Page 1

Cat. No. W440-E1-03

SYSMAC

CS/CJ Series

CS1W-FLN22 (100Base-TX)

CJ1W-FLN22 (100Base-TX)

FL-net Units

OPERATION MANUAL

Page 2

Page 3

CS1W-FLN22 (100Base-TX)

CJ1W-FLN22 (100Base-TX)

FL-net Units

Operation Manual

Revised October 2010

Page 4

iv

Page 5

Notice:

r

f

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 2004

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 6

vi

Page 7

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxi

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

7 Unit Versions of CS/CJ-series FL-net Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

SECTION 1

Features and System Configuration . . . . . . . . . . . . . . . . . . . 1

1-1 FL-net Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-3 Related Programming Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-4 Introducing the CX-FLnet Support Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-5 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-6 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

SECTION 2

Communications Functions . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2-1 FL-net . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-2 Cyclic Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2-3 Message Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

2-4 FINS Communications Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

SECTION 3

Startup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3-1 Before Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3-2 Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3-3 Nomenclature and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3-4 Hardware Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3-5 Mounting to the PLC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3-6 Network Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3-7 Connecting to the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3-8 Creating an I/O Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3-9 Creating Routing Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3-10 System Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3-11 Checking Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

vii

Page 8

TABLE OF CONTENTS

SECTION 4

System Setup and Memory Allocations . . . . . . . . . . . . . . . . 47

4-1 Allocated Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4-2 CPU Bus Unit System Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4-3 Allocated Words in the CIO Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4-4 Allocated Words in the DM Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

SECTION 5

Data Link. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5-1 Data Link Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5-2 Setting Data Link Tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

SECTION 6

Message Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6-1 Message Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

6-2 Details of Supported Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

SECTION 7

FINS Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

7-1 Overview of FINS Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

7-2 Sending Commands from a PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

7-3 Command Codes and Response Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

7-4 CS/CJ-series Memory Areas and Virtual Addresses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

7-5 Command/Response Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

SECTION 8

Communications Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

8-1 Network Communications System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

8-2 Communications Cycle Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

8-3 Influence on Cycle Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136

8-4 Calculating the Data Link I/O Response Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

8-5 Message Service Transmission Delays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

SECTION 9

Testing Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

9-1 Communications Testing Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

9-2 PING Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

9-3 Internode Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

viii

Page 9

TABLE OF CONTENTS

SECTION 10

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

10-1 Troubleshooting with Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

10-2 Error Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

10-3 Error Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

10-4 Troubleshooting Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .152

10-5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

10-6 Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

SECTION 11

CX-FLnet Support Software Operations . . . . . . . . . . . . . . . 167

11-1 CX-FLnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

11-2 Operating Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Appendices

A System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .189

B System Configuration Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

C Network System Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

D FL-net Network Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

E FL-net Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

F FL-net Unit Support Software Ver. 1.6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

G International System of Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

ix

Page 10

Page 11

About this Manual:

This manual describes the installation and operation of the CS1W-FLN22 (100Base-TX) and CJ1WFLN22 (100Base-TX) FL-net Units.

FL-net Units are used to connect to FL-net networks.

Please read this manual and all related manuals listed in the following table carefully and be sure you

understand the information provided before attempting to install and operate an FL-net Unit.

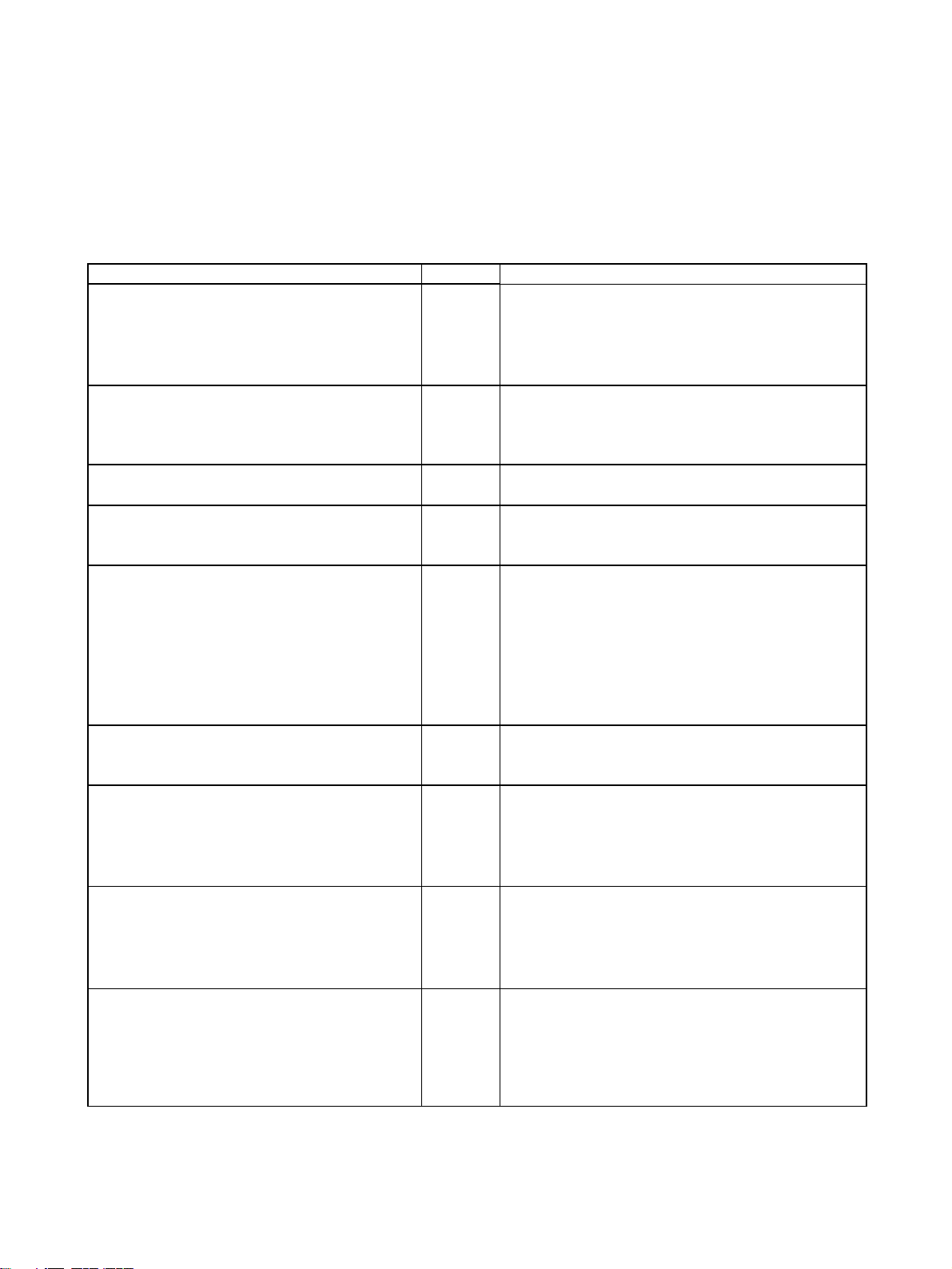

Name Cat. No. Contents

SYSMAC CS/CJ Series

CS1W-FLN22 (100Base-TX) and CJ1W-FLN22

(100Base-TX) FL-net Units

Operation Manual

(this manual)

SYSMAC CS/CJ Series

CS1W-ETN21, CJ1W-ETN21

100Base-TX Ethernet Units

Operation Manual, Construction of Network

CXONE-AL@@C-E

CX-One FA Integrated Tool Package Setup Manual

WS02-CXPC1-E-V61

SYSMAC CX-Programmer Ver. 6.1

Operation Manual

WS02-CXPC1-E-V61

SYSMAC CX-Programmer Ver. 6.1

Operation Manual Function Blocks

CXONE-AL@@C-E

CX-Integrator Operation Manual

SYSMAC CS Series

CS1G/H-CPU@@-EV1, CS1G/H-CPU@@H

Programmable Controllers Operation Manual

SYSMAC CJ Series

CJ1G-CPU@@, CJ1M-CPU@@, CJ1G-CPU@@P,

CJ1G/H-CPU@@H

Programmable Controllers Operation Manual

SYSMAC CS/CJ Series

CS1G/H-CPU@@-EV1, CS1G/H-CPU@@H,

CS1D-CPU@@H, CS1D-CPU@@S, CJ1GCPU@@, CJ1M-CPU@@, CJ1G-CPU@@P, C J 1G /

H-CPU@@H

Programmable Controllers Programming Manual

W440 Describes the installation and operation of the CS1W-

FLN22 and CJ1W-FLN22 FL-net Units.

Refer to the Communications Commands Reference

Manual (W342) for information on FINS commands that

can be addressed to CS/CJ-series CPU Units.

W420 Provides information on operating and installing

100Base-TX Ethernet Units, including details on basic

settings and FINS communications.

W444 Provides an overview of the CX-One FA Integrated Tool

and installation procedures.

W446 Provides information on installing and operating the CX-

Programmer for all functions except for function blocks.

W447 Provides specifications and operating procedures for

function blocks.

When programming, refer to the CJ Series (W339) or CJ

Series (W393) Programmable Controllers Operation

Manual, CS/CJ Series Programmable Controllers Programming Manual (W394), and CS/CJ Series Programmable Controllers Instructions Reference Manual

(W340).

W445 Describes CX-Integrator operating procedures and pro-

vides information on network configuration (data links,

routing tables, Communications Units setup, etc.

W339 Provides an outline of and describes the features, sys-

tem configuration, installation, wiring, I/O memory allocations, and troubleshooting for the CS-series PLCs.

Use this manual together with the CS/CJ Series Pro-

grammable Controllers Programming Manual (W394).

W393 Provides an outline of and describes the features, sys-

tem configuration, installation, wiring, I/O memory allocations, and troubleshooting for the CJ-series PLCs.

Use this manual together with the CS/CJ Series Pro-

grammable Controllers Programming Manual (W394).

W394 This manual describes programming, tasks, file memory

function, and other functions of the CS/CJ-series PLCs.

Use this manual together with the CJ Series (W339) or

CJ Series (W393) Programmable Controllers Operation

Manual.

xi

Page 12

Name Cat. No. Contents

SYSMAC CS/CJ Series

CS1G/H-CPU@@-EV1, CS1G/H-CPU@@H,

CS1D-CPU@@H, CS1D-CPU@@S, CJ1GCPU@@, CJ1M-CPU@@, CJ1G-CPU@@P, C J 1G /

H-CPU@@H

Programmable Controllers Instructions Reference

Manual

SYSMAC CS/CJ Series

CS1G/H-CPU@@-EV1, CS1G/H-CPU@@H,

CS1D-CPU@@H, CS1D-CPU@@S, CJ1MCPU@@, CJ1G-CPU@@, CJ1G-CPU@@P, C J 1G /

H-CPU@@H, CS1W-SCB21-V1/41-V1, CS1WSCU21-V1, CJ1W-SCU21-V1/41-V1

Communications Commands Reference Manual

W340 Describes the ladder diagram programming instructions

supported by CS/CJ-series PLCs.

Use this manual together with the CJ Series (W339) or

CJ Series (W393) Programmable Controllers Operation

Manual and the CS/CJ Series Programmable Controllers Programming Manual (W394).

W342 Describes the C-series (Host Link) and FINS communi-

cations commands used with CS/CJ-series PLCs.

This manual describes communications commands

addressed to the CPU Unit. The communications path is

not relevant, i.e., communications can be performed via

a serial port on the CPU Unit, Serial Communications

Unit/Board, or a Communications Unit.

xii

Page 13

About this Manual, Continued

This manual contains the following sections.

Section 1 introduces the overall structure of an FL-net (Ver. 2.00) network, outlines the features of the

FL-net (Ver. 2.00) Unit, describes the communications protocols used by an FL-net (Ver. 2.00) network, and provides basic precautions for use of the network.

Section 2 describes the communications functions that can be used with the FL-net (Ver. 2.00) Units.

Section 3 explains the procedure for starting up the FL-net (Ver. 2.00) Unit, including mounting to the

PLC, making the required settings, and checking communications.

Section 4 explains the System Setup and the words allocated in the CIO Area and the DM Area for

FL-net (Ver. 2.00) Units.

Section 5 explains the Data Link function, including an overview and examples of how to make the

required settings.

Section 6 describes the message transmission used by an FL-net (Ver. 2.00) network.

Section 7 provides information on communicating on FL-net Systems and interconnected networks

using FINS commands. The information provided in the section deals only with FINS communications

in reference to FL-net (Ver. 2.00) Units.

Section 8 describes the communications system, communications cycle time, communications cycle

time calculation, data link I/O response time, data link I/O response time calculation, and message service transmission delays.

Section 9 describes functions that allow you to test communications.

Section 10 describes information and procedures that can be used to troubleshoot problems that

sometimes occur with FL-net (Ver. 2.00) Unit and FL-net communications.

Section 11 describes the Support Software used to make settings for the FL-net Units.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

xiii

Page 14

xiv

Page 15

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xv

Page 16

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xvi

Page 17

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xvii

Page 18

xviii

Page 19

PRECAUTIONS

This section provides general precautions for using the CS/CJ-series Programmable Controllers (PLCs) and related devices.

The information contained in this section is important for the safe and reliable application of Programmable

Controllers. You must read this section and understand the information contained before attempting to set up or

operate a PLC system.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

7 Unit Versions of CS/CJ-series FL-net Units . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

xix

Page 20

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual close at hand for reference during operation.

!WARNING It is extremely important that a PLC and all PLC Units be used for the speci-

fied purpose and under the specified conditions, especially in applications that

can directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PLC System to the above-mentioned applications.

3 Safety Precautions

!WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing

so may result in electric shock.

!WARNING Do not touch any of the terminals or terminal blocks while the power is being

supplied. Doing so may result in electric shock.

!WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do

so may result in malfunction, fire, or electric shock.

!Caution Execute online editing only after confirming that no adverse effects will be

caused by extending the cycle time. Otherwise, the input signals may not be

readable.

xx

Page 21

Operating Environment Precautions 4

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

!Caution Tighten the screws on the terminal block of the AC Power Supply Unit to the

torque specified in the operation manual. The loose screws may result in

burning or malfunction.

4 Operating Environment Precautions

!Caution Do not operate the control system in the following locations:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

!Caution Take appropriate and sufficient countermeasures when installing systems in

the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

5 Application Precautions

Observe the following precautions when using the FL-net Unit.

!WARNING Always heed these precautions. Failure to abide by the following precautions

could lead to serious or possibly fatal injury.

• Always connect to a ground of 100 Ω or less when installing the Units. Not

connecting to a ground of 100 Ω or less may result in electric shock.

xxi

Page 22

Application Precautions 5

• Always turn OFF the power supply to the CPU Unit, Slaves, and Communications Units before attempting any of the following. Not turning OFF

the power supply may result in malfunction or electric shock.

• Mounting or dismounting I/O Units, CPU Units, Memory Packs, or

Master Units.

• Assembling the Units.

• Setting DIP switches or rotary switches.

• Connecting cables or wiring the system.

!Caution Failure to abide by the following precautions could lead to faulty operation of

the Ethernet Unit or the system, or could damage the Ethernet Unit. Always

heed these precautions.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal

lines, momentary power interruptions, or other causes.

• Interlock circuits, limit circuits, and similar safety measures in external circuits (i.e., not in the Programmable Controller) must be provided by the

customer.

• Always use the power supply voltages specified in the operation manuals.

An incorrect voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied. Be particularly careful in places

where the power supply is unstable. An incorrect power supply may result

in malfunction.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may result in burning.

• Make sure that all the Backplane mounting screws, terminal block screws,

and cable connector screws are tightened to the torque specified in the

relevant manuals. Incorrect tightening torque may result in malfunction.

• Leave the label attached to the Unit when wiring to prevent wire clippings

from entering the Unit. Removing the label may result in malfunction if foreign matter enters the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals. Connection of bare stranded wires may result in

burning.

• Double-check all wiring and switch settings before turning ON the power

supply. Incorrect wiring may result in burning.

• Wire all connections correctly.

• Mount Units only after checking terminal blocks and connectors completely.

• Make sure that the terminal blocks, expansion cables, and other items

with locking devices are locked in place.

• When transporting the Unit, use special packing boxes and protect it from

being exposed to excessive vibration or impacts during transportation.

xxii

Page 23

Conformance to EC Directives 6

• Check the user program and set parameters for proper execution before

actually running it on the Unit. Not checking the program may result in

unexpected operation.

• Observe the following precautions when wiring the communications

cable.

• Separate the communications cables from the power lines or high-tension lines.

• Do not bend the communications cables past their natural bending radius.

• Do not pull on the communications cables.

• Do not place heavy objects on top of the communications cables.

• Always lay communications cable inside ducts.

• Use appropriate communications cables.

• Before touching a Unit, be sure to first touch a grounded metallic object in

order to discharge any static build-up. Not doing so may result in malfunction or damage.

• Confirm that no adverse effect will occur in the system before attempting

any of the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PLC (including changing the Startup Mode setting).

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Check that data link tables and parameters are properly set before starting operation. Not doing so may result in unexpected operation. Even if

the tables and parameters are properly set, confirm that no adverse

effects will occur in the system before running or stopping data links.

• Install the FL-net Units separated sufficiently from devices that generate

high-frequency noise.

• Do not drop the FL-net Unit or subject it to excessive shocks or vibrations.

6 Conformance to EC Directives

6-1 Applicable Directives

• EMC Directives

• Low Voltage Directive

6-2 Concepts

EMC Directives

OMRON devices that comply with EC Directives also conform to the related

EMC standards so that they can be more easily built into other devices or the

overall machine. The actual products have been checked for conformity to

EMC standards (see the following note). Whether the products conform to the

standards in the system used by the customer, however, must be checked by

the customer.

EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions of

the equipment or control panel on which the OMRON devices are installed.

The customer must, therefore, perform the final check to confirm that devices

and the overall machine conform to EMC standards.

xxiii

Page 24

Unit Versions of CS/CJ-series FL-net Units 7

Note Applicable EMS (Electromagnetic Susceptibility) and EMI (Electromagnetic

Interference) Standards in the EMC (Electromagnetic Compatibility) standards are as follows:

Unit/Board EMS EMI

CS1W-FLN22

EN61000-6-2

EN61000-6-4

CJ1W-FLN22

Common Emission Standard EN61000-6-4, radiated emission standard

(10 m)

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 V AC and 75

to 1,500 V DC meet the required safety standards for the PLC (EN61131-2).

7 Unit Versions of CS/CJ-series FL-net Units

Unit Versions

A “unit version” has been introduced to manage CS/CJ-series FL-net Units

according to differences in functionality accompanying upgrades.

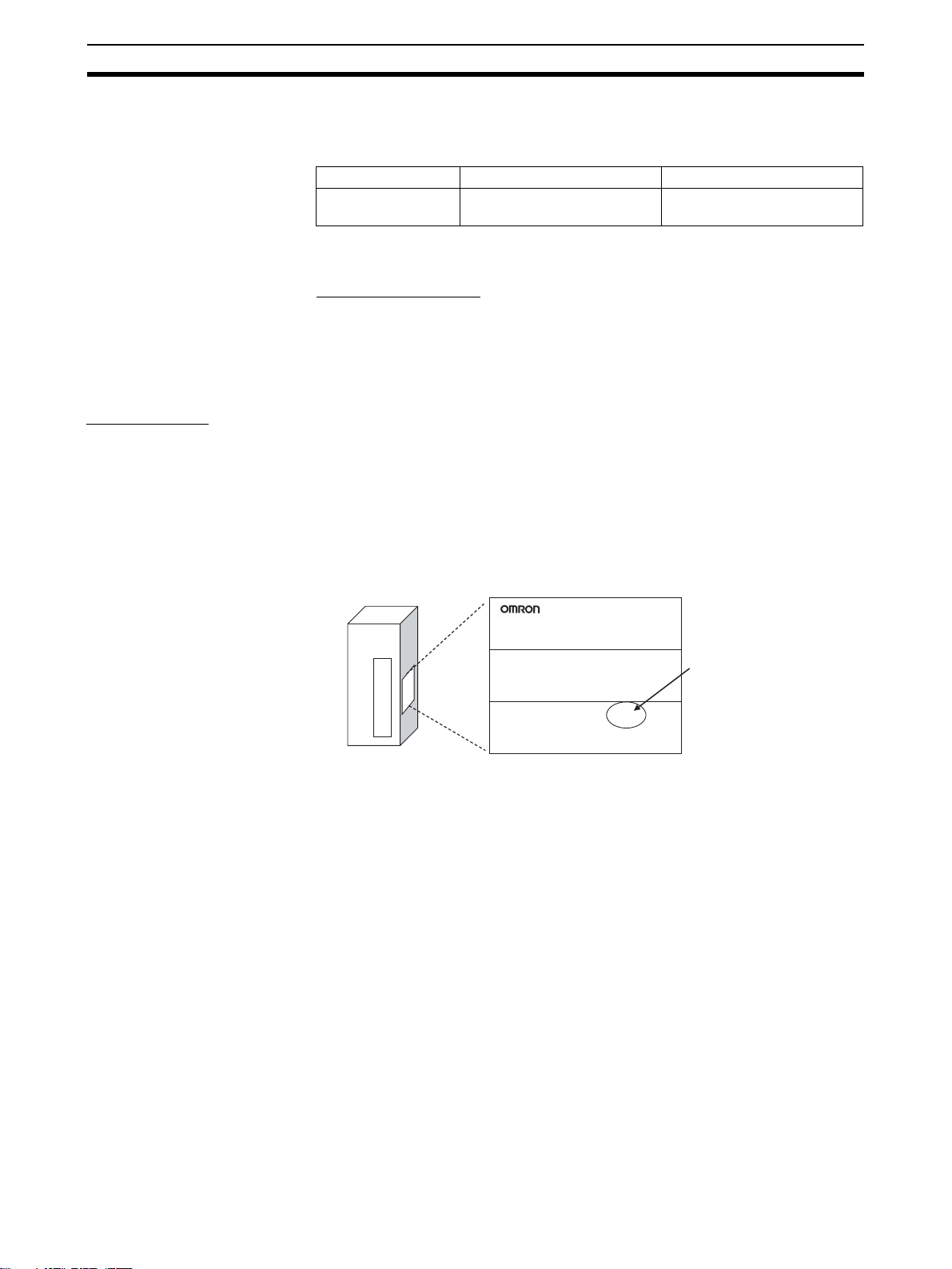

1. Unit Version Notation on Products

The unit version code is provided on the nameplate of the CS-series FL-net

Units for which unit versions are being managed, as shown below. This system applies to FL-net Units with unit version 1.0 or later.

Example: CS1W-FLN22 CS-series

FL-net Unit

Nameplate

CS1W-FLN22

FL-net UNIT

Unit version 1.0

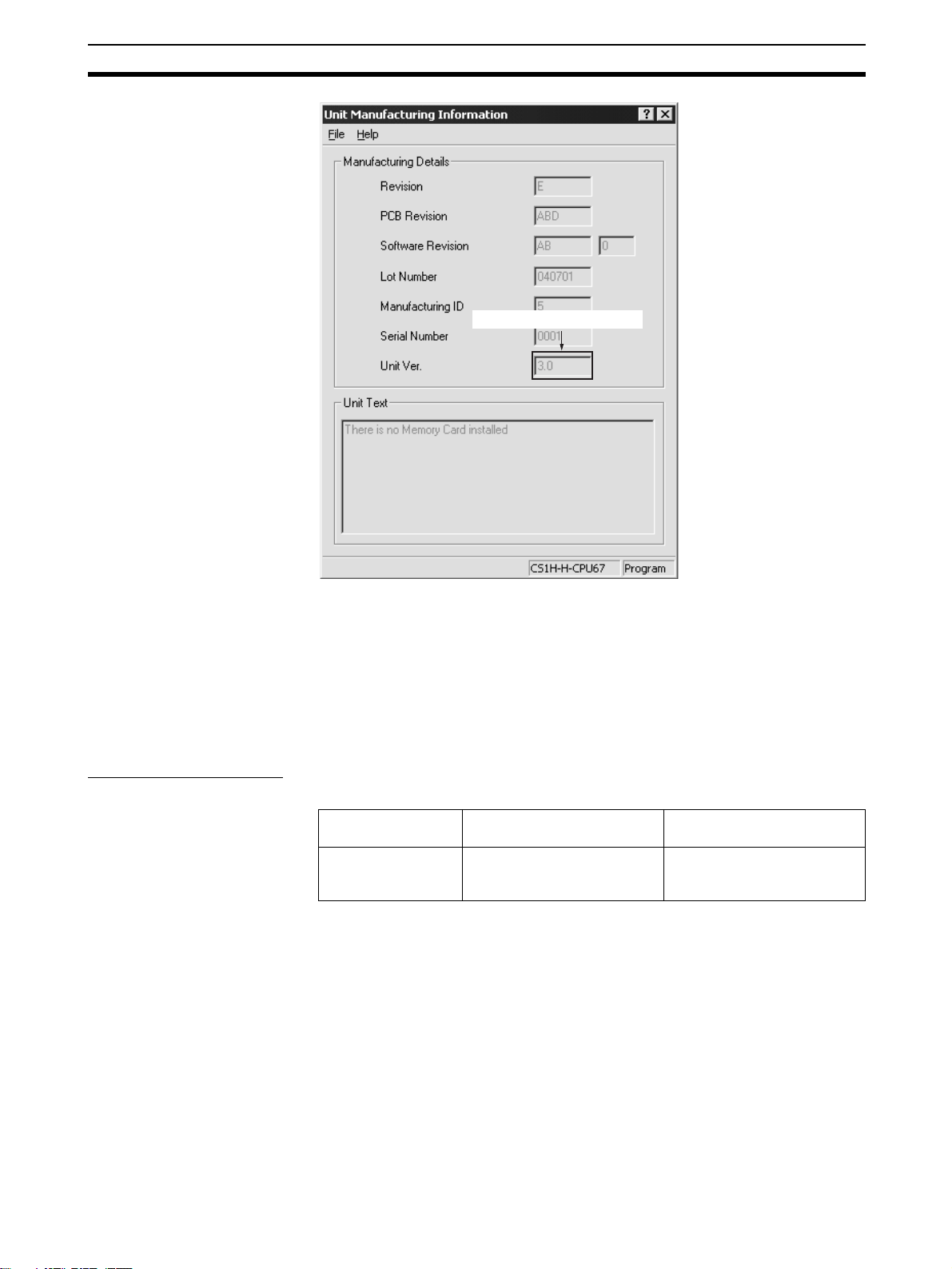

2. Confirming Unit Versions with Support Software

CX-Programmer version 5.0 can be used to confirm the unit version in the

Unit Manufacturing Information.

1. In the I/O Table Window, right-click on the FL-net Unit, and then select Unit

Manufacturing Information.

2. The following Unit Manufacturing Information Dialog Box will be displayed.

Lot No. 040301 0000 Ver.1.0

OMRON Corporation

MADE IN JAPAN

xxiv

Page 25

Unit Versions of CS/CJ-series FL-net Units 7

The unit version is displayed.

Example: In this Unit Manufacturing Information Dialog Box, unit version 1.0 is

displayed. Use this dialog box to confirm the unit version of the FL-net Unit

that is connected online.

3. Using the Unit Version Labels

Unit version labels are provided with the FL-net Unit. These labels can be

attached to the front of FL-net Units to differentiate from previous FL-net

Units.

Unit Version Notation

The unit versions are indicated in this manual as follows:

Notation in product

Ver.1.0 or later after

the lot number

nameplate

Notation in this manual Remarks

CS/CJ-series FL-net Units

with unit version 1.0 or later

Information for which no particular version is specified

applies to all unit versions.

xxv

Page 26

Unit Versions of CS/CJ-series FL-net Units 7

xxvi

Page 27

SECTION 1

Features and System Configuration

This section introduces the overall structure of an FL-net (Ver. 2.00) network, outlines the features of the FL-net (Ver. 2.00)

Unit, describes the communications protocols used by an FL-net (Ver. 2.00) network, and provides basic precautions for

use of the network.

1-1 FL-net Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-2-1 Device Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-3 Related Programming Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-4 Introducing the CX-FLnet Support Software . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-5 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-6 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1-6-1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1-6-2 Ethernet and IEEE802.3 Standards. . . . . . . . . . . . . . . . . . . . . . . . . . 13

1

Page 28

FL-net Overview Section 1-1

1-1 FL-net Overview

FL-net is an open FA network that was standardized by the Japan FA Open

Systems Promotion Group (JOP) of the Manufacturing Science and Technology Center (MSTC) under the Ministry of International Trade and Industry

(MITI). It has been established in the Japan Electrical Manufacturers standards (JEM 1479) and is becoming very popular.

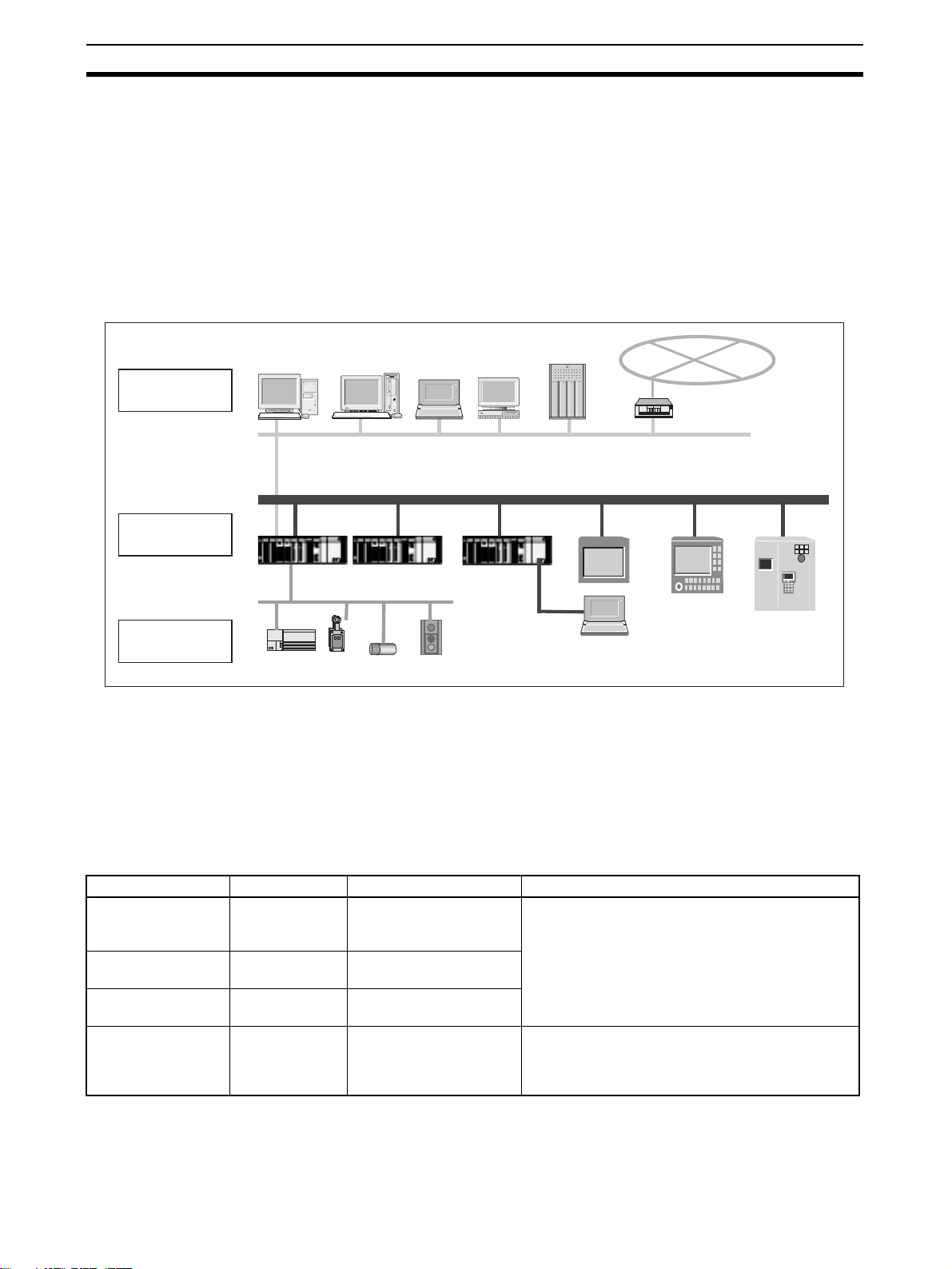

FL-net enables personal computers and FA controllers, such as programmable controllers (PLCs) or computerized numeric controllers (CNCs), by different manufacturers to be interconnected, controlled, and monitored, as shown

in the following diagram.

Personal

computer

EWS

Server

Computers

WAN

Host LAN Ethernet (TCP/IP, UDP)

FL-net Ethernet-based Control Network

Personal

computer

CNC

RC

Controllers

Devices

PLC

Field Network

PLC

PLC

Sensors

Actuators

FL-net Positioning FL-net Unit specifications have been designed to conform to Japan Electrical

Manufacturers standards (JEM 1479: 2001). It cannot be connected to communications devices based on the previous standards (JEM 1479: 2000).

The most recent FL-net specifications can be downloaded from the home

page of the Japan Electrical Manufacturers Association (http://www.jemanet.or.jp/English/).

The following table shows the relationship between these standards and the

FL-net Units manufactured and sold by OMRON.

Unit name Model Applicable standards Manufacture and sales

FL-net Unit,

100Base-TX

FL-net (Ver. 2.00)

Unit, 10Base-5

FL-net (Ver. 2.00)

Unit, 10Base-T

FL-net Unit CS1W-FLN01

CJ1W-FLN22

CJ1W-FLN22

(See note 2.)

CS1W-FLN02

(See note 2.)

CS1W-FLN12

(See note 2.)

(See note 1.)

Note 1. The

JEM1479: 2002 With FL-net Ver. 2.0 specifications (OPCN-2).

JEM 1479: 2001

JEM 1479: 2001

JEM 1479: 2000 Under the guidance of the JEMA, communications

devices conforming to JEM 1479: 2000 specifications cannot be manufactured or sold after April,

2001.

CS1W-FLN01 FL-net Unit cannot be connected to a network based on CS1W-

FLN02, CS1W-FLN12, CS1W-FLN22, or CJ1W-FLN22 FL-net Units.

2. CS1W-FLN02, CS1W-FLN12, CS1W-FLN22, or CJ1W-FLN22 FL-net Units cannot

be connected to a network based on the

CS1W-FLN01 FL-net Unit.

2

Page 29

FL-net Overview Section 1-1

FL-net Features FL-net System Concept

FL-net was designed to provide realtime communications between controllers

in manufacturing systems, such as programmable controllers (PLCs), robot

controllers (RCs), and computerized numeric controllers (CNCs). FL-net is

configured to broadcast tokens using the Ethernet UDP/IP protocols to enable

cyclic and message communications.

FL-net systems have the following features.

1. FL-net is an open system.

2. FL-net enables a multi-vendor network.

3. FL-net enables personal computers and FA controllers, such as programmable controllers (PLCs) or computerized numeric controllers (CNCs), by

different manufacturers to be interconnected, controlled, and monitored.

FL-net

Application layer User application Interface

FA link protocol layer Cyclic transmission Message service

Message

transmission

Token management

protocol

Transport layer UDP

Network layer IP

Data link layer Ethernet

Physical layer

Figure 1 Basic Configuration of FL-net Protocol

(IEEE802.3 standard)

Conforms to Widely Used Standards

Efficient communications can be achieved by this system based on Ethernet,

which has become the standard particularly for OA devices, combined with

standard UDP/IP. The use of Ethernet offers the following benefits.

1. Low cost

Configurations allowing the application of widely used communications de-

vices reduces costs.

2. Compatible with existing network devices

Transceivers, hubs, cables, LAN cards for personal computers, and other

network devices widely used for Ethernet can be used.

3. Higher speeds

Baud rates are expected to improve in the future, increasing to100 Mbps,

and 1 Gbps.

4. Optical communications

By using devices such as optical repeaters, which are widely used with

Ethernet, optic fiber can be used for necessary components to enable

long-distance transmission of over 500 m, improved noise resistance, and

measures against lightning surge on outdoor wiring.

3

Page 30

FL-net Overview Section 1-1

Supports Required Functions between FA Controllers

User-defined specifications allow the following range of features that are

required for FA systems.

1. Large-scale network

Up to 254 devices (nodes) can be connected in the physical layer of the

network.

2. Dual communications functions to suit application

The Common Memory function uses cyclic transmission so that each node

can always share the same data with other nodes on the network. FL-net

also supports message communications for use when handling only essential data is required.

3. Large-capacity Common Memory

The Common Memory is provided with a large capacity of 8 Kbits and 8

Kwords.

4. High-speed response

High-speed response time of 50 ms/32 nodes (for 2 Kbits and 2 Kwords)

is provided.

The absence of a master in the FL-net network enables nodes to be added

or removed readily without affecting any other nodes. This allows any node

to be turned ON or OFF easily and facilitates maintenance.

General Differences between Ethernet and FL-net

1. FL-net is a network designed for FA environments and is not compatible

with all general-purpose Ethernet devices. Some devices are not suitable

due to noise resistance and environment resistance requirements.

2. Only FL-net-compatible controllers and control devices can be connected

to FL-net to meet the demands of control applications requiring responsiveness in realtime communications.

3. FL-net is a cyclic communications method using the broadcasting supported by UDP/IP protocols based on the 10Base-5 and 10Base-T standards.

The following restrictions currently apply.

• Compatible devices mainly use 10 Mbps Ethernet LAN.

• Connection to other general-purpose Ethernet systems is not supported.

• TCP/IP are not supported.

• Switching hubs cannot be used effectively.

• Routers and similar devices may not be compatible.

FL-net FAQ

Question Answer

1 What is Ethernet? Ethernet is a standard defining a type of cable. It is used in a local area network (LAN). An

Ethernet network transmits data between computers at a baud rate of between 10 Mbps and

100 Mbps. Currently, the most commonly used Ethernet in offices and other OA systems is

twisted-pair cable (UTP) that uses 10 Mbps. Ethernet communications are possible using

software protocols provided by many vendors.

2 What is FL-net? The FL-net is a network to which programmable controllers (PLCs), computerized numeric

controllers (CNCs), and other FA controllers are connected, and on which control data is

exchanged between controllers at high speed. FL-net uses the same cables that are used for

Ethernet.

4

Page 31

FL-net Overview Section 1-1

Question Answer

3 What is the differ-

ence between FLnet and Ethernet?

4 How are FL-net

Units used?

5 What does “proto-

col” mean and what

protocols does FLnet support?

6 Can FL-net be con-

nected to a standard personal

computer?

7 What does “topol-

ogy” mean?

8 What type and

length of network

cables are used,

and how many Units

can be connected?

9 Do systems using

FL-net require special Ethernet specifications?

10 How do you connect

to FL-net?

11 What type of cables

should be used

when configuring an

FL-net system?

12 How is the FL-net IP

address set?

13 How compatible and

inter-connectable

are devices that

support FL-net?

With Ethernet, the host computer, personal computers, and controllers are connected to the

network for data exchange and control applications, such as executing production instructions

and compiling results. The FL-net is used to connect controllers together and allow highspeed control data exchange.

Be sure to connect cables properly when installing both Ethernet for communications with the

host and FL-net for communications between controllers for the same controllers.

FL-net Units are installed in FA controllers, such as programmable controllers (PLCs) and

computerized numeric controllers (CNCs). By simply setting link allocations for the local node

address (node number) and Common Memory (also called link registers), FL-net Units transmit data between controllers cyclically in the same way as CPU Link Units in standard PLCs.

This method does not require special communications programs for the PLC and other Units

on the network. Such programs are also not required by the PLC for operations conducted via

the personal computer, including reading or writing data, such as the PLC memory or communications parameters. Separate programs are required for each controller, however, when

transmitting data between controllers using message communications.

Protocol refers to rules for communications. The protocols supported by FL-net are UDP/IP

and FA Link Protocol. (The FA Link Protocol is located in the layer above UDP/IP and is a special protocol for use on FL-net networks.)

The FL-net Unit, which is mounted to FA controllers such as programmable controllers (PLCs)

and computerized numeric controllers (CNCs), is an intelligent unit with a processor on its

board. The Ethernet Card in the personal computer is a non-intelligent format called a “dumb

board,” so its capacity depends on the performance and functions of the personal computer.

Generally, an intelligent FL-net board is recommended.

Networking topology refers to the wiring formation of the network. The three main formations

are star (or tree), bus, and ring. Rather than physical wiring formations, however, it is easier to

understand them as theoretical formations. An FL-net system has star topology when using

10Base-T cables and bus topology when using 10Base-5 cables.

The most commonly used Ethernet cable standards and some of their characteristics and limitations are listed below. The figures in parentheses are applicable when repeaters are used.

• 10Base-T: Twisted-pair cables (UTP), maximum transmission distance is 100 m (500 m)

per segment, maximum number of Units is 254 per segment.

• 10Base-5: Thick coaxial cables (yellow cables), maximum transmission distance is 500 m

(2,500 m) per segment, and maximum number of Units that can be connected is 100

(254) per segment.

• 10Base-FL: Optic fiber cable, maximum transmission distance is 2,000 m per segment,

and maximum number of Units that can be connected is 254 per segment.

No. FL-net systems are configured using Ethernet (conforming to the IEEE802.3 standard).

Special specifications are not required.

Ethernet cables for different types of Ethernet media can be connected to each other using

repeaters, media adapters, and other devices. These products are available from many vendors.

In general, use the following cables.

• Basic wiring: 10Base-5 Thick coaxial cables; yellow cables.

• In the control panel and in offices: 10Base-T twisted-pair cables; UTP category 5.

• High-voltage wiring and noise-prone environments: 10Base-FL optic-fiber cables.

The FL-net IP address is set as follows:

Network address: 192.168.250

Host number (node number): 1 to 254 is standard. Nodes 250 to 254, however, are reserved

for maintenance devices.

FL-net has a certification system whereby compatibility and inter-connectivity tests are per-

formed.

Certification documents are provided for those devices that pass the tests, so devices sup-

porting FL-net can be used safely on the network.

5

Page 32

FL-net Overview Section 1-1

OMRON FL-net Unit (100Base-TX) Features

High-speed

Communications at

100 Mbps

Specify the Order of Data

Link Data

FINS Message

Communications

Controller Link Network

Connection

Abundant

Troubleshooting

Functions

A baud rate of 100 Mbps is supported. The baud rate can be automatically

selected or a fixed baud rate of 10 Mbps can be set.

The order of upper/lower bytes in data link data (word data) can be specified

for each node before sending or receiving the data, according to the specifications of the device connected in the data link.

The FL-net Unit also supports FINS message communications, OMRON’s

standard communications service, so other OMRON PLCs can be accessed

by using SEND(090), RECV(098), and CMND(490) instructions in ladder programs. In addition, the FINS gateway function can be used to allow access to

other PLCs on not only the same FL-net network but also on other networks

such as Ethernet or Controller Link.

Ethernet, the information-system network, can be connected to Controller

Link, the control-system network, using the FINS communications service.

This allows a PLC on the Ethernet or Controller Link network to be monitored

from an OMRON PLC on the FL-net network, and, conversely, for data to be

exchanged between a PLC on the Ethernet or Controller Link network and an

OMRON PLC on the FL-net network.

The Ethernet Unit is provided with a variety of troubleshooting functions for

prompt recovery in case of errors.

• Self-diagnostic function at startup

• PING command for checking other nodes

• Inter-nodal tests for checking other nodes

• Error log for recording error history data

6

Page 33

System Configuration Section 1-2

1-2 System Configuration

1-2-1 Device Configuration

10Base-T

FL-net (Ver. 2.00) (10 Mbps)

Terminator

Between nodes:

Integral multiples of 2.5 m

500 m/segment max.

10Base-5 coaxial cable

(or 10Base-T twisted-pair cable)

Terminator

Transceiver

Transceiver cable

CS/CJ-series

CS1W-FLN22 or

CJ1W-FLN22

FL-net Unit

100Base-TX

Twisted-pair

cable

50 m max.

Other company's

FL-net (Ver. 2.0) node

10Base-T

CS-series

PLC

CS-series

DeviceNet Unit

Hub

Hub Hub

Hub

100 m max.

CS-series

CS1W-FLN12

FL-net (Ver. 2.00) Unit

(10Base-T)

DeviceNet

SensorRemote Terminal Actuator

Ground

Other company's

FL-net (Ver. 2.0) node

10Base-T

CX-Programmer

CS-series

CS1W-FLN22

FL-net Unit

(100Base-TX)

100 m max. 100 m max. 100 m max.

CS-series PLC

CS-series

CJ1W-FLN22

FL-net Unit

(100Base-TX)

CS-series DeviceNet Unit

Remote Terminal Sensor Actuator

CS-series

CS1W-FLN22

FL-net Unit

(100Base-TX)

Note Do not combine nodes using a baud rate of 10 Mbps with nodes using a baud

rate of 100 Mbps in the same configuration, where possible. If nodes with a

baud rate of 10 Mbps are used, use a baud rate of 10 Mbps for all the connected devices in the configuration.

Other company's

FL-net node

100Base-TX

DeviceNet

7

Page 34

Related Programming Devices Section 1-3

1-3 Related Programming Devices

The FL-net Unit functions as a node on the FL-net network. The basic settings

for operation are made in the CPU Bus Unit System Setup in the CS/CJseries CPU Unit. Use the CX-FLnet or FL-net Unit Support Software to make

the settings.

Personal computer running Windows

CX-FLnet or FL-net Unit Support Software

CPU Bus Unit

System Setup

FL-net Unit

CS/CJ-series CPU Unit

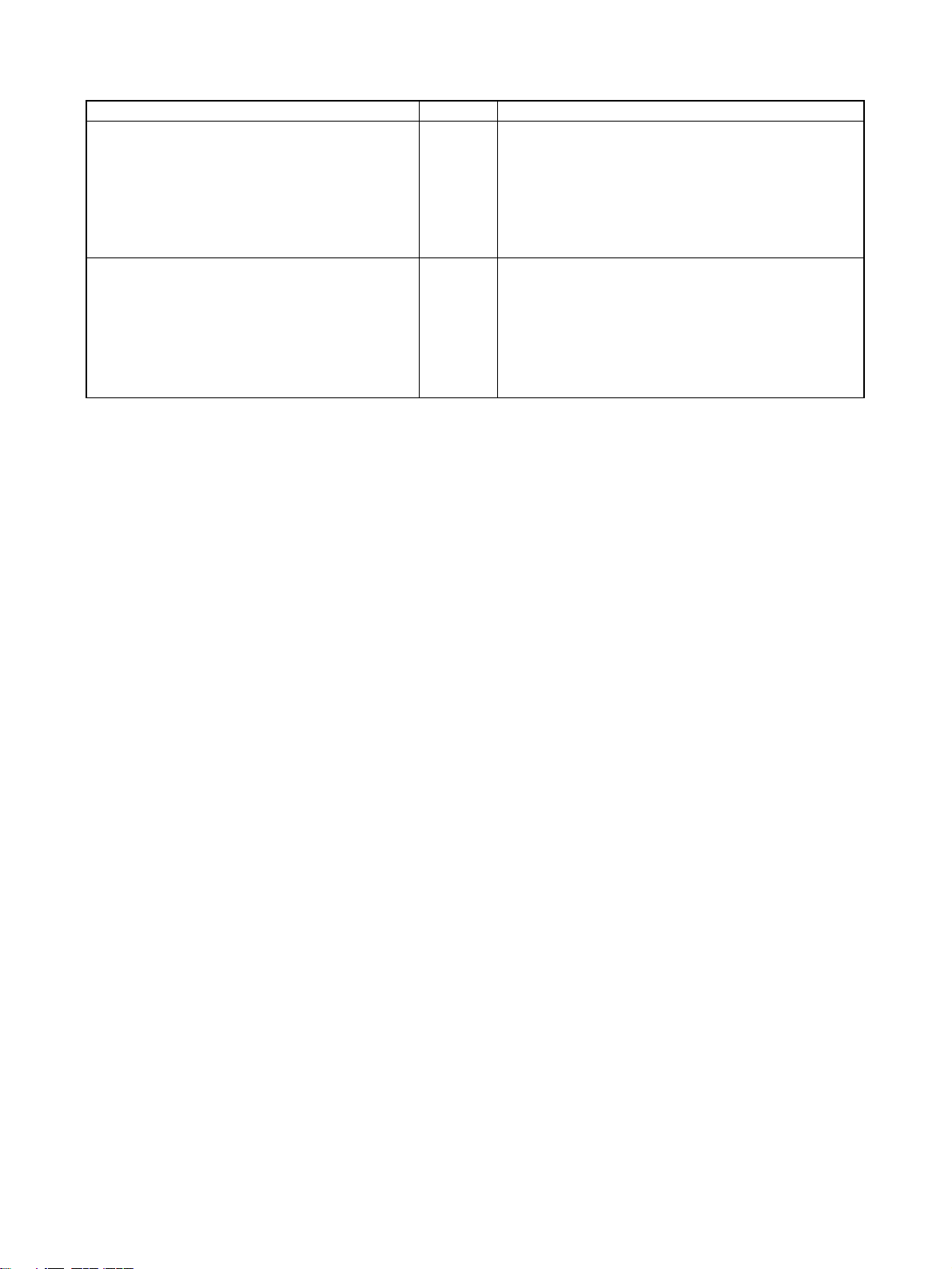

The following items are included in the Setup Area.

Screen Item Default Page

Setup Screen FA Link mapping table method PLC built-in method 50

FA Link startup method Automatic participation 50

Message protocol confirmation Yes 50

Broadcast type ***.***.***.255 50

IP address setting method 192.168.250.node number 50

Subnet mask 255.255.255.0 50

Baud rate 10 Mbps 50

Local node setup area Not set. 50

Other node setup area Not set. 50

Data order setting No swapping (sequential order) 79

Screen

When using the default values that are already stored in the CS/CJ-series

CPU Unit, there is no need to make any settings with the CX-FLnet or FL-net

Unit Support Software. Refer to 4-2 CPU Bus Unit System Setup for details on

the above settings.

1-4 Introducing the CX-FLnet Support Software

The FL-net Unit Support Software can be installed from the CX-One FA Integrated Tool Package (version 1.1 or higher) as the CX-FLnet. The following

table compares the FL-net and CX-FLnet. Other aspects are the same.

Item Previous Support Software:

Obtaining the software Downloaded from the OMRON Industrial

Website.

Simultaneously being online with

other Programming Device software that uses the CX-Server,

such as the CX-Programmer

Starting the software From the Windows Start Menu From the Windows Start Menu or from the

Not possible. Possible.

FL-net version 1.6

Provided with CX-One version 1.1 or

higher (CXONE-AL@@C-E)

I/O Table Window of the CX-Programmer

installed from CX-One. (Right-click the

FL-net Unit and use the pop-up menu.)

8

New Support Software:

CX-FLnet

Page 35

Specifications Section 1-5

1-5 Specifications

CS-series FL-net Units

Item Specifications

Model number CS1W-FLN22

Type 100Base-TX (10Base-T is also possible)

Applicable PLCs CS-series PLCs

Unit classification CS-series CPU Bus Unit

Mounting location CPU Rack or Expansion Rack

Number of Units that can be

mounted

Transfer

specifications

Current consumption (Unit) 380 mA max. at 5 VDC

Vibration resistance Conforms to JIS 0040.

Shock resistance Conforms to JIS 0041.

Ambient temperature Operating: 0 to 55°C

Humidity 10% to 90% (with no condensation)

Atmosphere Must be free from corrosive gas.

Weight 200 g max.

Dimensions 35 × 130 ×101 mm (W × H × D)

Media access method CSMA/CD

Modulation Baseband

Transmission paths Star

Baud rate 100 Mbps (100Base-TX) 10 Mbps (10Base-T)

Transmission media Unshielded twisted-pair (UTP) cable

Transmission distance 100 m max. (distance between hub and node)

Number of cascade

connections with

repeater hub

4 max. (including Expansion Racks)

Unshielded twisted-pair (UTP) cable

Categories: 5, 5e

Shielded twisted-pair (STP) cable

Categories: 100 Ω at 5, 5e

24

10 to 57 Hz, 0.075-mm amplitude, 57 to 150 Hz, acceleration: 9.8 m/s

directions for 80 minutes each

(Time coefficient; 8 minutes × coefficient factor 10 = total time 80 minutes)

147 m/s

Storage: –20 to 75°C

2

three times each in X, Y, and Z directions

Categories: 3, 4, 5, 5e

Shielded twisted-pair (STP) cable

Categories: 100 Ω at 3, 4, 5, 5e

2

in X, Y, and Z

9

Page 36

Specifications Section 1-5

CJ-series FL-net Units

Item Specifications

Model number CJ1W-FLN22

Type 100Base-TX (10Base-T is also possible)

Applicable PLCs CJ-series PLCs

Unit classification CJ-series CPU Bus Unit

Mounting location CPU Rack or Expansion Rack

Number of Units that can be

mounted

Transfer

specifications

Current consumption (Unit) 370 mA max. at 5 VDC

Vibration resistance Conforms to JIS 0040.

Shock resistance Conforms to JIS 0041.

Ambient temperature Operating: 0 to 55°C

Humidity 10% to 90% (with no condensation)

Atmosphere Must be free from corrosive gas.

Weight 100 g max.

Dimensions 31 × 90 × 65 mm (W × H × D)

Media access method CSMA/CD

Modulation Baseband

Transmission paths Star

Baud rate 100 Mbps (100Base-TX) 10 Mbps (10Base-T)

Transmission media Unshielded twisted-pair (UTP) cable

Transmission distance 100 m max. (distance between hub and node)

Number of cascade

connections with

repeater hub

4 max. (including Expansion Racks)

Unshielded twisted-pair (UTP) cable

Categories: 5, 5e

Shielded twisted-pair (STP) cable

Categories: 100 Ω at 5, 5e

24

10 to 57 Hz, 0.075-mm amplitude, 57 to 150 Hz, acceleration: 9.8 m/s

directions for 80 minutes each

(Time coefficient; 8 minutes × coefficient factor 10 = total time 80 minutes)

147 m/s

Storage: –20 to 75°C

2

three times each in X, Y, and Z directions

Categories: 3, 4, 5, 5e

Shielded twisted-pair (STP) cable

Categories: 100 Ω at 3, 4, 5, 5e

2

in X, Y, and Z

10

Page 37

Specifications Section 1-5

Dimensions

CS1W-FLN22

FLN22

RUN

HER

TX

RX

NODE

0

NO.

130

100BASE-TX

10BASE-T

CJ1W-FLN22

UNIT

NO.

16

100M

PER

LNK

MSG

TS

0

1

0

1

16

10135

(Unit: mm)

31

65

90 2.72.7

FLN22

RUN HER TX RX

PER LNK MSG TS100M

100BASE-TX

10BASE-T

5

4

UNIT

6

3

7

2

8

1

9

0

A

F

No.

B

E

C

D

5

4

NODE

6

3

7

2

8

1

9

0

A

F

No.

B

E

C

D

1

x16

5

4

6

3

7

2

8

1

9

0

A

F

B

E

C

D

0

x16

(Unit: mm)

11

Page 38

Specifications Section 1-5

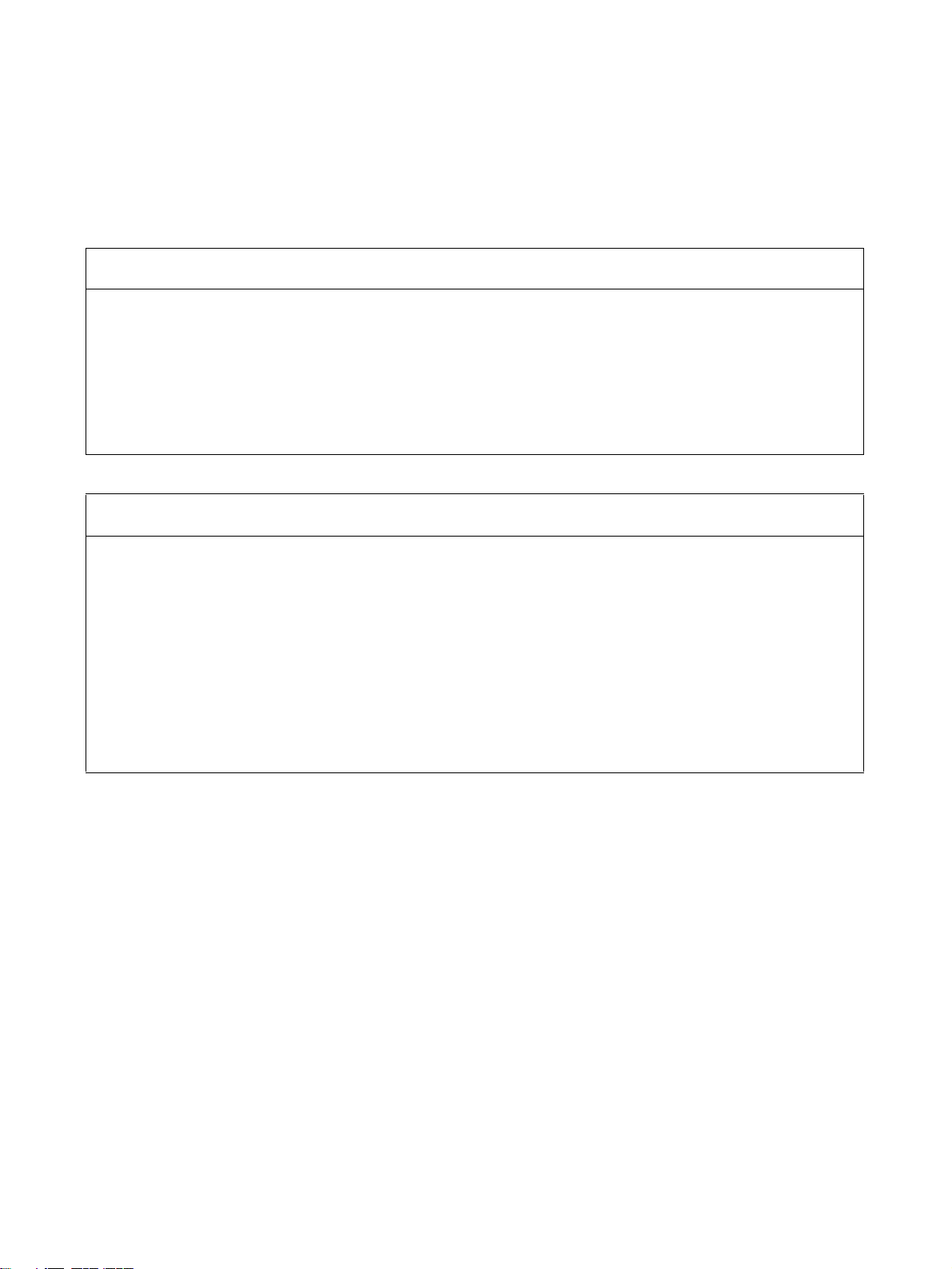

Comparison with Previous Models (CS1W-FLN02, CS1W-FLN12)

Model CS1W-FLN22

Type 100Base-TX (10Base-T is also possible) 10Base-5 (CS1W-FLN02)

Switches/indicators

Data link functions

100M indicator provided

This indicator indicates when baud rate of 100

Mbps is being used.

No rotary switch for setting the IP address.

The IP address is set using the CX-FLnet or FLnet Unit Support Software. Either of the following

two methods can be used to set the IP address.

1. 192.168.250 + node number

2. Setup area

Total capacity: 8,704 words

(Area 1: 512 words, Area 2: 8,192 words)

If the total number of words in Area 1 and Area 2

for a single node exceeds 7,677 words, the data

for the corresponding node will be refreshed over

two scans of the CPU Unit. The data will be split

from the 7,678th word counted from the beginning

of the combined Area 1 and Area 2.

The order of the upper and lower byte in the word

data can be swapped for each node when

exchanging data between the data link area in the

PLC and the FL-net.

CJ1W-FLN22

10Base-T (CS1W-FLN12)

No 100M indicator

Rotary switch provided on rear of Unit for setting

the IP address. Either of the following four methods can be used to set the IP address

1. 192.168.250 + node number

2. Rotary switch on rear of Unit.

3. Rotary switch on rear of Unit + node number

4. Setup area

Total capacity: 8,704 words

(Area 1: 512 words, Area 2: 8,192 words)

Data link tables that exceed the following conditions, however, cannot be set.

Number of words in local node setup area (Area 1

and Area 2) ≤ 7,677 words.

Number of words in local node setup area (Area 1

and Area 2) + the number of words in setup area

(Area 1 and Area 2) for node with the largest setup

area size (except local node) ≤ 7,677 words

The data order cannot be changed and is fixed as

shown in the following diagram.

Common memory

MSB LSB

CS1W-FLN02/12

Simple backup

function

Support Software

Supported. Not supported.

CX-FLnet or FL-net Unit Support Software version

1.60 or higher (CS1W-FLN22 and CJ1W-FLN22

settings cannot be made using Ver. 1.51 or lower)

Comparison between FL-net Unit Support Software

Version CX-FLnet or

FL-net Unit Support Software Ver. 1.60

New setting

function

Connection with

PLC

Setting file Setting files saved from Japanese version and

Set the baud rate.

Set the data link data order.

Set/monitor other nodes via the FL-net network. Only the local node can be set or monitored.

English version are compatible.

PLC memory area

D15 0

FL-net Unit Support Software Ver. 1.51 or higher

(CS1W-FLN02 and CS1W-FLN12 settings can

also be made using Ver. 1.60 or higher)

Ver. 1.51

None (these settings are not available)

No compatibility between setting files saved in the

English version and Japanese version.

12

Page 39

Precautions Section 1-6

1-6 Precautions

Be sure to observe the following precautions when installing and using an FLnet Unit.

1-6-1 Installation

Observe the following precautions when installing an FL-net Unit.

1,2,3... 1. Use transceiver cable that meets IEEE802.3 standards to ensure high

noise resistance.

2. Use a transceiver with a current consumption of not more than 0.4 A per

port.

3. Always turn OFF the power supply to the PLC before connecting or disconnecting the transceiver cable.

4. Be sure not to exceed the current capacity of the Power Supply Unit on the

Rack to which the FL-net Unit is mounted. The current consumption is 380

mA maximum for the CS-series FL-net Unit and 370 mA for the CJ-series

FL-net Unit. This value added to the current consumption of all other Units

mounted to the same Rack must not exceed the capacity of the Power

Supply Unit.

5. Do not install the transceiver cables or coaxial cables of the network near

power supply lines. If installation near possible sources of noise is unavoidable, install the cables in grounded metal ducts or take other measure to

eliminate noise interference.

1-6-2 Ethernet and IEEE802.3 Standards

The FL-net Unit was designed based on Version-2.0 Ethernet standards and

not on the international IEEE802.3 standards, which were developed based

on Ethernet specifications. Although these two sets of standards are similar,

they are not necessarily the same. Particularly, different frame formats are

used, making direct communications impossible between systems that do not

support the same standards. Standards for equipment used to configure networks are the same, allowing IEEE802.3-standard equipment to be used with

the FL-net Unit. In particular, the transceiver cable for the IEEE802.3 standards provides superior noise resistance and should be used for the FL-net

Unit.

Terminology also differs between Version-2.0 Ethernet and IEEE802.3 standards. These differences are shown in the following table. Version-2.0 Ether-

net terminology is used in this manual.

Ethernet IEEE802.3

Transceiver MAU

Transceiver cable AUI

Ethernet address MAC address

Ethernet 10Base-5/10Base-T

13

Page 40

Precautions Section 1-6

14

Page 41

SECTION 2

Communications Functions

This section describes the communications functions that can be used with the FL-net (Ver. 2.00) Units.

2-1 FL-net . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-2 Cyclic Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2-3 Message Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2-4 FINS Communications Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

15

Page 42

FL-net Section 2-1

2-1 FL-net

FL-net Concept FL-net is an Ethernet-based FA control network.

FL-net supports both cyclic transmission and message transmission functions.

The basic concepts of FL-net are as follows:

1,2,3... 1. To use Ethernet as the medium for communications between FA control-

lers.

2. To offer UDP/IP, which are widely used protocols in Ethernet communications, as the basic means for data communications.

3. To manage and control access of each node in the network to the communications media (to avoid collisions) and to ensure transmission within a

fixed time period, while using the above-mentioned basic means for data

communications.

FL-net is an FA control network enabling the exchange of data between control devices in manufacturing systems, such as programmable controllers

(PLCs), robot controllers (RCs), and computerized numeric controllers

(CNCs), and personal computers used for controlling them.

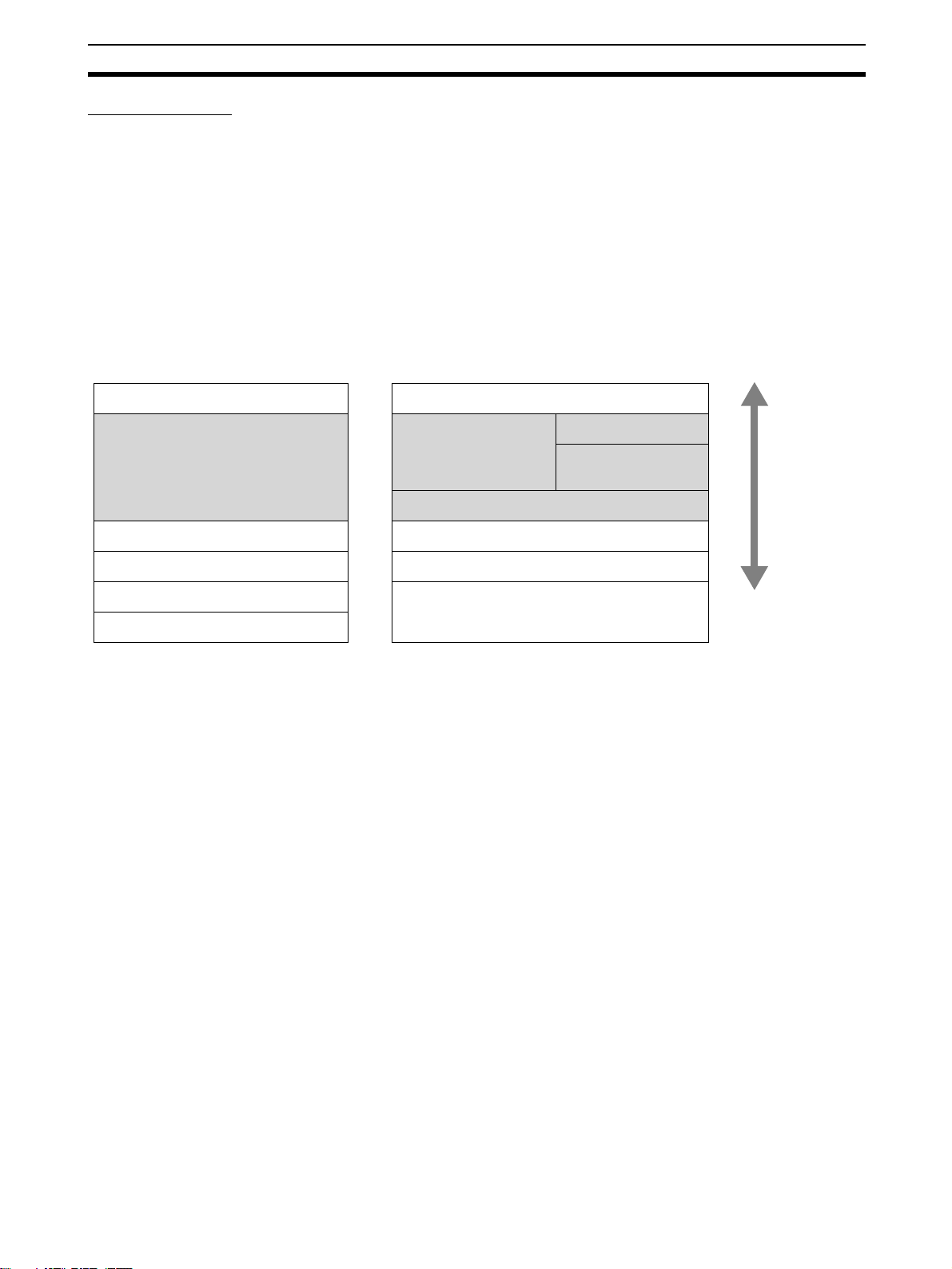

The following diagram shows the location of devices in an FL-net system.

Computers

Controllers

Devices

Personal

computer

Personal

computer

PLC

DeviceNet or other network

Personal

computer

Host LAN Ethernet (TCP/IP, UDP)

FL-net Ethernet-based Control Network

PLC

EWS

Sensors

Actuators

PLC

Server

Personal

computer

OMRON CX-FLnet or

FL-net Unit Support Software

WAN

CNC

RC

16

Page 43

FL-net Section 2-1

FL-net Protocol FL-net consists of six protocol layers, as shown in the following diagram.

Application layer User application Interface

Message service

Cyclic transmission

FA link protocol layer

Token management

Transport layer UDP

Network layer IP

Data link layer Ethernet

(IEEE802.3 standard)

Note The transport and network layers use UDP/IP, whereas Ethernet is used as

the protocol for the data link and physical layers.

Message transmis-

sion

FL-net

Protocol

FL-net Transmission

FL-net's FA link protocol layer is characterized by the following features.

Features

1,2,3... 1. Collisions are avoided by transmission control that uses the token method

that does not use a master.

2. The refresh cycle time can be regulated by fixing the cycle time of the token.

3. The designated token is transmitted together with cyclic data.

4. The token is transmitted first by the node that has the smallest number at

startup.

5. When no token is transmitted in a specified period of time, the next node

in the token rotation order sends a new token.

6. This token method prevents the network from stopping when there is a failure of only some of the nodes.

7. The information management tables provide useful information, such as

operation mode (RUN/STOP) and hardware malfunctions (ALARM), that

can be referenced to monitor the operating status of other nodes.

FL-net IP Addresses Unique class-C IP addresses must be assigned to each node in the FL-net

network.

An IP address is an address identifying each node (station) for transmission

using IP (internet protocol). Therefore, IP addresses must be set and managed so that no two nodes have the same IP address. FL-net uses Class-C IP

addresses. The default IP address for FL-net is 192.168.250.***, with *** representing the remote node number.

FL-net (Ver.

2.00) IP

address

Network address Host number

(node number)

192.168.250 n (n: 1 to 254)

17

Page 44

FL-net Section 2-1

Number of Connectable

Nodes and Node Numbers

Note 1. Not available to users.

Network address

Node number

Up to 254 nodes can be connected to an FL-net network. Each node is

assigned a node number from 1 to 254.

Node number Applications

1 to 249 Used for standard FL-net devices.

250 to 254 Used for FL-net maintenance purposes.

255 Reserved for the internal system use. (See notes 1 and 2.)

0 Reserved for internal system use. (See note 1.)

2. Used for broadcasting.

FL-net

192.

168.

250.

1

192.

168.

250.

2

192.

168.

250.

248

192.

168.

250.

249

192.

168.

250.

250

192.

168.

250.

254

Node number: 1 to 249 (for users)

Node number: 250 to 254

(for maintenance)

Data Communications FL-net supports data communications by cyclic transmission and message

transmission.

Message data

Cyclic transmission

Cyclic data with token

Cyclic transmission + message transmission

Transmission Cycle With cyclic communications, the Common Memory is refreshed on a fixed

cycle time. Message communications are controlled so that the Common

Memory refresh time does not exceed the allowable refresh cycle time.

Each node constantly monitors the message communications frames that

travel through the network from the time it receives one local-node-directed

token until it receives the next local-node-directed token. When no message

communications frame travels through the network in a single cycle, 120% of

the cycle time value becomes the allowable refresh cycle time. In this way the

allowable refresh cycle time is actively determined according to the number of

nodes in the network.

18

Page 45

FL-net Section 2-1

Data Areas and Memory

FL-net

FL-net Communications Unit

Cyclic transmission

Message transmission

Communications

Management Tables

Local Node Management

Table

Node number 1 byte 1 to 249

Common Memory Area 1 first word 2 bytes Word address (0 to 0xff)

Common Memory Area 1 data size 2 bytes Size (0 to 0x200)

Common Memory Area 2 first word 2 bytes Word address (0 to 0x1fff)

Common Memory Area 2 data size 2 bytes Size (0 to 0x2000)

Upper layer status 2 bytes RUN/STOP /ALARM/WARNING/NORMAL

Token monitoring time 1 byte Unit: 1 ms

Minimum allowable frame interval 1 byte Unit: 100 µs

Vendor code 10 bytes Vendor code

Manufacturer model 10 bytes Manufacturer model, device name

Node name (equipment name) 10 bytes User-defined node name

Protocol version 1 byte 0x80 (fixed)

FA link status 1 byte Participating, not participating, etc.

Local node status 1 byte Duplicate node number detection, etc.

CPU Unit

Common Memory Area 1

Common Memory Area 2

Message transmission buffer area

FL-net management table area

FL-net parameter area

Physical memory

Node status is managed using three types of management tables: Local node

management tables, participating node management tables, and network

management

The local node management table manages the local node settings.

Item Bytes Contents (data range)

Note “0x0012ab” refers to hexadecimal 0012AB.

19

Page 46

Cyclic Transmission Section 2-2

Participating Node

Management Table

Node number 1 byte 1 to 254

Upper layer status 2 bytes RUN/STOP /ALARM/WARNING/NOR-

Common Memory Area 1 data first word 2 bytes Word address (0 to 0x1ff)

Common Memory Area 1 data size 2 bytes Size (0 to 0x200)

Common Memory Area 2 data first word 2 bytes Word address (0 to 0x1fff)

Common Memory Area 2 data size 2 bytes Size (0 to 0x2000)

Minimum allowable refresh cycle time 2 bytes Unit: 1 ms

Token monitoring time 1 byte Unit: 1 ms

Minimum allowable frame interval 1 byte Unit: 100 ms

Link status 1 byte Participating, not participating, etc.

Network Management

Table

The participating node management table manages information on the nodes

in the network.

Item Bytes Contents (data range)

MAL

Note “0x0012ab” refers to hexadecimal 0012AB.

The network management table manages information that is shared by all

nodes on the network.

Item Bytes Contents (data range)

Token holding node number 1 byte Node currently holding the token

Minimum allowable frame interval 1 byte Unit: 100 µs

Allowable refresh cycle time 2 bytes Unit: 1 ms

Refresh cycle measurement value

(current)

Refresh cycle measurement value

(maximum)

Refresh cycle measurement value

(minimum)

2 bytes Unit: 1 ms

2 bytes Unit: 1 ms

2 bytes Unit: 1 ms

2-2 Cyclic Transmission

Cyclic transmission is used to transmit cyclic data. The data is shared by each

node through the Common Memory (shared memory) function.

To ke n D at a

Node 1 Node 2 Node 3 Node... Node n

Node 1

Node 2

Node 3

Node 4

Node...

Node n

Node 1

Node 2

Node 3

Node 4

Node...