Omron E5ZE-8AQHD1TCB-V2, E5ZE-8ACAD1PB-V2, E5ZE-8AQHD1PB-V2, E5ZE-8ACAD1TCB-V2, E5ZE-8VQHD1TCB-V2 Datasheet

...Page 1

Multipoint Temperature Controller E5ZE-8@D1@B-V2 1

Multipoint Temperature Controller

E5ZE-8@D1@B-V2

Multipoint Temperature Controller Connects

to the Programmable Controller with Ease

• Conforms to De viceNet req uirements wit h remote I/O and FINS

message communications, thus connecting to a CompoBus/D

Master without prog rams f or remot e I/O commu nications an d to

OMRON’s Programmable Controller with ease for explicit message communicat ion s .

• High-speed inpu t sampling of only 0.2 s at the maxi mum of eigh t

temperature inputs.

Model Number Structure

■Model Number Legend

1. Number of Control Points

8: 8 channels

2. Control Method

A: Standard (heating or cooling)

V: Heating and cooling

3. Control Output (H e a ting Side)

Q: Voltage output (for driving SSR)

C: Current output

4. Heater Burnout and SSR Failure Detection (See note 1.)

H: Available

A: Not available

5. Communications Function

D1: DeviceNet

6. Input

TC: Thermocouple

P: Platinum resistance thermometer

7. Case

B: Provided (Models with case)

8. Version

V2: Supports explicit messages

Note: 1. Heater burnout and SSR failure detection are not available when the control output on the heating side is current output.

2. Refer to the List of Models for combinations of functions.

1 234

5

6

7

8

E5ZE-8@@@D1@B-V2

Page 2

2 Multipoint Temperature Controller E5ZE-8@D1@B-V2

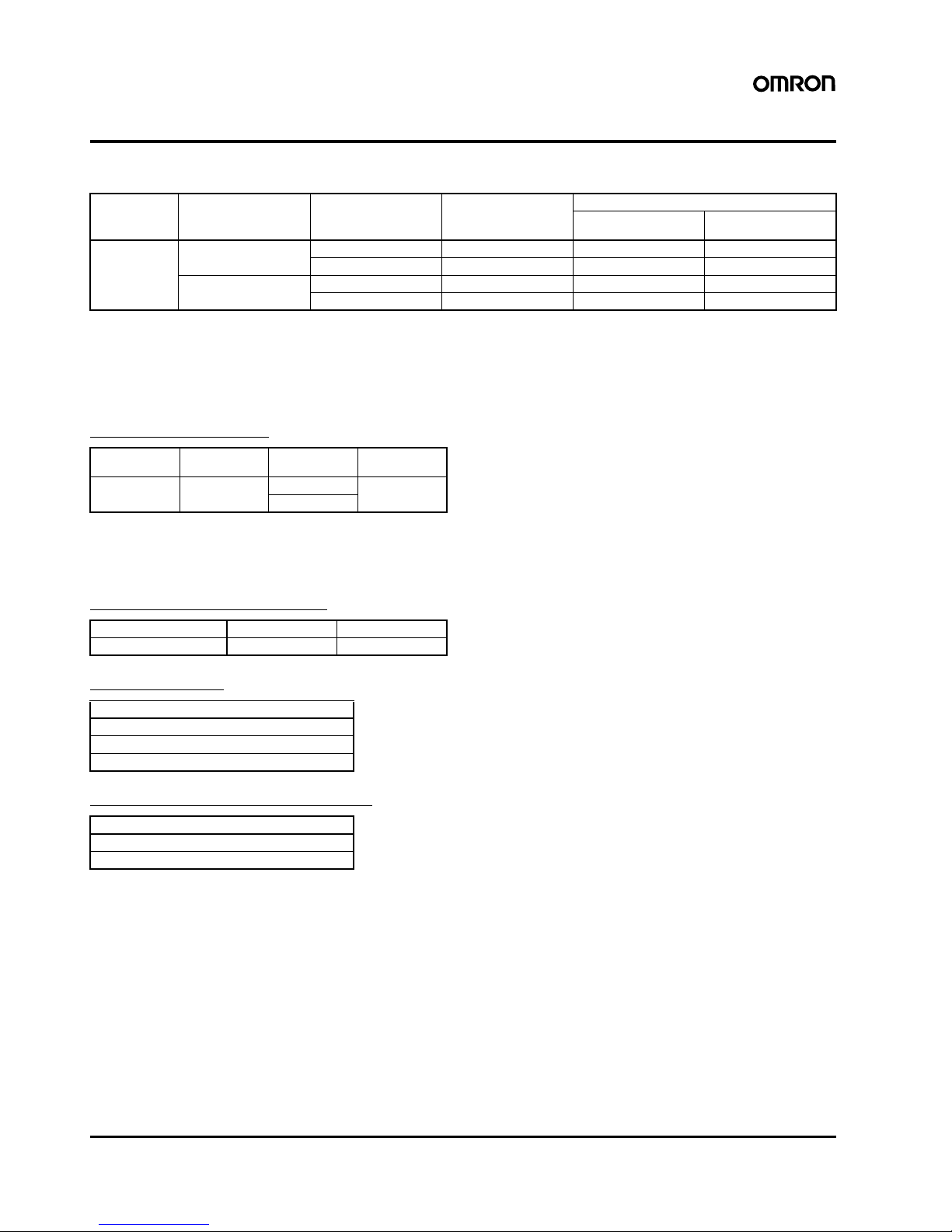

Ordering Information

■List of Models

Note: 1. Cooling control is possible by making a change in output operation.

2. Models without the heater burnout/SSR failure detection function are also available.

3. Cooling control output is an open collector output (NPN).

■Accessories (Order Separately)

Setting Display Unit

Note: Not all the functions of the E5ZE can be set, which should be

taken into consideration when designing the system. For details, refer to the E5ZD-SDL Setting Display Unit Datasheet

(H061).

Current Transformers (CT)

Special Cables

Recommended Power Supplies

No. of control

points

Control method Control output Heater burnout and

SSR failure detection

Input type

Thermocouple Platinum resistance

thermometer

8 Standard

(see note 1)

Voltage Available (see note 2) E5ZE-8AQHD1TCB-V2 E5ZE-8AQHD1PB-V2

Current Not available E5ZE-8ACAD1TCB-V2 E5Z E -8ACAD1PB-V2

Heating and cooling Voltage Available (see note 2) E5ZE-8VQHD1TCB-V2 E5ZE-8VQHD1PB-V2

Current (see note 3) Not available E5ZE-8VCAD1TCB-V2 E5ZE-8VCAD1PB-V2

Connecting

model

Connecting

part

Power supply Model

RS-232C Connector 100 to 240 VAC E5ZD-SDL1

24 VDC

Hole diameter 5.8 mm 12.0 mm

Model E54-CT1 E54-CT3

Model

E5ZE-CBL200

ES100-CT021-202 (25-pin)

ES100-CT023-202 (9-pin)

Series

S82J

S82K

Page 3

Multipoint Temperature Controller E5ZE-8@D1@B-V2 3

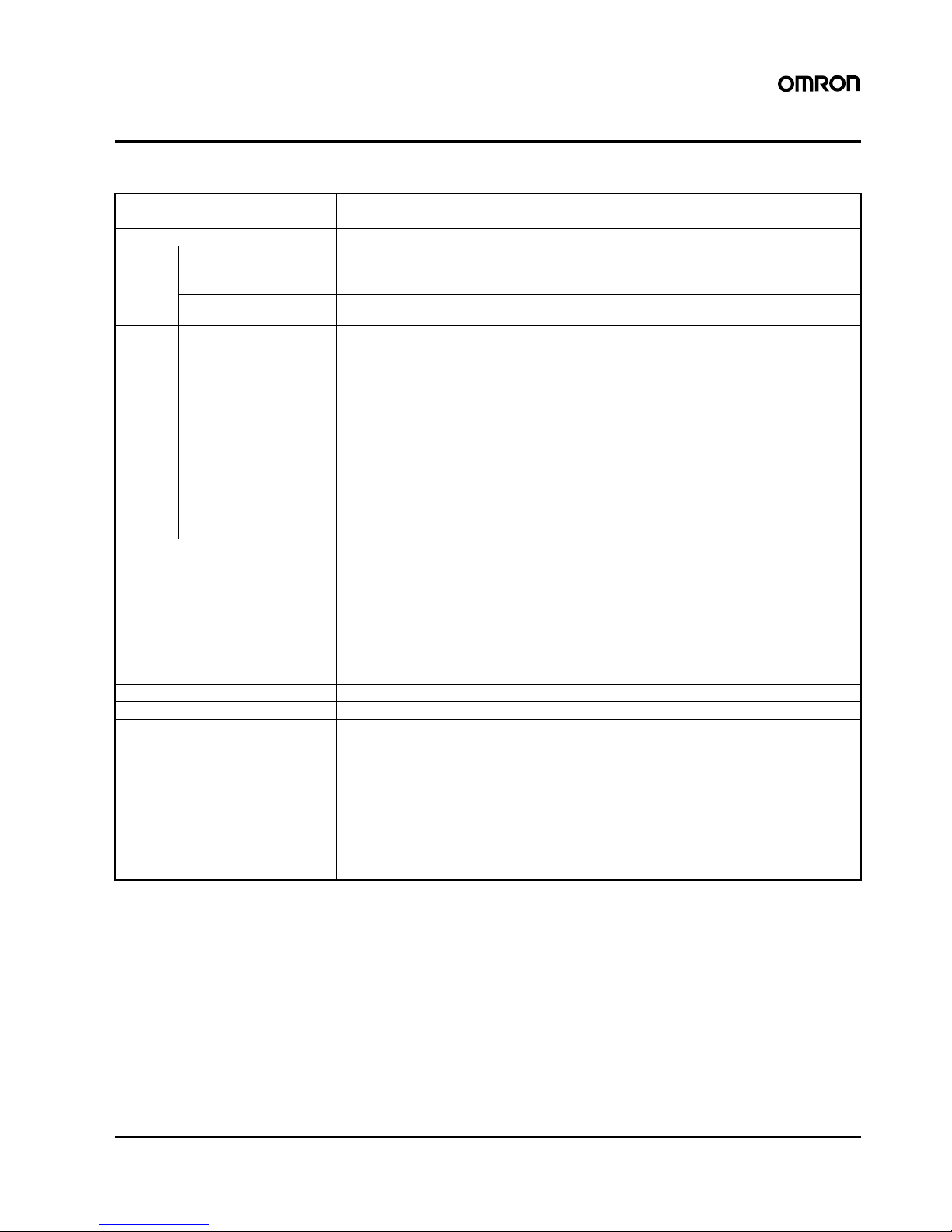

Specifications

■Ratings

Supply volt age 24 VDC

Operating voltage range 85% to 110% of rated supply voltage

Power cons um ption 15 W + 20% max. at rated supply voltage

Input Input type Thermocouple: K, J, R, S, T, E, B, N, L, U, W, PL-II

Platinum resistance thermometer: Pt100, JPt100

Input impedance Thermocouple: 1 M

Ω min.

Rated platinum resistance

thermometer current

1 mA

Control

outputs

Standard (Heating side) Voltage output (with short-circuit protecting function)

ON: 12

± 1.2 VDC

OFF: 0.5 VDC max.

Max. load current: 30 mA DC per point

Current output

Rated output range: 4 to 20 mA DC

Current output range: 0 to 22 mA DC

With an output value of 0%: 4

+0

/

–0.6

mA DC

With an output value of 100%: 20

+2

/–0 mA DC

Max. load resistance: 600

Ω per point

Cooling side Open collector output (NPN)

Max. applied voltage: 30 VDC

Max. load current: 50 mA DC per point

ON residual voltage: 2 VDC max.

OFF leakage current: 1 mA DC max.

Alarm outputs Temperature alarm: The total output of all control points (alarm 1 NPN open collector output and

alarm 2 NPN open collector output)

HB alarm (heater burnout detection): Total output of all control points (1-point NPN open collector

output)

HS alarm (SSR failure detection): Total output of all control points (1-point NPN open collector

output)

Temperature controller error output (memory, set value, or hardware error):

1-point NPN open collector output

Max. applied voltage: 30 VDC

Max. load current: 50 mA DC per point

No. of input control points 8 input and 8 control points

Setting method Via communication

Control modes ON/OFF control

Hybrid of advanced PID control and fuzzy control

Manual operation

Memory bank input No. of points: 8 for each control point

Designation method: Through communication or memory bank designation input

Memory bank designation inputs With contact signal input

ON short-circuit resistance: 1 k

Ω max.

OFF open resistance: 100 k

Ω min.

With no-contact signal input

ON residual voltage: 2 VDC max.

OFF leakage current: 1 mA DC max.

Page 4

4 Multipoint Temperature Controller E5ZE-8@D1@B-V2

■Input Ranges

Thermocouple

Platinum Resistance Thermometer

Note: 1. A temperature range is factory-set to a range of –200° to

1,300

°C (for K(CA)) or –100.0° to 500.0°C (for Pt 100).

2. Thermocouple W is W/ Re5-26 (tungsten rhenium 5, tungsten rhenium 26).

■Characteristics

Input

(switch

selectable)

K (CA)

Chromel

vs. alumel

(see

note 1)

J (IC)

Iron vs.

constan-

tan

R

Platinum

vs. Plati-

num rhod-

ium 13%

S

Platinum

vs. Plati-

num rhod-

ium 10%

T (CC)/U

Copper

vs. con-

stantan

E (CRC)

Chromel

vs. con-

stantan

B

Platinum

rhodium

30% vs.

platinum

rhodium

6%

N

Nichrosil

vs. nisil

L

Iron vs.

constan-

tan

U

Copper

vs. con-

stantan

W

(see

note 2)

PL-II

(Platinum)

Range

°C –200 to

1,300

–100 to

850

0 to 1,700 0 to 1,700 –200 to

400

0 to 600 100 to

1,800

0 to 1,300 –100 to

850

–200 to

400

0 to 2,300 0 to 1,300

°F –300 to

2,300

–100 to

1500

0 to 3,000 0 to 3,000 –300 to

700

0 to 1100 300 to

3,000

0 to 2,300 –100 to

1,500

–300 to

700

32 to 4,100 0 to 2,300

Setting no. 0123456789AB

Min. setting

unit

1

°C or 0.1°C

Input

(switch selectable)

Pt 100

(see note 1)

JPt 100

Range

°C –100.0 to 500.0 –100.0 to 500.0

°F –100.0 to 900.0 –100.0 to 900.0

Setting no. 01

Min. setting unit 1

°C or 0.1°C

Measurement accuracy (see note) Thermocouple:

(

±0.3% of the process value or ±2°C, whichever greater) ±1 digit max.

(

±0.3% of the process value or ±3.6°F, whichever greater) ±1 digit max.

Platinum resistance thermometer:

(

±0.3% of the process value or ±0.8°C, whichever greater) ±1 digit max.

(

±0.3% of the process value or ±1.5°F, whichever greater) ±1 digit max.

Hysteresis 0.0

° to 99.9°C/°F for ON/OFF control only (in units of 0.1°C/°F)

Cooling coefficient 0.0 to 10.0 (in units of 0.1)

Proportional band 0.0

° to 999.9°C/°F (in units of 0.1°C/°F)

Cooling side: Cooling coefficient

× Proportional band

Integral (reset) time 0 to 3,999 s (in units of 1 s) (for both heating and cooling)

Derivative (rate) time 0 to 3,999 s (in units of 1 s) (for both heating and cooling)

Control period Heating side: 1 to 99 s (in units of 1 s)

Cooling side: 1 to 99 s (in units of 1 s)

Sampling period 200 ms for 8 control points

Dead band/overlap band –999

° to 999°C/°F (in units of 1°C/°F)

Alarm output setting range –999

° to 9999°C/°F, 0 to 9999°C/°F (upper- and lower-limit alarm) (in units of 1°C/°F)

–999.9

° to 9999.9°C/°F, 0.0 to 9999.9°C/°F (upper- and lower-limit alarm) (in units of 0.1°C/°F) (see note

3)

Fuzzy strength 0% to 99% (in units of 1%)

Fuzzy scale 1 0.2

° to 999.9°C/°F (in units of 0.1°C/°F)

Fuzzy scale 2 0.02

° to 99.99°C/s or °F/s (in units of 0.01°C/s or °F/s)

Set value backup Lithium battery

Set value backup period 10 years min. provided that the ambient temperature is within the room temperature

Insulation resistance 20 M

Ω min. between the FG terminal and all analog input terminals (at 500 VDC)

Dielectric strength A leakage current of 1 mA A C max. with 500 VA C for 1 minutes between the FG terminal and all analog

input terminals

Vibration resistance

Malfunction: 10 to 55 Hz, 15 m/s

2

for 8 min each in X, Y, and Z directions

Destruction: 10 to 55 Hz, 20 m/s

2

for 8 min each in X, Y, and Z directions

Shock resistance

Malfunction: 150 m/s

2

, 3 times each in 6 directions

Destruction: 200 m/s

2

, 3 times each in 6 directions

Ambient temperature Operating: 0

° to 55°C (with no icing or condensation)

Storage: –25

° to 65°C (with no icing or condensation)

Ambient humidity Operating: 35% to 85%

Storage: 35% to 95%

Page 5

Multipoint Te mperature Controller E5ZE-8@D1@B-V2 5

Note: 1. The measurement accuracy of the E5ZE used with a thermocouple B at 400°C or 750°F max. is not guaranteed. The following measure-

ment accuracy values are applied to the E5ZE.

K and T at –100

°C max. and U: ±3°C ±1 digit max.

K and T at –100

°F max. and U: ±5.4°F ±1 digit max.

R, S, and W at 200

°C max., and B at 1,000°C max.: ±4°C ±1 digit max.

R, S, and W at 400

°F max., and B at 1,800°F max.: ±7.2°F ±1 digit max.

2. The measurement accuracy of the E5ZE used with any thermocouple is 1

°C/°F. The thermocouple can be used under the following tem-

perature ranges to increase the measurement accuracy to as high as 0.1

°C/°F.

K thermocouple: 0.0

°C to 1,300.0 °C, 0.0 °F to 2,300.0 °F

T or U thermocouple: 0.0

°C to 400.0 °C, 0.0 °F to 700.0 °F

N thermocouple: 400.0

°C to 1,300.0 °C, 700.0 °F to 2,300.0 °F

J, E, L, or PLII thermocouple: Any temperature

3. Upper limit is 3000.0

°C/°F when set from CompoBus/D.

■Communications Specifications

Conforming to DeviceNet Communications Protocol

For details, refer to the CompoBus/D (DeviceNet) Operation Manual (W267) and the E5ZE-8 Communication Manual (H114).

Note: 1. An external term inator must be attached.

2. Indicates the distance between nodes farthest from each other.

3. The maximum network length is 100 m if a thin dedicated cable is applied to the trunk line.

!NOTICE

This product has been tested by ODVA’s authorized Independent

Test Lab and found to comply with ODVA Conformance Test Software Version A-13.

For the specifications of objects in details, refer to the E5ZE-8 Com-

munication Manual (H114).

DeviceNet Communications Items

Note: Items for the OUT side of remote I/O are not included.

Dimensions With casing: 173.5 x 253 x 65 mm max.

Enclosure rating IP00

Weight With casing:1,700 g max.

Connection method Multi-drop or T-branching (see note 1)

Baud rate 500/250/125 kbps

Communications media Dedicated 5-wire cable (with 2 communications wires, 2 power wires, and 1 shield wire)

Communications distance Baud rate

Maximum network length (see note 2) Branch line length Total branch line length

500 kbps 100 m max. (see note 3) 6 m max. 39 m max.

250 kbps 250 m max. (see note 3) 6 m max. 78 m max.

125 kbps 500 m max. (see note 3) 6 m max. 156 m max.

Remote I/O points IN: 14 / OUT: 9

Error control CRC error and node address duplication check

Remote I/O communications IN: PV (process value) (8 points), Alarms 1 and 2 status, AT status, HB alarm status,

HS alarm status, and error status

OUT: RUN/STOP and SP (set point) (8 points)

Explicit message communications All read and write parameters (See note.)

Page 6

6 Multipoint Temperature Controller E5ZE-8@D1@B-V2

System Configuration

!Caution

Be sure to use the above Units, which save wiring effort, and connection cables for the prevention of malfunctions or accidents that

may be caused by mistakes in wiring.

Dimensions

Note: All units are in millimeters unless otherwise indicated.

ES100-CT021-202 or

ES100-CT023-202

Power supply input

Regulated DC

power supply

Temperature

sensor input

Thermocouple

Platinum resistance

thermometer

E5ZE-8@D1@B-V2

E5ZE-CBL200

E5ZE-CBL200

E5ZE-CBL200

XW2D-20G6

Connector−Terminal

Conversion Unit

XW2D-20G6

Connector−Terminal

Conversion Unit

G7TC-OC08/G7TC-OC16

I/O Block

G70D-V@O@16

Relay terminal

Host Unit Compatible with Explicit

Message Communications

OMRON's C200HW-DRM21-EV1,

CVM1-DRM21-EV1 and CS1W-DRM21

Note: When replacing with an E5ZE-

8@D1@B, part of the ladder

program must be changed.

E5ZD-SDL1

Setting Display Unit

Note: Do not use the RS-232C auxiliary jack for permanent

connection when the E5ZE is mounted to equipment.

E5ZE-8@D1-@B-V2

Mounting

bracket

Mounting Holes

Mounting

bracket

Four, M4

Page 7

Multipoint Te mperature Controller E5ZE-8@D1@B-V2 7

Precautions

Mounting the Controllers

Side-by-side, Close Mounting

Saves space and improves wiring efficiency.

Wall Mounting

Can be mounted to places with limited depth.

General Mounting Precautions

The side of the E5ZE with the terminal block and connectors must

not face up, otherwise operating errors may result.

Prepare four M4 screws to mount the E5ZE to control panels. Use

flat washers and spring washers with screws to mount the E5ZE to

control panels so that the screws will not loosen.

The mounting brackets must be attached to the E5ZE with the four

M3

×6 screws provided with the E5ZE and each of the screws should

be tightened to a torque of 0.43 to 0.58 N·m, or 4.4 to 5.9kgf·cm.

Do not mount as shown in the following diagram.

Control panel

Up

Control panel

Up

Control panel

Incorrect

Page 8

8

In the interest of product im pr ovement, specifications are subject to change without notice.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. H103-E1-02

OMRON Corporation

Industrial Automation Company

Industrial Devices and Components Division H.Q.

Measuring Components Department

Shiokoji Horikawa, Shimogyo-ku,

Kyoto, 600-8530 Japan

Tel: (81)75-344-7080/Fax: (81)75-344-7189

Printed in Japan

0703-0.3M (1098) (A)

Warranty and Limitations of Liability

■WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a period of one year (or other period if

specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENT ATION, EXPRESS OR IMPLIED, REGARDING NON-INF RINGEMENT , MERCHANT ABILIT Y ,

OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR USER ACKNOW LEDGES THAT THE BUYER OR USER

ALONE HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE. OMRON

DISCLAIMS ALL OTHER WARRANTIES, EXPRESS O R IMP L IE D.

■LIMITATIONS OF LIAB ILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS, OR

COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY,

NEGLIGENCE, OR STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REP AIR, OR O T HER CLAIMS REGARDING THE PRODUCTS UNLESS

OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORE D , INSTALLED, AND MAINTAINED AND NOT

SUBJECT TO CONTAMINATION, ABUS E, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Application Considerations

■SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the combination of products in the

customer's application or use of the products.

At the customer's request, OMRON will provide applicab le third party certification documents identifying ratings and limitations of use that apply

to the products. This information by itself is not sufficient for a complete determination of the suitability of the products in combination with the end

product, machine, system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not intended to be an exhaustive list of all

possible uses of the products, nor is it intended to imply that the uses listed may be suitable for the products.

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or uses not described in this catalog.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical equipment, amusement machines, vehicles,

safety equipment, and installations subject to separate industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOL V ING SERIOUS RISK TO LIFE OR PROPER TY WITHOUT ENSURING THAT THE

SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED

AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Loading...

Loading...