Page 1

Cat. No. W428-E1-02

SYSMAC

WS02-LCMC1-EV2

CX-Process Monitor Plus

(Ver. 2)

OPERATION MANUAL

Page 2

WS02-LCMC1-EV2 CX-Process Monitor Plus (Ver. 2)

Operation Manual

Revised January 2007

Page 3

iv

Page 4

Notice:

r

f

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

Before Installing the CX-Process Monitor Plus

Installing the CX-Process Monitor Plus signifies that you accept the software user’s license agreement

displayed during the installation process. Do not install this software if you do not accept the user’s

license agreement. Warranty and after-sales services are available only to users that register with the

enclosed registration form. Please fill in the registration form and return it to OMRON.

OMRON, 2005

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

v

Page 5

vi

Page 6

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

1 Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

2 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

4 Application Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiv

SECTION 1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 CX-Process Monitor Plus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1-2 Basic Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

SECTION 2

Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2-1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2-2 Connecting the PLC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

SECTION 3

Exchanging Data with Monitor Plus . . . . . . . . . . . . . . . . . . . 51

3-1 Data Exchange Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

3-2 Example Function Blocks for Data Exchange. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

3-3 Loop Control Unit Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

SECTION 4

Monitor Screen Functions and Operations . . . . . . . . . . . . . 73

4-1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

4-2 Using the CX-Process Monitor Plus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

4-3 CX-Process Tool Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

4-4 Starting and Stopping the CX-Process Monitor Plus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4-5 Overview Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

4-6 Screen Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

4-7 Control Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

4-8 Tuning Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

4-9 Trend Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

4-10 Batch Trend Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

4-11 Segment Program 2 Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

4-12 Graphic Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

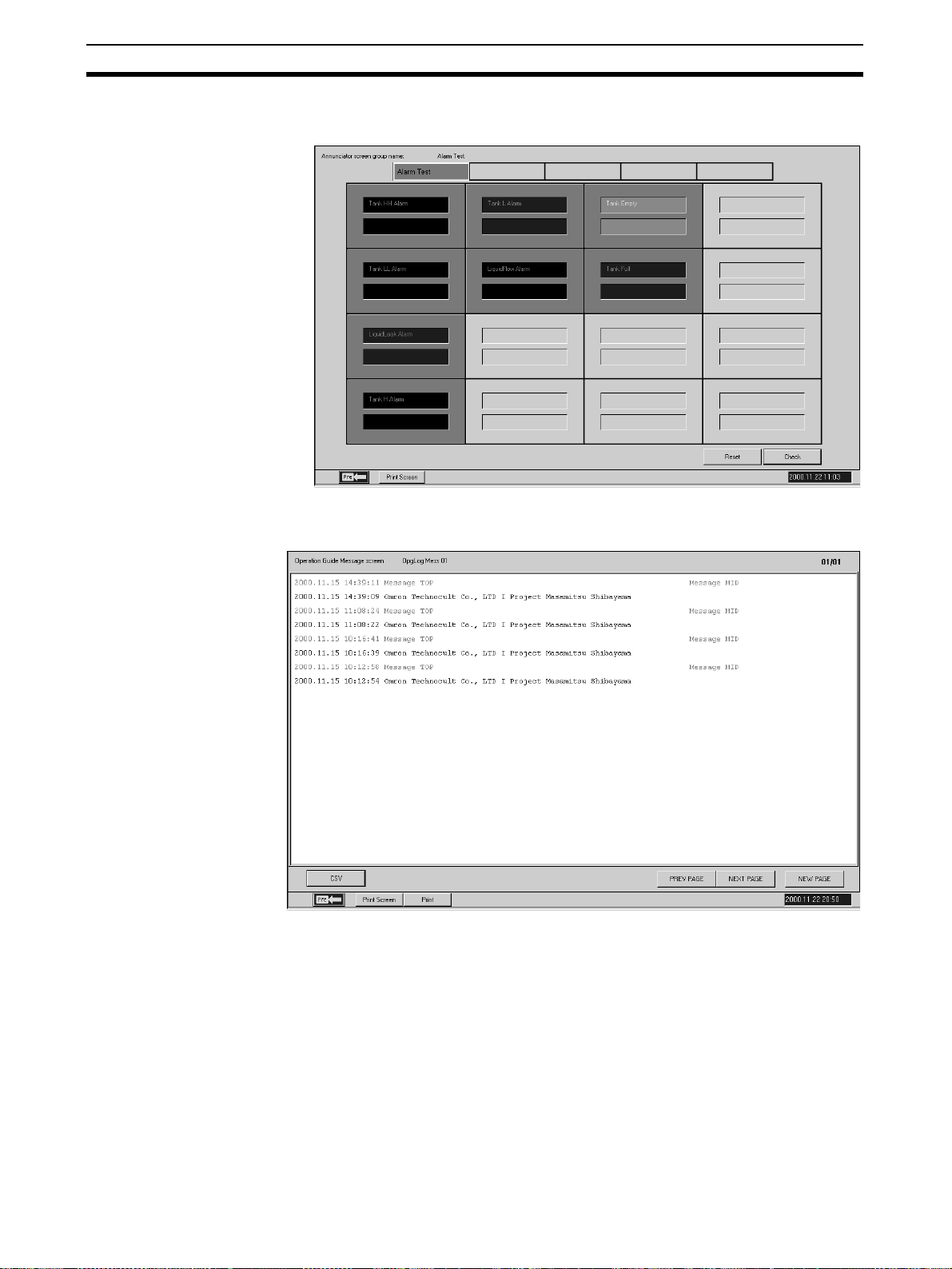

4-13 Annunciator Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

4-14 Operation Guide Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

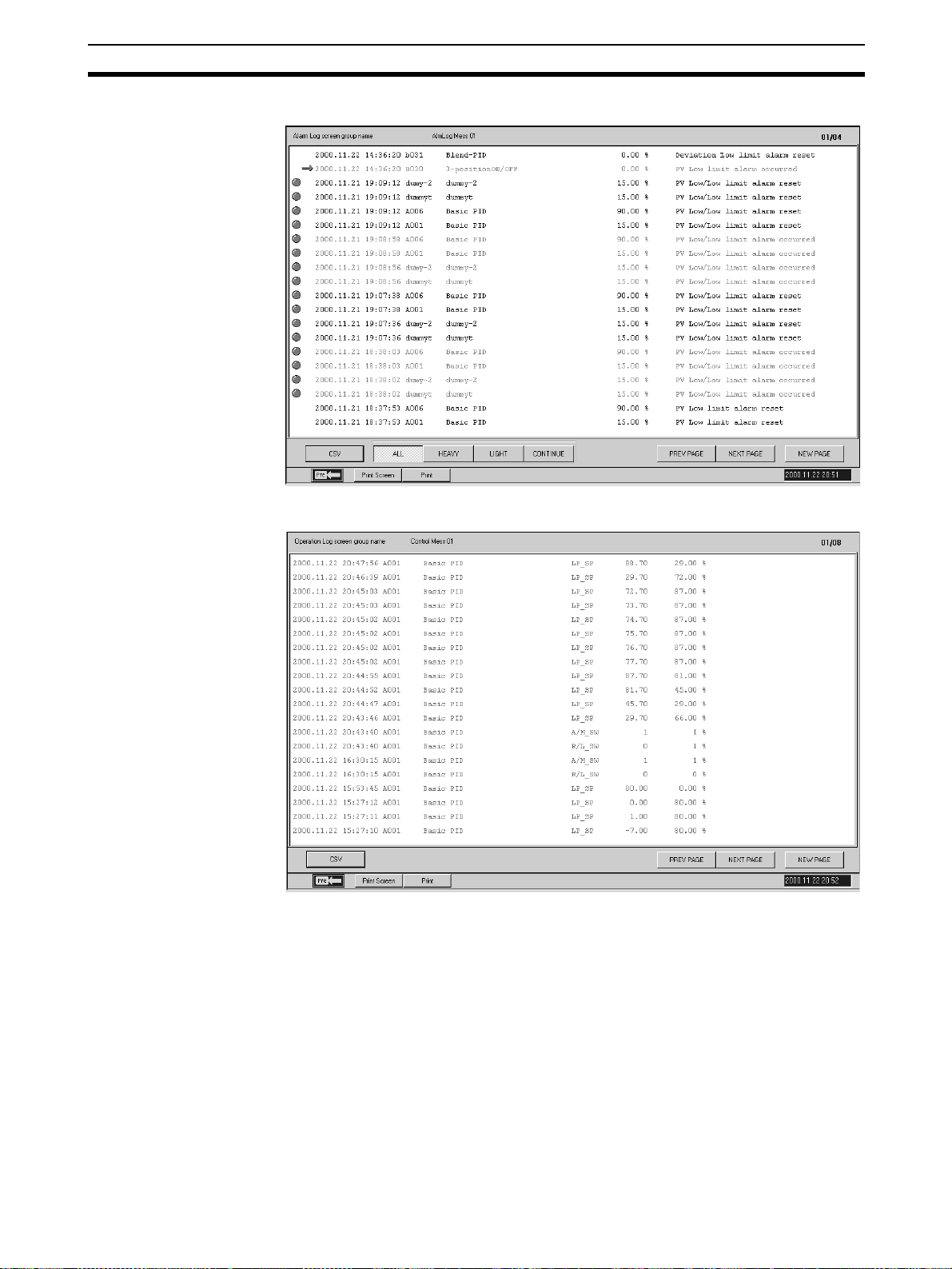

4-15 Alarm Log Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

4-16 Operation Log Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

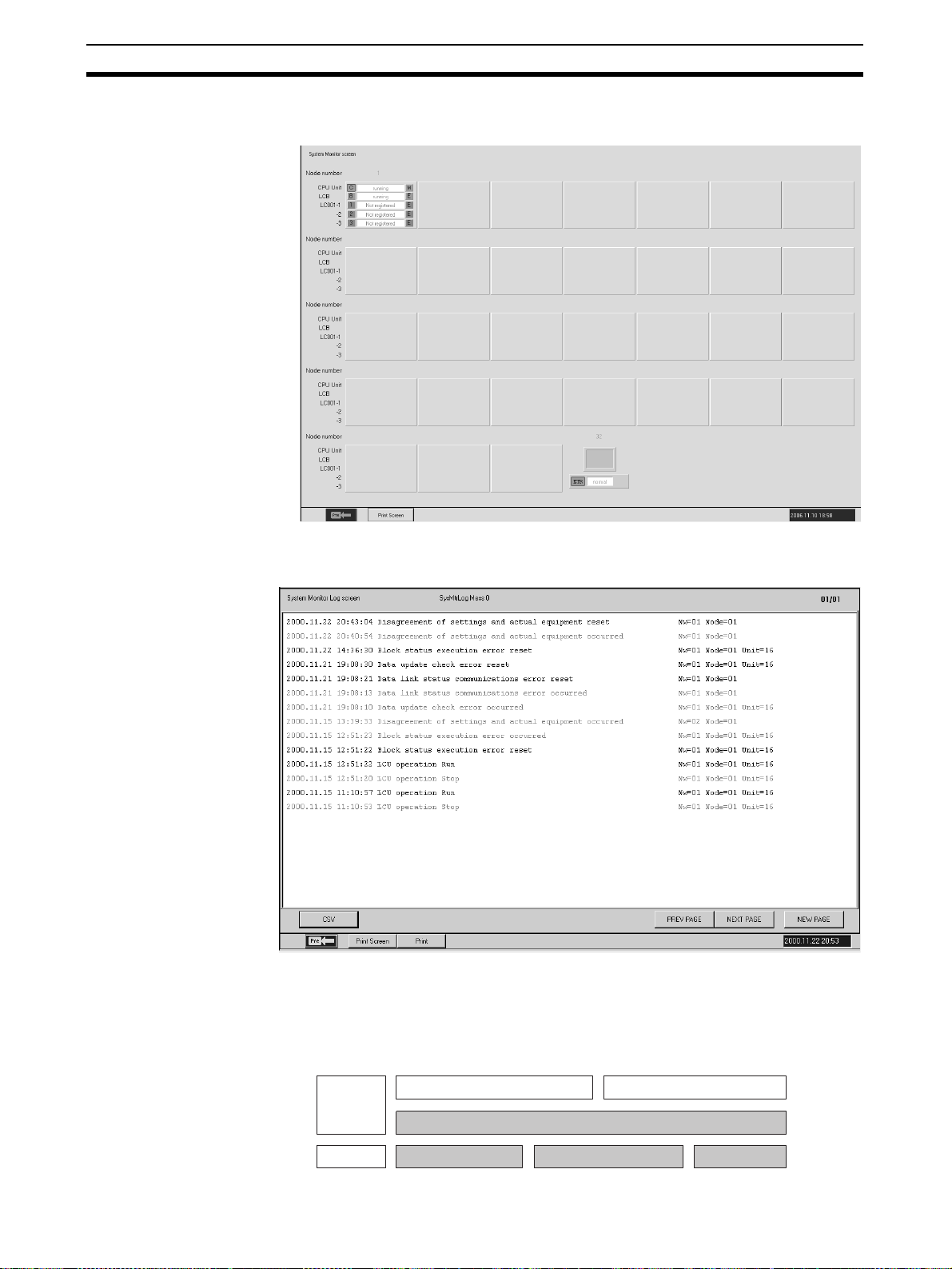

4-17 System Monitor Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

4-18 System Monitor Log Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

vii

Page 7

TABLE OF CONTENTS

SECTION 5

Configuration Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

5-1 Basic Configuration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

5-2 Basic Configuration Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

5-3 System Monitor Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .144

5-4 Creating Graphic Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147

5-5 Screen Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

5-6 System Information Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

5-7 Checking Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .226

SECTION 6

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Appendices

A Reading/Writing Function Block ITEMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

B Differences between Trend Screens and Batch Trend Screens . . . . . . . . . . . . . . . . . . . . . . . 253

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

viii

Page 8

About this Manual:

This manual describes the installation and operation of the WS02-LCMC1-EV2 CX-Process Monitor

Plus software package and includes the sections described below. The CX-Process Monitor Plus is

used to control and monitor the operation of the CS1W-LC001 Loop Control Unit, the CS1W-LCB01

Loop Control Board, the CS1W-LCB05 Loop Control Board, the CS1D-CPU@@P Process-control CPU

Units, and the CJ1G-CPU@@P Loop-control CPU Units.

Please read this manual carefully and be sure you understand the information provided before

attempting to install and operate the CX-Process Monitor Plus. Please read the following manuals

carefully and be sure you understand the information provided before setting up or using an application

for a Loop Control Unit or Loop Control Board.

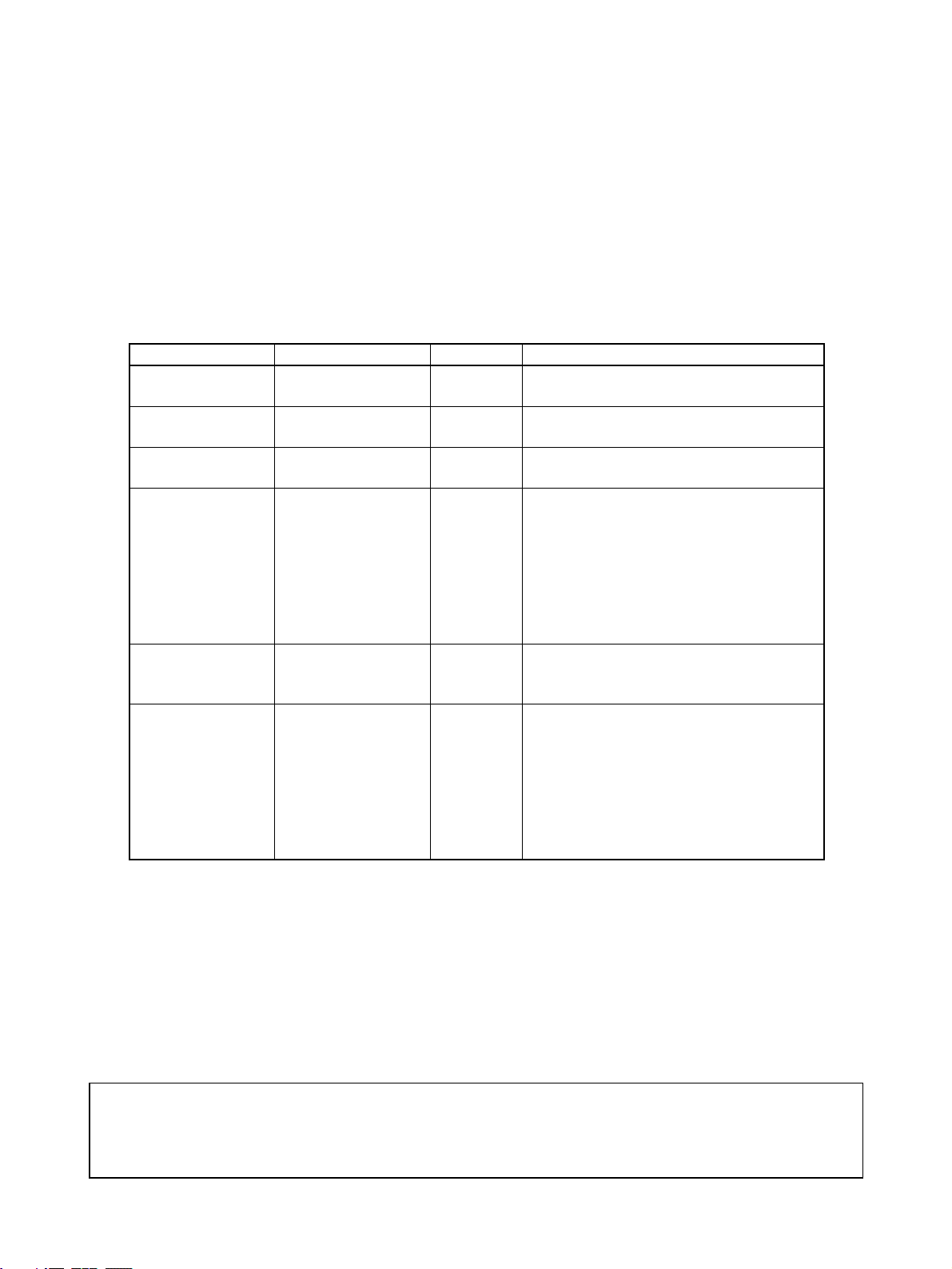

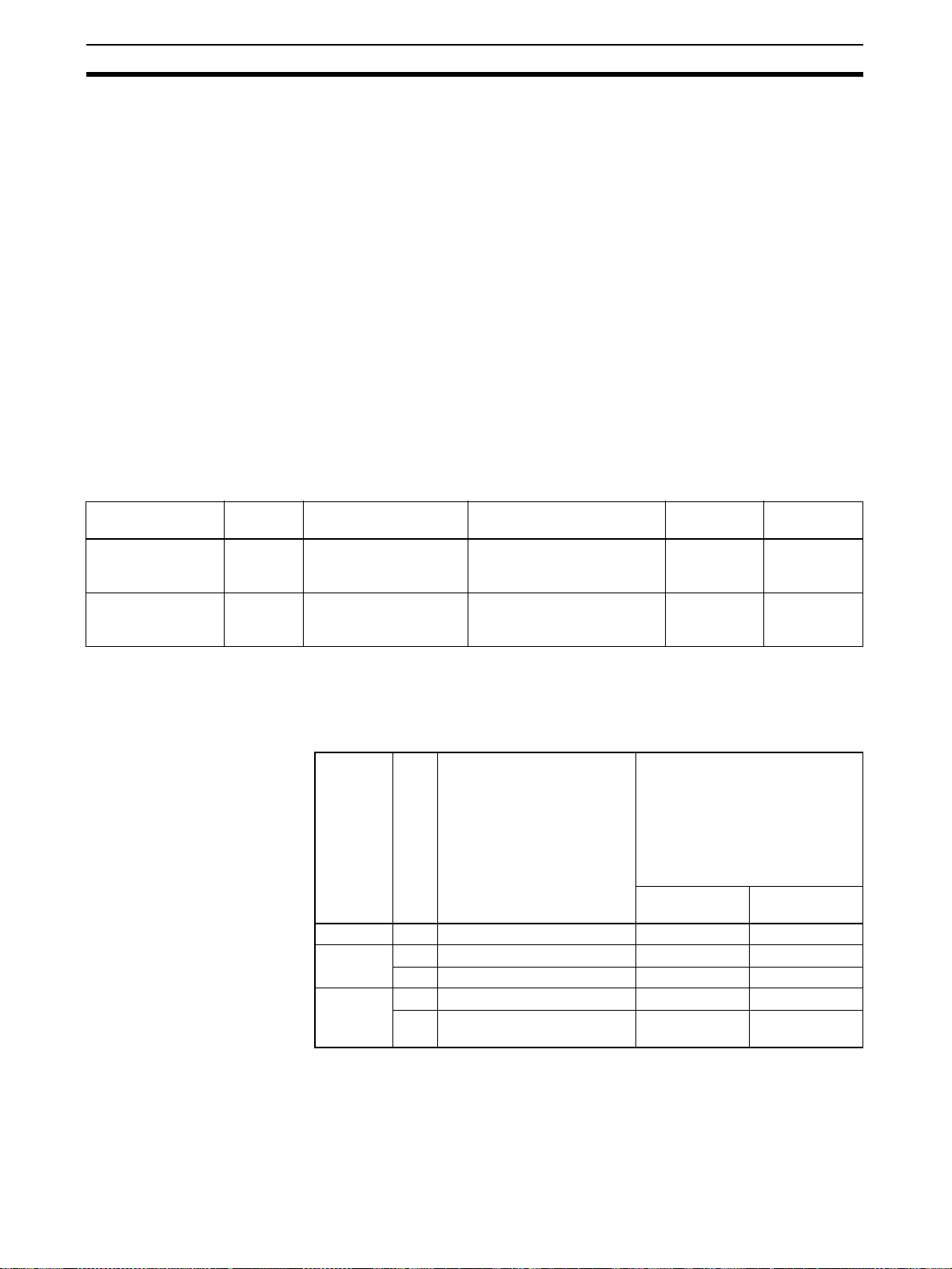

Product Manual name Cat. No. Contents

WS02-LCMC1-EV2 CX-Process Monitor

Plus Operation Manual

WS02-LCTC1-EV5

CX-Process Tool

CS1W-LC001

Loop Control Unit

CS1W-LCB01/05

Loop Control Boards,

CS1D-CPU@@P

Process-control CPU

Units, and

CJ1G-CPU@@P

Loop-control CPU

Units

CS1W-LC001

Loop Control Unit

CS1W-LCB01/05

Loop Control Boards,

CS1D-CPU@@P

Process-control CPU

Units, and

CJ1G-CPU@@P

Loop-control CPU

Units

CX-Process Tool

Operation Manual

Loop Control Unit

Operation Manual

Loop Control Boards

Operation Manual

Loop Control Unit

Function Block Reference Manual

Loop Control Boards

Function Block Reference Manual

W428

(this manual)

W372 Installation and operation procedures for the

W374 Installation and operation procedures for the

W406 Installation and operation procedures for the

W375 Detailed information on function blocks for

W407 Detailed information on function blocks for

Installation and operation procedures for the

CX-Process Monitor Plus.

CX-Process Tool.

Loop Control Unit (except for function blocks).

Loop Control Boards (except for function

blocks).

Loop Control Units.

Loop Control Boards.

Section 1 introduces the CX-Process Monitor Plus.

Section 2 describes installing the CX-Process Monitor Plus and connections to the PLC.

Section 3 described data exchange for the CX-Process Monitor Plus

Section 4 describes the monitor screens used with the CX-Process Monitor Plus.

Section 5 describes the procedures to create screens and monitor using the CX-Process Monitor

Plus.

Section 6 describes errors that can occur while using the CX-Process Monitor Plus.

The Appendix provides a list of ITEM settings for function blocks.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

ix

Page 9

x

Page 10

PRECAUTIONS

This section provides general precautions for using the CX-Process Monitor Plus.

The information contained in this section is important for the safe and reliable application of the CX-Process

Monitor Plus. You must read this section and understand the information contained before attempting to set up or

operate the CX-Process Monitor Plus.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

4 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

xi

Page 11

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent) and

knowledge about instrumentation system.

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, petrochemical plants, and other systems,

machines, and equipment that may have a serious influence on lives and

property if used improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual close at hand for reference during operation.

!WARNING It is extremely important that a PC and all PC Units be used for the specified

purpose and under the specified conditions, especially in applications that can

directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PC System to the above-mentioned applications.

3 Safety Precautions

!WARNING Check the following items before starting Loop Control Unit operation:

Analog I/O Units used in combination with the Loop Control Unit must be

mounted correctly, and the unit number set on the front panel of the Analog I/

O Unit must be the same as the unit number set on the Field Terminal Function Block. If the unit numbers are not the same, I/O (read/write) will be performed on the data for another Special I/O Unit (i.e., the one whose unit

number is set in the Field Terminal Function Block).

The initial settings of the System Common Block on the Loop Control Unit

must be set correctly. In particular, make sure that the Data Memory for the

Node Terminals in the CPU Unit controlling the Loop Control Unit is not used

for other applications on the PC. If the same words in Data Memory are used

for more than one application, the PC system may act unexpectedly and

cause injury.

xii

Page 12

Safety Precautions 3

When writing data to the I/O memory in the CPU Unit with function blocks

(e.g., using Send All Blocks, Expanded DO/AO Terminal to CPU Unit, or DO/

AO Terminal to CPU Unit), be sure that the words written to in the I/O memory

are not being used for any other purpose. If I/O memory words are allocated

to more than one purpose, the PC system may act unexpectedly and cause

injury.

!WARNING Check the following items before starting to run the Loop Control Board:

• Do not allow the bank of the EM Area with the number specified for allocation to the HMI (human-machine interface) data to be used by the CPU

Unit or other Units for any other purpose. The bank allocated for the HMI

is specified in ITEM 050 (EM Area Bank Allocated for HMI Memory = 0 to

12) of the System Common block. If the same memory area is used for

more than one purpose, the system may operate in an unexpected fashion, which may result in injury.

• Do not allow the area to which user link table data is written to be used by

the CPU Unit or other Units for any other purpose. If the same memory

area is used for more than one purpose, the system may operate in an

unexpected fashion, which may result in injury.

• Analog Input/Output Units used in combination with the Loop Control

Board must be mounted correctly, and the unit number set on the front

panel of the Analog Input/Output Unit must match the unit number set on

the Field Terminal block. If the unit numbers do not match, input/output

(read/write) will be performed on the data of another Special I/O Unit (i.e.,

the one whose unit number is set on the Field Terminal block).

• The defaults of the System Common block on the Loop Control Board

must be set correctly.

!WARNING Always stop the operation of the Loop Control Board before converting any of

the EM Area to file memory. If any part of the EM Area that is being used by

the Loop Control Board for the HMI is converted to file memory during Board

operation, the system may operate in an unexpected fashion, which may

result in injury.

!WARNING Do not perform processing in such a way that the Loop Control Unit/Board

and CPU Unit write to identical I/O memory words allocated to a contact output or analog output of an external Unit. If the same words are written to, the

externally connected loads may act unexpectedly and cause injury.

!WARNING Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal lines,

momentary power interruptions, or other causes.

!Caution Before transferring function block data (initial setting data or operation data) to

the Loop Control Unit/Board, confirm that the destination for the data is correct and also confirm the overall safety of the system (including the Loop Control Unit/Board). Not doing so may result in unexpected operation.

xiii

Page 13

Application Precautions 4

!Caution After updating the tag settings or network configuration for CX-Process Moni-

tor Plus, always confirm that the Monitor Plus screens will operate properly

with the new settings or configuration before attempting actual operation. If

the settings or configuration is not appropriate, unexpected operation may

result.

4 Application Precautions

Observe the following precautions when using CX-Process Monitor Plus.

!Caution Loop Control Unit/Board data is monitored and operated using CX-Process

Monitor Plus based on the tag files for Monitor Plus created using CX-Process

Tool. CX-Process Tool can be used on Microsoft Windows 95, 98, Me, 2000,

or NT (Service Pack 4 or later). CX-Process Tool Ver. 3.2 or higher must be

used to output tag files for the CX-Process Monitor Plus.

!Caution Before using function block data in actual operation, confirm operation by

monitoring run status (to check the load rate; select Execute/Operation/Mon-

itor Run Status) and validating actions (select Validate Action/Start) with

CX-Process Tool. In particular, be sure to confirm that the load rate will be

less than 60%. (For details on the load rate, refer to the Loop Control Unit/

Board Operation Manual.)

!Caution The Loop Control Unit/Board can read and write I/O memory in the CPU Unit

using the Field Terminal Function Blocks or CPU Terminal Blocks independent of the user program (Step Ladder Program) in the CPU Unit. Do not write

to the same I/O memory words from both the Loop Control Unit/Board and the

CPU Unit.

!Caution To hold an analog output or contact output at a specific value (for example, the

maximum value or minimum value) when the Loop Control Unit/Board stops

running, create a Step Ladder Program in the CPU Unit so that the corresponding output bit allocated to Analog Output Unit or Contact Output Unit is

set to the desired value using an NC condition of the Loop Control Unit/Board

Running Flag (bit 00 in allocated CIO word “n”) as an input condition.

!Caution If a fatal error occurs in the CPU Unit (including fatal errors created by execu-

tion of an FALS instruction), the Loop Control Unit/Board will also stop running. To hold analog outputs to the previous values before the stop occurred,

and to set analog outputs to either the minimum value or maximum value, use

the output hold function of the Analog Output Unit or Analog I/O Unit.

!Caution Before turning ON the power to the PC, make sure that the facilities are safe.

The analog output values and contact outputs from the Loop Control Unit/

Board are updated when the power to the PC is turned ON regardless of the

operating mode of the CPU Unit (including in the PROGRAM mode). (Internally, the analog output values and contact outputs are sent from the CPU

Unit to Basic I/O Units and Analog Output Units.)

xiv

!Caution Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal lines,

momentary power interruptions, or other causes.

Page 14

Application Precautions 4

!Caution Confirm that no adverse effect will occur in the system before attempting any

of the following:

• Changing the operating mode of the PC (including the setting of the Startup Mode)

• Force-setting/force-resetting any bit in memory

• Changing the present value or any set value in memory

!Caution Be sure that all mounting screws, terminal screws, and cable connector

screws are tightened to the torque specified in the user manuals. Incorrect

tightening torque may result in malfunction.

!Caution In the event of system or power failure, CX-Process function files (extension

“.ist”) may not be saved. It is recommended that function files are saved regularly.

!Caution If the power supply is turned OFF while function block data is being backed up

from RAM to flash memory, the backup will not be completed normally. If the

power supply is turned back ON within 24 hours, however, the super capacitor

will have held the RAM data. The backup operation will restart when power is

turned ON and operation will start when the backup has been completed. If

the power supply is turned OFF for more than 24 hours, however, RAM data

will be lost and operation will be started with the data that was previously

saved to flash memory. If this happens, the Cold Start Auto-execution Flag

(A35807) will turn ON to show that the previous data has been used. Use this

bit in programming to take whatever steps are necessary, such as downloading the most recent function block data.

xv

Page 15

Application Precautions 4

xvi

Page 16

This section introduces the CX-Process Monitor Plus.

1-1 CX-Process Monitor Plus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-2 Screen Outlines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-1-3 CX-Process Monitor Plus System Requirements . . . . . . . . . . . . . . . 10

1-1-4 Relationship to CX-Process Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1-1-5 Relation between Screens and Function Blocks. . . . . . . . . . . . . . . . 15

1-1-6 CX-Process Monitor Plus Software Specifications . . . . . . . . . . . . . 16

1-1-7 CX-Process Monitor Plus Setting and Monitoring Capabilities. . . . 20

1-1-8 Files Created Using CX-Process Monitor Plus . . . . . . . . . . . . . . . . 21

1-1-9 Version Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1-2 Basic Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

SECTION 1

Introduction

1

Page 17

CX-Process Monitor Plus Section 1-1

1-1 CX-Process Monitor Plus

1-1-1 Outline

The CX-Process Monitor Plus is a Windows NT-based application that monitors the Function Block data within a Loop Control Unit/Board using Control

screens (on-site instrument images), Trend screens, Graphic screens, and

Annunciator screens, etc., via the Controller Link, serial communications, or

Ethernet. The CX-Process Monitor Plus is used together with the CX-Process

Tool to create function blocks for Loop Control Units/Boards.

You can also perform the following four functions.

Monitoring Function

Blocks in a Loop Control

Unit/Board

Controlling Function

Blocks in a Loop Control

Unit/Board

Monitoring Function Block

Alarm Status in a Loop

Control Unit/Board

Configuring CX-Process

Monitor Plus Screens

Monitor PV, SP, and MV, etc., within the Control Block, monitor analog signals,

and monitor contact signals.

Perform Run/Stop instructions in the Loop Control Unit/Board.

Display the status of the CPU Unit, such as the current operating mode.

Change settings, switch between auto and manual, and perform manual operations, tune PID constants, etc., in the Control Block.

You can perform stop block operation commands for each Control Block

(when using the Tuning screen).

Display Control Block and Alarm Block alarms if they occur, and store the

alarms in the alarm history.

You can configure the screen to suit your needs.

2

Page 18

CX-Process Monitor Plus Section 1-1

CX-Process Monitor Plus Functions

--- Screen Monitoring operating

User-defined

screens

System screens Alarm Log --- --- OK (Stored when an

Overview --- --- OK

Control OK (Display PV bar) OK (Change SP, switch

Tuning OK (Display PV, SP, and

MV trends for 1 loop)

Trend OK (Display Control Block

or analog signal trends)

Batch Trend OK (Display Control Block

Segment

Program 2

Graphic OK (Display status for

Annunciator --- --- OK (Use colors or sound

Operation Guide OK (Display message

System Monitor OK (Display the run/stop

Operation Log --- OK (Stores run operation

System Monitor

Log

or analog signal trends)

OK (Display Segment

Program 2 trends)

contact or analog signal

graphics)

when Internal Switch is

turned ON)

status for the Loop Control Unit/Board, display

Execution errors, RAM

checksum errors, and

battery errors, and monitor the status of the CPU

Unit control mode, etc.)

OK (Displays run/stop

command history and

Execution error history

when an error occurs)

status

Controlling operation Monitoring alarm status

between auto/manual,

and perform manual operations)

OK (Change SP, and

change P, I, D, etc.)

--- OK

--- ---

OK (Run/stop operation

at the relevant Segment

Program 2 Block)

OK (Turn ON/OFF the

contact, and set the analog value)

--- OK

OK (Run/stop command

for the Loop Control Unit/

Board)

history, e.g., SP change,

etc.)

--- OK

OK

OK (Change bar graph

colors)

OK (Errors related to the

relevant Segment Program 2 Block)

OK

to notify of an alarm)

OK

alarm occurs)

OK

Note Only the following data can be monitored and set with the CX-Process Moni-

tor Plus and tag names must be set to enable monitoring and setting. Use CXProcess Tool Ver. 3.2 or higher to set the tag names.

3

Page 19

CX-Process Monitor Plus Section 1-1

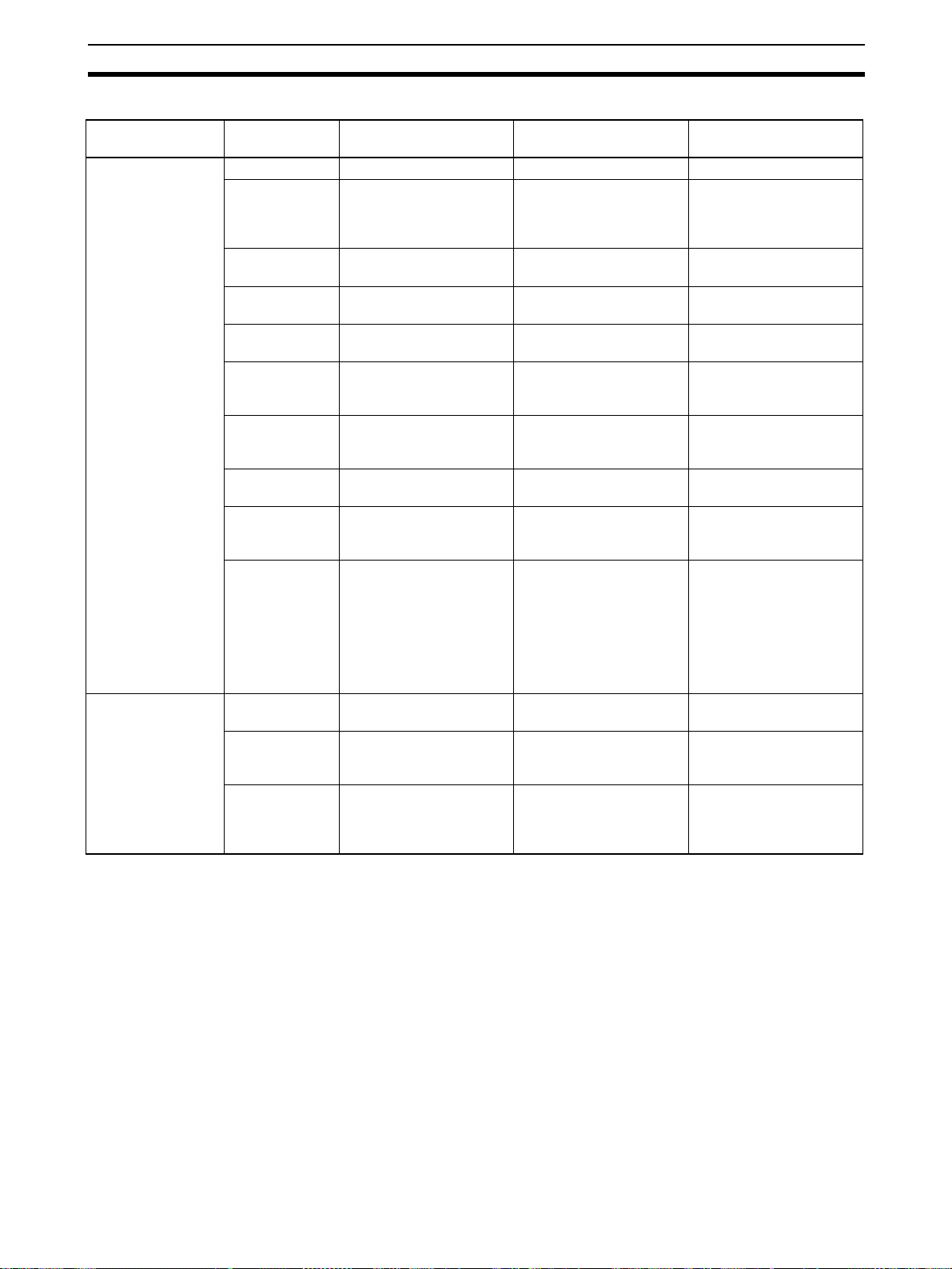

Data set/monitored

by CX-Process

Monitor Plus

Function block data Control Blocks:

Contact signals Contact signals through Contact Distributor (Block Model

Analog

signals

Sent to

Monitor Plus

Set from

Monitor Plus

Loop Control Unit Loop Control Board

Basic PID (Block Model 011), Advanced PID (Block Model

012), Blended PID (Block Model 013), Batch Flowrate Capture (Block Model 014), Indication and Setting (Block Model

031), Indication and Operation (Block Model 032), Ratio

Setting (Block Model 033), Indicator (Block Model 034), 2position ON/OFF (Block Model 001), and 3-position ON/

OFF (Block Model 002)

Operation Blocks:

High/Low Alarm (Block Model 111), Segment Program 2

(Block Model 157), ON/OFF Valve Manipulator (Block

Model 221), Motor Manipulator (Block Model 222), Reversible Motor Manipulator (Block Model 223), Motor Opening

Manipulator (Block Model 224), Timer (Block Model 205)

and Counter (Block Model 208)

201) + Internal Switch (Block Model 209)

Analog signals through Input Selector (Block Model 162)

Analog signals through Constant Generator (Block Model

166)

1-1-2 Screen Outlines

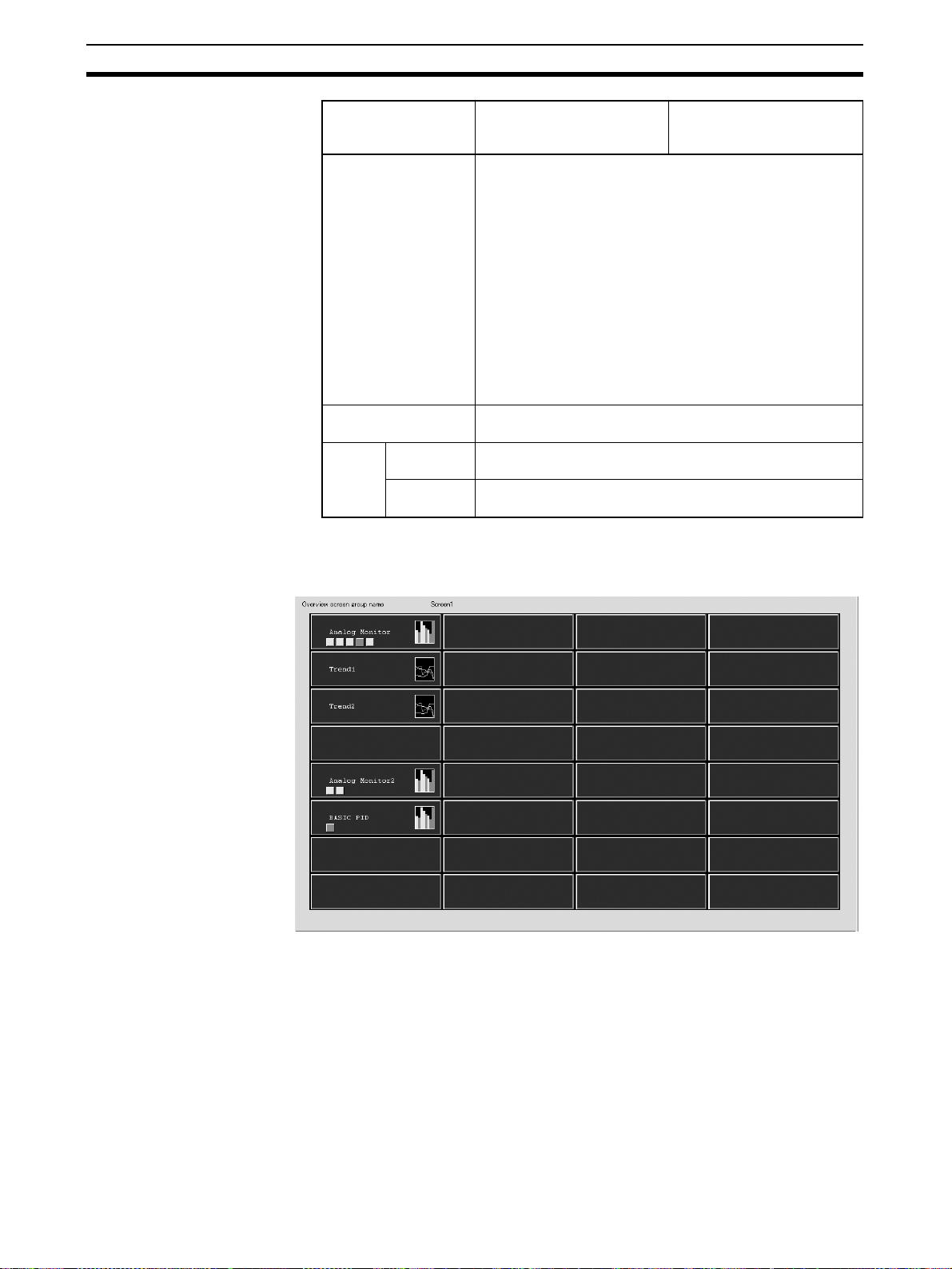

Overview Screen Possesses the functions of all menu screens and alarm display screens.

4

Page 20

CX-Process Monitor Plus Section 1-1

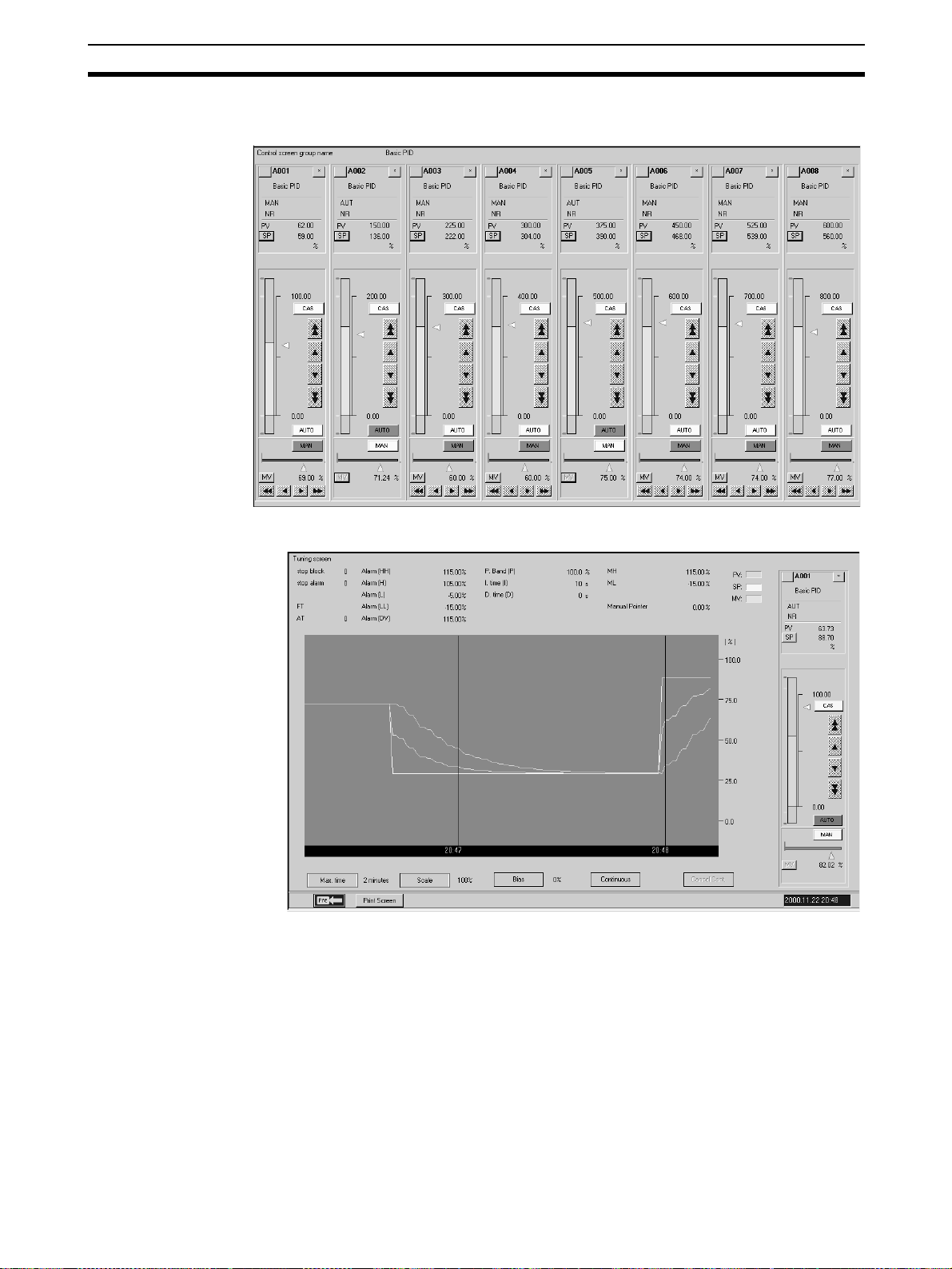

Control Screens Monitor and set the Control Block and part of the Operation Block, monitor

analog signals, and monitor and set contact signals.

Tuning Screens Use this screen to change Control Block P, I, D constants.

5

Page 21

CX-Process Monitor Plus Section 1-1

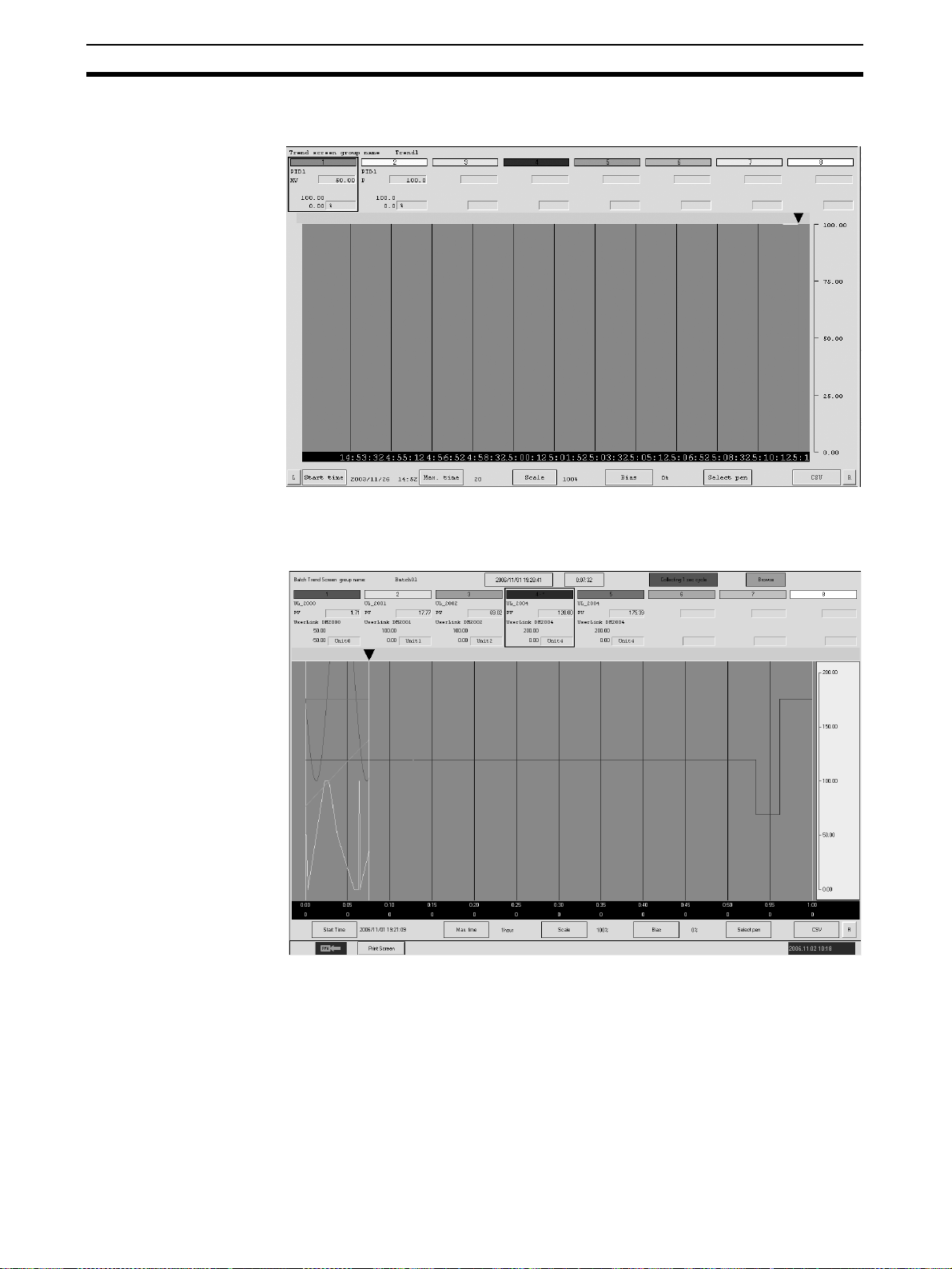

Trend Screens Display as an image changes due to the passage to time of the Control Block

PV, SP, MV, or other analog signals.

Batch Trend Screens Display a recorder image of the changes over time of the Control Block PV,

SP, MV, or other analog signals. Trend sampling is started and ended with tag

data (digital or analog) as the trigger.

6

Page 22

CX-Process Monitor Plus Section 1-1

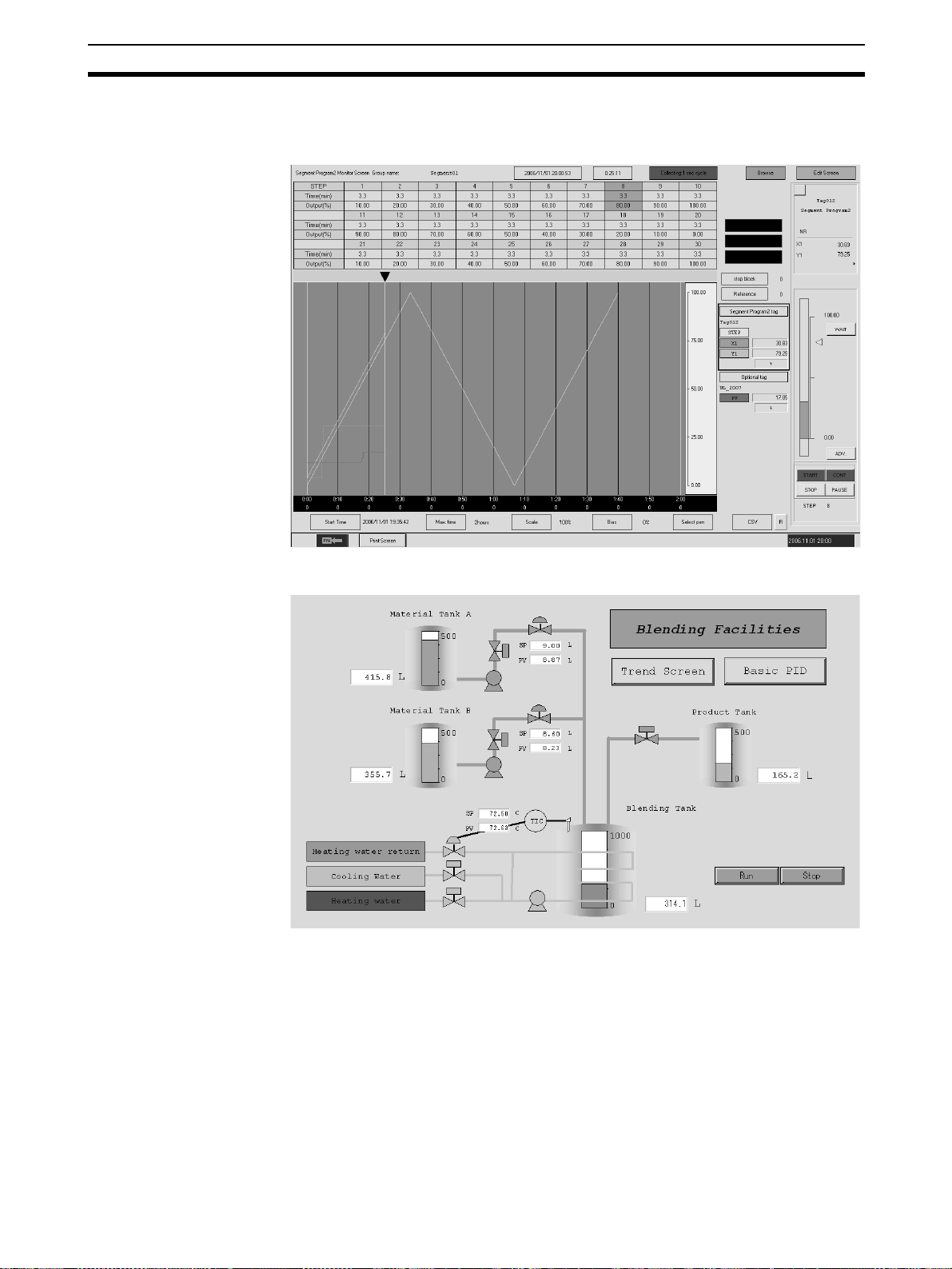

Segment Program 2

Screens

Display a recorder image of PV trends for Segment Program 2 (Block Model

157) set values. Segments can be set in table format while observing a time

axis graph.

Graphic Screens Use the screen to display the device status as a schematic.

7

Page 23

CX-Process Monitor Plus Section 1-1

Annunciator Screens Use this screen to display comprehensively the status (mainly the alarm sta-

tus) of the contacts.

Operation Guide Screens Use this screen to display registered messages when the contact signal is

ON.

8

Page 24

CX-Process Monitor Plus Section 1-1

Alarm Log Screens Use this screen to display the alarm history.

Operation Log Screens Use this screen to display the operation history.

9

Page 25

CX-Process Monitor Plus Section 1-1

System Monitor Screens Use this screen to display the system status, and run/stop the Loop Control

Unit/Board.

System Monitor Log

Screens

Use this screen to display the run/stop history and Execution error history, and

to record the time at which they occurred.

1-1-3 CX-Process Monitor Plus System Requirements

FinsGateway As shown below, the CX-Process Monitor Plus uses the communications

driver FinsGateway (Embedded version) to communicate with the PLC (Programmable Controller) mounted to the Loop Control Unit/Board.

CX-Process Tool CX-Process Monitor Plus

Software

FinsGateway (Embedded version)

Hardware

RS-232C port

Controller Link

Support Board

Ethernet board

10

Page 26

CX-Process Monitor Plus Section 1-1

You can use any one of the FinsGateway (Embedded version) given below.

• Serial Unit driver

• Controller Link driver

• CLK (PCI) driver

• ETN_UNIT driver

Note 1. You cannot start CX-Process Monitor Plus if FinsGateway (Embedded ver-

sion) is not installed.

2. CX-Process (Monitor Plus and Tool) cannot use FinsGateway Version 1 as

a communications driver. Be sure to use Version 3 or later.

3. If CX-Programmer, CX-Protocol, CX-Motion, or other Support Software

(i.e., CX-Server communications software), or applications that use special serial drivers, are connected online, they use the same COM port, so

CX-Process (Monitor Plus and Tool) cannot connect online (i.e., initialize

serial communications) using the Host link (SYSWAY). First disconnect offline other Support Software or applications that use special serial drivers,

before reconnecting online (i.e., initializing serial communications) CXProcess. Conversely, while CX-Process is connected online (i.e., initializing serial communications), other Support Software that communicate using CX-Server cannot connect online.

4. You cannot install CX-Process and FinsGateway Version 1 on the same

IBM PC/AT or compatible.

5. If using Windows NT 4.0 as your OS, you must use Service Pack 6a or later.

6. Both FinsGateway Version 3 and Version 2003 (Embedded version) are

bundled with the CX-Process Monitor Plus software.

When using FinsGateway for the communications driver, install one of

these versions. The FinsGateway Runtime Version can also be used. If the

runtime version is already installed, it is not necessary to install the embedded version.

Set Network Address,

Node Address, and Unit

Address.

Note The CX-Process Monitor and CX-Process Monitor Plus use FinsGateway as

The network address, node address, and unit address for communications

between the CX-Process Monitor Plus and PLC are set using the CX-Process

Tool address settings (Settings/Network Settings).

the communications driver for connections with the PLC. When using the CXProcess Monitor or CX-Process Monitor Plus, always set FinsGateway as the

communications driver for the CX-Process Tool. If the CX-Server is set, the

CX-Process Monitor or CX-Process Monitor Plus will not be able to go online

with the PLC.

11

Page 27

CX-Process Monitor Plus Section 1-1

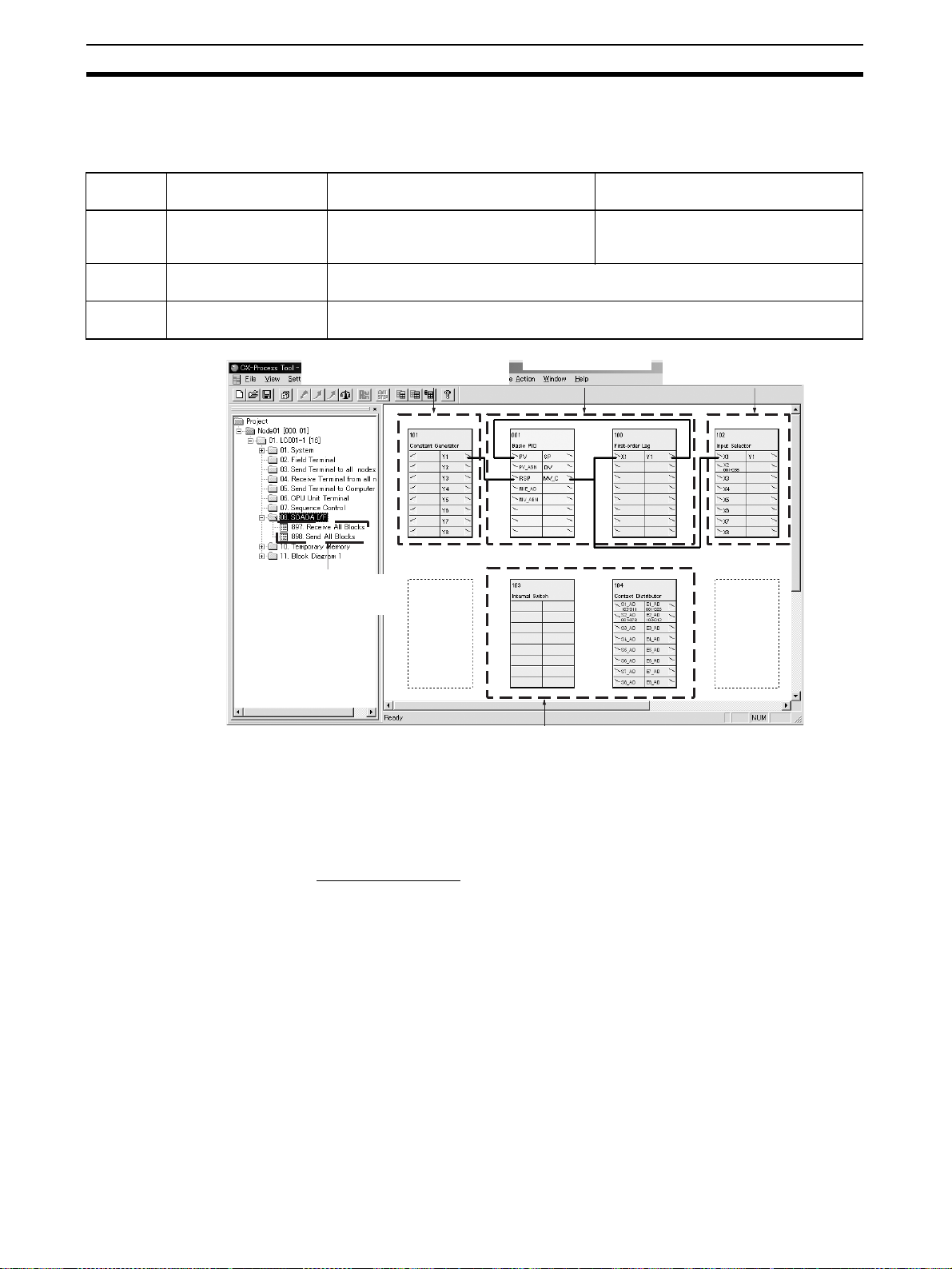

Register the Function

Blocks to Exchange Data

with the CX-Process

Monitor Plus.

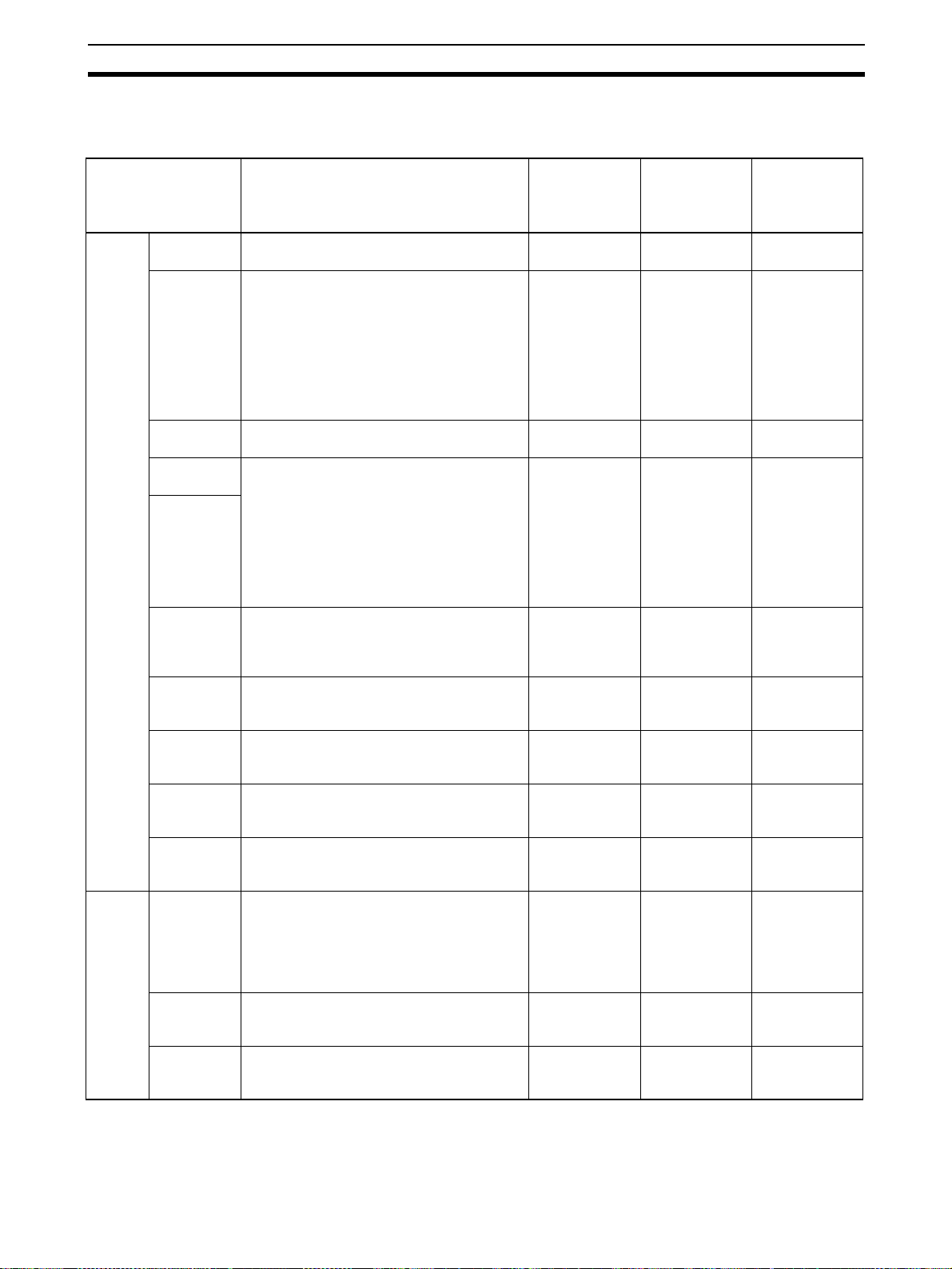

Items to

monitor

Function

block data

Contact

signals

Analog

signals

Registrations and

connections

Only register the function blocks.

Register and connect

the function blocks.

Register and connect

the function blocks.

Register and connect the function blocks to exchange data with the CX-Process Monitor Plus. The following function blocks can be used depending on

the items to be monitored.

Loop Control Unit Loop Control Board

Send All Blocks block (Block Model 462)

and Receive All Blocks block (Block

Model 461)

Contact Distributor (Block Model 201) or Internal Switch (Block Model 209)

Input Selector block (Block Model 162) and Constant Generator block (Block Model

166)

Block to input analog signals from

the CX-Process Monitor Plus.

Main function blocks Block to output analog signals to

HMI settings in the System Common

block (Block Mode 000)

the CX-Process Monitor Plus.

Blocks to monitor function

block ITEM tags from the

CX-Process Monitor Plus.

Set CSV Tags and Tags for

CX-Process Monitor Plus.

1,2,3... 1. Register the Send All Blocks block (Block Model 642) and Receive All

Blocks to manipulate or display contacts

from the CX-Process Monitor Plus.

The CX-Process Monitor Plus uses tags set from the CX-Process Tool (Ver.

3.2 or higher) to read and write data in Loop Control Units/Boards. To use the

CX-Process Monitor Plus, therefore, CSV tags and tags for the CX-Process

Monitor Plus must be set.

Loop Control Units

Blocks block (Block Model 641).

2. Set tags as follows:

• Function block data: Set CSV tags.

• Individual contact signals: Set tags for Monitor Plus for the contacts in the

Internal Switch block (Block Model 209).

• Individual analog signals from LCU to computer: Set tags for Monitor Plus

for the analog signals in the Input Selection block (Block Model 162).

• Individual analog signals from computer to LCU: Set tags for Monitor Plus

for the analog signals in the Constant Generator block (Block Model 166).

12

Page 28

CX-Process Monitor Plus Section 1-1

Loop Control Boards

1,2,3... 1. Make the settings for the HMI in the System Common block (Block Model

000).

2. Set tags as follows:

• Function block data: Set CSV tags.

• Individual contact signals: Set tags for Monitor Plus for the contacts in the

Internal Switch block (Block Model 209).

• Individual analog signals from LCU to computer: Set tags for Monitor Plus

for the analog signals in the Input Selection block (Block Model 162).

• Individual analog signals from computer to LCU: Set tags for Monitor Plus

for the analog signals in the Constant Generator block (Block Model 166).

Note For both the Loop Control Unit and Loop Control Board, the follow-

ing function blocks must be created and connected separately to

enable monitoring and setting individual contact signals and individual analog signals (i.e., other than function block data).

• To monitor and set individual contact signals, contact signals must be

input/output using the Contact Distributor block (Block Model 201) and

Internal Switch block (Block Model 209).

• To monitor individual analog signals, analog signals must be output

from the Input Selection block (Block Model 162).

• To set individual analog signals, analog signals must be input to the

Constant Generator block (Block Model 166).

Compile the Tag File for

the CX-Process Monitor

Plus.

Note The following dialog box will be displayed if a tag file for Monitor Plus is output

Download Function Block

Data to the Loop Control

Unit/Board.

Compile the Monitor Tag

Files.

The tag file for Monitor Plus must be compiled (Execute – Create Tag File –

Monitor Plus Tag).

while the CX-Process Monitor Plus is running.

Tag information will not be updated if a tag file for Monitor Plus is output during CX-Process Monitor Plus operation. To update the tag file, restart the CXProcess Monitor Plus.

Download the function blocks.

Start the CX-Process Monitor Plus. In the Main Window, click the Run Button

or the Setup Button. The monitor tag files (mtagmst and mtagsubmst) will be

automatically generated based on the tag file for Monitor Plus (monitor.csv).

13

Page 29

CX-Process Monitor Plus Section 1-1

1-1-4 Relationship to CX-Process Tool

Tag Names As shown earlier in CX-Process Monitor Plus Conditions of Use, if monitoring

or operating Function Blocks using CX-Process Monitor Plus, you must first

perform the following steps using CX-Process Tool.

1,2,3... 1. Set the network address, node address, and unit address.

2. Register the blocks for which data is to be exchanged with the CX-Process

Monitor Plus.

3. Set the CSV tags and tags for Monitor Plus.

4. Generate the tag file for Monitor Plus.

5. Download the function block data to the Loop Control Unit/Board.

6. Compile the monitor tag file.

CX-Process Monitor Plus handles all items allocated tag names as one string.

CX-Process Monitor Plus does not differentiate which Function Block was

used to specify the tag names.

ITEM Settings Function block ITEMs are set as shown in the following table. The CX-Process

Tool is normally used to set initial data S and the CX-Process Monitor Plus is

normally used to set operation data O.

CX-Process Tool

data classification

Initial settings S Initial setting parameter

Operation data O Operation parameters

Type ITEM Example: PID Block CX-Process

for each function block

for each function block

Note Initial settings O and operation data S classifications are displayed on ITEM

Setting Screens of the CX-Process Tool. For details on the ITEMs set each

function block, refer to the Function Block Reference Manual.

Example

ITEM type ITEM Contents R: Read, W: Write,

Parameter 004 Operation cycle (s) R/W (S) ---

Parameter 008 High/Low alarm R/W (O) R/W

012 Hysteresis set value R/W (S) ---

Parameter 023 Local SP set value R/W (O) R/W

024 SP set method (Initial setting)

0: Local, 1: Remote/Local

Forward/Reverse direction,

SP setting method, compensation method, etc.

Example: PID Block SP,

alarm settings, PID constants, etc.

R/W (S) R

Tool

Set Cannot be set

Set in special

cases

R/W: Read/write,

---: R/W disabled

r, t/w: CX-Process Tool

operation monitor/Operation

monitor read and write

(S): Initial setting,

(O): Operation data

CX-Process

Tool

CX-Process

Monitor Plus

Set

CX-Process

Monitor Plus

14

Note Analog values are normally set with the CX-Process Monitor Plus. They can

be set with the CX-Process Tool provided that they are in percentage increments between 0% and 100%. Scaling engineering units cannot be set with

the CX-Process Tool.

Page 30

CX-Process Monitor Plus Section 1-1

1-1-5 Relation between Screens and Function Blocks

The relation between screens and function blocks is shown below.

Userdefined

screens

System

screens

Screen Loop Control Unit: Register Send All

Overview

Screen

Control

Screens

Tuning

Screens

Trend

Screens

Batch Trend

Screen

Segment

Program 2

Screen

Graphic

Screens

Annunciator

Screens

Operation

Guide

Screens

System

Monitor

Screens

Alarm Log

Screens

Operation

History

Screens

System

Monitor Log

Screens

Blocks and Receive All Blocks blocks

Loop Control Boards: Make HMI settings

in the System Common block

--- --- --- ---

Basic PID, Advanced PID, Blended PID

(Block Model 013), Batch Flowrate Capture

(Block Model 014), Indication and Setting,

Indication and Operation, Ratio Setting,

Indicator, 2-Position ON/OFF, 3-Position

ON/OFF, High/Low Alarm, Segment Program 2, ON/OFF Valve Manipulator, Motor

Manipulator, Reversible Motor Manipulator,

Motor Opening Manipulator, Timer, Counter

Segment Program 2 --- --- ---

Basic PID, Advanced PID, Blended PID

(Block Model 013), Batch Flowrate Capture

(Block Model 014), Indication and Setting,

Indication and Operation, Ratio Setting,

Indicator, 2-Position ON/OFF, 3-Position

ON/OFF (PV, SP, MV only), Segment Program 2, ON/OFF Valve Manipulator, Motor

Manipulator, Reversible Motor Manipulator,

Motor Opening Manipulator

Segment Program 2 Can be desig-

Same tag ITEMs as for Control screens. Analog signal

Same tag ITEMs as for Control screens. --- Contact signal

--- --- Contact signal

--- --- --- ---

Contacts for which alarms were automatically allocated when registering tags

--- --- --- ---

--- --- --- ---

Input Selector

block (Block

Model 162)

Analog signal

or analog value

parameters

Analog signal

or analog value

parameters

nated as

expansion measurement tags

or analog value

parameters

--- Contacts for

Internal Switch

block (Block

Model 209)

Contact signal

or contact

parameters

Contact signal

or contact

parameters

Can be designated as

expansion measurement tags

Contact signal

or contact

parameters

or contact

parameters

or contact

parameters

which alarms

were automatically allocated

when registering tags

Constant

Generator

block (Block

Model 166)

Analog output

Analog output

Can be designated as

expansion measurement tags

Analog output

---

---

---

15

Page 31

CX-Process Monitor Plus Section 1-1

1-1-6 CX-Process Monitor Plus Software Specifications

CX-Process Monitor Plus Specifications

Item Descriptions

Product name CX-Process Monitor Plus

Model WS02-LCMC1-EV2

Applicable PLC-series CS/CJ-series

Applicable Unit Loop Control Unit Ver. 2.0 or later

Applicable

computer

Required software FinsGateway (One of the following must be installed according to the commu-

Connecting

method

Loop Control Unit/Board data specification method

Offline operation functions Prepare user configuration screens for use in the online operation screen.

Personal computer IBM PC/AT or compatible

CPU Min. required: Pentium MMX233 MHz or faster, Recommended: Celeron

OS Microsoft Windows NT 4.0 (Service Pack 6a or higher), Windows 2000 Profes-

Memory Min. required: 128 Mbytes, Recommended: 256 Mbytes or more

Hard disk drive Min. required: 650 Mbytes of free space, Recommended: 800 Mbytes or more

Monitor Min. required: XGA, Recommended: XGA or higher, min. 1024 × 768 dots, 256

CD-ROM drive At least one

Mouse Recommended: Microsoft mouse or compatible pointing device

Printer Any printer supported by Microsoft Windows

Sound board 1 board

Connection with CPU Unit

(or Serial Communications

Board/Unit)

Connection via Controller

Link

Connection via Ethernet Using Fins-

Loop Control Board

Process-control CPU Unit

Loop-control CPU Unit

400 MHz or faster

sional (Service Pack 4 or higher), Windows XP Professional (Operation is not

supported on Windows 95, 98, or ME.)

of free space

colors

nications method with the PLC.)

Serial Unit driver (Host Link)

Controller Link driver (Controller Link)

CLK (PCI) driver (Controller Link, PCI bus)

ETN_UNIT driver (Ethernet)

Using FinsGateway

Serial Unit

version

Using FinsGateway CLK

(PCI) Driver

Using FinsGateway

Controller

Link driver

Gateway

ETN_UNIT

driver

CSV tags and tags for Monitor Plus (CSV monitor tags) are set using the CXProcess Tool. These tags are used to specify Loop Control Unit/Board data.

The computer is connected to the CPU Unit peripheral ports or

integrated RS-232C port, or RS-232C port of the Serial Communications Unit. (Only a 1:1 connection is possible.)

– Connector cable:

When connecting to the CPU Unit peripheral ports: Model

CS1W-CN@@@ (2 m, 6 m)

When connecting to the CPU Unit’s RS-232C port: Model

XW2Z@@@-@ (2 m, 5 m)

– Communications protocol with PLC: Host Link (not supported

on Peripheral bus)

Install the driver in a computer equipped with a Controller Link

Support Board (PCI slot) to support communications between

the computer and PLCs equipped with a Controller Link Unit.

Install the driver in a computer equipped with a Controller Link

Support Board (ISA slot) to support communications between

the computer and PLCs equipped with a Controller Link Unit.

Install the FinsGateway ETN_UNIT driver on the computer on

which an Ethernet board is mounted to enable to enable communications with the PLC on which the Ethernet Unit is

mounted.

16

Page 32

CX-Process Monitor Plus Section 1-1

Item Descriptions

Online

operation

functions

User Configuration

screen

Overview

screen

Control

screen

Tuning

screen

Trend

screen

Place buttons for progressing to the Control screen, Trend screen and other

screens. 4 columns and 8 lines are displayed on each screen (max. 32

screens).

Control blocks such as the PID blocks and Indication blocks, and some Operation blocks are displayed for up to 8 loops in a single screen in the form of a

field device. The maximum number of screens is 400.

This screen displays the Set Point, PV and MV numeric values, displays PV as

a bar graph, and can be used for changing Set Point, MAN and other setting

values. The color of bar graphs changes when an alarm occurs.

You can progress to the Tuning screen from the Control screen.

Fine tuning according to the degree specified by the user is possible for PID

constants.

This screen is for setting P, I, D parameters in Control blocks such as the PID

blocks, and for setting alarm setting values. PV, Set Point and MV can be tuned

while their trends are monitored. The maximum number of screens is 3200.

Run stop/stop cancellation are possible on each function block.

Note Only the Control block that is designated as the source at the 1-Block

The analog signals output from each function block tag ITEM are collected at

fixed intervals and saved to a file. If necessary, up to 8 analog signals can be

displayed on one screen in the form of a multi-dot recorder.

Data collected

(logger function)

Data display Horizontal (time) axis: 2, 4, 8, 12 and 24 hour time units

Send Terminal to Computer block can be registered.

Real time trend

10, 20, 50, 100, or 300

hours of data is saved at 1,

2, 5, 10, or 30-second intervals for up to 480 tags.

Historic trend

30, 150, 300, 900, or 1,800

days of data is saved at 1,

5, 10, 30, or 60-minute

intervals for up to 960 tags.

Vertical (8-point common) axis: Graduation can be

Data is displayed from the time when the specified display

start time is reached.

Display color: red, yellow, green, blue, magenta, purple,

cyan, white

Data can be saved in CSV

format either using button

commands, or automatically at a set interval (every

1, 2, 3, 4, 6, 8, 10, 12, 18,

20, 24, 48, 72, 96, 120, or

240 hours)

can be scrolled

enlarged by a factor or 1,

2, 5 and 10.

17

Page 33

CX-Process Monitor Plus Section 1-1

Item Descriptions

Online

operation

functions

User Configuration

screen

Batch Trend

Screen

Segment

Program 2

Screen

The analog signals output from each function block tag ITEM are collected at

fixed intervals when tag data conditions are satisfied, and the data is automatically saved. Data can be displayed in combination with past data.

Data collection Four hours or ten days of

data is saved at 1-second

or 1-minute intervals for up

to 960 tags.

Data display Horizontal (time) axis: The following time units can be

Vertical (8-point common) axis: Gradation can be

When a display start time is specified, data is displayed

from that time.Display color: Red, yellow, green, blue,

magenta, purple, cyan, white

Displays PV trends for Segment Program 2 (Block Model 157) set values. Segments can be set in table format while observing a time axis graph.

Data collection 3, 30, or 180 days of data is

saved at 1-, 10-, or 60-second intervals.

Data display Horizontal (time) axis: 2, 4, 8, 12, 24, 72 hour time incre-

Vertical axis: Gradation can be enlarged by a factor of

1, 2, 5, or 10.

When a display start time is specified, data is displayed

from that time.

Display color: Yellow, light blue, green, purple

Data can be manually

saved in CSV format by button operations or automatically saved at the

completion of each batch.

Past data can be automatically saved in binary format.

scrolled.

1, 2, 4, 6, 8, 12, 24, 36, 48, and

72 hours; 7 or 10 days

enlarged by a factor of

1, 2, 5, or 10.

Data can be manually

saved in CSV format by button operations or automatically saved with each batch

completion.

Past data can be automatically saved in binary format.

ments can be scrolled.

18

Page 34

CX-Process Monitor Plus Section 1-1

Item Descriptions

Online

operation

functions

User Configuration

screen

System

Fixed screen

Graphic

screen

Annunciator

screen

Operation

Guide

Screen

Alarm Log

screen

Operation

Log screen

System

Monitor

screen

System

Monitor Log

screen

Graphic elements representing plant process control can be pasted to Graphic

Screens from a library. These elements can be used to display changes in

plant status. Up to 200 Graphic Screens can be created.

• Library Figures and Image Elements

Text displays, straight lines, rectangles, rectangle with round corners,

ellipses, polygons, images

• Library Functional Objects

• Fixed Graphic Display Elements:

Text, instruments, thermometers, transmitters, orifices

• Changeable Graphic Display Elements:

Analog displays: Bar graph displays, numeric displays, tanks

Analog settings: Numerical settings

Contact display: Pumps, valves, pipes

Contact operation: Switches

• Elements for Screen Display:

Screen jump elements

FP switch (faceplate popup) elements

• Individual graphic screens can be saved as files or read.

• Multiple graphic elements can be grouped and saved as files or read.

This screen notifies the operator of alarms or errors that occur by changing the

display color and emitting sound. At the same time, a 32-character message is

displayed over two lines on screen elements.

A total of 16 screen elements (4 columns × 4 lines) can be displayed on each

screen. The maximum number of screens is 5.

This screen displays pre-registered 128-character messages over two lines

together with the date of occurrence when the specified internal switch is set to

ON.

Max. number of registerable messages: 1000, Number of display colors: 16

Up to 1000 messages are displayed in a single screen.

Output possible in CSV format.

A record of alarms (time of error occurrence, tag name, PV or MV current

value at occurrence, alarm type, etc.) that occur and that are input from the

Control and Alarm blocks is saved and displayed as a list later.

Up to 1000 alarm messages are displayed in a single screen.

Output possible in CSV format.

A record of operations using graphic screen data and switch objects and

changes made to ITEM data in the Loop Control Unit/Board in the Control or

Tuning Screen can be saved and later displayed as an operation log. The operation log includes the date and time of change, tag name, original ITEM data

setting, new ITEM data setting, etc.

Up to 1000 operation messages are displayed in a single screen.

Output possible in CSV format.

This screen displays the Loop Control Unit/Board system error information.

This screen displays a log of the run/stop history and a history of execution

errors that occur on the Loop Control Unit/Board together with the date of

occurrence.

Output possible in CSV format.

The Loop Control Unit/Board does not itself have HMI functionality. To monitor

function block operation status, it is thus necessary to connect and use the

CX-Process Monitor Plus.

19

Page 35

CX-Process Monitor Plus Section 1-1

1-1-7 CX-Process Monitor Plus Setting and Monitoring Capabilities

The data that can be set and monitored using the CX-Process Monitor Plus is

listed in the following table.

Item Loop Control Unit Loop Control Board

Function block data Control Blocks:

Basic PID (Block Model 011), Advanced PID (Block Model

012), Blended PID (Block Model 013), Batch Flowrate Capture

(Block Model 014), Indication and Setting (Block Model 031),

Indication and Operation (Block Model 032), Ratio Setting

(Block Model 033), Indicator (Block Model 034), 2-position

ON/OFF (Block Model 001), and 3-position ON/OFF (Block

Model 002)

Operation Blocks:

High/Low Alarm (Block Model 111), Segment Program 2

(Block Model 157), ON/OFF Valve Manipulator (Block Model

221), Motor Manipulator (Block Model 222), Reversible Motor

Manipulator (Block Model 223), Motor Opening Manipulator

(Block Model 224), Timer (Block Model 205) and Counter

(Block Model 208)

Contact signals Contact signals through Contact Distributor (Block Model 201)

Analog

signals

Sent to

Monitor Plus

Set from

Monitor Plus

+ Internal Switch (Block Model 209)

Analog signals through Input Selector (Block Model 162)

Analog signals through Constant Generator (Block Model 166)

The following items must be set in advance using the CX-Process Tool.

Item Loop Control Unit Loop Control Board

1. Register the function

blocks used for data

exchange.

2. Set the tag names. Function Block Data:

3. Create the monitor tag file. Start the CX-Monitor Plus and click the Run or Setup Button.

Function block data

exchange

Contact signal data

exchange

Analog signal data

exchange

Receive All Blocks (Block Model

461) and Send All Blocks (Block

Model 462)

Contact Distributor block (Block Model 201) + Internal Switch block

(Block Model 209)

Input Selector block (Block Model 162) and Constant Generator

block (Block Model 166)

CSV tags are set in the CX-Process Tool by selecting the function

blocks and then selected Settings – Tag Setting – CSV Tags.

Contact Signals:

tags for Monitor Plus are set for each contact in the Internal Switch

blocks. The function blocks are then selected, the right mouse button

clicked, and Tag Setting – Monitor Plus Tag is selected.

Analog Signals:

tags for Monitor Plus are set for each analog signal in the Variable

ITEM Setting and Constant Generator blocks. The function blocks

are then selected, the right mouse button clicked, and Tag Setting –

Monitor Plus Tag is selected.

HMI functions in the System

Common block (Block Model

000)

Note Using CX-Process Monitor Plus, you can monitor and set only the data given

above to which tag names have been allocated. Also, be sure to use CX-Process Tool to make tag name settings.

20

Page 36

CX-Process Monitor Plus Section 1-1

1-1-8 Files Created Using CX-Process Monitor Plus

The following data can be created using the CX-Process Monitor Plus

Data type Contents

Graphic screen data

(filename extension: grf)

Object data

(filename extension: itm)

Graphic screen data, created for each screen.

Grouped object data (functional objects, figures,

images), created when a group file is saved. (Does

not include jump elements or FP switch elements.)

1-1-9 Version Upgrade

The CX-Process Monitor Plus has been upgraded from version 1.0 to version

2.0. The following table lists the contents of the version upgrade.

Item Previous (version 1.0) New (version 2.0)

Startup method There were two modes: Engineer Mode

Monitor display Maximum size: XGA 1,024 × 768 Individual monitor screens can be dis-

Segment Program 2 Screen No Yes

Batch Trend Screens No Yes

Trend

Screens

Graphic

Screens

Data collection cycle and

maximum retention period

for realtime trends

Data collection cycle and

maximum retention period

for historical trends

Graphic screen saving and

reading

and Operator Mode.

• Setup (Engineer Mode)

Start Button → Engineer Button →

Setup Button → Password input

• Operation

Start Button → Operator Button

Collection cycle: 10 s

Maximum retention period: 12 hours

Collection cycle: 1 min

Maximum retention period: 10 days

Yes (No filename extension) Yes (Filename extension: GRF)

Startup has been divided into setup and

operation.

• Setup

Setup Button → Password input →

Run Button

• Operation

Run Button

played on the entire desktop.

• PV trends for values set in the Segment Program 2 Monitor Screen are

displayed.

• Collection cycle: 1, 10, or 60 s

Maximum retention period:

3, 30, or 180 days, past data automatically saved, or CSV data automatically

saved

• Segments can be set in table format on

the Segment Program 2 Edit Screen.

• Past data can be read.

• Trend function that can start or end col-

lecting with tag data (contact or analog) as a trigger.

• Collection cycle: 1 min or 1 s

Maximum retention period: 10 days, 4

hours, past data automatically saved,

or CSV data automatically saved

• Data can be overlapped with past data.

Collection cycle: 1, 2, 5, 10, or 30 s

Maximum retention period: 10, 20, 50,

100, or 300 hours

Collection cycle: 1, 5, 10, 30, or 60 min

Maximum retention period: 30, 150, 300,

900, or 1,800 days

21

Page 37

CX-Process Monitor Plus Section 1-1

Item Previous (version 1.0) New (version 2.0)

Graphic

screen

objects

Function

objects

Figures

and

images

Individual

graphics

objects

Jumps (screen

call) objects

FR switch

(face plate

popup) objects

Figures No Yes

Images No Objects are provided for displaying

Grouping No Functional objects, figures and images

Displaying/hiding according

to tag values

Flashing

according to

tag values

Color changes

according to

tag values

Image

changes

according to

tag values

Full color

settings

Font specifications

Alignment and

fine position

adjustment

No Yes

No Yes

(Text display, straight lines, rectangle,

rectangles with round corners, ellipses,

and polygons) Color changes, displaying/hiding, and flashing can be enabled

by allocating tags.

images (BMP or JPEG) in frames rectangles. Color changes, displaying/hiding, and flashing can be enabled by

allocating tags.

(except for jump objects and FP switch

objects) can be grouped, and groups

can be cut, moved, deleted, saved in

files, or loaded from files (filename

extension: ITM).

No Yes

(Tanks, pipes, pumps, valves, meter

bars, data, parts, switches, and text

boxes)

Note: Also enabled for figures (text dis-

play, straight lines, rectangles,

rectangles with round corners,

ellipses, and polygons) and

images.

No Yes

(Tanks, pipes, pumps, valves, meter

bars, data, parts, switches, and text

boxes)

Note: Also enabled for figures (text dis-

play, straight lines, rectangles,

rectangles with round corners,

ellipses, and polygons) and

images.

No Yes

(Text display, straight lines, rectangles,

rectangles with round corners, ellipses,

and polygons)

No Yes

(Images)

No

(16 colors)

Fonts cannot be specified Fonts can be specified.

Vertical and horizontal alignment of

multiple objects, and alignment to grid

lines

Ye s

(Tanks, meter bars, data, parts,

switches, and text boxes)

The following functions have been

added: Arranging multiple objects with

even spacing, and fine adjustment of

positions (using the cursor) when moving objects.

22

Page 38

Basic Operating Procedure Section 1-2

Item Previous (version 1.0) New (version 2.0)

Graphic

screen

objects

Logs CSV file output (operation

Operation

guide

messages

Starting external applications and

starting/resetting from external applications

Confirmation message when exiting

the CX-Process Monitor Plus

Data

objects

Switch

objects

Data and

text box

objects

Data and

switch

objects

Number of simultaneous

Graphic Builder screens for

editing

logs, alarm logs, operation

logs, and system monitor

logs)

Number of operation guide

messages registered

Data input

range checks

Text s tr in g

positions

Text s tr in g

specification

Background

color transparency

Operation log No Yes

No Yes

(Upper and lower limits can be checked

for inputs.)

Left justified and centered vertically. The following are possible: Left justified,

horizontally centered, right justified, top

aligned, vertically centered, and bottom

aligned.

Only ON, OFF, START, and STOP can

be specified.

No Yes

One screen only Multiple Graphic Builder screens can be

Single lines are output without separating individual items.

100 max. 1,000 max.

A portion of the CX-Process Monitor

Plus display remains.

Exits with no message. A dialog box is displayed to confirm

Any text string can be specified.

displayed simultaneously for editing, and

objects can be copied between screens.

Each item can be separated in the output (making later analysis easier).

The CX-Process Monitor Plus Window

is completely cleared and the external

application is started. (The CX-Process

Monitor Plus runs in the background and

collects data.)

The CX-Process Monitor Plus can be

reset by starting the execution file from

an external application.

whether the Monitor Process is to be

ended during execution.

Note The CX-Process Monitor Plus does not support Loop Control Units earlier

than version 2.0.

1-2 Basic Operating Procedure

This section explains the procedure up to monitoring using CX-Process Monitor Plus.

1,2,3... 1. Install CX-Process Monitor Plus. (Refer to Section 2 Setup.)

• Install CX-Process Monitor Plus.

2. Make Settings and Transfer Using CX-Process Tool. (Refer to the CX-Pro-

cess Tool Operation Manual (W372).)

a. Set the network address, node address, and unit address (Settings –

Network).

b. Register and connect the function blocks that exchange data with the

CX-Process Monitor Plus.

c. Set the CSV tags and the tags for Monitor Plus.

23

Page 39

Basic Operating Procedure Section 1-2

• CSV tags: Settings – Tag Setting – CSV Tag

• Tags for Monitor Plus: Settings – Tag Setting – Monitor Plus Tag

d. Generate the tag file for Monitor Plus: Execute – Create Tag File –

Monitor Plus Tag

e. Download the function block data to the Loop Control Unit/Board.

f. Compile the monitor tags. Start the CX-Process Monitor Plus and click

the Setup Button.

g. Enter password.

Note (a) If the above steps are not performed using CX-Process Tool, you

cannot monitor using CX-Process Monitor Plus.

(b) The network address, node address, and unit address settings

made with CX-Process Tool are also used by the CX-Process

Monitor Plus.

3. Configure the Screen Using CX-Process Monitor Plus. (Refer to Section 4

Screen Configuration.)

• Design the monitor system using CX-Process Monitor Plus.

• Create and register the Control screens, Trend screens, Graphic screens,

and Annunciator screens on Overview screens.

• When registering, specify on the screen the Loop Control Unit/Board data

by selecting the tags (CSV tags and tags for Monitor Plus) set using CXProcess Tool.

• Set the communications conditions with the PLC using the system monitor setting window (if using serial communications).

Perform the following procedure.

a. Select Omron – CX-Process Monitor Plus – CX-Process Monitor

Plus from the Windows Start Menu.

b. Click the Setup Button in the Main Window.

c. Enter password.

d. Click the System Monitor Builder Button in the Setup Dialog Box,

and make settings using the System Monitor Setting Window.

e. Click the Graphic Builder Button in the Setup Dialog Box, create the

Graphic Screen Create Window (including tag name specifications),

and save.

f. Click the CRT Builder Button in the Setup Dialog Box, and register the

screen using the Builder Window (including Tag name specifications).

g. From the Builder Window Settings menu, select Save, and then click

the OK Button.

4. Check Screen Configuration Using CX-Process Monitor Plus. (Refer to 5-

7 Checking Configurations.)

• Check if you can monitor the Loop Control Unit/Board using the configured screen.

• Start FinsGateway Serial Unit communications according to the communications conditions set using the System monitor setting window by starting the monitoring process (i.e., start FinsGateway Controller Link and

Ethernet manually).

Perform the following operation.

a. Click the Setup Button in the Main Window.

b. Enter password.

24

Page 40

Basic Operating Procedure Section 1-2

c. In the Setup Dialog Box, click the Run Button (to start the monitoring

process for the configured screen, and to start communications).

d. Select the screens using the Overview Screen, and check that each

function is operating normally.

5. Start the Monitor Operation to monitor the Loop Control Unit/Board. (Refer

to Section SECTION 4 Monitor Screen Functions and Operations for de-

tails.)

Perform the following operation.

a. Click the Run Button in the Main Window.

b. Click the screens using the Overview Screen.

25

Page 41

Basic Operating Procedure Section 1-2

26

Page 42

This section describes installing the CX-Process and connections to the PLC.

2-1 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2-1-1 Before Installing FinsGateway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2-1-2 Installing FinsGateway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2-1-3 Uninstalling the CX-Process Monitor/Monitor Plus Version 1 . . . . 37

2-1-4 Installing CX-Process Monitor Plus . . . . . . . . . . . . . . . . . . . . . . . . . 38

2-1-5 Converting CX-Process Monitor Plus Data . . . . . . . . . . . . . . . . . . . 41

2-1-6 Converting Data from CX-Process Monitor. . . . . . . . . . . . . . . . . . . 43

2-1-7 CX-Process Monitor Plus Conversion Specifications . . . . . . . . . . . 46

2-2 Connecting the PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

2-2-1 Connecting via Host Link. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

2-2-2 Connecting through a Controller Link Support Board . . . . . . . . . . . 49

2-2-3 Connections via Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

SECTION 2

Setup

27

Page 43

Installation Section 2-1

2-1 Installation

Install the CX-Process Monitor Plus using the following procedure.

Install FinsGateway, Embedded Version.

(See sections 2-1-1 and 2-1-2)

Are CX-Process

Monitor and Monitor

Plus Version 1 already

installed?

New

installation

Ye s Ye s

No

Update

(Previous data will not

be used.)

(Screen configuration data

and trend information will

be lost.)

Is CX-Process

Monitor and Monitor

Plus Version 1 data to

be used with Monitor

Plus Version 2?

Uninstall the CX-Process Monitor

and Monitor Plus Version 1.

(See section 2-1-3)

Install CX-Process Monitor Plus Version 2. (See section 2-1-4.)

What is the version

of the CX-Process

Monitor and Monitor

Plus data?

CX-Process Monitor

Plus Version 1

Convert CX-Process Monitor Plus Version

1 data (See section 2-1-5)

Move the CX-Process Monitor Plus

Version 1 database.

Uninstall CX-Process Monitor Plus

Version 1. (See section 2-1-3)

Convert the CX-Process Monitor Plus

Version 1 data. (See section 2-1-5.)

Convert the CX-Process Monitor Plus

Version 1 database (using the Trend

Database Conversion Utility).

CX-Process Monitor

Convert the CX-Process Monitor data.

(See section 2-1-6.)

Reset to CX-Process Monitor Plus

tags all of the monitor tags set using

the CX-Process Tool.

Move the CX-Process Monitor

database.

Uninstall the CX-Process Monitor.

(See section 2-1-3.)

Convert the CX-Process Monitor data.

(See section 2-1-6.)

Convert the CX-Process Monitor (using

the Trend Database Conversion Utility).

28

Copy the data that was converted.

Redo the Graphic Screen data settings

(if Graphic Screens are being used).

Copy the data that was converted.

Redo the Graphic Screen data settings

(if Graphic Screens are being used).

Reallocate the reset tags for CXProcess Monitor Plus Version 2 on the

control and graphic screens.

Note 1. This software must be installed on an computer using Windows NT 4.0,

2000, or XP as its OS. It will not operate on Windows 95, 98, or Me.

2. Be sure to install FinsGateway Embedded before installing CX-Process

Monitor Plus. You cannot install CX-Process Monitor Plus first.

3. You cannot start CX-Process Monitor Plus if FinsGateway Embedded is

not installed.

4. If connecting CX-Process online using a PLC and Host Link, you cannot

install and use CX-Process on the same computer as FinsGateway Version 1.

Page 44

Installation Section 2-1

2-1-1 Before Installing FinsGateway

To use the CX-Process Monitor Plus software, the communications driver

(FinsGateway) must be installed in the computer in which the CX-Process

Monitor Plus software is installed.

FinsGateway

Versions

Selecting the

Communications Driver

Note 1. Supported for CX-Process Monitor Plus only with Windows NT 4.0 and

Both FinsGateway Version 3 and Version 2003 (Embedded version) are bundled with the CX-Process Monitor Plus software. When using FinsGateway for

the communications driver, install one of these versions.

The FinsGateWay Runtime version can also be used. If the Runtime version

is already installed, it is not necessary to install the Embedded version.

The CX-Process Monitor Plus software supports the following communications drivers.

• FinsGateway Ver. 3.12

• FinsGateway Ver. 2003

Select the communications driver to install according to the user's application.

The following tables show the main factors to use in selecting the driver.

OS

Driver OS

Windows NT 4.0

(See note 1.)

FinsGateway Ver. 3.12 Supported Supported Supported

FinsGateway Ver. 2003 Not supported Supported Supported

Service Pack 6a.

2. Supported for CX-Process Monitor Plus only with Windows 2000 Professional and Service Pack 4.

3. Supported for CX-Process Monitor Plus only with Windows XP Professional.

Windows 2000

(See note 2.)

Windows XP

(See note 3.)

Communications

Driver Communications method

FinsGateway Ver. 3.12 Not supported Not supported

FinsGateway Ver. 2003 Supported Supported (See note.)

Note When duplex Ethernet is used in the computer, the difference software is

stored in the following folder:

<CD-ROM drive>:\Fgw2003\Duplex\FgwEtnUpdate200301\setup.exe.

Items to Check before