Omron E5ZE-8 Communications Manual

E5ZE-8

Multipoint Temperature Controller

Communications Manual

Produced December 2000

Notice:

r

f

OMRON products are manufactured for use accordin g to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to ind icate and classify pr ecautions in this manual . Always heed

the information provided with them . Failure to heed precautions can result in in jur y to people or damage to property.

!DANGER Indicates an immine ntly hazardous situation whi ch, if not avoided, will result in death or

serious inj ury.

!WARNING Indicates a potentially hazardous situatio n which, if not avoided, could resu lt in death or

serious inj ury.

!Caution Indicates a potentially hazardous situat ion which, if not avoided, may result in mino r or

moderate injury, or property damage.

OMRON Product References

All OMRON products are c apitalized in this manual. The word “Unit” is als o capita lized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation

thing else.

“Ch,” which appears i n so me di sp lays and on some OMRON produc ts, o ften me ans

“PC” means Programmable Controller and is not used as an abbreviation for any-

Visual Aids

The following headings appear in the left co lumn of the manual to help you locate different types of

information.

Note Indicates information of pa rticular interest for efficient and convenient opera-

tion of the product.

1,2,3...

1. Indicates lists of one sort or another, such as procedures, checklists, etc.

ODVA Conformance

This product has been tested by a third party test laboratory officially recognized by the Open

DeviceNet Vendor Association, Inc. and conforms to the ODVA test software Ver. 2.0 to 1.00.

OMRON, 2000

All rights reserved. No part of this public ation may be reprod uc ed, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability i s a ssume d with re spec t to th e u se of th e info rmatio n con tain ed he re in. M oreover, beca use OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

v

TABLE OF CONTENTS

PART 1: DEVICENET COMMUNICATIONS

SECTION 1

Overview of Communications Functions . . . . . . . . . . . . 3

1-1 DeviceNet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-2 Remote I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-3 DeviceNet Explicit Message Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SECTION 2

Communications Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2-1 Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-2 Communications Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SECTION 3

Remote I/O Communications. . . . . . . . . . . . . . . . . . . . . . 9

3-1 Transmission Contents and Word Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3-2 Reading Process Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3-3 Reading Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3-4 Temperature Control Start/Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3-5 Writing Set Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3-6 Remote I/O Delay Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

SECTION 4

DeviceNet Explicit Message Communications . . . . . . . . 17

4-1 Transmitting DeviceNet Explicit Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4-2 E5ZE Fixed Command Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4-3 Instruction Execution Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4-4 DeviceNet Explicit Messages Set Values and Measurement Values . . . . . . . . . . . 21

SECTION 5

Communications Errors. . . . . . . . . . . . . . . . . . . . . . . . . . 33

5-1 End Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5-2 Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

SECTION 6

Communications Program Examples . . . . . . . . . . . . . . . 39

6-1 CVM1 and CV-series PCs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6-2 C200HX/C200HE/C200HG PCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6-3 CS1 PCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Appendix AMulti-vendor Applications. . . . . . . . . . . . . . 61

Appendix ABasic I/O Slave Device Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Appendix AObject Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

vii

TABLE OF CONTENTS

PART 2: SERIAL COMMUNICATIONS

SECTION 1

Serial Communications Control. . . . . . . . . . . . . . . . . . . . 67

1-1 Communications Control Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

1-2 Block Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

1-3 FCS Calculations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

1-4 Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

1-5 Error Processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

SECTION 2

Commands and Responses . . . . . . . . . . . . . . . . . . . . . . . . 71

2-1 Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

2-2 Writing Sets of Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

2-3 Reading Sets of Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

2-4 End Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

2-5 Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

SECTION 3

Basic Temperature Control Commands . . . . . . . . . . . . . 87

3-1 Set Point Write: WS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

3-2 Set Point Read: RS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

3-3 Process Value Read: RX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

3-4 Output Value Read: RO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

3-5 Proportional Band Write: WB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

3-6 Proportional Band Read: RB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

3-7 Integral Time Write: WN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

3-8 Integral Time Read: RN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

3-9 Derivative Time Write: WV. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

3-10 Derivative Time Read: RV. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

3-11 Control Period Write: WT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

3-12 Control Period Read: RT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

3-13 Output Operation (Normal/Reverse) Write: WU. . . . . . . . . . . . . . . . . . . . . . . . . . 101

3-14 Output Operation (Direct/Reverse) Read: RU. . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

3-15 Alarm Mode Write: W#. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

3-16 Alarm Mode Read: R#. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

3-17 Alarm Temperature Write: W%. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

3-18 Alarm Temperature Read: R%. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

3-19 Memory Bank Designation Write: WM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

3-20 Memory Bank Designation Read: RM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

3-21 Hysteresis Write: WH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

3-22 Hysteresis Read: RH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

3-23 Status Read: RX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

3-24 Error Read: RU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

viii

TABLE OF CONTENTS

SECTION 4

Commands According to Application. . . . . . . . . . . . . . . 119

4-1 Auto-tuning Start: AS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

4-2 Auto-tuning Stop: AP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

4-3 Setting Unit Write: Wt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

4-4 Setting Unit Read: Rt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

4-5 Input Shift Write: WI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

4-6 Input Shift Read: RI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

4-7 Manual Reset Value Write: WK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

4-8 Manual Reset Value Read: RK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

4-9 Ramp Value Write: WR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

4-10 Ramp Value Read: RR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

4-11 Present Set Point Read: Rs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

4-12 Manual Output Value Write: WO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

4-13 Output Variable Limit Value Write: WL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

4-14 Output Variable Limit Value Read: RL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

4-15 Output Variable Change Rate Limit Value Write: WG. . . . . . . . . . . . . . . . . . . . . . 134

4-16 Output Variable Change Rate Limit Value Read: RG. . . . . . . . . . . . . . . . . . . . . . . 136

4-17 Memory Write: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

4-18 Initialize Setting Data: MC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

4-19 Communication Test: TS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 38

SECTION 5

Heater Burnout and SSR Failure Detection Commands 141

5-1 HB Alarm and HS Alarm Point Write: WU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

5-2 HB Alarm and HS Alarm Point Read: RU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 43

5-3 Heater Burnout and SSR Failure Detection Current Value Write: WW. . . . . . . . . 144

5-4 Heater Burnout and SSR Failure Detection Current Value Read: RW . . . . . . . . . . 145

5-5 Heater Current Value and SSR Leakage Current Value Read: RZ . . . . . . . . . . . . . 1 46

SECTION 6

Heating and Cooling Control Commands . . . . . . . . . . . 149

6-1 Dead Band and Overlap Band Write: WD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

6-2 Dead Band and Overlap Band Read: RD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

6-3 Cooling Coefficient Write: WC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

6-4 Cooling Coefficient Read: RC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

ix

TABLE OF CONTENTS

SECTION 7

Fuzzy Control Commands . . . . . . . . . . . . . . . . . . . . . . . . 155

7-1 Fuzzy Strength Write: Wj . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

7-2 Fuzzy Strength Read: Rj . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

7-3 Fuzzy Scale 1 Write: Wk. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

7-4 Fuzzy Scale 1 Read: Rk. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

7-5 Fuzzy Scale 2 Write: Wl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

7-6 Fuzzy Scale 2 Read: Rl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

SECTION 8

Control Operation Start and Stop Commands. . . . . . . . 163

8-1 Operation Start: OS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

8-2 Operation Stop: OP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

8-3 Manual Operation Start: OM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

x

About this Manual:

This manual describes DeviceNet (CompoBus/D) and serial communications (using the RS-232C auxiliary se tting j ack) for E5Z E

tions described b elow. DeviceNet communications are de scrib ed in part 1 and se rial communicatio ns

are described in part 2.

Please read this manual carefully and be sure you understand the information provided before

attempting to use DeviceNet communications with an E5ZE Multipoint Temperature Controller.

Read the following manuals before operating a E5ZE

ler.

E5ZE Multipoint Temperature Controller Operation Manual (Cat. No. H076)

DeviceNet (CompoBus/D) Operation Manual (Cat. No. W267)

-DRM21 DeviceNet Unit Operation Manual (Cat. No. W380)

CS1W

DeviceNet PCI Board Operation Manual (Cat. No. W381)

Part 1: DeviceNet Communications

Section 1 provides an overv iew of remote I/O an d Expli cit Mes sages th at are supported by the E5ZE

for DeviceNet communications.

Section 2 provides details on installing the E5ZE in a DeviceNet Network and setting the DIP switch.

Section 3 provides details on remote I/O communications, including allocations in the PC, various

operating statuses, flags, and applications.

Section 4 provides details on DeviceNet explicit messages, including comm and and response for-

mats, the instructi ons used by the PC to execute DeviceNet explicit message communica tions, and

tables of set values and measure ment values showing s etting rang es, default values, data types, and

addresses.

Section 5 provides details on response end codes and indicators u sed to identify communications

errors.

Section 6 provides programming examples for both CV-series and C200HX/C200HE/C 200HG PCs.

The Appendix provides details on multi

-8@@@D1@B-V2 Multipoint Temperature Controllers and includes t he sec -

-vendor applications.

-8@@@D1@B-V2 Multipoint Temperature Control-

Part 2: Serial Communications

Section 1 provides general information on serial communications and communications checks.

Section 2 provides a li st of comm ands, end code s, and error co des. Informatio n on writi ng and rea d-

ing data sets are also provided.

Section 3 describes the basic temperature control commands

Section 4 describes the commands that are used according to the application.

Section 5 describes the commands used for heater burnout and SSR failure detection.

Section 6 describes the commands used for heating and cooling control.

Section 7 describes the commands used for fuzzy control.

Section 8 describes the commands used for starting and stopping operation.

The Appendices provide communications programming examples and an ASCII code list.

!WARNING Failure to read and understand the information provided in this manual may

result in personal in jury or dea th, damage to the product, or product failure.

Please read each section in its entirety and be sure you understand the information provided in the s ection and r elated secti ons before attempt ing any of

the procedures or operations given.

Part 1

DeviceNet Communications

This part of the manual provides information required to communicate on a DeviceNet network.

1

SECTION 1

Overview of Communications Functions

This section provides an overview of remote I/O and Explicit Messages that are supported by the E5ZE for DeviceNet

communications.

1-1 DeviceNet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-2 Remote I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-3 DeviceNet Explicit Message Communications. . . . . . . . . . . . . . . . . . . . . . . . 4

3

DeviceNet Section 1-1

1-1 DeviceNet

DeviceNet (CompoBus/D) is a multi-vendor, open-field network that combines

control and informatio n at the machine and line con tr ol l evel. The E5ZE Mult ipoint Temperature Controller with DeviceNet communications supports the

following transmission services.

• Remote I/O

• DeviceNet explicit message communications

For details on the methods for connecting and configuring a DeviceNet network, refer to the DeviceNet (CompoBus/D) Operation Manual (Cat. No.

W267).

This part of the manual describes mainly how to operate the E5ZE as a Slave

in a DeviceNet network. It is assumed that the E5ZE is connected to an

OMRON CVM1

DeviceNet Master Unit, or CS1W

When using DeviceNet, use an E5ZE

-DRM21-EV1 DeviceNet Master Unit, C200HW-DRM21-EV1

-DRM21 DeviceNet Unit.

-8@@@D1@B-V2 model.

1-2 Remote I/O

The remote I/O function allows I/O data to be exchanged automatically

between the DeviceNet Master Unit and the E5 ZE, without the need of any

special programs. The remote I /O function enables the following functi ons in

the E5ZE.

• Reading the process value and different operating statuses.

• Writing set points.

• Executing commands to start and stop temperature control.

1-3 DeviceNet Explicit Message Communications

DeviceNet explicit messages are used to read and write messages for Slaves,

and perform various contro l operations, acco rding to the program being used

by the host system. DeviceNet explicit message communications enable the

following functions in the E5ZE.

• Reading and writing set values and process values.

•

Starting and stopping auto-tuning (AT), and other operating directions.

4

SECTION 2

Communications Setup

This section provides details on installing the E5ZE in a DeviceNet network and setting the DIP switch.

2-1 Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-2 Communications Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5

Cable Connections Section 2-1

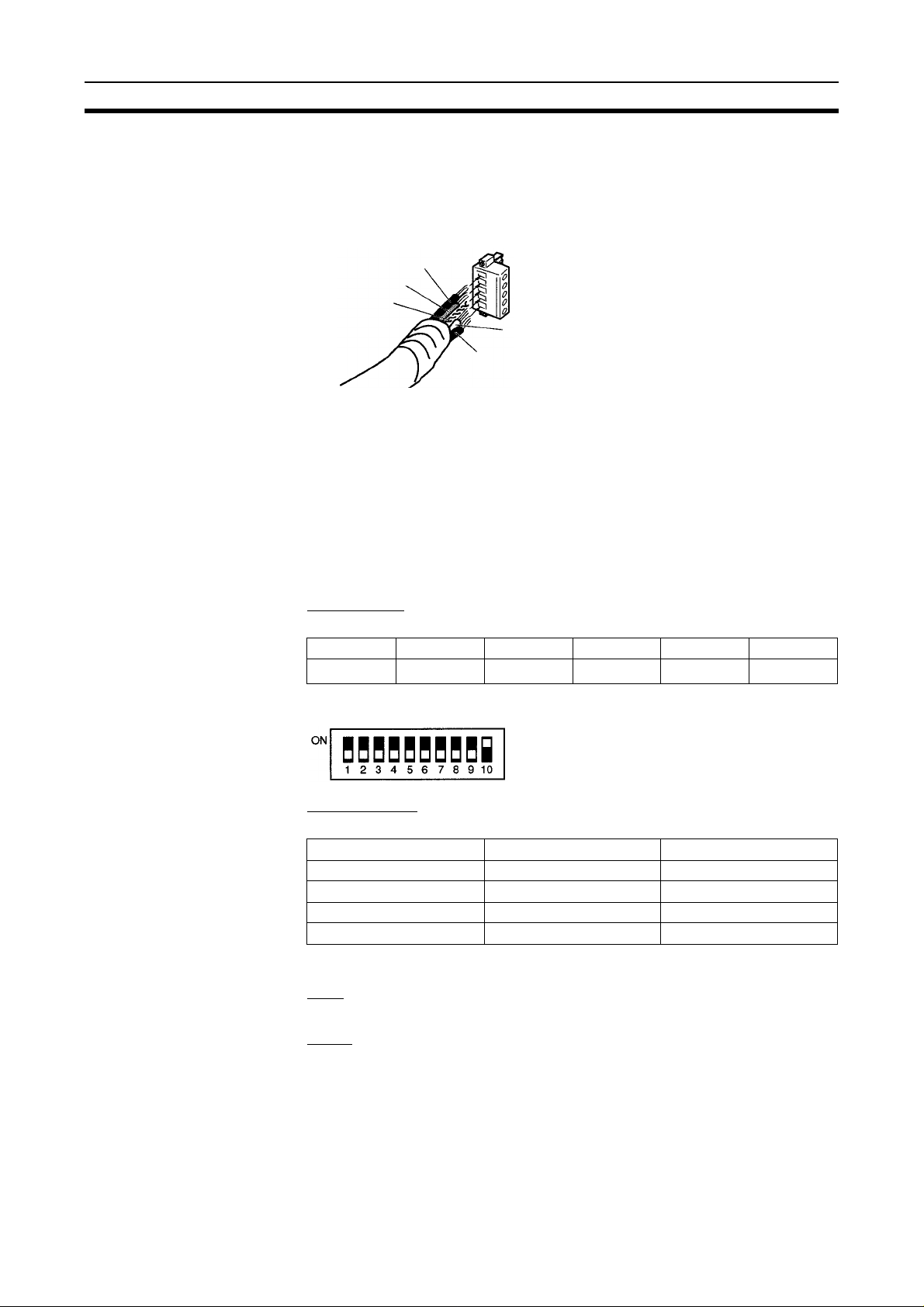

2-1 Cable Connections

Wire the DeviceNet co nnector as s hown in the following diagram. For details

on connecting the Mast er Unit to the E5ZE, refer to the D eviceNet (Compo-

Bus/D) Operation Manual ( Cat. No. W267). Multi

-drop connectors cann ot be

used to connect the E5ZE to the CompoBus/D Master Unit.

Black (-V)

Blue (CAN low)

Shield

White (CAN high)

Red (+V)

2-2 Communications Parameters

Be sure to set the following parameters.

• Node Address

Make sure that the E5ZE node addres s sett ing s and w ords allo ca ted to the

E5ZE are not the same as those set for any other Slave.

•

Baud Rate

Set the same baud rate on the E5ZE and DeviceNet Master Unit.

DeviceNet DIP Switch

Pin 1 to Pin 6

The node address is set using pins 1 to 6.

Pin 1 Pin 2 Pin 3 Pin 4 Pin 5 Pin 6

0

2

Pins 1 to 6 are all factory

1

2

2

2

3

2

4

2

5

2

-set to OFF (node address 00).

Pin 7 and Pin 8

The baud rate is set using pins 7 and 8.

Baud rate Pin 7 Pin 8

125 kbps OFF OFF

250 kbps ON OFF

500 kbps OFF ON

Not used ON ON

Pins 7 and 8 are both factory

-set to OFF (baud rate of 125 kbps).

Pin 9

Always set pin 9 to OFF.

Pin 10

When a DeviceNet communicatio ns error occurs, set th e E5ZE operation as

follows:

ON

Temperature control will continue accor ding to the data that was transmitted immediately before the error occurred.

OFF

Operation is stopped. (Pin 10 is set to ON at the factory.)

6

Communications Parameters Section 2-2

DeviceNet Communications Error

A DeviceNet communications error indic ates a transmission data error or a

connection time

-out error between the DeviceNet Master Unit and the E5ZE.

7

SECTION 3

Remote I/O Communications

This section provides details on remote I/O communicatio ns, including allocations in the PC, various operating statuses,

flags, and applications.

3-1 Transmission Contents and Word Allocations . . . . . . . . . . . . . . . . . . . . . . . . 10

3-2 Reading Process Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3-3 Reading Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3-3-1 Alarm Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3-3-2 Auto-tuning Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3-3-3 Operating Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3-4 Temperature Control Start/Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3-4-1 Startup Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3-4-2 Manual Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3-5 Writing Set Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3-6 Remote I/O Delay Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

9

Transmission Contents and Word Allocations Section 3-1

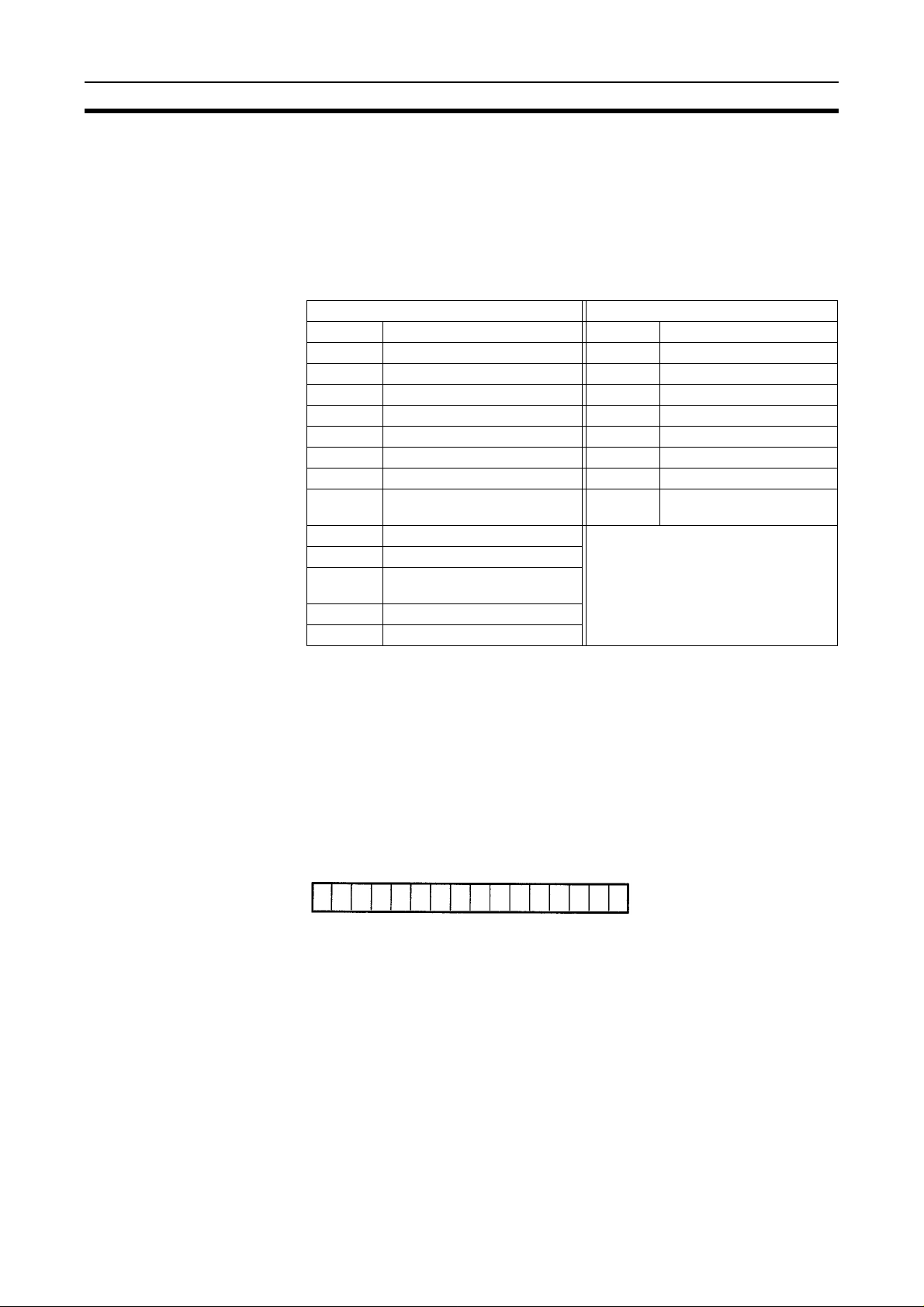

3-1 Transmission Contents and Word Allocations

When remote I/O c ommunications are used with the E5ZE, readi ng the process value, star ting and stoppin g temperature control, and writing s et points

are possible for any control point, without requiring a s pecial program to be

executed from the Master Unit. Data is autom atically ref reshed at every 200

ms cycle. There are 14 input words and 9 output words allocated to the E5ZE

in the Master Unit (I/O directions are in r eference to the Master Unit). Each

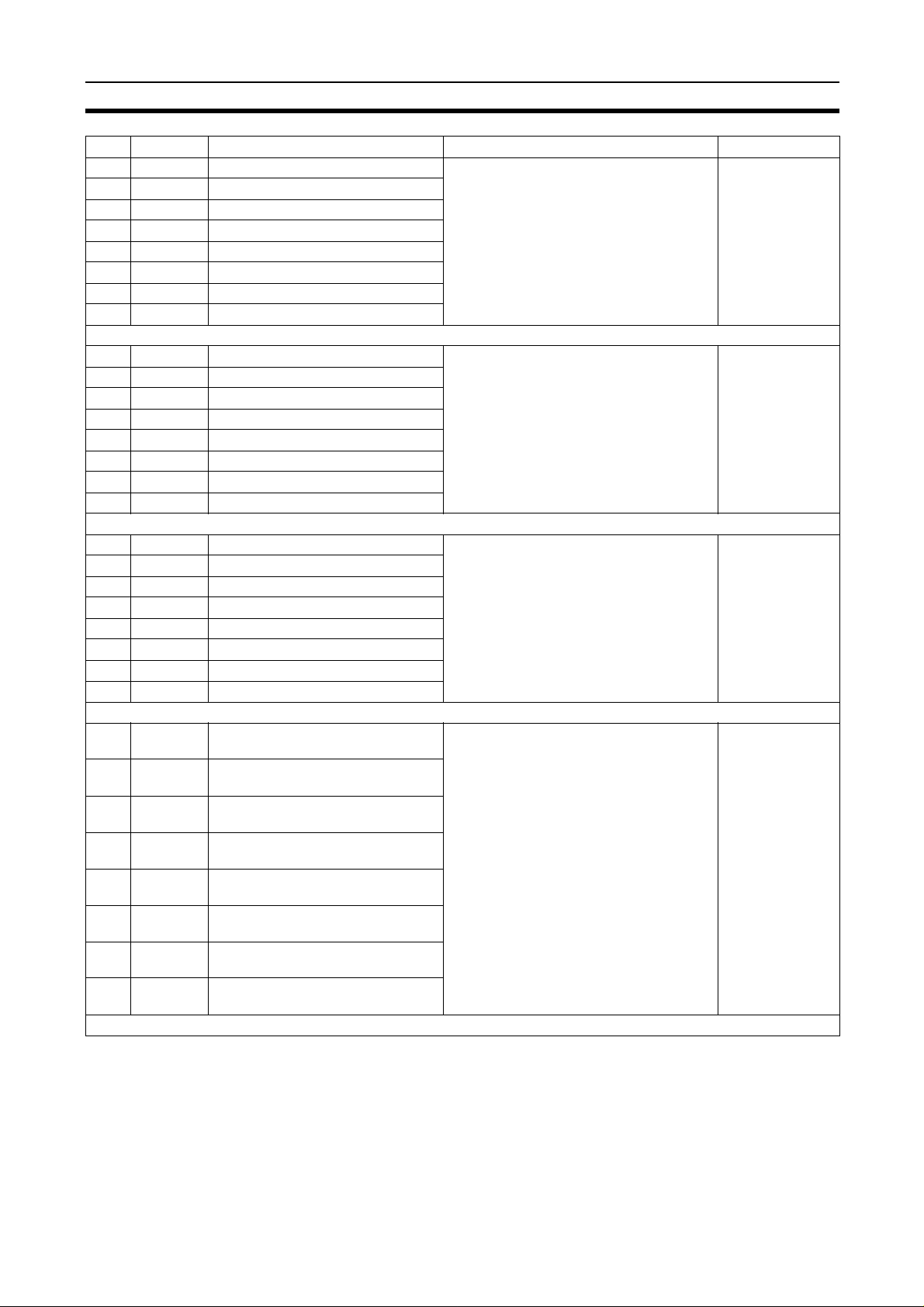

word is allocated according to the following table.

Inputs Outputs

First word Control point 0 process value First word Control point 0 set point

+ 1 Control point 1 process value + 1 Control point 1 set point

+ 2 Control point 2 process value + 2 Control point 2 set point

+ 3 Control point 3 process value + 3 Control point 3 set point

+ 4 Control point 4 process value + 4 Control point 4 set point

+ 5 Control point 5 process value + 5 Control point 5 set point

+ 6 Control point 6 process value + 6 Control point 6 set point

+ 7 Control point 7 process value + 7 Control point 7 set point

+ 8 Alarm 1 status + 8 Start/stop temperature

control

+ 9 Alarm 2 status --+ 10 Auto-tuning status

+ 11 HB (heater burnout) alarm sta-

tus

+ 12 HS (SSR failure) alarm status

+ 13 Operating status

-

The first input and output words are normally determined according to the

Master Unit being used and the node address. The first I/O words can be

changed and a Configurator is used to change the Master Unit settings.

3-2 Reading Process Values

The process value for each control point is expressed as 16 -bit s igned bin ar y

data (two

cated in the Master Unit mou nted to the PC. The unit used depends on the

position of the deci mal point in the E5ZE. T he default values are 1

thermocouples and 0.1

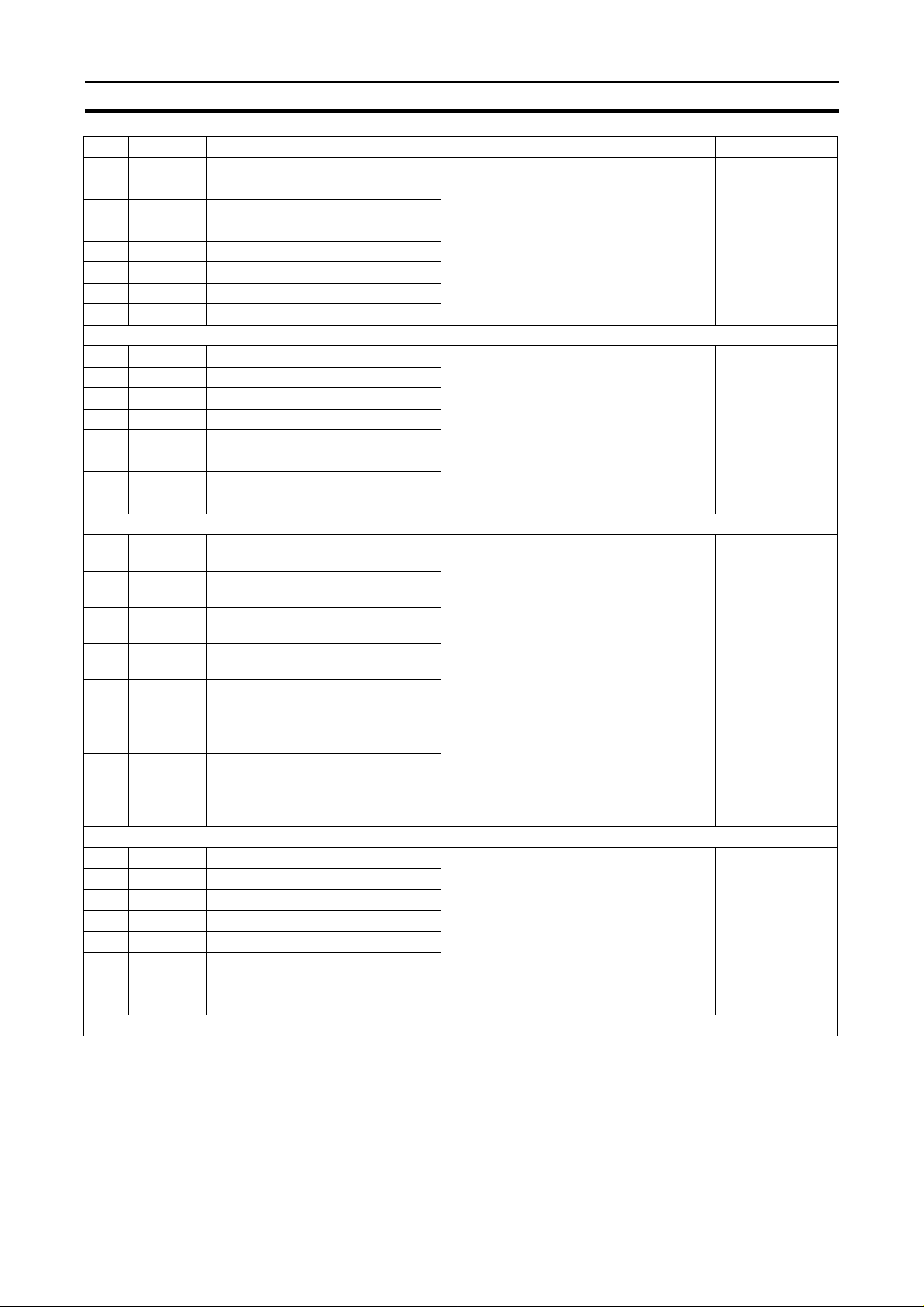

Leftmost bit Rightmost bit

Example

If the setting unit is 0.1°C/°F, and the value in the allocated word is

1111110001111100, the conversion values are as follows:

Binary Hexadecimal Decimal Process value

1111110001111100 FC7C -900 -90.0

If the value in the word is 0000010001001100, the values are as follows:

Binary Hexadecimal Decimal Process value

0000010001001100 044C 1100 110.0

’s complement for negative values) in the correspon ding word allo-

°C/°F for

°C/°F for platinum resistance thermometers.

°C

°C

10

Reading Status Section 3-3

The following table shows the values that will be contained in th e co rres po nding word under certain conditions.

Status details Value (hexadecimal)

Process value overflow or input error 7FFF

Process value underflow 8000

Temperature Controller error or connec-

tion confirmation standb y

Outside temperature display range 7D00

0000 or the last value sent

3-3 Reading Status

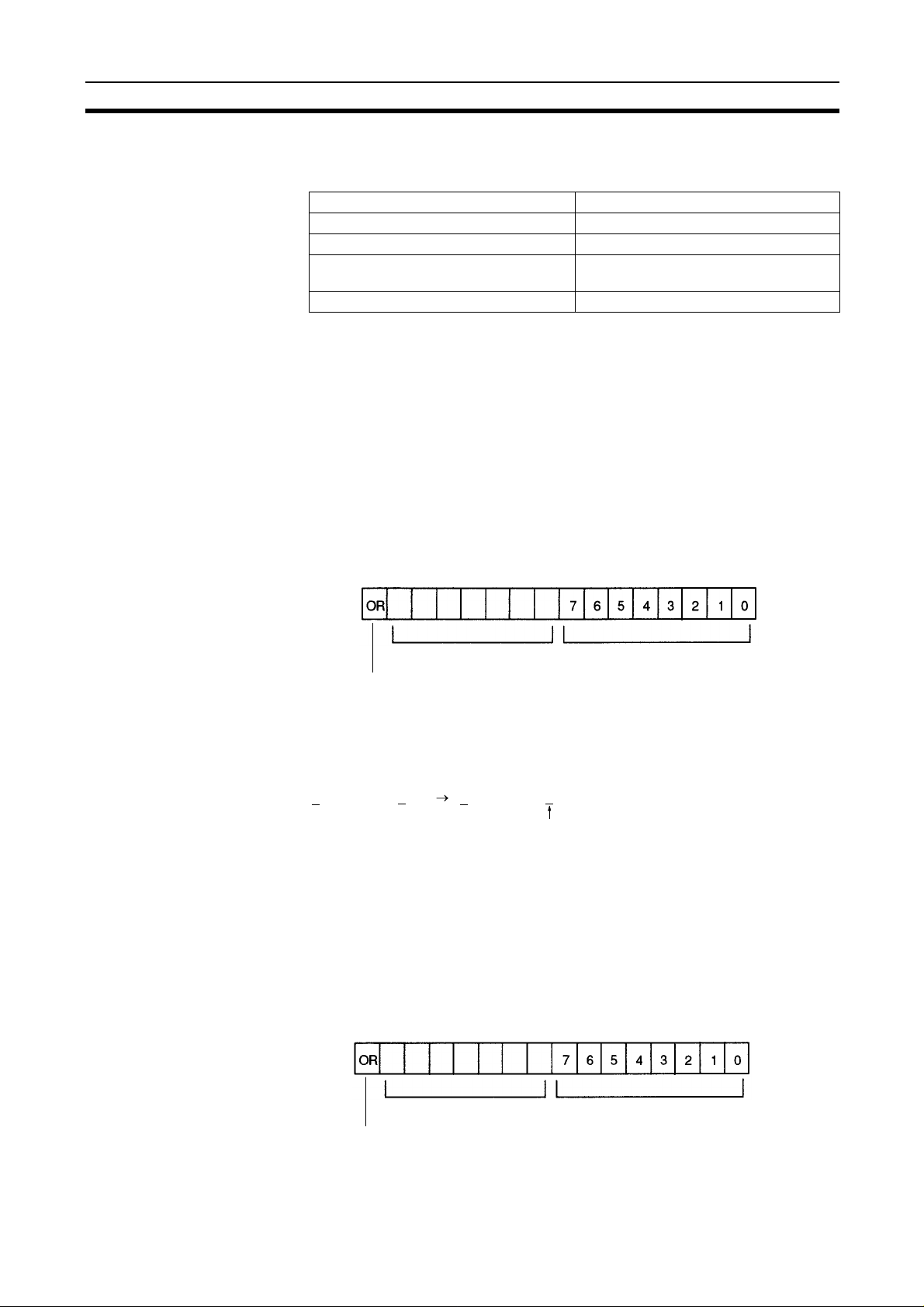

3-3-1 Alarm Status

Alarms 1 and 2, HB and HS Alarms

The alarm status is expressed in the corr esponding word in the PC to which

the Master Unit is connected as shown in the following diagram. The format is

the same for the alarm 1, alar m 2, HB (h eater burnout ) alar m, and HS (SS R

failure) alarm.

Alarm Status

This bit will change from 0 to 1 when an

alarm is ON for any control point.

Example

If the alarm 1 is OFF for all con trol poin ts and then t ur ns ON for contr ol point

3, the contents of the corresponding word in the PC will change as follows:

0000000000000000 ® 1000000000001000

When alarm 1 turns OFF for control point 3, the contents of the corresponding

word will return to 0000000000000000.

3-3-2 Auto-tuning Status

The auto-tuning status is reflected in the corresponding word in the PC to

which the Master Unit is mounted.

Leftmost bit Rightmost bit

0000000 (fixed) Alarm status for control points 0 to 7

Auto-tuning Status

(The bit corresponding to the control

point for which the alarm is ON will

change from 0 to 1.)

Alarm 1 ON for

control point 3

Leftmost bit Rightmost bit

0000000 (fixed) Auto-tuning status for control points 0 to 7

This bit will change from 0 to 1 when

any control point is being auto-tuned.

(The bits corresponding to the control

points that are being auto-tuned will

change from 0 to 1.)

11

Reading Status Section 3-3

Example

If no control points are being auto-tuned, and then auto-tuning begins for control point 3, the contents of the corresponding word in the PC wil l change as

follows:

0000000000000000 ® 1000000000001000

Control point 3 is

being auto-tuned.

When auto

corresponding word will return to 0000000000000000.

3-3-3 Operating Status

The status data showing whether an error has occurred in the E5ZE is

expressed in the contents of the correspondin g word in the PC to which the

Master Unit is mounted.

Operating status

Leftmost bit Rightmost bit

Outside T emperature

Display Range Flag

This bit changes from 0 to 1

if any of bits 0 to 8 changes

from 0 to 1.

Temperature Controller Ready Flag

The following table provides the m eaning and operation of the operating status flags.

Temperature Controller

Ready Flag

Outside Temperature Display Range Flag

Output Area Error Flag (See

note 1.)

Temperature Control Internal

T r ansmission Error Fl ag (See

note 1.)

Temperature Controller Error

Flag

Input Error Flag This flag changes from 0 to 1 if the temperature sen-

Process Value Overflow Flag This flag changes from 0 to 1 if the process value is

-tuning for control point 3 has been c omple ted, the co ntents of the

Heater Current Overflow Flag

Process Value Underflow Flag

Process Value Overflow Flag

Input Error Flag

Temperature Controller Error Flag

Temperature Control Internal Transmission Error Flag

Output Area Error Flag

Flag name Meaning

This flag changes from 0 to 1 when the E5ZE pow er is

turned ON and DeviceNet communications are

enabled.

After checking that this flag is ON, execute the program to start using I/O data.

This flag changes from 0 to 1 if the process value

exceeds 3200.0°F when a W/Re5-26 thermocouple

sensor is being used and the setting unit is 0.1°C/°F.

This flag changes from 0 to 1 if the output data from

the Master is not reflected in the E5ZE due to the

operating mode.

This flag changes from 0 to 1 if the remote I/O function has not been processed properly in the E5ZE.

This flag changes from 0 to 1 if there i s an error in the

Temperature Controller , su ch as an AD con verter

error or memory error.

sor is disconnected or short-circuited.

more than the maximum value of the setting range.

(See note 2.)

12

Temperature Control Start/Stop Section 3-4

Flag name Meaning

Process Value Underflow

Flag

Heater Current Overflow Flag This flag changes from 0 to 1 if the measured heater

This flag changes from 0 to 1 if the process value is

less than the minimum value of the setting range.

(See note 2.)

current exceeds 55.0 A when the HB and HS alarm

are being used.

Note 1. If the Output Area Er ror Flag or Te mperature Controller Err or Flag is ON

(1) for longer than 1 s, the remote I/O data will not be transmitted correctly

to the E5ZE.

2. The measurement range is from the setting range lower

ue (-20

40

°C or -40°F) to the setting range upper-limit positive value (20°C or

°F).

-limit negative val-

3-4 Temperature Control Start/Stop

The temperature contr ol of control po ints in the E 5ZE is star ted and stopped

by operating the bits in the corresponding word al located in the PC to which

the Master Unit is mounted, as follows:

Temperature Control Start/Stop

Leftmost bit Rightmost bit

Example

If the temperature contr ol of all control points is stopped and then star ts for

control point 3, the contents of the corre spond ing word in the PC will chang e,

as follows:

0000000000000000 ® 0000000000001000

3-4-1 Startup Operation

When pin 5 (star tup operation setting) of the FUNCTION switch on the fron t

panel of the E5ZE

ON, the Unit will operate as shown in the following diagram.

E5ZE status

Set to 00000000 Set the bits corresponding to the

control points for which temperature

control is to begin to 1.

To stop temperature control for any

control point, set the corresponding

bit to 0.

Temperature control

started for control

point 3

-8@@@D1@B-V2 Multipoint Temperature Controller is set to

Operation according to

control temperature and

operating status when

power was turned OFF

previously.

Operation according to control temperature

and operating status set by remote I/O.

E5ZE

power ON

DeviceNet communications

between Master and E5ZE

enabled.

Time

13

Writing Set Points Section 3-5

The time required for DeviceNet communicatio ns to be enabled will depend

on the order in which power is supplied, the number of Slaves connected to

the Master, the baud rate, and other variables.

3-4-2 Manual Operation

When the E5ZE-8@@@D1@B-V2 Multi point Temperature Controller is being

operated manually, the following procedure is required depending on the relationship to the remote I/O Temperature Control Start/Stop Bit.

Refer to page 28 for details on the rela tionship between remote I/O and the

E5ZE operating status.

Starting Manual Operation

1,2,3... 1. Se t the Temperature Control Start/Stop Bi t to 1 for the control point to be

manually operated and temperature control will start for the control point.

2. Execute the Manual Operation Star t command using DeviceNet explicit

Stopping Manual Operation

message communica tions or through the RS

Manual operation will start.

3. Set the manual output using DeviceNet explicit message communications

or through the RS

Set the Temperature Control Star t/Stop Bit to 0 for the control point being

manually operated and tempe rature control will stop for the specified control

point. Temperature control can then be restarted by setting the bit to 1 again.

-232C auxiliary setting jack.

-232C auxiliary setting jack.

3-5 Writing Set Points

The set point for each control point is written as 16-bit signed binary data

’s complement for negative values) in the correspondin g word in the PC

(two

to which the Master Unit is mounted. The value is automatically transmitted to

the E5ZE. The data w ill be written acc ording to the setting unit that is set i n

the E5ZE. The default value is 1

inum resistance ther mo mete r s.

Leftmost bit Rightmost bit

Example

If the set point is to be set to -90.0°C, and the setting unit is 0.1°C, the value

set in the corresponding word will be as follows:

Set Point Decimal Hexadecimal Binary

°C -900 FC7C 1111110001111100

-90.0

If the set point is to b e set to 11 0.0

set in the corresponding word will be as follows:

Set Point Decimal Hexadecimal Binary

°C 1100 044C 0000010001001100

110.0

If the set point is to be set to 110.0

in the corresponding word will be as follows:

Set Point Decimal Hexadecimal Binary

°C 110 006E 0000000001101110

110.0

Refer to page 25 for details on the permissible setting ranges.

°C/°F for thermocouples and 0.1°C/°F for plat-

°C, and the setting unit is 0.1°C, the value

°C, and the setting unit is 1°C, the value set

14

Remote I/O Delay Time Section 3-6

3-6 Remote I/O Delay Time

• The time required for the remot e I/O d ata reflec ti ng th e changed data to be

prepared at the E5ZE after a main i npu t to th e E 5Z E has ch ang ed i s cal le d

the input delay time.

• The time required fo r the da ta that has b een transmitted to the E 5ZE us in g

DeviceNet communicati ons to affect in the operation of the E5ZE is called

the output delay time.

• The maximum input and output delay times are 500 ms.

• For details on how to calculate the I/O delay time, refer to the DeviceNet

(CompoBus/D) Operation Manual (Cat. No. W267).

15

SECTION 4

DeviceNet Explicit Message Communications

DeviceNet explicit message communi cations are used to read and write the E5 ZE’s measurement values and set v alues that

cannot be read or written using remote I/O communications. Settings can also be made from a master not manufactured by

OMRON.

Parameters written using DeviceNet explicit messages are saved even if the power supply is turned OFF.

This section provides details on DeviceNet explicit messages, including command and response formats, the instructions

used by the PC to execute DeviceNet explicit message communications, and tables of set values and measurement values

showing setting ranges, default values, data types, and addresses.

4-1 Transmitting DeviceNet Explicit Messages . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4-1-1 Command Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4-1-2 Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4-1-3 Remote I/O and DeviceNet Explicit Messages. . . . . . . . . . . . . . . . . 19

4-2 E5ZE Fixed Command Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4-3 Instruction Execution Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4-3-1 CMND(194/490): CVM1, CV-series, and CS1-series PCs . . . . . . . 20

4-3-2 IOWR(223): C200HX/C200HE/C200HG PCs . . . . . . . . . . . . . . . . 20

4-3-3 Control Data for Sending DeviceNet Explicit Messages Using

4-4 DeviceNet Explicit Messages Set Values and Measurement Values . . . . . . . 21

4-4-1 Commonly Used Set Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4-4-2 Reading/Writing using Variable Type 90 . . . . . . . . . . . . . . . . . . . . . 27

4-4-3 Operation Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4-4-4 Relationship between Operating Status and Operating Commands. 28

4-4-5 Set Values in Memory Banks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4-4-6 Measurement Values for Individual Control Points . . . . . . . . . . . . . 30

4-4-7 Set Values for all Control Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4-4-8 Set Values for All Control Points . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

CMND(194/490) or IOWR(223) . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

17

Transmitting DeviceNet Explicit Messages Section 4-1

4-1 Transmitting DeviceNet Explicit Messages

DeviceNet explicit messages are executed from the user program using the

CMND(194/490) instruction for a CVM1, CV

the IOWR(223) instruction with a C200HX, C200HG, or C200HE PC.

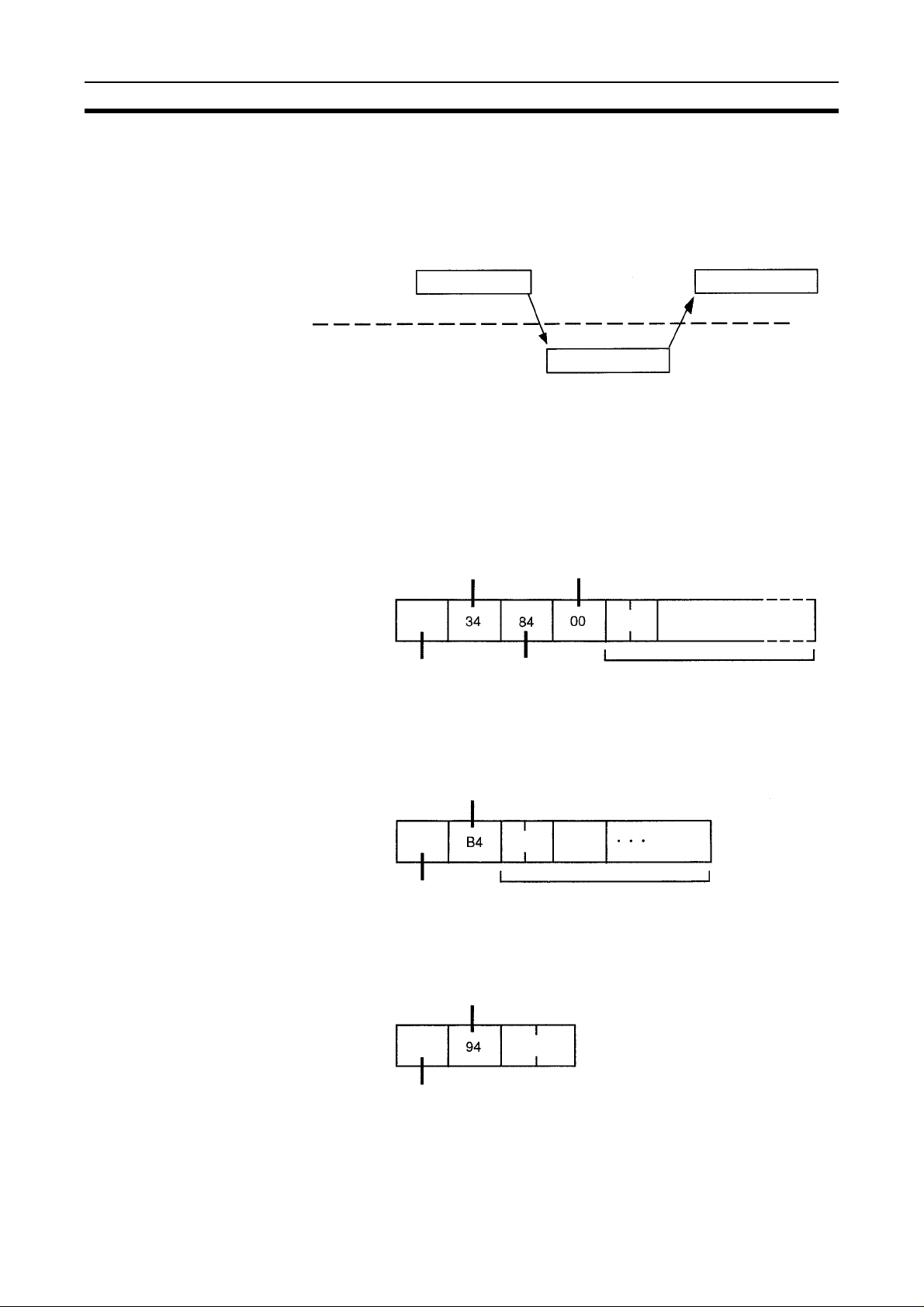

The transmission proced ure involves the Master sending a command to the

E5ZE and the E5ZE returning a response to the command back to the Master.

-series, or CS1-series PC, and

Master Unit

E5ZE

Refer to the DeviceNet (CompoBus/D) Operation Manual (Cat. No. W267) for

details on the transmission methods.

Details on the format of commands and responses used for transmission, and

the set values and measurem ent values specific to the E5ZE are provided

here.

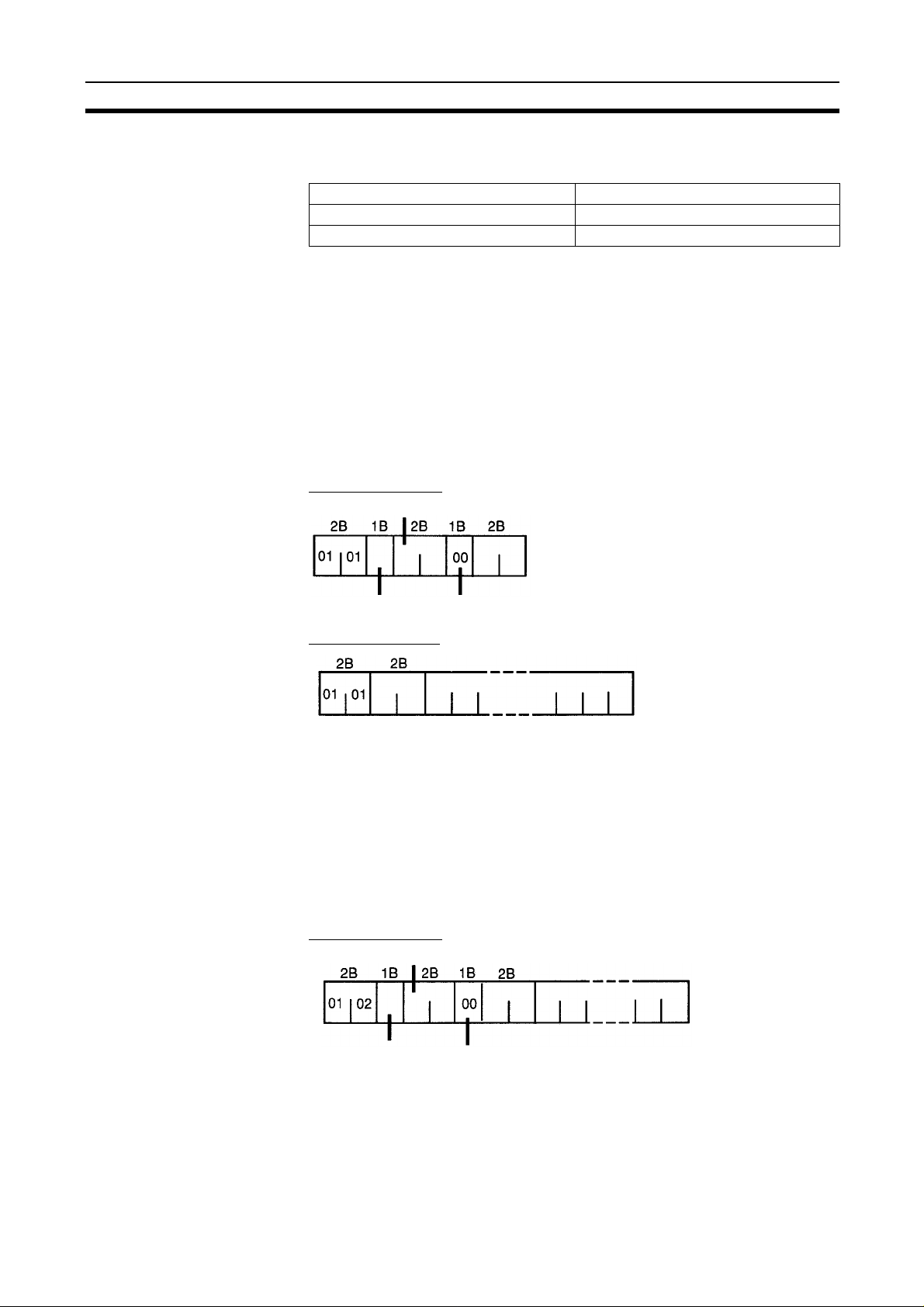

4-1-1 Command Format

The command format for DeviceNet explicit messages is given below.

Command

Command

Service code Instance ID

Destination

node address

Class ID

Command

Response

Command

code

E5ZE fixed command (Refer to 4-2 E5ZE

Fixed Command Configuration

Parameter

.)

Response

Normal

Error

Service code

Destination

node address

Service code

Destination

node address

Command

code

E5ZE fixed response (Refer to

Fixed Command Configuration

DeviceNet

error code

End code

4-2 E5ZE

.)

18

E5ZE Fixed Command Configuration Section 4-2

4-1-2 Commands

There are only two commands that can be used with the E5ZE.

Command type Command code

MEMORY AREA READ 0101

MEMORY AREA WRITE 0102

4-1-3 Remote I/O and DeviceNet Explicit Messages

Data written with the remote I/O allocated in the DeviceNet Network is

updated in the E5ZE every 200 ms. Data wr itten with DeviceNet explicit messages is updated when the command is executed.

4-2 E5ZE Fixed Command Configuration

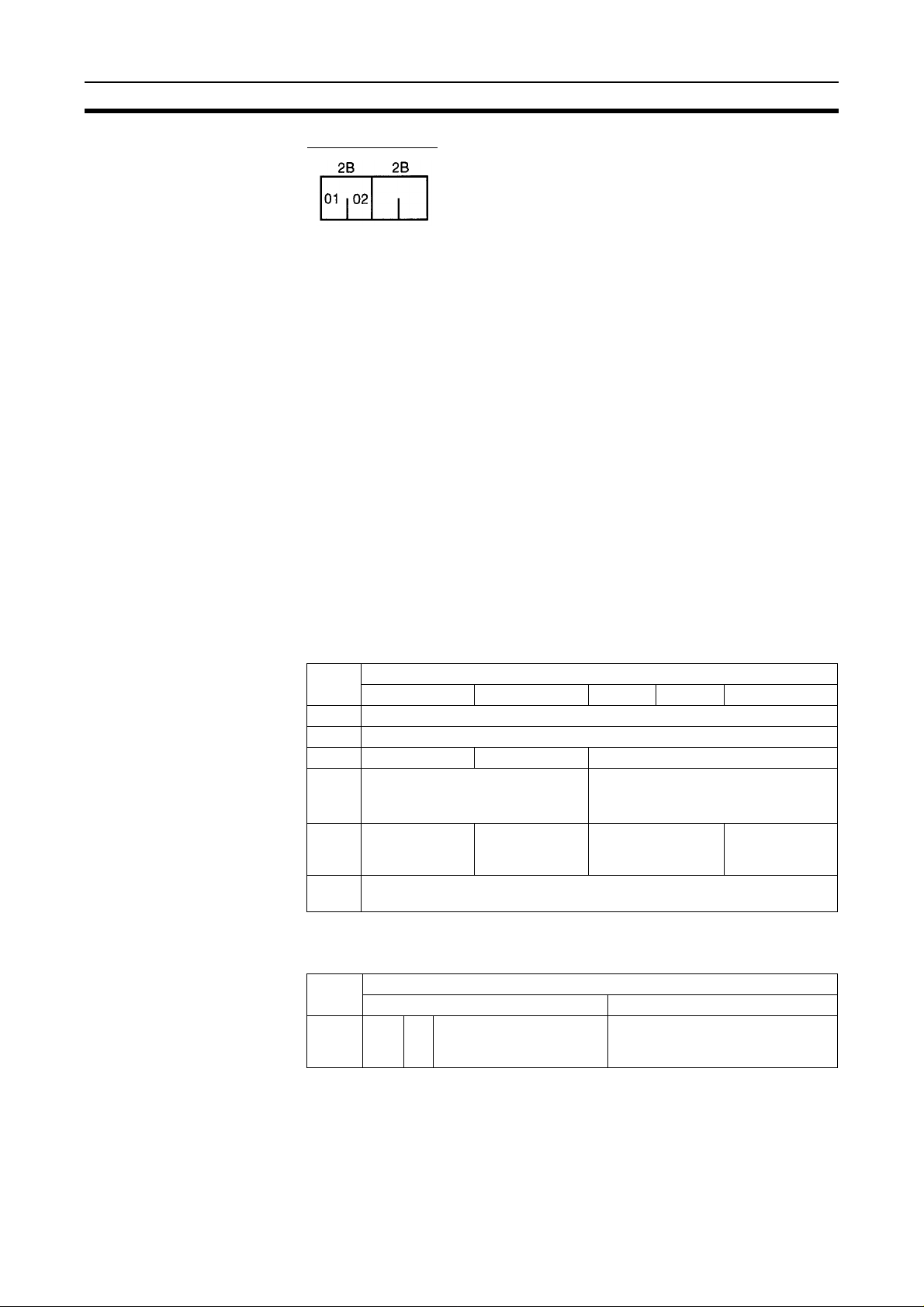

Reading PC Memory

The following diagram shows the format of command data and re sp ons e dat a

when messages are used to read set values and measurem ent values from

the E5ZE to which the Master Unit is mounted.

Command Format

First read address

Writing PC Memor y

Command

code

Variable type Bit position

Number of read data elements

Response Format

Read data

Command

code

End code

• The total number of read data bytes is 2 × Number of read data elemen ts.

• Refer to the table of DeviceNet expli cit mes s age s s et valu es and m eas urement values for details on addresses and variable types for read set values

and measurement values.

The following diagram shows the format of command data and re sp ons e dat a

when messages are u sed to write set values an d measurement values from

the E5ZE to which the Master Unit is mounted.

Command Format

First write address

Write data

Command

code

Variable type Bit position

Number of write data elements

19

Instruction Execution Precautions Section 4-3

Response Format

Command

code

End code

• The total number of write data bytes is 2 × Number of write data elements.

• Refer to the table of DeviceNet expli cit mes s age s s et valu es and m eas urement values for d etails o n addr e sses a nd va riabl e ty pes of write set val ues

and measurement values.

• If there is an error in even one part of the data being writ ten, all o f the data

written at the same time will not be saved in the E5ZE.

FINS command 2801 is sent using CMND(194/490) or IOWR(223) to s end

DeviceNet explicit messages from an OMRON PC Master Unit. For details,

refer to the DeviceNet (CompoBus/D ) Operation Manual (Cat. No. W267) or

the CS1W

-DRM21 DeviceNet Unit Operation Manual (Cat. No. W380).

4-3 Instruction Execution Precautions

When DeviceNet explicit messag e communications are us ed with the E5ZE,

there are settings that are specific to the control data for CMND(194/490) and

IOWR(223) instructions that must be set, as shown next.

For details on both inst ructions and their applicati ons, refer to the DeviceNet

(CompoBus/D) Operation Manual (Cat. No. W267).

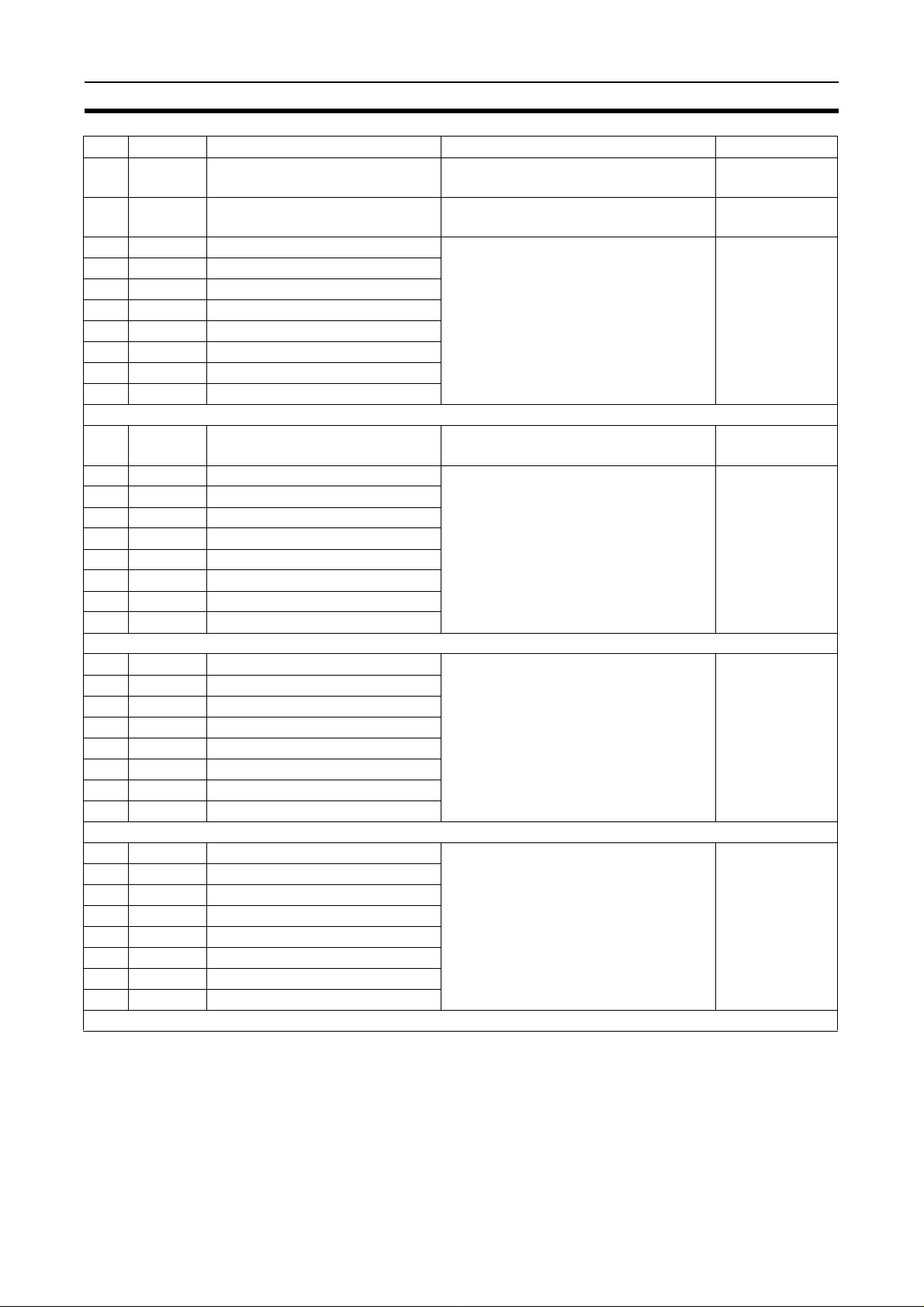

4-3-1 CMND(194/490): CVM1, CV-series, and CS1-series PCs

The control data for the CMND(194/490) instructions is as follows:

Word Bit

15 12 11 08 07 06 05 04 03 00

C Number of command data bytes

C+1 Number of response data bytes

C+2 0 0 Des ti nati on net w o rk address

C+3 Destination node address

(Local node DeviceNet Master

MAC ID)

C+4 0 (response

required)

C+5 Response monitoring time (0000 to FFFF), in 0.1 s incre ments (e xcept 0000

that is 2 s)

Communications port No.

(0 to 7)

Destination unit address

(Local node De vi ceNet Master Special

I/O Unit number or FE)

0 Number of

retries (0 to F)

4-3-2 IOWR(223): C200HX/C200HG/C200HE PCs

The control data for the IOWR(223) instruction is as follows:

Word Bit

15 08 07 00

C 0/1 0 Destination address

(Local node DeviceNet

Master MAC ID)

Bit 15 is used to set whether a response is required or not. If bit 15 is set to 0,

a response is required and if the bit is set to 1, a response is not required. Set

this bit to 0 (response required).

Bits 8 to 13 are used to set the destination node address (E5ZE node

address), and bits 0 to 7 are used to set the destination Unit address (the local

node DeviceNet Master Special I/O Unit number or FE).

20

Destination unit address

DeviceNet Explicit Messages Set Values and Measurement Section 4-4

4-3-3 Control Data for Sending DeviceNet Explicit Messages Using

CMND(194/490) or IOWR(223)

Master Unit

Unit No. 2

IOWR(223) control data

PC

Destination

node address

CMND(194/490) control data

No. of command data bytes

Destination Unit address FE or 12

(12 indicates Special I/O Unit No. 2)

Explicit message

Destination node address

No. of response data types

Send to local network

Destination Unit address FE or 12

(12 indicates Special I/O Unit No. 2)

Resend once

4-4 DeviceNet Explicit Messages Set V alues and Measurement

Values

This section provides tables that can be used when setting and monitoring the

set values for all control points. The tables are given by variable type.

4-4-1 Commonly Used Set Values

Variable Type: 90

No. Address Set value or measurement value Data setting or monitoring range Data type

1 0000 Control point 0 process value Range: Depends on sensor type used.

2 0001 Control point 1 process value

3 0002 Control point 2 process value

4 0003 Control point 3 process value

5 0004 Control point 4 process value

6 0005 Control point 5 process value

7 0006 Control point 6 process value

8 0007 Control point 7 process value

(See note 4.)

Unit:Depends on s etting (e ither 0.1°C/°F or

1°C/°F)

Numeric

Read only

9 000C Alarm 1 status Range: 0000 to 80FF Status

10 000D Alarm 2 status Range: 0000 to 80FF

11 000E Auto–tuning status Range: 0000 to 80FF

12 000F HB alarm status Range: 0000 to 80FF

13 0010 HS alarm status Range: 0000 to 80FF

Read only

Bit contents same

as remote I/O

contents.

21

DeviceNet Explicit Messages Set Values and Measureme nt Section 4-4

No. Address Set value or measurement value Data setting or monitoring range Data type

14 0011 Temperature control status

(See note 7.)

15 0012 Operation start/stop

(See notes 3 and 6.)

16 0013 Control point 0 set point Range: Depends on sensor type used.

17 0014 Control point 1 set point

18 0015 Control point 2 set point

19 0016 Control point 3 set point

20 0017 Control point 4 set point

21 0018 Control point 5 set point

22 0019 Control point 6 set point

23 001A Control point 7 set point

Range: 0000 to 811F Status

Read only

Range: 0000 to 00FF (Default: 0000) Status

Read

Numeric

(See notes 1 and 4.)

Unit: Depends on setting (either 0.1°C/

°F or 1°C/°F)

Read

24 001F Auto-tuning start/stop

(See note 2.)

25 0020 Control point 0 alarm 1 temperature Range: D8F1 to 7350 (-999.9 to 3000.0)

26 0021 Control point 1 alarm 1 temperature

27 0022 Control point 2 alarm 1 temperature

28 0023 Control point 3 alarm 1 temperature

29 0024 Control point 4 alarm 1 temperature

30 0025 Control point 5 alarm 1 temperature

31 0026 Control point 6 alarm 1 temperature

32 0027 Control point 7 alarm 1 temperature

33 002C Control point 0 alarm 2 temperature Range: D8F1 to 7530 (-999.9 to 3000.0)

34 002D Control point 1 alarm 2 temperature

35 002E Control point 2 alarm 2 temperature

36 002F Control point 3 alarm 2 temperature

37 0030 Control point 4 alarm 2 temperature

38 0031 Control point 5 alarm 2 temperature

39 0032 Control point 6 alarm 2 temperature

40 0033 Control point 7 alarm 2 temperature

41 0038 Control point 0 input shift value Range: FC19 to 03E7 (-99.9 to 99.9)

42 0039 Control point 1 input shift value

43 003A Control point 2 input shift value

44 003B Control point 3 input shift value

45 003C Control point 4 input shift value

46 003D Control point 5 input shift value

47 003E Control point 6 input shift value

48 003F Control point 7 input shift value

Range: 0000 to 00FF

Default: 0000

when setting unit is 0.1°C/°F. (See note 4.)

Range: D8F1 to 270F (-9999 to 9999)

when setting unit is 1°C/°F.

Default: 0000 (0.0 or 0)

when setting unit is 0.1°C/°F. (See note 4.)

Range: D8F1 to 270F (-9999 to 9999)

when setting unit is 1°C/°F.

Default: 0000 (0.0 or 0)

(See note 1.)

Unit: 0.1°C or °F

Default: 0000 (0.0)

Status

Write only

Numeric

Read/write

Numeric

Read/write

Numeric

Read/write

22

DeviceNet Explicit Messages Set Values and Measurement Section 4-4

No. Address Set value or measurement value Data setting or monitoring range Data type

49 0044 Control point 0 proportional band Range: 0000 to 270F (0.0 to 999.9)

50 0045 Control point 1 proportional band

51 0046 Control point 2 proportional band

52 0047 Control point 3 proportional band

53 0048 Control point 4 proportional band

54 0049 Control point 5 proportional band

55 004A Control point 6 proportional band

56 004B Control point 7 proportional band

(See note 1.)

Unit: 0.1°C or °F

Default: 0000 (0.0)

Numeric

Read/write

57 0050 Control point 0 integral time Range: 0000 to 0F9F (0 to 3999)

58 0051 Control point 1 integral time

59 0052 Control point 2 integral time

60 0053 Control point 3 integral time

61 0054 Control point 4 integral time

62 0055 Control point 5 integral time

63 0056 Control point 6 integral time

64 0057 Control point 7 integral time

65 005C Control point 0 derivative time Range: 0000 to 0F9F (0 to 3999)

66 005D Control point 1 derivative time

67 005E Control point 2 derivative time

68 005F Control point 3 derivative time

69 0060 Control point 4 derivative time

70 0061 Control point 5 derivative time

71 0062 Control point 6 derivative time

72 0063 Control point 7 derivative time

73 0068 Control point 0 heating output vari-

able

74 0069 Control point 1 heating output vari-

able

75 006A Control point 2 heating output vari-

able

76 006B Control point 3 heating output vari-

able

77 006C Control point 4 heating output vari-

able

78 006D Control point 5 heating output vari-

able

79 006E Control point 6 heating output vari-

able

80 006F Control point 7 heating output vari-

able

(See note 1.)

Unit: 1 s

Default: 0000 (0)

(See note 1.)

Unit: 1 s

Default: 0000 (0)

Range: 0000 to 03EB (0.0 to 100.0)

Unit: 0.1%

Numeric

Read/write

Numeric

Read/write

Numeric

Read only

23

DeviceNet Explicit Messages Set Values and Measureme nt Section 4-4

No. Address Set value or measurement value Data setting or monitoring range Data type

81 0074 Control point 0 heater current Range: 0000 to 0226 (0.0 to 55.0)

82 0075 Control point 1 heater current

83 0076 Control point 2 heater current

84 0077 Control point 3 heater current

85 0078 Control point 4 heater current

86 0079 Control point 5 heater current

87 007A Control point 6 heater current

88 007B Control point 7 heater current

(See note 8.)

Unit: 0.1 A

Numeric

Read only

89 0080 Control point 0 memory bank No. Range: 0000 to 0007

90 0081 Control point 1 memory bank No.

91 0082 Control point 2 memory bank No.

92 0083 Control point 3 memory bank No.

93 0084 Control point 4 memory bank No.

94 0085 Control point 5 memory bank No.

95 0086 Control point 6 memory bank No.

96 0087 Control point 7 memory bank No.

97 008C Control point 0 heater burnout

detection current

98 008D Control point 1 heater burnout

detection current

99 008E Control point 2 heater burnout

detection current

100 008F Control point 3 heater burnout

detection current

101 0090 Control point 4 heater burnout

detection current

102 0091 Control point 5 heater burnout

detection current

103 0092 Control point 6 heater burnout

detection current

104 0093 Control point 7 heater burnout

detection current

(See note 1.)

Default: 0000 (0)

Range: 0000 to 01F4 (0.0 to 50.0)

Unit: 0.1 A

Default: 0000 (0.0)

Numeric

Read/write

Numeric

Read/write

105 0098 Control point 0 cooling coefficient Range: 0000 to 0064 (0.0 to 10.0)

106 0099 Control point 1 cooling coefficient

107 009A Control point 2 cooling coefficient

108 009B Control point 3 cooling coefficient

109 009C Control point 4 cooling coefficient

110 009D Control point 5 cooling coefficient

111 009E Control point 6 cooling coefficient

112 009F Control point 7 cooling coefficient

(See note 1.)

Unit: 0.1

Default: 000A (1.0)

24

Numeric

Read/write

DeviceNet Explicit Messages Set Values and Measurement Section 4-4

No. Address Set value or measurement value Data setting or monitoring range Data type

113 00A4 Control point 0 dead band Range: FC19 to 03E7 (-999 to 999)

114 00A5 Control point 1 dead band

115 00A6 Control point 2 dead band

116 00A7 Control point 3 dead band

117 00A8 Control point 4 dead band

118 00A9 Control point 5 dead band

119 00AA Control point 6 dead band

120 00AB Control point 7 dead band

(See note 1.)

Unit: 1°C or °F

Default: 0000 (0)

Numeric

Read/write

121 00B0 Control point 0 fuzzy strength Range: 0000 to 0063 (0 to 99)

122 00B1 Control point 1 fuzzy strength

123 00B2 Control point 2 fuzzy strength

124 00B3 Control point 3 fuzzy strength

125 00B4 Control point 4 fuzzy strength

126 00B5 Control point 5 fuzzy strength

127 00B6 Control point 6 fuzzy strength

128 00B7 Control point 7 fuzzy strength

(See note 1.)

Unit: 1%

Default: 0032 (50)

Numeric data for the values in the above table is all expressed as 16-bit

signed binary (two

’s complement for negative values)

Note 1. Numeric data cannot be modified during auto

2. Auto

-tuning cannot be executed when operation is sto pped. The sequ en-

tial auto

-tuning function is not supported with DeviceNet communications.

3. If an instruction to stop operation is executed during auto

will stop after auto

-tuning is cancelled.

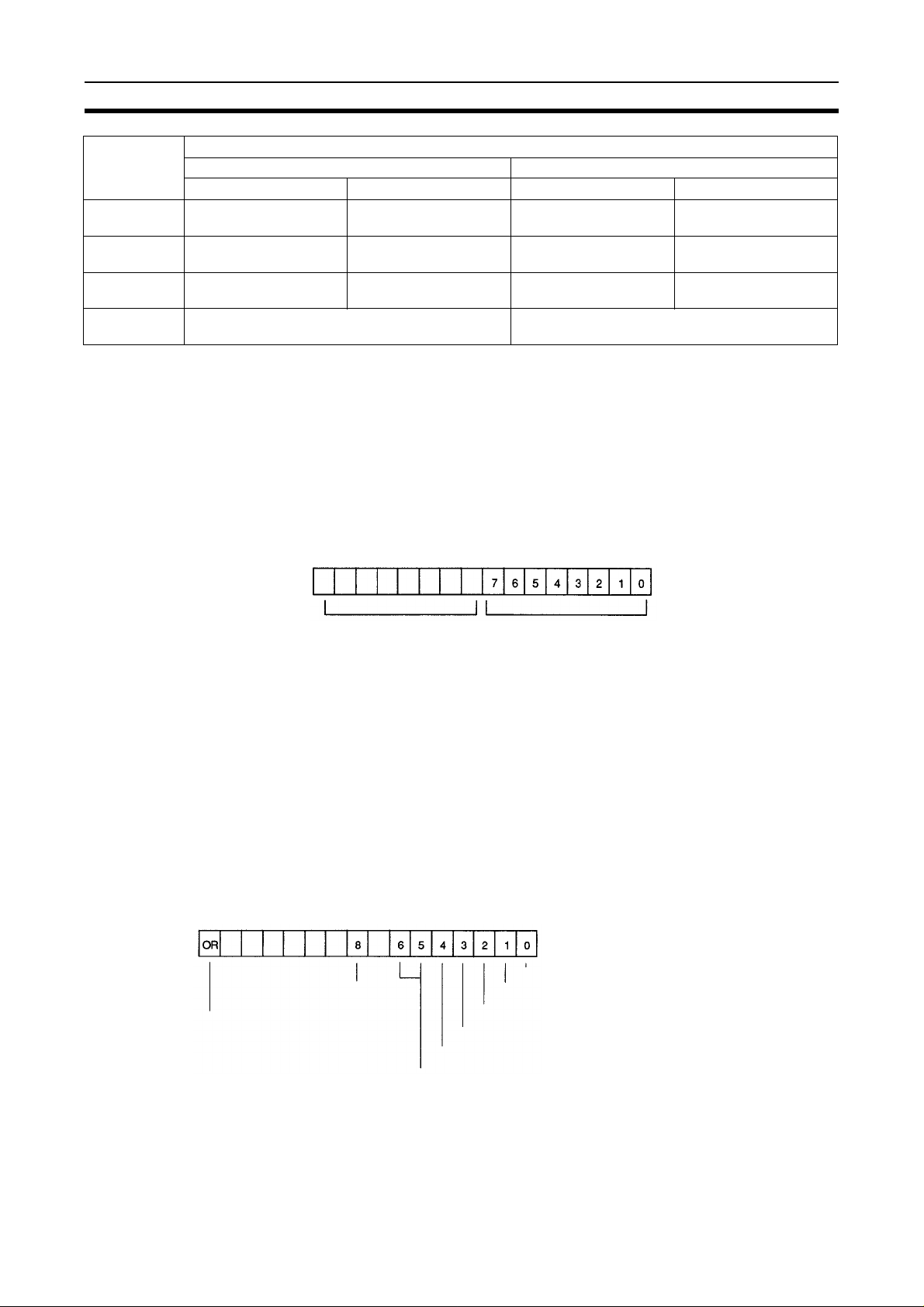

4. The setting ranges var y depending o n the setting unit used, as show n in

the following table.

Temperature

sensor

°C °F °C °F

K FF38 to 0514

(-200 to 1300)

J FF9C to 0352

(-100 to 850)

R 0000 to 06A4

(0 to 1700)

S 0000 to 06A4

(0 to 1700)

T FF38 to 0190

(-200 to 400)

E 0000 to 0258

(0 to 600)

B 0064 to 0708

(100 to 1800)

N 0000 to 0514

(0 to 1200)

L FF9C to 0352

(-100 to 850)

U FF38 to 0190

(-200 to 400)

W/Re5-26 0000 to 08FC

(0 to 2300)

Setting unit (1) Setting unit (0.1)

FED4 to 08FC

(-300 to 2300)

FF9C to 05DC

(-100 to 1500)

0000 to 0BB8

(0 to 3000)

0000 to 0BB8

(0 to 3000)

FED4 to 02BC

(-200 to 700)

0000 to 044C

(0 to 1100)

012C to 0BB8

(300 to 3000)

0000 to 08FC

(0 to 2300)

FF9C to 05DC

(-100 to 1500)

FED4 to 02BC

(-300 to 700)

0020 to 1004

(0 to 4100)

Setting range

F830 to 32C8

(-200.0 to 1300.0)

FC18 to 2134

(-100.0 to 850.0)

0000 to 4268

(0.0 to 1700.0)

0000 to 4268

(0.0 to 1700.0)

F830 to 0FA0

(-200.0 to 400.0)

0000 to 1770

(0.0 to 600.0)

03E8 to 4650

(100.0 to 1800.0)

0000 to 32C8

(0.0 to 1300.0)

FC18 to 2134

(-100.0 to 850.0)

F830 to 0FA0

(-200.0 to 400.0)

0000 to 59D8

(0.0 to 2300.0)

Numeric

Read/write

-tuning.

-tuning, operation

F448 to 59D8

(-300.0 to 2300.0)

FC18 to 3A98

(-100.0 to 1500.0)

0000 to 7530

(0.0 to 3000.0)

0000 to 7530

(0.0 to 3000.0)

F448 to 1B58

(-300.0 to 700.0)

0000 to 2AF8

(0.0 to 1100.0)

0BB8 to 7530

(300.0 to 3000.0)

0000 to 59D8

(0.0 to 2300.0)

FC18 to 3A98

(-100.0 to 1500.0)

F448 to 1B58

(-300.0 to 700.0)

0140 to 7D00

(32 to 3200.0)

25

DeviceNet Explicit Messages Set Values and Measureme nt Section 4-4

Temperature

sensor

°C °F °C °F

PL II 0000 to 0514

Pt FF9C to 01F4

JPt FF9C to 01F4

Alarm setting

range

(0 to 1300)

(-100 to 500)

(-100 to 500)

D8F1 to 270F (-9999 to 9999) D8F1 to 7530 (-999.9 to 3000.0)

Setting range

Setting unit (1) Setting unit (0.1)

0000 to 08FC

(0 to 2300)

FF9C to 0384

(-100 to 900)

FF9C to 0384

(-100 to 900)

0000 to 32C8

(0.0 to 1300.0)

FC18 to 1388

(-100.0 to 500.0)

FC18 to 1388

(-100.0 to 500.0)

0000 to 59D8

(0.0 to 2300.0)

FC18 to 2328

(-100.0 to 900.0)

FC18 to 2328

(-100.0 to 900.0)

• If an E5ZD-SDL Setting Display Unit is used with the E5ZE, and the setting

unit is 0.1

°C/°F, the setting range will be l imited to F8 31 to 270F (-19 9.9 to

999.9).

• If the alarm temperature that is read is more than 7530 (Hex), the temperature will be read as 7FFF (H ex), and if the alarm temper ature is less than

D8F1 (Hex), then the temperature will be read as 8000 (Hex).

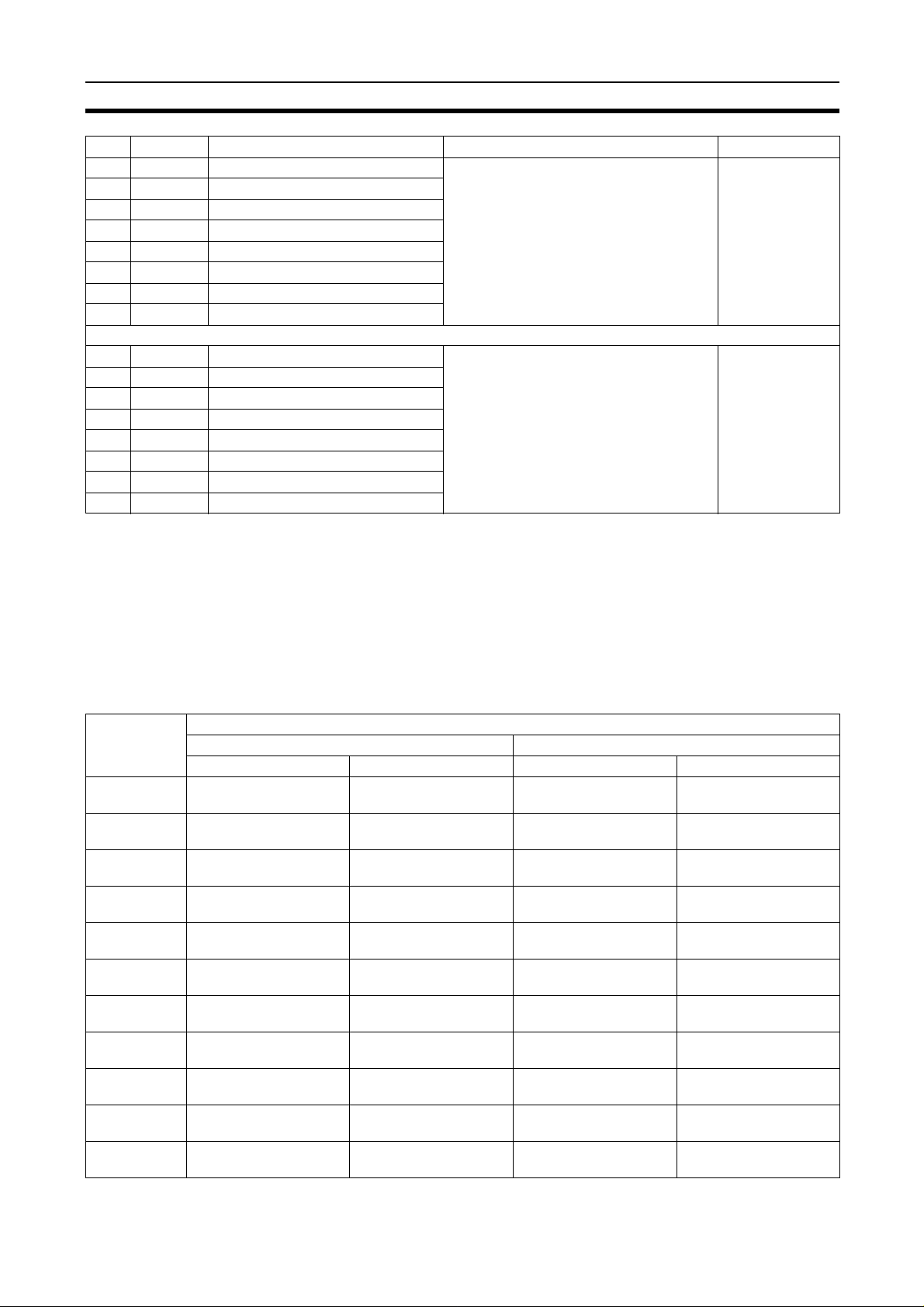

5. The meaning of the Auto-tuning Start/Stop Bits is as follows:

Auto-tuning Start/Stop

Leftmost bit Rightmost bit

Set bits 8 to 15 to 00000000. Set the bits corresponding to the control points

to be auto-tuned to 1 and then write the data.

To stop auto-tuning, set the bits corresponding

to the control points to be stopped to 0 and

then write the data.

6. The contents of the Operation Start/Stop Bit is the same as that for the re-

mote I/O, as shown here.

Read: 0: Operation stopped.

1: Controlling temperature or operating manually.

Write: 0: Stop operation.

1: Start or continue temperature control or continue manual operation. (Even if 1 is written to a control po int that is being operated

manually it will not start temperature control.)

7. The meaning of the operating status bits is as follows:

Operating Status

Leftmost bit Rightmost bit

Outside T emperature

Display Range Flag

Changes from 0 to 1 if any

bit is set to 1.

Temperature Controller Error Flag

Temperature Control Internal Transmission Error Flag

Reserved for the system

Process Value Underflow Flag

Process Value Overflow Flag

Input Error Flag

Heater Current Overflow Flag

26

8. Control points that have been se t to disable the HB and HS alarms, and

control points that are not operating will be read as 0000 (hex).

Loading...

Loading...