Page 1

E5ZE

Multipoint Temperature Controller

Operation Manual

Catalog No. H076-E3-1

Page 2

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

!

serious injury.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

!

serious injury.

Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

!

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 1997

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Note Indicates information of particular interest for efficient and convenient operation

of the product.

1, 2, 3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 3

TABLE OF CONTENTS

PRECAUTIONS xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 General Safety Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Operating Environment Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Application Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1

Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 Component Names and Functions 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 System Configuration 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 Main Functions 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

Preparations 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1 List of Models 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Mounting the Serial Communications Models 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 Setting Selectors and Switch 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 Installation 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5 Power Supply and Input Wiring 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6 Wiring CT Inputs and Control/Alarm Outputs 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7 Connecting Communications 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3

Functions 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1 Data Configuration 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 I/O Settings 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Set Point and Process Value 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Alarm Output Settings 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5 Output Limitations 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6 Ramp 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-7 Control Adjustments 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8 Control Method Selection 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-9 Heating and Cooling Control 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-10 Heater Burnout Detection 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-11 SSR Failure Detection 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4

Troubleshooting 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1 Troubleshooting Procedure 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Communications Errors 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Temperature Sensing Errors 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4 Temperature Control Errors 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-5 Output Errors 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-6 HB Alarm and HS Alarm Errors 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendices

A Specifications 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Current Transformer Specifications 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C Manually Setting PID Constants 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D Saving Data 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E Hardware Test 73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F Available Models 79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vii

Page 4

About this Manual:

This manual describes the installation and operation of E5ZE Multipoint Temperature Controllers and

includes the sections described below.

Refer to the following manuals according to the model being used before operating the E5ZE.

Refer to the following manual when using the E5ZE Serial Communications Models:

E5ZE Multipoint Temperature Controller Communications Manual (Cat. No. H77)

Refer to the following manual when using the DeviceNet Communications Models:

E5ZE-8 Multipoint Temperature Controller DeviceNet Communications Manual (Cat. No. H104)

DeviceNet Operation Manual (Cat. No. W267)

Please read this manual carefully and be sure you understand the information provided before at-

tempting to install or operate an E5ZE Multipoint Temperature Controller. Be sure to read the

Precautions section.

Precautions provides precautions for installing and using the E5ZE.

Section 1 provides information on the system configuration, component names, and functions.

Section 2 describes the installation and wiring procedures necessary before operating the E5ZE.

Section 3 describes each of the E5ZE functions.

Section 4 describes the troubleshooting procedure for the E5ZE.

The Appendices provide information on specifications, ratings, characteristics, the Current Transformer, PID constant manual adjustments, saving data, hardware tests, current outputs, and available

models.

!

WARNING Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section in its entirety and be sure you understand the information provided in the section

and related sections before attempting any of the procedures or operations given.

ix

Page 5

PRECAUTIONS

This section provides general precautions for using the E5ZE Multipoint Temperature Controller and related devices.

The information contained in this section is important for the safe and reliable application of the E5ZE Multipoint

Temperature Controller. You must read this section and understand the information contained before attempting to

set up or operate an E5ZE Multipoint Temperature Controller.

1 General Safety Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Operating Environment Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Application Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xi

Page 6

1 General Safety Precautions

WARNING Do not attempt to disassemble, apply pressure, distort, subject to temperatures

!

of 100°C or more, or throw the E5ZE into fire. A lithium battery is built into the

E5ZE and any attempt to any of the above may result in fire, explosion, or

combustion.

WARNING Do not attempt to disassemble, modify, or repair the E5ZE. Any attempt to do so

!

may result in malfunction, fire, or electric shock.

Caution Do not use any terminal that is marked “Don’t use.”

!

2 Operating Environment Precautions

Caution Be sure to check polarity when connecting the terminals.

!

Caution Do not install power lines or high-tension lines alongside lines connected to the

!

E5ZE to prevent the E5ZE from being influenced by inductive noise. Install lines

connected to the E5ZE through an independent conduit or use a shielded cable

for the lines to protect them from inductive noise.

3Application Precautions

Caution Separate the E5ZE from devices generating a strong high-frequency, such as

!

high-frequency welding machines, or devices that generate surge.

Caution Do not operate the E5ZE in the following locations:

!

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to corrosive or flammable gases.

• Locations subject to temperatures or humidity outside the range specified in

the specifications.

• Locations subject to condensation.

• Locations subject to shock or vibration.

• Locations subject to severe changes in temperature.

• Locations subject to icing.

Caution Do not install the E5ZE in a location with obstructions preventing radiant heat

!

from escaping.

3 Application Precautions

WARNING Make sure that no metal particles or wire chips are accidentally left in the

!

product. Doing so may result in malfunction, fire, or electric shock.

xii

WARNING Install a separate alarm to prevent the temperature from increasing excessively

!

if the E5ZE malfunctions. Insufficient safety precautions may cause serious

accidents if the temperature control malfunctions.

Page 7

Caution Tighten the screws on the terminal block to the torque specified in the manual.

!

Loose screws may result in burning or malfunction.

Caution Do not connect loads to the E5ZE that exceed the specified ratings. Excessively

!

large loads may result in malfunction or burning.

Caution Always use the power supply voltage specified in the manual. An incorrect volt-

!

age may result in malfunction or burning.

Caution Confirm that no adverse effects will occur in the system before attempting to per-

!

form a hardware test. Insufficient confirmation may result in unexpected operations.

Caution Make sure that all the E5ZE set values are suitable for the controlled system.

!

Unsuitable set values may result in unexpected operations causing damage to

the product or accidents.

3Application Precautions

xiii

Page 8

SECTION 1

Introduction

This section describes the components, a standard system configuration, and the functions of the E5ZE. Refer to Section 2

Preparations and later sections for details on functions and their applications.

1-1 Component Names and Functions 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 System Configuration 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 Main Functions 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

Page 9

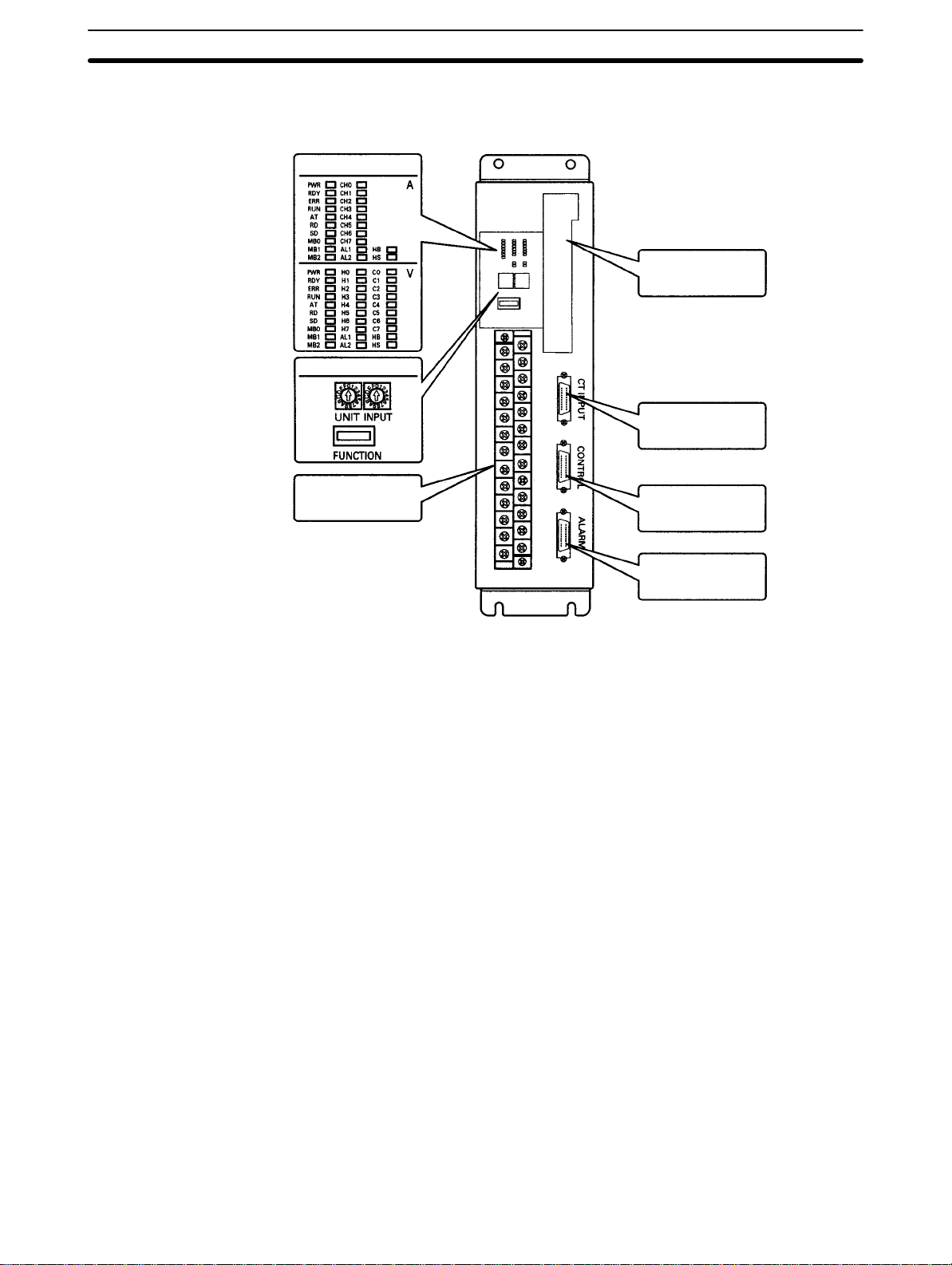

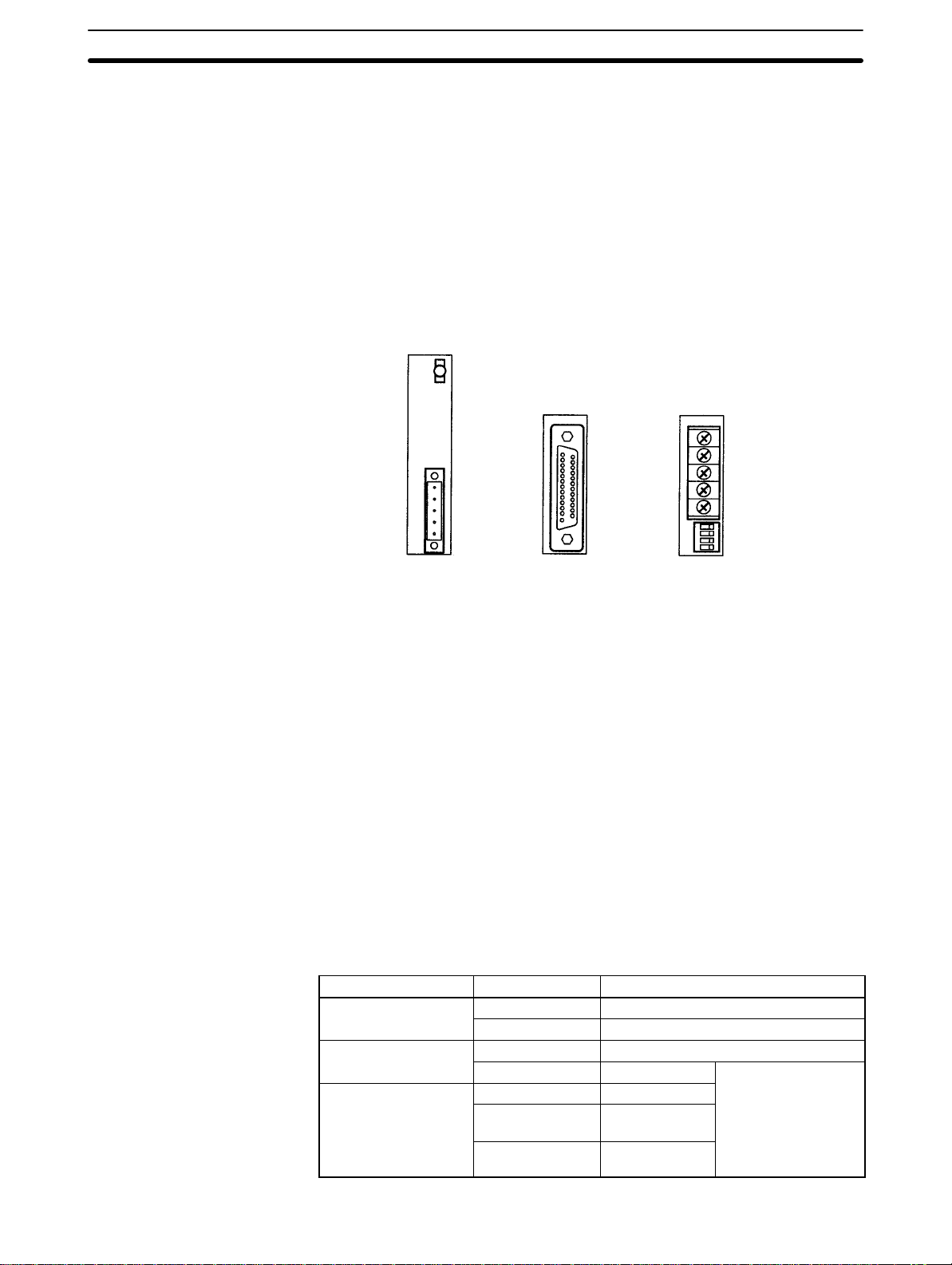

Component Names and Functions Section 1-1

1-1 Component Names and Functions

The component names and their functions are provided here.

Indicators

Communications

connector

Setting selectors and switch

CT INPUT

connector

Indicators

Input terminal block

Indicators

A: E5ZE-8AB (Standard Models with casing)

V: E5ZE-8VB (Heating and Cooling Control Models with casing)

The indicators show the operating status of the E5ZE, as follows:

PWR: Lit when power is ON.

RDY: Lit when the E5ZE is ready to operate.

ERR: Lit when an error occurs in the E5ZE.

RUN: Lit when the E5ZE is operating.

AT: Lit when auto-tuning is being executed.

RD: Lit when the E5ZE is receiving command data.

SD: Lit when the E5ZE is sending response data.

CH0 to CH7:

Lit for the control points for which the corresponding control outputs are ON.

(Not lit for Current Output Models.)

H0 to H7:

Lit for the control points for which the corresponding heating outputs are ON.

(Not lit for Current Output Models.)

C0 to C7:

Lit for the control points for which the corresponding cooling outputs are ON.

AL1: Lit when alarm 1 is ON.

AL2: Lit when alarm 2 is ON.

HB: Lit when the HB (heater burnout) alarm is ON.

HS: Lit when the HS alarm (SSR short circuit) is ON.

MB0 to MB2:

Lit when the memory bank designation inputs (bits 2

external contacts.

CONTROL

connector

ALARM connector

0

to 22) are turned ON with

2

Page 10

Component Names and Functions Section 1-1

Setting Selectors and

Switch

Input Terminal Block

Communications

Connector

The setting selectors and switch are used to select the temperature sensor type,

the unit number, and the functions to be used with the E5ZE. Refer to 2-3 Setting

Selectors and Switch for details on setting methods.

The input terminal block is connected to a DC power supply, temperature sensor, and ground wire. Refer to 2-5 Power Supply and Input Wiring for details on

wiring procedures.

The communications connector is connected to the communications cable. Refer to the E5ZE Multipoint Temperature Controller Communications Manual

(H77) or the E5ZE-8 Multipoint Temperature Controller DeviceNet Communications Manual (H104) for details on communications functions and their applica-

tions.

CT INPUT Connector

CONTROL Connector

ALARM Connector

E5ZE-8D1B

(for DeviceNet

communications)

E53-E01

(for RS-232C

Communications

Unit)

E53-E04

(for RS-422/485

Communications

Unit)

The CT INPUT connector is connected to the Current Transformer (CT) to detect

heater burnout or SSR failure. Use E5ZE-CBL Connecting Cables to connect to the Connector Terminal Conversion Unit (XW2B-20G5 for M3.5 terminal

screws or XW2B-20G4 for M2.4 terminal screws). Refer to 2-6 Wiring CT Inputs

and Control/Alarm Outputs for details on wiring procedures.

The CONTROL connector is used to connect the control output and memory

bank designation input contacts. Use E5ZE-CBL Connecting Cables to

connect to the Connector Terminal Conversion Unit (XW2B-20G5 for M3.5 terminal screws or XW2B-20G4 for M2.4 terminal screws). Refer to 2-6 Wiring CT

Inputs and Control/Alarm Outputs for details on wiring procedures.

The ALARM connector for the E5ZE-8A Standard Models is used for

an alarm output and that for the E5ZE-8V Heating and Cooling Control Models is used for cooling control output and alarm output. Use E5ZE-CBL Connecting Cables to connect to the following devices.

Device Model Specifications and Comments

Connector Terminal

Conversion Units

I/O Relay Terminal

I/O Relay Terminal

XW2B-20G4 M2.4 terminal screws

XW2B-20G5 M3.5 terminal screws

G7TC-OC08 8 relay outputs (no cooling outputs)

G7TC-OC16 16 relay outputs

G7VC-OC16 16 relay outputs

G7VC-OA16 16 SSR AC

outputs

G7VC-OD16 16 SSR DC

outputs

Cooling outputs

terminal is not

available on the

standard model.

3

Page 11

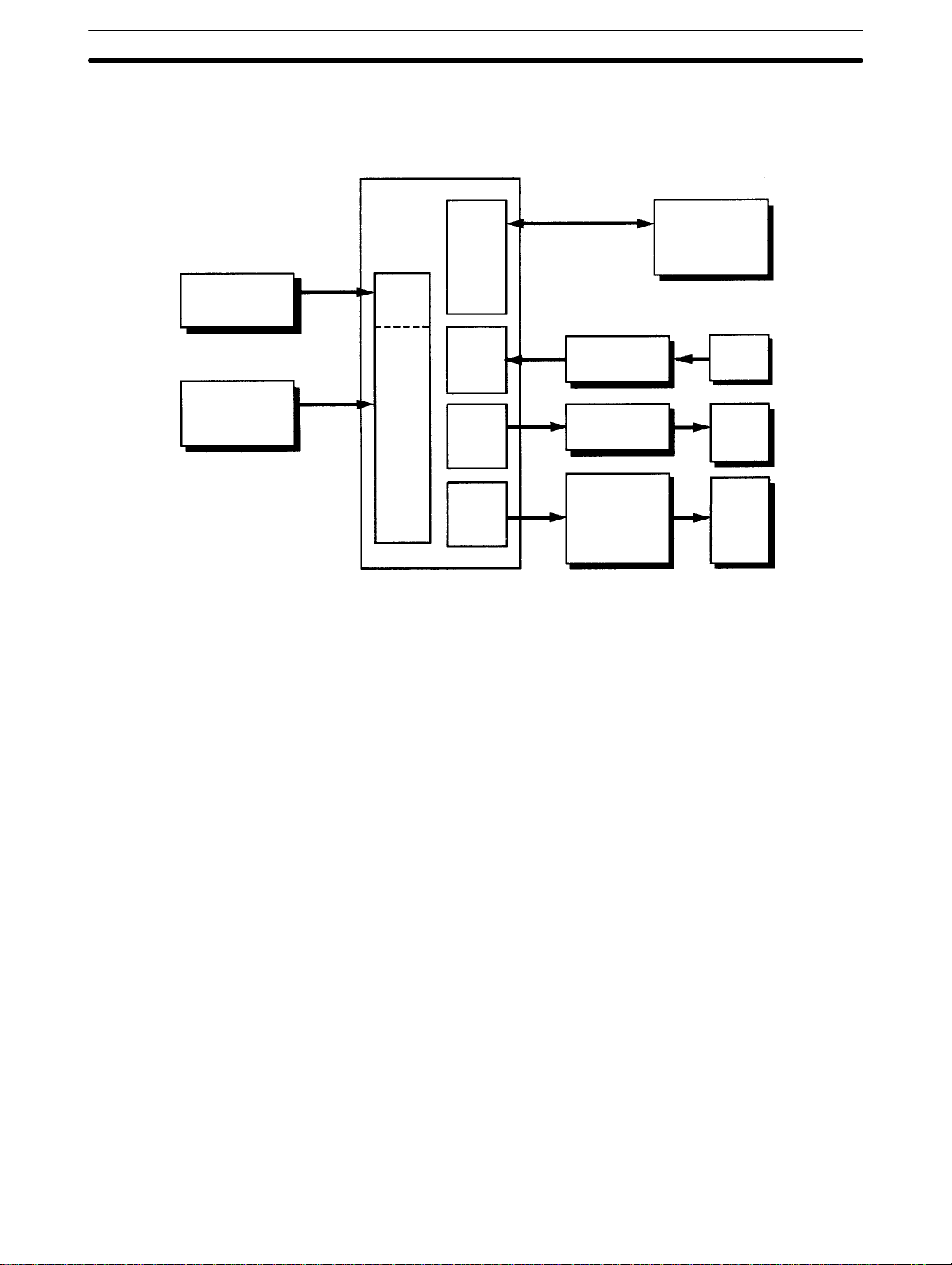

System Configuration

1-2 System Configuration

The following diagram shows the system configuration of the E5ZE.

Section 1-2

24-VDC power

supply

Platinum

resistance

thermometer or

thermocouple

E5ZE

Communications interface:

RS-232C, RS-422 or

RS-485, or DeviceNet

Host device

Computer

Communications

connector

Programmable

Controller

E5ZD-SDL Setting

Display Unit

E5ZE-CBL

Connecting Cables

CT INPUT

connector

XW2B-20G5/4

Connector Terminal

Conversion Unit

Current

Transformer

(CT)

Input

terminal

block

CONTROL

connector

ALARM

connector

XW2B-20G5/4

Connector Terminal

Conversion Unit

XW2B-20G5/4

Connector Terminal

Conversion Unit/

I/O Blocks

Control

outputs

Memory

bank designation inputs

Cooling

control

outputs

Alarm

outputs

Use the specified cables and wiring devices to prevent malfunctions or accidents caused by incorrect wiring.

• The connection between the communications connector and the host device

differs according to the communications interface used. Refer to the E5ZE

Multipoint Temperature Controller Communications Manual (H77) or the

E5ZE-8 Multipoint Temperature Controller DeviceNet Communications Manual (H104) for details.

• There are restrictions on the items that can be set or displayed from the E5ZDSDL Setting Display Unit. Refer to the E5ZD-SDL Setting Display Unit Data-

sheet (H61) for details.

4

Page 12

Main Functions

Isolation

Section 1-3

E5ZE

RS-232C

RS-422

RS-485

Power

supply

Input

terminal

block

FG

DeviceNet

CT INPUT

connector

CONTROL

connector

ALARM

connector

The components of the E5ZE contained within bold lines in the above diagram

are electrically isolated.

Note The covers of the CT INPUT, CONTROL, and ALARM connectors are con-

nected to the frame ground (FG).

For the E5ZE-8TC (Thermocouple Input Models), the thermocouple

inputs of the control points are insolated from each other.

1-3 Main Functions

Input Type

CONTROL Outputs

ALARM Outputs

Output Limitations

Ramp

The E5ZE is connected to platinum resistance thermometers or thermocouples,

depending on the model used. The type of temperature sensor is specified using

the INPUT selector on the front panel of the Unit. The input values can be adjusted using the input adjustment function.

The control outputs can be either voltage output or current output, depending on

the model. The control period and direct/reverse operation can be specified using the set values.

A maximum of 2 alarm outputs are possible. There are 12 alarm modes that can

be set for each alarm output according to set values. The outputs are comprehensive output for all control points.

The output values are limited by the following 2 limiters:

• Output limiter

• Output change rate limiter

If an output value is outside the upper or lower limit for the output, the output will

be limited to the preset upper or lower limit. The output change rate limiter limits

the rate at which output values change per unit time.

The ramp function is used to limit the control temperature (set point) from changing rapidly. If the set point changes quicker than the preset rate, the rate of temperature change will be limited to the preset rate, and the temperature will gradually change until it reaches the new temperature. The ramp can be set by the

user.

5

Page 13

Main Functions

Section 1-3

Control Adjustment

Heater Burnout and SSR

Failure Detection

Control Method Selection

Memory Banks

PID and fuzzy constants can be set by executing auto-tuning (AT). If an offset

occurs during P or PD control, manual adjustment is possible using the manual

reset function. Temperature turbulence caused by external disturbances can be

suppressed and controlled using the fuzzy function.

Output short circuits caused by heater burnout or SSR failure can be detected.

Control can be switched between ON/OFF control and the normal 2-PID control

(with 2 degrees of freedom). Manual operation is also possible.

The memory banks store different sets of set values for the control points. There

are 8 memory banks for each control point. Memory banks allow the set values

for a control point to be changed as a group rather than resetting them individually. Use the external contact inputs or communications to designate the required memory bank.

6

Page 14

SECTION 2

Preparations

This section provides details on operations that must be performed before starting the E5ZE, such as installation and wiring.

2-1 List of Models 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-1 Serial Communications Models 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-2 DeviceNet Communications Models 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Mounting the Serial Communications Models 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 Setting Selectors and Switch 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-1 UNIT Selector 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-2 INPUT Selector 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-3 FUNCTION Switch 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 Installation 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4-1 External and Panel Dimensions 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4-2 Mounting 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5 Power Supply and Input Wiring 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5-1 Terminal Block 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5-2 Wiring 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5-3 Terminal Arrangement 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5-4 Power Supply 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5-5 Ground 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5-6 Thermocouple Input 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5-7 Platinum Resistance Thermometer Input 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6 Wiring CT Inputs and Control/Alarm Outputs 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6-1 CT Inputs 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6-2 Outputs 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7 Connecting Communications 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7-1 RS-232C 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7-2 RS-422 and RS-485 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7-3 DeviceNet Interface 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

Page 15

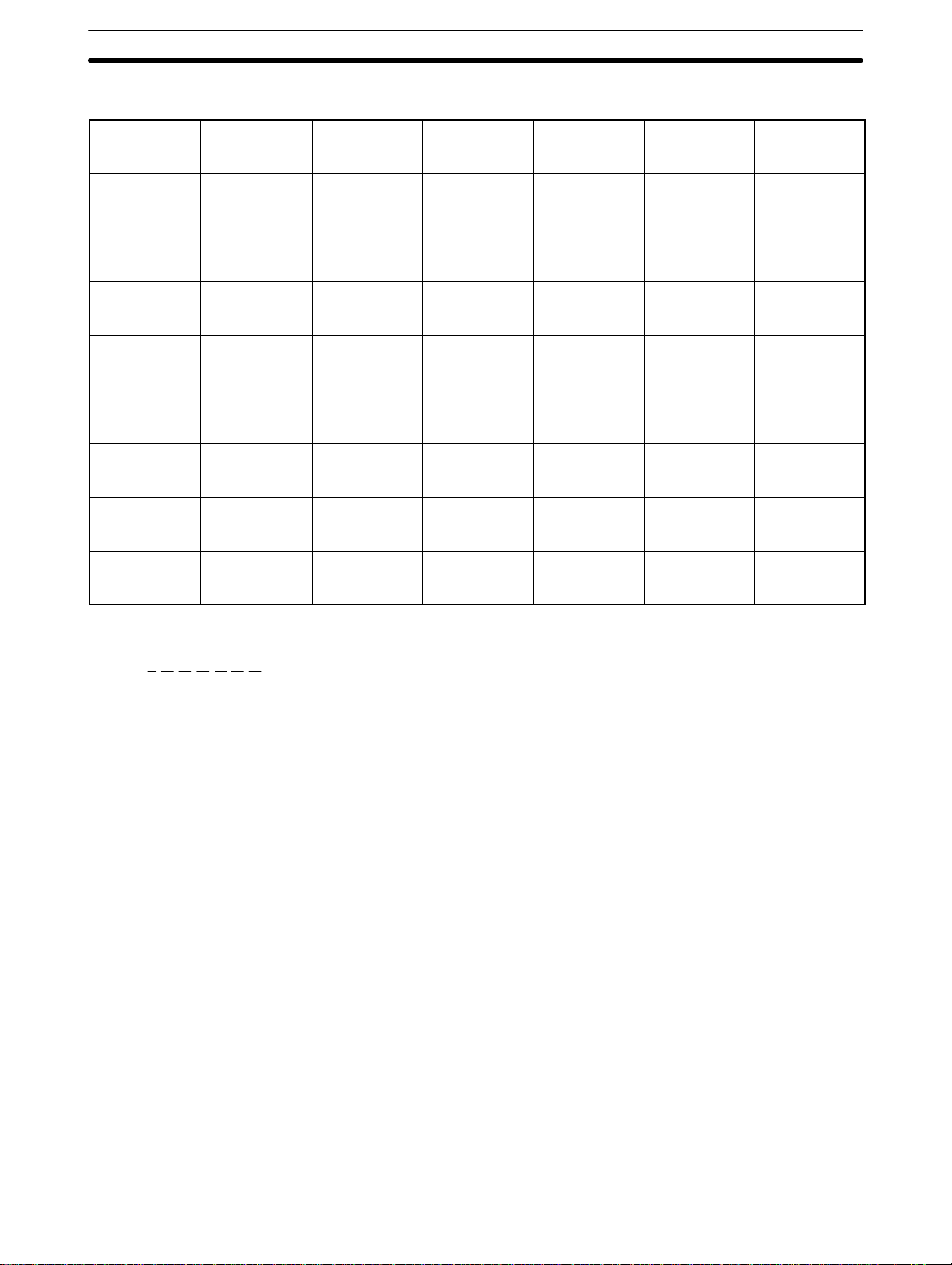

2-1 List of Models

2-1-1 Serial Communications Models

2-1SectionList of Models

No. of

control

Casing Control

method

points SSR failure

Control

output

Heater

burnout and

detection

Commu-

nications

Input type

Thermocouple Platinum

resistance

thermometer

8 Yes Standard Option Option Option E5ZE-8AAAMTCB-E E5ZE-8AAAMPB-E

Heating

Option Option Option E5ZE-8VAAMTCB-E E5ZE-8VAAMPB-E

and

cooling

Model Number Legend:

E5ZE-8AAM-E

1234567

1. Control Point

8: 8

2. Control Method

A: Standard

V: Heating and cooling

3. Control Output

A: Option (see note 1)

4. Heater Burnout and SSR Failure Detection (see note 2)

A: Option (see note 3)

5. Communications

M: Option (see note 4)

6. Input Type

TC: Thermocouple

P: Platinum resistance thermometer

7. Casing

B: Yes

Note: 1. The E53-E8Q Voltage Output Unit or the E53-E8C

Current Output Unit can be used with the E5ZE. The

E53-E8Q Voltage Output Unit and the E53-E8C

Current Output Unit are sold separately.

2. The heater burnout and SSR failure detection

function of the E5ZE will be invalid if the heating side

control output of the E5ZE is current output.

3. The E54-E8CT CT Input Unit is required for the

heater burnout and SSR failure detection. The

E54-E8CT CT Input Unit is sold separately.

4. The E53-E01 Communications Unit for RS-232C

communication or the E53-E04 Communications Unit

for RS-422 and RS-485 communication can be used

with the E5ZE. The E53-E01 Communications Unit

and the E53-E04 Communications Unit are sold

separately.

I/O Units (Order Separately)

Units Models

RS-232C Communications Unit E53-E01

RS-422/485 Communications Unit E53-E04

CT Input Unit E54-E8CT

Voltage Output Unit E53-E8Q

Current Output Unit E53-E8C

8

Page 16

2-1-2 DeviceNet Communications Models

2-1SectionList of Models

No of control

points

Casing Control

method

Control

output

HBA and SSR

failure

Iput type Name

detection

8 Yes Standard Voltage Yes Thermocouple E5ZE-8AQH

D1TCB

24VDC

8 Yes Standard Voltage Yes Platinum

resistance

E5ZE-8AQH

D1PB 24VDC

thermometer

8 Yes Standard Current No Thermocouple E5ZE-8ACA

D1TCB

24VDC

8 Yes Standard Current No Platinum

resistance

E5ZE-8ACA

D1PB 24VDC

thermometer

8 Yes Heating and

Cooling

Voltage Yes Thermocouple E5ZE-8VQH

D1TCB

24VDC

8 Yes Heating and

Cooling

Voltage Yes Platinum

resistance

E5ZE-8VQH

D1PB 24VDC

thermometer

8 Yes Heating and

Cooling

Current No Thermocouple E5ZE-8VCA

D1TCB

24VDC

8 Yes Heating and

Cooling

Current No Platinum

resistance

E5ZE-8VCA

D1PB 24VDC

thermometer

Model Number Legend:

E5ZE-8

1234567

1. Control Point

8: 8

2. Control Method

A: Standard control

V: Heating and cooling control

3. Control Output

Q: Voltage output

C: Current output

4. Heater Burnout and SSR Failure Detection Function

(Not available with Current Output Models.)

A: No

H: Yes

5. Communications Function

D1: DeviceNet

6. Input Type

TC: Thermocouple

P: Platinum resistance thermometer

7. Casing

B: Yes

9

Page 17

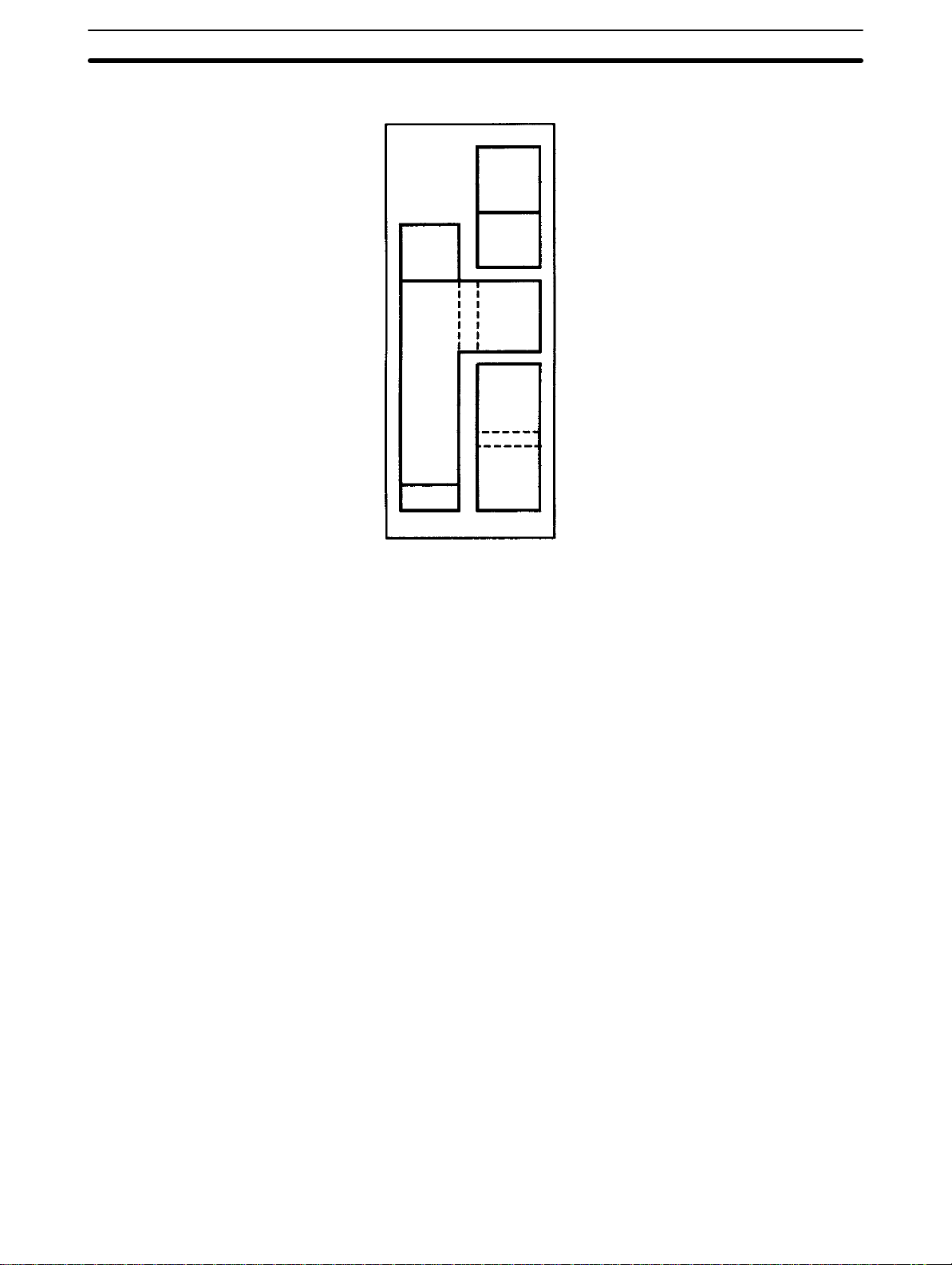

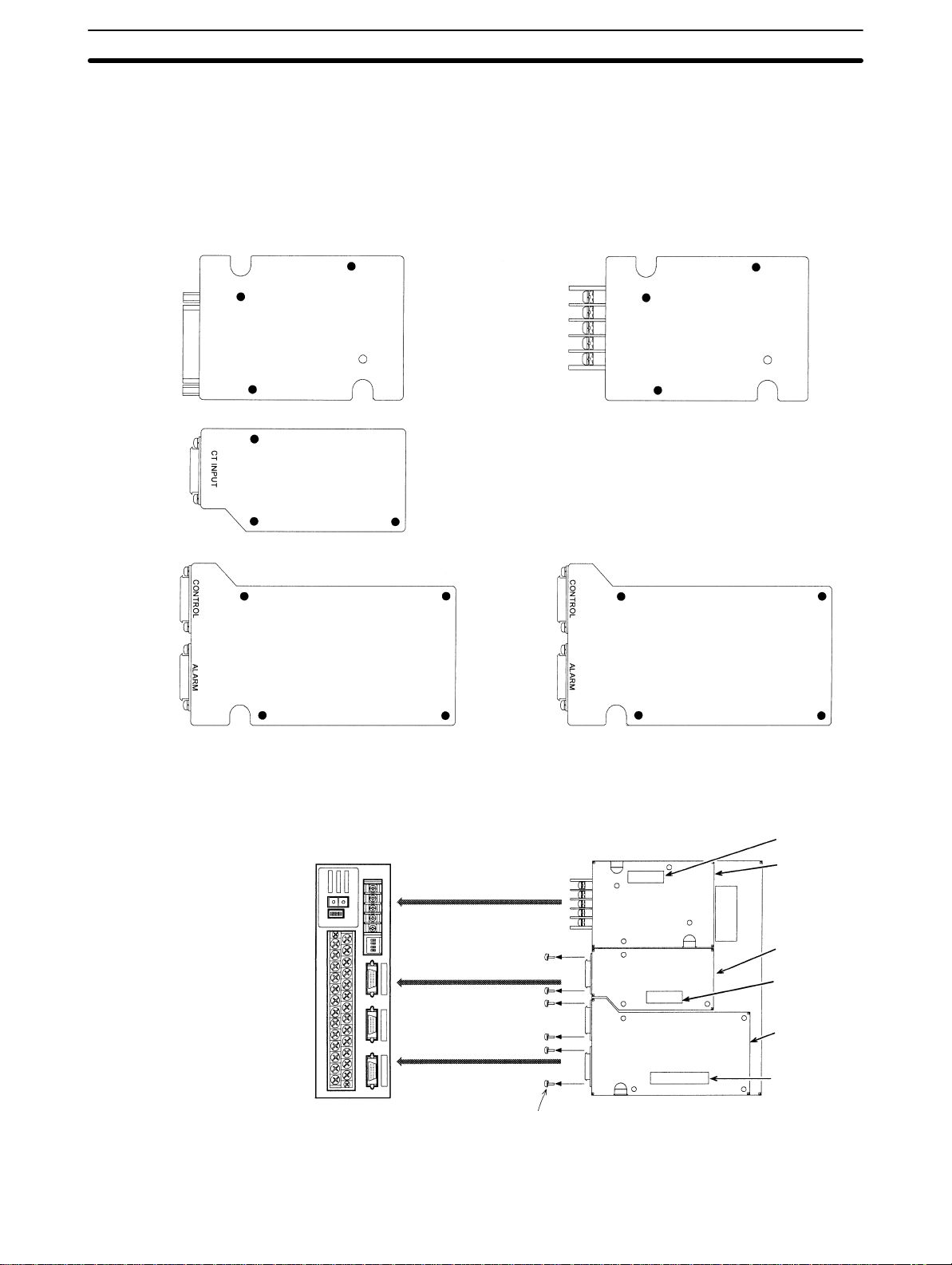

2-2 Mounting the Serial Communications Models

2-2SectionMounting the Serial Communications Models

I/O Units

Communication Unit

CT Input Unit

Output Unit

E53-E01 for

RS-232C

E54-E8CT

I/O Units are not mounted on the E5ZE.

Mount the appropriate I/O Units according to the specification of the E5ZE.

The diagram below is the view from the back of component side.

Type of I/O Units

E53-E04 for

or

Use this CT input unit in combination

with the E53-E8Q voltage output unit.

RS-422/RS-485

E53-E8Q for voltage

output

or

E53-E8C for current

output

Tighten the screws through the holes marked with a black dot () to the fixing

studs of the E5ZE.

Mounting Position of I/O Units

Communication Unit

CT Input Unit

Output Unit

Remove this screw when the Unit is

mounted on the model with casing.

Connector

Communication

Unit

CT Input Unit

Connector

Output Unit

Connector

10

Page 18

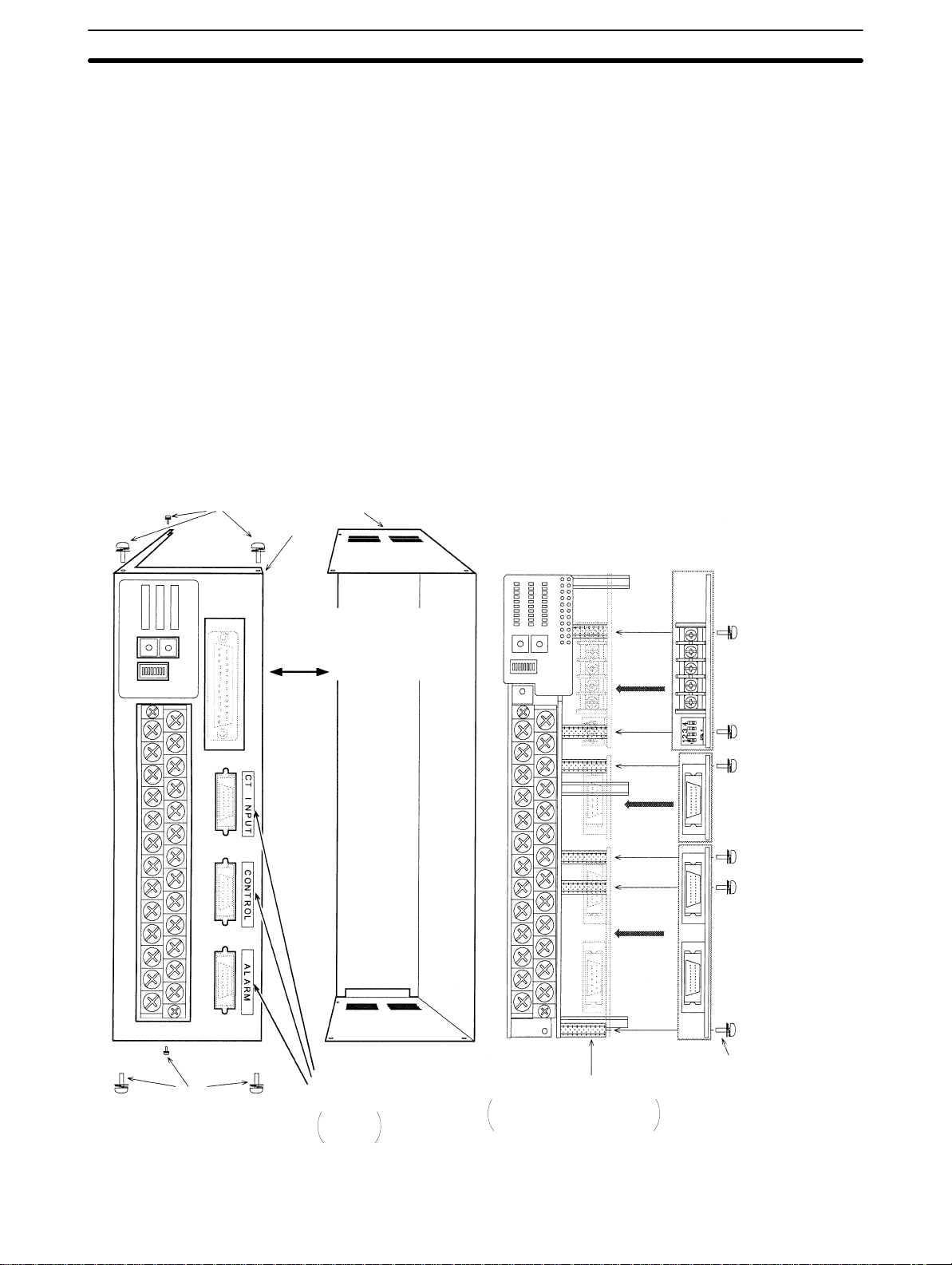

2-2SectionMounting the Serial Communications Models

Mounting the Units

Casing securing

Use appropriate Phillips screwdriver for the screws. Use of an inappropriate

screwdriver may damage the screws and cause insufficient tightening.

Mount the Units in an environment where anti-static electricity countermeasures

have been taken.

Store the removed screws carefully and use them again when required.

Model With Casing

1, 2, 3... 1. Remove the connector fixing screws (2 screws each for a connector) from

the Units (except for communication unit).

2. Remove the casing fixing screws (6 screws).

3. Remove the casing.

4. Mount the Units in the same manner as the model without casing.

5. Fix the connector to the case using the connector fixing screws with a torque

of 0.34 to 0.39 Nm.

6. Replace the casing in its original position using six casing fixing screws.

Casing

Case

Casing securing

Remove the casing after removing

the casing fixing screws(6 pcs.)

Identification label for

connector

CT INPUT

CONTROL

ALARM

Fixing studs for the Units

Communication Unit : 3 pcs.

CT Input Unit : 3 pcs.

Output Unit : 4 pcs.

Communication Unit

(sold separately)

E53-E01 or E53-E04

(The diagram shows

E53-E04)

CT Input Unit

(sold separately )

E54-E8CT

Output Unit

(sold separately)

E53-E8Q or E53-E8C

The Unit fixing screws are

mounted on the fixing studs at

the factory.

11

Page 19

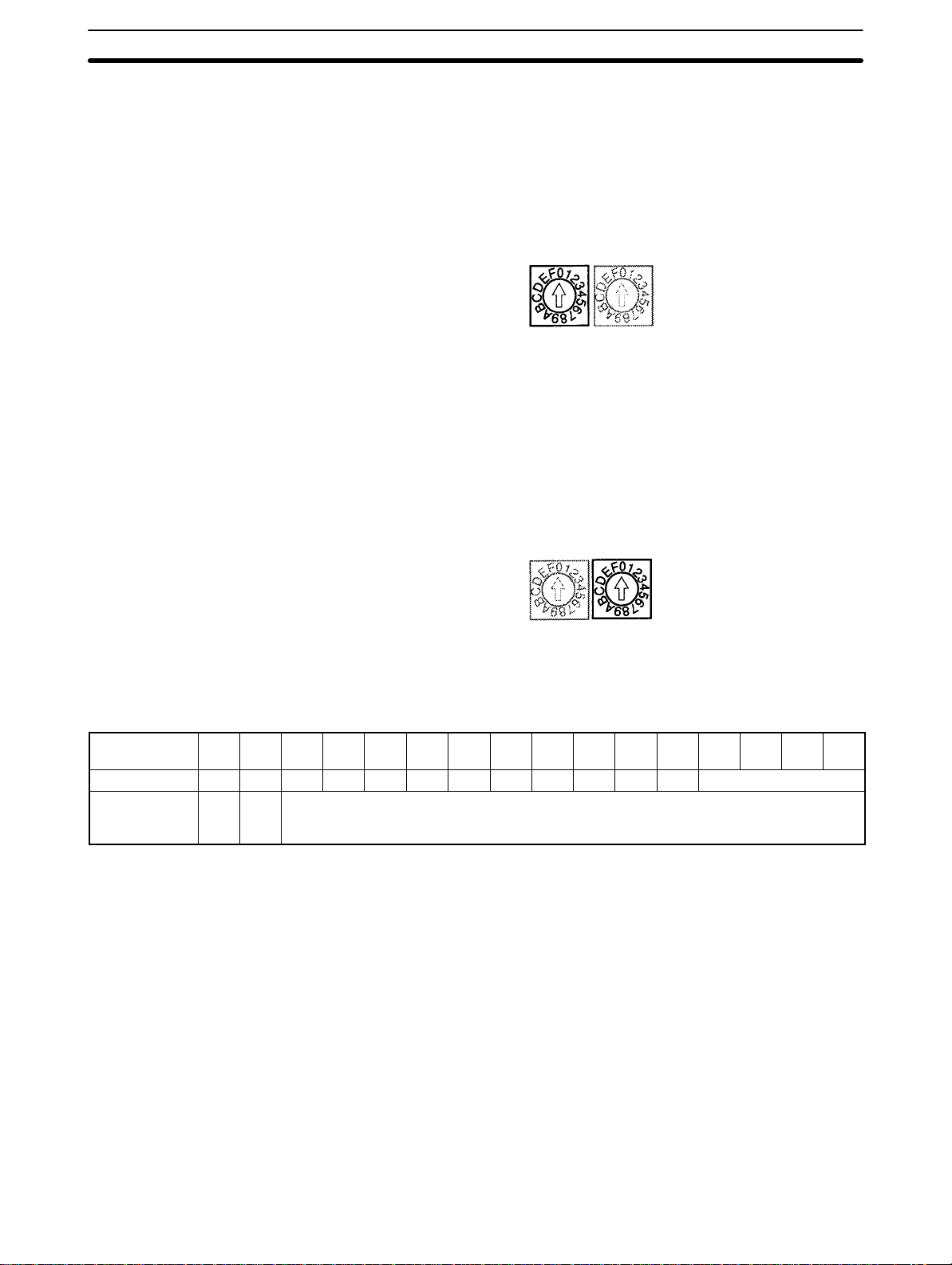

2-3 Setting Selectors and Switch

Observe the following precautions when operating the selectors and switch.

• Always make sure the power is OFF before changing the selectors and switch.

• Use a small flat-blade screwdriver to change the selector and switch settings,

and be sure that the selectors are correctly positioned.

2-3-1 UNIT Selector

When serial communications are being used, the UNIT selector must be set so

that the host device can recognize the E5ZE unit number.

When more than one E5ZE Multipoint Temperature Controller is being used with

RS-422 or RS-485 communications, set a different unit number for each E5ZE.

• The selector settings 0 to F correspond to unit numbers 00 to 0F. The factory

setting of 0 corresponds to unit number 00.

2-3SectionSetting Selectors and Switch

UNIT INPUT

2-3-2 INPUT Selector

UNIT INPUT

Set the INPUT selector according to the type of temperature sensor connected

to the E5ZE. The selector positions and corresponding temperature sensors are

as follows:

Selector

setting

Thermocouple K J R S T E B N L U W PLII Not used.

Platinum

resistance

thermometer

0 1 2 3 4 5 6 7 8 9 A B C D E F

Pt JPt Not used.

• The factory setting is 0.

• The platinum resistance thermometer settings “Pt” and “JPt” indicate Pt100

and JPt100 respectively.

12

Page 20

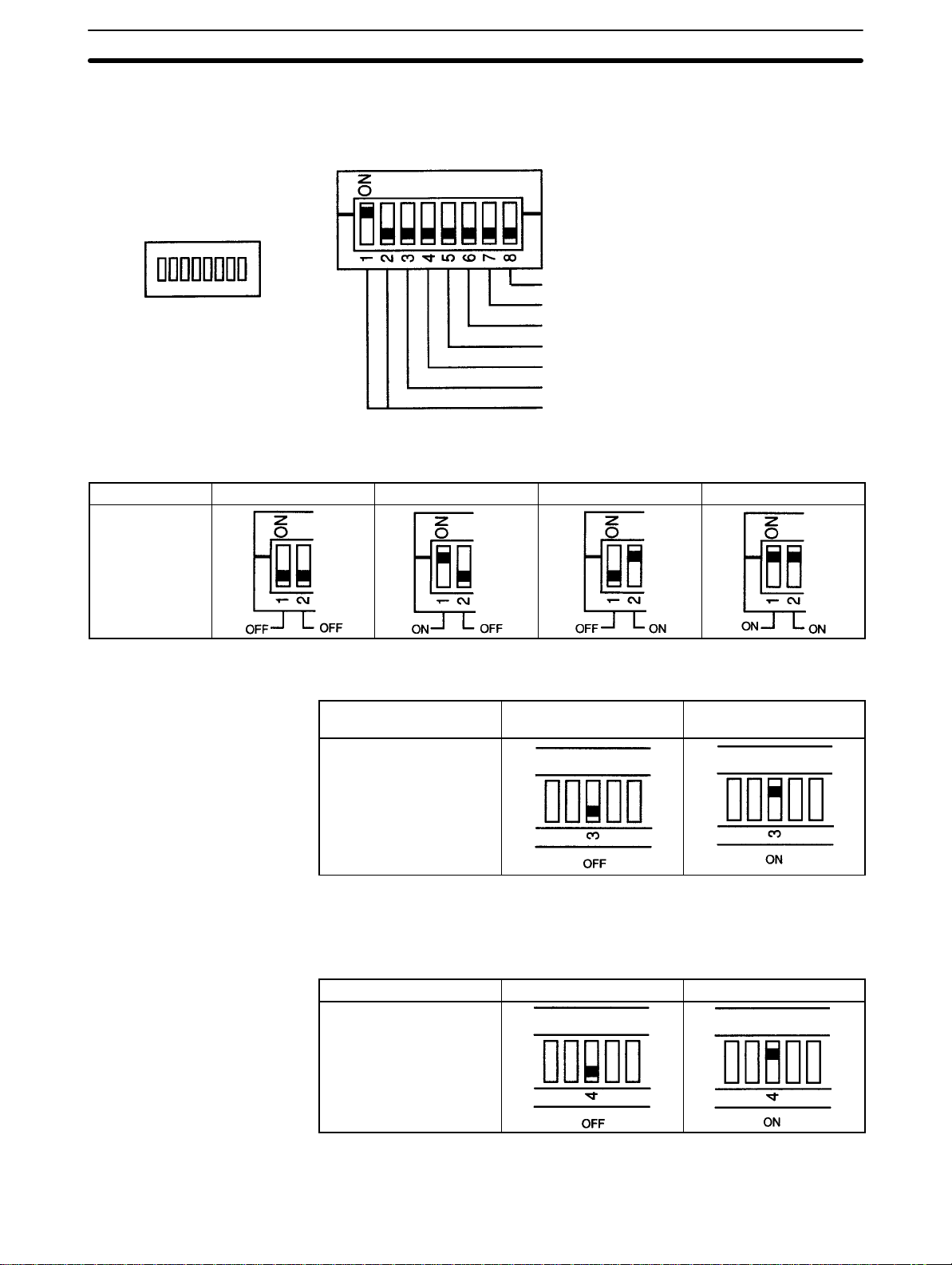

2-3-3 FUNCTION Switch

The FUNCTION switch is used to set the parameters of the E5ZE, such as the

baud rate and startup operation.

FUNCTION

2-3SectionSetting Selectors and Switch

Operation mode change

Not used. (Always set to OFF.)

Temperature unit (°C or °F)

Startup operation

E5ZD-SDL Setting Display Unit connection

Memory bank designation method

Baud rate (serial communications)

Baud Rate (Serial

Communications)

Baud rate 19,200 bps 9,600 bps 4,800 bps 2,400 bps

Pin 1

Pin 2

Set the baud rate using pins 1 and 2 to the baud rate of the host device connected to the EZ5E.

The factory setting is 9,600 bps (pin 1 ON, pin 2 OFF).

Memory Bank Designation

Method

Pin 3 is used to set the memory bank designation method.

Memory bank

designation

Pin 3

Communications Contact inputs

The factory setting is for communications (pin 3 OFF).

When contact inputs are used to switch memory banks, the specified memory

bank will be used for all control points.

E5ZD-SDL Setting Display

Unit Connection

Pin 4 is used to specify when an E5ZD-SDL Setting Display Unit is connected.

E5ZD-SDL connection Not connected Connected

Pin 4

The factory setting is for no connection (pin 4 OFF). Set pin 4 to ON when an

E5ZD-SDL Setting Display Unit is to be connected to the E5ZE.

13

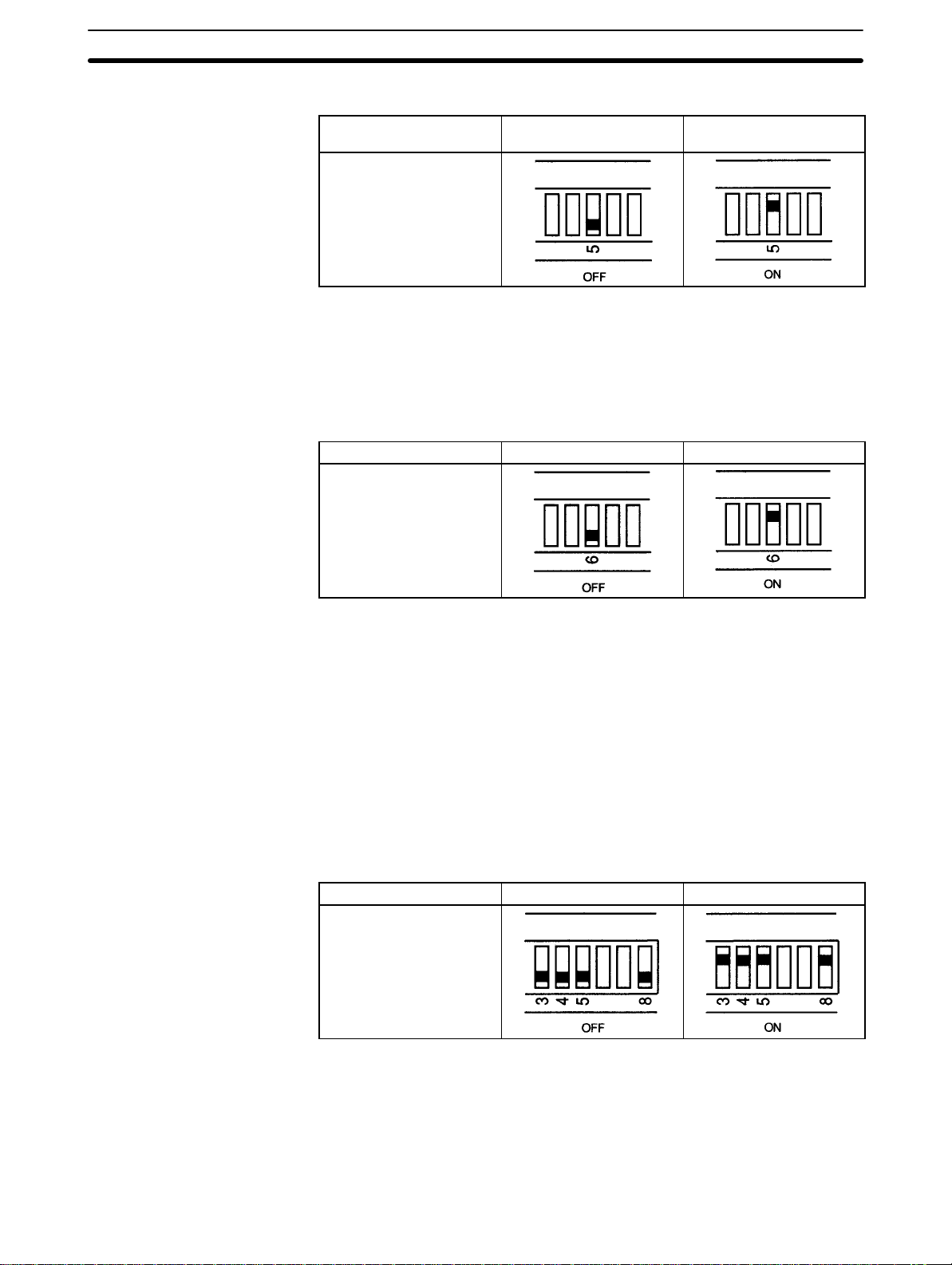

Page 21

2-3SectionSetting Selectors and Switch

Startup Operation

Temperature Unit

Pin 5 is used to set the startup operation.

Startup operation Stop operation control Continue status at

power OFF

Pin 5

The factory setting is for stop operation control (pin 5 OFF).

If the power is turned OFF during manual operation and pin 5 is set to ON (con-

tinuous operation), manual operation will automatically begin when the power is

turned ON again. The output value will be 0%.

Pin 6 is used to set the unit for measuring temperature.

Temperature unit

Pin 6

C F

1, 2, 3... 1. Initialize the setting data.

Operation Mode Change

The factory setting is for degrees Celsius (pin 6 OFF).

When the temperature unit is changed, the temperature data does not automati-

cally change, so make sure to reset the temperature using the following procedure.

2. Recalculate the data according to the following conversion formula and reset the control data within the setting range.

(value in F) = 1.8 x (value in C) + 32

3. Store the settings in memory.

Pins 3, 4, 5, and 8 are used to change the operation mode.

E5ZE operation mode Control mode Hardware test mode

Pins 3, 4, 5, and 8

The factory setting is for Control Mode (pins 3, 4, 5, and 8 all OFF).

14

Control Mode: Use for normal temperature control.

Hardware Test Mode: Use for testing Peripheral Devices and wiring.

Refer to Appendix E for details on how to use Hardware Test Mode. Outputs can

be turned ON and OFF in Hardware Test Mode regardless of the process value.

Page 22

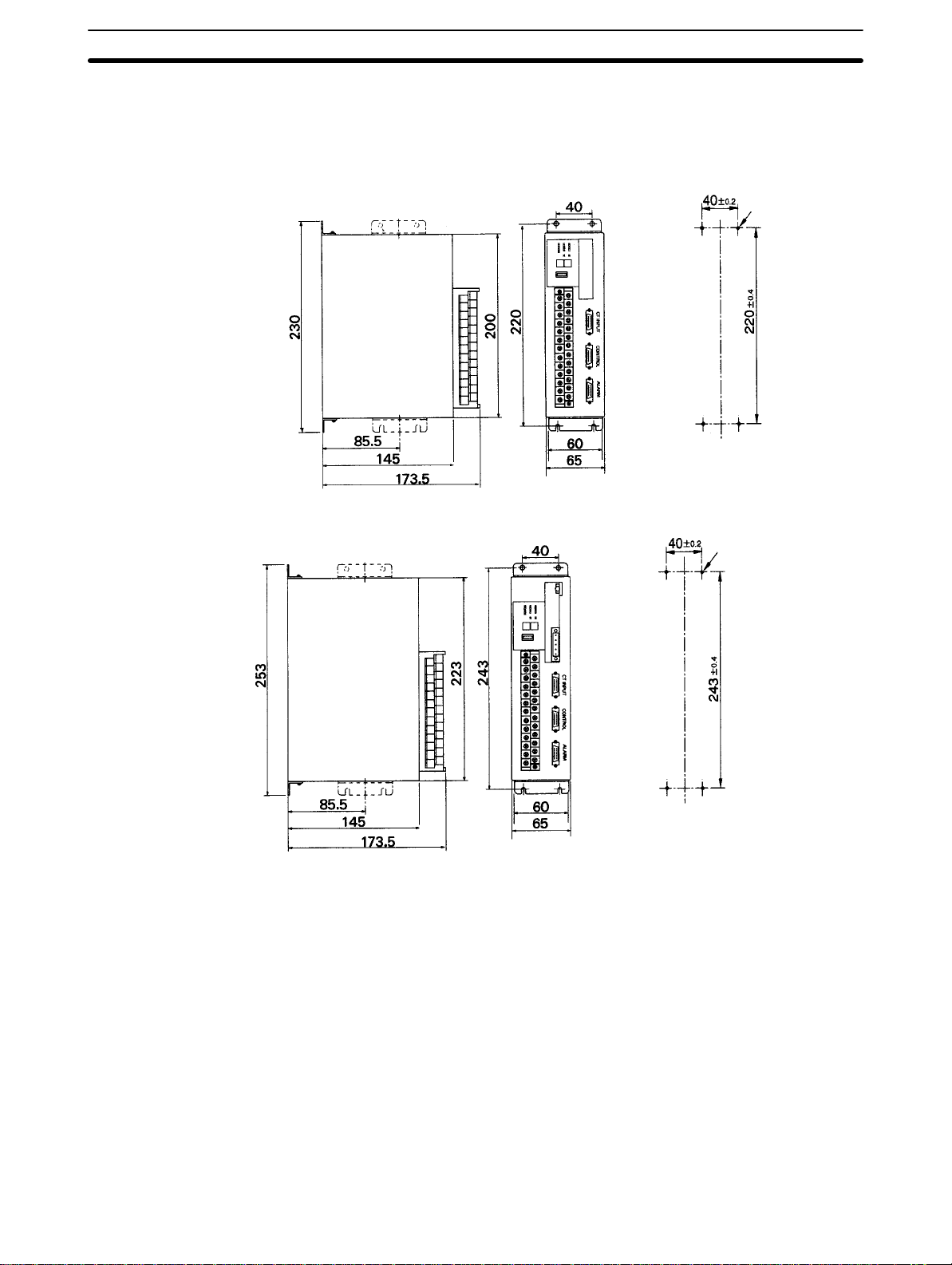

2-4 Installation

2-4-1 External and Panel Dimensions

2-4SectionInstallation

Serial Communications Model

E5ZE-8D1B

(DeviceNet Interface)

Unit: mm Mounting Hole Dimensions

Four, M4

Four, M4

15

Page 23

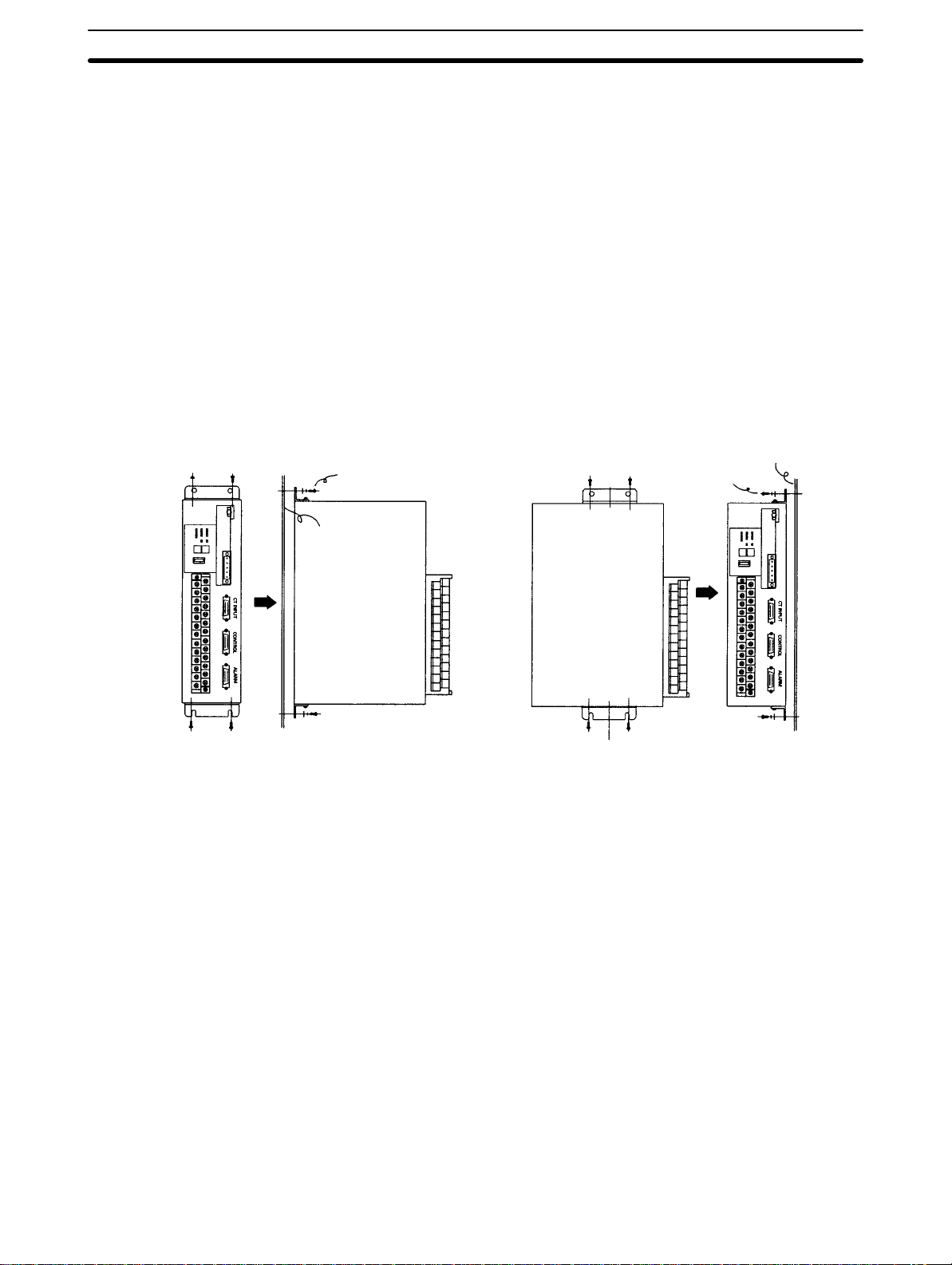

2-4-2 Mounting

Precautions

2-4SectionInstallation

Mount the Unit using the methods shown here. The Unit will not operate properly

if other methods are used to mount the Unit.

• Use the following mounting screws. Make sure the length of the screws is appropriate for the mounting panel used.

E5ZE-8B: 4 x M4 screws

• Use spring and flat washers and tighten to a torque of 0.43 to 0.58 N m {4.4 to

5.9 kgf cm}.

• Do not mount the terminal block with the connectors facing upwards. Doing so

may cause measurement errors.

Mounting Bracket

Mounting Models

Secure the mounting

bracket

Secure the mounting bracket using the screws provided according to the appropriate mounting method. Tighten to a torque of 0.43 to 0.58 N m {4.4 to

5.9 kgf cm}.

Mounting screws

(4 x M4 + spring

and flat washers)

Panel

Secure the mounting

bracket

Mounting screws

(4 x M4 + spring

and flat washers)

Panel

16

Page 24

2-5 Power Supply and Input Wiring

2-5-1 Terminal Block

The input terminal block has been designed with a removable terminal-screw

panel. When connecting the power supply or temperature sensor, the terminalscrew panel can be conveniently removed before wiring.

• To remove the terminal-screw panel, loosen the two screws alternately indicated by A in the above diagram.

• To mount the terminal-screw panel, insert it into the terminal block and secure

the two screws (A) alternately.

• If the terminal block has been removed from the E5ZE Thermocouple Input

Model, when reconnecting make sure that the E5ZE’s lot number and serial

number are the same as those of the terminal block. Accuracy cannot be guaranteed for a Unit that has been connected to a terminal block with a different lot

number and serial number.

2-5SectionPower Supply and Input Wiring

2-5-2 Wiring

• Always turn OFF the power supply before performing any wiring.

• Be sure to check polarity when connecting the power supply and temperature

sensor.

• Wire the power supply cables separately from the temperature sensor cables

to prevent noise interference.

• Use either crimp terminals or solder the wire ends when wiring terminals.

• Tighten the terminal screws.

• Wire the power lines close to the terminal block to prevent external force being

exerted on the power lines from torsion or weight.

• Do not use the terminals that are marked “Don’t use.”

• Do not bend the crimp terminals after they have been connected and the

screws have been tightened.

17

Page 25

• Use the crimp terminals shown in the following diagram.

2-5SectionPower Supply and Input Wiring

Crimp Terminals

End Soldering

Applicable wire size: AWG 22 to 16

2-5-3 Terminal Arrangement

The following diagram shows the arrangement of terminals on the terminal

block.

Terminal Block Screw Dimensions

9.5 mm

7.9 mm max.

8.1 mm

7.9 mm max.

Length of exposed wire: 6 to 8 mm

Thermocouple Platinum Resistance Thermometer

24 VDC 24 VDC

8 x M3.5 self-rising screws

2-5-4 Power Supply

ch 0

Don’t use

ch 1

Don’t use

ch 2

Don’t use

ch 3

FG

ch 4

Don’t use

ch 5

Don’t use

ch 6

Don’t use

ch 7

ch 0

ch 1

Don’t use

ch 2

ch 3

FG

ch 4

ch 5

Don’t use

ch 6

ch 7

The power supply specifications are as follows:

24 VDC (20.4 to 26.4 VDC) 15 W + 20% max.

Use a power supply with a minimum capacity of 2 A. Be sure to consider the inrush current.

2-5-5 Ground

18

Connect the ground wire to terminal 26. Ground to 100 Ω max.

Page 26

2-5-6 Thermocouple Input

• The terminal polarity varies with the control point. Be sure to check polarity

when connecting thermocouples to the terminal block.

• When extending the input lead wires, connect compensating conductors that

match the thermocouple used. Do not solder the ends of the thermocouple or

compensating conductors.

• Never remove the cold junction compensator connected to terminals 13 and

15.

• Do not touch the cold junction compensators.

• Short-circuit the positive and negative terminals of each control point that is not

used. The process value for each control point that is not being used will be the

ambient temperature of the terminal block.

2-5-7 Platinum Resistance Thermometer Input

• The terminal polarity varies with the control point. Be sure to check polarity

when connecting platinum resistance thermometers to the terminal block.

• When extending the input lead wires, make sure that the conductor resistance

is the same for the A terminal and two B terminals.

• Connect a 100- to 200-Ω resistor between the A and B terminals of any unused

control point, and short-circuit the two B terminals of any unused control point.

The process value for each control point that is not being used will correspond

to the resistance of the resistor connected to the terminals.

2-6SectionWiring CT Inputs and Control/Alarm Outputs

2-6 Wiring CT Inputs and Control/Alarm Outputs

CT inputs and control/alarm outputs are connected using wiring-reduction devices. Always use E5ZE-CBL Connecting Cables to connect the E5ZE to

the wiring-reduction devices. Refer to the wiring-reduction device datasheet for

details, including wiring precautions.

Use the identification labels provided for each cable to prevent incorrect wiring of

the CONTROL, ALARM, and CT INPUT connectors.

Cable identification label

Hood: Connect to

FG terminal: Connect to

improve noise resistance

E5ZE-CBL Connecting Cable

the FG terminal.

19

Page 27

2-6-1 CT Inputs

Cable Connections

2-6SectionWiring CT Inputs and Control/Alarm Outputs

The CT INPUT connector can be connected to an XW2B-20G5 Connector Terminal Conversion Unit (20-terminal M3.5 terminal block) or an XW2B-20G4

Connector Terminal Conversion Unit (20-terminal M2.4 terminal block).

E5ZE-CBL Connecting Cable

XW2B-20G5/4 Connector Terminal

Conversion Unit

Wiring

CT0 to CT7

The following diagram shows the terminal arrangement for CT inputs when a

XW2B-20G5/4 Connector Terminal Conversion Unit is connected. Connect CT0

to CT7 to the CT inputs for control points 0 to 7. For example, CT0 will detect

heater burnout or SSR failure for the output of control point 0.

Use the E54-CT1 or E54-CT3 Current Transformer (CT). Refer to Appendix B

for further details on the CT. Refer to 3-10 Heater Burnout Detection for details

on wiring the CT.

20

Page 28

2-6-2 Outputs

Cable Connections

E5ZE-CBL

Connecting Cable

2-6SectionWiring CT Inputs and Control/Alarm Outputs

XW2B-20G5/4 Connector Terminal

Conversion Unit

Heating control output, memory bank designation input

XW2B-20G5/4 Connector Terminal

Conversion Unit

G7TC-OC08/16, G7VC-O16

I/O Blocks

CONTROL Connector

Wiring

Cooling control output, ALM1 and ALM2, HB alarm,

HS alarm, temperature controller error

The CONTROL connector can be connected to an XW2B-20G5 Connector T erminal Conversion Unit (20-terminal M3.5 terminal block) or an XW2B-20G4

Connector Terminal Conversion Unit (20-terminal M2.4 terminal block).

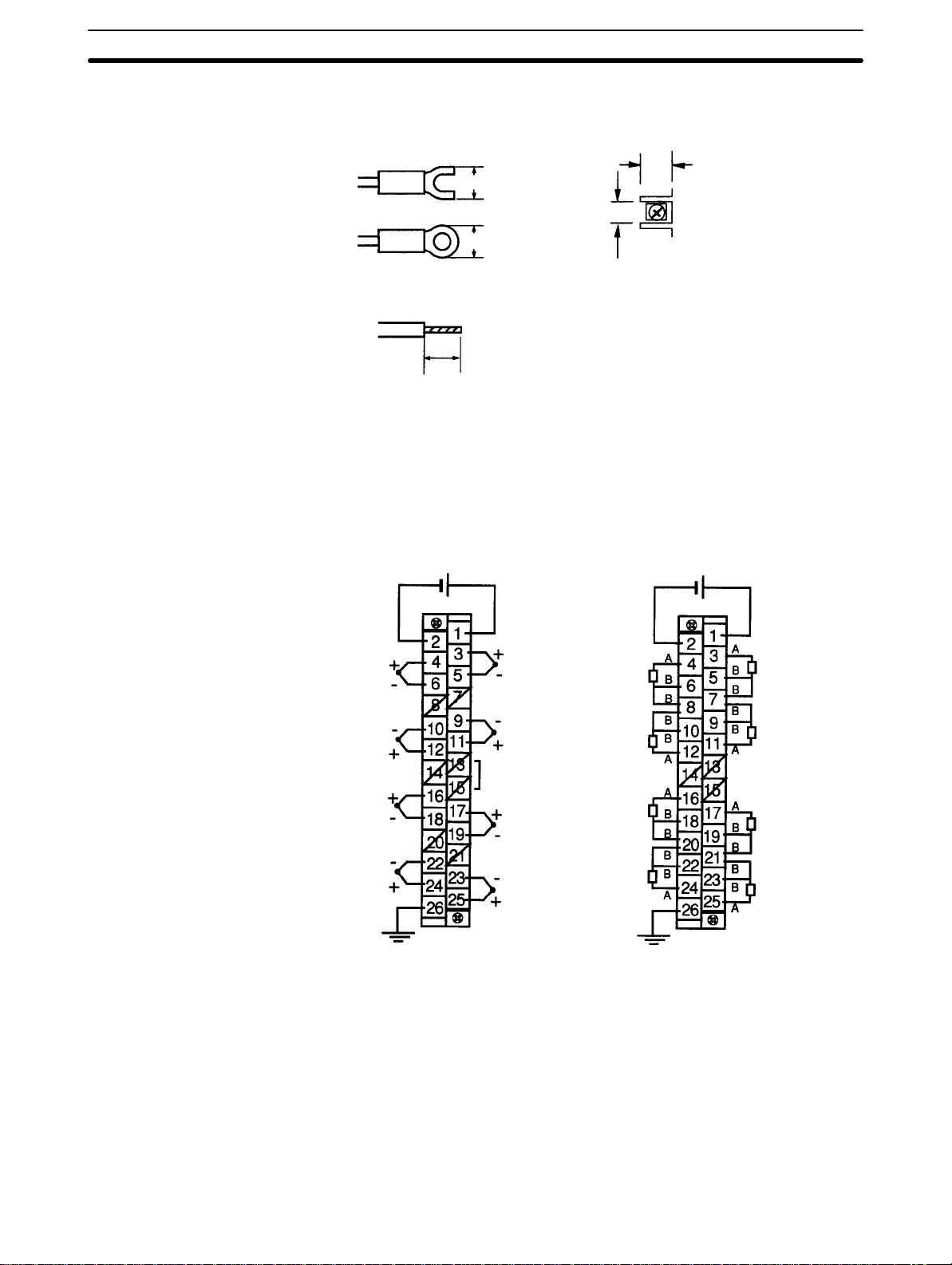

• The terminal arrangement for outputs when an XW2B-20G5/4 Connector Terminal Conversion Unit is connected is shown in the following diagram.

CONTROL Connector Terminal Block

2

1

2

2

2

0

• The output specifications are shown in the following table. Connect a load that

is compatible with the output type and output rating.

Output Specification

Voltage output Output voltage: 12 ± 1.2 VDC

Output current: 30 mA max.

Current output

Output current: 4+0/

–0.6

to 20

Load resistance: 600 Ω max.

+2

/–0 mA DC

21

Page 29

• When connecting a relay load, insert a diode to prevent surge.

2-6SectionWiring CT Inputs and Control/Alarm Outputs

E5ZE

ch n: Control point 0 to 7

ch n +

Relay

ch n –

• The following diagram shows the wiring when designating the memory bank

using contact inputs.

No Contact InputContact Input

E5ZE

Terminal

numbers 2,

3, and 4

Terminal

number 1

ON: Short-circuit resistance: 1 kΩ max.

Outflow current: 3 mA DC

OFF: Open resistance: 100 kΩ min.

E5ZE

Terminal

numbers 2,

3, and 4

Terminal

number 1

ON: Residual voltage: 2 VDC max.

Outflow current: 3 mA DC

OFF: Leakage current: 1 mA max.

ALARM Connector Wiring

The ALARM connector can be used with the following devices.

• XW2B-20G5 or XW2B-20G4 Connector Terminal Conversion Unit

• G7TC-OC16, G7TC-OC08, or G7VC-O16 I/O Block

The following diagram shows the terminal arrangement when the ALARM connector is connected to an XW2B-20G5 or XW2B-20G4 Connector Terminal

Conversion Unit. In the diagram, RL indicates a relay load.

Cooling control output (Do not use these terminals with E5ZE-8A Standard Models.)

Don’t use

Common

Don’t use Don’t use Don’t use Don’t use

ch 7 ch 6 ch 5 ch 4 ch 3 ch 2 ch 1 ch 0

Common

Temperature controller error

HS alarm HB alarm Alarm 2 Alarm 1

• The following table shows the specifications for alarm output and cooling control output. The E5ZE does not have an overcurrent protection function for

alarm output and cooling control output. Connect a load to each alarm output

and cooling control output that corresponds to the output ratings.

Output Specifications

Open collector output NPN, 30 VDC, 50 mA max.

Residual voltage when ON: 2 VDC max.

Leakage current when OFF: 1 mA max.

22

• Do not use the terminals marked “Don’t use.”

Page 30

• When connecting a relay load, insert a diode to prevent surge.

2-6SectionWiring CT Inputs and Control/Alarm Outputs

Connecting G7TC I/O

Blocks

G7TC-OC08

G7TC-OC16

E5ZE

ALM: Temperature Controller error, Alarm 1 and 2, HB, and HS

Relay

The following diagrams shows an ALARM connector connected to a G7TCOC08 and G7TC-OC16 I/O Block respectively.

Don’t use Don’t use

Internal circuit of G7TC I/O Block

24 VDC/

12 VDC

Alarm 1

Alarm 2

Don’t use Don’t use

HS

Temperature Controller error

alarm

HB alarm

G7T (SPST-NO)

Connecting G7VC I/O

Blocks

G7VC-O16

24 VDC/

12 VDC

Alarm 1

Alarm 2

HS

alarm

HB alarm

Temperature

Controller

error

0

Cooling control output (Do not use with

E5ZE-8A Standard Models.)

3

1

2

6

4

5

7

Points

• Do not use terminals marked “Don’t use.” Doing so may cause the E5ZE or

G7TC to malfunction.

• G7TC-OC08 I/O Blocks cannot be used with E5ZE-8V Heating and

Cooling Control Models.

• Refer to the separate datasheets for details on precautions for the I/O Blocks.

The following diagram shows an ALARM connector connected to a G7VCO16 I/O Block.

Cooling control output (Do not use with

E5ZE-8A Standard Models)

24 VDC

Alarm 2

Alarm 1

A2 to A6 common

HB alarm

Temperature

HS

controller error

alarm

A12 to A19 common

• Do not use terminals marked “Don’t use.” Doing so may cause the E5ZE or

G7VC to malfunction.

23

Page 31

• The following G7VC-O16 I/O Blocks for output are available.

G7VC-OC16: Relay outputs

G7VC-OA16: SSR AC outputs

G7VC-OD16: SSR DC outputs

• Refer to the separate datasheets for details on precautions for the I/O Blocks.

2-7 Connecting Communications

The wiring and connections of the communications interfaces are described

here. For further details, refer to the following manuals.

Serial communications: E5ZE Multipoint Temperature Controller Communica-

tions Manual (H77)

DeviceNet communications: E5ZE-8 Multipoint Temperature Controller Devi-

ceNet Communications Manual (H104)

2-7-1 RS-232C

• Mount the RS-232C Communications Unit on the E5ZE Serial Communications Model.

• The E5ZE is connected to the RS-232C interface in the ratio of 1:1.

• Refer to the E5ZE Multipoint Temperature Controller Communications Manual

(H77) for details on communications.

2-7SectionConnecting Communications

Cable Connections

• The maximum cable length is15 m. To extend the transmission path, use the

OMRON Z3RN RS-232C Optical Interface.

• Use shielded twisted-pair cable with a wire thickness of AWG28 minimum.

• Use the following OMRON 25-pin D-sub Connectors or equivalent.

Plug: XM2A-2501 Connector

Hood: XM2S-2511 Hood

Host device

RS-232C

Symbol

Pin

Shield

Pin

Symbol

E5ZE

Line driver/receiver

LT1181CS or

equivalent

• The E5ZE’s RS-232C communications do not support a CD (carrier detect)

signal from the host device. If the CD signal is required, provide support at the

host device.

When using the RS-232C auxiliary setting jack on the E5ZE-8D1B

(DeviceNet Model with casing), use the following Connecting Cables.

• ES100-CT021-202 (25-pin)

This Cable is used to connect the E5ZD-SDL1 Setting Display Unit.

• ES100-CT023-202 (9-pin)

The RS-232C auxiliary setting jack is designed to be used only temporarily for

initial settings and performing maintenance. Do not use the RS-232C auxiliary

setting jack to mount the E5ZE to a device. If the RS-232C auxiliary setting jack

is left connected for a long time, the reliability of the connection will deteriorate.

24

Page 32

2-7-2 RS-422 and RS-485

• Mount the RS-422/485 Communications Unit on the E5ZE Serial Communications Model.

• The E5ZE can be connected to the communications interface in the ratio of 1:N

with a maximum of 16 Units connected.

• The maximum cable length is 500 m.

• Refer to t h e E5ZE Multipoint Temperature Controller Communications Manual

(H77) for further details on communications.

Parameter Settings

• Specify the following parameters using the communications DIP switch. Always turn OFF the power before changing the switch.

• Communications interface

• Terminating resistance

2-7SectionConnecting Communications

Setting Pin RS-422 RS-485

Terminating

resistance

(pins 3 and 4)

Interface (pins 1 and 2) Pin 2

• Set the terminating resistance at both ends of the transmission path including

the host device. If terminating resistance is to be set at devices other than the

E5ZE, make sure that the total terminating resistance value of the transmission paths is at least 100 Ω.

Wiring the Communications Terminal Block

• Always turn OFF the power supply before wiring.

• Wire the power lines and communications cables separately to prevent noise

interference.

• Use crimp terminals or solder the wire ends when wiring the terminals.

E5ZE-804

Yes Pin 4

Pin 3

No Pin 4

Pin 3

Pin 1

• Tighten the terminal screws to a torque of 0.59 N m, or 6 kgf cm.

• Do not apply a force of more than 100 N or 10.2 kgf to the terminal screws.

• Do not bend any crimp terminals after connecting them to the terminal screws

and tightening.

25

Page 33

• The following crimp terminals can be used.

Crimp Terminal Terminal Block Screw Dimensions

2-7SectionConnecting Communications

RS-422 Wiring

End Soldering

Host device

Signal

6 mm max.

6.25 mm

6 mm max.

Length of exposed wire: 6 to 7 mm

Applicable wire size: AWG14 to 20

Shielded twisted-pair cable

E5ZE

Termi-

Signal

nal

Shield

10.4 mm

M3 x 7.2 screws with

square washers

+5 V

SN751177N or

equivalent

51 k

4.7 k

4.7 k

51 k

6.8 V

E5ZE

Terminal

Communications DIP switch

Signal

Terminating resistance

26

Page 34

RS-485 Wiring

• Do not use terminals 1 and 2.

Host device

Signal

Shield

E5ZE

Terminal

Signal

E5ZE

Terminal

Signa

2-7SectionConnecting Communications

+5 V

SN751177N or

equivalent

51 k

4.7 k

4.7 k

51 k

6.8 V

l

Communications DIP switch

2-7-3 DeviceNet Interface

• Use the E5ZE-8D1B for DeviceNet communications.

• Refer to the DeviceNet Operation Manual (W267) for details on DeviceNet

Network configurations and connection methods.

• Refer to the E5ZE-8 DeviceNet Communications Manual (H104) for details on

DeviceNet communications applications.

Communications Settings

RS-232C auxiliary

setting jack

DeviceNet DIP

switch

DeviceNet

connector

Set the following parameters using the DeviceNet DIP switch.

• Node addresses

• Baud rate

• E5ZE operation for DeviceNet communications errors.

Node address

Terminating resistance

Communications error operations

Always set to OFF

Baud rate

• Pins 1 to 6 are used to set the node address. The factory setting is 00 (pins 1 to

6 all OFF).

Pin 1 Pin 2 Pin 3 Pin 4 Pin 5 Pin 6

0

2

1

2

2

2

3

2

4

2

5

2

27

Page 35

2-7SectionConnecting Communications

• Pins 7 and 8 are used to set the baud rate. Be sure to set the baud rate to match

that of the DeviceNet Master Unit. The factory setting is 125 kbps (pins 7 and 8

OFF).

Baud rate Pin 7 Pin 8

125 kbps OFF OFF

250 kbps ON OFF

500 kbps OFF ON

Not used ON ON

• Pin 10 is used to set the E5ZE operation when a DeviceNet communications

error occurs.

ON: The E5ZE continues to operate according to the data that was

transmitted immediately before the error occurred.

OFF: The E5ZE stops operating.

The factory setting is ON.

• A DeviceNet transmission error is a connection time-out error or a transmission data error that has occurred during communications between the DeviceNet Master and the E5ZE.

Cable Connections

Number of Connectable

Units

• The following diagram shows how the DeviceNet connector is wired.

• Multi-drop connections cannot be used.

Black (V–)

Blue (CAN L)

Shield

White (CAN H)

Red (V+)

The number of E5ZE-8D1B DeviceNet Models with casing that can be

connected to one DeviceNet Master Unit depends on the capability of the Master

being used. The maximum number of Units that can be connected to one Master

is calculated according to the number of words allocated to the

E5ZE-8D1B and the number of words that can be used by the Master.

• The number of words allocated to the E5ZE-8D1B is as follows:

Inputs: 14 words

28

Outputs: 9 words

Message communications (FINS messages) are used.

Example: C200HW-DRM21-V1 DeviceNet Master Unit without Configurator

• The number of words used by the Master is 50 input words and 50 output

words (current as of July 31, 1998). The E5ZE-8D1B is allocated

14 words, so the maximum number of Units that can be connected is as follows:

50 14 = 3 Units.

Page 36

SECTION 3

Functions

This section provides details on the functions of the E5ZE and their applications. For details on the settings and measurement

values for the functions, refer to the E5ZE Multipoint Temperature Controller Communications Manual (H77) and the

E5ZE-8 Multipoint Temperature Controller DeviceNet Communications Manual (H104).

3-1 Data Configuration 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 I/O Settings 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-1 Input Type 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-2 Input Shift 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-3 Control Period 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-4 Direct/Reverse Operation 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Set Point and Process Value 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3-1 Setting Set Point 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3-2 Reading Process Value 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Alarm Output Settings 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-1 Alarm Modes 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-2 Alarm Temperatures 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5 Output Limitations 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-1 Output Limiter 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-2 Output Change Rate Limiter 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6 Ramp 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-7 Control Adjustments 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-7-1 Auto-tuning 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-7-2 Manual Reset 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8 Control Method Selection 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8-1 Manual Operation 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8-2 ON/OFF Control 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-9 Heating and Cooling Control 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-9-1 Dead Band/Overlap Band 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-9-2 Cooling Coefficient 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-10 Heater Burnout Detection 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-11 SSR Failure Detection 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29

Page 37

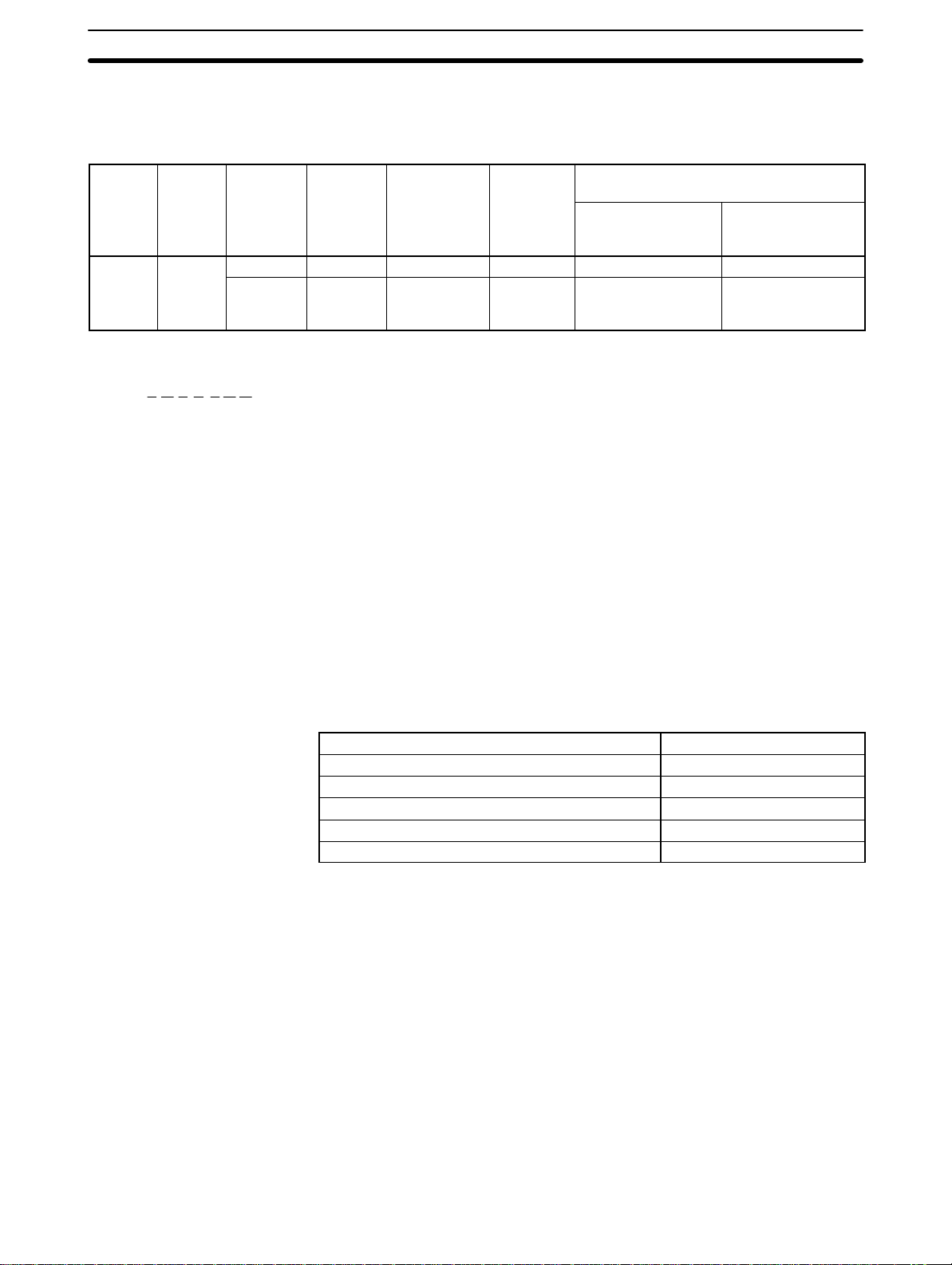

Data Configuration Section 3-1

3-1 Data Configuration

Set Values

CH0 (Control Point 0) Set Values

Memory bank number

Alarm mode

Manual output value

HB alarm, HS alarm detection

current value

Memory Bank 7 Set Values

Memory Bank 1 Set Values

Memory Bank 0 Set Values

Set point

Proportional band (P constant)

Integral time (I constant)

Derivative time (D constant)

Control period

Alarm temperature

Input shift value

Manual reset value

Output limit

Ramp value

Output change rate limit

Dead band/overlap band (See

note.)

Cooling coefficient (See note.)

Fuzzy strength

Fuzzy scale 1

Fuzzy scale 2

The following diagram shows how data is structured in the E5ZE.

Common set values: Output operation (direct/reverse operation)

Setting unit

HB alarm, HS alarm valid control points

CH1 (Control Point 1) Set Values

Memory bank number

Alarm mode

Manual output value

HB alarm, HS alarm detection

current value

Memory Bank 7 Set Values

Memory Bank 1 Set Values

Memory Bank 0 Set Values

Set point

Proportional band (P constant)

Integral time (I constant)

Derivative time (D constant)

Control period

Alarm temperature

Input shift value

Manual reset value

Output limit

Ramp value

Output change rate limit

Dead band/overlap band (See

note.)

Cooling coefficient (See note.)

Fuzzy strength

Fuzzy scale 1

Fuzzy scale 2

Memory Bank 0 Set Values

Set point

Proportional band (P constant)

Integral time (I constant)

Derivative time (D constant)

Control period

Alarm temperature

Input shift value

Manual reset value

Output limit

Ramp value

Output change rate limit

Dead band/overlap band (See

note.)

Cooling coefficient (See note.)

Fuzzy strength

Fuzzy scale 1

Fuzzy scale 2

CH7 (Control Point 7) Set Values

Memory bank number

Alarm mode

Manual output value

HB alarm, HS alarm detection

current value

Memory Bank 7 Set Values

Memory Bank 1 Set Values

Note The cooling coefficient and dead band/overlap band are applicable only to

Memory Banks

Memory Bank Designation

30

E5ZE-8V Heating and Cooling Control Models.

The E5ZE has 8 memory banks, 0 to 7, for each control point. The memory

banks store specific groups of setting data. The E5ZE controls each control point

according to the contents of the current memory bank.

• All set values are written (set) or read using communications. The control point

number and memory bank number must be specified for each command. For

DeviceNet, however, the control point and memory bank numbers do not always need to be specified.

• When DeviceNet (remote I/O) is used, set values will be read and written according to the current memory bank.

Memory banks are designated using contact inputs or through communications.

The method of memory bank designation is set using pin 3 of the FUNCTION

switch. Refer to 2-3 Setting Selectors and Switch for details on setting methods.

• When the E5ZE is turned ON, the memory banks previously selected through

communications will be in effect.

Page 38

I/O Settings

Section 3-2

• The memory bank numbers for control points that are being auto-tuned cannot

be changed.

• The following table shows the designation methods and functions of the

memory banks.

Item Operation Function

Setting the

memory bank

number

Confirming the selected memory bank

number

The following table shows the status of MB0 to MB2 and their relation to the designated memory bank.

Memory

Bank

MB0 --- ON --- ON --- ON --- ON

MB1 --- --- ON ON --- --- ON ON

MB2 --- --- --- --- ON ON ON ON

The dashed line “---” indicates that the input is OFF.

Through

communications

Using contact

inputs

0 1 2 3 4 5 6 7

A memory bank

number is

designated for

each control point

through

communications.

A memory bank

number is

designated by

setting contacts

MB0 to MB2 on

the terminal block

connected to the

CONTROL

connector.

A control point can

be designated and

read through

communications to

check the memory

bank.

The different

memory bank

numbers can be

designated for

each control point.

All control points

will switch to the

designated

memory bank

number.

---

3-2 I/O Settings

3-2-1 Input Type

3-2-2 Input Shift

3-2-3 Control Period

The E5ZE is available in models that can be used for thermocouple inputs or

platinum resistance thermometer inputs.

The input type is set using the INPUT selector on the front panel of the Unit. Refer to 2-3 Setting Selectors and Switch for details on settings.

Set the input shift parameter in each memory bank.

The input shift function adds the value set for the input shift to the process value

and the E5ZE then controls using this temperature as the process value. For example, if the process value is 100°C and the input shift is –12°C, the E5ZE will

use 100°C – 12°C = 88°C as the process value for control.

The input shift setting range is –99.9 to 99.9°C or –99.9 to 99.9°F (default: 0.0°C

or 0.0°F.)

If the Voltage Output Model is being used, set the control period in each memory

bank.

Set the length of the control output period. The setting range is between 1 and

99 s (default: 2 s). For direct operation, the default can be used.

31

Page 39

Set Point and Process Value

3-2-4 Direct/Reverse Operation

The direct/reverse operation parameter is the same for all control points.

Reverse operation is used for heating control and direct operation is used for

cooling control.

The default is 0000, i.e., all control points will operate in reverse (heating con-

trol).

3-3 Set Point and Process Value

The setting for the set point used to control the temperature and the process value includes a temperature unit and a setting unit.

The temperature unit (°C or °F) is specified using pin 6 of the FUNCTION switch

on the front panel of the Unit. Refer to 2-3 Setting Selectors and Switch for details on settings.

The setting unit is set using the setting unit parameter as either 0 or 0.1 (default).

If serial communications are used to read the set point and process value data, 4

digits will be indicated if the setting unit is “0” and 5 digits will be indicated if the

setting unit is “0.1.”

The same setting unit is used for all control points.

Section 3-3

3-3-1 Setting Set Point

Set the set point using the Set Point Write (WS) command in each memory bank

of each control point.

If DeviceNet communications are being used, the values in the memory of the

host devices will be automatically reflected in the settings.

The default is 0.0°C or 0.0°F.

3-3-2 Reading Process Value

Read the process value using the Process Value Read (RX) command. The process value will be read for each control point.

If DeviceNet is used, the values in the memory of the host device will be automatically read.

Setting Unit

The setting unit is used as the unit for the alarm temperature and current control

temperature during ramp control, as well as for the set point and process value.

The settings will not be affected if the setting unit is changed. If the settings are

read, however, they will be indicated as follows:

• If the setting unit is set to 0.1, and data is read after changing the setting unit to

0, any value after the decimal point will be rounded off to a whole integer. For

example, 1234.5 will be read as 1235.

• If the setting unit is set to 0, and data is read after changing the setting unit to

0.1, a zero will be added after the decimal point. For example, 1234 will be read

as 1234.0.

Operation Start and Stop

32

• Execute the Operation Start (OS) command for each control point to start temperature control.

• Execute the Operation Stop (OP) command to stop temperature control or

manual operation.

• When DeviceNet communications are used, specific bits are allocated in the

memory of the host device for starting and stopping temperature control. Temperature control is started and stopped by turning the corresponding bit ON or

OFF.

Page 40

Alarm Output Settings

3-4 Alarm Output Settings

• The alarm outputs can be set for alarms 1 and 2 for each control point. Each

alarm output will be output from the alarm 1 and alarm 2 terminals. The alarm 1

and 2 terminals are used for all control points.

• The alarm output conditions are determined by the combination of the alarm

mode and alarm temperature settings.

• In addition to normal alarm outputs, alarm outputs for both HB alarms and HS

alarms are also possible.

• The alarm outputs do not operate when the E5ZE is stopped.

3-4-1 Alarm Modes

• The following table shows the operations of the alarm modes of the E5ZE.

Section 3-4

Code Alarm mode

Positive alarm

temperature (X)

00 No alarms Always OFF (default setting)

01 Upper- and

Lower-limit Alarm

02 Upper-limit Alarm

03 Lower-limit Alarm

04 Upper- and

Lower-limit

Range Alarm

05 Upper- and

Lower-limit Alarm

with Standby

Sequence

06 Upper-limit Alarm

with Standby

Sequence

07 Lower-limit Alarm

with Standby

Sequence

08 Absolute Value

Upper-limit Alarm

Alarm output function

---

---

---

Negative alarm

temperature (X)

09 Absolute Value

Lower-limit Alarm

0A Absolute Value

Upper-limit Alarm

with Standby

Sequence

0B Absolute Value

Lower-limit Alarm

with Standby

Sequence

0C HB and HS Alarm Turns ON when the HB alarm or HS alarm is

output.

Set the alarm mode for each control point.

33

Page 41

Alarm Output Settings

3-4-2 Alarm Temperatures

• The alarm temperatures are indicated by X in the above alarm mode table. The

operation differs depending on whether the value is positive or negative.

• Set the alarm temperature in each memory bank. The alarm temperature setting is not required, however , if the alarm mode is set to 00 (no alarm function)

or 0C (HB and HS alarm).

Section 3-4

Standby Sequence

Alarm Operation Summary

The Standby Sequence enables delaying output of an alarm until the process

value enters the alarm range from outside the alarm range.

For example, if the alarm mode is set to Lower-limit Alarm without Standby Sequence, and the ambient temperature is lower than the alarm set value (i.e.,

within the alarm range), the alarm output will turn ON at startup. If, under the

same conditions, the alarm mode is set to Lower-limit Alarm with Standby Sequence, the alarm output will only turn ON when the process value rises once

above the alarm set value (i.e., outside the alarm range) and then drops back

below it (i.e., within the alarm range).

• When the alarm output turns ON, the standby sequence operation will be ended. The standby sequence will restart again, however, under the following

conditions.

• If temperature control or manual operation is started.

• If the power is turned ON.

• If the set point is changed.

• If the alarm temperature is changed during operation.

The following time-chart shows an example of the Lower-limit Alarm with Standby Sequence Mode.

Alarm mode: Lower-limit with Standby Sequence

Process value

Alarm temperature

Alarm hysteresis

34

Standby sequence

Alarm

ended

The alarm hysteresis is a fixed value: 1.0°C, 1.0°F

Time

Page 42

Output Limitations

3-5 Output Limitations

The upper and lower limits for the output value are limited by an output limiter

and the output change rate is limited by an output change rate limiter.

3-5-1 Output Limiter

If the output value calculated by the E5ZE is outside the range of the output limiter, the actual output will be restricted to the specified upper or lower limit.

• Set the upper limit and the lower limit within the range of 0.0% to 100.0%.

• The lower limit cannot be set to a value greater than the upper limit.

• If the lower limit is 100.0, the output value will be 100.0%.

• If the upper limit is 0.0, the output value will be 0.0%.

• If the upper limit is equal to the lower limit, the output value will be equal to the

output limits.

Section 3-5

Output value (%)

Output limiter

Upper limit

Output limiter

Lower limit

3-5-2 Output Change Rate Limiter

The change in output value during one sampling period (approx. 200 ms) is limited by the output change rate limiter. If the output value calculated by the E5ZE

changes too quickly, the actual output will be that allowed by the setting of the

output change rate limiter and will gradually change until it reaches the calculated output value.

Output value (%)

Point of change

• The change rate limit setting range is between 0.0% and 100.0% per 200 ms.

The change rate limiter is disabled if the value is set to 0.0 (default).

• Use the following formula to calculate and set the change rate limit when the

change rate is A% for 1 s of output.

Standard Control Models: A x 0.2

Heating and Cooling Control Models: A x 0.2 x 0.5

• The output change rate limiter will operate for both heating control and cooling

control.

Calculated output value

Change rate

limit value

200 ms

Time

35

Page 43

Ramp

Section 3-6

Limiter Operation

Conditions

3-6 Ramp

The limiter will be disabled and settings will not be required under the following

conditions.

• During manual operation.

• When a temperature sensor input error or temperature controller error occurs.

• When operation is stopped.

• During ON/OFF control.

• During auto-tuning (applies to the output change rate limiter only).

If the ramp function is enabled and the change in the set point exceeds the specified rate of change, the set point will change over an interval, as shown in the