Omron JX AB015, JX AB002, JX AB022, JX A2002, JX A2004 User Manual

...

Compact and complete

JX INVERTER

Cost and eco-friendly »

Communications built-in »

Quality & reliability you can depend on »

1

2

The smallest gets integrated...

Omron fully understands your needs, which

is why we put quality and reliability first.

And we keep listening, so our products come

with new features and functionality that save

you time and money.

With the RFI filter built-in, and the

communications integrated as standard, the

JX provides a compact and complete solution

to a whole range of simple applications, such

as conveyor control.

Key features include:

•

Ratings up to . kW

•

RS Modbus built-in

•

Side-by-side mounting

•

EMC filter built-in

•

PID function

•

Micro-surge voltage suppression

•

Automatic energy saving

•

Emergency shut-off

•

Second motor setting

•

Auto carrier-frequency reduction

•

PTC thermistor input

•

Cooling fan switch control

•

RoHS

Easy network integration

The RS485 Modbus is built into the

RJ45 port in the inverter front,

making it very easy to add inverters

into the network without any extra

option boards. Therefore, saving

money and space.

Easy communications setting

Modbus commands are implemented

even in low end CP1 PLC family by

Modbus-RTU Easy Master

functionality, making it easier than

ever to integrate the inverters into

the network.

Space and cost saving

The new JX has a built-in EMC filter

that saves on costs and space

compared with the standard

external filter solution.

1 ph : EN61800-3 cat. C1

3 ph : EN61800-3 cat. C2

120

110

100

90

80

70

60

50

40

30

20

10

0

Frequency (Hz)

Level (dBV)

Conducted emission data

Integrated EMC filter

No Filter

500k 1M 2M 5M 10M 20M 30M200150

OMRON Function Block for Pulse Output Positioning.

OMRON Function Block for Communications.

A

A

N

N

T

T

Y

Y

Y

Sensor?

3 54

5

3

4

6

6

No additional devices required

Even advanced functionality such as

PID control is standard with the JX

inverter making it a convenient

solution for applications such as

pumps & fans where pressure, flow

and other processes need

controlling.

Automatic energy saving

The Inverter always adopts the

optimum energy-saving setting for

cost savings in such applications as

fans and pumps. The inverter can

reduce energy consumption by

61% compared with standard

mechanical systems.

Reliability with environmental responsibility

Omron is renowned for the reliability of its products.

Moreover, Omron’s policy is to offer environmentally

safe products free from any banned substances.

Reliable emergency shutdown

The IGBT’s output is directly

switched off from the external input,

assuring no energy is supplied to the

motor. This hardware-based solution

is more reliable than other CPU

dependent solutions.

Convenient and efficient

The parameter settings of two

different motors can be stored,

allowing the inverter to drive

different motors with a unique

inverter. The two motors are never

working at the same time.

Silent operation

Depending on the inverter

temperature, switching off the fan

creates a noise-free atmosphere and

prolongs the life time of the product.

Maximise motor life

Advanced PWM control is used to

suppress micro-surge voltages that

sometimes cause malfunction in

400 V motors. The motor is thus

protected and its life is prolonged.

for your application

Everything on-board

Heating section

Motor

Sensor

Emergency stop switch

IGBT gate

Power supply

circuit

Set

Reset

24 V

Latch

Interruption 0 V

PCS

RS

EMR

M

~

90

80

70

60

50

40

30

20

10

0

Power (%)

1,250 V

76%

91%

61%

22%

Damper system

Energy-saving effect

Inverter system

Airflow (%)

10 20 30 40 50 60 70 80 90 100

Spikes in the terminal voltage are suppressed even when

the wiring distance from the inverter to the motor is long

6 Frequency inverters

JX

Compact & Complete

• V/f controlled inverter

• Side by side mounting

• Built-in EMC filter

• Built-in RS-485 Modbus

• Overload detection function (150% during 60s)

•PID

• Micro-surge voltage suppression

• Automatic energy saving

• Emergency shut-off

• Second motor setting

• Auto carrier-frequency reduction

• PTC thermistor input

• Cooling fan switch control

• PC configuration tool: CX-Drive

• CE, UL, cUL, RoHS

Ratings

• 200 V Class single-phase 0.2 to 2.2 kW

• 200 V Class three-phase 0.2 to 7.5 kW

• 400 V Class three-phase 0.4 to 7.5 kW

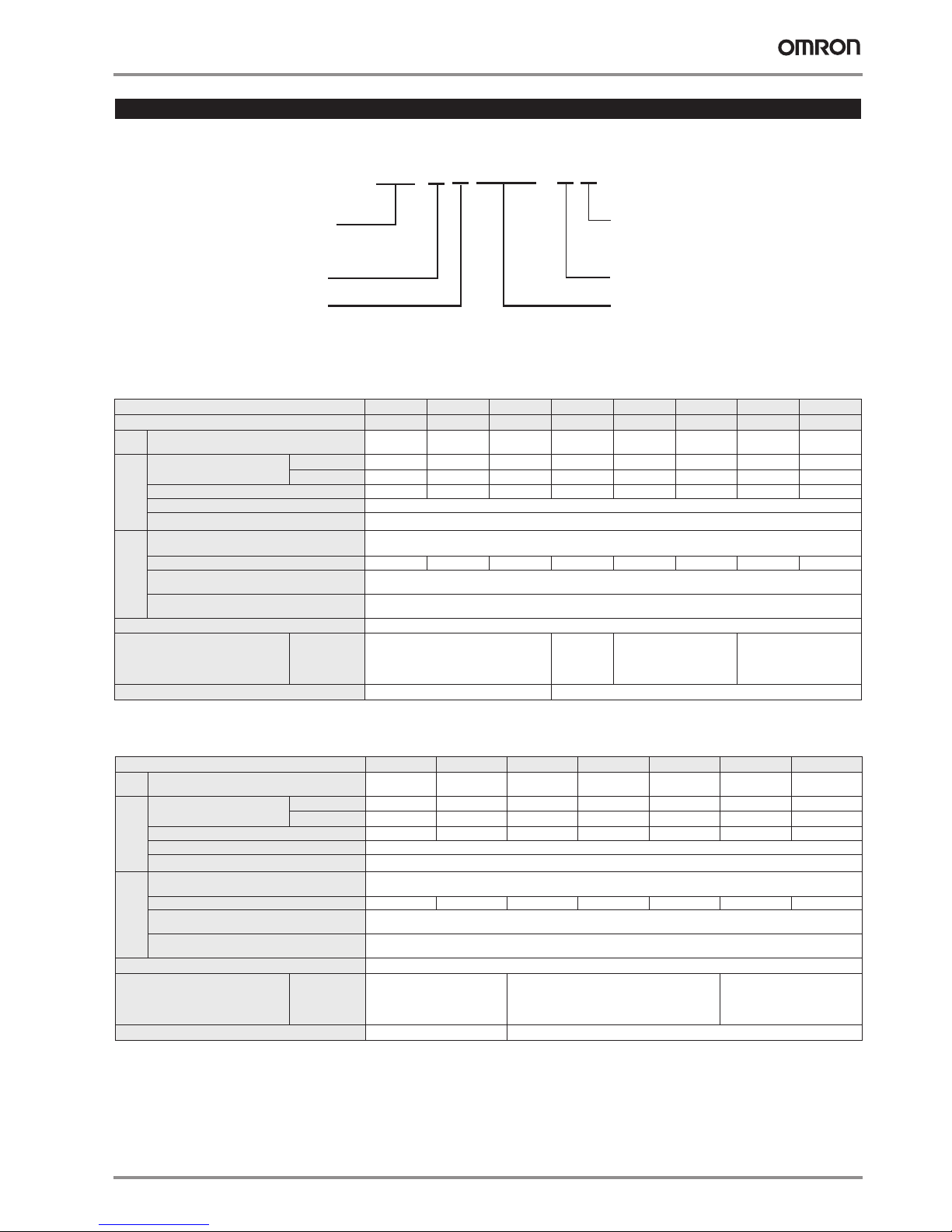

System configuration

Choke

LCD 2 lines

Remote Operator

Remote Operator

Extansion Cable

* Only needed for 3 phase 200V or to comply C1 on 3 phase 400V models

Output Reactor

RJ45 - USB Cable

CX-Drive

CX-One

*

MCCB

JX

Filter

AC Reactor

Motor

Ground

Power

Supply

DC Reactor

JX 7

Type designation

200 V class

400 V class

Specifications

Single-phase: JX@ AB002 AB004 AB007 AB015 AB022 - - -

Three-phase: JX@ A2002 A2004 A2007 A2015 A2022 A2037 A2055 A2075

Motor

kW

1

1. Based on a standard 3-Phase standard motor.

Applicable motor capacity 0.2 0.4 0.75 1.5 2.2 3.7 5.5 7.5

Output

characteristics

Inverter capacity kVA

200 V

0.4 0.9 1.3 2.4 3.4 5.5 8.3 11.0

240 V

0.5 1.0 1.6 2.9 4.1 6.6 9.9 13.3

Rated output current (A) 1.4 2.6 4.0 7.1 10.0 15.9 24.0 32.0

Max. output voltage Proportional to input voltage: 0…240 V

Max. output frequency

400 Hz

Power

supply

Rated input voltage

and frequency

Single-phase 200…240 V 50/60 Hz

3-phase 200…240 V 50/60 Hz

Rated input current (A) 1.8 3.4 5.2 9.3 13.0 20.0 30.0 40.0

Allowable voltage

fluctuation

-15%…+10%

Allowable frequency

fluctuation

+5%

Built-in filter

EMC filter (C1 single phase)

Braking torque

At short-time

deceleration

At capacitor

feedback

Approx. 50%

50% for

3-phase

20 to 40% for

1-phase

Approx 20% to 40% Approx 20%

Cooling method

Self cooling Forced-air-cooling

Three-phase: JX@ A4004 A4007 A4015 A4022 A4040 A4055 A4075

Motor

kW

1

1. Based on a standard 3-Phase standard motor.

Applicable motor capacity 0.4 0.75 1.5 2.2 4.0 5.5 7.5

Output

characteristics

Inverter capacity kVA

380 V

0.9 1.6 2.5 3.6 5.6 8.5 10.5

480 V

1.2 2.0 3.1 4.5 7.1 10.8 13.3

Rated output current (A) 1.5 2.5 3.8 5.5 8.6 13.0 16.0

Max. output voltage Proportional to input voltage: 0…480 V

Max. output frequency

400 Hz

Power

supply

Rated input voltage

and frequency

3-phase 380…480 V 50/60 Hz

Rated input current (A) 2.0 3.3 5.0 7.0 11.0 16.5 20.0

Allowable voltage

fluctuation

-15%…+10%

Allowable frequency

fluctuation

+5%

Built-in filter

EMC filter C2 class

Braking torque

At short-time

deceleration

At capacitor

feedback

Approx. 50% Approx. 20% to 40% Approx. 20%

Cooling method

Self cooling Forced-air-cooling

JX series

A: Standard specs

JXAB002-EF

Vol tage:

B: Single-phase 200 VAC

2: Three-phase 200 VAC

4: Three-phase 400 VAC

Max. applicable motor output

002: 0,2 kW

~

075: 7,5 kW

F: Built-in EMC Filter

E: Europe standard

Loading...

Loading...