Page 1

i4L

Robots

User's Manual

i4-350L

i4-450L

i4-550L

I658-E-03

Page 2

NOTE

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording, or other-

wise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover,

because OMRON is constantly striving to improve its high-quality products, the information contained

in this manual is subject to change without notice. Every precaution has been taken in the preparation

of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is

any liability assumed for damages resulting from the use of the information contained in this publica-

tion.

Trademarks

Company names and product names in this document are the trademarks or registered trademarks of

their respective companies.

Copyrights

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Page 3

Introduction

Thank you for purchasing the i4L robot.

This manual is OMRON's original instructions describing the setup, operations, and user maintenance

of the i4L robot (herein also referred to as robot).

Please read this manual and make sure you understand the functionality and performance of the robot

before attempting to use it.

Keep this manual in a safe place where it will be available for reference during operation.

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of factory automa-

tion (FA) systems and robotic control methods.

• Personnel in charge of introducing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and maintaining FA systems.

• Personnel in charge of managing FA systems and facilities.

Introduction

Applicable Products

This manual provides information for the following robot models.

When information varies between different robot models, details are provided. When information is

common to all robot models, an illustration of a single robot model is typically shown.

i4L Robot i4-350L

Additional Information

Refer to 1-4 Robot Configurations on page 1-12 for more information.

Product Models

i4-450L

i4-550L

i4-550L (350 mm Z)

i4L Robots User's Manual (I658)

1

Page 4

A

B

C

E

F

B

C

H

5 Installation

5 - 3

NY-series User's Manual (W555)

5-1 Unpack

5

5-1-1 Unpack Procedure

G

5-1

Unpack

This section provides details on how to unpack the Industrial Panel PC.

5-1-1

Unpack Procedure

1 Check the package for damage.

If there is any visible damage:

• Take photos of the package and save them.

• Inform your supplier immediately.

2 Open the package.

Ensure not to damage the contents.

3 Ensure that all items are present.

Additional Information

Refer to 5-1-2 Items Supplied with the Product

for the items supplied.

Manual Information

Manual Information

Page Structure

The following page structure is used in this manual.

Note: This illustration is provided as a sample. It will not literally appear in this manual.

Item Explanation Item Explanation

A Level 1 heading E Special Information

B Level 2 heading F Manual name

C Level 3 heading G Page tab with the number of the main section

D Step in a procedure H Page number

2

i4L Robots User's Manual (I658)

Page 5

Special Information

Special information in this manual is classified as follows:

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

Version Information

Manual Information

Information on differences in specifications and functionality between different versions.

i4L Robots User's Manual (I658)

3

Page 6

Manual Information

4

i4L Robots User's Manual (I658)

Page 7

Sections in this Manual

Maintenance

Operation

Troubleshooting

Installation

Specifications

Overview

1

2

3

4

5

6

1

2

3

4

6

5

1

A

A

Appendices

Sections in this Manual

i4L Robots User's Manual (I658)

5

Page 8

CONTENTS

CONTENTS

Introduction .............................................................................................................. 1

Intended Audience...........................................................................................................................................1

Applicable Products ......................................................................................................................................... 1

Manual Information.................................................................................................. 2

Page Structure.................................................................................................................................................2

Special Information .......................................................................................................................................... 3

Sections in this Manual ........................................................................................... 5

Terms and Conditions Agreement........................................................................ 10

Warranty and Limitations of Liability .............................................................................................................. 10

Application Considerations ............................................................................................................................11

Disclaimers ....................................................................................................................................................11

Safety Precautions................................................................................................. 13

Definition of Precautionary Information.......................................................................................................... 13

Symbols ......................................................................................................................................................... 13

Dangers .........................................................................................................................................................14

Warnings........................................................................................................................................................ 15

Cautions......................................................................................................................................................... 17

Precautions for Safe Use ...................................................................................... 18

Precautions for Correct Use ................................................................................. 20

Regulations and Standards .................................................................................. 22

Conformance to EU Directives ......................................................................................................................22

Conformance to KC Certification ...................................................................................................................22

Software Licenses and Copyrights ................................................................................................................23

Related Manuals..................................................................................................... 24

Related Product Manuals ..............................................................................................................................24

Glossary.................................................................................................................. 25

Revision History..................................................................................................... 26

Section 1 Overview

1-1 Intended Use ..........................................................................................................................1-2

1-2 Robot Features.......................................................................................................................1-3

1-2-1 Basic Robot Components ...........................................................................................................1-3

1-2-2 Front Panel..................................................................................................................................1-5

1-2-3 Connectors..................................................................................................................................1-7

1-3 Information Labels...............................................................................................................1-10

1-3-1 Robot Label...............................................................................................................................1-10

1-3-2 Controller Label......................................................................................................................... 1-11

1-4 Robot Configurations .......................................................................................................... 1-12

1-4-1 i4-350L ......................................................................................................................................1-12

1-4-2 i4-450L ......................................................................................................................................1-12

1-4-3 i4-550L ......................................................................................................................................1-12

6

i4L Robots User's Manual (I658)

Page 9

1-4-4 i4-550L (350 mm Z)...................................................................................................................1-13

1-4-5 Mounting and Cabling Options..................................................................................................1-13

1-5 Model Numbers ....................................................................................................................1-14

1-5-1 Robot Model Numbers ..............................................................................................................1-14

1-5-2 Controller Model Numbers ........................................................................................................1-14

1-6 Optional Hardware ...............................................................................................................1-15

1-6-1 IO Blox ......................................................................................................................................1-15

1-6-2 T20 Pendant..............................................................................................................................1-15

1-6-3 IPC Application Controller.........................................................................................................1-16

1-6-4 XIO Termination Block...............................................................................................................1-16

1-6-5 Optional Cables.........................................................................................................................1-17

Section 2 Specifications

2-1 Physical Specifications .........................................................................................................2-2

2-1-1 Robot Overall Dimensions ..........................................................................................................2-2

2-1-2 Mounting Flange Dimensions......................................................................................................2-4

2-1-3 Tool Flange Dimensions..............................................................................................................2-5

2-1-4 Front Panel Dimensions..............................................................................................................2-5

2-1-5 Robot Work Envelope Dimensions..............................................................................................2-6

2-1-6 Robot Weights.............................................................................................................................2-7

2-2 Performance Specifications..................................................................................................2-8

2-2-1 General Performance Information...............................................................................................2-8

2-2-2 Stopping Distances and Times....................................................................................................2-8

2-3 Electrical Specifications......................................................................................................2-12

2-3-1 Power Supply Specifications.....................................................................................................2-12

2-3-2 XIO and TIO Connector I/O Specifications ...............................................................................2-12

2-4 Environmental Specifications.............................................................................................2-14

2-5 Other Specifications ............................................................................................................2-15

2-5-1 Connector and Port Specifications............................................................................................2-15

2-5-2 Mounting Hardware and Torques..............................................................................................2-15

CONTENTS

Section 3 Installation

3-1 Robot Installation Procedure................................................................................................3-2

3-2 Mounting the Robot ............................................................................................................... 3-3

3-2-1 Robot Mounting Surface .............................................................................................................3-3

3-2-2 Mounting Procedure....................................................................................................................3-3

3-3 Installing End-of-Arm Tooling............................................................................................... 3-5

3-4 Installing Optional Equipment .............................................................................................. 3-6

3-4-1 Mounting External Equipment to the Robot ................................................................................3-6

3-5 Adjustable Hardstops............................................................................................................3-7

3-5-1 Joint 1 Adjustable Hardstops ......................................................................................................3-8

3-5-2 Joint 2 Adjustable Hardstops ......................................................................................................3-8

3-5-3 Joint 3 Adjustable Hardstop ........................................................................................................3-8

3-6 System Cable Installation ...................................................................................................3-10

3-6-1 System Cable Overview............................................................................................................3-10

3-6-2 System Cable Installation Procedure........................................................................................3-12

3-7 Connecting Digital I/O .........................................................................................................3-13

3-7-1 XIO Connector Signals and Wiring ...........................................................................................3-13

3-7-2 TIO Connector Signals and Wiring............................................................................................3-17

3-7-3 IO Blox Connections .................................................................................................................3-19

3-8 Installing Safety Equipment................................................................................................3-20

3-8-1 Installing the Front Panel ..........................................................................................................3-20

i4L Robots User's Manual (I658)

7

Page 10

CONTENTS

3-8-2 Safety Circuits...........................................................................................................................3-21

3-9 Supplying Power and Ground ............................................................................................3-28

3-9-1 Grounding the System ..............................................................................................................3-28

3-9-2 24 VDC Connections.................................................................................................................3-29

3-9-3 48 VDC Connections.................................................................................................................3-29

3-10 Verifying Installation............................................................................................................3-31

3-10-1 Mechanical Checks ...................................................................................................................3-31

3-10-2 System Cable Checks...............................................................................................................3-31

3-10-3 Safety Equipment Checks.........................................................................................................3-31

3-10-4 Switch Position Checks.............................................................................................................3-33

Section 4 Operation

4-1 Payload and Acceleration Considerations .......................................................................... 4-2

4-2 Robot Control Modes ............................................................................................................4-3

4-2-1 Manual Mode ..............................................................................................................................4-3

4-2-2 Automatic Mode ..........................................................................................................................4-3

4-3 Enabling and Disabling the Robot .......................................................................................4-5

4-3-1 Enabling Robot High Power........................................................................................................4-5

4-3-2 Disabling High Power..................................................................................................................4-6

4-4 LED Indicator..........................................................................................................................4-7

4-5 Brake Operation .....................................................................................................................4-8

4-5-1 Built-in Brake Release Button .....................................................................................................4-8

4-6 Connecting to the Robot ..................................................................................................... 4-10

4-6-1 Initial Connection Procedure.....................................................................................................4-10

4-7 Manually Jogging the Robot............................................................................................... 4-11

Section 5 Troubleshooting

5-1 Fault Detection .......................................................................................................................5-2

5-2 Emergency Stop Troubleshooting .......................................................................................5-3

5-3 Error Messages ......................................................................................................................5-4

Section 6 Maintenance

6-1 Field-replaceable Items .........................................................................................................6-2

6-2 Periodic Maintenance ............................................................................................................6-3

6-2-1 Periodic Maintenance Overview..................................................................................................6-3

6-2-2 Checking Safety Functions .........................................................................................................6-3

6-2-3 Checking Fastener Torques ........................................................................................................6-4

6-2-4 Checking Safety and Warning Labels .........................................................................................6-4

6-2-5 Checking for Oil Leaks................................................................................................................6-5

6-2-6 Lubricating Joint 3.......................................................................................................................6-6

6-2-7 Replacing Encoder Backup Batteries..........................................................................................6-7

6-2-8 Cleaning the Robot .....................................................................................................................6-8

6-3 Non-periodic Maintenance .................................................................................................... 6-9

6-3-1 Replacing the Tool Flange...........................................................................................................6-9

Appendices

A-1 Unpacking and Inspecting the Robot ................................................................................. A-2

8

i4L Robots User's Manual (I658)

Page 11

Index

CONTENTS

A-1-1 Before Unpacking the Robot ...................................................................................................... A-2

A-1-2 Unpacking the Robot.................................................................................................................. A-2

A-2 Repacking the Robot for Transport..................................................................................... A-4

A-3 Transportation and Storage Considerations...................................................................... A-5

A-4 I/O Signal Numbering ........................................................................................................... A-6

A-4-1 Input Signal Numbering.............................................................................................................. A-6

A-4-2 Output Signal Numbering........................................................................................................... A-6

A-5 Cable Pinouts ........................................................................................................................ A-7

A-5-1 XSYSTEM Cable Pinouts........................................................................................................... A-7

A-5-2 XBELTIO Adapter Cable Pinouts ............................................................................................... A-8

A-5-3 Belt Encoder Y-adapter Cable Pinouts....................................................................................... A-9

A-6 Parts List.............................................................................................................................. A-11

i4L Robots User's Manual (I658)

9

Page 12

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty and Limitations of Liability

Warranty

Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and work-

manship for a period of twelve months from the date of sale by Omron (or such other period ex-

pressed in writing by Omron). Omron disclaims all other warranties, expressed or implied.

Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-com-

plying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be re-

sponsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return

of any Products by Buyer must be approved in writing by Omron before shipment. Omron Compa-

nies shall not be liable for the suitability or unsuitability or the results from the use of Products in

combination with any electrical or electronic components, circuits, system assemblies or any other

materials or substances or environments. Any advice, recommendations or information given orally

or in writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitations of Liability

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CON-

SEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY. Further, in no event shall liability of Omron Com-

panies exceed the individual price of the Product on which liability is asserted.

10

i4L Robots User's Manual (I658)

Page 13

Application Considerations

Suitability for Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At Buy-

er’s request, Omron will provide applicable third party certification documents identifying ratings and

limitations of use which apply to the Product. This information by itself is not sufficient for a complete

determination of the suitability of the Product in combination with the end product, machine, system, or

other application or use. Buyer shall be solely responsible for determining appropriateness of the par-

ticular Product with respect to Buyer’s application, product or system. Buyer shall take application re-

sponsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND IN-

STALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Terms and Conditions Agreement

Programmable Products

• Omron Companies shall not be responsible for the user’s programming of a programmable Product,

or any consequence thereof.

• Omron Companies shall not be responsible for the operation of the user accessible operating sys-

tem (e.g. Windows, Linux), or any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual per-

formance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and oth-

er reasons. It is our practice to change part numbers when published ratings or features are changed,

or when significant construction changes are made. However, some specifications of the Product may

be changed without any notice. When in doubt, special part numbers may be assigned to fix or estab-

lish key specifications for your application. Please consult with your Omron’s representative at any

time to confirm actual specifications of purchased Product.

i4L Robots User's Manual (I658)

11

Page 14

Terms and Conditions Agreement

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; how-

ever, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

12

i4L Robots User's Manual (I658)

Page 15

Safety Precautions

Definition of Precautionary Information

The following notation is used in this manual to provide precautions required to ensure safe usage of

the i4L robot. The safety precautions that are provided are extremely important to safety.

Always read and heed the information provided in all safety precautions.

The following notation is used.

Identifies an imminently hazardous situation which, if not avoid-

DANGER

WARNING

ed, is likely to result in serious injury, and might result in fatality

or severe property damage.

Indicates a potentially hazardous situation which, if not avoid-

ed, could result in death or serious injury. Additionally, there

may be severe property damage.

Safety Precautions

Symbols

Indicates a potentially hazardous situation which, if not avoid-

CAUTION

The circle and slash symbol indicates operations that you must not do. The specific operation is shown in the circle and explained in text.

This example indicates prohibiting disassembly.

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the triangle and explained in text.

This example indicates a precaution for electric shock.

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the triangle and explained in text.

This example indicates a general precaution.

The filled circle symbol indicates operations that you must do.

The specific operation is shown in the circle and explained in text.

This example shows a general precaution for something that you must do.

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the triangle and explained in text.

This example indicates a precaution for high temperatures.

ed, may result in minor or moderate injury, or property damage.

i4L Robots User's Manual (I658)

13

Page 16

Safety Precautions

Dangers

General

An i4L robot can cause serious injury or death, or damage to itself and other equipment,

if the following safety precautions are not observed:

• All personnel who install, operate, teach, program, or maintain the system must read

this guide, read the Robot Safety Guide, and complete a training course for their responsibilities in regard to the robot.

• All personnel who design the robot system must read this guide, read the Robot Safe-

ty Guide, and must comply with all local and national safety regulations for the location

in which the robot is installed.

• The robot system must not be used for purposes other than described in 1-1 Intended

Use on page 1-2. Contact your local Omron support if you are not sure of the suitability for your application.

• The user is responsible for providing safety barriers around the robot to prevent any-

one from accidentally coming into contact with the robot when it is in motion.

• Power to the robot and its power supply must be locked out and tagged out before any

maintenance is performed.

• When the robot or robotic equipment is not investigated in conjunction with a system

work cell, the instructions shall call attention to the following: the interlocked portion of

barrier shall be installed, applied, and maintained so that it has the capability of being

easily unlocked from the inside of the safeguarded space, with or without power available, when the possibility of full body access exists.

i4L robots are not collaborative robots. They require a dedicated work area that will prevent personnel from coming into contact with them during operation.

The normal and intended use of these robots does not create hazards.

These robots have been designed and constructed in accordance with the relevant requirements of IEC 60204-1.

These robots are intended for use in parts assembly and material handling for payloads

up to 5.0 kg.

Refer to the Robot Safety Guide (Cat. No. I590) for details on the intended use of our

robots.

These robots are intended for industrial use only.

Perform a risk assessment before using.

These robots are not intended for:

• Use in the presence of ionizing or non-ionizing radiation.

• Use in potentially explosive atmospheres.

• Use in medical or life saving applications.

• Use in a residential setting.

DANGER

14

Installation

i4L Robots User's Manual (I658)

Page 17

The robot system must be installed with user-supplied interlock barriers. The interlocked

barriers must open the E-Stop circuit in the event of personnel attempting to enter the

work cell when High Power is enabled. Failure to install suitable guarding or interlocks

could result in injury or death. We strictly prohibit installation, commissioning, or operation of any robot without adequate safeguards. These must be compliant with applicable

local and national standards.

The placement of safety controls shall avoid requiring a person to enter a hazardous

area to actuate them.

Controls shall be located outside of the safeguarded space, except for certain controls

such as emergency stops or a teach pendant, where based on a risk assessment they

may be located within the safeguarded space.

After installing the robot, you must test it before you use it for the first time. Failure to do

this could cause death, serious injury, or equipment damage.

Failure to ground robot-mounted equipment or tooling that uses hazardous voltages

could lead to injury or fatality of a person touching the end-effector during an electrical

fault.

Any High Power push-buttons must be installed outside of the robot's workspace.

Safety Precautions

Warnings

General

The instructions for operation, installation, and maintenance given in this document must

be strictly observed.

If air pressure is present, disconnect it from the robot when servicing end-of-arm tooling

or other pneumatic components to prevent unsecured pneumatic air lines from accidentally injuring personnel.

Do not move the robot links if the robot is not secured. Failure to comply could result in

the robot falling and causing either personnel injury or property damage.

Installation

WARNING

Ensure that installation and post-installation checks of the product are performed by personnel in charge who possess a thorough understanding of the machinery to be installed.

Ensure compliance with all local and national safety and electrical codes for the installation and operation of the robot system.

i4L Robots User's Manual (I658)

15

Page 18

Safety Precautions

Provide appropriately-sized Branch Circuit Protection and Lockout / Tagout Capability in

accordance with the National Electrical Code and any local codes.

Always use proper lifting technique when lifting the robot. Failure to comply could result

in the robot falling and causing either personnel injury or equipment damage.

If you supply your own Front Panel, its design must comply with the requirements of IEC

60204-1 and ISO 13849. The E-Stop's push button must comply with ISO 13850 (Clause

5.5.2).

Disabling the High Power button violates IEC 60204-1. Do not alter its functionality.

If a robot is mounted to a surface with inadequate stiffness, damage to the z-axis quill or

other mechanical components can result from excessive oscillation during operation.

The robot's center of mass can cause the robot to fall over if the robot is not properly

secured with the mounting bolts.

The robot must be installed to avoid interference with buildings, structures, utilities, other

machines and equipment that may create trapping or pinch points. It must be installed in

accordance with Standard for Robots and Robotic Devices – Safety Requirements for Industrial Robots – Part 2: Robot Systems and Integration, ISO 10218-2.

Ensure that interconnecting cables or pneumatic lines are routed away from the robot

workspace.

To reduce the risk of fire or electric shock, install the robot in a controlled environment

relatively free of contaminants.

Operation

Before starting the operation of equipment, always confirm that the safety equipment of

the robot works properly. If a malfunction of the safety equipment is detected, follow the

troubleshooting procedure.

Use the total weight of the end-of-arm tooling and the payload to stay within the payload

rating of the robot. Ensure that the system never exceeds that maximum payload.

Perform a full risk assessment which includes the end-of-arm tooling and any payload to

prevent crushing, shearing, payload ejection, entanglement, stabbing or puncture hazard.

16

Releasing a brake may cause the quill, tool flange, end-of-arm tooling, and payload to

drop. To prevent possible injury to personnel or damage to the equipment, make sure

that the equipment is supported when releasing the brake and verify that the end-of-arm

tooling and payload are clear of all obstructions.

All signals that pass-through the USER connectors are not associated with any robot

controls, emergency stop circuits, or robot power. Implement appropriate safety measures to ensure that these signals are not active during emergency stop conditions or

while the robot is powered OFF.

i4L Robots User's Manual (I658)

Page 19

In Automatic mode, the robot can move unexpectedly. Ensure all personnel remain clear

of the cell when Automatic mode is enabled.

If an operator is going to be in the work cell with the switch in Manual mode, the operator

must carry an enabling device such as the T20 pendant.

Whenever possible, perform Manual mode operations with all personnel outside the

workspace.

The stopping time and distance, or angle, of a robot joint from initiation of a stop signal is

not negligible and must be taken into account when designing and applying safeguarding

devices.

Never connect or disconnect system cables while power is applied to the robot. Failure

to comply may cause unexpected behavior and can result in personnel injury and equipment damage.

Never run a robot system with all jumpers installed. This would leave the system with no

E-Stops.

Safety Precautions

Do not use the robot in hazardous environments (explosive gas, and oil mist).

The robot shall be operated within its specified temperature range to ensure proper operation.

The robot's physical hardstop devices are not intended to withstand repeated use and if

this occurs, the hardstop may become damaged. Implement proper programming and

configuration of joint range limits to prevent hardstop impacts.

Maintenance

Do not use organic solvents to clean any part of the robot unless directed in the cleaning

instructions. Organic solvents might damage electronics resulting in an unsafe operating

state that could cause injury or damage to equipment.

Cautions

CAUTION

The design and installation of the complete system must comply with the safety standards and regulations in the country of use. The integrators of the robot should understand the safety laws and regulations in their countries and prevent major hazards from

occurring in the complete system.

i4L Robots User's Manual (I658)

17

Page 20

Precautions for Safe Use

Precautions for Safe Use

• The Joint 3 quill and the tool flange are not grounded to protective earth. If hazardous voltages are

present at any user-supplied robot-mounted equipment or tooling, you must install a ground connec-

tion from that equipment or tooling to the ground point on the robot base.

• This equipment must be shipped and stored in a temperature-controlled environment, within the

range –25 to +55°C. The recommended humidity range is 5 to 90%, non-condensing. It should be

shipped and stored in the supplied packaging, which is designed to prevent damage from normal

shock and vibration.

• Output 8 can be assigned to indicate the robot's High Power state. When High Power is enabled,

this output will turn ON. When High Power is not enabled, this output will be OFF. This is not a safe-

ty-rated means of indicating a High Power state and should only be used for monitoring the robot

status. Use the ACE software to make this configuration if needed.

• Do not apply 48 VDC power until all installation steps are complete and verified and all safety meas-

ures are in place.

• High power cannot be enabled unless all safety circuits are satisfied.

• The LED indicator does not reflect the robot's High Power status. To see the robot's High Power sta-

tus, use the Front Panel indicator or a user-supplied indicator connected to the XFP connector.

• The braking mechanism operates passively. If 24 VDC Control Power is removed from the system,

the brake mechanism will automatically activate. 24 VDC Control Power must be supplied to release

the brake. To prevent possible damage to the equipment, remove any payload from the end-of-arm

tooling, make sure that Joint 3 is supported while releasing the brake, and verify that the end-of-arm

tooling or other installed equipment is clear of all obstructions.

• The High Power indicator must be operational to satisfy safety requirements.

• You can contribute to resource conservation and protecting the environment by the proper disposal

of Waste Electronics and Electrical Equipment (WEEE). All electrical and electronic products should

be disposed of separately from the municipal waste system according to local ordinances using des-

ignated collection facilities.

18

• The product contains lithium batteries with a perchlorate content of 6ppb or higher. When exporting

an end product containing the product to or shipping through California, USA, label all packing and

shipping containers appropriately. Special handling may apply. Refer to https://dtsc.ca.gov for more

information.

• Dispose of any battery that has been dropped or otherwise subjected to excessive shock. Batteries

that have been subjected to shock may leak if they are used.

• Batteries may leak, rupture, heat, or ignite. Never short-circuit, charge, disassemble, heat, or incin-

erate a battery or subject it to strong shock.

• Any person who programs, teaches, operates, maintains, or repairs robots or robot systems shall be

trained and can demonstrate competence to safely perform the assigned task.

• Any person who programs, teaches, operates, maintains, or repairs robots or robot systems shall be

trained on responding to emergency or abnormal situations.

• Do not connect user-supplied Manual / Automatic contacts or other control signals in parallel with

the Front Panel switch contact. This would violate the Single Point of Control principle and might al-

low Automatic mode to be selected while an operator is in the cell.

i4L Robots User's Manual (I658)

Page 21

Precautions for Safe Use

• Acoustic emission from these robots may be up to 70 dB (A) at 1 m distance under worst-case con-

ditions. Typical values will be lower, depending on payload, speed, acceleration, and mounting. Ap-

propriate safety measures should be taken, such as ear protection and display of a warning sign.

• Any moving robot requires some distance to stop. This requires more distance at high operating

speeds or heavier payloads. When stopping a robot, make sure that there is no interference with

other equipment.

• Do not expose the shipping container to excessive shock and vibration. This could damage the ro-

bot.

• Using improper lubrication products on the robot may damage it.

• After an operator places the robot in Manual mode using the Front Panel key switch, they should

remove the key for safety purposes.

• If the supplied Front Panel is not used, a High Power indicator light must be present in the system.

This indicator light must be amber in color. It must be either mounted to the robot or integrated into

the work cell where it is visible from all approaches or entry points.

• If a supplementary audible means of robot operation is provided, it shall exceed the ambient noise

at the end-use application.

• You can burn yourself. Do not touch the robot after it has been running at high ambient tempera-

tures or at fast cycle times (over 60 cycles per minute). The robot surface temperature can exceed

85° C.

• During manual operation, ensure all persons are a safe distance away from the robot work enve-

lope.

• The robot can be lifted by hand. Only use the base and inner link when lifting the robot. Never ma-

neuver the robot using the quill or flyover assemblies.

• To stop the robot in an emergency, press any E-stop button and then follow the internal procedures

of your company or organization defined for an emergency situation.

• If a fire occurs on the robot, use a CO2 type fire extinguisher.

• In case of entrapment of a person by the robot or any other emergency or abnormal situation, you

can manually move the inner and outer links to a safe position while 48 VDC High Power is disa-

bled. A brake device prevents Joints 3 and 4 from moving when High Power is disabled and can

only be released while 24 VDC Control Power is present.

• Prior to placing the robot in Automatic Mode, all safeguards must be returned to their safe state.

i4L Robots User's Manual (I658)

19

Page 22

Precautions for Correct Use

Precautions for Correct Use

• Robot motion is not possible until High Power is supplied and has been enabled. Refer to 4-3 Ena-

bling and Disabling the Robot on page 4-5 for more information.

• Control power must be present before High Power can be enabled.

• The T20 pendant can only control the robot it is directly connected to.

• Either a Front Panel or equivalent circuits are required to enable High Power to the robot. Refer to

XFP Wiring Diagram on page 3-24 for more information.

• If the Front Panel High Power ON / OFF indicator fails, you might incorrectly assume that High Pow-

er is OFF, and the robot is safe. To prevent this, a failed indicator causes an error (-924) *Front pan-

el HIGH POWER lamp failure* and locks out the High Power enabling until you replace the indicator.

Refer to the eV+ Language Reference Guide (Cat. No. I605) for more information about error han-

dling. Refer to High Power Indicator Check Procedure on page 3-32 for information about High Pow-

er indicator operation verification.

• It is recommended to use a properly secured, 18 mm (minimum) thick steel plate with a maximum

surface roughness of 25 μm as a robot mounting surface.

• The mounting surface should be clean and prepared according to the information provided in

3-2-1 Robot Mounting Surface on page 3-3 before attempting to mount the robot.

• Do not over-tighten the tool flange setscrew. This will cause off-center alignment of the tool flange

on the quill.

• Always reduce joint motion limits with software configuration settings when hardstops are used to

restrict range of motion. Refer to the Automation Control Environment (ACE) Version 4 User's

Manual (Cat. No. I633) for more information.

• Never loosen or remove the quill clamp collar while the z-axis brake is released.

• If Teach Pendant cabling is installed, the jumper plug or the Teach Pendant must be connected to

satisfy safety circuits and allow High Power to be enabled.

• Do not disable or bypass the High Power button. This will violate IEC 60204-1.

• Operating the robot outside of the payload and speed constraints described in this document can

damage or reduce the service life of the z-axis quill.

• If a Front Panel is not present, the High Power indicator and High Power button signals can be ac-

cessed with the XFP system cable connector. Refer to Front Panel Connections on page 3-21 for

more information.

• Attempting to release the brake while High Power is ON will automatically disable High Power. If the

robot is moving, this will cause it to stop abruptly.

• If no controller(s) is detected, check the Ethernet network and cables and ensure that a network

connection is available to the robot and the PC.

• Only replace items on the robot system with the parts supplied by OMRON.

• Only use the recommended grease on the joint 3 quill. Use THK AFF Grease (part number

20950-000). Refer to the provided Safety Data Sheet for proper handling.

• When removing and replacing the tool flange, you must reinstall it in the same position to avoid los-

ing the calibration for the robot.

• Use surge suppression when switching inductive loads such as relays to prevent damage to the out-

put circuits.

• Any externally mounted equipment is considered robot payload. Consideration to the payload at-

tached to the Tool Flange should be made when mounting external equipment to the robot.

20

i4L Robots User's Manual (I658)

Page 23

Precautions for Correct Use

• If the robot has a bottom Primary Interface Panel orientation, do not temporarily set the robot upright

on a flat surface because this can damange the Primary Interface Panel connectors.

• Avoid rotating the quill / Joint 4 when the brake is released. This could result in an out-of-range con-

dition and may prevent program execution.

• All fastener torque values provided must be applied within ±5%.

• Keep a minimum of 300 mm clearance from the Primary Interface Panel to allow for switch and ca-

ble connection access.

i4L Robots User's Manual (I658)

21

Page 24

Regulations and Standards

Regulations and Standards

Conformance to EU Directives

The robot complies with the following EN Directives.

Directives

• 2006/42/EC

Machinery Directive

• 2014/30/EU

EMC Directive

EN Harmonized Standards

The robot system conforms to the following EN standards.

• EN ISO 12100

Safety of Machinery

General Principles for Design

Risk Assessment and Reduction

• EN ISO 13849-1

Safety of Machinery

Safety Related Parts of Control Systems SRP/CS – Part 1

• EN ISO 10218-1

Robots for industrial environments

Safety requirements, Part 1: Robot

• EN 60204-1

Safety of Machinery

Electrical equipment of machines, Part 1 General Requirements

• EN 61000-6-4

EMC, Part 6-4: Emissions Standard for Industrial Environments

• EN 61000-6-2

EMC, Part 6-2: Immunity Emissions Standard for Industrial Environments

Conformance to KC Certification

When you use this product in South Korea, observe the following precautions.

This product meets the electromagnetic compatibility requirements for business use. There is a risk of

radio interference when this product is used in home.

22

i4L Robots User's Manual (I658)

Page 25

Software Licenses and Copyrights

This product incorporates certain third party software. The license and copyright information associat-

ed with this software is available at http://www.fa.omron.co.jp/nj_info_e/.

Regulations and Standards

i4L Robots User's Manual (I658)

23

Page 26

Related Manuals

Related Manuals

Use the following related manuals for reference.

Related Product Manuals

Manual Name Description

eV+ Language User's Guide (Cat. No.

I604)

eV+ Language Reference Guide (Cat. No.

I605)

eV+ Operating System User's Guide (Cat.

No. I606)

eV+ Operating System Reference Guide

(Cat. No. I607)

Robot Safety Guide (Cat. No. I590) Contains safety information for OMRON industrial robots.

Automation Control Environment (ACE)

Version 4 User's Manual (Cat. No. I633)

T20 Pendant User's Manual (Cat. No. I601) Describes the use of the T20 manual control pendant.

Adept XIO Termination Block Installation

Guide (00340-000)

Omron Adept IO Blox User's Guide

(04638-000)

IPC Application Controller User's Manual

(Cat. No. I632)

Provides the concepts and strategies of programming with eV+.

Provides references to eV+ language and functionality.

Describes the eV+ operating system for v2.x.

Provides eV+ operating system keyword descriptions.

Contains information that is necessary to use Automation Control

Environment (ACE) software.

Describes the use of the XIO Termination Block unit.

Describes the use of the IO Blox unit.

Describes the use of the IPC Application Controller.

24

i4L Robots User's Manual (I658)

Page 27

Glossary

Term / Abbreviation Description

Application Controller Industrial PC that provides additional functionality to the robot to execute

Automatic Mode Operating state of the robot during normal conditions. In this mode, pro-

Control Power 24 VDC supply that energizes control and other non-servo motor circuits.

End-of-arm Tooling Any device mounted to the robot's tool flange intended for performing work

Emergency Stop An action or device used to immediately stop the robot. This may be refer-

Flyover The cable assembly that connects the robot base to the outer link.

Hardstop Physical limit that restricts the range of motion for a robot axis.

High Power 48 VDC supply that energizes all internal servo motors to allow robot mo-

Joint Mechanical robot component that connects its moving parts.

LED Indicator Multi-colored light on top of the outer link that provides a visual indication of

Link Mechanical robot component that moves in a radial motion.

Manual Mode Operating state of the robot during commissioning, position teaching, and

SCARA Selective Compliance Assembly Robot Arm

T20 Pendant Optional, handheld device used to manually jog the robot, teach locations,

Quill Mechanical robot component that provides motion in the z-axis and rotary

Work Envelope Working area that is accessible by the robot considering any end-of-arm

Workspace Total area that the robot occupies considering all capable range of motion.

Glossary

PackManager and Robot Vision Manager applications.

gram execution will control the robot up to the maximum allowable speed.

during robot operation.

red to as emergency stop, E-stop, or ESTOP.

tion.

the robot operating state.

other setup operations.

and debug programs without a PC. This is also referred to as a Teach

Pendant or a pendant.

motion for the tool flange. This is a ball-screw mechanism.

tooling and part shapes that are attached.

i4L Robots User's Manual (I658)

25

Page 28

I658-E-03

Cat. No.

Revision code

Revision History

Revision History

A manual revision code appears as a suffix to the catalog number on the front and back covers of the

manual.

Revision code Date Revised content

01 November 2020 Original production

02 December 2020 Minor modifications

03 January 2021 Corrections and revisions

26

i4L Robots User's Manual (I658)

Page 29

Overview

This section provides general information about the robot.

1-1 Intended Use................................................................................................... 1-2

1-2 Robot Features............................................................................................... 1-3

1-3 Information Labels .......................................................................................1-10

1-4 Robot Configurations ..................................................................................1-12

1-5 Model Numbers ............................................................................................1-14

1-6 Optional Hardware .......................................................................................1-15

1

1-2-1 Basic Robot Components................................................................................ 1-3

1-2-2 Front Panel...................................................................................................... 1-5

1-2-3 Connectors...................................................................................................... 1-7

1-3-1 Robot Label................................................................................................... 1-10

1-3-2 Controller Label..............................................................................................1-11

1-4-1 i4-350L .......................................................................................................... 1-12

1-4-2 i4-450L .......................................................................................................... 1-12

1-4-3 i4-550L .......................................................................................................... 1-12

1-4-4 i4-550L (350 mm Z)....................................................................................... 1-13

1-4-5 Mounting and Cabling Options...................................................................... 1-13

1-5-1 Robot Model Numbers .................................................................................. 1-14

1-5-2 Controller Model Numbers ............................................................................ 1-14

1-6-1 IO Blox........................................................................................................... 1-15

1-6-2 T20 Pendant.................................................................................................. 1-15

1-6-3 IPC Application Controller ............................................................................. 1-16

1-6-4 XIO Termination Block ................................................................................... 1-16

1-6-5 Optional Cables............................................................................................. 1-17

1

i4L Robots User's Manual (I658)

1-1

Page 30

1 Overview

1-1

Intended Use

The i4L robot is a selective compliance assembly robot arm (SCARA) for use within factory environ-

ments. It is designed to perform automated motion control typically used with material handling opera-

tions.

The i4L robot is capable of high speed, high-precision motion for payloads up to 5 kg. Its compact de-

sign and flexible programmability make it ideal for a wide variety of robotic applications.

1-2

i4L Robots User's Manual (I658)

Page 31

1-2

Outer Link

Inner Link

Base

Wall Mount Flange

Table Mount Flange

Quill

Tool Flange

Flyover

1 Overview

Robot Features

This section provides information about the hardware features of the i4L robot.

• The robot can be mounted on a horizontal surface (table mount) or a vertical surface (wall mount)

without the need for additional adapters or brackets.

• Cable connections can be arranged so that they exit through the mounting surface or parallel to the

mounting surface.

• A highly visible, multi-colored LED light dome provides convenient indication of the robot status.

• The multi-colored LED light dome has an integrated brake release button built-in.

• A small and compact form factor is achieved with advanced internal controls and circuitry.

• Mounting points are available on the exterior of the robot for items such as cameras and solenoid

valves.

• Pass through electrical and pneumatic ports are available from the base of the robot to the outer

link.

• Mechanical accommodations are present on the outer link cover and tool flange for user-supplied

bellows.

• The Primary Interface Panel provides a central location for all cable connections and a Secondary

Interface Panel on the outer link provides connections for end-of-arm tooling and other hardware.

• Built-in, optically isolated I/O provides 17 inputs and 12 outputs. I/O is expandable with optional I/O

Blox units.

• Work envelope limits can be adjusted with configurable hard-stop points for robot joints 1, 2, and 3.

1-2 Robot Features

1

1-2-1 Basic Robot Components

1-2-1

Basic Robot Components

The robot consists of the following components that are referred to throughout this manual. Use the

information below to identify the robot's basic components.

Mechanical Components

Use the image below to identify the robot's mechanical components.

i4L Robots User's Manual (I658)

1-3

Page 32

Joint 1

Joint 2

Joint 4

Joint 3

(Z-axis)

+

+

+

-

-

-

+

-

Primary Interface

Panel

Secondary Interface

Panel

1 Overview

Axes of Motion

Use the following diagrams to understand the robot's 4 axes of motion.

Interface Panels

Use the information below to identify the robot's interface panels and their functions.

Primary Interface Panel

The Primary Interface Panel is located on the base of the robot and provides access to the follow-

ing items.

1-4

i4L Robots User's Manual (I658)

Page 33

Control Power

Connector

High Power

Connector

XSYSTEM

Connector

XBELTIO

Connector

Reserved

for future

use

XIO

Connector

Ethernet Interface Port

Reserved for future use

Pneumatic Pass-through

Ports

USER Connector

Encoder Backup

Battery Access

USER Connector

TIO Connector

LED Indicator /

Brake Release

Pneumatic

Pass-through

Ports

1 Overview

1-2 Robot Features

1

1-2-2 Front Panel

1-2-2

i4L Robots User's Manual (I658)

Secondary Interface Panel

The Secondary Interface Panel is located on top of the outer link and provides access to the follow-

ing items.

Front Panel

The Front Panel is a device that provides remote control and status functions when mounted a safe

distance outside of the robot workspace. The Front Panel provides the following functions.

• Setting the robot mode to Manual or Automatic mode. Refer to 4-2 Robot Control Modes on page

4-3 for more information.

• Indicating the robot High Power and Control Power state.

• Enabling robot High Power. Refer to 4-3-1 Enabling Robot High Power on page 4-5 for more in-

formation.

• Activating an emergency stop and disabling robot High Power.

If Front Panel signals need to be relocated, refer to XFP Wiring Diagram on page 3-24 for internal

circuit details.

1-5

Page 34

Control Power

LED Indicator

Mode Selection

Switch

High Power

Enable Button

Emergency

Stop Button

High Power

Indicator

1 Overview

Precautions for Safe Use

If the supplied Front Panel is not used, a High Power indicator light must be present in the system. This indicator light must be amber in color. It must be either mounted to the robot or integrated into the work cell where it is visible from all approaches or entry points.

Precautions for Correct Use

• Either a Front Panel or equivalent circuits are required to enable High Power to the robot. Refer to XFP Wiring Diagram on page 3-24 for more information.

• If the Front Panel High Power ON / OFF indicator fails, you might incorrectly assume that

High Power is OFF, and the robot is safe. To prevent this, a failed indicator causes an error

(-924) *Front panel HIGH POWER lamp failure* and locks out the High Power enabling until

you replace the indicator. Refer to the XeV+ Language Reference Guide (Cat. No. I605) for

more information about error handling. Refer to High Power Indicator Check Procedure on

page 3-32 for information about High Power indicator operation verification.

Additional Information

• The Front Panel is supplied with an extension cable that must be used to connect it to the

XFP connector on the XSYSTEM cable. Refer to 3-8-1 Installing the Front Panel on page

3-20 for more information.

• Design of the factory-supplied Front Panel E-Stop is in accordance with the requirements of

IEC 60204-1 and ISO 13849.

WARNING

• If you supply your own Front Panel, its design must comply with the requirements of

IEC 60204-1 and ISO 13849. The E-Stop's push button must comply with ISO

13850 (Clause 5.5.2).

• If an operator is going to be in the work cell with the switch in Manual mode, the

operator must carry an enabling device such as the T20 pendant.

• Whenever possible, perform Manual mode operations with all personnel outside the

workspace.

• Disabling the High Power button violates IEC 60204-1. Do not alter its functionality.

• In Automatic mode, the robot can move unexpectedly. Ensure all personnel remain

clear of the cell when Automatic mode is enabled.

1-6

Use the information in the table below to understand Front Panel item details.

Item

Control Power LED Indicator Provides an indication that the robot is receiving 24 VDC Control Power

Description

with a green LED.

i4L Robots User's Manual (I658)

Page 35

1 Overview

1-2-3

Item Description

Mode Selection Switch Controls the robot's operating mode. The left position selects Manual

mode. The right position selects Automatic mode.

Refer to 4-2 Robot Control Modes on page 4-3 for more information.

High Power Indicator Provides an indication of the robot's High Power state with an amber

LED.

Refer to 4-3 Enabling and Disabling the Robot on page 4-5 for more

information.

High Power Enable Button Button to request robot High Power.

Emergency Stop Button

*1. This switch is a dual-channel, passive E-stop device that supports Category 3 CE safety requirements.

*1

Button for emergency stopping of the robot.

Connectors

This section describes all connectors on the robot.

USER Connectors

The USER connectors provide pass-through electrical signals from the Primary Interface Panel to the

Secondary Interface Panel.

Pass-through electrical signals are typically used for end-of-arm tooling sensing and control.

All USER connector pin associations between the Primary Interface Panel and the Secondary Inter-

face Panel are one-to-one. For example, pins 1 through pins 15 of the USER connector on the Pri-

mary Interface Panel are directly connected to pins 1 through 15 of the USER connector on the Sec-

ondary Interface Panel.

1-2 Robot Features

1

1-2-3 Connectors

CAUTION

All signals that pass-through the USER connectors are not associated with any robot

controls, emergency stop circuits, or robot power. Implement appropriate safety measures to ensure these signals are not active during emergency stop conditions or while

the robot is powered OFF.

Additional Information

Refer to 2-5-1 Connector and Port Specifications on page 2-15 for more information about the

USER connector signal specifications.

Control Power Connector

The Control Power connector is used to supply 24 VDC to the robot logic circuits. When power is sup-

plied to this connector, the robot will boot up and control functions such as programming and configu-

ration are possible.

A mating connector is supplied with the robot.

Additional Information

Control power is user-supplied. Refer to 2-3-1 Power Supply Specifications on page 2-12 for

information about Control Power specifications. Refer to 3-9-2 24 VDC Connections on page

3-29 for information about Control Power wiring.

i4L Robots User's Manual (I658)

1-7

Page 36

1 Overview

High Power Connector

The High Power connector is used to supply 48 VDC to the internal servo amplifiers.

When power is supplied to this connector and High Power has been enabled, the robot is ready to

move.

A mating connector is supplied with the robot.

Precautions for Correct Use

Robot motion is not possible until High Power is supplied and has been enabled. Refer to

4-3 Enabling and Disabling the Robot on page 4-5 for more information.

Additional Information

High Power is user-supplied. Refer to 2-3-1 Power Supply Specifications on page 2-12 for information about High Power specifications. Refer to 3-9-3 48 VDC Connections on page 3-29

for information about High Power wiring.

Precautions for Correct Use

Control Power must be present before High Power can be enabled.

XSYSTEM Connector

The XSYSTEM connector provides connections to external equipment such as a Front Panel, Teach

Pendant, and user-supplied safety devices.

The robot is supplied with an XSYSTEM cable and jumper plugs. This cable provides connections for

a Front Panel, Teach Pendant, and other user-supplied safety devices.

• The part number for the XSYSTEM cable is 13322-000.

• The length of this cable is 1.8 m.

Additional Information

Refer to 3-6-1 System Cable Overview on page 3-10 for more information.

XBELTIO Connector

The XBELTIO connector provides access to the following signals.

• Belt encoder inputs 1 and 2

• Expansion I/O

• Force sensor

• RS-232

1-8

Additional Information

Refer to Optional Connections on page 3-11 for more information.

i4L Robots User's Manual (I658)

Page 37

1 Overview

XIO Connector

The XIO connector provides access to built-in I/O of the robot (12 inputs, 8 outputs).

Additional Information

Refer to the 3-7-1 XIO Connector Signals and Wiring on page 3-13 for more information about

XIO connector wiring.

Ethernet Interface Port

The Ethernet interface port provides communications for programming and configuration. It also pro-

vides communications for runtime operation when an IPC Application Controller is present in the sys-

tem.

1-2 Robot Features

1

1-2-3 Connectors

Pneumatic Pass-through Ports

The pneumatic pass-through ports provide pass-through air lines from the Primary Interface Panel to

the Secondary Interface Panel.

Pneumatic pass-through ports are typically used for end-of-arm tooling control.

TIO Connector

The TIO connector provides 5 digital inputs and 4 digital outputs for use with end-of-arm tooling.

These signals are fully programmable for integration with robot motion, part sensing, and other robot

functions.

Additional Information

Refer to 3-7-2 TIO Connector Signals and Wiring on page 3-17 for more information.

i4L Robots User's Manual (I658)

1-9

Page 38

1 2

3

4

5

6

1 Overview

1-3

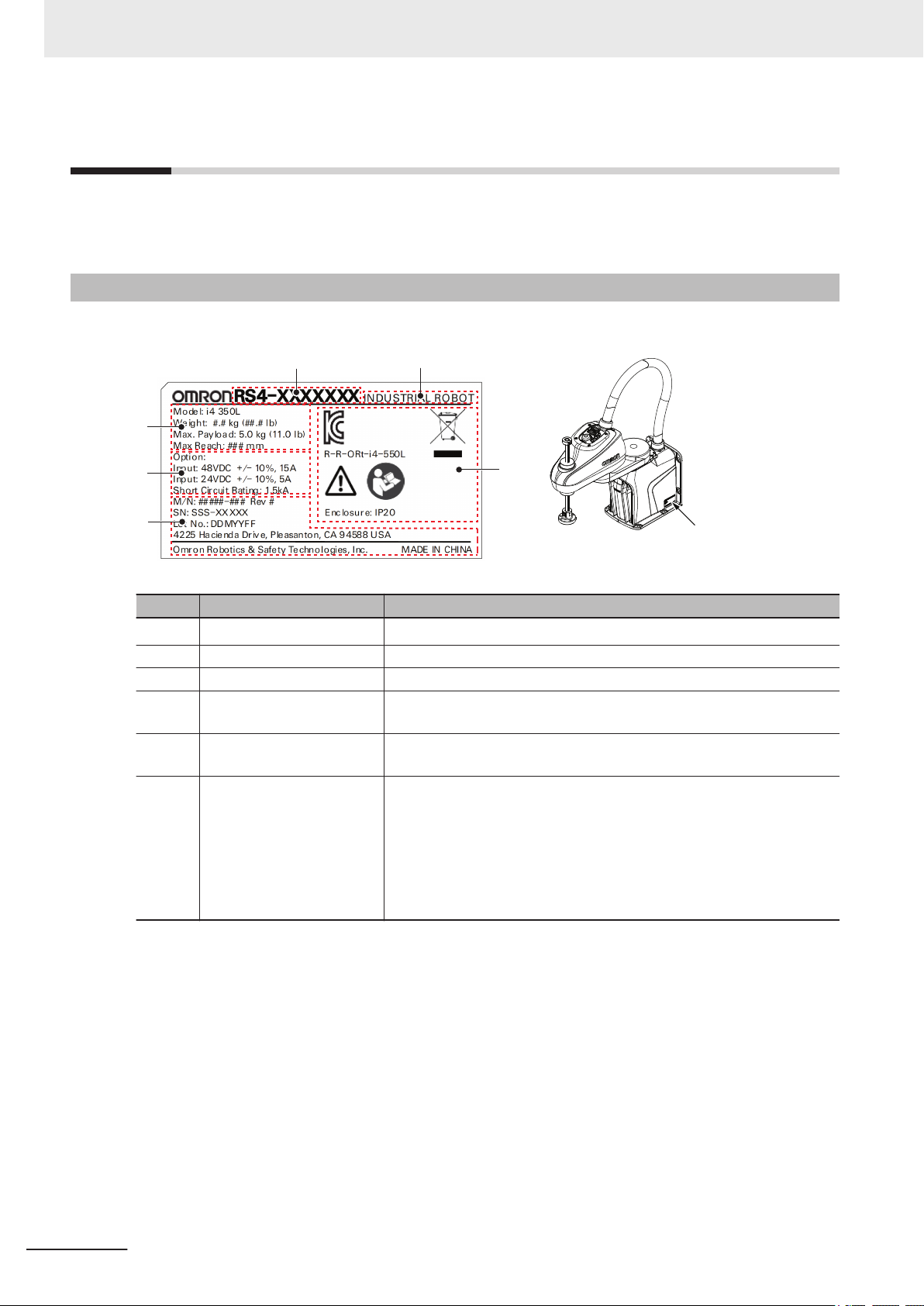

1-3-1

Information Labels

The information labels contain relevant information about the robot and the controller.

The following examples will be different from your product label.

Robot Label

The robot label is described below.

Item Name Description

1

2 Product type The product type is displayed.

3 Alerts and compliance General alerts and compliance information is displayed.

4 Robot information The robot model, weight, maximum payload, and maximum reach is

5 Electrical information General electrical power supply information about the robot is dis-

6 Production information The following information is provided.

*1. Refer to 1-5 Model Numbers on page 1-14 for model information.

Part number

*1

The robot part number is displayed.

displayed.

played.

• M/N indicates the model number and revision level.

• SN indicates the serial number.

• Lot. No. indicates the lot number in the format of DDMYYFF. Month

number 1 to 9 for January to September, X for October, Y for November, and Z for December. FF is reserved for internal use.

• Product origin information is displayed.

1-10

i4L Robots User's Manual (I658)

Page 39

1-3-2

1 2

3

4

5

6

1 Overview

Controller Label

The controller label is described below.

Item Name Description

1

2 Product type The product type is displayed.

3 Alerts and compliance General alerts and compliance information is displayed.

4 Controller information The controller model and general electrical power supply information is

5 MAC Address Reserved for future use.

6 Production information The following information is provided.

*1. Refer to 1-5 Model Numbers on page 1-14 for model information.

Part number

*1

The controller part number is displayed.

displayed.

• SN indicates the serial number.

• Lot. No. indicates the lot number in the format of DDMYYFF. Month

number 1 to 9 for January to September, X for October, Y for November, and Z for December. FF is reserved for internal use.

• Product origin information is displayed.

1-3 Information Labels

1

1-3-2 Controller Label

i4L Robots User's Manual (I658)

1-11

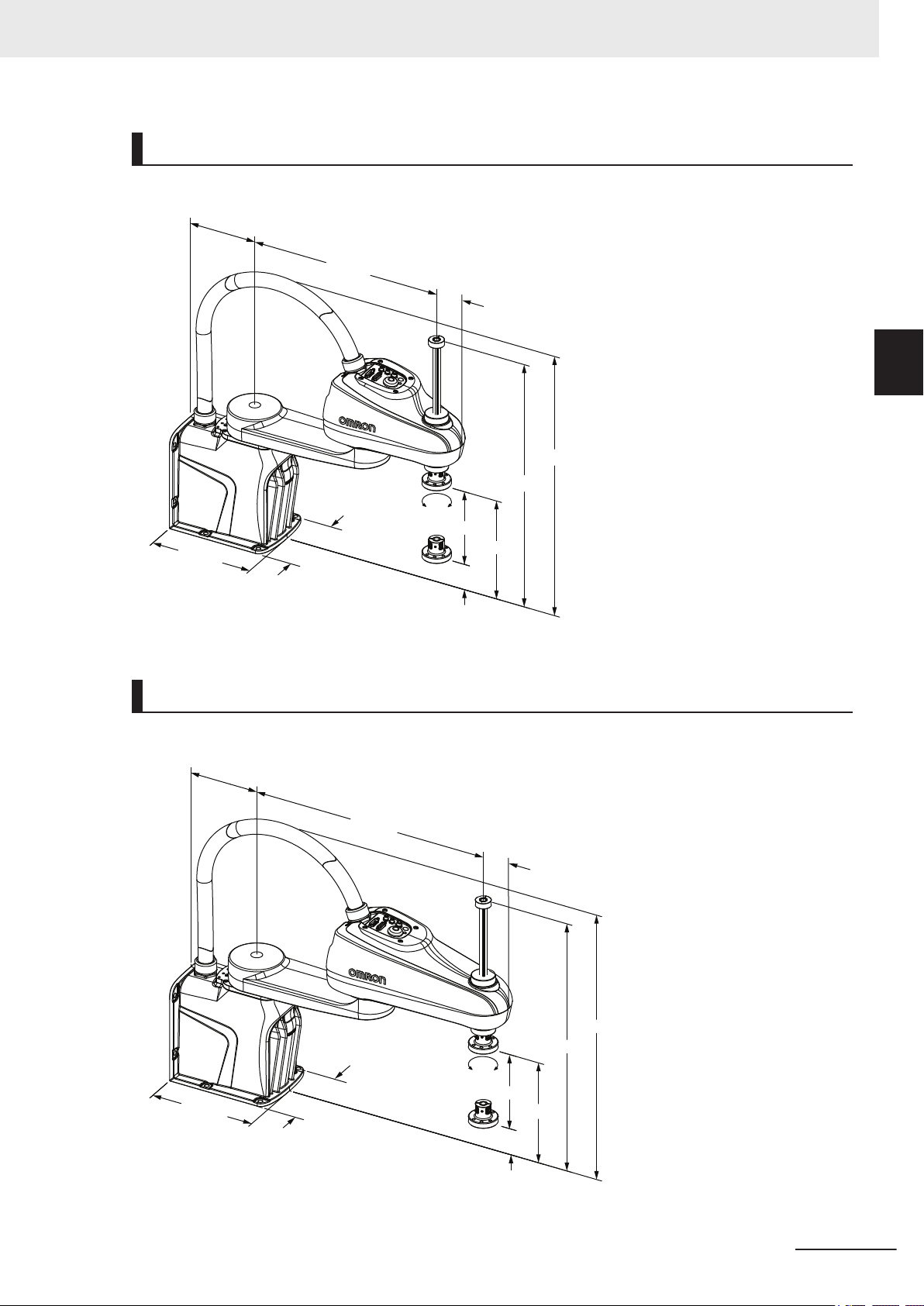

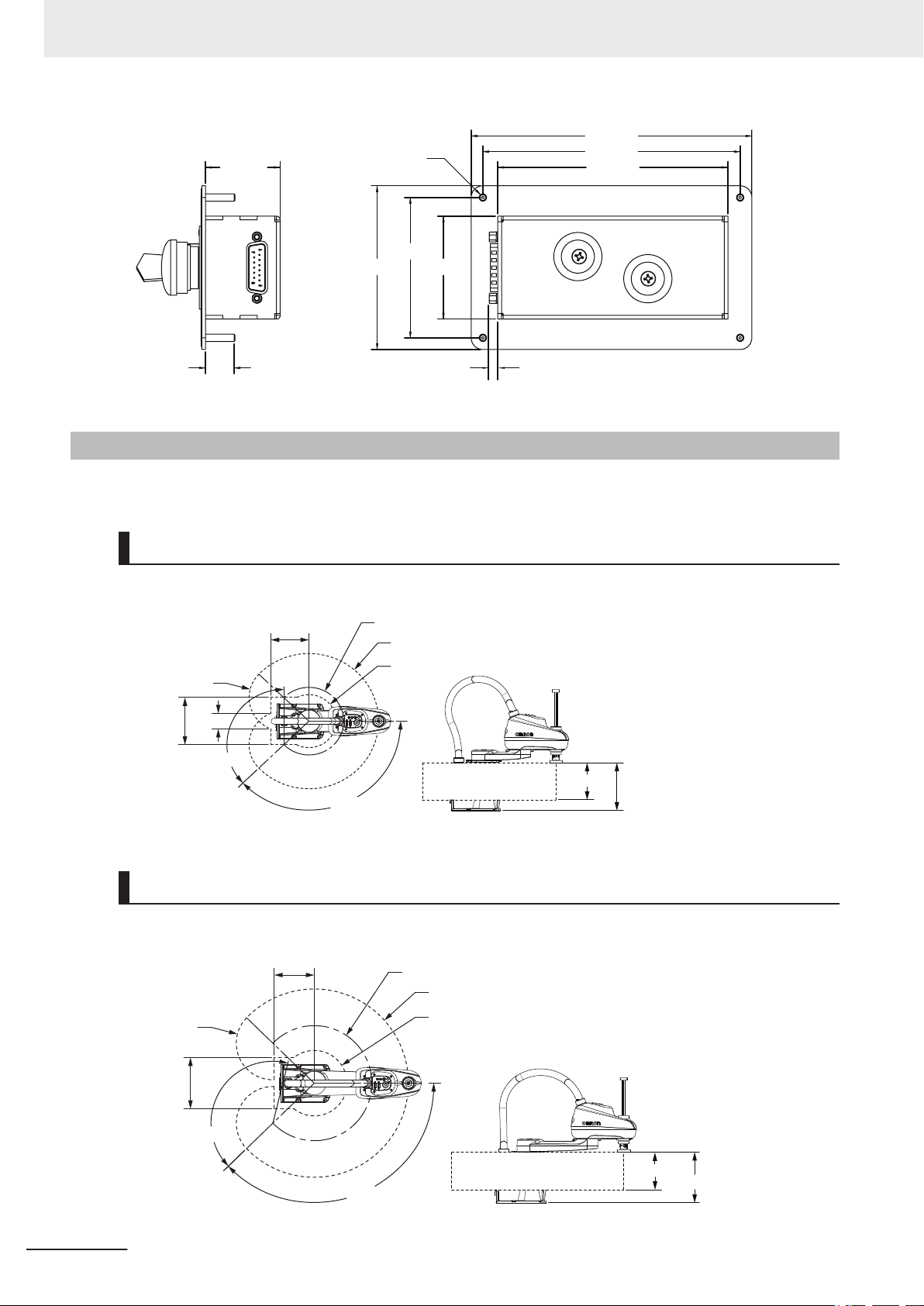

Page 40

180 mm

350 mm

180 mm

450 mm

180 mm

550 mm

1 Overview

1-4

1-4-1

1-4-2

Robot Configurations

The i4L robot is offered in a variety of configurations with different work envelopes and z-axis stroke

lengths.

i4-350L

The i4-350L configuration has a reach of 350 mm and a z-axis stroke of 180 mm.

i4-450L

1-4-3

The i4-450L configuration has a reach of 450 mm and a z-axis stroke of 180 mm.

i4-550L

The i4-550L configuration has a reach of 550 mm and a z-axis stroke of 180 mm.

1-12

i4L Robots User's Manual (I658)

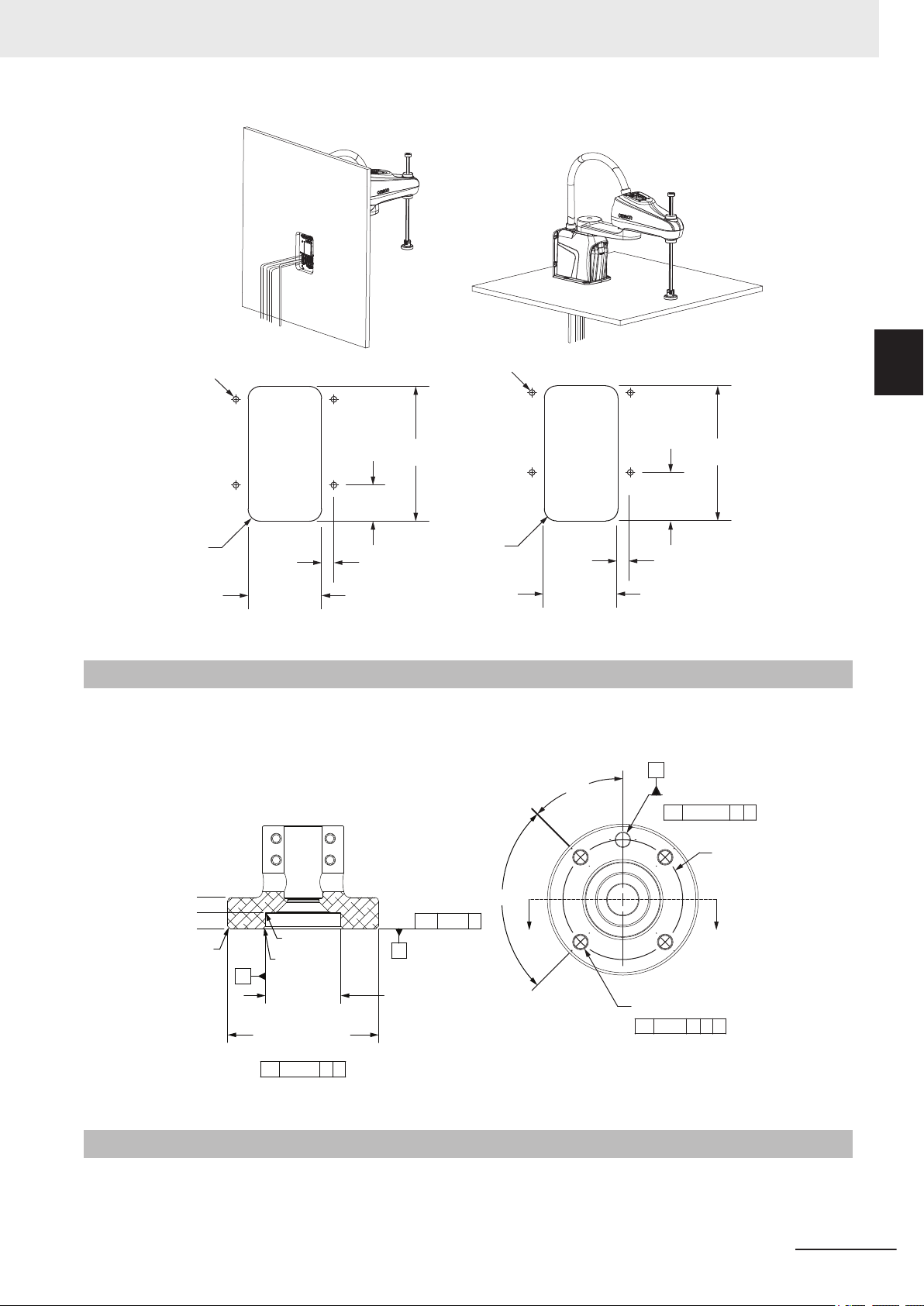

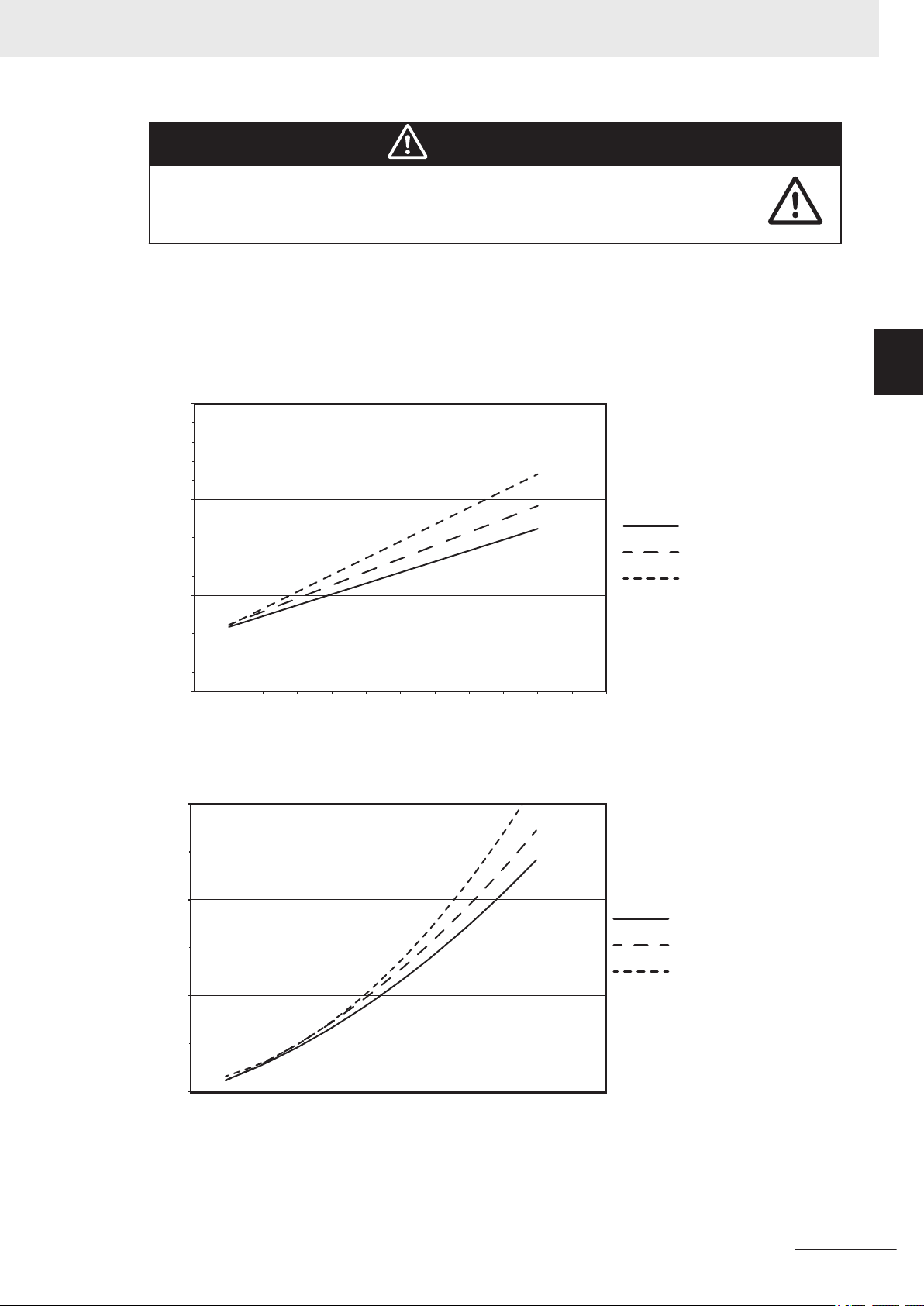

Page 41

350 mm

550 mm

1 Overview

1-4 Robot Configurations

1-4-4

1-4-5

i4-550L (350 mm Z)

The i4-550L (350 mm Z) configuration has a reach of 550 mm and a z-axis stroke of 350 mm.

1

1-4-4 i4-550L (350 mm Z)

Mounting and Cabling Options