Page 1

Page 2

Chapter 1 Overview of CX-Simulator

CONTENTS

Overview of CX-Simulator

Relationship between CX-Simulator and CX-Programmer

Before Installation

Major Characteristics of CX-Simulator

Chapter 2 Creation of Sample Program

2-1 Starting CX-Programmer

2-2 New Project Opening and Device Type Settings

2-3 Creating Sample Program

– Car Entry by Opening/Closing a Shutter –

2-4 Saving Program

Chapter 3 Executing Program by CX-Simulator

3-1 Connection of CX-Simulator Virtual PLC and CX-Programmer

3-2 Program Transfer to Virtual PLC

3-3 Operating Mode Change of Virtual PLC

3-4 Cycle Time Check in Virtual PLC

3-5 Ladder Monitoring in Virtual PLC

Chapter 4 Program Debug by CX-Simulator

∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ 1-1

∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ 1-1

∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ 2-1

∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ 2-5

∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ 1-1

∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ 1-2

∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ 2-2

∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ 2-3

∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ 3-1

∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ 3-2

∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ 3-4

∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ 3-5

∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ 3-6

4-1 Debug with Sample Program

4-2 Debug by Virtual External Input

4-2-1 Settings of Virtual External Input [IO Condition Tool]

4-2-2 Starting I/O Condition Tool

4-2-3 Setting I/O Conditions

4-2-4 Saving and Ending I/O Condition Settings

4-2-5 Debug by Virtual External Input

4-2-6 Program Debug Operation Using Virtual External Input

4-3 Debug by IO Break Condition Settings

4-3-1 Setting Contents of IO Break Condition [IO Break Condition Settings]

4-3-2 Setting IO Break Conditions

4-3-3 Example of Program Debug Operation by Using IO Break Condition

4-4 Other Debug Functions

Running Program in the Unit of Step and Scan, Break Point Setting

Chapter 5 Startup from CX-Simulator Menu

5-1 Starting CX-Simulator

5-2 Creating Virtual PLC

5-3 Saving/Ending CX-Simulator

∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ 5-1

∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ 5-2

∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ 4-1

∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ 4-2

∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ 4-2

∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ 4-4

∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ 4-7

∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ 4-8

∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ 4-11

∙ 4-15

∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ 4-15

∙ ∙ 4-18

∙ ∙ 4-22

∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ 5-7

Page 3

Chhaapptteerr 11

C

Ovveerrvviiee

O

w ooff

w

CXX--SSii

C

muullaattoorr

m

Page 4

Overview of CX-Simulator

CX-Simulator enables you to realize SYSMAC CS/CJ series CPU Units in your

computer as a virtual PLC and operate (simulate) it equally as actual CPU Units.

Combination use of CX-Simulator and CX-Programmer enables you to verify ladder

program operation and cycle time in advance on a PC without an actual PLC.

Moreover, various debug functions of CX-Simulator make it possible to debug ladders,

which used to be impossible by using an actual PLC only.

Relationship between CX-Simulator and CX-Programmer

CX-Simulator creates a virtual PLC on a virtual network in your PC. If you use the

“Work Online Simulator“ function of CX-Programmer Ver.3.0 or greater versions,

CX-Simulator automatically starts up a virtual PLC of the current project’s device type to

open connection between CX-Programmer and the virtual PLC.

Before Installation

There are two setup types in CX-Simulator V1.3, but choose “1. For online with

CX-Programmer” if CX-Programmer has already been installed in your computer.

CX-Simulator is automatically installed in the directory where CX-Programmer is

installed.

Choose “2. For online with FinsGateway Applications” if you want to use a virtual PLC

for the debug of an application using the FinsGateway network.

Page 5

Major Characteristics of CX-Simulator

Program execution, monitoring, debug without actual PLC

Monitoring of programs and IO memory present values is enabled. Moreover, normal

debugs such as force on/off, differential monitoring, data trace and online edit are

enabled from CX-Programmer. Also, any cyclic task can be started/stopped and

interrupt tasks can be started in simulation.

Cycle time check without actual PLC

It is possible to check estimated cycle time (current, minimum, maximum, and mean

values, servicing time *1) when the program is executed in an actual PLC in advance.

Program execution per step or scan, I/O brake condition settings

Debugs that cannot be realized in actual PLCs are provided.

Step Run: Executes a program per instruction

Scan Run: Executes a program per scan (cycle)

I/O Break Condition Settings: Aborts execution when the conditions set in I/O

memory are satisfied.

Designation of the start and break points

Debugs in connection with display devices and serial communications devices *1

Regarding the serial communications port of a PC as the communications port of a PLC,

it is possible to debug a program in combination with display devices or serial

communications devices (barcode reader, ID sensor, etc.).

Display of the send messages of serial communications and network

communications *1

It is possible to check the send messages issued by TXD instruction (communications

port output), SEND instruction (network send), and CMND instruction (command send).

It is useful for the debugs of serial communications and network communications.

*1: Yo u need to start CX-Simulator from the Windows [Start] menu and set a virtual PLC. See Chapter

5 and the operation manual of CX-Simulator for the detailed operations.

Page 6

Chhaapptteerr 22

f

C

Crreeaattiioonn ooff SSaa

C

mppllee PPrrooggrraa

m

m

m

This chapter explains basic functions such as programming and comment entry of a simple

ladder by using CX-Programmer.

Here, a sample program “a program of car entry control by opening/closing shutters” is

created as an example. This program is used to explain how to use the debug functions o

CX-Simulator, which are mentioned after Chapter 3.

Page 7

p

prog

proj

Starting CX-

g

Pro

rammer

[Start]

|

[Programs]

|

[Omron]

|

[CX-Programmer]

|

[CX-Programmer]

Or double-click the

CX-Programmer icon.

Opening a

new

2-1 Starting CX-Programmer

Start up CX-Programmer from Windows.

ect

Creating a

sam

le program

Saving a

ram

The initial screen of CX-Programmer shows up.

Page 8

p

prog

proj

Starting CX-

r

Programme

Click the left

mouse button.

Click the left

mouse button.

Opening a

new

ect

Creating a

sam

le program

Saving a

ram

2-2 New Project Opening and Device Type Settings

Click the toolbar button [New] in CX-Programmer.

Set the device type to “CS1H” and the CPU type to “CPU63” in this example.

Click the left mouse button on the

“Settings” button to show the

[Device Type Settings] dialog.

The PLC type is set.

In this example, set

“CS1H”.

The CPU type is set.

In this example, se

t

“CPU63”.

Click the left mouse button on

the spin control button

and select a CPU type.

Here is the end of the

setting.

Now CX-Programmer is

ready for the

connection with

CX-Simulator.

Click OK to decide the

selected device type.

Page 9

prog

p

proj

Starting CX-

g

f

A

Pro

rammer

Opening a

new

ect

Creating a

sam

le program

Saving a

ram

2-3 Creating Sample Program

The following is coding of a simple ladder program by using CX-Programmer.

This is a sample program of controlling car entry in a shed by opening/closing shutters.

When a car approaches, the shutters automatically open; and in two seconds after the

car passes the gate, the shutters close.

Upper limit SW (000001)

Lower limit SW (000002)

Normal rotation motor

(000500)

Reverse rotation motor

(000501)

rrival detection sensor (000000)

Operation Flow

(1) When a car enters, the arrival detection sensor (000000) is turned on.

(2) The normal rotation motor (000500) of the shutters is turned on.

(3) The shutters reach the upper limit in three seconds, the upper limit SW (000001) is

turned on, and the shutters open.

(4) When the car passes the gate, the arrival detection sensor (000000) is turned off.

(5) In two seconds, the reverse rotation motor (000501) is turned on.

(6) In three seconds, the shutters reach the lower limit, the lower limit SW (000002) is

turned on, and the shutters close.

See CX-Programmer Introduction Guide or the operation manual o

CX-Programmer for the detailed entry method of a ladder program.

Page 10

prog

p

proj

Starting CX-

g

Pro

rammer

Shutter elevating

processing

Opening a

new

ect

Creating a

sam

le program

Saving a

ram

Completed Sample Program

The program is modularized in two sections “Shutter elevating processing” and “Entries

count processing” by the section function of CX-Programmer V2 or grater versions.

Since processing is simplified in the below program, it’s different from the actual

program.

Entries count

processing

Page 11

prog

Starting CXProgrammer

Opening a

new project

Creating a

sample program

Saving a

ram

Or select [File] |

[Save as] from the

menu.

2-4 Saving Program

Save the created program.

Here, save the program as “sample”.

The program is saved.

This sample program is used in the following operations to explain CX-Simulator.

Keep CX-Programmer open.

Page 12

gr

Chhaapptteerr 33

C

EExxeeccuuttiinngg PPrrooggrraam

m bbyy

CXX--SSii

C

muullaattoorr

m

This chapter explains how to operate CX-Programmer functions such as program transfer, PLC

mode change, cycle time check, and ladder program monitoring, when CX-Programmer is connected

to a CX-Simulator virtual PLC.

In addition, you can use CX-Programmer when connecting to a virtual PLC by the exactly same

operation as when connecting to an actual PLC. For detailed operations, see the operation manual

of CX-Pro

ammer.

Page 13

Connecting to

a virtual PLC

Program transfer

to a virtual PLC

Operation mode

change of a

Cycle time check

in a virtual PLC

Ladder

monitoring in a

3-1 Connection of CX-Simulator Virtual PLC and CX-Programmer

Connect CX-Programmer with a CX-Simulator virtual PLC.

The sample program created in Chapter 2 is used for the explanation here.

Select “Sample”.

Starting CX-Programmer

Click the [Open] button from the toolbar of CX-Programmer.

Select the sample program created in Chapter 2.

The sample program

is loaded.

Page 14

Connecting to

f

a virtual PLC

Or select [PLC] |

[Work Online

Simulator] from the

menu.

Program transfer

to a virtual PLC

Operation mode

change of a

3-2 Program Transfer to Virtual PLC

Click the [Work Online Simulator] button.

Cycle time check

in a virtual PLC

Ladder

monitoring in a

The background

color of Ladder

Window changes to

gray and online

connection is

established.

Now a CX-Simulator virtual PLC and CX-Programmer have been connected.

The Simulator Online function automatically shows the

Transfer dialog after this and enables you to transfer the

ladder program to the virtual PLC; however, you can change it

to the setting of connection only in the option settings o

CX-Programmer.

Page 15

Connecting to

a virtual PLC

The Transfer dialog is

automatically

displayed.

Program transfer

to a virtual PLC

Operation mode

change of a

Cycle time check

in a virtual PLC

Ladder

monitoring in a

Page 16

Connecting to

a virtual PLC

Program transfer

to a virtual PLC

Operation mode

change of a

Cycle time check

in a virtual PLC

Ladder

monitoring in a

3-3 Operating Mode Change of Virtual PLC

You can change the operating mode of a virtual PLC from the [CX-Simulator Debug

Console] screen or CX-Programmer.

(Run: Monitor mode)

(Stop: Program mode)

Click the right mouse

button on [NewPLC1]

and select [Operating

Mode].

Or

Select [PLC] |

[Operating Mode] from

the menu.

Operation from CX-Simulator Debug Console Tool

To start running a program (Monitor mode)

To stop running a program (Program mode)

The number shown in the title bar of Debug Console Tool indicates the count number of

the present cycle in the virtual PLC.

Operation in CX-Programmer

Page 17

Connecting to

a virtual PLC

Select [PLC] | [Edit] |

[Cycle Time] from the

menu of

CX-Programmer.

Program transfer

to a virtual PLC

Operation mode

change of a

Cycle time check

in a virtual PLC

3-4 Cycle Time Check in Virtual PLC

Change the operating mode of a virtual PLC to the Monitor mode.

Ladder

monitoring in a

Estimated Cycle Time and Simulated Cycle Time

Set Estimated Cycle Time when you want to simulate with accuracy, for instance, when

you want to operate data traced per scan as input. At this point, the time of one scan is

enlarged, so the present values of instructions such as TIM proceed depending on your

PC performance.

On the other hand, set Simulated Cycle Time, the accuracy is inferior to Estimated Cycle

Time though, when you want to check the exterior operation of instructions such as TIM.

The default cycle time information in CX-Simulator is set to “Simulated Cycle Time”

which is the time for running a program on an active PC. To check the estimated

cycle time when running a program on an actual PLC, change “Cycle Time Mode

Settings” from “Simulated Cycle Time” to “Estimated Cycle Time” in the PLC Clock

Settings of CX-Simulator.

Set “Cycle Time Mode Settings” to “”Simulated Cycle Time” previous to the

following operations.

Page 18

Connecting to

a virtual PLC

Program transfer

to a virtual PLC

Operation mode

change of a

3-5 Ladder Monitoring in Virtual PLC

Start monitoring of ladders in CX-Programmer.

Cycle time check

in a virtual PLC

Ladder

monitoring in a

Besides ladder monitoring, debug operations such as force on/of, differential

monitoring, data trace and online edit are enabled on CX-Programmer as is the case

with connecting to an actual PLC.

Page 19

Chhaapptteerr 44

C

PPrrooggrraam

m

Deebbuugg bbyy

D

CXX--SSii

C

muullaattoorr

m

The debug operations of a ladder program by using the original functions of CX-Simulator,

which are unavailable by actual PLCs, are explained in this chapter.

Page 20

Debug with a

r

r

A

sample program

Debug by virtual

external input

Debug by I/O

break settings

Other debug

functions

4-1 Debug with Sample Program

CX-Simulator has various program-debug functions. Not only ladder program

execution by a virtual PLC instead of an actual PLC, but also the ON operation of a limit

switch after a work moves (I/O condition operation settings)

, the stop operation of

program execution when a memory value becomes a designated value (I/O break

condition settings), program execution of optional range (Start point/Break point

settings), etc.

This section explains each function by using the sample program “Car entry control

program by opening/closing a shutter“ created in Chapter 2.

The below figure shows the image and operation flow of the sample program in Chapter

2:

Upper limit SW (000001)

Lower limit SW (000002)

Normal rotation moto

(000500)

Reverse rotation moto

(000501)

rrival detection sensor (000000)

Operation Flow

(1) When a car enters, the arrival detection sensor (000000) is turned on.

(2) The normal rotation motor (000500) of the shutter is turned on.

(3) The shutter reaches the upper limit in three seconds

, the upper limit SW

(000001) is turned on, and the shutter opens.

(4) When the car passes the gate, the arrival detection sensor (000000) is turned off.

(5) In two seconds, the reverse rotation motor (000501) is turned on.

(6) In three seconds, the shutter reaches the lower limit

, the lower limit SW

(000002) is turned on, and the shutter closes.

In the I/O condition operation settings, you can set the ON operations of the

upper/lower limit switches by shutter elevating operations and the time until the limit

switches are turned on, as virtual external input. In this example, the virtual external

input that turns on the limit switches of the shutter in three seconds after the motors

are turned on is designated.

Page 21

p

Debug with a

sample program

Debug by virtual

external in

ut

Debug by I/O

break settings

Other debug

functions

4-2 Debug by Virtual External Input

CX-Simulator allows you to set external input; for example, the upper limit SW is turned

on in three seconds after the shutter goes up (ON operation of the upper limit switch).

How to set the I/O Condition tool of CX-Simulator is explained below.

4-2-1 Settings of Virtual External Input

In this example, the operations of two external input signals are set.

(1) The upper limit SW (000001) is turned on in three seconds after the normal rotation

motor (000500) is turned on. (At this point, the lower limit SW (000002) is off.)

(2) The lower limit SW (000002) is turned on in three seconds after the reverse rotation

motor (000501) is turned on. (At this point, the upper limit SW (000001) is actually

off.)

Setting in I/O Condition Tool

The following section explains how to set virtual external input by using I/O Condition

Tool:

Select [Replay] | [IO

Condition] from the

menu in the Debug

Console screen.

I/O Condition Tool

starts up.

4-2-2 Starting I/O Condition Tool

Select [I/O Condition] from the Debug Console screen.

Page 22

p

Debug with a

play

sample program

Debug by virtual

external in

ut

Debug by I/O

break settings

Other debug

functions

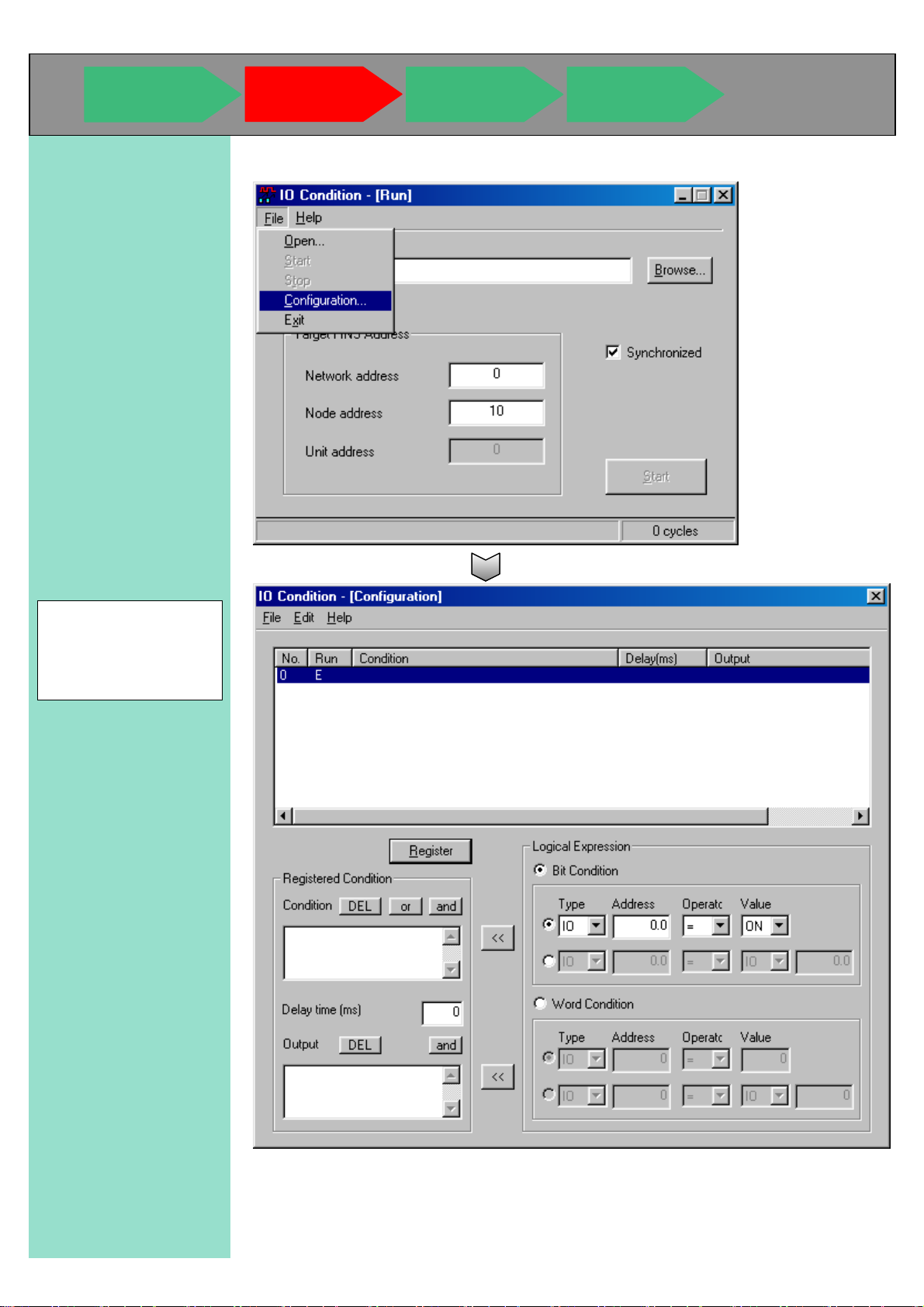

Select [File] |

[Configuration] from

the menu in the I/O

Condition tool.

Select [File] | [Configuration] in the I/O Condition tool.

The [Configuration]

screen of the I/O

Condition tool is

dis

ed.

Page 23

)

p

Debug with a

sample program

Debug by virtual

external in

ut

Debug by I/O

break settings

Other debug

functions

4-2-3 Setting I/O Conditions

How to set I/O conditions is explained in the following example:

In three seconds after the normal rotation motor (000500) is turned on, the upper limit

SW (000001) is turned on. (At this point, the lower limit SW (000002) is actually

turned off at the same time.

In this example, the following formulas are set:

Condition: The normal rotation motor (000500) is turned on.

Delay time: 3 seconds (3000ms)

Output: The lower limit SW (000002) is turned off. In three seconds, the upper limit

Condition Settings

(1) Click “Bit

Condition” in the

“Logical

Expression” field.

(2) Set “IO” to “Type”.

(3) Set “5.0” to

“Address”.

(4) Set “=” to

“Operator”.

(5) Set “ON” to

“Value”.

(6) Click the register

button

.

SW (000001) is turned on.

(1) Click “Bit Condition”.

(2) Set “IO”.

(3) Set “5.0”.

(4) Set “=”.

(5) Set “ON”.

(6) Click the register button.

Delay Time Setting

Enter 3000 (3

seconds) in the text

box of “Delay time”.

Enter 3000(ms) (=3 seconds) in the text box of “Delay time”.

Page 24

p

Debug with a

sample program

Debug by virtual

external in

ut

Debug by I/O

break settings

Other debug

functions

Output Settings

(1) Click “Bit

Condition” in the

“Logical

Expression” field.

(2) Set “IO” to “Type”

(3) Set “0.1” to

“Address”.

(4) Set “=” to

“Operator”.

(5) Set “ON” to

“Value”.

(6) Set the register

button

(7) Click the

.

button.

(8) Click “Bit

Condition” in the

“Logical

Expression” field.

(9) Set “IO” to “Type”.

(10) Set “0.2” to

“Address”.

(11) Set “=” to

“Operator”.

(12) Set “OFF” to

“Value”.

(13) Click the register

button

.

(1)(8) Click “Bit Condition”.

(2)(9) Set “IO”.

(3) Set “0.1”. (10) Set “0.2”.

(4)(11) Set “=”.

(5) Set “ON”.

(12) Set “OFF”.

(6)(13) Click the register button.

(7) Click “and”.

Double-click the

registered formula

The “Run” column is

changed from “N” to

“D”. It means this

formula will be

Click the “Register” button.

Page 25

p

Debug with a

r

f

)

sample program

Debug by virtual

external in

ut

Debug by I/O

break settings

Other debug

functions

Select [Edit] | [Insert

line] from the menu in

“I/O Condition –

[Configuration]”.

Add a new line to enter the second formula.

Like the registration operation of the first formula, set the followings.

The lower limit SW (000002) is turned on three seconds after the reverse rotation moto

(000501) is turned on. (At this point, the upper limit SW (0000001) is actually turned of

at the same time.

In this example, the following formulas are set:

Condition: The reverse rotation motor (000501) is turned on.

Delay time: 3 seconds (3000ms)

Output: The upper limit SW (000001) is turned off. In three seconds, the upper

limit SW (000002) is turned on.

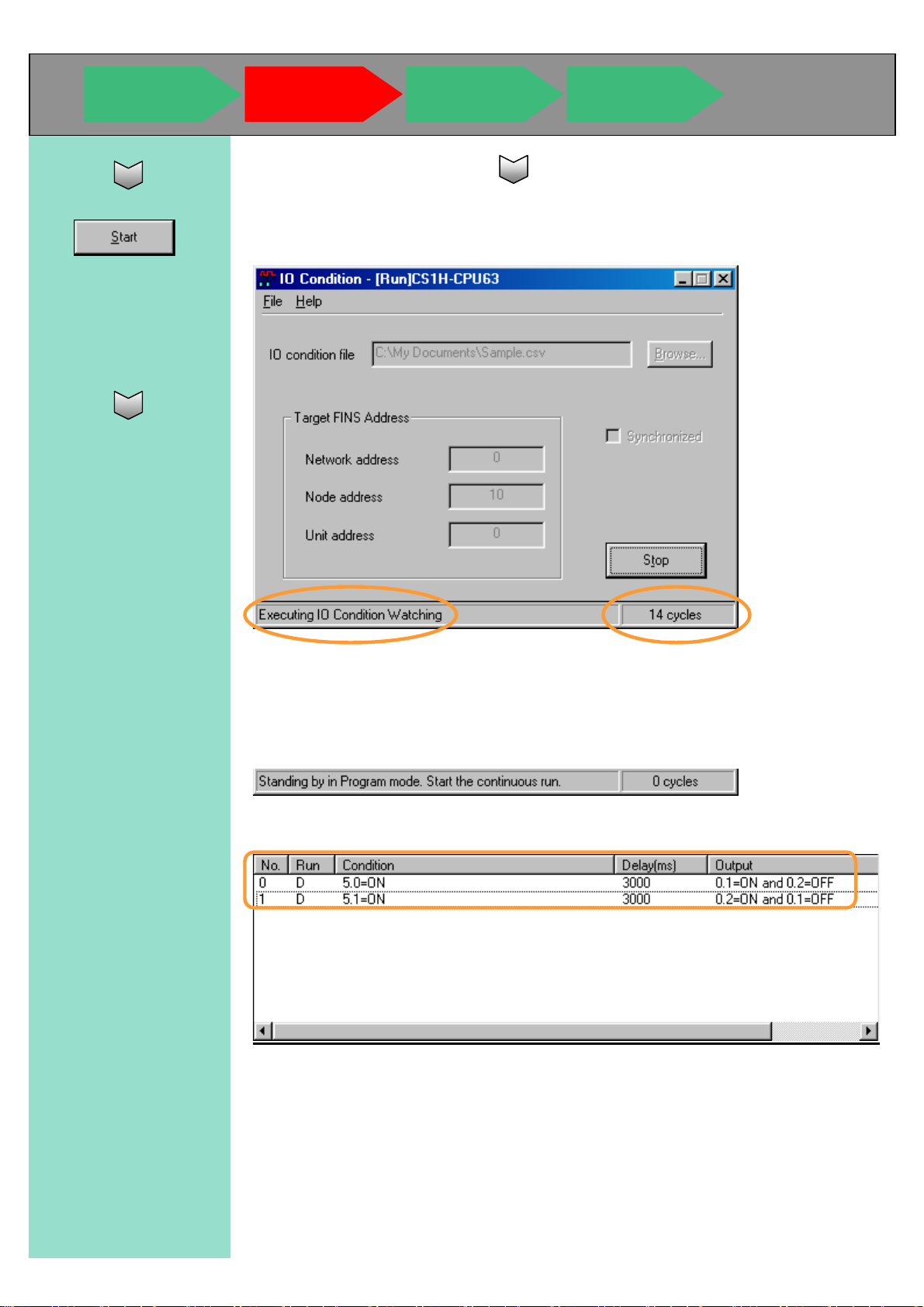

After the two formulas are registered, the set screen is displayed as follows:

You can enter the conditions and output formulas in each column directly from the

keyboard.

Page 26

p

Debug with a

sample program

Select [File] | [Save

As] from the menu in

“I/O Condition –

[Configuration]”.

Enter “sample” in

Debug by virtual

external in

4-2-4 Saving and Ending I/O Condition Settings

ut

Debug by I/O

break settings

Other debug

functions

“File name”.

Select [File] | [Exit]

from the menu in “I/O

Condition –

[Configuration]”.

End I/O Condition [Configuration].

Page 27

p

Debug with a

p

sample program

Debug by virtual

external in

ut

Debug by I/O

break settings

Other debug

functions

Prepare the external

input debug by I/O

Condition

Configuration.

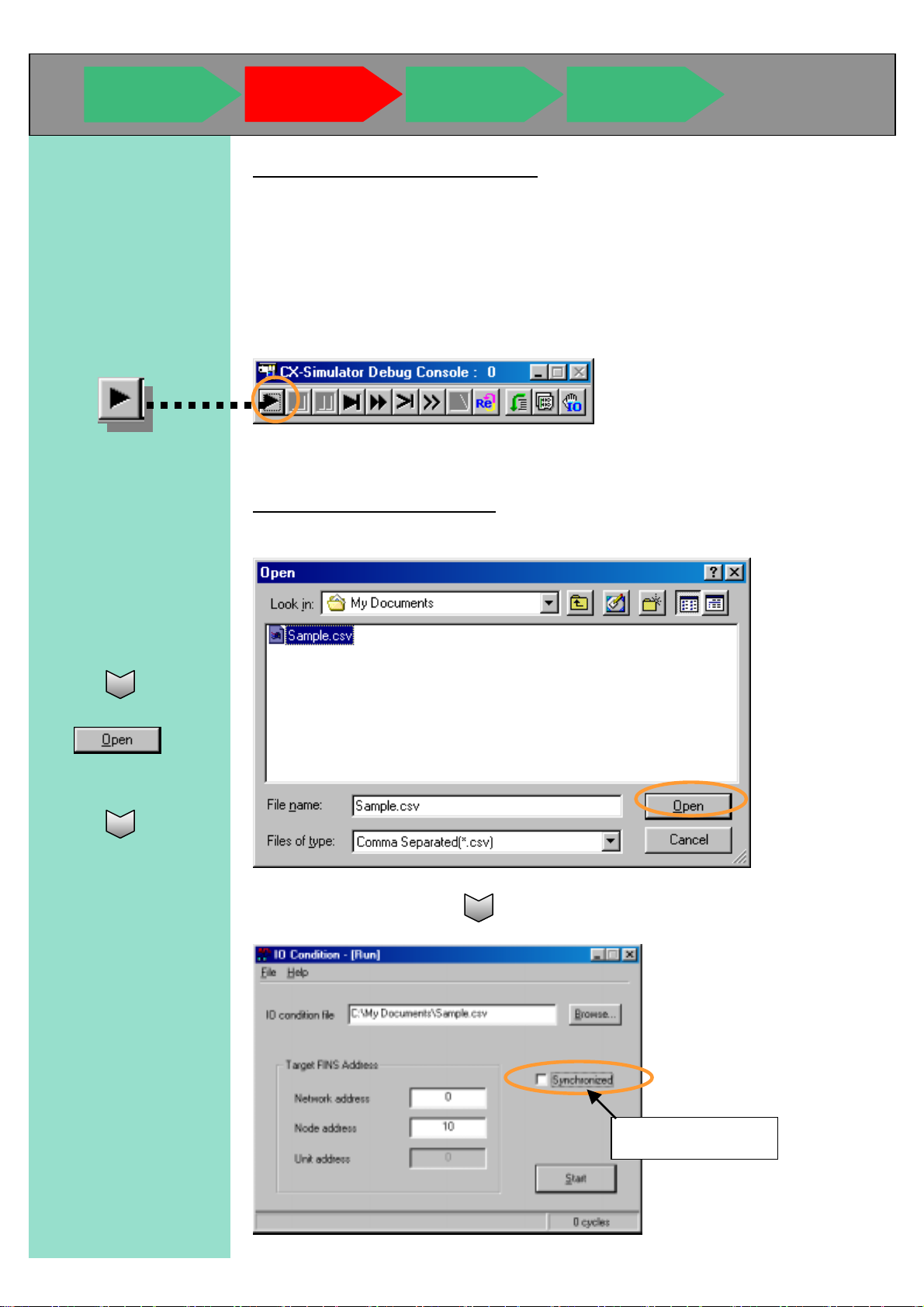

Select [File] | [Open]

from the menu in “I/O

Configuration – [Run]

“ and select

“Sam

le.csv”.

4-2-5 Debug by Virtual External Input

Execute the followings before starting debug:

Load the sample program (Sample.cxp) created in Chapter 2 in CX-Programmer).

Start the virtual PLC created in Chapter 3.

Follow the procedure in Chapter 4 to connect CX-Programmer and the

CX-Simulator virtual PLC.

Start running the ladder of the virtual PLC.

Now you are ready to start debugging.

Execution of I/O Condition Tool

Load the file (Sample.csv) set in “I/O Condition [Configuration]”.

Click the check box of

“Synchronized” to

deactivate it.

Remove the check of

“Synchronized”.

Page 28

p

Debug with a

sample program

Debug by virtual

external in

ut

Debug by I/O

break settings

Other debug

functions

Click the [Start] button. I/O condition watching is started to check whether the set

conditions are established.

After I/O condition watching is started, the screen shows the message ”Executing IO

Condition Watching” and the number of cycles gradually increases.

If the ladder of a virtual PLC has not started running yet, the screen shows the message

as follows. In this case, start running the ladder of the virtual PLC.

By the above procedure, the following two formulas are established and the output

operation after the establishment is started.

Page 29

p

Debug with a

A

sample program

Or select [PLC] |

[Monitor] |

[Monitoring] from the

menu in

CX-Programmer.

Debug by virtual

external in

ut

Debug by I/O

break settings

Other debug

functions

Show “Shutter Elevating Processing” of the ladder of CX-Programmer and start

monitoring.

By the procedures so far, the ladder is running and the condition set in IO Condition

Configuration is monitored by the virtual PLC.

fter this, pseudo input of car arrival and gate passing is executed and debug of a

ladder program is executed.

Page 30

p

Debug with a

sample program

Debug by virtual

external in

ut

Debug by I/O

break settings

Other debug

functions

Waiting for car arrival

Car arrival

Shutter up

4-2-6 Program Debug Operation Using Virtual External Input

Check the following processing flow in order.

(1) Waiting for car arrival

(2) Car arrival

(3) Start of shutter up

The arrival detection sensor (000000) is set

from CX-Programmer.

The normal rotation motor (000500) is

(4) After 3 seconds

(5) End of shutter up

turned on by the conditions and

output formulas set in IO Condition

Configuration, and in 3 seconds

(after the shutter is completely pulled

up), the upper limit SW is turned on.

Car passing

Shutter down

End of car entry

(6) Car passing

(7) After 2 seconds

(8) Start of shutter down

(9) After 3 seconds

The arrival detection sensor (000000) is

reset from CX-Programmer.

The ladder program counts 2 seconds after

car passing.

The reverse rotation motor (000501) is

turned on by the conditions and

output formulas set in IO Condition

Configuration, and in 3 seconds (after

(10) End of shutter down

(11) End of car entry

the shutter is completely brought

down), the lower limit SW is turned

on.

The ladder program counts the number of

car entries.

Page 31

p

Debug with a

[On]

sample program

Waiting for car arrival

After clicking the

contact 0.00, click the

right button of the

mouse to select [Set] |

.

Debug by virtual

external in

Operation Check by Pseudo Input of Car Arrival

ut

Debug by I/O

break settings

Other debug

functions

After this, program debug is proceeded according to the processing flow.

First, use the Set On function of CX-Programmer for simulating the waiting for car arrival

status through the car arrival status.

Select [Set | On] on the arrival detection sensor (000000) to simulate car arrival.

Car arrival

Setting on the arrival

detection sensor

(0.00) turns on the

normal rotation

motor (5.00).

Shutter up

After car arrival (Set on the arrival detection sensor), the normal rotation motor is turned

on.

If the motor isn’t turned on, once switch the op eratio n mode of the virtual PLC to Program Mode, and repeat

the same operation.

In three seconds, the shutter turns on the upper limit SW and the normal rotation motor

is turned off. (Turn on the upper limit SW by the condition/output formulas set in

I/O Condition Configuration)

Page 32

p

Debug with a

sample program

Debug by virtual

external in

ut

Debug by I/O

break settings

Other debug

functions

Car passing

After click the bit 0.00,

click the right-mouse

button and select [Set]

| [Off].

Operation Check by Pseudo Input of Car Arrival

Next, use the Set Off function of CX-Programmer for simulating the car passing status.

Set off the arrival detection sensor (000000) to simulate the car passing status.

Setting off the arrival

detection sensor

(0.00) turns on the

timer calculating flag

(W0.02).

Timer starts

calculating.

After car passing (Set off the arrival detection sensor), the Timer Calculating flag is

turned on.

Page 33

p

Debug with a

r

sample program

Debug by virtual

external in

ut

Debug by I/O

break settings

Other debug

functions

After the timer

completes

two-second

calculation, the

reverse rotation

motor (5.01) is

turned on.

Shutter down

After the timer calculates two seconds, the timer flag is turned on, and the reverse

rotation motor is turned on.

In three seconds, the shutter turns on the lower limit switch and the reverse rotation

motor is turned off.

(The lower limit SW is turned on according to the condition/output formulas set in

Set I/O Condition.)

The following operation makes it possible to debug a series of operation from car arrival

to car passing.

The Set On/Off functions of CX-Programmer enable you to simulate the car arrival and

passing statuses as explained above.

Moreover, setting I/O conditions enables you to automatically generate the shutte

elevating operations.

Page 34

Debug with a

sample program

Debug by virtual

external input

Debug by I/O

break settings

Other debug

functions

4-3 Debug by IO Break Condition Settings

CX-Simulator allows you to stop a program, for instance, when the number of entered

cars reaches to a certain number. This is a function for break when I/O memory status

is monitored and the set conditions are satisfied.

4-3-1 Setting Contents of IO Break Condition

Here, the way to stop the program by using IO Break Condition when the number of

entered cars turns three is explained.

D0 (0 word of data memory) is set as the storing memory for the number of completed

entries.

Settings in IO Break Condition Settings

4-3-2 Setting IO Break Conditions

Start IO Break Condition Settings from Debug Console.

Page 35

Debug with a

sample program

Debug by virtual

external input

Debug by I/O

break settings

Other debug

functions

(1) Click “Register

Word Condition”.

(2) Set “D” to “Type”.

(3) Set “0” to

“Address”.

(4) Set “=” to

“Operator”.

(5) Set “3” to “Value”.

(6) Press

.

(1) Click “Register Word”

(2) Set “D”

(3) Set “0”

(4) Set “=”

(5) Set “3”

(6) Press OK

Page 36

Debug with a

f

sample program

Debug by virtual

external input

Debug by I/O

break settings

Other debug

functions

Check the formula

registered in the list

(Activate the formula).

The setting is registered in a list (AND LIST).

Now, the program is aborted when the number of completed entries (the value of D0)

reaches to three (Hex: #0003).

Setting IO Break Condition makes it possible to abort the execution of a program when

a certain address value becomes a specified value.

It enables you to check the IO memory status when the conditions are satisfied.

Using this function together with the Watch Window or PLC Memory function o

CX-Programmer allows you to check all IO memory statuses with the program

Page 37

Debug with a

sample program

Debug by virtual

external input

Debug by I/O

break settings

Other debug

functions

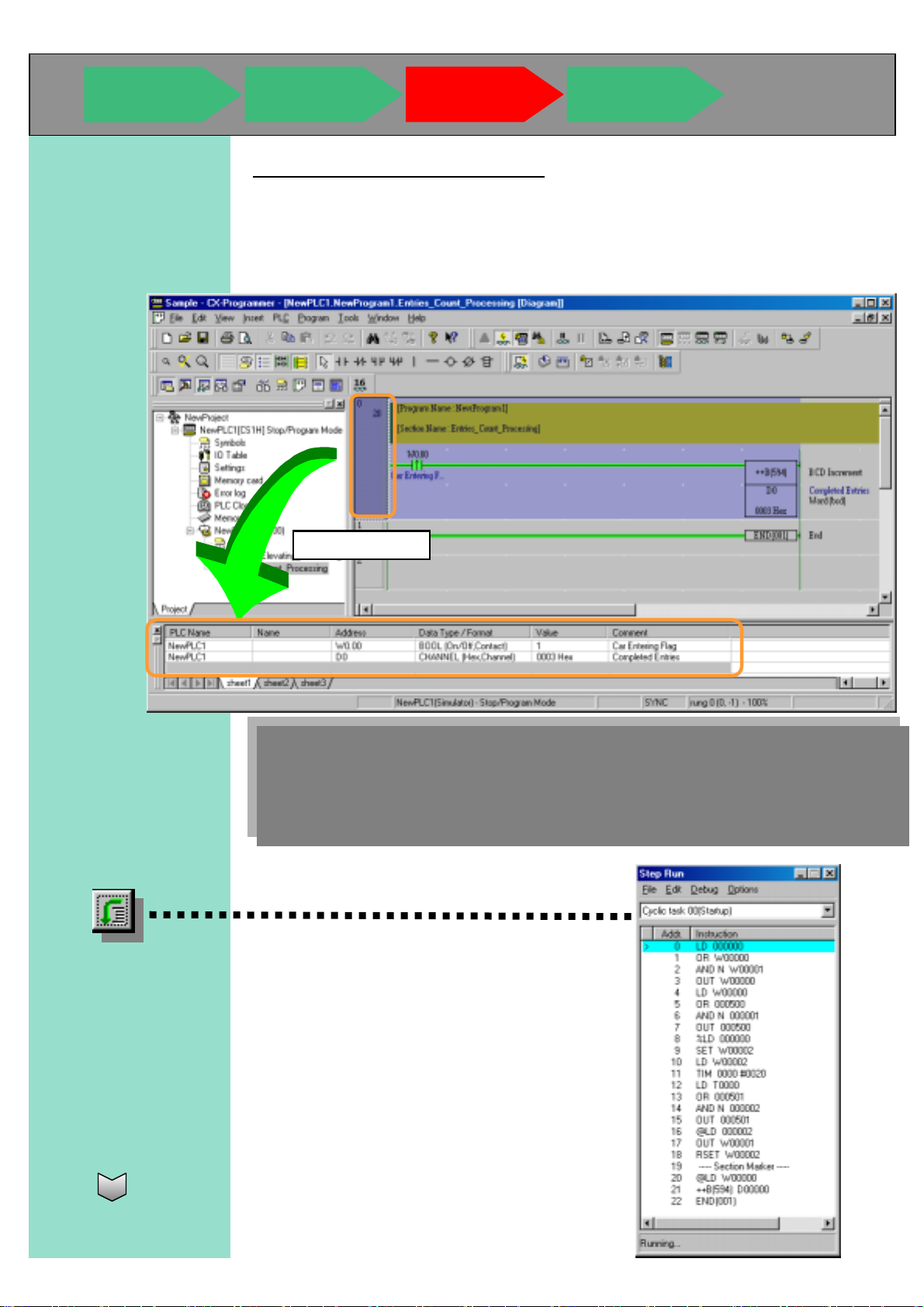

4-3-3 Example of Program Debug Operation by Using IO Break Condition

Double-click the sample program “Entries Count Process“ and start monitoring in

advance.

To display Watch

Window, press

and

3

together.

Alt

Simulate car arrival and passing by using the Set On/Off functions of CX-Programmer.

Here, use Watch Window (IO Monitor function).

Display Watch Window in advance.

Run the virtual PLC in advance.

Page 38

Debug with a

r

A

sample program

Debug by virtual

external input

Debug by I/O

break settings

Other debug

functions

Register Addresses in Watch Window

Since the number of car entries is counted in the entry count (D0) by rise of the car

entering flag (W0.00) in this sample program, enter these two addresses in Watch

Window.

To register addresses, use Drag & Drop function from Ladder Window.

Click the icon in

Debug Console.

Drag & Drop

It is possible to register addresses to be monitored in Watch Window easily by Drag &

Drop operation from Ladder Window. Not only the registration per r ung but also pe

contact, coil, and advanced instruction is enabled by the same operation.

lso, Set On/Off and Change Value operations ar e enabled to the registered addresses

easily.

Display the view of Step Run in advance.

(The status is currently displayed as “Running”.)

Page 39

Debug with a

sample program

Debug by virtual

external input

Debug by I/O

break settings

Other debug

functions

Double-click D0 on

Watch Window.

(Or, select D0 and

press the Return key.)

Enter “0” in “Value”,

and press the Return

key.

First, initialize the value of the number of completed entries (D0) (change the value to 0).

The value of D0 is

changed to “0000

Hex”.

Page 40

Debug with a

sample program

Debug by virtual

external input

Debug by I/O

break settings

Other debug

functions

Double-click W0.00 on

Watch Window.

Enter “1” (Set) in

“Value” and press the

Return key.

The number of

completed entries

(D0) is incremented

to “0001 Hex”.

Double-click W0.00 in

Watch Window.

Enter “0” (Set Off) and

press the Return key.

Pause by IO Break (Pseudo Input of Car Arrival/Car Passing)

Set W0.00 on for simulating the car arrival operation.

Set W0.00 off for simulating the car passing operation.

Repeat until the value

of D0 turns “0003”.

When the number of completed entries (D0) turns “0003”, the message shown bottom of

the Step Rung view is changed to “Pause by IO break”, and the program execution is

aborted.

Page 41

Debug with a

p

sample program

Debug by virtual

external input

4-4 Other Debug Functions

Debug by I/O

break settings

Other debug

functions

Scan run

Running Program in the Unit of Step and Scan, Break Point Setting

If “Step run” is used, for instance, it is possible to

inspect a sequence calling subroutine processing or

check the values in progress from FOR to NEXT

(Fig 1).

Also, when a break point is specified and “Scan run”

is executed, it is possible to execute the program

until the break point and then abort it. It enables

you to restart the program execution from any line

(Fig 2).

Step run: Executes a program per instruction.

Continuous step run: Executes instructions one by one

automatically.

Pause: Aborts continuous step running temporarily.

Scan run: Executes one scan and then aborts.

Continuous scan run: Repeats the operation of one scan.

Continuous scan run

Show Ste

Continuous step run

Step run

Pause

run

Fig 1. Debug example by step running Fig 2. Debug example of break point

Break point

Page 42

Chhaapptteerr 55

C

SSttaarrttuupp ffrroom

m

CXX--SSii

C

muullaattoorr

m

Meennuu

M

This chapter explains how to start and end CX-Simulator and how to set CX-Simulator for creating

a virtual PLC in your PC.

Creating a virtual PLC from the CX-Simulator menu enables you to use the following functions.

See the operation manual of CX-Simulator for the detailed operations.

- Serial communications for connecting with PT

- Network communications by network communications instructions

- Measurement of I/O refresh time with an I/O unit registered

- Display of message instructions or network communications instructions on your PC screen

- Record of the communications log of FINS Commands sent/received by a virtual PLC

Page 43

Starting

r

r

CX-Simulato

Creating a

virtual PLC

3-1 Starting CX-Simulator

Saving/ending

CX-Simulato

[Start]

↓

[Programs]

↓

[Omron]

↓

[CX-Simulator]

↓

[CX-Simulator]

Or double-click the

CX-Simulator icon.

Start up CX-Simulator from Windows.

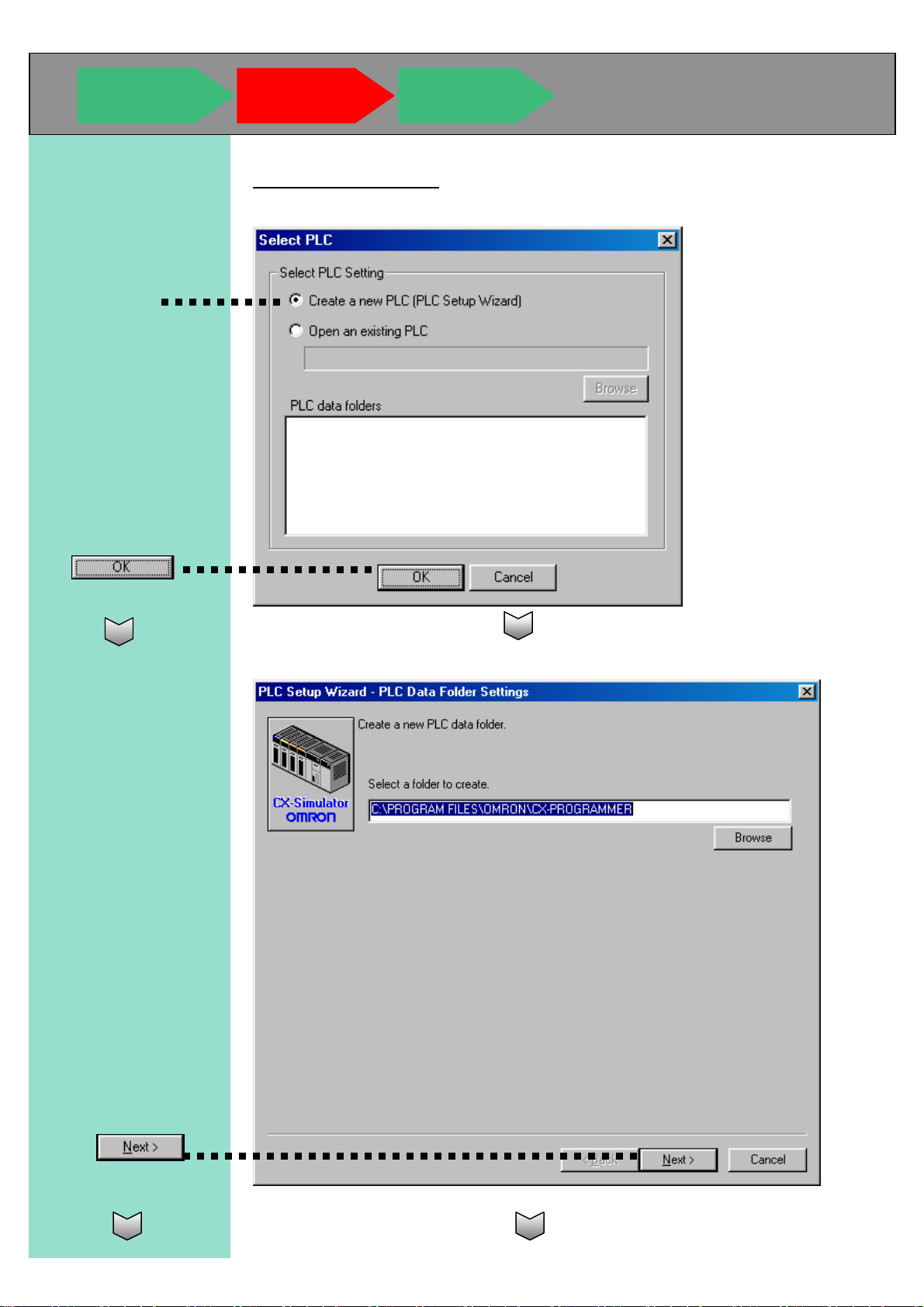

The [Select PLC] and [CX-Simulator Debug Console] screens show up.

Page 44

Starting

r

r

CX-Simulato

Check [Create a new

PLC].

Creating a

virtual PLC

Saving/ending

CX-Simulato

5-2 Creating Virtual PLC

Create a virtual PLC according to the contents of the [Select PLC] screen.

Select a directory to

create data.

Select a directory to save data. Use the default directory this time.

Page 45

Starting

r

r

CX-Simulato

Creating a

virtual PLC

Saving/ending

CX-Simulato

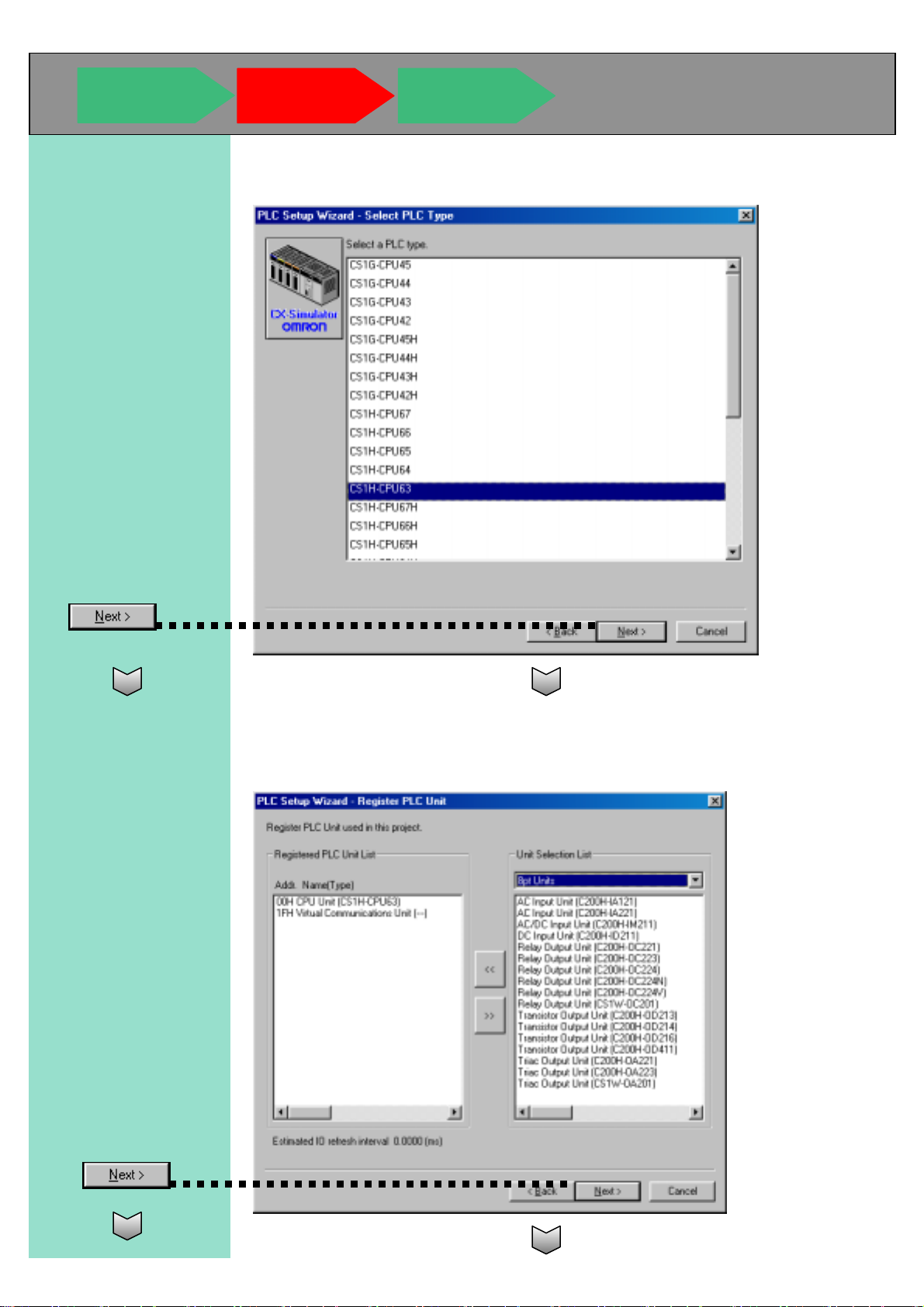

Select a PLC type.

Select a CPU unit type. Select “CS1H-CPU63” this time.

Register PLC Unit.

You can register IO Units and Special IO Units. Register the units to be used in the

actual case, and you’ll improve the accuracy of the advance verification of cycle time.

Do not register any unit in this example.

Page 46

Starting

r

r

CX-Simulato

Creating a

virtual PLC

Saving/ending

CX-Simulato

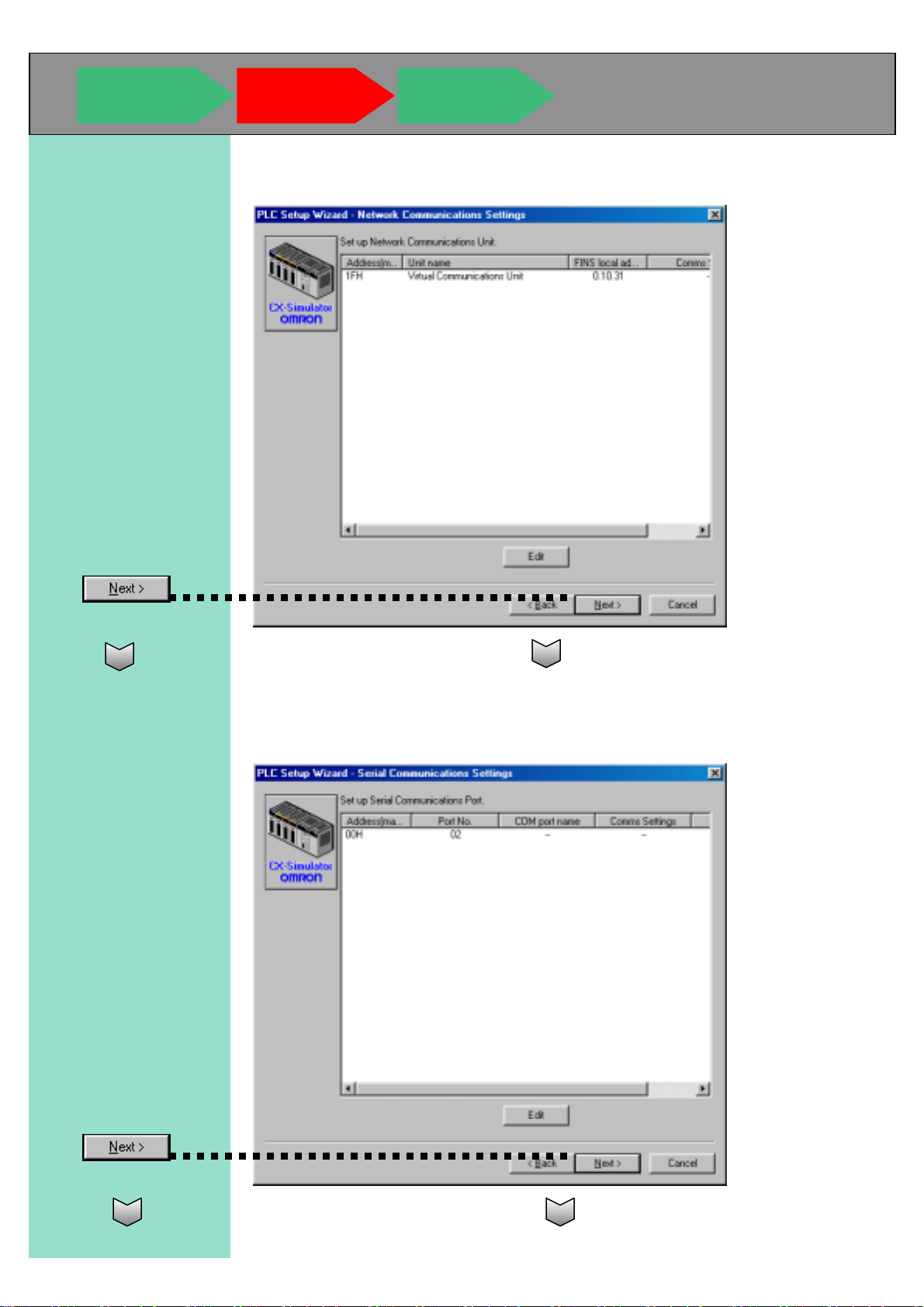

Set network

communications.

Network settings for connecting to a virtual PLC. Normally, do not change.

Set serial

communications.

Regarding the serial port of you PC as the built-in serial port of CPU Unit, you can

connect with external equipment such as Programmable Terminal. Do not set anything

this time.

Page 47

Starting

r

r

CX-Simulato

Contents List

Creating a

virtual PLC

Saving/ending

CX-Simulato

Page 48

Starting

r

r

CX-Simulato

Creating a

virtual PLC

Saving/ending

CX-Simulato

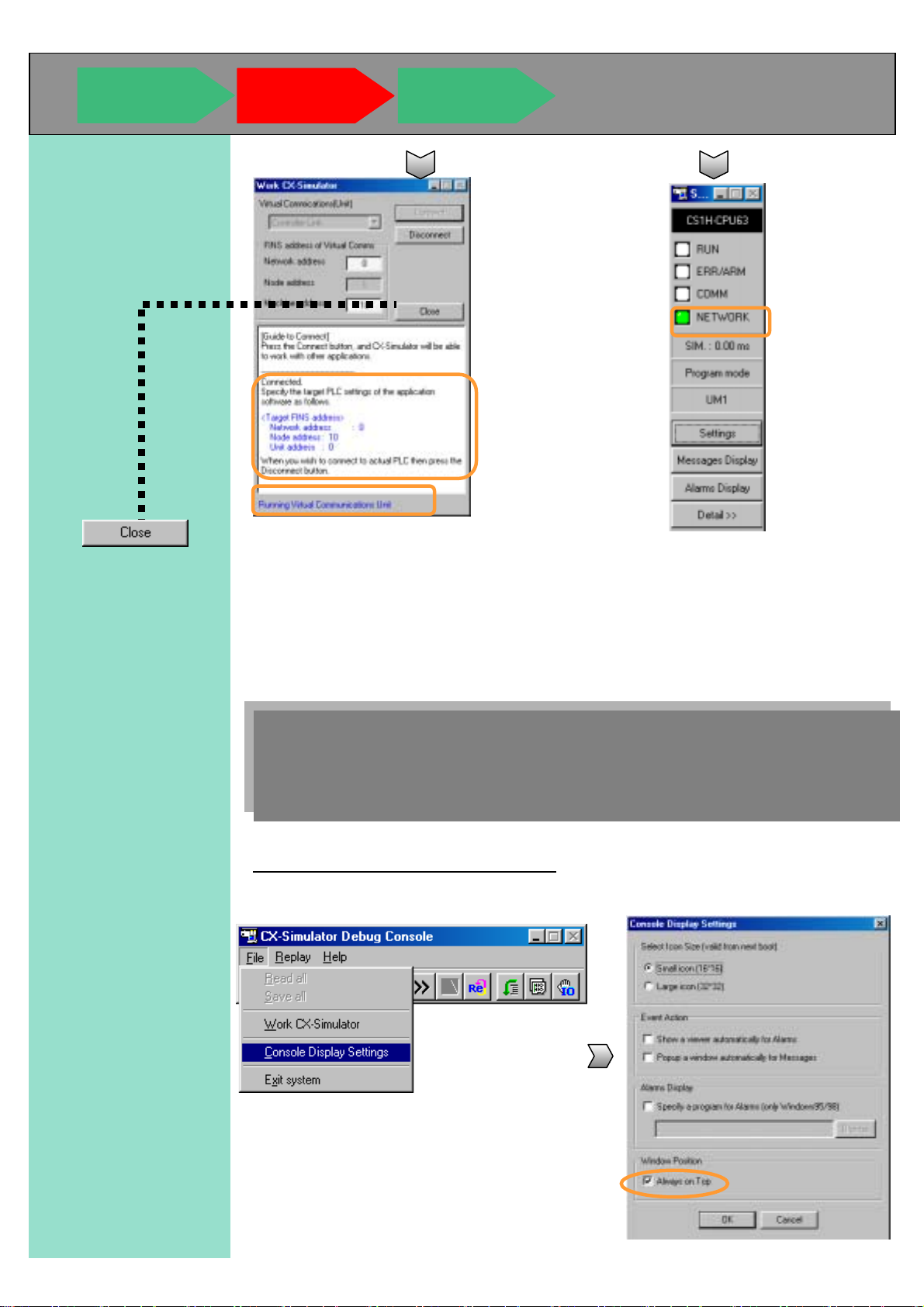

After checking that a virtual PLC is created, you can close the window.

It is the end of creating a virtual PLC.

Now the virtual PLC CS1H-CPU63 exists in your PC.

After a virtual PLC is created, [NETWORK] in [Status Settings] (above right) starts

blinking.

The virtual PLC is created in your PC with the network address 1 and the node address

10. You can connect CX-Programmer and the virtual PLC by the exactly same

procedure as the actual PLC. To connect to the virtual PLC from CX-Programmer, set

the above addresses to the destination PLC.

CX-Simulator Console Display Settings

You can set display settings. Check [Always on Top] for your convenience.

Page 49

Starting

r

r

CX-Simulato

Creating a

virtual PLC

Saving/ending

CX-Simulato

Select [File] | [Work

CX-Simulator] on

the [Debug Console]

screen.

5-3 Saving/Ending CX-Simulator

Take the following procedure to save the data of a set virtual PLC and to end

CX-Simulator.

Loading...

Loading...