Page 1

INTRODUCTION GUIDE

CX-Process Tool

Cat. No. R143-E1-01

Page 2

The CX-Process Tool Operation Manual is included as a PDF file

on the CX-One CD-ROM under OMRON/CX-One/CX-Process

Tool. Be sure to read the Precautions and other information at the

beginning of the manual before using the CX-Process Tool.

This CX-Process Tool Introduction Guide describes basic

operating procedures for the CX-Process Tool. For application

precautions and detailed descriptions, refer to the Help or the PDF

Operation Manual.

Note: Acrobat Reader 4.0 or higher is required to display the PDF file.

Page 3

The CX-Process Tool

A Loop Controller is a Controller that has the functionality of multiple high-

performance Controllers. Combining function blocks that form functional

components enables programming control without restrictions for analog values,

such as temperatures, pressures, and flowrates.

Programming with the CX-Process Tool enables graphical engineering to paste

function blocks and connect lines with the mouse. The system also has the

following features compared with single-loop controllers and dedicated temperature

controllers.

1. The system is based on PLCs, so a wide variety of PLC Units, such as Process

I/O Units, Analog I/O Units, and Communications Units, can be used.

2. Data can be exchanged with the ladder-programmed CPU Unit at a high speed

without any programming, so loop control programming can be coordinated with

sequence control.

3. Changes, such as increasing or decreasing the number of loops and changing

the control methods, can also be flexibly performed by combining function

blocks.

A simple example of programming for one-loop temperature control will be

presented as a sample in this Introduction Guide. Function blocks can also be

combined for multi-loop control, cascade control, heating/cooling control, and

program control.

Page 4

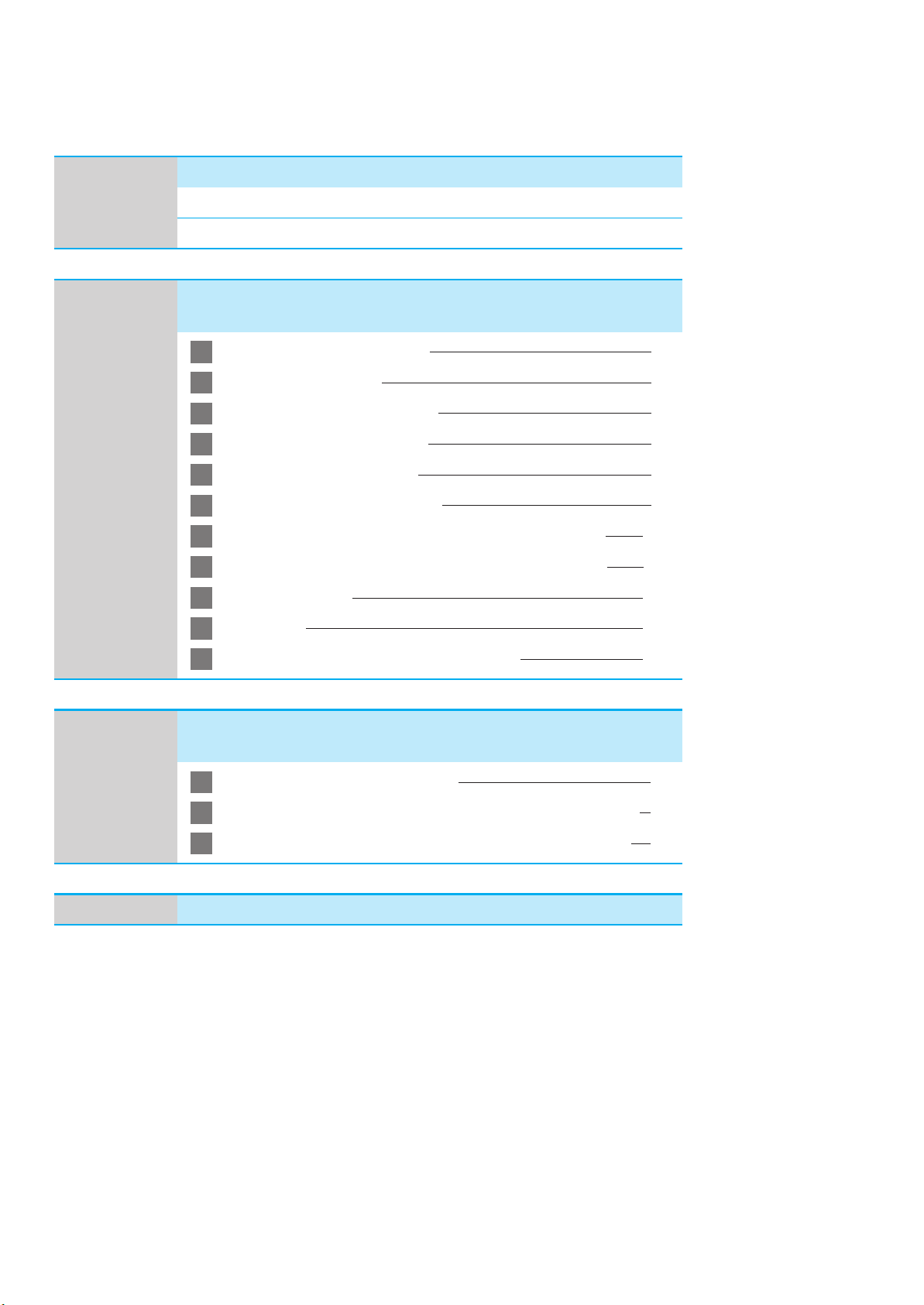

CONTENTS

Overview

SECTION 1

Example System

System Configuration

Creating Function Block Data

Creating Simple Function Block Data

for the Loop Controller

Starting the CX-Process Tool 1-2

1

Making a New Project

2

Registering the Loop Controller

3

Creating Function Block Data

4

Connecting Function Blocks

5

Set ITEMs for Function Blocks

6

Communications Settings between Computer and PLC

7

Transferring Function Block Data to the Loop Controller

8

Starting Operation

9

1-1

1-2

1-4

1-5

1-8

1-9

1-12

1-14

1-15

SECTION 2

Appendix

PID Tuning

10

Uploading and Saving Function Block Data

11

Making the NS-series PT Screen

for the Loop Controller

Setting the CSV Tags in Advance

1

Automatically Creating the NS-series PT Screen for the Loop Controller

2

Displaying the NS-series PT Screen for the Loop Controller

3

Useful Functions

1-16

1-19

2-1

2-2

2-2

2-6

Page 5

Overview

Example

System

Page 6

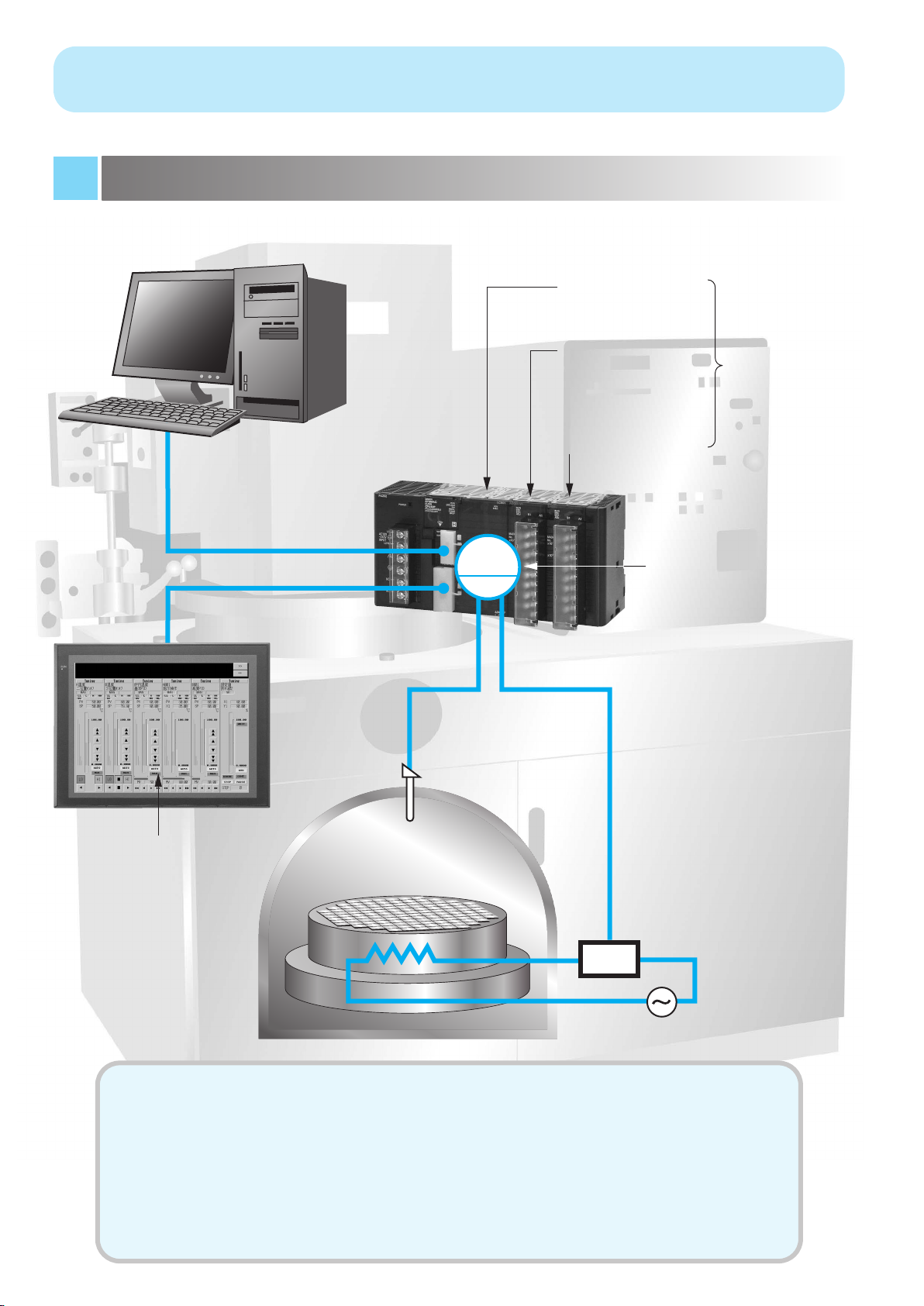

This section provides an explanation of basic CX-Process Tool operation

using the following simple system as an example.

System Configuration

CX-Process Tool

(Support Software)

CJ-series Loop-control

CPU Unit

CJ1G-CPU45P

Isolated-type Thermocouple Input Unit

CJ1W-PTS51

Analog Output Unit

CJ1W-DA041

Cable (2 m) for

Peripheral Bus (Toolbus)

CS1W-CN226

Note: The Loop

Controller itself does not

have analog

I/O. Therefore,

PLC CPU Bus

Units must be

used.

NS-series PT

(Touch Panel)

NS12

Screen for Loop Controller

RS-232C Cable

XW2Z-200T (2 m)

Temperature sensor

Type K thermocouple

PID

Input 1 Output 1

4 to 20 mA

Refer to Creating Function

Block Data on the

following page.

Thyristor Unit

(Power Controller)

G3PX

SCR

● This system controls one loop.

- A type K thermocouple is used for the temperature sensor input.

- The temperature range is 0.0 to 500.0°C.

-

The output is 4 to 20 mA and heater control is performed using a Thyristor Unit (Power Controller).

- Continuous proportional PID is set.

Note: The default operation cycle (1 s) is used.

●

The screen for the Loop Controller is displayed by connecting a NS-series PT (Touch Panel).

Page 7

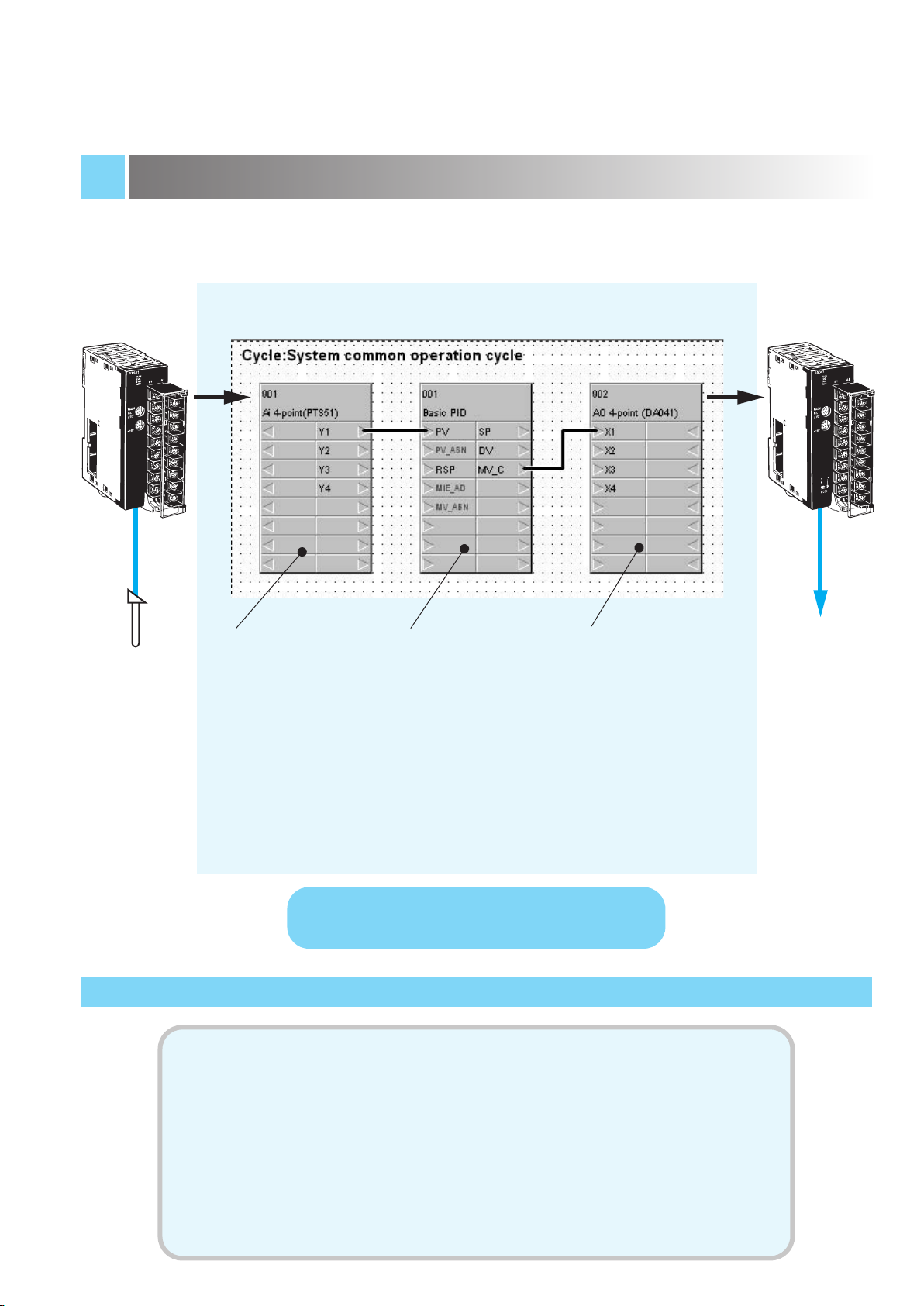

Creating Function Block Data

Thermocouple

Input Unit

CJ1W-PTS51

Type K

thermocouple

Function Block Data

Field Terminal Block for

Analog Input (Isolated

Ai 4-point Terminal

(PTS51)) (Block Model

566)

Inputs the analog signal

from the CJ1W-PTS51.

Control Block for PID

Control (Basic PID)

(Block Model 011)

Performs PID

calculations.

Field Terminal Block for

Analog Output (Ao 4point Terminal (DA041)

(Block Model 587)

Outputs the analog

signal from the CJ1WDA041.

Analog Output Unit

CJ1W-DA041

4 to 20 mA

Loop Controller

(in CJ-series CJ1G-CPU45P Loop-control CPU Unit)

To simplify descriptions, operations for startup settings at the PLC

(such as creating I/O tables (see note) and setting DM Area words

allocated to Analog I/O Units) is not included in the following

description of operations for the CX-Process Tool. Be sure to

separately make the settings using the CX-Programmer.

Note: With CJ-series Loop-control CPU Units, I/O tables can be automatically generated

based on the mounted Units when the power supply is turned ON without

performing the operation to create I/O tables. (With CS-series CPU Units, an

operation must be performed to create the I/O tables.)

Page 8

Page 9

Creating Simple

Function Block Data

for the Loop

Controller

This section presents the flow of operations for

starting the CX-Process Tool (Support

Software), inputting the thermocouple, creating

function block data for one PID loop with an

output of 4 to 20 mA, downloading the data to

the Loop Controller, tuning PID control, and

saving files.

1-1

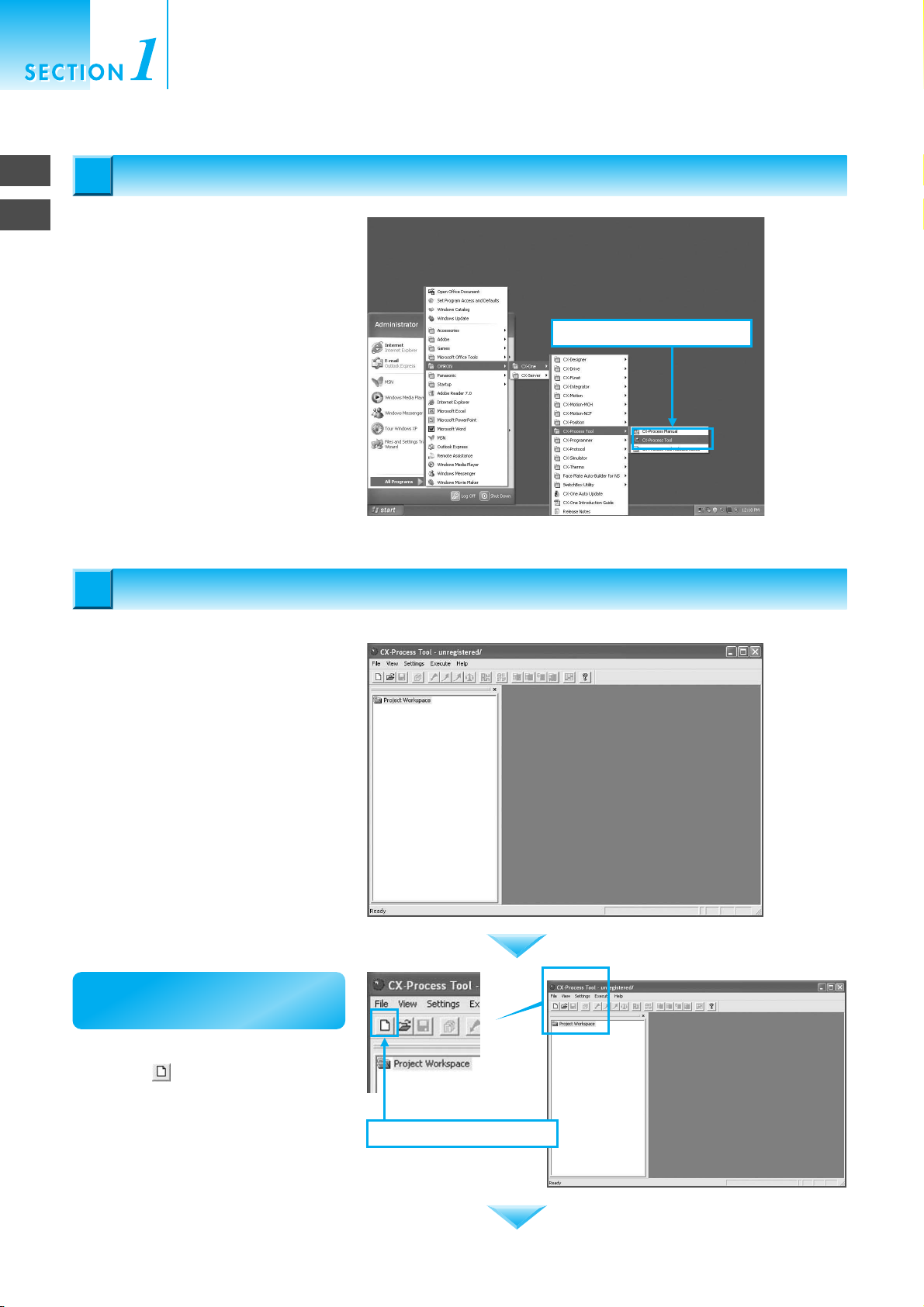

Page 10

Creating Simple Function Block Data for

the Loop Controller

1

2

Starting the CX-Process Tool/Making a New Project

Starting the CX-Process Tool

Starting the CX-Process Tool

1

1

From the Start Menu, select All

Programs - OMRON - CX-One - CXProcess Tool - CX-Process Tool to

start the CX-Process Tool.

Making a New Project

Making a New Project

2

2

1. Select CX-Process Tool.

The window at the right will open when

the CX-Process Tool starts.

First, make a project.

Click the Make a New Function Block

File Button to make a new project.

1-2

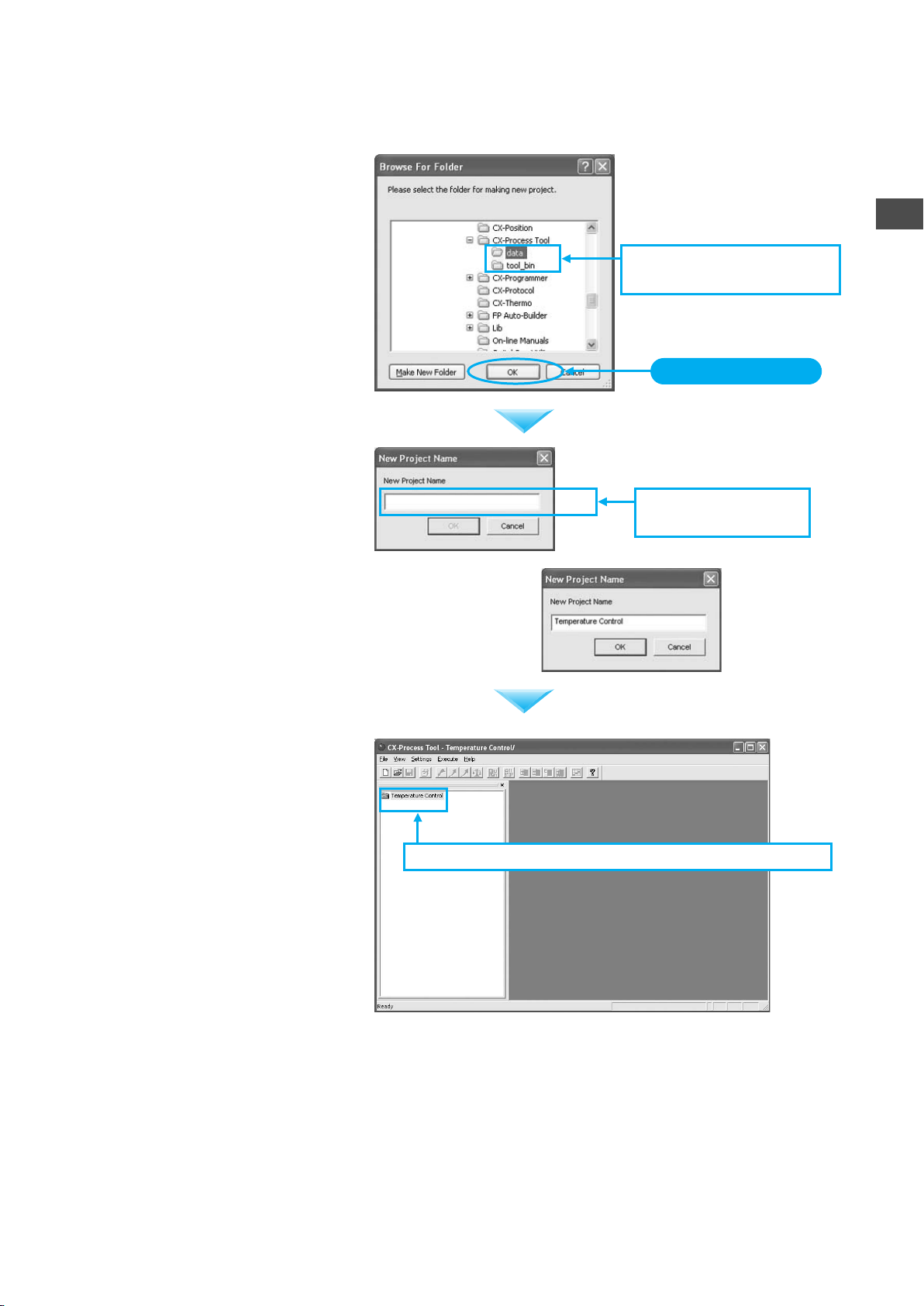

2-1. Make a new project.

Page 11

Select a folder in which to save the

data, and then click the OK Button.

The window at the right will open when

the OK Button is pressed. Enter the

project name.

● For example, enter

"Temperature

Control."

2-2. Select the folder in which

to save the data.

Click the OK Button.

2-3. Enter the project

name.

2

Making a New Project

The folder in which the project name

was entered (called the project folder)

will be created in the window on the left

(called the project workspace).

2-4. A project folder called "Temperature Control" is created.

1-3

Page 12

Registering the Loop Controller

Registering the Loop Controller

3

3

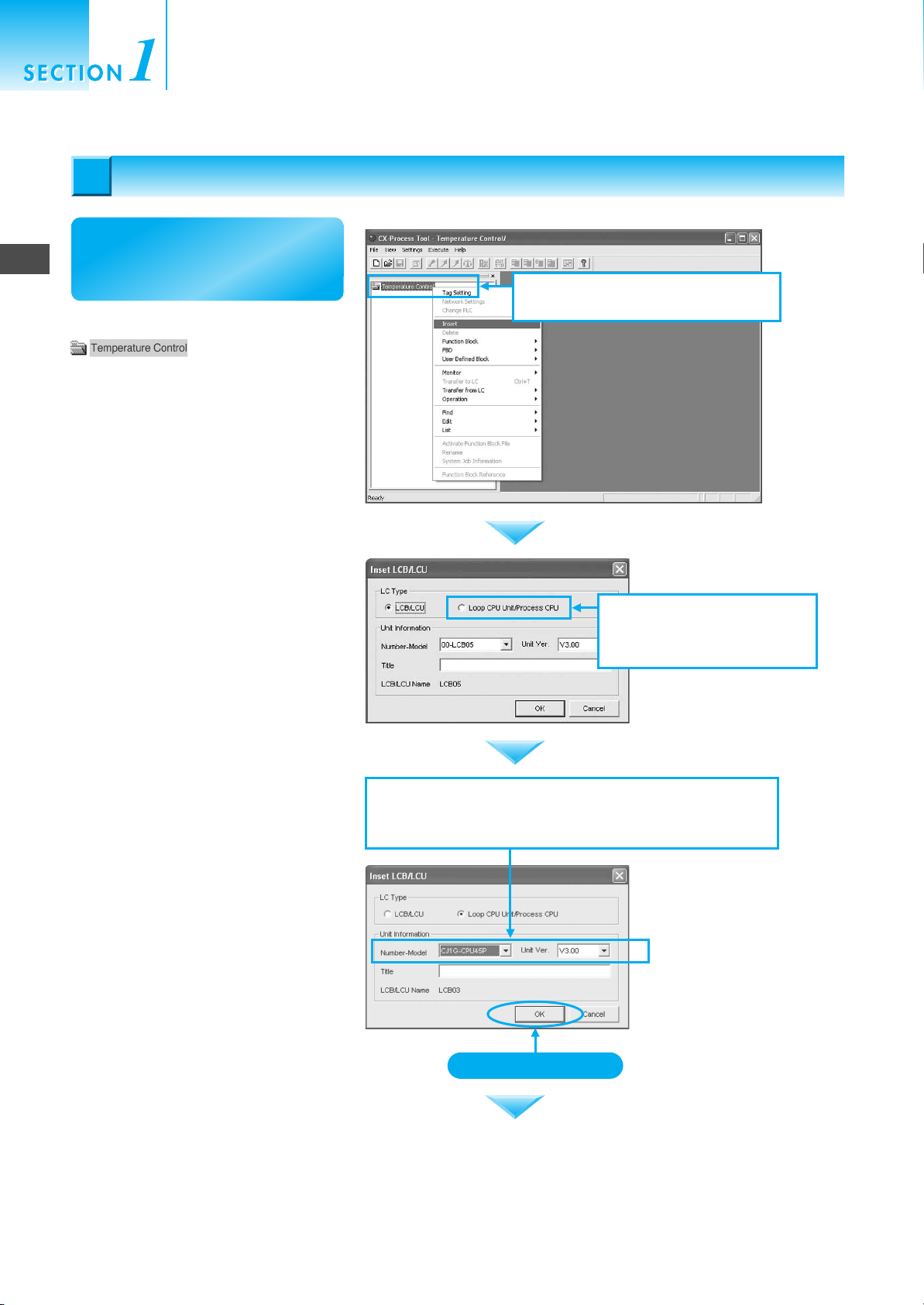

Next, register the Loop

3

Registering the Loop Controller

Controller to be used.

Right-click the Project Folder

Creating Simple Function Block Data for

the Loop Controller

3-1. Right-click the Temperature

Control Folder and select Insert.

and select Insert.

A dialog box for selecting the Loop

Controller will open.

The Loop Controller to be used is a

CJ-series Loop-control CPU Unit.

Therefore, first select Loop CPU

Unit/Process Unit for the LC type.

Next, select the model number and

LCB Unit version. The model number

is the CJ1G-CPU45P and the version

is 3.0.

3-2. Select the Loop CPU

Unit/Process CPU Option

for the LC type.

3-3. Select the model number and the LCB Unit version

in the Unit Information Field. Select CJ1G-CPU45P

for the model number and 3.0 for the version.

1-4

Click the OK Button.

Page 13

A node function block file labeled

will be added

under the Temperature Control

Project Folder .

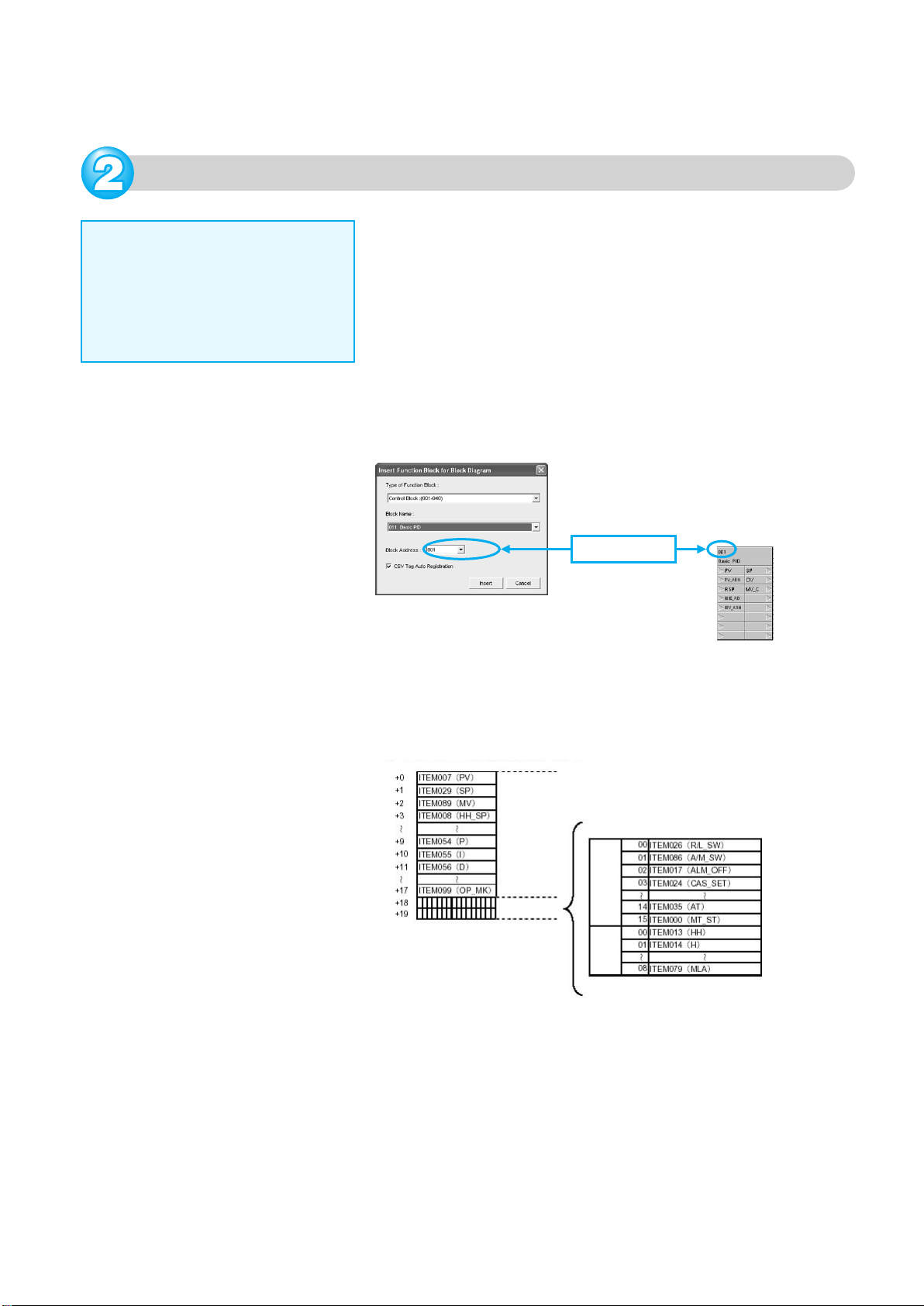

Creating Function Block Data

Creating Function Block Data

4

4

Next, actually create

simple function block data.

3-4. A node function block file will be added

under the Temperature Control Folder.

3

4

Creating Function Block Data

Click the plus sign (+) to the left of the

node function

block file, and then click the plus sign

on the LCU/LCB element folder

underneath it. The tree structure will be

opened.

The window shown on the right will

open when the 04. Block Diagram 1

Folder in the tree is double-clicked.

Paste the following three items into the

Function Block Diagram Window at the

right.

• Function block for analog input:

Isolated Ai 4-point Terminal (PTS51)

• Function block for PID: Basic PID

• Function block for analog output:

Isolated Ao 4-point Terminal (DA041)

4-1. Click the plus signs (+) to

display the tree structure.

4-2. Double-click the 04. Block

Diagram 1 Folder.

Seven folders will be

displayed under the Loop

Controller LCB03 V3.0

Folder: System, Field

Terminal, Sequence

Control, Block Diagram 1,

Block Diagram 2, and

Block Diagram 3.

Maximize

Function block diagrams

can be drawn at this point,

but to increase the area,

click the middle of the

three buttons. The window

will be maximized.

1-5

Page 14

Creating Simple Function Block Data for

the Loop Controller

4

Creating Function Block Data

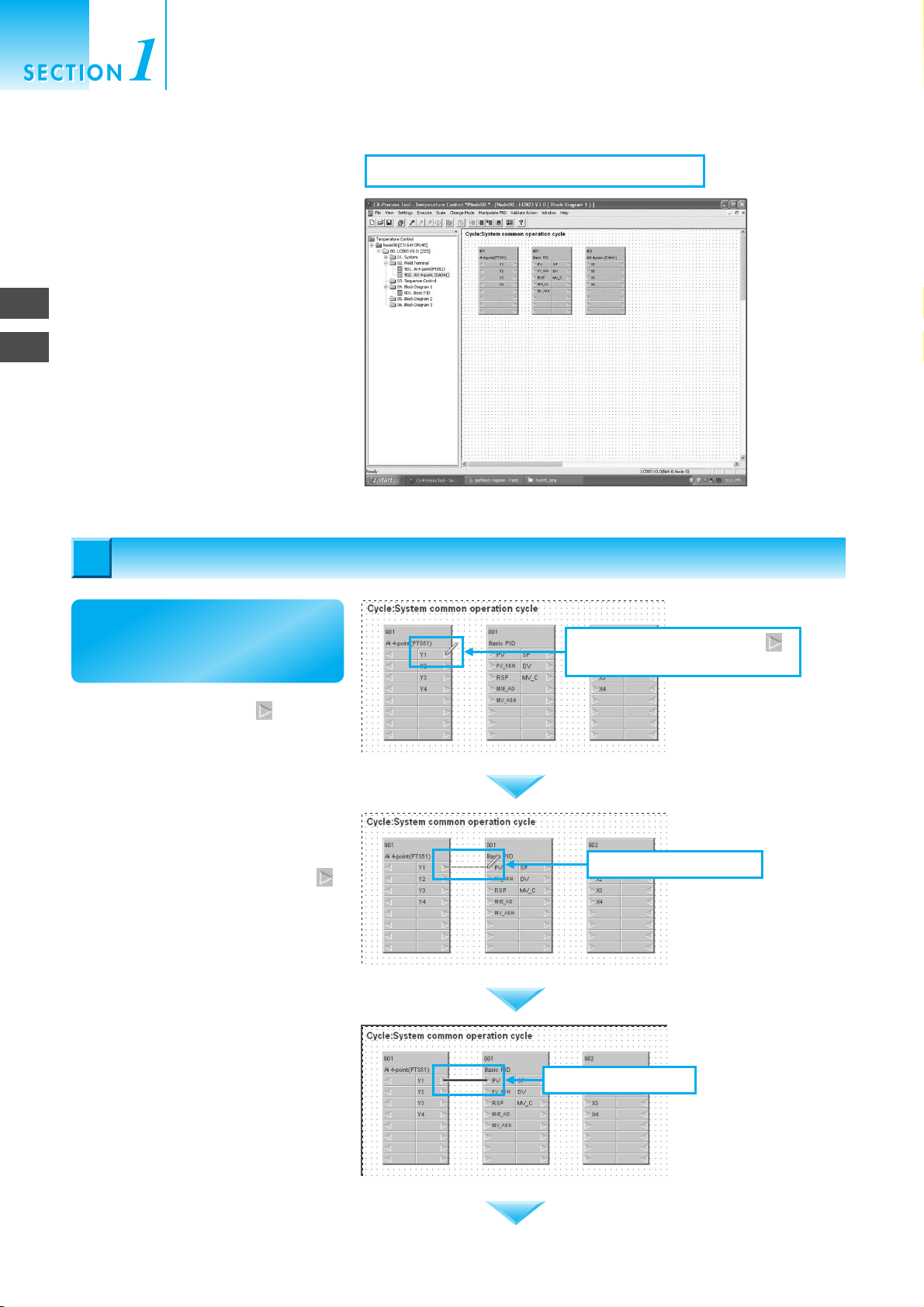

First, paste the function block Isolated

Ai 4-point Terminal (PTS51) for

analog input. Right-click in the window

at the right. The pop-up menu shown

in the figure at the right will be

displayed. Select Register - Field

Terminal from the menu.

The dialog box shown at the right will

be displayed. Press the Insert Button.

4-3. Paste the function blocks. First, register

the Isolated Ai 4-point Terminal.

4-3-1. Right-click and selected Register -

Field Terminal.

4-3-2. Select 566 Ai 4-point

(PTS51).

A window for the Isolated Ai 4-point

Terminal (PTS51) Block will appear.

Click the Insert Button.

4-3-3. The Isolated Ai 4-point

Terminal Block will appear.

1-6

Page 15

The function block can be moved

without restriction by dragging it with

the mouse.

4-3-4. Move the function block

to the desired location.

4

Creating Function Block Data

Next, paste the Basic PID Block. Just

as in the previous procedure, rightclick and select Register - Control

Block.

A window for selecting the function

block will open. Click the Down-

Arrow .

4-4. Register the Basic PID Block.

4-4-1. Right-click and select

Register - Control Block.

4-4-2. Select the control block.

Click.

Select Basic PID from the function

block names and click the Insert

Button.

4-4-3. Select Basic PID and

click the Insert Button.

1-7

Page 16

Creating Simple Function Block Data for

the Loop Controller

4

5

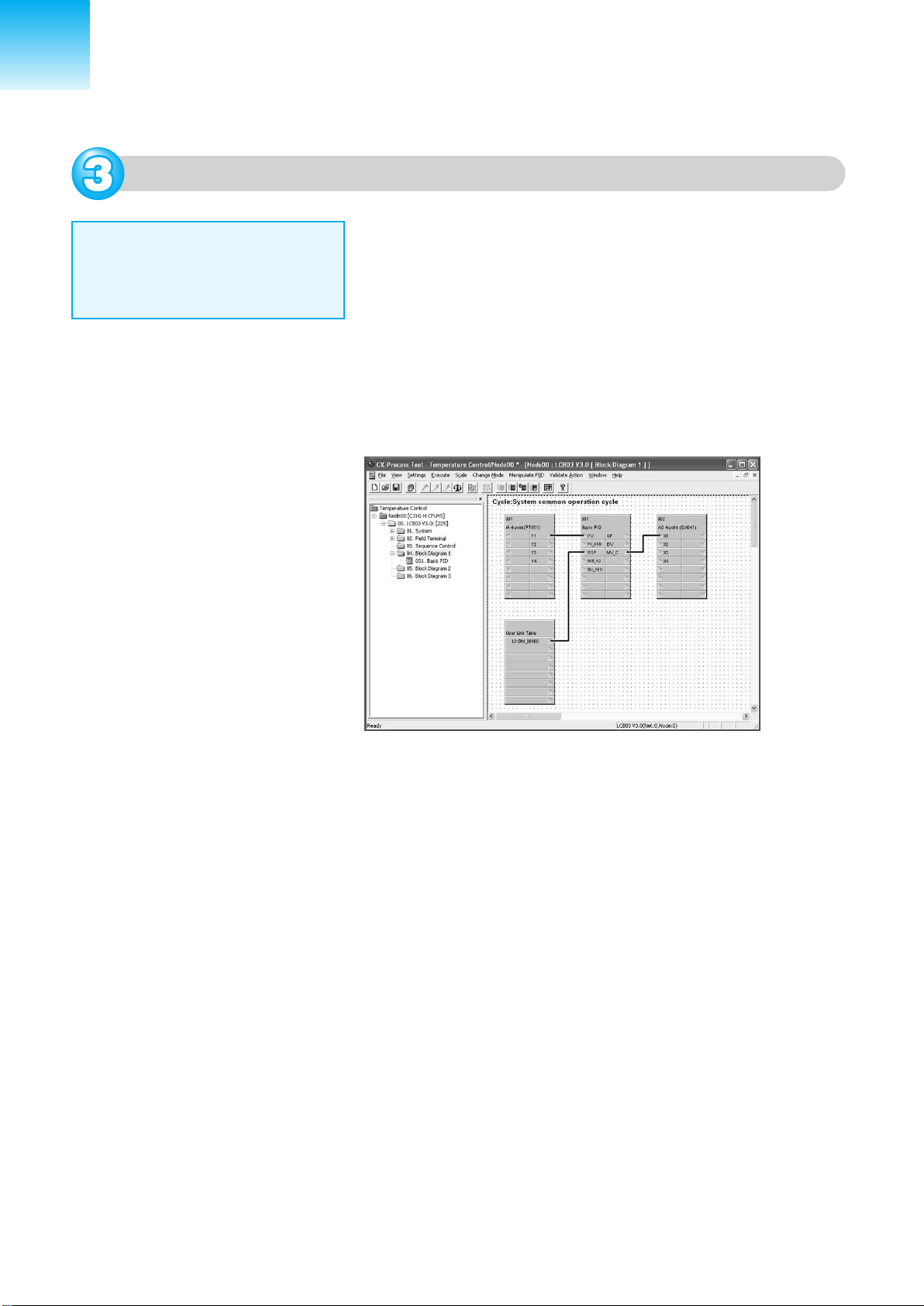

Connecting Function Blocks

Paste the function block Isolated Ao 4point Terminal (DA041) for analog

output in the same way. Right-click in

the window on the right and select

Register - Field Terminal. Set the

Field Terminal to Ao 4-point (DA041).

This completes pasting the function

blocks.

Connecting Function Blocks

Connecting Function Blocks

5

5

4-5. Register the Ao 4-point Terminal (DA041).

Next, connect the function

blocks that were pasted.

First, click the Right Arrow of the

Y1 Terminal of the Ai 4-point (PTS51)

block.

Drag the mouse to the PV Terminal

of the Basic PID Block and double-click.

5-1-1. Click the Right Arrow

of the Y Terminal.

5-1-2. Drag the mouse.

1-8

5-1-3. Double-click.

Page 17

In the same way, connect the Right

Arrow of the MV_C Terminal for

Basic PID with the Right Arrow for

the X1 Terminal of Ao 4-point (DA041).

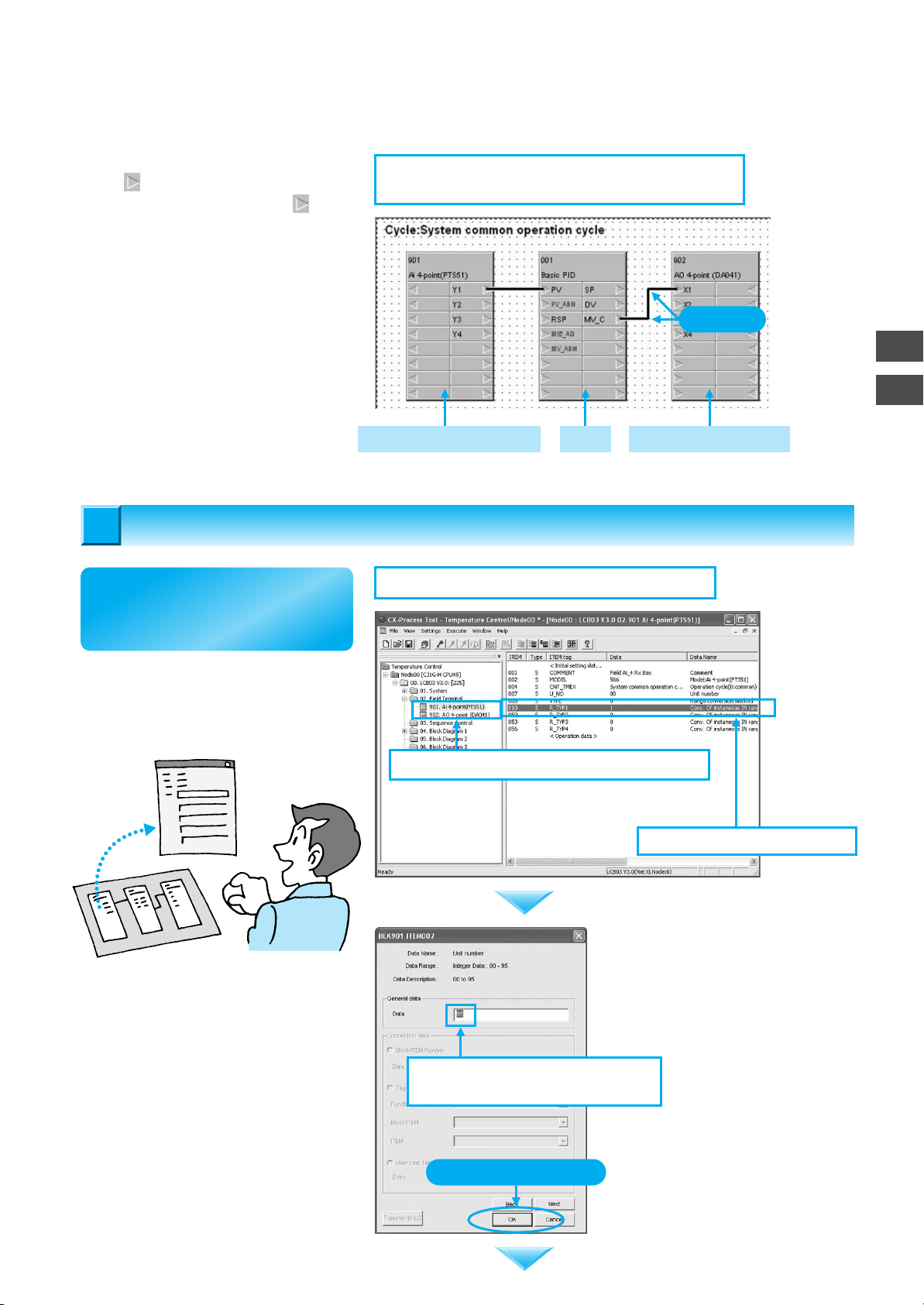

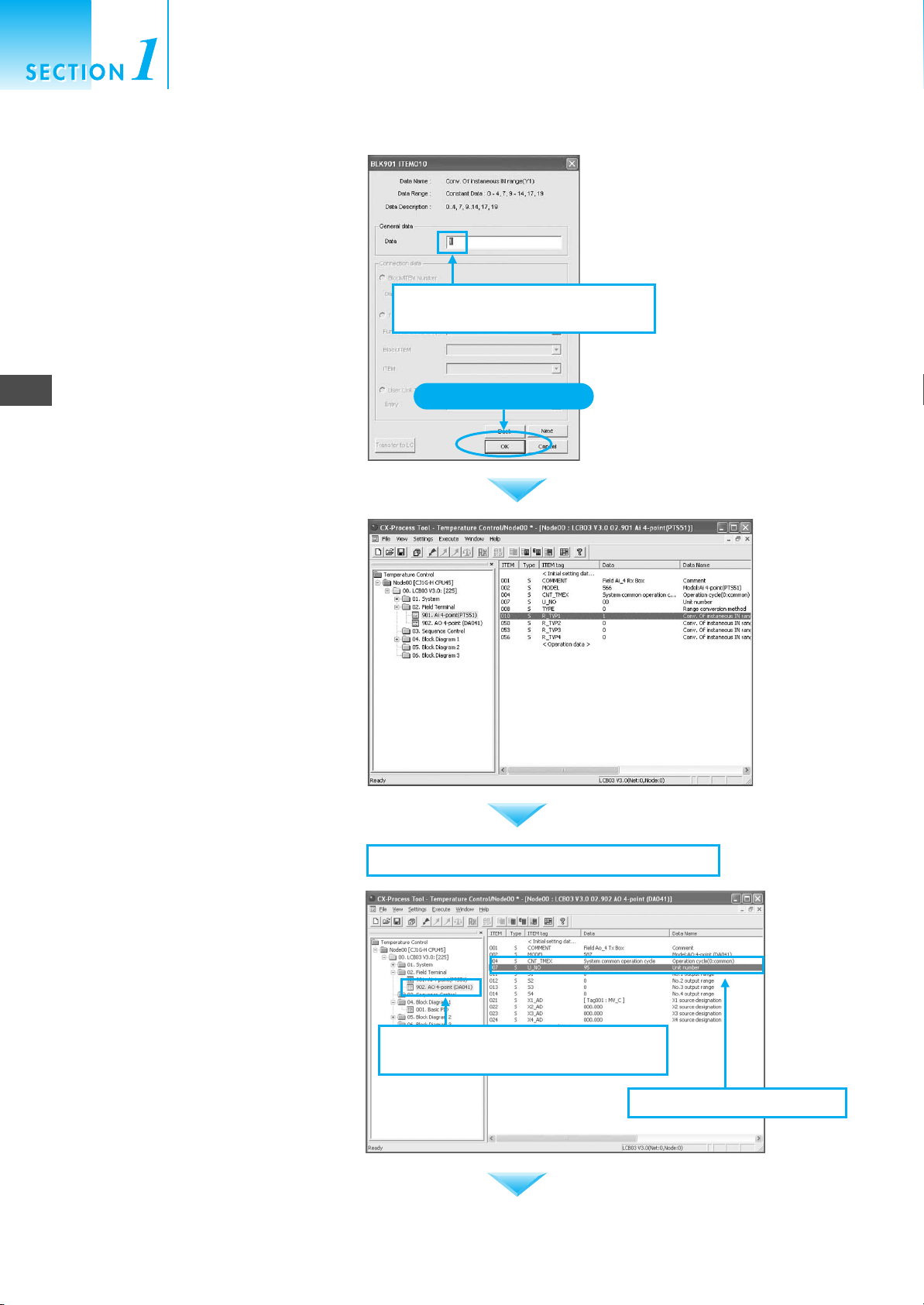

Set ITEMs for Function Blocks

Set ITEMs for Function Blocks

6

6

5-2. Connect the Basic PID block to the Ao 4-point

Terminal (DA041).

Click.

Thermocouple Input Unit PID Analog Output Unit

5

6

Set ITEMs for Function Blocks

Next, make settings so that

the pasted function blocks

can be used.

Double-click 901. Ai 4-point (PTS51)

in the tree in the window on the left.

The details of the function block will

be displayed in the window on the

right.

6-1. Setting the Function Block for Analog Input

6-1-1. Double-click 901. Ai 4-point (PTS51).

6-1-2. Double-click ITEM 007.

First, change the unit number. Doubleclick ITEM 007 in the window on the

right. The window shown at the right will

be displayed.

The unit number is currently set to "95."

Set the unit number to be used (00) and

press the OK Button.

6-1-3. Set ITEM 007 (Unit Number)

to 00.

Click the OK Button.

1-9

Page 18

Creating Simple Function Block Data for

the Loop Controller

Double-click ITEM 010 to use Input 1.

Next, because a type K thermocouple

is being used and the input range is

0.0 to 500.0°C, change Data to 1 and

click the OK Button.

Note: The input type setting (i.e., parameter) for the

CJ1W-PTS51 Isolated-type Thermocouple

Input Unit must be set to a type K

thermocouple (decimal point) = 0001 hex as

given below:

DM Area Word Allocated in the CPU Unit

6

Set ITEMs for Function Blocks

D20019 = 0001 hex

(When the unit number is 0.)

(It is not necessary to know the address if the setting

is made by editing parameters by double-clicking

CJ1W-PTS51 in the I/O tables in the CXProgrammer.)

The ITEM Setting Window will close.

Confirm that the settings have

changed.

6-1-4. Set ITEM 010 (Input Range)

to 1.

Click the OK Button.

1-10

Next, double-click 902. Ao 4-point

(DA041) in the tree in the window on

the left. Change the unit number in the

same way as above.

Double-click ITEM 007 in the window

on the right.

6-2. Setting the Function Block for Analog Output

6-2-1. Double-click 902. Ao 4-point

(DA041).

6-2-2. Double-click ITEM 007.

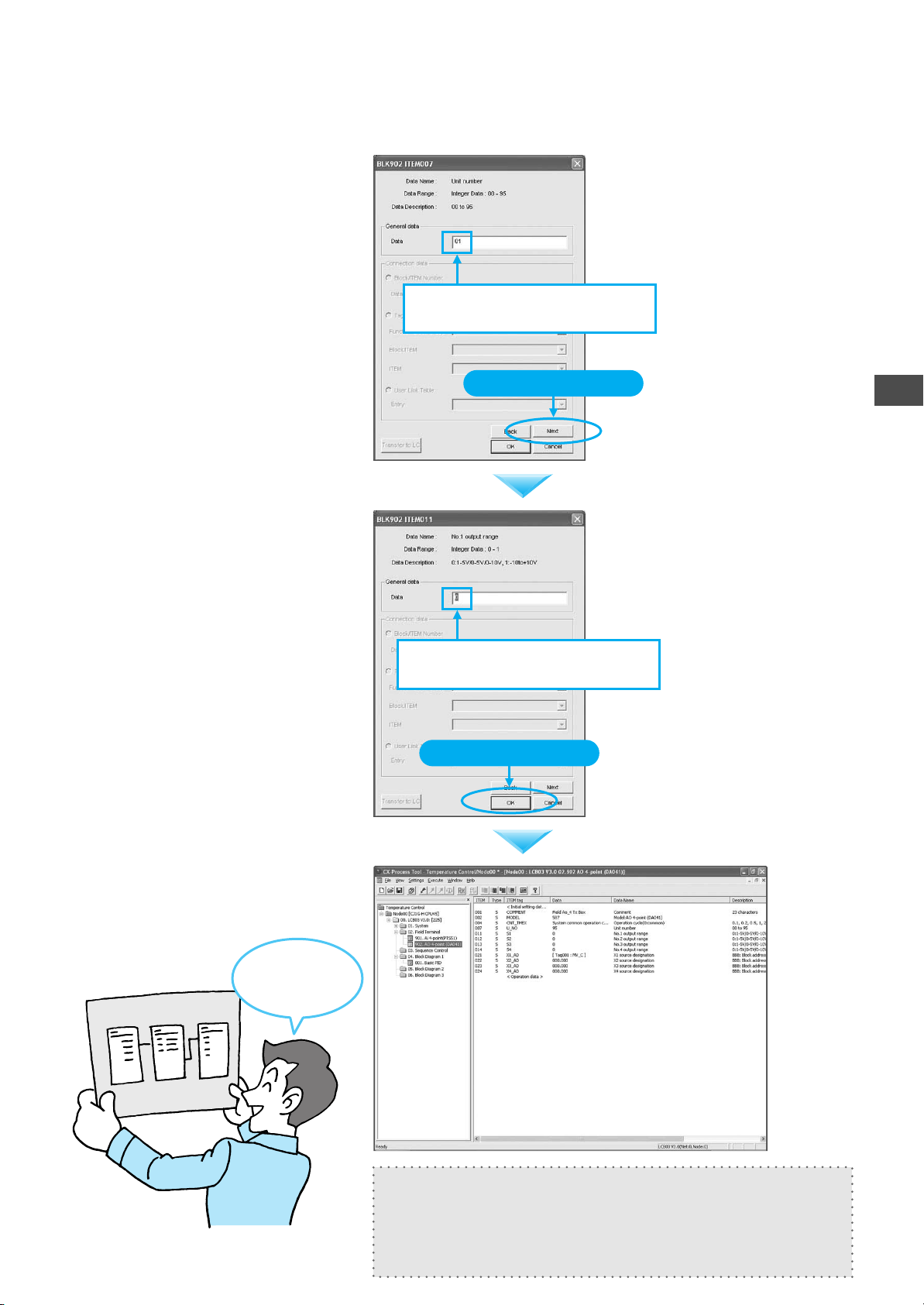

Page 19

The unit number is currently set to

"95." Set the unit number to be used

(01) and press the Next Button.

6-2-3. Set ITEM 007 (Unit Number)

to 01.

An output of 4 to 20 mA is used for the

system. To keep Output 1 the same

as the default setting of 0, simply

press the OK Button. The window will

close.

Note: Analog Output Unit

The output range setting (parameter) for the

CJ1W-DA041 must be set to 1 to 5 V/4 to

20 mA = 0002 hex as listed below:

DM Area Word Allocated in the CPU Unit

D20101 = 0002 Hex

(When the unit number is 1 and Output 1 is

used)

(It is not necessary to know the address if the setting

is made by editing parameters by double-clicking

CJ1W-DA041 in the I/O tables in the CXProgrammer.)

Click the Next Button.

6-2-4. Set ITEM 011 (Input Range)

to 0.

Click the OK Button.

6

Set ITEMs for Function Blocks

This completes pasting function

blocks, connecting function blocks,

and setting ITEMs.

I made the

function block

Thermocouple

Input Unit

PID

Analog

Output Unit

data!

In this example, the operation cycle is set to 1 s for the entire system

and the start mode is set to a hot start (i.e., operation starts with the

auto/manual status held immediately before the power supply was

turned OFF.) Therefore, System Common block is used at its default

values.

1-11

Page 20

Creating Simple Function Block Data for

the Loop Controller

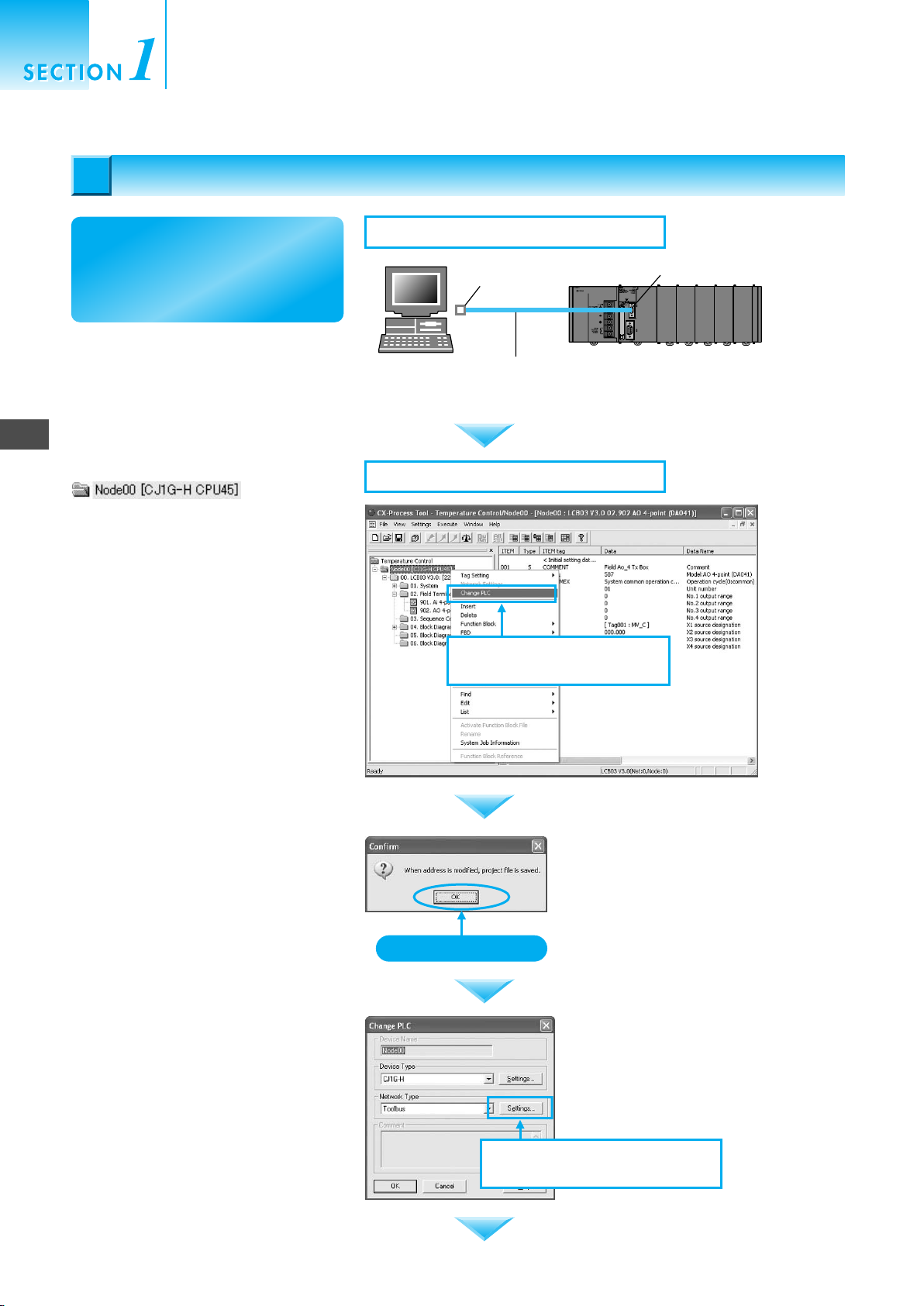

Communications Settings between Computer and PLC

Communications Settings between Computer and PLC

7

7

7

Communications Settings between Computer and PLC

Next, connect the computer and

the PLC with a cable and make

the communications settings to

enable sending the function

blocks to the Loop Controller.

Connect the computer to the PLC at

the peripheral port using a Peripheral

Port Connecting Cable.

Right-click Node00[CJ1G-H CPU45]

in the tree in

the window on the left to set the

communications port and select

Change PLC from the pop-up menu.

7-1. Connect the cable.

RS-232C

IBM PC/AT or

compatible

(9-pin RS-232C)

7-2. Setting Communications Conditions

7-2-1. Right-click and select

CS1W-CN226/626

Peripheral Port

Connecting Cable

Change PLC.

Peripheral port

1-12

A dialog box will open. Click the OK

Button.

Click the OK Button.

The Change PLC Window will open.

Click the Settings Button.

7-2-2. Click the Settings Button in

the Change PLC Window.

Page 21

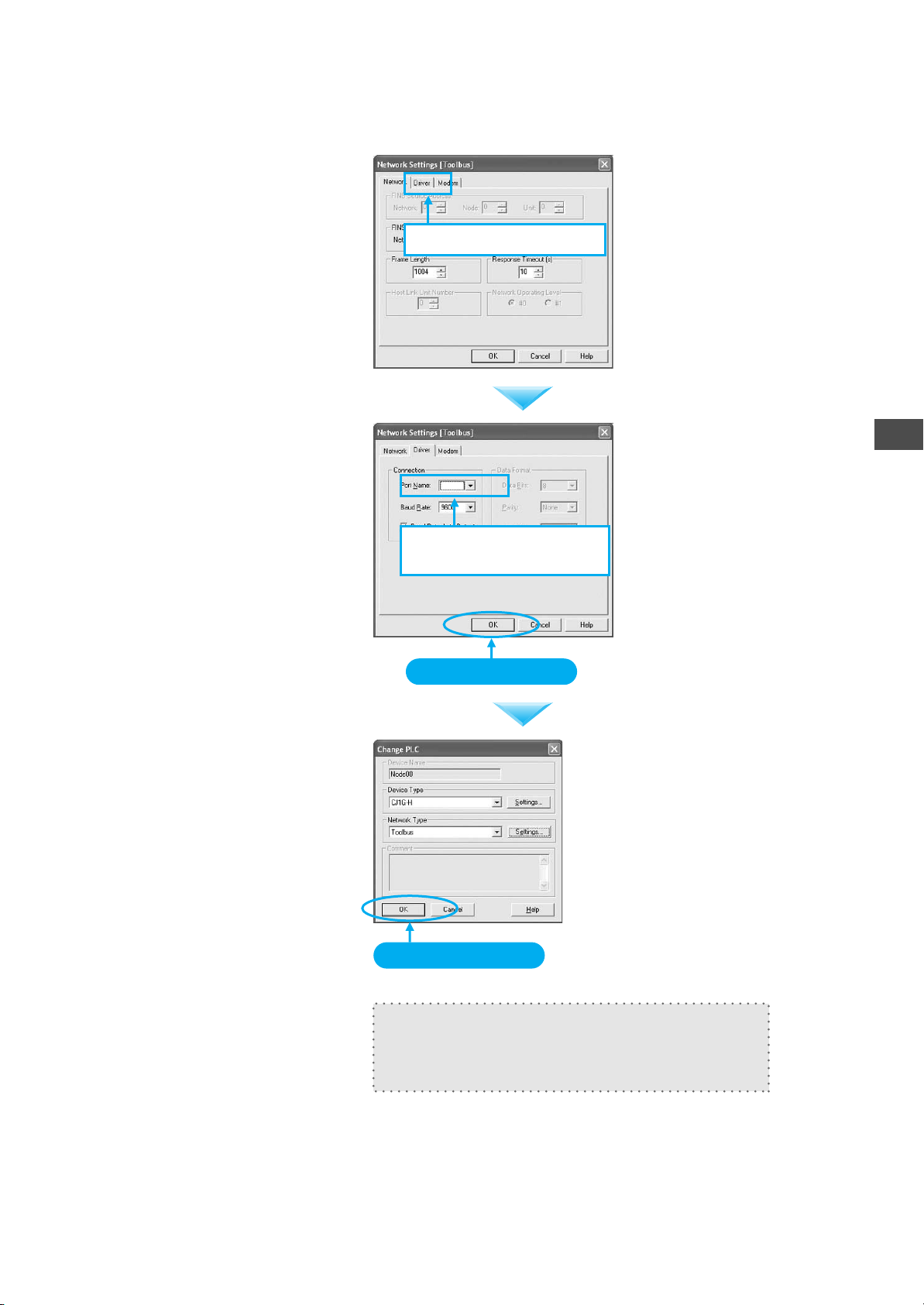

The Network Settings [Toolbus]

Window will open. Click the Driver

Tab.

7-2-3. Click the Driver Tab.

Set the Port Name to the actual port to

be used, and then click the OK Button

to close the window.

The communications setting will be

completed once the OK Button is

clicked once again.

7-2-4. Set the COM port for

the computer.

Click the OK Button.

7

Communications Settings between Computer and PLC

Click the OK Button.

With the CX-Process Tool, an online connection

will be made automatically when online operations,

such as downloading, are performed after making

the communications settings described above.

1-13

Page 22

8

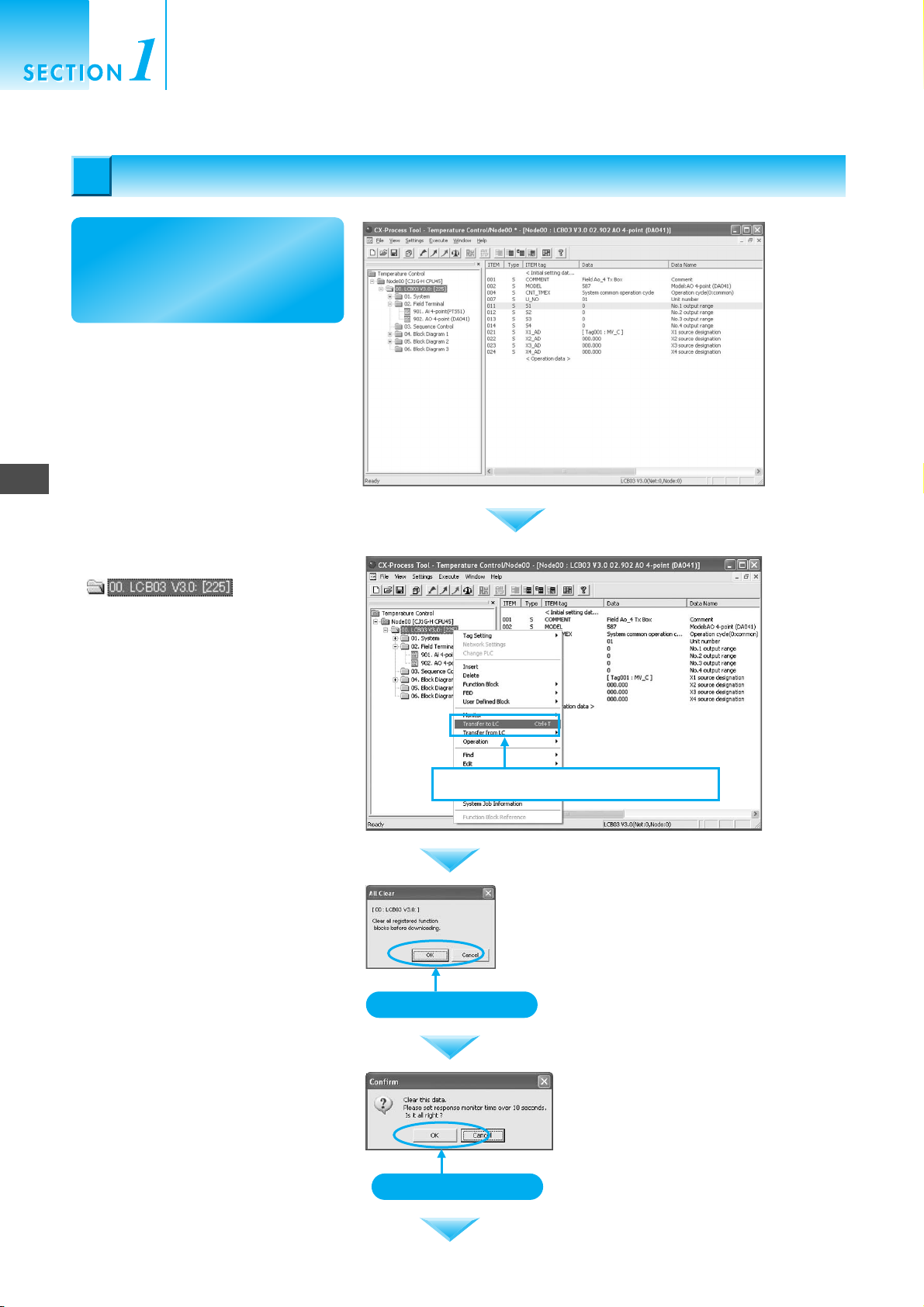

Transferring Function Block Data to the Loop Controller

Creating Simple Function Block Data for

the Loop Controller

Transferring Function Block Data to the Loop Controller

Transferring Function Block Data to the Loop Controller

8

8

Now that communications

settings have been completed,

transfer the function block data

to the Loop Controller.

Right-click

on the tree in

the window at the left and select

Transfer to LC from the pop-up

menu.

Click the OK Button.

Right-click and select Transfer to LC .

Click the OK Button.

1-14

Click the OK Button.

Page 23

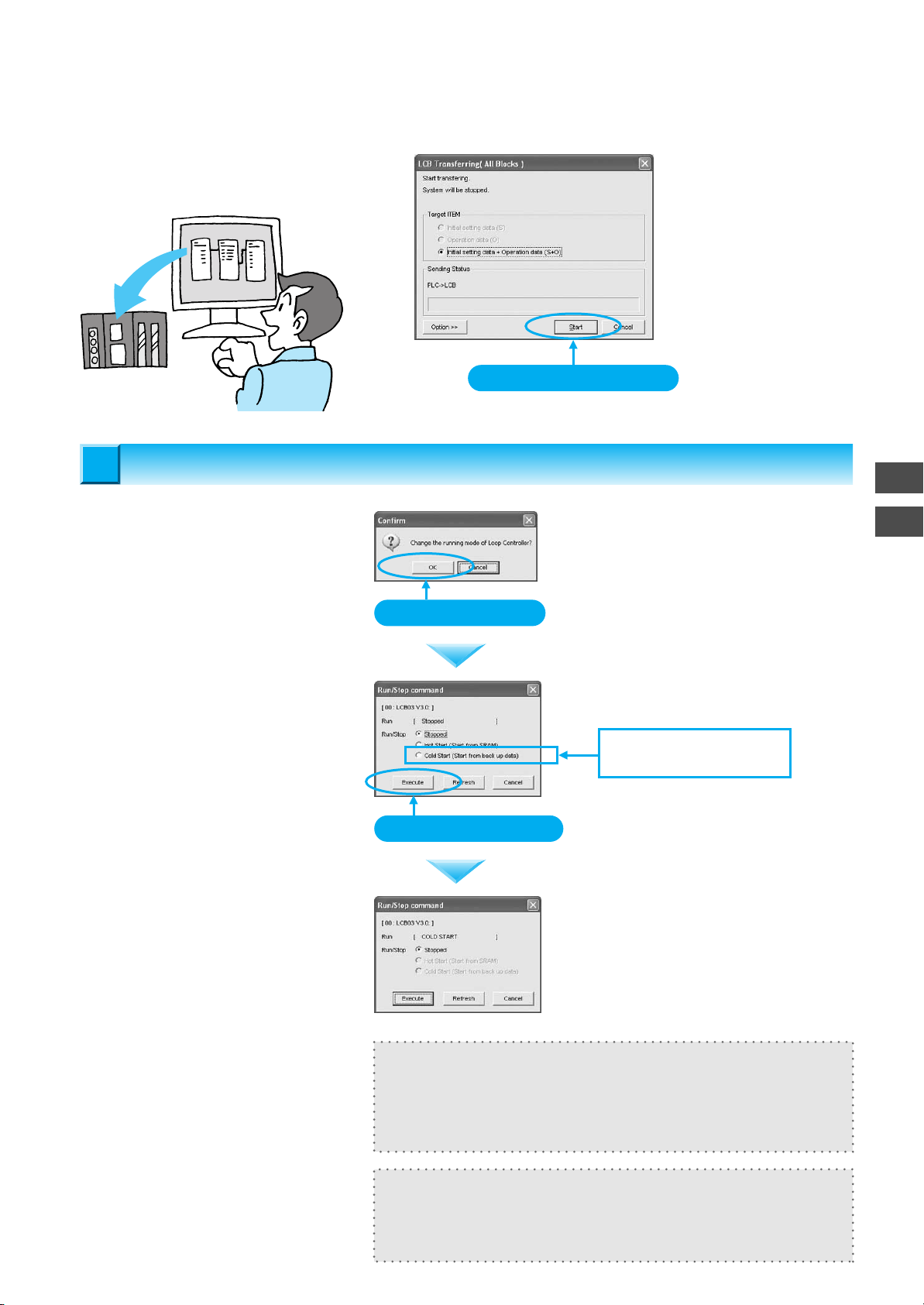

Click the Start Button. The window

will automatically close when the

download has been completed.

Downloading

Downloading

Function

block data

Loop Controller

Starting Operation

Starting Operation

9

9

The window to start transferring will be

displayed continuing with the transfer

operation. Click the OK Button.

Select Cold Start and click the

Execute Button.

Click the Start Button.

Click the OK Button.

Select Cold Start for the

Run/Stop Command.

8

9

Starting Operation

The operation status display will

change to Cold Start when operation

has been started.

Click the Execute Button.

In this example, the operation is started right after downloading, but

operation can also be started by using an operation command from the

menu, or operation automatically when the power is turned ON (but a

hot start will be used by default).

Use Hot Start to hold the manipulated variable (MV) and other settings

from immediately before a momentary stop. Otherwise, normally use

Cold Start.

1-15

Page 24

Creating Simple Function Block Data for

the Loop Controller

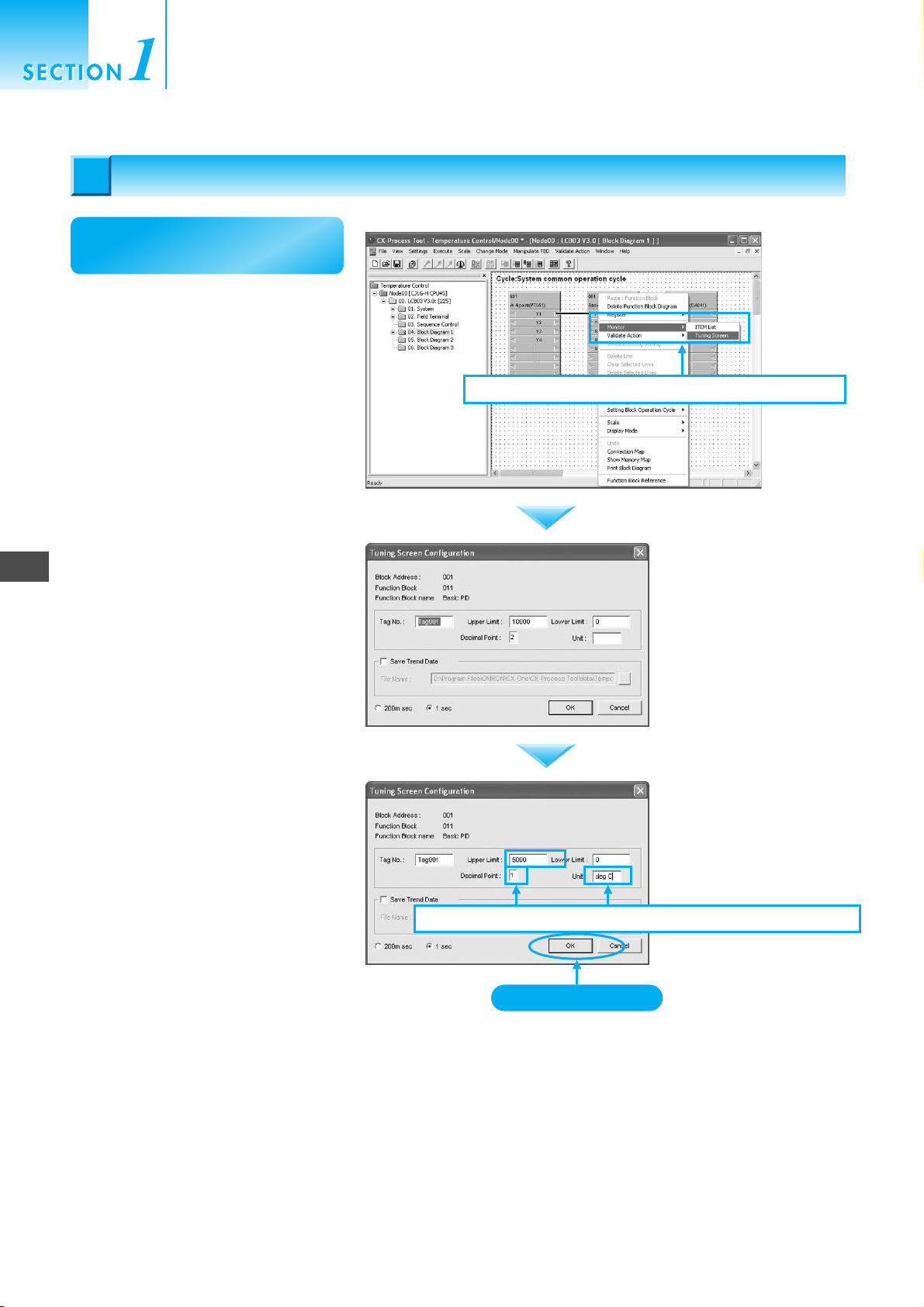

PID Tuning

10

PID Tuning

10

Tune PID constants for the

Basic PID Block.

Right-click the Basic PID Block and

select Monitor - Tuning Screen from

the pop-up menu.

10-1. Right-click and select Monitor - Tuning Screen.

10

PID Tuning

The Tuning Screen Configuration

Window will open. At this point, set the

tuning screen.

For the system configuration specified

at the beginning of this guide, the

temperature range is to be set to 0.0

to 500.0°C. Therefore, input 5000 for

the Upper Limit, 1 for the Decimal

Point, and deg C for the Unit. When

finished, click the OK Button.

10-2.

Set the temperature range in the Tuning Screen Configuration Window.

Click the OK Button.

1-16

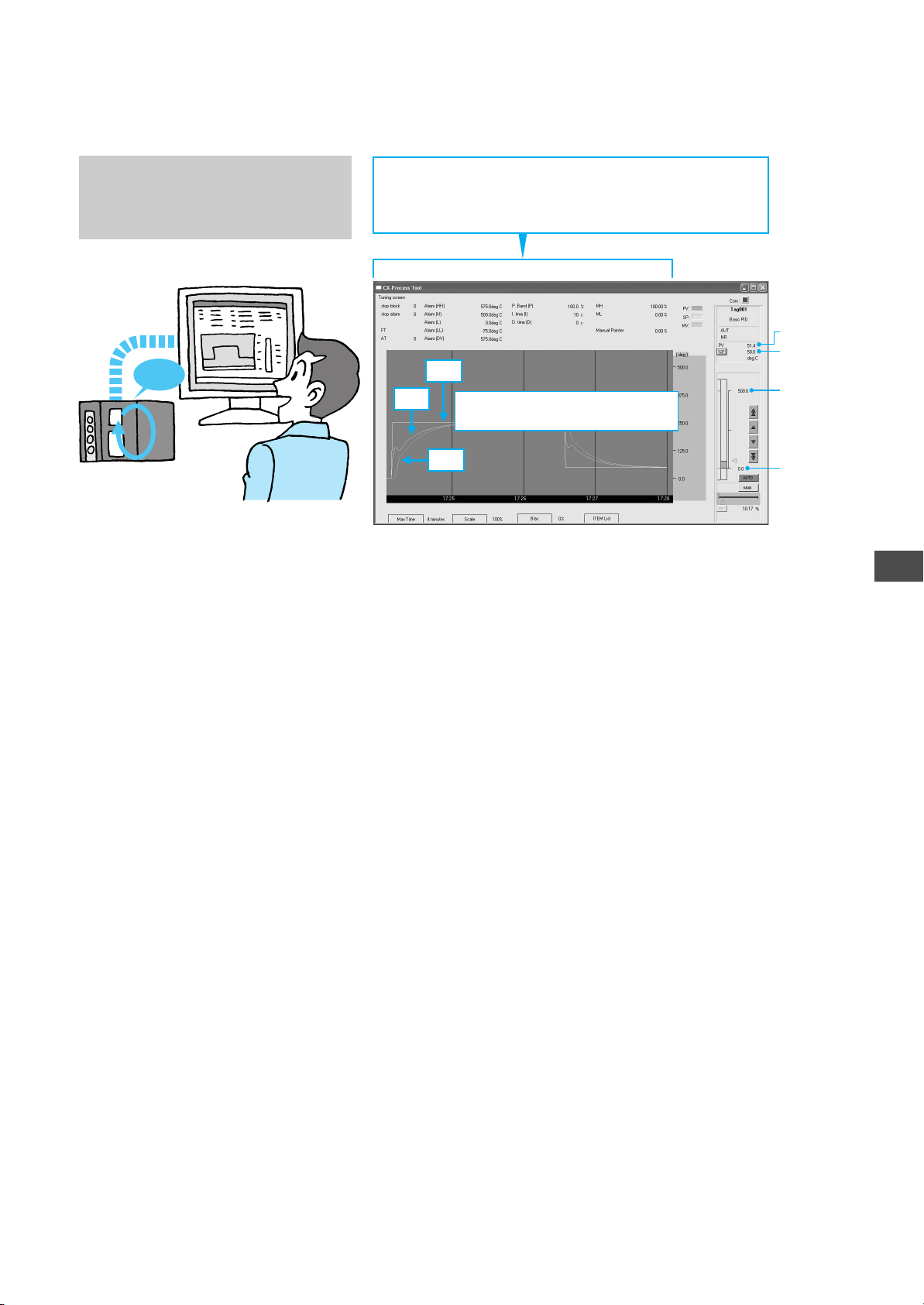

Page 25

The window shown at the right will not

be displayed if the PLC is not actually

connected. The window, however, is

included here as reference.

PID tuning

Operation

Clicking on a setting name will display a dialog box to

change the setting. Change the setting with the 10-key pad

dialog box (using the mouse) or by using the keyboard.

SP

MV

The window will be displayed and

then trend data will be displayed.

PV

SP

Upper limit

Loop Controller

PV

Lower limit

10

PID Tuning

1-17

Page 26

Creating Simple Function Block Data for

the Loop Controller

Reference Information

10

PID Tuning

● Autotuning (AT)

● Fine Tuning (FT)

Autotuning is provided as a convenient means for tuning PID control.

To perform autotuning, click the AT Button. The PID constants will be

tuned when autotuning is started.

The following figure shows an example of AT execution and the response of the subsequent temperature control loop. Compared with

the response example on the previous page, temperature settings are

changed faster.

Execute fine tuning (FT) when the control performance produced by

autotuning is not acceptable, when autotuning produces instability in

the PV, or when interruption of control cannot be allowed.

Fine tuning improves control by automatically setting PID constants

using three user settings listed below along with fuzzy logic applied to

the previous control conditions.

• Hunting

• Overshooting

• Responsiveness

Either one or two of the user settings can be set to any of five adjustment levels. For example, to improve control responsiveness and

overshooting, the Responsiveness and Hunting parameters can be

set to the desired levels.

1-18

Page 27

Uploading and Saving Function Block Data

11

11

Uploading and Saving Function Block Data

Upload the data from the actual

Loop Controller and save the

data in a file.

Upload the parameters (e.g., PID constants) tuned in the actual Loop Controller to the computer. Right-click

in the tree in the

window on the left and select Transfer

from LC - Previous.

Click the OK Button.

11-1. Upload the data from the actual Loop Controller.

11-1-1. Right-click and select Transfer from LC - Previous.

11

Uploading and Saving Function Block Data

Click the Start Button.

Transferring the setting parameters

from the Loop Controller to the computer will begin. The window will close

when the transfer has been completed.

Click the Save Button on the toolbar

to save the function block data.

Tuned function

block data

Uploading

Uploading

Click the OK Button.

11-1-2. Start the transfer.

11-2. Save the function block data.

Saving data

Loop Controller

1-19

Page 28

Page 29

Making the NS-series

PT Screen for the

Loop Controller

This section describes the operational flow

from using the Face Plate Auto-Builder for NS

to automatically generate the NS-series PT

screen for the Loop Controller based on the

function block data that was created, up to

displaying the screen on the CX-Designer

(Screen Creation Support Software for NSseries PTs).

2-1

Page 30

Making the NS-series PT Screen

for the Loop Controller

1

2

CSV tags must be set in advance (i.e.,

Setting the CSV Tags in Advance/Automatically Creating the NS-series PT Screen for the Loop Controller

before creating the NS-series PT

screen for the Loop Controller).

Right-click 001.Basic PID in the tree in

the window on the left and select Tab

Setting - CSV Tag from the pop-up

menu.

Input the Scaling Upper Limit, Scaling

Lower Limit, DP (i.e., decimal point

position), and Unit. Click the OK

Button.

Setting the CSV Tags in Advance

Setting the CSV Tags in Advance

1

1

1-1. Right-click 001.Basic PID and select Tab Setting -

CSV Tag.

Automatically Creating the NS-series PT Screen for the Loop Controller

Automatically Creating the NS-series PT Screen for the Loop Controller

2

2

Automatically create the NS-series PT

screen for the Loop Controller.

Start the Face Plate Auto-Builder for

NS (NSFP) and the project for the CXDesigner will be generated

automatically.

Select Execute - Create Tag File -

Start NSFP from the menu.

I can make it

all by myself!

Click the OK Button.

2-1. Start the Face Plate Auto-Builder for NS (NSFP)

at the same time as creating tag files.

2-1-1. Select Execute - Create Tag File -

Start NSFP.

2-2

Page 31

Click the OK Button.

Click the OK Button. The following

window will be displayed.

2-2. Compile the tags.

Click the OK Button.

Click the OK Button.

2

Automatically Creating the NS-series PT Screen for the Loop Controller

Click the OK Button.

Give the file a name (in this case,

TagList) and click the Save Button.

Click the OK Button.

The Face Plate Auto-Builder for NS will

start.

Click the OK Button.

Click the Save Button.

Click the OK Button.

2-3

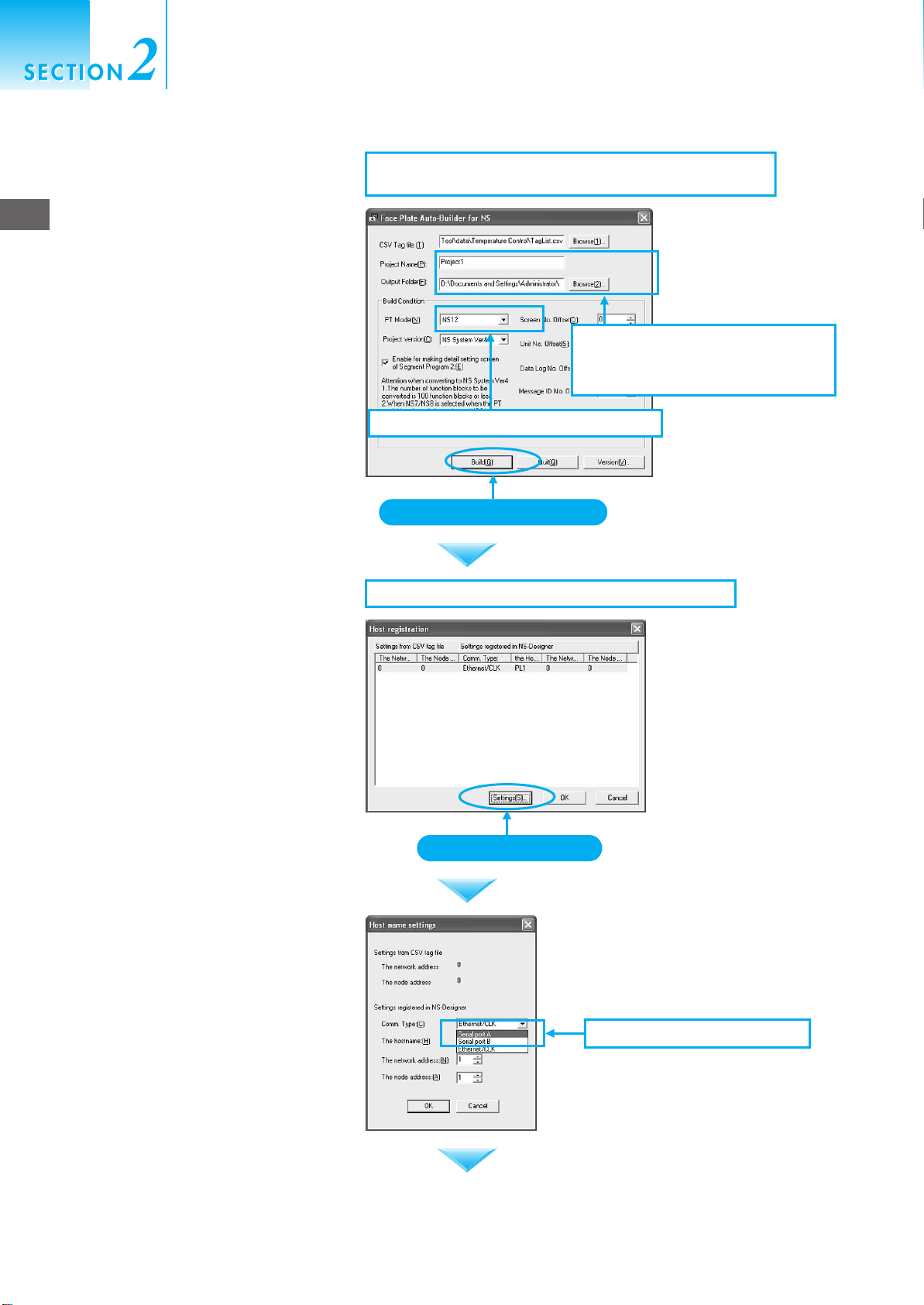

Page 32

Making the NS-series PT Screen

for the Loop Controller

Name the project and click the Browse

(2) Button. Set the output folder, set NS

12 for the PT Model, and click the

2

Automatically Creating the NS-series PT Screen for the Loop Controller

Build Button.

Register the host (i.e., host registration

in CX-Designer project) so that the NSseries PT and the PLC can

communicate. When the window is

displayed, click the Settings Button.

2-3. The project for the CX-Designer will be automatically

generated when the Build Button is clicked.

2-3-2. Select NS12 for the PT Model.

Click the Build Button.

2-4. Registering the host in the CX-Designer project.

2-3-1. Give the project a name. Click

the Browse (2) Button and

select the folder to save in.

2-4

Click the Settings Button.

Select Serial Port A for Comm. Type.

2-4-1. Select Serial Port A.

Page 33

Click the OK Button.

Click the OK Button.

Click the OK Button.

Click the OK Button.

2

Automatically Creating the NS-series PT Screen for the Loop Controller

Click the OK Button.

A progress dialog box will be displayed.

A message saying that building has

been completed will be displayed. Click

the OK Button.

Click the OK Button.

Click the OK Button.

2-5

Page 34

Making the NS-series PT Screen

for the Loop Controller

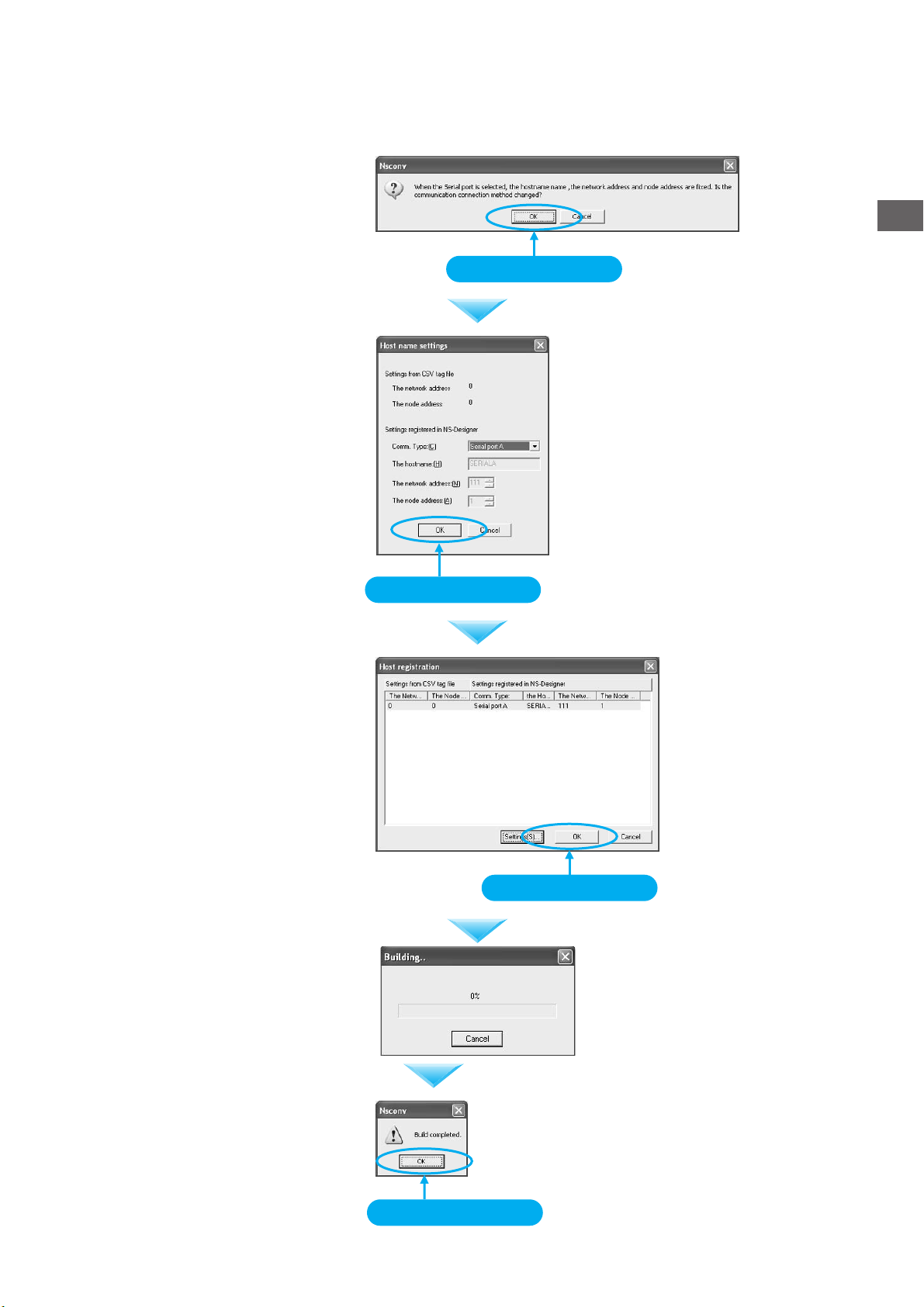

Displaying the NS-series PT Screen for the Loop Controller

Displaying the NS-series PT Screen for the Loop Controller

3

3

Display the NS-series PT screen for the

Loop Controller.

3

Double-click the automatically created

Displaying the NS-series PT Screen for the Loop Controller

project file (with the name given above)

for the CX-Designer. The CX-Designer

will start.

3-1. Double-click the CX-Designer project file.

The generated faceplate can be

checked by selecting items on the

screen.

Reference Information

The trend screen that is created can be

checked by selecting items on the

screen.

3-2. The screen for the Loop Controller is generated automatically.

2-6

Page 35

Useful

Functions

Page 36

Useful Functions

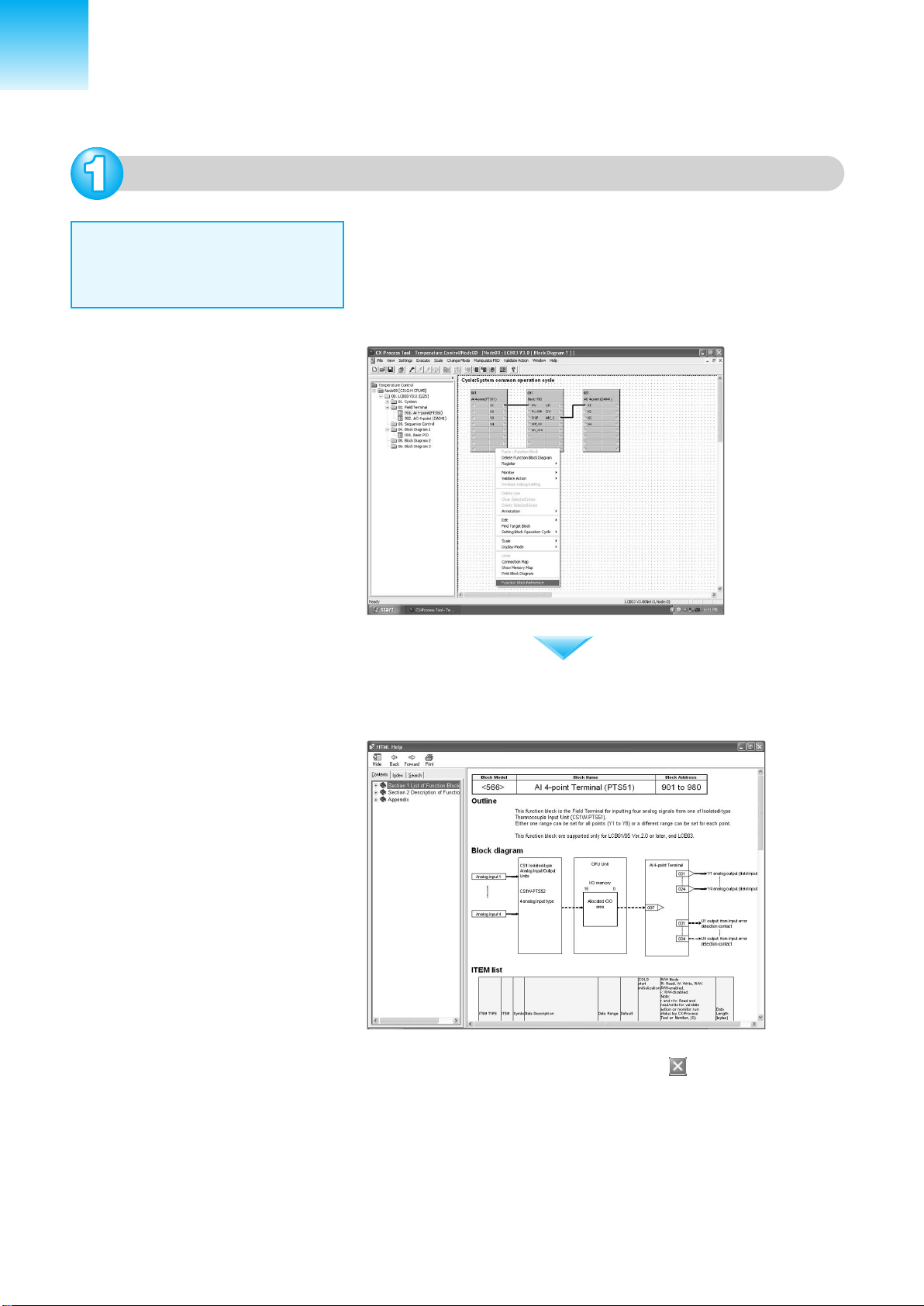

Viewing the Online Manual

The online manual is useful to find

proper settings, such as for setting

ITEMs in function blocks.

To view the online manual, double-click 04. Block Diagram 1 in the

tree in the window on the left. A block diagram will be displayed.

Next, right-click the function block you want to find information about

(in this case, Isolated Ai 4-point Terminal). A menu will be displayed.

Click Function Block reference at the bottom of the menu.

The online manual will open and the function block will be explained.

This explanation may be useful for reference.

To close the window, click the Close Button at the upper right of

the window.

Page 37

HMI Function

This function automatically assigns

function block data (e.g., PV, SP,

and MV) in order of function block address to addresses in the specified

bank in the EM Area of the CPU Unit

as a constant data conversion area.

The HMI function is set in the System Common Block (Block Model

000). By default, the refresh cycle in EM0 is set to 1 s. The blocks

that are allocated are determined according to the block addresses

given to the registered function blocks.

For example, the block address will be 001 if the Basic PID Block is

pasted first. A total of 40 words (fixed) are allocated for each block

address: 20 words for send data from the Loop Controller to the CPU

Unit memory (E00000 + block address x 20, i.e., E00020 to E00039 if

the block number is 001) and 20 words for receive data from the CPU

Unit memory to the Loop Controller (E15000 + block address x 20,

i.e., E15020 to E15039 if the block number is 001).

Block address

The ITEMs for which memory is allocated depends on the function

block, but with the Basic PID Block, for example, ITEMs will be

transferred as shown in the following figure.

Example: Basic PID (Block Model 011) (Offset from Beginning Word)

Word

Analog data

Bit data

Bit

+18

+19

Allocated addresses can be output as a list in a CSV file by selecting

Execute - Create Tag File - Create HMI I/F Memory Map.

Page 38

Useful Functions

User Link Tables

User link tables are used to exchange data between user-set I/O

memory in the CPU Unit and function blocks in the Loop Controller.

Normally, Field Terminals are used for data exchange with I/O Units

and the HMI function is used for data exchange with I/O memory for

CPU Units. With these functions, however, the I/O memory

addresses for the CPU Unit are automatically allocated. User link

tables are useful for reading and writing data in the Loop Controller

to user-set memory area addresses in the CPU Unit. For example,

to read the remote set point (RSP) data from the DM Area in the

CPU Unit's I/O memory, allocate addresses in the DM Area to a

user link table and connect the table to the RSP of the PID Block. In

the following figure, D100 is allocated to a user link table, and the

table is connected to the RSP of the Basic PID Block.

Page 39

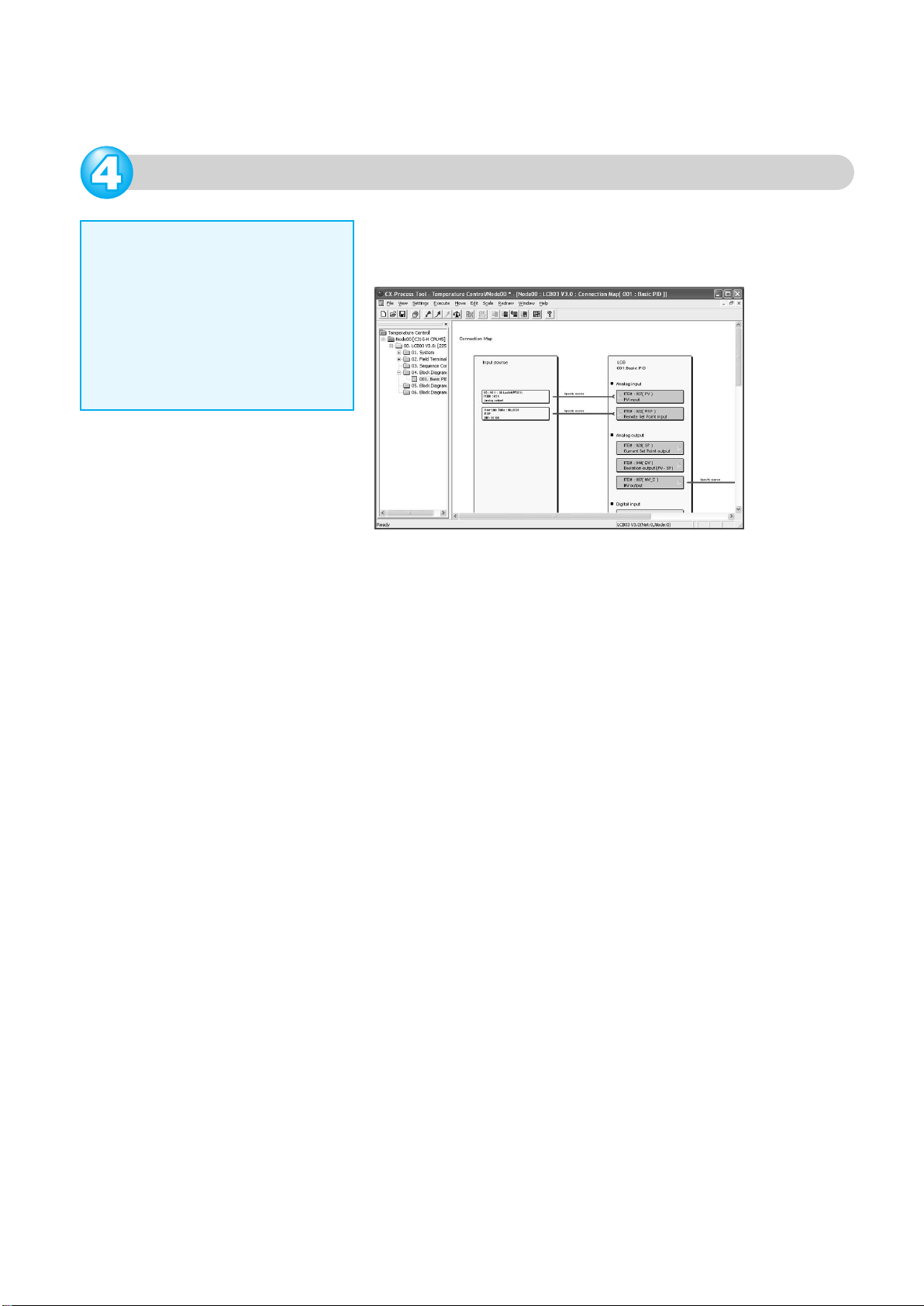

Connection Maps

Analog and contact information is

connected to function blocks. To

check the relationship of all I/O for

a function block, use a connection

map to display a relational diagram

for input source ITEMs and output

source ITEMs as a list.

To use connection maps, right-click the Basic PID Block on the

function block diagram. The connection map can be used by

selecting it from the menu.

Page 40

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and

workmanship for a period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED,

REGARDING NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR

PURPOSE OF THE PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER

OR USER ALONE HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE

REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL

DAMAGES, LOSS OF PROFITS, OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH

THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY,

NEGLIGENCE, OR STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product

on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER

CLAIMS REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE

PRODUCTS WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND

NOT SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION

OR REPAIR.

Note: Do not use this document to operate the Unit.

This catalog mainly provides information that is necessary for selecting suitable models, and does

not contain precautions for correct use. Always read the precautions and other required information

provided in product operation manuals before using the product.

The application examples provided in this catalog are for reference only. Check functions and

safety of the equipment before use.

Never use the products for any application requiring special safety requirements, such as nuclear

energy control systems, railroad systems, aviation systems, medical equipment, amusement

machines, vehicles, safety equipment, or other application involving serious risk to life or property,

without ensuring that the system as a whole has been designed to address the risks, and that the

OMRON products are properly rated and installed for the intended use within the overall equipment

or system.

Printed on 100%

Recycled Paper

OMRON Corporation

Industrial Automation Company

Control Devices Division H.Q.

Shiokoji Horikawa, Shimogyo-ku,

Kyoto, 600-8530 Japan

Tel: (81)75-344-7109

Fax: (81)75-344-7149

Regional Headquarters

OMRON EUROPE B.V.

Wegalaan 67-69, NL-2132 JD Hoofddorp

The Netherlands

Tel: (31)2356-81-300/

Fax: (31)2356-81-388

OMRON ELECTRONICS LLC

1 East Commerce Drive, Schaumburg,

IL 60173 U.S.A.

Tel: (1)847-843-7900/ Fax: (1)847-843-8568

OMRON ASIA PACIFIC PTE. LTD.

83 Clemenceau Avenue,

#11-01, UE Square,

Singapore 239920

Tel: (65)6835-3011/Fax :(65)6835-2711

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120 China

Tel: (86)21-5037-2222/Fax: (86)21-5037-2200

Authorized Distributor:

Note: Specifications subject to change without notice. Cat. No. R143-E1-01

Printed in Japan

0606-1M

Loading...

Loading...