Page 1

1J1000

JZ

J1000

The basic inverter

• V/f controlled inverter

• Good torque performance (150% / 3 Hz)

• Double rating ND 120%/1min and HD 150%/1 min

• Overload detection function (150% during 60s)

• Motor thermal function

• Freely configurable V/f curve

• 5 programmable digital input

• 1 programmable digital output

• 1 programmable analog output

• Optional RS-232C/485 communication - Modbus,

• CE, UL, cUL and TUV, RoHS

Ratings

• 200 V Class single-phase 0.1 to 1.5 kW

• 200 V Class three-phase 0.1 to 4.0 kW

• 400 V Class three-phase 0.2 to 4.0 kW

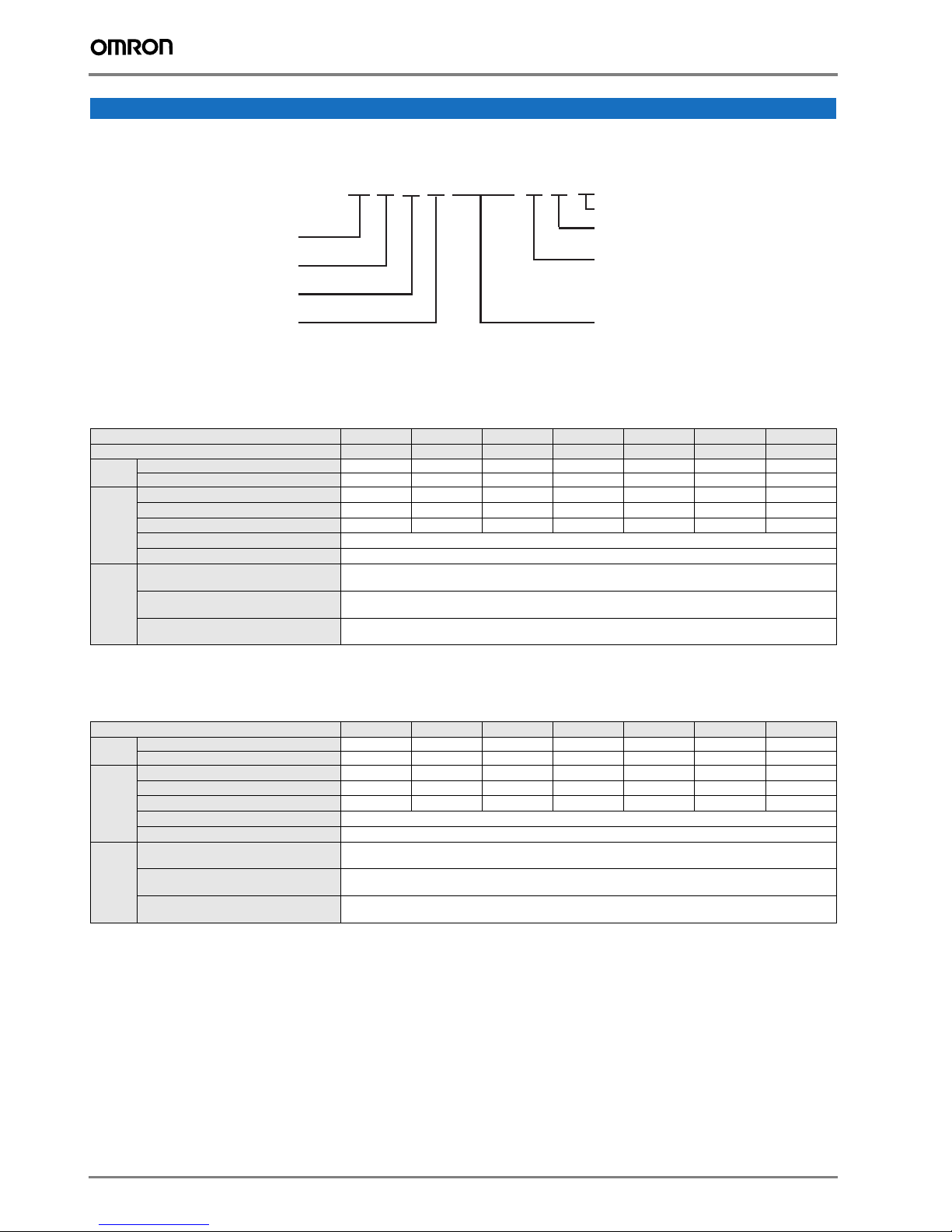

System configuration

Copy

V

erify

Read

L

O

C

K

Y

A

S

K

AW

A

J

V

O

P

-

1

8

1

U

S

B

C

o

p

y

U

n

i

t

C

O

M

E

R

R

MCCB

J1000

Filter

AC Reactor

Motor

Ground

Power

Supply

Braking Resistor

DC Reactor

Mounting Accesories

Choke

LED Remote

Operator

Remote Operator

Extansion Cable

RS232 Communications cable with PC

Communication Unit

RJ-45 / USB

Adapter

USB Cable

CX-Drive

CX-One

Page 2

2 Frequency inverters

Type designation

200 V class

400 V class

Specifications

Single-phase: JZA@ B0P1 B0P2 B0P4 B0P7 B1P5 - -

Three-phase: JZA@ 20P1 20P2 20P4 20P7 21P5 22P2 24P0

Motor

kW

1

1. Based on a standard 4-pole motor for maximum applicable motor output:

Heavy Duty (HD) mode with a 150% overload capacity

Normal Duty (ND) mode with a 120% overlaod capacity

For HD setting 0.12 0.25 0.4 1.1 1.5 2.2 4.0

For ND setting 0.18 0.37 0.55 1.1 2.2 3.0 5.5

1

Output

characteristics

Inverter capacity kVA

0.3 0.6 1.1 1.9 3.0 4.2 6.7

Rated output current (A) at HD

0.8 1.6 3.0 5.0 8.0 11.0 17.5

Rated output current (A) at ND

1.2 1.9 3.5 6.0 9.6 12.0 21.0

Max. output voltage

Proportional to input voltage: 0..240 V

Max. output frequency

400 Hz

Power

supply

Rated input voltage

and frequency

Single-phase 200..240 V 50/60 Hz

3-phase 200..240 V 50/60 Hz

Allowable voltage

fluctuation

-15%..+10%

Allowable frequency

fluctuation

+5%

Three-phase: JZA@

40P2 40P4 40P7 41P5 42P2 43P0 44P0

Motor

kW

1

1. Based on a standard 4-pole motor for maximum applicable motor output:

Heavy Duty (HD) mode with a 150% overload capacity

Normal Duty (ND) mode with a 120% overlaod capacity

For HD setting 0.37 0.55 1.10 1.5 2.2 3.0 4.0

For ND setting 0.37 0.75 1.5 2.2 3.0 4.0 5.5

Output

characteristics

Inverter capacity kVA

0.9 1.4 2.6 3.7 4.2 5.5 7.2

Rated output current (A) at HD

1.2 1.8 3.4 4.8 5.5 7.2 9.2

Rated output current (A) at ND

1.2 2.1 4.1 5.4 6.9 8.8 11.1

Max. output voltage

0..480V (proportional to input voltage)

Max. output frequency

400 Hz

Power

supply

Rated input voltage

and frequency

3-phase 380..480 VAC, 50/60 Hz

Allowable voltage

fluctuation

-15%..+10%

Allowable frequency

fluctuation

+5%

J1000 series

A: Standard specs

JZAB0P1BAA

Ver sion

B: IP20

Voltage:

B: Single-phase 200 VAC

2: Three-phase 200 VAC

4: Three-phase 400 VAC

Z: European standard

specifications

Coating specs:

A: Standard

[”P” indicates a decimal point]

Max. applicable motor output

0P1: 0.1 kW

~

4P0: 4 kW

Page 3

J1000 3

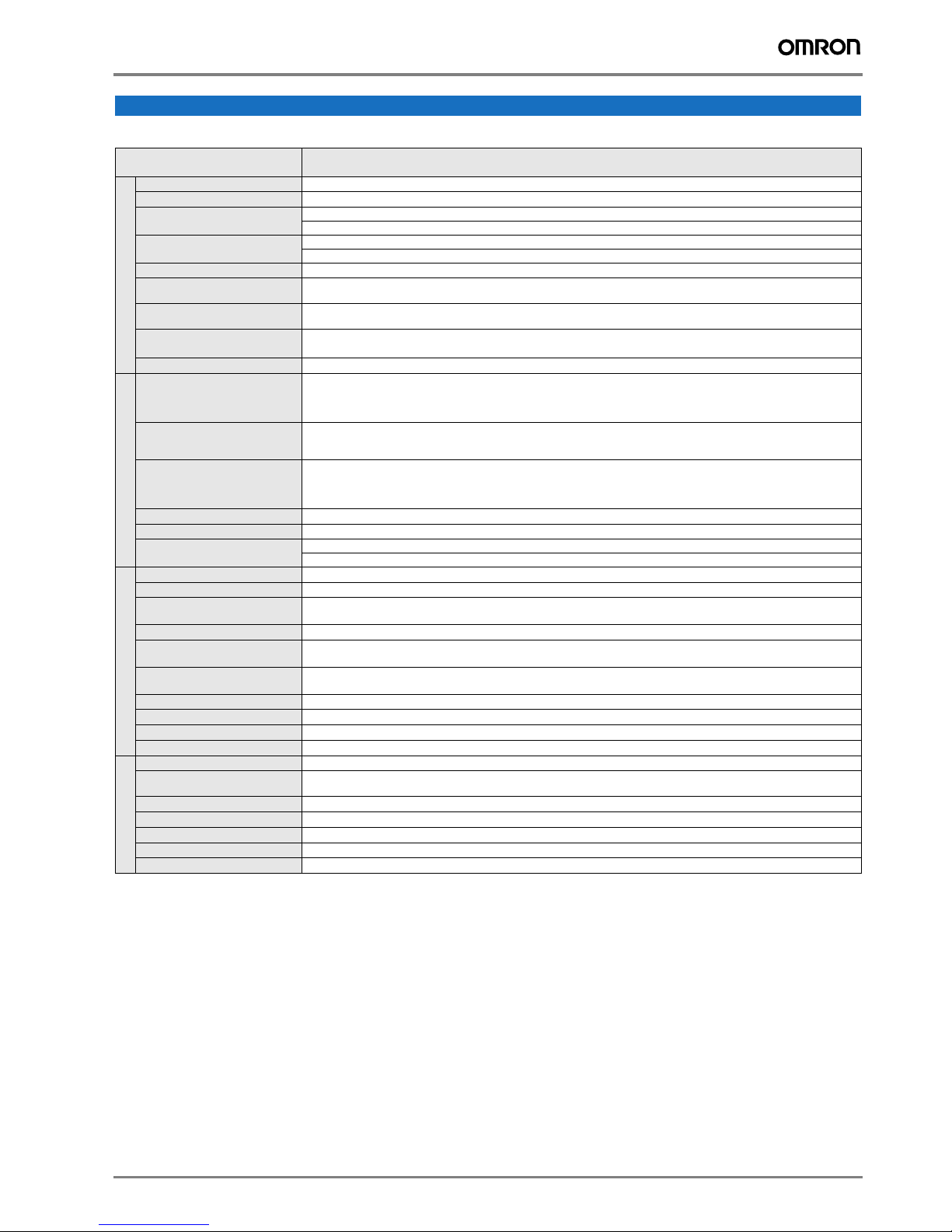

Commom specifications

Specifications

Model number

JZA@

Specifications

Control functions

Control methods

V/f control

Output frequency range

0.1..400 Hz

Frequency tolerance

Digital set value: ±0.01% (-10..+50 ºC)

Analogue set value: ±0.1% (25 ±10 ºC)

Resolution of frequency set value

Digital set value: 0.01 Hz (<100 Hz), 0.1 Hz (>100 Hz)

Analogue set value: 1/1000 of maximum frequency

Resolution of output frequency

0.01 Hz

Overload capability

Heavy duty use: 150% rated output current for one minute

Normal duty use: 120% rated output current for one minute

Frequency set value

0..10 V (20 kΩ), 4..20 mA (250 Ω), 0..20 mA (250 Ω)

Frequency setting value (selectable)

Braking torque

(short term peak torque)

Short-term average deceleration torque: 150% (up 1.5 kW), 100% (for 1.5 kW), 50% (for 2.2 kW), 20% (fof bigger size)

Continous regenerative torque: Aprox 20% (125% with optional braking resistor, 10%ED, 10 s, braking transistor built itn)

V/f Characteristics

Possible to program any V/f pattern

Functionality

Inputs signals

Five of the following input signals are selectable: Forward/reverse run (3-wire sequence), fault reset, external fault (NO/NC

contact input), multi-step speed operation, Jog command, accel/decel time select, external baseblock, speed search com-

mand, UP/DOWN command, accel/decel hold command, LOCAL/REMOTE selection, emergency stop fault, emergency

stop alarm, self test

Output signals

Following output signals are selectable (NO/NC contact output, MA, MB and MC realay: Fault, running, zero speed, speed

agree, frequency detection (output frequency <= or => set value), undervoltage detection, minor error, during baseblock, op-

eration mode, inverter run ready, during fault retry, reverse running, during speed search.

Standard functions

Full-range automatic torque boost, slip compensation, 9-step speed operation (max.), restart after momentary power loss,

DC injection braking current at stop/start (50% of inverter rated current, 0.5 sec, or less), frequency reference bias/gain, ME-

MOBUS communications (Option), fault retry, speed search, frequency upper/lower limit setting, overtorque detection, fre-

quency jump, accel/decel time switch, accel/decel prohibited, S-curve accel/decel

Analogue inputs

1 analogue input, 0..10 V, 4..20 mA, 0..20 mA

Braking/acceleration times

0.01..6000 s

Display

Optionally frequency, current or set value

Error and status LED

Protection functions

Motor overload protection Electronic thermal overload relay

Instantaneous overcurrent Motor coasts to a stop at approx. 250% of inverter rated current

Overload

Heavy Duty: Motor coasts to a stop after 1 minute at 150% of inverter rated output current

Normal Duty: Motor coasts to a stop after 1 minute at 120% of inverter rated output current

Overvoltage Motor coasts to a stop if DC bus voltage exceed 410 V (double for 400 V class)

Undervoltage

Stops when DC bus voltage is approx. 190 V or less (double for 400 V class)

(approx. 150 V or less for single-phase series)

Momentary power loss

Following items are selectable: not provided (stop if power loss is 15 ms or longer), continuous operation if power loss is

approx. 0.5 s or shorter, continuous operation

Cooling fin overheat Protected by thermistor

Stall prevention level Stall prevention during acceleration/deceleration and constant speed operation

Ground fault Protected by electronic circuit (operation level is approx. 250% of rated output current)

Power charge indication Indicates until the main circuit voltage reaches 50 V.

Ambient conditions

Degree of protection

IP20, NEMA1

Cooling

Cooling fan is provided for 200 V (3-phase) 0.75 kW (1HP) to 4.0 KW, 200V (single-phase) 1.5 KW

400 V 1.5 kW (2HP) to 4.0 KW, others are self-cooling

Ambient humidity

95% RH or less (without condensation)

Storage temperature

-20 ºC..+60 ºC (short-term temperature during transportation)

Installation

Indoor (no corrosive gas, dust, etc.)

Installation height

Max. 1000 m

Vibration

Up to 9.8 m/s2 at 10 to less than 20 Hz, Up to 6.37 m/s2 at 20 to 50 Hz

Page 4

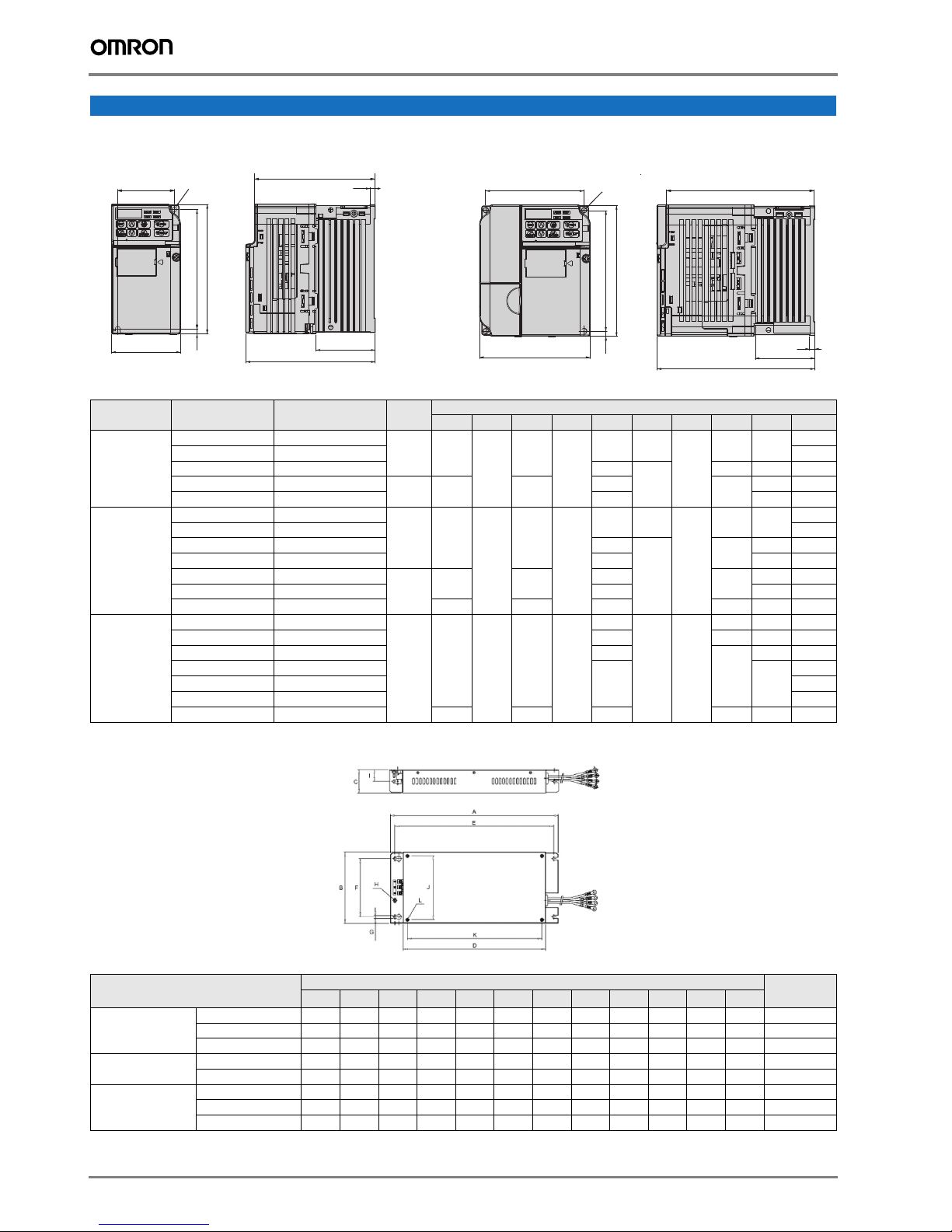

4 Frequency inverters

IP 20 type 0.1 to 4 kW

Schaffner footprint Filters

Dimensions

Voltage class

Max. applicable

motor output kW

Inverter model JZA@ Figure

Dimensions in mm

W1 H1 W H D t1 H2 D1 D2 Weight

Single-phase

200 V

0.12 B0P1

156

118

68

128

76 3

5

6.5 67.5

0.6

0.25 B0P2 0.6

0.55 B0P4 118

5

38.5 109.5 1.0

1.1 B0P7

296 108

137.5

58

129 1.7

1.5 B1P5 154 145.5 1.8

Three-phase 200

V

0.12 20P1

156

118

68

128

76 3

5

6.5 67.5

0.6

0.25 20P2 0.6

0.55 20P4 108

5

38.5

99.5 0.9

1.1 20P7 128 119.5 1.1

1.5 21P5

2

96 108

129

58

120.5 1.7

2.2 22P2 137.5 129 1.7

4.0 24P0 128 140 143 65 134.5 2.4

Three-phase

400 V

0.37 40P2

2

96

118

108

128

81

55

10 72.5 1.0

0.55 40P4 99 28 90.5 1.2

1.1 40P7 137.5

58

129 1.7

1.5 41P5

154 145.5

1.7

2.2 42P2 1.7

3.0 43P0 1.7

4.0 44P0 128 140 143 65 134.5 2.4

Schaffner model

Dimensions

Weight

KG

A B C D E F G H I J K L

3x200 V

A1000-FIV2010-SE 194 82 50 160 181 62 5.3 M5 25 56 118 M4 0.40

A1000-FIV2020-SE 169 111 50 135 156 91 5.5 M5 25 96 118 M4 0.58

A1000-FIV2030-SE 174 144 50 135 161 120 5.3 M5 25 128 118 M4 0.90

1x200 V

A1000-FIV1010-SE 169 71 45 135 156 51 5.3 M5 22 56 118 M4 0.44

A1000-FIV1020-SE 169 111 50 135 156 91 5.3 M5 25 96 118 M4 0.75

3x400 V

A1000-FIV3005-SE 169 111 45 135 156 91 5.3 M5 22 96 118 M4 0.5

A1000-FIV3010-SE 169 111 45 135 156 91 5.3 M5 22 96 118 M4 0.7

A1000-FIV3020-SE 174 144 50 135 161 120 5 M5 25 128 118 M4 0.9

Figure 1

Figure 2

t1

D

D1

4-M4

H

W1

W

H2 H1

D2

t1

D1

D

W

H1H2

H

2-M4

W1

D2

Page 5

J1000 5

Rasmi footprint Filters

Chokes

Resistor Dimensions

A1000-REJ0K15xxx A1000-REJ0K10xxx

Rasmi model

Dimensions

Weight

KG

W H L X Y M

3x200 V

A1000-FIV2010-RE 82 50 194 181 62 M4 0.8

A1000-FIV2020-RE 111 50 194 181 62 M4 1.1

A1000-FIV2030-RE 144 50 174 161 120 M4 1.3

1x200 V

A1000-FIV1010-RE 71 45 169 156 51 M4 0.6

A1000-FIV1020-RE 111 50 169 156 91 M4 1.0

3x400 V

A1000-FIV3005-RE 111 45 169 156 91 M4 1.1

A1000-FIV3010-RE 111 45 169 156 91 M4 1.1

A1000-FIV3020-RE 144 50 174 161 120 M4 1.3

Description D

diameter

Motor

KW

Dimensions Weight

Kg

L W H X Y m

A1000-FEV2102-RE 21 < 2.2 85 22 46 70 - 5 0.1

A1000-FEV2515-RE 25 < 15 105 25 62 90 - 5 0.2

X

H

YW

Ø m

L

Ø d

168

11.5

45

20

182

105

27

36

Page 6

6 Frequency inverters

DIN rail mounting bracket

Inverter JZA@ DIN rail mounting bracket

3-phase 200 VAC

20P1/ 20P2 / 20P4/ 20P7 EZZ08122A

21P5/ 22P2 EZZ08122B

24P0 EZZ08122C

Single-phase 200 VAC

B0P1/ B0P2/ B0P4 EZZ08122A

B0P7/ B1P5 EZZ08122B

3-phase 400 VAC

40P2/ 40P4/ 40P7/ 41P5/ 42P2 EZZ08122B

44P0 EZZ08122C

EZZ08122A EZZ08122B

Four, M4 tap

EZZ08122C

Side view

(common to

all the units)

35.1

DIN rail

Four, M4 tap

Four, M4 tap

Page 7

J1000 7

Standard connections

Main circuit

Installation

Terminal Name Function (signal level)

R/L1, S/L2, T/L3

Main circuit power supply input Used to connect line power to the drive.

Drives with single-phase 200 V input power use only terminals R/L1 and S/L2

(T/L3 is not connected to anything)

U/T1, V/T2, W/T3

Inverter output Used to connect the motor

B1, B2

Braking resistor connection Available for connecting a braking resistor or the braking resistor unit option.

+2, +1

DC reactor connection Remove the short bar between +2 and +1 when connecting DC reactor (option)

+1, –

DC power supply input For power supply input (+1: positive electrode; – : negative electrode)*

Grounding For grounding (grounding should conform to the local grounding code.)

SA

Motor

Cooling fan

Forward run/stop

Reverse run/stop

External fault

Fault reset

0 to +10 VDC

(2 mA)

Fault

J1000

Main circuit

Control circuit

Fault relay

1 MCCB

MC

2 MCCB

r1

s1

t1

R/L1

S/L2

T/L3

S1

S2

S3

S4

S5

<3>

<1>

<2>

-

B1+1+2 B2

R/L1

S/L2

T/L3

MC

THRX

TRX

MC

TRX

MC MA

U/T1

V/T2

W/T3

24

V

MA

MB

MC

IV

M

M

r1

s1

t1

FU

FV

FW

U

V

W

SC

AM

AC

+

-

AM

+V

A1

AC

2 kΩ

Ground

10 Ω or less (400 V class)

100 Ω or less (200 V class)

Setting power supply

+10.5 max. 20 mA

Digital output

250 VAC, 10 mA to 1 A

30 VDC, 10 mA to 1 A

(default setting)

2 MCCB

THRX

OFF

ON

MC

SA

SA

Jumper

DIP switch S1

Sink

Source

main circuit terminal

shielded line

twisted-pair shielded line

control terminal

<4>

<5>

<6>

<7>

0 to +10 V (20 kΩ)

(0)4 to 20 mA (250Ω)

Terminals +1, +2, −, B1, and B2

are for connecting options.

Never connect power supply

lines to these terminals.

For single phase 200 V

power supply, use

R/L1 and S/L2.

Three phase

power supply

200 to 240 V

Option unit

connector

Thermal relay for

motor cooling fan

Multi-step

speed 1

main/aux switch

Digital inputs

(default setting)

Main speed

frequency

reference.

Multi-function

programmable

Shield ground

terminal

DIP

switch S3

+24 V 8 mA

DC reactor

(option)

Thermal relay

(option)

Braking resistor

(option)

Analog monitor

output

Monitor

output

Page 8

8 Frequency inverters

Control Circuit

Inverter heat loss

Three-phase 200 V class

Single-phase 200 V class

Type No.

Signal name Function Signal level

Digital

input

signals

S1

Multi-function input selection 1 Factory setting: runs when CLOSED, stops when OPEN.

24 VDC, 8 mA

photocoupler

insulation

S2

Multi-function input selection 2 Factory setting: runs when CLOSED, stops when OPEN.

S3

Multi-function input selection 3 Factory setting: External Fault (N.O.)

S4

Multi-function input selection 4 Factory setting: Fault reset

S5

Multi-function input selection 5 Factory setting: Multi-step speed cmd 1

SC

Multi-function input selection Common Common for control signal

Analog

input

signal

FS

Power Supply for Frequency Setting +10 V (allowable max current 20 mA)

FR1

Main Speed Freq Ref

Voltage input or current input

0 to +10 VDC (20 kΩ) (resolution 1/1000)

4 to 20 mA (250 Ω) or 0 to 20 mA (250 Ω) Resolution: 1/500

FC

Frequency reference common 0V

Digital

output

signals

MA

NO contact output

Factory setting: "fault"

Contact capacity

250 VAC, 1 A or less

30 VDC, 1 A or less

MB

NC Output

MC

Relay Output common

Analog

output

signals

AM

Analog monitor output Factory setting: "output frequency" 0 to +10 V output Resolution: 1/1000

0 to 10 V 2 mA or less

Resolution: 8 bits

AC

Analog monitor common 0V

Model JZA 20P1 20P2 20P4 20P7 21P5 22P2 24P0

Inverter capacity kVA 0.3 0.6 1.1 1.9 3.0 4.2 6.7

Rated current (A) at HD 0.8 1.6 3 5 8 11 17.5

Rated current (A) at ND

1.2 1.9 3.5 6.0 9.6 12.0 21.0

Heat

loss W

HD

Fin 4.3 7.9 16.1 27.4 54.8 70.7 110.5

Inside unit 7.3 8.8 11.5 15.9 23.8 30.0 43.3

Total heat loss 11.6 16.7 27.7 43.3 78.6 100.6 153.8

Heat

loss W

ND

Fin 4.7 7.2 14.0 35.6 48.6 57.9 93.3

Inside unit 7.9 9.4 13.4 16.9 25.0 29.6 45.0

Total heat loss 12.6 16.6 28.5 43.1 73.6 87.5 138.2

Cooling Method Self Cooled Fan Cooled

Model JZA B0P1 B0P2 B0P4 B0P7 B1P5

Inverter capacity kVA 0.3 0.6 1.1 1.9 3.0

Rated current (A) at HD 0.8 1.6 3 5 8

Rated current (A) at ND

1.2 1.9 3.5 6.0 9.6

Heat

loss W

HD

Fin 4.3 7.9 16.1 42.5 54.8

Inside unit 7.4 8.9 11.5 19.0 25.9

Total heat loss 11.7 16.7 27.7 61.5 80.7

Heat

loss W

ND

Fin 4.7 7.2 15.1 26.2 48.6

Inside unit 8.4 9.6 14.3 20.8 29.0

Total heat loss 13.1 16.8 28.3 56.5 77.6

Cooling Method Self Cooled Fan Cooled

2 mm

A

B

B

C

D

C

A- Line up the tops of the drives.

C - 100 m minimum

B- 30 mm minimum.

D - Airflow direction

Page 9

J1000 9

Three-phase 400 V class

Connections for braking resistor

AC reactor

DC reactor

Model JZA 40P2 40P4 40P7 41P5 42P2 43P0 44P0

Inverter capacity kVA

0.9 1.4 2.6 3.7 4.2 5.5 7.2

Rated current (A) at HD

1.2 1.8 3.4 4.8 5.5 7.2 9.2

Rated current (A) at ND

1.2 2.1 4.1 5.4 6.9 8.8 11.1

Heat

loss W

HD

Fin 19.2 28.9 42.3 70.7 81.0 84.6 107.2

Inside unit 11.4 14.9 17.9 26.2 30.7 32.9 41.5

Total heat loss 30.6 43.7 60.2 96.9 111.7 117.5 148.7

Heat

loss W

ND

Fin 8.2 15.5 26.4 37.5 49.7 55.7 71.9

Inside unit 9.2 13.1 15.8 20.0 26.3 29.4 43.6

Total heat loss 17.4 28.6 42.2 57.5 76.0 85.1 115.5

Cooling Method Self Cooled Fan Cooled

200 V class 400 V class

Max. applicable

motor output

kW

Current

value

A

Inductance

mH

Max. applicable

motor output

kW

Current

value

A

Inductance

mH

0.12 2.0 2.0 ------

0.25 2.0 2.0 0.2

1.3 18.0

0.55 2.5 4.2 0.4

1.1 5 2.1 0.75 2.5 8.4

1.5 10 1.1 1.5 5 4.2

2.2 15 0.71 2.2 7.5 3.6

4.0 20 0.53 4.0 10 2.2

200 V class 400 V class

Max. applicable

motor output

kW

Current

value

A

Inductance

mH

Max. applicable

motor output

kW

Current

value

A

Inductance

mH

0.12

5.4 8

--------

0.25 0.2

3.2 280.55 0.4

1.1 0.75

1.5

18 3

1.5

5.7 11

2.2 2.2

4.0 4.0 12 6.3

Power

supply

Thermal

relay

Motor

JZ

Braking resistor

Thermal relay switch for

external braking resistor

Fault contact

MC

SA

SA

SA

MCON

MC

OFFTHRX

THRX

TRX

MC

TRX

FLT-A FLT-B

R/L1

B1 B2

S/L2

T/L3

U/T1

V/T2

W/T3

MCCB

MCCB

Power supply

AC reactor

JZ

R/L1U

V

W

X

YZS/L2

T/L3

Power

supply

JZ

DC reactor

R/L1

+1 +2

MCCB

S/L2

T/L3

Page 10

10 Frequency inverters

J1000

Ordering information

Specifications Model

Heavy Duty Normal Duty Standard

1x200 V

0.12 kW 0.8 A 0.18 kW 0.8 A JZAB0P1BAA

0.25 kW 1.6 A 0.37 kW 1.6 A JZAB0P2BAA

0.55 kW 3.0 A 0.75 kW 3.5 A JZAB0P4BAA

1.1 kW 5.0 A 1.1 kW 6.0 A JZAB0P7BAA

1.5 kW 8.0 A 2.2 kW 9.6 A JZAB1P5BAA

3x200 V

0.12 kW 0.8 A 0.18 kW 0.8 A JZA20P1BAA

0.25 kW 1.6 A 0.37 kW 1.6 A JZA20P2BAA

0.55 kW 3.0 A 0.75 kW 3.5 A JZA20P4BAA

1.1 kW 5.0 A 1.1 kW 6.0 A JZA20P7BAA

1.5 kW 8.0 A 2.2 kW 9.6 A JZA21P5BAA

2.2 kW 11.0 A 3.0 kW 12.0 A JZA22P2BAA

4.0 kW 17.5 A 5.5 kW 21.0 A JZA24P0BAA

3x400 V

0.37 kW 1.2 A 0.37 kW 1.2 A JZA40P2BAA

0.55 kW 1.8 A 0.75 kW 2.1 A JZA40P4BAA

1.1 kW 3.4 A 1.5 kW 4.1 A JZA40P7BAA

1.5 kW 4.8 A 2.2 kW 5.4 A JZA41P5BAA

2.2 kW 5.5 A 3.0 kW 6.9 A JZA42P2BAA

3.0 kW 7.2 A 4.0 kW 8.8 A JZA43P0BAA

4.0 kW 9.2 A 5.5 kW 11.1 A JZA44P0BAA

C

A

C

C

C

C

D

E

F

A

B

Copy

V

erify

Read

L

O

C

K

Y

A

S

K

AW

A

J

V

O

P

-

1

8

1

U

S

B

C

o

p

y

U

n

i

t

C

O

M

E

R

R

Choke

LED Remote

Operator

Remote Operator

Extansion Cable

RS232 Communications cable with PC

Communication Unit

RJ-45 / USB

Adapter

USB Cable

CX-Drive

CX-One

MCCB

J1000

Filter

AC Reactor

Motor

Ground

Power

Supply

Braking Resistor

DC Reactor

Mounting Accesories

Page 11

J1000 11

A Line filters

A Chokes

B Communication cards

C Accessories

D Computer software

E Braking unit, braking resistor unit

Inverter Line filter Schaffner

Line filter Rasmi

Voltage Model JZA@ Reference Rated current (A) Weight (kg) Reference Rated current (A) Weight (kg)

3-Phase

200 VAC

20P1 / 20P2 / 20P4 / 20P7 A1000-FIV2010-SE 10 0.7 A1000-FIV2010-RE 10 0.8

21P5 / 22P2 A1000-FIV2020-SE 20 0.9 A1000-FIV2020-RE 20 1.1

24P0 A1000-FIV2030-SE 30 1.0 A1000-FIV2030-RE 30 1.3

Single-Phase

200 VAC

B0P1 / B0P2 / B0P4 A1000-FIV1010-SE 10 0.5 A1000-FIV1010-RE 10 0.6

B0P7 / B1P5 A1000-FIV1020-SE 20 0.7 A1000-FIV1020-RE 20 1.0

3-Phase

400 VAC

40P2 / 40P4 A1000-FIV3005-SE 5 0.5 A1000-FIV3005-RE 5 1.1

40P7 / 41P5 / 42P2 / 43P0 A1000-FIV3010-SE 10 0.75 A1000-FIV3010-RE 10 1.1

44P0 A1000-FIV3020-SE 15 1.0 A1000-FIV3020-RE 20 1.3

Model Diameter Description

A1000-FEV2102-RE 21

Recommended for motors below 2.2 KW

A1000-FEV2515-RE 25

Recommended for motors below 15 KW

Type Model Description Function

Option units

SI-232/JC RS-232C serial communication interface

• RS232C communications interface to connect the drive to a PC or the

optional copy unit

SI-232/J Remote operator interface

• RS232C communication interface for usage with the external LED

operator JVOP-182

SI-485/J

RS-422/485 Serial

communications interface

• Interface for RS-422/485 communications using the MEMOBUS/

Modbus RTU protocol

AI-V3/J Potentiometer Option

• Potentiometer option for setting the frequency reference directly at the

drive

Types Model Description Functions

Digital

operator

JVOP-182 LED remote operator Remote operator with LED display and copy function, cable length max. 3m.

A1000-CAVOP300-EE Remote operator cable 3 meters cable for connecting remote operator

Accessories

JVOP-181 USB converter / USB cable

Allows the user to copy and verify parameter settings between drives. Can

also be used as adapter to connect the drive to a PC USB port. SI-232/JC

option is required

A1000-CAVPC232-EE PC connection cable RS232 PC tool connection cable

Types Model Description Installation

Software

CX-drive Computer software Configuration and monitoring software tool

CX-One Computer software Configuration and monitoring software tool

Inverter Braking resistor unit

Voltage

Max.

applicable

motor

output kW

Inverter model JZA@

Connectable min.

resistance Ω

Inverter-mounted type (3 %ED, 10 sec max)

3-phase 1-phase Type Resistance Ω No. of used Braking torque %

200 V

(single-/

three-phase)

0.12 20P1 B0P1 300

A1000-REJ0K15400-IE 400 1

220

0.25 20P2 B0P2 300 220

0.55 20P4 B0P4 200

A1000-REJ0K15200-IE 200 1

220

1.1 20P7 B0P7 120 125

1.5 21P5 B1P5 60 A1000-REJ0K15100-IE 100 1 125

2.2 22P2 - 60 A1000-REJ0K15070-IE 70 1 120

4.0 24P0 - 32 A1000-REJ0K15062-IE 62 1 100

400 V

(three-phase)

0.37 40P2 – 750

A1000-REJ0K10750-IE 750 1

230

0.55 40P4 – 750 230

1.1 40P7 – 510 130

1.5 41P5 – 240 A1000-REJ0K15400-IE 400 1 125

2.2 42P2 – 200 A1000-REJ0K15300-IE 300 1 115

3.0 43P0 –

100 A1000-REJ0K15400-IE 400 2 105

4.0 44P0 –

Page 12

12 Frequency inverters

F Mounting accesories

Types Model Description Applicable models JZA@

DIN Rail

EZZ08122A

Necessary to mount the inverter on a

DIN rail

20P1/20P2/20P4/20P7

B0P1/B0P2/B0P4

EZZ08122B

21P5/22P2

B0P7/B1P5

40P2/40P4/40P7/41P5/42P2

EZZ08122C

24P0

B2P2

44P0

Heatsink external mounting attachment

100-034-075

Additional items to mount the inverter with

the heatshink out of the panel.

20P1/20P2

B0P1/B0P2

100-034-076

20P4

B0P4

100-034-077

20P7

100-034-078

40P2

100-034-79

21P5/22P2

B1P5

41P5/42P2/43P0

100-034-80

24P0

B2P2

44P0

100-036-357

B4P0

100-036-418

B0P7

40P4/40P7

In the interest of product improvement, specifications are subject to change without notice.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. I81E-EN-01A

Loading...

Loading...