2018 Made changes to the contents related to the upgrade to CPU

unit version 1.16, added an error log table for CJ-series Special Units, and corrected mistakes.

unit version 1.17, and corrected mistakes.

26

NJ/NX-series Troubleshooting Manual (W503)

Page 29

Overview of Errors

This section provides information that is required to troubleshoot errors. It introduces

the types of errors that can occur on an NJ/NX-series Controller, the operation that

occurs in response to errors, and the methods yo u can use to che ck for erro rs. Refer to

Section 2 Error Troubleshooting Methods for information on troubleshooting errors.

1-1 Overview of NJ/NX-series Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-1-1 Types of Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-1-2 CPU Unit Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-2 Fatal Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-2-1 Types of Fatal Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-2-2 Checking for Fatal Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1-3 Non-fatal Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1-3-1 Types of Non-fatal Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1-3-2 Checking for Non-fatal Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

1-3-3 Resetting Non-fatal Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

1

NJ/NX-series Troubleshooting Manual (W503)

1-1

Page 30

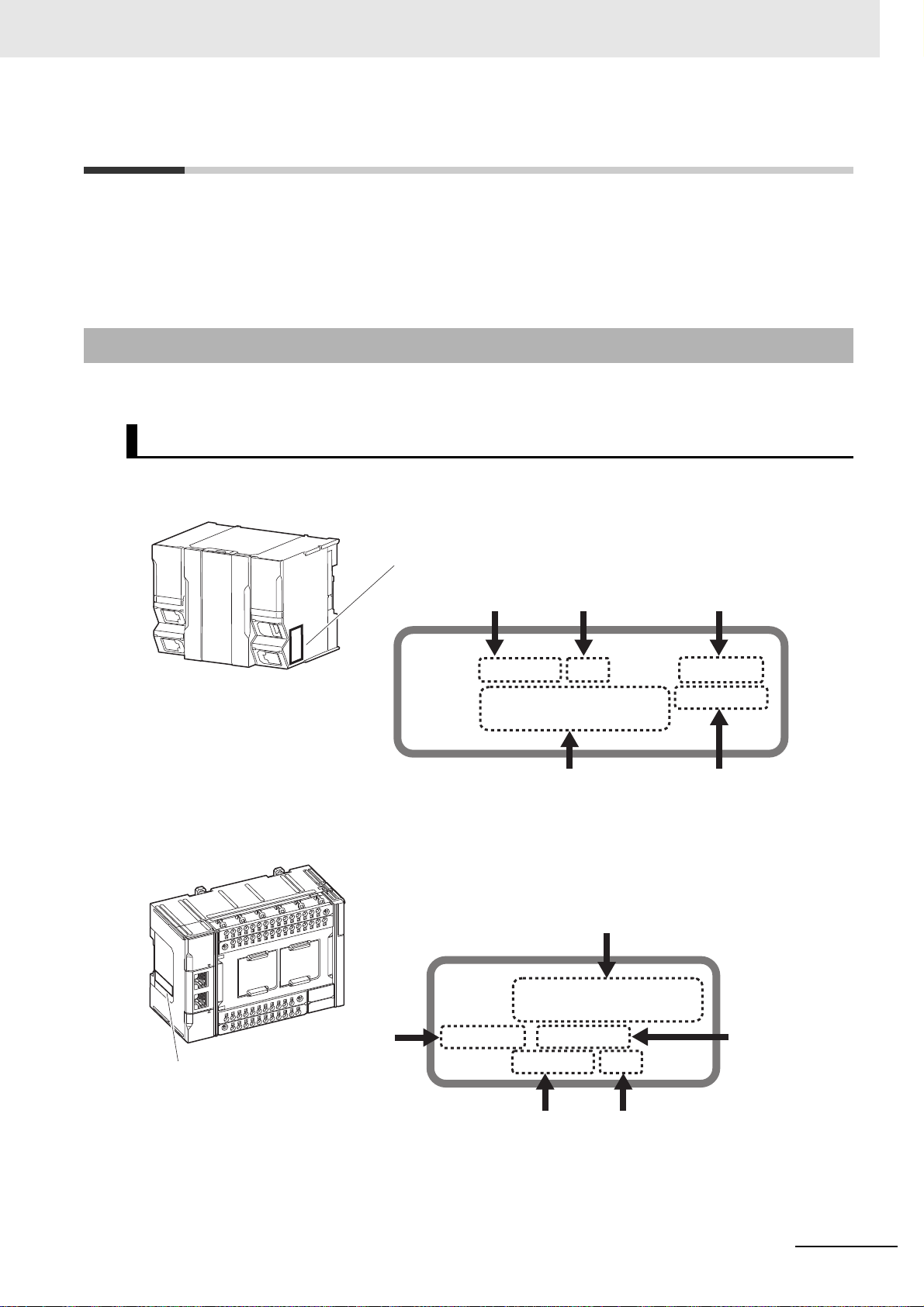

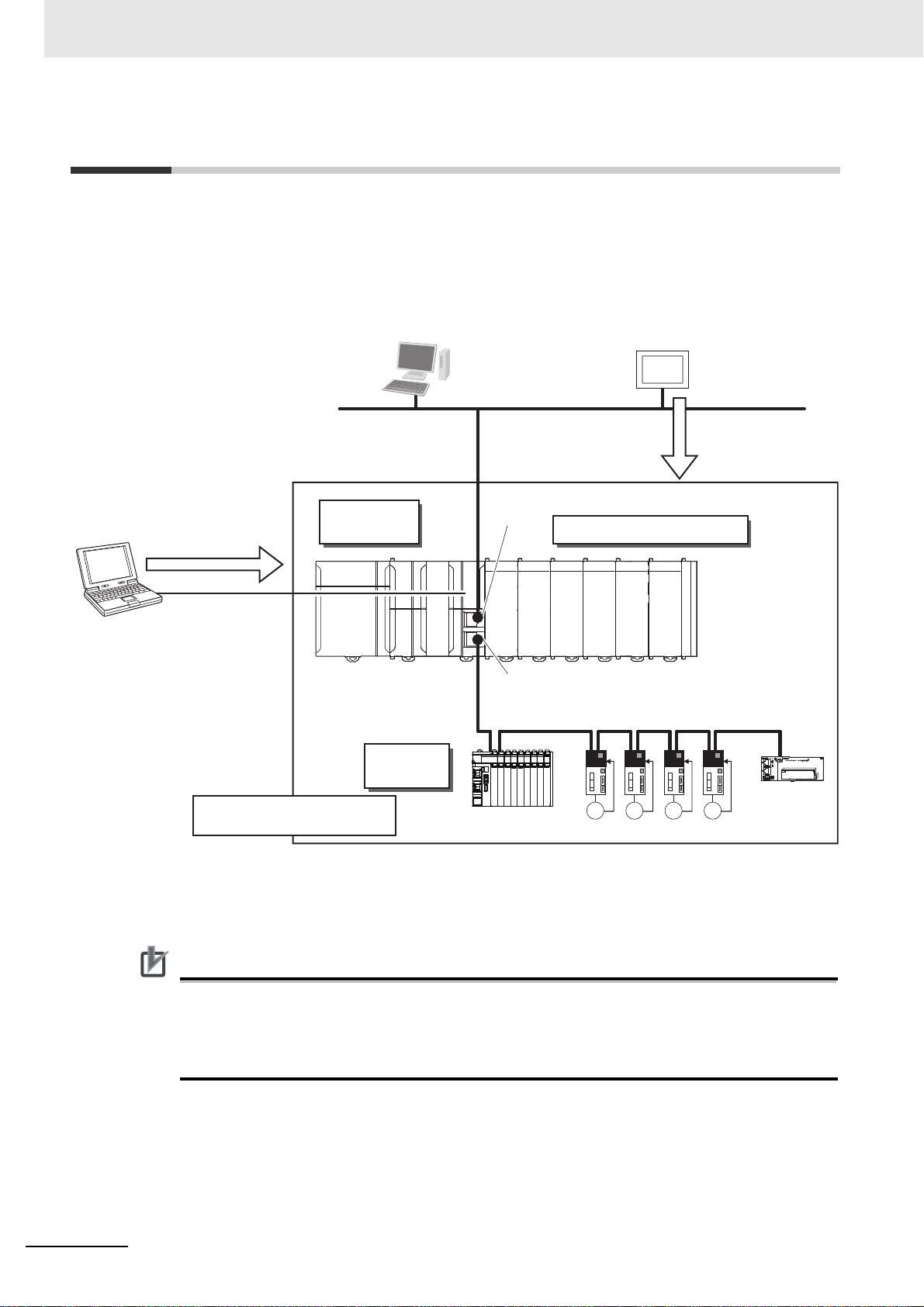

1 Overview of Errors

Precautions for Correct UsePrecautions for Correct Use

HMI

Host computer

Built-in EtherCAT port

Built-in EtherNet/IP

port

Troubleshooting functions

Troubleshooter

EtherNet/IP

EtherCAT

Sysmac Studio

CJ-series Units and NX Units

NJ/NX-series

CPU Unit

Error management range for

NJ/NX-series Controller

EtherCAT

slaves

1-1 Overview of NJ/NX-series Errors

You manage all of the errors that occur on the NJ/NX-series Controller as events. The same methods

are used for all events. This allows you to see what errors have occurred and find corrections for them

with the same methods for the entire range of errors that is managed (i.e., CPU Unit, NX Units, NXseries Slave Terminals, EtherCAT slaves,* and CJ-series Units).

* Only Sysmac devices are supported. For information on EtherCAT sl aves that are Sysmac devices, refer to the

NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (Cat. No. W505).

1-2

You can use the troubleshooting functions of the Sysmac Studio or the Troubleshooter on an HMI to

quickly check for errors that have occurred and find corrections for them.

To perform troubleshooting from an HMI, connect the HMI to the built-in EtherNet/IP port on the CPU

Unit.

• CJ-series Units can be used only with an NJ-series CPU Unit.

• The only CPU Unit on which NX Units can be mounted is an NX1P2 CPU Unit.

• Refer to A-1 Applicable Range of the HMI Troubleshooter for the applicable range of the HMI

Troubleshooter.

NJ/NX-series Troubleshooting Manual (W503)

Page 31

1-1-1 Types of Errors

There are two main types of errors (e vents) depending on whether the NJ/NX-series Controller can

manage them or not.

Fatal Errors

These errors are not detected by the event management function of the NJ/NX-series Controller

because the CPU Unit stops operation. You cannot identify or reset these errors with the Sysmac

Studio or an HMI.

Refer to 1-2 Fatal Errors for error types and confirmation methods for fatal errors.

Non-fatal Errors

These errors are detected and mana ged with the event management functio n of the NJ/NX-series

Controller. You can confirm these errors with the Sysmac Studio or an HMI.

Refer to 1-3 Non-fatal Errors for error types and confirmation methods for non-fatal errors.

1 Overview of Errors

1-1 Overview of NJ/NX-series

Errors

1

1-1-1 Types of Errors

NJ/NX-series Troubleshooting Manual (W503)

1-3

Page 32

1 Overview of Errors

Power Supply Unit CPU Unit

RUN

ERROR

BUSY

SHTDWN

NET RUN

PORT1

EtherNet/IP

NET ERR

LINK/ACT

SD PWR

SD BUSY

L1

L2/N

L1

L2/N

AC100-2

INPUT

PWR indicator

RUN indicator

ERROR indicator

05060708091011

12

IN

010203

04

COM

00--++

POWER

RUN

ERROR

BUSY

SD PWR

SD BUSY

PORT1

EtherNet/IP

PORT1 EtherNet/IP

SW SETTING

NX1P2

POWER indicator

RUN indicator

ERROR indicator

CPU Unit

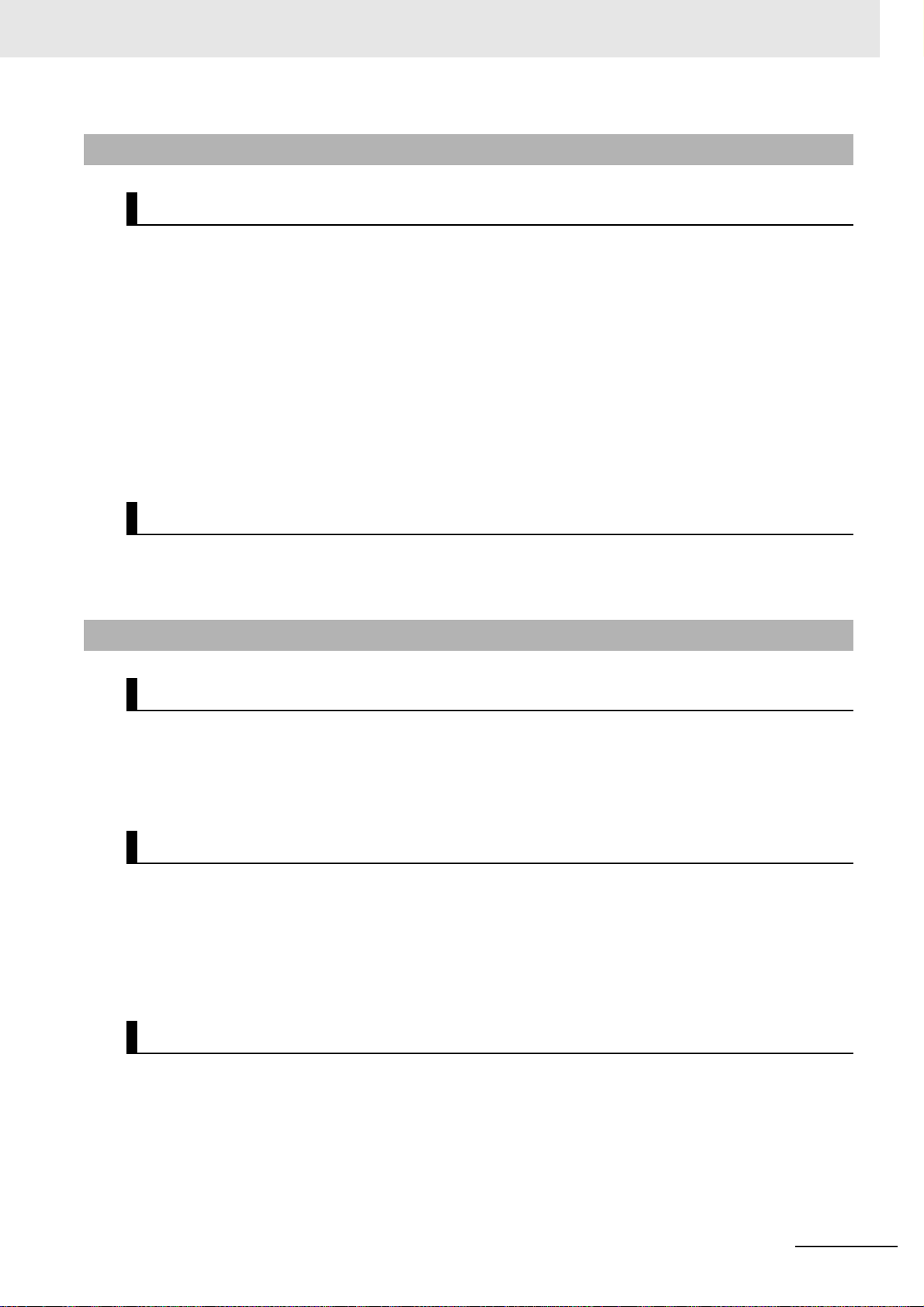

1-1-2 CPU Unit Status

You can check the ope ratin g status o f the CPU Un it with the PWR/POWER, RUN, and ER ROR indic ators on the front panels of the Power Supply Unit and CPU Unit.

NX-series CPU Units

NX701 CPU Unit

NX1P2 CPU Unit

1-4

NJ/NX-series Troubleshooting Manual (W503)

Page 33

1 Overview of Errors

Precautions for Correct UsePrecautions for Correct Use

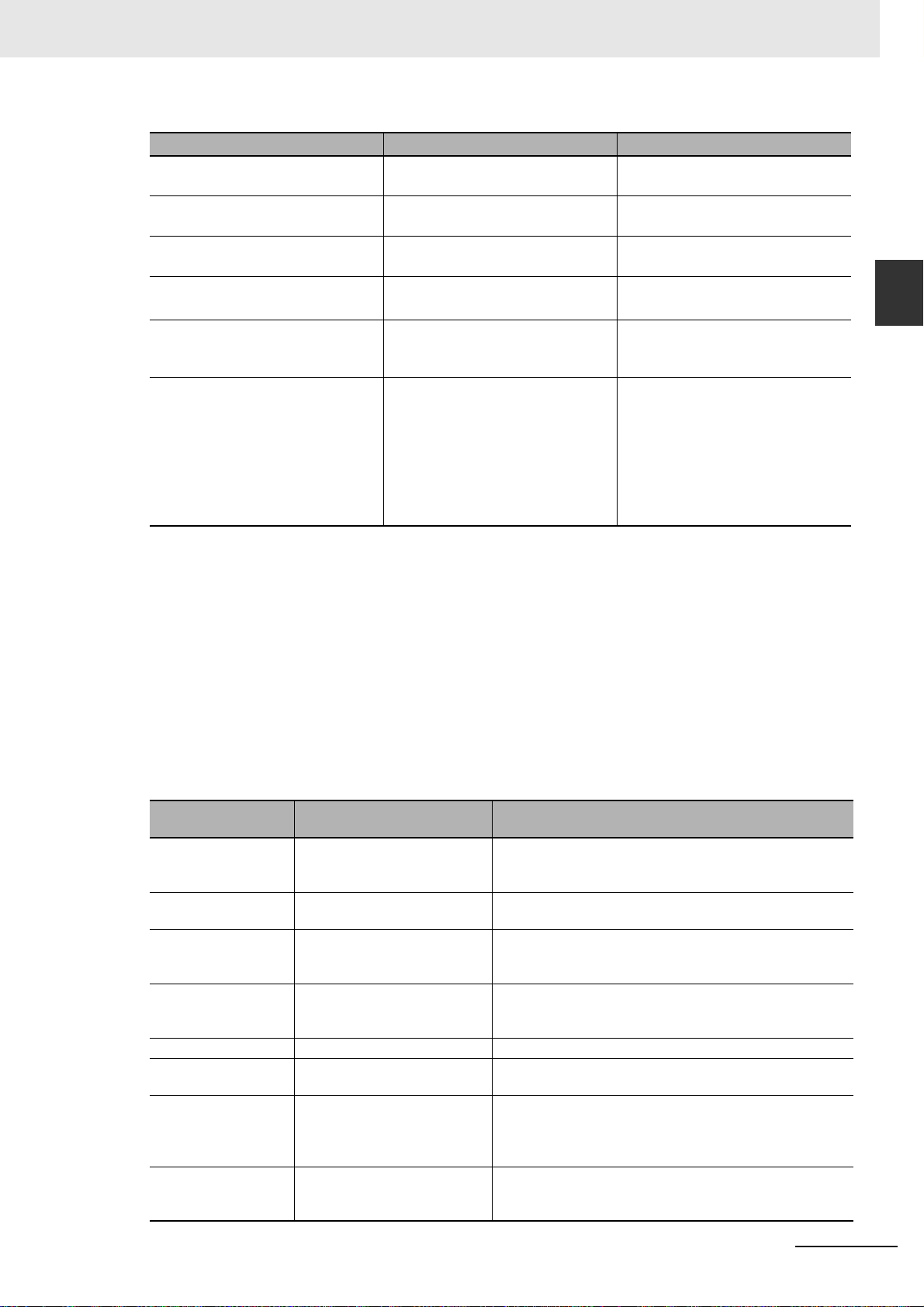

The following table shows the status of front-p anel indicators, the st atus of user program execution, and

the ability to connect communications to the Sysmac Studio or an HMI during startup, during normal

operation, and when errors occur.

1-1 Overview of NJ/NX-series

CPU Unit operating status

Startup

Normal

operation

Fatal error in

CPU Unit

Non-fatal error

in CPU Unit

RUN mode Lit Lit Not lit Continues. Possible.

PROGRAM mode Lit Not lit Not lit Stopped.

Power Supply

Error

CPU Unit Reset

/Hardware Initialization Error

CPU Unit Error

System Initialization Error

Major fault

Partial fault

Minor fault

Observation

Power

Supply

Unit/

CPU Unit

PWR/

POWER

(green)

Lit Flashing

Not lit Not lit Not lit Stopped. Not possible.

*1

*1*2

Lit Not lit Not lit Stopped.

*1*3

Lit Not lit or

*1

Lit Flashing

*1

*4

*4

*4

*4

Lit Not lit Lit Stopped. Possible. (CommuLit Lit Flashing

Lit Lit Flashing

Lit Lit Not lit Continues.

RUN (green) ERROR (red)

(2-s intervals

followed by

0.5-s intervals)

Flashing (2-s

intervals or

0.5-s intervals)

(2-s intervals)

for 30 s or longer

CPU Unit

Not lit Stopped. Not possible.

Lit Stopped.

Not lit Stopped.

(1-s intervals)

(1-s intervals)

User pro-

gram execu-

tion status

Continues.

Continues.

*5

Communications

with Sysmac Stu-

dio or HMI

nications can be

connected from an

HMI if EtherNet/IP

is operating normally.)

Errors

1

1-1-2 CPU Unit Status

*1 Refer to 1-2 Fatal Errors for information on individual errors.

*2 This error can occur for NX701 CPU Units. If the status of indicators shown above continues 30 secon ds or longer, this

error exists.

*3 This error can occur for NX1P2 CPU Units. If the status of indicators shown above continues 30 seconds or longer, this

error exists.

*4 Refer to 1-3 Non-fatal Errors for information on individual errors.

*5 The function module where the error occurred stops.

When an NX1P2 CPU Unit is used, a power shortage may occur at the CPU Rack d ep ending on

the configuration of NX Units mounted to the CPU Unit. If one of the followings occurs, use the

Sysmac Studio to check if the power consumed by the Units on the CPU Rack exceeds the supplied power.

• The CPU Unit is operating but the mounted NX Units do not operate.

• Power is supplied to the CPU Unit, but the CPU Unit does not turn ON.

NJ/NX-series Troubleshooting Manual (W503)

1-5

Page 34

1 Overview of Errors

PWR indicator

RUN indicator

ERROR indicator

Power Supply Unit CPU Unit

NJ-series CPU Units

The following table shows the status of front-panel indi cators, the status of user progra m execution, and

the ability to connect communications to the Sysmac Studio or an HMI during startup, during normal

operation, and when errors occur.

Power

CPU Unit operating status

Supply Unit

PWR (green) RUN (green) ERROR (re d)

Startup

Normal

operation

Fatal error

in CPU

Unit

Non-fatal

error in

CPU Unit

RUN mode Lit Lit Not lit Continues. Possible.

PROGRAM mode Lit Not lit Not lit Stopped.

Power Supply Error

CPU Unit Reset

*1

Incorrect Power Supply Unit Connected

CPU Unit Watchdog

Timer Error

Major fault

Partial fault

Minor fault

Observation

*1

*2

*2

*2

*2

Lit Flashing

(1-s intervals)

*1

Not lit Not lit Not lit Stopped. Not possible.

Lit Not lit Not lit Stopped.

Lit Flashing

*1

(3-s intervals)

Lit Not lit Lit Stopped.

Lit Not lit Lit Stopped. Possible. (ComLit Lit Flashing

Lit Lit Flashing

Lit Lit Not lit Continues.

*1 Refer to 1-2 Fatal Errors for information on individual errors.

*2 Refer to 1-3 Non-fatal Errors for information on individual errors.

*3 The function module where the error occurred stops.

CPU Unit User pro-

gram execu-

tion status

Not lit Stopped. Not possible.

Lit Stopped.

Continues.

*3

(1-s intervals)

Continues.

(1-s intervals)

Communica-

tions with Sys-

mac Studio or

HMI

munications can

be connected

from an HMI if

EtherNet/IP is

operating normally.)

1-6

NJ/NX-series Troubleshooting Manual (W503)

Page 35

1 Overview of Errors

1-2 Fatal Errors

1-2-1 Types of Fatal Errors

This section describes the errors that cause the operation of the NJ/NX-series CPU Unit to stop.

The errors that can occur depend on the CPU Unit.

Communications with the Sysmac Studio or an HMI are not possible if there is a fatal error in the Controller.

Error name

Power Supply Error Yes Yes Yes

CPU Unit Reset Yes Yes

Hardware Initialization Error Yes

Incorrect Power Supply Unit Connected Yes

CPU Unit Error Yes Yes

CPU Unit Watchdog Timer Error Yes

System Initialization Error Yes Yes

1-2 Fatal Errors

1

1-2-1 Types of Fatal Errors

(Yes: Error th at can occur)

CPU Unit

NX701 NX1P2 NJ-series

The above errors are described in detail as follows.

Power Supply Error

Power is not supplied, the voltage is outside of the allowed range, or the Power Supply Unit or

power supply section is faulty.

CPU Unit Reset

The CPU Unit stopped operation because of a hardwa re erro r. For an NJ-series CPU Unit, this error

can also occur for reasons other than hardware failures, as given below.

• The power supply to an Expansion Rack is OFF.

• The I/O Connecting Cable is incorrectly installed.

• The IN and OUT connectors are reversed.

• The connectors are not mated properly.

• There is more than one I/O Control Unit on the CPU Rack or there is an I/O Control Unit on an

Expansion Rack.

Hardware Initialization Error

This error can occur for an NX1P2 CPU Unit. It indicates a dat a error in minimum program s req uired

to initialize the hardware. Only the POWER indicator will be lit while the CPU Unit is starting, but if it

is lit for 30 seconds or longer, then this error occurs.

Incorrect Power Supply Unit Connected

There is a CJ-series Power Supply Unit connected to the NJ-series CPU Unit. The ope ration of the

Controller is stopped.

NJ/NX-series Troubleshooting Manual (W503)

1-7

Page 36

1 Overview of Errors

CPU Unit Watchdog Timer Error

This error can occur for an NJ-series CPU Unit . This error occurs when the watchdog timer times

out because of a hardware failure or when temporary data corruption causes the CPU Unit to hang.

CPU Unit Error

This error can occur for an NX-series CPU Unit. It indicates that there is a hardware failure or that

the CPU is running out of control due to temporary data corruption.

System Initialization Error

This error can occur for an N X-series CPU Unit. It indicates a hardware failure or data error. The

RUN indicator will flash at 2-second intervals while the CPU Unit is starting, but if it flashes for 30

seconds or longer, then this error occurs.

1-2-2 Checking for Fatal Errors

You can identify fatal errors based on the status of the PWR/POWER, RUN, and ERROR indicators, as

well as by the ability to connect communications to the Sysmac Studio. Refer to Section 2 Error Trou-

bleshooting Methods for information on identifying errors and corrections.

NX-series CPU Units

Indicators

PWR/POWER

(green)

Not lit Not lit Not lit Not possible.* Power Supply Error

Lit Not lit Not lit CPU Unit Reset/Hardware Ini-

Lit Not lit or Flash-

Lit F lashing (2-s

* An online connection to the Sysmac Studio is necessary to differentiate between CPU Unit Resets/Hardware Ini-

tialization Errors, CPU Unit Errors, and non-fatal errors in the CPU Unit. Power Supply Errors and System Initialization Errors can be differentiated with the indicators. There is no need to see if you can go online with the CPU

Unit from the Sysmac Studio.

RUN (green) ERROR (red)

Lit CPU Unit Error

ing (2-s intervals

or 0.5-s inter-

vals)

Not lit System Ini tia lization Error

intervals) for 30 s

or longer

Communications

with Sysmac Studio

CPU Unit operating status

tialization Error

NJ-series CPU Units

Indicators

PWR (green) RUN (green) ERROR (red)

Not lit Not lit Not lit Not possible.* Power Supply Error

Lit Not lit Not lit CPU Unit Reset

Lit F lashing (3-s

intervals).

Lit Not lit Lit CPU Unit Watchdog Timer

* An online connection to the Sysmac Studio is necessary to differentiate between CPU Unit Resets, CPU Unit

Watchdog Timer Errors, and non-fatal errors in the CPU Unit. Power Supply Errors and Incorrect Power Supply

Unit Connected errors can be differentiated with the indicators. There is no need to see if you can go online with

the CPU Unit from the Sysmac Studio.

Lit Incorrect Power Supply Unit

Communications

with Sysmac Studio

CPU Unit operating status

Connected

Error

1-8

NJ/NX-series Troubleshooting Manual (W503)

Page 37

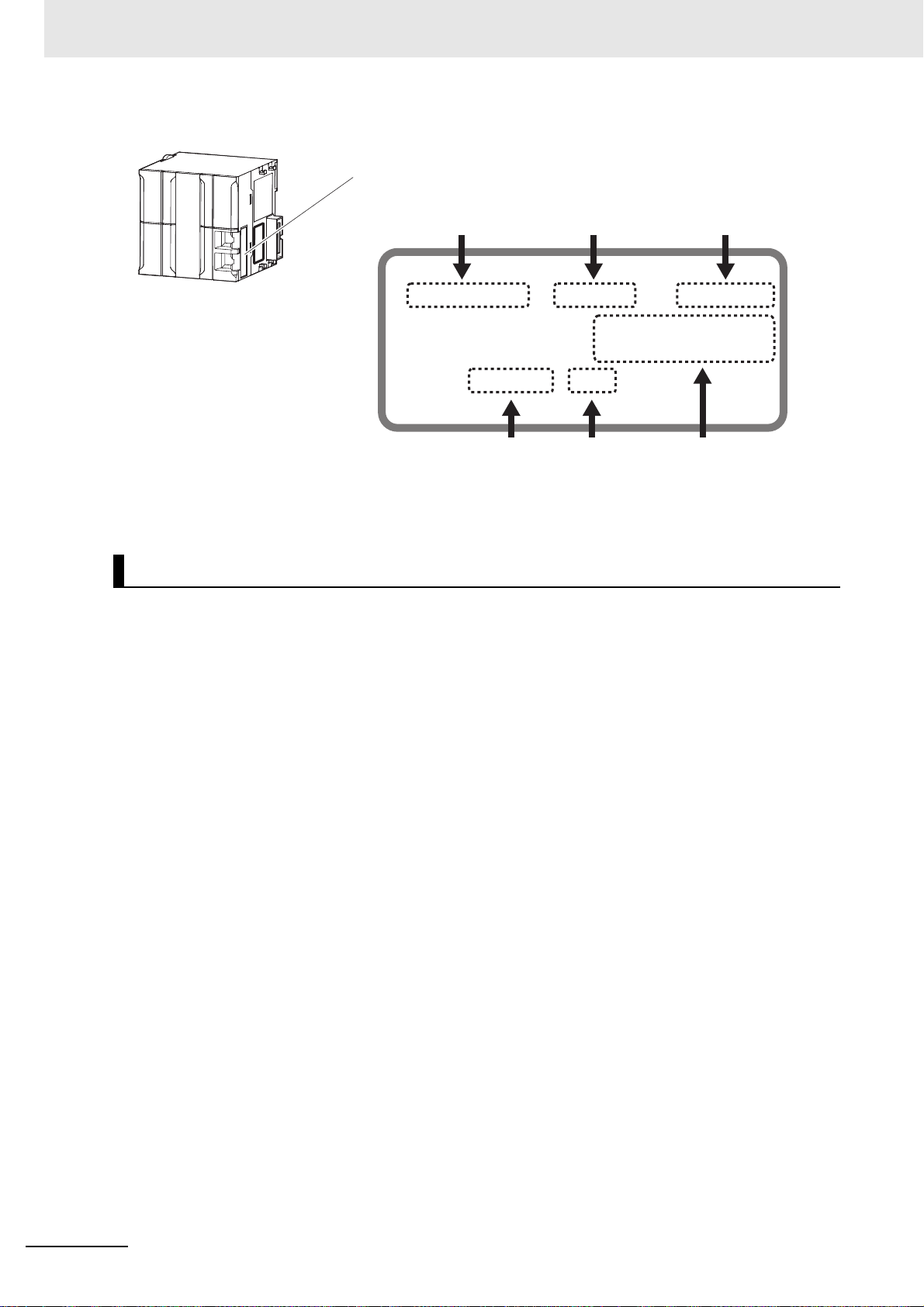

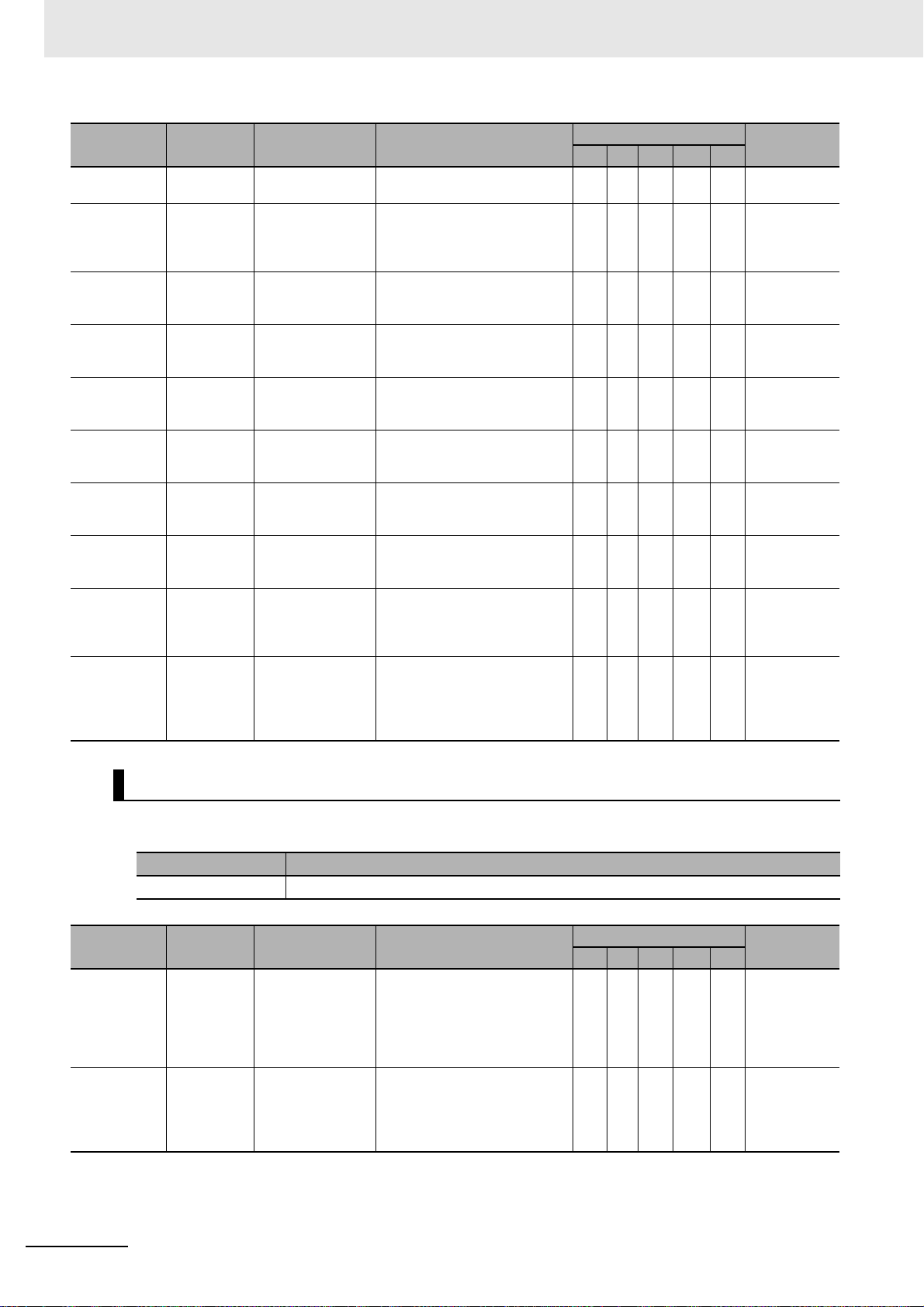

1-3 Non-fatal Errors

Precautions for Correct UsePrecautions for Correct Use

NX-series CPU Unit

Event logs

Event source

Sysmac Studio

HMI

NX Units

Backup battery

*1

Create User-defined

Error instruction:

SetAlarm

Create User-defined

Information

instruction: SetInfo

User program

Or

Check current Controller

events and the event log

of past events.

Check current Controller

events and the event log

of past events.

PLC Function

Module

Motion Control

Function Module

EtherCAT Master

Function Module

EtherNet/IP

Function Module

EtherCAT

Slave

Terminal

Event logs

EtherCAT

slave

NX Bus

Function Module

NX Units

Event logs

*1. For NX701, the event logs are saved in battery-backup memory. For NX1P2, they are saved in non-volatile memory.

Non-fatal errors that occur are managed as events in the NJ/NX-series Controller. You can check the

event to find out what type of error occurred.

1 Overview of Errors

1-3 Non-fatal Errors

1-3-1 Types of Non-fatal Errors

Overview of Controller Events (Errors and Information)

You use the same methods to manage all of the events that occur on the NJ/NX-series Controller. The

events that occur are saved in the CPU Unit or NX-series Slave Terminals.

You can use th e Sysmac Studio or an HMI to confirm current Controller even ts and the log of events

that occurred before. This log is called an event log.

To use an HMI to check events, connect the HMI to the built-in EtherNet/IP port on the CPU Unit.

The event management for NX-series Units is shown below.

1

1-3-1 Types of Non-fatal Errors

• The only CPU Unit on which NX Units can be mounted is an NX1P2 CPU Unit.

NJ/NX-series Troubleshooting Manual (W503)

1-9

Page 38

1 Overview of Errors

Precautions for Correct UsePrecautions for Correct Use

The event management for NJ-series Units is shown below.

Check current Controller

events and the event log

of past events.

Sysmac Studio

Or

HMI

Check current Controller

events and the event log

of past events.

Event source

PLC Function

Module

Backup battery

NJ-series CPU Unit

Motion Control

Function Module

Event logs

EtherCAT Master

Function Module

EtherNet/IP

Function Module

EtherCAT

Slave

Terminal

Event logs

User program

Create User-defined

Error instruction:

SetAlarm

Create User-defined

Information

instruction: SetInfo

EtherCAT

slave

CJ-series

Units

Errors in

Special Units

For an NX-series or NJ-series CPU Unit, use the following information to handle errors that

occurred in an EtherCAT Slave T erminal or EtherCAT slave.

• Refer to the manual for the Commun ications Coupler Unit for details on the event log in a

Slave Terminal.

• When there is an emergency message that notifies an error from an EtherCAT slave to the

CPU Unit, it is recorded in the event log of the EtherCAT Master Function Module as the

Emergency Message Detected (64200000 hex) event.

• You cannot confirm the event log for an EtherCAT slave that has no event log. To reco rd an

error history as an event, you have to change the setting of the EtherCA T slave to notify emergency messages, then the Emergency Message Detected (64200000 hex) event is recorded.

However, errors which cannot be notified by emergency messages from EtherCAT slaves are

not recorded in the event log.

Meanwhile, there is a way to display error histo ry of some EtherCAT slaves that do not have

the event log, on the Sysmac Studio version 1.15 or high er as the e ven t log. Refe r to releva nt

manuals for EtherCAT slaves for the possibility to display error history as the event log.

• Refer to relevant manuals for the slaves for the procedures to read error history of EtherCAT

slaves.

The following events can occur.

Controller Events

The Controller automatically detects these events. Controller events include events for the function

modules in the CPU Unit, NX Units, NX-series Slave Terminal, EtherCAT slaves, and CJ-series

Units.

1-10

NJ/NX-series Troubleshooting Manual (W503)

Page 39

1 Overview of Errors

Additional Information

Version Information

• You cannot check the error logs that are managed independently by EtherCAT slaves because

they are not for Controller events. Refer to relevant manuals for the slaves for the procedures

to read error logs and correct errors.

• Error causes and corrections are not displayed on the Controller Event Log Tab Page in the

Sysmac Studio, although error codes, which are registered in the error logs that are managed

independently by CJ-series Special Units, are displayed. Refer to relevant manuals for the

Units for the procedures to read error logs and correct errors.

User-defined Events

These are events that occur in applications that the user developed.

Refer to the NJ/NX-series CPU Unit Software User’s Manual (Cat. No. W501) for information on

user-defined events.

Non-fatal errors are managed as Controller event s. This section describes mainly the Controller events.

1-3 Non-fatal Errors

1

1-3-1 Types of Non-fatal Errors

Details on Controller Events (Errors and Information)

Controller Event Times

The time of occurrence is recorded when an event occurs.

The times of occurrence are based on the CPU Unit’s built-in clock data.

For events that occur in EtherCAT Slave Terminals, the times of occurre nce are re corded base d on

the CPU Unit’s built-in clock data that the EtherCAT Slave Terminal receives from the CPU Unit.

If the EtherCAT Slave Term inal cannot obtain the clock data from the CPU Unit, the time of occurrence on the Sysmac Studio is displayed as ----/--/-- -- :--:--. For an event occurred before the Ether-

CAT Slave Terminal obtains the clock data from the CPU Unit, the time of occurrence is also

displayed as ----/--/-- --:--:--.

If the EtherCAT Slave Terminal cannot obtain the clock data from the CPU Unit or an event

occurred before the EtherCAT Slave Terminal obtains the clock data from the CPU Unit, the time

of occurrence is displayed as 1970/1/1 0:00:00 with Sysmac Studio version 1.14 or lower.

Sources of Controller Events

The Event source information indicates the location where an event occurred. The event source

identifies the particular function module in the CPU Unit in which the event occurred. For some function modules, there is more detailed info rmation about the event source. This information is called

the Source details. The following information is provided as the event source details.

Event source Source details

PLC Function Module Instructions, power supply, built-in I/O, Option Board, I/O bus

NX Bus Function Module

Motion Control Function Module Common, axis, or axes group

EtherCAT Master Function Module Communications port, EtherCA T master, EtherCAT Coupler

EtherNet/IP Function Module Communications port, communications port 1, communications

NJ/NX-series Troubleshooting Manual (W503)

*1

master, or CJ-series Unit

Master or NX Unit

Unit, NX Unit, or EtherCAT slave

port 2, CIP, CIP1, CIP2, FTP, NTP, or SNMP

1-11

Page 40

1 Overview of Errors

*1 Only for NX1P2 CPU Units.

Note An NC Integrated Controller has the CNC Function Module. For how to check and correct errors in the CNC

Function Module, refer to the NJ/NY-series NC Integrated Controller User’s Manual (Cat. No. O030).