Page 1

WS02-MCTC1-EV

CX-Motion

Creates programs to control the motion controller and monitors controller status

Provides the ideal environment for motion control support, from motion controller

program development to full system operation.

Key Features

The CX-Motion software can be used to create, edit, and print the various parameters, position data, and motion

control programs (G code) required to operate Motion Controllers, transfer the data to the Motion Control Units, and

monitor operation of the Motion Control Units. Increase productivity in every step of the motion control process,

from development of the motion control program to system operation.

Motion Control Programs

Easily create motion control G Code programs and parameters.

CX-Motion can create all of the data needed in the Motion Control Unit,

such as parameters, position data, and the program. The program can be

input in either G code or mnemonics.

● When the Unit is connected online, data can be transferred,verified, and

saved.

● Data for different Units can be registered and managed as separate projects.

Operation Monitor

Powerful support during startup and operation

The MC Unit Monitoring function can display vital information at the computer, such as the present position, task being executed, I/O status, error dis-

plays, and servo system trace data.

● Up to 20 errors that have occurred in the Motion Control Unit can be stored and displayed (CS1W-MC421/221 and CV500-MC421/221 Motion

Control Units only).

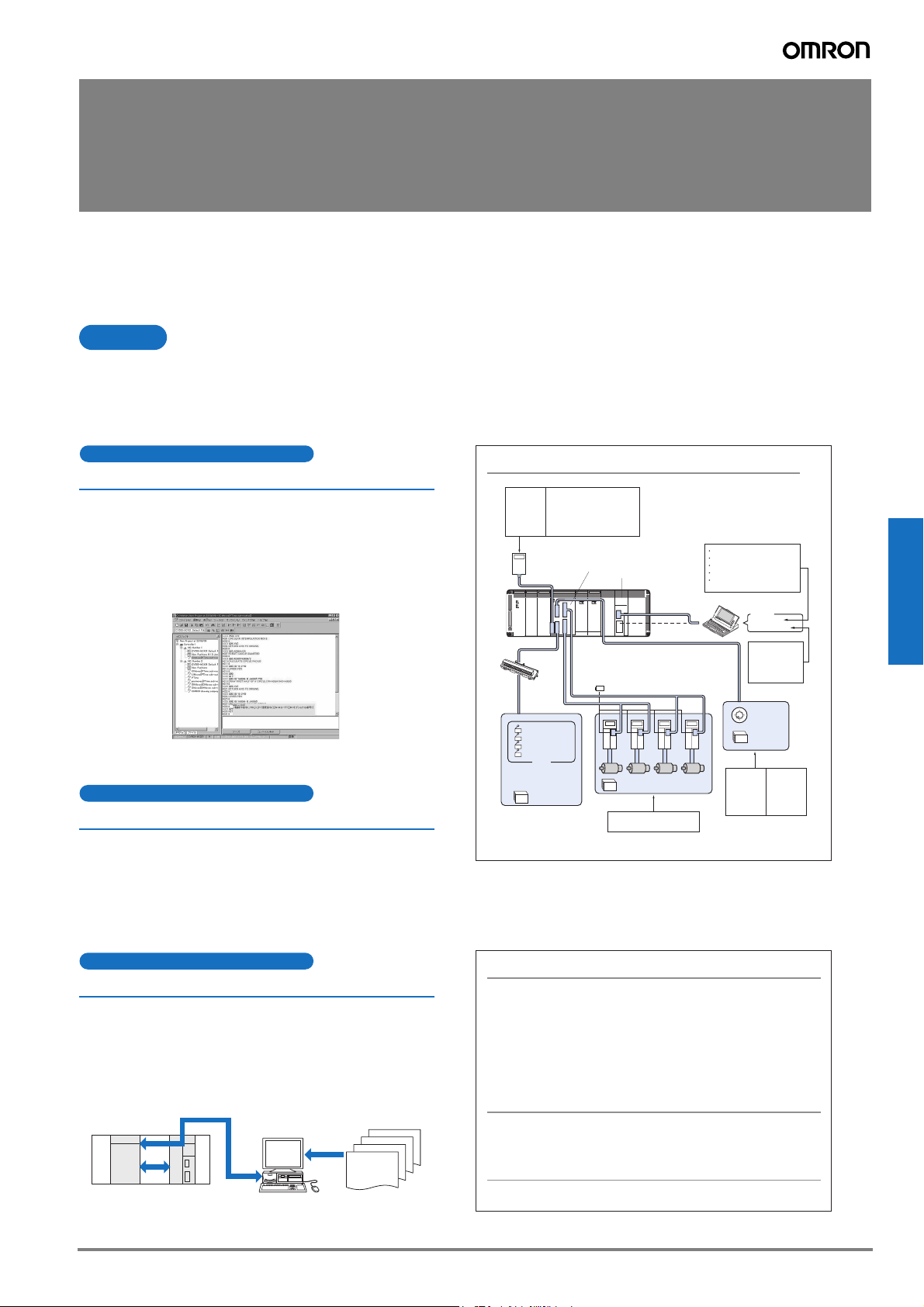

System Configuration with CS1W-MC421/221

Used for

Monitoring (PVs, I/O signals)

testruns,

Origin search

debugging,

JOG feed

teaching, etc.

Error reset

Teaching

Teaching Box

External I/O

CCW limit input

CW limit input

Origin proximity input

Emergency stop input

4 axes

4 general inputs

4 general outputs

24 V for interface

Note: A data backup battery is required when an ABS encoderis used.

MC Unit

CPU Unit

ABS data backup

battery (See note.)

Either ABS or INC

encoders can be used.

Peripheral port

connection

RS-232C port

connection

24 V for interface

Servo Driver

Set/transfer system parameters

Create/transfer position data

Set/transfer G code program

Monitor status

File management

Computer

CX-Motion

CX-Programmer

Creating/transferring ladder program

Monitoring

File management

MPG

MPG

1 channel

5 V for

interface

Used for fine

Axis selection

positioning

during

Multiplier

selection

teaching, etc.

Software

Automatic Loading Function

Ideal for flexible, small-lot production lines

Various programs and position data can be stored on disks for the

computer running the CX-motion software and the required

program/position data can be substituted into the Motion Control Unit when

necessary. More than 100 different application programs can be used in

this way. A wide variety of programs can be available for execution if the

computer is used to storedata for the MC Unit.

Computer run-

Lot No.

MC Unit

ning CX-Motion

CPU Unit

Job No. 3

Job No. 2

Job No. 1

<program>

P000, P001......

<position data>

POSIT......

Job No. X

Specifications

Basic Functions

Other Functions

Created files

Create/transfer/print various parameters, position data, and the

MC program, transfer data to the MC Unit, and monitor MC

Unit’s operating status.

Automatic loading, Servo data tracing

CX-Motion project files (*.mci) Contents: System parameters,

position data, program, scripts, etc.

Operating Environment

CPU:

OS:

Pentium 100 MHz or faster CPU

Windows 95, 98, NT4.0, W2000 or XP.

Compatible PLCs:

CS Series, C200HX/HG/HE Series, and CVM1/CV Series

291CX-Motion

Page 2

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. I27E-EN-01

In the interest of product improvement, specifications are subject to change without notice.

292 Software

Loading...

Loading...