Page 1

MX2

Choke

LCD 5 lines remote

operator

Remote operator

extension cable

Output AC reactor

Communication option board

USB cable

Braking resistor

CX-Drive

CX-One

MCCB

MX2

Filter

Input AC reactor

Motor

Ground

Power

supply

DC reactor

Born to drive machines

• Current vector control

• High starting torque: 200% at 0.5 Hz

• Double rating VT 120%/1 min and CT 150%/1 min

• Speed range up to 1000 Hz

• IM & PM motor control

• Torque control in open loop vector

• Positioning functionality

• Built-in application functionality (i.e. Brake control)

• User programmable as standard

• Safety embedded compliant with ISO13849-1 (double input

circuit and external device monitor EDM)

• USB port for PC programming

• 24 VDC backup supply for control board

• Fieldbus communications: Modbus, DeviceNet, Profibus,

Componet, Ethercat, ML-II and CanOpen

• PC configuration tool: CX-Drive

• RoHS, CE, cULus

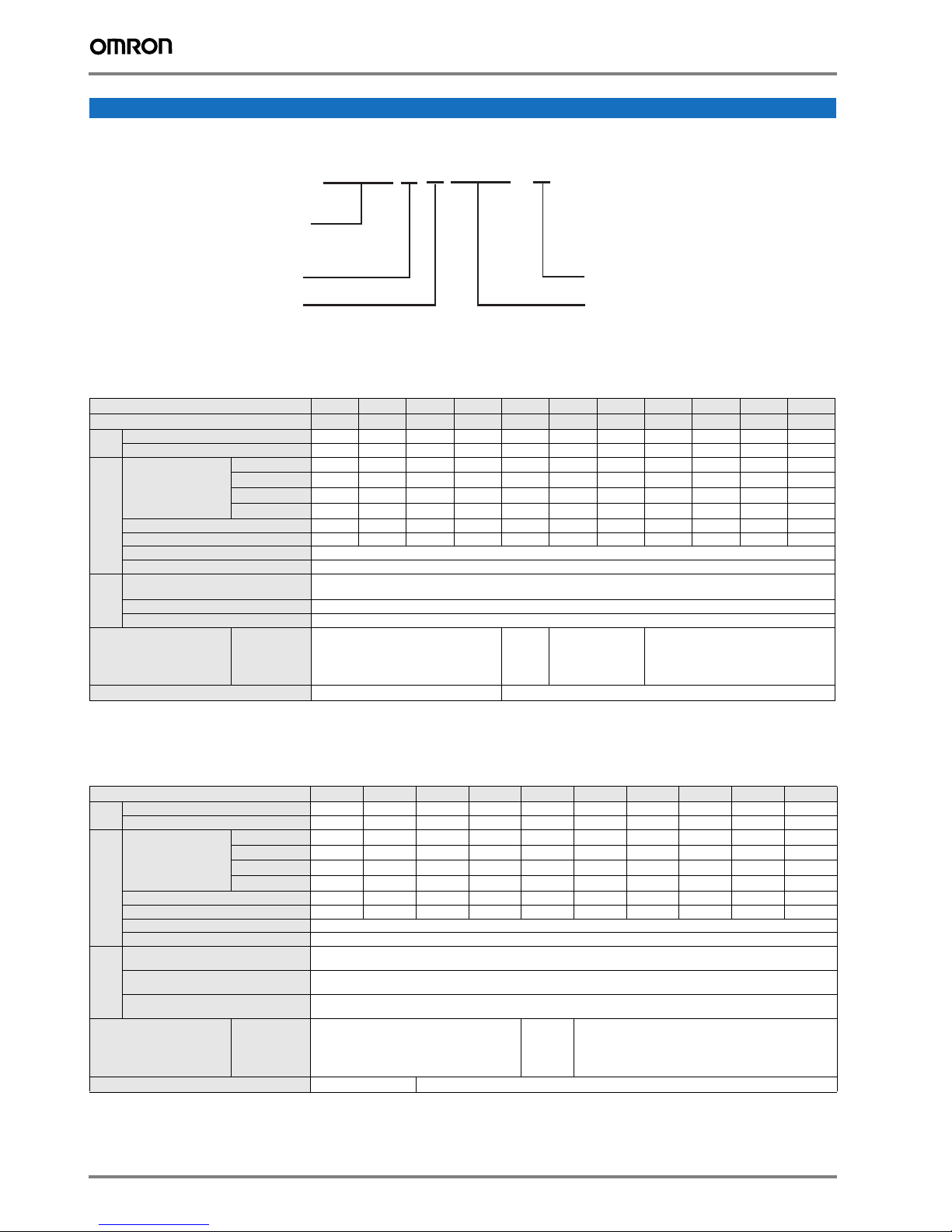

Ratings

• 200 V Class single-phase 0.1 to 2.2 kW

• 200 V Class three-phase 0.1 to 15.0 kW

• 400 V Class three-phase 0.4 to 15.0 kW

System configuration

1MX2

Page 2

Specifications

MX2 series

A: Standard specs

MX2AB002-E

Vol tage:

B: Single-phase 200 VAC

2: Three-phase 200 VAC

4: Three-phase 400 VAC

Max. applicable motor output

002: 0,2 kW

~

150: 15,0 kW

E: Europe standard

Type designation

200 V class

Single-phase: MX2@ AB001 AB002 AB004 AB007

Three-phase: MX2@ A2001 A2002 A2004 A2007 A2015 A2022 A2037 A2055 A2075 A2110 A2150

Motor

2

kW

Inverter capacity kVA

Rated output current (A) at VT 1.2 1.9 3.5 6.0 9.6 12.0 19.6 30.0 40.0 56.0 69.0

Output

Rated output current (A) at CT 1.0 1.6 3.0 5.0 8.0 11.0 17.5 25.0 33.0 47.0 60.0

characteristics

Max. output voltage Proportional to input voltage: 0..240 V

Max. output frequency 1000 Hz

Rated input voltage

and frequency

Allowable voltage fluctuation -15%..+10%

Power

supply

Allowable frequency fluctuation 5%

Braking torque

1. Three phase model use forced-air-cooling but single phase model is self cooling.

2. Based on a standard 3-Phase standard motor.

3. Above 400 Hz with some function limitation.

For VT setting 0.2 0.4 0.55 1.1 2.2 3.0 5.5 7.5 11 15 18.5

For CT setting 0.1 0.2 0.4 0.75 1.5 2.2 3.7 5.5 7.5 11 15

200 VT

200 CT

240 VT

240 CT

At short-time

deceleration

At capacitor

feedback

Cooling method

0.4 0.6 1.2 2.0 3.3 4.1 6.7 10.3 13.8 19.3 23.9

0.2 0.5 1.0 1.7 2.7 3.8 6.0 8.6 11.4 16.2 20.7

0.4 0.7 1.4 2.4 3.9 4.9 8.1 12.4 16.6 23.2 28.6

0.3 0.6 1.2 2.0 3.3 4.5 7.2 10.3 13.7 19.5 24.9

100%: <50Hz

50%: <60Hz

Self cooling

1

AB015 AB022 - - - - -

3

Single-phase 200..240 V 50/60 Hz

3-phase 200..240 V 50/60 Hz

70%:

<50Hz

50%:

Approx 20% -

<60Hz

Forced-air-cooling

400 V class

Three-phase: MX2@ A4004 A4007 A4015 A4022 A4030 A4040 A4055 A4075 A4110 A4150

Motor

1

kW

Inverter capacity kVA

Rated output current (A) at VT 2.1 4.1 5.4 6.9 8.8 11.1 17.5 23.0 31.0 38.0

Output

Rated output current (A) at CT 1.8 3.4 4.8 5.5 7.2 9.2 14.8 18.0 24.0 31.0

characteristics

Max. output voltage Proportional to input voltage: 0..480 V

Max. output frequency 1000 Hz

Rated input voltage

and frequency

Allowable voltage

fluctuation

Power

supply

Allowable frequency

fluctuation

Braking torque

1. Based on a standard 3-Phase standard motor.

2. Above 400 Hz with some function limitation.

2 Frequency inverters

For VT setting 0.75 1.5 2.2 3.0 4.0 5.5 7.5 11 15 18.5

For CT setting 0.4 0.75 1.5 2.2 3.0 4.0 5.5 7.5 11 15

Cooling method

At short-time

deceleration

At capacitor

feedback

380 VT

380 CT

480 VT

480 CT

*3

1.3 2.6 3.5 4.5 5.7 7.3 11.5 15.1 20.4 25.0

1.1 2.2 3.1 3.6 4.7 6.0 9.7 11.8 15.7 20.4

1.7 3.4 4.4 5.7 7.3 9.2 14.5 19.1 25.7 31.5

1.4 2.8 3.9 4.5 5.9 7.6 12.3 14.9 19.9 25.7

2

3-phase 380..480 V 50/60 Hz

-15%..+10%

5%

70%:

100%: <50Hz

50%: <60Hz

<50Hz

50%:

-

<60Hz

Self cooling Forced-air-cooling

Page 3

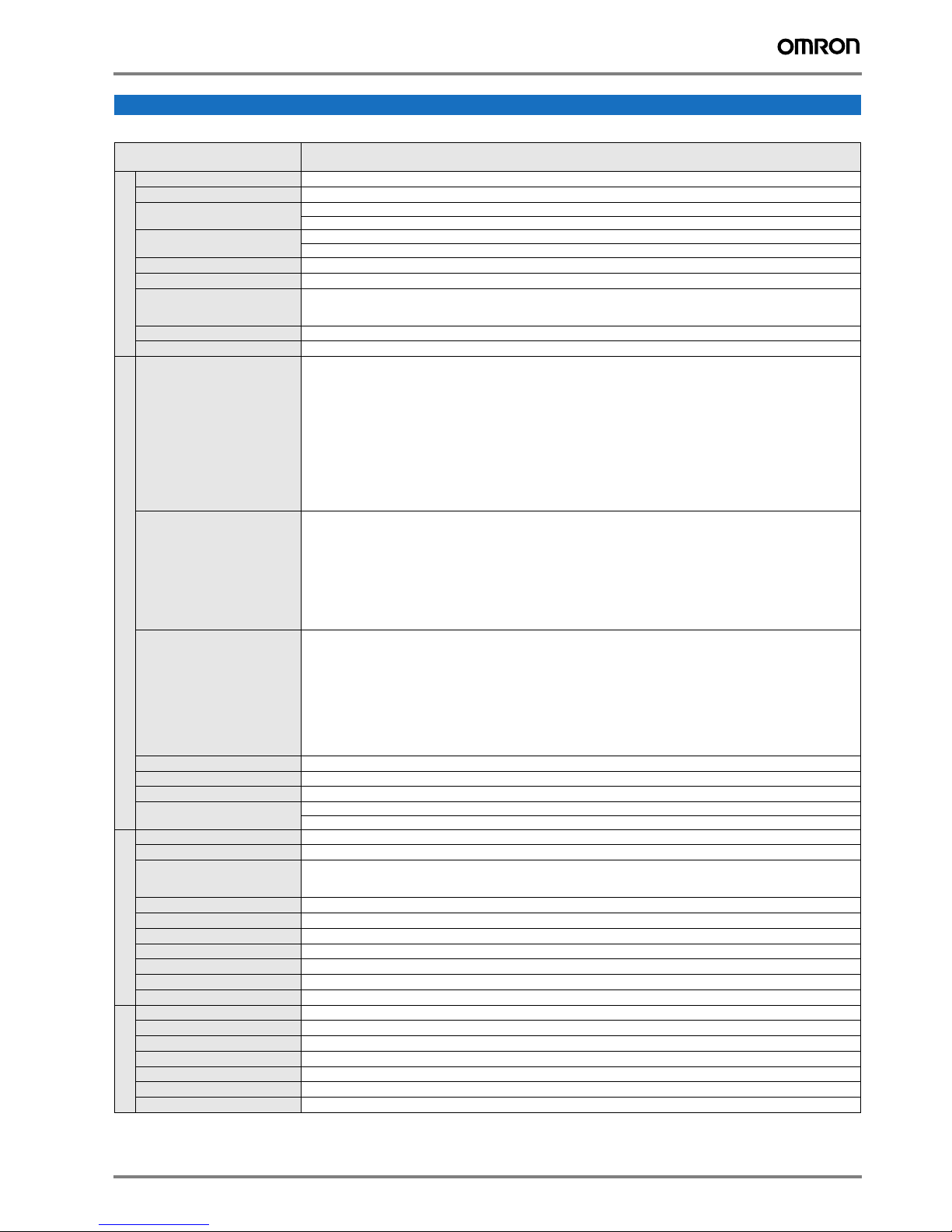

Specifications

Commom specifications

Model number

Control methods

Output frequency range

Frequency precision

Resolution of frequency set value

Resolution of output frequency

Starting torque

Control functions

Overload capability

Frequency set value

V/f Characteristics

Inputs signals

Output signals

Functionality

Standard functions

Analogue inputs

Pulse train input terminal

Accel/Decel times

Display

Motor overload protection

Instantaneous overcurrent

Overload

Overvoltage

Undervoltage

Momentary power loss

Cooling fin overheat

Protection functions

Stall prevention level

Ground fault

Power charge indication

Degree of protection

Ambient humidity

Storage temperature

Ambient temperature

Installation

Installation height

Ambient conditions

Vibration

MX2@

Specifications

Phase-to-phase sinusoidal pulse with modulation PWM (Sensorless vector control, V/F)

0.10..1000.00 Hz (with restrictions above 400Hz)

Digital set value: ±0.01% of the max. frequency

Analogue set value: ±0.2% of the max. frequency (25 ±10ºC)

Digital set value: 0.01 Hz

Analogue set value: 1/1000 of maximum frequency

0.01Hz

200% / 0.5 Hz

Dual rating:

Heavy duty (CT): 150% for 1 minute

Normal Duty (VT): 120% for 1 minute

0 to 10 VDC (10 KΩ), 4 to 20 mA (100 Ω), RS485 Modbus, Network options

Constant/ reduced torque, free V/f

FW (forward run command), RV (reverse run command), CF1~CF4 (multi-stage speed setting), JG (jog command), DB (external braking), SET (set second motor), 2CH (2-stage accel./decel. command), FRS (free run stop command), EXT (external

trip), USP (startup function), CS (commercial power switchover), SFT (soft lock), AT (analog input selection), RS (reset), PTC

(thermistor thermal protection), STA (start), STP (stop), F/R (forward/reverse), PID (PID disable), PIDC (PID reset), UP (remote control up function), DWN (remote control down function), UDC (remote control data clear), OPE (operator control),

SF1~SF7 (multi-stage speed setting; bit operation), OLR (overload restriction), TL (torque limit enable), TRQ1 (torque limit

changeover1), TRQ2 (torque limit changeover2), BOK (Braking confirmation), LAC (LAD cancellation), PCLR (position deviation clear), ADD (add frequency enable), F-TM (force terminal mode), ATR (permission of torque command input), KHC (Cumulative power clear), MI1~MI7 (general purpose inputs for EzSQ), AHD (analog command hold), CP1~CP3 (multistageposition switches), ORL (limit signal of zero-return), ORC (trigger signal of zero-return), SPD (speed/position changeover),

GS1~GS2 (STO inputs, safety related signals), 485 (Starting communication signal), PRG (executing EzSQ program), HLD

(retain output frequency), ROK (permission of run command), EB (rotation direction detection of B-phase), DISP (display limitation), OP (option control signal), NO (no function)

RUN (run signal), FA1~FA5 (frequency arrival signal), OL,OL2 (overload advance notice signal), OD (PID deviation error signal), AL (alarm signal), OTQ (over/under torque threshold), UV (under-voltage), TRQ (torque limit signal), RNT (run time expired), ONT (power ON time expired), THM (thermal warning), BRK (brake release), BER (brake error), ZS (0Hz detection),

DSE (speed deviation excessive), POK (positioning completion), ODc (analog voltage input disconnection), OIDc (analog

current input disconnection), FBV (PID second stage output), NDc (network disconnect detection), LOG1~LOG3 (Logic output signals), WAC (capacitor life warning), WAF (cooling fan warning), FR (starting contact), OHF (heat sink overheat warning), LOC (Low load), MO1~MO3 (general outputs for EzSQ), IRDY (inverter ready), FWR (forward operation), RVR (reverse

operation), MJA (major failure), WCO (window comparator O), WCOI (window comparator OI), FREF (frequency command

source), REF (run command source), SETM (second motor in operation), EDM (STO (safe torque off) performance monitor),

OP (option control signal), NO (no function)

Free-V/f, manual/automatic torque boost, output voltage gain adjustment, AVR function, reduced voltage start, motor data

selection, auto-tuning, motor stabilization control, reverse running protection, simple position control, simple torque control,

torque limiting, automatic carrier frequency reduction, energy saving operation, PID function, non-stop operation at

instantaneous power failure, brake control, DC injection braking, dynamic braking (BRD), frequency upper and lower

limiters, jump frequencies, curve accel and decel (S, U, inversed U,EL-S), 16-stage speed profile, fine adjustment of start

frequency, accel and decel stop, process jogging, frequency calculation, frequency addition, 2-stage accel/decel, stop mode

selection, start/end freq., analog input filter, window comparators, input terminal response time, output signal delay/hold

function, rotation direction restriction, stop key selection, software lock, safe stop function, scaling function, display

restriction, password function, user parameter, initialization, initial display selection, cooling fan control, warning, trip retry,

frequency pull-in restart, frequency matching, overload restriction, over current restriction, DC bus voltage AVR

2 analogue inputs 0 to 10 V (10 KΩ), 4 to 20 mA (100 Ω)

0 to 10 V (up to 24 V), up to 32 kHz

0.01 to 3600.0 s (line/curve selection), 2nd accel/decel setting available

Status indicator LED’s Run, Program, Alarm, Power, Hz, Amps

Digital operator: Available to monitor 32 items: frequency reference, output current, output frequency...

Electronic Thermal overload relay and PTC thermistor input

200% of rated current

Dual rating:

Heavy duty (CT): 150% for 1 minute

Normal Duty (VT): 120% for 1 minute

800 V for 400 V type and 400 V for 200 V type

345 V for 400 V type and 172.5 V for 200 V type

Following items are selectable: Alarm, decelerates to stop, decelerates to stop with DC bus controlled, restart

Temperature monitor and error detection

Stall prevention during acceleration/deceleration and constant speed

Detection at power-on

On when power is supplied to the control part

IP20, Varnish coating on PCB

90% RH or less (without condensation)

-20ºC..+65ºC (short-term temperature during transportation)

−10°C to 40°C

Indoor (no corrosive gas, dust, etc.)

Max. 1000 m

5.9 m/s2 (0.6G), 10 to 55 Hz

MX2 3

Page 4

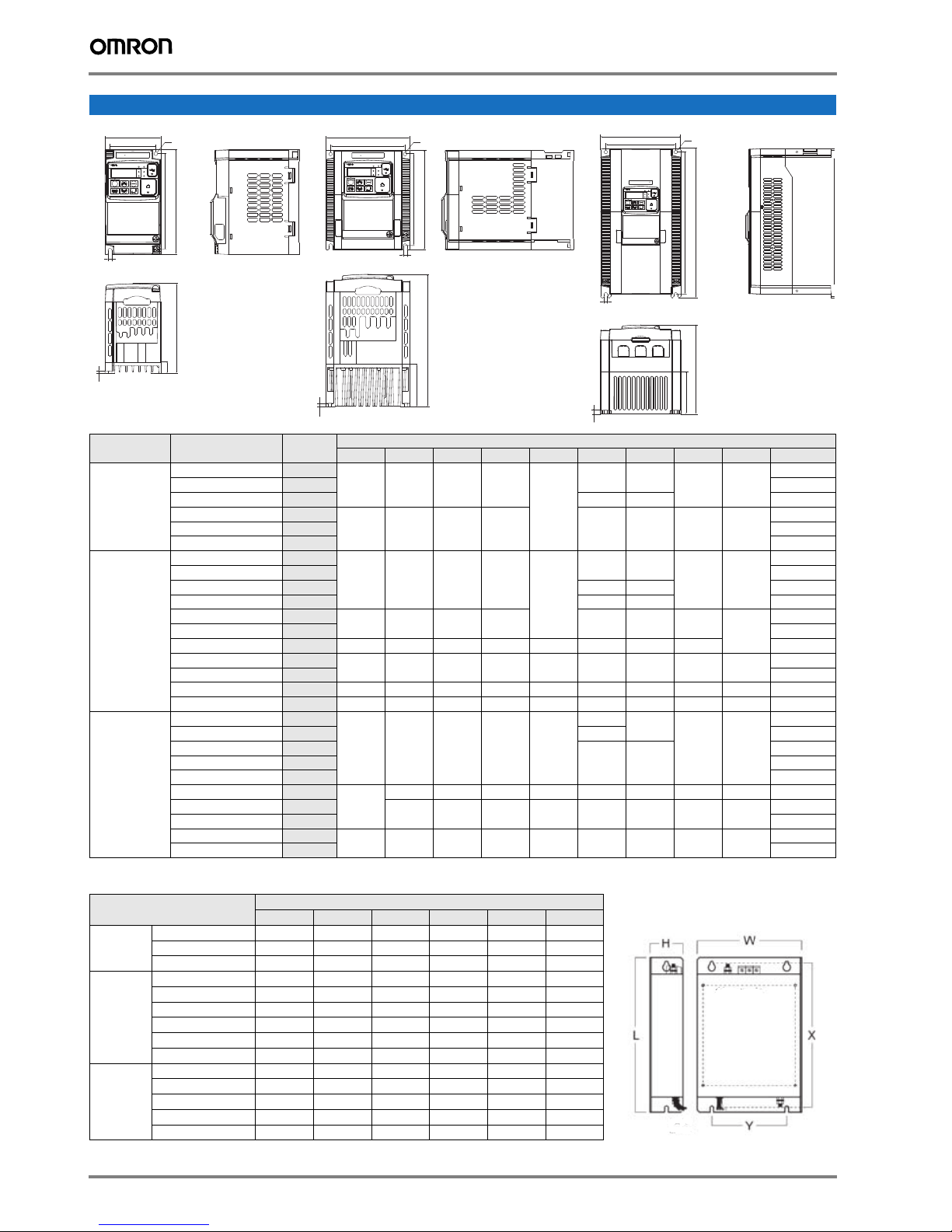

Dimensions

‚o‚v‚q

‚`‚k‚l

‚q‚t‚m

‚g‚š

‚o‚q‚f

‚q‚t‚m

‚r‚s‚n‚o

‚q‚d‚r‚d‚s

‚R‚f‚R‚l‚w‚Q?@?@

‚h‚m‚u‚d‚q‚s‚d‚q

‚o‚v‚q

‚`‚k‚l

‚q‚t‚m

‚g‚š

‚o‚q‚f

‚q‚t‚m

‚r‚s‚n‚o

‚q‚d‚r‚d‚s

‚R‚f‚R‚l‚w‚Q?@?@

‚h‚m‚u‚d‚q‚s‚d‚q

‚r‚x‚r‚c‚q‚h‚u‚d

‚o‚v‚q

‚`‚k‚l

‚q‚t‚m

‚g‚š

‚o‚q‚f

‚q‚t‚m

‚r‚s‚n‚o

‚q‚d‚r‚d‚s

‚R‚f‚R‚l‚w‚Q?@?@

‚h‚m‚u‚d‚q‚s‚d‚q

W

φ 4.5

W1

‚o‚v‚q

‚q‚t‚m

‚R‚f‚R‚l‚w‚Q

‚h‚m‚u‚d‚q‚s‚d‚q

‚`‚k‚l

‚g‚š

‚`‚`‚o‚q‚f

‚r‚s‚n‚o

‚q‚t‚m

‚q‚d‚r‚d‚s

W

W1

‚r‚x‚r‚c‚q‚h‚u‚d

‚R‚f‚R‚l‚w‚Q

‚h‚m‚u‚d‚q‚s‚d‚q

‚r‚s‚n‚o

‚q‚t‚m

‚q‚d‚r‚d‚s

HH1

φ 2-d

‚o‚v‚q

‚q‚t‚m

‚`‚k‚l

‚g‚š

‚`‚`‚o‚q‚f

H1

H

W

W1

‚R‚f‚R‚l‚w‚Q

‚h‚m‚u‚d‚q‚s‚d‚q

‚q‚t‚m

φ 2-d

‚o‚v‚q

‚q‚t‚m

‚`‚k‚l

‚g‚š

‚`‚`‚o‚q‚f

‚r‚s‚n‚o

‚q‚d‚r‚d‚s

H

H1

5

D

Figure 1

D1

2,6

Voltage class Inverter model MX2@ Figure

Single-phase

200 V

AB001

AB002

AB004

AB007

1

1 1.0

1

2

AB015 2 1.8

2 1.8

1

1 1.0

1 113 27 1.1

1 146 50 1.2

2

2 1.8

3 140 128 128 118 5 170.5 55 4.4 2.0

3

3 3.4

3 180 160 296 284 7 175 97 5 7 5.1

3 220 192 350 336 7 175 84 5 7 7.4

2

2 171 1.6

2

2 1.9

2 1.9

3

3

3 3.5

3

3 5.2

Three-phase

200 V

Three-phase

400 V

AB022

A2001

A2002

A2004

A2007

A2015

A2022

A2037

A2055

A2075

A2110

A2150

A4004

A4007

A4015

A4022

A4030

A4040

A4055

A4075

A4110

A4150

t

t

D

D1

D2

Figure 2

D

D1

D2

Dimensions in mm

W W1 H H1 t D D1 D2 d Weight (KG)

68 56 128 118

109 13.5

123 27 1.1

-

--

108 96 128 118 170.5 55 4.4 4.5

109 13.5

68 56 128 118

--

-

108 96 128 118 170.5 55 4.4

4.5

140 122 260 248 6 155 73.3 6 6

144

108 96 128 118 -

28

--

171 55

128 128 118 5 171 55 4.4 4.5 2.1

140

122 260 248 6 155 73.3 6 6

180 160 296 284 7 175 97 5 7

Figure 3

1.0

1.4

1.0

1.6

3.0

1.5

1.8

3.5

4.7

Rasmi footprint filters

Rasmi model

AX-FIM1010-RE 71 45 169 156 51 M4

1x200 V

3x200 V

AX-FIM1014-RE 111 50 169 156 91 M4

AX-FIM1024-RE 111 50 169 156 91 M4

AX-FIM2010-RE 82 50 194 181 62 M4

AX-FIM2020-RE 111 50 169 156 91 M4

AX-FIM2030-RE 144 50 174 161 120 M4

AX-FIM2060-RE 150 52 320 290 122 M5

AX-FIM2080-RE 188 62 362 330 160 M5

AX-FIM2100-RE 220 62 415 380 192 M6

AX-FIM3005-RE 111 45 169 156 91 M4

AX-FIM3010-RE 114 45 169 156 91 M4

3x400 V

AX-FIM3014-RE 144 50 174 161 120 M4

AX-FIM3030-RE 150 52 306 290 122 M5

AX-FIM3050-RE 182 62 357 330 160 M5

W H L X Y M

4 Frequency inverters

Dimensions

Page 5

Option board

31.3

Input AC reactor

Voltage Reference

AX-RAI02800080-DE 120 70 120 80 52 5.5 1.78

AX-RAI00880200-DE 120 80 120 80 62 5.5 2.35

200 V

AX-RAI00350335-DE 180 85 190 140 55 6 5.5

AX-RAI00180670-DE 180 85 190 140 55 6 5.5

AX-RAI07700050-DE 120 70 120 80 52 5.5 1.78

AX-RAI03500100-DE 120 80 120 80 62 5.5 2.35

400 V

AX-RAI01300170-DE 120 80 120 80 62 5.5 2.50

AX-RAI00740335-DE 180 85 190 140 55 6 5.5

Dimensions Weight

A

B2 C2 D E F

kg

DC Reactor

Voltage Reference

AX-RC21400016-DE

AX-RC10700032-DE

AX-RC06750061-DE

AX-RC03510093-DE

AX-RC02510138-DE

AX-RC01600223-DE

200 V

AX-RC01110309-DE

AX-RC00840437-DE

AX-RC00590614-DE

AX-RC00440859-DE

AX-RC43000020-DE

AX-RC27000030-DE

AX-RC14000047-DE

AX-RC10100069-DE

AX-RC06400116-DE

400 V

AX-RC04410167-DE

AX-RC03350219-DE

AX-RC02330307-DE

AX-RC01750430-DE

Output AC Reactor

Voltage Reference

AX-RAO11500026-DE 120 70 120 80 52 5.5 1.78

AX-RAO07600042-DE 120 70 120 80 52 5.5 1.78

AX-RAO04100075-DE 120 80 120 80 62 5.5 2.35

AX-RAO03000105-DE 120 80 120 80 62 5.5 2.35

200 V

AX-RAO01830180-DE 180 85 190 140 55 6 5.5

AX-RAO01150220-DE 180 85 190 140 55 6 5.5

AX-RAO00950320-DE 180 85 205 140 55 6 6.5

AX-RAO00630430-DE 180 95 205 140 65 6 9.1

AX-RAO00490640-DE 180 95 205 140 65 6 9.1

A

B C D E F G H

96

Dimensions Weight

84 113

101 66 5 7.5 2

105 1.60

116 1.95

108 135 124 120 82 6.5

120 152

136

135 94

146 6.00

160

150 177

160 115 2

182.

6

96

84 113

101 66 5 7.5 2

105 1.60

116 1.95

108 135 133 120 82 6.5

120 152

136

135 94 7

146 6.00

160

150 177

160 115 7 2

182.

6

Dimensions Weight

A

B2 C2 D E F

kg

1.22

9.5 3.20

9.5

7-

5.20

11.4

14.3

1.22

9.5 3.70

9.5

5.20

-

11.4

14.3

kg

MX2 5

Page 6

Voltage Reference

X

H

YW

Ø

m

L

Ø

d

AX-REM00K1200

Fig 1

Fig 3

Fig 4

A

Dimensions Weight

B2 C2 D E F

kg

AX-RAO16300038-DE 120 70 120 80 52 5.5 1.78

AX-RAO11800053-DE 120 80 120 80 52 5.5 2.35

AX-RAO07300080-DE 120 80 120 80 62 5.5 2.35

400 V

AX-RAO04600110-DE 180 85 190 140 55 6 5.5

AX-RAO03600160-DE 180 85 205 140 55 6 6.5

AX-RAO02500220-DE 180 95 205 140 55 6 9.1

AX-RAO02000320-DE 180 105 205 140 85 6 11.7

Chokes

Reference D

diameter

AX-FER2102-RE 21 < 2.2 85 22 46 70 - 5 0.1

AX-FER2515-RE 25 < 15 105 25 62 90 - 5 0.2

AX-FER5045-RE 50 < 45 150 50 110 125 30 5 0.7

Motor

kW

Dimensions Weight

L W H X Y m

Resistor dimensions

kg

Fig 2

Type Fig.

AX-REM00K1400-IE

AX-REM00K2070-IE

AX-REM00K2120-IE

AX-REM00K2200-IE

AX-REM00K4075-IE

AX-REM00K4030-IE

AX-REM00K5120-IE 260 27 36 249 - 0.58

AX-REM00K6100-IE

AX-REM00K6035-IE

AX-REM00K9070-IE

AX-REM00K9017-IE

AX-REM01K9070-IE

AX-REM01K9017-IE

AX-REM02K1070-IE

AX-REM02K1017-IE

AX-REM03K5035-IE

AX-REM03K5010-IE

1

2 200 62 100 74 - 1.41AX-REM00K9020-IE

3 365 73 105 350 70 4

4

L H M I T kg

105 27 36 94 - 0.2

200 27 36 189 - 0.425AX-REM00K4035-IE

320 27 36 309 - 0.73

310 100 240 295 210 7

365 100 240 350 210 8

Dimensions

Weight

6 Frequency inverters

Page 7

Standard connections

Power source,

3-phase or

1-phase, per

inverter model

NOTE: For the wiring

of intelligent I/O and

analog inputs, be sure

to use twisted pair/

shielded cable. Attach

the shielded wire for

each signal to its

respective common

terminal at the inverter

end only.

Input impedance of

each intelligent input is

4.7kΩ

Thermistor

Breaker, MCCB

or GFI

Intelligent inputs,

7 terminals

Short bar

(Source type)

GND for logic inputs

Meter

Meter

Analog reference

Pulse train input

24Vdc 32kHz max.

GND for analog signals

Forward

0~10VDC

4~20mA

R

(L1)

S

(L2)

T

N(L3)

P24

MX2

24V

+ -

1

2

3/GS1

Input

circuits

4/GS2

6

[5] configurable as

discrete input or

thermistor input

Output circuit

5/PTC

7/EB

U

(T1)

V

(T2)

W

(T3)

PD/+1

P/+

RB

N/-

AL1

Relay contacts,

type 1 Form C

AL0

AL2

Open collector output

11/EDM

DC reactor

(optional)

Brake

resistor

(optional)

Freq. arrival signal

Load

(optional)

Motor

Braking

unit

PLC

L

L

12

Load

+

-

CM2

GND for logic outputs

EO

L

AM

L

H

O

OI

Apprx.10kΩ

Apprx.100Ω

L

EA

L

Termination resistor (200Ω)

(Change by slide switch)

10Vdc

+

-

L

L

RS485

transceiver

L

RS485

transceiver

USB

transceiver

Option port

controller

)

SP

Serial communication port

(RS485/ModBus)

SN

RJ45 port

L

L

L

(Optional operator port)

USB (mini-B) port

(PC communication port)

USB power: Self power

Option port connector

Terminal Block Specifications

Terminal Name Function (signal level)

R/L1, S/L2, T/L3

U/T1, V/T2, W/T3

PD/+1, P/+

P/+, N/-

P/+, RB

Main circuit power supply input Used to connect line power to the drive.

Inverter output Used to connect the motor

External DC reactor terminal Normally connected by the short-circuit bar. Remove the short-circuit bar between +1 and P/

Regenerative braking unit terminal

Braking resistor terminals

Grounding For grounding (grounding should conform to the local grounding code.)

MX2 7

Drives with single-phase 200 V input power use only terminals R/L1 and N (T/L3), terminal

S/L2 is not available for these units

+2 when a DC reactor is connected.

Connect optional regenerative braking units (If a braking torque is required)

Connect option braking resistor (if a braking torque is required)

Page 8

Control Circuit

Enclosure

Type No.

PLC

P24

1

2

3/ST1

4/ST2

5/PTC

Digital input signals

train

Pulse

signal

Analog input

signals

Digital output

6

7/EB

L

EA

EO

H

O

OI

L

11/EDM

12

CMD

AL0

AL1

AL2

Signal name Function Signal level

Intelligent input common

Internal 24 VDC 24 VDC, 30mA 24 VDC, 30 mA

Multi-function Input selection 1 Factory setting: Forward/ Stop

Multi-function Input selection 2 Factory setting: Reverse/ Stop

Multi-function Input selection 3 / safe stop input 1 Factory setting: External trip

Multi-function Input selection 4 / safe stop input 2 Factory setting: Reset

Multi-function Input selection 5 / PTC thermistor input Factory setting: Multi-step speed reference 1

Multi-function input selection 6 Factory setting: Multi-step speed reference 2

Multi-function input selection 7 / Pulse train input B Factory setting: Jog

Multi-function Input selection common (in upper row) -- --

Pulse train input A Factory setting: Speed reference

Pulse train output LAD frequency

Frequency reference power supply 10 VDC 10 mA max

Voltage frequency reference signal 0 to 10 VDC (10 kΩ)

Current frequency reference signal 4 to 20 mA (250 Ω)

Frequency reference common (bottom row) --

Discrete logic output 1 / EDM output

Discrete logic output 2 Factory setting: Frequency arrival type 1

GND logic output --

Relay commom contact

Relay contact, normally open

Relay contact, normally closed

Source type: connecting [P24] to [1]-[7] turns inputs ON

Sink type: connecting [L] to [1]-[7] turns inputs ON

Factory setting: During Run

Factory setting: Alarm signal

Under normal operation

AL1 - AL0 Closed

AL2 - AL0 Open

-

27 VDC max

32 kHz max

5 to 24 VDC

10 VDC 2 mA

32 kHz max

27 VDC, 50 mA max

EDM based on

ISO13849-1

R load

250 VAC 2.5 A

30 VDC 3.0 A

I load

250 VAC 0.2 A

30 VDC 0.7 A

Signal

Monitor

Comms

AM

SP

SN

Analog voltage output Factory setting: LAD frequency 0 to 10 VDC 1 mA

Serial communication terminal RS485 Modbus communication

Side by side mounting

Inverter heat loss

Three-phase 200 V class

Model MX2 A2001 A2002 A2004 A2007 A2015 A2022 A2037 A2055 A2075 A2110 A2150

Inverter

capacity

kVA

Rated current (A) VT

Rated current (A) CT

Efficiency at rated load

Cooling Method Self cooling

200 VT

200 CT

240 VT

240 CT

Total heat loss

0.4 0.6 1.2 2.0 3.3 4.1 6.7 10.3 13.8 19.3 23.9

0.2 0.5 1.0 1.7 2.7 3.8 6.0 8.6 11.4 16.2 20.7

0.4 0.7 1.4 2.4 3.9 4.9 8.1 12.4 16.6 23.2 28.6

0.3 0.6 1.2 2.0 3.3 4.5 7.2 10.3 13.7 19.5 24.9

1.2 1.9 3.4 6.0 9.6 12.0 19.6 30.0 40.0 56.0 69.0

1.0 1.6 3.0 5.0 8.0 11.0 17.5 25.0 33.0 47.0 60.0

12 22 30 48 79 104 154 229 313 458 625

89.5 90 93 94 95 95.5 96 96 96 96 96

Forced-air-cooling

8 Frequency inverters

Page 9

Single-phase 200 V class

Model MX2 AB001 AB002 AB004 AB007 AB015 AB022

Inverter

capacity

kVA

Rated current (A) VT

Rated current (A) CT

Efficiency at rated load

200V VT

200V CT

240V VT

240V CT

Total heat loss

Cooling Method Self cooling Forced-air-cooling

Three-phase 400 V class

Model MX2 A4004 A4007 A4015 A4022 A4030 A4040 A4055 A4075 A4110 A4150

Inverter

capacity

kVA

Rated current (A) VT

Rated current (A) CT

Efficiency at rated load 92 93 94 95 96 96 96 96.2 96.4 96.6

380V VT

380V CT

480V VT

480V CT

Total heat loss 35 56 96 116 125 167 229 296 411 528

Cooling Method Self cooling Forced-air-cooling

Input AC Reactor

0.4 0.6 1.2 2.0 3.3 4.1

0.2 0.5 1.0 1.7 2.7 3.8

0.4 0.7 1.4 2.4 3.9 4.9

0.3 0.6 1.2 2.0 3.3 4.5

1.2 1.9 3.4 6.0 9.6 12.0

1.0 1.6 3.0 5.0 8.0 11.0

12 22 30 48 79 104

89.5 90 93 94 95 95.5

1.3 2.6 3.5 4.5 5.7 7.3 11.5 15.1 20.4 25.0

1.1 2.2 3.1 3.6 4.7 6.0 9.7 11.8 15.7 20.4

1.7 3.4 4.4 5.7 7.3 9.2 14.5 19.1 25.7 31.5

1.4 2.8 3.9 4.5 5.9 7.6 12.3 14.9 19.9 25.7

2.1 4.1 5.4 6.9 8.8 11.1 17.5 23.0 31.0 38.0

1.8 3.4 4.8 5.5 7.2 9.2 14.8 18.0 24.0 31.0

Power supply

MCCB

AC reactor

V

W

X

YZS/L2

MX2

R/L1U

T/L3

Max. applicable

motor output kW

1.5 AX-RAI02800080-DE 8.0 2.8 1.5 AX-RAI07700050-DE

3.7 AX-RAI00880200-DE 20.0 0.88 4.0 AX-RAI03500100-DE 10.0 3.5

7.5 AX-RAI00350335-DE 33.5 0.35 7.5 AX-RAI01300170-DE

15 AX-RAI00180670-DE 67.0 0.18 15 AX-RAI00740335-DE

3 phase 200 V class 400 V class

Reference

Current value AInductancemHMax. applicable

motor output kW

Reference

Current value AInductance

5.0 7.7

17.0 1.3

33.5 0.74

DC Reactor

Power

supply

Max. applicable

motor output kW

0.2 AX-RC21400016-DE 1.6 21.4 0.4 AX-RC43000020-DE

0.4 AX-RC10700032-DE 3.2 10.7 0.7 AX-RC27000030-DE 3.0 27.0

0.7 AX-RC06750061-DE 6.1 6.75 1.5 AX-RC14000047-DE

1.5 AX-RC03510093-DE 9.3 3.51 2.2 AX-RC10100069-DE 6.9 10.1

2.2 AX-RC02510138-DE 13.8 2.51 3.0 AX-RC08250093-DE 9.3 8.25

3.7 AX-RC01600223-DE 22.3 1.60 4.0 AX-RC06400116-DE 11.6 6.40

5.5 AX-RC01110309-DE 30.9 1.11 5.5 AX-RC04410167-DE 16.7 4.41

7.5 AX-RC00840437-DE 43.7 0.84 7.5 AX-RC03350219-DE 21.9 3.35

11.0 AX-RC00590614-DE 61.4 0.59 11.0 AX-RC02330307-DE 30.7 2.33

15.0 AX-RC00440859-DE 85.9 0.44 15.0 AX-RC01750430-DE 43.0 1.75

Output AC

Max. applicable

motor output kW

Reactor

0.4 AX-RAO11500026-DE 2.6 11.50

0.75 AX-RAO07600042-DE 4.2 7.60

1.5 AX-RAO04100075-DE 7.5 4.10

2.2 AX-RAO03000105-DE 10.5 3.00 2.2 AX-RAO11800053-DE 5.3 11.80

3.7 AX-RAO01830160-DE 16.0 1.83 4.0 AX-RAO07300080-DE

5.5 AX-RAO01150220-DE 22.0 1.15 5.5 AX-RAO04600110-DE 11.0 4.60

7.5 AX-RAO00950320-DE 32.0 0.95 7.5 AX-RAO03600160-DE 16.0 3.60

11 AX-RAO00630430-DE 43.0 0.63 11 AX-RAO02500220-DE 22.0 2.50

15 AX-RAO00490640-DE 64.0 0.49 15 AX-RAO02000320-DE 32.0 2.00

200 V class 400 V class

Reference

200 V class 400 V class

Reference

Current value AInductancemHMax. applicable

Current value AInductancemHMax. applicable

MCCB

motor output kW

motor output kW

MX2

R/L1

S/L2

T/L3

+1 P/+2

DC reactor

Reference

Reference

1.5 AX-RAO16300038-DE

Current value AInductance

2.0 43.0

4.7 14.0

Current value AInductance

3.8 16.30

8.0 7.30

mH

mH

mH

MX2 9

Page 10

Ordering information

Choke

A

B

B

LCD 5 lines remote

operator

Remote operator

extension cable

A

A

C

A

Output AC reactor

Communication option

USB cable

Braking resistor

D

B

E

A

CX-Drive

CX-One

MCCB

MX2

Filter

Input AC reactor

Motor

Ground

Power

supply

DC reactor

MX2

Voltage class

Single-phase 200 V

Three-phase 200 V

Three-phase

400 V

Specifications Model

Constant torque

Max motor kW

0.1 1.0 0.2 1.2 MX2-AB001-E

0.2 1.6 0.4 1.9 MX2-AB002-E

0.4 3.0 0.55 3.5 MX2-AB004-E

0.75 5.0 1.1 6.0 MX2-AB007-E

1.5 8.0 2.2 9.6 MX2-AB015-E

2.2 11.0 3.0 12.0 MX2-AB022-E

0.1 1.0 0.2 1.2 MX2-A2001-E

0.2 1.6 0.4 1.9 MX2-A2002-E

0.4 3.0 0.55 3.5 MX2-A2004-E

0.75 5.0 1.1 6.0 MX2-A2007-E

1.5 8.0 2.2 9.6 MX2-A2015-E

2.2 11.0 3.0 12.0 MX2-A2022-E

3.7 17.5 5.5 19.6 MX2-A2037-E

5.5 25.0 7.5 30.0 MX2-A2055-E

7.5 33.0 11 40.0 MX2-A2075-E

11 47.0 15 56.0 MX2-A2110-E

15 60.0 18.5 69.0 MX2-A2150-E

0.4 1.8 0.75 2.1 MX2-A4004-E

0.75 3.4 1.5 4.1 MX2-A4007-E

1.5 4.8 2.2 5.4 MX2-A4015-E

2.2 5.5 3.0 6.9 MX2-A4022-E

3.0 7.2 4.0 8.8 MX2-A4030-E

4.0 9.2 5.5 11.1 MX2-A4040-E

5.5 14.8 7.5 17.5 MX2-A4055-E

7.5 18.0 11 23.0 MX2-A4075-E

11 24.0 15 31.0 MX2-A4110-E

15 31.0 18.5 38.0 MX2-A4150-E

Rated current A Max motor kW Rated current A

Variable torque

Standard

10 Frequency inverters

Page 11

A Line filters A Input AC reactors

Inverter

Voltage Model MX2-@ Reference

1-Phase 200

VAC

3-Phase 200

VAC

3-Phase 400

VAC

AB001 / AB002 / AB004 AX-FIM1010-RE 10

AB007 AX-FIM1014-RE 14

AB015 / AB022 AX-FIM1024-RE 24

A2001 / A2002 /

A2004 / A2007

A2015 / A2022 AX-FIM2020-RE 20

A2037 AX-FIM2030-RE 30

A2055 / A2075 AX-FIM2060-RE 60

A2110 AX-FIM2080-RE 80

A2150 AX-FIM2100-RE 100

A4004 / A4007 AX-FIM3005-RE 5

A4015 / A4022 /

A4030

A4040 AX-FIM3014-RE 14

A4055 / A4075 AX-FIM3030-RE 23

A4110 / A4150 AX-FIM3050-RE 50

Line filter Rasmi

Rated current

(A)

AX-FIM2010-RE 10

AX-FIM3010-RE 10

Voltage Model MX2-@ Reference

Inverter

3-Phase 200 VAC

1-Phase 200 VAC

3-Phase 400 VAC

A DC reactors

200V single phase

Inverter

MX2-AB001

MX2-AB002 MX2-A2002 MX2-A4007 AX-RC27000030-DE

MX2-AB004 AX-RC06750061-DE MX2-A2004 AX-RC10700032-DE MX2-A4015 AX-RC14000047-DE

MX2-AB007 AX-RC03510093-DE MX2-A2007 AX-RC06750061-DE MX2-A4022 AX-RC10100069-DE

MX2-AB015 AX-RC02510138-DE MX2-A2015 AX-RC03510093-DE MX2-A4030 AX-RC08250093-DE

MX2-AB022 AX-RC01600223-DE MX2-A2022 AX-RC02510138-DE MX2-A4040 AX-RC06400116-DE

DC Reactor

AX-RC10700032-DE

-

200V 3-phase 400V 3-phase

Inverter

MX2-A2001

MX2-A2037 AX-RC01600223-DE MX2-A4055 AX-RC04410167-DE

MX2-A2055 AX-RC01110309-DE MX2-A4075 AX-RC03350219-DE

MX2-A2075 AX-RC00840437-DE MX2-A4011 AX-RC02330307-DE

MX2-A2011 AX-RC00590614-DE MX2-A4015 AX-RC01750430-DE

MX2-A2015 AX-RC00440859-DE -

DC Reactor

AX-RC21400016-DE

MX2-A4004 AX-RC43000020-DE

AC Reactor

A2002 / A2004 / A2007 AX-RAI02800080-DE

A2015 / A2022 / A2037 AX-RAI00880200-DE

A2055 / A2075 AX-RAI00350335-DE

A2110 / A2150 AX-RAI00180670-DE

AB002 / AB004

AB015 / AB022

A4004 / A4007 / A4015 AX-RAI07700050-DE

A4022 / A4030 / A4040 AX-RAI03500100-DE

A4055 / A4075 AX-RAI01300170-DE

A4110 / A4150 AX-RAI00740335-DE

Inverter

Under developmentAB007

DC Reactor

A Chokes A Output AC reactor

Model Diameter Description

AX-FER2102-RE 21 For 2.2 KW motors or below

AX-FER2515-RE 25 For 15 KW motors or below

AX-FER5045-RE 50 For 45 KW motors or below

Voltage Model MX2-@ Reference

200 VAC

400 VAC

B Accessories

Types Model Description Functions

Digital

operator

Accessories

AX-OP05-E LCD remote operator 5 Line LCD remote operator with copy function, cable length max. 3m.

3G3AX-CAJOP300-EE Remote operator cable 3 meters cable for connecting remote operator

3G3AX-OP01 LED remote operator LED remote operator, cable length max. 3m

4X-KITMINI Mounting kit for LED operator Mounting kit for LED operator on panel

AX-CUSBM002-E PC configuration cable Mini USB to USB connector cable

Inverter

A2001 / A2002 / A2004

AB001 / AB002 / AB004

A2007/AB007 AX-RAO07600042-DE

A2015 / AB015 AX-RAO04100075-DE

A2022 / AB022 AX-RAO03000105-DE

A4004 / A4007 / A4015 AX-RAO16300038-DE

A4030 / A4040 AX-RAO07300080-DE

AC Reactor

AX-RAO11500026-DE

A2037 AX-RAO01830160-DE

A2055 AX-RAO01150220-DE

A2075 AX-RAO00950320-DE

A4022 AX-RAO11800053-DE

A4055 AX-RAO04600110-DE

A4075 AX-RAO03600160-DE

MX2 11

Page 12

C Communication option boards

In the interest of product improvement, specifications are subject to change without notice.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. I113E-EN-02

Types Model Description Functions

3G3AX-MX2-PRT Profibus option card

3G3AX-MX2-DRT DeviceNet option card

3G3AX-MX2-ERT Ethercat option card Under development

3G3AX-MX2-CRT CompoNet option card

Communication options

3G3AX-MX2-ML2 Mechatrolink II option card Under development

3G3AX-MX2-CORT CanOpen option card Under development

Used for running or stopping the inverter, setting or referencing parameters, and monitoring

output frequency, output current, or similar items through Profibus communications with the

host controller.

Used for running or stopping the inverter, setting or referencing parameters, and monitoring

output frequency, output current, or similar items through DeviceNet communications with the

host controller.

Used for running or stopping the inverter, setting or referencing parameters, and monitoring

output frequency, output current, or similar items through CompoNet communications with the

host controller.

D Braking unit, braking resistor unit

Voltage

200 V

(single-/

three-

phase)

400 V

(three-

phase)

Inverter Braking resistor unit

Max.

motor

kW

0.12 2001 B001

0.25 2002 B002 180 180

0.55 2004 B004

1.1 2007 B007

1.5 2015 B015

2.2 2022 B022

4.0 2040 - REM00K4075-IE 75 50 REM00K6035-IE 35 100

5.5 2055 – 20

7.5 2075 –

11 2110 - REM00K6035-IE 35 40 REM02K1017-IE 17 75

15 2150 - 10 REM00K9017-IE 17 55 REM03K5010-IE 10 95

0.55 4004 –

1.1 4007 – 200 200

1.5 4015 – REM00K1200-IE 200 190 REM00K2200-IE 200 190

2.2 4022 –

3.0 4030 –

4.0 4040 – 120 REM00K6100-IE 100 140

5.5 4055 –

7.5 4075 – 100 REM01K9070-IE 70 110

11 4110 - REM00K6100-IE 100 50 REM02K1070-IE 70 75

15 4150 - 35 REM00K9070-IE 70 55 REM03K5035-IE 35 110

Inverter MX2@

3-phase 1-phase Type AX- Resist Ω Type AX- Resist Ω

Connectable

min.

resistance Ω

100

50

35

17

180

100

70

Inverter mounted type

(3 %ED, 10 sec max)

REM00K1400-IE 400

REM00K1200-IE 200

REM00K2070-IE 70

REM00K4035-IE 35

REM00K1400-IE 400

REM00K2200-IE 200 130

REM00K2120-IE 120

REM00K4075-IE 75

Braking

torque %

200

180 REM00K1200-IE 200 180

100 REM00K2070-IE 70 200

140 REM00K4075-IE 75 130

90 REM00K4035-IE 35 180

75 REM00K9020-IE 20 150

55 REM01K9017-IE 17 110

200

160 160

140 REM00K9070-IE 70 150

E Computer software

Types Model Description Installation

CX-drive Computer software Configuration and monitoring software tool

Inverter mounted type

(10%ED, 10 sec max)

REM00K1400-IE 400

REM00K1400-IE 400

REM00K5120-IE 120

Braking

torque %

200

200

200

Software

CX-One Computer software Configuration and monitoring software tool

12 Frequency inverters

Loading...

Loading...