Page 1

TEMPERATURE CONTROLLER E5EX–H

DIN-sized (96 x 48-mm) Temperature

Controller Featuring Advanced PID

Control and Heater Burnout Detection

Advanced

PID control with two

degrees of freedom

improves stability and response speed.

Heater burnout alarm built in.

Select

from seven temperature sensors and a total

of 14 temperature ranges (seven Fahrenheit and

seven Celsius).

High accuracy: 0.3% of set value.

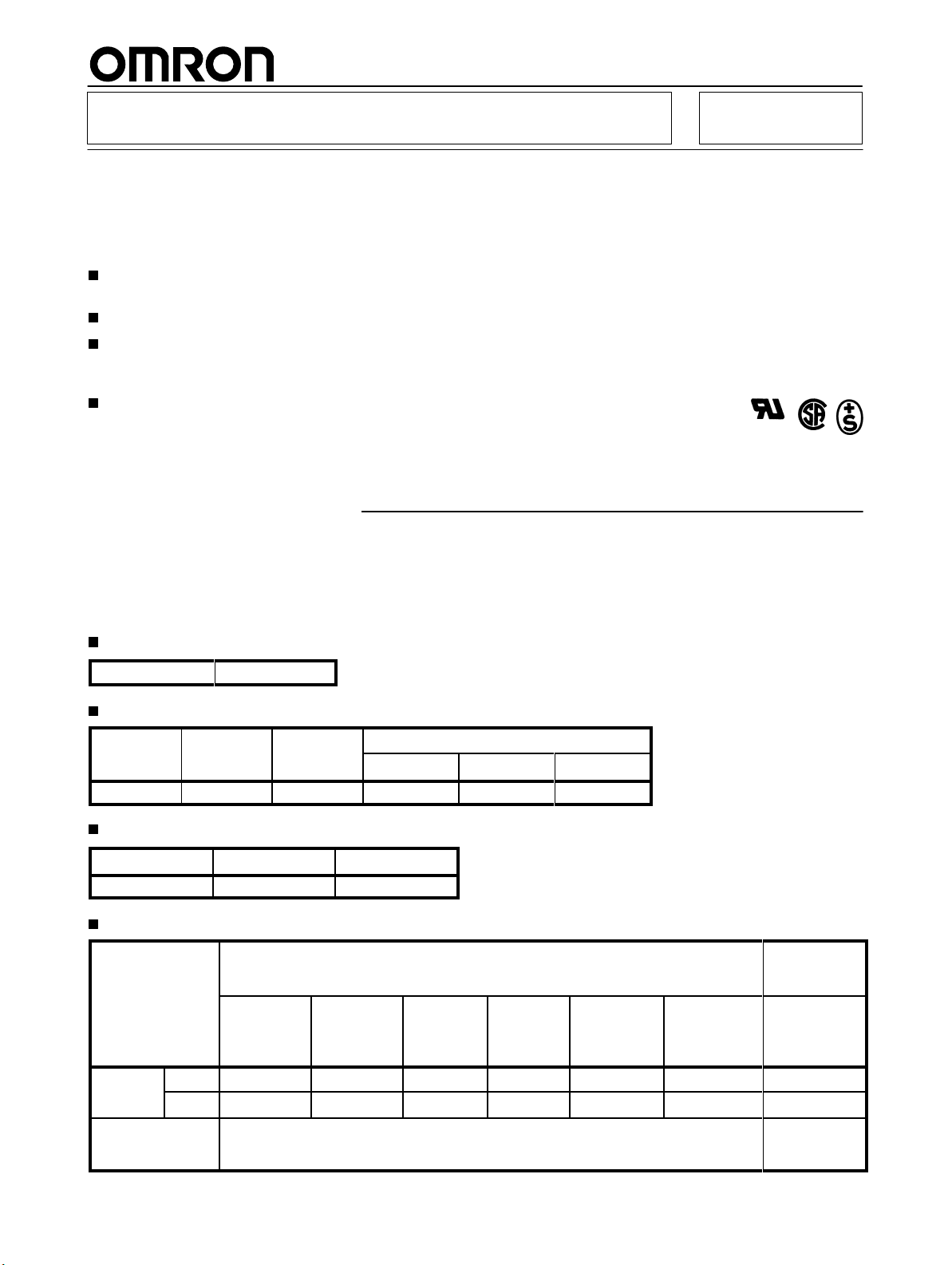

Ordering Information

The

model numbers for the

to

specify an Control Output Unit and Current T

Example: E5EX–AH, Relay Output Unit E53–R, Current T

Models set to display in degrees Fahrenheit (°F) can be ordered by adding “–F” to the end of the model number

The scale indication switch will then be set to °F prior to shipment from the factory

Temperature Controllers

Model E5EX–AH

Control Output Units

Output Relay output SSR output Voltage output (for driving SSR)

Model E53–R E53–S E53–Q E53–Q3 E53–Q4

basic T

emperature Controller

, its five Control Output Units, and two Current T

ransformer when ordering.

ransformer E54–CT1

.

12 VDC, NPN 24 VDC, NPN 24 VDC, PNP

ransformers are given below

. Be sure

. Example: E5EX–AH–F

Current Transformers

Hole

diameter

Model E54–CT1 E54–CT3

5.8 mm

12.0 mm

Temperature Ranges

Input

(switch

selectable)

Range °C

°F

Resolution (

(main settings and

alarm)

°C/°F)

K (CA)

Chromel vs.

alumel

–200 to 1,300 –100 to 850 –200 to 400 0 to 600 0 to 1,700 0 to 1,700 –99.9 to 450.0

–300 to 2,300 –100 to 1,500 –300 to 700 0 to 1,100 0 to 3,000 0 to 3,000 –99.9 to 800.0

1 0.1

J/L (IC)

Iron vs.

constantan

Thermocouple Temperature

T/U (CC)

Copper vs.

constantan

E (CRC)

Chromel

vs.

constantan

R (PR)

Platinum vs.

platinum

rhodium 13%

S

Platinum vs.

platinum

rhodium 10%

resistance

thermometer

PT platinum

resistance

thermometer

(Pt100/JPt100)

1

Page 2

E5EX–H

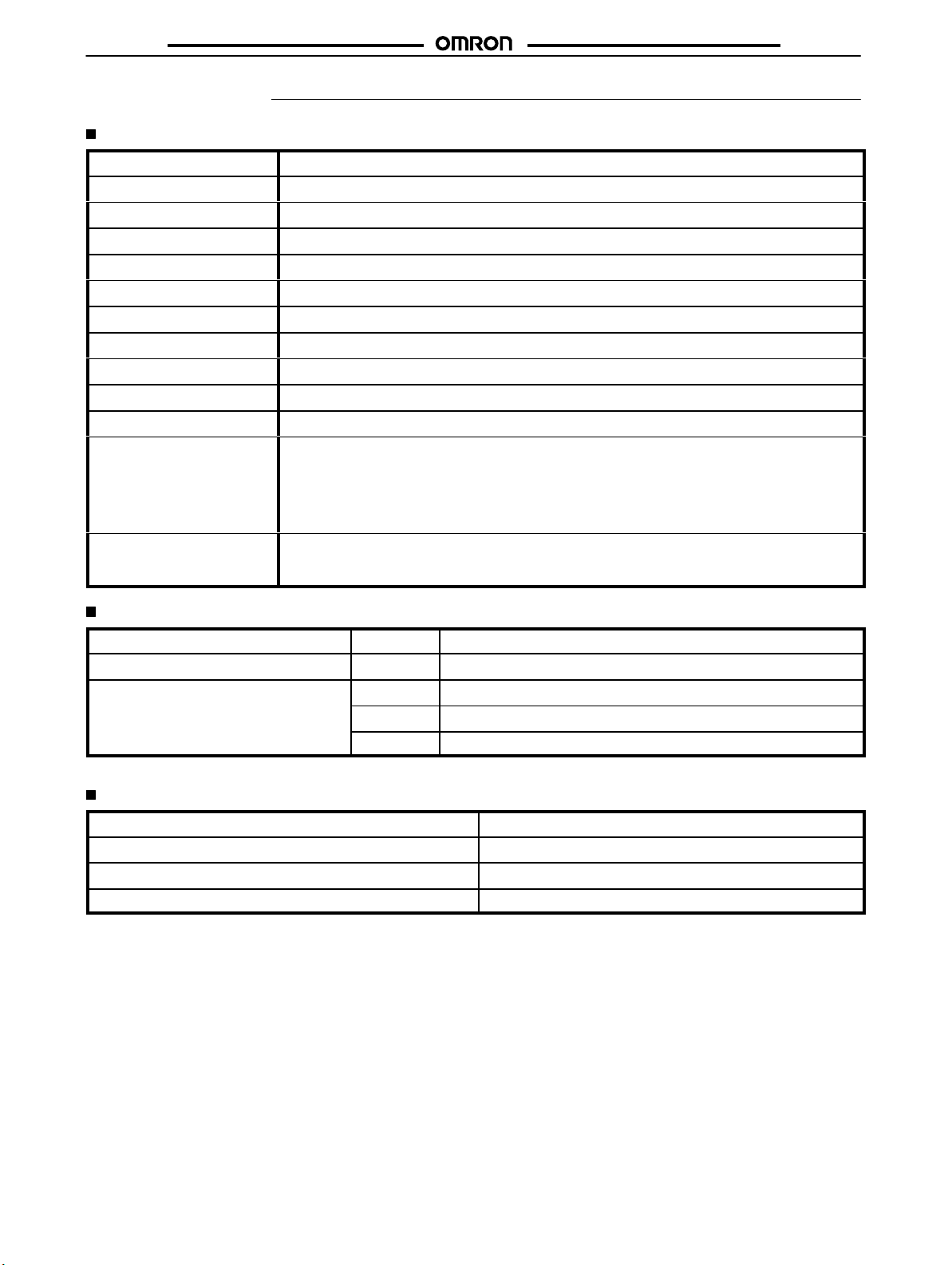

Specifications

Temperature Controller Ratings

Supply

voltage

Operating voltage range

Power consumption

Input

Current T

Control output

Operating mode

Alarm output

Heater burnout alarm output

Setting method

Indication method

Other functions

Approved standards

ransformer input

100 to 240 V

85% to 1

Approx. 10 V

Thermocouple (K/J/T/E/R/S/L/U) or temperature resistance thermometer (Pt100/JPt100) selectable

See

See

ON/OFF or PID with auto-tuning

Relay output: SPST–NO; 3 A, 250 V

Relay output: SPST–NO; 1 A, 250 V

Digital setting via up and down keys

Digital indication (character heights: 1

Upper and lower limits for set value

Key protection

Input shift

Display unit selection (

Normal and reverse output selection

W

atchdog timer function (Detects failures in the CPU and restores the CPU.)

UL (File No. E68481)

CSA (File No. LR59623)

SEV

AC, 50/60 Hz

10% of rated supply voltage

Current T

Control Output Unit Ratings

A (at 100 V

ransformer Ratings

AC) to 15 V

°C/°F)

A (at 240 V

.

.

AC

AC

1 mm and 8 mm)

E5EX–H

AC)

Control Output Unit Ratings

Relay Output Unit E53–R SPDT

SSR Output Unit E53–S

E53–Q

Voltage Output Unit (for driving SSR) E53–Q3

E53–Q4

Note:

The control output is optically insulated from the internal circuits.

SPST–NO; 1 A, 75 to 250 V

40 mA, 12 VDC; NPN (with short-circuit protection)

20 mA, 24 VDC; NPN (with short-circuit protection)

20 mA, 24 VDC; PNP (with short-circuit protection)

Current Transformer Ratings

Max.

continuous heater current

Dielectric strength

Vibration

Weight

; 5 A, 250 V

50 A

1,000 V

50 Hz (approx. 10G)

E54–CT1: Approx. 1

AC (resistive load)

AC

AC

1.5 g; E54–CT3: Approx 50 g

2

Page 3

E5EX–H

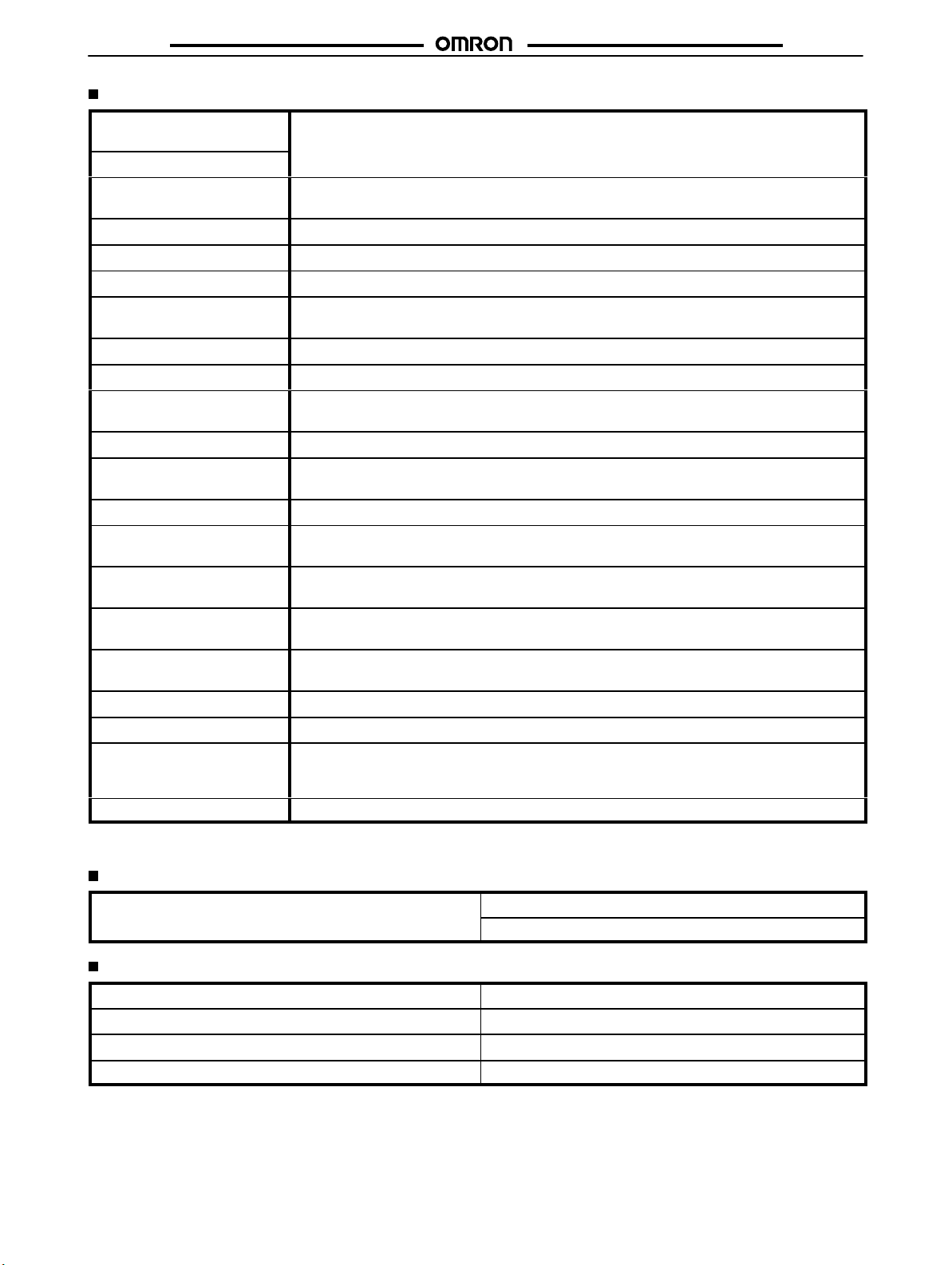

Temperature Controller Characteristics

Setting

accuracy*

Indication accuracy

+

0.3% of set value or

Set value coincides with the indicated value, because no relative error exists between both values.

±1°C, whichever ±

E5EX–H

1 digit max.

Hysteresis (during ON/OFF

control action)

Proportional band

Integral time (Reset time)

Derivative time (Rate time)

Alarm output setting range

Control period

Sampling period

Output refresh period

Display refresh period

Input shift

Insulation resistance

Dielectric strength

Vibration

Shock

0.0°

to 999.9

0.0°

to 999.9

0 to 3,999 s (in units of 1 s)

0 to 3,999 s (in units of 1 s)

Thermocouple: –999° to 9,999

Platinum resistance thermometer (Pt100): –99.9° to 999

Pulse output: 1 to 99 s (in units of 1 s)

500 ms

Pulse output:

Current output:

500 ms

Thermocouple: –999° to 9,999

Platinum resistance thermometer (Pt100): –99.9° to 999.9

20 MΩ min. (at 500 VDC) (measured with a Control Output Unit attached)

2,000 V

Output Unit attached)

Malfunction durability: 2 to 55 Hz, 2G 10 min each in X, Y

Mechanical durability: 10 to 55 Hz, 0.75-mm double amplitude 2 hrs each in X, Y

Malfunction durability: 100 m/s2 3 times each in 6 directions

Mechanical durability: 300 m/s2 3 times each in 6 directions

°C/°

F (in units of 0.1

°C/°

F (in units of 0.1

500 ms

500 ms

AC 50/60 Hz for 1 minute between terminals of dif

°)

°)

°C/°F

°C/°F

°C/°F

°C/°F

ferent polarity (measured with a Control

, and Z directions

, and Z directions

Ambient temperature

Humidity

Memory protection

Enclosure ratings

Weight

*The accuracy of U at temperatures from –150° to 400°C (–240°C to 700°F) is ±2°C (±3.6°F) ±1 digit. Accuracy is reduced below –150°C

(–240°F).

The accuracy of R and S from 0° to 200

Operating:–10°

Storage: –25°

35% to 85%

Non-volatile memory

Front panel controls:

Rear case:

Terminals:

300 g

to 55

to 65

°C (0°

°C

°C

IEC standard IP50 (dust-proof)

IEC standard IP20

IEC standard IP00

to 400

°F) is ±3°C (±5.4°

F) ±1 digit.

Output Unit Characteristics

Relay

unit life expectancy

Mechanical: 10,000,000 operations min.

Electrical: 100,000 operations min.

Current Transformer Characteristics

Max.

heater current

Indication accuracy of heater current

Heater current setting range

Min. detectable ON time

*Heater burnout is not detected when current is set to 0.0 A; the burnout alarm will be automatically turned ON when current is set to 50.0

**When the control output is ON for less than 200 ms, heater burnout is not detected and heater current is not measured.

50 A, single-phase

±

5% of full scale ±1 digit max.

0.1 to 49.9 A* (in units of 0.1 A)

200 ms**

3

Page 4

E5EX–H

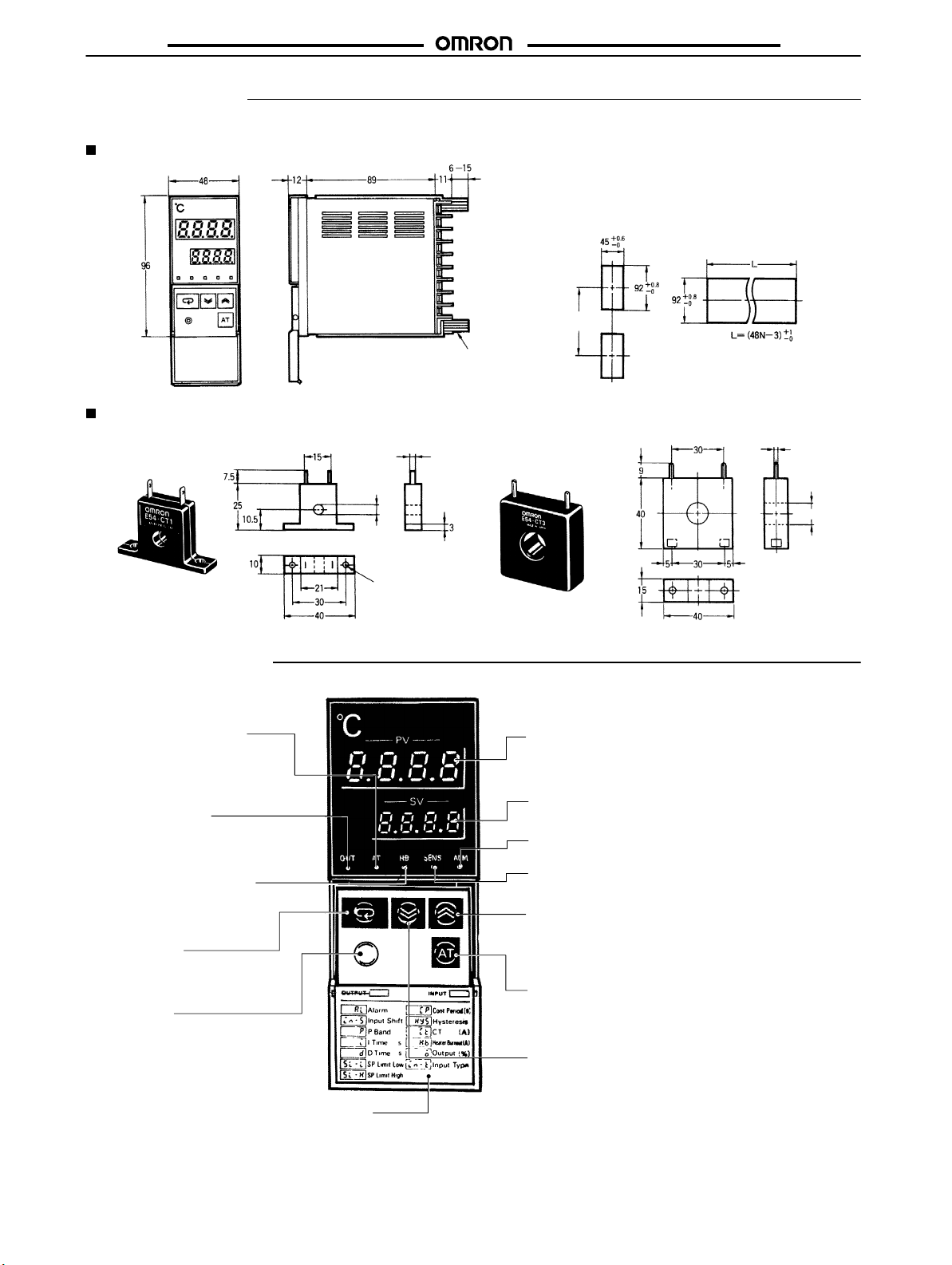

Dimensions

Note:

All units are in millimeters.

Temperature Controller

Current Transformer

E54–CT1 E54–CT3

5.8

dia.

2.8 dia

Mounting

screw

120 min.

Panel Cutout

Side-by-side Mount

ing of N Controllers

E5EX–H

2.36 dia

-

12

dia.

Nomenclature

Auto-tuning

Flashes on and off about every

second when auto-tuning is taking

place.

Output Indicator

Lit

when the control output is

Heater Burnout Indicator

Lights when a heater burnout is

detected

Display

Use

this key when

play

to the next parameter

Level Key

Press for 2 seconds minimum to

change levels to set different

groups

Indicator

ON.

and stays lit until reset.

Key

shifting the dis

.

of parameters.

-

Front Cover

Two,

3.5 dia. holes

Process V

Displays not only the process temperature but also indicates the parameter being displayed on the SV display

and error messages.

Set V

Displays set temperature and other parameters.

Alarm Indicator

Lit when the alarm output is ON.

Sensor Error Indicator

Lights when sensor malfunctions

Up Key

When pressed, increases the set temperature or other

parameters. Successively increases the value when

held

Auto-tuning Key

Press

has

1

second or more during auto-tuning to stop auto-tuning.

Down Key

When

perature

sively decreases the value when held

down.

alue (PV) Display

alue (SV) Display

down.

this key for 1 second or longer when PID operation

been designated to start auto-tuning. Press this key for

pressed, decreases the set tem

or

other parameters. Succes

-

-

4

Page 5

E5EX–H

Operation

NOTICE: Always turn of

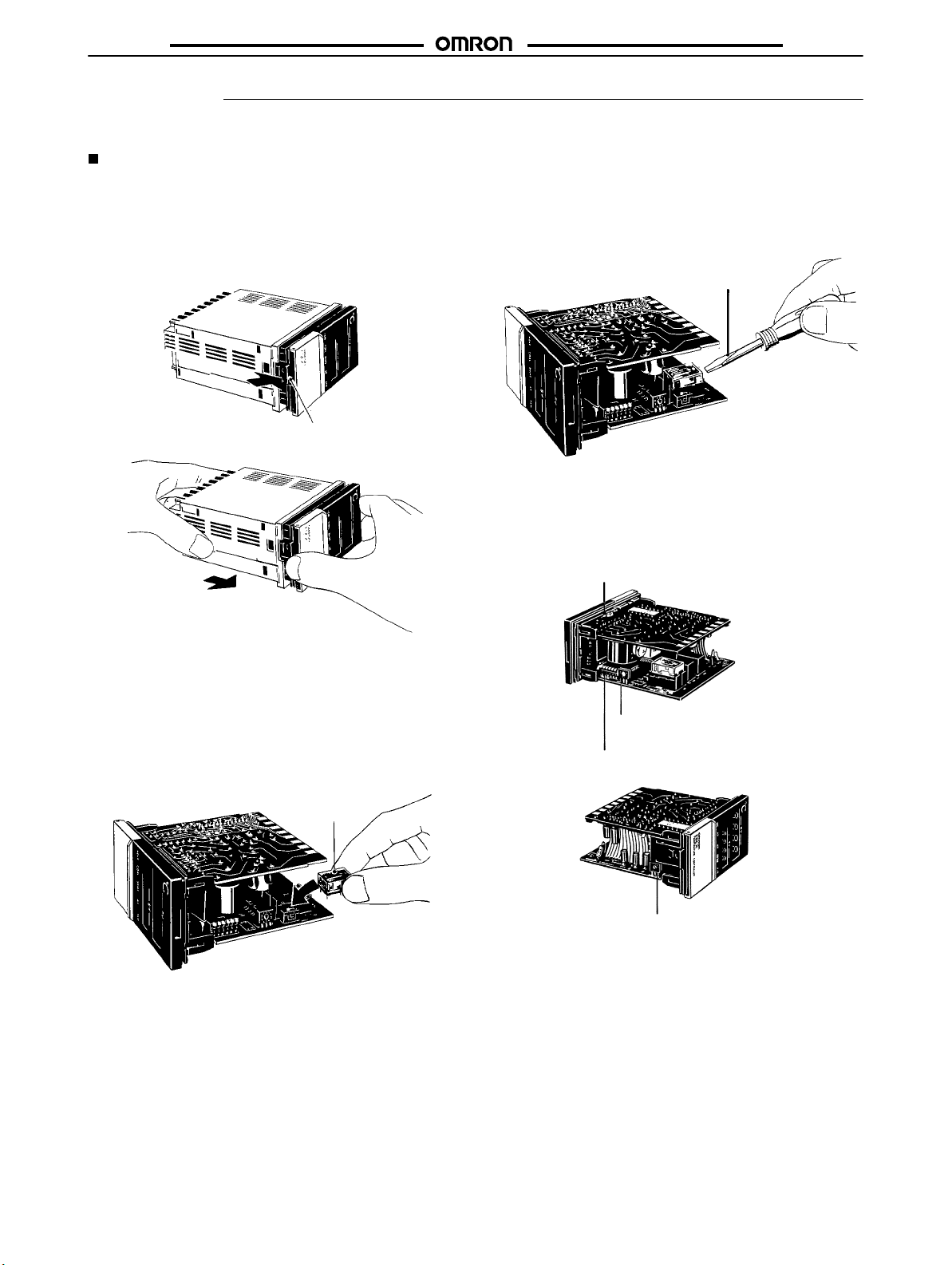

Accessing Switches and Selectors

Before

supplying power to the T

functions,

must

1.

and alarm mode. The T

be ordered separately

Remove the internal mechanism from the housing. Lift the

internal

mechanism while pressing the hook at the bottom of

the

front panel.

f the power supply to the T

emperature Controller

emperature Controller must be equipped with one of the six

.

Hook

, the selectors and switches shown below must be set to specify the temperature sensor

emperature Controller before changing any switch settings.

Control Output Units. The Control Output Unit

T

o remove a Control Output Unit, push it up with the tip of a

flat-bladed screwdriver as illustrated below

Flat-blade

screwdriver

3.

Three

internal switches must be set: the temperature sensor

selector, the operating mode selector, and the alarm mode

selector.

switches on the internal mechanism.

The following figure shows the locations of internal

E5EX–H

,

.

Pull out the internal mechanism while holding

down the hook with your finger

2.

Connect

a Control Output Unit to the vacant socket

the printed circuit boards (see the figure below). A white

square

is marked

the

Unit with this

arrow

in the figure below

on the Control Output Unit. Be sure to install

marking facing the direction indicated by the

.

.

Mount the Control Output Unit

with this mark facing the di

rection indicated by the arrow

on one of

.

Protection switch (SW101)

Alarm mode selector (SW205)

Operating mode selector (SW201)

T

emperature sensor

selector (SW206)

5

Page 6

E5EX–H

E5EX–H

Temperature Sensor Selector (SW206,

INPUT)

This

selector determines the temperature sensor to be used. It is set

to position 2 before shipment

thermocouple)

er

possible settings for temperature sensors. Refer to temperature

range

charts under

The

scale displayed (°C or °F) is set on the operating mode selector

Switch

setting

0 R

1 S

2 K

3 J

4 T

5 E

6 JPt100*

7 Pt100*

8 L

9 U

*JPt100: 100°

**Pt100:

temperature sensor

Temperature

sensor

C/139.16 Ω (JIS (Japan Industrial Standard)).

100°

C/138.5

to designate a K-type (chromel-alumel

. The

following table lists the oth

Ordering Information

code

0 to 1,700 0 to 3,000

0 to 1,700 0 to 3,000

–200 to 1,300 –300 to 2,300

–100 to 850 –100 to 1,500

–200 to 400 –300 to 700

0 to 600 0 to 1,100

–99.9 to 450.0 –99.9 to 800.0

–99.9 to 450.0 –99.9 to 800.0

–100 to 850 –100 to 1,500

–200 to 400 –300 to 700

Ω (DIN, JIS).

for further information.

T

emperature range

°C °F

Function

Operating mode

Control output

.

Input shift

Not used.** 4

Indication 5 ON

PID display 6 ON Enabled

*PID with 2 degrees of freedom

**Always

operate with pin 4 OFF

sult

in malfunction.

Pin

number

1 ON

2 ON

3 ON Enabled

Pin

setting

OFF

OFF

OFF Disabled

Leave turned OFF

OFF

OFF Disabled

. Operating with pin 4 ON could re

Control setting

ON/OFF operation

PID operation*

Normal (cooling)

Reverse (heating)

°F

°C

.

-

Operating Mode Selector (SW201,

FUNCTION)

This

DIP switch selects the operational aspects listed in the follow

ing

table.

-

6

Page 7

E5EX–H

Alarm Mode Selector (SW205: ALM)

An

alarm mode selector is provided. T

2

before shipment, i.e., the upper-limit alarm mode.

en alarm modes, listed in the following table, can be selected using this switch. The switch is set to position

E5EX–H

Switch

setting

0 Alarm

1

2

3

4

5

6

7

8

Alarm operation

Upper- and lower-limit

alarms

Upper-limit alarm

Lower-limit alarm

Upper- and lower-limit

range alarm

Inverse upper- and

lower-limit alarm with

standby sequence

Upper-limit alarm with

standby sequence

Lower-limit alarm with

standby sequence

Event alarm

Mode (SW205)

No display

)--(

---(

)ĆĆ---

-()-

3--e

---e

3---

1--(

Display

Alarm output

OFF –––

XX

SP

X

X

XX

XX

X

X

Y

Thermocouple: 0° to

9,999°

Platinum resistance

thermometer: 0° to

999.9°

(See Note 1.)

Thermocouple: –999° to

9,999°

Platinum resistance

thermometer: –99.9° to

999.9°

Thermocouple: 0° to

9,999°

Platinum resistance

thermometer: 0° to

999.9°

(See Note 1.)

Thermocouple: –999° to

9,999°

Platinum resistance

thermometer: –99.9° to

999.9°

Setting range

9

Note: 1.

0

X

X

SP

SP

See Note 2.

Proportional alarm

the proportional alarm function is used for cooling control, so that

PB: proportional band (fixed to 42

Proportional period is 20 seconds.

The operation of the alarm is not af

2 of the operating mode selector (SW201).

X

SP

When the tempera

°C)

fected by pin

Proportional alarm

If a negative value is set as X, operation will be as follows:

Lower-limit alarm

Upper-limit alarm

2. The

alarm mode selector can be used to select the proportional alarm mode. The proportional alarm function is initiated when the

temperature

ture rises to the upper limit of the proportional band (point B in the figure), the alarm output is turned ON. This alarm function is

convenient

heating

reaches the set alarm point (A in the figure below), which is the lower limit of a proportional band.

when the main setting is used for heating control, while

and cooling control actions can be easily performed.

X

SP

pro

ON

A

B

PB

-

7

Page 8

E5EX–H

E5EX–H

Standby Sequence

Alarm

functions with standby sequence suppress nuisance alarms

when

the controller is first powered up. As shown

charts

at right, the alarm output is suppressed until the temperature

exceeds

the alarm band or alarm limit one time.

in the temperature

Protection Switch (SW101, PROTECT)

When the protection switch is set to the ON position, the level key, up and down keys, and auto-tuning key will not operated. In effect, the

Temperature

Controller is write-protected and the set values (such as the alarm value) can be read out only

.

Inputting Parameters

The Temperature Controller has three indication levels, 0, 1, and 2, in which only specific parameters can be set. Level 0 is the default and is

automatically

onds

entered during power up. T

or more. The indication level mode changes as shown below

o change the mode to manipulate a dif

.

ferent group of parameters, hold down the

level key for 2 sec

-

Power up

Level 0

Press the level key. Press the level key. Press the level key.

–––––––

Process temperature,

alarm value, input shift,

PID constants

Setting limits, control peri

od, hysteresis, heater cur

rent, heater burnout set

ting

Level 0

In

this

mode, parameters such as the alarm values, PID constants,

and input shift values

ters are being set or changed, the new values are displayed on the

SV display

ing the display key the required number of times. Note that the PID

constants

lector

ON position. (The flow chart shown below assumes the settings are

as

. The parameter to be manipulated is selected by press

are displayed

DIP switch (SW201) is set

preset at the factory

Process temperature

can

be set or changed. When these parame

only when pin 1 on the operating mode se

to the OFF position and pin 6 to the

.)

Power up (temperature

setting)

Press a.

al

Alarm value

Press a.

-

-

-

Level 1 Level 2

–––––––

After

PID constants can be manually set or changed, provided pin 6 on

the internal operating mode selector (SW201) has been set to the

ON

shown

Control output variable,

temperature sensor type,

alarm mode

al has been displayed, press the display key again. Then the

position. The message displayed on the PV

below each time the display key is pressed.

Process temperature

al

p

i

d

–––––––

display changes as

Power up (temperature

setting)

Press a.

Alarm value

Press a.

Proportional band

Press a.

Integral time

Press a.

Derivative time

Press a.

8

Page 9

E5EX–H

E5EX–H

Alarm: al

When al is displayed on the PV display

output

can be set on the SV display

or

falls below the set alarm value, the corresponding alarm output is

produced and the ALM indicator on the front panel lights. Usually,

the

alarm value is set as a deviation from the set temperature (set

point), but it can also be set as an absolute value when the event

alarm

mode is selected. Set the alarm

key

while al is displayed. The message is not displayed if the alarm

mode

selector is set to position 0.

Proportional Band: p

While p is displayed on the PV display, the proportional band (P

constant)

will

range from 0.0° to

ting

Integral T

The

is

I constant.

1

Derivative T

The

ter

change

onds

Input Shift: in-5

When pin 3 on the internal operating mode selector DIP switch

(SW201) is set to the ON position, the input shift function can be

used.

measured

the

can be changed using the

be displayed on the SV display

is 40.0

integral time (I constant) can be changed when the character

displayed on the PV display

second. The factory setting is 240 seconds.

derivative time (D constant) can be changed

d is displayed on the

the D constant.

in units of 1 second. The factory setting is 60 seconds.

This function is used to shift the temperature

following table:

999.9

°C/°F

°C/°F.

ime (Reset T

The

allowable range is from 0 to 3,999 seconds in units of

ime (Rate T

value by a desired

in units of 0.1

ime):

i

. Use the up or down key

ime):

PV display

The allowable range is from 0 to 3,999 sec

value, as illustrated by the examples in

, the alarm

. When the temperature exceeds

value by using the up or down

up or down key

. The P constant

d

. Use the up or down key to set or

value for alarm

. The new value

can be set in a

°C/°F

. The factory set

to change the

when the charac

display from the

Power up (temperature

Process temperature

Press a.

al

Press a.

in-5

Press a.

p

Press a.

i

Press a.

d

i

While

in-5 is

by

which the measured

set and displayed on the SV display. The range in which the input

shift can be set differs depending on whether a thermocouple or

-

temperature resistance thermometer is used as the temperature

sensor.

-

–999

tance thermometer is used. The input shift function remains ef

tive even if pin 3 on the operating mode selector DIP switch

(SW201)

has been set. If the displayed temperature does not need to be

shifted,

displayed on the PV display

When a thermocouple is used, the allowable range is from

to 9,999

°C/°

is changed to the OFF position after the input shift value

set 0

°C/°

Press a.

temperature is shifted and displayed, can be

F in

units of 0.1

F in response to

setting)

Alarm value

Input shift

Proportional band setting

Integral time setting

derivative time setting

, the input

°C/°

F when a temperature resis

in-5.

shift, the value

-

fec-

Input shift value

0 (without shift)

10 (of

fset by 10

–10 (of

fset by

–10°C)

This function can be used mainly for fine tuning compensation,

while

leaving the

pressing

°C) 100°C 110°C

set temperature unaf

the display key three times in display level 0, as follows:

Temperature

measured by

sensor

100°C 100°C

100°C 90°C

fected. Select this function by

temperature

Displayed

9

Page 10

E5EX–H

E5EX–H

Level 1

In this level, the upper- and lower-limit values of the temperature

range, control period, hysteresis, heater current, and heater burnout

alarm can be set.

When pin 1 on the operating mode selector (SW201) is set to the

OFF position (PID action), the temperature setting range limit values,

control period, heater current, and heater burnout alarm value

can

be set or changed. Any of these

pressing

display key the required number of times as follows:

5l-l

Press a.

5l-h

Press a.

cp

Press a.

ct

Press a.

hb

Press a.

Lower/Upper Limits of T

–200 0

SL–L SL–H

Basically, the temperature range that can be measured is determined

by the temperature sensor to be

K-type (chromel-alumel thermocouple) temperature sensor is selected,

the measurable range is from –200°C to 1,300°C. However

this

temperature range can be narrowed, say

this, set the lower-limit value of the temperature setting range, in this

case to 0°C, on the SV display by using the up or down key while

5l-l is displayed on the PV display. Similarly, set the upper-limit

value, 400°C, while 5l-h is displayed. If the process temperature

falls below the set lower-limit value or exceeds the set upper-limit

value,

it is displayed on the PV display provided it is

perature

Control Period: cp

To use a control period, pin 1 on the operating mode selector

(SW201)

the

from

seconds. When a Voltage Output Unit is used, it is recommended

that

seconds), so that the control action can be performed more accurately.

range of the temperature sensor

must be set to the

PV display

1 to 99 seconds in units of 1 second. The factory setting is 20

the control period be set to 20 seconds or less (ideally

, the control period can be set or changed

emperature Range:

parameters can be selected by

Lower-limit value of temper

ature setting range

Upper-limit value of tem

perature setting range

Control period

Heater current

Heater burnout alarm

sl-l, sl-h

400

used. For example, when a

OFF position. When cp is displayed on

1,300

, to 0°C to 400°C. T

within the tem

.

-

-

o do

in a range

, about 2

,

-

Heater Burnout Alarm: ct

Set

a

burnout current value to determine disconnections of the heat

er. Firstly, a current measured in the heater current value mode is

displayed

with

rent

Use display key and set the PV display to hb. The difference between

should

tect the disconnection of the heater may be not stable. The value

can

Note

Heater Burnout Alarm and Sensor Abnormality Alarm

in amperes. The normal current value is the current value

the control output ON. Disconnect the

value and obtain the set value from the following:

Normal

current value + Current value

the normal current

be 2.5 A minimum. If it is less than 2.5 A, the operation to de

be set with in increments of 0.1 A from 0.0 to 50.0 A.

1:Do not allow a current of more than 50 A to flow in the Con

troller;

the maximum continuous heater current is 50 A.

2: Set

the value to 0.0 A if the heater burnout alarm is not used,

in

which case the alarm will not function at all.

Alarm Heater burnout

Output terminal

Output ON

Output

display

monitor

Output retention

function

Output reset

Influence on con

trol output/alarm

output

-

,

hb

heater and read the cur

with disconnected heater

2

and the one with the disconnected heater

alarm

T

erminal output is ON when either alarm

is ON.

When a heater

burnout

is

detected.

hb

on front panel is

lit.

Yes No

Set heater burnout

alarm value to 0.0

A or switch power

OFF and then turn

on power

None

.

Sensor

abnormality

alarm

When sensor is in

error.

5en5

on front panel

is lit.

Output is OFF

when sensor ab

normal condition is

solved

Control output:

OFF; Alarm output:

ON (proportional

alarm output is

OFF)

-

-

-

-

-

Control

ON

OFF

10

output

When control period is

set to 20 seconds

20 seconds

Page 11

E5EX–H

E5EX–H

Connected

alarm

Sensor abnormality

Heater burnout

*This wiring must be passed through the hole of the special current

transformer. The current transformer can be connected to the sensor in any polarity

*Wire through the hole on the Current

Transformer.

the Temperature Controller can be connected with wires without polarity.

to T

Temperature

Controller

The Current T

emperature Controller

Heater load

Input

sensor

ransformer and

Connected to Temperature Controller.

*Current

Output

controller

200VAC

transformer

2. ON/OFF Control

When

pin 1 on the operating mode selector (SW201) is set

to the ON

position, the temperature setting range limit values, hysteresis,

heater current, and heater burnout alarm value can be set or

changed.

play

Any of these parameters can be selected by pressing dis

key the required number of times as follows.

5l-l

Lower-limit value of temper

ature setting range

-

Press a.

5l-h

Upper-limit value of tem

perature setting range

-

Press a.

hys

Hysteresis

Press a.

ct

Heater current

Press a.

hb

Heater burnout alarm

Press a.

Of the above parameters, only the hysteresis, which is described

below, differs from the parameters for PID control. Refer to 1. PID

Control

for details on other parameters.

Hysteresis:

The

hysteresis value for the ON/OFF control action can be

range

hys

from 0.0° to 999.9

°C/°

F while

hy5

is displayed on the PV dis

set in a

play. Use the up or down key to do this. The factory setting is

0.8°C/°F.

-

-

Connected to heater.

Reverse operation

(heating control)

Low temperature High temperature

Normal operation

(Cooling control)

Hysteresis

SP

Hysteresis

SPLow temperature High temperature

11

Page 12

E5EX–H

E5EX–H

Level 2

In level 2 the control output variable, temperature sensor, and

modes

for alarm output can

itoring

level only and thus no parameter can be changed. When the

level

key is pressed for more than 2 seconds after power up,

displayed on the PV display. After this message has been displayed, holding down the Level key again for 2 seconds or more

causes

o to be displayed on the PV display

been displayed, the control output variable, selected temperature

sensor, and alarm modes can be monitored each time the display

key is pressed, as follows:

o

in-t

al

Control Output V

When

the T

amount

Temperature

When in-t is displayed on the PV display, a message identifying

the

perature

The following table shows the messages that may be displayed:

emperature Controller enters level 2, the control output

is displayed on the SV display in a

Sensor:

selected temperature sensor

sensor selector (SW206), is displayed on the SV display

be monitored. Note that level 2 is a mon

. When this message has

Control output variable

Press a.

T

emperature sensor

Press a.

Alarm mode

Press a.

ariable:

o

range of 0.0% to 100.0%.

in-t

, i.e., the present setting of the tem

5l-l is

Display

-

No display No alarm

)--(

---(

)---

-()-

3--e

Upper- and lower-limit

alarms

Upper-limit alarm

Lower-limit alarm

Inverse upper- and lower-

limit alarm

Upper- and lower-limit

alarms with standby se-

Alarm mode

quence

---e

3---

1--c

pro

.

Upper-limit alarm with

standby sequence

Lower-limit alarm with

standby sequence

Event alarm

Proportional alarm

Display Sensor

r pr

5 pr

k ca

j ic

t cc

e cr

jpt

pt

l ic

u cc

*Meets

JIS 1981.

**Meets JIS 1989, DIN.

AL (Alarm Mode):

While

al is displayed on the PV display in level 2,

fying

the mode for alarm output or the present setting of the corre

sponding

play.

pear

alarm mode selector

The following table shows the possible messages that may ap

on the SV display

al

.

R

S

K

J

T

E

JPt100*

Pt100**

L

U

a message identi

(SW205) is displayed on the SV dis

-

-

-

-

12

Page 13

E5EX–H

E5EX–H

Beginning Control Operation

Temperature

er

is turned

the parameters that have been input. To operate the Temperature

Controller

and

then on again.

Auto-tuning

When

Controller

tuning is taking place, the auto-tuning indicator on the front panel will

flash. The Temperature Controller executes control based on the

set

PID constants (factory set to P = 40°C, I = 240 seconds, and D =

60

seconds) until the temperature of the controlled system reaches

the

set temperature. After that, the T

ically

the

automatic tuning of the PID constants has been completed, the

auto-tuning

Auto-tuning

ture Controller is performing reverse (heating) or normal (cooling)

operation. To stop auto-tuning, hold down the AT key again for 1

control is begun

on, and temperature control is carried out according to

after all the parameters are input, turn the power off once

the A

T key is pressed for 1 second or more, the T

automatically starts tuning the PID constants. While auto-

adjusts the PID constants using the limit cycle method. After

display goes out.

can be carried out regardless of whether the T

for the set values as soon as the pow

emperature

emperature Controller

automat

empera-

-

-

Advanced PID Control

Advanced

ward (FF)

ventional PID controller responds to disturbance (d) to quickly

achieve

control,

This is prevented in advanced PID control because the feed-forward loop is not affected by disturbance. Here, the feed-forward

loop

out

PID control with two degrees of freedom adds a feed-for

loop to the conventional PID controller

stability

, it overshoots the target because it lacks suf

as shown below

operates from the target

overshooting.

.

value (r) to achieve fast response with

. Whereas the con

-

-

ficient

-

second

or more. Automatic tuning can be executed at any time: on

power

up, while the temperature is rising, and after the control ac

tion has stabilized.

Limit Cycle Method

Set

temperature

AT key is pressed

Limit cycle method:

The

optimum

ing

the control output variable and generating external oscillation.

Old PID

constants

A

T indicator blinks

PID constants are calculated by this method by vary

New PID constants

-

-

r

Normal

PID

operation

E5EX–H

FF

+

PID

–++

If response to target value improves, response to external

disturbances degrades.

If response to external disturbances value improves, response to target value degrades.

Excellent response to both target value and external

disturbances.

d

–+

Control

object

y

13

Page 14

E5EX–H

Error Messages

E5EX–H

The Temperature Controller is provided with self-diagnostic functions, and will display

an

error

.

Message

ffff

----

5.err (flashes)

e111 (flashes)

e333 (flashes)

*When the J thermocouple is used, however

range

by more than 70

**When the temperature resistance thermometer is used, this message is displayed when the temperature has fallen to –99.9

The T

emperature Controller displays the following error message in case of a Current T

Message

ffff

Input temperature has risen beyond the upper limit of

the temperature range by more than 20

Input temperature has fallen below the lower limit of

the temperature range by more than 20

The

thermocouple has burned out or short-circuit bar

has been removed. The platinum resistance thermom

eter has burned out or A and B have been short-cir

cuited.

Memory failure (

has occurred. T

if recovery is not made by turning power of

on again.

°C.

CT input current is

over 50.0 A

emperature Controller must be repaired

Cause Control output

Cause Control output Alarm output

°C

°C.

-

e111

) or A/D converter failure (

, this error message is not displayed

Normal

e333)

f once and

Retains condition there was before

output and sensor abnormality alarm output can function nor

mally.

the following error messages on the PV display in case of

OFF during reverse

(heating) operation

On during normal (cool

ing) operation

On during reverse

(heating) operation

OFF during normal

(cooling) operation

OFF

-

OFF OFF

until the temperature has risen above the set temperature

ransformer input error

Heater disconnection alarm output

Sends alarm signal in accor

dance with the set alarm

-

mode.*

Sends alarm signal in accor

dance with the set alarm

mode.*

Sends alarm signal in accor

dance with the set alarm

mode. Proportional alarm out

put is OFF

ffff

, however

.

is displayed. Alarm

-

-

-

-

.

°C.

-

Installation

Wiring

*Current Transformer must be either

E54–CT1 or E54–CT3.

**Heater burnout alarm output terminal is

used to indicate both heater disconnection

and sensor errors.

For SSR

output

For voltage

output

For relay

output

40 mA,

12 VDC

Alarm output

Heater burnout alarm output**

Current Transformer*

Control

output

FG

Ground FG terminal 18 to avoid ambient noise.

Do not connect unused terminals.

100 to 240 VAC, 50/60 Hz

Use these terminals when connecting a

platinum

resistance thermometer (remove short

bar from terminals 13 and 14).

Use these terminals when connecting a

thermocouple (do not remove short bar

from terminals 13 and 14).

14

Page 15

E5EX–H

Precautions

Mounting

The dimensions of the Temperature Controller conform to DIN

43700.

Recommended panel thickness is 1 to 8 mm.

Do not install the Temperature Controller in a location exposed to

excessive

ject

tures.

erates

ers.

Attach

and

mounting

dust or corrosive gases. Moreover

to heavy vibration

Isolate the T

strong, high-frequency

the two mounting fixtures supplied with E5EX–AH on the top

bottom

of the T

fixtures with your fingers.

or shock, water or oil spray

emperature

emperature Controller

Controller from equipment that gen

noises such as high-frequency weld

, avoid locations sub

, or high tempera

. T

ighten the screws of the

short-circuit bar shown in the terminal block diagram

ing.

Use lead wires having a small resistance for temperature

tance

thermometers.

Be sure to remove the short-circuit bar from the terminals when a

temperature

-

-

Sequenced Circuits

Several

er

has been supplied to the T

this time delay into consideration when designing sequenced circuits

resistance thermometer is used.

seconds are

which incorporate a T

required until the relay is turned ON after pow

emperature Controller

emperature Controller

. Therefore, take

.

Terminal Layout Diagram on the Housing

The Temperature Controller allows an input and output device to be

freely selected. Use the terminal layout diagram attached on the

housing

of the T

mounted

follows:

emperature Controller to identify the output

in the Temperature Controller

, by making the diagram as

Check here with a felt-tip pen.

E5EX–H

on the hous

resis

device

-

-

-

Connection Examples

With

Solderless T

Use M3.5 solderless terminals with the Temperature Controller’s

M3.5 self-rising pressure plate screws.

Solder-dipped Leads:

Strip

6 to 12 mm of

Do

not tighten the

block

of the T

wires

can be connected to all the

erminal:

the lead wires and carefully arrange the wire tips.

terminal screw with excessive force. The terminal

emperature Controller is

constructed so that the lead

terminals from the same direction.

Top

Bottom

Temperature Sensor Connection

To

reduce induced

sensor

to the T

er

lines and load lines.

Use the specified compensating conductors for thermocouples.

When

using a thermocouple as the temperature

noise, the lead wires connecting the temperature

emperature Controller must be separated from pow

sensor

, attach the

-

Stickers

Stickers

indicating the

Control

Output Unit (R, S,

Controller.

ing

Temperature

Attach these stickers on the front panel as shown,

the temperature sensor and Control

Controller can be easily discerned.

Sticker identifying

Control Output Unit

temperature sensor type (R, S, K, J, etc.) and

and Q) are supplied with the T

Output Unit mounted in the

Sticker identifying

temperature sensor

emperature

allow

-

15

Page 16

E5EX–H

E5EX–H

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To

convert millimeters into inches, multiply by 0.03937. T

o convert grams into ounces, multiply by 0.03527.

Cat. No. H49–E1–1 In the interest of product improvement, specifications are subject to change without notice.

OMRON Corporation

Temperature Control Devices Division

9th Fl., Osaka Center Bldg.

4-1-3, Kyutaro-machi, Chuo-ku,

Osaka 541 Japan

Phone: 06-282-2500 Fax: 06-282-2749

Telex: 522-2484 OMRONO J

16

Printed

in Japan

0590–3M (0590)

Loading...

Loading...