Page 1

Multi-channel Power Controller

r

)

G3ZA

Optimum Cycle Control for High-precision Control

with Low Noise

• Smaller than a Normal Power Controller.

• Enables low-noise power control in combination with zero-cross SSRs.

(See note.)

• One Controller can control up to 8 SSRs.

• RS-485 communications to set manipulated variables and heater

burnout detection. The Smart FB Library for the G3ZA can also be used.

•CE Marking

Main Upgraded Functions

• Soft-start function added for lamp heaters.

• Three-phase optimum cycle control added for three-phase heaters.

Version Upgrade for Improved Functionality (V2)

• Combining with special CT for150-A current detection.

Note: The G3ZA must be used in combination with an SSR without the zero cross

function when the soft-start function is used.

Refer to Safety Precautions on page 9 for safety

information.

Features

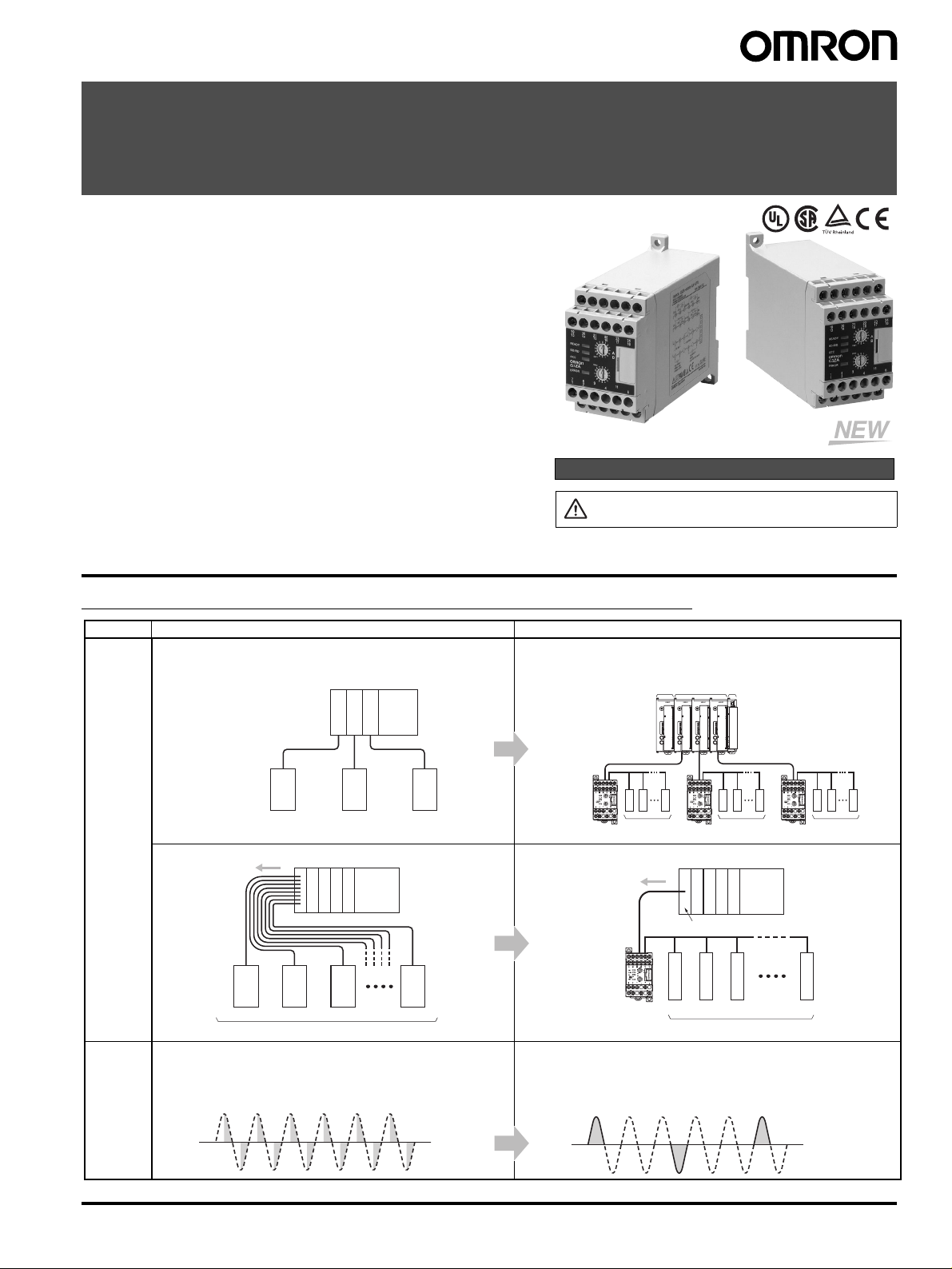

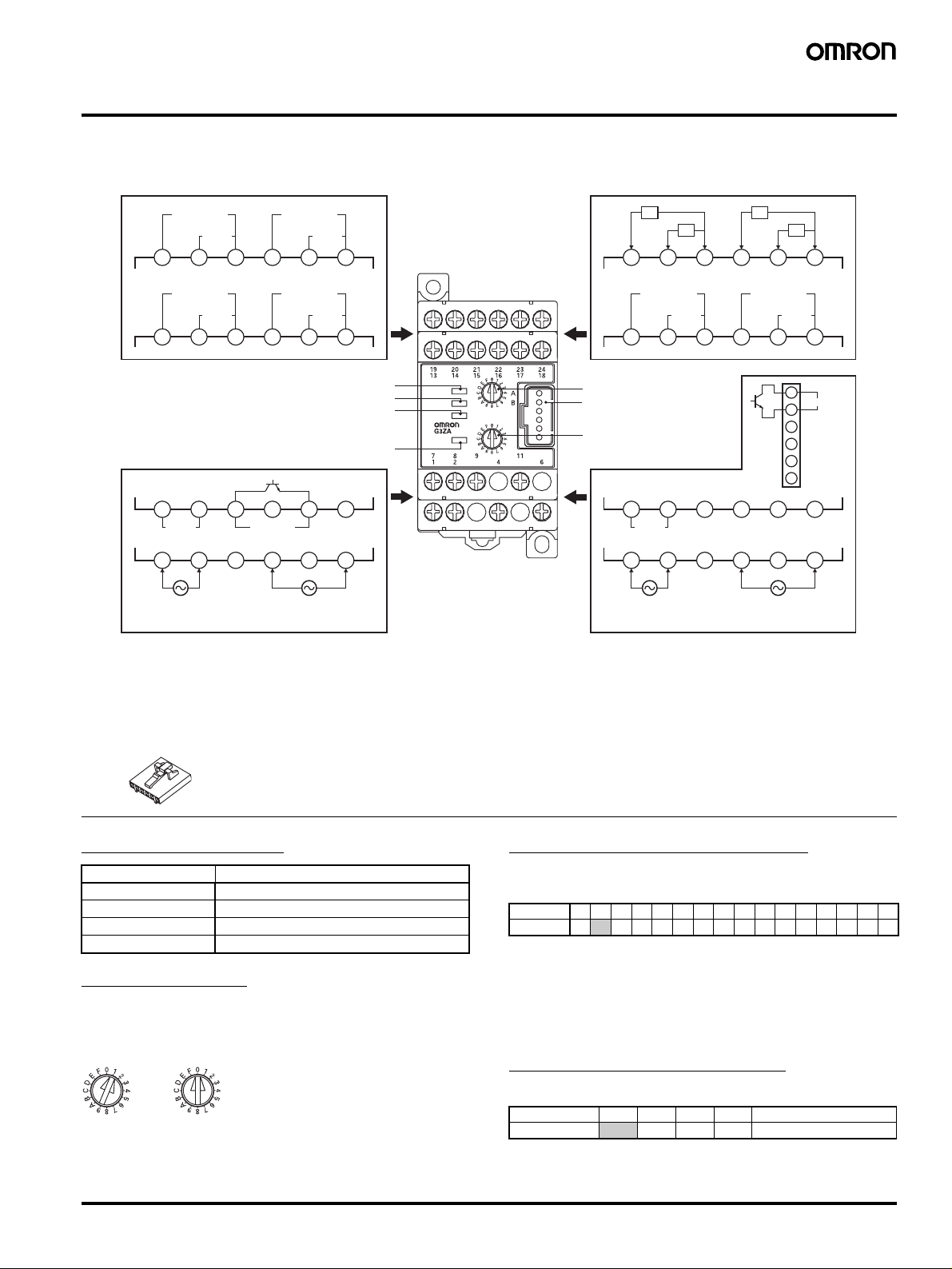

Comparison between the G3ZA and Normal Power Controllers

Item Normal Power Controllers G3ZA

Connections

Power Controllers Controlled Using Current Output of 4 to 20 mA Control Using Communications from a Host Device

Multi-channel Temperature Controller

• Direct connection is possible using an EJ1 Modular Temperature Controller.

EJ1N

EJ1N-TC4 or

-HFU

PWR

PWR

COM1

RUN

RUN

COM2

EJ1-HFU

ERR

ERR

COM3

ALM

ALM

F

E

D

D

C

C

0

B

B

1

A

A

2

9

9

3

8

8

4

7

7

5

6

SW1

Modular Temperature

Controller (EJ1)

SW1

ON

ON

21345678

21345678

SW2

SW2

EJ1N-TC2

PWR

COM1

RUN

COM2

EJ1-TC4

ERR

COM3

ALM

F

F

E

E

D

C

0

0

B

1

1

A

2

2

9

3

3

8

4

4

7

5

5

6

6

SW1

ON

21345678

SW2

®

EJ1C

-EDU

PWR

COM1

COM1

RUN

COM2

COM2

EJ1-TC4

EJ1-TC4

ERR

COM3

COM3

ALM

F

E

D

C

0

B

1

A

2

9

3

8

4

7

5

6

SW1

ON

21345678

SW2

Control

method

Power Controller

4 to 20 mA commands

Power Controller Power Controlle

Programmable Controller

Power controller Power controller Power controller Power controller

8 total

Phase Control

• Response is fast and high-precision temperature control is possible.

• Harmonics and noise are problems.

READY

SD/RD

SW1

OCC

SW2

ERROR

Eight SSRs

G3ZA

RS-485 commands

READY

SD/RD

SW1

OCC

SW2

ERROR

Eight SSRs

G3ZA

Programmable Controller

READY

SD/RD

SW1

OCC

SW2

ERROR

G3ZA

Eight SSRs

Serial Communications Unit (RS-485

G3ZA-8 SSR SSR SSR SSR

8 total

Optimum Cycle Control (High-precision Zero Cross Control)

• Outputs are turned ON and OFF each half cycle.

• Zero-cross control is performed.

• Noise is suppressed while achieving high-speed response with high-

precision temperature control.

Multi-channel Power Controller G3ZA 1

Page 2

Model Number Structure

■ Model Number Legend

G3ZA- @ @ @ @ @ - @ - @

12 34

No. Meaning Code Specifications No. Meaning Code Specifications

1 No. of control points 4 4 channels 4 Load power supply voltage 2 100 to 240 VAC

2 Control method None Optimum cycle control 5 Communications specifications 03 RS-485

3 Heater burnout detection H Yes 6 Communications protocol FLK CompoWay/F

567

8 8 channels 4 400 to 480 VAC

A None 7 International standards UTU Approved by TÜV, UL, and

CSA.

Ordering Information

■ List of Models

Name Number of control channels Heater burnout detection Load power supply voltage Model

Multi-channel Power

Controller

Note: When using the heater burnout detection function, CTs must be ordered separately.

4 Supported 100 to 240 VAC G3ZA-4H203-FLK-UTU

400 to 480 VAC G3ZA-4H403-FLK-UTU

8 Not supported 100 to 240 VAC G3ZA-8A203-FLK-UTU

400 to 480 VAC G3ZA-8A403-FLK-UTU

Upgraded Functionality

Refer to page 7 for details. Upgrade functions are marked with “V2”.

■ Accessories (Order Separately)

Name Hole diameter Detection

Current Transformer

(CT)

5.8 dia. 0 to 50 A E54-CT1

12.0 dia. 0 to 50 A E54-CT3

30.0 dia. 0 to 150 A G3ZA-CT150L

current

Model

Name Model

DIN Track PFP-100N

PFP-50N

End Plates (stoppers) PFP-M

Be sure to read the precautions for correct use and other precautions in the following user’s manual before using the

Power Controller.

G3ZA Multi-channel Power Controller User’s Manual (Cat. No. Z200)

2 Multi-channel Power Controller G3ZA

Page 3

Specifications

■ Ratings

Item

Power supply voltage 100 to 240 VAC (50/60 Hz)

Operating voltage range 85 to 264 VAC

Power consumption 16 VA max.

Load power supply voltage 100 to 240 VAC 400 to 480 VAC

Load power supply voltage range 75 to 264 VAC 340 to 528 VAC

Manipulated variable input 0.0% to 100.0% (via RS-485 communications)

Current transformer input (See note 1.) Single-phase AC, 0 to 50 A (primary current of CT)

Trigger output One voltage output for each channel, 12 VDC

Alarm output NPN open collector, one output

Indications LED indicators

Control method Optimum cycle control

Ambient operating temperature

Ambient operating humidity 25% to 85%

Storage temperature −25 to 65°C (with no icing or condensation)

Elevation 2,000 m max.

Accessories Instruction Sheet

Note: 1. CT inputs are provided only on Models with heater burnout detection.

2. Use an SSR without the zero-cross function (G3PA-@BL-VD) for soft-start optimum cycle control. (Refer to page 11.)

Load power supply

voltage range

Single-phase AC, 0 to 150 A (primary current of CT)

(with built-in short-circuit protection circuit)

Max. applicable voltage: 30 VDC, Max. load current: 50 mA

Residual voltage: 1.5 V max., Leakage current: 0.4 mA max.

Soft-start optimum cycle control (See note 2.)

Three-phase optimum cycle control

−10 to 55°C (with no icing or condensation)

■ Performance

100 to 240 VAC 400 to 480 VAC

V2

±15%, Max. load current: 21 mA

V2

V2

■ Communications Specifications

Current indication

accuracy

Insulation resistance 100 M

Dielectric strength 2,000 VAC, 50/60 Hz for 1 min between primary

Vibration resistance Vibration frequency: 10 to 55 Hz,

Shock resistance

Weight Approx. 200 g (including terminal cover)

Degree of protection IP20

Memory protection EEPROM (non-volatile memory) (number of

Installation environment Overvoltage category III,

Approved standards UL508 (Listing), CSA22.2 No. 14

Note: When measured with percentage selected for the current monitor

parameter and the maximum current measurable with the CT at 100%.

Current Range

0 to 50 A,

0 to 150 A, ±9 A

0 to 100%, ±6% (See note.)

(for models with heater burnout detection)

secondary

and secondary

acceleration: 50 m/s

300 m/s

three axes

writes: 100,000)

pollution degree 2 (according to IEC 60664-1)

EN50178

EN61000-6-4 (EN55011: 1998, A1: 1999 Class A,

Group 1)

EN61000-6-2: 2001

±3 A

Ω min. (at 500 VDC) between primary and

2

2

three times each in six directions along

in X, Y, and Z directions

Transmission line connections Multipoint

Communications method RS-485

Max. transmission distance 500 m

No. of nodes 31 (via multidrop connections)

Synchronization method Stop-start synchronization

Communications baud rate 9.6, 19.2, 38.4 or 57.6 kbps,

Transmission code ASCII

Communications data length 7 or 8 bits, Default: 7

Communications stop bits 1 or 2 bits, Default: 2

Communications parity Vertical parity: None, even, or odd,

Flow control None

Current Transformer Specifications

■

(Order Separately)

Item Specification

Model number E54-CT1 E54-CT3 G3ZA-CT150L

Max. continuous

heater current

Detection current

with G3ZA

connected

Dielectric strength 1,000 VAC for 1 min 2,000 VAC for 1

Vibration resistance

Weigh t Approx. 11.5 g Approx. 50 g Approx. 130 g

Accessories None Connection

Note: The maximum continuous current is 50 A for the G3ZA in combination

with the E54-CT3.

50 A 120 A (See note.) 150 A

50 A 150 A

98 m/s

Default: 9.6 kbps

Default: Even

2

, 50 Hz

terminals (2)

Plugs (2)

min

None

Multi-channel Power Controller G3ZA 3

Page 4

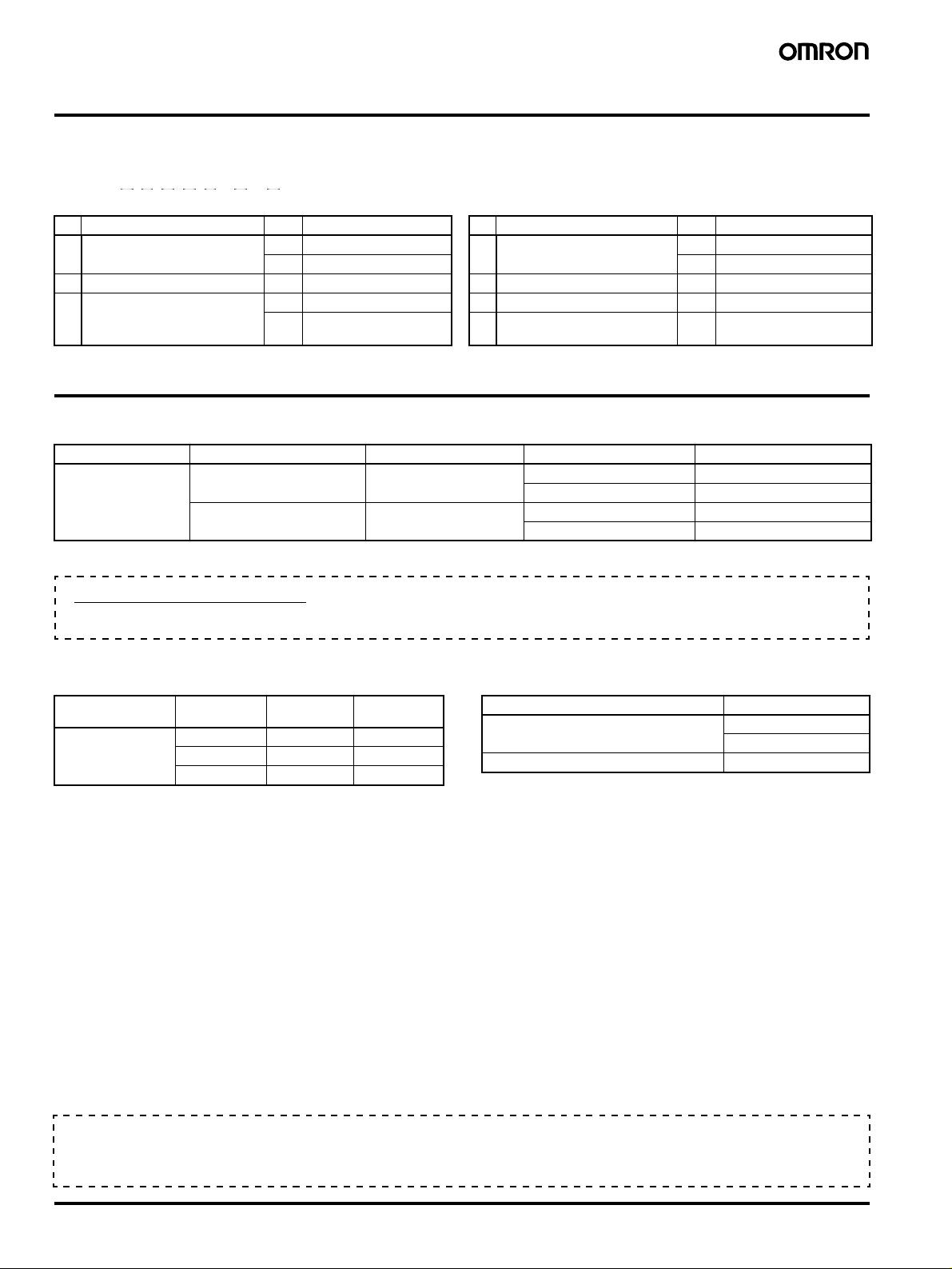

Applicable SSR and Control

e

Methods

The G3ZA can be used for a variety of applications by selecting the

SSR drive. For example, inrush current can be reduced at startup by

selecting soft-start optimum cycle control if a single-phase halogen

heater is used.

SSR Control

Single-phase

heater SSR

with zerocross function

Single-phase

heater SSR

without zerocross function

Three-phase

heater SSR

with zerocross function

V2

method

Optimum cycle

control

Soft-start

optimum cycle

control

Three-phase

optimum cycle

control

CT (4-channel

models only)

0 to 50 A or 0

to 150 A: 4

Units

0 to 50 A or 0

to 150 A: 4

Units

0 to 50 A or 0

to 150 A: up to

2 Units

Example of

supported

heater

SIngle-phase

heater

Single-phase

halogen

heater

Three-phase

heater

V2

V2

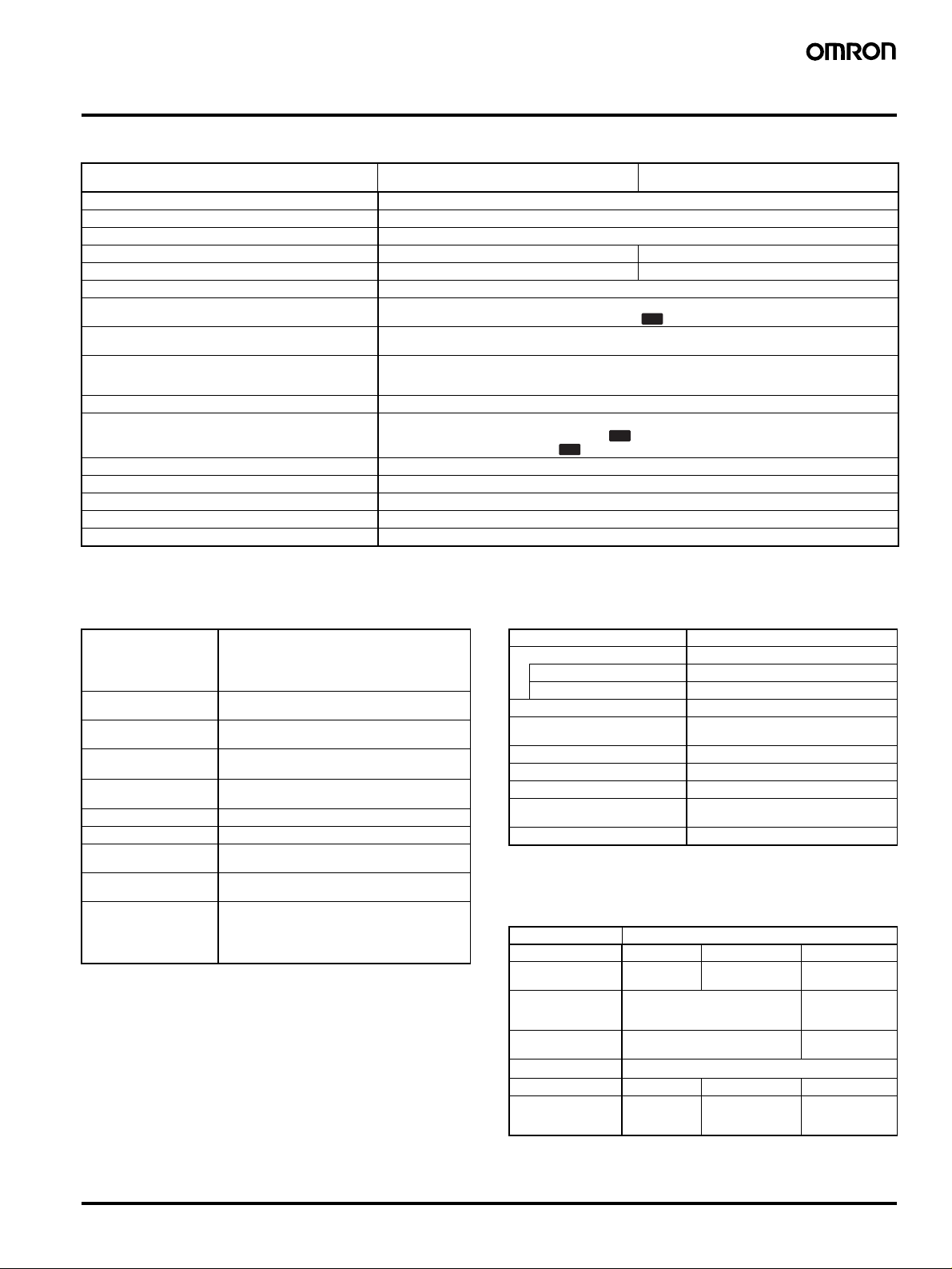

Optimum Cycle Control

• Optimum cycle control is performed by driving SSRs according to

load power detection and trigger signals. (Zero-cross SSRs are

used.)

• Noise is suppressed while ensure high-speed response by turning

outputs ON and OFF each half cycle to achieve high-precision

temperature control.

1/5th ON (20%)

Manipulated

variable: 20%

Setting the Control Switching MV Threshold

The Control Switching MV Threshold function is enabled when softstart optimum cycle control is used. Setting the Control Switching MV

Threshold enables switching to phase control when the current value

is below the set value, and switching to optimum cycle control when

the current value is above the set value. The default setting is 20.0%.

Variable

type

85/C5 Ch1 to Ch8 Control

Example: For channel 1, soft-start optimum cycle control is

performed under the following conditions: control switching MV:

40.0%, MV: 100.%, soft startup time: 20 s.

(1) Ch 1 Control Switching MV Threshold is set to 40.0% and Ch1

MV is set to 100.0% by writing to the variable area.

(2) Ch1 Soft Startup Time remains at the default. Setting is not

required.

(3) Once the Control Switching MV Threshold is written, the

changes are saved and become enabled the next time the

power is turned ON.

MV

100.0%

40.0%

Parameter Setting

Switching MV

Threshold

Soft startup time (20 s)

range

0.0% to

100.0%

Default

20.0

Tim

Note: Refer to Connection Configuration on page 6 for connecting to

an SSR.

Soft-start Optimum Cycle Control

V2

• Soft-start optimum cycle control is a control method that combines

phase control and optimum cycle control.

• Smooth switching for phase control and optimum cycle control

enables control of outputs with limited inrush current even for loads

with characteristics like halogen heaters.

• Use a single-phase heater SSR (without the zero-cross function)

for soft-start optimum cycle control. Refer to G3PA on page 11 for

details on SSRs without the zero-cross function.

• Control is switched according to the Control Switching MV Threshold.

• Set the Soft-start Up/Down Time to control output.

• Current is not detected during phase control. The current value

(heater ON current value, heater OFF current value, and effective

current value) will be 0 A, and the current error alarm (heater burnout detection, SSR short-circuit detection, and heater overcurrent

detection) will always turn OFF.

Phase control Optimum cycle control

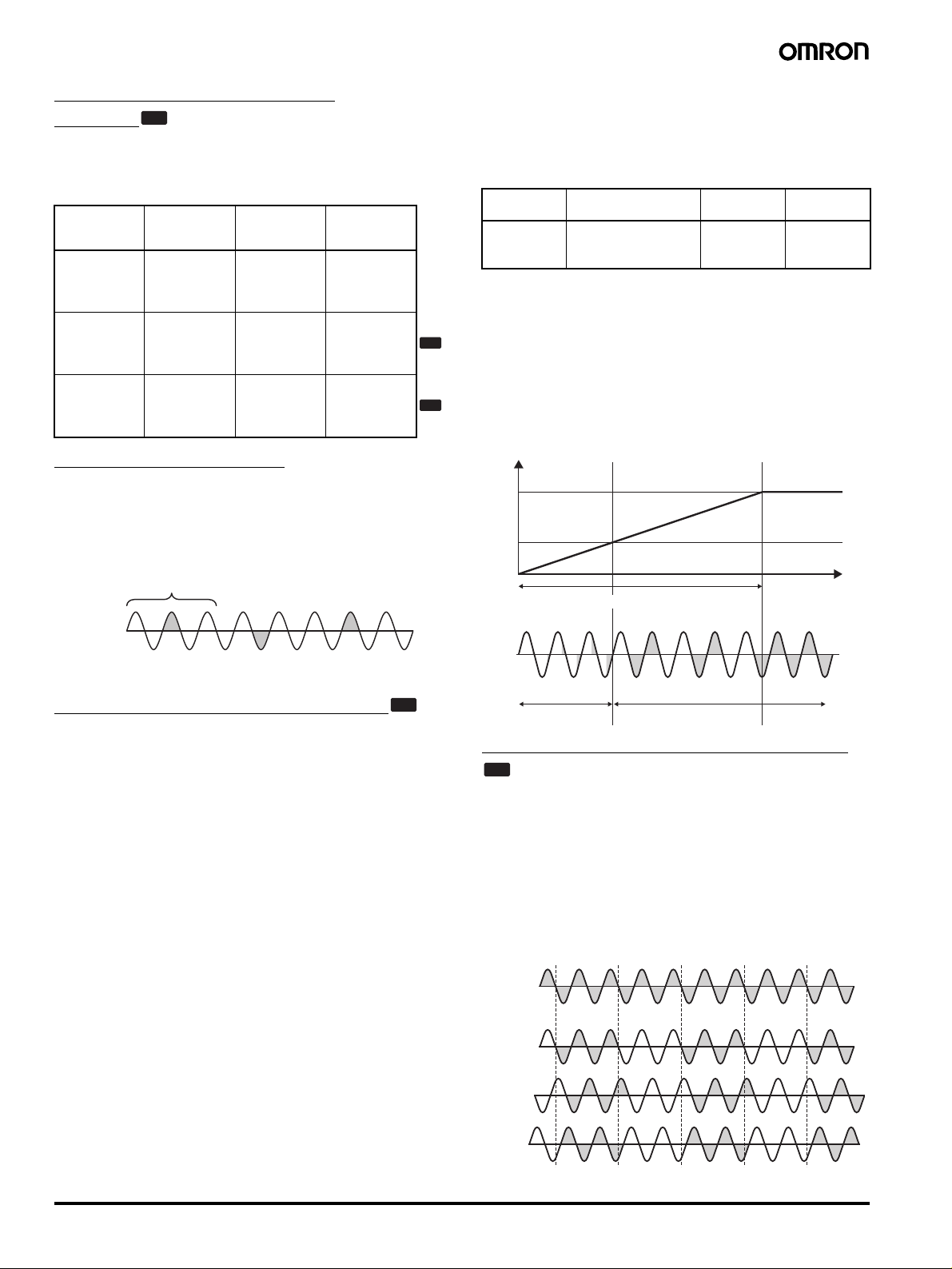

Three-phase Optimum Cycle Control

V2

• Three-phase optimum cycle control is a control method that turns

the output ON and OFF every two cycles.

• Turning the output ON and OFF every two cycles enables optimum

cycle control for three-phase heaters.

• Use a three-phase heater SSR with a zero-cross function for threephase optimum cycle control.

Note: Refer to page 6 for details on connecting to three-phase

heaters.

The following figure shows the current waveform of each phase for a

MV of 50% when a three-phase heater SSR is connected.

Load power

supply

R-S phase

S-T phase

R-T phase

4 Multi-channel Power Controller G3ZA

Page 5

Connections

■ Terminal Arrangement

Models with 8 Channels (Control Points),

No CT Inputs, and No Heater Burnout Detection

Trigger output

12 VDC, 21 mA

+

Trigger output

+

12 VDC,

21 mA

19 20 21 22 23 24

CH5 CH6 COM CH7 CH8 COM CH1 CH2 COM CH3 CH4 COM

Trigger output

12 VDC, 21 mA

+

Trigger output

+

12 VDC,

21 mA

Trigger output

+

−

12 VDC, 21 mA

Trigger output

Trigger output

−

+

12 VDC, 21 mA

Trigger output

+

+

12 VDC,

21 mA

12 VDC,

21 mA

−

−

13 14 15 16 17 18

CH1 CH2 COM CH3 CH4 COM CH1 CH2 COM CH3 CH4 COM

READY

SD/RD

OCC

Models with Load Power Supply Voltage

ERROR

of 100 to 240 V

7

89 11

RS-485

B (+) A (−)

Alarm output

30 VDC, 50 mA

12 4 6

Power supply voltage

100 to 240 VAC

50/60 Hz

Load power supply voltage

100 to 240 VAC

50/60 Hz

Note: Connect the power supply (100 to 240 VAC) for the

G3ZA across terminals 1 and 2 and the load power

supply for the SSR loads across terminals 4 and 6.

Note: 1. The following CTs can be used (sold separately):

0 to 50 A: E54-CT1 and E54-CT3

0 to 150 A: G3ZA-CT150L

2. Use C-Grid SL connectors from Molex Inc.

C-Grid SL Housing

Model: 51030-0630

READY

SD/RD

OCC

ERROR

Models with 4 Channels (Control Points),

CT Inputs, and Heater Burnout Detection

(See note 1.)

CT

(See note 1.) (See note 1.)

CT

CT

(See note 1.)

CT

19 20 21 22 23 24

+

Trigger output

12 VDC, 21 mA

Trigger output

+

12 VDC,

21 mA

Trigger output

+

−

12 VDC, 21 mA

Trigger output

+

12 VDC,

21 mA

−

13 14 15 16 17 18

SW1

SW1

SW2

Alarm output connector (See note 2.)

(only models with load power supply

voltage of 400 to 480 V)

SW2

Models with Load Power

Supply Voltage of 400 to 480 V

7

8

RS-485

B (+) A (−)

A

B

30 VDC, 50 mA

Alarm output

12 4 6

Power supply voltage

100 to 240 VAC

50/60 Hz

Load power supply voltage

400 to 480 VAC

50/60 Hz

Note: Connect the power supply (100 to 240 VAC) for the

G3ZA across terminals 1 and 2 and the load power

supply for the SSR loads across terminals 4 and 6.

Operation Indicators

Operation indicator Meaning

READY (Green) Lit while power is being supplied.

SD/RD (Orange) Lit while communicating with the host.

OCC (Orange) Lit while a control output is ON.

ERROR (Red) Lights or flashes when an error is detected.

Setting Switches

• Always turn OFF the power supply before setting the switches. The

switch settings are read only when the power supply is turned ON.

• Use a flat-blade screwdriver to set the switches and be sure not to

leave a switch set between two settings.

SW1 SW2

Communications Unit Number

Set a communications unit number on SW1 so that the host system

can identify the Controller.

SW1 0123456789ABCDEF

Unit No. 00 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15

▲

Default

Note: A unique unit number must be set for each node (Controller) on

the same communications line. Do not set the same unit

number for more than one node.

If 17 or more Units must be connected, refer to the G3ZA Multichannel Power Controller User’s Manual (Cat. No. Z200).

Communications Baud Rate

Set the baud rate for communicating with the host system on SW2.

SW2 01234 to F

Baud rate 9.6 19.2 38.4 57.6 Do not set.

▲

Default

Multi-channel Power Controller G3ZA 5

Page 6

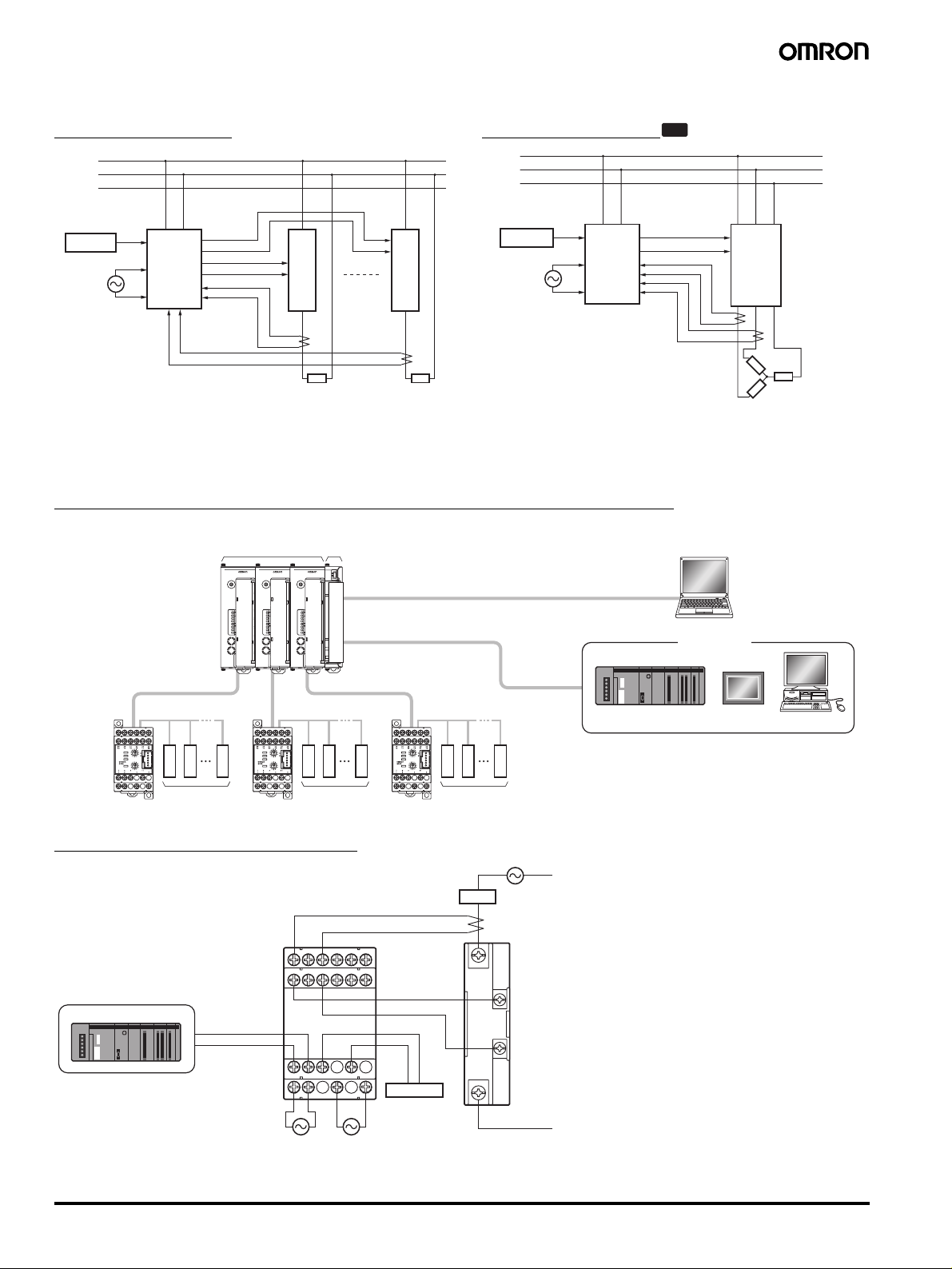

■ Connection Configuration

Single-phase SSR

R phase

S phase

T phase

Host device

Control

power

supply

Load power

supply

G3ZA

Trigger

signal

SSR

SSR

Three-phase SSR

R phase

S phase

T phase

Load power

supply

Host device

Control

power

supply

G3ZA

Trigger signal

CT (4-channel model only)

CT (4-channel model only)

Example for Connecting Two SSRs

Note: Connect a power supply with the same phase as the SSRs to

the load power supply terminals on the G3ZA.

Load

(e.g., heater)

Load

(e.g., heater)

Note: Connect to one of the three phases on the load power supply

input terminals of the G3ZA.

■ Host Device Connection Example

Example of Connection to EJ1 Modular Temperature Controller

EJ1N-TC4

PWR

RUN

ERR

ALM

SW1

SW2

F

E

D

C

0

B

1

A

2

9

3

8

4

7

5

6

ON

21345678

EJ1N-TC2

PWR

COM1

RUN

COM2

EJ1-TC4

ERR

COM3

ALM

SW1

SW2

or

F

E

D

C

0

B

1

A

2

9

3

8

4

7

5

6

ON

21345678

EJ1C-EDU

PWR

COM1

COM1

RUN

COM2

COM2

EJ1-TC4

EJ1-TC4

ERR

COM3

COM3

ALM

F

E

D

C

0

B

1

A

2

9

3

8

4

7

5

6

SW1

ON

21345678

SW2

Port A (connector): USB connection possible

using a E58-CIFQ1 (sold separately)

Port B: RS-485 (CompoWay/F)

V2

PC

Host Devices

SSR

(threephase)

Load

CX-Thermo for setup

G3ZA

Connection port

READY

SD/RD

SW1

OCC

SW2

ERROR

G3ZA

Connection port

READY

SD/RD

SW1

OCC

SW2

ERROR

G3ZA

Example of Connection to PLC

PLC

RS-485

G3ZA

Power supply for

Multi-channel

Power Controller

Load power supply

(for zero-cross detection)

G3ZA

Connection port

READY

SD/RD

SW1

OCC

SW2

ERROR

G3ZAG3ZA

Alarm output

Eight SSRs Eight SSRs Eight SSRs

Heater

SSR

PLC PT

PC

6 Multi-channel Power Controller G3ZA

Page 7

Upgraded Functions

n

V2

Upgraded Functions

1. Added soft-start optimum cycle control.

2. Added three-phase optimum cycle control.

3. Increased heater burnout detection to 150 A.

4. Achieved effective current value monitoring.

5. Changed current error detection from a fixed value to a variable value.

6. Changed detection time unit to seconds for communications errors.

New functions are marked with “V2”.

V2

Identifying Upgraded Models

Check the label on the Power Controller or the box to determine the version. Models not marked “Ver. 2.0” are version 1.0.

Box Label Power Controller Label

Version

OMRON Corporation

MADE IN JAPAN

Dimensions

Note: All units are in millimeters unless otherwise indicated.

■ Multi-channel Power Controllers

G3ZA-4H203-FLK-UTU

G3ZA-4H403-FLK-UTU

G3ZA-8A203-FLK-UTU

G3ZA-8A403-FLK-UTU

4.6 dia.

9

7 × 5 = 35

Versio

5.3

91

Mounting Hole Dimensions

(For Direct Mounting)

Two, 4.2 dia. or M4

76 max.

9

READY

63

SD/RD

43

ERROR

SW2

±0.3

35

45 max.

R 2.3

R 4.5

5.6

84

111 max.

(TYP. 110)

SW1

OCC

±0.3

84

±0.3

35

Multi-channel Power Controller G3ZA 7

Page 8

■ Accessories (Order Separately)

(22)

Current Transformer (CT)

E54-CT1

21

15

5.8 dia.

25

3

40

Two, 3.5 dia.

10

30

2.8

7.5

10.5

Current Transformer (CT)

E54-CT3

40 × 40

15

30

30

Current Transformer (CT)

Two, M3 (depth: 4)

2.36 dia.

12 dia.

9.3

1.7

G3ZA-CT150L

63

54

50

57

14.5

86

10

10

1.8

4.1

Note: The G3ZA-CT150L is for use only in combination with the G3ZA.

Wire terminal k and terminal l. (Do not use terminal kt and terminal lt.)

76

E54-CT3 Accessories

• Contactors

9

Approx.

3 dia.

• Plugs

Approx. 6 dia.

9.3

1.7

4.7

11

Four, M4 × 6 screws

14.5

5.2

5.9

Plug

18

26 max.

20

17

8.5

13.5

34.5

81.5

33.5

6

30 dia.

20

Contactor

Lead

Mounting Hole Dimensions

Two M5 screw holes or

two 5.5-dia. holes

76

DIN Track

PFP-100N

PFP-50N

0.15

4.5

15 25 25

10 10

1,000 (500)*

25 25 15 (5)*

7.3±

0.3

35±

* Dimensions in parentheses

are for the PFP-50N.

27±

1

8 Multi-channel Power Controller G3ZA

End Plate (Stopper)

10

PFP-M

M4 x 8

pan-head

screw

50

0.15

11.5

10

M4 spring

washer

6.2

1.8

1

35.5 35.3

1.8

1.3

4.8

Page 9

Safety Precautions

!WARNING

Do not touch the terminals and the wires while power is

being supplied. Doing so may possibly result in electric

shock. Make sure that the terminal cover is installed

before using the product.

!CAUTION

Do not allow pieces of metal, wire clippings, or fine

metallic chips or filings from installation to enter the

product. Doing so may occasionally result in electric

shock, fire, or malfunction.

Do not use the product in locations of flammable or

explosive gases. Doing so may occasionally result in

minor or moderate explosion, causing minor or moderate

injury, or property damage.

Do not attempt to disassemble, repair, or modify the

product. Doing so may occasionally result in minor or

moderate injury due to electric shock.

Perform correct setting of the product according to the

application. Failure to do so may occasionally cause

unexpected operation, resulting in minor or moderate

injury, or damage to the equipment.

Ensure safety in the event of product failure by taking

safety measures, such as installing a separate monitoring

system to provide alarms for preventing excessive

temperature rise. Product failure may occasionally

prevent control operation, resulting in damage to the

connected facilities and equipment.

Tighten the terminal screws securely using a tightening

torque within the following ranges. Loose screws may

occasionally cause fire, resulting in minor or moderate

injury, or damage to the equipment.

Terminal screws: 0.40 to 0.56 N·m

■ Precautions for Safe Use

1. Do not use the product in the following locations.

• Locations subject to direct radiant heat from heating equipment

• Locations where the product may come into contact with water

or oil

• Locations subject to direct sunlight

• Locations where dust or corrosive gases (in particular, sulfuric

or ammonia gas) are present

• Locations subject to extreme temperature changes

• Locations where icing or condensation may occur

• Locations subject to excessive shocks or vibration

2. Use this product within the rated load and power supply.

3. Ensure that the rated voltage is achieved no longer than 2 s after

turning the power ON.

4. Use/store within the rated temperature and humidity ranges.

5. Minimum mounting distance of G3ZA is 10 mm.

When mounting the G3ZA near the SSRs, mount the G3ZA so as

to not interfere with the heat dissipation of the SSR.

6. Use the specified size of insulated-type crimp terminals (M3,

width: 5.8 mm max.) for wiring and attach insulative sleeves. To

connect bare wires, use AWG22 (cross section: 0.326 mm

AWG14 (cross section: 2.081 mm

terminals and AWG22 (cross section: 0.326 mm

(cross section: 1.039 mm

7. Be sure to confirm the correct terminal and polarity when wiring

the terminal block and connectors.

8. Do not connect any conductors to unused terminals.

2

) to wire the power supply

2

) for other terminals.

2

) to AWG16

2

) to

9. In order to prevent inductive noise, wire the lines connected to the

product separately from power lines carrying high voltages or

currents. Do not wire in parallel with or in the same cable as

power lines. Other measures for reducing noise include running

lines along separate ducts and using shield lines.

10.Attach a surge suppressor or noise filter to peripheral devices that

generate noise (in particular, motors, transformers, solenoids,

magnetic coils, or other devices that have an inductance

component).

Do not install the product near devices generating strong highfrequency fields or surges. When using a noise filter, check the

voltage and current and install it as close to the product as

possible.

11.For a safety disconnection of the power-line in the application, the

equipment must be provided with disconnecting devices suitable

for isolation.

(e.g., circuit breakers defined in IEC60947-2, power switches

defined in IEC60947-3, power plugs, etc.)

Version 1.0 Usage Precautions

Version 1.0 is for single-phase loads only. Connect a single-phase

zero-cross SSR. Do not connect a three-phase SSR, or to an SSR

that is not magnet relay or zero-cross.

Version 2.0 Usage Precautions

• Check the G3ZA settings and select the correct SSR from the

following when wiring an SSR.

• SSR with zero-cross function for single-phase heaters

• SSR without zero-cross function for single-phase heaters

• Three-phase SSR

Do not connect a magnet relay.

• Check the G3ZA settings and select the correct CT from the

following when wiring a CT.

• E54-CT1

• E54-CT3

• G3ZA-CT150L

Multi-channel Power Controller G3ZA 9

Page 10

■ Precautions for Correct Use

)

Wiring

Use M3 crimp terminals.

5.8 mm max.

Mounting End Plates

Be sure to mount an End Plate on each side of the G3ZA so that it

does not slide on the DIN Track.

To mount an End Plate, hook the bottom of the End Plate on the

bottom of the DIN Track (1), place the top of the End Plate on the DIN

Track (2), and then pull down on the End Plate. Tighten the screw on

the End Plate to secure it.

5.8 mm max.

Use wires that withstand a minimum of 70

°C.

DIN Track

Secure the DIN Track with screws in at least three locations.

DIN Track: PFP-50N (50 cm)/PFP-100N (100 cm)

Mounting the G3ZA

Mount the G3ZA as shown in the diagram. First, pull down the DIN

Track mounting hook (1) and hook the top of the G3ZA on the DIN

Track (2). Then press the G3ZA onto the DIN Track far enough so

that it can be locked in place (3) and push the DIN Track mounting

hook up to lock the G3ZA in place (4).

(2)

(2)

ΡΕΑ∆Ψ

Σ∆/Ρ∆

ΣΩ1

ΟΧΧ

ΣΩ2

ΕΡΡΟΡ

End Plate End Plate

(1)

Note: Always mount one End Plate on each side of the G3ZA.

Installation Example

When installing the SSRs next to the G3ZA, provide sufficient space

between the G3ZA and SSRs, as shown in the following diagram.

Reference example:

When applying 25 A to the G3PB-225B-VD (a manipulated variable

of 100%), separate the SSRs from the G3ZA by at least 50 mm.

Do not touch the G3ZA while power is being supplied.

SSR

G3ZA

READY

SD/RD

SW1

OCC

SW2

ERROR

SSR

(3)

(1)

(4)

Removing the G3ZA

Use a flat-blade screwdriver to pull down the DIN Track mounting

hook (1) and then pull out on the bottom of the G3ZA (2).

(2

(1)

50 mm min. 50 mm min.

Mounting with Screws

Mounting Dimensions (Unit: mm)

Two, 4.2 dia.

or M4

0.3

84±

0.3

35±

10 Multi-channel Power Controller G3ZA

Page 11

Solid State Relays

G3PA

Extremely Thin Relays Integrated with Heat

Sinks

• Comply with VDE 0160 (finger protection), with a dielectric

strength of 4,000 V between input and load.

• Downsizing achieved through optimum design of heat sink.

• Mounting possible via screws or via DIN track.

• Certified by UL, CSA, EN, and VDE (reinforced insulation).

• Recommended for use with the soft-start function of the G3ZA.

Ordering Information

■ List of Models

Isolation Zero cross function Indicator Rated output load (See note 1.) Rated input voltage Model

Phototriac

coupler

Note: 1. The rated output load depends on the ambient temperature. Refer to Engineering Data.

2. The loss time will increase if 75 VAC or less is used. Check operation using the actual load.

No Yes 10 A at 24 to 240 VAC (See note 2.) 5 to 24 VDC G3PA-210BL-VD DC5-24

20 A at 24 to 240 VAC (See note 2.) G3PA-220BL-VD DC5-24

40 A at 24 to 240 VAC (See note 2.) G3PA-240BL-VD DC5-24

60 A at 24 to 240 VAC (See note 2.) G3PA-260BL-VD DC5-24

Solid State Relays G3PA 11

Page 12

Specifications

■ Certified Standards

UL508, CSA22.2 No. 14, and EN60950-1

■ Ratings

Input (at an Ambient Temperature of 25°C)

Rated voltage Operating Voltage range Input current impedance

5 to 24 VDC 4 to 30 VDC 20 mA max. 4 VDC max. 1 VDC min.

Note: The G3PA uses the input current as a constant current (at an ambient temperature of 25°C).

(See note.)

Must operate voltage Must release voltage

Voltage level

Output

Model Applicable load

Rated load voltage Load voltage range Load current (See note.) Inrush current

G3PA-210B(L)-VD 24 to 240 VAC (50/60 Hz) 19 to 264 VAC (50/60 Hz) 0.1 to 10 A (at 40°C) 150 A (60 Hz, 1 cycle)

G3PA-220B(L)-VD 0.1 to 20 A (at 40°C) 220 A (60 Hz, 1 cycle)

G3PA-240B(L)-VD 0.5 to 40 A (at 40°C) 440 A (60 Hz, 1 cycle)

G3PA-260B(L)-VD 0.5 to 60 A (at 40°C) 440 A (60 Hz, 1 cycle)

Note: The load current depends on the ambient temperature.

Refer to Engineering Data for further details.

■ Characteristics

Item G3PA-210BL-VD G3PA-220BL-VD G3PA-240BL-VD G3PA-260BL-VD

Operate time 1 ms max.

Release time 1/2 of load power source cycle + 1 ms max.

Output ON voltage drop 1.6 V (RMS) max.

Leakage current 5 mA max. (at 100 VAC)

Insulation resistance 100 M

Dielectric strength 4,000 VAC, 50/60 Hz for 1 min

Vibration resistance Destruction: 10 to 55 to 10 Hz, 0.375–mm single amplitude (mounted to DIN rail)

Shock resistance

Ambient operating

temperature

Certified standards UL508, CSA C22.2 (No.14, No.950), EN60950 File No. 5915ÜG

Ambient operating

humidity

Weight Approx. 260 g Approx. 340 g Approx. 460 g Approx. 900 g

10 mA max. (at 200 VAC)

Ω min. (at 500 VDC)

Destruction: 300 m/s

Operating: –30

Storage: –30

Operating: 45% to 85%

2

(mounted to DIN rail)

°C to 80°C (with no icing or condensation)

°C to 100°C (with no icing or condensation)

10 mA max. (at 100 VAC)

20 mA max. (at 200 VAC)

12 Solid State Relays G3PA

Page 13

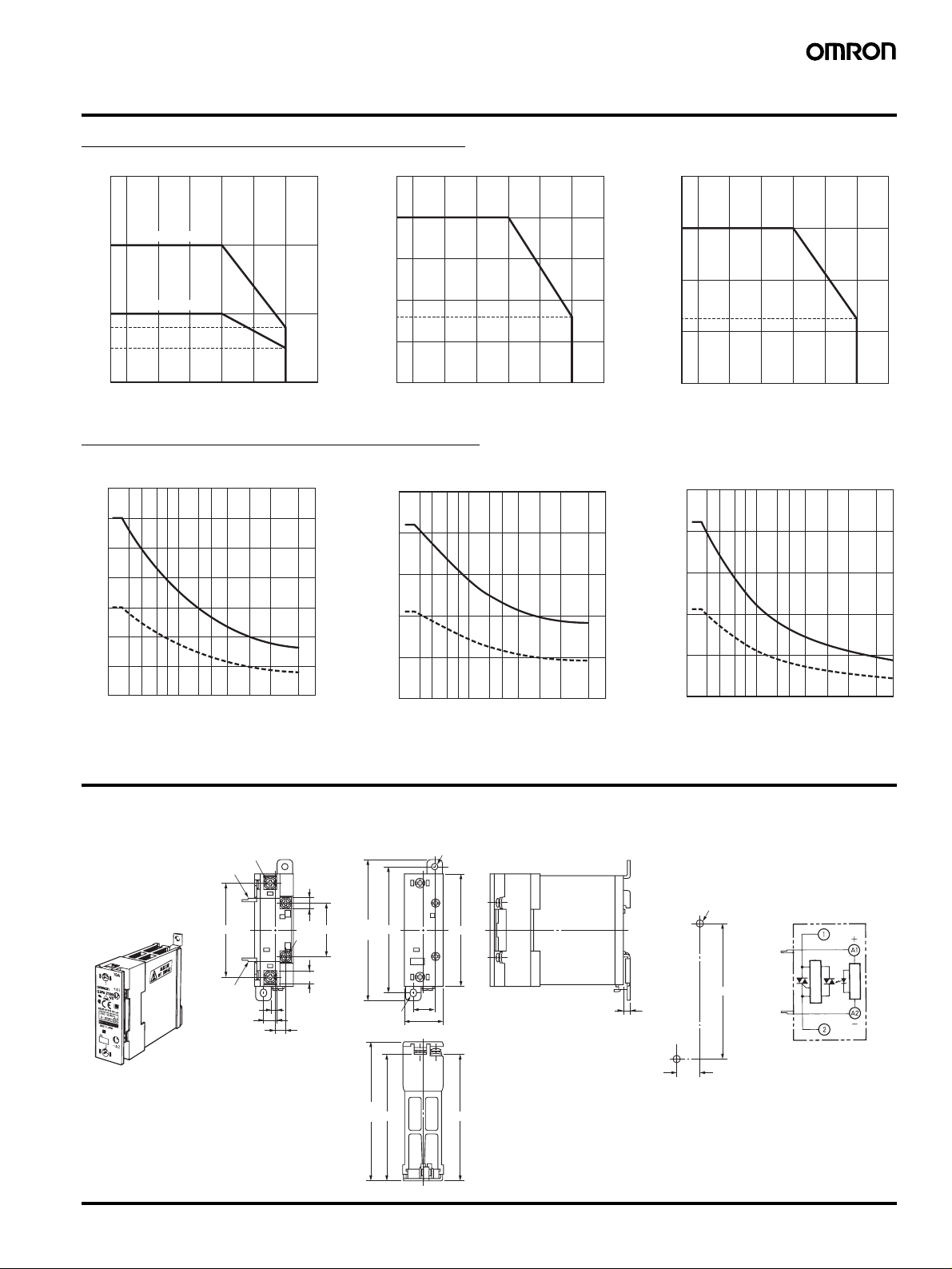

Engineering Data

p

)

p

)

)

4

G

Load Current vs. Ambient Temperature

G3PA-210BL-VD, G3PA-220BL-VD G3PA-240BL-VD G3PA-260BL-VD

30

50

80

Load current (A)

G3PA-220BL-VD

20

G3PA-210BL-VD

10

8

5

0

Ambient tem

erature (˚C

40

Load current (A)

30

20

16

10

100806040200−20−30

0

Ambient tem

100806040200−20−30

erature (˚C

60

Load current (A)

40

25

20

0

Ambient temperature (˚C

One Cycle Surge Current: Non-repetitive

Note: Keep the inrush current to half the rated value if it occurs repetitively.

G3PA-210BL-VD G3PA-220BL-VD G3PA-240BL-VD, G3PA-260BL-VD

Inrush current (A. Peak)

150

100

200

150

Inrush current (A. Peak)

100

50

50

Inrush current (A. Peak)

400

300

200

100

100 806040200−20−30

0

5,0001,000500200100503010

Energized time (ms)

0

Energized time (ms)

5,0001,000500200100503010

0

Energized time (ms)

5,0001,000500200100503010

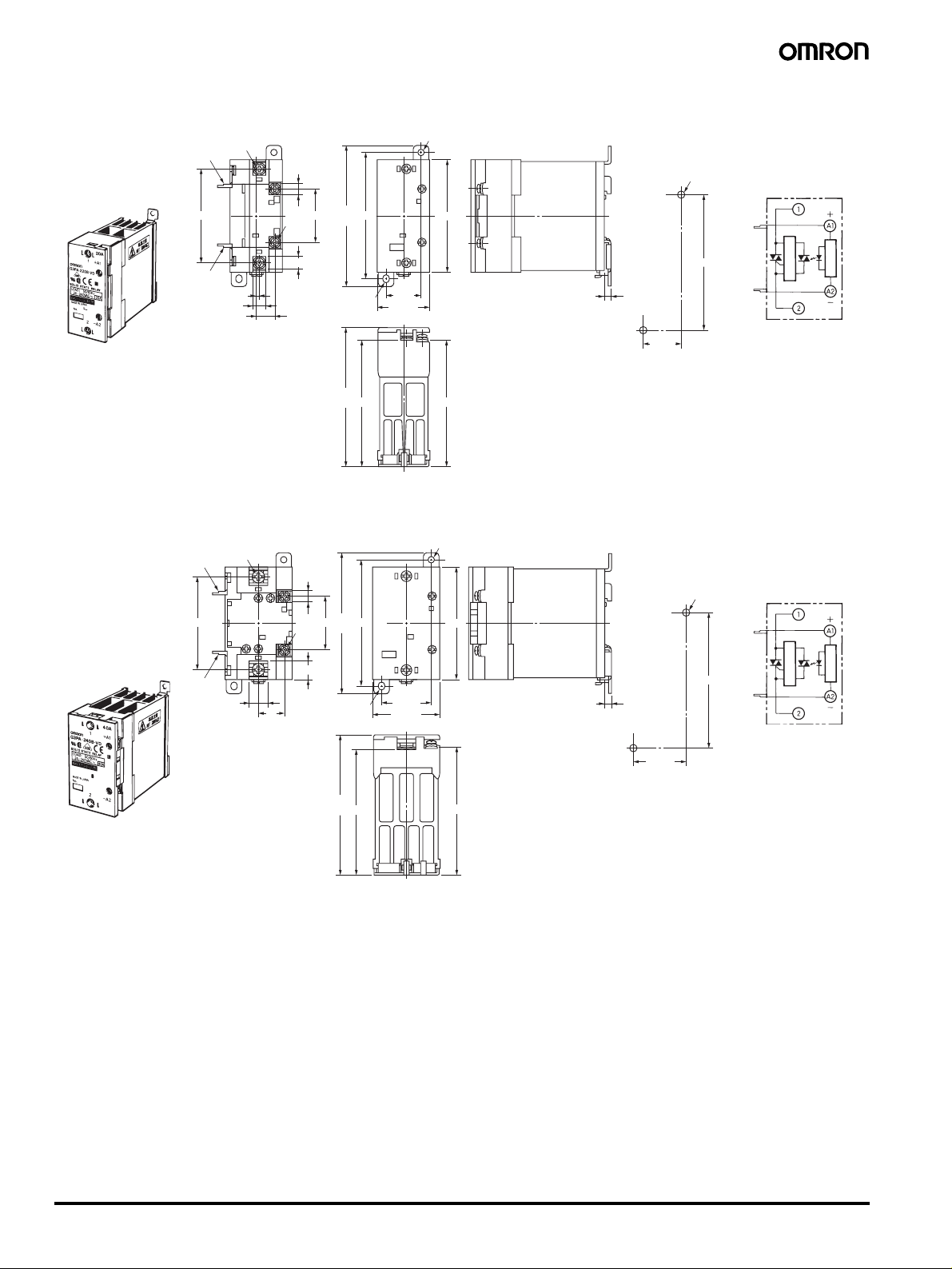

Dimensions

Note: All units are in millimeters unless otherwise indicated.

3PA-210BL-VD

Note: Without Terminal

Cover

Two, M4 × 8

Linking

terminal B1

67

Linking

terminal B2

2.8

8.8

8.2

7.6

Two ,

M3.5

× 7.5

8.6

Note: With Terminal

100

38

max.

4.6 × 5.6

elliptical

hole

100

max.

Cover

4.6 dia.

90

±0.2

15

±0.2

27 max.

90 91

Mounting holes

Two, 4.5 dia. or M

80

90±0.3

4.5

15

±0.3

Terminal Arrangement/

Internal Connections

Input circuit

Trigger circuit

Solid State Relays G3PA 13

Page 14

G3PA-220BL-VD

Note: Without Terminal

Cover

Linking

Two, M4 × 8

terminal B1

Note: With Terminal

Cover

4.6 dia.

7.6

Mounting holes

Two, 4.5 dia.

or M4 holes

Terminal Arrangement/

Internal Connections

G3PA-240BL-VD

67

Linking

terminal B2

Linking

terminal B1

Linking

terminal B2

2.2

8.8

13.2

Note: Without Terminal

Cover

Two, M5 × 12

67

13

8.6

7.6

Two ,

M3.5

× 7.5

13

100

38

90±0.2

max.

4.6 × 5.6

elliptical

hole

100

90 91

max.

Note: With Terminal

100

38

90

±0.2

max.

4.6 × 5.6

elliptical

hole

25±0.2

37 max.

Cover

35±0.2

47 max.

80

4.6 dia.

90

±0.3

4.5

25±0.3

Mounting holes

Terminal Arrangement/

Trigger circuit

Input circuit

Internal Connections

Two, 4.5 dia.

or M4

80

90

±0.3

4.5

Trigger circuit

Input circuit

Two ,

M3.5

× 7.5

18

100

max.

35±0.3

89

91

14 Solid State Relays G3PA

Page 15

G3PA-260BL-VD

Note: Without Terminal Cover Note: With Terminal Cover

Two, M5 × 12

67

Two, M3.5 × 7.5

7.6

100

38

max.

90±0.2

80

13

4.6 dia.

Mounting holes

Two, 4.5 dia.

or M4

90

±0.3

100

max.

89

4.6 × 5.6

elliptical hole

13

18

±0.2

35

110 max.

4.5

Terminal Arrangement/

Internal Connections

1

A1

35±0.3

91

Input circuit

Trigger circuit

A2

2

Solid State Relays G3PA 15

Page 16

Safety Precautions

Close Mounting

SSR Mounting Pitch

Panel Mounting (At a rated ambient temperature of 40°C).

Duct or airflow obstruction

SSR

Vertical direction

80 mm min.

min.

Relationship between SSRs and Ducts

Duct Height

Mounting surface

Do not surround the SSR

with ducts, otherwise the

heat radiation of the SSR

will be adversely affected.

Countermeasure (1) Countermeasure (2)

50 mm max.

Mounting surface

(A height of no

more than half

the SSR's height is

recommended.)

Duct or

airflow

obstruction

SSR

Vertical

direction

Duct or

airflow

obstruction

Use short ducts.

60 mm min.

30 mm min.

SSR

Mounting surface

If the ducts cannot be

shortened, place the SSR

on a metal base so that it

is not surrounded by the

ducts.

Airflow

• Please reduce the ambient temperature of SSRs.

The rated load current of an SSR is measured at an ambient

operating temperature of 40

°C.

• An SSR uses a semiconductor in the output element. This causes

the temperature inside the control panel to increase due to heating

resulting from the passage of electrical current through the load. To

restrict heating, attach a fan to the ventilation outlet or air inlet of

the control panel to ventilate the panel. This will reduce the ambient

temperature of the SSRs and thus increase reliability. (Generally,

each 10

°C reduction in temperature will double the expected life.)

SSR rated current (A) 10 A 20 A 30 A 40 A 60 A

Required number of fans

0.16 0.31 0.47 0.62 0.93

per SSR

Example: For 10 SSRs with load currents of 20 A,

0.31

× 10 = 3.1

Thus, 4 fans would be required.

Size of fans: 92 mm

Ambient temperature of control panel: 30

2

, Air volume: 0.7 m3/min,

°C

If there are other instruments that generate heat in the control

panel other than SSRs, additional ventilation will be required.

EMC Directive Compliance

The G3PA complies with EMC Directives under the following

conditions.

SSR

Input cable length

G3PA

OutputInput

Load

Film capacitor

• 1 µF, 250 VAC

(G3PA-2@@)

• A film capacitor is connected to both sides of the load power supply

output.

• The input power supply cable length for 200-V models is less than

10 m.

Loss Time

Loss time will increase if the G3PA is used at a low voltage or

current. Check that there will be no problems with operation before

using the G3PA.

Ventilation

Be aware of air flow

Duct or

air flow

obstruction

SSR

SSR

Air inlet

Ventilation

outlet

(axial fan)

SSR

Note: 1. If the air inlet or air outlet has a filter, clean the filter regularly

to prevent it from clogging and ensure an efficient flow of air.

2. Do not locate any objects around the air inlet or air outlet,

otherwise the objects may obstruct the proper ventilation of

the control panel.

3. A heat exchanger, if used, should be located in front of the

SSR Units to ensure the efficiency of the heat exchanger.

16 Solid State Relays G3PA

Loss time

Page 17

Solid State Relays G3PA 17

Page 18

18 Solid State Relays G3PA

Page 19

Solid State Relays G3PA 19

Page 20

Warranty and Application Considerations

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a period of one year (or

other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NON-INFRINGEMENT,

MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR USER

ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET

THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS,

OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON

CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE

PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORED,

INSTALLED, AND MAINTAINED AND NOT SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE

MODIFICATION OR REPAIR.

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the combination of

products in the customer's application or use of the products.

Take all necessary steps to determine the suitability of the product for the systems, machines, and equipment with which it will

be used.

Know and observe all prohibitions of use applicable to this product.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY WITHOUT

ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON

PRODUCTS ARE PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR

SYSTEM.

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other reasons. Consult with

your OMRON representative at any time to confirm actual specifications of purchased product.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. J147-E1-02A

In the interest of product improvement, specifications are subject to change without notice.

OMRON Corporation

Industrial Automation Company

Control Devices Division H.Q.

Analog Controller Division

Shiokoji Horikawa, Shimogyo-ku,

Kyoto, 600-8530 Japan

Tel: (81)75-344-7080/Fax: (81)75-344-7189

0107 (0604)

Loading...

Loading...