Page 1

Temperature Controllers E5CSV 1

Temperature Controllers

E5CSV

Easy Setting Using DIP Switch and Simple

Functions in DIN 48 x 48 mm-size

Temperature Controllers

• Easy setting using DIP and rotary switches.

• Multi-input (thermocouple/platinum resistance thermometer).

• Clearly visible digital display with character height of 13.5 mm.

• RoHS compliant.

Model Number Structure

■ Model Number Legend

Models with Terminal Blocks

1. Output type

R: Relay

Q: Voltage for driving SSR

2. Number of alarms

1: 1 alarm

3. Input type

T: Thermocouple/platinum resistance

thermometer (multi-input)

4. Power supply voltage

Blank: 100 to 240 VAC

D: 24 VAC/VDC

5. Terminal cover

500: Finger protection cover

Ordering Information

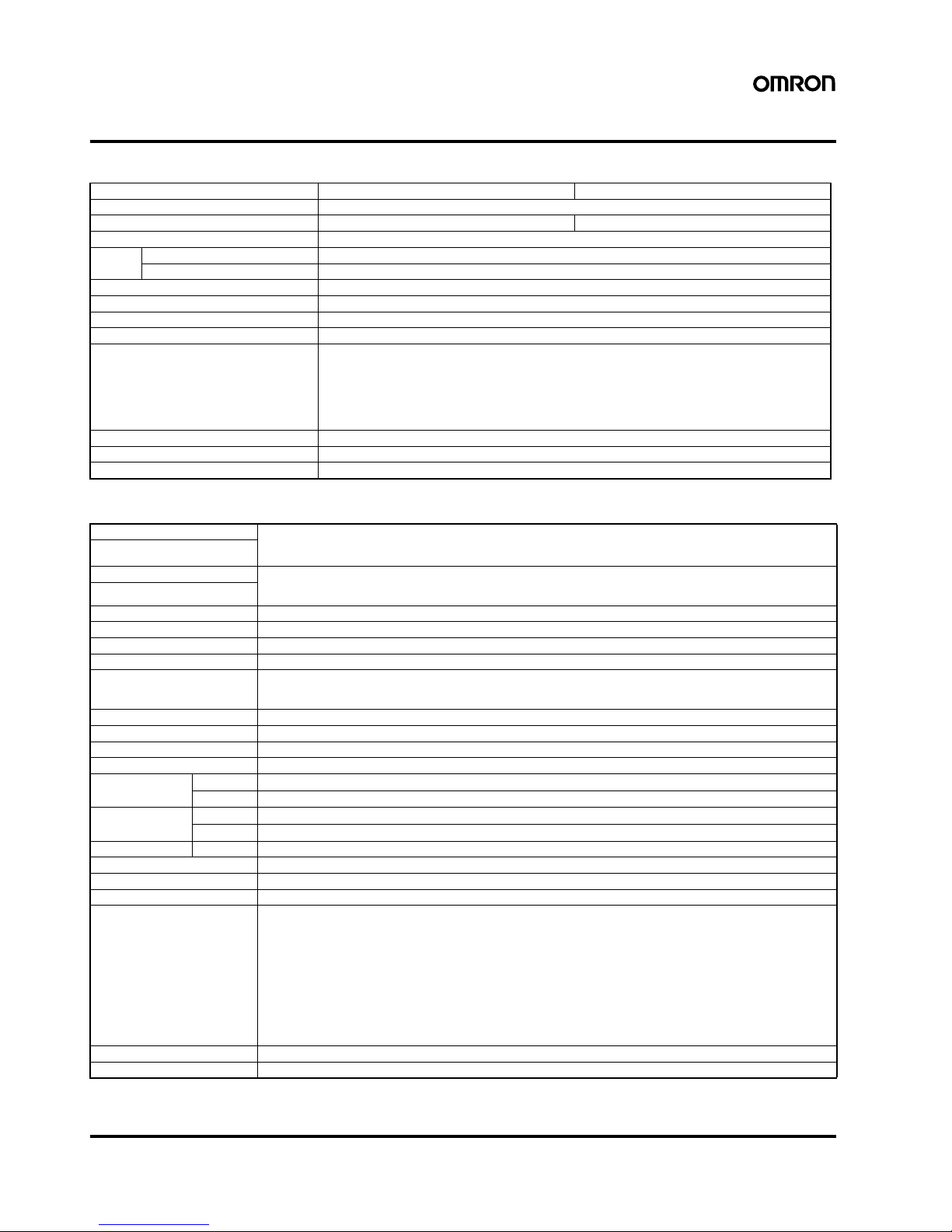

■ List of Models

■ Accessories (Order Separately)

Protective Front Cover

1 2 3 4 5

E5CSV-@1T@-500

Size Power supply

voltage

Number of

alarm points

Control output TC/Pt multi-input

Incl. terminal cover

1/16 DIN

48 x 48 x 78 mm

(W x H x D)

100 to 240 VAC 1 Relay E5CSV-R1T-500

Voltage (for driving SSR) E5CSV-Q1T-500

24 VAC/VDC 1 Relay E5CSV-R1TD-500

Voltage (for driving SSR) E5CSV-Q1TD-500

Type Model

Hard Protective Cover Y92A-48B

Page 2

2 Temperature Controllers E5CSV

Specifications

■ Ratings

■ Characteristics

Note: 1. The following exceptions apply to thermocouples.

• U, L: ±2°C ±1 digit max.

• R: ±3° C ±1 digit max. at 200° C or less

2. The following exceptions apply to platinum resistance

thermometers.

Input set values 0, 1, 2, 3 for E5CSV: 0.5% FS ±1 digit max.

Input set value 1 for E5CSV: 0.5% FS ±1 digit max.

Supply voltage 100 to 240 VAC, 50/60 Hz 24 VAC/VDC, 50/60 Hz

Operating voltage range 85% to 110% of rated supply voltage

Power consumption 5 VA 3 VA/2 W

Sensor input Multi-input (thermocouple/platinum resistance thermometer) type: K, J, L, T, U, N, R, Pt100, JPt100

Control

output

Relay output SPST-NO, 250 VAC, 3A (resistive load)

Voltage output (for driving the SSR) 12 VDC, 21 mA (with short-circuit protection circuit)

Control method ON/OFF or 2-PID (with auto-tuning)

Alarm output SPST-NO, 250 VAC, 1A (resistive load)

Setting method Digital setting using front panel keys (functionality set-up with DIP switch)

Indication method 3.5 digit, 7-segment digital display (character height: 13.5 mm) and deviation indicators

Other functions • Setting change prohibit (key protection)

• Input shift

• Temperature unit change (°C/° F)

• Direct/reverse operation

• Control period switching

• 8-mode alarm output

• Sensor error detection

Ambient temperature -10 to 55° C (with no condensation or icing)

Ambient humidity 25% to 85%

Storage temperature -25 to 65° C (with no condensation or icing)

Setting accuracy Thermocouple (See note 1.): (±0.5% of indication value or ±1°C, whichever is greater) ±1 digit max.

Platinum resistance thermometer (See note 2.): (±0.5% of indication value or ±1°C, whichever is greater) ±1 digit max.

Indication accuracy

(ambient temperature of 23°C)

Influence of temperature R thermocouple inputs: (±1% of PV or ±10°C, whichever is greater) ±1 digit max.

Other thermocouple inputs: (±1% of PV or ±4°C, whichever is greater) ±1 digit max.

Platinum resistance thermometer inputs: (±1% of PV or ±2° C, whichever is greater) ±1 digit max.

Influence of voltage

Hysteresis (for ON/OFF control) 0.1% FS

Proportional band (P) 1 to 999° C (automatic adjustment using auto-tuning/self-tuning)

Integral time (I) 1 to 1,999 s (automatic adjustment using auto-tuning/self-tuning

Derivative time (D) 1 to 1,999 s (automatic adjustment using auto-tuning/self-tuning)

Alarm output range Absolute-value alarm: Same as the control range

Other: 0% to 100% FS

Alarm hysteresis: 0.2° C or ° F (fixed)

Control period 2/20 s

Sampling period 500 ms

Insulation resistance 20 MΩ min. (at 500 VDC)

Dielectric strength 2,000 VAC, 50/60 Hz for 1 min between current-carrying terminals of different polarity

Vibration

resistance

Malfunction

10 to 55 Hz, 20 m/s

2

for 10 min each in X, Y, and Z directions

Destruction 10 to 55 Hz, 0.75-mm single amplitude for 2 hr each in X, Y, and Z directions

Shock resistance Malfunction

100 m/s

2

min., 3 times each in 6 directions

Destruction

300 m/s

2

min., 3 times each in 6 directions

Life expectancy Electrical 100,000 operations min. (relay output models)

Weight Approx. 120 g (Controller only)

Degree of protection Front panel: Equivalent to IP66; Rear case: IP20; Terminals: IP00

Memory protection EEPROM (non-volatile memory) (number of writes: 1,000,000)

EMC EMI Radiated: EN 55011 Group 1 Class A

EMI Conducted: EN 55011 Group 1 Class A

ESD Immunity: EN 61000-4-2: 4 kV contact discharge (level 2)

8 kV air discharge (level 3)

Radiated Electromagnetic Field Immunity: EN 61000-4-3: 10 V/m (80-1000 MHz, 1.4-2.0 GHz amplitude modulated) (level 3)

10 V/m (900 MHz pulse modulated)

Conducted Disturbance Immunity: EN 61000-4-6: 3 V (0.15 to 80 MHz) (level 2)

Noise Immunity (First Transient Burst Noise): EN 61000-4-4

Burst Immunity: 2 kV power-line (level 3), 1 kV I/O signal-line (level 3)

Surge Immunity: EN 61000-4-5: Power line: Normal mode 1 kV; Common mode 2 kV

Output line (relay output): Normal mode 1 kV; Common mode 2 kV

Voltage Dip/Interrupting Immunity: EN 61000-4-11 0.5 cycle, 100% (rated voltage)

Approved standards UL 61010C-1 (listing), CSA C22.2 No.1010-1

Conformed standards EN 61326, EN 61010-1, IEC 61010-1, VDE 0106 Part 100 (finger protection), when the terminal cover is mounted.

Page 3

Temperature Controllers E5CSV 3

Installation

• All models in the E5CSV Series conform to DIN 43700 standards.

• The recommended panel thickness is 1 to 4 mm.

• Be sure to mount the E5CSV horizontally.

Mounting the E5CSV

1. For waterproof mounting, waterproof packing must be installed on the Controller. Waterproofing is not possible when group mounting several

Controllers.

2. Insert the E5CSV into the mounting hole in the panel.

3. Push the adapter from the terminals up to the panel, and temporarily fasten the E5CSV.

4. Tighten the two fastening screws on the adapter. Alternately tighten the two screws little by little to maintain a balance. Tighten the screws to a

torque of 0.29 to 0.39 N·m.

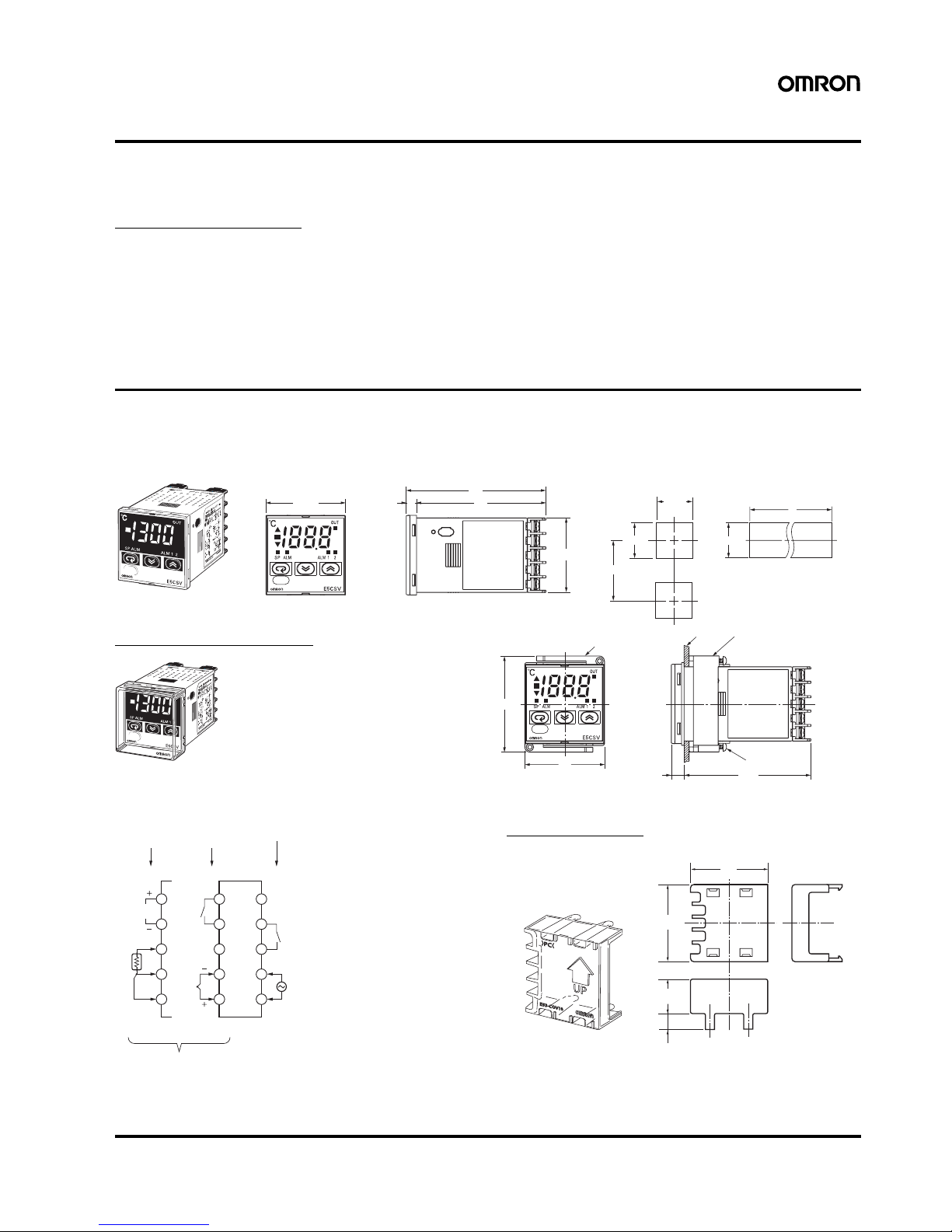

Dimensions

Note: All units are in millimeters unless otherwise indicated.

■ Controller

Terminal Cover

Note: 1. The voltage output (12 VDC, 21 mA) is not electrically isolated from the internal circuits. When using a grounding thermocouple, do not

connect output terminals 1 or 2 to ground. Otherwise, unwanted current paths will cause measurement errors.

2. Models with 100 to 240 VAC and 24 VAC/VDC are separate. Models using 24 VDC have no polarity.

Panel Cutout Dimensions

44.8×44.8

84

786

48×48

60 min.

L = (48 × N−2.5)

+1

0

Mounting side-by-side

(group mounting of N Controllers)

45

+0.6

0

45

+0.6

0

45

+0.6

0

L

Tightening

screws

48

76.5

7.5

Adapter for flush mounting

Panel

Y92F-30 Adapter for flush mounting

58

E5CSV

Note: 1. The recommended panel thickness is 1 to 4 mm.

2. Group mounting is possible in one direction only.

Note: Terminals cannot be removed.

Hard Protective Cover

The Y92A-48B Protective Cover (hard type) is

available for the following applications.

• To protect the set from dust and dirt.

• To prevent the panel from being accidentally

touched causing displacement of set values.

• To provide effective protection against water

droplets.

°C

92A-48B

92A -48 B

92A-48B

8

9

10

7

6

3

4

5

2

11

2

1

2

3

4

5

12 VDC,

21 mA

Alarm output

Alarm output 1

Relay output

models

Voltage output

models

(See note 1.)

Thermocouple/

platinum resistance thermometer multi-input

100 to 240 VAC, 50/60 Hz

(24 VAC/VDC)

(See note 2.)

A

B

B

Thermocouple

input

Relay outputVoltage output

Platinum resistance

thermometer input

48

48.8

22

9.1

E53-COV10

Page 4

4 Temperature Controllers E5CSV

Operation

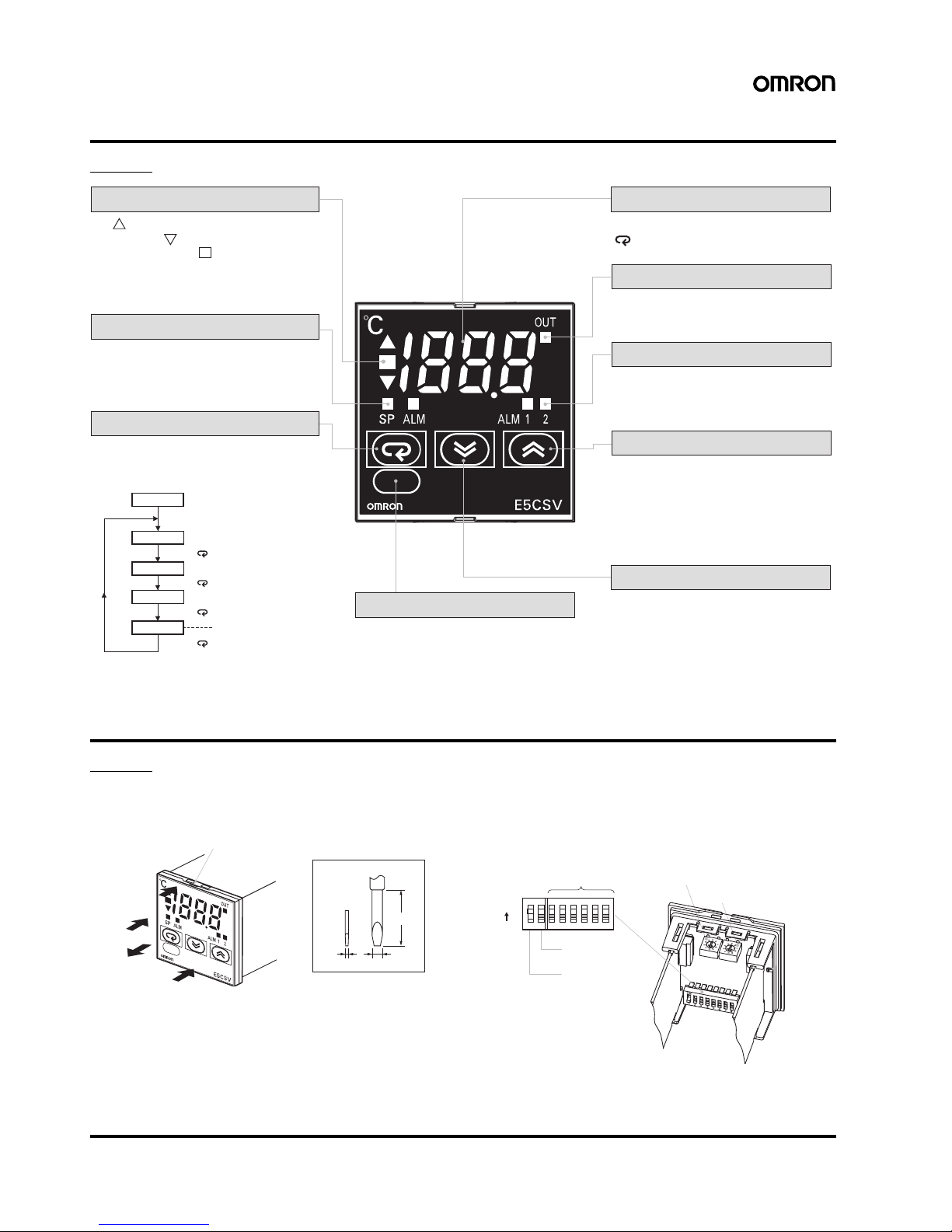

E5CSV

Settings before Turning ON the Power

E5CSV

Remove the E5CSV from the case to make the settings.

1. Insert the tool into the two tool insertion holes (one on the top and

one on the bottom) and release the hooks.

2. Insert the tool in the gap between the front panel and rear case,

and pull out the front panel slightly. Grip the front panel and pull

out fully. Be sure not to impose excessive force on the panel.

3. When inserting the E5CSV, check to make sure that the sealing

rubber is in place and push the E5CSV toward the rear case until

it snaps into position. While pushing the E5CSV into place, push

down on the hooks on the top and bottom surfaces of the rear

case so that the hooks are securely locked in place. Make sure

that electronic components do not come into contact with the

case.

Note: 1. The INIT switch is always OFF during normal operation.

Deviation indicators

The indicator lights when the PV is greater than

the SP and the indicator lights when the PV is

less than the SP. The indicator (green) lights

when the deviation is less than 1% FS (0.25% FS

for multi-input models). These indicators flash

during ST (self-tuning)/AT (auto-tuning).

Mode indicators

The SP indicator lights when the setting

temperature is being displayed. The ALM

indicator lights when the alarm value 1 is

being displayed.

PV, SP, Alarm Value, Input Shift Display

Alarm indicators

ALM1 (Alarm 1): Lights when the alarm 1

output is ON.

ALM2 (Alarm 2): For future use.

Up Key

Pressing the Up Key increases the

SP/alarm value display. Keeping the Up

Key pressed continues to increase the

display value. When the internal protect

switch is ON, press the Up Key while

holding down the Lock Release Key.

Output indicator

Lights when the control output is ON.

The display switches each time the

Key is pressed.

Lock Release Key

When the protect switch is ON, the set

value can be changed by pressing the Up

and Down Keys while holding down the

Lock Release Key.

Down Key

Pressing the Down Key decreases the

SP/alarm value display. Keeping the Down

Key pressed continues to decrease the

display value. When the internal protect

switch is ON, press the Down Key while

holding down the Lock Release Key.

When the power is turned ON, normally the

display will use the display items in the following

order each time the Mode Key is pressed.

Mode Key

PV

SP

Alarm value 1

Input shift value

Power ON

Press the Key.

Press the Key.

Press the Key.

Press the Key.

This item is not displayed when

the Control Mode Switch 4 is OFF.

Flat-blade screwdriver

(Unit: mm)

(1)

(1)

(2)

(3)

Tool insertion hole

0.4 2.0

20 min.

PONX123456

Alarm mode switch (See note 1.)

Temperature range switch

Control mode switches

INIT switch

(See note 2.)

Protect switch

ON

Page 5

Temperature Controllers E5CSV 5

1. Sensor Type Specification

Multi-input (Thermocouple/Platinum

Resistance Thermometer) Models

• Using Thermocouple Sensors, Control Mode Switch 5: OFF

• The control range is -20° C to +20° C of the input temperature

range.

Note: 1. The input indication range is the range that can be displayed for

the control range (-99 to 1999). If the input is within the control

range but exceeds the display range (-99 to 1999), values below

-99 will be displayed as “[[[“ and values above 1,999 will be

displayed as “]]].”

2. If unit is changed to 1 degree when the SP and alarm value for

the temperature range are displayed in 0.1-units from 0.0 to

199.9 or 0.0 to 99.9, the values will be multiplied by 10 (e.g., 0.5

becomes 5). If the unit is changed in the reverse direction, the

values will be divided by 10. After changing the range, set the

SP and alarm value again.

• Using Platinum Resistance Thermometers,

Control Mode Switch 5: ON

• The control range is -20° C to +20° C of the input temperature

range.

Note: 1. The input indication range is the range that can be displayed for

the control range (-99 to 1999). If the input is within the control

range but exceeds the display range (-99 to 1999), values below

-99 will be displayed as “[[[“ and values above 1,999 will be

displayed as “]]].”

2. If unit is changed to 1 degree when the SP and alarm value for

the temperature range are displayed in 0.1-units from 0.0 to

199.9 or 0.0 to 99.9, the values will be multiplied by 10 (e.g., 0.5

becomes 5). If the unit is changed in the reverse direction, the

values will be divided by 10. After changing the range, set the

SP and alarm value again.

ST (Self-tuning) Features

Executing AT (Auto-tuning)

■ Electrical Life Expectancy

Curve for Relays (Reference

Values)

Input K J L T U N R

SP

range

1,700

1,600

1,500

1,400

1,300

1,200

1,100

1,000

900

800

700

600

500

400

300

200

100

0

-100

1,700

1,300 1,300

850 850

400 400

199.9 199.9 199.9

0.0 0.0 0.0 0

-99 -99 -99 -99 -99 -99

Setting number

0123456789

Input Pt100 JPt100

SP

range

1,000

900

800

700

600

500

400

300

200

100

0

-100

850

500

400 400

199.9 20 0 199.9 200

99 99

0.0 0 0 0.0 0 0

-99-99 -99-99

Setting number

0123456789

Mode Key Display Order

• If the SP falls outside the temperature

range when the temperature range is

changed, the SP will be displayed first.

The SP will be changed automatically

either to the minimum value or the

maximum value, whichever is nearest.

• If the alarm value falls outside the

temperature range when the

temperature range is changed, the

alarm value will be displayed first. The

alarm value will be changed

automatically to the maximum value in

the new temperature range.

PV

SP

Alarm value 1

Input shift value

Power ON

Press the Key.

Press the Key.

Press the Key.

Press the Key.

ST (self-tuning) is a function that finds PID constants by using step

response tuning (SRT) when Controller operation begins or when

the set point is changed. Once the PID constants have been

calculated, ST is not executed when the next control operation is

started as long as the set point remains unchanged. When the ST

function is in operation, be sure to turn ON the power supply of the

load connected to the control output simultaneously with or before

starting Controller operation.

AT (auto-tuning) is executed by pressing the U Up and D Down

Keys for at least 2 s while the PV is displayed. The deviation

indicators flash during auto-tuning (AT) execution. AT will be

cancelled by performing the same operation that AT is executing

during AT operation. Flashing stops when AT is completed.

Note: One of the deviation indicators (▲■▼) will flash.

AT execution in progress

Press for

at least 2 s.

Press for

at least 2 s.

UD

UD

AT execution in progress

AT execution

AT cancelled

500

300

100

50

30

10

5

3

1

0123456

Switching current (A)

Life (

×

10

4

operations)

E5CSV

250 VAC, 30 VDC

(resistive load)

cosφ = 1

Page 6

6 Temperature Controllers E5CSV

2. Operation Settings

Use the control mode switches ( ) to change the

control mode. (All switches are OFF for the default settings.)

Note: The previous name Pt100 has been changed to JPt100 in

accordance with revisions to JIS. The previous name J-DIN has

been changed to L in accordance with revisions to DIN

standards.

3. Alarm Modes

Select the number of the alarm mode switch when changing

the alarm mode. (The default is 2).

Note: 1. No alarm. The alarm value (alarm operation display) will not

be displayed when the setting is 0 or 9 even if the selection

key is pressed.

Alarm Setting Range

X: 0 to FS (full scale); Y: Within temperature range

The value of X is the deviation setting for the SP (set point).

2. Standby Sequence Function (The standby sequence

operates when the power is turned ON.)

For details on the position of the temperature range switch, control mode switches, and alarm mode switch, refer to page 4.

Function selection 123456

ON/OFF

PID

PID control

ON

ON/OFF control

OFF

Control

period

2 s

ON

20 s

OFF

Direct/

reverse

operation

Direct operation

(cooling)

ON

Reverse operation

(heating)

OFF

Input

shift

display

Enabled

ON

Disabled

OFF

Temperature

Sensor

selection

Platinum

resistance thermometer

input

ON

Thermocouple

input

OFF

Tem perature

unit

° F

ON

° C

OFF

654321

ON

654321

ON

Set

value

Alarm type Alarm output operation

0, 9 Alarm function OFF OFF

1

Upper- and lowerlimit

2

Upper-limit

3

Lower-limit

4

Upper- and lowerlimit range

5

Upper- and lowerlimit with standby

sequence (See note

2.)

6

Upper-limit with

standby sequence

(See note 2.)

7

Lower-limit with

standby sequence

(See note 2.)

8

Absolute-value

upper-limit

0

1

2

3

4

5

6

7

8

9

XSPX

ON

OFF

SP

X

ON

OFF

X

SP

ON

OFF

XSPX

ON

OFF

XSPX

ON

OFF

X

SP

ON

OFF

X

SP

ON

OFF

0

Y

ON

OFF

Upper-limit

alarm

SP

Lower-limit

alarm

Alarm

output

ON

OFF

Upper-limit

alarm

SP

Lower-limit

alarm

Alarm

output

ON

OFF

Rising Temperature

Dropping Temperature

Note: Turn OFF the power before changing the DIP switch settings on the E5CSV. Each of the switch settings will be enabled after the power is

turned ON.

Page 7

Temperature Controllers E5CSV 7

4. Using the Control Mode Switches

(1) Using ON/OFF Control and PID Control

(1.1) ON/OFF Control

The control mode is set to ON/OFF control as the default setting. To perform cooling control of freezers, etc., turn ON switch 3.

(1.2) PID Control

Turn ON switch 1 to use PID control.

1. Set the control period.

Performing Control via Relay Output, External Relay, or

Conductor

Switch 2: OFF (control period: 20 s)

Quick Control Response Using an SSR

Switch 2: ON (control period: 2 s)

2. Set direct/reverse operation for the output.

Performing Heating Control for Heaters

Switch 3: OFF

Performing Cooling Control for Freezers

Switch 3: ON

654321

ON

Switch 1 OFF: ON/OFF control

OFF

ONControl output

SP

654321

ON

OFF

ONControl output

SP

654321

ON

Switch 1 ON: PID control

654321

ON

OFF

ONControl output

20 s

654321

ON

OFF

ONControl output

2 s

654321

ON

0%

100%

SP

Output level

654321

ON

0%

100%

SP

Output level

Page 8

8 Temperature Controllers E5CSV

(2) Using the E5CSV in Devices for Fahrenheit-scale Users

(Displaying in ° F)

Turn ON switch 6 to display temperatures in ° F.

Temperature Range for ° F

The temperature is set to ° F using the same temperature range switch as ° C.

Note: The control range for multi-input (thermocouple/platinum resistance thermometer) models is -40 to +40° F of each temperature range.

The previous name J-DIN has been changed to L in accordance with revisions to DIN standards.

(3) Setting Input Shift

Turn ON switch 4, and after turning ON the power, press the Mode

Key until h0 (indicates input shift of 0) is displayed. Press the Up and

Down Keys to set the shift value.

Shift Example

Note: When control mode switch 4 is turned OFF (no input shift

display), the input shift is not displayed but the shift value is

enabled. To disable input shift, set the input shift value to h0.

The shift range depends on the setting unit.

5. Protect Switch

When the protect switch is ON, Up Key and Down Key operations are prohibited to prevent setting mistakes.

654321

ON

Multi-input (Thermocouple/

Platinum Resistance

Thermometer)

Control mode switch 5: OFF

Multi-input (Thermocouple/

Platinum Resistance

Thermometer)

Control mode switch 5: ON

Setting

° FSet-

ting

° F

0 K -99 to 1999 0 Pt100 -99 to 1500

1 0.0 to 199.9 1 0.0 to 199.9

2 J -99 to 1500 2 -99 to 99

3 0.0 to 199.9 3 0 to 200

4 L -99 to 1500 4 0 to 400

5 T -99 to 700 5 JPt100 -99 to 900

6 0.0 to 199.9 6 0.0 to 199.9

7 U -99 to 700 7 -99 to 99

8 N -99 to 1999 8 0 to 200

9 R 0 to 1999 9 0 to 400

654321

ON

Input shift display Measured temperature Temperature

display

h0 (no shift) 100° C 100° C

h9 (+9° C shift) 100°C 109° C

l9 (-9° C shift) 100° C91° C

Setting unit 1° C0.1° C

Compensation range -99 to +99° C -9.9 to +9.9° C

Input shift display L99 to H99 L9.9 to H9.9

PONX123456

Protect Switch

Page 9

Temperature Controllers E5CSV 9

Error Displays and Causes

In addition to the alarm indicator, errors notification is provided on the display. Be sure to remove the cause of the error promptly.

Note: In models with an alarm, fff appears or flashes on the display to indicate that the temperature has exceeded the maximum display temperature and the output

is set according to the alarm mode. In the same way, --- appears or flashes on the display to indicate that the temperature has exceeded the minimum display

temperature and the output is set according to the alarm mode.

Sensor Error Displays and Causes

■ Thermocouple

Note: The room temperature is displayed if an input short-circuit occurs.

■ Platinum Resistance Thermometer

Note: The resistance value for platinum resistance thermometers is 100 Ω at 0° C and 140 Ω at 100° C.

Display status Cause Control output

PV displayed as

fff

The process value is higher than the control temperature range (overflow). Heating control (reverse operation): OFF

Cooling control (direct operation): ON

PV displayed as

---

The process value is lower than the control temperature range (underflow). Heating control (reverse operation): ON

Cooling control (direct operation): OFF

fff flashing (1)Thermocouple models and platinum resistance thermometer models:

The process value is higher than the overflow temperature, or a Sensor error has

occurred.

(2)Multi-input (Thermocouple/platinum resistance thermometer) models:

The process value is higher than the control temperature range or a Sensor error

has occurred.

OFF

--- flashing (1)Thermocouple and platinum resistance thermometer input:

The process value is lower than the underflow temperature, or a Sensor error has

occurred.

(2) Thermocouples: The polarity is reversed.

(3)Multi-input (Thermocouple/platinum resistance thermometer) models:

The process value is lower than the control temperature range or a Sensor error has

occurred.

OFF

e11 is

displayed

A memory error (E11) has occurred. Turn the power ON again. If the display remains

the same, the Controller must be repaired.

The control outputs and alarm outputs

turn OFF.

Status Display Control output

Burnout fff flashing OFF

Status Display Control output

Burnout fff flashing OFF

--- flashing OFF

2 or 3 wires disconnected fff flashing OFF

Short-circuit --- flashing OFF

3

4

5

3

4

5

3

4

5

Page 10

10 Temperature Controllers E5CSV

Precautions

!CAUTION

Note: 1. A SELV circuit is one separated from the power supply with

double insulation or reinforced insulation, that does not

exceed 30 V r.m.s. and 42.4 V peak or 60 VDC.

2. A class 2 power supply is one tested and certified by UL as

having the current and voltage of the secondary output

restricted to specific levels.

■ Precautions for Safe Use

Be sure to observe the following precautions to prevent operation

failure, malfunction, or adverse affects on the performance and

functions of the product. Not doing so may occasionally result in

unexpected events.

1. The product is designed for indoor use only. Do not use the

product outdoors or in any of the following locations.

• Places directly subject to heat radiated from heating equipment.

• Places subject to splashing liquid or oil atmosphere.

• Places subject to direct sunlight.

• Places subject to dust or corrosive gas (in particular, sulfide gas

and ammonia gas).

• Places subject to intense temperature change.

• Places subject to icing and condensation.

• Places subject to vibration and large shocks.

2. Use and store the product within the rated temperature and

humidity ranges.

Group-mounting two or more Temperature Controllers, or

mounting Temperature Controllers above each other may cause

heat to build up inside the Temperature Controllers, which will

shorten their service life. In such a case, use forced cooling by

fans or other means of air ventilation to cool down the

Temperature Controllers.

3. To allow heat to escape, do not block the area around the product.

Do not block the ventilation holes on the product.

4. Use the specified size (M3.5, width of 7.2 mm or less) crimped

terminals for wiring. To connect bare wires to the terminal block,

use copper braided or solid wires with a gage of AWG24 to

AWG18 (equal to a cross-sectional area of 0.205 to 0.832 mm

2

).

(The stripping length is 5 to 6 mm.) Up to two wires of the same

size and type, or two crimp terminals can be inserted into a single

terminal.

5. Be sure to wire properly with correct polarity of terminals. Do not

wire any of the I/O terminals incorrectly.

6. Do not wire the terminals that are not used.

7. The voltage output (control output) is not electrically isolated from

the internal circuits. When using a grounded temperature sensor,

do not connect any of the control output terminals to ground.

Otherwise unwanted current paths will cause measurement

errors.

8. To avoid inductive noise, keep the wiring for the Temperature

Controller's terminal block away from power cables carrying high

voltages or large currents. Also, do not wire power lines together

with or parallel to Temperature Controller wiring. Using shielded

cables and using separate conduits or ducts is recommended.

Attach a surge suppressor or noise filter to peripheral devices that

generate noise (in particular, motors, transformers, solenoids,

magnetic coils or other equipment that have an inductance

component).

When a noise filter is used at the power supply, first check the

voltage or current, and attach the noise filter as close as possible

to the temperature controller.

Allow as much space as possible between the Temperature

Controller and devices that generate powerful high frequencies

(high-frequency welders, high-frequency sewing machines, etc.)

or surge.

Do not touch the terminals while power is being supplied.

Doing so may occasionally result in minor injury due to

electric shock.

Do not allow pieces of metal, wire clippings, or fine

metallic shavings or filings from installation to enter the

product. Doing so may occasionally result in electric

shock, fire, or malfunction.

Do not use the product where subject to flammable or

explosive gas. Otherwise, minor injury from explosion

may occasionally occur.

Never disassemble, modify, or repair the product or touch

any of the internal parts. Minor electric shock, fire, or

malfunction may occasionally occur.

CAUTION - Risk of Fire and Electric Shock

a) This product is UL listed as Open Type Process

Control Equipment. It must be mounted in an

enclosure that does not allow fire to escape externally.

b) More than one disconnect switch may be required to

de-energize the equipment before servicing the

product.

c) Signal inputs are SELV, limited energy. (See note 1.)

d) Caution: To reduce the risk of fire or electric shock, do

not interconnect the outputs of different Class

2 circuits. (See note 2.)

If the output relays are used past their life expectancy,

contact fusing or burning may occasionally occur. Always

consider the application conditions and use the output

relays within their rated load and electrical life

expectancy. The life expectancy of output relays varies

considerably with the output load and switching

conditions.

Loose screws may occasionally result in fire.

Tighten terminal screws to the specified torque of 0.74 to

0.90 N·m.

Unexpected operation may result in equipment damage

or accidents if the settings are not appropriate for the

controlled system. Set the Temperature Controller as

follows:

• Set the parameters of the Temperature Controller so

that they are appropriate for the controlled system.

• Turn the power supply to the Temperature Controller

OFF before changing any switch setting. Switch settings

are read only when the power supply is turned ON.

• Make sure that the INIT switch in the control mode

switches is turned OFF before operating the

Temperature Controller.

A malfunction in the Temperature Controller may

occasionally make control operations impossible or

prevent alarm outputs, resulting in property damage.

To maintain safety in the event of malfunction of the

Temperature Controller, take appropriate safety

measures, such as installing a monitoring device on a

separate line.

Faulty terminal contact or decreased waterproofing

capability may result in a fire or equipment malfunction.

When inserting the Temperature Controller into the rear

case after setting the switches, check the watertight

packing and make sure that the top and bottom hooks are

locked securely in place.

Page 11

Temperature Controllers E5CSV 11

9. Use the product within the rated load and power supply.

10.Use a switch, relay, or other contact so that the power supply

voltage reaches the rated voltage within 2 seconds. If the applied

voltage is increased gradually, the power supply may not be reset

or malfunctions may occur.

11.When using PID operation (self-tuning), turn ON the power supply

to the load (e.g., heater) at the same time or before turning the

power supply to the Temperature Controller ON. If power is turned

ON for the Temperature Controller before turning ON power

supply to the load, self-tuning will not be performed properly and

optimum control will not be achieved.

12.Design the system (e.g., control panel) to allow for the 2 seconds

of delay required for the Temperature Controller's output to

stabilize after the power is turned ON.

13.A switch or circuit breaker should be provided close to this unit.

The switch or circuit breaker should be within easy reach of the

operator, and must be marked as a disconnecting means for this

unit.

14.Approximately 30 minutes is required for the correct temperature

to be displayed after turning the power supply to the Temperature

Controller ON. Turn the power supply ON at least 30 minutes prior

to starting control operations.

15.Be sure that the platinum resistance thermometer type and the

input type set on the Temperature Controller are the same.

16.When extending the thermocouple lead wires, always use

compensating conductors suitable for the type of thermocouple.

Do not extend the lead wires on a platinum resistance

thermometer. Use only low-resistance wire (5 Ω max. per line) for

lead wires and make sure that the resistance is the same for all

three wires.

17.When drawing out the Temperature Controller from the case, do

not apply force that would deform or alter the Temperature

Controller.

18.When drawing out the Temperature Controller from the case to

replace the Temperature Controller, check the status of the

terminals. If corroded terminals are used, contact faults with the

terminals may cause the temperature inside the Temperature

Controller to increase, possibly resulting in fire. If the terminals

are corroded, replace the rear case as well.

19.When drawing out the Temperature Controller from the case, turn

the power supply OFF first, and absolutely do not touch the

terminals or electronic components or apply shock to them. When

inserting the Temperature Controller, do not allow the electronic

components to come into contact with the case.

20.Static electricity may damage internal components. Always touch

grounded metal to discharge any static electricity before handling

the Temperature Controller. When drawing out the Temperature

Controller from the case, do not touch the electronic components

or patterns on the board with your hand. Hold the Temperature

Controller by the edge of the front panel when handling it.

21.Do not use paint thinner or similar chemical to clean with. Use

standard grade alcohol.

22.Use tools when separating parts for disposal. Contact with the

sharp internal parts may cause injury.

■ Precautions for Correct Use

Service Life

Use the Temperature Controller within the following temperature and

humidity ranges:

Temperature: -10 to 55° C (with no icing or condensation)

Humidity: 25% to 85%

If the Controller is installed inside a control board, the ambient

temperature must be kept to under 55° C, including the temperature

around the Controller.

The service life of electronic devices like Temperature Controllers is

determined not only by the number of times the relay is switched but

also by the service life of internal electronic components. Component

service life is affected by the ambient temperature: the higher the

temperature, the shorter the service life and, the lower the

temperature, the longer the service life. Therefore, the service life

can be extended by lowering the temperature of the Temperature

Controller.

When two or more Temperature Controllers are mounted horizontally

close to each other or vertically next to one another, the internal

temperature will increase due to heat radiated by the Temperature

Controllers and the service life will decrease. In such a case, use

forced cooling by fans or other means of air ventilation to cool down

the Temperature Controllers. When providing forced cooling,

however, be careful not to cool down the terminals sections alone to

avoid measurement errors.

Measurement Accuracy

When extending or connecting the thermocouple lead wire, be sure

to use compensating wires that match the thermocouple type. Do not

extend the lead wire of the platinum resistance thermometer. If the

lead wire of the platinum resistance thermometer must be extended,

be sure to use wires that have low resistance and keep the

resistance of the three lead wires the same.

Mount the Temperature Controller so that it is horizontally level.

If the measurement accuracy is low, check whether the input shift

has been set correctly.

Waterproofing

The degree of protection is as shown below. Sections without any

specification on their degree of protection or those with IP@0 are not

waterproof.

Front panel: IP66, rear case: IP20, terminals: IP00

Page 12

12 Temperature Controllers E5CSV

Warranty and Application Considerations

Read and Understand this Catalog

Please read and understand this catalog before purchasing the products. Please consult your OMRON representative if you

have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a period of one year (or

other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NON-INFRINGEMENT,

MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR USER

ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET

THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS,

OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON

CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE

PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORED,

INSTALLED, AND MAINTAINED AND NOT SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE

MODIFICATION OR REPAIR.

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the combination of

products in the customer's application or use of the products.

Take all necessary steps to determine the suitability of the product for the systems, machines, and equipment with which it will

be used.

Know and observe all prohibitions of use applicable to this product.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY WITHOUT

ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON

PRODUCTS ARE PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR

SYSTEM.

Disclaimers

PERFORMANCE DATA

Performance data given in this catalog is provided as a guide for the user in determining suitability and does not constitute a

warranty. It may represent the result of OMRON's test conditions, and the users must correlate it to actual application

requirements. Actual performance is subject to the OMRON Warranty and Limitations of Liability.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other reasons. Consult with

your OMRON representative at any time to confirm actual specifications of purchased product.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

In the interest of product improvement, specifications are subject to change without notice.Cat. No. H138-E2-01-X

OMRON EUROPE B.V.

Wegalaan 67-69,

NL-2132 JD, Hoofddorp,

The Netherlands

Phone: +31 23 568 13 00

Fax: +31 23 568 13 88

www.eu.omron.com

Loading...

Loading...