Page 1

Programmable Digital Controller

E5AR-T/E5ER-T

A new High-speed, High-precision Digital

Controller that is Programmable!

• Create up to 32 programs with up to 256 segments total.

• Coordinated operation for up to four channels with one Digital Controller.

•0.01°C; High resolution for Pt input.

• High-speed sampling at 50 ms.

Refer to “Precautions” on pages 24 and 25.

■ Features

Up to 32 Programs

You can create up to 32 programs with up to 8 segments each, or

you can create up to 8 programs with up to 32 segments each. Either

way, you get up to a total of 256 segments of programming. This feature is ideal for testing equipment to make a variety of settings.

Up To

32 Programs

100.0

SP

Segment 1 Segment 2 Segment 3 Segment 4 Segment 6Segment 5

100.0

50.0

70.0

SP

Segment 1 Segment 2 Segment 3 Segment 4

100.0

50.0

5: 00 5: 00 5: 00 5: 00 5: 00

5: 00

50.0

5: 00

SP

5: 00 5: 00 5: 00 5: 00 5: 00

5: 00

5: 008: 00 10: 00

Time (hours and minutes)

Segment 6Segment 5Segment 4Segment 3Segment 2Segment 1

Time (hours and minutes)

Time (hours and minutes)

Coordinated Operation for Up to Four

Channels with One Digital Controller

Up to four channels are supported for analog control in a compactsized body to contribute to downsizing control panels.

High-speed and High-resolution

Performance

Sample at the high speed of 50 ms for 4 channels to achieve stable

control even for items requiring high-speed response. And, the resolution is 0.01

°C for a Pt input. Temperature, humidity, and other fac-

tors for ambient testing equipment can be measured, variations

detected, and data logged at a high resolution.

SP

Easy Settings from a Computer Using the

CX-Thermo

The CX-Thermo setting software (version 3.1 or higher) lets you set,

edit, and transfer parameters all at once.

High-speed

sampling

50 ms

High-speed startup in a few seconds

Time

Four

Channels,

One Digital

Controller

Note: Coordinated operation

refers to a slave operating

using the same program

as the master.

RoHS Compliance for World-wide

Application

Available Soon: It will soon be possible to easily setup and monitor

screens online using the SAP Library.

Programmable Digital Controller E5AR-T/E5ER-T 1

Page 2

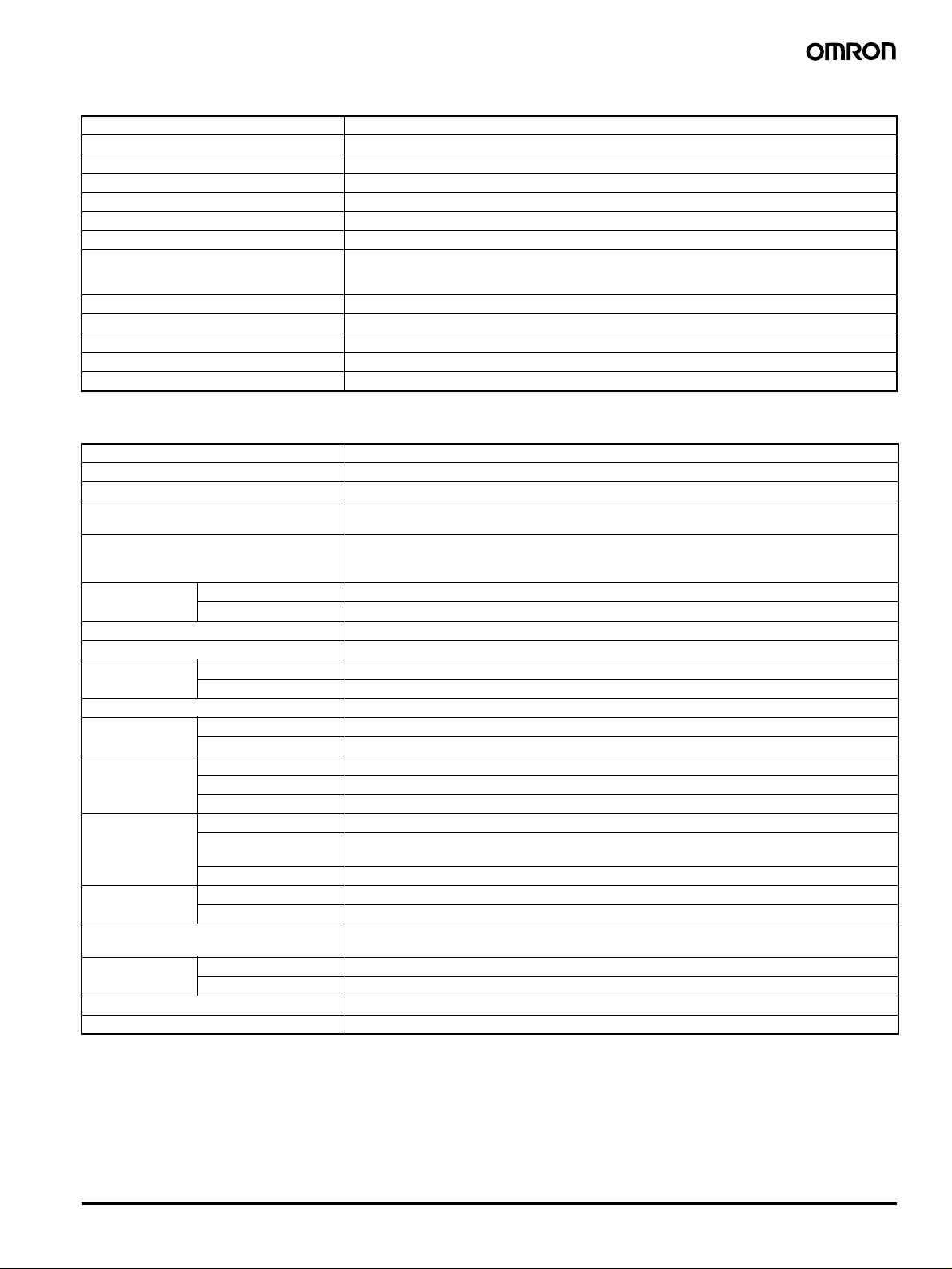

■ Product Lineup

Programmable

E5AR-T

(96 × 96 mm)

Page 4

Basic models

(1 loop)

1 loop for standard control/

1 loop for heating and

cooling control

2-loop models

2 loops for standard control/

1 loop for heating and cooling

control

1 loop for cascade control

1 loop for control with remote SP

1 loop for proportional control

4-loop models

4 loops for standard control

2 loops for heating and cooling

control

Control valve

control models

1 loop for

position-proportional control

4 auxiliary outputs, 2 event inputs,

2 outputs (control/transfer)

10 auxiliary outputs, 10 event inputs,

RS-485 communications, 2/4 outputs (control/transfer)

4 auxiliary outputs, 4 event inputs,

RS-485 communications, 2 outputs (control/transfer)

10 auxiliary outputs, 8 event inputs,

RS-485 communications, 4 outputs (control/transfer)

10 auxiliary outputs, 8 event inputs,

RS-485 communications, 4 outputs (control/transfer)

4 auxiliary outputs, 4 event inputs,

2 relay outputs (open, closed)

10 auxiliary outputs, 8 event inputs,

2 relay outputs (open, closed)

RS-485 communications, 1 output (transfer)

Programmable

E5ER-T

(48 × 96 mm)

Page 15

Basic models

(1 loop)

1 loop for standard control/

1 loop for heating and

cooling control

2-loop models

2 loops for standard control/

1 loop for heating and cooling control

1 loop for cascade control

1 loop for control with remote SP

1 loop for proportional control

Control valve

control models

1 loop for

position-proportional control

4 auxiliary outputs, 2 event inputs,

2 outputs (control/transfer)

4 auxiliary outputs, 2 event inputs,

RS-485 communications, 2 outputs (control/transfer)

2 auxiliary outputs, 4 event inputs,

RS-485 communications, 2 outputs (control/transfer)

2 auxiliary outputs, 4 event inputs, 2 relay outputs

(open, closed)

4 auxiliary outputs, no event input, 2 relay outputs

(open, closed)

RS-485 communications, 1 output (transfer)

2 Programmable Digital Controller E5AR-T/E5ER-T

Page 3

■ Peripheral Devices

AGHTURW

Connection Example for E5@R Series, Temperature Sensors, and SSRs

Voltage output

terminal

(for driving SSR)

Analog values representing temperature,

flowrate, or concentration

Converter, digital panel meter, flowrate

meter, non-contact temperature sensor,

displacement sensor, etc.

E52

Controller

Direct connection possible

E5AR-T/E5ER-T

E5AR-T

SUB1 SUB2 SUB3 SUB4 WAIT FSP

PV

SV

CMW MANU

OUT2 OUT3 OUT4 RST RSP HOLD

OUT1

PF1

PF2

RUN/RST

PRG.

SEG

SSR

INPUT LOAD

Max. No. of SSRs

connectable in parallel

→

5 Units

5 Units

4 Units

5 Units

Load

Heater

Load power

G3PC (SSR with failure detection)

240 VAC (20 A)

Rated input voltage:

12 to 24 VDC

Compact and slim

models with a built-in

heat sink

G3PB (Single-phase)

240 VAC (15 A, 25 A, 35 A, 45 A)

Rated input voltage:

12 to 24 VDC

Compact and slim

models with a built-in

heat sink

G3PB (Three-phase)

240 VAC/400 VAC (15 A, 25 A, 35 A, 45 A)

Rated input voltage:

12 to 24 VDC

Simultaneous threephase control with a

built-in heat sink

A

G

H

T

A

G

H

T

A

A

A

G

G

G

H

HT

HT

T

U

U

R

R

W

W

N

N

AG

BVC

BVC

H

T

D

D

U

S

S

RW

N

BVC

AGHTURW

D

S

NBVC

AGHTURWNBVC

DS

DS

AG

HT

U

R

W

N

BVC

A

A

G

G

D

H

H

S

T

T

U

U

R

R

W

W

A

G

H

T

A

G

H

T

A

G

A

H

G

T

H

T

A

G

A

H

G

T

H

T

A

G

H

A

T

G

H

T

A

G

H

T

G3PA

240 VAC (10 A, 20 A, 40 A, 60 A)

400 VAC (20 A, 30 A, 50 A)

Rated input voltage:

5 to 24 VDC

Compact and slim

models with a built-in

heat sink

A

A

A

A

G

A

A

T

O

N

O

M

R

O

N

A

G

H

T

U

R

A

G

A

G

H

T

U

R

W

N

B

V

C

A

G

H

T

Calculating the Maximum Number of

SSRs Connectable in Parallel

A: The maximum load current of the

voltage output (for SSR drive) of the

Digital Controller is 40 mA (E5AR-T).

For the E5AR-TQQE3MW-FLK and

E5AR-TQQE3MWW-FLK, however,

the maximum load current is 21 mA.

B: SSR’s input impedance is 7 mA for

G3NA

In this case, the maximum number of

SSRs connectable in parallel would be

as follows:

A/B = 5

The maximum load current in the

connection example is 40 mA.

E5ER-T

SUB1 SUB2 SUB3 SUB4 WAIT

FSP

CH2

CMW

MANU

OUT1

OUT2

RST RSP

HOLD

PF2PF1

RUN/RST

E5ER

PV

SV

PRG.

SEG

5 Units

2 Units

240 VAC (5 A, 10 A, 20 A, 40 A)

480 VAC (10 A, 20 A, 40 A)

Rated input voltage:

5 to 24 VDC

Standard models with

screw terminals

240 VAC (5 A, 10 A, 20 A)

Rated input voltage:

12 VDC

Compact and low-cost

models with tab

terminals

G3NA

G3NE

A

A

G

H

T

O

AGHTU

U

M

AGHTURWNBVCD

R

R

W

O

AGHTURWNBVCD

N

N

B

AGHTURWNBVCD

V

C

A

A

SIOLHGF

G

H

SIOLHGF

T

U

A

SIOLHGF

R

W

N

B

V

AGHTU

C

A

G3NH

440 VAC (75 A, 150 A)

8 Units

Rated input voltage:

5 to 24 VDC

For controlling highpower heaters

Programmable Digital Controller E5AR-T/E5ER-T 3

Page 4

Programmable Digital Controller

E5AR-T

A new High-speed, High-precision Digital

Controller that is Programmable!

• Create up to 32 programs with up to 256 segments total.

• Coordinated operation for up to four channels with one Digital

Controller.

•0.01°C High resolution for Pt input.

• High-speed sampling at 50 ms.

• Settings easily made from a computer using the CX-Thermo.

• RoHS compliance for world-wide application.

Refer to “Precautions” on pages 24 and 25.

Model Number Structure

■ Model Number Legend

E5AR-T@@@@@@@@-@@@

2345 96781

1. Control method

Blank:Standard or heating/cooling control

P: Position proportional control

2. Output 1

R: NO relay output + NO relay output

Q: Pulse output/current output + pulse output

C: Current output + current output

3. Output 2

R: NO relay output + NO relay output

Q: Pulse output/current output + pulse output

C: Current output + current output

4. Auxiliary Outputs

Blank:None

4: NO relay output + NO relay output

E: 5 transistor outputs + 5 transistor outputs

5. Communications

Blank:None

3: RS-485 communications

6. Optional function

Blank:None

D: 4 event inputs

M: 4 event inputs + 4 event inputs

7. Input 1

B: Multi-input and 2 event inputs

F: Multi-input and FB (Potentiometer input)

W: Multi-input and multi-input

8. Input 2

Blank:None

W: Multi-input and multi-input

9. Other

FLK: CompoWay/F communications

Note: Be sure to read the precautions for correct use and other precautions in the following user's manual before using the Digital

Controller.

E5AR/ER Programmable Digital Controller User's Manual (Cat. No. Z182)

A PDF version of the user's manual can be downloaded from the following web site:

OMRON Industrial Web http://www.fa.omron.co.jp/

4 Programmable Digital Controller E5AR-T

Page 5

Ordering Information

■ Digital Controllers

Programmable Digital Controllers

Size Control type Control mode Outputs

× 96

96

mm

Basic control

(1 loop)

2-loop control 2-loop standard control

4-loop control 4-loop standard control

Control valve

control

(1 loop)

Standard control

Heating and cooling control

Single-loop heating and cooling control

Single-loop cascade control

Single-loop control with remote SP

Single-loop proportional control

2-loop heating and cooling control

(See note 4.)

Single-loop position-proportional control Relay outputs

(control/transfer)

2 (pulse + pulse/current)

2 (current + current) E5AR-TC4B

2 (pulse + pulse/current)

2 (current + current) E5AR-TC43B-FLK

2 (pulse + pulse/current)

2 (current + current) E5AR-TCE3MB-FLK

4 (pulse + pulse/current + 2 current)

2 (pulse + pulse/current)

2 (current + current) E5AR-TC43DW-FLK

4 (2 pulse + pulse/2

current)

4 (4 current) 10 (See

4 (2 pulse + pulse/2

current)

(1 open, 1 closed)

Relay outputs

(1 open, 1 closed) +

1 current

Optional functions Model

Auxiliary

outputs

(SUB)

4 2 None E5AR-TQ4B

10 (See

note 3.)

4 4 RS-485 E5AR-TQ43DW-FLK

10 (See

note 3.)

note 3.)

4 4 None E5AR-TPR4DF

10 (See

note 3.)

Event

inputs

10 E5AR-TQE3MB-FLK

8 E5AR-TQQE3MW-

8 RS-485 E5AR-TCCE3MWW-

8 RS-485 E5AR-TPRQE3MF-

Serial

communi-

cations

RS-485 E5AR-TQ43B-FLK

(See note 2.)

(See note 2.)

(See note 2.)

(See note 2.)

E5AR-TQCE3MB-FLK

(See note 2.)

(See note 2.)

FLK

FLK

E5AR-TQQE3MWWFLK (See note 2.)

FLK

Note 1: Specify the power supply specifications when ordering. Model numbers for 100 to 240 VAC are different from those for 24 VAC/VDC.

2: These models are for 100 to 240 VAC only.

3: The outputs are transistor output.

4: Only for coordinated operation. (A separate program cannot be set for each channel.)

Inspection Results

If an inspection report is required, it can be ordered at the same time

as the Digital Controller using the following model number.

Inspection Report (Order Separately)

Model

E5AR-K

■ Accessories (Order Separately)

Terminal Cover

Descriptions Model

Terminal Cover for E5AR E53-COV14

Unit Label Sheet

Model

Y92S-L1

Rubber Packing

Model

Y92S-P4

Note: The Rubber Packing is provided with the Digital Controller.

Programmable Digital Controller E5AR-T 5

Page 6

Specifications

■ Ratings

Supply voltage

(See note 2.)

CE marking 100 to 240 VAC, 50/60 Hz 24 VAC, 50/60 Hz; 24 VDC

UL certification 100 to 120 VAC, 50/60 Hz 24 VAC, 50/60 Hz; 24 VDC

Operating voltage range 85% to 110% of rated supply voltage

Power consumption 22 VA max. (with maximum load) 15 VA/10 W max. (with maximum load)

Sensor input (See note 3.) Thermocouple: K, J, T, E, L, U, N, R, S, B, W

Platinum resistance thermometer: Pt100

Current input: 4 to 20 mA DC, 0 to 20 mA DC (including remote SP input)

Voltage input: 1 to 5 VDC, 0 to 5 VDC, 0 to 10 VDC (including remote SP input)

(Input impedance: 150

Ω for current input, approx. 1 MΩ for voltage input)

Control output Voltage (pulse) output 12 VDC, 40 mA max. with short-circuit protection circuit (E5AR-TQQE3MW-FLK: 21 mA max.)

Current output 0 to 20 mA DC, 4 to 20 mA DC; load: 500

Relay output Position-proportional control type (open, closed)

Auxiliary output Relay Output

Potentiometer input 100

(Resolution: Approx. 54,000 for 0 to 20 mA DC; Approx. 43,000 for 4 to 20 mA DC)

N.O., 250 VAC, 1 A (including inrush current)

N.O., 250 VAC, 1 A (resistive load)

Transistor Output

Maximum load voltage: 30 VDC; Maximum load current: 50 mA; Residual voltage: 1.5 V max.; Leakage current: 0.4 mA max.

Ω to 2.5 kΩ

Ω max. (including transfer output)

Event input Contact Input ON: 1 kΩ max.; OFF: 100 kΩ min.

No-contact Input ON: Residual voltage of 1.5 V max.; OFF: Leakage current of 0.1 mA max.

Short-circuit: Approx. 4 mA

Remote SP input Refer to the information on sensor input.

Transfer output Refer to the information on control output.

Control method 2-PID or ON/OFF control

Setting method Digital setting using front panel keys or setting using serial communications

Indication method 7-segment digital display and single-lighting indicator

Character Height

PV display: 12.8 mm; SV display: 7.7 mm; MV display: 7.7 mm

Other functions Depends on model.

Ambient operating temperature

−10 to 55°C (with no icing or condensation)

For 3 years of assured use:

−10 to 50°C (with no icing or condensation)

Ambient operating humidity 25% to 85%

Storage temperature

−25 to 65°C (with no icing or condensation)

Note 1: Do not use an inverter output as the power supply. (Refer to page 25.)

2: The supply voltage (i.e., 100 to 240 VAC or 24 VAC/VDC) depends on the model. Be sure to specify the required type when ordering.

3: The Controller is equipped with multiple sensor input. Temperature input or analog input can be selected with the input type setting switch. There is basic

insulation between power supply and input terminals, power supply and output terminals, and input and output terminals.

■ Input Ranges

Platinum Resistance Thermometer, Thermocouple, Current, or Voltage Input

Input type

Name

Temperature

range (

°C)

Setting 0 1 2345678910111213141516171819

Minimum

setting unit

(SP and alarm)

Input type

setting switch

Note: The shaded area indicates the setting status at the time of purchase.

6 Programmable Digital Controller E5AR-T

Platinum

resistance

thermometer

Thermocouple Current Voltage

Pt100 K J T E L U N R S B W

2300

1800

1300

850.0 85 0.0 850. 0

900

800

700

600

400

200

100

0

−100

−200

−200.0 −150.00 −200.0 −200.0 −200.0 −200.0

0.1°C

1300.0 1300.0

500.0 60 0.0

150.00

−20.0 −100.0 −20.0 −100.0

0.01

°C

400.0 400. 0 400.0

0.0 0.0 0.0 0.0

0.1

TC.PT

Set to TC.PT. Set to ANALOG

IN1

TYPE

ANALOG

°C

1700.0 1700.0 1800.0

100.0

W/Re

()

5-26

2300.0

mA V

20 to 420 to

0

5 to 1 5 to 0

(Depends on scaling and number

of decimal places.)

TC.PT

IN1

TYPE

ANALOG

10 to

0

Page 7

■ Characteristics

Indication accuracy Thermocouple input with cold junction compensation: (±0.1% of PV or ±1°C, whichever is greater) ±1 digit max. (See note 1.)

Control mode Standard control (heating or cooling control), heating/cooling control, standard control with remote SP (2-input models only), heating/

Influence of temperature Thermocouple input (R, S, B, W):

Influence of voltage

Control period 0.2 to 99.0 s (in units of 0.1 s) for time-proportioning control output

Proportional band (P) 0.00% to 999.99% FS (in units of 0.01% FS)

Integral time (I) 0.0 to 3,999.9 s (in units of 0.1 s)

Derivative time (D) 0.0 to 3,999.9 s (in units of 0.1 s)

Hysteresis 0.01% to 99.99% FS (in units of 0.01% FS)

Manual reset value 0.0% to 100.0% (in units of 0.1% FS)

Alarm setting range −19,999 to 99,999 EU (See note 3.)

Input sampling period 50 ms

Insulation resistance 20 MΩ min. (at 500 VDC)

Dielectric strength 2,000 VAC, 50/60 Hz for 1 min (between charged terminals of different polarities)

Vibration resistance (malfunction)

Shock resistance (malfunction)

Inrush current 100 to 240-VAC models: 50 A max.

Weight Controller only: Approx. 450 g; Mounting bracket: Approx. 60 g; Terminal cover: Approx. 30 g

Degree of protection Front panel: NEMA4X for indoor use (equivalent to IP66); Rear case: IP20; Terminals: IP00

Memory protection Non-volatile memory (number of writes: 100,000)

Applicable standards UL 61010C-1, CSA C22.2 No. 1010-1

EMC EMI: EN61326

Note 1: K-, T-, or N-type thermocouple at −100°C max.: ±2°C ±1 digit max.

U- or L-type thermocouple:

B-type thermocouple at 400

R- or S-type thermocouple at 200

W-type thermocouple: (

2: U- or L-type thermocouple:

R- or S-type thermocouple at 200

3: “EU” (Engineering Unit) represents the unit after scaling. If a temperature sensor is used, it is either

Thermocouple input without cold junction compensation: (±0.1% FS or ±1°C, whichever is smaller) ±1 digit (See note 2.)

Analog input: ±0.1% FS ±1 digit max.

Platinum resistance thermometer input: (±0.1% of PV or ±0.5°C, whichever is greater) ±1 digit max.

Position-proportional potentiometer input: ±5% FS ±1 digit max.

cooling control with remote SP (2-input models only), cascade standard control (2-input models only), cascade heating/cooling control

(2-input models only), proportional control (2-input models only), position-propor tional control (control-valve control models only)

(±1% of PV or ±10°C, whichever is greater) ±1 digit max.

Other thermocouple input:

( ±1% of PV or ±4°C, whichever is greater) ±1 digit max.

*K thermocouple at -100°C max.: ±10°C max.

Platinum resistance thermometer:

(±1% of PV or ±2°C, whichever is greater) ±1 digit max.

Analog input: (±1%FS) ±1 digit max.

(The decimal point position depends on the input type and the decimal point position setting.)

10 to 55 Hz, 20 m/s

2

100 m/s

, 3 times each in X, Y, and Z directions

24 VAC/VDC models: 30 A max.

(Power supply voltage: 100 to 120 VAC): Pollution degree 2/Overvoltage category 2

EN 61010-1 (IEC 61010-1) (Power supply voltage: 100 to 240 VAC): Pollution degree 2/Overvoltage category 2

Radiated Interference Electromagnetic Field Strength: EN55011 Group 1 Class A

Noise Terminal Voltage: EN55011 Group 1 Class A

EMS: EN61326

ESD Immunity: EN61000-4-2: 4 kV contact discharge (level 2)

Electromagnetic Immunity: EN61000-4-3: 10 V/m (amplitude-modulated, 80 MHz to 1 GHz, 1.4 GHz to 2 GHz) (level 3)

Burst Noise Immunity: EN61000-4-4: 2 kV power line (level 3)

Conducted Disturbance Immunity: EN61000-4-6: 3 V (0.15 to 80 MHz) (level 3)

Surge Immunity: EN61000-4-5: 1 kV line to line (power line, output line (relay output)) (level 2)

Power Frequency Magnetic Field Immunity: EN61000-4-8: 30 A/m (50 Hz) continuous field

Voltage Dip/Interrupting Immunity: EN61000-4-11: 0.5 cycle, 100% (rated voltage)

±2°C ±1 digit max.

°C max.: No accuracy specification.

±0.3% of PV or ±3°C, whichever is greater) ±1 digit max.

°C max.: ±3°C ±1 digit max.

±1°C ±1 digit

°C max.: ±1.5°C ±1 digit

2

for 10 min each in X, Y, and Z directions

8 kV air discharge (level 3)

2 kV output line (relay output) (level 4)

1 kV measurement line, I/O signal line (level 4)

1 kV communications line (level 3)

2 kV line to ground (power line, output line (relay output)) (level 3)

°C or °F.

Programmable Digital Controller E5AR-T 7

Page 8

■ Communications Specifications

Transmission path connection Multiple points

Communications method RS-485 (two-wire, half duplex)

Synchronization method Start-stop synchronization

Baud rate 9,600, 19,200, or 38,400 bps

Transmission code ASCII

Data bit length 7 or 8 bits

Stop bit length 1 or 2 bits

Error detection Vertical parity (none, even, odd)

Flow control None

Interface RS-485

Retry function None

Communications buffer 217 bytes

Communications response send wait time 0 to 99 ms, Default: 20 ms

Block check character (BCC): CompoWay/F

CRC-16: Modbus

■ Program Control Functions

Number of programs (patterns) 32 (with 8 segments/program)

Number of segments (steps) 32 (with 8 programs)

Maximum number of segments 256

Segment setting method Time setting (Segment set with set point and time.)

Segment times 0 h 0 min to 99 h 59 min

Alarm group number specifications

Reset operation Select either stopping control or fixed SP operation.

Startup operation Select continuing, resetting, manual operation, run mode, or ramp back operation.

PID groups Number of groups 8

Alarm SP function Select from ramp SP and target SP.

Program status

control

Wait operation Wait method Select from waiting at segment ends and always waiting.

Time signals Number of outputs 6

Segment outputs Number of outputs 10

Program status output Program end output (pulse width can be set)

Program startup

operation

Operation end operation Select from resetting, continuing control at final set point, and fixed SP control.

Number of event inputs 10 max.

Number of groups 4

Setting method Set separately for each program.

Setting method Set separately for each program (automatic PID group selection also supported).

Segment operation Advance, hold, and back

Program operation Program repetitions and program links

Wait width setting Wait width upper limit and lower limit set separately for each program.

Setting method ON/OFF setting for each segment

Number of ON/OFF

operations

Setting method Set separately for each program.

Setting method ON/OFF set for each segment.

PV start Select from segment 1 set point, slope-priority PV start, and time-priority PV start.

Standby Standby

Gradient setting (Segment set with set point, gradient, and time.)

0 min 0 s to 99 min 59 s

0 min 00.0 s to 99 min 59.9 s

3 each per output

Segment number output

8 Programmable Digital Controller E5AR-T

Page 9

Wiring Terminals

■ E5AR-T (Programmable Type)

E5AR-TQ4B E5AR-TC4B

24 VAC/DC 100 to 240 VAC

−

+

+

−

Input power supply

depends on model.

100 to 240 VAC or 24

VAC/DC (no polarity)

!

OUT2

Voltage output 12 V

40 mA

OUT1

Voltage output 12 V

40 mA or

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output type setting.)

BEDCA

1

2

3

4

5

6

1

Auxiliary output

(Relay output)

B

1

2

3

4

5

6

COM

SUB1

SUB2

COM

SUB3

SUB4

2

3

4

5

6

KJIHGF

1

2

+

3

−

4

+

5

−

6

F

Event input

EV1

EV2

COM

+

−

+

VI

(Voltage)

−

+

TCPT

(Thermocouple)

−

(Current)

(Resistance temperature input sensor)

1

2

3

4

5

6

K

24 VAC/DC

−

+

+

−

Input power supply

depends on model.

100 to 240 VAC or 24

VAC/DC (no polarity)

OUT2

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output

type setting.)

OUT1

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output

type setting.)

100 to 240 VAC

!

BEDCA

1

2

3

4

5

6

1

2

Auxiliary output

(Relay output)

B

1

2

3

4

5

6

COM

SUB1

SUB2

COM

SUB3

SUB4

3

4

5

6

KJIHGF

1

2

+

3

−

4

+

5

−

6

F

Event input

EV1

EV2

COM

+

−

+

(Voltage)

−

+

TCPTVI

(Thermocouple)

−

(Current)

(Resistance temperature input sensor)

1

2

3

4

5

6

K

E5AR-TQ43B-FLK E5AR-TC43B-FLK

B(+)

RS-485

OUT2

Voltage output 12 V 40 mA

OUT1

Voltage output 12 V

40 mA or

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output type setting.)

A(−)

100 to 240 VAC

!

+

1

−

2

+

3

−

4

+

5

−

6

F

Auxiliary output

(Relay output)

BEDCA

1

2

3

4

5

6

B

COM

1

SUB1

2

SUB2

3

COM

4

SUB3

5

SUB4

6

1

2

3

4

5

6

KJIHGF

Event input

EV1

EV2

COM

+

−

−

++

(Voltage)

(Current)

(Resistance temperature input sensor)

−

TCPTVI

(Thermocouple)

1

2

3

4

5

6

K

100 to 240 VAC

!

OUT2

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output

type setting.)

OUT1

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output

type setting.)

RS-485

B(+)

A(−)

1

2

3

4

5

6

1

2

3

4

5

6

+

−

The power supply voltage must be 100 to 240 VAC or 24 VAC/DC for the E5AR-T to comply with CE

Note

marking requirements.

The power supply voltage must be 100 to 120 VAC or 24 VAC/DC for the E5AR-T to comply with UL

requirements.

BEDCA

Auxiliary output

(Relay output)

B

1

2

3

4

5

6

COM

SUB1

SUB2

COM

SUB3

SUB4

KJIHGF

1

2

+

3

−

4

+

5

−

6

F

Event input

EV1

EV2

COM

+

−

+

VI

(Voltage)

−

+

TCPT

(Thermocouple)

−

(Current)

(Resistance temperature input sensor)

1

2

3

4

5

6

K

Programmable Digital Controller E5AR-T 9

Page 10

E5AR-TQE3MB-FLK E5AR-TCE3MB-FLK

100 to 240 VAC

RS-485

OUT2

Voltage output 12 V 40 mA

OUT1

Voltage output 12 V

40 mA or

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output type setting.)

1

!

2

3

4

5

6

1

2

3

4

5

6

+

B(+)

1

−

A(−)

2

+

3

−

4

+

5

−

6

F

E5AR-TQCE3MB-FLK

24 VAC/DC

OUT2

Voltage output 12 V

40 mA

OUT1

Voltage output 12 V

40 mA or

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output type setting.)

100 to 240 VAC

-

+

+

Input power supply

depends on model.

100 to 240 VAC or 24

VAC/DC (no polarity)

RS-485

OUT4

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output

type setting.)

OUT3

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output type setting.)

!

-

+

B(+)

1

−

A(−)

2

+

3

−

4

+

5

−

6

F

Auxiliary output

(Transistor output)

BEDCA

1

COM

SUB1(B), SUB6(C)

SUB2(B), SUB7(C)

SUB3(B), SUB8(C)

SUB4(B), SUB9(C)

SUB5(B), SUB10(C)

EV3(E), EV7(D)

EV4(E), EV8(D)

EV5(E), EV9(D)

KJIHGF

EV6(E), EV10(D)

COM

Event input

EV1

EV2

COM

+

−

−

++

VI

(Thermocouple)

(Voltage)

(Current)

(Resistance temperature input sensor)

BEDCA

2

3

4

5

6

1

2

3

4

5

6

1

2

+

3

−

+

4

+

5

−

−

6

G

(Current)

(Resistance temperature input sensor)

−

+

+

+

+

+

Event input

1

2

3

4

−

5

6

TCPT

K

Auxiliary output

(Transistor output)

COM

SUB1(B), SUB6(C)

SUB2(B), SUB7(C)

SUB3(B), SUB8(C)

SUB4(B), SUB9(C)

SUB5(B), SUB10(C)

Event input

EV3(E), EV7(D)

EV4(E), EV8(D)

EV5(E), EV9(D)

EV6(E), EV10(D)

COM

KJIHGF

Event input

−

++

(Voltage)

EV1

EV2

COM

1

2

3

4

−

5

6

TCPTVI

K

(Thermocouple)

Auxiliary output

C

B

1

2

3

100 to 240 VAC

!

4

5

6

E

D

1

2

3

4

BEDCA

1

2

3

4

5

6

1

2

3

4

5

6

5

6

OUT2

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output

type setting.)

OUT1

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output type setting.)

C

B

-

1

+

2

+

3

+

4

+

5

+

6

E

D

1

RS-485

B(+)

A(−)

+

1

−

2

+

3

−

4

+

5

−

6

F

(Transistor output)

COM

SUB1(B), SUB6(C)

SUB2(B), SUB7(C)

SUB3(B), SUB8(C)

SUB4(B), SUB9(C)

SUB5(B), SUB10(C)

Event input

EV3(E),EV7(D)

EV4(E),EV8(D)

EV5(E),EV9(D)

KJIHGF

EV6(E),EV10(D)

COM

Event input

EV1

EV2

COM

+

−

−

++

PTIV

(Voltage)

(Current)

(Resistance temperature input sensor)

1

2

3

4

−

5

6

TC

K

(Thermocouple)

B

C

−

1

+

2

+

3

+

4

+

5

+

6

E

D

1

2

3

4

5

6

2

3

4

5

6

The power supply voltage must be 100 to 240 VAC or 24 VAC/DC for the E5AR-T to comply with CE

Note

marking requirements.

The power supply voltage must be 100 to 120 VAC or 24 VAC/DC for the E5AR-T to comply with UL

requirements.

10 Programmable Digital Controller E5AR-T

Page 11

E5AR-TQ43DW-FLK (2-loop Control) E5AR-TC43DW-FLK (2-loop Control)

Auxiliary output

(Relay output)

B

COM

100 to 240 VAC

B(+)

RS-485

OUT2

Voltage output 12 V 40 mA

OUT1

Voltage output 12 V

40 mA or

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output type setting.)

A(−)

BEDCA

1

!

2

3

4

5

+

6

1

1

−

2

2

+

3

3

−

4

4

+

5

5

6

−

6

F

Input 2

Input 1

(Current)

(Resistance temperature input sensor)

1

2

3

4

5

6

Event input

EV3

EV4

EV5

KJIHGF

EV6

COM

+

−

−

+

−

−

+

+

VI

TCPT

−

−

++

VI

TCPT

(Thermocouple)

(Voltage)

SUB1

SUB2

COM

SUB3

SUB4

1

2

3

4

5

6

K

E

1

2

3

4

5

6

OUT2

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output

type setting.)

OUT1

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output type setting.)

RS-485

100 to 240 VAC

+

B(+)

−

A(−)

+

−

+

−

BECA

1

!

2

3

4

5

6

1

1

2

2

3

3

4

4

5

5

6

6

F

D

KJIHGF

+

−

−

Input 2

+

+

I

V

−

−

Input 1

+

VI

(Voltage)

(Current)

(Resistance temperature input sensor)

E5AR-TQQE3MW-FLK (2-loop Control)

Auxiliary output

24 VAC/DC 100 to 240 VAC

−

+

+

−

Input power supply

depends on model.

100 to 240 VAC or 24

VAC/DC (no polarity)

B(+)

RS-485

OUT2

Voltage output 12 V

40 mA

OUT1

Voltage output 12 V

40 mA or

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output type setting.)

OUT4

OUT3

A(−)

Voltage output 12 V

40 mA

Voltage output 12 V

40 mA or

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output type setting.)

(Transistor output)

!

+

1

−

2

+

3

−

4

+

5

−

6

F

BECA

1

2

3

4

5

6

1

2

3

4

5

6

1

2

Input 2

+

3

−

4

+

5

Input 1

−

6

G

COM

D

SUB1(B), SUB6(C)

SUB2(B), SUB7(C)

SUB3(B), SUB8(C)

SUB4(B), SUB9(C)

SUB5(B), SUB10(C)

EV3(E), EV7(D)

EV4(E), EV8(D)

EV5(E), EV9(D)

KJIHGF

EV6(E), EV10(D)

COM

+

−

−

+

+

VII

−

−

++

(Voltage)

(Current)

(Resistance temperature input sensor)

PT

PT

1

−

2

3

+

TC

4

−

5

6

TCV

K

(Thermocouple)

Event input

C

B

−

1

+

2

+

3

+

4

+

5

+

6

ED

1

2

3

4

5

6

Auxiliary output

(Relay output)

B

1

2

3

4

5

6

Event input

EV3

EV4

EV5

EV6

COM

−

+

TCPT

−

+

TCPT

(Thermocouple)

COM

SUB1

SUB2

COM

SUB3

SUB4

E

1

2

3

4

5

6

1

2

3

4

5

6

K

Note

The power supply voltage must be 100 to 240 VAC or 24 VAC/DC for the E5AR-T to comply with CE

marking requirements.

The power supply voltage must be 100 to 120 VAC or 24 VAC/DC for the E5AR-T to comply with UL

requirements.

Programmable Digital Controller E5AR-T 11

Page 12

E5AR-TCCE3MWW-FLK (4-loop Control) E5AR-TQQE3MWW-FLK (4-loop Control)

Auxiliary output

24 VAC/DC

OUT2

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output

type setting.)

OUT1

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output type setting.)

OUT4

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output

type setting.)

OUT3

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output type setting.)

100 to 240 VAC

−

+

+

−

Input power supply

depends on model.

100 to 240 VAC or 24

VAC/DC (no polarity)

B(+)

RS-485

A(−)

(Transistor output)

COM

SUB1(B), SUB6(C)

D

!

+

1

−

2

+

3

−

4

+

5

−

6

F

1

2

+

3

−

4

+

5

−

6

G

BECA

1

2

3

4

5

6

1

2

3

4

5

6

Input 2(K)

Input 4(J)

Input 1(K)

Input 3(J)

(Current)

(Resistance temperature input sensor)

+

−

+

I

−

I

(Voltage)

KJIHGF

−

+

V

−

+

V

SUB2(B), SUB7(C)

SUB3(B), SUB8(C)

SUB4(B), SUB9(C)

SUB5(B), SUB10(C)

EV3(E), EV7(D)

EV4(E), EV8(D)

EV5(E), EV9(D)

EV6(E), EV10(D)

COM

−

+

TCPT

−

+

TCPT

(Thermocouple)

Event input

1

2

3

4

5

6

J, K

C

B

−

1

+

2

+

3

+

4

+

5

+

6

E

D

1

2

3

4

5

6

OUT2

Voltage output 12 V 21 mA

OUT1

Voltage output 12 V

21 mA or

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output type setting.)

OUT4

Voltage output 12 V 21 mA

OUT3

Voltage output 12 V

21 mA or

Current output

100 to 240 VAC

!

+

B(+)

RS-485

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output type setting.)

1

−

A(−)

2

+

3

−

4

+

5

−

6

F

+

−

+

−

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

G VI

E5AR-TPR4DF E5AR-TPRQE3MF-FLK

Auxiliary output

(Relay output)

100 to 240 VAC

24 VAC/DC

−

+

+

−

Input power supply

depends on model.

100 to 240 VAC or 24

VAC/DC (no polarity)

OUT2

OUT1

!

1

2

3

4

5

6

1

2

3

4

5

6

1

Relay output

2

250 VAC 1 A

3

4

5

6

F

BEDCA

Closed

Open

Potentiometer

+

−

I

(Current)

(Resistance temperature input sensor)

B

1

2

3

4

5

6

Event input

EV3

EV4

EV5

EV6

KJIHGF

COM

O

1

W

2

C

3

PT

4

−

5

6

TC

K

(Thermocouple)

−

++

V

(Voltage)

COM

SUB1

SUB2

COM

SUB3

SUB4

E

1

2

3

4

5

6

24 VAC/DC

OUT4

Voltage output 12 V

40 mA

OUT3

Voltage output 12 V

40 mA or

Current output

4 to 20 mA DC,

500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output type setting.)

100 to 240 VAC

−

+

+

−

Input power supply

depends on model.

100 to 240 VAC or 24

VAC/DC (no polarity)

+

−

+

−

B(+)

RS-485

A(−)

OUT2

OUT1

1

!

2

3

4

5

1

6

1

2

2

3

3

4

4

5

6

5

G

6

+

1

−

Relay output

2

250 VAC 1 A

3

4

5

6

F

BECA

Input 2(K)

Input 4(J)

Input 1(K)

Input 3(J)

SUB2(B), SUB7(C)

SUB3(B), SUB8(C)

SUB4(B), SUB9(C)

SUB5(B), SUB10(C)

EV3(E), EV7(D)

EV4(E), EV8(D)

EV5(E), EV9(D)

KJIHGF

EV6(E), EV10(D)

COM

+

−

−

+

+

I

V

−

−

+

(Voltage)

(Current)

(Resistance temperature input sensor)

COM

SUB1(B), SUB6(C)

D

BEDCA

Potentiometer

+

Closed

Open

−

−

+

I

(Current)

(Resistance temperature input sensor)

Auxiliary output

(Transistor output)

Event input

−

+

TCPT

−

+

TCPT

(Thermocouple)

Auxiliary output

(Transistor output)

COM

SUB1(B), SUB6(C)

SUB2(B), SUB7(C)

SUB3(B), SUB8(C)

SUB4(B), SUB9(C)

SUB5(B), SUB10(C)

EV3(E), EV7(D)

EV4(E), EV8(D)

EV5(E), EV9(D)

EV6(E), EV10(D)

COM

KJIHGF

−

+

PTV

TC

(Thermocouple)

(Voltage)

C

B

−

1

+

2

+

3

+

4

+

5

+

6

E

D

1

2

3

4

5

6

1

2

3

4

5

6

J, K

BEDC

−

1

+

2

+

3

+

4

+

5

+

6

Event input

1

2

3

4

5

6

O

1

W

2

C

3

4

5

6

K

The power supply voltage must be 100 to 240 VAC or 24 VAC/DC for the E5AR-T to comply with CE

Note

marking requirements.

The power supply voltage must be 100 to 120 VAC or 24 VAC/DC for the E5AR-T to comply with UL

requirements.

12 Programmable Digital Controller E5AR-T

Page 13

Nomenclature

E5AR-T

Operation

Indicators

Channel

Indicator

SUB1 SUB2 SUB3 SUB4 WAIT FSP

PV

Rear

No. 1 Display

Bar Graph

Program Status

Indicators

Function Key 1/

Run/Reset Key

CMW MANU

OUT1

PF1

RUN/RST

Function Key 2

OUT2 OUT3 OUT4 RST RSP HOLD

PF2

Level Key

Mode Key Down Key Up Key

Dimensions

Note: All units are in millimeters unless otherwise indicated.

96

SUB1 SUB2 SUB3 SUB4 WAIT FSP

96

CMW MANU

OUT2 OUT3 OUT4 RST RSP HOLD

OUT1

PF2

PF1

RUN/RST

SV

PRG.

SEG

No. 2 Display

No. 3 Display

11.5 95

3

PV

SV

PRG.

SEG

110

2

111

91 × 91

120 min.

Panel Cutouts

+0.8

92

0

Crimp terminal size: M3

110 min.

+0.8

92

0

Terminal cover (E53-COV14: order separately)

• Recommended panel thickness is 1 to 8 mm.

• Group mounting is not possible. (Maintain the specified

mounting space between Controllers.)

• When two or more Controllers are mounted, make sure

that the surrounding temperature does not exceed the

allowable operating temperature specified in the specifications.

Programmable Digital Controller E5AR-T 13

Page 14

■ Accessories (Order Separately)

Terminal Cover

E53-COV14 (for E5AR)

95

28.5

10.1

Unit Label Sheet

Y92S-L1

11.8

95

Rubber Packing

Y92S-P4 (for DIN96 × 96)

4.8

Order the Rubber Packing separately if it becomes lost or damaged. (Refer to page 5.)

(Deterioration, shrinking, or hardening of the rubber packing may occur depending on the operating

environment. Therefore, periodic replacement is recommended to ensure the level of waterproofing

specified in NEMA4. The time for periodic replacement depends on the operating environment. Be

sure to confirm this point at your site. Consider one year a rough standard. OMRON shall not be liable for the level of water resistance if the customer does not perform periodic replacement.)

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

14 Programmable Digital Controller E5AR-T

Page 15

Programmable Digital Controller

E5ER-T

A new 48 x 96-mm High-speed, Highprecision Digital Controller that is

Programmable!

• Create up to 32 programs with up to 256 segments total.

•0.01°C High resolution for Pt input.

• High-speed sampling at 50 ms.

• Settings easily made from a computer using the CX-Thermo.

• RoHS compliance for world-wide application.

Refer to the “Precautions” on pages 24 and 25.

Model Number Structure

■ Model Number Legend

E5ER-T@@@@@@@@-@@@

2345 96781

1. Control method

Blank:Standard or heating/cooling control

P: Position proportional control

2. Output 1

R: NO relay output + NO relay output

Q: Pulse output/current output + pulse output

C: Current output + current output

3. Output 2

R: NO relay output + NO relay output

Q: Pulse output/current output + pulse output

C: Current output + current output

4. Auxiliary Outputs

Blank:None

4: NO relay output + NO relay output

T: 2 transistor outputs

5. Communications

Blank: None

3: RS-485 communications

6. Optional Function

Blank: None

D: 4 event inputs

7. Input 1

B: Multi-input and 2 event inputs

F: Multi-input and FB (Potentiometer input)

W: Multi-input and multi-input

8. Input 2

Blank: None

W: Multi-input and multi-input

9. Other

FLK: CompoWay/F communications

(3 digits):(Modification type)

Note: Be sure to read the precautions for correct use and other precautions in the following user's manual before using the Digital

Controller.

E5AR/ER Programmable Digital Controller User's Manual (Cat. No. Z182)

A PDF version of the user's manual can be downloaded from the following web site:

OMRON Industrial Web http://www.fa.omron.co.jp/

Programmable Digital Controller E5ER-T 15

Page 16

Ordering Information

■ Digital Controllers

Programmable Digital Controllers

Size Control type Control mode Outputs (control/

× 96

48

mm

Note 1: Specify the power supply specifications when ordering. Model numbers for 100 to 240 VAC are different from those for 24 VAC/VDC.

Basic control

(1 loop)

2-loop control 2-loop standard control

Control valve

control

(1 loop)

2: The outputs are transistor output.

Standard control

Heating and cooling control

Single-loop heating and cooling control

Single-loop cascade control

Single-loop control with remote SP

Single-loop proportional control

Single-loop position-proportional control Relay outputs

transfer)

2 (pulse + pulse/current)

2 (current + current) E5ER-TC4B

2 (pulse + pulse/current)

2 (pulse + pulse/current)

2 (current + current) E5ER-TCT3DW-FLK

(1 open, 1 closed)2 (See Note

Relay outputs

(1 open, 1 closed) +

1 current

Optional functions Model

Auxiliary

outputs

(SUB)

4 2 None E5ER-TQ4B

2

(See Note

2.)

2.)

4 None RS-485 E5ER-TPRQ43F-

Event

inputs

4 RS-485 E5ER-TQT3DW-FLK

4 None E5ER-TPRTDF

Serial

commu-

nications

RS-485 E5ER-TQC43B-FLK

FLK

Inspection Results

If an inspection report is required, it can be ordered at the same time

as the Digital Controller using the following model number.

Inspection Report (Order Separately)

Model

E5ER-K

■ Accessories (Order Separately)

Terminal Cover

Descriptions Model

Terminal Cover for E5ER E53-COV15

Rubber Packing

Model

Y92S-P5

Note: The Rubber Packing is provided with the Digital Controller.

16 Programmable Digital Controller E5ER-T

Page 17

Specifications

■ Ratings

Supply voltage

(See note 2.)

CE marking 100 to 240 VAC, 50/60 Hz 24 VAC, 50/60 Hz; 24 VDC

UL certification 100 to 120 VAC, 50/60 Hz 24 VAC, 50/60 Hz; 24 VDC

Operating voltage range 85% to 110% of rated supply voltage

Power consumption 17 VA max. (with maximum load) 11 VA/7 W max. (with maximum load)

Sensor input (See note 3.) Thermocouple: K, J, T, E, L, U, N, R, S, B, W

Platinum resistance thermometer: Pt100

Current input: 4 to 20 mA DC, 0 to 20 mA DC (including remote SP input)

Voltage input: 1 to 5 VDC, 0 to 5 VDC, 0 to 10 VDC (including remote SP input)

(Input impedance: 150

Ω for current input, approx. 1 MΩ for voltage input)

Control output Voltage (pulse) output 12 VDC, 40 mA max. with short-circuit protection circuit

Current output 0 to 20 mA DC, 4 to 20 mA DC; load: 500

Relay output Position-proportional control type (open, closed)

Auxiliary output Relay Output

Potentiometer input 100

(Resolution: Approx. 54,000 for 0 to 20 mA DC; Approx. 43,000 for 4 to 20 mA DC)

N.O., 250 VAC, 1 A (including inrush current)

N.O., 250 VAC, 1 A (resistive load)

Transistor Output

Maximum load voltage: 30 VDC; Maximum load current: 50 mA; Residual voltage: 1.5 V max.; Leakage current: 0.4 mA max.

Ω to 2.5 kΩ

Ω max. (including transfer output)

Event input Contact Input ON: 1 kΩ max.; OFF: 100 kΩ min.

No-contact Input ON: Residual voltage of 1.5 V max.; OFF: Leakage current of 0.1 mA max.

Short-circuit: Approx. 4 mA

Remote SP input Refer to the information on sensor input.

Transfer output Refer to the information on control output.

Control method 2-PID or ON/OFF control

Setting method Digital setting using front panel keys or setting using serial communications

Indication method 7-segment digital display and single-lighting indicator

Character Height

PV display: 9.5 mm; SV display: 7.2 mm; MV display: 7.2 mm

Other functions Depends on model.

Ambient operating temperature

−10 to 55°C (with no icing or condensation)

For 3 years of assured use:

−10 to 50°C (with no icing or condensation)

Ambient operating humidity 25% to 85%

Storage temperature

−25 to 65°C (with no icing or condensation)

Note 1: Do not use an inverter output as the power supply. (Refer to page 25.)

2: The supply voltage (i.e., 100 to 240 VAC or 24 VAC/VDC) depends on the model. Be sure to specify the required type when ordering.

3: The Controller is equipped with multiple sensor input. Temperature input or analog input can be selected with the input type setting switch.

There is basic insulation between power supply and input terminals, power supply and output terminals, and input and output terminals.

■ Input Ranges

Platinum Resistance Thermometer, Thermocouple, Current, or Voltage Input

Input type

Name

Temperature

range (

°C)

Setting 0 1 2345678910111213141516171819

Minimum

setting unit

(SP and alarm)

Input type

setting switch

Note: The shaded area indicates the setting status at the time of purchase.

Platinum

resistance

thermometer

Thermocouple Current Voltage

Pt100 K J T E L U N R S B W

2300

1800

1300

850.0 85 0.0 850. 0

900

800

700

600

400

200

100

0

−100

−200

−200.0 − 150.00 −200.0 −200.0 −200.0 −200.0

0.1°C

1300.0 1300.0

500.0 60 0.0

150.00

−20.0 −100.0 −20.0 −100.0

0.01

°C

400.0 400. 0 40 0.0

0.0 0.0 0.0 0.0

0.1

TC.PT

Set to TC.PT. Set to ANALOG

IN1

TYPE

ANALOG

°C

1700.0 1700.0 18 00.0

Programmable Digital Controller E5ER-T 17

100.0

W/Re

()

5-26

2300.0

mA V

20 to 420 to

0

5 to 1 5 to 0

(Depends on scaling and number

of decimal places.)

TC.PT

IN1

TYPE

ANALOG

10 to

0

Page 18

■ Characteristics

Indication accuracy Thermocouple input with cold junction compensation: (±0.1% of PV or ±1°C, whichever is greater) ±1 digit max. (See note 1.)

Control mode Standard control (heating or cooling control), heating/cooling control, standard control with remote SP (2-input models only), heating/

Influence of temperature Thermocouple input (R, S, B, W):

Influence of voltage

Control period 0.2 to 99.0 s (in units of 0.1 s) for time-proportioning control output

Proportional band (P) 0.00% to 999.99% FS (in units of 0.01% FS)

Integral time (I) 0.0 to 3,999.9 s (in units of 0.1 s)

Derivative time (D) 0.0 to 3,999.9 s (in units of 0.1 s)

Hysteresis 0.01% to 99.99% FS (in units of 0.01% FS)

Manual reset value 0.0% to 100.0% (in units of 0.1% FS)

Alarm setting range −19,999 to 99,999 EU (See note 3.)

Input sampling period 50 ms

Insulation resistance 20 MΩ min. (at 500 VDC)

Dielectric strength 2,000 VAC, 50/60 Hz for 1 min (between charged terminals of different polarities)

Vibration resistance (malfunction)

Shock resistance (malfunction)

Inrush current 100 to 240-VAC models: 50 A max.

Weight Controller only: Approx. 330 g; Mounting bracket: Approx. 60 g; Terminal cover: Approx. 16 g

Degree of protection Front panel: NEMA4X for indoor use (equivalent to IP66); Rear case: IP20; Terminals: IP00

Memory protection Non-volatile memory (number of writes: 100,000)

Applicable standards UL 61010C-1, CSA C22.2 No. 1010-1

EMC EMI: EN61326

Note 1: K-, T-, or N-type thermocouple at −100°C max.: ±2°C ±1 digit max.

U- or L-type ther mocouple:

B-type thermocouple at 400

R- or S-type thermocouple at 200

W-type thermocouple: (

2: U- or L-type thermocouple:

R- or S-type thermocouple at 200

3: “EU” (Engineering Unit) represents the unit after scaling. If a temperature sensor is used, it is either

Thermocouple input without cold junction compensation: (±0.1% FS or ±1°C, whichever is smaller) ±1 digit (See note 2.)

Analog input: ±0.1% FS ±1 digit max.

Platinum resistance thermometer input: (±0.1% of PV or ±0.5°C, whichever is greater) ±1 digit max.

Position-proportional potentiometer input: ±5% FS ±1 digit max.

cooling control with remote SP (2-input models only), cascade standard control (2-input models only), cascade heating/cooling control

(2-input models only), proportional control (2-input models only), position-proportional control (control-valve control models only)

(±1% of PV or ±10°C, whichever is greater) ±1 digit max.

Other thermocouple input:

( ±1% of PV or ±4°C, whichever is greater) ±1 digit max.

*K thermocouple at -100°C max.: ±10°C max.

Platinum resistance thermometer:

(±1% of PV or ±2°C, whichever is greater) ±1 digit max.

Analog input: (±1%FS) ±1 digit max.

(The decimal point position depends on the input type and the decimal point position setting.)

10 to 55 Hz, 20 m/s

2

100 m/s

, 3 times each in X, Y, and Z directions

24 VAC/VDC models: 30 A max.

(Power supply voltage: 100 to 120 VAC): Pollution degree 2/Overvoltage category 2

EN 61010-1 (IEC 61010-1) (Power supply voltage: 100 to 240 VAC): Pollution degree 2/Overvoltage category 2

Radiated Interference Electromagnetic Field Strength: EN55011 Group 1 Class A

Noise Terminal Voltage: EN55011 Group 1 Class A

EMS: EN61326

ESD Immunity: EN61000-4-2: 4 kV contact discharge (level 2)

Electromagnetic Immunity: EN61000-4-3: 10 V/m (amplitude-modulated, 80 MHz to 1 GHz, 1.4 GHz to 2 GHz) (level 3)

Burst Noise Immunity: EN61000-4-4: 2 kV power line (level 3)

Conducted Disturbance Immunity: EN61000-4-6: 3 V (0.15 to 80 MHz) (level 3)

Surge Immunity: EN61000-4-5: 1 kV line to line (power line, output line (relay output)) (level 2)

Power Frequency Magnetic Field Immunity: EN61000-4-8: 30 A/m (50 Hz) continuous field

Voltage Dip/Interrupting Immunity: EN61000-4-11: 0.5 cycle, 100% (rated voltage)

±2°C ±1 digit max.

°C max.: No accuracy specification.

±0.3% of PV or ±3°C, whichever is greater) ±1 digit max.

°C max.: ±3°C ±1 digit max.

±1°C ±1 digit

°C max.: ±1.5°C ±1 digit

2

for 10 min each in X, Y, and Z directions

8 kV air discharge (level 3)

2 kV output line (relay output) (level 4)

1 kV measurement line, I/O signal line (level 4)

1 kV communications line (level 3)

2 kV line to ground (power line, output line (relay output)) (level 3)

°C or °F.

18 Programmable Digital Controller E5ER-T

Page 19

■ Communications Specifications

Transmission path connection Multiple points

Communications method RS-485 (two-wire, half duplex)

Synchronization method Start-stop synchronization

Baud rate 9,600, 19,200, or 38,400 bps

Transmission code ASCII

Data bit length 7 or 8 bits

Stop bit length 1 or 2 bits

Error detection Vertical parity (none, even, odd)

Flow control None

Interface RS-485

Retry function None

Communications buffer 217 bytes

Communications response send wait time 0 to 99 ms, Default: 20 ms

Block check character (BCC): CompoWay/F

CRC-16: Modbus

■ Program Control Functions

Number of programs (patterns) 32 (with 8 segments/program)

Number of segments (steps) 32 (with 8 programs)

Maximum number of segments 256

Segment setting method Time setting (Segment set with set point and time.)

Segment times 0 h 0 min to 99 h 59 min

Alarm group number specifications

Reset operation Select either stopping control or fixed SP operation.

Startup operation Select continuing, resetting, manual operation, run mode, or ramp back operation.

PID groups Number of groups 8

Alarm SP function Select from ramp SP and target SP.

Program status

control

Wait operation Wait method Select from waiting at segment ends and always waiting.

Time signals Number of outputs 6

Segment outputs Number of outputs 10

Program status output Program end output (pulse width can be set)

Program startup

operation

Operation end operation Select from resetting, continuing control at final set point, and fixed SP control.

Number of event inputs 10 max.

Number of groups 4

Setting method Set separately for each program.

Setting method Set separately for each program (automatic PID group selection also supported).

Segment operation Advance, hold, and back

Program operation Program repetitions and program links

Wait width setting Wait width upper limit and lower limit set separately for each program.

Setting method ON/OFF setting for each segment

Number of ON/OFF

operations

Setting method Set separately for each program.

Setting method ON/OFF set for each segment.

PV start Select from segment 1 set point, gradient-priority PV start, and time-priority PV star t.

Standby Standby

Gradient setting (Segment set with set point, gradient, and time.)

0 min 0 s to 99 min 59 s

0 min 00.0 s to 99 min 59.9 s

3 each per output

Segment number output

Programmable Digital Controller E5ER-T 19

Page 20

Wiring Terminals

■ E5ER-T (Programmable Type)

E5ER-TQ4B E5ER-TC4B

24 VAC/DC

OUT1

100 to 240 VAC

−

+

+

−

Input power supply

depends on model.

100 to 240 VAC or 24

VAC/DC (no polarity)

OUT2

Voltage output 12 V

40 mA

Voltage output 12 V

40 mA or

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output type setting.)

!

+

−

+

−

E5ER-TQC43B-FLK

24 VAC/DC

OUT2

Voltage output 12 V

40 mA

OUT1

Voltage output 12 V

40 mA or

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output type setting.)

100 to 240 VAC

−

+

+

−

Input power supply

depends on model.

100 to 240 VAC or 24

VAC/DC (no polarity)

OUT4

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output

type setting.)

OUT3

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output type setting.)

RS-485

!

B(+)

A(−)

Auxiliary output

(Relay output)

B

A

1

2

3

4

5

6

1

2

3

4

5

6

A

1

2

3

4

5

6

+

1

−

2

+

3

−

4

+

5

−

6

1

2

+

3

−

4

+

5

−

6

COM

SUB1

SUB2

COM

SUB3

SUB4

Event input

EV1

EV2

COM

−

+

TC PT

EDC

(Thermocouple)

(Resistance temperature input sensor)

B

EDC

V

Auxiliary output

(Relay output)

COM

SUB1

SUB2

COM

SUB3

SUB4

Event input

EV1

EV2

COM

−

+

TC

PT

(Thermocouple)

(Resistance temperature input sensor)

OUT2

Current output

+

−

−

+

I

(Current)(Voltage)

+

−

−

+

V

I

(Current)(Voltage)

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output

type setting.)

OUT1

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output type setting.)

D

24 VAC/DC

−

+

+

−

Input power supply

depends on model.

100 to 240 VAC or 24

VAC/DC (no polarity)

100 to 240 VAC

Auxiliary output

(Relay output)

B

A

1

!

2

3

4

5

6

1

2

+

3

−

4

+

5

−

6

COM

SUB1

SUB2

COM

SUB3

SUB4

Event input

EV1

EV2

COM

−

+

EDC

TC

PT

(Thermocouple)

(Resistance temperature input sensor)

V

+

−

−

+

I

(Current)(Voltage)

The power supply voltage must be 100 to 240 VAC or 24 VAC/DC for the E5ER-T to comply with CE

Note

marking requirements.

The power supply voltage must be 100 to 120 VAC or 24 VAC/DC for the E5ER-T to comply with UL

requirements.

20 Programmable Digital Controller E5ER-T

Page 21

E5ER-TQT3DW-FLK (2-loop Control) E5ER-TCT3DW-FLK (2-loop Control)

24 VAC/DC

OUT2

Voltage output 12 V

40 mA

OUT1

Voltage output 12 V

40 mA or

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output type setting.)

100 to 240 VAC

−

+

+

−

Input power supply

depends on model.

100 to 240 VAC or 24

VAC/DC (no polarity)

RS-485

Auxiliary output

(Transistor output)

B(+)

A(−)

!

SUB1

SUB2

B

A

EDC

1

2

3

4

5

6

Event input

EV3

EV4

EV5

EV6

COM

−

−

+

+

PT

TC I

TC

(Thermocouple)

(Resistance temperature input sensor)

V

−

−

+

+

PT

V

I

(Current)(Voltage)

+

−

Input 2

+

−

Input 1

1

2

3

4

5

6

+

1

−

2

+

3

−

4

+

5

−

6

+

−

+

−

24 VAC/DC

OUT2

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output

type setting.)

OUT1

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output type setting.)

100 to 240 VAC

−

+

+

−

Input power supply

depends on model.

100 to 240 VAC or 24

VAC/DC (no polarity)

RS-485

Auxiliary output

(Transistor output)

B(+)

A(−)

!

+

−

+

−

+

−

SUB1

SUB2

D

E5ER-TPRTDF E5ER-TPRQ43F-FLK

24 VAC/DC

100 to 240 VAC

−

+

+

−

Input power supply

depends on model.

100 to 240 VAC or 24

VAC/DC (no polarity)

1

Relay output

2

250 VAC 1 A

3

OUT2

4

5

OUT1

6

C

Auxiliary output

(Transistor output)

Closed

Open

SUB1

SUB2

A

B

EDC

1

2

3

4

5

6

Event input

EV3

EV4

EV5

EV6

COM

Potentiometer

O

W

C

−

−

+

TC

(Thermocouple)

(Resistance temperature input sensor)

+

I

VPT

(Current)(Voltage)

+

−

!

1

2

3

4

5

6

1

2

3

4

5

6

+

−

+

−

D

24 VAC/DC 100 to 240 VAC

−

+

+

−

Input power supply

depends on model.

100 to 240 VAC or 24

VAC/DC (no polarity)

+

B(+)

A(−)

OUT2

OUT1

1

−

Relay output

2

250 VAC 1 A

3

4

5

RS-485

6

C

OUT4

Voltage output 12 V

40 mA

OUT3

Voltage output 12 V

40 mA or

Current output

4 to 20 mA DC, 500 Ω max.

0 to 20 mA DC, 500 Ω max.

(Switched by output type setting.)

!

Closed

Open

B

A

1

2

3

4

5

6

1

2

3

4

5

6

Event input

EV3

EV4

EV5

EV6

COM

−

+

TC

−

+

TC

EDC

(Thermocouple)

(Resistance temperature input sensor)

+

−

−

Input 2

+

+

I

VPT

−

−

Input 1

+

VPT

I

(Current)(Voltage)

1

2

+

3

−

4

+

5

−

6

D

Auxiliary output

(Relay output)

A

B

1

2

3

4

5

6

1

2

3

4

5

6

1

2

+

3

−

4

+

5

−

6

COM

SUB1

SUB2

COM

SUB3

SUB4

Potentiometer

O

W

C

−

+

EDC

TC PT V

(Thermocouple)

(Resistance temperature input sensor)

+

−

−

+

I

(Current)(Voltage)

D

Note

The power supply voltage must be 100 to 240 VAC or 24 VAC/DC for the E5ER-T to comply with CE

marking requirements.

The power supply voltage must be 100 to 120 VAC or 24 VAC/DC for the E5ER-T to comply with UL

requirements.

Programmable Digital Controller E5ER-T 21

Page 22

Nomenclature

E5ER-T

Operation

Indicators

SUB1 SUB2 SUB3 SUB4 WAIT

FSP

PV

SV

CH2

CMW

MANU

OUT1

OUT2

RST RSP

HOLD

PRG.

SEG

Level Key

PF2PF1

Function Key 1/

Run/Reset Key

RUN/RST

E5ER

Function Key 2

Dimensions

Note: All units are in millimeters unless otherwise indicated.

48

No. 1 Display

No. 2 Display

No. 3 Display

Down KeyMode Key

Up Key

11.5

3

Rear

110

2

95

44

SUB1 SUB2 SUB3 SUB4 WAIT

FSP

C

H

2

C

M

W

M

A

N

U

96

PV

SV

CH2

PRG.

CMW

MANU

SEG

OUT1

OUT2

RST RSP

HOLD

PF2PF1

RUN/RST

E5ER

111 91

Crimp terminal size: M3

Panel Cutouts

+0.8

45

0

60 min.

Terminal cover (E53-COV15; order separately)

120 min.

• Recommended panel thickness is 1 to 8 mm.

• Group mounting is not possible. (Maintain the specified

+0.8

92

0

mounting space between Controllers.)

• When two or more Controllers are mounted, make sure

that the surrounding temperature does not exceed the

allowable operating temperature specified in the specifications.

22 Programmable Digital Controller E5ER-T

Page 23

■ Accessories (Order Separately)

Terminal Cover

E53-COV15 (for E5ER)

95

28.5

10.1

Unit Label Sheet

Refer to page 14 for details on the Y92S-L1.

Rubber Packing

Y92S-P5 (for DIN48 × 96)

Order the Rubber Packing separately if it becomes lost or damaged. (Refer to page 16.)

(Deterioration, shrinking, or hardening of the rubber packing may occur depending on the operating

environment. Therefore, periodic replacement is recommended to ensure the level of waterproofing

specified in NEMA4. The time for periodic replacement depends on the operating environment.

Be sure to confirm this point at your site. Consider one year a rough standard. OMRON shall not be

liable for the level of water resistance if the customer does not perform periodic replacement.)

48

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Programmable Digital Controller E5ER-T 23

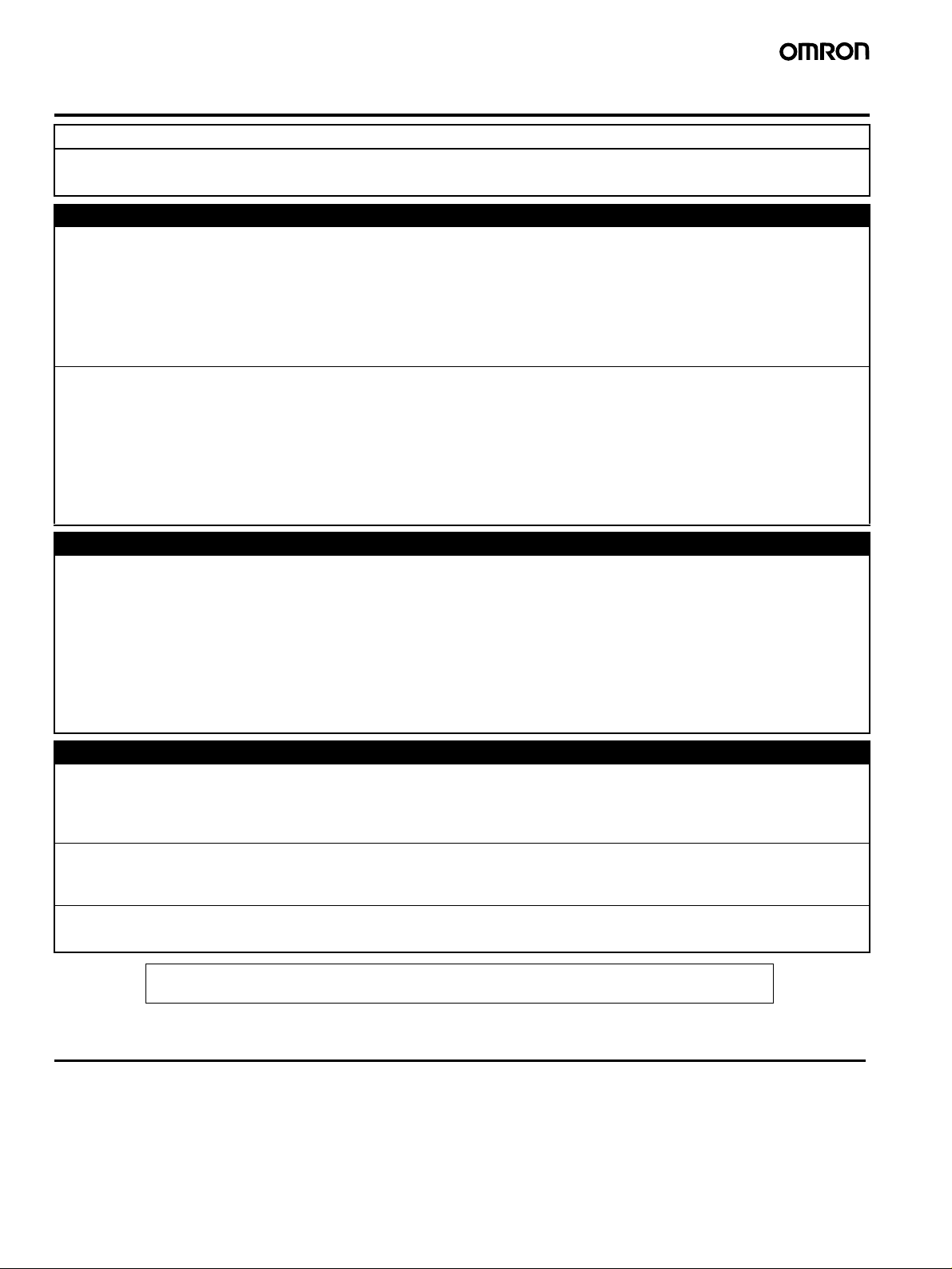

Page 24

Precautions

!CAUTION

Do not touch the terminals while power is being supplied.

Doing so may occasionally result in minor injury due to

electric shock.

Do not touch the terminals or the electrical components

or patterns on the PCB within 1 minute after turning OFF

the power supply. Doing so may occasionally result in

minor injury due to electric shock.

Do not allow pieces of metal, wire clippings, or fine

metallic shavings or filings from installation to enter the

product. Doing so may occasionally result in electric

shock, fire, or malfunction.

Do not use the product in locations where flammable or

explosive gases are present. Doing so may occasionally

result in minor or moderate explosion, causing minor or

moderate injury, or property damage.

Tighten the screws on the terminal block to the following

specified torque. Loose screws may occasionally cause

fire, resulting in minor or moderate injury, or damage to

the equipment.

Terminal block screws: 0.40 to 0.56 N·m

Perform correct setting of the product according to the

application. Failure to do so may occasionally cause

unexpected operation, resulting in minor or moderate

injury, or damage to the equipment.

A malfunction in the Product may occasionally make

control operations impossible or prevent alarm outputs,

occasionally resulting in property damage to the system

or equipment connected to the Product. To maintain

safety in the event of malfunction of the Product, take

appropriate safety measures, such as installing a

monitoring device in a separate system.

Do not use the equipment for measurements within

measurement categories II, III, or IV (according to

IEC61010-1). Doing so may occasionally cause

unexpected operation, resulting in minor or moderate

injury, or damage to the equipment. Use the equipment

for measurements only within the measurement

categories for which the product is designed.

The service life of the output relays depends on the

switching capacity and switching conditions. Consider the