Page 1

Cat. No. S101-E1-02

GridConnect Photovoltaic Inverter

KP100L-OD-

USER’S MANUAL

Note: Dec,2010

KP100L does not have the compatibility with thin-film module at this moment.

The compatibility is under evaluation.

Page 2

Introduction

Thank you for choosing the KP100L Grid Connect Photovoltaic Inverter (hereinafter called "the KP100L"). This

User's Manual (hereinafter called "this manual") describes essential information regarding functions,

performance, and usage of the KP100L.

The KP100L is designed for use in Grid Connect Solar Systems. The installation must always be carried out by

qualified personnel with knowledge of electrical systems and according to national standards for electrical

installations.

The software and the protective functions are not accessible and/or changeable to the user.

• This manual is intended for: Users and Installers of the KP100L

• Read this manual carefully and make sure that you understand it well to ensure that you are using the KP100L

correctly.

• Keep this manual in a safe location so that it is available for reference when required.

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

1

Page 3

Read and Understand this Manual

Read and understand this manual before using the KP100L. Please consult your OMRON representative if you

have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a period of

five years (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS.

ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS

OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH

CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which liability

is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING

THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY

HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO CONTAMINATION, ABUSE,

MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

2

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 4

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying ratings and

limitations of use that apply to the products. This information by itself is not sufficient for a complete determination of

the suitability of the products in combination with the end product, machine, system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not intended to

be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses listed may be

suitable for the products:

• Uses involving potential chemical contamination or electrical interference, or conditions or uses not described in

this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical equipment,

amusement machines, vehicles, safety equipment, and installations subject to separate industry or government

regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY

WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS,

AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED FOR THE INTENDED USE

WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

3

Page 5

Disclaimers

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does not

constitute a warranty. It may represent the result of OMRON's test conditions, and the users must correlate it to actual

application requirements. Actual performance is subject to the OMRON Warranty and Limitations of Liability.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other reasons.

Consult with your OMRON representative at any time to confirm actual specifications of purchased product.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are

shown.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no responsibility

is assumed for clerical, typographical, or proofreading errors, or omissions.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any consequence thereof.

COPYRIGHT AND COPY PERMISSION

This document shall not be copied for sales or promotions without permission.

This document is protected by copyright and is intended solely for use in conjunction with the product. Please notify

us before copying or reproducing this document in any manner, for any other purpose. If copying or transmitting this

document to another, please copy or transmit it in its entirety.

4

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 6

WARNING

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, will result in minor or moderate injury, or may

result in serious injury or death. Additionally there may be

significant property damage.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury, or in

property damage.

Safety Precautions

Indications and Meanings of Safety Information

In this user's manual, the following precautions and signal words are used to provide information to ensure the

safe use of the KP100L.

The information provided here is vital to safety. Strictly observe the precautions provided.

Meanings of Signal Words

Meanings of Alert Symbols

General

Used for general CAUTION, WARNING, or DANGER precautions for which

there is no specified symbol.

High temperature precaution

Used to warn of the risk of minor injury caused by high temperatures.

General

Used for general prohibitions for which there is no specific symbol.

General

Used for general mandatory action precautions for which there is no

specified symbol.

Electric shock precaution

Used to warn of the risk of electric shock under specific conditions.

Example of symbols

Always ground

Used to instruct the user to always connect the ground wire when using a

device equipped with a safety ground terminal.

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

5

Page 7

WARNING

CAUTION

Alert Symbols in This Document

Important user information:

Observe the following warnings and cautions when using the KP100L.

Significant property damage may possibly occur. Do not use the product in other

country than the designated country.

Functional lesion by injury and fire damage may possibly occur. Do not remove the

MC cap on the back of the product when you exchange the FAN Assembly.

Ask to the store where you purchased the product or to an authorized service person

when disposing of the product.

Injury by electric shock may possibly occur. Read this manual before installation,

operating and maintenance of the product, and follow the instructions carefully.

Injury by electric shock may possibly occur. Do not open the cover foreside R during

energizing.

Significant injury by electric shock may possibly occur. Do not touch the terminal of

the MC connector. Do not remove the MC connector excluding the instruction of this

manual.

Burn injury may occasionally occur. Do not touch the upper part of the product while

operating or immediately after having turned off power.

Fire damage or functional lesion of internal part may occasionally occur. Do not

obstruct the heat sink or place any objects within 200mm of the heat sink.

Fire damage and malfunction may occasionally occur. Do not use the product that

dropped or applied a strong impact.

Functional lesion by fire damage may occasionally occur. Do not unfasten of the MC

connector and the cable clamp during operating.

The limitation of the output electric power by the ventilation trouble may

occasionally occur. Clean the top and bottom of the heat sink regularly.

Injury or fire by electric shock may possibly occur. Do not open, disassemble,

modify, or repair the cover front and the cover foreside L during operating.

6

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 8

Important installer information:

WARNING

Observe the following warnings and cautions when installing the KP100L..

Significant property damage may possibly occur. Do not use the product in other

country than the designated country.

Significant property damage may possibly occur. Do not use the product with a

mistake of the country setting.

Functional lesion by injury and fire damage may possibly occur. Do not remove the

MC cap on the back of the product when you exchange the FAN Assembly.

Significant property damage may possibly occur. Execute the installation by a

person who has the qualification that authorized by the electric power company in

the region.

Electric shock and significant property damage may possibly occur. Do a correct

connection after confirming the polarity of the cable from the solar modules and

from the grid.

Fire by loose connection of AC terminal block may possibly occur. Confirm there is

no looseness in the screw of the AC terminal block during the maintenance.

When using the product by the state that tightening the screw of AC terminal block is

insufficient, fire by loose connection may possibly occur.

Insert the electric cable in the inner of AC terminal block by using special Rod

terminal and crimping pliers, and tighten the screw by tightening torque of

1.2-1.5N•m.

Fire by loose connection of the MC connector may possibly occur. Use the

specialized tool for the crimping process of the MC connector. Insert the MC

connector surely until locking.

Injury by electric shock may possibly occur. Read this manual before installation,

operating and maintenance of the product, and follow the instructions carefully.

Injury or functional lesion by electric shock or burn injury may possibly occur. Do

not install the product in places that child's hand reaches.

Injury by electric shock may possibly occur. Do not open the cover foreside R during

energizing.

Significant injury by electric shock may possibly occur. Do not touch the terminal of

the MC connector. Do not remove the MC connector excluding the instruction of this

manual.

Significant injury by electric shock may possibly occur. Do not open the cover

foreside R and not touch the MC connector for three minutes after turning OFF the

breaker of the grid side and the solar module side.

Injury by electric shock may possibly occur. Connect the PE cable to the earth.

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

7

Page 9

CAUTION

Burn injury may occasionally occur. Do not touch the upper part of the product while

operating or immediately after having turned off power.

Fire damage or functional lesion of internal part may occasionally occur. Do not

obstruct the heat sink or place any objects within 200mm of the heat sink.

Fire damage and malfunction may occasionally occur. Do not use the product that

dropped or applied a strong impact.

Breakdown of DC input plug may occasionally occur. Do not put the product on

ground with it had the DC input plug side below.

Injury may occasionally occur. Transport and place the product carefully by two

persons or more.

Functional lesion by the fall of the product may occasionally occur. Use the

installation parts and materials that are included in the product.

Functional lesion by fire damage of terminal may occasionally occur. Detach the MC

connector by the state that turns off the breaker of the solar modules side. In the

state that the current flows, inserting and removing of the MC connector is not

allowed.

Break down or deterioration of the solar modules may occasionally occur. Install the

breaker between the transformer and the KP100L when you connect the transformer.

Connect the Neutral of the transformer to the earth.

Breakdown of internal part by static electricity may occasionally occur. Execute

wiring after discharging static electricity.

Functional lesion by fire damage may occasionally occur. Confirm there is no

looseness of the AC cable clamp, the communication cable clamp and the AUX cable

clamp. Confirm the MC connector is locked.

Injury or fire by electric shock may possibly occur. Do not open, disassemble,

modify, or repair the cover front and the cover foreside L during operating

Human hazard by electric shock or property damage by fire damage may

occasionally occur. Mount the enclosed MC caps onto MC connector that is not

used.

Electric shock or fire by the foreign body going into the product may occasionally

occur. Prevent the foreign body from invading from the cover foreside R when

wiring.

Functional lesion by injury and fire damage by the fall of the product may

occasionally occur. Install the product in the location where the weight (41.5kg) of

the product can be endured (the power of 176N•m torque per one screw can be

endured).

8

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 10

Precautions for Safe Use

To use the product safely, what is executed or should evaded is shown.

Installation

Put the space of 200mm or more between the following.

• Between the product and the ceiling or eave

• Between the product and the floor

• Between the product and right and left wall

When you install the multiple KP100L, put the space of 200mm or more on the side of each KP100L.

Do not install the multiple KP100L vertically.

Do not install in the location where the product receives direct sunlight or rain when you install in outdoor.

Do not install the product in the home or near the place where the person work because the audible noise

generates when the product is oparating.

Transporting

Provide sufficient safety measures, such as scaffolding, to prevent danger during installation work.

Installation and Wiring

Make sure the following points when you install the product.

(1) Use the accessories included with KP100L.

(2) Make sure there is neither danger nor malfunction by the peripheral and the wire, etc.

other than the accessory.

• When wiring to the AC terminal block, do not insert two or more wires into one terminal.

• Use the wire of the diameter that corresponds to the capacity of the Solar modules.

Fire or smoke from fire may occur.

• IP65 performance can not be provided, if you don't follow these instructions:

(3) Use the cable of 18.5-20.5mm when you use the rubber bush of one hole for the AC cable clamp.

(4) Use the five cables of 3.5-4.0mm when you use the rubber bush of five holes

for the AC cable clamp.

(5) Use the cable of 4mm for the communications cable and the AUX cable.

(6) Tighten the cable clamp.

(7) Tighten the screws of the cover foreside R by tightening torque 1.5-1.7 Nm.

(8) Make sure the wire doesn't come off the terminal block after wiring the communication wire and the

AUX wire to the terminal block.

Exchanging Fans (FAN Assembly)

Make sure the following precautions when exchanging FAN Assembly.

(1) Exchange the FAN Assembly after turning off the breaker of the grid side and the Solar module side

and 3 minute or more pass. Electric shock and injury may occur.

(2) Use the specified FAN Assembly.

(3) Make sure the mounting direction of the FAN Assembly

(4) Tighten the screw correctly by tightening torque 1.5-1.7Nm after exchanging FAN Assembly.

(5) Connect each connector of the FAN Assembly to the product correctly.

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

9

Page 11

Solar Module

• Do not connect the solar module that has an open-circuit voltage in excess of 850 VDC.

• Do not connect the solar module that require earthing of negative or positive pole.

Breaker

• Use the breaker that corresponds to the capacity of the solar modules for the breaker of the Solar modules

side.

• Use the 20A trip breaker with B or C or D trip characteristics for the breaker of the grid side.

Maintenance - Inspection

• Be sure to inspect install condition, wiring connection, before doing a trial operation.

• To secure the IP65 performance, execute the additional tightening of the cable clamp regularly.

10

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 12

Precautions for Correct Use

To prevent the adverse effect on the operation, what is executed or should be evaded is shown below.

Installation

• Install the product in a regulated direction.

• Do not install the product in the following places.

(1) Locations subject to intense temperature change.

(2) Locations subject to volatile, flammable, corrosive, or other toxic gas.

(3) Locations subject to vibration and large shocks.

(4) Locations subject to water vapor, oil vapor, or condensation.

(5) Locations where the product may be immersed in water.

(6) Locations subject to electric fields, direct sunlight, poor ventilation

(ex. Narrow places where the ventilation would be obstructed or the ambient temperature conditions

would be exceeded.).

(7) Locations subject to temperature and humidity conditions outside of the following ranges

• Temperature: 20 to 60C

• Humidity: 4 to 100%RH (Without condensation or freezing)

(8) Locations more than 2,000 m above sea level.

(9) Locations subject to saltwater spray, such as on oceangoing vessels or near a seacoast.

(10) Locations subject to falling snow, accumulated snow, or wind-blown snow.

Protect the product by building a protective roof when you install the product in the snowy region.

(11) Locations near highly combustible something or heat sources (stoves, heaters, boilers, etc.

(12) Locations subject to being damaged the wiring by animals or other factors.

Protect the wiring by, for example, placing wiring ducts.

(13) Locations subject to near the equipment (such as a radio or TV) that is likely to be affected by electric

waves, or to near an antenna.

Use the Product

• Do not stand on the product or place any objects on the product.

• Serious human hazard by fire may possibly occur.

• Do not use the product in a flammable gas atmosphere (including flammable sprays such as pesticides).

• Electric shock or fire may occur. Ask an authorized service person or a qualified person with knowledge of

electrical system when you install, add on, move or reinstall the product.

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

11

Page 13

Surge protection

• Install the surge measures circuit corresponding to the output voltage

• and input voltage to protect the inverter from the lightning surge.

• To do a steady operation, install and use the product in places where the following situations are avoided.

(1) Locations where surge voltage of the grid is generated by influence of neighborhood facilities and

equipment.

(2) Locations where the grid is unstable caused by influence of neighborhood facilities and equipment.

(3) In factory or the vicinity where the grid is unstable.

(4) Locations subject to noise that ungrounded consumer electronics generate.

Maintenance o Inspection

• Confirm that there is no abnormality such as rust on outside of the product during the maintenance.

Storage

• Store in locations where the temperature is within the range of 25 to 60C

• (with no condensation or icing), and the humidity is 95 % maximum.

• Store in locations that is no more than 2,000 m above sea level.

12

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 14

Warning Labels

Warning Labels and Warning Description

The Warning labels are located on the KP100L as shown in the follow illustration.

Be sure to follow the instructions

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

13

Page 15

Checking After Unpacking

Checking the Product

On delivery, be sure to check that the delivered product is the KP100L that you ordered.

Should you find any problems with the product, immediately contact your nearest local sales representative or

OMRON Sales Office.

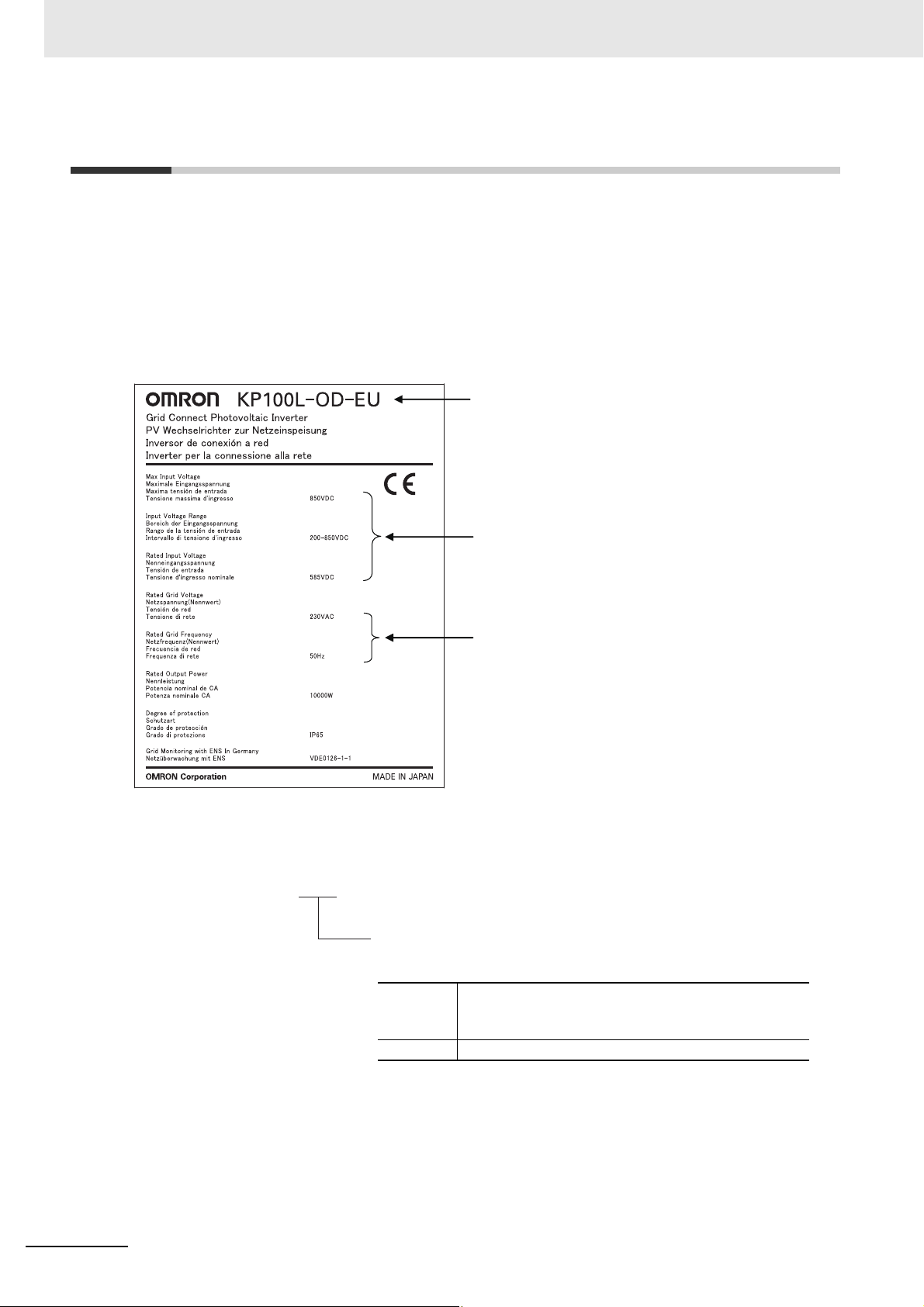

Checking the rating label

Model

Checking the Model

Type:KP100L-OD-

Specifications in DC

Specifications in AC

Correspondence country

14

Germany, Spain, Italy, France, Greece(Only mainland),

EU / EU-T

KR Korea

Czech Republic, Denmark, Portugal, Turkey,

Republic of South Africa

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 16

KP100L

Mounting base plate QIG (Quick Install Guide)

Only KP100L-OD-EU/EU-T

User’ s Manual

Only KP100L-OD-KR

For KP100L-OD-EU/EU-T, PDF file is

provided.Consult your OMRON representative

to get PDF file

Checking the Accessories

The follow items are included in the KP100L package. Check that all of the items shown in the package before

you start the installation.

The complete set of Accessories

Items Number Note

For installation of Mounting base plate

Mounting Screw 8

Snap Bushing 8

M4 x 12mm Screw with

plain washer and spring

washer

M4 x 6mm Screw with plain

washer and spring washer

Rubber Bush

Tool of assistance when screw is stopped to hard wall

like concrete.

5

2

1

For fixation of product set up in Mounting base plate

(4 peaces are for mounting, a peace is for reserve)

Spare screw to fix the cover foreside R

For connection of AC cable

For connection of AC cable

1

Spare rubber bush

For connection of AUX and communication

2

Caps for MC connection ( + )

2

These are attached to KP100L.

MC Caps

2

Safekeeping of the Original Carton Box

Keep the original carton box and use it when you transport the KP100L for repair service etc.

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Caps for MC connection ( - )

These are attached to KP100L

15

Page 17

About This Manual

This Manual is compiled chapter by chapter for user's and installer's convenience as follows.

You understand the follow configuration ensures more good operation of the product

Content / Exposition For Users

Chapter 1 Overview Describes features and names of parts.

Provides external dimensions, installation

Chapter 2 Design

Chapter 3 Operation

Chapter 4 Maintenance Operations

Chapter 5

Chapter 6 After-Sales Service

Chapter 7 Specifications Describes specifications of the product.

Appendix

Inspection and

Maintenance

dimensions and other information necessary for

design.

Describes the name of parts of the operations

and the monitor. Describes the monitor function

of the product.

Describes the causes and their

countermeasures if the product fails, including

the solutions to possible troubles

(troubleshooting).

Describes inspection and maintenance of the

product.

Describes after-sales service and contact of the

product.

Describes contents of the displays other than

English.

For

Installers

16

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 18

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

17

Page 19

Contents

Introduction............................................................................................................................... 1

Read and Understand this Manual.......................................................................................... 2

Safety Precautions ................................................................................................................... 5

Precautions for Safe Use ......................................................................................................... 9

Precautions for Correct Use...................................................................................................11

Warning Labels....................................................................................................................... 13

Checking After Unpacking..................................................................................................... 14

About This Manual ................................................................................................................. 16

Chapter 1 Overview ............................................................................ 1-1

1-1 Model Name ........................................................................................................................... 1-2

1-2 Functions ............................................................................................................................... 1-3

1-3 Appearance and Names of Parts.......................................................................................... 1-9

Chapter 2 Design ................................................................................ 2-1

2-1 Typical System Configuration .............................................................................................. 2-2

2-2 Application information ........................................................................................................ 2-5

2-3 Installation............................................................................................................................. 2-7

2-4 Wiring ................................................................................................................................... 2-11

2-5 Check List ............................................................................................................................ 2-24

2-6 Connecting to the Grid........................................................................................................ 2-25

2-7 Maintenance Parts............................................................................................................... 2-27

2-8 Options ................................................................................................................................. 2-28

Chapter 3 Operation ........................................................................... 3-1

3-1 Part Names and Descriptions of Operation and Display Part ........................................... 3-4

3-2 Procedure at the First Time Operation ................................................................................ 3-5

3-3 Display transition .................................................................................................................. 3-8

3-4 State Display .......................................................................................................................... 3-9

3-5 Mode Selection Display ...................................................................................................... 3-11

3-6 Setting in Particular Countries ........................................................................................... 3-20

3-7 Confirm method of LCD display......................................................................................... 3-28

Chapter 4 Maintenance Operations .................................................. 4-1

4-1 Outline of error ...................................................................................................................... 4-2

4-2 Remedy for errors ................................................................................................................. 4-3

4-3 Buzzer................................................................................................................................... 4-10

4-4 Troubleshooting .................................................................................................................. 4-11

18

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 20

Chapter 5 Inspection and Maintenance ............................................ 5-1

5-1 Inspection and Maintenance ................................................................................................ 5-2

5-2 Storage ................................................................................................................................... 5-6

Chapter 6 After-Sales Service............................................................ 6-1

6-1 After-Sales Service................................................................................................................ 6-2

6-2 Contact ................................................................................................................................... 6-3

Chapter 7 Specifications.................................................................... 7-1

7-1 Standard Specification List ..................................................................................................7-2

Chapter A Appendix............................................................................A-1

A-1 Error list..................................................................................................................................A-2

A-2 LCD messages (Local Language) ........................................................................................A-4

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

19

Page 21

20

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 22

Overview

1-1 Model Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-3 Appearance and Names of Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1

4

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

1 - 1

Page 23

1 Overview

1-1 Model Name

Model Country

KP100L-OD-EU / EU-T

KP100L-OD-KR Korea

Germany, Spain, Italy, France, Greece(Only mainland),Czech Republic,

Denmark, Portugal, Turkey, Republic of South Africa

1 - 2

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 24

1 Overview

EMI

Filter

Booster1

MPPT

Booster2

MPPT

Booster3

MPPT

EMI

Filter

DC/AC

L2

EMI

Filter

L1

L3

N

PE

EMI

AC breaker

Ground fault

breaker (RCD)

SPD

DC

switch

or

breaker

SPD

DC Bus

RLY1

RLY2

CPU1 CPU2

Communication

facility

RS-232C or RS-485

AUX facility

AUX_IN AUX_OUT

Solar module

Grid

1-2 Functions

System description

The KP100L converts DC power obtained from the solar modules into the AC power that is used in businesses,

and enables interconnection with the grid.

This makes it possible to purchase power from the grid during periods when the load is high, and to sell power to

the grid during periods when the load is low. (Please note that a contract must be concluded with the grid for this

purchasing and selling transaction.) The system configuration of the KP100L is shown in the figure bellow.

1-2 Functions

1

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

1 - 3

Page 25

1 Overview

Input specifications:

a) DC input voltage range: 200 to 850 VDC

b) MPPT voltage range: 225 to 800 VDC

Input limitations:

a) Maximum input open-circuit voltage: 850 VDC

b) Maximum input current per Tracking: 13 ADC

MPPT controls not to exceed 13 ADC.

c) Maximum input power per Tracking: 5500 W

MPPT controls not to exceed 5500 W.

Solar module 1

Solar module 2

Solar module 3

+

-

+

-

+

-

DCP

DCV

DCP

DCV

DCP

DCV

MPPT (Maximum Power Point Tracking)

3 pairs of positive and negative DC input channels are connected to three sets of MPP Tracking.

The output power of solar modules varies depending on the sunshine irradiation and the temperature of the

modules. In order to use the unstable output of the solar modules efficiently, the KP100L searches for the

operating voltage that will produce the maximum output power while it converts the DC input voltage. The

KP100L has 3 MPPT. The topology of the MPPT is mainly a booster. Each booster steps up the DC input voltage

to a higher DC BUS voltage. User can connect differently-aligned string as 3 MPPT operate independently as

illustrated in the figure bellow. This construction achieves high power generation and flexible sizing of PV string.

DC Bus

The three sets of MPPT store DC power via the DC/DC booster to the DC bus.

DC/AC Inverter

The DC bus is connected to the DC/AC inverter, which converts DC power to AC power.

Grid-Connection Relays

The two relays, RLY1 and RLY2, control the connection of the KP100L to grid via CPU1 and CPU2.

Output Lines

4 output lines (L1, L2, L3 and N) and PE represent the 3-phase 4-wire AC power transmission to grid.

1 - 4

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 26

1 Overview

[example 1] up to 31 units

[example 2] up to 31 units

RS-232C/RS-485

Converter

RS-485

RS-232C

RS-485

modem modem

Communication Facility

RS-485 Communications

To communicate with multiple KP100L Units, you can connect them to a personal computer via RS-485 ports.

The maximum cable length is 500 m.

RS-485 allows communication with up to 31 Units.

RS-485 communications require a cable of the appropriate length and a personal computer installed with

monitoring software.

Baud rate is 4,800bps, 9,600bps or 19,200bps. Default value is 19,200bps.

Available communication protocol is Compoway/F or MODBUS.

1-2 Functions

1

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

1 - 5

Page 27

1 Overview

RS-485

RS-485

RS-485

RS-485

PLC

PLC

PLC

PLC

RS-232C

[example 3] PLC(Programmable Logic Controller):up to 4 units KP100L:up to 124 units

RS-232C Communications

The simplest and least expensive way to communicate between a single KP100L and a personal computer is to

connect directly via RS-232C ports. The maximum cable length between the personal computer and the KP100L

is 15 m.

1 - 6

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 28

1 Overview

1 2 3 4 5 6 7 8 9

10

KP100L

AUX_OUT1 AUX_OUT2

AUX Terminal Block

AUX_IN

(*)The external DC voltage and resistance value are example.

Select appropriate value according to your application.

1 2 3 4 5 6 7 8 9

10

KP100L

AUX_OUT1 AUX_OUT2

1234 56 78 9

KP100L

AUX_OUT1 AUX_OUT2

AUX_IN

24VDC

24VDC

AUX Terminal Block

AUX Terminal Block

AUX_IN

510Ω

(*)

(*)

510

Ω

10

1 2 3 4 5 6 7 8 9

10

KP100L

AUX_OUT1

AUX_OUT2

1

2 3 4 5 6 7 8 9

KP100L

AUX_OUT1

AUX_OUT2

AUX_IN

AUX Terminal Block AUX Terminal Block

AUX_IN

10

AUX Facility

Relay Output

The KP100L has the 2 relays for 2 output signals of the table below. Refer to"3-5 Parameter List" for the setting of

the output signal. Refer to"2-4 Wiring " for connecting the AUX cable.

Name Type of contact Specifications

AUX_OUT1 SPST-NO

AUX_OUT2 SPST-NO

250 VAC / 1 A, 30 VDC / 1 A ( Resistive load)

Minimum permissive load 20mA

1-2 Functions

1

[Example when you use AUX_OUT1 or AUX_OUT2]

[Example when you use AUX_OUT1 of multiple products]

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

1 - 7

Page 29

1 Overview

1234 56 78910

AUX_OUT1 AUX_OUT2

AUX_IN

24VDC

AUX Terminal Block

10mA

KP100L

Photo-Coupler Input

The KP100L has the photo-coupler for input signals of the table below. Refer to"3-5 Parameter List" for the

setting of the input signal.

Name Type of contact Specifications

10mA Use 24 VDC to use AUX_IN.

Minimum ON time : 100ms

AUX_IN Photo-Coupler

[Example when you use AUX_IN]

Leakage current at OFF status 0.1mA

Residual voltage at ON status 2.0V

Capacity of external switch 20mA

1 - 8

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 30

1-3 Appearance and Names of Parts

AC Cable Clamp

3-pairs of

DC Input plug

(MC4 connectors)

Communication

Cable Clamp

AUX Cable Clamp

Key

Display

Cover foreside R

(for Wiring)

Cover front

Cover foreside L

Fans

Heat sink

1 Overview

1-3 Appearance and Names of

Parts

1

(1) Fan

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Fans

1 - 9

Page 31

1 Overview

L1 L2 L3 PEN

AC Cable Clamp

AC Terminal Block

(2) 3-pairs of DC input plug (standard MC4 connectors):

Each input pair consists of positive and negative terminals, Refer to "2-4 Wiring".

(3) AC Output:

Delivering AC to the grid

DC1

DC2

DC3

DC Input plug ( + )

DC Input plug ( - )

1 - 10

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 32

(4) AUX Interface

AUX Cable Clamp

Communication Cable Clamp

AUX Terminal Block

Communication Terminal Block

AUX Interface has the two relay output and the one photo coupler input.

(5) RS-232C or RS-485 Communication Interface:

The interface allows the communication with computer via RS-232C or RS-485.

1 Overview

1-3 Appearance and Names of

Parts

1

(6) Display and Key

Display

Key

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

1 - 11

Page 33

1 Overview

1 - 12

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 34

Design

2

2-1 Typical System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-2 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2-4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2-5 Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2-6 Connecting to the Grid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2-7 Maintenance Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

2-8 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

2 - 1

Page 35

2 Design

• Ground fault breaker / RCD

• AC breaker

• SPD

• DC fuse

• DC switch/breaker

• SPD

The equipments in AC and DC side are used

depends on the design of the customer.

Solar module 1

Solar module 2

Solar module 3

Connection with grid network type TN Connection with grid network type TT

Connection with grid network type IT

Impedance

N

L1

L2

L3

L1

L2

L3

PEN

N

PE

L1

L2

L3

N

L1

L2

L3

2-1 Typical System Configuration

The figure below shows the typical system configuration of the KP100L.

Applicable grid network

The KP100L is designed to operate with grid network system type TT, TN as shown in the figure below. If the

KP100L is connected to the different type of grid network such as IT, it may be fault occur.

2 - 2

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 36

2 Design

The KP100L is designed with grid network system type TT, TN. Then If you use transformer, connect the Neutral

to the ground as shown in the figure below.

3P+N

3P

Grid

N

Neutral in KP100L side should be

connected to the ground.

3P+N

3P+N

Grid

N

2-1 Typical System Configuration

2

Neutral in KP100L side should be

connected to the ground.

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

2 - 3

Page 37

2 Design

U

SG

0

Voltage of solar module

The voltage of the negative

pole is controlled as same

voltage level of Neutral.

Solar module

+

-

Solar module

+

-

Applicable solar module

The KP100L is designed to control the voltage of negative pole on solar module as same voltage level as Neutral

of grid as shown in figure below. This can be achieved by new inverter circuit (ZCC).

As a result, the voltage of negative pole on solar module is approx. zero. According to this function, you can use

the solar module which does not allow negative voltage on solar module.

Do not use the solar module that require earthing of negative or positive pole. Otherwise, the failure might occur.

Applicable type of solar module is shown in the table below.

Solar module manufacture

requirement

(1) No requirement

(2) No negative voltages on solar

module

(3) Earthing of negative pole on

solar module

(4) No positive voltages on solar

module

(5) Earthing of positive pole on

solar module

Type of solar module Applicable or not

Conventional silicon-based solar

modules

Some thin-film or silicon modules Basically, KP100L can be used.

Some thin-film or silicon modules KP100L can not be used.

Specific solar module KP100L can not be used.

Specific solar module KP100L can not be used.

KP100L can be used.

Note: Dec,2010

KP100L does not have the compatibility with thin-film module at this moment.

The compatibility is under evaluation.

2 - 4

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 38

2 Design

Example of SPD

• Class II

• PV voltage 1000 VDC

• Nominal discharge current (8/20us) I

n

:20 kA

• Maximum discharge current (8/20us)I

max

:40 kA

• Protection revel: 4 kV

This is just example. Contact company of

protection device for selection.

SPD on each input

Grid

N

3P

3P+N

Breaker Breaker

2-2 Application information

DC side

DC switch / breaker

DC switch / circuit breaker is an obligatory prerequisite stipulated by DIN VDE 0100-712, the installation standard

for PV systems in Germany. For safety point of view during working on an electrical device, it is necessary to

disconnect from the energy supply. DC circuit breaker between the PV modules and the inverter is used. Select

DC circuit breaker with rate current is larger than designed PV short circuit current on each DC input.

SPD (Surge Protective Device) in DC side

SPD (Surge protective device) is used to protect the inverter against lightening surge voltage.

2-2 Application information

2

AC Grid side

AC breaker

For protection of AC over current, use a 20 A trip breaker with B or C or D trip characteristics.

If you use the transformer, install the breaker between the transformer and the KP100L as shown in the figure

below.

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

2 - 5

Page 39

2 Design

712.413.1.1.1.2 Where an electrical installation includes a PV power supply system without

at least simple separation between the AC side and the DC side, an RCD installed to provide

fault protection by automatic disconnection of supply shall be type B according to IEC 60755,

amendment 2.

Where the PV inverter by construction is not able to feed DC fault currents into the electrical

installation, an RCD of type B according to IEC 60755 amendment 2 is not required.

Example of SPD

• Class II

• Nominal voltage 230/400 VAC

• Nominal discharge current (8/20us) I

n

:20 kA

• Maximum discharge current (8/20us)I

max

:40 kA

• Protection revel: 1.5 kV

This is just example. Contact company of

protection device for selection.

L1

L2

L3

N

PE

Ground fault breaker / RCD (Residual Current Device)

For KP100L, the use of RCDs type B is not indispensable and RCDs type A can be used.

IEC712.413.1.1.2 describes about Residual Current Devices (RCDs) as follows:

KP100L has built-in fault current protection function required in Germany standard of

VDE V 0126-1-1:2006-02, so DC residual current can be detected and cannot flow to the grid.

Notice of selecting RCD

• The use of RCDs for each unit is recommended.

• In(rated residual operating current of RCD) has to be selected according to the local regulations about the

system configuration, and residual current caused by capacitive characteristic of cable and PV modules.

• In the systems which DC current detection of In<30mA is required, type B has to be used.

• KP100L has built-in fault current protection function but residual current is not zero, so the more KP100L

installed units, the much residual current flows in the grid. When multiple KP100L are installed, downstream

RCD(for KP100L) and upstream RCD has to be determined by consideration of increasing residual current.

• Ultimately, the selection of RCD depends on System Integrators' judgment. OMRON provide this information

for selection of RCDs, but we are not responsible for the selection of RCD.

SPD in Grid side

SPD is used to protect the inverter against lightening surge voltage in AC line.

2 - 6

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 40

2-3 Installation

455 270

700

253

40

53.2

444.8

404.8

200mm

200mm

200mm

200mm

2 Design

Dimensional Drawing

Mounting Dimensions

Installation Environment

• Do not install the product on ocean-going vessels or in places near the seacoast that are subject to saltwater

spray.

• When you install outdoors, be sure to provide an awning or eave of some kind to prevent direct sunlight or rain

from striking the Unit.

• Leave specific space as shown in the figure below between the KP100L and the ceiling or eave, the floor or

ground, and wall when you install the KP100L.

2-3 Installation

2

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

2 - 7

Page 41

2 Design

Mount Inverter Straight

Never mount tilted to front Never use in tower orientation

200mm

• When you install multiple Inverters, leave a space of 200mm the minimum to the side of the Inverter. Do not

install multiple Inverters vertically.

2 - 8

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 42

2 Design

Snap bushing

Use Snap Bushings when the wall is

a hard wall like concrete

8mm diameter

55mm depth

Snap bushing

Wall

Mounting

base plate

Installation

(1) Set up "Mounting base plate" in the place where the weight (41.5kg) of KP100L can be endured. The

installation location should endure the torque of 176Nm with each installation screw.

Use the reinforced board when strength of the wall is insufficient.

Please prepare the board to reinforce it .

(2) Mark the positions of the 8 outer mounting holes onto the wall with the mounting base plate.

(3) Drill the 8 marked holes in the wall, and then drive the 8 Snap Bushings by the hammer into the wall,

when the wall is a hard wall like concrete.

2-3 Installation

2

(4) Fix the mounting base plate to the wall by using 8 mounting screws of the attachment.

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

2 - 9

Page 43

2 Design

(5) Set it in product so that 4 places in the part where both sides of the mounting base plate are curved

may come outside of the heat sink.

(6) Set it up so that the 2 screws in the both sides of the heat sink may fall into the ditch of the mounting

base plate.

(7) Fix the heat sink and the mounting base plate by using bundled M4X12 with plane washer and spring

washer in 4 points. (Tightening torque: 1.5 to1.7 Nm)

2 - 10

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 44

2-4 Wiring

Cap

Rubber Bush (none hole)

Remove the cover foreside R.

Remove the 4 screws, and the cover foreside R.

2 Design

2-4 Wiring

2

Connecting the AC Cable

Connect the AC cable to the KP100L as follow steps

(1) Remove the cap of the AC cable clamp, and take the rubber bush (None hole) out.

(2) Pass the AC cable through the cap and the rubber bush of the cable clamp.

Rubber bush (one hole type and five hole type) is bundled.

(2)-1In the case of you use the rubber bush of the one hole type

The rubber bush of one hole is used for connection with multiple-cable.

Rubber Bush (one hole)

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Cap

2 - 11

Page 45

2 Design

Rubber Bush (five holes)

Cap

(2)-2 In the case of you use the rubber bush of the five holes type

The rubber bush of five holes is used for connection with five individual cables.

(2)-3 Use the cable and the wire in the table below

Diameter of cable Cross-sectional area of wire

The rubber bush for one hole 18.5 to 20.5mm

The rubber bush for five holes 3.5 to 4.0mm

2

4mm

/ AWG12 or more

2

4mm

/ AWG12

Don't use cables that the loss is more than 1% of nominal power of the inverter.

Refer to the figure below to check possible cable lengths for the different cross-sectional area.

2.0%

4[mm2]

6[mm2]

1.5%

1.0%

Cable lossses

0.5%

0.0%

0

10[mm2]

20

40

Cable length [m]

60

80

100

(3) Use the special Rod terminal and crimping pliers for AC wiring like the picture below when connected

with KP100L.

Cross-

sectional area of wire

2

4 mm

2

6mm

2

10 mm

12mm or more

AI 4-10 GY CRIMFFOX 6, CRIMPFOX 10s

AI 6-12 YE CRIMFFOX 6, CRIMPFOX 10s

AI 10-12 RD CRIMPFOX 10s

Rod terminal

(Phoenix Contact)

Rod terminal

Cut in 10mm

crimping pliers

(Phoenix Contact)

2 - 12

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 46

(4) Insert wire in the interior of AC terminal block, and tighten by a flathead screwdriver.

(Tightening torque :1.2 to1.8 Nm)

L1 L2 L3 N PE

(5) Tighten the cap of the cable clamp surely.

When tightening the cable clamp is insufficient, the effect of the waterproof is not achieved.

2 Design

2-4 Wiring

2

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

2 - 13

Page 47

2 Design

Cap

Rubber Bush

Cap

Rubber Bush

Connecting the Communication Cable

Wiring for the communications cable to the KP100L as follow steps

(1) Remove the cap of communications cable clamp, and take the rubber bush out.

(2) Puncture only the necessary parts of the rubber bush taken out with a tool like gimlet, and pass wiring.

Use the cable and the wire in the table below.

Diameter of cable 4.0mm

Diameter of wire solid wire / 0.4-1.2 (AWG26-16)

Length in which the insulating coating of the

cable is peeled off and taken

7mm

Two spare rubber bush are bundled. Use bundled rubber bush when you make a mistake in the

punctured processing.

(3) Pass the communication cable through the hole of the product. Set the rubber bush in the main body of

the cable clamp, and tighten the cap lightly.

Tighten the cap lightly

2 - 14

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 48

2 Design

TB402

TB401

12345678910

Communication terminal block

(4) KP100L has 2 kinds of communications (RS-232C, RS-485), and the following tables show each wiring

step. The PIN arrangement of "Communication terminal block" is shown below.

No Name Note

1 RS-232C_TXD 2 RS-232C_RXD 3GO 4 RS-485_DB(+) 5 RS-485_DA(-) 6 GO GO is internally connected with Terminal No.3.

7 RS-485_DB(+) RS-485_DB (+) is internally connected with Terminal No.4.

8 RS-485_DA(-) RS-485_DA (-) is internally connected with Terminal No.5.

9 RS-485_END1

10 RS-485_END2

When using RS-485 and termination is required, Terminal

No.9, and 10 are connected.

When using RS-485 and termination is required, Terminal

No.9, and 10 are connected.

2-4 Wiring

2

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

2 - 15

Page 49

2 Design

TB402

TB401

Black button

12345678910

GO

RS-232C(TXD)

RS-232C(TXD)

TB402

TB401

Black button

12345678910

GO RS-485_DB(+) RS-485_DA(-)

(5)-1 RS-232C

Connect the wire to 1: RS-232C(TXD), 2 : RS-232C(RXD), and 3 : GO of communication terminal block

(TB401). When you connect the wire, insert the wire while pushing the black button of TB401 and

release the button.

*Note: Note the wrong wiring of the signal wire, and the catch of the insulating coating.

(5)-2 RS-485

(5)-2-1 Wiring for RS-485

Connect the wire to 3: GO, 4: RS-485_DB(+), 5: RS-485_DA(-) of communication terminal

block(TB401). When you connect the wire, insert the wire while you push the black button of TB401

and release the button.

*Note: Note the wrong wiring of the signal wire, and the catch of the insulating coating.

2 - 16

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 50

2 Design

12345678910

1 2 3 4 5 6 7 8 9 10

KP100L

L1

L2

L3

N

PE

GO GO

SG

RS-485 interface equipment

< 50V

(5)-2-2 Wiring when connecting 2 or more products

Connect the wire to 3: GO, 4: RS-485_DB(+) and 5: RS-485_DA(-) of the communication terminal

block(TB401). Connect the other wire to 6: GO, 7: RS-485_DB(+) and 8: RS-485_DA(-).

(5)-2-3 Terminal processing of wiring when connecting 2 or more products

Connect the other wire to 9: RS-485_END1 and 10: RS-485_END2. Be short-circuited.

2-4 Wiring

2

12345

67

89

10

Keep the voltage between GOof Communication terminal block and PE.is less than 50V.

RS-485_END2RS-485_END1

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

2 - 17

Page 51

2 Design

Cap

Rubber Bush

Connecting the AUX Cable

Wiring for the AUX cable to the KP100L as follow steps

(1) Remove the cap of the AUX cable clamp, and take the rubber bush out.

Cap

Rubber Bush

(2) Puncture only the necessary parts of the rubber bush taken out with a tool like gimlet, and pass wiring.

Use the cable and the wire in the table below.

Diameter of cable 4.0mm

Diameter of wire solid wire / 0.4-1.2 (AWG26-16)

Length in which the insulating coating of the cable is

peeled off and taken

7mm

Two spare rubber bush are bundled. Use bundled rubber bush when you make a mistake in the

punctured processing.

(3) Pass the AUX cable through the hole of the product. Set the Rubber Bush in the main body of the cable

clamp, and tighten the cap lightly.

Tighten the cap lightly

2 - 18

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 52

2 Design

TB402

TB401

12345678910

AUX terminal block

(4) KP100L has one input signal and two output signal, and shows each wiring steps in the follow.

The PIN arrangement of "AUX terminal block" is shown below.

No Name Note

1 AUX_IN+ Photo-coupler input +. Refer to"1-2 Function"

2 AUX_IN- Photo-coupler input -. Refer to"1-2 Function"

3NC 4 AUX_OUT1+ Relay out put. Refer to"1-2 Function"

5

6 AUX_OUT1- Relay out put. Refer to"1-2 Function"

7 AUX_OUT1- AUX_OUT1- is connected Terminal No.6 and internally.

8NC 9 AUX_OUT2+ Relay out put. Refer to"1-2 Function"

10 AUX_OUT2- Relay out put. Refer to"1-2 Function"

AUX_OUT1+

AUX_OUT1+ is connected Terminal No.4 and

internally.

2-4 Wiring

2

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

2 - 19

Page 53

2 Design

TB402

TB401

Black button

12345678910

TB402

TB401

12345678910

(5)-1-1 AUX_OUT1

Connect the wire to 4 : AUX_OUT1+ÅA6 : AUX_OUT1- of AUX terminal block(TB402). When you

connect the wire, insert the wire while you push the black button of TB402 and release the button.

*Note: Note the wrong wiring of the signal wire, and the catch of the insulating coating.

(5)-1-2 Wiring when connecting 2 or more products (AUX_OUT1)

Connect the wire to 4 : AUX_OUT1+ and 6 : AUX_OUT1- of AUX terminal block(TB402).

Connect the other wire to 5 : AUX_OUT1+ and 7 : AUX_OUT1-.

12345678910

TB402

TB401

TB401

(5)-2 AUX_OUT2

Connect the wire to 9 : AUX_OUT2+ and 10 : AUX_OUT2- of AUX terminal block(TB402). When you

connect the wire, insert the wire while you push the black button of TB402 and release the button.

*Note: Note the wrong wiring of the signal wire, and the catch of the insulating coating.

2 - 20

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 54

2 Design

TB402

TB401

12345678910

(5)-3 AUX_IN

Connect the wire to 1 : AUX_IN+, 2 : AUX_IN- of AUX terminal block(TB402). When you connect the

wire, insert the wire while you push the black button of TB402 and release the button.

Note: Note the wrong wiring of the signal wire, and the catch of the insulating coating.

2-4 Wiring

2

(6) Tighten the cap of the cable clamp surely.

If the tightening is insufficient, the effect of the waterproof is not achieved.

Attachment of cover foreside R

Mount the cover foreside R by the 4 screws surely (tightening torque : 1.5 to1.7Nm)

When tightening the screws is insufficient, the effect of the waterproof is not achieved.

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

2 - 21

Page 55

2 Design

Wiring the KP100L to the Solar Modules

• First make sure the maximum open circuit voltage Voc of each PV string is below 850 VDC under any

condition.

• Always connect solar module positive (+) terminal to KP100L DC positive (+) terminal, and the solar module

negative (-) terminal to KP100L DC negative (-) terminal.

• KP100L has 3 MPPT. Usually solar modules are connected to 3 DC terminals as illustrated in figure below.

Mount the enclosed MC caps onto MC connector that is not used. Each set of DC terminals takes a maximum

DC input of 13A. 3 pairs of DC terminals can take a combined input of up to 33A. Maximum PV input power for

each tracking is 5,500W.

• One PV-panel can be connected to 3 DC input as illustrated in figure below. To fully optimize the PV output

set-up, use the following configuration guidelines:

(a) For PV output 13A, use a single pair of DC terminals.

(b) For 13A PV output 26A, use 2 sets of DC terminals.

(c) For 26A PV output 33A, use 3 sets of DC terminals.

Attach the enclosed MC caps that is not used

Each input ≤ 13A, 5500W

Attach the enclosed MC caps that is not used

DC input ≤ 33A

13A ≤ DC input ≤ 26A

Be especially careful about electric shocks during the daytime, because that is when the solar modules are in the

power generating mode. Confirm the polarity of the cable from the solar modules to ensure correct connection

and make sure that there is no slackness of MC connectors.

2 - 22

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 56

2 Design

PV-ADBP4

PV-ADSP4

PV-KST3

PV-KBT3

PV-ADBP4

PV-ADSP4

PV-A-KBT3 / KST4

PV-A-KBT4 / KST3

For the DC terminal of the KP100L, use the standard MC4 connectors.

Model type of connectors is shown below.

Solar module side (MC4 series) KP100L side (MC4 series)

Do not disconnect

under load

PV-KST4

PV-KBT4

Multi-Contact sells the conversion cable to MC3 and MC4(PV-A-KBT3/KST4,PV-A-KBT3/KST3). If you use MC3

series in the solar module, refer to these conversion cable below.

Solar module side (MC3 series) KP100L side (MC4 series)

2-4 Wiring

2

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

2 - 23

Page 57

2 Design

2-5 Check List

Each of the Inverter has been installed to be used in accordance with the instructions listed in the manual or the

product specification; eg. ambient temperature, annual operation time, installation place, no direct exposure to

sun light and direct rain fall, mounting distances and protection against toxic gas and other harmful gas

environment, dust and other contamination.

Ensure that you have checked and verified the following points:

The provided mounting base plate for the KP100L is attached and fixed securely and correctly.

The inverter is mounted securely in the mounting base plate.

There has been no use of parts or accessory other than Omron has provided and/ or specify.

There has been no drop-off of the inverter or damage given when the inverter are installed and set up.

There has been no mechanical stress, which applies continuously yet negligible, such as vibration or shock to

the inverter.

The heat sink of the inverters is purged to avoid any clog of air convection and do not place any objects close

to the air duct.

All the wires and cables are connected to correct polarity.

MC connectors have been fastened and not deteriorated.

"Screws of AC cable" has been fastened.

Cover foreside R has been fastened and the cable clamps have been tightened correctly.

Solar modules have been installed properly and they perform as designated.

Open circuit voltage MUST not exceed 850 VDC under operating temperature (-20 to 60C).

Short-circuit DC current MUST not exceed 13 A DC per one DC input.

Cables on AC side have low resistance enough to constrain an increase of the grid voltage at the terminal of

connection (or other side of grid transformer) and loss is less than 1% of rated power of the inverter.

There has been a protection against lightening surge put on DC side of the inverter, in particular, in a place

where it is often seen

There has been a protection against surge (spike) voltage and grid instability on AC grid lines to avoid any

adverse influence from a nearby construction work or similar unusual event

There has been a protection against a less quality grid connection, in particular, in an industrial estate or near

one

There has been no modifications performed by a party other than OMRON in a product specification.

There has been no other apparatus without grounding (eg. washing machine) on the same grid lines.

There has been no installation or set-up such as that cause the inverter to chatter repeatedly intervention and

re-generation of power at startup and stop.

2 - 24

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 58

2 Design

AC cable

(4mm2 or AWG12)

AC connection

(Consisting of

Ground fault breaker,

AC breaker, SPD, terminals etc.)

Grid

2-6 Connecting to the Grid

Wiring the KP100L to the Grid

The AC connection unit is an interface between the KP100L and the grid. It may consist of an electrical breaker,

fuse and terminals for connection to both the KP100L and the grid. This AC connection unit must be designed by

qualified technician to comply with local safety standards.

Use a 20 A trip AC breaker.

2-6 Connecting to the Grid

2

Preliminary Confirmations

Check the following items before wiring.

No. Inspection Item Procedure, Measurement or Confirmation Checkmark

1

2

3

4

Solar module installation

condition

KP100L installation condition Visual confirmation:

Wiring, connection, and

conductivity

KP100L ground resistance Measurement confirmation:

Visual confirmation:

Refer to the technical manual for the solar modules.

Make sure none of the mounting screws are loose.

Make sure that the KP100L and the mounting base plate are

securely fixed with the mounting screws.

Visual confirmation:

Inspect for looseness in clamps and screws, proper wire

connection, and conductivity.

Standard: 100max.

KP100L actual measurement:

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

2 - 25

Page 59

2 Design

No. Inspection Item Procedure, Measurement or Confirmation Checkmark

Connect the Solar modules High voltages exist when the Solar modules are exposed to

the sun. Exposed terminals of the Solar modules are live, and

can cause electric shock. Avoid making physical contact with

live parts of the device.

After the Solar modules are connected to KP100L, the input

voltage is greater than 200 VDC, the LCD displays the country

setting at first time operation.

Set a specified country. Refer to "3-2 Procedure at the First

5

Grid voltage confirmation Measure to confirm that the grid voltage is about 230 V.

6

Time Operation" for detail.

After the country setting, the input voltage is greater than 200

VDC and the AC grid is not connected to the KP100L, the LCD

displays.

Fault E1-0

No Utility

Voltage measurement for each solar module string

Measurement confirmation: DC1 V

Actual measurement: AC

(L1) V AC(L2) V AC(L3) V

DC2 V DC3 V

Power-ON delay time for

grid-connected operation

7

Step 1:

Check the connection between KP100L and AC Connection

System. And then check the connection between the Grid and

AC Connection unit.

Close the AC breaker or fuse in the unit.

Step 2

Measure the time until operation resumes.

Step 3

Confirm that the displays the status "Normal" and that the

KP100L performs the grid connect operation.

Pac 1.5kW

0.50/0.50/0.50kW

The KP100L is feeding power to the grid, and the green LED

displays.

Confirm the wattmeter The Wattmeter installed to count the injected electricity should

8

work while the inverter displays that electricity is being

injected.

2 - 26

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 60

2 Design

2 Cooling Fans

2-7 Maintenance Parts

FAN

The KP100L has the two fans of maintenance parts. Refer to "Chapter 4 Maintenance Operations" for the alarm

of the fans exchange. Refer to "Chapter 5 Inspection and Maintenance" for exchange procedure of the fans.

2-7 Maintenance Parts

2

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

2 - 27

Page 61

2 Design

2-8 Options

The screw of hexagon (For Italy)

The customer who uses KP100L in Italy must buy the following screw. And, fix Cover foreside R according to the

following procedure. This is a requirements of ENEL guideline.

Execute the procedure below to seal the cover foreside after AC connection.

(1) Remove the screw 2 points where cover foreside R is fixed, and fix with the bought screw.

(Tightening torque :1.5 to 1.7 Nm)

(2) Pass the steel wire through the part of the fixed hole of 2 screws. And, pass the steel wire through

attachment as shown the figure.

2 - 28

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 62

(3) Pull the wires as shown in figure. Once you pull the wire firmly, you can not loose it.

2 Design

2-8 Options

2

DC SWITCH

It is necessary to use DC switch or circuit breaker which complies to the installation standard for photovoltaic

systems (VDE0100-712).

When you install where you require the DC switch such as Germany, please consult your OMRON representative

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

2 - 29

Page 63

2 Design

2 - 30

Grid Connect Photovoltaic Inverte KP100L-OD-USER’S MANUAL

Page 64

Operation

3-1 Part Names and Descriptions of Operation and Display Part . . . . . . . . . . 3-4

3-2 Procedure at the First Time Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3-3 Display transition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3-4 State Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3-5 Mode Selection Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3-6 Setting in Particular Countries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

3-7 Confirm method of LCD display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

3

Grid Connect Photovoltaic Inverter KP100L-OD- USER’S MANUAL

9

3 - 1

Page 65

3 Operation

WARNING

CAUTION

Important user information:

Observe the following warnings and cautions when using the KP100L.

Injury or fire may occur due to electric shock. Do not open, disassemble, modify, or repair

the front cover and the cover foreside L.

Death may possibly occur by injury because the solar modules operate at a high voltage. Do

not remove the MC connector.

Electric shock may occur. Do not open the cover foreside R during energizing.

Burn injury may occur. Do not touch the upper part of the product while operating or

immediately after having turned off power.

Fire may occur. Do not obstruct ventilation holes or place any objects within 200mm of the

ventilation holes.

Injury due to electric shock or property damage due to burning may occur. Do not unfasten

of MC connector and cable clamp.

3 - 2

Grid Connect Photovoltaic Inverter KP100L-OD- USER’S MANUAL

Page 66

Important installer information:

WARNING

CAUTION

Observe the following warnings and cautions when installing the KP100L.

Injury or fire may occur due to electric shock. Do not open, disassemble, modify, or repair

the front cover and the cover foreside L.

Electric shock may occur. Do not open the cover foreside R during energizing.

3 Operation

3

Burn injury may occur. Do not touch the upper part of the product while operating or

immediately after having turned off power.

Fire may occur. Do not obstruct ventilation holes or place any objects within 20 0mm of the

ventilation holes.

The product may break down. Install the breaker between the transformer and the KP100L

when you connect the transformer. Do not turn off the breaker on the grid side of the

transformer while driving the KP100L.

Electric shock or fire may occur due to the foreign body going into the main body. Install the

cover foreside L and the cover foreside R to the product when operating. Moreover, prevent

the foreign body from invading from the cover foreside when wiring.

Precautions for Correct Use

Use the Product

• Do not stand on the product or place any objects on the product.

• Serious injury may occur due to fire. Do not use the product in a flammable gas atmosphere (including

flammable sprays such as pesticides).

9

Grid Connect Photovoltaic Inverter KP100L-OD- USER’S MANUAL

3 - 3

Page 67

3 Operation

RUN

MODE ENT

ERR

<< >>

Display[1] Display[2]

Display[3]

3-1 Part Names and Descriptions of

Operation and Display Part

Name Description

LED(Green) RUN Lit when the KP100L is running.

LED (Red) ERR Lit when the KP100L error occur.

LCD Display [1] Displays the data name of Display [3].

Display [2] Displays the status data.

Display [3] Displays measurement value, error content and set value that user

selected.

Key MODE Changes display modes.

<< Changes (Reverse-sending) the display mode and set value.

>> Changes (Order-sending) the display mode and set value.

ENT Enter the display mode and set value.

3 - 4

Grid Connect Photovoltaic Inverter KP100L-OD- USER’S MANUAL

Page 68

3 Operation

WARNING

3-2

Procedure at the First Time Operation

Procedure at the First Time Operation

The procedure at the first time operation shows below.

(1) Connect the Solar modules to the KP100L.

(2) After the LCD becomes the display of the country setting, set a specified country.

(3) Make sure that the display of the country setting is correct.

(4) After turning OFF the AC breaker, wire the AC to the KP100L.

(5) Turn ON the AC breaker.

(6) Make sure that the KP100L starts running as indicated by the LCD.

Country Setting

Procedure of the Country Setting

The display moves to the display of the setting of the country when you start KP100L with Country Setting not

fixed. Refer to the figure below for setup. Table shows the relation between the menu and the country. You can't

set the country other than countries shown in the table. The KP100L complies with local and national standards

when correct country is selected.