Page 1

Cat. No. F04E-EN-02

Safety Light Curtain Type 4

MS4800E

OPERATION MANUAL

Page 2

Page 3

MS4800E

Safety Light Curtain Type 4

Installation and Operating Manual

March 2010

Omron Europe B.V.

Wegalaan 67-69

NL-2132 JD, Hoofddorp

Pays-Bas

Tel.: +31 (0) 23 568 13 00

Fax: +31 (0) 23 568 13 88

www.industrial.omron.eu

Page 4

iv

Page 5

Notice:

© OMRON, 2010

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

OMRON products are manufactured for use according to proper procedures

by a qualified operator and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this

manual. Always heed the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also

capitalized when it refers to an OMRON product, regardless of whether or not

it appears in the proper name of the product.

Visual Aids

The following headings appear in the left column of the manual to help you

locate different types of information.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 6

vi

Page 7

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

1 Precautions on Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

2 Alert Statements in this manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

3 Precautions for Safe Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

4 Precautions for Correct Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

SECTION 1

Important Safety Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SECTION 2

Product features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SECTION 3

System Components and Indicators . . . . . . . . . . . . . . . . . . . 4

SECTION 4

System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4-1 Operating States. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4-2 Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4-3 MS4800FS Cascaded Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SECTION 5

Detection Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5-1 Fixed Blanking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5-2 Floating Blanking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5-3 Fixed Blanking with Floating Blanking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5-4 Optical Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

SECTION 6

Diagnostic and Test Features. . . . . . . . . . . . . . . . . . . . . . . . . 17

6-1 Individual Beam Indicators (IBI). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6-2 External Device Monitoring (EDM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6-3 Machine test signal (MTS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

6-4 Range selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6-5 Start/Restart Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

vii

Page 8

SECTION 7

Using selector switches to set features. . . . . . . . . . . . . . . . . . 19

7-1 Access to the selector switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

7-2 Operating mode selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

7-3 Selecting and programming Fixed Blanking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7-4 Selecting and programming Floating Blanking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7-5 Selecting External Device Monitoring (EDM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7-6 Selecting Machine Test Signal (MTS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7-7 Selecting Scan Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

SECTION 8

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8-1 Safety Outputs (OSSDs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

8-2 Auxiliary Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

SECTION 9

Safe Mounting Distances . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9-1 Safety distance for safeguarding danger points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9-2 Safety distance for safeguarding danger areas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

9-3 Safety distance and beam heights in access guarding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

SECTION 10

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10-1 Reflective Surface Interference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

10-2 Cross Talk Mitigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

10-3 General Mounting Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

SECTION 11

Connection to the Machine Control Circuit. . . . . . . . . . . . . 35

11-1 Interconnect cables for cascaded MS4800FS system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

11-2 Connection to two forcibly guided relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

11-3 Connection to a safety relay unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

SECTION 12

Muting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

12-1 Muting Controller RM-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

SECTION 13

Checkout and test procedure . . . . . . . . . . . . . . . . . . . . . . . . . 41

13-1 Checkout Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

13-2 Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

13-3 Using the test object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

viii

Page 9

SECTION 14

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

SECTION 15

Specifications and additional information . . . . . . . . . . . . . . 45

15-1 System Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

15-2 MS4800 system Dimensional Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

15-3 MS4800 system data with 14 mm resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

15-4 MS4800 system data with 30 mm resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

15-5 MS4800FS system Dimensional Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

15-6 MS4800FS system data with 14 mm resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

15-7 MS4800FS system data with 30 mm resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

15-8 List of models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

15-9 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

SECTION 16

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

SECTION 17

Diagnostics and Troubleshooting . . . . . . . . . . . . . . . . . . . . . 73

17-1 Transmitter Diagnostic information and troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

17-2 Receiver Diagnostic Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

17-3 Receiver Endcap Indicator Lights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

17-4 Receiver Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

17-5 Receiver Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

17-6 FAQ. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

SECTION 18

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

18-1 Appendix A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

18-2 Appendix B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

18-3 EC Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

ix

Page 10

Introduction

Thank you for purchasing the MS4800 series Safety Light Curtain. This is the instruction manual

describing the use of the MS4800 system.

Important notice

This manual provides installation and operating information on the following models:

Resolution 14 mm, standalone MS4800S-EB-014 MS4800S-EA-014

Resolution 14 mm, cascadable MS4800FS-EB-014 MS4800FS-EA-014

Resolution 30 mm, standalone MS4800S-EB-030 MS4800S-EA-030

Resolution 30 mm, cascadable MS4800FS-EB-030 MS4800FS-EA-030

Where information is common on all models the term "MS4800 system" will be used. Where information is given for a specific model the model number will be used.

Always heed the following points when using the MS4800 system:

1. Be sure to have MS4800 system handled by a "Responsible Person" who is well aware of and

familiar with the machine to be installed.

2. The term "Responsible Person" used in this Instruction manual means the person qualified,

authorized and responsible to secure "safety" in each process of the design, installation, operation, maintenance services and disposition of the machine.

3. It is assumed that MS4800 system will be used properly according to the installation environment, performance and function of the machine. Responsible Person should conduct risk

assessment on the machine and determine the suitability of this product before installation.

4. Read this Manual thoroughly to understand and make good use of the descriptions before

installing and operating the product.

5. Keep this Manual at the place where the operator can refer to whenever necessary.

Basic Advanced

x

Page 11

Read and understand this document

Please read and understand this document before using the products. Please consult your OMRON

representative if you have any questions or comments.

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship

for a period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS, ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OR THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR

STRICT LIABILITY.

In no event shall responsibility of OMRON for any act exceed the individual price of the product on

which liability asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINTAION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to

the combination of products in the customer's application or use of the product.

At the customer's request, OMRON will provide applicable third party certification documents identifying ratings and limitations of use that apply to the products. This information by itself is not sufficient for

a complete determination of the suitability of the products in combination with the end product,

machine, system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is

not intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that

the uses listed may be suitable for the products:

Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions

or uses not described in this document.

Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, and installations subject to separate industry or government regulations.

Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PERFORMANCE DATA

Performance data given in this document is provided as a guide for the user in determining suitability

and does not constitute a warranty. It may represent the result of OMRON's test conditions, and the

users must correlate it to actual application requirements. Actual performance is subject to the

OMRON Warranty and Limitations of Liability.

xi

Page 12

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and

other reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the product may be

changed without any notice. When in doubt, special model numbers may be assigned to fix or establish key specifications for your application on your request. Please consult with your OMRON representative at any time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

ERRORS AND OMISSIONS

The information in this document has been carefully checked and is believed to be accurate; however,

no responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any consequence thereof.

COPYRIGHT AND COPY PERMISSION

This document shall not be copied for sales or promotions without permission.

This document is protected by copyright and is intended solely for use in conjunction with the product.

Please notify us before copying or reproducing this document in any manner, for any other purpose. If

copying or transmitting this document to another, please copy or transmit it in its entirety.

xii

Page 13

1 Precautions on Safety

In order to use the MS4800 system safely, the precautions listed in this manual indicated by alert symbols and descriptions must be followed. Failure to

follow all precautions and alerts may result in an unsafe use or operation.

The following indications and symbols are used for the application:

!WARNING This sign indicates a potentially hazardous situation which, if not avoided, will

result in minor or moderate injury, or may result in serious injury or death.

Additionally there may be significant property damage.

2 Alert Statements in this manual

2-1 For users

!WARNING The MS4800 system must be installed, configured, and incorporated into a

machine control system by a sufficiently trained and qualified person. An

unqualified person may not be able to perform these operations properly,

which may cause a person to go undetected, resulting in serious injury.

!WARNING When changes are made to each function using the selector switches, the

administrator must manage the detail of the changes and perform the

changes. Accidental functional setting change may cause failure of human

body detection, resulting in a serious injury.

PRECAUTIONS

2-2 For machines

!WARNING Do not use this sensor for machines that cannot be stopped by electrical con-

trol. For example, do not use it for a pressing machine that uses full-rotation

clutch. Otherwise, the machine may not stop before a person reaches the

hazardous part, resulting in serious injury.

!WARNING Do not use the auxiliary output or external indicator output for safety applica-

tions. Human body may not be detected when MS4800 system fails, resulting

in serious injury.

2-3 For installations

!WARNING After unpacking and before installing the MS4800 system please check the

mechanical condition of the system carefully. Do not install a mechanically

damaged product. Return this to your OMRON service for inspection or repair.

Failure to do so may result in serious injury.

!WARNING Do not drop the products. Dropping the products may lead to internal or exter-

nal damage. Please return a MS4800 system that was dropped on the floor to

your OMRON service for inspection or repair. Failure to do so may result in

serious injury.

!WARNING Make sure to test the operation of the MS4800 system after installation to ver-

ify that the MS4800 system operates as intended. Make sure to stop the

machine until the test is complete. Unintended function settings may cause a

person to go undetected, resulting in serious injury.

xiii

Page 14

Alert Statements in this manual 2

!WARNING Make sure to install the MS4800 system at the safe distance from the hazard-

ous part of the equipment. Otherwise, the machine may not stop before a person reaches the hazardous part, resulting in serous injury.

!WARNING Install a protective structure so that the hazardous part of a machine can only

be reached by passing through the sensor's detection zone. Install the sensors so that part of the person is always present in the detection zone when

working in a machine's hazardous areas. If a person is able to step into the

hazardous area of a machine and remain behind the MS4800 system's detection zone, configure the system with an interlock function that prevents the

machine from being restarted. Failure to do so may result in serious injury.

!WARNING Install the interlock reset switch in a location that provides a clear view of the

entire hazardous area and where it cannot be activated from within the hazardous area.

!WARNING The MS4800 system cannot protect a person from a projectile exiting the haz-

ardous zone. Install protective cover(s) or fence(s).

!WARNING To prevent personnel approach to dangerous part of the machine through a

zone disabled by the fixed blanking function, you must install a protective

structure to cover the whole disabled zone. Failure to do so may cause failure

of human body detection, resulting in a serious injury.

!WARNING You must ensure that a test rod is detected for all detection zones except

where fixed or floating blanking function is used. Failure to do so may cause

failure of human body detection, resulting in a serious injury.

!WARNING Detection capability gets larger if fixed or floating blanking function is used.

You must use the detection capability for fixed and floating blanking functions.

Failure to do so may cause failure of machine stop before reaching the

machine's dangerous part, resulting in a serious injury.

!WARNING The muting and override functions disable the safety functions of the device.

You must ensure safety using other method when these functions are operating.

!WARNING Install muting sensors so that they can distinguish between the object that is

being allowed to pass through the detection zone and a person. If the muting

function is activated by the detection of a person, it may result in serious

injury.

!WARNING Muting lamps (external indicators) that indicate the state of the muting and

override functions must be installed where they are clearly visible to workers

from all the operating positions.

!WARNING Muting related time must be properly configured for its application by a suffi-

ciently trained and qualified person, and the person must have responsibility

for settings, especially when setting the muting time limit to infinite.

xiv

!WARNING Use independent 2 input devices for muting inputs.

!WARNING You must install MS4800 system muting sensor, and physical barrier, and con-

figure time settings for muting so that an operator should not enter hazardous

zone.

Page 15

Alert Statements in this manual 2

!WARNING Install the switch that activates the override in a location that provides a clear

view of the entire hazardous area and where it cannot be activated from within

the hazardous area. Make sure that nobody is in the hazardous area before

activating the override function.

!WARNING Do not place fluorescent lights within the effective aperture angle of the

receiver, as it may influence the MS4800 system under certain circumstances.

!WARNING Install the sensor system so that it is not affected by any reflective surfaces.

Failure to do so may hinder detection, resulting in serious injury.

!WARNING When using more than 1 set of MS4800 system, install them so that mutual

interference does not occur, such as by configuring series connections or

using physical barriers between adjacent sets.

!WARNING Make sure that the MS4800 system is securely mounted and its cables and

connectors are properly connected.

!WARNING Make sure that foreign objects such as water, oil, or dust do not enter the

inside of the MS4800 system while the cover for the selector switches is open

and tighten the screws of the cover firmly after changing the settings.

!WARNING Do not use the sensor system with mirrors in a retro-reflective configuration.

!WARNING Perform an inspection for all MS4800 systems as described in the chapter

2-4 For wiring

!WARNING Connect the load between the output and 0V line (PNP output). Connecting

!WARNING Do not short-circuit the output line to the +24 V line. Otherwise, the output is

!WARNING Configure the system by using the optimal number of safety outputs that sat-

!WARNING Do not connect each line of MS4800 system to a DC power supply of more

Doing so may hinder detection. It is possible to use mirrors to "bend" the

detection zone to a 90° angle.

"Checkout and test procedure". When using series connections, perform

inspections for every connected MS4800 system.

the load between the output and +24 V line will result in a dangerous condition because operation is reversed to "ON when blocked".

always ON. Also, the 0 V of the power supply must be grounded so that output

does not turn ON due to grounding of the output line.

isfy the requirements of the necessary safety category.

than 24 VDC+20%. Also, do not connect to an AC power supply. Failure to do

so may result in electric shock.

xv

Page 16

Alert Statements in this manual 2

!WARNING For the MS4800 system to comply with IEC 61496-1 and UL 508, the DC

power supply unit must satisfy all of thefollowing conditions:

• Must be within the rated power voltage (24 V DC ± 20%)

• Must have tolerance against the total rated current of devices if it is

connected to multiple devices

• Must comply with EMC directives (industrial environment)

• Double or reinforced insulation must be applied between the primary

and secondary circuits

• Automatic recovery of overcurrent protection characteristics

• Output holding time must be 20 ms or longer

• Must satisfy output characteristic requirements for class 2 circuit or

limited voltage current circuit defined by UL508

• Must comply with laws and regulations, regarding EMC and electrical

equipment safety, of the country or region where the MS4800 system

is used (Ex: In EU, the power supply must comply with the EMC Directive and the Low Voltage Directive.)

!WARNING Double or reinforced insulation from hazardous voltage must be applied to all

input and output lines. Failure to do so may result in electric shock.

!WARNING Extension of the cable must be within a specified length. If it isn't, safety func-

2-5 Other

!WARNING To use the MS4800 system in PSDI mode (Re-initiation of cyclic operation by

!WARNING Do not try to disassemble, repair, or modify this product. Doing so may cause

!WARNING Do not use the MS4800 system in environments where flammable or explo-

!WARNING Perform daily and 6-month inspections for the MS4800 system. Otherwise,

!WARNING If the MS4800 system is used in an environment where foreign materials such

!WARNING Do not use the MS4800 system in an athmosphere containing oil mist or cor-

tion may not work properly, resulting in danger.

the protective equipment), you must configure an appropriate circuit between

the MS4800 system and the machine. For details about PSDI, refer to

IEC61496-1, and other relevant standards and regulations.

the safety functions to stop working properly.

sive gases are present. Doing so may result in explosion.

the system may fail to work properly, resulting in serious injury.

as spatter may adhere to the product use a cover to protect the MS4800 system or inspect and clean the MS4800 system periodically.

rosive gas. Failure to do so may result in damage of the product.

xvi

!WARNING When scrapping the MS4800 system, please make sure to comply with the

waste treatment regulations of the country where the product has been used.

Page 17

Precautions for Safe Use 3

3 Precautions for Safe Use

Make sure to observe the following precautions that are necessary for ensuring safe use of the product.

• Thoroughly read this manual and understand the installtion procedures,

operation check procedures, and maintenance procedures before using

the product.

• Loads must satisfy both of the following conditions:

• Not short-circuited

• Not used with a current that is higher than the rating

• Do not drop the product

• Dispose of the product in accordance with the relevant rules and regulations of the country or are where the product is used.

xvii

Page 18

Precautions for Correct Use 4

4 Precautions for Correct Use

Observe the precautions described below to prevent operation failure, malfunctions, or undesirable effects on product performance.

4-1 Installation environment

Do not install the MS4800 system in the following types of environments:

• Areas exposed to intense interference light, such as direct sunlight

• Areas with high humidity where condensation is likely to occur

• Areas where corrosive gases are present

• Areas exposed to vibration or shock levels higher than in the specification

provisions

• Areas where the product may come into contact with water

• Areas where the product may get wet with oil that can solve adhesive

Do not use radio equipment such as cellular phones, walkie-talkies, or transceivers near the MS4800 system.

4-2 Wiring and installation

• Make sure to perform wiring while the power supply is OFF. Otherwise,

the MS4800 system may fail to operate due to the diagnosis function.

• When replacing the cable connectors with other types of connectors, use

connectors that provide a proper grade of protection.

• Properly perform the wiring after confirming the signal names of all the

terminals.

• Do not operate the control system until 2 seconds or more (2,2 seconds

or more in case of series connection) after turning ON the power of the

MS4800 system.

• Be sure to route the MS4800 system cable separate from high-potential

power lines or through an exclusive conduit.

• When using a commercially available switching regulator power supply,

make sure to ground the FG terminal (frame ground terminal).

• Install the emitter and receiver so that their vertical direction should

match.

4-3 Cleaning

Do not use thinner, benzene, or acetone for cleaning, they affect the product's

resin parts and paint on the case.

4-4 Object detection

The MS4800 system cannot detect transparent and/or translucent objects.

xviii

Page 19

SECTION 1

Important Safety Warnings

!WARNING Read and understand this section prior to installing an MS4800 system.

An MS4800 system is a general purpose sensing device designed to guard

personnel working around moving machinery.

Whether a specific machine application and MS4800 system installation complies with safety regulations depends on the proper application, installation,

maintenance and operation of the MS4800 system. These items are the

responsibility of the purchaser, installer and employer.

The employer is responsible for the selection and training of personnel to

properly install, operate and maintain the machine and its safeguarding systems. An MS4800 system should only be installed verified and maintained by

a qualified person. A qualified person is defined as "an individual who understands, is trained on, and demonstrates competence with the construction,

operation or maintenance of the machinery and the hazards involved."

To use the MS4800 system the following requirements must be met:

• The national/international rules and regulations apply to the installation,

use and periodic technical inspections of the safety light curtain, in particular:

• Machine Directive (98/37/EC) and (2006/42/EC)

• Equipment Usage Directive (89/655/EC)

• The work safety regulations/safety rules

• Other relevant health and safety regulations

• Observe the instructions in this manual regarding test regulations (e.g. on

use, mounting, installation or integration into the existing machine control

system) carefully.

• The tests must be carried out by specialist personnel or specially qualified

and authorized personnel and must be recorded and documented to

ensure that the tests can be reconstructed and retraced at any time.

• Check the effectiveness of the protective device after every change

because a change may degrade the safety function.

• The operating instructions must be made available to the operator of the

machine where the MS4800 system is installed.

• The machine operator is to be instructed in the use of the device by specialist personnel and must be instructed to read the operating instructions.

• The guarded machine must not present a hazard from flying parts.

• The guarded machine must have a consistent stopping time and adequate control mechanisms.

• Additional guarding may be required for access to dangerous areas not

covered by the MS4800 system.

Protection of the environment

This product has been designed to minimize environmental impact. For this

reason please note that disposal of irreparable/unserviceable devices has to

be in compliance with your local/national rules and regulations. Please contact your local OMRON sales representative for assistance.

1

Page 20

Section

2

Page 21

SECTION 2

Product features

The MS4800 safety light curtain family is available in two versions. These versions are identified as the MS4800-EA and EB versions. Configuration of the

safety light curtains can be changed through selector switches located under

an access cover.

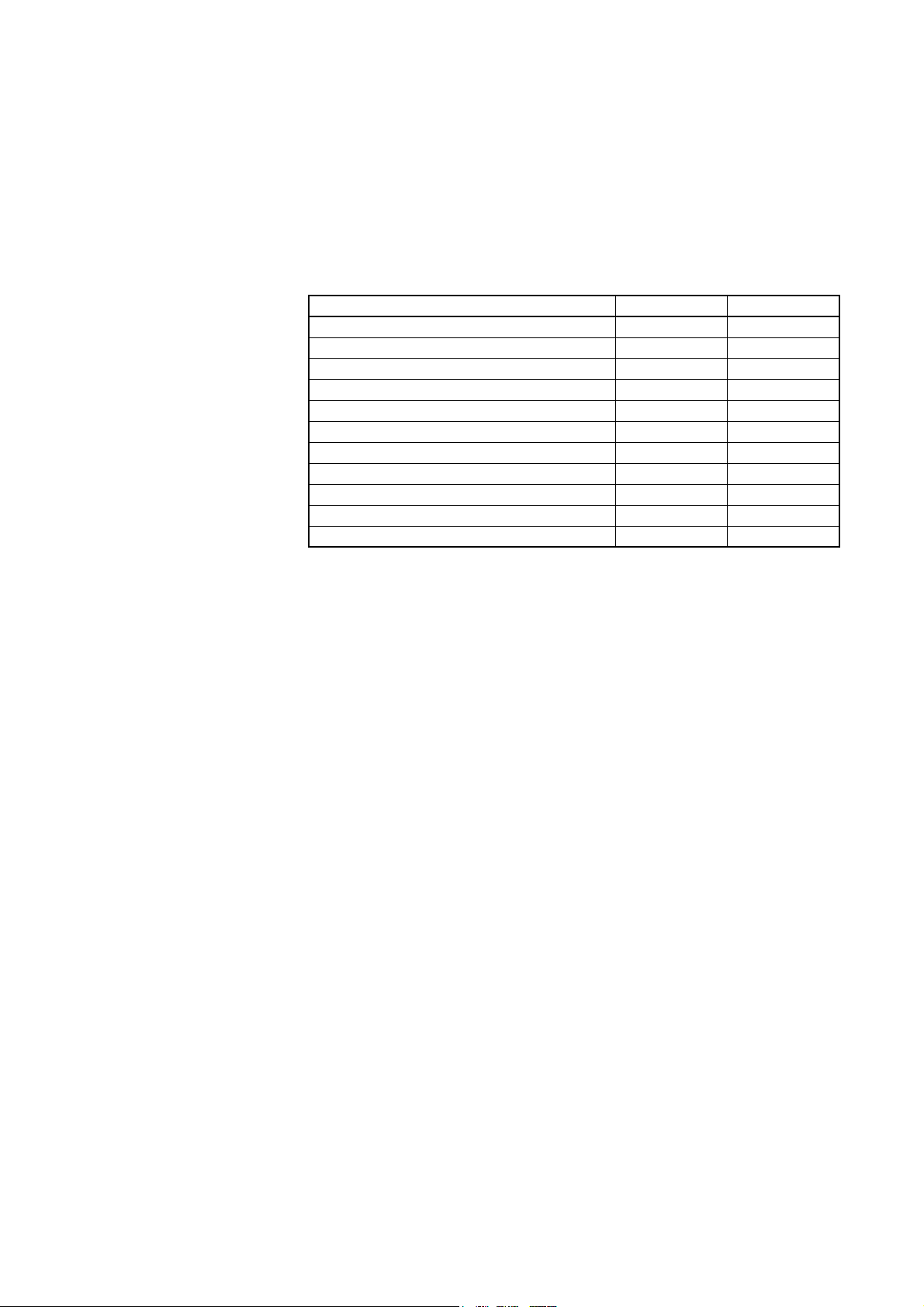

MS4800 series feature comparison

Feature MS4800-EB MS4800-EA

Flex Bus, Multi segmented Head Configurations X X

Scan Code for Cross-Talk-Mitigation X X

EDM External Device Monitoring X X

Adjustable Mounting Brackets and T-Slots X X

Non-shielded Main Cables X X

Two PNP safety outputs X X

Auxiliary outputs (PNP only) X X

Muting through RM6 Muting Module X

Floating Blanking X

Fixed Blanking X

Range Selection X X

3

Page 22

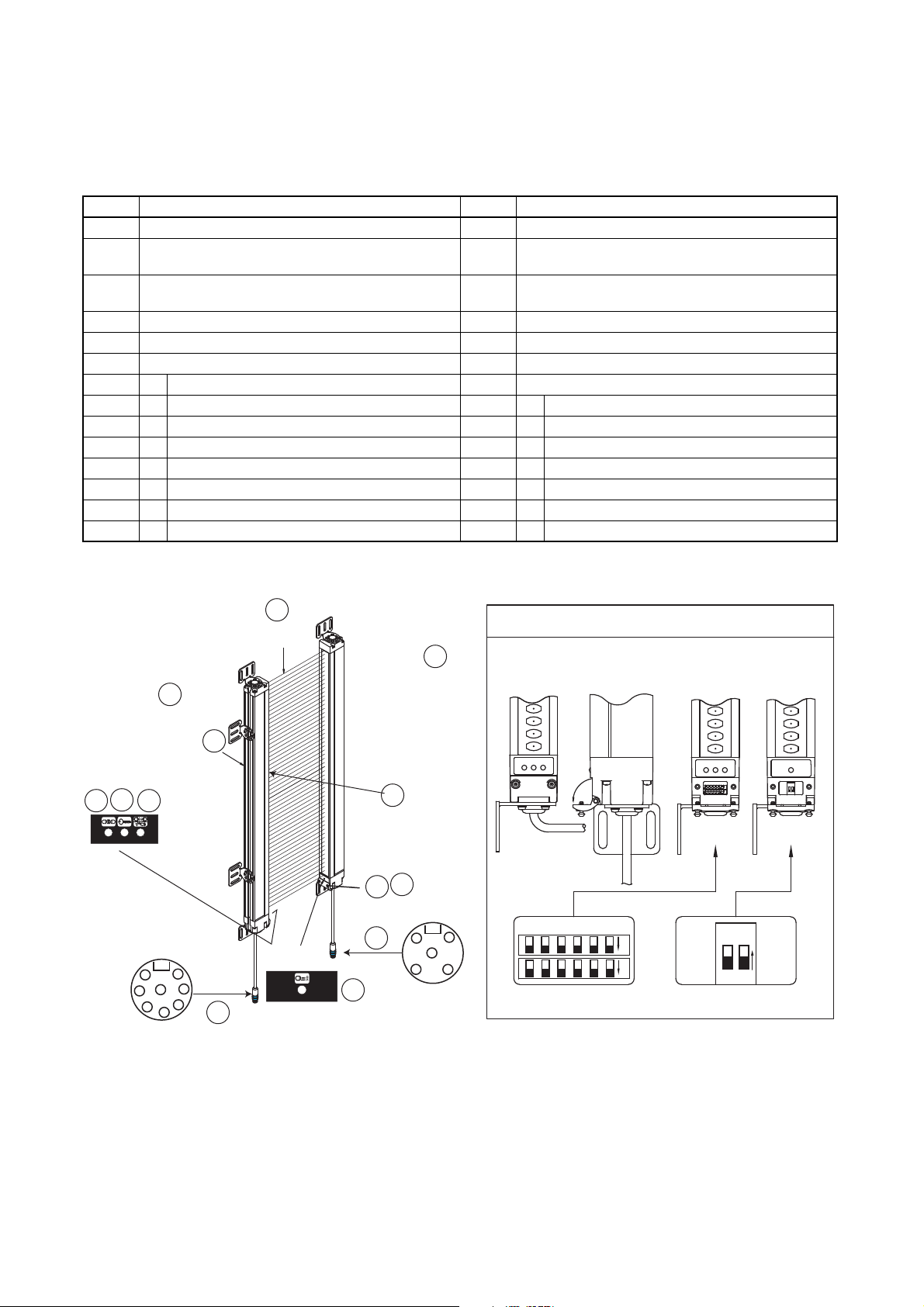

SECTION 3

System Components and Indicators

Chart Chart

1 Receiver 7 Transmitter

2 Individual beam Indicators (one with every beam) -

Red LED

3 Blanking Active - Amber LED 9 Flip door, Access to configuration switches (on

4 INTERLOCK or ALARM indicator - Yellow LED 10

5 MACHINE RUN/STOP indicator - Green/Red LED 11 Status Indicator - Yellow LED

6 RECEIVER connections M12 (Male) 12 Slide Mounting T-Slot

1 +24 V DC - Brown 13 Transmitter connections M12 (Male)

2 0 V DC - Blue 1 0 V DC - Blue

3 Earth - Green 2 +24 V DC - Brown

4 OSSD 2 - White 3 MTS - White

5 Start or EDM (Mode Select) - Yellow 4 MTS return - Black

6 EDM - Red 5 Earth - Green

7 Auxiliary Out - Pink

8 OSSD 1 - Black

8 Detection Zone

transmitter and receiver)

RECEIVER LED

INDICATORS

4

3

3

8

DETECTION

ZONE

TRANSMITTER

1

RECEIVER

12

5

ALTERNATE

T-SLOT

MOUNTING

9

13

TRANSMITTER

1

2

7

8

6

4

5

6

LED INDICATOR

11

7

2

10

1

2

5

3

4

MS4800 - SELECTOR SWITCH ACCESS

ENDCAP

WITH

DOOR

321 546

321546

RECEIVER SWITCHES TRANSMITTER SWITCHES

ON

ON

SELECTOR SWITCH

ACCESS

RECEIVER

12

TRANSMITTER

ON

4

Page 23

The MS4800 system is a microprocessor-controlled, infrared, transmittedbeam safety light curtain. The system consists of a receiver assembly and a

transmitter assembly. The receiver and transmitter assemblies are not physically interconnected.

It complies with a Type 4 according to EN/IEC 61496 and category 4 according to EN954-1.

An MS4800 system is used where personnel protection is required. Typical

applications include packaging machines, back side protection of presses and

textile machinery.

4-1 Operating States

The operating condition of an MS4800 system is described in terms of states.

The following operating states exist for an MS 4800 system.

4-1-1 Machine Run

The two receiver safety outputs are in the ON state, the green MACHINE RUN

indicator is lit, and the auxiliary output is in a state consistent with its configuration. The protected machine is allowed to operate. Pressing and releasing

the start button has no effect.

SECTION 4

System Operation

4-1-2 Machine Stop

4-1-3 Interlock

4-1-4 Alarm

The two receiver safety outputs are in the OFF state the red MACHINE STOP

indicator is lit, and the auxiliary output is in a state consistent with its configuration. The protected machine is not allowed to operate.

The two receiver safety outputs are in the OFF state, the red MACHINE STOP

indicator and yellow INTERLOCK indicator are lit. The auxiliary output is in a

state consistent with its configuration. The INTERLOCK state does not allow

the protected machine to operate until the detection zone is clear of obstructions and the start button is pressed and released.

The two receiver safety outputs are in the OFF state, the red MACHINE STOP

indicator is lit, the yellow INTERLOCK indicator is flashing and the auxiliary

output is in the OFF state. The alarm state does not allow the protected

machine to operate. The primary difference between ALARM and INTERLOCK is that the MS4800 system will remain in the alarm state until the alarm

is corrected, and then applying a power cycling or an external start button

press and release.

5

Page 24

Operating Modes Section 4-2

4-2 Operating Modes

System operating modes determine the start-up and operating behavior of an

MS4800 system. Operating modes definitions rely on the operating states

presented above. Operating mode selection may be performed via the configuration switches on the MS4800 transmitter and receiver.

Note If internal alarms are detected by the system during power-up or operation, it

will enter the Alarm state with its safety outputs in the OFF state.

4-2-1 Automatic start

The MS4800 will power-up with its safety and auxiliary outputs OFF, and if the

detection zone is not obstructed, enters the MACHINE RUN state. In this

state, when an object is sensed entering the detection zone, the MS4800 system will change from MACHINE RUN to MACHINE STOP and remain in this

state until the obstruction is removed. Once the detection zone is clear, the

MS4800 system will automatically

RUN.

4-2-2 Start/Restart Interlock

The MS4800 will power-up with its safety outputs off end enter the INTERLOCK state if the detection zone is clear (or the fixed blanking pattern is satisfied) and no alarms are detected. To initially enter the MACHINE RUN state

the operator must press and release the Start button. Once in the MACHINE

RUN state, when an object is sensed entering the detection zone, the system

will change to the MACHINE STOP state. When the detection zone is cleared,

the system will not automatically change to MACHINE RUN but enter the

INTERLOCK state instead. The operator must always press and release the

Start button to enter MACHINE RUN. If the detection zone is not clear the

Start button will have no effect.

change from MACHINE STOP to MACHINE

Note The definitions above mention a start button. See SECTION 11 Connection to

the Machine Control Circuit for wiring of the start button.

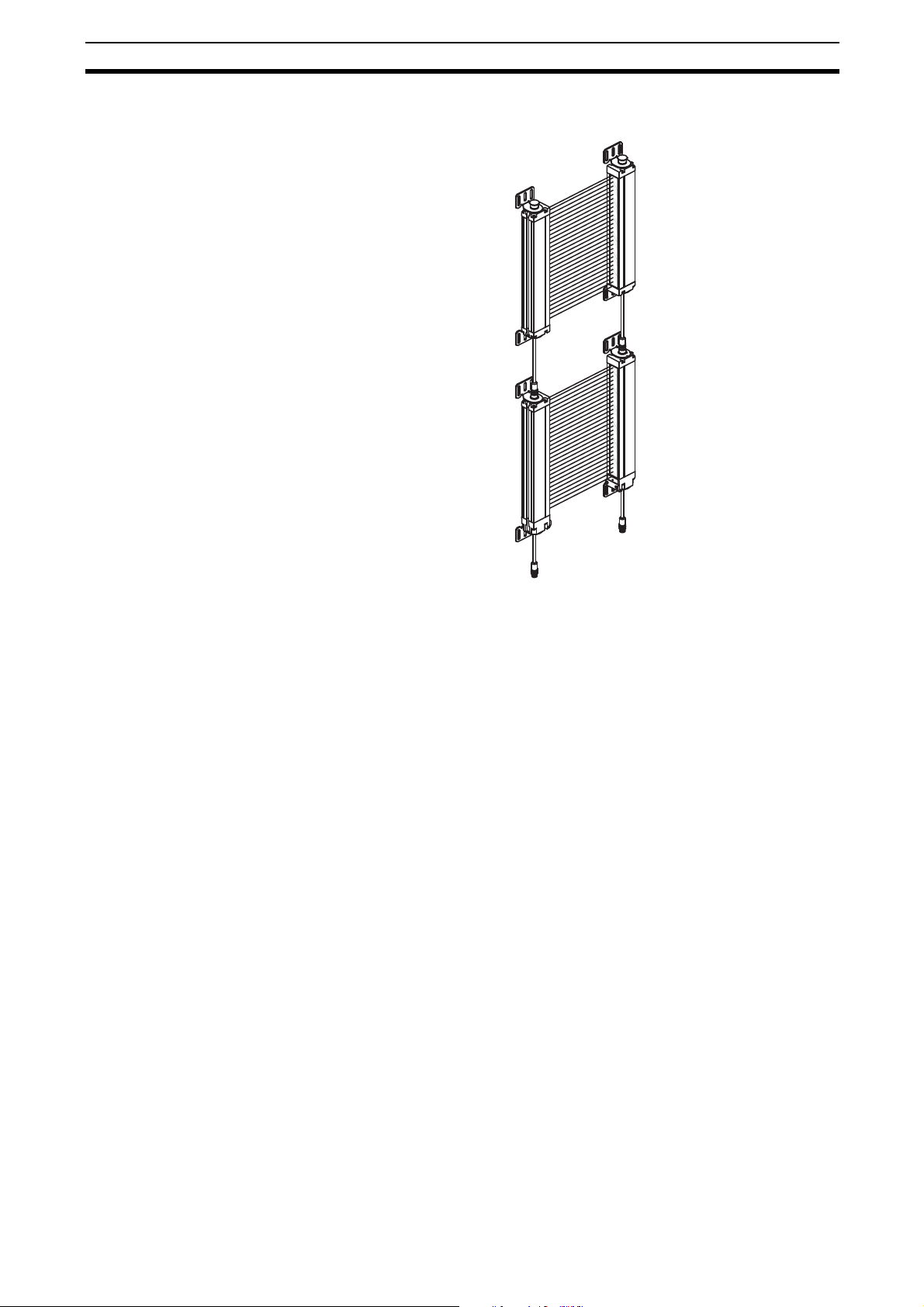

4-3 MS4800FS Cascaded Series

The MS4800 series safety light curtain is available in a "cascaded" version,

referred to as the MS4800FS series. The MS4800FS series allows multiple

transmitters/receivers to be "daisy-chained" in series. This type of arrangement permits the MS4800FS to guard multiple areas of a machine.

4-3-1 MS4800FS Requirements

The MS4800FS is offered in protective heights ranging from 280 mm to

1800 mm for 14 mm resolution and 280 mm to 2120 mm for 30 mm resolution.

• An MS4800FS system has a maximum size limitation based on the number of beams. A master (first) segment cannot exceed 180 beams and the

total of the combined segments cannot exceed 256 beams.

• A cascaded slave segment cannot exceed 128 beams.

• An MS4800FS system may have up to four daisy-chained segments. As

long as the total number of beams does not exceed 256.

• The interconnect cable length limitation between any two segments is in

total max.10 meter for transmitter and receiver.

6

Page 25

MS4800FS Cascaded Series Section 4-3

• It is possible to mix segments with different resolutions within an

MS4800FS system.

"Cascaded" Segment

(Slave)

"Cascaded" Segment

(Slave)

Transmitter

Segment

Receiver

Segment

(Master)

(Master)

4-3-2 MS4800FS Segment Reduction Restart Procedure

!WARNING Do not remove cascaded segments from your installation without making sure

that the accessible areas are protected by other measures. Failure to do so

may result in serious injury.

When you reduce the number of cascaded segments you cause a flex bus

fault. The MS4800FS will enter a fault condition, indicated by error code "95"

on the indicators in the bottom part of the device. This fault code indicates that

there was a reduction in the number of cascaded segments. If the number of

segments is reduced while power is off, the light curtain will power on with

fault code "100".

There is one possibility to clear this fault and restore operation on the reduced

size MS4800FS. The start switch needs to be pressed while the power is

applied. The three indicator LEDs (red, yellow, amber) will flash for approximately three seconds. The start switch must be released while the LEDs are

flashing to clear fault code "100". Since the MS4800FS has a configurable

start input, care must be taken to ensure that the correct contact configuration

is used and that it is wired properly.

The transmitter will not fault if the number of segments is reduced. However,

to operate normally the transmitter must always match the receiver in the

number of segments and beams.

7

Page 26

MS4800FS Cascaded Series Section 4-3

8

Page 27

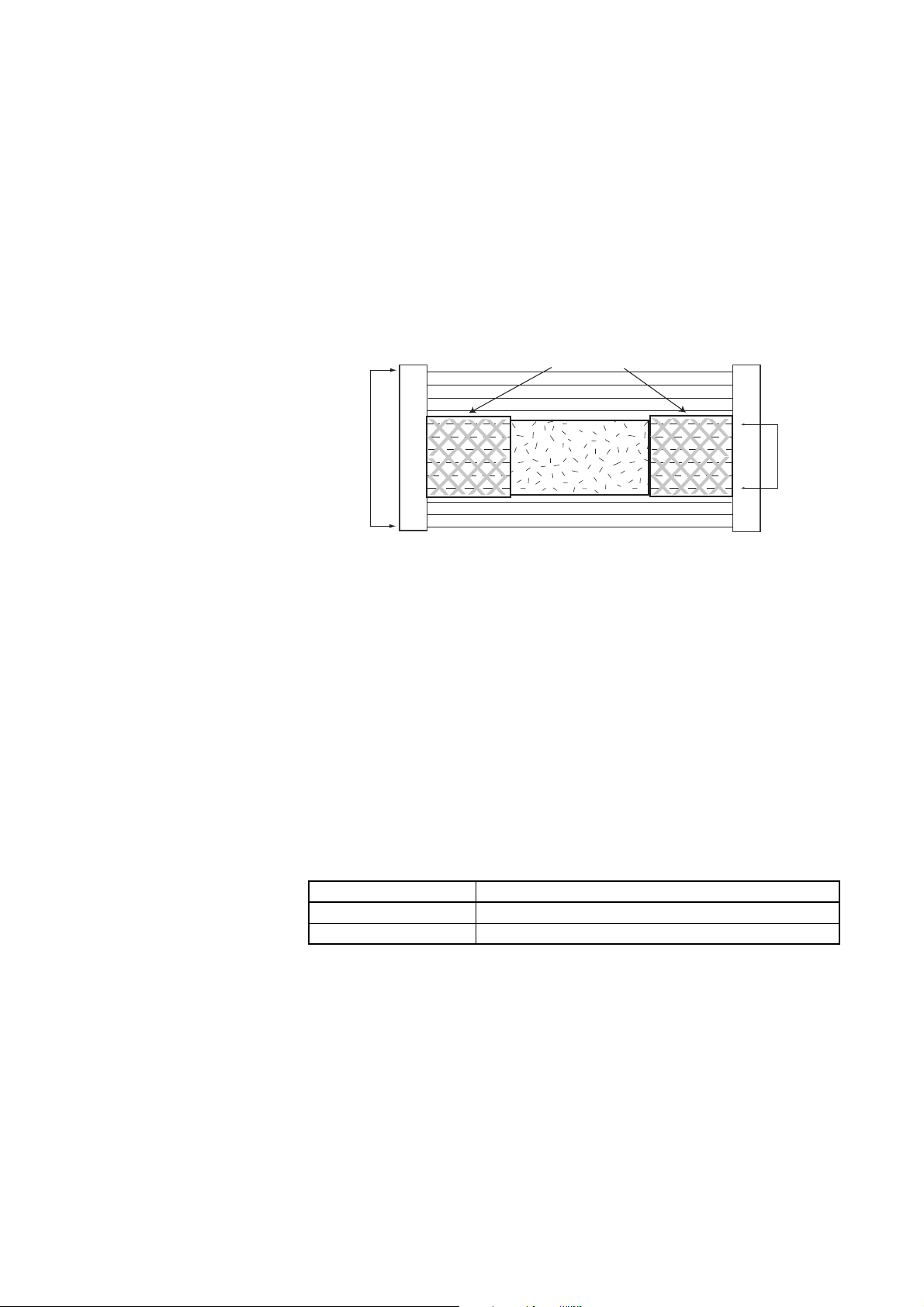

!WARNING Use of Fixed Blanking and Floating Blanking will make an MS4800 system

less sensitive to objects in the detection zone. Improper use of these features

can result in severe injury to personnel. Fixed Blanking may require a hard

barrier guard. Fixed Blanking and Floating Blanking may require an increase

in the safety distance. Read the following section carefully.

5-1 Fixed Blanking

SECTION 5

Detection Options

Additional Hard Guarding

Fixed Blanking Area

Obstruction

Detection Zone

Light Curtain Light Curtain

Fixed Blanking allows a system to blank optical beams and record the exact

pattern. A system can record and store a single pattern. The protected zone's

object detection is then based on the stored pattern. All obstructed optical

beams recorded during the selection must remain blocked and all clear

beams recorded during the selection must remain clear for the system to

enter or remain in the MACHINE RUN state.

A Fixed Blanking pattern may consist of more than one Fixed Blanked area.

Individual Fixed Blanked areas must be separated by at least one beam that

is always clear. A Fixed Blanking area may not crossover between "flexible"

segment boundaries.

Each Fixed Blanked area has a size and positional tolerance of ±1 beam to

allow for slight position variance and only the two beams on the edges of the

blanked area are allowed to vary. Because of this position tolerance, a reduction of the optical resolution takes place on the border area of Fixed Blanking

patterns. This reduction comprises two beams.

Tolerance effect of Fixed Blanked area on Resolution

Standard Resolution Effective Resolution at Ends of Fixed Blanked Areas

14 mm 34 mm

30 mm 60 mm

Note The tolerance does not reduce the resolution of the entire light curtain, only

the ends of Fixed Blanked Areas. The user must consider the increased resolution of the two beams at the ends of each Fixed Blanked Area.

9

Page 28

Fixed Blanking Section 5-1

The effect of this tolerance also allows the number of blocked beams to vary

±1. For example, a Fixed Blanked area of 8 blanked beams is allowed to

increase to 9 beams or decrease to 7 beams and the light curtain will remain

in MACHINE RUN.

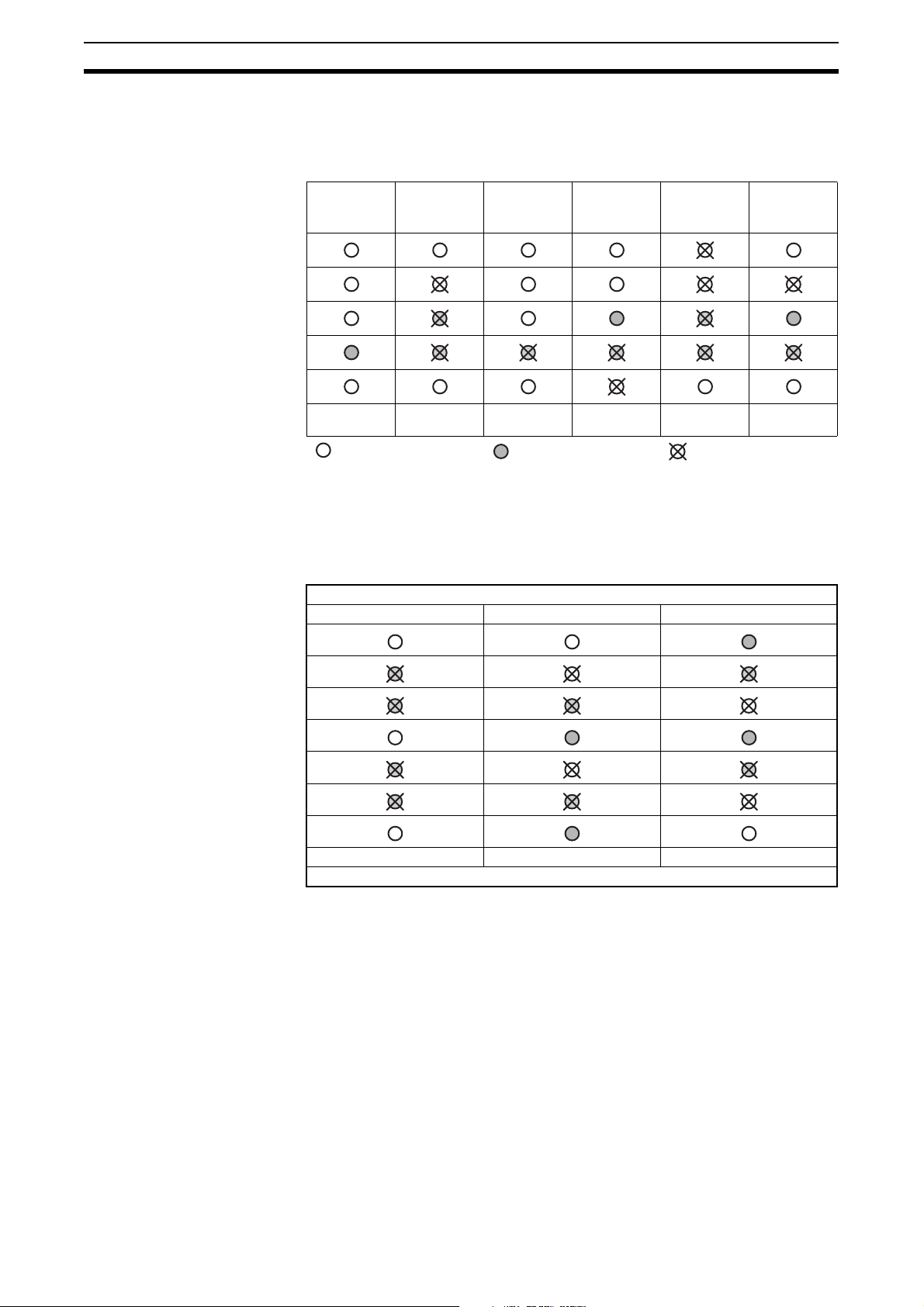

No Fixed

Blanking

MACHINE

STOP

Clear Optical

Channel

Fixed

Blanking

Enabled

MACHINE

RUN

Fixed

Blanking

Enabled

MACHINE

RUN

Blocked Optical Channel

Fixed

Blanking

Enabled

MACHINE

RUN

Fixed

Blanking

Enabled

MACHINE

STOP

Optical Channel

Selected by Fixed

Blanking

Fixed

Blanking

Enabled

MACHINE

STOP

There is an exception when there is only one clear beam separating Fixed

Blanked areas. For only this case, there is no positional tolerance allowed on

that side of the clear beam for the object closest to the entry endcap so that

clear beam can only be used by the object further away from the entry endcap. See the following table:

Opposite to entry endcap end

Fixed blanking enabled Fixed blanking enabled Fixed blanking enabled

10

MACHINE RUN MACHINE RUN MACHINE STOP

Entry endcap end

The minimum number of beams in a Fixed Blanking area is one. If only one

beam is blanked, the number of blocked beams has a size tolerance of +1/-0

meaning the number of blocked beams can increase to two but the area cannot be completely eliminated.

The Fixed Blanking pattern must not prevent the light curtain from synchronizing. This means that the size of the blanked object can not exceed certain limits as long as synchronization is maintained.

Fixed Blanking is allowed during all modes of operation (automatic start, start

and start/restart interlock).

Page 29

Fixed Blanking Section 5-1

IBIs of blocked

beams flash.

Red and amber LEDs and IBIs

flash to indicate the

Program switch is active.

321 546

321546

ON

ON

321 546

321546

ON

ON

off

off

on

on

SWA

SWB

IBIs of blocked

beams flash.

Yellow LED turns on to indicate

the pattern has been programmed

and the Start button is active.

321 546

321546

ON

ON

ononFlip

SWA

SWB

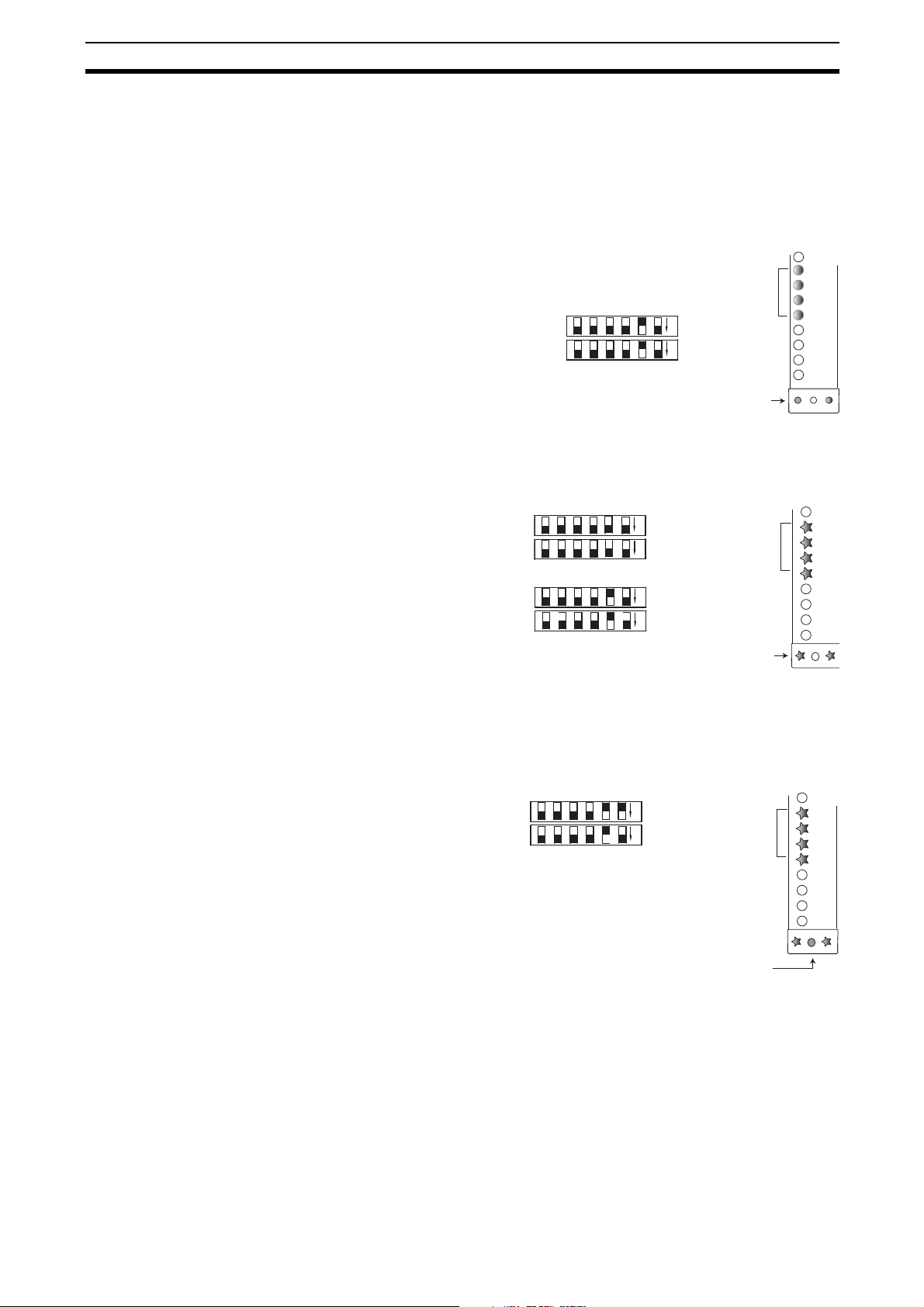

5-1-1 Selecting Fixed Blanking with selector switches

To use Fixed Blanking, the operator enables the option using the selector

switches. A new Fixed Blanking pattern is recorded when the MS4800

receiver is in MACHINE STOP, the blanking function is active and the Program

function is activated. If the Fixed Blanking feature is disabled, the stored protected zone patterns are cleared.

1. The obstruction is placed

ON

ON

IBIs of blocked

beams are On.

within the detection zone

and the receiver goes to

MACHINE STOP state.

An authorized user then

sets the selector switches

321 546

321546

in the receiver endcap to

select Fixed Blanking Enable. The MS4800 enters

Amber LED turns on to indicate

in Fixed Blanking mode.

a fault state and power is

cycled or the Start switch is activated to clear the fault. When the receiver

powers up it will be in Fixed Blanking mode with the red and amber LEDs

lit.

2. The authorized user then

enables the Program

switch by setting both

Fixed Blanking switches to

the off position and then

both to the on position.

When the first Fixed

Blanking switch is flipped,

the red LED begins flashing at a rate of 3Hz. When

the final Fixed Blanking

switch is flipped, both the red and amber LEDs and the IBIs (Individual

Beam Indicators) of the blocked beams start flashing to indicate the Program switch is enabled. The authorized user has 10 minutes to complete

the programming of a pattern.

3. To program a pattern, the

authorized user must flip

(off/on or on/off) the Program switch once. Once

pattern is programmed the

yellow LED (INTERLOCK)

turns on. During 10

minute period, the user

may program as many

times as needed, allowing

for adjustment in the

placement of the obstruction.

11

Page 30

Fixed Blanking Section 5-1

4. The user must then press

and release the Start button or perform a power cycle. The MS4800 receiver

then resets. If no faults are

detected and the state of

the optical beams matches the recorded Fixed

Blanking pattern, the re-

on

321 546

321546

on

Amber LED is on to indicate

ceiver will enter the INTERLOCK or MACHINE RUN condition depending upon the selected Start

Mode. The amber receiver Blanking Active LED will be on.

5. If the 10 minutes period

expires, the amber LED

and IBIs (Individual Beam

Indicators) quit flashing

and the yellow LED (INTERLOCK) goes on. The

user can start another

programming sequence

by setting both Fixed

Blanking switches off and

on

321 546

321546

on

Amber LED is off to indicate

in Fixed Blanking is disabled.

then on. The user may

start normal operation by a press and release of the start button or by performing a power cycle.

6. To exit Fixed Blanking the

user sets both selector

switches to the off position, then either presses

and releases the Start button or performs a power

cycle. The receiver will

power up with the amber

LED off.

The amber LED and IBIs quit flashing

to indicate program switch is disabled.

The yellow LED turns on to indicate the

Start button is active.

off

321 546

321546

off

IBIs of blocked

beams off.

ON

SWA

ON

SWB

in Fixed Blanking mode.

IBIs of blocked

beams on.

ON

SWA

ON

SWB

IBIs of blocked

beams on.

ON

SWA

ON

SWB

Note Please refer for further information to the FAQ to section 17-6.

12

Page 31

Floating Blanking Section 5-2

5-2 Floating Blanking

!WARNING Use of Fixed Blanking and Floating Blanking will make the MS4800 system

less sensitive to objects in the detection zone. Improper use of these features

can result in severe injury to personnel. Fixed Blanking may require a hard

barrier. Fixed Blanking and Floating Blanking may require an increase in the

safety distance. Read the following section carefully.

One channel can be obstructed at any location in the detection zone as long

as the optical synchronization is maintained. Please refer to chapter 5-4 Opti-

cal Synchronization for further details.

This means that an object can freely float from one end of the protective field

to the other without the MS4800 system entering the MACHINE STOP state.

The obstructed channels are not fixed at a single location but "float" through

the detection zone.

1

Channel

Floating

Blanking Active

Channel 1

Floating

Blanking

Inactive

1

Channel

Floating

Blanking Active

1

Channel

Floating

Blanking Active

1

Channel

Floating

Blanking Active

Channel 2

Channel 3

Channel 4

Channel 5

System

Response

MACHINE STOP

Clear Optical Channel

1

Exception

0

Exceptions

Machine

Run

1

Exception

Machine

Run

Optical Channel is obstructed

MACHINE STOP

Note Please refer for further information to the FAQ to section 17-6.

5-2-1 Selecting Floating Blanking with selector switches

Using the selector switches an authorized user can activate the Floating

Blanking function. This allows the system to operate with one obstructed optical beam anywhere within the protected zone. This obstruction is permitted

anywhere within the protected zone and is permitted to move over time. After

setting the appropriate selector switches, the receiver enters the Power-On

Self Test state and if no faults are detected the receiver shall enter the INTERLOCK or MACHINE RUN condition depending upon the selected operating

mode.

2

Exceptions

2

Exceptions

MACHINE STOP

!WARNING Two-Beam Floating Blanking is not available on the MS4800 system.

Floating Blanking Effects on Minimum Object Resolution

Standard Minimum Object Resolution

(No Floating Blanking)

14 mm 24 mm

30 mm 50 mm

Minimum Object Resolution with

1 Beam Blanking

13

Page 32

Fixed Blanking with Floating Blanking Section 5-3

5-3 Fixed Blanking with Floating Blanking

!WARNING Use of Fixed Blanking and Floating Blanking will make MS4800 system less

sensitive to objects in the detection zone. Improper use of these features can

result in severe injury to personnel. Fixed Blanking may require a hard barrier

guard. Fixed Blanking and Floating Blanking may require an increase in the

safety distance. Read the following section carefully.

Possible combinations:

Function Fixed Blanking Floating Blanking

Fixed Blanking N/A Yes

Floating Blanking Yes N/A

When both Fixed Blanking and Floating Blanking are selected, the floating

channels are allowed to occur anywhere within the detection zone except the

area selected by Fixed Blanking.

5-3-1 The effect of Fixed or Floating Blanking on minimum object

resolution

When fixed Blanking and/or Floating are active, the safe mounting distance is

affected. Fixed and Floating Blanking desensitize the light curtain and

increase the size of the minimum detectable object. The increase is equal to

the beam spacing distance for each beam that is disabled.

If the size of the object detected by the system increases the minimum safe

distance must also be increased. Use the minimum object sensitivity given in

the following tables to determine the new figure to use when computing the

safety distance.

MS4800 system - 14 mm resolution

Total number of Beams Disabled by

Fixed and/or Floating Blanking

None 14 mm

1 Beam 24 mm

2 Beams 34 mm

3 Beams 44 mm

4 Beams 54 mm

5 Beams 64 mm

> 64 mm

Effective Resolution

14

MS4800 system - 30mm resolution

Total number of Beams Disabled by

Fixed and/or Floating Blanking

None 30 mm

1 Beam 50 mm

> 64mm

Effective Resolution

Page 33

Optical Synchronization Section 5-4

5-4 Optical Synchronization

The synchronization between the MS4800 system transmitter and receiver is

optical, so the system does not use one specific beam. To establish synchronization the system needs to have a certain number of consecutive clear

beams (see following table) within the first master segment. If they are not satisfied, the system will enter a MACHINE STOP state and every other Individual Beam Indicator will light. When the beams are cleared, the system will resynchronize itself and enter a state consistent with its operating mode. Once

the synchronization is established, it can be maintained as long as the

required number of consecutive clear beams can be satisfied anywhere in the

system (including flex segments).

Light Curtain Beam Count Synchronization Beam Requirement

12 - 16 beams 6 consecutive clear beams

17 - 32 beams 7 consecutive clear beams

33 - 64 beams 8 consecutive clear beams

65 - 128 beams 9 consecutive clear beams

129 - 256 beams 10 consecutive clear beams

Because of these restrictions, when programming a fixed blanking object(s),

the size of the fixed or monitored blanking object(s) (8 beams +/- 1 beam

tolerance) must comply with the number of consecutive clear beams stated in

the previous table within the first master segment.

In addition to that, any fixed or monitored blanking programming must be done

with at least one (1) clear beam on each flex segment.

Example:

A MS48000S-EA-014-1320 has 132 beams. In blanking application,

10 consecutive beams have to be free for optical synchronization. The

remaining 122 beams can be used for fixed blanking applications (max

8±1 beams).

15

Page 34

Optical Synchronization Section 5-4

16

Page 35

Diagnostic and Test Features

6-1 Individual Beam Indicators (IBI)

All MS4800 systems have a visible red LED as an Individual Beam Indicator

adjacent to each infrared beam. These IBIs are located on the receiver. The

IBI will light when the infrared beam fails to meet the conditions necessary for

the system to remain in the MACHINE RUN state. When less than 10 consecutive beams are clear, every other IBI will light indicating that the MS4800 is

not synchronized. IBIs are not a safety critical component. An IBI failure will

not cause an alarm condition and the system will continue to operate.

Additionally, error codes are displayed using the IBIs close to the connector

endcap.

6-2 External Device Monitoring (EDM)

EDM is an important safety function. It monitors the MS4800 system interface

to the guarded machine, checks to ensure that the control elements are

responding correctly to the light curtain and detects any inconsistency

between the two external control devices. This is necessary to detect a malfunction within the interface which prevents a stop signal from reaching the

machine controller. The connection for the EDM is made at the receiver. On

power-up, the MS4800 system looks for a closed to 0VDC condition. If this is

found, it will enter a state consistent with the selected operating mode. When

the MS4800 system enables its safety outputs, it monitors the external

devices for a closed to open transition. This transition must occur within

300ms or the MS4800 system will then enter an alarm state. Additionally, if

the EDM connections are incorrectly wired, the system will enter an alarm

state.

SECTION 6

Note For proper operation of the MS4800 system when EDM is not active, the EDM

input must be wired to the MS4800 system 0 VDC line.

The EDM function can be activated and deactivated using the selector

switches on the receiver unit.

6-3 Machine test signal (MTS)

Some applications require that the machine guarding system be tested by the

machine controller during a non-hazardous portion of the machine cycle to

verify that the guarding system is functioning properly. The MTS option on the

transmitter provides this capability. The MTS is provided by placing a normally-closed switch across the MTS and MTS Return lines of the transmitter.

When the transmitter recognizes a close-to-open transition on this switch a

beam block state will be simulated on the transmitter and the receiver will

enter the MACHINE STOP state. MTS is active as long as the switch is held

open.

6-4 Range selection

The MS4800 offers operating range selection: short range is 3 m and long

range is 7 m for the 14 mm models. For the 30mm models the short range is

8m and long range is 20 m. This function is useful when there are many light

curtains operating within a small space and the possibility of cross-talk is

likely.

17

Page 36

Start/Restart Input Section 6-5

6-5 Start/Restart Input

The characteristic of the Start/Restart Input is shown in the following schematic:

MS4800

Start

N.O.

+24 VDC

+24 VDC

0 VDC

Reset

18

Page 37

Using selector switches to set features

ENDCAP WITH DOOR SELECTOR SWITCH ACCESS

RCVR XMTR

RECEIVER SELECTOR SWITCHES

TRANSMITTER SELECTOR SWITCHES

SELECTOR SWITCH ACCESS

321 546

12

321546

ON

ON

ON

Scan Code

Frequency A 1 = Off

Frequency B 1 = On

MTS

Disabled 2 = Off

Enabled 2 = On

ON

MTS

Scan Code

TRANSMITTER SELECTOR SWITCHES

(Shown in factory default positions)

1

2

!WARNING Make sure that foreign objects such as water, oil, or dust do not enter the

inside of the MS4800 system while the cover for the selector switches is open.

7-1 Access to the selector switches

The switches are located behind a flip door on both the transmitter and

receiver. The flip up doors are opened by loosening two retaining screws (see

illustration below).

SECTION 7

7-1-1 Transmitter selector switch settings

Switch Position Function Factory default

1 SCAN CODE SCAN CODE A

2MTSMTS OFF

19

Page 38

Operating mode selection Section 7-2

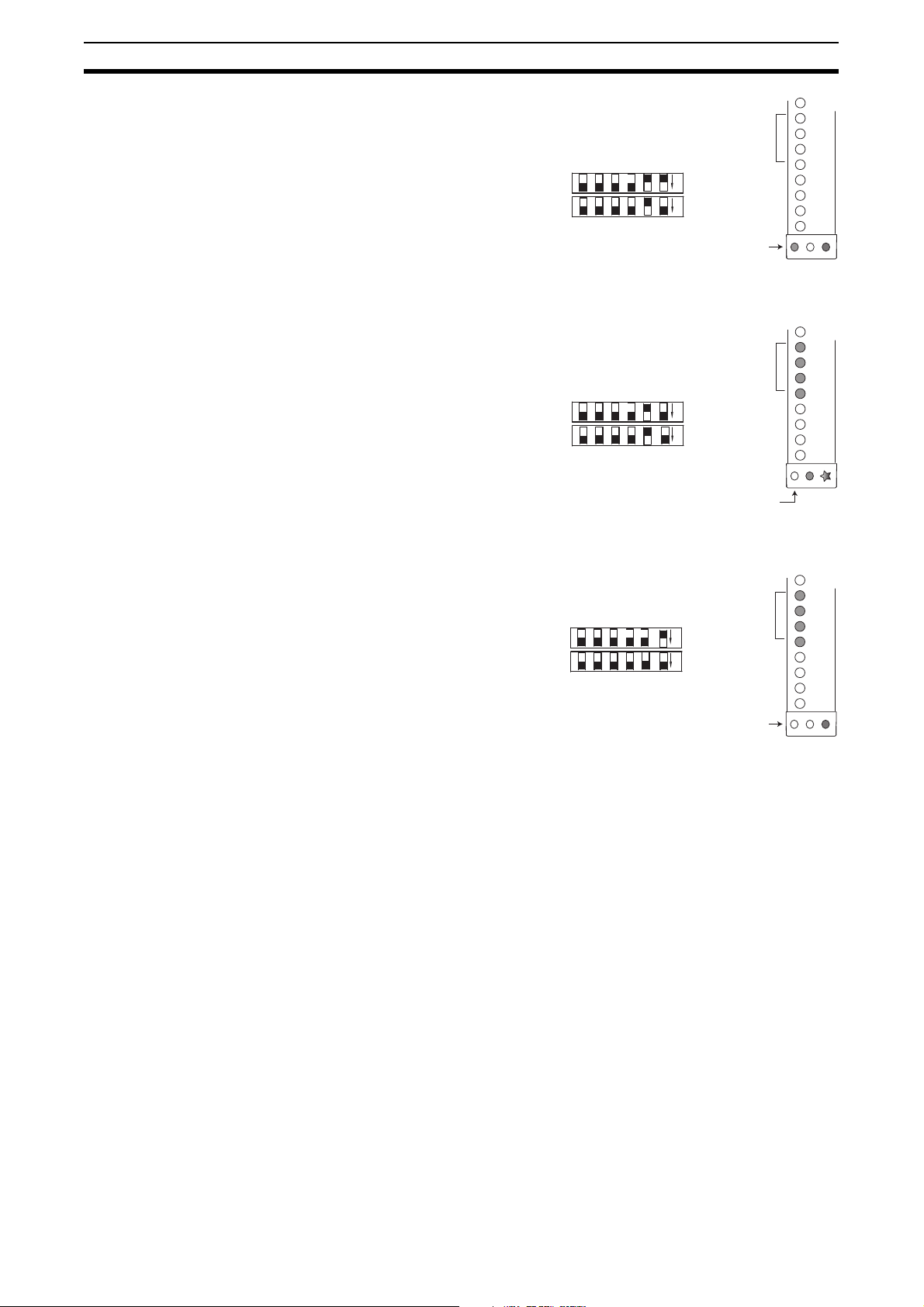

7-1-2 Receiver selector switch settings

Switch A Position Function Switch B Position Function Factory Default

1 Auto Start or Start/

Restart Interlock

2 EDM 2 EDM Disabled (OFF)

3 Scan Code 3 Scan Code Scan Code A (OFF)

4 Floating Blanking 1 4 Floating Blanking 1 Disabled (OFF)

5 Fixed Blanking 5 Fixed Blanking Disabled (OFF)

6 Program (Non-safety) 6 Range (Non-safety) Program (toggle)

1 Auto Start or Start/

Restart Interlock

Auto Start (OFF)

Short Range (OFF)

Operating Mode

Automatic Start 1 = Off 1 = Off

Start/Restart Int 1 = On 1 = On

EDM Disabled 2 = Off 2 = Off

EDM Enabled 2 = On 2 = On

Scan Code A 3 = Off 3 = Off

EDM

Auto/SRI

SW A

SW B

RECEIVER SELECTOR SWITCHES

(Shown in factory default positions)

321 546

321546

EDM

Auto/SRI

Scan Code

FB1

FB1

Program

ON

ON

Range

Fixed BK

Fixed BK

Scan Code

Scan Code B 3 = On 3 = On

FB1 Disabled 4 = Off 4 = Off

FB1 Enabled 4 = On 4 = On

Fixed Blanking

Disabled 5 = Off 5 = Off

Enabled 5 = On 5 = On

Program 6 = Toggle

Operating Range

Short Range 6 = Off

Long Range 6 = On

7-2 Operating mode selection

The operating mode is selected by setting position 1 of switches A and B,

located on the receiver. Any mismatch between the settings of switches A and

B will result in an alarm condition. The available operating modes are automatic start and Start/Restart Interlock.

7-3 Selecting and programming Fixed Blanking

SW A SW B

Refer to section 5-1 Fixed Blanking for details on selecting and programming

Fixed Blanking function.

7-4 Selecting and programming Floating Blanking

Floating Blanking is activated by setting position 4 of Switches A and B

located on the receiver.

Note When Floating Blanking is active, the amber LED will illuminate to indicate

that the system is operating in a less sensitive state.

7-5 Selecting External Device Monitoring (EDM)

EDM is activated by setting position 2 of Switches A and B located on the

receiver. Any mismatch between the settings of Switches A and B will result in

an alarm condition.

7-6 Selecting Machine Test Signal (MTS)

MTS is activated by setting position 2 located on the transmitter end cap.

20

Page 39

Selecting Scan Codes Section 7-7

Scan Code A

Scan Code B

7-7 Selecting Scan Codes

The MS4800 receiver and transmitter offer scan code selection to minimize

cross talk. On the transmitter this is activated by setting position 1. On the

receiver this is activated by setting position 3 of switch A and switch B.

Note Both receiver and transmitter must be set to the same code.

Example:

To mitigate interference from other light curtains, the MS4800 system has two

possible scan codes, A and B. The transmitter and receiver units must be set

to the same scan code for the receiver to enter the MACHINE RUN state.

21

Page 40

Selecting Scan Codes Section 7-7

22

Page 41

8-1 Safety Outputs (OSSDs)

!WARNING This product is designed for use on a 24 VDC, negative ground (protective

earth) electrical system only. Never connect the MS4800 system to a positive

ground (protective earth) system. With a positive ground (protective earth)

wiring scheme, certain simultaneous shorts of both safety outputs may not be

detected and the guarded machine may not stop, resulting in severe operator

injury.

The MS4800 system receiver supplies two independent PNP type safety outputs to provide run/stop signals to the guarded machine. In the MACHINE

RUN state, the safety outputs are electrically conducting and source 625 mA

of current at 24 VDC. In the MACHINE STOP state, the outputs are not electrically conducting.

8-2 Auxiliary Output

!WARNING Do not use the auxiliary output or external indicator output for safety applica-

tions. Human body may not be detected when MS4800 system fails, resulting

in serious injury.

SECTION 8

Outputs

This is not a safety output. The MS4800 system supplies one auxiliary output.

The configuration of this output is "PNP follow". So the signal on the auxiliary

output is similar to the status of the OSSD outputs. It will source up to 100 mA

at 24 VDC.

23

Page 42

Auxiliary Output Section 8-2

24

Page 43

Safe Mounting Distances

!WARNING Never install an MS4800 system without

regard to the safety distance. If the MS4800

system is mounted too close to the point of

operation hazard, the machine may not stop in

time to prevent an operator injury.

An MS4800 system must be mounted far enough from the machine danger

zone so the machine will stop before a hand or other body part reaches the

hazardous area. This distance is called the safety distance. It is a calculated

number based on a formula.

The safety distance "S" is the minimum safe distance between the safety light

curtain and the point of operation (pinch point).

Calculation of the safety distance "S" is based on the European standard

EN999 and applies to safety light curtains that are used in industrial environments.

SECTION 9

Light Curtain

S

9-1 Safety distance for safeguarding danger points

Additional countermeasures

S

Direction of

approach

!WARNING Additional countermeasures may be necessary to prevent access to the dan-

gerous area from above, below, the sides or the rear of the machine.

25

Page 44

Safety distance for safeguarding danger points Section 9-1

9-1-1 Calculation example for systems with a resolution of <40 mm

Formula according to EN999: S = (K x T) + C

Where S = minimum distance in millimeters from the danger zone to the

detection point, line, plane or zone. If the result of the calculation is less than 100 mm, a distance of at least 100 mm must

still be maintained.

K = Approach speed in mm/s. In the close area of 500 mm, the

speed is calculated at 2000 mm/s. If the distance is greater

than 500 mm, K can be calculated as 1600 mm/s. In this

case, however, a minimum of 500 mm applies for the safety

distance.

T = the overall system stopping performance in seconds

T = t

+ t2 + t

1

t1 = response time of the safety light curtain in seconds,

t

= response time of the safety interface tsi, if any.

2

t

= maximum stopping time of the machine tm in

3

Please refer to the technical information of the safety

Interface and the machine for the response time and stopping

time details.

C = 8 x (d-14 mm), but not less than zero.

d = minimum object resolution of the MS4800 system in

S = (2000 mm/s x T) + 8 x (d-14 mm)

This formula applies for all minimum distances of S up to and

including 500 mm. The minimum value of S shall not be less

than 100 mm.

If S is found to be greater than 500 mm using the formula

above, then the formula below can be used. In this case the

minimum value of S shall not be less than 500 mm.

S = (1600 mm/s x T) + 8 x (d-14 mm)

3

given in the table in chapter 16.

seconds.

millimeters, therefore:

26

Page 45

Safety distance for safeguarding danger areas Section 9-2

H

S

Direction of

approach

50 mm - maximum distance

to avoid walking behind

9-2 Safety distance for safeguarding danger areas

!WARNING Additional countermeasures may be necessary to prevent access to the dan-

gerous area from above, below, the sides or the rear of the machine.

The height of the protective field "H" above the reference plane and the resolution "d" of the MS4800 system have the following relationship:

= 15 x (d -50) or d = (H

H

min

H

= Height of the protective field above the reference plane,

min

maximum height = 1000 mm.

It is considered that if height is equal or less than 300 mm,

adults can not crawl under.

d = resolution of the MS4800 system

S = (K x T) + C

For K and T please refer to the previous chapter

C = (1200 mm - 0,4 x H) but not less than 850 mm

(arm length)

H = Height of protective field above the floor

S = (1600 mm x T) + (1200 - 0,4 x H)

/ 15) + 50

min

27

Page 46

Safety distance and beam heights in access guarding Section 9-3

H

S

L

Direction of

approach

9-3 Safety distance and beam heights in access guarding

!WARNING Additional countermeasures may be necessary to prevent access to the dan-

gerous area from above, below, the sides or the rear of the machine.

According to EN999 and EN294:

Resolution Lowest beam above

reference plane

14 mm In accordance with

EN 294

30 mm In accordance with

EN 294

The height of the protective field "H" above the reference plane and the resolution "d" of the MS4800 system have the following relationship:

S = (K x T) + C

For K and T please refer to the previous chapter

C = 8 x (d - 14)

d = resolution of the MS4800 system

S = (2000 mm x T) + 8 x (d - 14)

Highest beam above

reference plane

In accordance with

EN 294

In accordance with

EN 294

Additional

amount C

(see formula)

0mm

128 mm

28

Page 47

!WARNING Install the sensor system so that it is not affected by reflective surfaces. Fail-

ure to do so may hinder detection, resulting in serious injury.

10-1 Reflective Surface Interference

A reflective surface adjacent to the detection zone can deflect the optical

beam and may cause an obstruction in the zone not to be detected. The

reflective surface may be part of the machine, mechanical guard or workpiece. Therefore, a minimum distance (d) must exist between the reflective

object and the center line of the detection zone. The Test procedure (Appendix B) must be used to test for this condition.

In this picture, the interruption is clearly detected. The reflective object is outside of the beam angle.

SECTION 10

Installation

Operating range R

Approach direction

Interruption

EAA

Tr ansmitter Receiver

d = distance to

reflective surface

Reflective surface

Operating range R: is the effective working distance of the MS4800 system,

from the transmitter to the receiver.

EAA: is the effective aperture angle of the Safety Sensor.

it is ±2,5° for MS4800 system

distance d: is the minimum distance to a reflective surface.

This distance must be bigger than:

d

MS4800 system = tan(2,5°)×R

min

Be aware that reflective surface interference may also appear above and

below the sensing field.

29

Page 48

Cross Talk Mitigation Section 10-2

0

0,2

0,4

0,6

0,8

1

1,2

1,4

1,6

1,8

2

0,1 0, 2 0,5 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Range [m]

Minimum Distance d [m]

Scan Code A

Scan Code B

This example shows the minimum distance from the reflective surface, d, to

one side of the beam center line

10-2 Cross Talk Mitigation

To mitigate interference from other light curtains, the MS4800 system has two

possible scan codes, A and B. The transmitter and receiver units must be set

to the same scan code for the receiver to enter the MACHINE RUN state.

30

Page 49

General Mounting Considerations Section 10-3

MS4800 point of

operation guarding

MS4800FS 3-sided guarding MS4800FS 2-Axis guarding

10-3 General Mounting Considerations

10-3-1 Additional Guarding

Areas of access to the point of hazardous operation not guarded by the

MS4800 system must be protected by suitable means such as a fixed barrier

guard, an interlocked guard or a safety mat system.

Supplemental

D

s

LIGHT CURTAIN

Hazard

Mechanical

Barrier

Zone

Supplemental

Guarding

Example

Supplemental

Guarding

Supplemental

Guarding

Supplemental

Guarding

Guarding

10-3-2 Added Mounting Rigidity

ALTERNATE

T-SLOT

MOUNTING

ALTERNATE

T-SLOT

MOUNTING

It is recommended that when installing a

MS4800 larger than 1000 mm in length,

you use an additional mounting bracket.

This is to be installed using the T-slot on

the backside of the transmitter and

receiver.

Note

For light curtain > 1000 mm its recommended to buy extra T - slot mounting

bracket as Accessory.

31

Page 50

General Mounting Considerations Section 10-3