Page 1

Cat.No. I62E-EN-01

L7Z

Quick Start Guide

Page 2

Page 3

L7Z Quick Start Guide

Table of Contents

Warnings..............................................................................1

Safety Precautions and Instructions ................................................................... 2

EMC Compatibility .............................................................................................. 3

Installation ...........................................................................5

Mechanical Installation ....................................................................................... 5

Electrical Connection .......................................................................................... 6

Keypad Operation ............................................................. 11

Digital Operator Display (optional) ................................................................... 11

Power Up and Basic Parameter Setup ............................12

Start Up Procedure ........................................................................................... 12

Before Power Up .............................................................................................. 13

Display after Power Up ..................................................................................... 13

Control Mode Selection .................................................................................... 13

Autotuning .........................................................................14

Autotuning Mode Selection .............................................................................. 14

Autotuning Alarms and Faults .......................................................................... 15

Autotuning Procedure with Induction Motors ................................................... 16

Autotuning Procedure for PM Motors ............................................................... 17

PM Motor Encoder Offset Tuning ..................................................................... 18

Ride Profile and Sequence Setup....................................19

Up and Down Commands and Speed Reference Selection ............................. 19

Speed Selection Sequence Using Digital Inputs .............................................. 19

Acceleration / Deceleration / Jerk Settings ....................................................... 22

Brake Sequence ............................................................................................... 22

Inertia Compensation (Feed Forward) ............................................................. 22

Troubleshooting ................................................................24

Fault and Alarm Detection ................................................................................ 24

Operator Programming Errors (OPE) ............................................................... 26

Auto-tuning Faults ........................................................................................... 27

Parameter Table ................................................................28

Page 4

Warnings

Cables must not be connected or disconnected, nor signal tests carried out, while the power is

switched on.

The Varispeed L7 DC bus capacitor remains charged even after the power has been switched off. To

avoid an electric shock hazard, disconnect the frequency inverter from the mains before carrying out

maintenance. Then wait for at least 5 minutes after all LEDs have gone out.

Do not perform a withstand voltage test on any part of the inverter. It contains semiconductors,

which are not designed for such high voltages.

Do not remove the digital operator while the mains supply is switched on. The printed circuit board

must also not be touched while the inverter is connected to the power.

Never connect general LC/RC interference suppression filters, capacitors or overvoltage protection devices to

the inverter input or output.

CAUTION

To avoid unnecessary over current faults, etc., being displayed, the signaling contacts of any contactor or switch fitted between inverter and motor must be integrated into the inverter control logic

(e.g. baseblock).

This is absolutely imperative!

This manual must be read thoroughly before connecting and operating the inverter. All safety precautions and instructions for use must be followed.

The inverter must be operated with the appropriate line filters, following the installation instructions

in this manual and with all covers closed and terminals covered.

Only then will adequate protection be provided. Please do not connect or operate any equipment

with visible damage or missing parts. The operating company is responsible for any injuries or

equipment damage resulting from failure to heed the warnings in this manual.

EN-1

Page 5

Safety Precautions and Instructions

1. General

Please read these safety precautions and instructions for use thoroughly before installing and operating this

inverter. Also read all of the warning signs on the inverter and ensure they are never damaged or removed.

Live and hot inverter components may be accessible during operation. Removal of housing components, the

digital operator or terminal covers runs the risk of serious injuries or damage in the event of incorrect installation or operation. The fact that frequency inverters control rotating mechanical machine components can give

rise to other dangers.

The instructions in this manual must be followed. Installation, operation and maintenance may only be carried

out by qualified personnel. For the purposes of the safety precautions, qualified personnel are defined as individuals who are familiar with the installation, starting, operation and maintenance of frequency inverters and

have the proper qualifications for this work. Safe operation of these units is only possible if they are used

properly for their intended purpose.

The DC bus capacitors can remain live for about 5 minutes after the inverter is disconnected from the power. It

is therefore necessary to wait for this time before opening its covers. All of the main circuit terminals may still

carry dangerous voltages.

Children and other unauthorized persons must not be allowed access to these inverters.

Keep these Safety Precautions and Instructions for Use readily accessible and supply them to all persons with

any form of access to the inverters.

2. Intended Use

Frequency inverters are intended for installation in electrical systems or machinery.

Their installation in machinery and systems must conform to the following product standards of the Low Voltage Directive:

EN 50178, 1997-10,Equipping of Power Systems with Electronic Devices

EN 60204-1, 1997-12Machine Safety and Equipping with Electrical Devices

Part 1: General Requirements (IEC 60204-1:1997)/

Please note: Includes Corrigendum of September 1998

EN 61010-1, A2, 1995Safety Requirements for Information Technology Equipment

(IEC 950, 1991 + A1, 1992 + A2, 1993 + A3, 1995 + A4, 1996, modified)

CE marking is carried out to EN 50178, using the line filters specified in this manual and following the appropriate installation instructions.

3. Transportation and storage

The instructions for transportation, storage and proper handling must be followed in accordance with the technical data.

4. Installation

Install and cool the inverters as specified in the documentation. The cooling air must flow in the specified

direction. The inverter may therefore only be operated in the specified position (e.g. upright). Maintain the

specified clearances. Protect the inverters against impermissible loads. Components must not be bent nor insulation clearances changed. To avoid damage being caused by static electricity, do not touch any electronic

components or contacts.

EN-2

Page 6

5. Electrical Connection

Carry out any work on live equipment in compliance with the national safety and accident prevention regulations. Carry out electrical installation in compliance with the relevant regulations. In particular, follow the

installation instructions ensuring electromagnetic compatibility (EMC), e.g. shielding, grounding, filter

arrangement and laying of cables. This also applies to equipment with the CE mark. It is the responsibility of

the manufacturer of the system or machine to ensure conformity with EMC limits.

Contact your supplier or Omron-Yaskawa Motion Control representative when using leakage current circuit

breaker in conjunction with frequency inverters.

In certain systems it may be necessary to use additional monitoring and safety devices in compliance with the

relevant safety and accident prevention regulations. The frequency inverter hardware must not be modified.

If Permanent Magnet Motors are used:

If a PM motor is turned by any external force, high voltage is generated in the windings.

• During wiring, maintenance or inspection make sure, that the motor is stopped and can not turn.

• If the inverter is turned off and the motor must be turned, make sure that motor and inverter output are

electrically disconnected.

6. Inverter Setup

This L7 inverter can drive induction motors as well as permanent magnet motors.

Always select the appropriate control mode:

• For induction motors use V/f, Open Loop Vector or Closed Loop Vector control (A1-01 = 0, 2 or 3).

• For permanent magnet motors use no other control mode than Closed Loop Vector for PM (A1-01 = 6).

A wrong control mode selection can damage the inverter and motor.

If a motor is exchanged or operated the first time, always set up the motor control relevant parameters using

the nameplate data or perform autotuning. Do not change the parameters recklessly. To ensure a safe operation

with PM motors always set the:

• correct motor data

• the PG open detection parameters

• the speed deviation detection parameters

• the over acceleration detection parameters

Wrong parameter settings can cause dangerous behavior or motor and inverter damage.

Refer to page 12, Start Up Procedure for details about the correct start up procedure.

7. Notes

The Varispeed L7 frequency inverters are certified to CE, UL, and c-UL.

EMC Compatibility

1. Introduction

This manual was compiled to help system manufacturers using Omron-Yaskawa Motion Control frequency

inverters to design and install electrical switch gear. It also describes the measures necessary to comply with

the EMC Directive. The manual's installation and wiring instructions must therefore be followed.

EN-3

Our products are tested by authorized bodies using the standards listed below.

Product standard: EN 61800-3:1996

EN 61800-3; A11:2000

Page 7

2. Measures to Ensure Conformity of Omron-Yaskawa Motion Control Frequency

Inverters to the EMC Directive

Omron-Yaskawa Motion Control frequency inverters do not necessarily have to be installed in a switch cabinet.

It is not possible to give detailed instructions for all of the possible types of installation. This manual therefore

has to be limited to general guidelines.

All electrical equipment produces radio and line-borne interference at various frequencies. The cables pass

this on to the environment like an aerial.

Connecting an item of electrical equipment (e.g. drive) to a supply without a line filter can therefore allow HF

or LF interference to get into the mains.

The basic countermeasures are isolation of the wiring of control and power components, proper grounding and

shielding of cables.

A large contact area is necessary for low-impedance grounding of HF interference. The use of grounding

straps instead of cables is therefore definitely advisable.

Moreover, cable shields must be connected with purpose-made ground clips.

3. Laying Cables

Measures Against Line-Borne Interference:

Line filter and frequency inverter must be mounted on the same metal plate. Mount the two components as

close to each other as possible, with cables kept as short as possible.

Use a power cable with well-grounded shield. Use a shielded motor cable not exceeding 20 meters in length.

Arrange all grounds so as to maximize the area of the end of the lead in contact with the ground terminal (e.g.

metal plate).

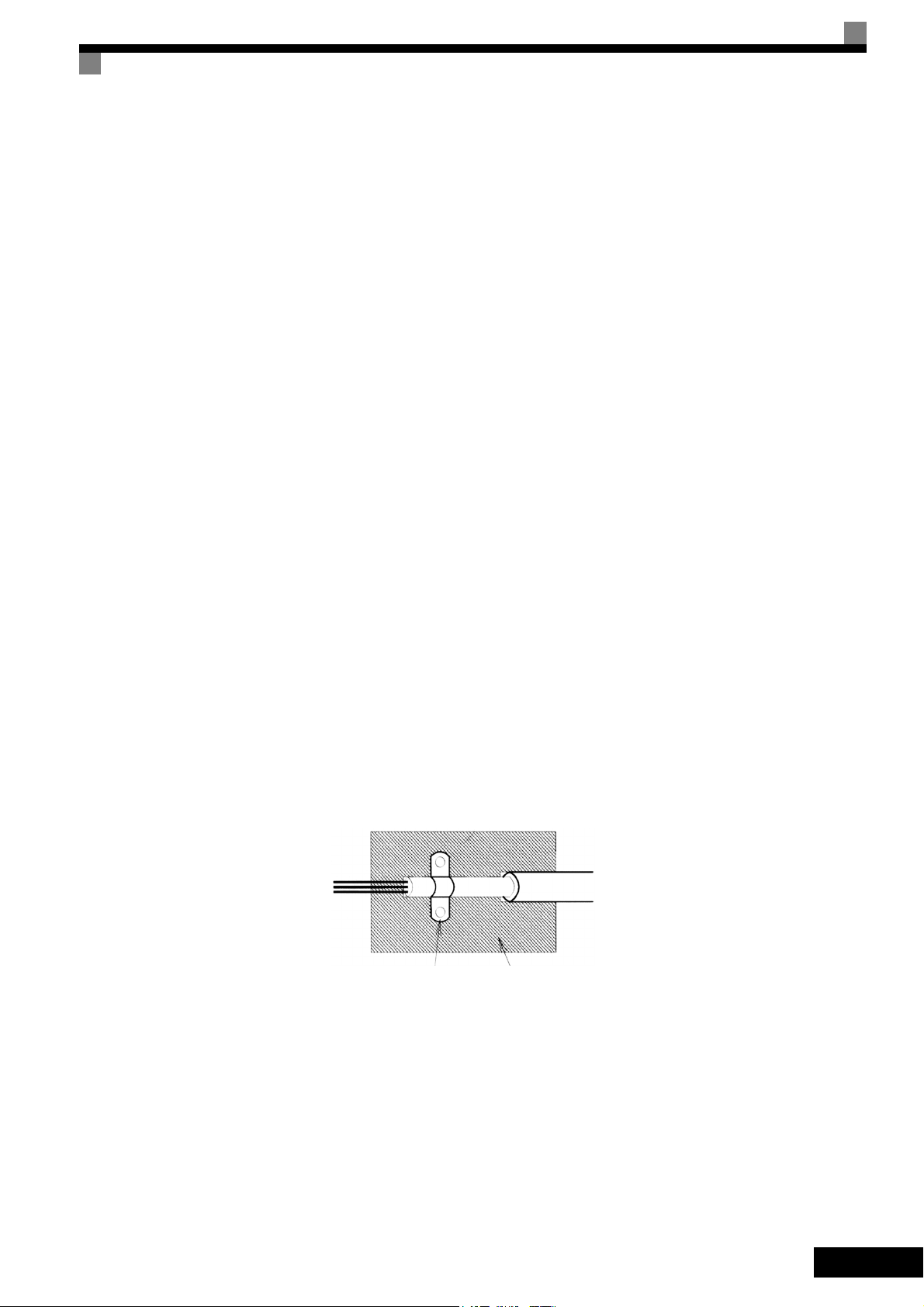

Shielded Cable:

• Use a cable with braided shield.

• Ground the maximum possible area of the shield. It is advisable to ground the shield by connecting the

cable to the ground plate with metal clips (see following figure).

Ground clip

The grounding surfaces must be highly conductive bare metal. Remove any coats of varnish and paint.

– Ground the cable shields at both ends.

– Ground the motor of the machine.

Ground plate

EN-4

Page 8

Installation

Mechanical Installation

Unpacking the Inverter

Check the following items after unpacking the inverter.

Item Method

Has the correct model of Inverter been delivered? Check the model number on the nameplate on the side of the Inverter.

Is the Inverter damaged in any way?

Are any screws or other components loose? Use a screwdriver or other tools to check for tightness.

If you find any irregularities in the above items, contact the agency from which you purchased the Inverter or

your Omron-Yaskawa Motion Control representative immediately.

Checking the Installation Site

Before installing the inverter check the following:

• Make sure that the ambient temperature is not exceeded

• Install the Inverter in a clean location which is free from oil mist and dust. It can be installed in a totally

enclosed panel that is completely shielded from floating dust.

• When installing or operating the Inverter, always take special care so that metal powder, oil, water, or other

foreign matter does not get into the Inverter.

• Do not install the Inverter on combustible material, such as wood.

• Install the Inverter in a location free from radioactive materials and combustible materials.

• Install the Inverter in a location free from harmful gasses and liquids.

• Install the Inverter in a location without excessive oscillation.

• Install the Inverter in a location free from chlorides.

• Install the Inverter in a location free from direct sunlight.

Inspect the entire exterior of the Inverter to see if there are any scratches or other

damage resulting from shipping.

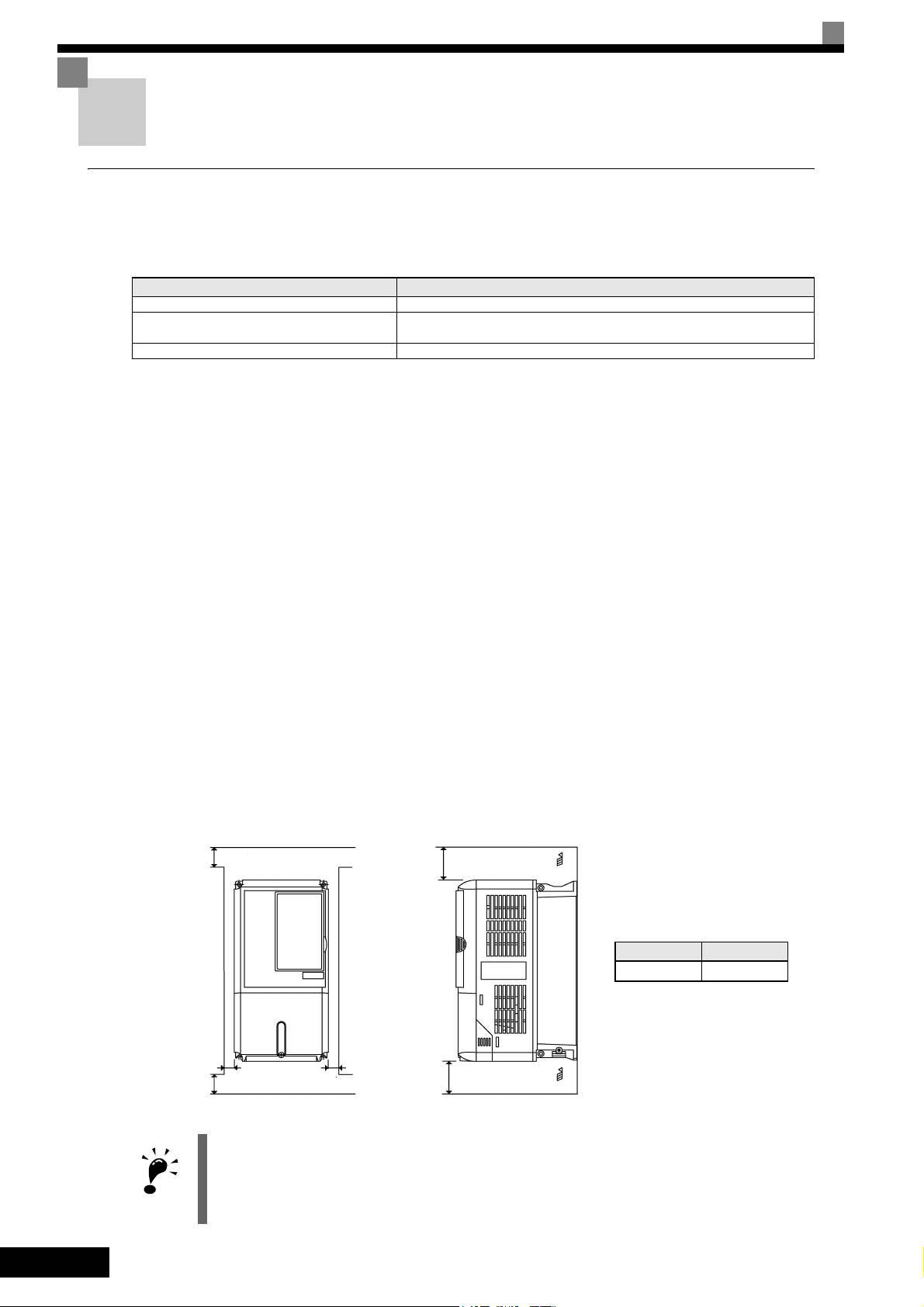

Installation Orientation

Install the Inverter vertically so as not to reduce the cooling effect. When installing the Inverter, always provide the following installation space to allow normal heat dissipation.

Air

A B

50 mm 120 mm

Air

50 mm min.

IMPORTANT

A

30 mm min.

30 mm min.

Horizontal Space

1. The same space is required horizontally and vertically for IP00, IP20 and NEMA 1 Inverters.

2. Always remove the top protection cover after installing an Inverter with an output of 18.5 kW or less in a

panel.

Always provide enough space for suspension eye bolts and the main circuit lines when installing an

Inverter with an output of 22 kW or more in a panel.

B

120 mm min.

Vertical Space

EN-5

Page 9

Electrical Connection

Installation of Inverters and EMC filters

PEL1L2

L3

Ground Bonds

Remove any paint!

For an EMC rules compliant installation consider the following

points:

• Use a line filter.

• Use shielded motor cables.

• Mount the inverter and filter on a grounded conductive plate.

• Remove any paint or dirt before mounting the parts in order to

reach the lowest possible grounding impedance.

Wiring Main Circuit Inputs

PE

Line

Filter

Load

Cable Length

as short as possible

Grounded

Metal Plate

GND

Ground Bonds

Remove any paint!

Inverter

L2

U

L1

L3

V

M

~3

W

GND

Screened

Motor cable

Consider the following precautions for the main circuit power supply input.

• If a moulded case circuit breaker is used for the power supply connection (R/L1, S/L2, and T/L3), ensure

that the circuit breaker is suitable for the Inverter.

• If an earth leakage breaker is used, it should be able to detect all kinds of current should be used in order to

ensure a safe earth leakage current detection

• A magnetic contactor or other switching device can be used at the inverter input. The inverter should not

be powered up more than once per hour.

• The input phases (R/S/T) can be connected in any sequence.

• If the Inverter is connected to a large-capacity power transformer (600 kW or more) or a phase advancing

capacitor is switched nearby, an excessive peak current could flow through the input power circuit, causing

an inverter damage. As a countermeasure install an optional AC Reactor at the inverter input or a DC reactor at the DC reactor connection terminals.

• Use a surge absorber or diode for inductive loads near the Inverter. Inductive loads include magnetic con-

tactors, electromagnetic relays, solenoid valves, solenoids, and magnetic brakes.

Wiring the Output Side of the Main Circuit

The following precautions should be considered for the output circuit wiring.

• Never connect any power source to the inverter output terminals. Otherwise the inverter can be damaged.

• Never short or ground the output terminals. Otherwise the inverter can be damaged.

• Do not use phase correction capacitors. Otherwise the inverter and capacitors can be damaged.

• Check the control sequence to make sure, that the magnetic contactor (MC) between the Inverter and

motor is not turned ON or OFF during inverter operation. If the MC is turned ON during the Inverter is

operation, a large inrush current will be created and the inverter’s over current protection may operate.

Ground Connection

The following precautions should be considered for the ground connection.

• Do not share the ground wire with other devices, such as welding machines or power tools.

• Always use a ground wire, that complies with technical standards on electrical equipment and minimize

the length of the ground wire.

EN-6

Page 10

Leakage current is caused by the Inverter. Therefore, if the distance between the ground electrode and the

ground terminal is too long, potential on the ground terminal of the Inverter will become unstable.

• When more than one Inverter is used, do not to loop the ground wire.

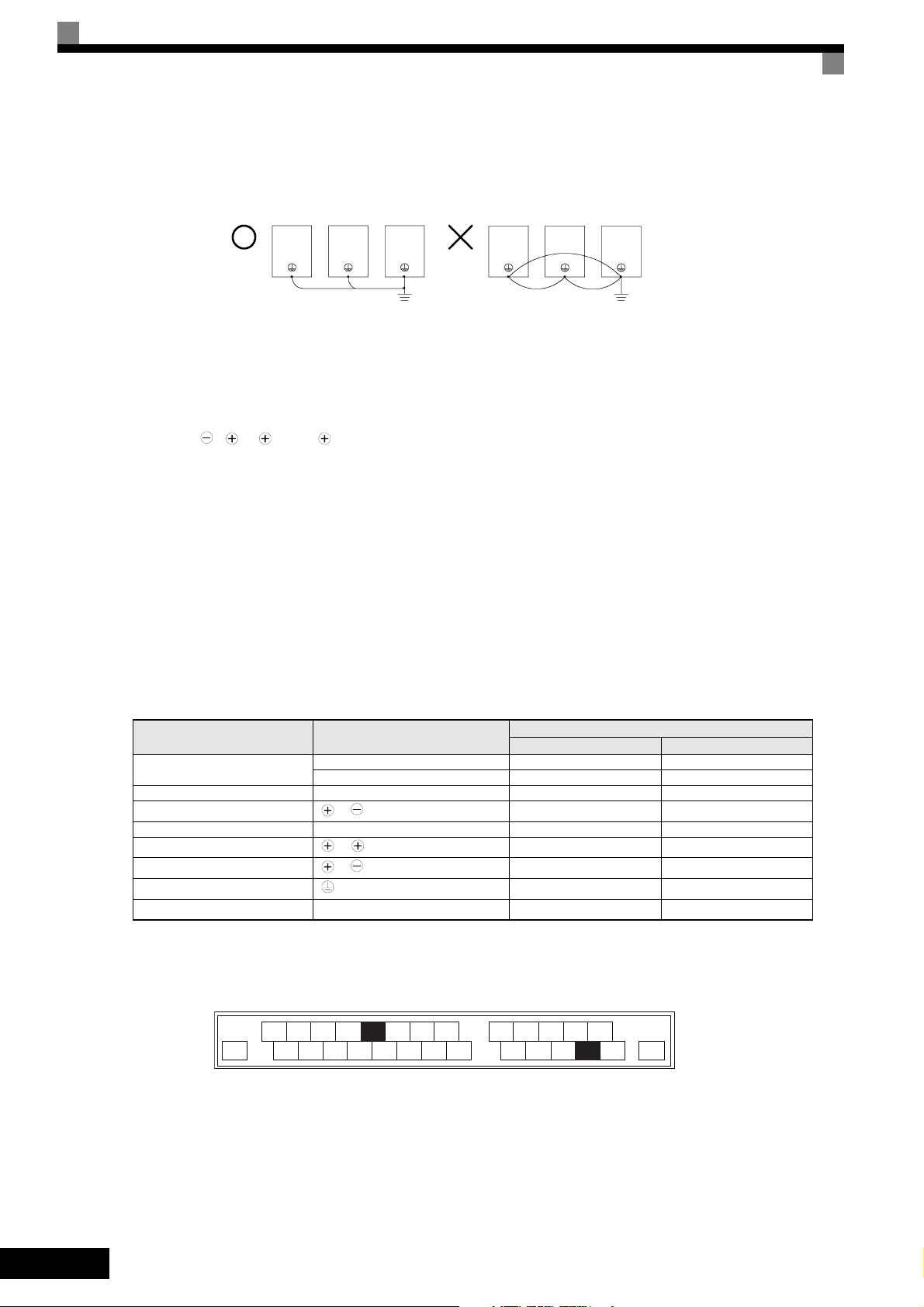

OK

NO

Fig 1 Ground Wiring

Control Circuit Wiring Precautions

Consider the following precautions for wiring the control circuits.

• Separate control circuit wiring from main circuit wiring (terminals R/L1, S/L2, T/L3, B1, B2, U/T1, V/T2,

W/T3, , 1, 2, and 3, PO, NO) and other high-power lines.

• Separate wiring for control circuit terminals MA, MB, MC, M1, M2, M3, M4, M5, and M6 (contact out-

puts) from wiring to other control circuit terminals.

• If an optional external power supply is used, it should be a UL Listed Class 2 power supply.

• Use twisted-pair or shielded twisted-pair cables for control circuits to prevent operating faults.

• Ground the cable shields with the maximum contact area of the shield and ground.

• Cable shields have to be grounded on both cable ends.

Main Circuit Terminals

Main circuit terminal functions are summarized according to terminal symbols in Table 1. Wire the terminals

correctly for the desired purposes.

Table 1 Main Circuit Terminal Functions (200 V Class and 400 V Class)

Purpose Terminal Symbol

Main circuit power input

Inverter outputs U/T1, V/T2, W/T3 23P7 to 2055 43P7 to 4055

DC bus terminals

Braking Resistor Unit connection B1, B2 23P7 to 2018 43P7 to 4018

DC reactor connection

Braking Unit connection

Ground 23P7 to 2055 43P7 to 4055

Control Power Supply PO, NO 23P7 to 2055 43P7 to 4055

R/L1, S/L2, T/L3 23P7 to 2055 43P7 to 4055

R1/L11, S1/L21, T1/L31 2022 to 2055 4022 to 4055

1,

1, 2

3,

Model: CIMR-L7Z

200 V Class 400 V Class

23P7 to 2055 43P7 to 4055

23P7 to 2018 43P7 to 4018

2022 to 2055 4022 to 4055

EN-7

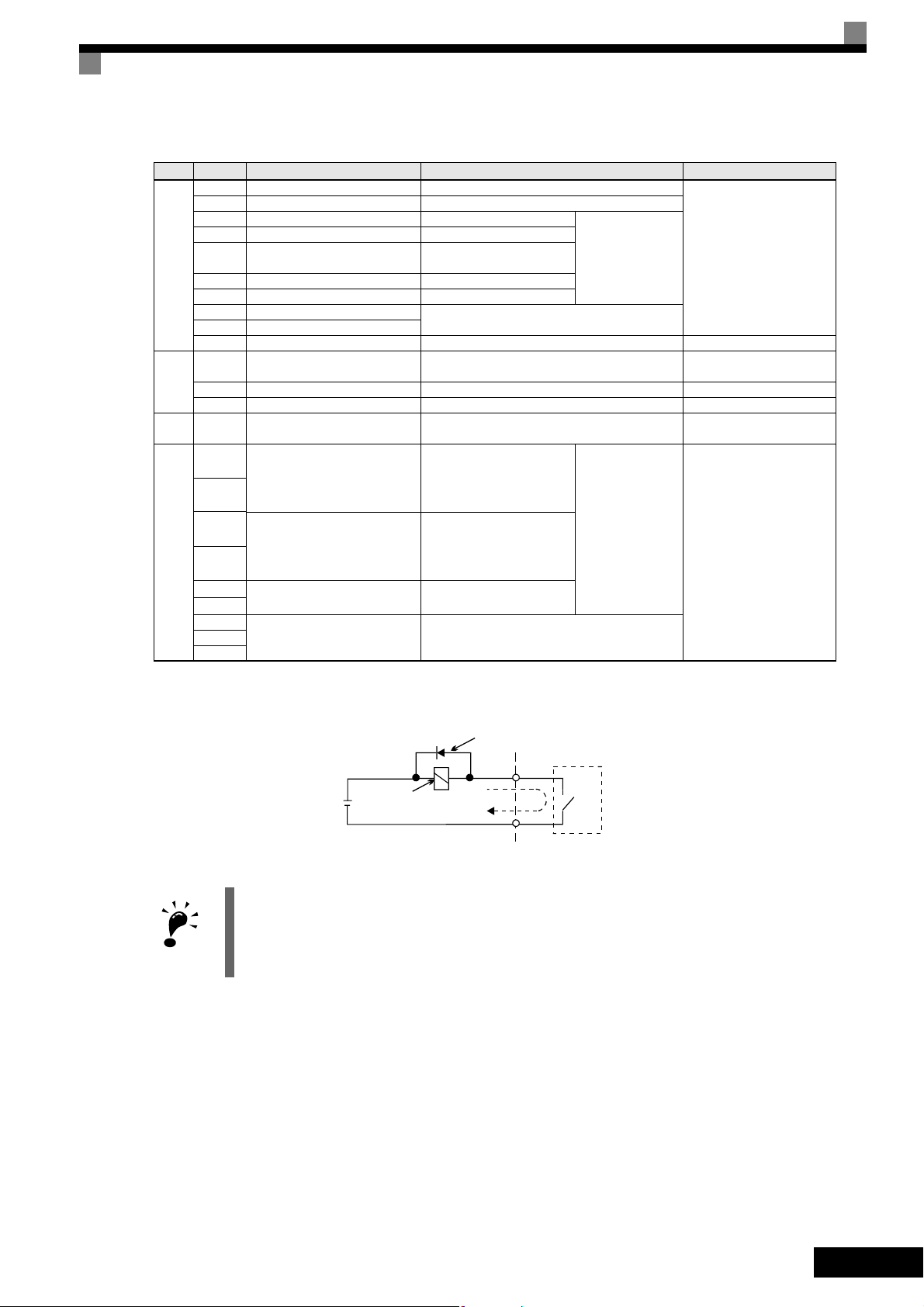

Control Circuit Terminals

Fig 2 shows the control terminal arrangement. The functions of the control circuit terminals are shown in

Table 2. Use the appropriate terminals for the correct purposes.

E(G)

SC SC SC

S1

S2

BB

S3 S4

Fig 2 Control terminal arrangement

+V

A1 AC

S5 S6 S7 BB1

M5

M6

M3

MA MB MC

M4

M1

M2

E(G)

Page 11

Table 2 Control Circuit Terminals with default settings

Type No. Signal Name Function Signal Level

S1 Forward run/stop command Forward run when ON; stopped when OFF.

S2 Reverse run/stop command Reverse run when ON; stopped when OFF.

S3 Nominal speed Nominal speed when ON.

Dig-

input

signals

S4 Inspection Run Inspection RUN when ON.

S5 Intermediate speed

ital

Intermediate speed when

ON.

S6 Leveling speed Leveling speed when ON.

S7 Not used –

BB Hardware baseblock Both inputs must be enabled to enable the inverter

outputBB1 Hardware baseblock 1

SC Digital input common – –

Ana-

input

signals

Dig-

output

signals

+V

log

15 V power supply

A1 Frequency reference 0 to +10 V/100% 0 to +10 V(20 kΩ)

AC Analog reference neutral – –

Shield wire, optional ground line

E(G)

connection point

M1

Brake command

(1NO contact)

M2

M3

ital

*1. Do not use this power supply for supplying any external equipment.

*2. When driving a reactive load, such as a relay coil with DC power supply, always insert a flywheel diode as shown in Fig 3.

Contactor Control

(1NO contact)

M4

M5

Inverter Ready

(1NO contact)

M6

MA

Fault output signal (SPDT)

MB

(1 Change over contact)

MC

*1

15 V power supply for analog references

––

Brake command when ON.

Contactor Control when ON

Inverter Ready when ON.

Fault when CLOSED across MA and MC

Fault when OPEN across MB and MC

Functions are

selected by setting

H1-01 to H1-05.

Multi-function contact outputs

24 VDC, 8 mA

Photo-coupler

15 V

(Max. current: 20 mA)

Relay contacts

Contact capacity:

1 A max. at 250 VAC

1 A max. at 30 VDC

*2

Flywheel diode

The rating of the flywheel diode must

External power: 30

VDC max.

Coil

1 A max.

be at least as high as the circuit voltage.

Fig 3 Flywheel Diode Connection

1. In Fig 4 the wiring of the digital inputs S1 to S7 and BB, BB1 is shown for the connection of contacts or NPN

transistors (0V common and sinking mode). This is the default setting.

For the connection of PNP transistors or for using a 24V external power supply, refer to Ta ble 3.

IMPORTANT

2. A DC reactor is an option only for Inverters of 18.5 kW or less. Remove the short circuit bar when connecting a

DC reactor.

Sinking/Sourcing Mode (NPN/PNP Selection)

The input terminal logic can be switched over between sinking mode (0-V common, NPN) and sourcing mode

(+24V common, PNP) by using the jumper CN5. An external power supply is also supported, providing more

freedom in signal input methods.

EN-8

Page 12

Table 3 Sinking/Sourcing Mode and Input Signals

S1

S2

SC

IP24V

(+24V)

CN5

A1 A3

B1

B3B2

A2

S1

S2

SC

IP24V

(+24V)

CN5

A1 A3

B1

B3B2

A2

24 VDC

+

S1

S2

SC

IP24V

(+24V)

CN5

A1 A3

B1

B3B2

A2

24 VDC

-

Internal Power Supply – Sinking Mode (NPN)

Internal Power Supply – Sourcing Mode (PNP)

S1

S2

B1

SC

A1 A3

A2

B3B2

CN5

IP24V

(+24V)

External Power Supply – Sinking Mode (NPN)

External Power Supply – Sourcing Mode (PNP)

EN-9

Page 13

Wiring the Inverter

3-phase power

380 to 480V

50/60Hz

Multi function

Inputs

(Factory setting)

Magnetic

Contactor

L1

L2

L3

PE

Forward run/stop

Reverse run/stop

Nominal Speed

Inspection Run

Intermediate Speed

Leveling Speed

Not used

Hardware Baseblock (note 3)

Line

Filter

DC reactor to improve input

power factor (optional)

Link

(+1) (+2)

L1(R)

L2(S)

L3(T)

S1

S2

S3

S4

S5

S6

S7

BB

BB1

SC

(-)

+24V, 8mA

IP24V (24V)

Braking Resistor

unit (optional)

B1

U/T1

V/T2

W/T3

TA 1

PG-X2

(Optional)

TA 3

TA 2

B2

A Pulse

B Pulse

Z Pulse

Pulse Monitor Output

RS-422

(100m or less)

Motor

IM/PM

P

P

PG

Voltage adjustment

Analog input

(Speed reference)

2kOhm

Optional control power

supply input for Rescue

Operation

Note:

1

. Main circuit terminals are indicatied with double circles and

control circuit terminals are indicatied with a single circles

2. The CN5 factory setting is NPN

3. To enable the inverter both inputs, BB and BB1 must be closed. If

only one of the inputs is closed, “BB” will be displayed in the

operator panel and the inverter will not start.

2kOhm

0 to 10 V

P

Input option cards

to terminal B1

to terminal -

CN5(NPN setting)

E(G)

+V

Analog input power

supply +15V, 20mA

A1

Master speed

reference 0 to 10V

AC

0 V

2CN

P0

Control Power

Supply Input

N0

Shielded

wires

Fig 4 Wiring Diagram

MA

MB

MC

M1

M2

M3

M4

M5

M6

3CN

Twisted-pair

wires

Fault contact output

250VAC, max. 1A

30VDC, max. 1A

Brake Command

(Factory setting)

Contactor Control

(Factory setting)

Inverter Ready

(Factory setting)

Output option

cards

Multi-function

contact output

250VAC, max. 1A

30VDC, max. 1A

EN-10

Page 14

Keypad Operation

Digital Operator Display (optional)

The key names and functions of the Digital Operator are described below

Drive Status Indicators

FWD: Lights up when a forward run command is input.

REV: Lights up when a reverse run command is input.

SEQ: Lights up when any other run command source

REF: Lights up when any other frequency reference

ALARM:Lights up when an error or alarm has

Data Display

Displays monitor data, parameter numbers and parameter settings.

Mode Display (displayed at the upper left of data display)

DRIVE: Lights up in Drive Mode.

QUICK: Lights up in Quick Programming Mode.

ADV: Lights up in Advanced Programming Mode.

VERIFY: Lights up in Verify Mode.

A. TUNE: Lights up in Autotuning Mode.

Keys

Execute operations such as setting parameters, monitoring, jogging, and autotuning.

than the digital operator is selected

source than the digital operator is selected

occurred.

Digital Operator Keys

Key Name Function

LOCAL/REMOTE Key

MENU Key Selects menu items (modes).

ESC Key Returns to the status before the DATA/ENTER key was pressed.

JOG Key

FWD/REV Key

Shift/RESET Key

Increment Key

Decrement Key

DATA/ENTER Key Enters menus and parameters, and set validates parameter changes.

Switches between operation via the Digital Operator (LOCAL) and the settings in

b1-01 and b1-02 (REMOTE).

This key can be enabled or disabled by setting parameter o2-01.

Starts jog operation when the inverter is operated by the Digital Operator and d1-18

is set to 0.

Selects the rotation direction of the motor when the Inverter is operated by the Digital Operator.

Sets the active digit when programming parameters.

Also acts as the Reset key when a fault has occurred.

Selects menu items, sets parameter numbers, and increments set values.

Used to move to the next item or data.

Selects menu items, sets parameter numbers, and decrements set values.

Used to move to the previous item or data.

EN-11

RUN Key Starts the Inverter operation when the Inverter is controlled by the Digital Operator.

STOP Key

Note: Except in diagrams, Keys are referred to the key names listed in the above table.

Stops Inverter operation.

This key can be enabled or disabled using parameter o2-02 when operating from a

source different than the operator.

Page 15

Power Up and Basic Parameter Setup

Start Up Procedure

START

Mechanical installation

Main and control circuit wiring

Check the encoder power supply selection

Select the control mode in parameter A1-02

Perform motor data / encoder offset auto tuning

* V/f control

* Open Loop Vector Control

* Closed Loop Vector Control

* Closed Loop Vector Control for PM

Speed reference

source

Set up the analog/digital I/O’s in the H1-xx,

H2-xx and H3-xx parameters

* (Closed Loop only)

Switch on the power supply

page 16, Autotuning Procedure with Induction Motors

page 17, Autotuning Procedure for PM Motors

Digital operator (b1-02 = 0)

Analog Input

Select the control sequence in

paramerter d1-18

Set up the digital I/O’s in the H1-xx

and H2-xx parameters

* Acceleration / Deceleration times (C1-xx)

Set up the

* S-Curves (Jerk) (C2-x)

Make test runs

Fine Tuning

* Brake sequence tuning

* Special functions setup

FINISH

Fig 5 Basic Start Up Sequence

* Preset speed values (d1-xx)

Set up the

* Acceleration / Deceleration times (C1-xx)

* S-Curves (Jerk) (C2-xx)

EN-12

Page 16

Before Power Up

The following points should be checked carefully before the power is switched on.

• Check if the power supply meets the inverter specification.

• Check if the power supply cables are tightly connected to the right terminals (L1, L2, L3).

• Check if the motor cables are tightly connected to the right terminals on the inverter side (U, V, W) as well

as on the motor side.

• Check if the braking unit / braking resistor is connected correctly.

• Check if the Inverter control circuit terminal and the control device are wired correctly.

• Set all Inverter control circuit terminals to OFF.

• When a PG card is used, check if it is wired correctly.

Display after Power Up

After normal power up without any problems the operator display shows the following messages

-DRIVE-

Display for normal operation The Baseblock message blinks.

Base Block

Rdy

BB

When a fault occurs or an alarm is active, a fault or alarm message will appear. In this case, refer to page 28,

Factory settings are in bold..

Display for fault operation

-DRIVE-

UV

Main Power Loss

A fault or alarm message is shown on the

display.

The example shows a low voltage alarm.

Control Mode Selection

As the first thing after power up one of the four control modes must be selected depending on the machine

type. The Closed Loop Vector modes require PG feedback cards. Table 4 shows the required / possible PG

cards for each mode.

Table 4 Control Mode Selection

Machine Type Control Mode

Induction motor without encoder

Induction motor with incremental encoder Closed Loop Vector Control 3 PG-B2 / PG-X2

Permanent magnet motor with Hiperface

encoder

Yaskawa IPM motor with incremental encoder

y

or EnDat 2.1

Closed Loop Vector Control for

Closed Loop Vector Control for

V/f control 0 -

Open Loop Vector Control 2 -

PM motors

PM motors

A1-02 setting PG Card

6PG-F2

6 PG-X2

EN-13

CAUTION

• For Permanent Magnet motors do not use any other control mode than Closed Loop Vector for PM

(A1-02 = 6). Using any other control mode can cause damage to the equipment or can cause dangerous

behavior.

Page 17

Autotuning

The motor data autotuning function sets the V/f pattern parameters (E1-), motor data parameters

(E2-, E5-) and the encoder data (F1-01) automatically. The steps which have to be performed during

the autotuning depend on the tuning mode selection.

Autotuning Mode Selection

The autotuning mode has to be selected according to selected control mode and the mechanical system (motor

no load rotation possible or not). Table 5 shows the selectable tuning mode for each control mode.

Table 5 Motor Data Autotuning Modes

Tuning

Autotuning Mode Function

Standard tuning with rotating motor Tunes all motor parameters. 0 No Yes Yes Yes

IM tuning with not rotating motor Tunes the basic motor parameters. 1 No Yes Yes No

IM Line-to-line resistance tuning

Encoder offset tuning

Tunes the line-to-line resistance

only

Tunes the offset between the

encoder and magnetic zero position.

Mode

Selection

(T1-01)

2YesYesYesNo

4NoNoNoYes

V/f

Control Mode

Open

Loop

Vector

Closed

Vector

Loop

Closed

Loop

Vector

(PM)

Autotuning Modes

Autotuning with Rotating Motor (T1-01 = 0)

This autotuning mode can be used in any Vector control mode. After the motor nameplate data have been

input, the inverter will operate the motor for approximately 1~2 minutes and set the required motor parameters

automatically.

Use this tuning mode only, if the motor can rotate freely which means that the ropes must be removed

and the brake must be open. The gearbox can remain connected to the motor.

IMPORTANT

Autotuning with Not Rotating Motor (T1-01 = 1)

This autotuning mode can be used for Open Loop and Closed Loop Vector control for IM only. The inverter

supplies power to the motor for approximately 1 minute and some of the motor parameters are set automatically while the motor does not turn. The motor no-load current and the rated slip value will automatically be

fine tuned during the first time operation.

Verify the rated slip value (E2-02) and the no-load current (E2-03) after the first run with nominal speed.

Autotuning for Line-to-Line Resistance (T1-01 = 2)

Non-rotating autotuning for line-to-line resistance can be used in V/f control, Open Loop Vector control and

Closed loop Vector control. The Inverter supplies power to the motor for approximately 20 seconds to measure

the motor line-to-line resistance and cable resistance. The motor does not turn during this tuning procedure.

Encoder Offset Tuning (T1-01=4)

This tuning mode is available in Closed Loop Vector control for PM motors only. It automatically sets the offset between the magnetic pole and the encoder zero position. It can be used to retune the offset after an

encoder change without changing the motor data settings.

EN-14

Page 18

General Precautions:

1. Use rotating autotuning whenever high precision is required or for a motor that is not connected to a load.

2. Use not rotating autotuning whenever the load cannot be disconnected from the motor (e.g. the ropes can’t be

IMPORTANT

removed).

3. Make sure, that the mechanical brake is not open for not rotating autotuning.

4. During autotuning the motor contactors have to be closed.

5. For autotuning the BB and BB1 signals must be ON (Inverter must not be in base block condition).

6. Confirm, that the motor is mechanically fixed and can not move.

7. Power is supplied during auto tuning, even though the motor does not turn. Do not touch the motor until autotuning has been completed.

8. Remove the feather key from the motor shaft before performing a tuning with rotating motor with a stand alone

motor (no traction sheave or gear mounted).

9. To cancel autotuning, press the STOP key on the Digital Operator.

Precautions for rotating and encoder offset autotuning:

1. The load should be disconnected which means, that the ropes have to be removed and the brake must be open.

2. If the load can’t be removed, the tuning can be done with a balanced car. The tuning result accuracy will be

lower which can result in a performance loss.

3. Make sure that the brake is open during autotuning.

4. During autotuning the motor can be started and stopped repeatedly. When the tuning is finished, “END” will be

displayed in the operator panel. Do not touch the motor until this display is shown and the motor has completely

stopped.

Autotuning Alarms and Faults

Data Input Errors

The inverter will show a “Data Invalid” message and will not perform autotuning if:

• the motor speed, rated frequency and pole pair number do not correspond.

Base Frequency 60⋅

Motor Speed

---------------------------------------------------

<

2 Motor pole⋅

• the rated current does not correspond to the rated power value

The inverter calculates the motor power using the input current value and data from the internal motor data

table. The calculated value must be between 50% and 150% of the input value for the rated power.

Other Alarms and Faults During Autotuning

For an overview of possible autotuning alarms or faults and corrective actions refer to page 27, Auto-tuning

Faults.

EN-15

Page 19

Autotuning Procedure with Induction Motors

Fig 6 shows the autotuning procedure for an induction motor with or without encoder in V/f-, Open loop vec-

tor and Closed loop vector control.

START

Set the Base Block Inputs BB and

BB1

No

V/f Control ?

(A1-02 = 0)

(A1-02 = 2/3)

Yes

Enter auto tuning mode and

set parameter T1-01 = 2

Set:

T1-02 - Motor rated power

T1-04 - Motor rated current

Press the UP button until

“Tuning Ready” display appears

Can the motor

rotate freely ?

No

Enter auto tuning mode and

set parameter T1-01 = 1

T1-02 - Motor rated power

T1-03 - Motor rated voltage

T1-04 - Motor rated current

T1-05 - Rated motor frequency

T1-06 - Motor pole number

T1-07 - Motor rated speed

T1-08 - PG pulse number*

“Tuning Ready” display appears

Set:

(*CLV only)

Press the UP button until

Yes

(ropes removed?)

“Tuning Ready” display appears

Enter auto tuning mode and

set parameter T1-01 = 0

T1-02 - Motor rated power

T1-03 - Motor rated voltage

T1-04 - Motor rated current

T1-05 - Rated motor frequency

T1-06 - Motor pole number

T1-07 - Motor rated speed

T1-08 - PG pulse number*

Set:

(*CLV only)

Press the UP button until

Open the brake

Refer to

page 27, Auto-tuning Faults

and eliminate the fault source

Close the motor contactor(s)

Press the RUN button

Tuning

No

(Fault code is

displayed)

Open the contactors, open the base

block inputs and close the brake if auto

tuning with rotating motor was performed

successful ?

(” Tuning successful”

Yes

is displayed)

FINISH

Fig 6 Autotuning for Induction Motors

EN-16

Page 20

Autotuning Procedure for PM Motors

Fig 7 shows the autotuning procedure for permanent magnet motors. Before tuning make sure that the control

mode is set to PM Closed Loop Vector (A1-02 = 6).

START

* Remove the ropes so that the motor can rotate freely

* Set the Base Block inputs BB and BB1

Switch ON the power supply if it is OFF

Does a OPE06 fault

occur?

No

Does a CPF24 fault

occur?

No

Does a OPE02 fault

occur?

No

S3-13 - Tr acti on sheave diam eter

S3-14 - Ropi ng

turn the motor slowly in Forward direction*

Set mechanical constants:

Open the brake, close the motor contactor,

Does PGO (no

encoder feedback)

occur?

No

Yes

Yes

Yes

S3-15 - Gear r atio

1

and check monitor U1-05.

Yes

Check parameter

* F1-01

* n8-35

* Check parameter n8-35

* If EnDat / Hiperface is used

- check the encoder power supply

- check the CLOCK and DATA signal wiring

* Switch off the power supply.

* Check if the correct PG constant (F1-01) and

absolute encoder resolution (F1-21) has been set.

* Refer to:

page 26, Operator Programming Errors (OPE)

Switch off the power supply

and check if the right PG card

is correctley installed

and eliminate the fault source

* C heck the w ir ing

* C heck/r eadjust the encoder

power supply

EN-17

U1-05 value positive

T1- 01 = 0 - R otational Tuning

T2-01 - Motor rated power

T2- 02 - Mot or base fr equency

T2-03 - Motor rated voltage

Pres s the UP but ton until the “T uning Ready” displ ay appears

Cl ose the mot or cont actor( s) and pr ess the R UN butt on

(”Tuning successful” is displayed)

Set the autot uning par ameter s:

Wait until tuning is finsihed

Tuning successful?

Yes

Open the cont actors , open the basebloc k

inputs and close t he brake

Fig 7 Autotuning for Permanent Magnet Motors

Is the sign of the

(not -)?

Yes

FINISH

No

T2-04 - Motor rated current

T2- 05 - Mot or pole num ber

T2-09 - Encoder resolution

T2- 10 - Mot or vol tage constant

No

(Fault code is displayed)

* 1. Forward direction means:

* C heck the enc oder wi ring

* C hange param eter F 1-05

Refer to

page 27, Auto-tuning Faults

and eli mi nate the faul t sourc e

The direction the motor turns with an UP command at terminal S1 (i.e.

with a clockwise rotating 3 phase supply and U-U, V-V, W-W wiring

between inverter and motor). Usually the direction is clockwise seen

from the motor shaft (traction sheave) side.

Refer to the motor instruction manual or consult the manufacturer for

details about the rotation direction.

Page 21

PM Motor Encoder Offset Tuning

Fig 8 shows the autotuning procedure for an encoder offset tuning. The procedure should be performed if the

encoder has been changed or has not been aligned correctly. Before tuning make sure that PM losed loop vector control is selected (A1-02 = 6) and that the E1- and E5- parameters are set up correctly.

START

Is it possible to remove

the ropes ?

Yes

Remove the ropes.

Set the Base Block inputs BB and BB1

Switch ON the power supply if it is OFF

Does a OPE06 fault

occur?

No

Does a CPF24 fault

occur?

No

Does a OPE02 fault

occur?

No

Open the brake, close the motor contactor,

turn the motor slowly in Forward direction*

monitor U1-05.

No

Yes

Yes

Yes

1

and check

Balance the car so that it does not move

with open brakes.

Note: The tuning accuracy will be lower

in this tuning mode

Check parameter

* F1-01

* n8-35

* Check parameter n8-35

* If EnDat / Hiperface is used

- check the encoder power supply

- check the CLOCK and DATA signal wiring

* Switch off the power supply.

* Check if the correct PG constant (F1-01) and

absolute encoder resolution (F1-21) has been set.

* Refer to:

page 26, Operator Programming Errors (OPE)

and eliminate the fault source

Switch off the power supply

and check if PG card is

correctly installed

Press the UP button until the “Tuning

(”Tuning successful”

display is shown)

Yes

Does PGO (no

encoder feedback)

occur?

No

Is the sign of the

U1-05 value positive

(not -)?

Yes

T1-01 = 4 - Encoder Offset Tuning

Close the motor contactor(s) and

Wait until the tuning is finished.

Open the contactors, open the base

block inputs and close the brake

Set:

Ready” display appears.

press the RUN key.

Tuning successful?

FINISH

Fig 8 Encoder Offset Autotuning

Yes

No

No

(Fault code is

displayed)

* C heck the wi ri ng

* Chec k/readj ust the encoder

power supply

* Chec k the encoder wir ing

* C hange parameter F1- 05

Refer to

page 27, Auto-tuning Faults

and eliminate the fault source.

* 1. Forward direction means:

The direction the motor turns with an UP command at terminal S1 (i.e.

with a clockwise rotating 3 phase supply and U-U, V-V, W-W wiring

between inverter and motor). Usually the direction is clockwise seen

from the motor shaft (traction sheave) side.

Refer to the motor instruction manual or consult the manufacturer for

details about the rotation direction.

EN-18

Page 22

Ride Profile and Sequence Setup

Up and Down Commands and Speed Reference Selection

Up / Down Command Source Selection

The input source for the Up and Down signal can be selected in parameter b1-02. The factory setting is Up/

Down command by the terminals S1/S2 (b1-02 = 1).

Travel start in Up or Down direction

To start in the elevator in Up or Down direction the following conditions have to be fulfilled:

• At least one speed reference must be selected if digital inputs are used for speed reference selection.

• The hardware base block signal (Terminal BB and BB1) must be set (not base block condition).

• The Up/Down signal must be set to start in the corresponding direction.

Travel stop

The inverter can be stopped as follows:

• The direction command (UP or Down) signal is removed.

• The speed reference selection signal is removed if digital inputs are used for speed reference selection.

• If d1-18 is set to 3 and all speed inputs are removed

Speed Reference Source Selection

The speed reference source can be selected using parameter b1-01. The factory setting is the digital operator

(b1-01 = 0), i.e. the speeds can be selected using digital inputs.

Speed Selection Sequence Using Digital Inputs

If the digital inputs are used for speed selection, the speed selection method and the speed priority depends on

the setting of parameter d1-18 (Speed priority selection).

Multi-Step Speed Operation 1/2 (Binary Input) (d1-18=0/3)

If d1-18 = 0

8 preset speed steps (defined in the parameters d1-01 to d1-08) can be selected using 3 binary coded digital

inputs. The Up/Down command starts the inverter. It stops when the Up/Down command is removed.

If d1-18 = 3

7 preset speed steps (defined in the parameters d1-02 to d1-08) can be selected using 3 binary coded digital

inputs. The Up/Down command starts the inverter. It is stopped when the Up/Down command is removed or

when no speed is selected (all D/Is off).

Multi-function Digital Input Settings (H1-01 to H1-05) (Example)

EN-19

Terminal

S4 H1-02 3 Multi-step speed command 1

S5 H1-03 4 Multi-step speed command 2

S6 H1-04 5 Multi-step speed command 3

Parameter

Number

Set Value Details

Page 23

Speed Selection Table

The following table shows the combinations of the digital input and the according speed.

If b1-02 is set to “1”, frequency reference 1 is input as analog reference at terminal A1.

Multi-step

Speed

Speed Com-

mand 1

1 OFF OFF OFF Frequency reference 1 d1-01 Stop

2 ON OFF OFF Frequency reference 2 d1-02 Frequency reference 2 d1-02

3 OFF ON OFF Frequency reference 3 d1-03 Frequency reference 3 d1-03

4 ON ON OFF Frequency reference 4 d1-04 Frequency reference 4 d1-04

5 OFF OFF ON Frequency reference 5 d1-05 Frequency reference 5 d1-05

6 ON OFF ON Frequency reference 6 d1-06 Frequency reference 6 d1-06

7 OFF ON ON Frequency reference 7 d1-07 Frequency reference 7 d1-07

8 ON ON ON Frequency reference 8 d1-08 Frequency reference 8 d1-08

Multi-step

Speed Com-

mand 2

Multi-step

Speed Com-

mand 3

Selected Frequency

d1-18 = 0 d1-18 = 3

Separate Speed Selection Inputs, High Speed Has Priority (d1-18=1)

With this setting 6 different speeds (defined in the parameters d1-09 to d1-17) can be set and selected using

four digital inputs.

Digital Input Factory Settings

Terminal

S3 H1-01 80 Nominal speed selection (d1-09)

S4 H1-02 84 Inspection speed selection (d1-14)

S5 H1-03 81 Intermediate speed selection (d1-10)

S6 H1-04 83 Leveling speed selection (d1-17)

Parameter

Number

Set Value Details

Higher Speed has Priority and a Leveling Speed Input is Selected (H1-=83)

If d1-18 is set to 1 and one multi-function digital input is set to leveling speed selection (H1-=83), the

inverter decelerates to the leveling speed (d1-17) when the selected speed signal is removed. Inspection Speed

can not be selected as travel speed. The higher speed has priority over the leveling speed, i.e. as long as a

higher speed is selected, the leveling signal is disregarded (see the fig. below)

The inverter stops when the leveling signal or the Up/Down signal is removed.

DC Injection/

zero servo

No effect

Input is set

Speed

Hardware BB

Up/Donw

Leveling speed

Selected speed

DC Injection/

zero servo

Higher Speed Priority is Selected and a Leveling Speed Input is Not Selected (H1-K83)

When the leveling speed command is not selected for any digital input, the inverter decelerates to the leveling

speed (d1-17) when the selected speed signal is removed. Inspection Speed can not be selected as travel speed

To select the leveling speed as travel speed the frequency reference loss detection must be disabled (S3-09=0).

The inverter stops when the direction signal Up/Down is removed.

EN-20

Page 24

When no speed selection input is set the leveling speed is taken as the speed reference.

Speed

Hardware BB

Up/Down

Selected speed

DC Injection/

zero servo

DC Injection/

zero servo

The inverter stops when the direction signal (UP or DOWN signal) is removed.

With this configuration the drive stops with a “FRL” (frequency reference loss fault) when no speed

reference input is selected during the start.

IMPORTANT

To disable the FRL detection, set parameter S3-09 to “0”.

Separate Speed Selection Inputs, Leveling Speed Has Priority (d1-18=2)

The related parameters and the digital input pre-settings are the same as for the High Speed Priority setting

(d1-18=1).

Leveling Speed has Priority and a Leveling Speed Input is Selected (H1-=83)

If d1-18 is set to “2” and one multi-function digital input is set to leveling speed (H1-=83) the inverter

decelerates to the leveling speed (d1-17) when the leveling speed selection input is activated. The leveling signal has priority over the selected speed, i.e. the selected speed is disregarded. The selected travel speed must

be different from inspection speed.

The inverter stops when the leveling speed command is removed.

Speed

Hardware BB

Up/Down

Leveling speed

Selected speed

DC Injection/

zero servo

DC Injection/

zero servo

Leveling speed has priority

Leveling Speed Priority is Selected and a Nominal Speed Input is Not Selected (H1-K80))

If d1-18 is set to “2” and no digital input is set to nominal speed selection, the speed reference with speed

selection input set is nominal speed (d1-09). When the leveling speed signal is set, the inverter starts to decelerate to the leveling speed. The leveling speed signal has priority over all other speed signals, i.e. the intermediate speed 1 and 2 and the revelling signals are disregarded when leveling speed is selected.

The inverter can be stopped by removing the leveling speed signal or the Up/Down command.

CAUTION: This sequence can be risky if e.g. the speed selection doesn’t work for any reason (broken wire

etc.).

Speed

Hardware BB

Up/Down

Leveling speed

DC Injection/

zero servo

DC Injection/

zero servo

EN-21

Page 25

Acceleration / Deceleration / Jerk Settings

The acceleration time indicates the time to increase the speed from 0% to 100% of the maximum speed set in

E1-04. The deceleration time indicates the time to decrease the speed from 100% to 0% of E1-04.

The standard acceleration/deceleration times are set in the parameters C1-01/02, the jerk settings (S-curve) are

set in the C2- parameters as shown in Fig 9.

C2-02

Accel Time

C2-01

C1-01

Fig 9 Acceleration / Deceleration and Jerk (S-curve) settings

Brake Sequence

The figure below shows the standard brake sequence.

S1-04

Zero servo/

S1-16

DC Injection

at start

RUN delay time

Speed

S1-06

Delay time

Brake open

RUN

Inverter Hardware BB D/I

Brake Open Command

Decel Time

C1-02

Selected Speed

C2-03

C2-04

C2-05

Leveling Speed

Leveling Speed

S1-07

Brake close

delay time

S1-05

Zero servo/

DC inhection

at stop

S1-19

Contactor open delay

Fig 10 Timing chart of Brake sequence without torque compensation at start

Inertia Compensation (Feed Forward)

Feed Forward Control is used to eliminate the speed overshoot or undershoot by compensating inertia effects.

It can be enabled by setting parameter n5-01 to 1. After that the motor acceleration time n5-05 must be tuned.

Motor Acceleration Time Auto Tuning (n5-05)

Before the n5-02 auto tuning is performed, the motor data autotuning and the general setup should have been

finished. Do the tuning with the factory settings for the n5- parameters.

Use the following procedure:

1. Set n5-05 to “1” to enable the auto tuning and go back to the speed reference display.

2. Set the base block input.

3. Enable the inspection speed input. “FFCAL” will blink in the display to signalize that the calculation is

active.

4. Set an UP command. The inverter will accelerate the motor up to the nominal speed. Release the UP command a few seconds after the top speed has been reached.

EN-22

Page 26

5. When the motor has stopped, apply a DOWN command. The inverter will accelerate the motor in the

opposite direction to the nominal speed. Release the DOWN command a few seconds after the nominal

speed has been reached.

To abort the tuning set parameter n5-05 to “0”.

1. The order of giving the UP or DOWN command has no influence.

2. n5-01 should not be changed from the factory value for the tuning.

3. After the run in both directions is finished, parameter n5-05 is automatically set back to “0”.

IMPORTANT

4. The autotuning will be performed only if the inspection speed input is set.

5. Do not change the mechanical constants (load, inertia) between the runs.

Feed Forward Compensation P-Gain Setup

• Increase the gain to improve the responsiveness to the speed reference.

• Decrease the gain if vibrations or oscillations occur.

EN-23

Page 27

Troubleshooting

Fault and Alarm Detection

Faults and Alarms are functions that indicate unusual inverter / application conditions.

An alarm does not necessarily switch of the inverter but a message is displayed on the keypad and an alarm

output is generated at the multi-function outputs (H2-01 to H2-03) if programmed. An alarm automatically

disappears if the alarm condition is not present anymore.

A fault switches the inverter off immediately, a message is displayed on the keypad and the fault output is

switched. The fault must be reset manually after the cause has been removed.

The following tables shows a list of faults and alarms with their corrective actions.

Display

BUS

Option Com Err

(flashing)

CF

Out of Control

CPF00

CPF01

COM-

ERR(OP&INV)

CPF02 - CPF 04

CPF24

Option Comm Err

DEV

Speed Deviation

DV3

DV4

DV6

Over Accelera-

tion

EF0

Opt External Flt

EF

Ext Fault S

EF

External Fault

(flashing)

Ext Run Active

Cannot Reset

Displayed as

Alarm Fault

Meaning Corrective Actions

Option Communications Alarm

After initial communication was established, the connection was lost.

A torque limit was reached continuously for 3 seconds or longer during a deceleration stop in Open

Loop Vector control.

• Digital Operator/LED Monitor Communication

Fault 1 / 2

• Communication fault between Operator and

inverter

• CPU External RAM Fault

• Baseblock circuit error

•EEPROM error

• CPU Internal A/D Converter Fault

Hiperface serial communication error

Detected when no data were received from the

encoder for 200 msec

F1-04 = 0, 1 or 2 and A1-02 = 3 or 6

The speed deviation is higher than the F1-10 value

for the time F1-11 or longer.

F1-04 = 3 and A1-02 = 3 or 6

The speed deviation is higher than the F1-10 value

for the time F1-11 or longer.

Wrong rotation direction

Detected when the speed deviation is higher than

30% and the torque reference and acceleration have

opposite signs.

Wrong rotation direction

Detected when F1-19 is not 0, the speed reference

and motor speed have opposite signs and the detection threshold set in F1-19 is exceeded.

An over acceleration of the car was detected

(A1-02 = 6 only)

External fault input from Communications Option

Card

External fault at terminal S ( stands for terminals

S3 to S7)

Forward/Reverse Run Commands Input Together

Both the forward and the reverse run commands are

input simultaneously for 500ms or more. This alarm

stops the motor.

Fault reset was tried during run.

Check the connections and all user-side software configurations.

Check the motor parameters.

• Disconnect the Digital Operator/LED Monitor and

then connect it again.

• Replace the Inverter.

• Cycle the Inverter power supply.

• Replace the Inverter.

• Perform an initialization to factory defaults.

• Cycle the Inverter power supply.

• Replace the Inverter.

Check the encoder connection or replace the encoder

if necessary

• Reduce the load.

• Lengthen the acceleration time and deceleration

time.

• Check the mechanical system.

• Check the settings of F1-10 and F1-11.

• Check the sequence and if the brake is opened when

the inverter starts to increase the speed.

•Check the PG wiring

• Correct the wiring

• Verify the PG direction and execute an encoder offset auto tuning

• Reduce the load and check the brake

• Verify the PG direction and execute an encoder offset auto tuning

• Reduce the load and check the brake

• Reduce the load

• Check the PG direction, check F1-22 and perform

an encoder offset tuning.

• Verify the settings of S3-13, S3-14 and S3-15.

• Adjust the acceleration and deceleration times.

• Check for an external fault condition.

• Verify the parameters.

• Verify communication signals

Eliminate the cause of the external fault condition.

Check external sequence logic, so that only one input

is received at a time.

• Remove the direction signal and retry a fault reset.

• If a PLC handles the fault reset, check the sequence.

EN-24

Page 28

Display

FF_CAL

FRL

Ref Missing

GF

Ground Fault

LF

Output Phase

Loss

OC

Over Current

OH

Heatsink Over-

temp

OH1

Heatsink Max

Tem p

OL1

Motor Overload

OL2

Inv Overload

OS

Motor Over speed

Det

OV

DC Bus Overvolt

PF

Input Phase Loss

PGO

PG Open

(PG Disconnec-

tion)

Displayed as

Alarm Fault

(only in

stop

condi-

tion)

Meaning Corrective Actions

Feed forward motor acceleration time active

No speed was selected before the inverter start. Check the speed selection/start sequence.

The ground current at the Inverter output exceeded

50% of the Inverter rated output current and L8-09=1

(Enabled).

An open-phase occurred at the Inverter output.

The fault is detected when the output current falls

below 5% of the inverter rated current and L8-07=1

The Inverter’s output current exceeded the over cur-

rent detection level.

L8-03 = 0,1 or 2 and the temperature of the Inverter's

cooling fin exceeded the L8-02 value.

Inverter's Cooling Fan Stopped

L8-03 = 3 and the temperature of the Inverter's cooling fin exceeded the L8-02 value.

The temperature of the Inverter’s heatsink exceeded

105 °C.

Inverter’s Cooling Fan Stopped

Detected when L1-01 is set to 1,2 or 3 and the

Inverter’s output current exceeded the motor overload curve.

The overload curve is adjustable using parameter E2-

01 (Motor Rated Current), L1-01 (Motor Protection

Selection) and L2-02 (Motor Protection Time Constant)

The Inverter output current exceeded the Inverter’s

overload capability.

F1-03 = 0, 1 or 2 and A1-02 is set to 3 or 6.

The motor speed feedback (U1-05) exceeded the F1-

08 value for the time F1-09.or longer.

F1-03 = 3 and A1-02 is set to 3 or 6.

The motor speed feedback (U1-05) exceeded the F108 value for the time F1-09.or longer.

The DC bus voltage has exceeded the overvoltage

detection level.

Default detection levels are:

200 V class: 410 VDC

400 V class: 820 VDC

Too big DC bus voltage ripple.

Only detected when L8-05=1 (enabled)

F1-02 = 0, 1 or 2 and A1-02 = 3 or 6

No PG (encoder) pulses are received for the time F1-

14 or longer.

F1-02 = 3 and A1-02 = 3 or 6.

No PG (encoder) pulses are received for the time F114 or longer.

• Perform the complete tuning procedure

• Abort the tuning by setting

n5-05 = 0.

• Remove the motor and run the Inverter without the

motor.

• Check the motor for a phase to ground short.

• Check the output current with a clampmeter to verify the DCCT reading.

• Check the control sequence for wrong motor contactor signals.

• Reset the fault after correcting its cause.

• Check the motor and Inverter capacity.

• Remove the motor and run the Inverter without the

motor.

• Check the motor for a phase-to-phase short.

• Verify the accel/decel times

•(C1-).

• Check the Inverter for a phase-to-phase short at the

output.

• Check for dirt build-up on the fans or heatsink.

• Reduce the ambient temperature around the drive.

• Replace the cooling fan(s).

• Check for dirt build-up on the fans or heatsink.

• Reduce the ambient temperature around the drive.

• Replace the cooling fan(s).

• Recheck the cycle time and the size of the load as

well as the accel/decel times

•(C1-).

• Check the V/f characteristics (E1-).

• Check the setting of Motor Rated Current Setting

(E2-01).

• Recheck the cycle time and the size of the load as

well as the accel/decel times

•(C1-).

• Check the V/f characteristics (E1-).

• Check the setting of Motor Rated Current Setting

(E2-01).

• Adjust the ASR settings in the C5 parameter group.

• Check the reference circuit and reference gain.

• Check the settings in F1-08 and F1-09.

• Increase the deceleration time (C1-02/04/06/08) or

connect a braking option.

• Check the power supply and decrease the voltage to

meet the inverter’s specifications.

• Check the braking chopper / resistor.

• Tighten the input terminal screws

• Check the power supply voltage

• Fix the broken/disconnected wiring.

• Fix the wiring.

• Supply power to the PG

•properly.

• Check the sequence and if the brake is opened when

the inverter starts to increase the speed.

EN-25

Page 29

Display

PUF

DC Bus Fuse

Open

RR

DynBrk Transistr

SE1

Sequence Error 1

SE2

Sequence Error 2

SE3

Sequence Error 3

SVE

Zero Servo Fault

UV1

DC Bus Under-

volt

UV2

CTL PS Under-

volt

Displayed as

Alarm Fault

(only in

condi-

tion)

stop

Meaning Corrective Actions

The fuse in the main circuit is blown.

War ni ng:

Never run the Inverter after replacing the DC bus

fuse without checking for shorted components.

The built-in dynamic braking transistor failed.

No output contactor response S1-16 or longer. Check the output contactor.

The output current at start was below 25% of no-load

current.

The output current during run was below 25% of noload current.

The motor position moved during Zero Servo Operation.

The DC bus voltage is below the under voltage

Detection Level

(L2-05). The default settings are:

200V class: 190 VDC

400 V class: 380 VDC

Main Circuit MC Operation Failure

No MC response during Inverter operation.

Control Power Supply Undervoltage

Undervoltage of the control circuit while the Inverter

was running.

• Check the motor and the motor cables for short circuits or insulation failures (phase-to-phase).

• Replace the inverter after correcting the fault.

• Cycle power to the Inverter.

• Replace the Inverter.

Check the output contactor.

Check the output contactor.

• Increase the torque limit.

• Decrease the load torque.

• Check for signal noise.

• Check the input voltage.

• Check the wiring of the input terminals.

• Check the input voltage and the wiring of the input

terminals.

• Extend the settings in

• C1-01/03/05/07

Replace the Inverter.

• Remove all connection to the control terminals and

cycle the power to the Inverter.

• Replace the Inverter.

Operator Programming Errors (OPE)

An Operator Programming Error (OPE) occurs when two or more parameter related to each other are set inappropriate or an individual parameter setting is incorrect. The Inverter does not operate until the parameter setting is set correctly; however, no other alarm or fault outputs will occur. If an OPE occurs, change the related

parameter by checking the cause shown in the table below. When an OPE error is displayed, press the ENTER

key to see U1-34 (OPE Detected). This monitor displays the parameter that is causing the OPE error.

Display Meaning Corrective Actions

OPE01

kVA Selection

OPE02 Limit

OPE03

Ter mi nal

OPE05

Sequence Select

OPE06

PG Opt Missing

OPE08

Constant Selection

OPE10

V/f Ptrn Setting

Inverter kVA Setting Error Enter the correct kVA setting in o2-04.

Parameter Setting out of Range

Hiperface selected (n8-35=4) and:

• F1-01 is different from 512 or 1024

• F1-21 is set to 2

EnDat selected (n8-35=5) and:

• F1-01 is different from 512 or 2048

• F1-21 is set to 0 or 1

Multi-function Input Selection Error (H1-01 to H1-05):

• Functions were selected duplicative.

• External Baseblock NO (8) and External Baseblock NC

(9) were selected at the same time.

The Emergency Stop Command NO (15) and NC(17) are

set simultaneously.

RUN/Reference Command Selection Error

The Reference Source Selection b1-01 and/or the RUN

Source Selection parameter b1-02 are set to 3 (option

board) but no option board is installed.

Control method selection error /

PG-card missing

Function Selection Error Verify the control method and the function.

V/f Parameter Setting Error

Verify the parameter settings.

Verify the parameter settings in H1-

• Verify that the board is installed. Remove the power supply

and re-install the option board again

• Recheck the setting of b1-01 and b1-02.

Verify the control method selection in parameter A1-02 and/or

the installation of the PG option board.

Check parameters (E1-). A frequency/voltage value may

be set higher than the maximum frequency/voltage.

EN-26

Page 30

Auto-tuning Faults

Auto-tuning faults are shown below. When the following faults are detected, the fault is displayed on the dig-

ital operator and the motor coasts to stop. No fault or alarm outputs will be operated.

Display Meaning Corrective Actions

Acceleration error (detected during rotating autotuning

Accelerate

End - 1

V/f Over Setting

End - 2

Saturation

End - 3

Rated FLA Alm

Fault Motor data fault

I-det. Circuit

KE_ERR

(PM motor only)

LD_ERR

(PM motor only)

Leakage Induc-

tance Fault

Minor Fault

Motor Speed

No-Load Current No-Load Current Fault • Check the input data.

Resistance Line-to-Line Resistance Fault

Rated slip Rated Slip Fault

RS_ERR

(PM motor only)

STOP key STOP key input -

Z_SRCH_ERR

(PM motor only)

only)

The motor did not accelerate in the specified time.

V/f Settings Alarm

Displayed after auto-tuning is complete

The torque reference exceeded 100% and the no-load current exceeded 70% during auto-tuning.

Motor Core Saturation Fault

Displayed after auto-tuning is complete.

Detected only for rotating autotuning

Rated Current Setting Alarm

Displayed after auto-tuning is complete

During auto-tuning, the measured value of motor rated

current (E2-01) was higher than the set value.

Current detection error

The current exceeded the motor rated current or any output phase is open

Voltage constant error Check the motor wiring

Inductance error Check the motor wiring

The leakage inductance measurement caused an error.

The leakage inductance tuning current was too high or too

low (Closed Loop Vector for PM only)

Any of the above listed alarms occured during autotuning

or the inverter was in Base Block condition when the tuning was started.

Motor Speed Fault

Detected only for rotating autotuning

The torque reference exceeded 100% during acceleration.

Detected only when A1-02 is set to 2 (Open Loop Vector

control).

Line-to-line resistance error

All encoders:

The motor speed exceeded 20 rpm at the auto tuning start.

The magnetic pole position tuning could not be performed

in the specified time.

Encoder with Z-pulse:

The difference between two measurements of the magnet

pole position was higher than 3°.

Serial encoders:

The difference between two measurements of the magnet

pole position was higher than 5° or an encoder serial communication error has occurred during the tuning.

• Increase C1-01 (Acceleration Time 1).

• Increase L7-01 and L7-02 (Torque Limits) if they are low.

• Remove the ropes and repeat the tuning.

• Check and correct the motor settings

• If the motor and the machine are connected, disconnect the

motor from the machine.

• Check the input data.

• Check the motor wiring.

• If the motor and the machine are connected, disconnect the

motor from the machine.

Check the motor rated current value.

• Check the input data.

• The motor and inverter capacity do not fit. Check the Inverter

and motor capacity.

• Check the motor rated current and no-load current.

Check wiring of the Inverter and the mounting.

• Check the motor wiring.

• Check the motor rated current input value

• Reduce or increase the current level for leakage inductance

tuning by changing parameter n8-46.

• Leave the tuning menu, check the alarm content and remove

the cause as described in the alarm list above.

• Check the input data.

• Make sure that the inverter is not in Base Block condition

during the tuning.

• If the motor is connected to the machine, disconnect it.

• Increase C1-01 (Acceleration Time 1).

• Check the input data (particularly the number of PG pulses

and the number of motor poles).

• Perform not rotating auto tuning

• Check the motor wiring.

• If the motor is connected to the machine, disconnect it.

• If the setting of T1-03 is higher than the Inverter input power

supply voltage (E1-01), change the input data.

• Check the motor wiring

• Check the motor input data

• Remove the ropes and repeat the tuning

• Check the encoder rotation direction and if necessary change

F1-05.

• Check the encoder wiring (order, shield etc.)

• Check the encoder power supply.

Replace the encoder.

EN-27

Page 31

Parameter Table

Note: Factory settings are in bold.

Param.

Num.

Name Description

Initialize Data

Language

selection for

Digital Opera-

A1-00

tor display

(JVOP-160-OY

only)

Parameter

A1-01

access level

Control method

A1-02

selection

A1-03 Initialize

0:English

1:Japanese

2:German

3:French

4:Italian

5:Spanish

6: Portuguese

0:Monitoring only (Monitoring drive

mode and setting A1-01 and A1-04.)

1:Used to select user parameters (Only

parameters set in A2-01 to A2-32 can

be read and set.)

2:Advanced

(Parameters can be read and set in both,

quick programming mode (Q) and

advanced programming mode (A).)

0:V/f control

2: Open loop vector

3:Closed Loop Vector

6:Closed Loop Vector for PM motors

0: No initializing

1110:Initializes to user parameters

2220:.Initializes to the factory setting

Sequence / Reference Source

b1-01

b1-02

Reference

source selection

RUN command source

selection

0:Digital Operator

1:Control circuit terminal (analog input)

3:Option Card

0:Digital Operator

1:Control circuit terminal (digital

multi function inputs)

3:Option Card

Acceleration / Deceleration Settings

Accel./Decel.

C1-

C2-

time 1

S-curve characteristic

Refer to page 1-22

Set the S-curve times at speed changes to

reduce the jerk. Refer to page 1-22

Slip Compensation

• Increase the value if slip compensation

C3-01

C3-02

Slip compensation gain

Slip compensation delay time

value is too low

• Decrease the value if slip is overcompensated

• Reduce the value if the slip compensation responsiveness is low.

• When speed is not stable, increase the

setting.

Automatic Speed Regulator (ASR)

ASR propor-

C5-01

tional (P) gain 1

ASR integral (I)

C5-02