Page 1

Cat. No. W123-E1-3

SYSMAC

C-series

Link Adapters

Page 2

SYSMAC C-series Link Adapters

Installation Guide

Revised June 1999

Page 3

iv

Page 4

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

!

serious injury.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

!

serious injury.

Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

!

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 1990

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Note Indicates

1, 2, 3...

information of particular interest for ef

of the product.

1. Indicates lists of one sort or another, such as procedures, checklists, etc.

ficient and convenient operation

v

Page 5

vi

Page 6

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Link Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 Repeater Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

Wiring and Power Supply . . . . . . . . . . . . . . . . . . . . . . . . .

2-1 Power Supply and Cable Lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 RS-422 and RS-232C Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 Optical Fiber Cable (APF/PCF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 Crystal Optical Fiber Cable (AGF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5 Backup Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6 Link Adapter Repeater Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3

Repeater Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4

System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1 PC Link Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Host Link Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Optical Remote I/O Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4 Wired Remote I/O Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5

Dimensions and Internal Configuration . . . . . . . . . . . . .

5-1 Link Adapter AL001 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Link Adapter AL002-(P)E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 Link Adapter AL004-(P)E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-4 Link Adapter AL005-(P)E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5 Link Adapter AL006-(P)E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-6 Link Adapter AL007-P . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix

Standard Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vii

Page 7

PRECAUTIONS

This section provides general precautions for using the SYSMAC C-series Link Adapters and related devices.

The

information contained in this section is important for the safe and r

must read this section and understand the information contained before attempting to set up or operate the Link

Adapters.

eliable application of the Link Adapters. You

1 Intended

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Audience

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ix

Page 8

1 Intended Audience

This

manual is intended for the following personnel, who must also have knowl

edge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The

user must operate the product according to the performance specifications

described in the relevant manuals.

Before

using the product under conditions which are

or applying the product to nuclear control systems, railroad systems, aviation

systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that

have a serious influence on lives and property if

may

your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient

systems, machines, and equipment with double safety mechanisms.

Be

this manual close at hand for reference during operation.

for

sure

to read this manual before attempting to use the Link Adapter and keep

3Safety Precautions

-

not described in the manual

used improperly

the systems, machines, and equipment, and be sure to provide the

, consult

WARNING It

!

is extremely important that the Link Adapter be used for the specified purpose

and

under the specified conditions, especially in applications that can directly or

indirectly

before

applying the Link Adapter system to the above-mentioned

3 Safety Precautions

WARNING Do

!

WARNING Do not touch any of the terminals or terminal blocks while the power is being

!

WARNING Provide safety measures in external circuits (i.e., not in the Programmable

!

not attempt to take any Unit apart while the power is being supplied. Doing

may result in electric shock.

supplied. Doing so may result in electric shock.

Controller),

if

an abnormality occurs due to malfunction of the PC or another external factor

affecting the PC operation. Not doing so may result in serious accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The

PC will turn OFF all outputs when its self-diagnosis

error

or when

termeasure

sure safety in the system.

• The PC outputs may remain ON or OFF due to deposition or burning of the

output

relays or

such

problems, external safety measures must be provided to ensure safety in

the system.

af

fect

human life. Y

including the following items, in order to ensure safety in the system

a severe failure alarm (F

for such errors, external safety measures must be provided to en

destruction of the output transistors. As a countermeasure for

ou must consult with your OMRON representative

applications.

function detects any

ALS) instruction is executed. As a coun

so

-

-

x

Page 9

• When the 24-VDC output (service power supply to the PC) is overloaded or

short-circuited, the voltage may drop and result in the outputs being turned

OFF.

As a countermeasure for such problems, external safety measures must

be provided to ensure safety in the system.

5Application Precautions

WARNING Do

!

not

attempt to disassemble, repair

may result in malfunction, fire, or electric shock.

, or modify any Units. Any attempt to do so

4 Operating Environment Precautions

Caution Do not operate the control system in the following locations:

!

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified in

the specifications.

subject to condensation as the result of severe changes in tempera

appropriate and suf

ficient countermeasures when installing systems in the

Caution Take

!

• Locations

ture.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

-

Caution The

!

operating environment of the Link Adapter system can have a large ef

on

the longevity and reliability of the system. Improper operating environments

can

lead to malfunction, failure, and other unforeseeable problems with the Link

Adapter

conditions

life of the system.

system. Be sure that the operating environment is

at

installation and remains within the specified conditions during the

5 Application Precautions

WARNING Always heed these precautions. Failure to abide by the following precautions

!

could lead to serious or possibly fatal injury.

• Always

necting to a ground of 100 Ω or less may result in electric shock.

• Always

ing

function or electric shock.

ground the system to 100 Ω or less when installing the Units. Not con

turn OFF the power supply to the Link Adapter system before attempt

any of the following. Not turning OFF the power supply may result in mal

• Mounting or dismounting the Units.

• Assembling the Units.

• Setting DIP switches or rotary switches.

• Connecting cables or wiring the system.

• Connecting or disconnecting the connectors.

fect

within the specified

-

-

-

xi

Page 10

5Application Precautions

Caution Failure

!

Link

Always heed these precautions.

Observe the following precautions when using the Link Adapter system.

• Tighten

• Fail-safe measures must be taken by the customer to ensure safety in the

• Always use the power supply voltages specified in this manual. An incorrect

• Take

• Install

• Disconnect

• Be sure that all the mounting screws, terminal screws, and cable connector

• Use

• Double-check

• Be

• Do

• Do

• When

• Before

• Install the Units properly as specified in the operation manuals. Improper

to abide by the following precautions could lead to faulty operation of the

Adapters or the system,

the screws on the terminal block of the AC Power Supply Unit to the

torque

specified in the operation manual. The loose screws may result in

ing or malfunction.

event

of incorrect, missing, or abnormal signals caused by broken signal lines,

momentary power interruptions, or other causes.

voltage may result in malfunction or burning.

appropriate measures to ensure that the specified power with the rated

voltage

power

ing

result in burning.

tests.

screws

tightening torque may result in malfunction.

terminals. Connection of bare stranded wires may result in burning.

ply. Incorrect wiring may result in burning.

are properly locked into place. Improper locking may result in malfunction.

either of these may break the cables.

break the cables.

Not doing so may result in malfunction or burning.

to

age.

installation of the Units may result in malfunction.

and frequency is supplied. Be particularly careful in places where the

supply is unstable. An incorrect power supply may result in malfunction.

external breakers and take other safety measures against short-circuit

in external wiring. Insuf

the functional ground terminal when

Not disconnecting the functional ground terminal may result in burning.

are tightened to the torque specified in the

crimp terminals for wiring. Do not connect bare stranded wires directly to

all wiring and switch settings before turning ON the power sup

sure that the terminal blocks, cables, and other items with locking

not pull on the cables or bend the cables beyond their natural limit.

not place objects on top of the cables or other wiring lines. Doing so may

replacing parts, be sure to confirm that the

touching a Unit, be sure to first touch a

discharge any

static built-up. Not doing so may result in malfunction or dam

or could damage the Link Adapters or the system.

burn

ficient safety measures against short-circuiting may

performing withstand voltage

relevant manuals. Incorrect

devices

Doing

rating of a new part is correct.

grounded metallic object in order

-

-

-

-

xii

Page 11

SECTION 1

Introduction

This document is designed to introduce the reader to the principles of Link Adapters and Repeater Units.

Link

Adapters and Repeater Units are connecting devices for SYSMAC

are

used to interconnect system devices such as host computers, PC Link Units, Host Link Units, and Remote I/O Units, and/or

to convert back and forth between wire cable and optical fiber cable.

1-1 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Link Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3

Repeater Units

1-4 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C-Series Programmable Controllers. Link Adapters

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

Page 12

1-1 Nomenclature

1-2 Link Adapters

1-2SectionLink Adapters

Names of specific OMRON products, as well as generic names for groups of

OMRON

refers either specifically or generically to an OMRON product. For convenience,

prefixes

“(P)”

the

their

this manual, PC always means Programmable Controller; Master means Remote I/O Master Unit; and Slave means Remote I/O Slave Unit.

products, are capitalized in this manual. Unit is also capitalized when

are omitted from model numbers of Link Adapters and Repeater Units.

in a model number

Appendix for a complete list

indicates two Units, one with the P and one without. See

of all products covered in this manual, along with

full model numbers. In addition, abbreviations are used for certain Units. In

it

Link Adapters are used to interconnect system devices such

PC

Link Units,

Host Link Units, and Remote I/O Units, and/or to convert between

as host computers,

wire cable and optical fiber cable.

Using optical links between Units provides greater transmission distance and

noise resistance. In addition, Link Adapters provide inputs to bypass a Unit

is improperly connected or which suf

which

fers a power interruption, thereby al

lowing other Units connected in series to continue operating normally.

Some

Link Adapters can ensure that a System will not begin operating until, for

example, a particular Subsystem has started up.

There

are various models of Link Adapters to perform a variety of functions. For

example,

the Link Adapter

generally used for connecting PC Link Systems is the

AL001, but when optical cable is used it is replaced by combinations of the

AL002-(P)E and AL004-(P)E.

Link Adapter AL002-(P)E is used to branch optical cables; the AL004-(P)E is

used to convert between optical and wire cables; and the AL005-(P)E and

AL006-(P)E

optical

are used for branching and/or converting between

fiber cables. Link Adapter AL007-P is used exclusively

dif

ferent types of

in Wired Remote

I/O Systems.

Link

Adapters

input

terminals which can be connected

tion even when the AC power supply is cut of

Link

Adapters AL002-(P)E and AL006-(P)E have repeater input terminals. (See

2-6 Link Adapter Repeater Input

AL002-(P)E, AL005-(P)E, and AL006-(P)E have auxiliary power

to a battery to ensure continued opera

f. (See

2-5 Backup Power Supply

.)

-

-

.)

The

following diagram illustrates how Link

Adapters can be used to connect sev

-

eral Units in a simple configuration.

Link

Adapter

Rack with

linkable Unit

Link

Adapter

Rack with

linkable Unit

Link

Adapter

Rack with

linkable Unit

Rack with

linkable Unit

2

Page 13

1-3 Repeater Units

Repeater

tical

Unit

Repeater Units are used with the cables shown here:

3G2A9-RPT01-P

3G2A9-RPT01

APF: All-plastic optical fiber cable

PCF: Plastic-clad optical fiber cable

Units are used when the number of Optical T

Slave Racks, etc., connected in series exceeds 32. Insertion of a Repeater

after the 32nd Unit allows the connection of additional Units. The following

Model

Applicable Cables

APF/PCF

PCF

1-4 General Specifications

Basic

specifications for the Link Adapters and Repeater Units are shown in the

following table:

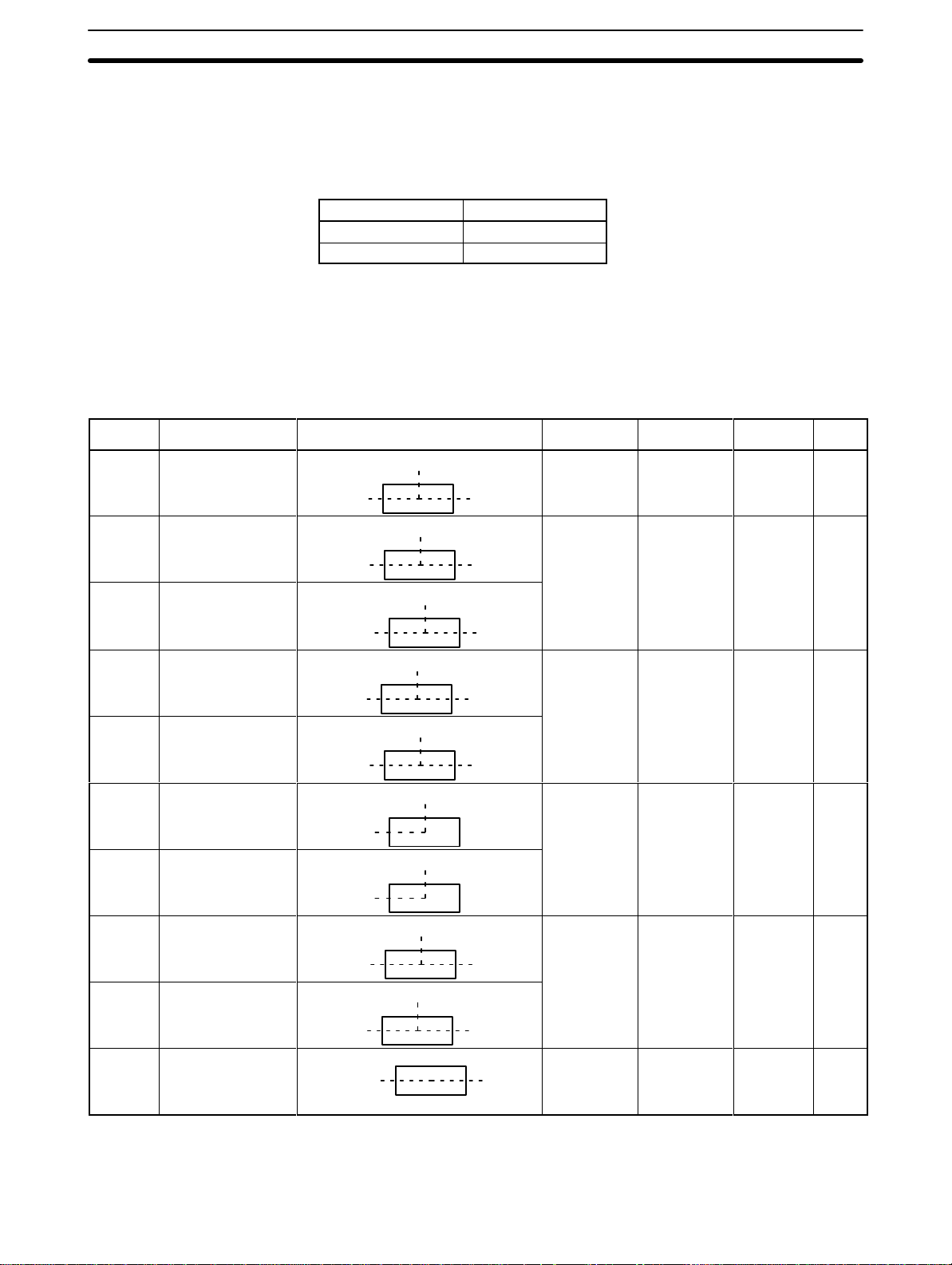

Link Adapters

Model Function Connection Supply

AL001

AL002-PE

AL002-E

AL004-PE Converting

AL004-E

AL005-PE Converting

AL005-E

AL006-PE

AL006-E

AL007-P Used

Branching RS-422 cable

Branching optical fiber

(APF/PCF) cable

Branching optical fiber

(PCF) cable

cal fiber (APC/PCF) and

wire (RS-232C/RS-422)

cable

Converting between opti

cal fiber (PCF) and wire

(RS-232C/RS-422) cable

cal fiber (APF/PCF) and

crystal optical fiber

(AGF) cable

Converting between opti

cal fiber (PCF) and crys

tal optical fiber (AGF)

cable

Converting between opti

cal fiber (APF/PCF) and

crystal optical fiber

(AGF) cable

Converting between opti

cal fiber (PCF) and crys

tal optical fiber (AGF)

cable

exclusively for

Wired Remote I/O Sys

tems. Converts between

optical fiber (APF/PCF)

and wire (RS-485) cable

between opti

between opti

RS-422

cab;e

Optical fiber

(APP/PCF)

Optical fiber

(PCF)

-

Optical fiber

(APF/PCF)

-

Optical fiber

(PCF)

-

Optical fiber

(AGF)

-

-

Optical fiber

(AGF)

-

Optical fibber

(APF/PCF)

-

-

Optical fiber

(PCF)

-

Optical fiber

(APF/PCF)

APF:

PCF: Plastic-clad optical fiber cable

AGF: Crystal optical fiber cable (GI 50 or 125)

RS–422 cable

RS-422

cable

Optical fiber (APF/PCF)

Optical fiber

(APF/PCF)

Optical fiber (PCF)

Optical fiber

RS–422 cable

RS-232C

cable

RS–422 cable

RS-232

cable

Optical fiber (APF/PCF)

Optical fiber (PCF)

Optical fiber (AGF)

Optical fiber

(AGF)

Optical fiber (AGF)

Optical fiber

(AGF)

RS-485

All-plastic optical fiber cable

(PCF)

voltage

Not necessary

100

to 120/200

to 240 V

AC or

12 to 24 V

DC

110

220 to 240 V

100

to 240 V

12 to 24 V

DC

100

to 240 V

12 to 24 V

DC

100

AC/

to 120/

to 120/200

AC or

AC/

to 120/200

AC or

AC/

to 200 V

85 to 132/170 to

246 V

to 26.4 V

94 to 132/

AC

187 to 264 V

85 to 132/170 to

254 V

to 26.4 V

85 to 132/170 to

264 V

to 26.4 V

AC

85 to 264 V

ransmitting I/O Units, Op

Operating

voltage range

--- ---

AC or 10.2

AC/DC

AC

AC or 10.2

AC/DC

AC or 10.2

AC/DC

AC

Power

consumption

10 V

A max.

10 V

A max. 1 kg

10 V

A max.

10 V

A max.

10 V

A max. 1 kg

1-4SectionGeneral Specifications

W

eight

250 g

max.

900 g

max.

max.

1.5 kg

max.

1.5 kg

max.

max.

-

3

Page 14

Repeater Units

Model

RPT01-P,

RPT01

Used

ting I/O Units, Slave Racks, etc., are connected in series.

Function

when more than 32 Optical T

ransmit-

Supply voltage Operating

voltage range

100

to 120/200 to

240 VAC or 12 to

24 VAC/DC

85 to 264 VAC 8 VA max. 600 g max.

Power

consumption

1-4SectionGeneral Specifications

Weight

4

Page 15

SECTION 2

Wiring and Power Supply

2-1 Power Supply and Cable Lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS-422 and RS-232C Cable

2-2

2-3 Optical Fiber Cable (APF/PCF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 Crystal Optical Fiber Cable (AGF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5 Backup Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6 Link Adapter Repeater Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

Page 16

2-1 Power Supply and Cable Lengths

For

Power Supply

all but AL001 Link Adapters, connect the

of the Link Adapter. A fuse is internally connected to the common line.

2-2SectionRS-422 and RS-232C Cable

AC hot line to the common terminal

Cable Lengths

Maximum

length for RS-232C cable is 15 m. For RS-422 it is 500 m, with a maxi

mum of 10 m for any given branch line. For RS-485 cable it is 200 m.

Maximum

mined

Link

lengths for optical fiber cables connected to Link Adapters are deter

by the type of

Adapters whose model numbers are

cable and the particular model of Link Adapter employed.

followed by “-P” can be connected to

either APF (all-plastic optical fiber) or PCF (plastic-clad optical fiber) cable.

Those without “-P” can be connected only to PCF cable. The model numbers,

cable types, and transmission distances are related as follows:

Cable Model No. With P Model No. Without P

APF

PCF

20 m

200 m 800 m

Not connectable

If transmission distances over 800 meters are required, it is necessary to use

AGF

(crystal optical fiber) cable, which calls for the

(see

1-4 General Specifications

cable, see

Caution Never use a Link Adapter with its terminal cover removed. Keep the cover se-

!

curely

2-4 Crystal Optical Fiber Cable (AGF

attached.

If the Link Adapter is installed in an office or on a desk, take ex

). For calculating maximum length for AGF

use of specific Link Adapters

).

tra care to avoid electrical shock.

-

-

-

2-2 RS-422 and RS-232C Cable

When

using optical fiber or RS-422 cable, it is possible to connect several Host

Link Units to one host computer. When RS-232C cable is used, however, the

connection

to convert to optical or RS-422 cable. As described below, wiring will vary depending

whether it is connected indirectly through a Link Adapter.

When

Adapter,

of

the host computer to the RD (receive data) terminal of the Host Link Unit. Like

wise, connect the RD terminal of the host computer to the SD terminal of the

Host

SDB

gram illustrates the proper connections when using RS-232C cable.

must either be on a one-to-one basis or a Link Adapter must be used

on whether a Host Link Unit is connected directly to a host computer or

a Host Link Unit is connected one-to-one to a host computer

and RS-232C cable is being used, connect the SD (send data) terminal

Link Unit. When using RS-422 cable,

and RDB terminals should be connected in a similar way

Host computer

FG

1

SG

7

SD

2

RD

3

, with no

Link

-

the SDA and RDA terminals and the

. The following dia

Link Unit

Host

FG

1

SG

7

SD

2

RD

3

-

Pin No. Symbol Symbol Pin No.

6

Page 17

Connecting Link Adapter

AL004-(P)E

Host

computer

When

using a Link Adapter

across,

puter,

as shown in the following diagram. Here the SD terminal of the host

for example, is connected to the SD terminal of the Link Adapter

Link Adapter AL004-(P)E

Link Adapter

AL004-(P)E

, connect both RS-232C and

RS-422 cable straight

for the internal configuration of the Link Adapter.

2-2SectionRS-422 and RS-232C Cable

com

. See

Host Link Unit

-

5-4

FG

1

SG

7

SD

2

RD

3

FG

SG

SD

RD

Wiring RS-232C and RS-422 Cable Connectors

Cable Preparation

1, 2, 3...

Prepare cables as follows before soldering:

1. Cut the cable to the required length.

2. Thread the end of the cable through a boot at least 50 mm up the cable.

3. Being

careful not to

cut

away 25

cable.

4. Using scissors, cut away all but 10 mm of the exposed braiding.

5. Using wire strippers, remove the covering from the last 5 mm of all wires.

6. Move

the boot to the

the end of it.

7. Wrap

aluminum foil tape 1 1/2 turns over the top of the braiding on top of the

boot.

1

7

2

3

FG

7

SG

3

SDA

9

SDB

5

RDA

6

RDB

1

FG

SG

SDA

SDB

RDA

RDB

7

3

9

5

6

1

damage the braiding underneath, use a razor blade to

mm of sheath for an RS-442 cable or 40 mm for an RS-232C

cut edge of the sheath and fold the braiding back over

7

Page 18

2-3SectionOptical Fiber Cable (APF/PCF)

Soldering

1, 2, 3...

Hood Assembly

Observe the following when soldering wires onto the connector.

1. Place

2. Pre-solder all wires and connector terminals.

3. Solder

4. Slide the heat-shrink tubing onto the soldered area and shrink into place.

Assemble the connector hood as shown in the following diagram.

heat-shrink tubing onto all wires far enough from the end so as to not

interfere with soldering.

all wires, inserting 4 mm of the exposed 5 mm of wire into the connec

tor terminal.

2-3 Optical Fiber Cable (APF/PCF)

Although

tical

cables.

nectors

customer. Note the following precautions when handling optical fiber cables:

the

special characteristics of optical fiber call for care in connecting op

devices, laying optical fiber cables basically does

All

OMRON PCF and the PF10l APF (length: 1 m) cables come with con

attached. Connectors for all other APF cables must be assembled by the

Boot

Aluminum

foil tape

not dif

fer from laying wire

-

-

-

1, 2, 3...

1. Always turn the power off to the Link Adapter when connecting or disconnecting an optical fiber cable.

2. Always

pull on the cable.

3. APF

do not try to force them in the wrong way.

4. Insert APF and PCF connectors until they lock into position.

5. Always place the protective caps on unused Link Adapter modules.

6. If

alcohol if necessary. Do not use any solvent other than ethyl alcohol.

hold the connector when disconnecting an optical fiber cable; never

and PCF connectors are designed to be inserted only in one direction;

dirty

, clean connectors gently with a tissue or sanitary cotton, using ethyl

8

Page 19

7. Do

not allow heavy objects to fall on optical cable or otherwise subject it to

excessive shock or strain.

2-4SectionCrystal Optical Fiber Cable (AGF)

2-4 Crystal Optical Fiber Cable (AGF)

Link

Adapters AL005-(P)E and

cal fiber cable in accordance with the following specifications:

Item Specifications

Conforming optical fiber Graded index 50/125

Applicable wavelength 800-900 nm

Transmit/receive differential 13 dB (min)

The

transmission distance between Link Adapters AL005-(P)E and AL006-(P)E

is basically determined by the dif

levels

of the Link Adapters and by the transmission loss over the crystal optical

fiber

cable. It is also af

the method of connection, as well as by the particular type of cable which is

used. Use the calculation method shown below to determine whether a given

cable length will fall within tolerable limits.

fected, however

AL006-(P)E can be connected with crystal opti

ference between the transmitting and receiving

, by the number of

-

connecting points and

9

Page 20

2-5SectionBackup Power Supply

When

total transmission loss from the system is subtracted from the transmit/re

ceive

dif

ferential of the Link Adapters, the margin must be at least 4 dB. T

mine

total transmission loss, first calculate the loss over the

the

loss/km by

nections

ly,

add the cable loss and the connector loss. Subtract this figure, the total trans

mission loss, from the transmit/receive differential. If the difference is greater

than 4 dB, then the cable length is acceptable.

the total length of the cable. Then calculate the loss at the con

by multiplying the loss/connection by

the number of connections. Final

cable by multiplying

o deter

-

-

-

-

-

Example 1

Example 2

Distance: 2.5 km; Connecting points: 4; Connecting method: permanent

When

this total transmission loss of 7.9 dB is subtracted from the 13 dB transmit/

receive

includes all loss at the Link Adapter connectors.

Distance: 2 km; Connecting points: 3; Connecting method: connectors

dif

ferential of the Link Adapters, it leaves a margin of 5.1 dB. The 13

dB

When

this total transmission loss of 8.1 dB is subtracted from the 13 dB transmit/

receive differential of the Link Adapters, it leaves a margin of 4.9 dB, safely

above the minimum margin of 4 dB.

2-5 Backup Power Supply

Link

Adapters which depend on a power

unable to transmit signals when power is cut off. Link Adapters AL002-(P)E,

AL005-(P)E, and AL006-(P)E, however, have auxiliary power input terminals

can be connected to a battery to ensure continued operation even when

which

the AC power supply is cut off.

Using the Auxiliary

Power Input Terminal

10

Only

the three Link Adapters listed above have this terminal.

on a low voltage (12-24 VAC/DC) power supply in place of their normal power

supply of 100/200 VAC. When it is necessary to have a backup power supply,

connect

od

ing

use a 24V battery.

a 12V battery to this terminal. If the battery is left unused for a long peri

it will discharge. It must either be periodically charged or connected to a float

charging device. T

supply (i.e., all except the AL001) are

They can operate

o avoid overcharging, set the output voltage at 13V

. Do not

-

-

Page 21

The

following diagram illustrates

backup

backup

signal

tery in Plant B this is avoided, and continued transmission is assured.

power supply

power supply in this case, then a power failure in Plant B

transmission between Plant A and Plant C. By connecting

, connected to the Link Adapter in Plant B. If

a situation in which a 12V battery is used as a

there were no

would cut of

the backup bat

2-5SectionBackup Power Supply

f

-

11

Page 22

2-6 Link Adapter Repeater Input

Link

Adapters AL002-(P)E and AL006-(P)E have repeater input terminals. They

are

used when it is necessary to

in a system connected to a branch line of the Link Adapter before signals are

transmitted

needed. When they are connected across, signals are relayed along the Link

Adapter’s

ue to be relayed even if the repeater input terminals are opened (OFF).

along the main line. They should be kept connected (ON) when not

main line. Once main line transmission has started, signals will contin

Link

Adapter

Master Branch system Terminator

Main line Main line

2-6SectionLink Adapter Repeater Input

be sure that power has already been turned on

-

Link

Adapter

AL002-(P)E or

AL006-(P)E

Relay input

Branch

line

Link

Adapter

Units which may be connected to a branch line (as is branch system above)

Units with repeat input

terminals (I/O Link Units)

Branch

Connect the Link Adapter

repeat input to the I/O Link

Unit’

If

the repeater

ple,

control system operation will begin when

even

if power to the branch system is of

To the repeater input

line

Repeater output

s repeater output.

input is connected across directly (not used) in the above exam

Units without repeater input terminals

(Units other than I/O Link Units)

Branch line

Power

source

’s

Connect so that the repeater input sill be ON when

power is turned on in the Unit connected to the

branch line (in this case a Remote I/O Slave).

the Master detects the terminator

f. In other words, the branch system is

X

Relay

X

ignored. The repeater input is used to prevent this from happening. When the

repeater

input is connected as shown above, then the Link Adapter’s main line

will not transmit data as long as power is not turned on in the branch system,

thereby

preventing the entire system from starting. Once the branch system is

operating normally, however, signals will continue to be transmitted along the

main line even if the repeater input turns OFF.

,

12

Page 23

SECTION 3

Repeater Units

13

Page 24

Repeater Unit RPT01-(P) must be used when the number of Optical Slave

Racks, Optical Transmitting I/O Units, I/O Link Units, and Link Adapters connected

in series exceeds 32. Insert a Repeater Unit between the 32nd and 33rd

Units.

The example below shows an Optical

I/O Units connected in series. Note that a Repeater Unit is inserted after the

ting

Slave Rack and Optical T

ransmit-

total of these Units reaches 32. When I/O Link Units or Link Adapters

AL002-(P)E, AL005-(P)E or AL006-(P)E are used, each of them must also be

counted as one of the 32 Units.

3SectionRepeater Units

CPU Rack

with Optical

Master

Optical

Slave

Rack

Nomenclature and Indicator Lights

Optical

T

ransmitting

I/O Units

32 Units total

Repeater Unit

Optical T

I/O Units

1

- 32 Units

ransmitting

14

The on/off indicator stays lit while power is turned on. The reception indicator

flashes

The

when

the optical bidirectional module receives signals from either side.

transmission indicator flashes when signals are sent

to either side from the

optical bidirectional module.

Page 25

Connections

Dimensions

3SectionRepeater Units

15

Page 26

SECTION 4

System Configuration

Various

illustrate

mote

system configurations call for the use of particular Link Adapters. This section presents a number of examples which

the usage of Link Adapters in PC Link Systems, Host Link Systems, Optical Remote I/O Systems, and W

I/O Systems. See

4-1 PC Link Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2

Host Link Systems

Optical Remote I/O Systems

4-3

4-4 Wired Remote I/O Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 General Specifications

for details on the functions and specifications of

ired Re

particular Link Adapters.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

17

Page 27

4-1 PC Link Systems

It

is necessary to use Link Adapters when 3 or more PC Link Units are connected

in a System.

Example 1

PC

A

diagram below.

4-1SectionPC Link Systems

Link System can be connected using Link Adapter AL001 as shown in the

Example 2

C-Series PC with

PC Link Unit

CPU Rack with

PC Link Unit

RS-422 branch line

RS-422 RS-422 RS-422

(10 m max.)

Link Adapter

AL004-(P)E

CPU Rack with

PC Link Unit

Link Adapter

AL001

CPU Rack with

PC Link Unit

RS-422 branch line

Link Adapter

AL001

CPU Rack with

PC Link Unit

(10 m max.)

Link Adapters AL002-(P)E and AL004-(P)E can be used to insert optical links

between

sistance

connect

PC Link Units to extend transmission distance and provide superior re

to noise. Optical links connect

to the PC Link Units themselves. In the diagram below

only Link Adapters; they do not directly

, the straight lines

represent wire cables and the jagged lines represent optical fiber cables.

Link Adapter

AL004-(P)E

Link Adapter

AL004-(P)E

Link Adapter

AL004-(P)E

Link Adapter

AL004-(P)E

Link Adapter

AL004-(P)E

C-Series

Optical fiber (APF/PCF)

PC with

PC Link Unit

-

C-Series PC with

PC Link Unit

C-Series PC with

PC Link Unit

18

Page 28

4-2 Host Link Systems

Link

Adapters are used in Host Link Systems for branching and for converting to

the type of cable required by the host computer.

A

Example 1

Host computer

RS-232C(15 m max.)

Link

Adapter

AL004-(P)E

RS-422

Link Adapter

AL001

RS-422 RS-422 RS-422

Wired Host Link System can be

and AL001 as shown below. Link Adapter AL004-(P)E is used to convert between

RS-232C and RS-422 cable. Link Adapter AL001 is used for

Link Adapter

AL001

4-2SectionHost Link Systems

connected using Link Adapters AL004-(P)E

branching.

Link Adapter

AL001

CPU Rack with

Host Link Unit

Example 2

RS-422 branch line

(10 m max.)

Optical fiber (APF/PCF)

RS-422 branch line

(10 m max.)

CPU Rack with

Host Link Unit

CPU Rack with

Host Link Unit

RS-422 branch line

(10 m max.)

CPU Rack with

Host Link Unit

Optical Host Link Systems can be connected in series using Link Adapter

AL004-(P)E as shown below.

Host computer

RS-422 or RS-232C

Link

Adapter

AL004-(P)E

.

C-Series PC

with

Optical Host

Link Unit

C-Series PC

with

Optical Host

Link Unit

Optical fiber (APF/PCF)

C-Series PC

with

Optical Host

Link Unit

C-Series PC

with

Optical Host

Link Unit

C-Series PC

with

Optical Host

Link Unit

19

Page 29

Example 3

4-3SectionOptical Remote I/O Systems

As

shown in Example 3, more than one Optical Host Link Unit can be

in

series using optical fiber cables. However

nection,

also

AL002-(P)E

etc.) occurs in one of the Units, all the subsequent Host Link Units will

cease to operate.

as shown below

This can be prevented by using Link Adapters such as the

. These Link Adapters bypass any malfunctioning

, if any failure (power failure, discon

Host Link Unit, thereby allowing the rest of the system to operate normally. In

other words, even if a power failure occurs in a Host Link Unit connected to a

branch

line of a Link Adapter

, signals are still transmitted to the other Host Link

Units.

connected

-

Host computer

Optical fiber (APF/PCF)

C-Series PC

with

Optical Host

Link Unit

RS-422 or RS-232C

Link

Adapter

AL004-(P)E

Link Adapter

AL002-(P)E

C-Series PC

with

Optical Host

Link Unit

Link Adapter

AL002-(P)E

.

C-Series PC

with

Optical Host

Link Unit

4-3 Optical Remote I/O Systems

Example 1

Example

1: In an Optical System, Units can be connected in

any failure (power failure, disconnection, etc.) occurs

the

subsequent Units will also cease to operate. This can be prevented by using

Link Adapters such as the AL002-(P)E as shown below. These Link Adapters

bypass

any malfunctioning Unit connected to a branch line, thereby allowing the

rest of the system to operate normally.

Link Adapter

AL002-(P)E

C-Series PC

Optical Host

Link Unit

Link Adapter

AL002-(P)E

Optical fiber (APF/PCF)

with

in one of the Units, all of

C-Series PC

with

Optical Host

Link Unit

series. However

, if

20

CPU Rack with

Optical Master

Optical fiber (APF/PCF)

Link

Adapter

AL002-(P)E

Optical Link Rack Optical Slave Rack

Link Adapter

AL002-(P)E

C120 CPU Rack

C120 I/O Link Rack

Page 30

4-3SectionOptical Remote I/O Systems

Example 2

Link

Adapter

AL005-(P)E

CPU Rack with

Optical Master

An Optical System with Optical Transmitting I/O Units can be connected with

crystal

optical fiber cable (AGF) by using Link

Adapter AL005-(P)E as shown be

low:

Link Adapter

AL005-(P)E

Crystal optical fiber (AGF)

Optical Slave Rack

Optical fiber (APF/PCF)

Optical T

ransmitting

I/O Units

-

Example 3

Link

AL005-(P)E

CPU Rack with

Optical Master

Adapter

An Optical System with an I/O Link Unit can be connected with crystal optical

fiber cable by using Link Adapters AL005-(P)E and AL006-(P)E as shown below:

Crystal optical fiber (AGF)

Optical fiber (APF/PCF)

A maximum of 8 Link Adapters can be used in this configuration.

Link Adapter

AL006-(P)E

I/O Link Rack

Link Adapter

AL005-(P)E

Crystal optical fiber (AGF)

Optical Slave Rack

Cable Length

Maximum total cable length is 10 km. Follow the instructions contained in

Crystal Optical Fiber Cable (AGF)

for calculating the length of AGF cable.

Be sure to turn power off before disconnecting a cable. If an optical fiber

cable is disconnected while power is on in the Link Adapters and CPU, data

may be retained in the Slave.

2-4

21

Page 31

4-4 Wired Remote I/O Systems

Wired

Remote I/O Master Units, Remote I/O Slave Units,

can

be directly connected with RS-485 cable, which has a maximum transmis

sion distance of 200 m. In order to extend the transmission distance and/or to

reduce

an

ing

by using a pair of AL007-P Link Adapters.

noise interference, a pair of AL007-P Link Adapters can be used to insert

optical link between any two Remote I/O Units/Remote T

example shows two Wired Remote I/O Units connected by optical fiber cable

Link

Adapter

AL007-P

Optical fiber (APF/PCF)

and Remote T

erminals. The follow

Link Adapter

AL007-P

RS-485 cableRS-485 cable

4-4SectionWired Remote I/O Systems

erminals

-

-

Wired Slave

Master

, Slave, or

Remote T

The

Link Adapters must always be used in pairs, as they convert between wire

and

optical signals, thereby allowing optical transmission between Units which

cannot

themselves be connected directly to optical fiber cable. The entire Sub

system,

ing.

Up to 8 Link

diagram

system,

erminal

from Master to

terminator

, must be connected in series, with no branch

Adapters (4 pairs) can be used for each Master

illustrates an acceptable

configuration for a Wired Remote Master Sub

using the maximum of 8 Link Adapters for one Master

Master

, Slave, or

Remote T

erminal

. The following

. Note that all

Units

are connected in series and all Link Adapters are used in pairs.

***

Wired SlaveWired Master

***

Link Adapter

AL007-P

**

Link Adapter

AL007-P

**

Link Adapter

AL007-P

Link Adapter

AL007-P

Wired Slave

Link Adapter

AL007-P

*

Wired

Slave

* RS-485

cable

**

Optical fiber

(APF/PCF)

-

-

-

Link Adapter

22

AL007-P

**

Link Adapter

AL007-P

* * ** *

Wired Slave

Maximum

tic

optical fiber cable (APF) and 200 m for plastic-clad optical fiber cable (PCF).

T

o take full advantage of an optical link, shorten wire

cable length for any single section of optical cable is 20 m for all-plas

Link Adapter

AL007-P

Link Adapter

AL007-P

Terminator

links as much as possible,

-

even to the point of placing the Link Adapter on the same control panel as the

Remote I/O Unit/Remote Terminal.

Page 32

SECTION 5

Dimensions and Internal Configuration

5-1 Link Adapter AL001 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Link Adapter AL002-(P)E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 Link Adapter AL004-(P)E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-4 Link Adapter AL005-(P)E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5 Link Adapter AL006-(P)E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-6 Link Adapter AL007-P . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23

Page 33

5-1 Link Adapter AL001

Note Unit of measurement: mm

5-1SectionLink Adapter AL001

24

Page 34

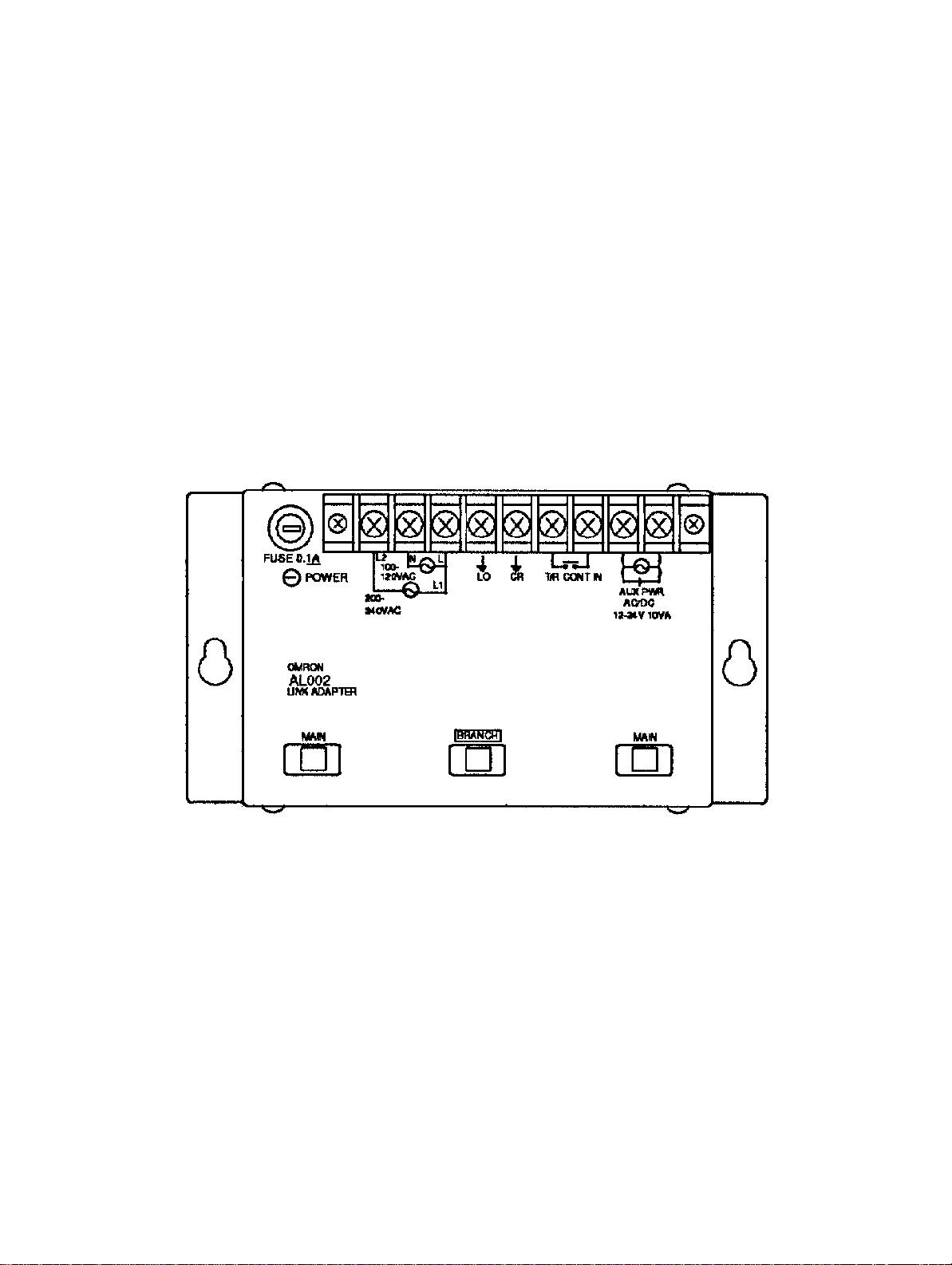

5-2 Link Adapter AL002-(P)E

5-2SectionLink Adapter AL002-(P)E

The

Link Adapter can run on either 100/200 V

input

terminals should be shorted across when not being

usage of the repeater input, refer to

power supplies, see

2-5 Backup Power Supply

2-6 Link Adapter Repeater Input

AC or 12-24 VAC/DC. The repeater

used. For details on the

. For backup

.

25

Page 35

5-3 Link Adapter AL004-(P)E

0 V

External

line

Available

(Yes)

Not

available

(No)

5-3SectionLink Adapter AL004-(P)E

Terminating resistance

selector switch

Switch Settings

CTS Selector

Termination Resistance

26

Set

to 0 V to have the clear-to-send (CTS)

signal always ON. Set to external to

receive an external CTS signal.

When

set to ON, connects the built-in termination resistance (220 Ω); when set

to

OFF

, disconnects it. T

urn ON the termination resistance of the last Link Adapt

er at each end of each Subsystem.

-

Page 36

5-4 Link Adapter AL005-(P)E

5-4SectionLink Adapter AL005-(P)E

Use

FC connecters for AGF (crystal optical fiber;) cable. AGF connecters have

fixed

positions for reception and transmission, so be careful to connect them

rectly.

The

Link Adapter can operate on either 100/200 V

tails on auxiliary power supplies, see

2-5 Backup Power Supply

AC or 12-24 V

AC/DC. For de

.

cor

27

-

-

Page 37

5-5 Link Adapter AL006-(P)E

5-5SectionLink Adapter AL006-(P)E

28

Use

FC connecters for AGF cable. AGF connecters have fixed positions for re

ception and transmission, so be careful to connect them correctly.

This Link Adapter can operate on either 100/200 VAC or 12-24 VAC/DC. The

repeater

tails

details on auxiliary power supplies, see

input terminals should be shorted across when not being used. For de

on how to use the repeater input, see

2-6 Link Adapter

2-5 Backup Power Supply

Repeater Input

.

. For

-

-

Page 38

5-6 Link Adapter AL007-P

5-6SectionLink Adapter AL007-P

The AL007-P is used exclusively for Wired Remote I/O Systems. It cannot be

used

in Optical Remote I/O Systems, nor can it be used in combination with an

AL002-(P)E.

29

Page 39

Appendix A

Standard Models

Name Specifications Model Number

Optical (APF/PCF) (3 connectors) 3G2A9-AL002-PE

RS-422 (2 connectors), RS-232C (1 connector) 3G2A9-AL003-E

Optical (APF/PCF), RS-422, RS-232C (1 conn. each) 3G2A9-AL004-PE

Optical (APF/PCF), (AGF) (1 connector each) 3G2A9-AL005-PE

Optical (APF/PCF) (1 connector), (AGF) (2 connectors) 3G2A9-AL006-PE

Link Adapter RS-422 (3 connectors) 3G2A9-AL001

Optical (PCF) (3 connectors) 3G2A9-AL002-E

Optical (PCF), RS-422, RS-232C (1 connector each) 3G2A9-AL004-E

Optical (PCF), (AGF) (1 connector each) 3G2A9-AL005-E

Optical (PCF) (1 connector), (AGF) (2 connectors) 3G2A9-AL006-E

Optical (APF/PCF) (1 connector), (AGF) (2 connectors) B500-AL007-P

0.1 m w/connector 3G5A2-0F011

1 m w/connector 3G5A2-0F101

2 m w/connector 3G5A2-0F201

3 m w/connector 3G5A2-0F301

Optical fiber cable 5 m w/connector Ambient temperature: 3G5A2-0F501

(indoor) (PCF) 10 m w/connector -10°

20 m w/connector 3G5A2-0F211

30 m w/connector 3G5A2-0F311

40 m w/connector 3G5A2-0F411

50 m w/connector 3G5A2-0F511

Optical fiber cable (PCF)

(for indoors or outdoors) (Order in units of 10 m.) -10°

Optical fiber cable (APF) Cable only; for 5 m to 100 m, order in multiples of 5 m; or in

Optical fiber cable set (APF) 1 m cable with connector at each end (connector A) 3G5A2-PF101

Optical connector A 2 optical connectors (brown); for APF cable 10 m max. 3G5A2-CO001

Optical connector B 2 optical connectors (black); for APF cable 8 to 20 m long 3G5A2-CO002

Repeater Unit To use more than 32 Optical Transmitting I/O Units in se-

10 to 500 m

501 to 800 m

(Order in units of 10 m) 0°

multiples of 200 m or 500 m.

ries, 85 to 250 VAC

to 70

°C 3G5A2-0F111

Ambient temperature:

to 70

°C 3G5A2-OF002

Ambient temperature:

to 55

°C (Must not be ex-

posed to direct sunlight)

3G5A2-PF002

3G5A2-RPT01-P

(APC/PCF)

3G5A2-RPT01 (PCF)

Note Optical

fiber cable is not easily connected. Figure

connections and extensions.

Crystal Optical Fiber Cable

Crystal

GI 50/25; connector: FC)

optical fiber cable is not available from OMRON. Order it directly from the manufacturer

in extra length when determining cable lengths for making

. (Applicable fiber:

31

Page 40

Wire Cable

We recommend the following cables for RS-422, RS-232C, and RS-485 connections.

Cable type Recommended Cable

RS-232C CO-DS-IREVV-SX-10P x 0.18 mm2 (Hitachi Cable)

RS-422 CO-HC-ESV-3P x 7/0.2 (Hirakawa Cable)

RS-485 VCTF 0.75 x 2C (JIS)

Appendix AStandard Models

32

Page 41

Index

A

application precautions,

C

cable connectors

optical fiber cable,

soldering,

wire cable,

wiring,

CTS selector,

H

host computers, ,

connecting to, ,

Host Link Systems, , , ,

optical,

wired,

I

P

PC Link Systems, , , ,

power interruption,

backup power supply, ,

bypassing malfunctioning Unit, ,

power supply,

specifications, ,

precautions,

applications,

general,

operating environment,

safety,

R

Remote I/O Master Units, ,

Remote I/O Slave Units, ,

Remote Terminals,

repeater input, , ,

Repeater Units, , , ,

I/O Link Units, ,

installation precautions,

O

operating environment precautions,

optical fiber cable,

applicable Link Adapters,

branching,

cable length, ,

converting to wire cable, , , ,

crystal optical fiber, , ,

calculating transmission distance, ,

connectors, ,

specifications,

handling,

Repeater Units,

types,

Optical Host Link Units,

optical links between Units, ,

Optical Remote I/O Systems, , ,

Optical Slave Racks, ,

Optical Transmitting I/O Units, , ,

S

safety precautions. See precautions

specifications, ,

switch settings,

T

termination resistance,

W

wire cable,

branching,

cable length,

converting to optical fiber cable, , , , ,

RS-422 or RS-232C, ,

RS-485,

specifications,

Wired Remote I/O Systems, , , ,

33

Page 42

Revision History

A manual revision code appears as a suffix to the catalog number on the front cover of the manual.

Cat. No. W123-E1-3

Revision code

The following table outlines the changes made to the manual during each revision. Page numbers refer to

previous version.

Revision code Date Revised content

1 1990 Original production

2 September 1990 First production in Interleaf. Put into current manual format.

Changes: Added 3G2A9-AL003-E to Standard Model list

Minor prose changes for readability

2A September 1995 Page 3: The table row containing AL004-PE corrected.

3 June 1999 Manual format changed.

Page 3: Supply voltage and operating voltage range information changed for

AL004-PE/E.

Page 24:

Page 26: Switch information added to the upper-left diagram.

Grounding information added to the pin number diagram.

Precautions

section added before Section 1.

35

Page 43

Authorized Distributor:

Cat.

No. W123-E1-3

Note: Specifications subject to change without notice.

Printed in Japan

Loading...

Loading...