Page 1

Motor Timer H2C 1

Motor Timer

H2C

Please read and understand this catalog before purchasing the

products. Please consult your OMRON representative if you have any

questions or comments. Refer to Warranty and Application

Considerations (page 12), and Safety Precautions (page 10).

DIN-sized (48 x 48, 45 x 75 mm) Motor Timer

with Variable Time Ranges

• Five time ranges are selectable per timer unit.

• Easy-to-monitor neon lamp for timing operation indication (for

110, 120, 220, 240 VAC types only).

• Easy-to-set large transparent knob and easy-to-read single pattern scale facilitate time setting.

• Equipped with timing operation indicator and moving pointer.

• Conforms to EN61812-1 and IEC60664-1 4 kV/1 for Low Voltage, and EMC Directives (except for H2C-F@).

Model Number Structure

■ Model Number Legend

1. External Connection/Attachment

None: 11-pin socket

S: 11-pin socket/time setting ring

8: 8-pin socket

F: Front screw

2. Operation/Resetting System

None: Time-limit operation/self-resetting

R: Time-limit operation/electric resetting

Ordering Information

■ List of Models

12

H2C-@ @

Operation/resetting

system

Internal

connection

Terminal Time-limit

contact

Instantaneous

contact

Attachment Model

Time-limit operation/

self-resetting

Parallel motor and

clutch connection

8-pin socket SPDT SPDT --- H2C-8

Separate motor

and clutch connection

11-pin socket H2C

Y92A-Y1 Time Setting Ring

H2C-S

Front screw --- H2C-F

Time-limit operation/

electric resetting

8-pin socket SPDT --- --- H2C-8R

11-pin socket SPDT H2C-R

Y92A-Y1 Time Setting Ring

H2C-SR

Front screw --- H2C-FR

Note: Specify both the supply voltage and time range code (A, B, or C) in addition to the model number when ordering.

Example: H2C-S 24 VAC B

Time range code

Su

pply

voltage

Page 2

2 Motor Timer H2C

■ Accessories (Order Separately)

Note: 1. Supplied with H2C-S/-SR models.

2. Y92A-48G is a finger safe terminal cover which is attached to the P3G-08 or P3GA-11 Socket.

3. Hold-down Clips are sold in sets of two.

Specifications

■ Time Ranges

Five time ranges are available for each timer by turning the time range selector every 60 degrees.

Note: Rated time is displayed on the window.

■ Ratings

Note: The front panel of the timer is color coded to identify the following supply voltage classifications:

100 to 120 V: Blue

200 to 240 V: Red

Other classes: Black

Name/specifications Models

Flush Mounting Adapter Y92F-30

Time Setting Ring (See note 1.) Y92A-Y1

Mounting Track 50 cm (l)

´ 7.3 mm (t) PFP-50N

1 m (l)

´ 7.3 mm (t) PFP-100N

1 m (l)

´ 16 mm (t) PFP-100N2

End Plate PFP-M

Spacer PFP-S

Protective Cover Y92A-48B

Track Mounting/Front Connecting

Socket

8-pin P2CF-08

8-pin, finger safe type P2CF-08-E

11-pin P2CF-11

11-pin, finger safe type P2CF-11-E

Back Connecting Socket 8-pin, screw terminal P3G-08

8-pin, finger safe type P3G-08 with Y92A-48G (See note 2.)

11-pin P3GA-11

11-pin, finger safe type P3GA-11 with Y92A-48G (See note 2.)

Hold-down Clip (See note 3.) For PL08 and PL11 Sockets Y92H-1

For PF085A Socket Y92H-2

Time range code Position of time range selector

A 1.25 to 30 s 7.5 s to 3 min 1.25 to 30 min 7.5 min to 3 h 1.25 to 30 h

B 0.2 to 6 s 2 to 60 s 0.2 to 6 min 2 to 60 min 0.2 to 6 h

C 0.5 to 12 s 5 to 120 s 0.5 to 12 min 5 to 120 min 0.5 to 12 h

Item H2C

Rated supply voltage (motor and

clutch)

24, 48, 100, 110, 115, 120, 200, 220, or 240 VAC (50/60 Hz) (see note)

Operating voltage range 85% to 110% of rated supply voltage

Power consumption 4.2 VA max. (3.96 W max.)

Reset voltage 10% max. of rated supply voltage

Reset time Minimum power-opening time: 0.5 s

Minimum pulse width: 0.5 s

Control outputs 6 A at 250 VAC, resistive load (cos

φ = 1)

Mounting method Flush mounting (except for H2C-F/-FR models), surface mounting, DIN track mounting

Page 3

Motor Timer H2C 3

■ Characteristics

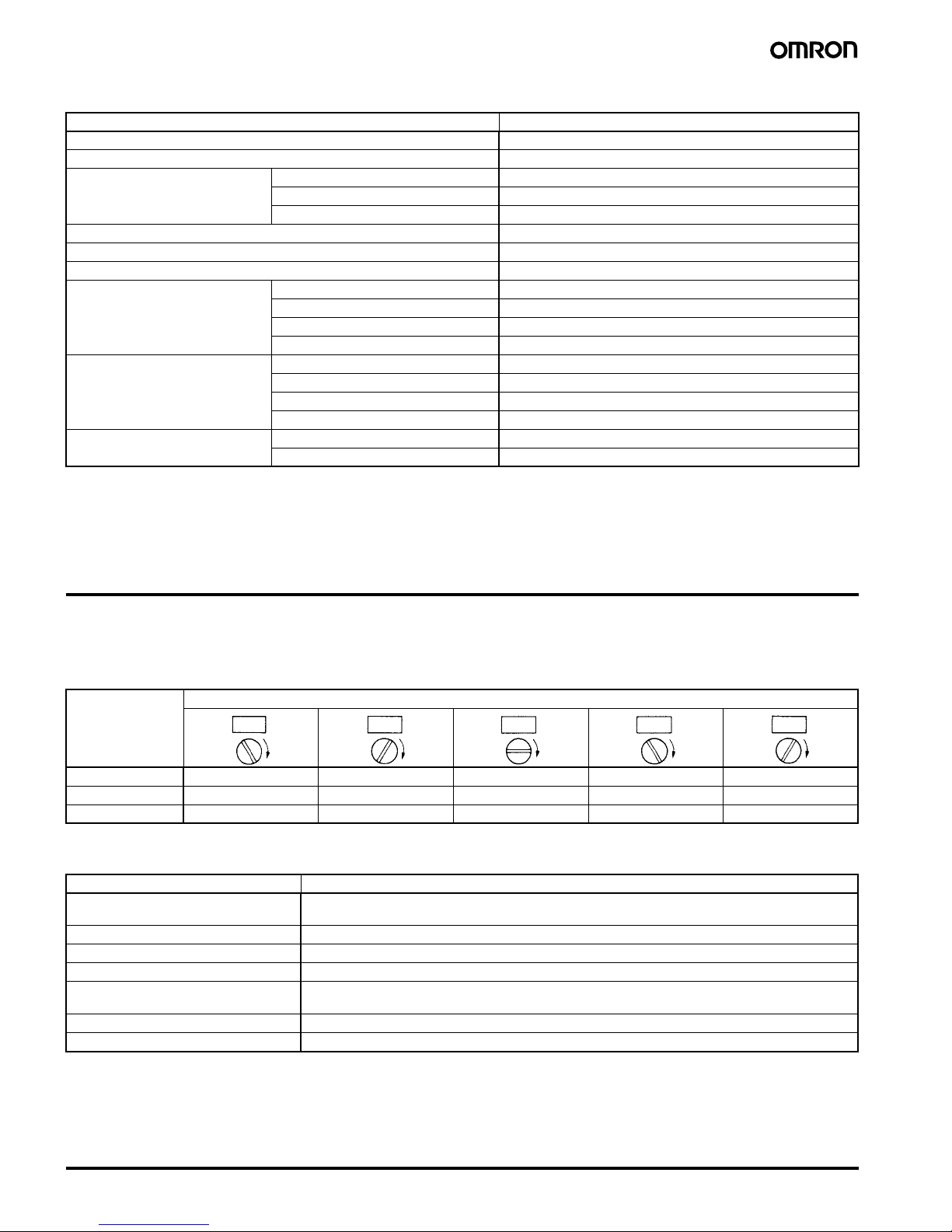

■ Life-test Curve

Accuracy of operating time ±0.5% FS max. á±1% max. at 0.2 to 6 s for the time range code B or at 0.5 to 12 s for the time range

code C)

Setting error

±2% FS max.

Reset time 0.5 s max.

Influence of voltage

±1% FS max.

Influence of temperature

±2% FS max.

Insulation resistance 100 M

Ω min. (at 500 VDC)

Dielectric strength 2,500 VAC, 50/60 Hz for 1 min (between current-carrying and non-current-carrying parts)

2,000 VAC, 50/60 Hz for 1 min (between contact and control circuit and between contacts of different

polarities)

1,000 VAC, 50/60 Hz for 1 min (between non-continuous contacts)

Vibration resistance Destruction: 10 to 55 Hz with 0.375-mm single amplitude for 1 h each in three directions

Malfunction: 10 to 55 Hz with 0.25-mm single amplitude for 10 min each in three directions

Shock resistance

Destruction: 1,000 m/s

2

Malfunction: 150 m/s

2

Ambient temperature Operating: –10°C to 50°C

Storage: –25

°C to 65°C

Ambient humidity Operating: 45% to 85%

Life expectancy Mechanical: 10,000,000 operations min. (under no load at 1,800 operations/h)

Electrical: 500,000 operations min. (3 A at 250 VAC, resistive load at 1,800 operations/h)

See Life-test Curve for other details.

Motor life expectancy 20,000 h

Approved standards UL917, CSA C22.2 No.14.

Conforms to EN61812-1 and IEC60664-1 4 kV/1 (except for H2C-F@ models).

Output category according to EN60947-5-1 (except for H2C-F@ models).

EMC (except for H2C-F@ models) (EMI) EN61812-1

Emission Enclosure: EN55011 Group 1 class A

Emission AC Mains: EN55011 Group 1 class A

(EMS) EN61812-1

Immunity ESD: IEC61000-4-2: 6 kV contact discharge (level 3)

8 kV air discharge (level 3)

Immunity RF-interference from AM Radio Waves: IEC61000-4-3: 10 V/m (80 MHz to 1 GHz) (level 3)

Immunity Burst: IEC61000-4-4: 2 kV power-line (level 3)

2 kV I/O signal-line (level 4)

Immunity Surge: IEC61000-4-5: 1 kV line to line (level 3)

2 kV line to ground (level 3)

Case color Light gray (Munsell 5Y7/1)

Degree of protection IP40 (panel surface)

Weight H2C series: approx. 180 g

H2C-F series: approx. 270 g

300

200

100

50

40

30

20

10

5

1234 56

300

200

100

50

40

30

20

10

5

123456

Switching operations (x 10

4

)

Load current (A

)

Switching operations (x 10

4

)

Load current (A

)

250 VAC cosφ = 1

24 VDC cosφ = 1

250 VAC cosφ = 0.4

24 VDC L/R = 7 msec

Page 4

4 Motor Timer H2C

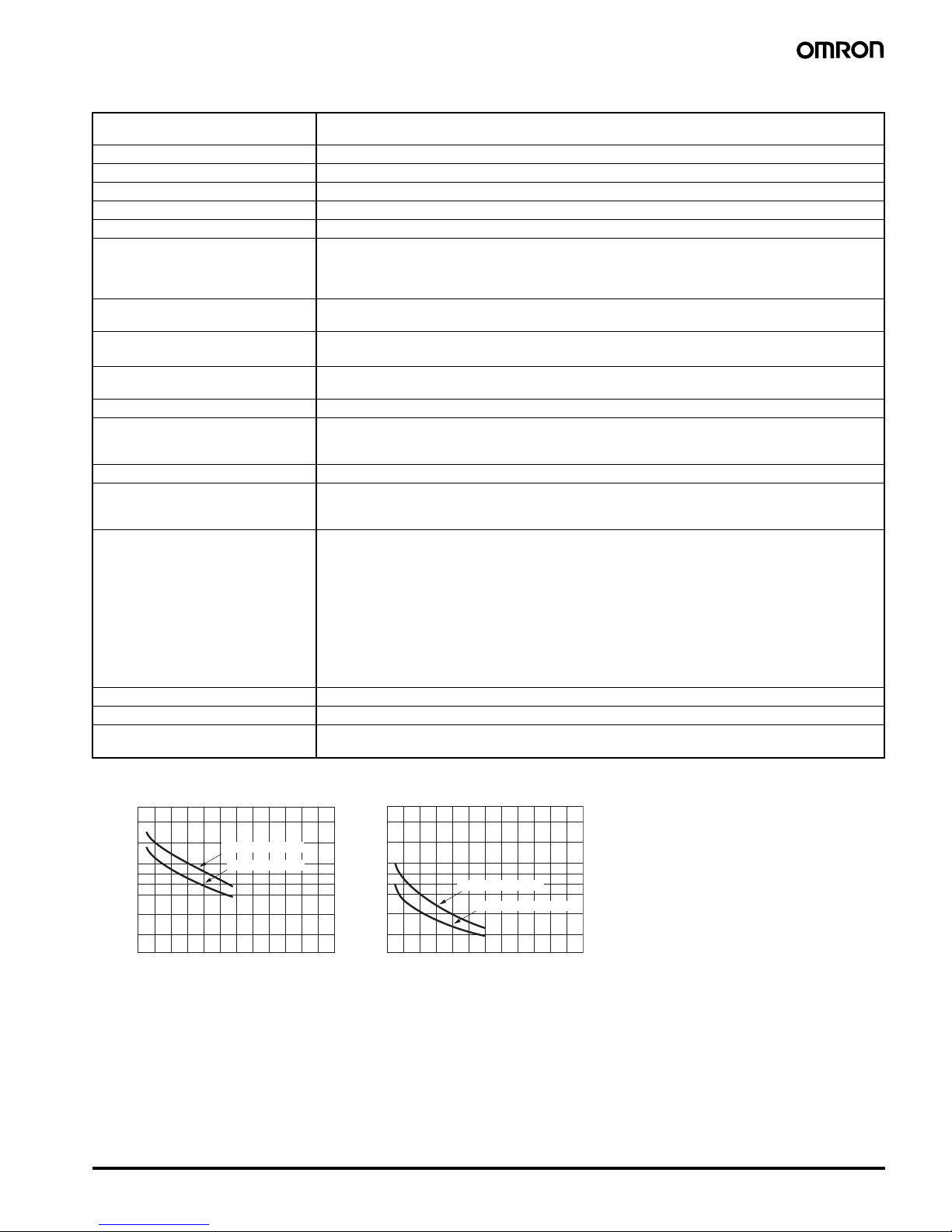

Connections

■ Terminal Arrangement

Note: The connections diagrams are for when the clutch is in the excited, reset state.

H2C-8

H2C(-F)/H2C-S H2C-(F)R/H2C-SR

H2C-8R

(B2)

(B1)

(22)

(24)

(A2)

(21)

(15)

(A1)

(18)

(16)

(B2)

(B1)

(22)

(24)

(A2)

(21)

(15)

(A1)

(18)

(16)

6

7

8

9

10

11

1

2

3

4

5

(B2)

(B1)

(22)

(24)

(A2)

(21)

(15)

(A1)

(18)

(16)

6

7

8

9

10

11

1

2

3

4

5

Clutch coil

(DIN 46 199-5)

Clutch coil

(DIN 46 199-5)

Page 5

Motor Timer H2C 5

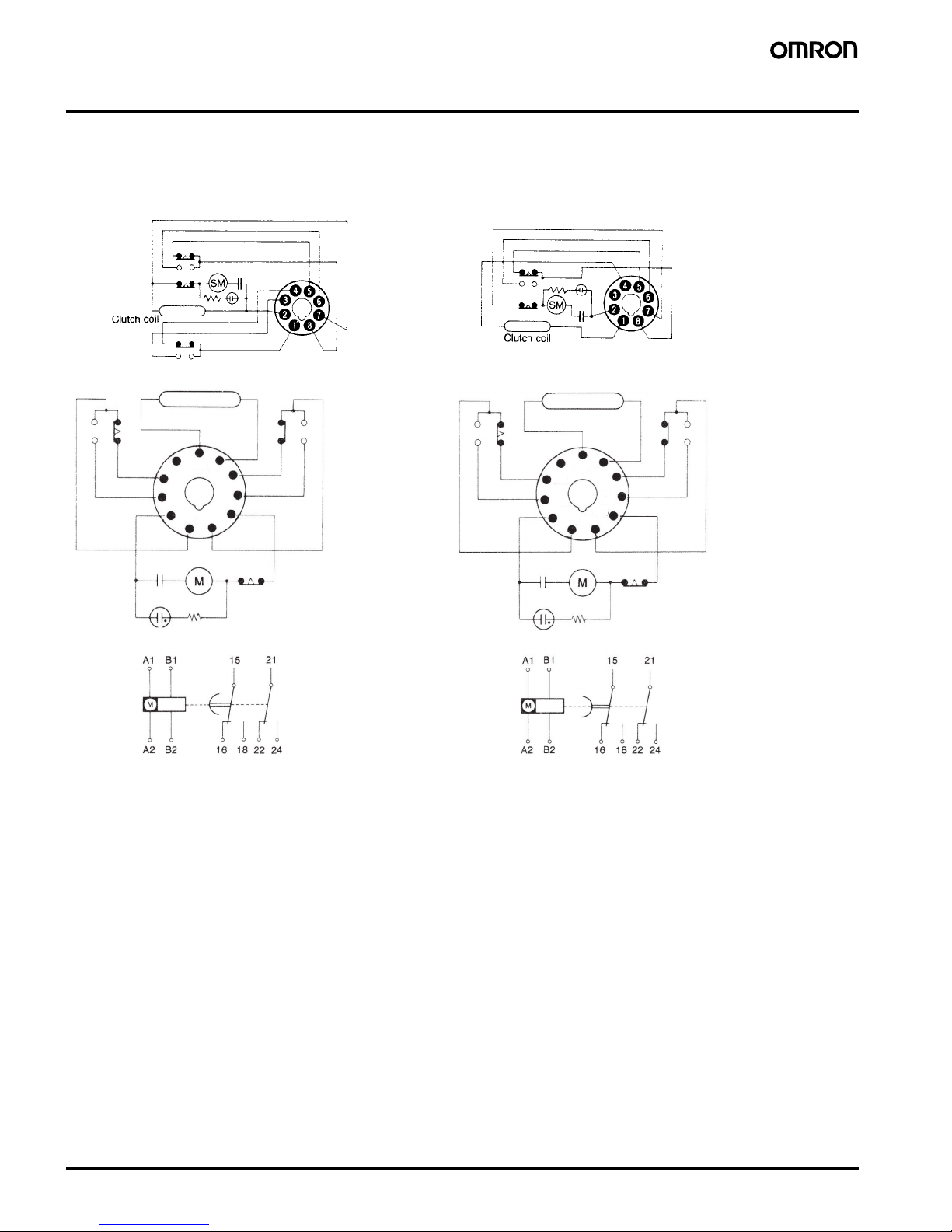

Operation

■ Timing Chart

Nomenclature

ttRt

Rt

t

Rt

Rt Rt

t+t'

t

Rt

tRt

t

Rt

Rt

Rt

t+t'

H2C(-F)/H2C-S H2C-(F)R/H2C-SR

Rt: Resetting time

Note: For the types rated at 24 and 48 VAC, the timing operation indicator is not equipped.

Rt: Resetting time

H2C-8RH2C-8

Power (2-7)

Instantaneous contacts

NC (1-4)

Instantaneous contacts

NO (1-3)

Timing operation indicator

lamp (OFF at time-up)

Power and motor (2-7)

Power and clutch (1-4)

Timing operation indicator

lamp (OFF at time-up)

Power failure

time (t')

Rt: Resetting time

Instantaneous contacts

NC 11(21)-8(22)

Instantaneous contacts

NO 11(21)-9(24)

Timing operation indicator

lamp (OFF at time-up)

(See note.)

Instantaneous contacts

NC 11(21)-8(22)

Instantaneous contacts

NO 11(21)-9(24)

Timing operation indicator

lamp (OFF at time-up)

(See note.)

Power failure

time (t')

Rt: Resetting tim

e

Time-limit contacts

NC (8-5)

Time-limit contacts

NO (8-6)

Time-limit contacts

NC 1(15)-4(16)

Time-limit contacts

NO 1(15)-3(18)

Time-limit contacts

NC (8-5)

Time-limit contacts

NO (8-6)

Time-limit contacts

NC 1(15)-4(16)

Time-limit contacts

NO 1(15)-3(18)

Power and motor

2(A1)-10(A2)

Power and clutch

7(B1)-6(B2)

Power and motor

2(A1)-10(A2)

Power and clutch

7(B1)-6(B2)

Timing operation

indicator

Time range

selector

Rated voltage

color code

Page 6

6 Motor Timer H2C

Dimensions

Note: All units are in millimeters unless otherwise indicated.

44.8 x 44.8

45

+0.6

−0

45

+0.6

−0

H2C/H2C-S/H2C-R/H2C-SR/H2C-8/H2C-8R

H2C-F/H2C-FR

For Flush Mounting

Mounting Holes

For a load current of 3 A max., dimension L becomes

3 mm min. with an interval of 0 mm between timers.

For a load current of 6 A max., dimension L becomes

8 mm min. with an interval of 5 mm between timers.

When using in locations with high ambient

temperatures, ensure that there is an interval of at

least 5 mm between timers.

For a load current of 1 A max., dimension L becomes

10 mm min. with an interval of 0 mm between timers.

For a load current of 3 A max., dimension L becomes

15 mm min. with an interval of 5 mm between timers.

For a load current of 6 A max., dimension L becomes

20 mm min. with an interval of 10 mm between timers.

Two, M4 or 4.5 dia. holes

37 dia.

100.8

*

103.1

*

80

16.3

16.3

85.7

81.5

92.2

H2C-8

H2C-8R

*These dimensions vary with the kind of DIN track (reference value).

Y92F-30

P3GA-11

Y92F-30

P3G-08

H2C

H2C-S

H2C-R

H2C-SR

P2CF-11

P2CF-11-E

P2CF-08

P2CF-08-E

H2C

H2C-S

H2C-R

H2C-SR

+

Adapter

(When

Y92A-48G

mounted)

H2C-8

H2C-8R

+

Adapter

(When

Y92A-48G

mounted)

Dimensions with Front Connecting Socket

P2CF-08-@/P2CF-11-@

Dimensions with Back Connecting Socket

P3G-08/P3GA-11

Page 7

Motor Timer H2C 7

■ Accessories (Order Separately)

Adapter for Flush Mounting

Y92F-30

Track Mounting/Front Connecting Socket

7.8

34.5

35.4

4

40±0.2

40±0.2

7.8

4

35.4

20.3

19

3

1.3

54.5

70 max.

50 max.

20.3 max.

P2CF-08-E (Finger Safe Terminal Type)

Conforming to VDE0106/P100

Surface Mounting Holes

Two, 4.5 dia. or two, M4

50 max.

70 max.

21.5 max.

P2CF-08

Eight,

M3.5 x 7.5 sems

Two, 4.5 dia.

holes

Terminal Arrangement/

Internal Connections

(Top View)

Two, 4.5 dia.

holes

Eight,

M3.5 x 7.5 sems

Page 8

8 Motor Timer H2C

Track Mounting/Front Connecting Socket

Back Connecting Socket

40±0.2

7.8

34.5

35.4

4

7.8

4

40±0.2

35.4

30

54.5

3

1.2

Surface Mounting Holes

Two, 4.5 dia. or two, M4

70 max.

50 max.

31.2 max.

P2CF-11-E (Finger Safe Terminal Type)

Conforming to VDE0106/P100

70 max.

50 max.

31.2 max.

P2CF-11

Eleven,

M3.5 x 7.5 sems

Terminal Arrangement/

Internal Connections

(Top View)

Two, 4.5 dia.

holes

Two, 4.5 dia.

holes

Eleven,

M3.5 x 7.5 sems

45

45

4.9

17

45

45

25.6

4.5

16.3

6.2

34

47.7 x 47.7

48 x 48

47.4

16.5

24.6

27.6

27 dia.

P3GA-11

27 dia.

Finger Safe Terminal Cover

Conforming to VDE0106/P100

Y92A-48G

Twelve, 6.4 dia. holes

P3G-08

Terminal Arrangement/

Internal Connections

(Bottom View)

Terminal Arrangement/

Internal Connections

(Bottom View)

(Attachment for P3G-08/

P3GA-11 Socket)

Page 9

Motor Timer H2C 9

Mounting Track

Timer Hold-down Clips

4.5

15 25 25 25 25

10 10

7.3±0.15

35±0.3

27±0.15

1

4.5

15 25 25 25 25 15

10 10

35±0.3

27

24

16

29.2

11.5

1,000

PFP-100N2PFP-100N, PFP-50N

1,000 (500)

(see note)

Note: The value shown in parentheses are for the

PFP-50N.

15 (5)

(see note)

50

11.5

10

6.2

1.8

1

35.5 35.3

1.8

1.3

4.8

5

16

12

44.3

34.8

16.5

10

End Plate

PFP-M

M4 x 8

pan head

screw

Spacer

PFP-S

Y92A-Y1 Y92A-48B

Time Setting Ring Protective Cover

The time setting ring locks the time setting knob to

store the set time to facilitate its resetting. A maximum

of two time setting rings are connectable per timer.

The protective cover shields the front panel, particularly the time setting section, from dust, dirt, and water,

as well as prevents the set value from being altered

due to accidental contact with the time setting knob.

Y92H-2

(for PF085A/PF113A

Connecting Socket)

Y92H-1

(for PL08/PL11

Connecting Socket)

Page 10

10 Motor Timer H2C

Safety Precautions

■ Precautions for Safe Use

Observe the following items to ensure the safe use of this product.

Environmental Precautions

• Store the H2C within the specified ratings. If the H2C has been

stored at temperatures –10

°C or lower, let it stand for 3 hours or

longer at room temperature before turning ON the power supply.

• Use the H2C within the specified ratings for operating temperature

and humidity.

• Do not operate the H2C in locations subject to sudden or extreme

changes in temperature, or locations where high humidity may

result in condensation.

• Do not use the H2C in locations subject to vibrations or shock.

Extended use in such locations may result in damage due to stress.

• Do not use the H2C in locations subject to excessive dust,

corrosive gas, or direct sunlight.

• Install the H2C well away from any sources of static electricity, such

as pipes transporting molding materials, powders, or liquids.

• The H2C is not waterproof or oil resistant.

Do not use it in locations subject to water or oil.

• The life expectancy of internal components may be reduced if the

H2C is mounted side-by-side.

• Do not use organic solvents (such as paint thinner or benzine),

strong alkaline, or strong acids because they will damage the

external finish.

Usage Precautions

• Install a switch or circuit breaker that allows the operator to

immediately turn OFF the power, and label it to clearly indicate its

function.

• Be sure to wire the terminals correctly.

• Do not install input lines in the same duct or conduit as power

supply or other high-voltage lines. Doing so may result in

malfunction due to noise. Separate the input lines from highvoltage lines.

• Internal elements may be destroyed if a voltage outside the rated

voltage is applied.

• Maintain voltage fluctuations in the power supply within the

specified range.

• Use a switch, relay, or other contact so that the rated power supply

voltage will be reached within 0.1 s. If the power supply voltage is

not reached quickly enough, the H2C may malfunction or outputs

may be unstable.

• Leaving the H2C with outputs ON at a high temperature for a long

time may hasten the degradation of internal parts (such as

electrolytic capacitors). Therefore, use the H2C in combination with

relays and avoid leaving the H2C for more than 1 month with an

output turned ON.

■ Precautions for Correct Use

How to Change the Time Range

Change the time range by turning the knob clockwise using a flatblade screwdriver or an Allen wrench. There are five possible

settings. The selected time is displayed in the time range display

window above the knob.

Do not change the time range while the timer is in operation.

How to Select Power Frequency

Before using the timer, set the frequency selector located at the rear

panel to the proper power frequency (50 to 60 Hz).

How to Mount the Timer on Mounting

Track

Mounting

First hook portion A of the timer to the mounting track, then press the

timer in direction B.

Dismounting

Pull out portion C with a round-blade screwdriver and remove the

timer from the mounting track.

Electrical Set

The motor and clutch do not need to be reset simultaneously.

Use the voltage applied to the clutch for resetting with the H2C-@R.

Do not allow power to be continuously applied to the motor and

clutch for extended periods of time.

This may occasionally cause electric shock, fire, or malfunction.

Never disassemble, repair, or modify the H2C.

This may occasionally cause electric shock, fire, or malfunction.

Do not allow metal fragments or lead wire scraps to fall inside the

H2C.

!CAUTION

X

X1T X2

X1/aX2/b T/a X1/a

Auxiliary relay

(e.g., MY Relay)

Time range

display window

Hex. hole for

Allen wrench

Groove for flatblade screwdriver

50 Hz

60 Hz

B

A

C

Page 11

Motor Timer H2C 11

Others

Do not turn the operation time setting knob beyond the range of the

scale. To achieve higher accuracy in setting, measure the operation

time while turning the operation time setting knob.

The deviation and setting error for the operation time shows the

percent of FS. The absolute value of the deviation and setting error

will not change even if the set time is changed. The time

specifications should therefore be selected to use the operation time

as close to FS as possible.

At high temperatures, the operation voltage will be 90% or less if

voltage is applied continuously after timeout. Be sure to keep the

voltage within the allowable voltage fluctuation range.

Precautions for EN61812-1

The H2C (except for H2C-F@) as a built-in timer conforms to

EN61812-1, provided that the following conditions are satisfied.

Handling

Before dismounting the H2C from the Socket, make sure that no

voltage is imposed on any terminal of the H2C.

Applicable Sockets: P2CF-@@, P2CF-@@-E, PF085A, PL@@.

Wiring

Basic insulation is ensured between the motor circuit, clutch circuit,

and control output circuit. (However, the H2C-8 motor circuit and

clutch circuit use the same input.) Basic insulation is also ensured

between the output circuits of models with instantaneous output.

Basic insulation: Overvoltage category III, pollution degree 1 (See

note.)

Operating parts: Reinforced insulation (double insulation)

(with a clearance of 5.5 mm and a creepage distance of 5.5 mm at

240 VAC)

Output parts: Basic insulation

(with a clearance of 3.0 mm and a creepage distance of 3.0 mm at

240 VAC)

Note: Overvoltage category II, pollution degree 1 if the Timer is

mounted to the PL11 Socket.

Page 12

12

Warranty and Application Considerations

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a period of one year (or

other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NON-INFRINGEMENT,

MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR USER

ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET

THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS,

OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON

CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which liability is asser ted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE

PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORED,

INSTALLED, AND MAINTAINED AND NOT SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE

MODIFICATION OR REPAIR.

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the combination of

products in the customer's application or use of the products.

Take all necessary steps to determine the suitability of the product for the systems, machines, and equipment with which it will

be used.

Know and observe all prohibitions of use applicable to this product.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY WITHOUT

ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON

PRODUCTS ARE PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR

SYSTEM.

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other reasons. Consult with

your OMRON representative at any time to confirm actual specifications of purchased product.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

In the interest of product improvement, specifications are subject to change without notice.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. L007-E1-10

OMRON Corporation

Industrial Automation Company

Industrial Devices and Components Division H.Q.

Industrial Control Components Department

Shiokoji Horikawa, Shimogyo-ku,

Kyoto, 600-8530 Japan

Tel: (81)75-344-7119/Fax: (81)75-344-7149

Printed in Japan

0804-0.5C (0696) (M)

Loading...

Loading...