Omron SYSMAC CS, CS1W-HCA12-V1, CS1W-HCA22-V1, CS1W-HCP22-V1, CS1W-HIO01-V1 Operation Manual

Page 1

Cat. No. W378-E1-02

SYSMAC CS Series

CS1W-HIO01-V1/HCP22-V1/HCA22-V1/HCA12-V1

Customizable Counter Units

OPERATION MANUAL

Page 2

Page 3

CS1W-HIO01-V1/HCP22-V1/HCA22-V1/

HCA12-V1

Customizable Counter Units

Operation Manual

Revised December 2003

Page 4

Terms and Conditions of Sale

1. Offer; Acceptance. These terms and conditions (these "Terms") are deemed

part of all quotes, agreements, purchase orders, acknowledgments, price lists,

catalogs, manuals, brochures and other documents, whether electronic or in

writing, relating to the sale of products or services (collectively, the "Products

by Omron Electronics LLC and its subsidiary companies (“Omron”). Omron

objects to any terms or conditions proposed in Buyer’s purchase order or other

documents which are inconsistent with, or in addition to, these Terms.

2. Prices; Payment Terms.

out notice by Omron. Omron reserves the right to increase or decrease prices

on any unshipped portions of outstanding orders. Payments for Products are

due net 30 days unless otherwise stated in the invoice.

3. Discounts.

sent to Buyer after deducting transportation charges, taxes and duties, and will

be allowed only if (i) the invoice is paid according to Omron’s payment terms

and (ii) Buyer has no past due amounts.

4. Interest.

the maximum legal rate, whichever is less, on any balance not paid within the

stated terms.

5. Orders

6. Governmental Approvals.

costs involved in, obtaining any government approvals required for the importation or sale of the Products.

7. Taxes

real property and income taxes), including any interest or penalties thereon,

imposed directly or indirectly on Omron or required to be collected directly or

indirectly by Omron for the manufacture, production, sale, delivery, importation, consumption or use of the Products sold hereunder (including customs

duties and sales, excise, use, turnover and license taxes) shall be charged to

and remitted by Buyer to Omron.

8. Financial.

to Omron, Omron reserves the right to stop shipments or require satisfactory

security or payment in advance. If Buyer fails to make payment or otherwise

comply with these Terms or any related agreement, Omron may (without liability and in addition to other remedies) cancel any unshipped portion of Products sold hereunder and stop any Products in transit until Buyer pays all

amounts, including amounts payable hereunder, whether or not then due,

which are owing to it by Buyer. Buyer shall in any event remain liable for all

unpaid accounts.

9. Cancellation; Etc.

unless Buyer indemnifies Omron against all related costs or expenses.

10. Force Majeure

resulting from causes beyond its control, including earthquakes, fires, floods,

strikes or other labor disputes, shortage of labor or materials, accidents to

machinery, acts of sabotage, riots, delay in or lack of transportation or the

requirements of any government authority.

11. Shipping; Delivery.

a. Shipments shall be by a carrier selected by Omron; Omron will not drop ship

b. Such carrier shall act as the agent of Buyer and delivery to such carrier shall

c. All sales and shipments of Products shall be FOB shipping point (unless oth-

d. Delivery and shipping dates are estimates only; and

e. Omron will package Products as it deems proper for protection against nor-

12. Claims.

Products occurring before delivery to the carrier must be presented in writing

to Omron within 30 days of receipt of shipment and include the original transportation bill signed by the carrier noting that the carrier received the Products

from Omron in the condition claimed.

13. Warranties

Products will be free from defects in materials and workmanship for a period of

twelve months from the date of sale by Omron (or such other period expressed

in writing by Omron). Omron disclaims all other warranties, express or implied.

(b) Limitations

EXPRESS OR IMPLIED, ABOUT NON-INFRINGEMENT, MERCHANTABIL-

Cash discounts, if any, will apply only on the net amount of invoices

Omron, at its option, may charge Buyer 1-1/2% interest per month or

. Omron will accept no order less than $200 net billing.

. All taxes, duties and other governmental charges (other than general

If the financial position of Buyer at any time becomes unsatisfactory

except in “break down” situations.

constitute delivery to Buyer;

erwise stated in writing by Omron), at which point title and risk of loss shall

pass from Omron to Buyer; provided that Omron shall retain a security interest in the Products until the full purchase price is paid;

mal handling and extra charges apply to special conditions.

Any claim by Buyer against Omron for shortage or damage to the

. (a) Exclusive Warranty. Omron’s exclusive warranty is that the

All prices stated are current, subject to change with-

Buyer shall be responsible for, and shall bear all

Orders are not subject to rescheduling or cancellation

. Omron shall not be liable for any delay or failure in delivery

Unless otherwise expressly agreed in writing by Omron:

. OMRON MAKES NO WARRANTY OR REPRESENTATION,

ITY OR FITNESS FOR A PARTICULAR PURPOSE OF THE PRODUCTS.

BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

")

INTENDED USE. Omron further disclaims all warranties and responsibility of

any type for claims or expenses based on infringement by the Products or otherwise of any intellectual property right. (c) Buyer Remedy

gation hereunder shall be, at Omron’s election, to (i) replace (in the form

originally shipped with Buyer responsible for labor charges for removal or

replacement thereof) the non-complying Product, (ii) repair the non-complying

Product, or (iii) repay or credit Buyer an amount equal to the purchase price of

the non-complying Product; provided that in no event shall Omron be responsible for warranty, repair, indemnity or any other claims or expenses regarding

the Products unless Omron’s analysis confirms that the Products were properly handled, stored, installed and maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of any Products by

Buyer must be approved in writing by Omron before shipment. Omron Companies shall not be liable for the suitability or unsuitability or the results from the

use of Products in combination with any electrical or electronic components,

circuits, system assemblies or any other materials or substances or environments. Any advice, recommendations or information given orally or in writing,

are not to be construed as an amendment or addition to the above warranty.

See http://

lished information.

14. Limitation on Liability; Etc

FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS

BASED IN CONTRACT, WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual

price of the Product on which liability is asserted.

15. Indemnities

their employees from and against all liabilities, losses, claims, costs and

expenses (including attorney's fees and expenses) related to any claim, investigation, litigation or proceeding (whether or not Omron is a party) which arises

or is alleged to arise from Buyer's acts or omissions under these Terms or in

any way with respect to the Products. Without limiting the foregoing, Buyer (at

its own expense) shall indemnify and hold harmless Omron and defend or settle any action brought against such Companies to the extent based on a claim

that any Product made to Buyer specifications infringed intellectual property

rights of another party.

16. Property; Confidentiality.

sive property of Omron Companies and Buyer shall not attempt to duplicate it

in any way without the written permission of Omron. Notwithstanding any

charges to Buyer for engineering or tooling, all engineering and tooling shall

remain the exclusive property of Omron. All information and materials supplied

by Omron to Buyer relating to the Products are confidential and proprietary,

and Buyer shall limit distribution thereof to its trusted employees and strictly

prevent disclosure to any third party.

17. Export Controls.

licenses regarding (i) export of products or information; (iii) sale of products to

“forbidden” or other proscribed persons; and (ii) disclosure to non-citizens of

regulated technology or information.

18. Miscellaneous

and no course of dealing between Buyer and Omron shall operate as a waiver

of rights by Omron. (b) Assignment

without Omron's written consent. (c) Law.

law of the jurisdiction of the home office of the Omron company from which

Buyer is purchasing the Products (without regard to conflict of law principles). (d) Amendment

Buyer and Omron relating to the Products, and no provision may be changed

or waived unless in writing signed by the parties. (e) Severability

sion hereof is rendered ineffective or invalid, such provision shall not invalidate

any other provision. (f) Setoff

against the amount owing in respect of this invoice. (g) Definitions

herein, “including

nies” (or similar words) mean Omron Corporation and any direct or indirect

subsidiary or affiliate thereof.

www.omron247.com or contact your Omron representative for pub-

. OMRON COMPANIES SHALL NOT BE LIABLE

. Buyer shall indemnify and hold harmless Omron Companies and

Any intellectual property in the Products is the exclu-

Buyer shall comply with all applicable laws, regulations and

. (a) Waiver. No failure or delay by Omron in exercising any right

. Buyer may not assign its rights hereunder

These Terms are governed by the

. These Terms constitute the entire agreement between

. Buyer shall have no right to set off any amounts

” means “including without limitation”; and “Omron Compa-

. Omron’s sole obli-

. If any provi-

. As used

Certain Precautions on Specifications and Use

1. Suitability of Use. Omron Companies shall not be responsible for conformity

with any standards, codes or regulations which apply to the combination of the

Product in the Buyer’s application or use of the Product. At Buyer’s request,

Omron will provide applicable third party certification documents identifying

ratings and limitations of use which apply to the Product. This information by

itself is not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine, system, or other application

or use. Buyer shall be solely responsible for determining appropriateness of

the particular Product with respect to Buyer’s application, product or system.

Buyer shall take application responsibility in all cases but the following is a

non-exhaustive list of applications for which particular attention must be given:

(i) Outdoor use, uses involving potential chemical contamination or electrical

interference, or conditions or uses not described in this document.

(ii) Use in consumer products or any use in significant quantities.

(iii) Energy control systems, combustion systems, railroad systems, aviation

systems, medical equipment, amusement machines, vehicles, safety equipment, and installations subject to separate industry or government regulations.

(iv) Systems, machines and equipment that could present a risk to life or property. Please know and observe all prohibitions of use applicable to this Product.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS

RISK TO LIFE OR PROPERTY OR IN LARGE QUANTITIES WITHOUT

ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON’S PRODUCT IS PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE

OVERALL EQUIPMENT OR SYSTEM.

2. Programmable Products.

user’s programming of a programmable Product, or any consequence thereof.

3. Performance Data

and other materials is provided as a guide for the user in determining suitability and does not constitute a warranty. It may represent the result of Omron’s

test conditions, and the user must correlate it to actual application requirements. Actual performance is subject to the Omron’s Warranty and Limitations

of Liability.

4. Change in Specifications

changed at any time based on improvements and other reasons. It is our practice to change part numbers when published ratings or features are changed,

or when significant construction changes are made. However, some specifications of the Product may be changed without any notice. When in doubt, special part numbers may be assigned to fix or establish key specifications for

your application. Please consult with your Omron’s representative at any time

to confirm actual specifications of purchased Product.

5. Errors and Omissions.

checked and is believed to be accurate; however, no responsibility is assumed

for clerical, typographical or proofreading errors or omissions.

Omron Companies shall not be responsible for the

. Data presented in Omron Company websites, catalogs

. Product specifications and accessories may be

Information presented by Omron Companies has been

Page 5

Notice:

r

f

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Program-

ming Device displays to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Reference Indicates supplementary information on related topics that may be of inter-

Ó OMRON, 2001

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Note Indicates information of particular interest for efficient and convenient op-

eration of the product.

est to the user.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 6

vi

Page 7

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

4 Operating Environment Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiv

6 Data Backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

7 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

SECTION 1

Features and System Configuration . . . . . . . . . . . . . . . . . . . 1

1-1 Outline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Models and System Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

SECTION 2

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2-1 Performance Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

2-2 Contact I/O Specifications (All Units) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

SECTION 3

Nomenclature, Installation, and Wiring. . . . . . . . . . . . . . . . 35

3-1 Names and Functions of Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3-2 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3-3 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3-4 Programming Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

3-5 Fail-safe Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

SECTION 4

Exchanging Data with the CPU Unit . . . . . . . . . . . . . . . . . . 59

4-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4-2 Words Allocated in CIO Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4-3 Words Allocated in DM Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4-4 LR Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4-5 Difference between I/O Refreshing in Customizable Counter Units and

That in Other Special I/O Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

SECTION 5

Unit Setup Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5-1 Unit Setup Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

vii

Page 8

TABLE OF CONTENTS

SECTION 6

I/O Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

6-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

6-2 Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

6-3 SR Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

6-4 AR Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

SECTION 7

Special Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

7-1 Outline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

7-2 Interrupt Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

7-3 Interrupt Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

7-4 Executing Interrupt Tasks in the CPU Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

7-5 Pulse Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

7-6 Pulse Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

7-7 Analog Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

7-8 Functions Compatible with Servo Drivers with Absolute Encoders . . . . . . . . . . . . . . . . . . 142

7-9 Analog Input Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

7-10 Virtual Pulse Output Function (-V1 unit with lot No. 0209__or later only). . . . . . . . . . . . . 161

7-11 Constant Cycle Time Over Clear Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

7-12 Ladder Library Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

7-13 Back Up Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

7-14 Improved Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

SECTION 8

Unit Operation and Processing Time . . . . . . . . . . . . . . . . . . 185

8-1 Customizable Counter Unit Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

8-2 Power Interruptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

8-3 Cycle Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

SECTION 9

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

9-1 Types of Troubleshooting Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

9-2 Error Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

9-3 Troubleshooting Tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

9-4 User-defined Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

9-5 Troubleshooting Flowcharts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Appendix

A Precautions when Using the CX-Programmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

viii

Page 9

About this Manual:

This manual describes the installation and operation of the CS1W-HIO01-V1, CS1W-HCP22-V1,

CS1W-HCA22-V1 and CS1W-HCA12-V1 Customizable Counter Units and includes the sections

described below. The Customizable Counter Units provide both normal contact I/O with special I/O

as ideal control capabilities for many applications. The Customizable Counter Units are classified

as CS-series Special I/O Units.

Please read this manual and all other manuals for the Customizable Counter Units listed below

carefully and be sure you understand the information provided before attempting to install or operate a Customizable Counter Unit.

Manual Cat. No. Contents

CS1W-HIO01-V1/HCP22-V1/

HCA22-V1/HCA12-V1

Customizable Counter Units

Operation Manual

(this manual)

CS1W-HIO01-V1/HCP22-V1/

HCA22-V1/HCA12-V1

Customizable Counter Units

Programming Manual

SYSMAC WS02-CX-@@-EV3

CX-Programmer

User Manual

CQM1H Series

Programmable Controllers

Operation Manual

W378 Describes the hardware and software operation of the Cus-

tomizable Counter Units.

W384 Describes the memory areas and programming instructions

of the Customizable Counter Units.

W414 Provide information on how to use the CX-Programmer, a

Windows-based Programming Device that supports the

CQM1H-series PLCs.

W363 Describes Programming Console operations that can be

used connected to the Customizable Counter Units.

Section 1 describes the features of the Customizable Counter Units and the devices required in

an extended system configuration.

Section 2 provides performance specifications and I/O specifications for the Customizable

Counter Unit.

Section 3 provides the names of the different components of the Customizable Counter Unit and

explains the procedures required for installing and wiring the Unit.

Section 4 provides details on the way in which data is exchanged between the Customizable

Counter Unit and the CPU Unit.

Section 5 provides details on the settings made using the Unit Setup Area in the Customizable

Counter Unit.

Section 6 provides details of the settings made using the I/O memory areas in the Customizable

Counter Unit.

Section 7 provides information on interrupts, pulse inputs, pulse outputs, and analog outputs.

Section 8 explains the internal processing of the Customizable Counter Unit, and the time

required for processing and execution.

Section 9 provides information on troubleshooting errors that can occur with the Customizable

Counter Unit.

The Appendix provides precautions required when programming or monitoring the Customizable

Counter Unit with the CX-Programmer.

ix

Page 10

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

x

Page 11

PRECAUTIONS

This section provides general precautions for using the CS1W-HIO01-V1, CS1W-HCP22-V1, CS1W-HCA22-V1 and

CS1W-HCA12-V1 Customizable Counter Units.

The information contained in this section is important for the safe and reliable application of the Customizable

Counter Units. You must read this section and understand the information contained before attempting to set

up or operate a Customizable Counter Unit.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

4 Operating Environment Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

6 Data Backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

6-1 Automatic Backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

6-2 User Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

6-3 Backing Up DM Area to Flash Memory . . . . . . . . . . . . . . . . . . . . . xviii

7 Conformance to EC Directives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

7-1 Applicable Directives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

7-2 Concepts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

7-3 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

xi

Page 12

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual close at hand for reference during operation.

!WARNING It is extremely important that a PLC and all PLC Units be used for the speci-

fied purpose and under the specified conditions, especially in applications that

can directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PLC System to the above-mentioned applications.

3 Safety Precautions

!WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing

so may result in electric shock.

!WARNING Do not touch any of the terminals or terminal blocks while the power is being

supplied. Doing so may result in electric shock.

!WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do

so may result in malfunction, fire, or electric shock.

!WARNING Do not touch the Power Supply Unit while power is being supplied or immedi-

ately after power has been turned OFF. Doing so may result in electric shock.

!WARNING Provide safety measures in external circuits, i.e., not in the Programmable

Controller (CPU Unit including associated Units; referred to as “PLC”), in

order to ensure safety in the system if an abnormality occurs due to malfunction of the PLC or another external factor affecting the PLC operation. Not

doing so may result in serious accidents.

xii

Page 13

Operating Environment Precautions 4

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PLC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instruction is executed.

As a countermeasure for such errors, external safety measures must be

provided to ensure safety in the system.

• The PLC outputs may remain ON or OFF due to deposition or burning of

the output relays or destruction of the output transistors. As a countermeasure for such problems, external safety measures must be provided

to ensure safety in the system.

• When the 24-VDC output (service power supply to the PLC) is overloaded

or short-circuited, the voltage may drop and result in the outputs being

turned OFF. As a countermeasure for such problems, external safety

measures must be provided to ensure safety in the system.

!Caution Execute online edit only after confirming that no adverse effects will be

caused by extending the cycle time. Otherwise, the input signals may not be

readable.

!Caution Confirm safety at the destination node before transferring a program to

another node or changing contents of the I/O memory area. Doing either of

these without confirming safety may result in injury.

!Caution Tighten the screws on the terminal block of the AC power supply to the torque

specified in the operation manual. The loose screws may result in burning or

malfunction.

4 Operating Environment Precautions

!Caution Do not operate the control system in the following locations:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

!Caution Take appropriate and sufficient countermeasures when installing systems in

the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

xiii

Page 14

Application Precautions 5

!Caution The operating environment of the PLC System can have a large effect on the

longevity and reliability of the system. Improper operating environments can

lead to malfunction, failure, and other unforeseeable problems with the PLC

System. Be sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life

of the system.

5 Application Precautions

!WARNING Always heed these precautions. Failure to abide by the following precautions

could lead to serious or possibly fatal injury.

• Always connect to a ground of 100

connecting to a ground of 100

• A ground of 100

terminals on the Power Supply Unit.

• Always turn OFF the power supply to the PLC before attempting any of

the following. Not turning OFF the power supply may result in malfunction

or electric shock.

• Mounting or dismounting Power Supply Units, I/O Units, CPU Units, Inner Boards, or any other Units.

• Assembling the Units.

• Setting DIP switches or rotary switches.

• Connecting cables or wiring the system.

• Connecting or disconnecting the connectors.

!Caution Failure to abide by the following precautions could lead to faulty operation of

the PLC or the system, or could damage the PLC or PLC Units. Always heed

these precautions.

• Always turn ON power to the PLC before turning ON power to the control

system. If the PLC power supply is turned ON after the control power supply, temporary errors may result in control system signals because the

output terminals on DC Output Units and other Units will momentarily turn

ON when power is turned ON to the PLC.

• Fail-safe measures must be taken by the customer to ensure safety in the

event that outputs from Output Units remain ON as a result of internal circuit failures, which can occur in relays, transistors, and other elements.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal

lines, momentary power interruptions, or other causes.

• Interlock circuits, limit circuits, and similar safety measures in external circuits (i.e., not in the Programmable Controller) must be provided by the

customer.

• Always use the power supply voltages specified in the operation manuals.

An incorrect voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied in places where the power supply

is unstable. An incorrect power supply may result in malfunction.

W or less must be installed when shorting the GR and LG

W or less when installing the Units. Not

W or less may result in electric shock.

xiv

Page 15

Application Precautions 5

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may result in burning.

• Do not apply voltages to the Input Units in excess of the rated input voltage. Excess voltages may result in burning.

• Do not apply voltages or connect loads to the Output Units in excess of

the maximum switching capacity. Excess voltage or loads may result in

burning.

• Disconnect the functional ground terminal when performing withstand

voltage tests. Not disconnecting the functional ground terminal may result

in burning.

• Install the Units properly as specified in the operation manuals. Improper

installation of the Units may result in malfunction.

• Be sure that all the mounting screws, terminal screws, and cable connector screws are tightened to the torque specified in the relevant manuals.

Incorrect tightening torque may result in malfunction.

• Leave the label attached to the Unit when wiring. Removing the label may

result in malfunction if foreign matter enters the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals. Connection of bare stranded wires may result in

burning.

• Wire all connections correctly.

• Double-check all wiring and switch settings before turning ON the power

supply. Incorrect wiring may result in burning.

• Mount Units only after checking terminal blocks and connectors completely.

• Be sure that the terminal blocks, Memory Units, expansion cables, and

other items with locking devices are properly locked into place. Improper

locking may result in malfunction.

• Check switch settings, the contents of the DM Area, and other preparations before starting operation. Starting operation without the proper settings or data may result in an unexpected operation.

• Check the user program for proper execution before actually running it on

the Unit. Not checking the program may result in an unexpected operation.

• Confirm that no adverse effect will occur in the system before attempting

any of the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PLC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Resume operation only after transferring to the new CPU Unit the contents of the DM Area, HR Area, and other data required for resuming

operation. Not doing so may result in an unexpected operation.

• Do not pull on the cables or bend the cables beyond their natural limit.

Doing either of these may break the cables.

• Do not place objects on top of the cables or other wiring lines. Doing so

may break the cables.

xv

Page 16

Data Backup 6

• When replacing parts, be sure to confirm that the rating of a new part is

correct. Not doing so may result in malfunction or burning.

• Before touching a Unit, be sure to first touch a grounded metallic object in

order to discharge any static build-up. Not doing so may result in malfunction or damage.

• When transporting or storing circuit boards, cover them in antistatic material to protect them from static electricity and maintain the proper storage

temperature.

• Do not touch circuit boards or the components mounted to them with your

bare hands. There are sharp leads and other parts on the boards that

may cause injury if handled improperly.

• Data in the DM Area, error log, EM Area, or Timer/Counter Area may

become corrupted if power is not supplied for an extended period of time.

Program the PLC to check SR 24914 before starting operation. If SR

24914 is ON, the memory areas that are normally held during power interruptions will not have been held properly (i.e., the data will be corrupted).

(The data in the DM Area can be backed up to flash memory by turning

ON SR 25200.)

6Data Backup

6-1 Automatic Backup

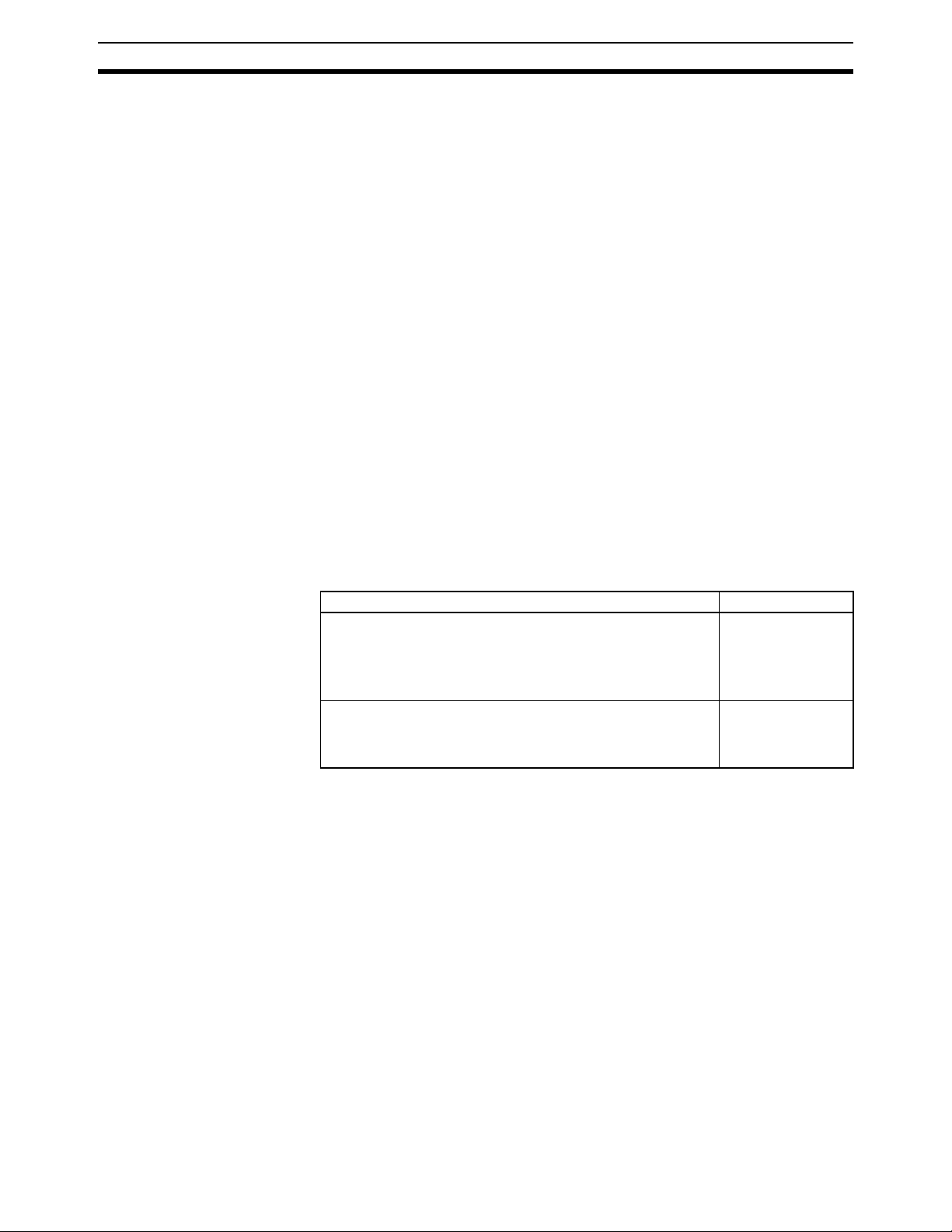

Data in the Customizable Counter Units is backed up either by a super capacitor or flash memory, as listed in the following table.

DM Area (DM 0000 to DM 6143), EM Area (EM 0000 to EM

2047), error log (DM 6144 to DM 6199), and counter present

values.

A setting is provided to either enable or disable holding EM

Area data. The default is to not hold the data.

User program, read-only DM Area words (DM 6200 to DM

6599), Unit Setup Area (DM 6600 to DM 6655), expansion

instructions information, read/write DM Area words (DM 0000

to DM 6143, see note.)

Note The contents of DM 0000 to DM 6143 are written to flash memory only when

SR 25200 (DM Area Backup Bit) is turned ON.

The data in RAM is backed up by the super capacitor for 10 days at 25

backup time varies with the ambient temperature as shown in the following

graph.

Data Data backup

RAM with super

capacitor

Flash memory

°C. The

xvi

Page 17

Data Backup 6

Backup time

10th day

5th day

1st day

Ambient temperature

25°C40°C75°C

Note The times give above assume that the capacitor is completely charged. Power

must be supply to the Unit for at least 15 minutes to completely charge the

capacitor.

The data backed up by the capacitor will become unstable or corrupted if the

backup time is exceeded.

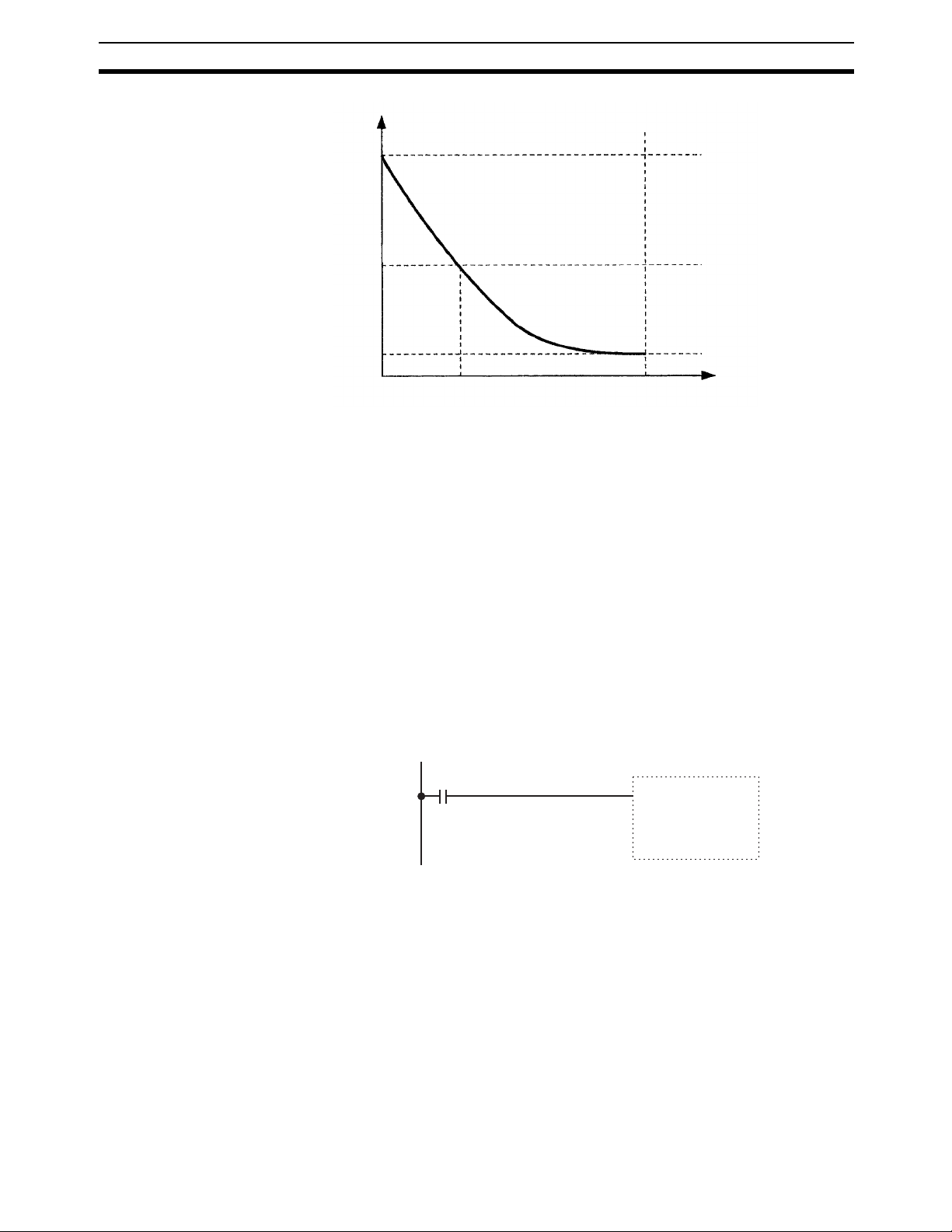

6-2 User Programming

If the power supply is turned OFF for longer than the data backup time (10

days at 25

counter present values, will be lost and any data that is read will be unstable.

If the power supply is to be turned OFF for an extended period of time, the

contents of DM 0000 to DM 6143 can be backed up in flash memory. The

Backup Data Corrupted Flag (SR 24914) can also be used as shown below to

detect when backup data (i.e., data in the DM Area, EM Area, and Error Log,

as well as counter present values) has become corrupted to perform appropriate error processing.

DM 0000 to DM 6143 (read/write portion of DM Area) can be backed up in

flash memory by the user as described in the next section.

°C), the data in the DM Area, EM Area, and Error Log, as well as

24914

Processing for

corruption of data

backed up for

power interruptions

xvii

Page 18

Conformance to EC Directives 7

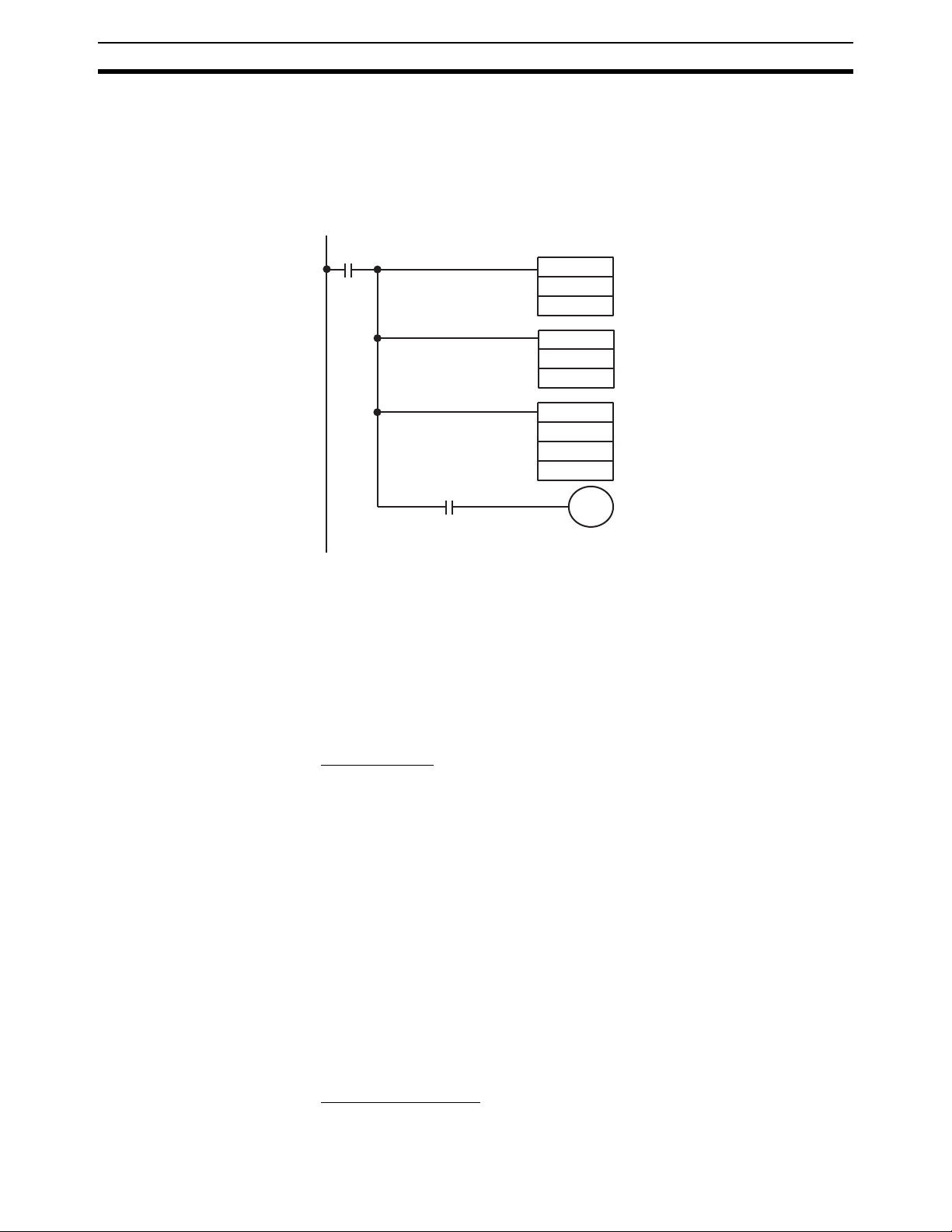

6-3 Backing Up DM Area to Flash Memory

The contents of DM 0000 to DM 6143 can be written to flash memory by turning ON SR 25200 (DM Flash Memory Backup Bit) in PROGRAM mode.

(SR 25200 will turn OFF automatically when transfer has been completed.)

The data stored in flash memory can be read back to DM 0000 to DM 6143 by

using the XFER(70) instruction as shown below.

Execution

condition

25503

MOV(21)

#0100

LR00

MOV(21)

#0000

LR01

@XFER(70)

#9999

LR00

DM0000

ER Flag

7 Conformance to EC Directives

7-1 Applicable Directives

•EMC Directives

• Low Voltage Directive

7-2 Concepts

EMC Directives

OMRON devices that comply with EC Directives also conform to the related

EMC standards so that they can be more easily built into other devices or

machines. The actual products have been checked for conformity to EMC

standards (see the following note). Whether the products conform to the standards in the system used by the customer, however, must be checked by the

customer.

EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions of

the equipment or control panel in which the OMRON devices are installed.

The customer must, therefore, perform final checks to confirm that devices

and the overall machine conform to EMC standards.

xviii

Note Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN61000-6-2

EMI (Electromagnetic Interference): EN50081-2

(Radiated emission: 10-m regulations)

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 VAC or 75 to

1,500 VDC meet the required safety standards for the PLC (EN61131-2).

Page 19

Conformance to EC Directives 7

7-3 Conformance to EC Directives

The CS1W-HIO01-V1, CS1W-HCP22-V1, CS1W-HCA22-V1 and CS1WHCA12-V1 Customizable Counter Units comply with EC Directives. To ensure

that the machine or device in which the Customizable Counter Unit is used

complies with EC directives, the Unit must be installed as follows:

1,2,3... 1. The Customizable Counter Unit must be installed within a control panel.

2. Reinforced insulation or double insulation must be used for the Customizable Counter Unit DC power supplies used for the communications and

I/O power supplies.

3. The Customizable Counter Units complying with EC Directives also conform to the Common Emission Standard (EN50081-2). When a Customizable Counter Unit is built into a machine, however, changes can occur,

particularly for the radiated emission (10-m regulations), due to the structure of the machine, other connected devices, wiring, etc. The customer

must, therefore, perform final checks to confirm that devices and the overall machine using a Customizable Counter Unit conform to EC standards.

xix

Page 20

Conformance to EC Directives 7

xx

Page 21

SECTION 1

Features and System Configuration

This section describes the features of the Customizable Counter Units and the devices required in an extended system

configuration.

1-1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-1-3 Application Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-2 Models and System Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1-2-1 Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1-2-2 System Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1

Page 22

Outline Section 1-1

1-1 Outline

1-1-1 Outline

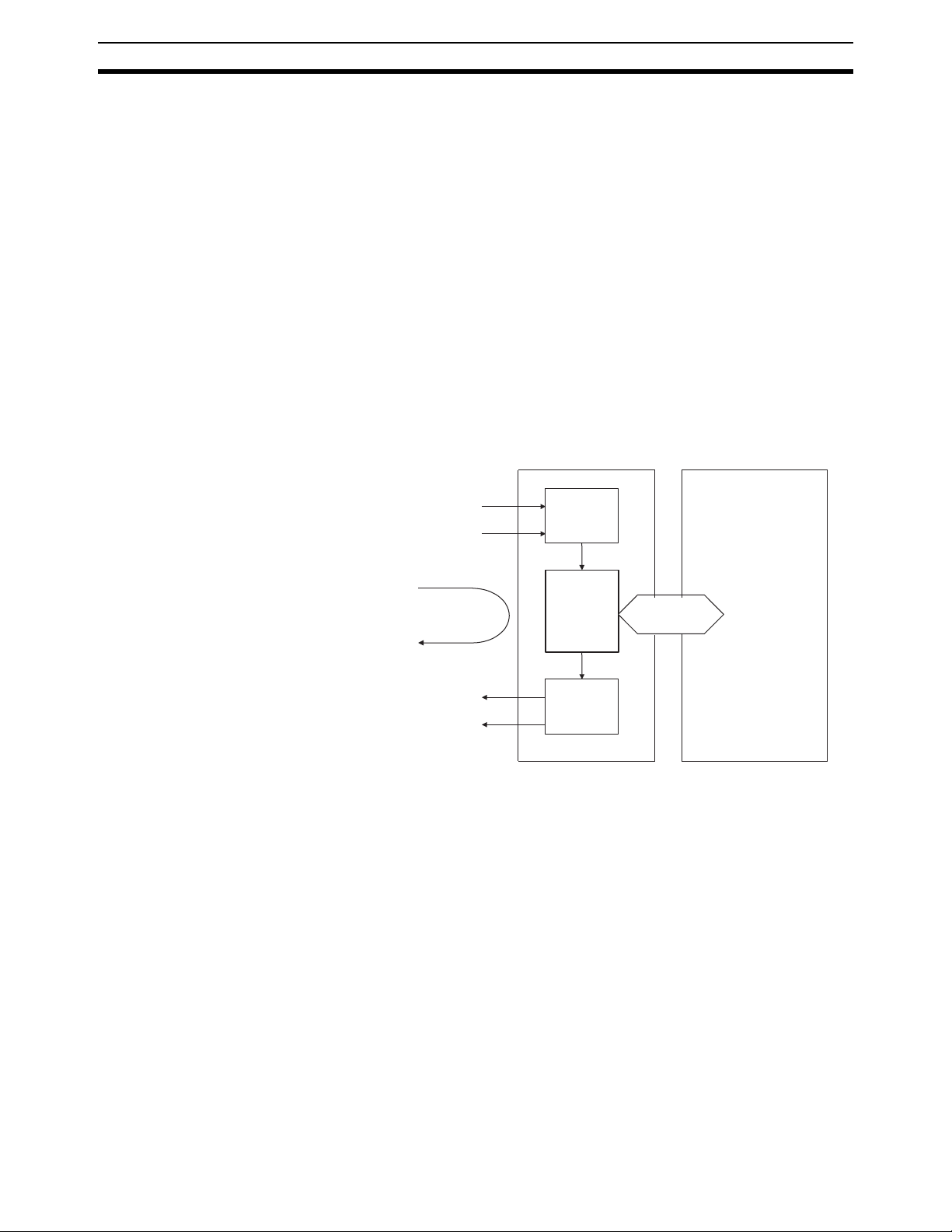

The Customizable Counter Units are CS-series Special I/O Units that can be

programmed using a ladder program and provide both standard contact I/O

and special I/O (including pulse inputs, pulse outputs, and analog outputs).

(I/O support depends on the model of the Unit.)

The I/O of a Customizable Counter Unit can be controlled by the ladder program in it without intervention from the program in the CPU Unit to achieve

high-speed I/O processing. By customizing a Customizable Counter Unit

using its I/O, programming, and interrupt functions, a wide range of applications requiring high-speed response can be implemented in a distributed processing system where the Customizable Counter Unit functions as a

coprocessor for the CPU Unit.

Customizable Counter Unit capabilities also facilitate machine modularization

and standardization, and make machine and device maintenance much easier.

Normal inputs

Pulse inputs

High-speed control loop

Normal outputs

Pulse or analog outputs

Customizable Counter Unit

Input data

Ladder

program

Output data

Data exchange

with the CPU Unit

CS-series CPU Unit

• High-speed I/O processing is enabled by the small-capacity ladder program in the Customizable Counter Unit that achieves a high-speed cycle.

The Customizable Counter Unit also supports various types of interrupt

programming, enabling it to handle special high-speed applications previously handled by sensor controllers and microcomputer boards. The Customizable Counter Unit can also perform part of the functions previously

performed by High-speed Counter Units, Position Control Units, and Analog Output Units.

• Other features include normal interrupts, interval timer interrupts, and

high-speed counter interrupts, in addition to a high-precision timer that

uses a pulse counter (CS1W-HCP22-V1 only), target value interrupts for

a pulse output value (CS1W-HCP22-V1 only), analog output instructions

for analog slope control (CS1W-HCA22-V1 only), and range comparisons

for the present value of a high-precision pulse output counter timer.

• The CS1W-HCA12-V1 is a special I/O unit of CS-series, having all of 1

high-speed analog input, 1 pulse input (compatible with servo drivers with

absolute encoders), 2 high-speed analog outputs, and operations by builtin ladder program (simplified positioning, discriminant and counting processes) within 1 unit. The unit by itself can process both the "linear sensor

2

Page 23

Outline Section 1-1

control" and "simplified position/speed control", which have been processed separately by the dedicated unit or system in existing models.

1) High-speed input of analog signals from displacement sensors etc,

which have been processed in the linear sensor controller in the existing system, enables the ladder program processing.

2) This unit can perform the simplified position controls that have been

operated with motion control and position control units in the existing

system. Taking in the encoder signals enables the unit to drive the servo driver with analog output. In addition, using the other analog output

makes it possible to limit the torque and control inverters.

3

Page 24

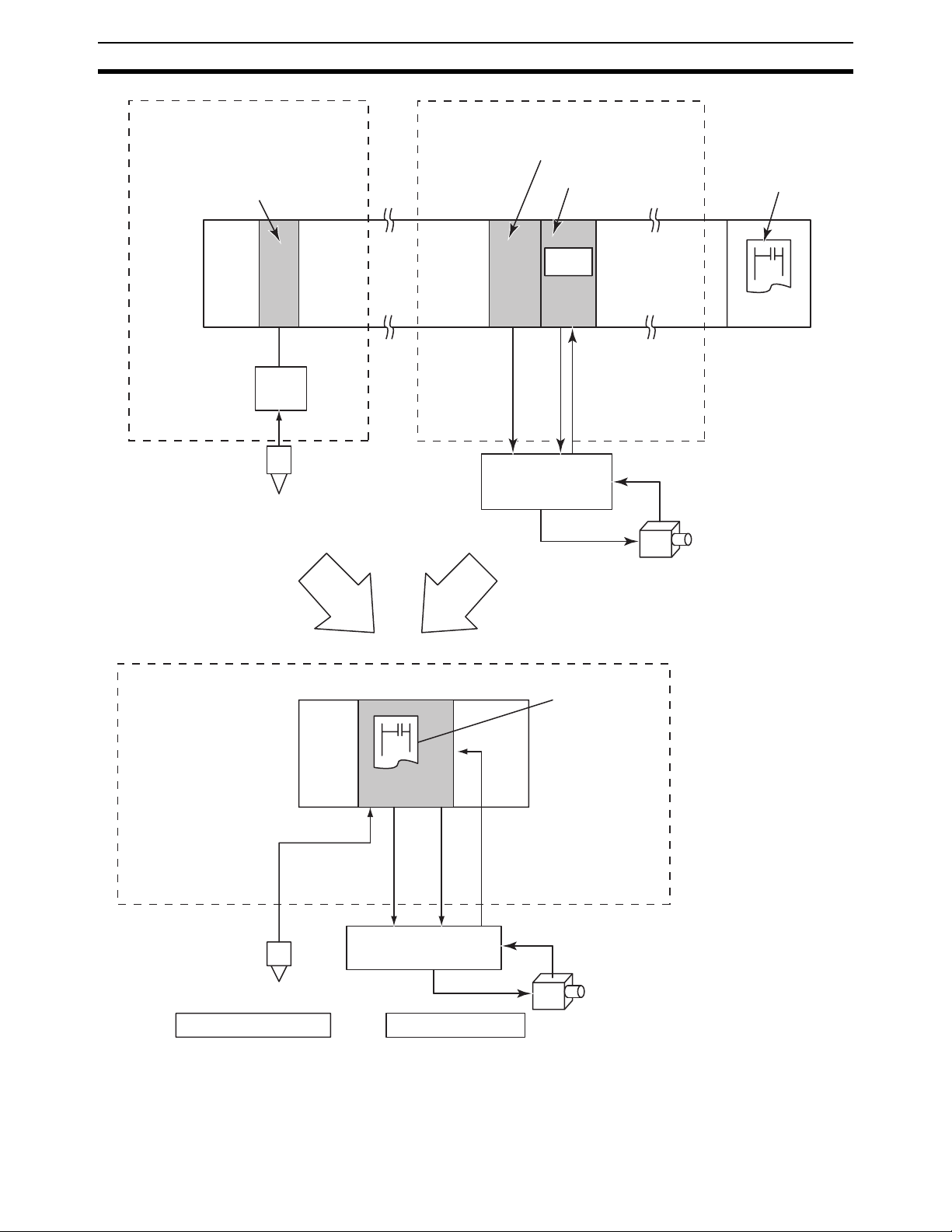

Outline Section 1-1

High-speed input of analog signals from

displacement sensors etc.

Basic I/O Unit

contact input

Linear sensor

control

Displacement sensors

Pressure sensors

discrimination

4 to 20 mA

Integrate

Control the servo by the high-speed analog

output

Analog Output Unit

Motion Control Unit

programs

Analog output

(limit the torque)

Analog

output

(speed

control)

Position information

(Absolute encoder

output)

Absolute encoders

servo driver

CPU Unit

High-speed analog input is

possible.

it is possible to take in the

output data directly from the

displacement sensors or the

pressure sensors etc.

4 to 20 mA

High-speed analog input Simplified position control

Customizable Counter Units

Analog

Analog output

(limit the torque)

output

(speed

control)

Position information

(Absolute encoder output)

Absolute encoders

It is possible to

encapsulate the

programs as the

ladder library.

servo driver

• On the models with "V1" at the rightmost 2 digits, all or a part (subroutine)

of the ladder programs in the unit are encapsulated and stored in the

Flash memory, also provided in the unit. The real customization is made

possible.

4

Page 25

Outline Section 1-1

1-1-2 Features

Programmable I/O Control • The program capacity for the ladder program in the Customizable Counter

Unit is 4 Kwords.

• Standard features include 12 contact inputs and 8 contact outputs.

• For special I/O, the CS1W-HCP22-V1 provides 2 pulse inputs and 2 pulse

outputs, while the CS1W-HCA22-V1 provides 2 pulse inputs and 2 analog

outputs.

• Pulse inputs on the CS1W-HCP22-V1 and CS1W-HCA22-V1 can be used

for a high-speed counter (50 or 200 kHz, signal phase), and the present

value of the counter can be used to create target value interrupts or range

comparison bit pattern outputs. Trapezoid pulse (speed) outputs or conditional ON/OFF outputs can thus be created for the present value pulse

input. Furthermore, an Electronic Cam Mode can be used to change the

pulse output value for absolute positioning or the pulse output frequency

for speed control in response to the present value of the pulse input (e.g.,

for a rotational angle). You can also monitor changes in the present value

of the high-speed counter or measure the frequency from the present

value of the high-speed counter.

• Pulse outputs on the CS1W-HCP22-V1 can be used for specified frequency outputs with or without acceleration/deceleration, as well as for

one-shot outputs (turned ON for a specified time between 0.01 and

9,999 ms). The one-shot pulse output function can also be used to

achieve a high-precision pulse counter timer with a minimum time of

0.01 ms, and the present value can be used to create target value interrupts or range comparison bit pattern outputs. Trapezoid pulse (speed)

outputs or conditional ON/OFF outputs can thus be created for the

present value of the pulse output.

• Analog outputs on the CS1W-HCA22-V1 can be used with the SPED or

ACC instruction to step analog outputs or for rising or falling sloped outputs.

• Combinations with timer instructions enable time-stepped or trapezoid

analog outputs.

• Analog outputs can be set to be held at the peak, current, or cleared

value by turning OFF an Output Conversion Enable Bit when required

or for errors.

• The SPED and ACC instructions can be used to control the analog output value independent of the END refresh.

• The I/O refresh time can be reduced by disabling the analog outputs

when they are not required.

• Rate-of-change measurements are possible at a sampling time for the

high-speed counter input.

• High-speed counter input frequency measurements can be taken.

• The present value of the high-speed counters can be cleared or held

when power is turned ON.

• The high-speed counters can be started and started by controlling the

status of a control bit.

• Any of four pulse output ranges can be specified: 6 Hz to 20 kHz, 25 Hz to

50 kHz, 100 Hz to 100 kHz, or 400 Hz to 200 kHz.

• The present value of the pulse output can be reset.

5

Page 26

Outline Section 1-1

Advanced Processing • Either high-speed or normal-speed execution can be selected for basic

instructions. The execution time for basic instructions in High-speed Execution Mode is approximately twice as fast as the time in Normal Execution Mode. (The program must be approximately 1 Kword or less to use

High-speed Execution Mode.) (Example for LD instruction: Normal Execution: 0.4

• Faster execution of CTBL and other instructions using table data can be

achieved by not holding the EM Area status when power is turned OFF.

ms; High-speed Execution: 0.2 ms)

Coordinating Operation

with the CPU Unit

Special I/Os that Can

Support Various

Applications

• Data can be exchanged in three different areas of memory shared with

the CPU Unit to perform handshaking and other operations without programming a special interface.

• Ten words of the CIO Area in the CPU Unit are shared with SR Area

Words in the Customizable Counter Unit.

• Up to 90 words of the DM Area in the CPU Unit can be shared with

user-set words in the Customizable Counter Unit.

• Up to 32 user-set words in the CPU Unit can be shared with LR Area

words in the Customizable Counter Unit.

• External interrupt tasks in the CPU Unit can be executed by programming

the MCRO instruction in the Customizable Counter Unit. The Customizable Counter Unit can thus activate programming in the CPU Unit

depending on the control status of the Customizable Counter Unit to synchronize processing with other Units.

• 1 high-speed analog input (CS1W-HCA12-V1)

High-speed analog input (A/D conversion time = 50

ports 0 to 10 V, 1 to 5 V,

enables the control supporting the analog input from the displacement

and pressure sensors through the linear sensor.

• 2 high-speed analog outputs (CS1W-HCA12-V1)

High-speed analog output (D/A conversion time = 50

supports 0 to 10 V, 1 to 5 V,

and the use of servo drivers of an analog input type enables the speed

control, torque commands, etc. in addition, it can be used for the inverter

control (frequency commands).

• 1 input for taking in the absolute encoder output data (CS1W-HCP22-V1/

HCA22-V1/HCA12-V1)

With this input, it is possible to take in the absolute encoder output data

directly from the servo drivers manufactured by OMRON, etc. Since it

enables the feedback input of the absolute value information, the analog

output mentioned above can be used for position control.

-10 to 10 V, 0 to 5 V, and 4 to 20 mA. This

-10 to 10 V, 0 to 5 V. The combination of this

ms) is possible. It sup-

ms) is possible. It

Ladder Library Function

(All -V1 Models)

Back-up Function (All -V1

Models)

6

These units has the built-in ladder programs. It is possible to encapsulate the

programs as the ladder library. The ladder library is saved to the Flash memory in the unit. The encapsulation of the programs to the library enables the

"protection of the ladder software assets from the third party" and "execution

of the ladder software functions quasi-without programming".

Through the bit manipulation from the CPU unit, it is possible to back up

(write) or restore (read) the data of the unit to or from the memory card. With

the use of CS1-H CPU units, the data can be backed up or restored through

the simplified back-up operation on the front panel of the CPU unit.

Page 27

Outline Section 1-1

1-1-3 Application Examples

The following are a few examples of the types of applications that are possible

by combining various features.

• Contact Input

High-speed interrupt I/O processing or IORF instruction execution can be

used to refresh outputs whenever required.

• Pulse Input

• An Electronic Cam Mode can be used to perform a specific absolute

positioning operation and speed change for the rotational angle or current position of a workpiece. For example, the encoder output from a

main control axis can be input to the high-speed counter, and a specified movement for a target position (number of output pulses) for the

followup axis can be defined using linear approximation with the APR

instruction. The PULS instruction can also be used to change the number of output pulses (target position) based on the defined value to

change the pulse output during operation.

• Speed control via a pulse output can be achieved in response to the

position of a workpiece. The present value of either a high-speed

counter or pulse output can be used with a target value interrupt for an

interrupt program that contains an instruction to change the frequency,

i.e., SPED or ACC.

• High-speed processing, such as for coating or valve control, can be

achieved for a fast-moving object by outputting a one-shot output pulse

with a minimum unit of 0.01 ms from a specified position. This is

achieved by combining an interrupt for the present value of a pulse input, and then programming a one-shot pulse output using the STIM instruction in the interrupt program.

• Pulse Input

• Simple positioning with an analog output can be achieved with an inverter and motor. This is achieved by combining an interrupt for the

present value of a pulse input, and then programming a stepped analog output using the SPED instruction or a slopped analog output using

the ACC instruction in the interrupt program.

• Trapezoid torque control with an analog output for the position of a

workpiece. This is achieved by combining an interrupt for the present

value of a pulse input, and then programming a slopped analog output

using the ACC instruction in the interrupt program.

• Trapezoid analog output for a specified time can be achieved by combining a timer instruction with a slopped analog output using the ACC

instruction.

• Torque control (Clamping in molding applications, transfer control in injection-molding applications) (CS1W-HCA12-V1 only)

pressure control (speed control and torque limit)

• Using this unit with a servo driver of an analog input type and a pressure sensor enables the control as described below. Note that the servo driver (W series manufactured by OMRON in the example) is to be

in the "speed control" mode.

® Programming ® Contact Output:

® Program ® Pulse Output for CS1W-HCP22-V1

® Program ® Analog Output for CS1W-HCA22-V1

® Position control ®

® position control

7

Page 28

Outline Section 1-1

• System configuration

Customizable Counter Unit

CS1W-HCA12-V1

CS-series CPU Unit

ON/OFF

Position

detector

Pressure

sensor

• Operation Process

1) Position control by the unit (CS1W-HCA12-V1):

A speed command is issued to the servo driver with the analog

output. The servo driver feeds back the absolute position information with the absolute encoder input. Using the feedback, position control is executed (through the speed command output)

following SPED or ACC instructions on the ladder program of the

unit.

2) Pressure control by the unit (speed control and torque limit):

Reaching a certain position (position for pressure control) causes the unit to output a speed and a torque limit command for the

speed control and torque limit. The pressure control (clamping

etc) is executed after the unit converts the analog inputs (load

cell, strain gauge, etc) from the pressure sensor to the analog

outputs (torque limit by the speed command and torque limit output) for the servo driver.

3) Position control by the unit

Once the operation (molding, etc) is completed, a speed command output from the unit returns the mechanical system to its

origin.

Analog input

(4 to 20 mA)

Analog output (−10 to +10 V):

Speed control

Analog output (0 to 10 V):

Torque limit)

Signal from

absolute encoder

Servo driver

Servo motor

8

Page 29

Outline Section 1-1

Customizable Counter Unit

CS1W-HCA12-V1

Position control,

or

Speed control

(SPED or ACC

instruction)

Pressure

control

switch

Analog output

(Speed control)

−10 to 10 V, etc.

SEN signal

Signal from

ABS encoder

Analog output

(Torque limit)

−10 to 10 V, etc.

Servo driver (Omron W-series)

Control mode:

Speed control (analog commands)

Speed control

+

Torque limit

Analog input

4 to 20 mA,

0 to 10 V etc.

Displacement

Count

Threshold

Absolute encoder signal

(line driver)

Pressure

sensor

Clamping

in pressing

Power cable

(U, V, W)

Servo motor

with

Absolute encoder

• Linear sensor control (control based on monitoring the ups and downs/

distortion/thickness/height/diameter of objects) (CS1W-HCA12-V1 only)

• Example) Counting ups and downs (piles)

With the use of a displacement sensor, the unit can count the number

of ups and downs (piles) by monitoring the change in the displacement

amount as the sensor measures them on the surface of objects moving at high speed.

1

23 4

Time

9

Page 30

Outline Section 1-1

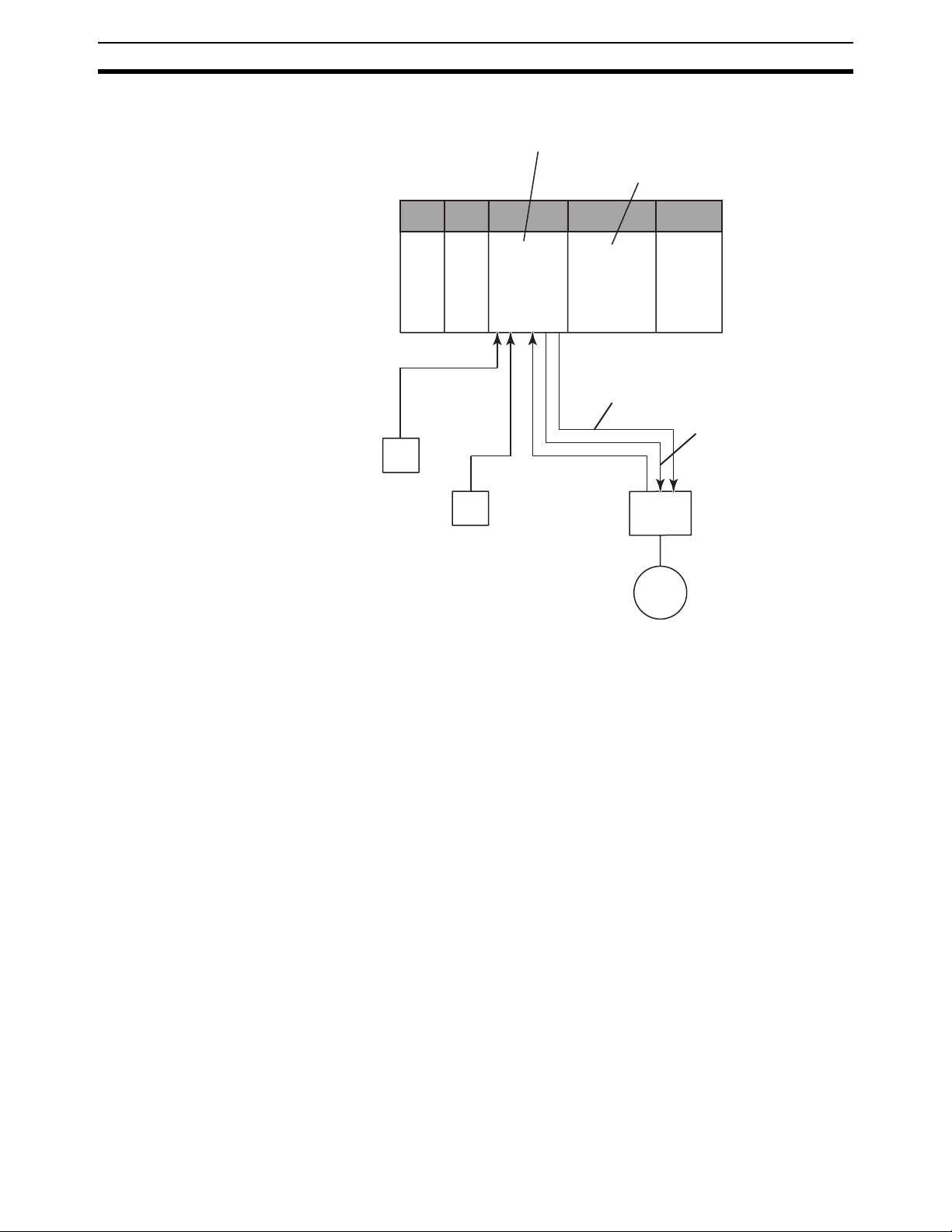

• System configuration

Customizable Counter Unit

CS1W-HCA12-V1

CS-series CPU Unit

4 to 20 mA

Displacement

Sensor

• Operation Process

ON/OFF

Photo-electric Switches

Moving at high speed

1) High-speed analog input (immediate refresh)

4 to 20 mA signals from the displacement sensor are input to and

refreshed in the unit at every PRV instruction execution. The displacement data is stored in the areas (Ex: DM) that have the I/O

memory.

2) Counting process with the ladder program

A ladder program has to be arranged (Ex: The unit compares the

ranges with BCMP instruction, and the unit counts rises of the results with INC instruction) so that the counter will count the number

of times of when the stored displacement data exceed a certain

threshold value. The execution of the program will make the unit

count.

10

Page 31

Outline Section 1-1

Customizable Counter Unit

CS1W-HCA12-V1

Ladder program

Displacement

Sensor

4 to 20 mA

Acquire the analog

input value by PRV

instruction (immediate refresh)

The unit compares the

ranges with BCMP

instruction, and the unit

counts rises of the results

with INC instruction

I/O memory

Displacement

Store

Count value

• Linear sensor control (High-speed trace of in-line quality data) (CS1WHCA12-V1 only)

• Example) Quality check of high-speed assembling process (injection

etc)

With the use of a displacement sensor, the sensor inputs the characteristic data of objects flowing at high speed, and the unit' data memory stores the input data at constant intervals.

a) The data can be transferred to the memory card by batch process-

ing, and can be read using the PC for analyses.

b) The data can be transferred to the CPU unit's data memory by

batch processing, and the line plot of the data can be displayed on

the screen of the programmable terminal (NS series by OMRON).

11

Page 32

Outline Section 1-1

r

• System configuration

NS series PT

Customizable Counter Unit

CS1W-HCA12-V1

CS-series CPU Unit

Memory card

Injection

Process

Displacement

Sensor

4 to 20 mA

ON/OFF

Photo-electric Switches

Moving at high speed

Store the line plot

Analyze

Personal compute

12

Page 33

Outline Section 1-1

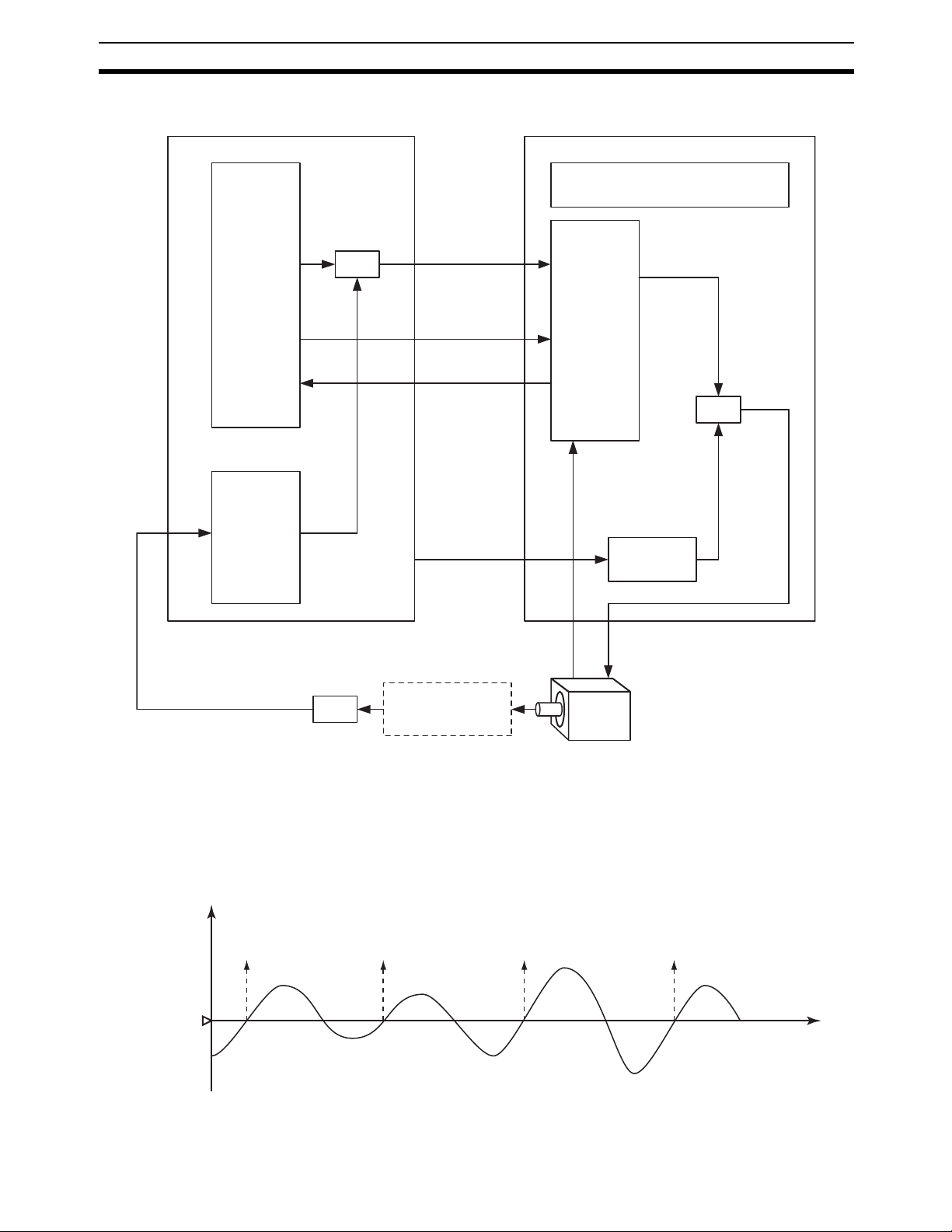

• Operation Process

1) High-speed analog input by scheduled interrupts with the ladder

program (immediate refresh)

The PRV instruction is executed at each of constant executions of

subroutine programs with the scheduled interrupts (interval timer).

4 to 20 mA signals from the displacement sensor are input, refreshed, and stored (trace data) in the I/O memory area (Ex. DM)

of the main unit.

2) Transferring the traced data to the CPU unit

The data traced in the unit is transferred to the CPU unit. (Ex.

Through the cyclic transfer to DM allocated in the CPU unit)

3) Transferring the data to the memory card inserted in the slot of the

CPU unit

The data in the DM area is stored in the memory card as a data

file (.CSV etc) through the FWRIT instruction of the CPU unit.

4) Analysis performed on the spreadsheet software

Through the memory card adaptor connected to the PC, the data

file (.CSV etc) can be analyzed on the spreadsheet software.

5) Line plot displayed on PT (NS series)

The trace data in the CPU unit can be displayed as the line plot on

PT (NS series).

Customizable Counter Unit

CS1W-HCA12-V1

CS-series CPU Unit

Displacement

Sensor

4 to 20 mA

Ladder program Ladder program

Start the interval timer

by STIM instruction

Interrupt subroutines

SBN

Acquire the analog

input value by PRV

instruction (immediate

refresh)

RET

I/O memory

Traced data

Store

Displacement

value 1

Displacement

value 2

Displacement

value n

I/O memory

Allocated DM area

Refresh

Store the data to

memory card

PT (NS series)

Display

a line graph

Store

Memory card

13

Page 34

Models and System Configurations Section 1-2

1-2 Models and System Configurations

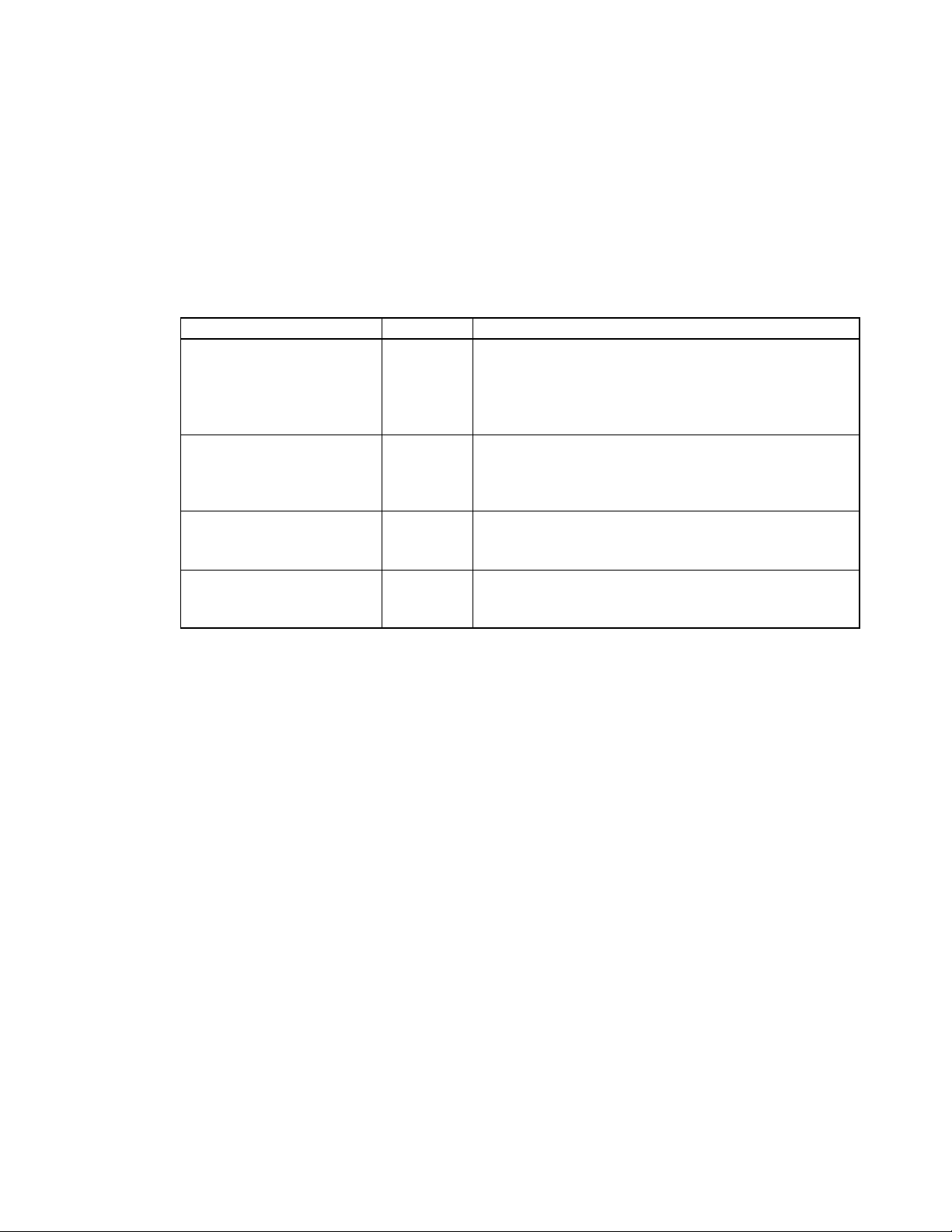

1-2-1 Models

There are three models of Customizable Counter Unit, all of which are classified as CS1 Special I/O Units.

Model number Functions

CS1W-HIO01-V1 12 contact inputs, 8 contact outputs

CS1W-HCP22-V1 12 contact inputs, 8 contact outputs, 2 pulse inputs, 2 pulse out-

puts

CS1W-HCA22-V1 12 contact inputs, 8 contact outputs, 2 pulse inputs, 2 analog out-

puts

CS1W-HCA12-V1 12 contact inputs, 8 contact outputs, 1 analog input, 1 pulse input

1-2-2 System Configurations

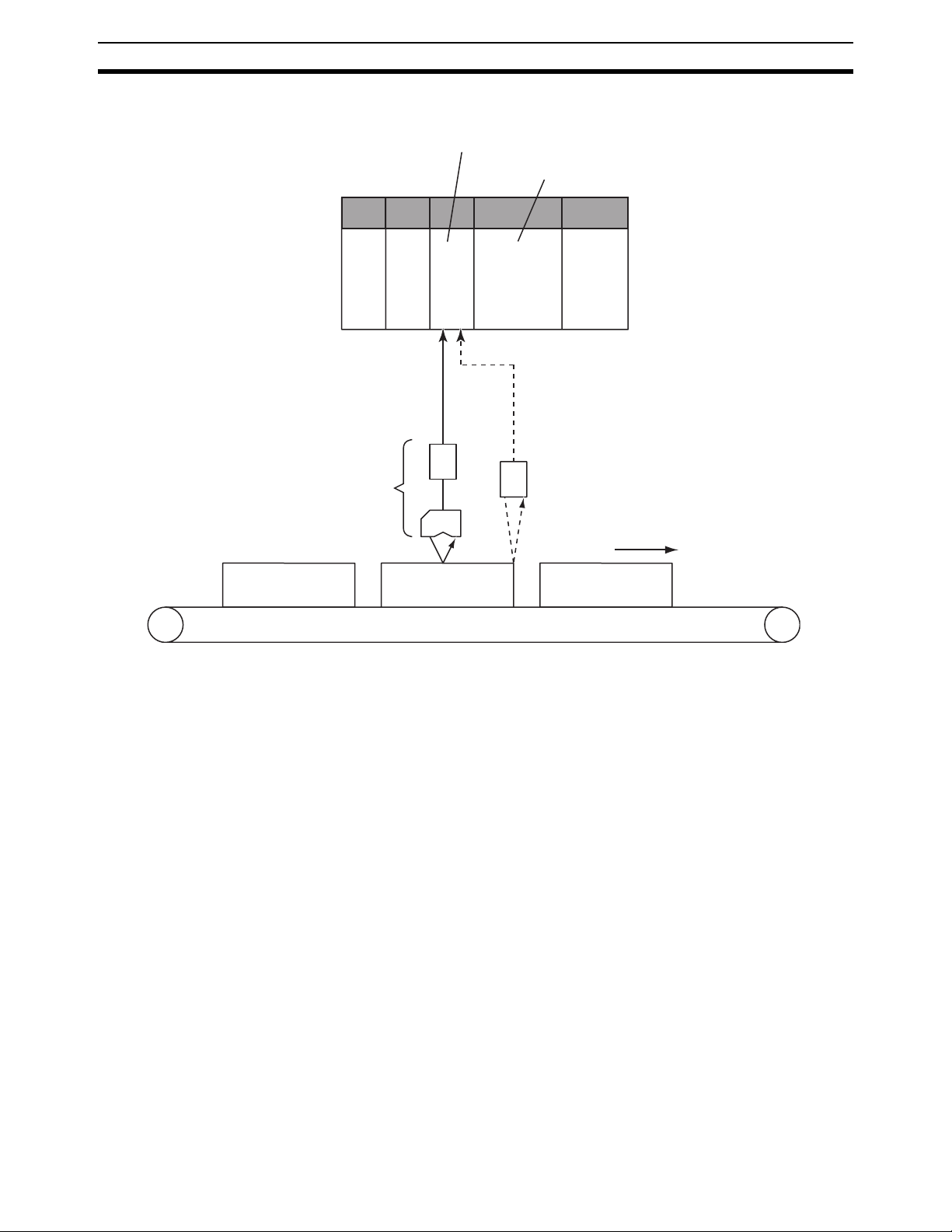

CS1W-HIO01-V1(Basic Model)

(compatible with servo drivers with absolute encoders), 2 analog

outputs

Programming

Device

CX-Programmer

Creating, transferring, and

monitoring the program for the

Customizable Counter Unit.

12 contact inputs, 4 of

which can be used as

interrupt inputs

8 contact outputs

CS1W-HIO01-V1

Customizable

Counter Unit

Peripheral port

Contact I/O

Ladder

program

I/O

memory

Peripheral Port Connecting Cable

(peripheral bus)

CS-series CPU Unit

Ladder

program

I/O

memory

OR

Programming

Console

14

Page 35

Models and System Configurations Section 1-2

CS1W-HCP22-V1 (Pulse Inputs and Pulse Outputs)

Programming

12 contact inputs, 4 of

which can be used as

interrupt inputs

CS1W-HCP22-V1

Customizable

Counter Unit

Device

Peripheral Port Connecting Cable

(peripheral bus)

CS-series CPU Unit

CX-Programmer

Creating, transferring, and

monitoring the program for

the Customizable Counter

Unit.

OR

Programming

Console

2 pulse inputs

(compatible with

servo drivers with

absolute encoders)

2 pulse outputs

8 contact outputs

Rotary encoder, etc.

Rotary encoder, etc.

Servodriver, etc.

Servodriver, etc.

Peripheral port

Contact I/O

Ladder

program

I/O

memory

Special I/O

Ladder

program

I/O

memory

15

Page 36

Models and System Configurations Section 1-2

CS1W-HCA22-V1 (Pulse Inputs and Analog Outputs)

CX-Programmer

Creating, transferring, and

monitoring the program for

the Customizable Counter

Unit.

OR

Programming

Console

12 contact inputs, 4 of

which can be used as

interrupt inputs

Programming

Device

CS1W-HCA22-V1

Customizable

Counter Unit

Peripheral Port Connecting Cable

(peripheral bus)

CS-series CPU Unit

8 contact outputs

2 pulse inputs

(compatible with

servo drivers with

absolute encoders)

2 analog outputs

Rotary encoder, etc.

Rotary encoder, etc.

Operation

terminal,

etc.

Operation

terminal,

etc.

Peripheral port

Contact I/O

Ladder

program

I/O

memory

Special I/O

Ladder

program

I/O

memory

CS1W-HCA12-V1 (Analog Inputs, Pulse Input and Analog Outputs)

Programming

Device

CS1W-HCA12-V1

Customizable

Counter Unit

Peripheral Port Connecting Cable

(peripheral bus)

CS-series CPU Unit

CX-Programmer

Creating, transferring, and

monitoring the program for

the Customizable Counter

Unit.

OR

Programming

Console

16

12 contact inputs, 4 of

which can be used as

interrupt inputs

8 contact outputs

1 analog inputs

1 pulse inputs

(compatible with

servo drivers with

absolute encoders)

2 analog outputs

Sensor inputs

(Pressure,

displacement,

etc.)

Rotary encoder, etc.

Operation

terminal,

etc.

Operation

terminal,

etc.

Peripheral port

Contact I/O

Ladder

program

I/O

memory

Special I/O

Ladder

program

I/O

memory

Page 37

Models and System Configurations Section 1-2

Programming Devices

The CX-Programmer versions that can be used with the Customizable

Counter Unit are given in the following table.

Name Model number Computer Serial communications

CX-Programmer

Ver. 1.2 or later

(on CD-ROM)

WS02-CXPC1-E IBM PC/AT or compatible

The Programming Consoles that can be used with the Customizable Counter

Unit are given in the following table.

Model number Cable

C200H-PRO27 CS1W-CN224 or CS1W-CN624 required separately.

CQM1-PRO01 2-m cable provided with Programming Console, but CS1W-N114

CQM1H-PRO01 2-m cable provided with Programming Console

Connecting Contact and Special I/O

Special connectors are required to connect the contact I/O and special I/O to

the connectors on the Customizable Counter Unit. These connectors are provided with the Customizable Counter Unit and can be purchased separately.

The cables for these connectors must be provided and wired to the connectors by the user. An OMRON Connector–Terminal Block Conversion Unit can

also be used for the special I/O. Refer to 3-3 Wiring for details.

mode

Peripheral bus CQM1H-CPU61

OS: Microsoft Windows

95 or 98

Model setting on the

CX-Programmer

Note There are some functional limitations in using the CX-Programmer

with the Customizable Counter Unit. Refer to 3-4 Programming Devices for details.

required separately.

17

Page 38

Models and System Configurations Section 1-2

18

Page 39

SECTION 2

Specifications

This section provides performance specifications and I/O specifications for the Customizable Counter Unit.

2-1 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2-1-1 Available Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2-1-2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2-1-3 Program and Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2-1-4 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2-1-5 I/O Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2-2 Contact I/O Specifications (All Units) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2-2-1 Contact I/O Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2-2-2 I/O Connector Pin Arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

19

Page 40