Page 1

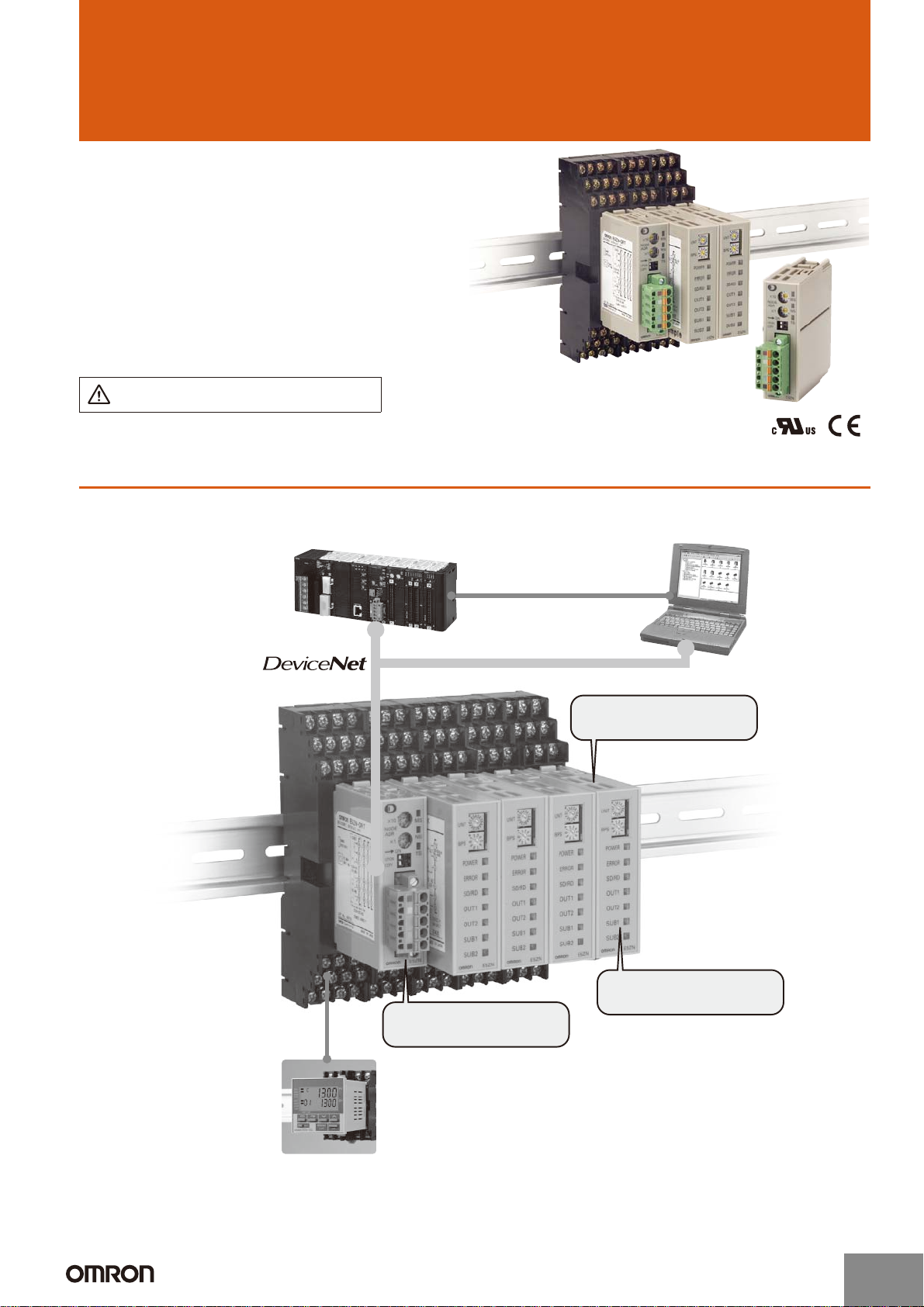

DeviceNet Communications Unit

E5ZN-DRT

Streamlined Communications from

Temperature Controller to PLC

• The E5ZN Modular Temperature Controller is connected to

the DeviceNet network.

• The I/O link function allows setting and monitoring (e.g., of

present values) for the E5ZN Modular Temperature Controller to

be performed without communications programming.

• Up to 16 E5ZN Modular Temperature Controllers can be connected to one Unit.

• All the parameters for the E5ZN can be uploaded or downloaded in one operation using DeviceNet Configurator.

Refer to Safety Precautions for All

Temperature Controllers.

Features

DeviceNet Communications Unit Enables Program-free Communications with Temperature

Controllers

DeviceNet

Master

DeviceNet

Configurator

Connect up to 16 E5ZN.

http://www.ia.omron.com/

DeviceNet Communications Unit

E5ZN-DRT

Setting Display Unit

E5ZN-SDL

Operational performance equivalent to

E5CN Digital Temperature Controllers.

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

Modular Temperature Controller

E5ZN

1

Page 2

E5ZN-DRT

Features

Startup Time Is Six Times Faster and No Communications Programs Are Needed

Previously, a time-consuming process of creating

communications programs, debugging, and checking

operations was required for the Temperature Controller to

communicate with the PLC.

● For example, setting 10 Units required 60 minutes.

● Incorrect inputs were a concern.

● Separate debugging for each Unit was needed.

No-protocol Example

Trigger

Trigger

Send Ready Flag

NG

Beep

Beep

Beep

Trigger

Receive Completion Flag

Receive Completion Flag

Receive Completion Flag

D'f

ASC ← Converts SP data into ASCII.

DM000

K

Sd

FSC

← Calculates FSC.

C

S

Sf

← Sends command.TDX

S

C

N

← Receives response.RXD

D

C

N

← Checks end code.

CMP

De

#3030

Normal completion

← Checks FCS.

FCS

C

D

D'f

CMP

Df

D'f

FCS check OK

DeviceNet Communications Units enable high-speed data

communications by allocating settings and monitoring

parameters in the PLCs I/O Memory Area, contributing to greater

reductions in the time required for communications program

development.

● For example, set 10 Units in 10 minutes.

● Batch download using the personal computer.

● Debugging is easy using the personal computer.

OUT Area IN Area

Wd 0 and 1

Wd 2 and 3

Wd 4 and 5

Wd 6 to 37

Wd 38

User-specified

allocations

are possible.

Wd 98

Wd 99

Wd 100

Manage All E5ZN Together from the DeviceNet Configurator

Use the DeviceNet Configurator for E5ZN

initial settings and temperature control wiring

to enable immediate execution.

PLC Memory

OUT enabled

Control ON/OFF

AT executing

Set value (SV)

Wd 0 and 1

Wd 2 and 3

Wd 4 and 5

Wd 6 and 7

Wd 8 to 37

Wd 38

Wd 98

Wd 99

Wd 100

Comm status

Control ON/OFF

AT executing

Alarm output

Process value (PV)

User-specified

allocations

are possible.

Improved Maintenance with Monitoring, Comment, and Copying Functions

● Measure the heater control time (RUN

time monitor) to manage heater life

expectancy.

● Monitor supply voltages, such as those

for Temperature Controller and

Communications Unit power supplies,

and network power supplies.

● User-specified names can be set for

each heater and Communications Unit,

enabling the location of errors to be

checked quickly.

● Upload/download Temperature Controller

parameters to the Communications Unit.

This shortens the time required to

replace Temperature Controllers.

Check the settings

for the heater of

oven No. 3.

DeviceNet

Configurator

DeviceNet

Master

Control data

Maintenance data

UNIT

UNIT

UNIT

BPS

BPS

BPS

POWER

POWER

POWER

ERROR

ERROR

ERROR

SD/RD

SD/RD

SD/RD

OUT1

OUT1

OUT1

OUT2

OUT2

OUT2

SUB1

SUB1

SUB1

SUB2

SUB2

SUB2

E5ZN

E5ZN

E5ZN

E5ZN

UNIT

UNIT

UNIT

UNIT

BPS

BPS

BPS

BPS

POWER

POWER

POWER

POWER

ERROR

ERROR

ERROR

ERROR

SD/RD

SD/RD

SD/RD

SD/RD

OUT1

OUT1

OUT1

OUT1

E5ZN-SCT24S

OUT2

OUT2

OUT2

OUT2

SUB1

SUB1

SUB1

SUB1

SUB2

SUB2

SUB2

SUB2

E5ZN

E5ZN

E5ZN

E5ZN

UNIT

BPS

POWER

ERROR

SD/RD

OUT1

OUT2

SUB1

SUB2

E5ZN

UNIT

BPS

POWER

ERROR

SD/RD

OUT1

OUT2

SUB1

SUB2

E5ZN

Check the actual

operating time

of the heater.

UNIT

UNIT

UNIT

BPS

BPS

BPS

POWER

POWER

POWER

ERROR

ERROR

ERROR

SD/RD

SD/RD

SD/RD

OUT1

OUT1

OUT1

OUT2

OUT2

OUT2

SUB1

SUB1

SUB1

SUB2

SUB2

SUB2

E5ZN

E5ZN

E5ZN

E5ZN

UNIT

UNIT

UNIT

UNIT

BPS

BPS

BPS

BPS

POWER

POWER

POWER

POWER

ERROR

ERROR

ERROR

ERROR

SD/RD

SD/RD

SD/RD

SD/RD

OUT1

OUT1

OUT1

OUT1

E5ZN-SCT24S

OUT2

OUT2

OUT2

OUT2

SUB1

SUB1

SUB1

SUB1

SUB2

SUB2

SUB2

SUB2

E5ZN

E5ZN

E5ZN

E5ZN

UNIT

BPS

POWER

ERROR

SD/RD

OUT1

OUT2

SUB1

SUB2

E5ZN

UNIT

BPS

POWER

ERROR

SD/RD

OUT1

OUT2

SUB1

SUB2

E5ZN

http://www.ia.omron.com/

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

2

Page 3

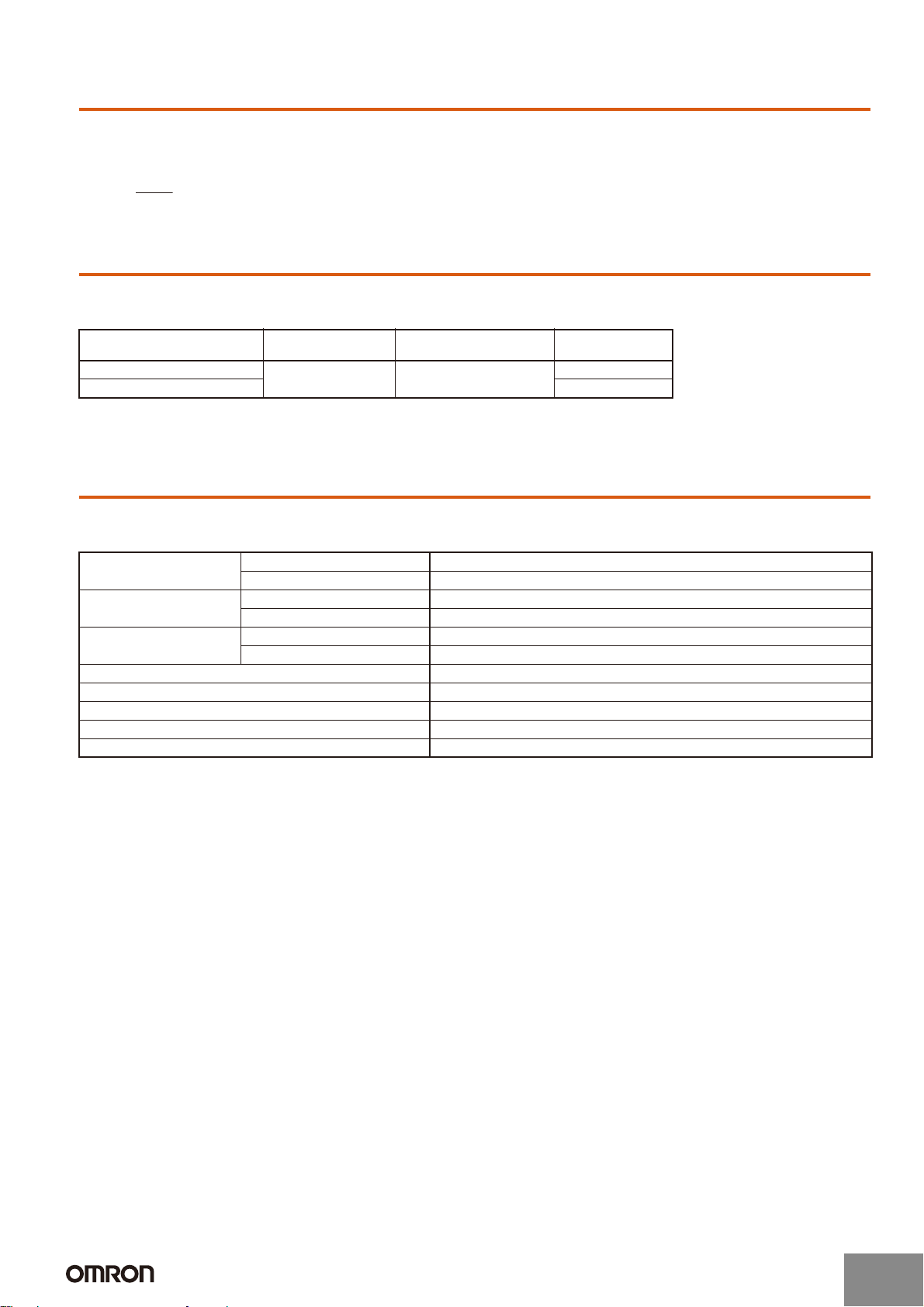

Model Number Structure

■ Model Number Legend

E5ZN-DRT

E5ZN-DRT

1

1.

DRT: DeviceNet communications

Ordering Information

■ List of Models

Name External input power

DeviceNet Communications Unit 24 VDC E5ZN E5ZN-DRT

Te r m i n a l U n i t E5ZN-SCT24S

Note: A DeviceNet Communications Unit and Terminal Unit are required to connect to DeviceNet. Two End Plates are provided with E5ZN-SCT24S

Terminal Units. When mounting to a DIN track, be sure to mount End Plates on both sides.

supply voltage

Applicable Temperature

Controller

Model

Specifications

■ Ratings

Power supply voltage DeviceNet 24 VDC (for internal circuits)

External input power supply 24 VDC (for RS-485 communications circuits and Temperature Controllers)

Allowable voltage range DeviceNet 11 to 25 VDC

External input power supply 20.4 to 26.4 VDC

Power consumption

(See note 2.)

Connectable Temperature Controllers E5ZN Series

Maximum number of connectable Temperature Controllers 16

Ambient operating temperature −10 to 55°C (with no icing or condensation)

Ambient operating humidity 25% to 85%

Ambient storage temperature −25 to 65°C (with no icing or condensation)

Note: 1. Do not use an inverter output as the power supply. (Refer to Safety Precautions for All Temperature Controllers.)

2. The power consumption for the Temperature Controllers is not included.

DeviceNet Approx. 1.1 W (for a current of 45 mA at 24 VDC)

External input power supply Approx. 0.5 W (for a current of 20 mA at 24 VDC)

http://www.ia.omron.com/

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

3

Page 4

E5ZN-DRT

■ Characteristics

Insulation resistance 20 MΩ min. (at 100 VDC)

Dielectric strength 500 VAC, 50/60 Hz for 1 min between the DIN track and all DeviceNet connector terminals and between the DIN track

Vibration resistance

Shock resistance

Weight 100 g max.

Safety standards cULus508

■ Communications (for Temperature Controller Expansion)

and all terminal socket terminals

2

10 to 55 Hz, 10 m/s

2

150 m/s

, 3 times each in ±X, ±Y, and ±Z directions

for 2 hrs each in ±X, ±Y, and ±Z directions

EMS: Electrostatic Discharge (ESD) EN61006-2, EN61000-4-2 (4 kV/contact, 8 kV/air)

Radiated Electromagnetic Fields EN61006-2, EN61000-4-3 (10 V/m)

Electrical Fast transients/BURST EN61006-2, EN61000-4-4 (2 kV/DC power-line, 1 kV/Signal-line)

Surge Transients EN61006-2, EN61000-4-5 (line to ground : 1 kV/DC power-line)

: 2 kV/Signal-line

line to line : 0.5 kV/DC power-line)

Conducted Disturbances EN61006-2, EN61000-4-6 (10 V)

EMI: Radiated Emissions (electric field) EN50081-2 Class A

Transmission line

RS-485 multipoint

connection method

Communications method RS-485 (2-wire, half-duplex)

Synchronization

Start-stop synchronization

method

Baud rate 38,400 bps

Transmission code ASCII

Data bit length 7 bits

Stop bit length 2 bits

Error detection Vertical parity (even)

BCC (block check character)

Flow control None

Number of Units that can

16 Units max. (32 channels)

be connected in parallel

Connections

■ Terminal Arrangement

E5ZN-DRT E5ZN-SCT24S

×10

Color

Red

Communications power, positive (+V)

Communications signal, high (CAN H)

White

---

Shield

Blue

Communications signal, low (CAN L)

Black

Communications power, negative (–V)

Signal

NODE

ADR

×1

UP/DN

COPY

MS

NS

ON

TS

External input power

supply (24VDC)

Setting Display Unit

communications

Communications for

Temperature

Controller expansion

(TOP VIEW)

+

−

B (+)

A (−)

B (+)

A (−)

19

13

20 14

21 15

22 16 10

23 17 11

24 18 12

71

82

93

4

5

6

http://www.ia.omron.com/

Not used with the DeviceNet

Communications Unit

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

4

Page 5

Nomenclature

E5ZN-DRT

E5ZN-DRT

Front Panel Rotary Switches

Used to set the node address when

functioning as a DeviceNet slave.

Front Panel DIP Switch

Used to copy (backup) parameters between

×10

NODE

ADR

×1

UP/DN

COPY

ON

the Temperature Controllers and DeviceNet.

UP/DN (Pin 2): Sets the copy operationmode

(i.e., upload or download).

COPY (Pin 1): Starts the copying.

DeviceNet Connector

Connects to DeviceNet communications

cables. Power for DeviceNet communications is also supplied though this

connector. An FCK2.5/5-STF-5.08AU

connector (Phoenix Contact) is

provided.

Dimensions

Note: All units are in millimeters unless otherwise indicated.

E5ZN-DRT

MS

NS

TS

D

C

E

B

F

A

0

9

1

8

2

7

3

6

4

5

Indicators

Dimensions when Mounted to the

E5ZN-SCT24S Terminal Unit

Back Panel DIP Switch

Used to specify whether the connection

configuration and I/O allocation is set

using simple I/O allocation or Configurator

I/O allocation.

Pin 1: I/O allocation setting switch

Pin 2: Not used (Set to OFF.)

Back Panel Rotary Switch

Used to set the maximum unit number

when simple I/O allocation is used.

Terminal Unit Connector

Connects to the E5ZN-SCT24S

Terminal Unit.

130

4.7

30

72.8

27

35

46

89.6

(107.5)

Note: Be sure to read the precautions for correct use and other precautions in the following user’s manuals before using the

Communications Unit.

E5ZN-DRT DeviceNet Communications Unit Operation Manual (Cat. No. H119)

DeviceNet Operation Manual (Cat. No. W267)

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

In the interest of product improvement, specifications are subject to change without notice.

http://www.ia.omron.com/

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

5

Page 6

Safety Precautions for All Temperature Controllers

Refer to the precautions of individual product for more specific details.

Warning

The following products contain lithium batteries. Do not

disassemble, deform under pressure, heat to over

100°C, or incinerate these products. The lithium battery may ignite or explode. Applicable models: E5ZE,

E5LD, and E5LC.

Caution

Do not touch any of the terminals while the power is

being supplied. Doing so may result in electric shock.

Do not allow pieces of metal or wire cuttings to get

inside the Temperature Controller. Doing so may

result in electric shock, fire, or malfunction.

Do not attempt to disassemble, repair, or modify the

Temperature Controller. Any attempt to do so may

result in electric shock, fire, or malfunction.

Do not use the Temperature Controller in locations

subject to flammable or explosive gases. Doing so

may result in an explosion.

The switching capacity and switching conditions will

significantly affect the longevity of the output relays.

Use the Temperature Controller within the rated load,

and do not use the Temperature Controller beyond the

number of operations specified under electrical life.

Using the Temperature Controller beyond its electrical

life may result in contact welding or burning.

Use Temperature Controller settings that are

appropriate for the controlled system. Failure to do so

may cause unexpected operation resulting in damage

to equipment or personal injury

Prepare a circuit with an overheating prevention alarm

and implement other safety measures to ensure safe

operation in the event of a malfunction. Loss of

operational control due to malfunction may result in a

serious accident.

Tighten the terminal screws to the following

torque:

M3.5 screws: 0.74 to 0.90 N·m

M3 screws: 0.40 to 0.56 N·m

E5GN: Terminals 1 to 6: 0.23 to 0.25 N·m

Terminals 7 to 9: 0.12 to 0.14 N·m

Failure to tighten terminal screws to the correct torque

may result in fire or malfunction.

Make sure there will be no adverse affects from the

device connected to the Temperature Controller

before using the hardware test mode. Devices

connected to the Temperature Controller may reach a

dangerous state during the test.

1. Do not use the Temperature Controller in the following locations:

2. Use and store the Temperature Controller within the rated

3. Allow enough space around the Temperature Controller to

4. Be sure to wire properly with correct polarity of terminals.

5. To wire the E5AN, E5EN, or E5CN using crimp terminals, use

6. When wiring the E5GN, use a cable gauge of AWG24

7. After wiring is completed, do not pull on or bend a terminal

8. Do not connect anything to unused terminals.

9. Make sure that the power supply voltages and loads are

10. To avoid inductive noise, keep the wiring for the Temperature

11. Make sure that the rated voltage is attained within two sec-

12. Allow at least 30 seconds for the Temperature Controller to

13. When using self-tuning, turn ON power for the load (e.g.,

Operating Environment Precautions

• Locations exposed to radiated heat from heating devices

• Locations subject to exposure to water or oil

• Locations subject to direct sunlight

• Locations subject to dust or corrosive gases (in particular,

sulfide gas and ammonia gas)

• Locations subject to severe changes in temperature

• Locations subject to icing or condensation

• Locations subject to excessive shock or vibration

temperature or humidity range specified for each model.

When two or more Temperature Controllers are mounted horizontally close to each other or vertically next to one another,

the internal temperature will increase due to the heat they

radiate and the service life of the products will decrease. In

such cases, forced cooling by fans or other means of air ventilation will be required to cool down the Temperature Controllers.

ensure proper heat dissipation. Do no block the ventilating

holes.

crimp terminals designed for M3.5 screws and with a width of

7.2 mm max.

7.2 mm max.

2

(0.205 mm

use a cable gauge of AWG28 (0.081 mm

(0.326 mm

ing part to be inserted into terminals must be 5 to 6 mm.

block lead wire with a force of 30 N or higher.

within specification and rating ranges before using the Temperature Controller.

Controller's terminal board away from power cables carrying

high voltages or large currents. Also, do not wire power lines

together with or parallel to Temperature Controller wiring.

Using shielded cables to separate pipes and ducts is recommended.

Attach surge absorbers or noise filters to peripheral devices

that generate noise (e.g., motors, transformers, solenoids,

magnetic coils, or other equipment that has an inductance

element). If using a noise filter with the power supply, be sure

to confirm the voltage and the current, and then mount the

power supply as near as possible to the Temperature Controller.

Set up the Temperature Controller, along with its power supply, as far away as possible from devices that generate

strong, high-frequency waves, such as high-frequency welders and high-frequency machines, and from devices that generate surges.

onds of turning the power ON.

warm up.

heater) at the same time as or before supplying power to the

Temperature Controller. If power is turned ON for the Temperature Controller before turning ON power for the load,

self-tuning will not be performed properly and optimum control will not be achieved.

) to AWG14 (2.081 mm2) for terminals 1 to 6, and

2

) for terminals 7 to 9. The exposed current-carry-

2

) to AWG22

http://www.ia.omron.com/

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

C-1

Page 7

14. In order that power can be turned OFF in an emergency by

the person operating the Temperature Controller, install the

appropriate switches and circuit breakers, and label them

accordingly.

15. Turn OFF the power before drawing out the Temperature

Controller body. Do not touch or apply excessive force to the

terminals or electronic parts. When inserting the body, make

sure that electronic parts do not come in contact with the

case.

16. When the terminal block for the E5GN is detached, do not

touch or apply excessive force to any electronic parts.

17. Use alcohol to clean the Temperature Controller. Do not use

thinner or other solvent-based substances.

18. Inverters with an output frequency of 50/60 Hz are available,

but they may cause the internal temperature of Temperature

Controller to rise, possibly resulting in smoke or burning. Do

not use an inverter output to supply power to a Temperature

Controller.

Precautions for Correct Use

● Service Life

1. Use the Temperature Controller within the specified temperature

and humidity ranges. If the product is installed inside a control

panel, the temperature around the Temperature Controller and

not the temperature around the control panel must be kept within

the specified temperature range.

2. The service life of electronic devices such as Temperature

Controllers is determined not only by the number of switching

operations performed by the relay, but also by the service life

of the internal electronic components. The service life of

these components depends on the ambient temperature: it

will be shorter if the ambient temperature is high and longer if

the ambient temperature is low. For this reason, the service

life of the product can be extended by keeping the internal

temperature of the Temperature Controller low.

3. If several Temperature Controllers are mounted side-by-side

or are arranged vertically, the heat generated by them may

cause the internal temperature of the products to rise, thus

reducing their service life. To prevent this, take steps to

ensure that the Temperature Controllers are cooled, such as

installing fans. When providing forced cooling, however, be

careful not to cool down the terminal sections alone to avoid

measurement errors.

● Measurement Accuracy

1. When extending the lead wires for thermocouples, use a compensating conductor appropriate for the type of thermocouple

use.

2. When extending the lead wires for platinum resistance thermometers, use lead wires with low resistance, and make the

resistance in the 3 lead wires equal.

3. The type of Temperature Sensor and the input type for the

Temperature Controller must be set the same.

4. There are two types of platinum resistance thermometers: Pt

and JPt. Accurate measurement will not be possible if the

input type for the Temperature Sensor is not set correctly.

5. Mount the Temperature Controller horizontally.

6. If significant errors occur, check to see if the input shift has

been set correctly.

● Waterproofing

Sections without any specification on their degree of protection or

those with IP@0 specifications are not waterproof.

● EN/IEC Compliance

Installing the following fuse in the power supply terminal block is recommended if the Temperature Controller is used in applications

requiring EN/IEC compliance.

Recommended fuse: A T2A, 250-VAC, time lag fuse with low breaking capacity

● Operating Precautions

1. It takes approximately five seconds for the outputs to turn ON

from the moment the power is turned ON. Due consideration

must be given to this time when incorporating Temperature Controllers in a sequence circuit.

2. When using the self-tuning capability of the E5@N, E5@ K, or

E5@J, supply power to the load (e.g., heater) at the same

time as or before supplying power to the Temperature Controller. If power is turned ON for the Temperature Controller

before turning ON power for the load, self-tuning will not be

performed properly and optimum control will not be achieved.

When starting operation after the Temperature Controller has

warmed up, turn OFF the power and then turn it ON again at

the same time as turning ON power for the load. (Instead of

turning the Temperature Controller OFF and ON again,

switching from STOP mode to RUN mode can also be used in

this case.)

3. The reception of the Temperature Controller may be affected

if it is used close to radios, television sets or wireless

devices.

http://www.ia.omron.com/

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

C-2

Page 8

Parameter Displays

The following displays are use to represent the characters for parameter names on the Temperature Controller.

● Seven-segment Digital DIsplay

ABCDEFGH I JK LMNOPQRSTUVWXY Z

● Eleven-segment Digital Display

ab cd e fgh ijk lm nopq rstuvw xyz

ABCDEFGH I JKLMNOPQRSTUVWXYZ

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

In the interest of product improvement, specifications are subject to change without notice.

http://www.ia.omron.com/

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

C-3

Page 9

Read and Understand This Catalog

Please read and understand this catalog before purchasing the products. Please consult your OMRON representative if you have any questions or

comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a period of one year (or other period if

specifi ed) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NON-INFRINGEMENT, MERCHANTABILITY, OR

FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE

HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS, OR COMMERCIAL

LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR

STRICT LIABILITY.

In no event shall responsibility of OMRON for any act exceed the individual price of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE PRODUCTS UNLESS

OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT

SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the combination of products in the customer's

application or use of the product.

At the customer's request, OMRON will provide applicable third party certifi cation documents identifying ratings and limitations of use that apply to the

products. This information by itself is not suffi cient for a complete determination of the suitability of the products in combination with the end product,

machine, system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not intended to be an exhaustive list of all possible

uses of the products, nor is it intended to imply that the uses listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or uses not described in this catalog.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical equipment, amusement machines, vehicles, safety

equipment, and installations subject to separate industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE

SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifi cations and accessories may be changed at any time based on improvements and other reasons.

It is our practice to change model numbers when published ratings or features are changed, or when signifi cant construction changes are made.

However, some specifi cations of the product may be changed without any notice. When in doubt, special model numbers may be assigned to fi x

or establish key specifi cations for your application on your request. Please consult with your OMRON representative at any time to confi rm actual

specifi cations of purchased product.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

ERRORS AND OMISSIONS

The information in this catalog has been carefully checked and is believed to be accurate; however, no responsibility is assumed for clerical,

typographical, or proofreading errors, or omissions.

PERFORMANCE DATA

Performance data given in this catalog is provided as a guide for the user in determining suitability and does not constitute a warranty. It may represent

the result of OMRON’s test conditions, and the users must correlate it to actual application requirements. Actual performance is subject to the OMRON

Warranty and Limitations of Liability.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any consequence thereof.

COPYRIGHT AND COPY PERMISSION

This catalog shall not be copied for sales or promotions without permission.

This catalog is protected by copyright and is intended solely for use in conjunction with the product. Please notify us before copying or reproducing this

catalog in any manner, for any other purpose. If copying or transmitting this catalog to another, please copy or transmit it in its entirety.

OMRON Corporation

Industrial Automation Company

http://www.ia.omron.com/

In the interest of product improvement, specifications are subject to change without notice.

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

2007.7

Loading...

Loading...