Page 1

Patient Monitor BP-S510

Service Manual

Part Number: A7086 Rev.XC3 (1731071A)

Revised Date: 11/2006

Printed in Korea

Copyright © 2005-2006 All rights reserved.

Page 2

Directive

z Copyright law allows no part of this instruction manual to be reproduced without

permission.

z The content of this manual are subject to change without notice.

z The contents of this manual should be correct. If, for some reason, there are any

questionable points, please do not hesitate to contact our service center.

z The manual will be replaced if any pages are missing or collation is incorrect.

Warranty

z Please contact your local distributor about the warranty period.

z Device failure or damage related to the following situations during the guarantee period

is not covered by this warranty:

z Installation, transfer installation, maintenance and repairs by any person other than

an authorized Omron Healthcare Co., Ltd. employee or technician specified by

Omron Healthcare Co., Ltd..

z Damage sustained to the Omron Healthcare product(s) caused by product(s) from

another company excluding products delivered by Omron Healthcare Co., Ltd.

z Damage – caused by mishandling and/or misuse – is the responsibility of the user.

z Maintenance and repairs utilizing maintenance components that are not specified

by Omron Healthcare Co., Ltd.

z Device modifications or use of accessories not recommended by Omron

Healthcare Co., Ltd.

z Damage caused by accidents or natural disasters (earthquakes, flooding, etc.).

z Damage resulting from usage where caution statements and operating instructions

shown in this manual have not been followed.

z Damage due to neglect of specified maintenance checks.

z This warranty only covers the hardware of the BP-S510. The warranty does not cover the

following selections:

z Whatever damage or loss results from the attachment of accessories or their

operation.

z In the event of a defect in the product, contact our sales outlet or EU representative

as noted on the back cover.

z The BP-S510 conforms to the EMC standard IEC60601-1-2.

Note that mobile phones should not be used in the vicinity of the BP-S510.

Note, however, any device not complying to the EMC standard that is used with the BP-S510

renders the BP-S510 as non-compliable to the EMC standard.

Revision History

Product brand names shown in this manual are likely to be the trademark or registered

trademark of the company concerned.

Page 3

CONTENTS

CONTENTS....................................................................................................................................................i

SAFETY INFORMATION ..............................................................................................................................1

General Safety Information ...................................................................................................................1

Warnings................................................................................................................................................1

Cautions ................................................................................................................................................2

Manual Overview................................................................................................................................... 3

Related Documents...............................................................................................................................3

Intended Use for the BP-S510 Monitor .................................................................................................3

Identifying the BP-S510 monitor Configurations ................................................................................... 3

Front Panel Components ......................................................................................................................4

Rear Panel Components .......................................................................................................................5

Left Panel Components.........................................................................................................................6

Right Panel Components ......................................................................................................................7

ROUTINE MAINTENANCE........................................................................................................................... 9

Cleaning ................................................................................................................................................9

Periodic Safety and Functional Checks.................................................................................................9

Batteries ..............................................................................................................................................10

Environmental Protection .................................................................................................................... 10

PERFORMANCE VERIFICATION .............................................................................................................. 11

General................................................................................................................................................ 11

Required Equipment............................................................................................................................ 11

System Tests .......................................................................................................................................12

Performance Tests...............................................................................................................................17

Safety Tests .........................................................................................................................................34

Verification Check Sheet .....................................................................................................................38

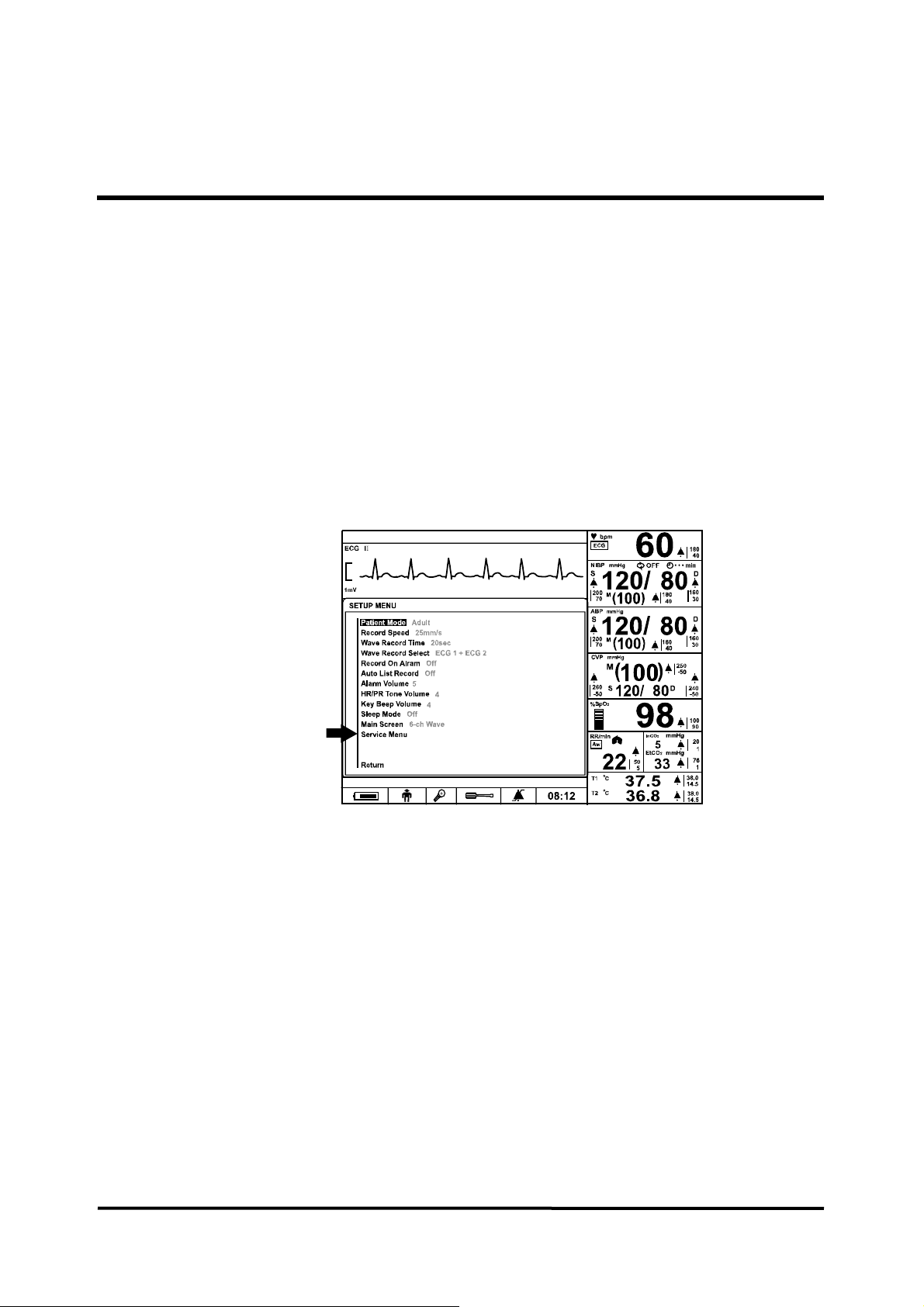

SERVICE MENU AND FACTORY DEFAULT............................................................................................. 43

General................................................................................................................................................43

Service Menu.......................................................................................................................................43

Demo Mode ......................................................................................................................................... 48

Factory Default Settings ......................................................................................................................49

FIRMWARE DOWNLOAD ..........................................................................................................................53

General................................................................................................................................................53

Equipment Needed.............................................................................................................................. 53

How to Download ................................................................................................................................53

TROULBESHOOTING................................................................................................................................55

General................................................................................................................................................55

How to Use This Section .....................................................................................................................55

Who Should Perform Repairs..............................................................................................................55

Replacement Level Supported............................................................................................................55

Troubleshooting Guide ........................................................................................................................56

DISASSEMBLY GUIDE ..............................................................................................................................69

General................................................................................................................................................69

Replacement Level Supported............................................................................................................71

Prior to Disassembly............................................................................................................................71

Fuse Replacement ..............................................................................................................................71

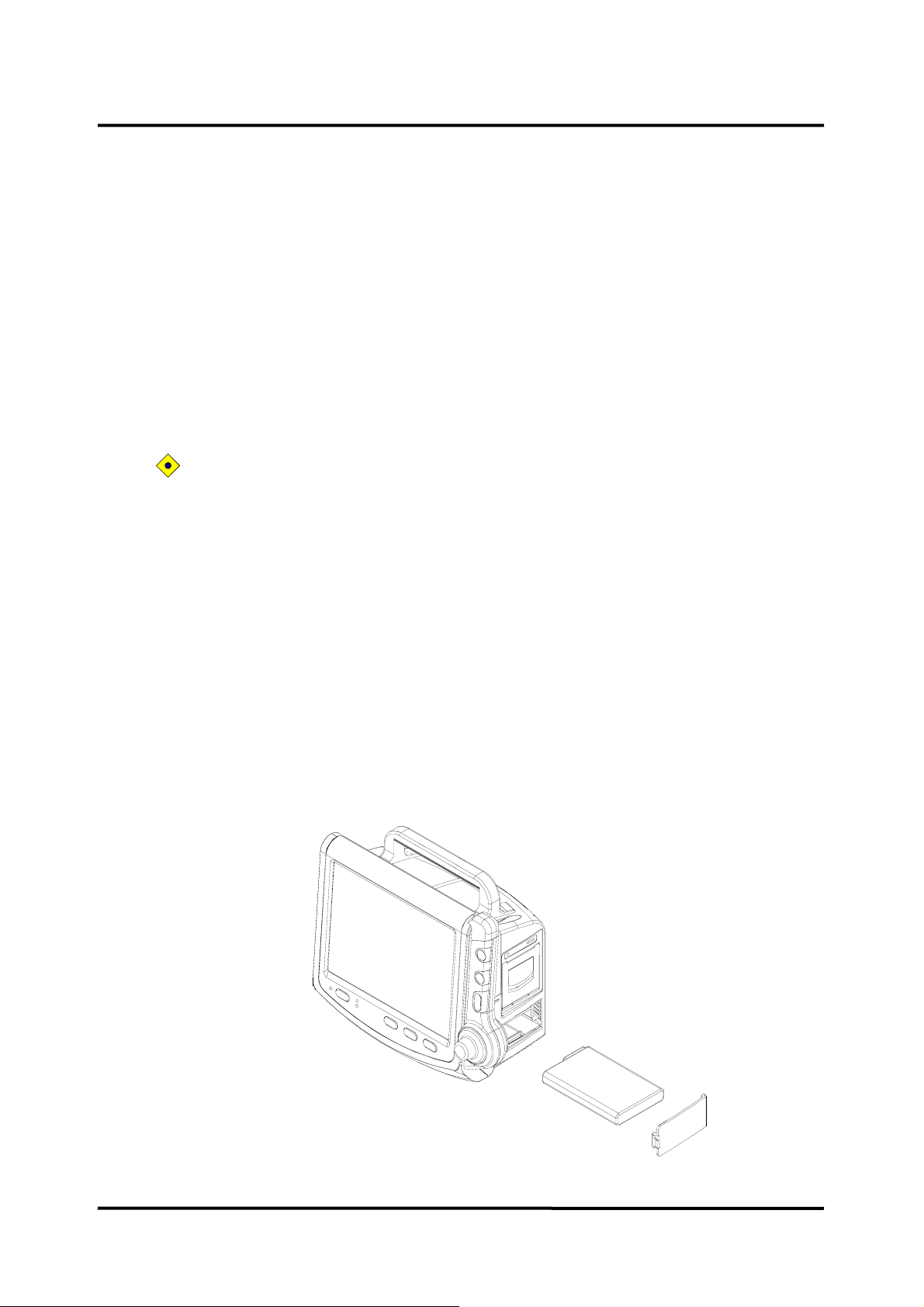

Battery Replacement (A) .....................................................................................................................71

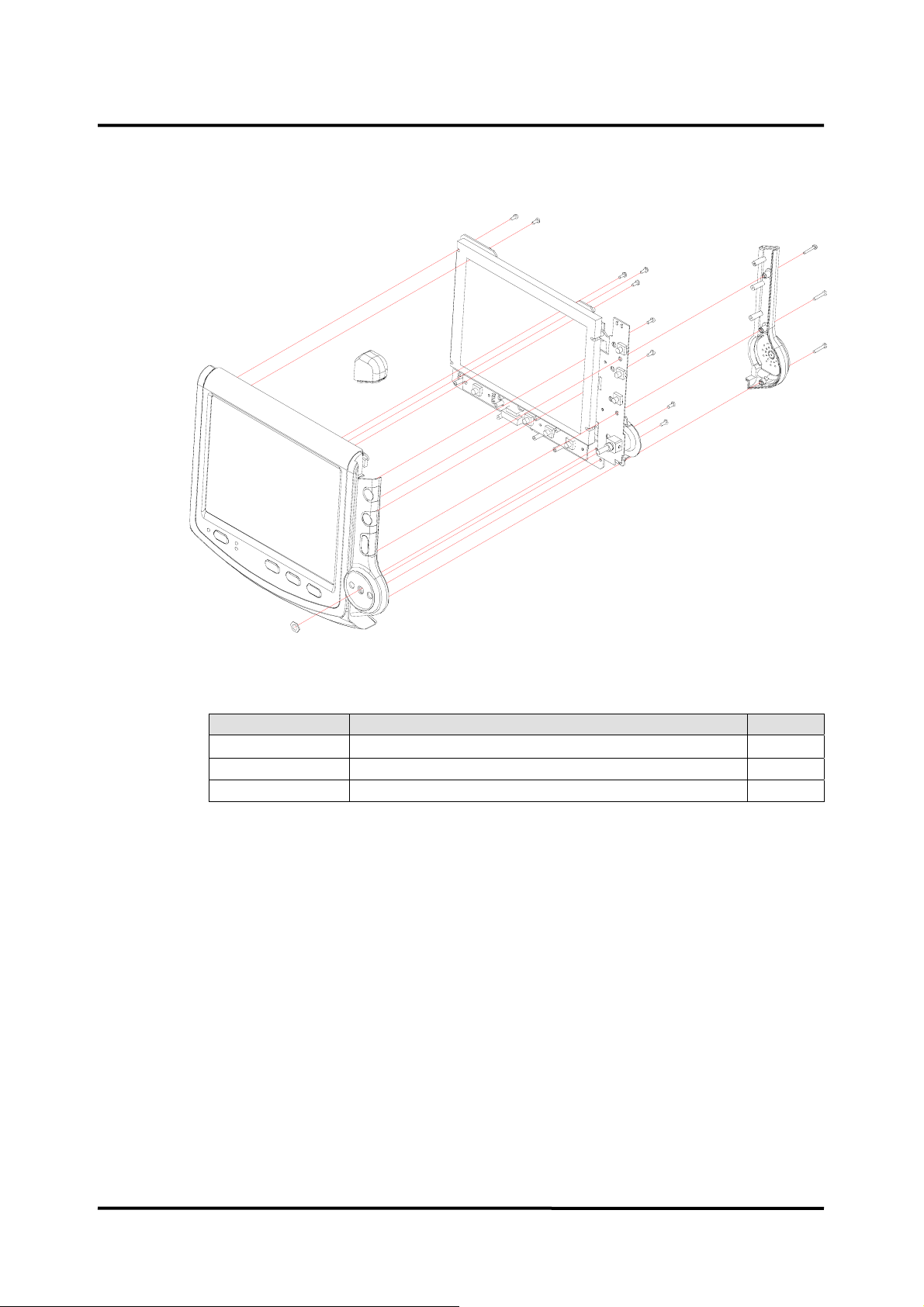

Monitor Disassembly ...........................................................................................................................72

i

Page 4

Front Case Disassembly (B) ...............................................................................................................73

Rear Case Disassembly (C)................................................................................................................77

SPARE PARTS ...........................................................................................................................................87

General................................................................................................................................................87

Obtaining Replacement Parts..............................................................................................................87

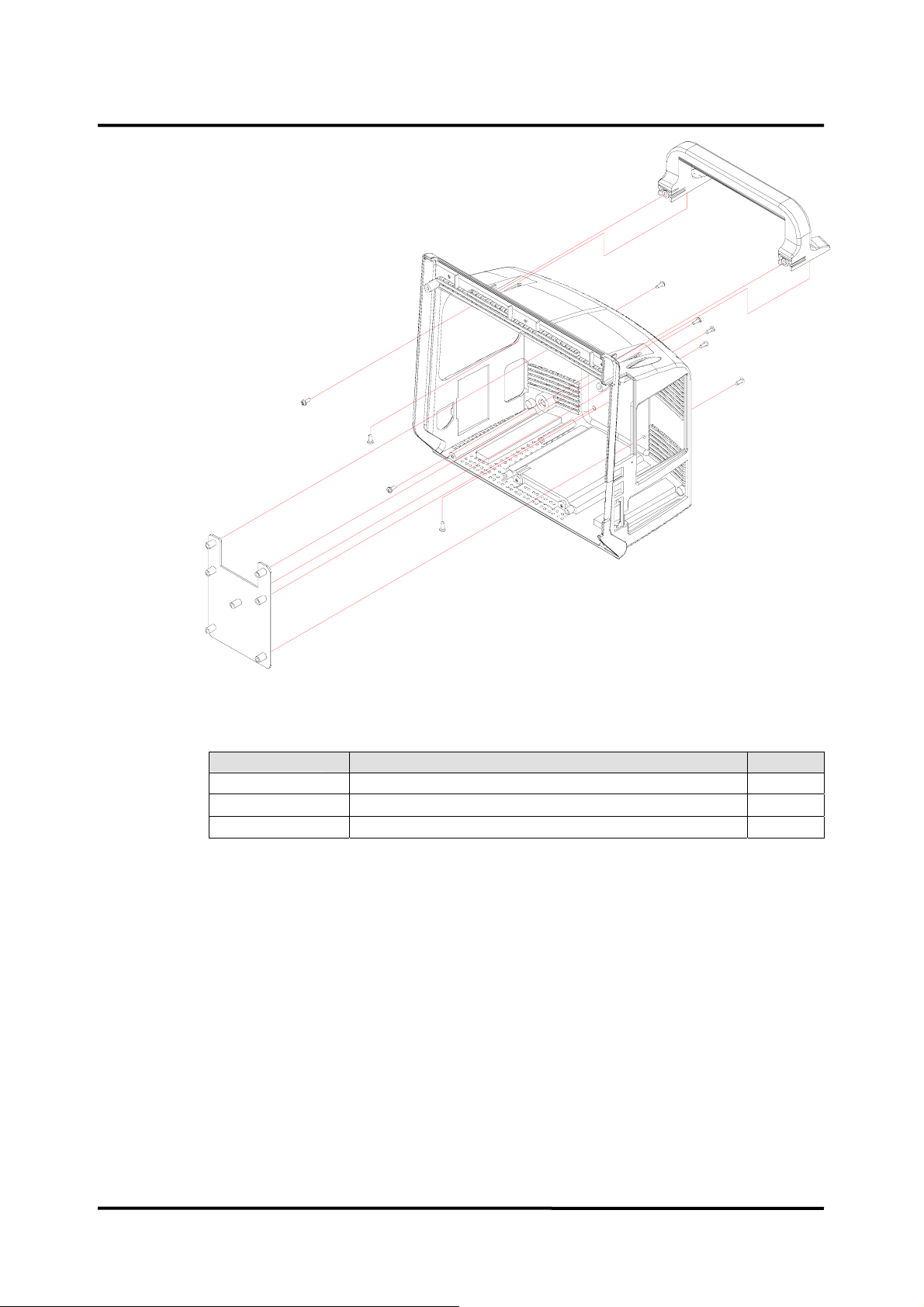

PACKING FOR SHIPMENT........................................................................................................................91

General Instructions ............................................................................................................................91

Returning the BP-S510 monitor ..........................................................................................................91

Repacking In Original Carton ..............................................................................................................91

Repacking In a Different Carton..........................................................................................................91

SPECIFICATION ......................................................................................................................................... 93

Display.................................................................................................................................................93

Controls ............................................................................................................................................... 93

Alarms .................................................................................................................................................93

Physical Characteristics and Recorder ...............................................................................................93

Electrical ..............................................................................................................................................94

Environmental Conditions ...................................................................................................................94

Measurement Parameters...................................................................................................................95

Trends..................................................................................................................................................98

Compliance..........................................................................................................................................99

SYSTEM PROCESSING...........................................................................................................................101

System Overview...............................................................................................................................101

System Block Diagram ......................................................................................................................101

ECG Processing ................................................................................................................................ 108

NIBP Processing ...............................................................................................................................108

SpO

Processing ...............................................................................................................................110

2

Respiration Processing ..................................................................................................................... 112

Temperature Processing ................................................................................................................... 112

Invasive Blood Pressure Processing................................................................................................. 113

ii

Page 5

Figures

Figure 1. Front Panel Components........................................................................................................................................................ 4

Figure 2. Rear Panel Components......................................................................................................................................................... 5

Figure 3. Left Panel Components .......................................................................................................................................................... 6

Figure 4. Right Panel Components........................................................................................................................................................ 7

Figure 5. Switch/LED Test.................................................................................................................................................................... 12

Figure 6. Alarm Audible Test................................................................................................................................................................ 13

Figure 7. Tone Audible Test.................................................................................................................................................................. 14

Figure 8. Recorder Test........................................................................................................................................................................ 15

Figure 9. Backup RAM Clear ............................................................................................................................................................... 16

Figure 10. Pressure Sensor Accuracy Test.......................................................................................................................................... 28

Figure 11. Air Leakage Test ................................................................................................................................................................. 29

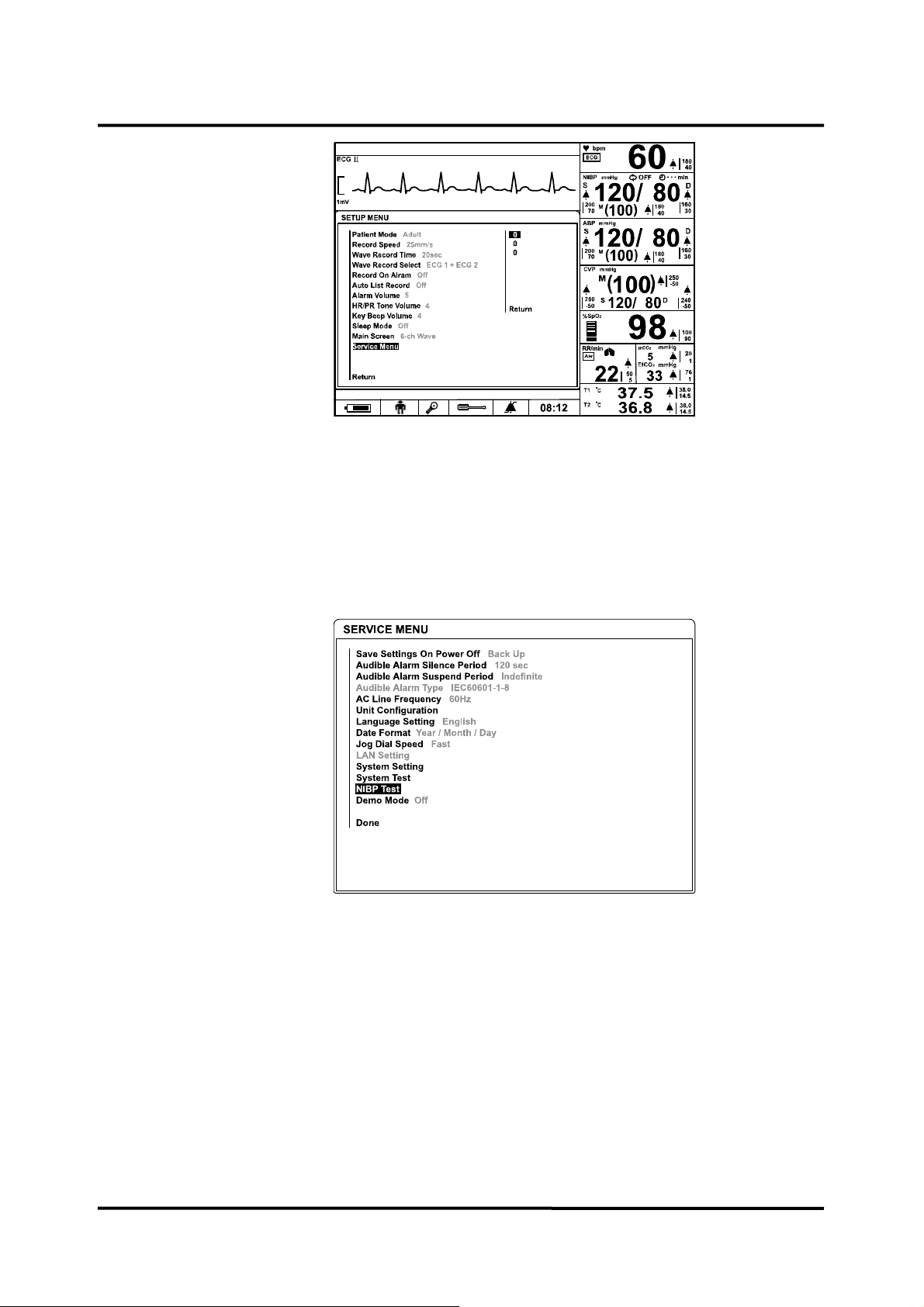

Figure 12. The access of Service Menu via Set-up menu ................................................................................................................... 43

Figure 13. Entering the pass code....................................................................................................................................................... 44

Figure 14. Service Menu...................................................................................................................................................................... 44

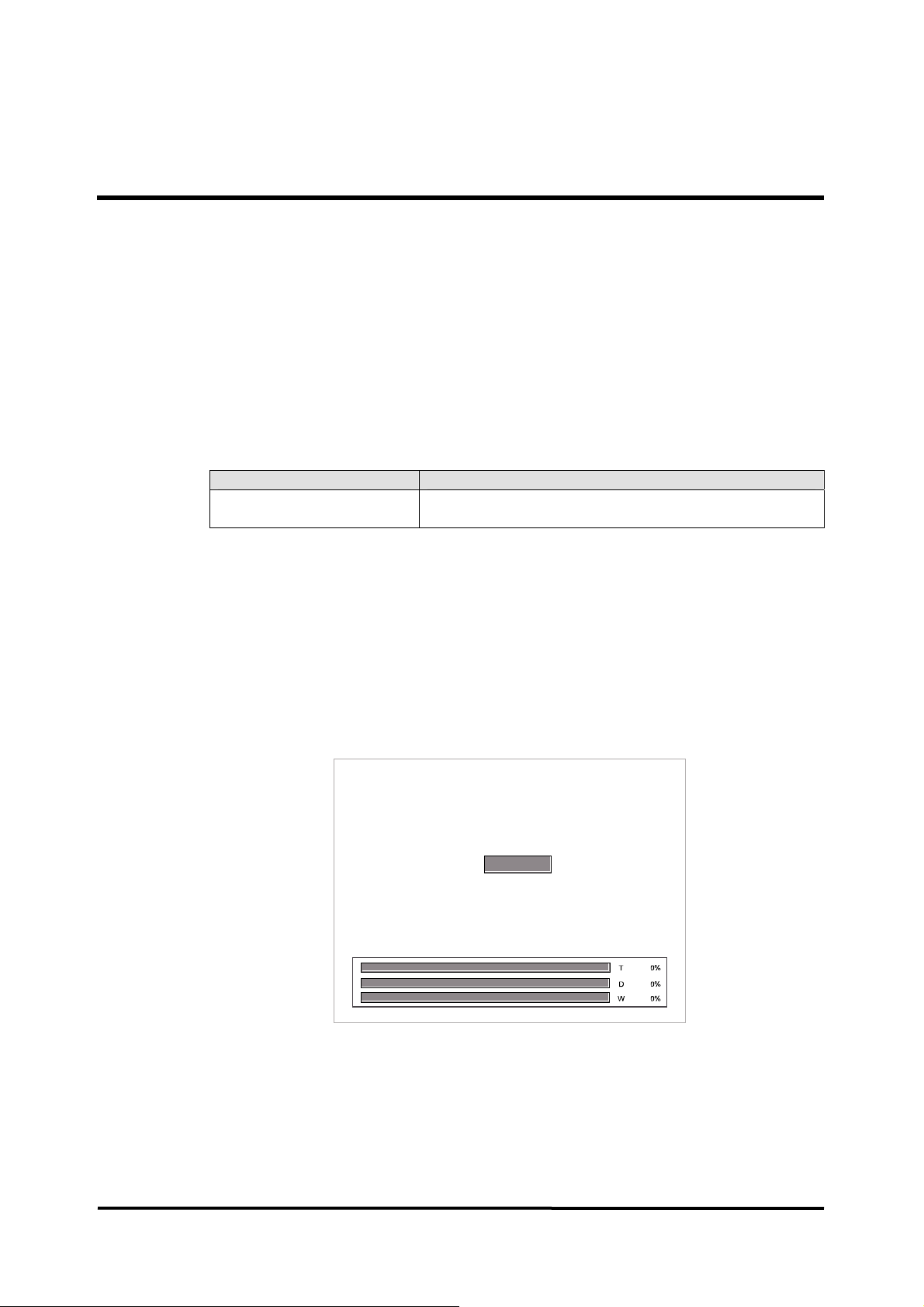

Figure 15. Firmware downloading display ........................................................................................................................................... 53

Figure 16. Firmware downloading completion ..................................................................................................................................... 54

Figure 17. Disassembly Sequence Flow Chart.................................................................................................................................... 70

Figure 18. Battery Replacement .......................................................................................................................................................... 71

Figure 19. Monitor Disassembly........................................................................................................................................................... 72

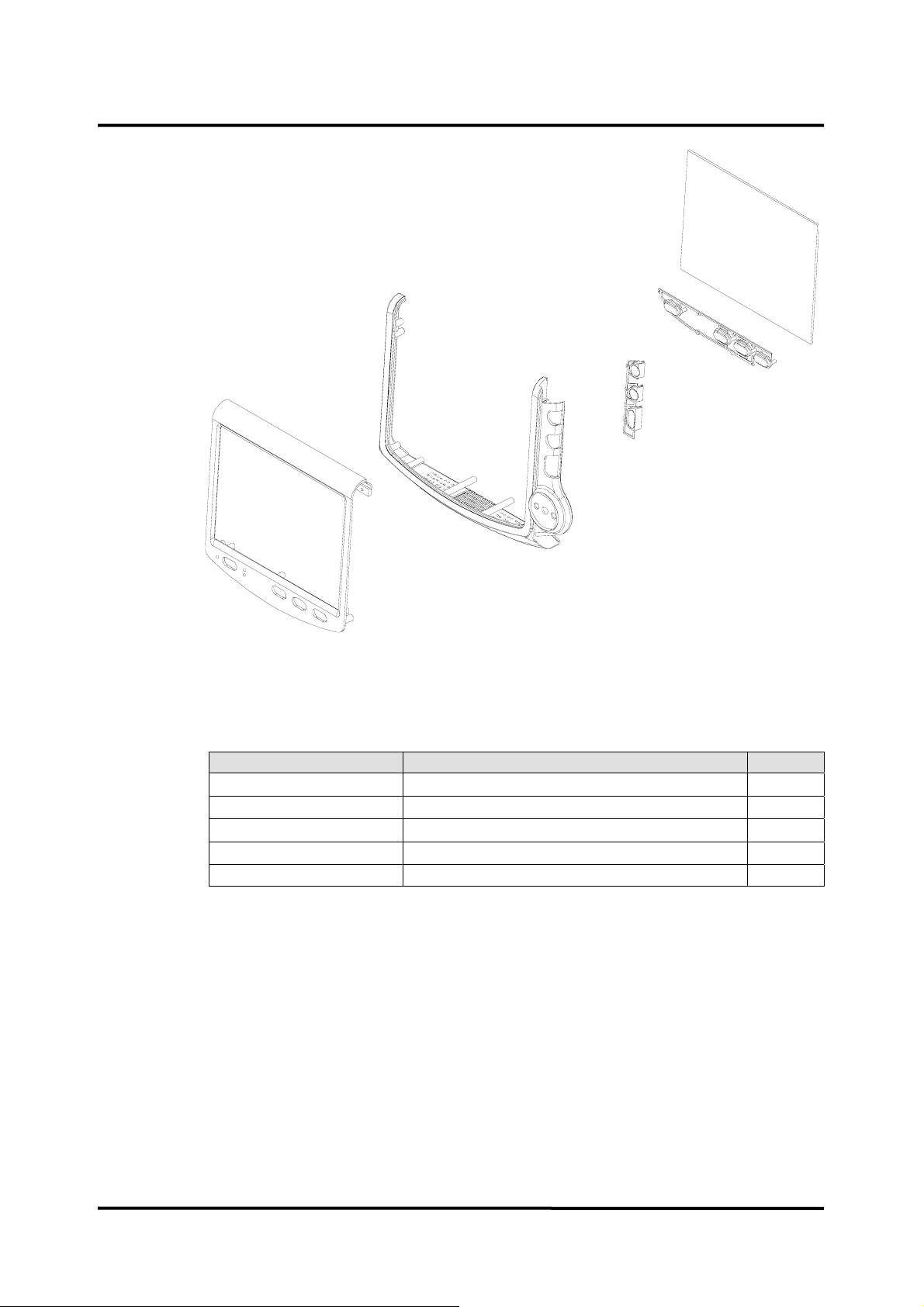

Figure 20. Front Case Disassembly – LCD Bracket, Side Key Case .................................................................................................. 73

Figure 21. Front Case Disassembly – LCD, Insulation, Inverter Board, Front Key Board,.................................................................. 74

Figure 22. Front Case Disassembly – Bezel, LCD Window, Front Key Array, Side Key Array............................................................ 76

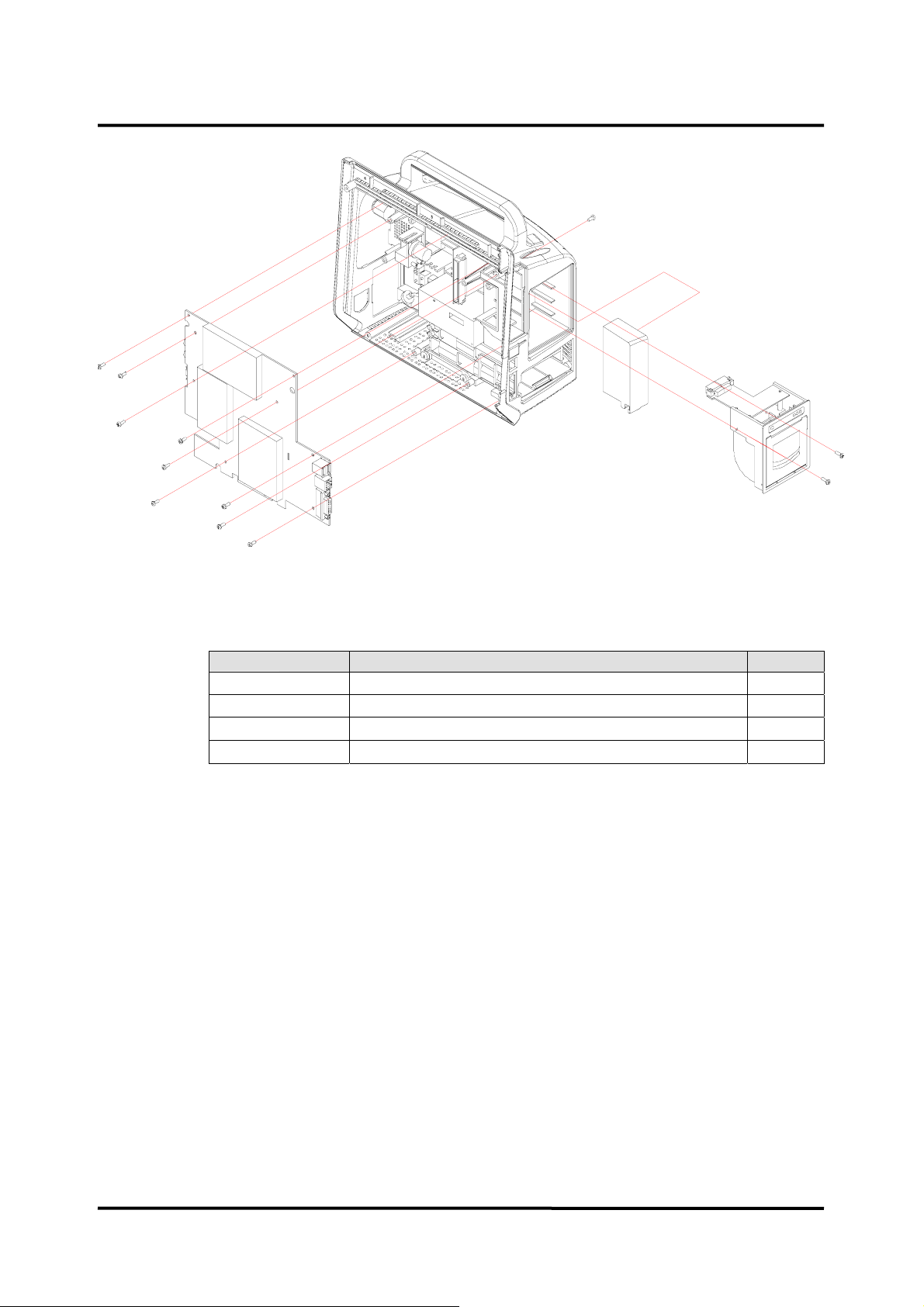

Figure 23. Rear Case Disassembly – Patient Sensor Case, Water Trap, CO

Figure 24. Rear Case Disassembly – TRX-02 Module Option Cover, Recorder, Main Board............................................................. 79

Figure 25. Rear Case Disassembly – ECG Board, SpO

Module, CPU Module................................................................................. 80

2

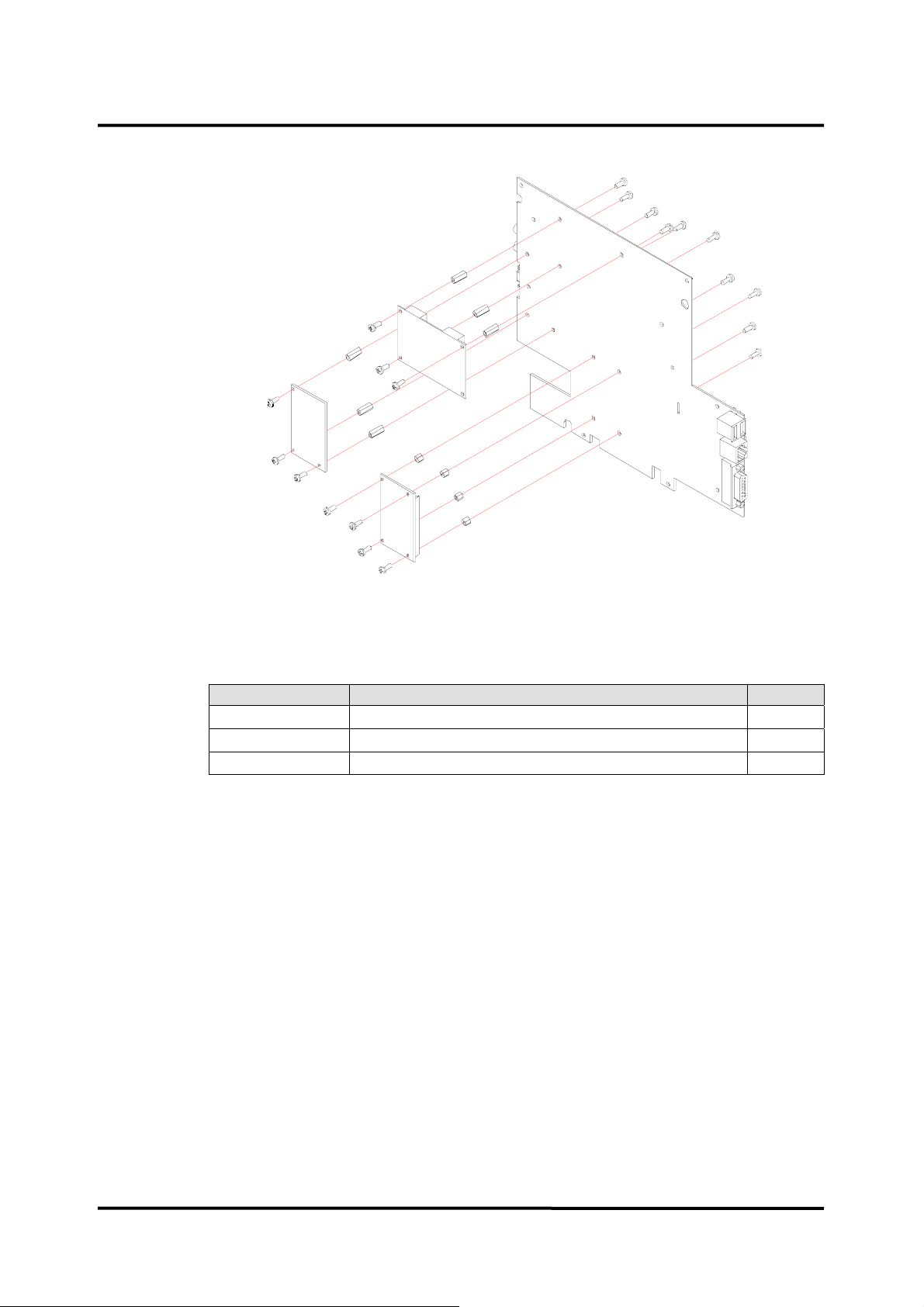

Figure 26. Rear Case Disassembly – NIBP Module, Hub Board, ECG Wire, CO

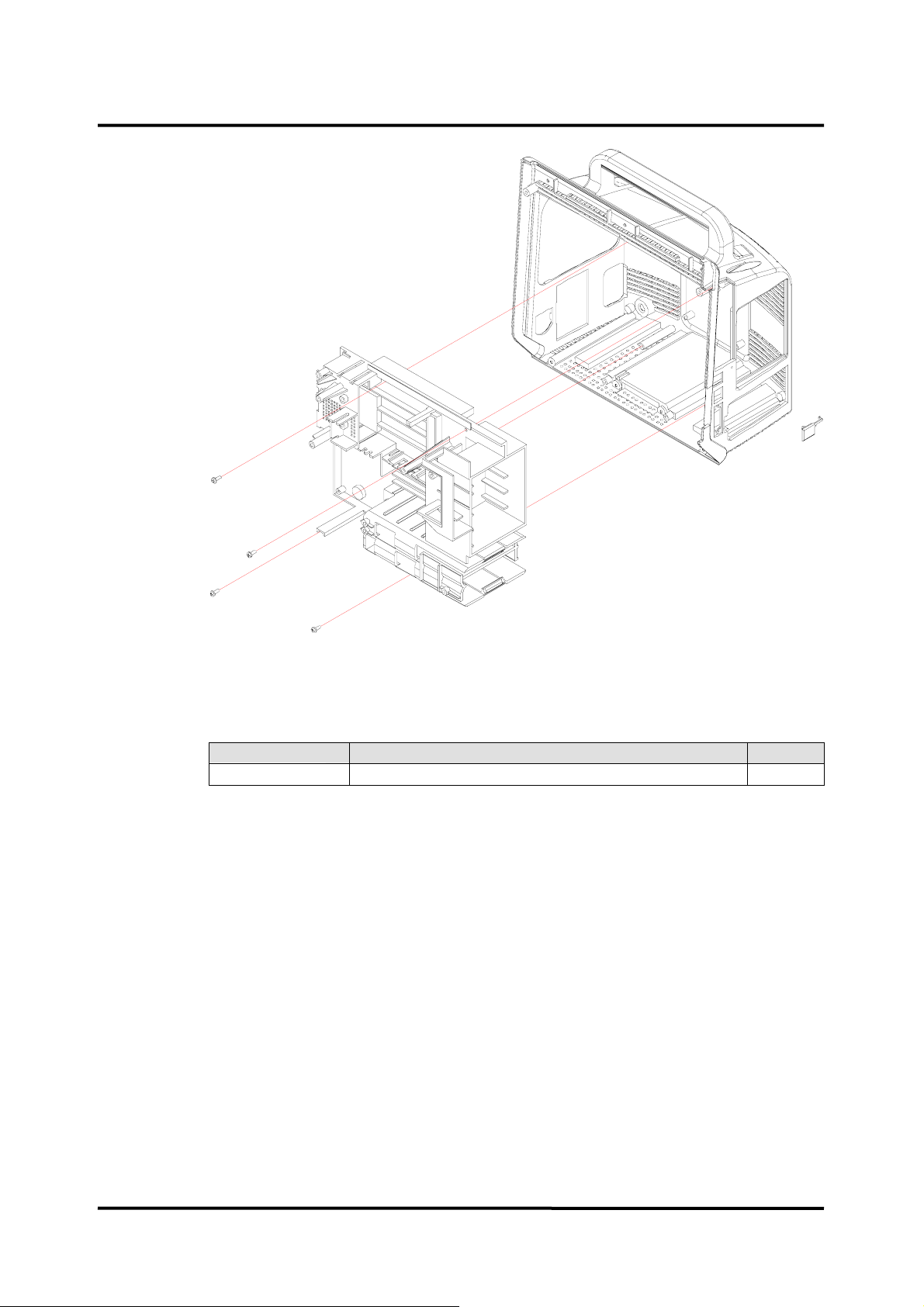

Figure 27. Rear Case Disassembly – In-Case..................................................................................................................................... 82

Figure 28. Rear Case Disassembly – SMPS....................................................................................................................................... 83

Figure 29. Rear Case Disassembly – VESA Bracket, Handle............................................................................................................. 84

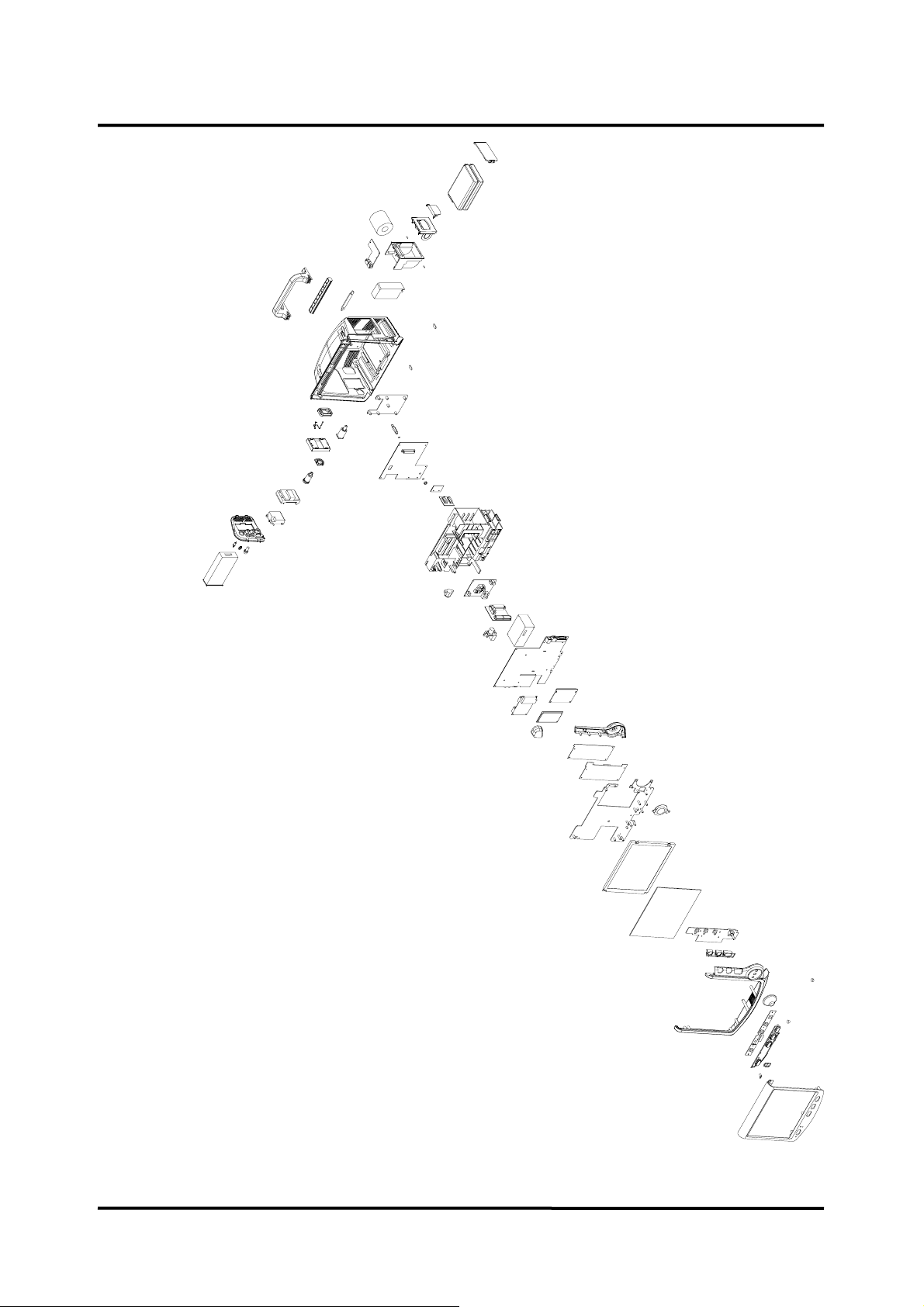

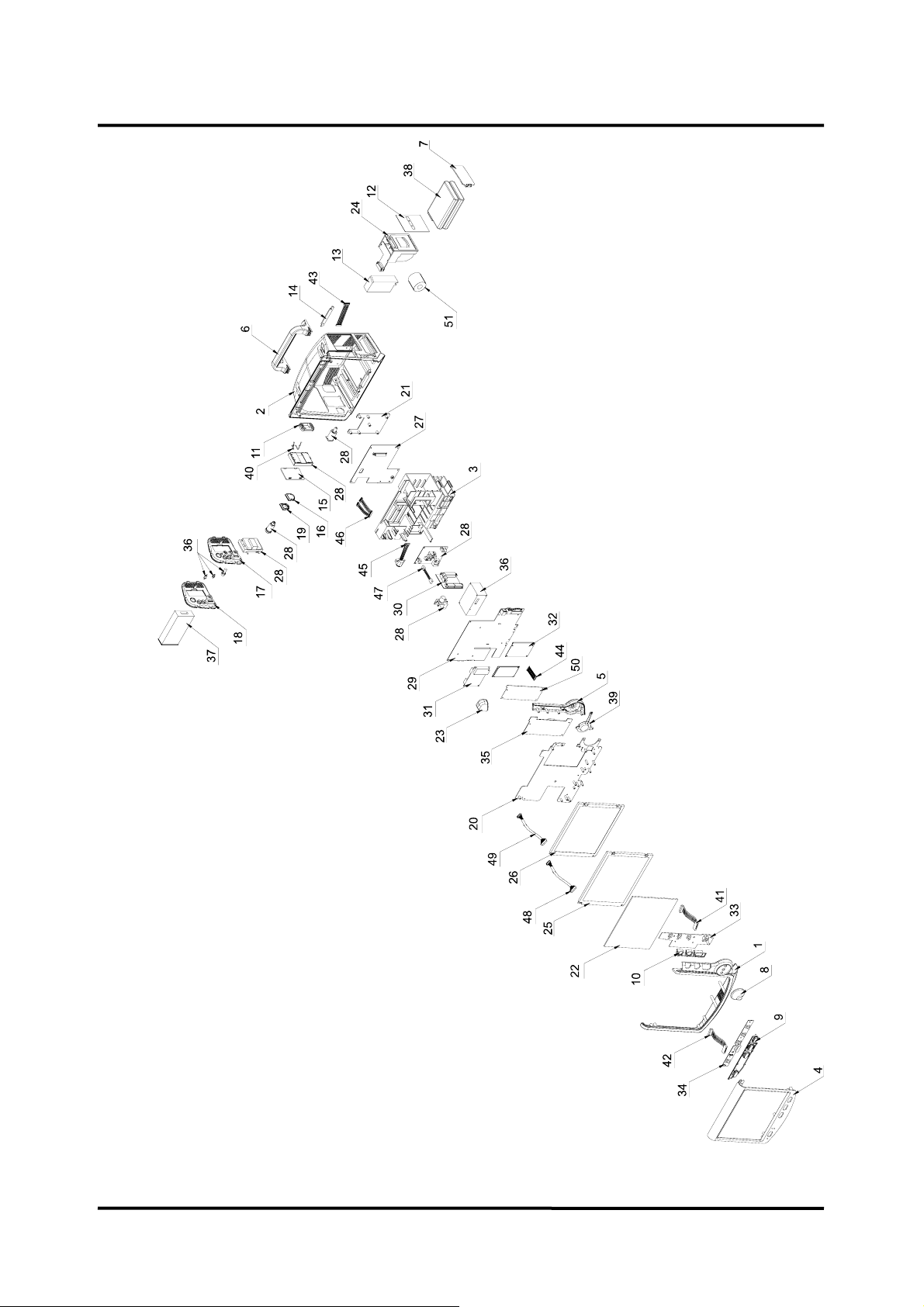

Figure 30. BP-S510 Exploded View..................................................................................................................................................... 85

Figure 31. BP-S510 Exploded View – Spare Parts.............................................................................................................................. 88

Figure 32. System Block Diagram ..................................................................................................................................................... 101

Figure 33. Power Unit Block Diagram................................................................................................................................................ 102

Figure 34. Process Unit Block Diagram............................................................................................................................................. 102

Figure 35. User-Control Unit Block Diagram...................................................................................................................................... 103

Figure 36. Sound Unit Block Diagram................................................................................................................................................ 103

Figure 37. Communication Unit Block Diagram................................................................................................................................. 103

Figure 38. GUI Unit Block Diagram.................................................................................................................................................... 104

Figure 39. Thermal Recorder Unit Block Diagram............................................................................................................................. 104

Figure 40. NIBP Unit Block Diagram.................................................................................................................................................. 104

Figure 41. ECG Unit Block Diagram .................................................................................................................................................. 105

Figure 42. Respiration Unit Block Diagram........................................................................................................................................ 105

Figure 43. SpO

Unit Block Diagram.................................................................................................................................................. 105

2

Figure 44. Temperature Unit Block Diagram...................................................................................................................................... 106

Figure 45. IBP Unit Block Diagram .................................................................................................................................................... 106

Figure 46. CO

Unit Block Diagram ................................................................................................................................................... 107

2

Figure 47. TRX-02 Unit Block Diagram.............................................................................................................................................. 107

Figure 48. Oxyhemoglobin Dissociation Curve...................................................................................................................................111

Absorber & Holder, AC Cord Clasp & Holder............. 77

2

Module ................................................................. 81

2

iii

Page 6

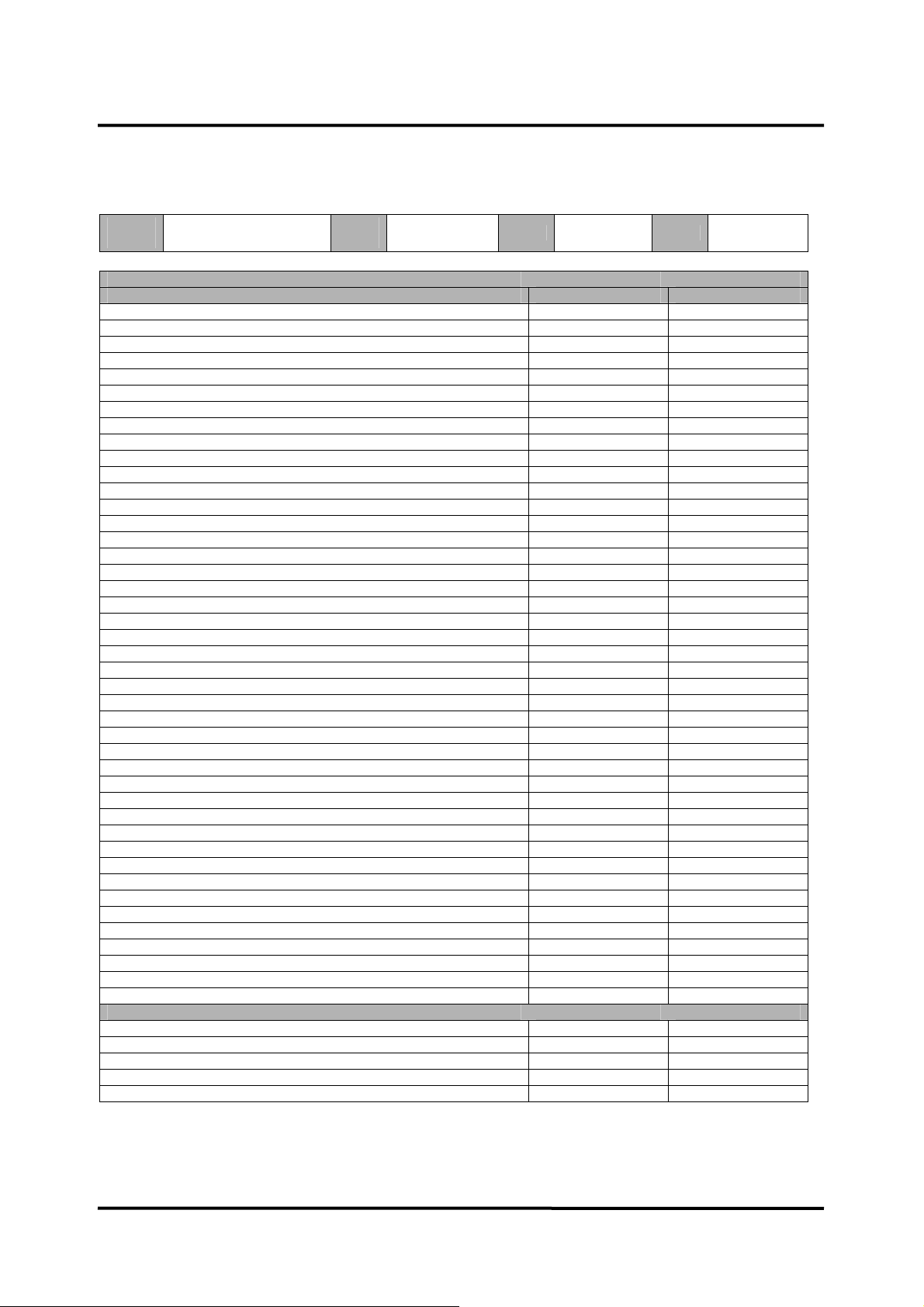

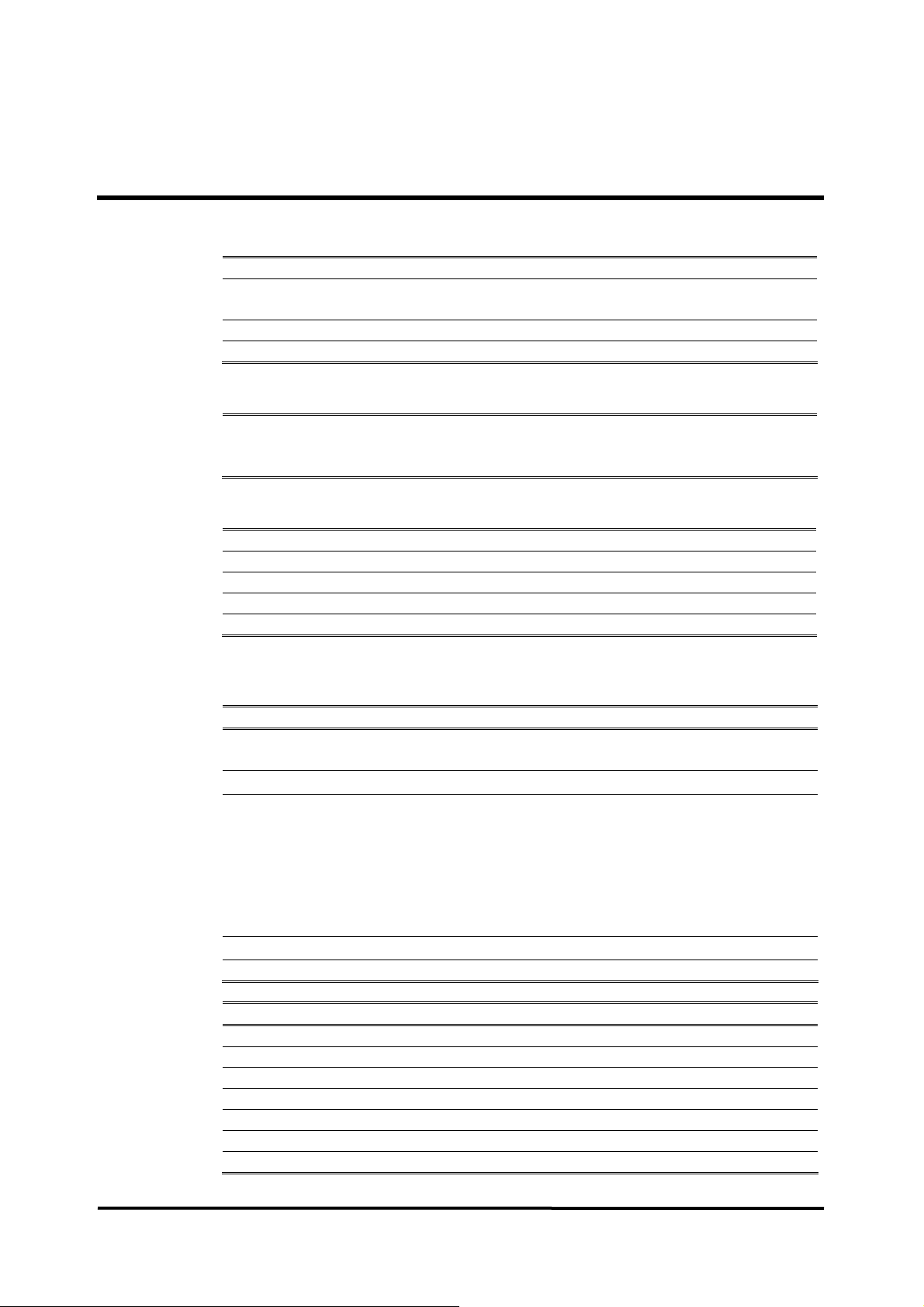

Tables

Table 1. Required Equipment................................................................................................................................................................11

Table 2. Parameter Alarm Limit Factory Defaults................................................................................................................................. 20

Table 3. Earth Leakage Current Values............................................................................................................................................... 34

Table 4. Enclosure Leakage Current.................................................................................................................................................... 35

Table 5. Patient Leakage Current Values............................................................................................................................................. 36

Table 6. Patient Leakage Current Values - Mains Voltage on Applied Part ......................................................................................... 36

Table 7. Test Lead Combinations......................................................................................................................................................... 37

Table 8. Allowable Leakage Current.................................................................................................................................................... 37

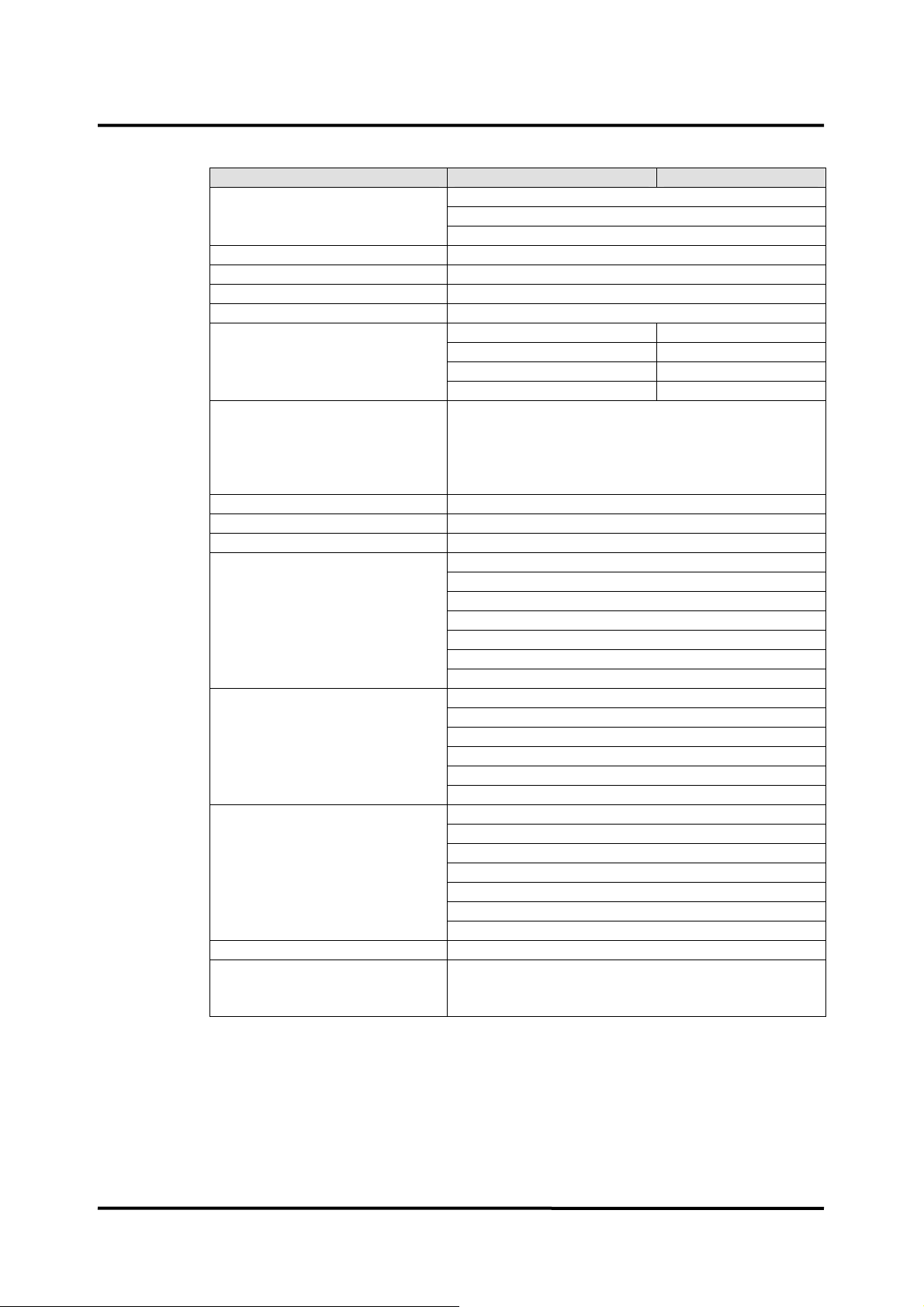

Table 9. Service menu ......................................................................................................................................................................... 45

T able 10. Audible Alarm Characteristics .............................................................................................................................................. 46

Table 11. System Test.......................................................................................................................................................................... 48

Table 12. NIBP Test.............................................................................................................................................................................. 48

Table 13. Factory Default Settings....................................................................................................................................................... 49

Table 14. Required Equipments for Firmware Download..................................................................................................................... 53

Table 15. Completion codes................................................................................................................................................................. 54

Table 16. Problem Categories.............................................................................................................................................................. 56

Table 17. Firmware Downloading Error Codes .................................................................................................................................... 62

Table 18. Alarm Messages and Check Items....................................................................................................................................... 62

Table 19. Part Descriptions – Front Case and Rear Case Assembly .................................................................................................. 72

Table 20. Part Descriptions – LCD Bracket, Side Key Case................................................................................................................ 73

Table 21. Part Descriptions – LCD, Insulation, Inverter Board, Front Key Board, ............................................................................... 74

Table 22. Part Descriptions – Bezel, LCD Window, Front Key Array, Side Key Array ......................................................................... 76

Table 23. Part Descriptions – Patient Sensor Case, Water Trap, CO2 Absorber & Holder, AC Cord Clasp & Holder......................... 77

Table 24. Part Descriptions – TRX-02 Module Option Cover, Recorder, Main Board.......................................................................... 79

Table 25. Part Descriptions – ECG Board, SpO2 Module, CPU Module............................................................................................. 80

Table 26. Part Descriptions – NIBP Module, Hub Board, ECG Wire, CO2 Module............................................................................. 81

Table 27. Part Descriptions – In Case.................................................................................................................................................. 82

Table 28. Part Descriptions – SMPS.................................................................................................................................................... 83

Table 29. Part Descriptions – VESA Bracket, Handle.......................................................................................................................... 84

Table 30. Spare Part List...................................................................................................................................................................... 88

iv

Page 7

SAFETY INFORMATION

General Safety Information

This section contains important safety information related to general use of the BP-S510

multi-parameter patient monitor. Other important safety information appears throughout

the manual. The BP-S510 will be referred to as the monitor throughout this manual.

Important! Before use, carefully read this manual, accessory directions for use, all

precautionary information and specifications.

Warnings

Warnings are identified by the WARNING symbol shown above.

Warnings alert you to potential serious outcomes (death, injury, or adverse events)

to the patient or user.

WARNING: Explosion hazard. Do not use the monitor in the presence of flammable

anesthetics or gases.

WARNING: Do not spray, pour, or spill any liquid on the monitor, its accessories,

connectors, switches, or openings in the chassis.

WARNING: Do not immerse the monitor or its accessories in liquid or clean with

caustic or abrasive cleaners.

WARNING: Ensure that conductive portions of the electrodes, leads, and cable do

not come into contact with any other conductive parts,

WARNING: Before attempting to open or disassemble the monitor, disconnect the

power cord from the monitor.

WARNING: Chemicals from a broken LCD display panel are toxic when ingested.

Use caution when handling a monitor with a broken display panel.

WARNING: The use of accessories, transducers, and cables other than those

specified may result in increased emission and/or decreased immunity of the

monitor.

WARNING: Do not silence the monitor audible alarm or decrease its volume if

patient safety could be compromised.

WARNING: During the safety test, AC main voltage will be present on the applied

part terminals, Exercise caution to avoid electrical shock hazard.

WARNING: Do not place the monitor into operation after repair or maintenance has

been performed, until all Performance Tests and Safety Tests listed in

Performance Verification section of this service manual have been performed.

Failure to perform all tests could result in erroneous monitor readings.

WARNING: High voltage is generated by the LCD backlight driver. Exercise

caution when operating monitor with covers open.

1

Page 8

Cautions

Cautions are identified by the CAUTION symbol shown above.

Caution statements identify conditions or practices that could result in damage to

the equipment or other property.

CAUTION: Observe ESD (electrostatic discharge) precautions when working within

the unit and/or when disassembling and reassembling the monitor and when

handling any of the components of the monitor.

CAUTION: When reassembling the monitor, over-tightening could strip out the

screw holes in the cases, rendering it unusable.

CAUTION: If any problem with the monitor built in an optional recorder, check a

recorder’s door is closed well. Operating error may be caused if the cover is not

closed correctly.

CAUTION: If internal battery cable has been disconnected, pay particular attention

to polarity of the cable before reattaching. If battery cable polarity is reversed, it is

likely that circuit damage will occur.

CAUTION: Ferrite Cores are used for electromagnetic compatibility. Please do not

remove Ferrite Cores while disassembling or reassembling, otherwise the monitor

can be affected by electromagnetic interference and measure inaccurate data to be

displayed or stored.

CAUTION: For continued protection against risk of fire, replace only with same type

and rating of fuse.

2

Page 9

Manual Overview

This manual contains information for servicing the BP-S510 monitor.

The monitor subsequently referred to as the monitor throughout this manual. Only

qualified service personnel should service this product. Before servicing the monitor, read

the operator’s manual carefully for a thorough understanding of safe operation.

Read and understand all safety warnings and service notes printed in this service manual

and the operator’s manual part number A7072

Related Documents

To perform test and troubleshooting procedures and to understand the principles of

operation and circuit analysis sections of this manual, you must know how to operate the

monitor. Refer to the monitor operator’s manual part number A7072

To understand the various SpO

probes, IIBP transducer and CO

individual directions for use that accompany these accessories.

sensors, ECG leads, blood pressure cuffs, temperature

2

accessories that work with the monitor, refer to the

2

Intended Use for the BP-S510 Monitor

The BP-S510 is intended to be used to monitor electrocardiography, heart rate,

noninvasive blood pressure (systolic, diastolic and mean arterial pressures), functional

arterial oxygen saturation, pulse rate, respiration, temperature, invasive blood pressure

and capnography for adult and neonatal patients in all areas of a hospital and hospitaltype facilities. Monitor users should be skilled at the level of a technician, doctor, nurse or

medical specialist.

Note: Hospital use typically includes such areas as general care floors, operating rooms,

special procedure areas, intensive and critical care area, within the hospital.

Hospital-type facilities include physician office-based facilities, sleep labs, skilled

nursing facilities, surgical centers, and sub acute care centers.

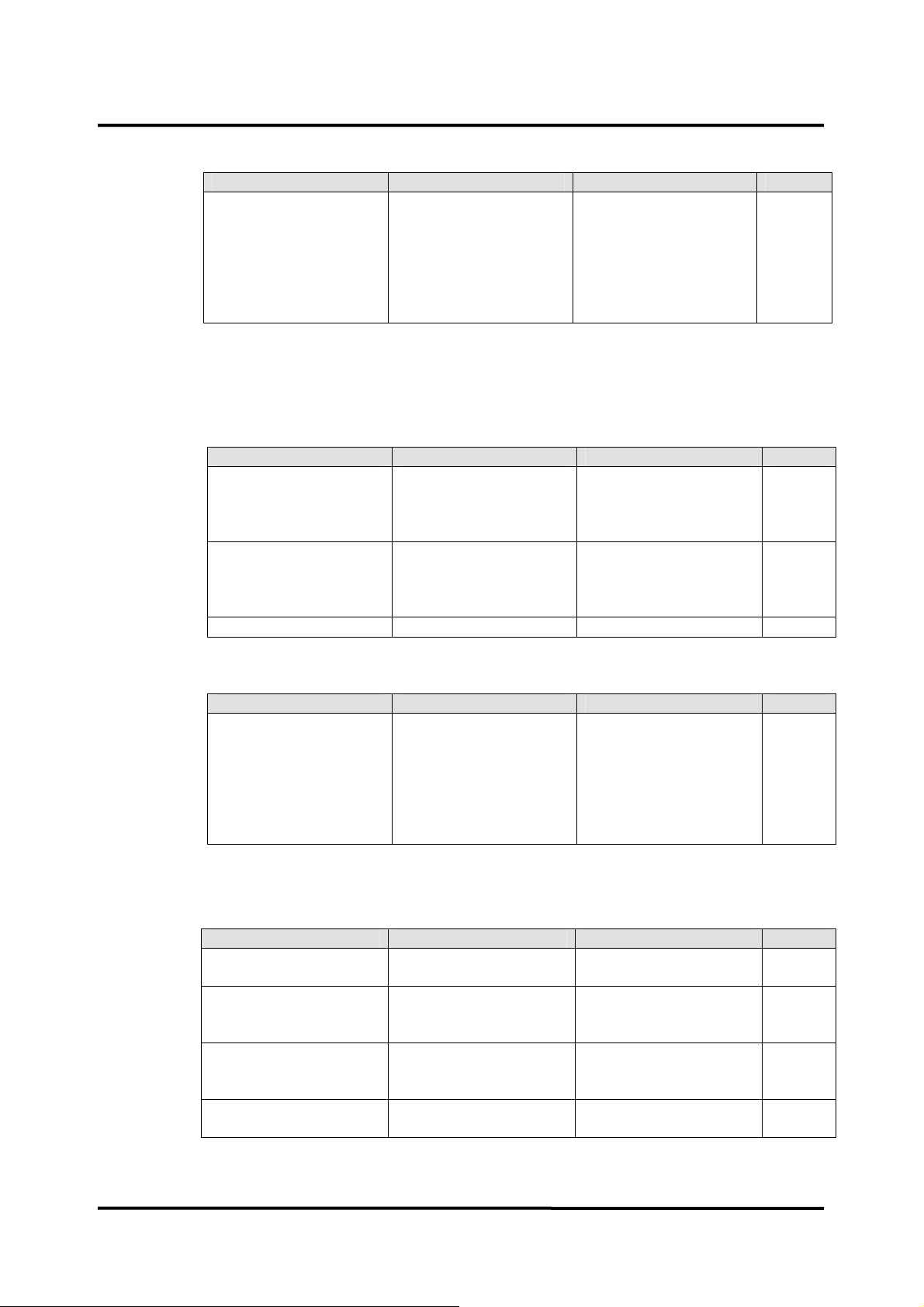

Identifying the BP-S510 monitor Configurations

The following table identities BP-S510 monitor configurations and how they are indicated.

The model-option number and serial number are located on the back of the monitor.

All information in this manual, including the illustrations, is based on a monitor configured

with Capnography (EtCO

exist, please verify your unit configuration.

and InCO2), IBP and recorder. If the relevant functions do not

2

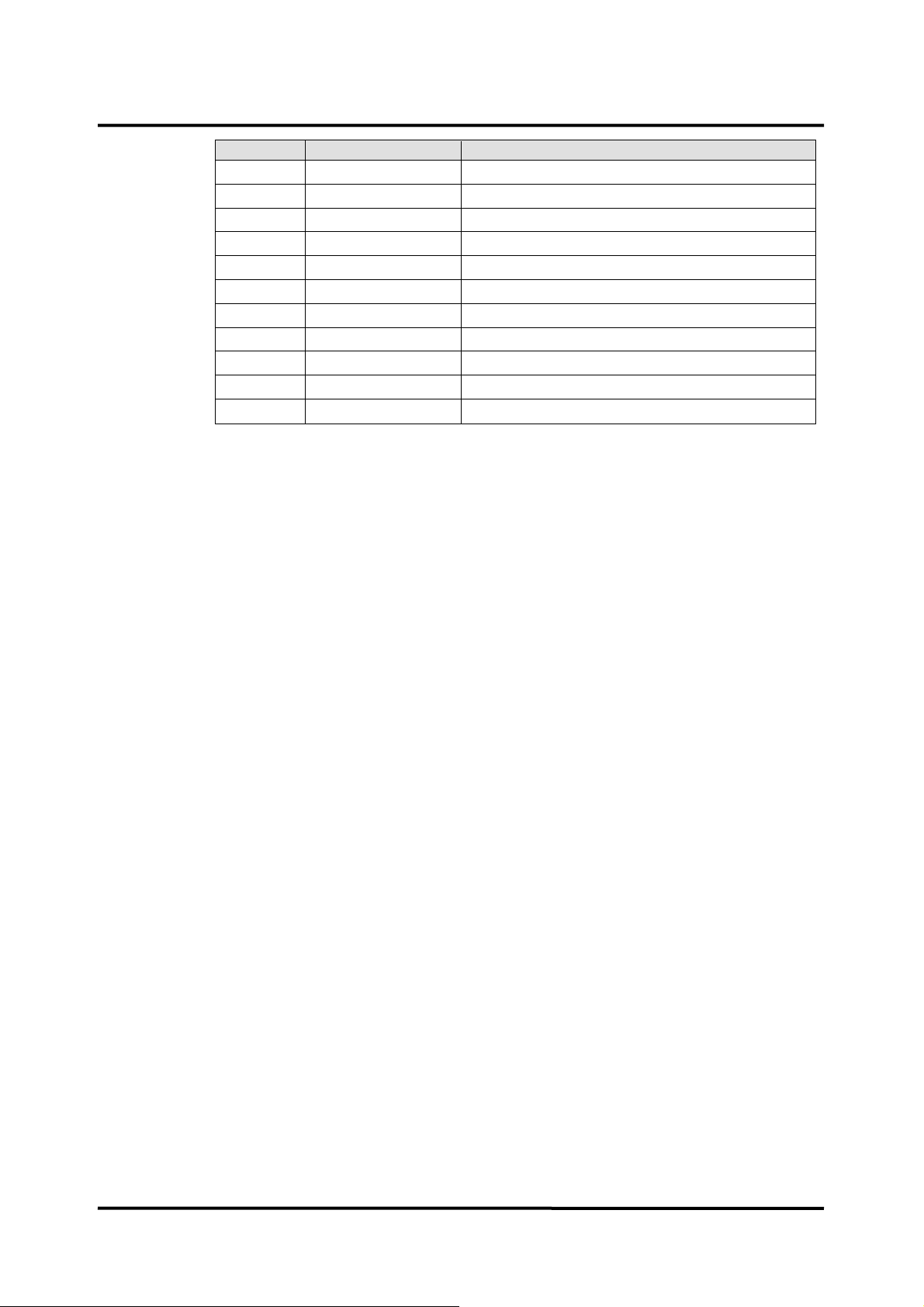

Configuration REF No. Description

BP-S510 112580 Standard

(ECG, NIBP, SpO

BP-S510P 112581 Standard + Recorder

BP-S510C 112582 Standard + Capnography

BP-S510PC 112583 Standard + Capnography + Recorder

S510-IBP 131324 2-channel IBP module

, 2-channel Temperature, Respiration)

2

3

Page 10

Front Panel Components

1 Visual alarm indicator

2 Alarm silence button

3 NIBP interval button

4 NIBP start/stop button

5 LCD

6 Jog dial

7 Power on indicator

8 Power on/off button

9 Battery charging indicator 1

10 Battery charging indicator 2

11 Record button

12 Trend button

13 Home button

Figure 1. Front Panel Components

4

Page 11

Rear Panel Components

1 Handle 4 Equipotential terminal

2 Ventilators 5 Speaker

3 VESA connector holes

Figure 2. Rear Panel Components

5

Page 12

Left Panel Components

1 ECG connector 7 NIBP connector

2 Temperature channel 1 8 AC power connector

3 Temperature channel 2 9 Water trap (option)

4 SpO

5 IBP channel 1 (option) 11 CO

6 IBP channel 2 (option) 12 CO

connector 10 CO2 connector (option)

2

filter (option)

2

exhaust port (option)

2

Figure 3. Left Panel Components

6

Page 13

Right Panel Components

1 USB port 4 Battery cover

2 LAN port 5 Recorder (option)

3 RS-232 port

Figure 4. Right Panel Components

7

Page 14

This page is intentionally left blank.

8

Page 15

ROUTINE MAINTENANCE

WARNING: Do not spray or pour any liquid on the monitor or its accessories. Do

not immerse the monitor or its accessories in liquid or clean with caustic or

abrasive cleaners.

Cleaning

The monitor may be surface-cleaned by using a soft cloth dampened with either a

commercial, nonabrasive cleaner or one of the solution listed in the below. Lightly wipe

the top, bottom and front surfaces of the monitor lightly.

z 70% Isopropyl alcohol

z 10% Chlorine bleach solution

For cables, sensors, cuffs, transducer and probes, follow cleaning instructions in the

directions for use shipped with those components.

Avoid spilling liquid on the monitor, especially in connector areas. If liquid is accidentally

spilled on the monitor, clean and dry thoroughly before reuse. If in doubt about monitor

safety, refer the unit to qualified service personnel for checking.

Periodic Safety and Functional Checks

The following performance verification tests may be used following repair or during routine

maintenance (if required by your local institution). The following checks should be

performed at least every year by qualified service personnel.

1. Inspect labels for legibility. If the labels are not legible, contact your local supplier.

2. If the monitor has been visibly damaged or subjected to mechanical shock (for example,

if dropped), perform the performance tests as described in Performance Verification

section. If the unit fails these performance tests, refer to Troubleshooting section.

3. Perform the electrical safety tests described in Performance Verification section. If

the unit fails these electrical safety tests, do not attempt to repair. Contact your local

supplier.

4. Inspect the fuses for proper value and rating.

qty 2, 6.3 A, 250 volts for AC mains

9

Page 16

Batteries

If the monitor has not been used for a long period of time, more than 2 months, the battery

will need charging. To charge the battery, connect the monitor to an AC outlet as

described in Battery Charge paragraph in this service manual or the Battery Operation

section of the operator’s manual.

Note: Storing the monitor for a long period without charging the battery may degrade the

battery capacity. The battery may require a full charge/discharge cycle to restore

normal capacity. Omron Healthcare recommends that the monitor’s sealed, Ni-MH

batteries be replaced at 2 year intervals. Refer to Disassembly Guide section.

CAUTION: If the monitor is to be stored for a period of 2 months or longer, it is

recommended to notify service personnel to remove the battery from the monitor

prior to storage. To replace or remove the battery, refer to Disassembly Guide

section. Recharging the battery is strongly recommended when the battery has not

been recharged for 2 or more months.

CAUTION: If the battery shows any signs of damage, leakage, or cracking, it must

be replaced immediately.

CAUTION: Discarded battery may explode during incineration. Recycle used

batteries properly. Do not dispose of batteries in refuse containers.

Environmental Protection

Follow local governing ordinances and recycling plans regarding disposal or recycling

batteries and other device components.

Note: The monitor should be disposed of separately from the municipal waste stream via

designated collection facilities appointed by the government or the local authorities.

Note: The correct disposal of your old appliance will help prevent potential negative

consequences for the environment and human health.

Note: For more detailed information about disposal of your old appliance, please contact

your city office, waste disposal service or the shop where you purchased the

monitor.

10

Page 17

PERFORMANCE VERIFICATION

General

This section discusses the tests used to verify performance following repairs or during

routine maintenance. All tests can be performed without removing the monitor covers. All

tests except the battery charge and battery discharge tests must be performed as the last

operation before the monitor is returned to the user.

If the monitor fails to perform as specified in any test, repairs must be made to correct the

problem before the monitor is returned to the user.

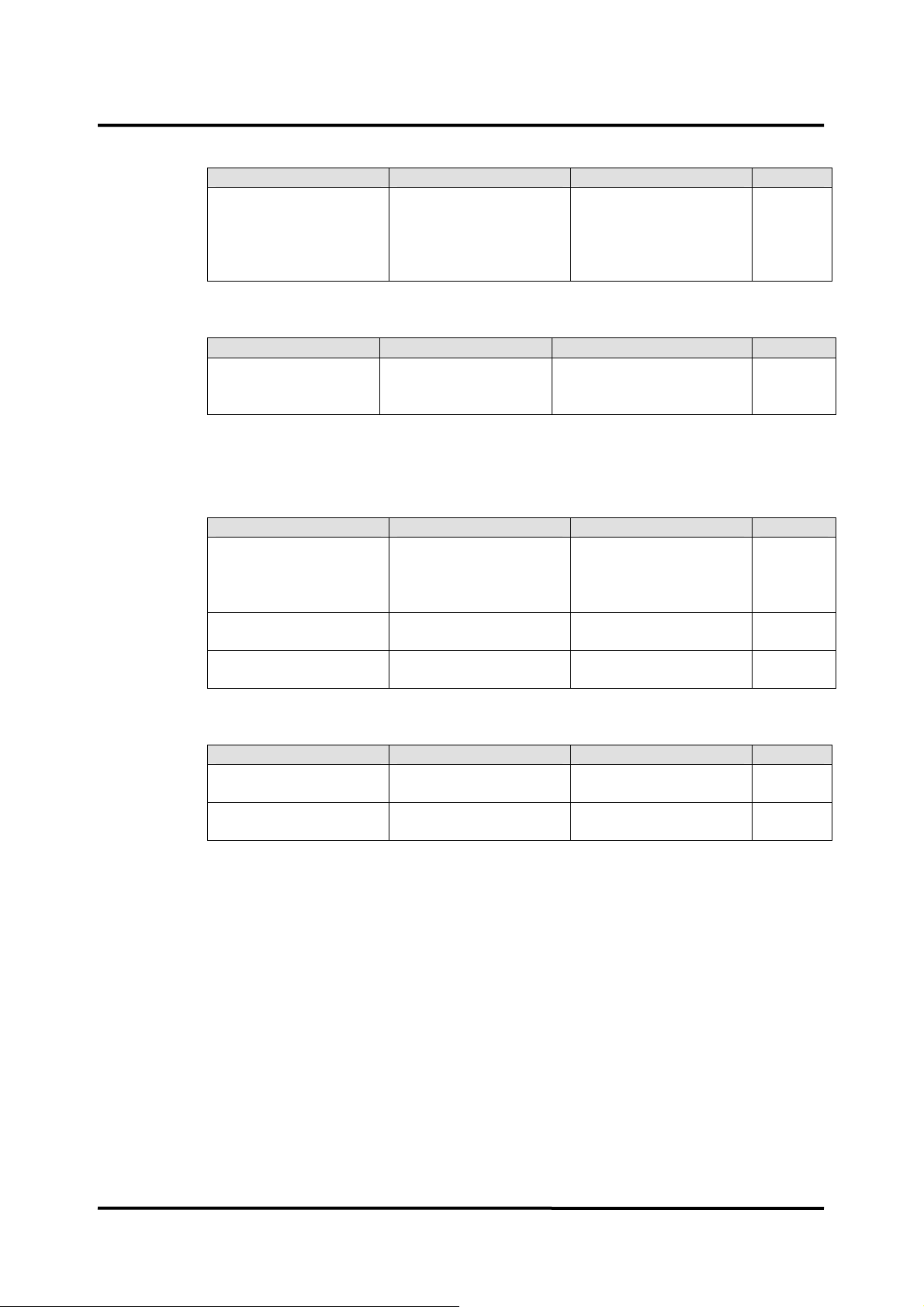

Required Equipment

Table 1 lists the equipment required for performance verifications.

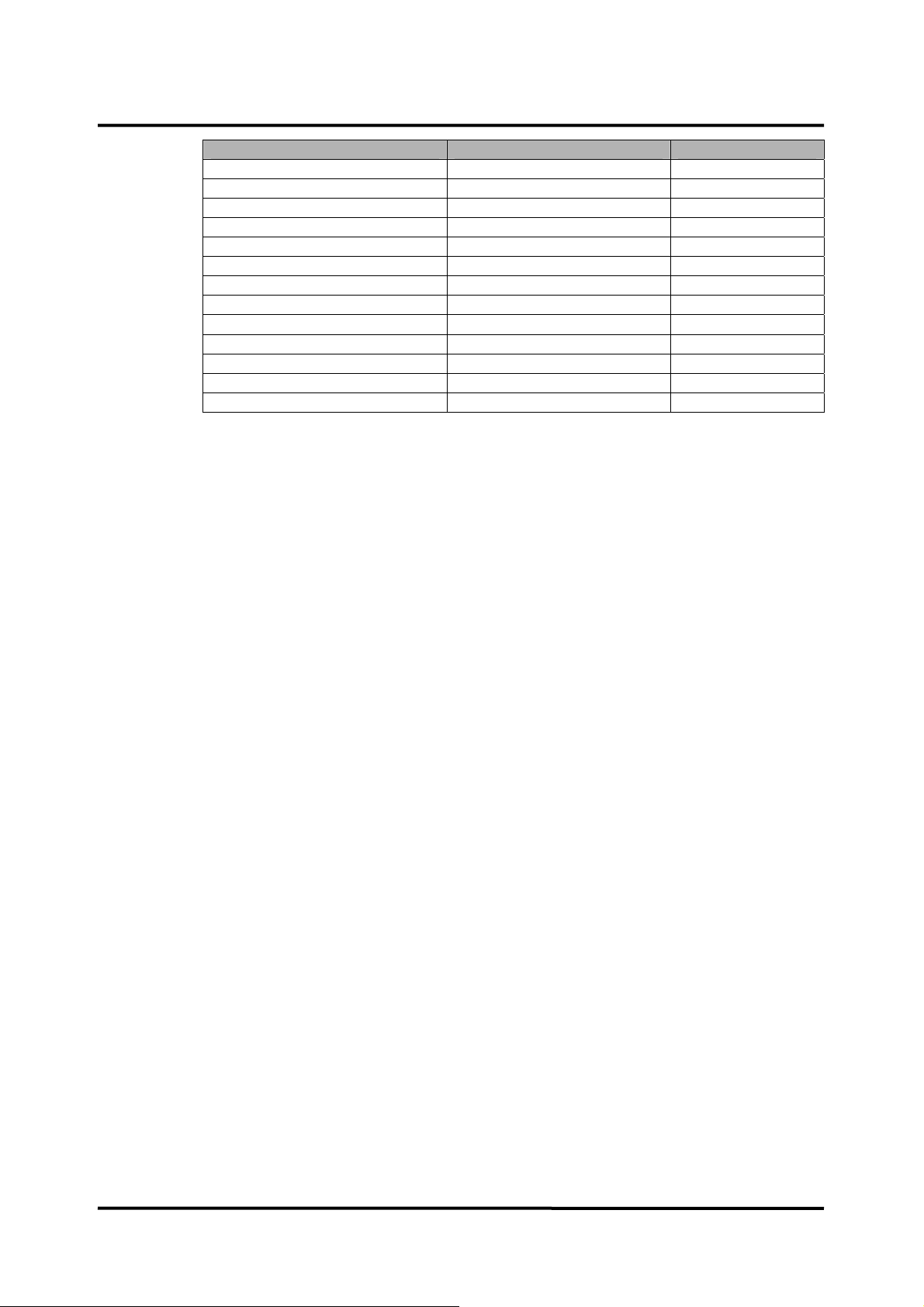

Table 1. Required Equipment

Equipment Description

Digital multimeter (DMM) Fluke Model 87 or equivalent

ECG cable ECG cable No.8

ECG 3 lead wires ECG 3 lead wires No.5

ECG 5 lead wires ECG 5 lead wires No.6 (optional)

NIBP cuff for neonatal NIBP cuff No.11 (3cm)

NIBP cuff for adult NIBP cuff No.3 (12cm)

NIBP cuff hose for neonatal NIBP cuff hose No.3 (3.5m)

NIBP cuff hose for adult NIBP cuff hose No.1 (3.5m)

NIBP rigid PVC vessel 9 cm diameter

NIBP rigid PVC vessel 5 cm diameter

SpO2 extension cable DOC-10

SpO2 sensor (durable) DS-100A

Temperature probes YSI-400 series

IBP extension cable IBP extension cable

ECG simulator Metron PS-420 or equivalent

SpO2 simulator Nellcor SRC-MAX simulator

NIBP simulator Bio-Tek BP Pump 2 or equivalent

Sphygmomanometer small Common used sphygmomanometer

Y tube Omron Y tube

Cuff joint Omron cuff joint

Inflation bulb Omron inflation bulb

Temperature simulator Metron PS-420 or equivalent

IBP simulator Metron PS-420 or equivalent

IBP test cable Omron IBP test cable

CO2 gas flow meter STEC SEF-21A or equivalent

Safety analyzer Metron QA-90 or equivalent

Data interface cable RS-232 cable

LAN cable Common used LAN cable

USB memory Common used USB memory

Stopwatch Manual or electronic

Note: The sphygmomanometer small shall be calibrated periodically. The correct value

can not be found if the sphygmomanometer has not been calibrated.

Note: Contact your local supplier for pricing and ordering information.

11

Page 18

System Tests

The monitor must be placed in the service menu. For a detailed explanation to access the

service menu, refer to Service Menu and Factory Default Settings section.

1. Rotate the jog dial to select System Test in the service menu, and then press the jog

Switch/LED Test

This tests the buttons, jog dial and the visual alarm indicator.

dial.

Figure 5. Switch/LED Test

1. Select Switch/LED Test in the system test. The image screen will appear as Figure

5.

2. Verify that the alarm visual indicator flashes with red and yellow.

3. Press all the buttons one by one, except for the power on/off button.

When a button is pressed, the same button on the image screen will turn blue.

For example, when the jog dial is pressed, the jog dial on the screen turns blue.

When the jog dial is rotated, the sign indicating the rotate direction will appear.

4. After finishing the test, press the jog dial twice to exit.

Pass/Fail Results

If a pressed button turns blue on the screen, the button is in a normal state.

12

Page 19

LCD Test

This tests the LCD display.

1. Select LCD Test in the system test.

2. The screen color will change over the following sequence:

3. After testing the test, press jog dial twice to exit.

Pass/Fail Results

When the color of the test screen changes in the order from Red, Green, Blue, White to

Black, the LCD display is in a normal state.

Alarm Audible Test

This tests the alarm tones by displaying the level of the alarm tone on the screen.

Red Æ Green Æ Blue Æ White Æ Black … every two seconds

Figure 6. Alarm Audible Test

1. Select Alarm Audible Test in the system test.

2. The level of the alarm tone will appear on the screen as the alarm tone sounds. Then,

the level goes up gradually. When the tone reaches the maximum level 8, it returns to

the minimum level 1.

3. After finishing the test, press the jog dial to select Cancel. The menu box will

disappear.

Pass/Fail Results

When the alarm tone changes to eight steps, the alarm tone is in a normal state.

13

Page 20

Tone Audible Test

This tests HR/PR tones, key beeps and completion sounds.

1. Select Tone Audible Test in the system test.

2. Rotate the jog dial to select HR/PR Tone.

3. Press Cancel to finish the test.

4. Rotate the jog dial to select Key Beep or Completion Sound.

5. Verify that Key Beep or Completion sound sounds properly.

6. After finishing the test, press the jog dial to select Cancel. The menu box will

Pass/Fail Results

When the HR/PR tone changes to seven steps and the pitch changes to three steps, the

HR/PR tone is normally set.

When the key beep changes to seven steps, the key beep is normally set.

When the completion sound is heard, it is normally set.

Figure 7. Tone Audible Test

The HR/PR tone sounds intermittently as the level goes up gradually. When the tone

reaches the maximum level 7, it returns to the minimum 1.

When the tone returns to the minimum, the pitch will change automatically.

There are three pitches – High, Med and Low.

disappear.

14

Page 21

Recorder Test

This tests the printing condition.

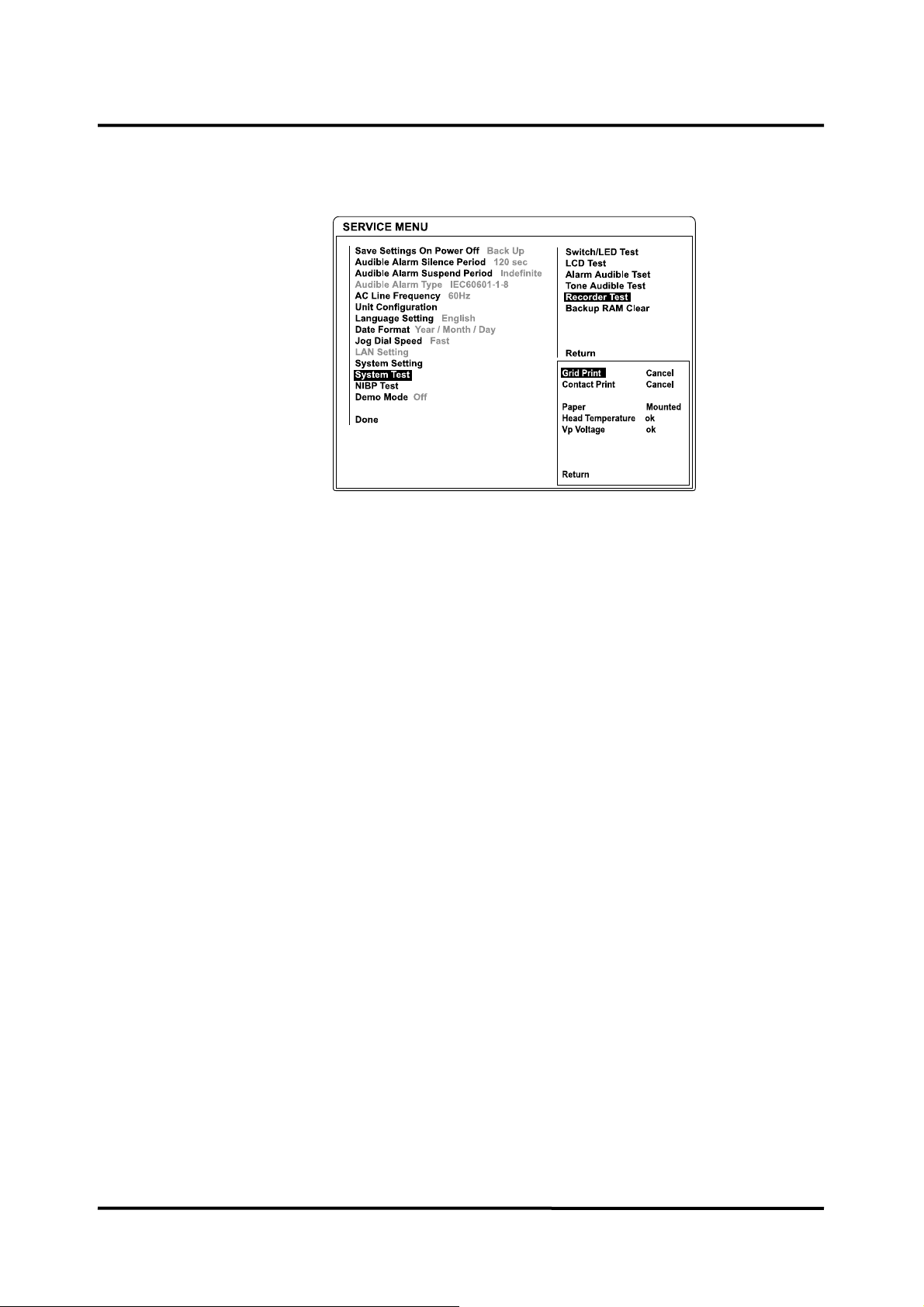

Figure 8. Recorder Test

1. Select Recorder Test in the system test.

The recorder condition is displayed as follows:

Paper: The “ Mounted” sign appears when the paper is installed properly. If the paper

runs out or the printer door is open, “empty” sign will appear in red.

Head Temperature: The “OK” sign appears when the head temperature is normal. If

the head temperature is abnormal, the ”error” sign appears.

Vp Voltage: The “OK” sign appears when the voltage is normal. If the voltage is

abnormal, the “error” sign appears.

2. Select Grid Print. Verify that printing can be done without meandering.

3. After checking, select Cancel to stop printing.

4. Select Contact Print. Verify that printing can be done at an equal density.

5. After checking, select Cancel to stop printing.

Pass/Fail Results

When the printed line is free from meandering on unevenness in density, the printing

function is normal.

15

Page 22

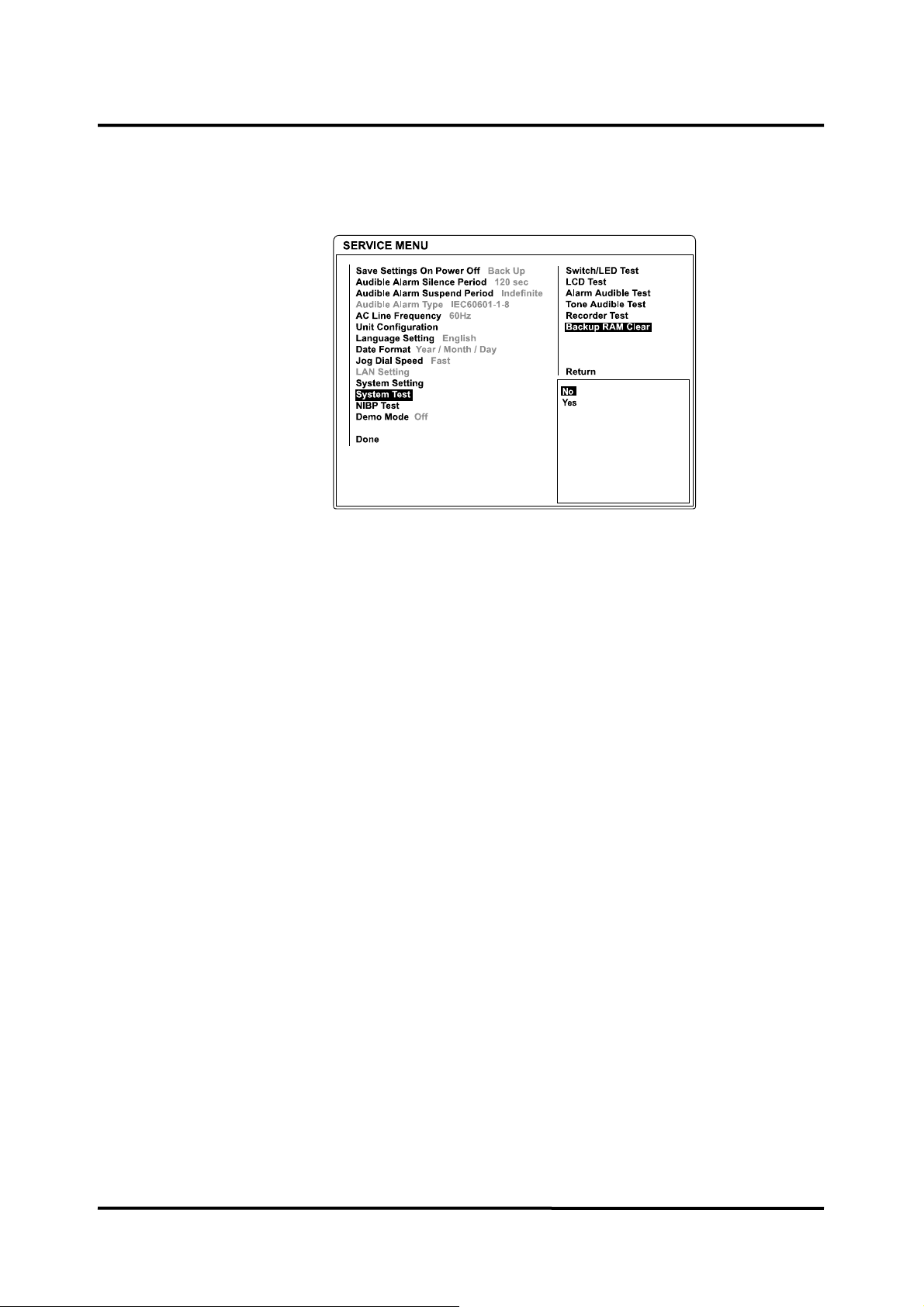

Backup RAM Clear

When Backup RAM Clear is set to Yes, all settings of the monitor including the service

settings return to the factory defaults from the next cycle.

Note: Set the monitor to appropriate AC line frequency (50Hz or 60Hz) again after Back

Figure 9. Backup RAM Clear

Up RAM clearance.

16

Page 23

Performance Tests

The battery charge and battery discharge test should be performed before monitor repairs

whenever the battery is suspected as being a source of the problems. All other tests may

be used following repairs or during routine maintenance (if required by your local

institution). Before performing the battery discharge test, ensure that the battery is fully

charged. This section is written using factory defaults as power-up. If your institution has

preconfigured custom defaults, those values will be displayed.

Power

1. Connect the monitor to AC power source using proper power cord.

2. Verify that Battery charging indicator is lit.

3. Press Power on/off button.

4. Verify that the monitor is turned on and that Power on indicator is lit.

5. After the monitor operates in normal mode, disconnect the power cord.

6. Verify that Battery status icon appears on the screen instead of lighting Battery

charging indicator.

7. Press Power on/off button over 1 second, and then verify that the monitor is turned off.

Battery Charge

1. Connect the monitor to AC power source using proper power cord.

2. Verify that Battery charging indicator is lit with orange.

3. Charge the battery fully until Battery charging indicator 1 and 2 are changed to green.

It will be take about 12 hours.

4. To check for a full charge, perform the procedure in paragraph “Battery Discharge”.

Note: The battery may require a complete charge/discharge cycle to restore its normal

Battery Discharge

1. Disconnect the power cord from the monitor with a fully charge battery.

2. Turn on the monitor by pressing Power on/off button.

3. Verify that Battery status icon appears at bottom of the screen after power-on self-test

is completed. The bar in battery status icon should be filled, indicating battery is

charged.

4. Connect the SpO

5. Connect the NIBP simulator to the monitor via NIBP cuff hose.

capacity, depending on its previous usage.

simulator to monitor via the SpO2 extension cable.

2

6. Set the SpO

simulator as follows: SpO2 of 95% and pulse rate of 60bpm.

2

7. Set the NIBP simulator to simulate pressure setting of 120/80 mmHg and heart rate of

80 bpm.

8. Set NIBP auto mode interval to 5 minutes.

9. The monitor must operate for 1 hour with a fully charged battery. The monitor must

operate for at least 15 minutes before the monitor powers down due to the low battery

condition.

10. Verify that the low priority alarm occurs and the alarm message “System: Low

battery” is displayed about 15 minutes before battery fully discharges.

17

Page 24

11. Allow monitor to operate until it automatically powers down due to the low battery

condition. Verify that the high priority alarm occurs and the alarm message “System:

Critically low-battery condition” is displayed about 5 minutes before the monitor

automatically shuts down.

12. If the monitor passes this test, immediately recharge the battery. (paragraph “Battery

Charge”)

Power-On Self-Test (POST)

1. Connect the monitor to AC power source and verify that Battery charging indicator is

lit.

2. Observe the monitor’s LCD screen. With the monitor off, press Power on/off button.

The monitor must perform the following sequence.

a. The monitor progresses the checksum for the flash memory and displays the

bar while the checksum is proceeding.

b. After the checksum for flash memory is completed, the copyright screen

appears and all indicators are lit for a few seconds. The copyright screen

displays the company logo, the version of system and the current time.

c. Then the monitor performs the power-on self-test (POST).

d. Upon successful completion of power-on self-test (POST), the post pass tone

sounds and the monitor will be in normal monitoring screen.

Note: Power-on self-test (POST) including the checksum for the flash memory takes

approximately 13 seconds to complete.

Note: If an error condition occurs during the POST, the monitor will be display an error

message.

Note: During the POST, the integrity of all programming is checked first. If software testing

is successful, hardware tests are initiated. If all testing is successful, the monitor is

ready for use. If an error message is displayed during the POST, please refer to

Troubleshooting section.

18

Page 25

General Operation Tests

Alarms and Alarm Silence

1. Connect the monitor to an AC power source.

2. Press Power on/off button to turn on the monitor.

3. Connect the SpO

simulator to the SpO2 extension cable and connect the cable to the

2

monitor.

4. Set the SpO

simulator as follows: SpO2 of 75% and pulse rate of 60bpm.

2

5. Verify following the monitor reaction:

a. The pulse amplitude indicator begins to track artificial pulse signal from the

simulator.

SpO

2

b. After about 10 to 20 seconds, the monitor displays oxygen saturation and pulse

rate as specified by simulator. Verify values are within following tolerances:

z Tolerance of Oxygen Saturation : ±2 %

z Tolerance of Pulse Rate : ±3 bpm

c. Audible alarm sounds and “SpO

displayed and %SpO

numerical area will flash, indicating the parameter has

2

: Lower limit violated” message will be

2

violated default alarm limits. (High priority alarm)

6. Press Alarm silence button on the monitor’s front panel. Audible alarm will be

temporarily silenced.

7. Verify the following:

a. An audible alarm remains silenced.

b. Alarm silence icon appears in SpO

numerical area on the screen.

2

c. %SpO

d. Audible alarm returns in approximately 120 seconds.

HR/PR Tone Volume Control

1. Press Power on/off button to turn on the monitor.

2. Connect the SpO

monitor.

3. Set the SpO

4. Verify %SpO

5. Press Alarm silence button on front panel of the monitor to temporarily silence audible

alarm.

6. Select Setup icon to display Setup menu.

7. Select HR/PR tone Volume in Setup menu.

8. Set HR/PR tone volume level 1 to level 7 and return to the monitoring screen. Verify

beeping pulse rate tone increases.

9. Set HR/PR tone volume level 7 to level 1 and return to the monitoring screen. Verify

beeping pulse rate tone decreases.

display continues flashing.

2

simulator to SpO2 extension cable and connect the cable to the

2

simulator as follows: SpO2 of 75% and pulse rate of 60bpm.

2

and pulse rate values are correctly displayed.

2

19

Page 26

10. Set HR/PR tone volume to Off and return to the monitoring screen. Verify beeping

pulse rate tone is no longer audible.

11. Return HR/PR tone volume to a comfortable level.

Sensor LED Excitation Test

This procedure uses normal system components to test circuit operation. An SpO

DS-100A is used to examine LED intensity control. The red LED is used to verify intensity

modulation caused by the LED intensity control circuit.

1. Connect the monitor to an AC power source.

2. Press the Power on/off button to turn on the monitor.

3. Connect the SpO

4. Connect the SpO

extension cable to the monitor.

2

sensor to the SpO2 extension cable.

2

5. Leave the sensor open with the LEDs and photo detector visible.

6. After the monitor completes its normal power-up sequence, verify that the sensor LED

is brightly lit.

7. Slowly move sensor LED in proximity of photodetector element of the sensor (close the

sensor slowly). Verify; as LED approaches the optical sensor, that the LED intensity

decreases.

8. Open the sensor and notice that the LED intensity increases.

9. Repeat step 7 and intensity will again decrease. This variation is an indication that the

microprocessor is in proper control of LED intensity.

10. Press Power on/off button to turn off the monitor.

Restoring Power-On Default Settings

sensor,

2

The following test procedures will verify that alarms are activated at the level of factory

default alarm limits and that any changed settings are saved and in effect when the user

changes alarm limit settings and saves the current settings as a power default.

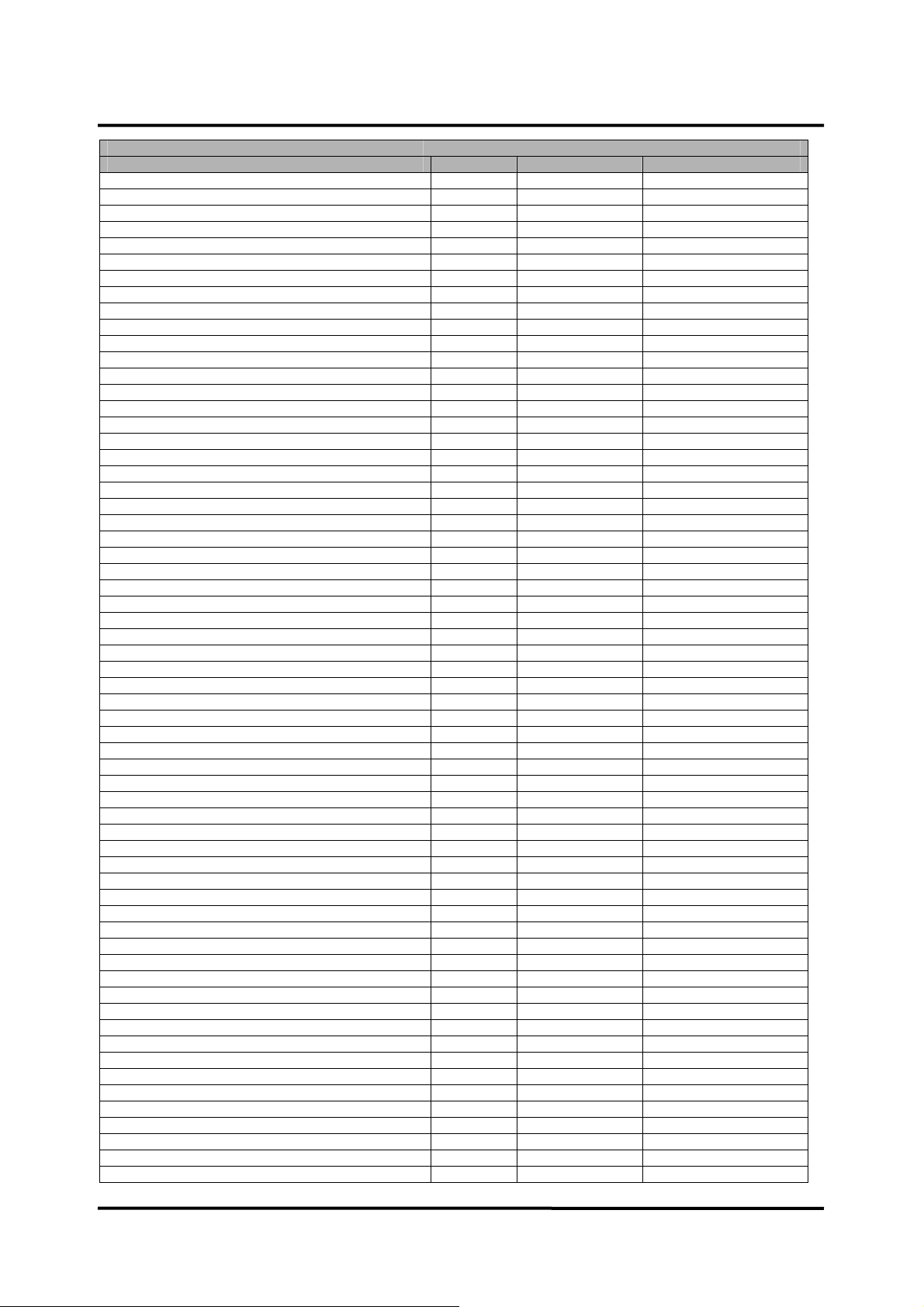

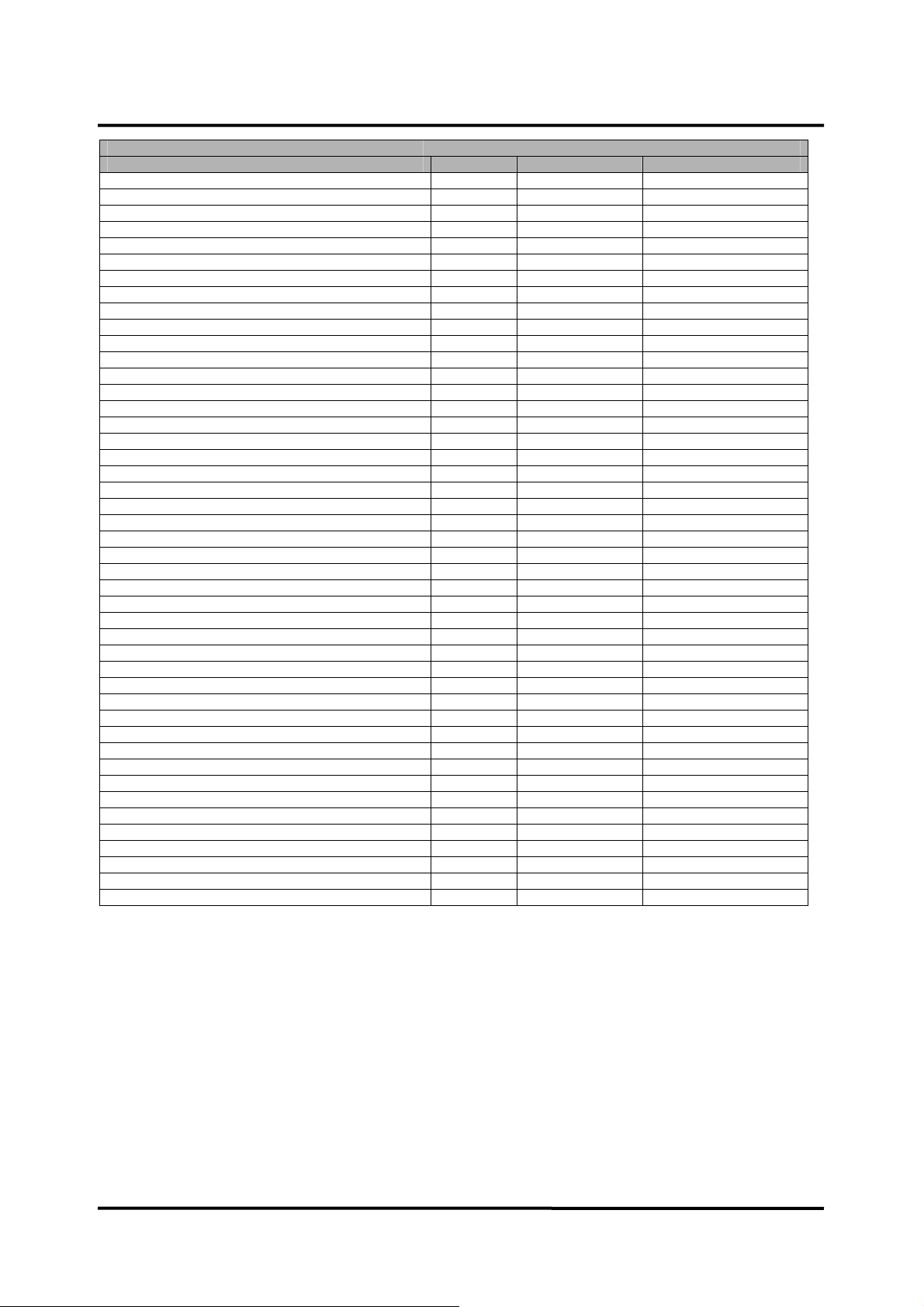

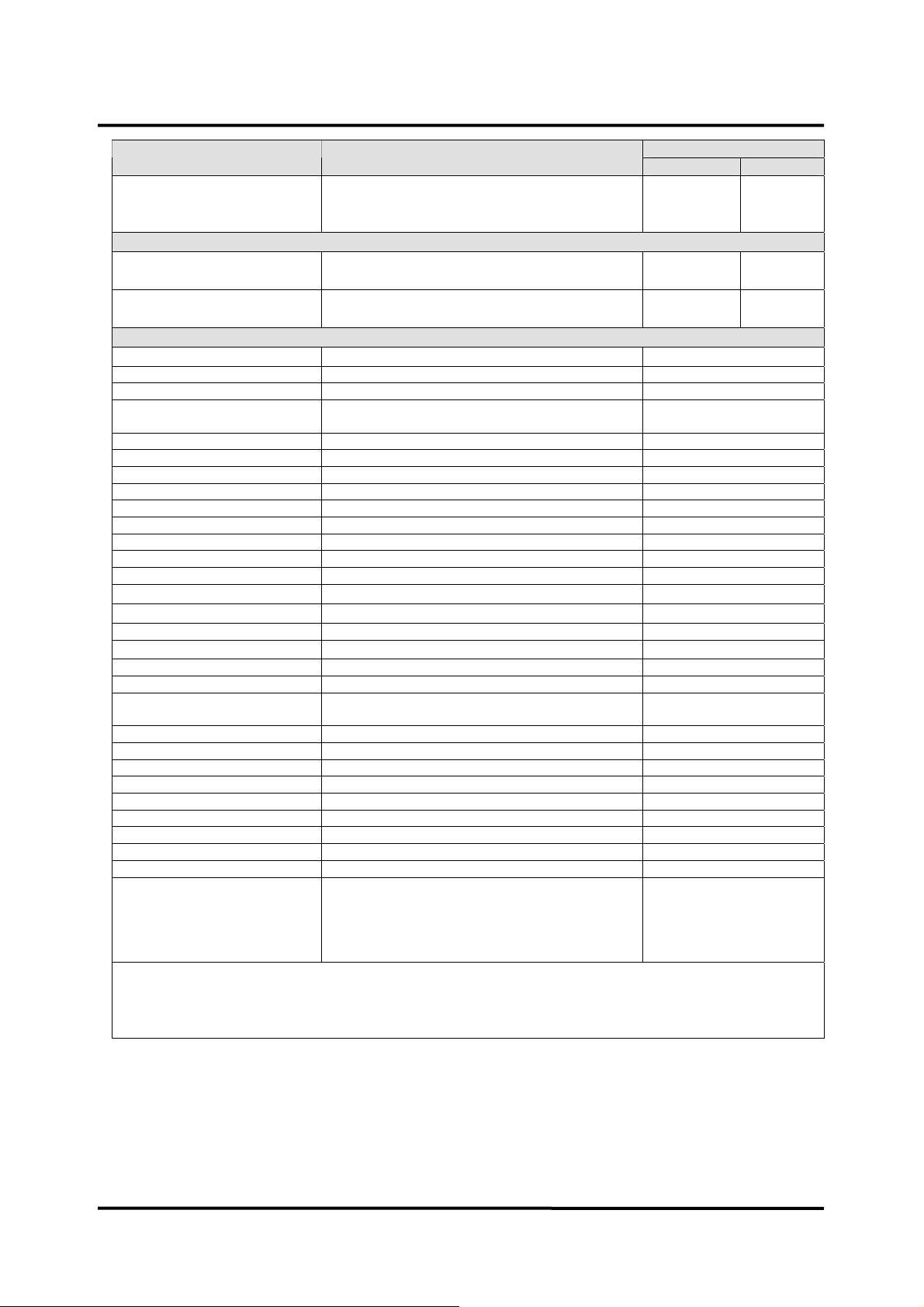

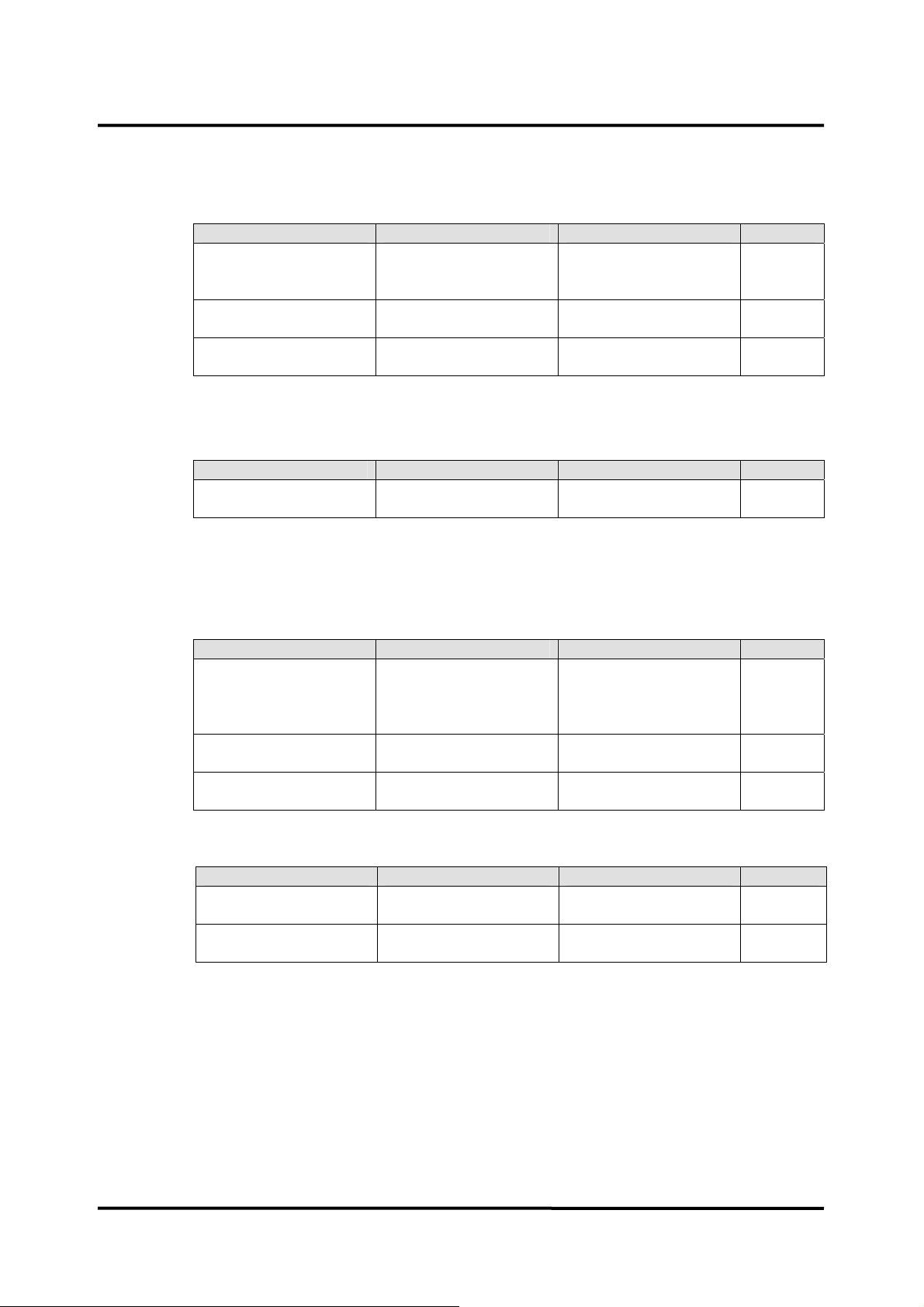

Table 2. Parameter Alarm Limit Factory Defaults

Factory Defaults Adult Neonatal

HR/PR Upper Alarm Limits 180 bpm (beats per minute) 200 bpm

HR/PR Lower Alarm Limits 40 bpm 50 bpm

NIBP SYS Upper Alarm Limits 200mmHg 130 mmHg

NIBP SYS Lower Alarm Limits 70 mmHg 50 mmHg

NIBP DIA Upper Alarm Limits 160 mmHg 100 mmHg

NIBP DIA Lower Alarm Limits 30 mmHg 10 mmHg

NIBP MAP Upper Alarm Limits 180 mmHg 110 mmHg

NIBP MAP Lower Alarm Limits 40 mmHg 20 mmHg

%SpO2 Upper Alarm Limits 100 % 100 %

%SpO2 Lower Alarm Limits 90 % 85 %

RESP Upper Alarm Limits 30 bpm (breaths per minute) 50 bpm

RESP Lower Alarm Limits 0 bpm 0 bpm

TEMP1, 2 Upper Alarm Limits 38.0°C (100.4°F) 39.0°C (102.2°F)

TEMP1, 2 Lower Alarm Limits 14.5°C (58.1°F) 14.5°C (58.1°F)

EtCO2 Upper Alarm Limits 80mmHg 80mmHg

EtCO2 Lower Alarm Limits 0mmHg 0mmHg

InCO2 Upper Alarm Limits 20mmHg 20mmHg

20

Page 27

Factory Defaults Adult Neonatal

InCO2 Lower Alarm Limits 0mmHg 0mmHg

IBP1 SYS Upper Alarm Limits 200 mmHg 130 mmHg

IBP1 SYS Lower Alarm Limits 70 mmHg 50 mmHg

IBP1 DIA Upper Alarm Limits 160 mmHg 100 mmHg

IBP1 DIA Lower Alarm Limits 30 mmHg 10 mmHg

IBP1 MEAN Upper Alarm Limits 180 mmHg 110 mmHg

IBP1 MEAN Lower Alarm Limits 40 mmHg 20 mmHg

IBP2 SYS Upper Alarm Limits 200 mmHg 130 mmHg

IBP2 SYS Lower Alarm Limits 70 mmHg 50 mmHg

IBP2 DIA Upper Alarm Limits 160 mmHg 100 mmHg

IBP2 DIA Lower Alarm Limits 30 mmHg 10mmHg

IBP2 MEAN Upper Alarm Limits 180 mmHg 110 mmHg

IBP2 MEAN Lower Alarm Limits 40 mmHg 20 mmHg

1. Turn on the monitor at the factory default settings.

2. Select Alarm limits icon to display Alarm limits menu.

3. Verify that alarm limits are set to as shown in Table 2.

4. Change Patient mode in the setup menu Adult to Neonatal, then verify that alarm limits

are set to as shown in Table 2.

5. Change alarm limit value via Alarm limits menu.

6. Save the changed alarm limit values as a power on default setting via Service menu

(see Service Menu and Factory Defaults section). Turn off the monitor.

7. Press Power on/off button to turn on the monitor.

8. Verify alarm limits are set to the changed alarm limit values.

Recorder Test (Option)

If Recorder option is installed in the monitor, the following test procedures will verify the

recorder performance.

1. Connect the monitor to an AC power source.

2. Press Power on/off button to turn on the monitor.

3. Connect all necessary simulators to the monitor.

4. Select Setup icon on the screen to display Setup menu.

5. Test #1: 20 sec printing

a. Set Wave record time to 20 sec via setup menu.

b. Press Record button when all the parameter signals display normally.

c. Verify that the parameter values and waveforms are printed out for 20

seconds.

6. Test #2: Continuous printing

a. Set Wave record time to Continuous via setup menu

b. Press Record button when all the parameter signals display normally.

c. Verify the parameter values and waveforms are printed out continuously.

d. Verify printing stops with pressing Record button again.

21

Page 28

7. Test #3: Record speed

a. Set Record speed to 25 mm/s.

b. Press Record button when all the parameter signals display normally.

c. Verify the parameter values and waveforms are printed out with 25 mm/s.

d. Set Record speed to 50 mm/s.

e. Press Record button when all the parameter signals display normally.

f. Verify that the parameter values and waveforms are printed out with 50 mm/s.

8. Test #4: Wave Record Select

a. Set Wave Record Select to ECG1+ECG2 via Setup menu.

b. Press Record button when all the parameter signals display normally.

c. Verify the two ECG waveforms are printed out.

d. Repeat this test for other selections.

9. Test #5: Record on Alarm

a. Set Record on Alarm to ON via Setup menu.

10. Test#6: Auto List Record

Note: If no recorder is installed in the monitor, the record setup menus will be grayed out

Note: If there is no recorder paper left or recorder paper places improperly, the monitor

Serial Interface Test

Perform the following procedure to test the serial port. The serial connector DSub-15,

located on the monitor’s right panel, identified with the data interface symbol (RS-232).

1. Turn on the monitor, and select the service menu via the setup menu.

2. Enter the service code, 6, 1, 6, in order.

b. Set Heart rate of ECG simulator to 30 bpm.

c. Verify “HR: Lower limit violated” alarm is activated and the parameter

values and waveforms are printed out.

a. Set Auto list record to ON via Setup menu.

b. Set Save time interval to 0.5 minutes via Tabular trend menu.

c. Verify that the monitor automatically prints out the data after stored 8 data in

the trend memory.

in Setup menu.

will display an informative message.

22

3. Connect the serial interface cable between the monitor and PC COM1 port.

4. Run “BP-S510_Comm_Test.exe” on PC.

5. Click Serial on the left side of dialog box for the serial interface test.

Page 29

6. Click Connect, then verify that log message “RS232C [Com1] Connected” appears on

the PC.

7. Click Send, then verify the followings:

- The monitor displays three dashes (-) with the beep sound.

- The log message “RS232 Test OK!!!” appears on the PC.

8. Click Disconnect to stop the serial interface test.

23

Page 30

Network Test

Perform the following procedure to test the Network. The Network connector is located on

the monitor’s right panel, identified with the Network symbol.

Prior to the network test, configure the network setting on PC with the followings.

- IP address 192.168.124.1.

- Gateway 192.168. 124. 254.

- Subnet Mask 255.255.255.0.

When completed the network setting on the PC properly, follow the below test procedure.

1. Turn on the monitor, and select the service menu via the setup menu.

2. Enter the service code, 6, 1, 6, in order.

3. Connect a network line to the monitor. (Do not connect PC to the monitor directly)

4. Run “BP-S510_Comm_Test.exe” on PC.

5. Click TCP/IP on the left side of the dialog box for the network test.

6. Click Connect, then verify that log message “TCP/IP [192.168.124.2] Connected”

appears on the PC.

24

Page 31

7. Click Send, then verify the followings:

- The monitor displays three dashes (-) with the beep sound.

- The log message “TCP/IP Test OK!!!” appears on the PC.

8. Click Disconnect to stop the network test.

USB Interface Test

Perform the following procedure to test the USB port. The USB connector is located on

the monitor’s right panel, identified with the USB interface symbol.

1. Copy the file named “BP-S510_USB_Test.muf” to USB memory’s root directory.

2. Connect the USB memory to the monitor,

3. Turn on the monitor, and select the service menu via the setup menu.

4. Enter the service code, 6, 1, 6, in order..

5. After a few seconds, verify that the monitor displays “OK” with the beep sound.

Note: Do not change the file name, “BP-S510_USB_Test.muf” for the USB connection test.

Note: For a detailed explanation to access the service menu, refer to Service Menu and

Factory Default Settings section.

25

Page 32

Measurement Parameter Operation Tests

ECG Operation

1. Press Power on/off button to turn on the monitor.

2. Connect the ECG 3 lead wires to appropriate jacks on the ECG simulator.

3. Connect lead wires to the ECG cable.

4. Connect ECG cable to the ECG connector on the monitor’s left panel.

5. Set the ECG simulator as follows:

z Heart rate: 30 bpm

z Amplitude: 1 millivolt

z Lead select: II

z Normal sinus rhythm

z Adult mode

6. After normal power-up sequence, verify that the following monitor reactions:

a. After about 15 seconds, the monitor displays a heart rate of 30 ± 3 bpm.

b. Verify that audible alarm sounds and that “HR: Lower limit violated” message

displays on the message area.

c. Verify that the HR/PR numerical area flashes and that the heart rate is below

default lower alarm limit (high priority alarm).

7. Increase the heart rate setting on the ECG simulator to 240 bpm.

a. After about 15 seconds, verify that the monitor displays heart rate of 240 ± 3

bpm.

b. Verify that audible alarm sounds and that “HR: Upper limit violated” message

displays

c. Verify that the HR/PR numerical area flashes and that the heart rate is above

default upper alarm limit (high priority alarm).

8. Decrease the heart rate setting on the ECG simulator to 120 bpm.

a. After about 15 seconds, verify the monitor displays heart rate of 120 ± 3 bpm.

9. Disconnect the LL lead from the ECG simulator.

a. Verify that the “ECG: Check ECG leads & electrodes” message appears, that

three dashes are displayed in the HR/PR numerical area, and that medium

priority alarm sounds.

b. Reconnect the LL lead to the ECG simulator. Verify that “ECG: Check ECG

leads & electrodes” message no longer appears and that the audible alarm is

stopped.

c. Repeat this test for the LA and the RA leads.

26

10. Connect all the leads to the monitor.

a. Select ECG waveform menu and set Lead select to Lead I.

b. Verify that the lead selection is displayed on the ECG waveform area.

c. Repeat step 10-a for all the ECG Lead selections.

11. Set ECG Lead selection to Lead II.

12. Change ECG waveform size to all the selectable sizes and verify that an appropriate

size is displayed on the ECG waveform area.

Page 33

13. Set the ECG cable select to Auto via ECG waveform menu.

14. Verify that Lead Select in ECG waveform menu displays I, II, III.

15. Disconnect 3 ECG leads and connect 5 ECG leads.

16. Verify that Lead Select in ECG waveform menu displays I, II, III. aV

R, aVL, aVF, V

(Chest Lead).

17. Repeat step 9 to 12.

18. Turn off the monitor.

Note: The accuracy of the monitor ECG measurements is ±3 bpm. In the procedure, add

the tolerance of the simulator to the acceptable range of readings.

27

Page 34

NIBP Operation

The monitor must be placed in the service menu. For a detailed explanation to access the

service menu, refer to Service Menu and Factory Default Settings section.

1. Rotate the jog dial to select NIBP Test in the service menu, and then press the jog

dial.

Note: Inflation Speed Test, Initial Deflation Test (I), Initial Deflation Test (II), Deflation

Speed Test and Offset Test are intended for factory use only.

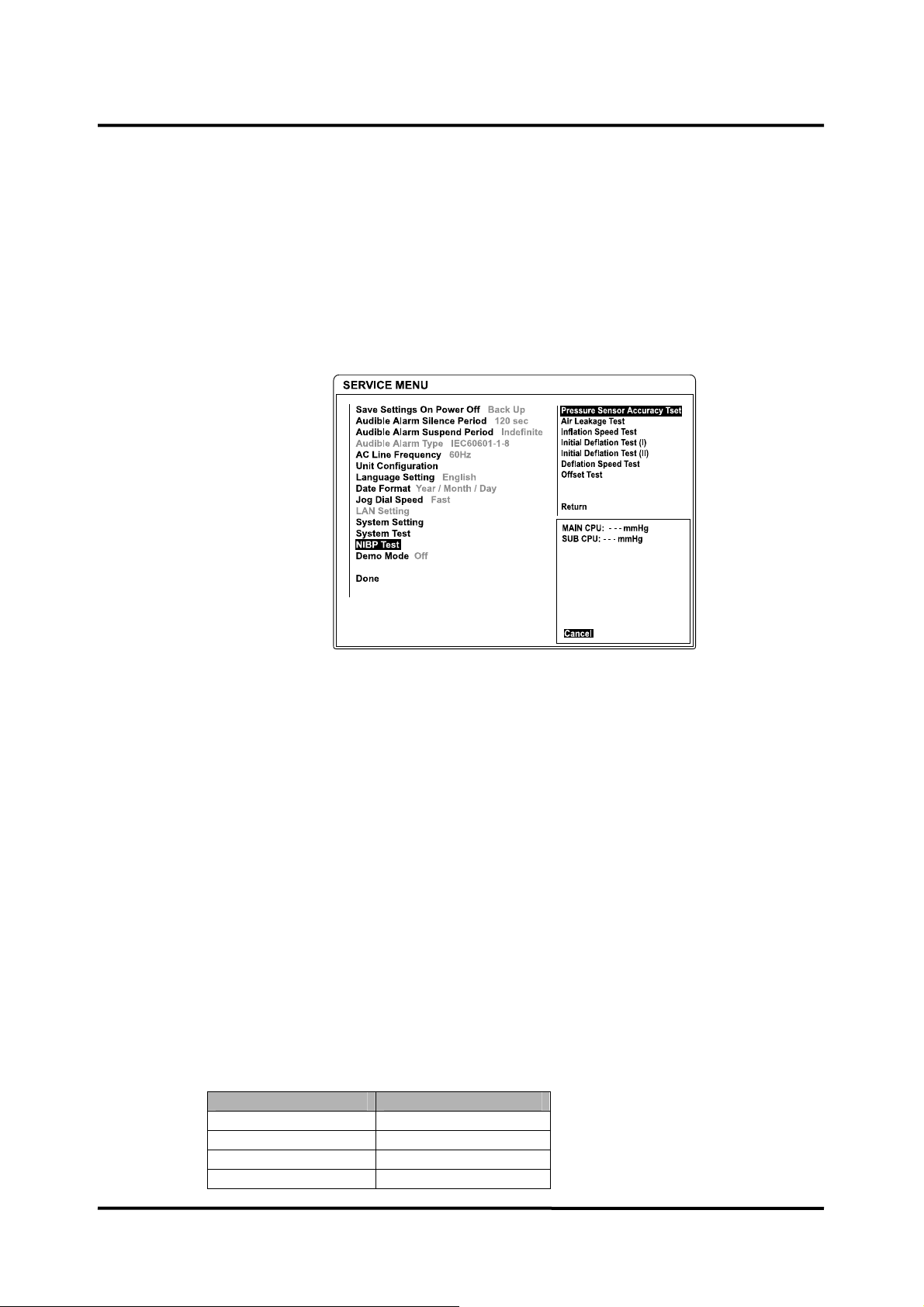

Pressure Sensor Accuracy Test

Figure 10. Pressure Sensor Accuracy Test

1. Connect the NIBP cuff hose to the NIBP connector on the monitor’s left panel.

2. Connect the other end of the NIBP cuff hose to the Y tube via the cuff joint.

3. Connect the sphygmomanometer and the Inflation bulb to the Y tube.

4. Select Pressure Sensor Accuracy Test, and then press the jog dial.

5. Raise the pressure of the sphygmomanometer to 0, 50, 100 and 200 mmHg by

pumping the inflation bulb and compare the pressure of the sphygmomanometer with

the pressure displayed by the monitor.

If air leakage disables accurate comparison of the above pressures, eliminate the

cause of air leakage.

6. After finishing the test, press the jog dial to select Cancel. The menu box will

disappear. If Cancel is selected during the test progressing, the test will stop and the

menu box will disappear.

Pass/Fail Results

The difference between the sphygmomanometer’s and the monitor’s readings are as

follows:

Sphygmomanometer Monitor’s Readings

0 mmHg ±0 mmHg

50 mmHg 50±6 mmHg

100 mmHg 100±6 mmHg

200 mmHg 200±6 mmHg

28

Page 35

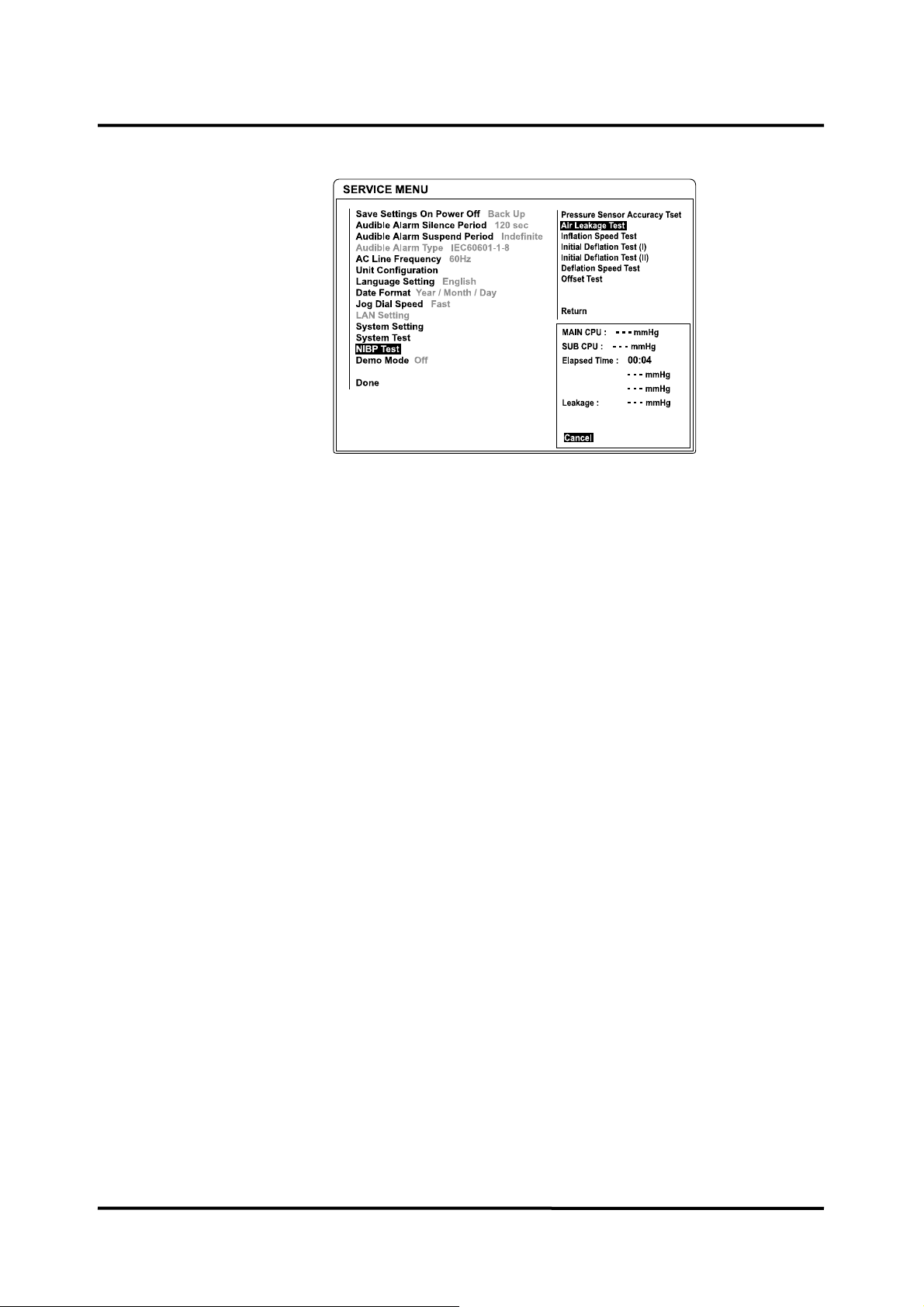

Air Leakage Test

Figure 11. Air Leakage Test

1. Place the adult cuff with a rigid PVC vessel (5 cm diameter).

2. Connect the cuff to the NIBP connector on the monitor’s left panel via NIBP cuff hose.

3. Select Air Leakage Test, and then press the jog dial.

4. The result will be displayed in four minutes.

5. After finishing the test, press the jog dial to select Cancel. The menu box will

disappear. If Cancel is selected during the test progressing, the test will stop and the

menu box will disappear.

Pass/Fail Results

It passes if the leak value is less than 12mmHg/3minutes.

29

Page 36

Pulse Oximetry Operation

1. Connect the monitor to an AC power source.

2. Turn on the monitor by pressing the Power on/off button.

3. Connect the SpO

extension cable to SpO2 connector on the monitor’s left panel after

2

the monitor completes POST.

4. Connect the SpO

simulator to the other end of the SpO2 extension cable.

2

5. The monitor will:

- be in SpO

- display an SpO

alarm

2

of 75 (Test pass criteria is 73 to 77 % SpO2)

2

- display a pulse rate of 60 (Test pass criteria is 57 to 63 bpm)

- display low level modulation

6. Test #1: SpO

a. Press the % SpO

2

selection button on the SpO

2

RATE 90 LED will light:

b. The monitor will display three dashes until the the SpO

stabilizes at 90 %SpO

c. The monitor will display: - 90 % SpO

. The test pass criteria is 88 to 92 % SpO2.

2

2

- 60 bpm

- no alarm

7. Test #2: Pulse rate (bpm)

a. Press the PULSE RATE selection button on the SpO

PULSE RATE 200 LED will light:

b. The monitor will increase to 200 bpm. The test pass criteria is 197 to 203

bpm.

simulator. The PULSE

2

simulator

2

simulator. The

2

c. The monitor will display:

- 90 % SpO

2

- 200 bpm

- alarm: “PR (SpO

HR/PR area will flash, indicating pulse rate is above default upper alarm

limit (High priority alarm).

d. Press the SRC-MAX PULSE RATE selection button on the SpO

simulator. The PULSE RATE 60 LED will light.

e. The monitor will decrease to 60 and stabilize at 60 bpm. The test pass

criteria is 57 to 63 bpm.

f. The monitor will display:

- 90 % SpO

2

- 60 bpm

- no alarm

- low level modulation

8. Test #3: Modulation Level

a. Press the %MODULATION selection button on the SpO

The %MODULATION LED will light.

b. The monitor’s waveform area will spike and stabilizes at a higher

modulation level.

): Upper limit violated” message will display and the

2

simulator.

2

2

30

Page 37

Respiration Operation

1. Press Power on/off button to turn on the monitor.

2. Connect ECG lead wires to an appropriate jack on the respiration simulator.

3. Connect ECG lead wires to the ECG cable.

4. Connect the ECG cable to the ECG connector on the monitor’s left panel.

5. Set the respiration simulator to 120 breaths per minute.

6. After the normal power-up sequence, verify the following reactions:

a. The monitor displays respiration rate of 120 ±3 breaths per minute.

b. Audible alarm will sound, “Resp: Upper limit violated” message will display

c. he monitor will display:

- 90 % SpO

2

- 60 bpm

- no alarm

d. Disconnect all equipments and turn off the monitor.

and the Respiration numerical area will flash, indicating a respiration rate is

above default upper alarm limits. (high priority alarm)

7. Decrease the respiration rate setting on the respiration simulator to 20 breaths per

minute.

a. Verify that the monitor displays the respiration rate of 20 ±3 breaths per minute.

Note: The accuracy of Respiration measurements is ±3 breaths per minute. In the

procedure below, add the tolerance of the simulator to the acceptable range of

readings.

Temperature Operation

1. Press Power on/off button to turn on the monitor.

2. Connect the temperature probe (supplied with the temperature simulator) to an

appropriate jack on the temperature simulator.

3. Connect the temperature probe to the temperature connector on the monitor’s left panel.

4. Set the temperature simulator as follows:

z Temperature: 37°C (98.0°F)

z Probe type: YSI-400 series Temperature Probes (Probe accuracy: ±0.1°C)

5. After the normal power-up sequence, verify that the temperature reads 37°C ±0.1°C

(98.6°F ±0.2°F if Fahrenheit is selected for the temperature unit).

6. Turn off the monitor.

Note: The accuracy of temperature measurements is ±0.1°C (±0.2°F) in the range of

25°C to 45°C and ±0.2°C in the range of 15° C to less than 25° C. In the procedure

above, add the tolerance of the simulator and the probe to the acceptable range of

readings.

31

Page 38

IBP Operation

1. Connect the monitor to an AC power source.

2. Turn on the monitor by pressing the Power on/off button.

3. Connect the IBP test cable to the IBP simulator, then turn on the IBP simulator.

4. Press 6, zero button on the IBP simulator, then press enter button on the IBP

simulator.

5. Connect the other end of IBP test cables to IBP channel 1 and 2 connectors on the

monitor’s left panel after completed the POST.

6. The monitor will display IBP waveform’s baseline on the screen.

7. Select IBP waveform menu or IBP menu, then set Pressure Zero Setting, to Yes to

perform the zero calibration.

8. If zero calibration is successful, the monitor will display the value “0” on the IBP

numerical area.

9. Press the 5, wavef button on the IBP simulator, then press enter button on the IBP

simulator.

10. The monitor will:

‐ display IBP waveform on the screen.

‐ display systolic, mean, diastolic measurement values on the IBP numerical area.

Note: Initial values of IBP simulator are systolic 120mmHg, diastolic 80mmHg at channel

1, systolic 120mmHg, diastolic 0mmHg at channel 2.

32

Page 39

CO2 Operation

2. Connect the monitor to an AC power source. Turn on the monitor.

3. Rotate the jog dial to highlight CO

the CO

menu.

2

numerical area and then press the jog dial to display

2

4. Verifying that Capno Measurement is set to On in CO

5. Test #1: Display Accuracy

a. Connect the 10% calibration gas cylinder with the valve to the sampling tube

connected to the water trap of the monitor.

b. After passed the warm up time (about 3 minutes), repeat 3 or 4 times turning

on and off the valve of the gas cylinder with the interval of 1 to 2 seconds.

c. Verifying that the monitor displays 76mmHg ± 2mmHg in CO

6. Test #2: Flow Rate

a. Connect the flow meter to the sampling tube connected to the monitor.

b. Connect a sampling tube to the other side of the flow meter and make the

other side of the sampling tube open.

c. Verify that the flow rate is between 150 ± 2mmHg.

7. Test #3: Water Trap

a. Check that the module does not indicate a "Water trap full" message when a

clean water trap is installed. If this is correct, remove the water bottle and

block the path between the water trap LED and detector.

b. Verify that a "water trap full" message appears.

menu.

2

numerical area.

2

8. Test #4: Occlusion

a. Block the sample input. The module should enter the "occlusion" state. Verify

that it does correctly enter this occlusion state.

b. Unblock the input. Verify that after the modules occlusion sequence of high

flow rates and valve actuations the occlusion message disappears and the

module restores normal function.

33

Page 40

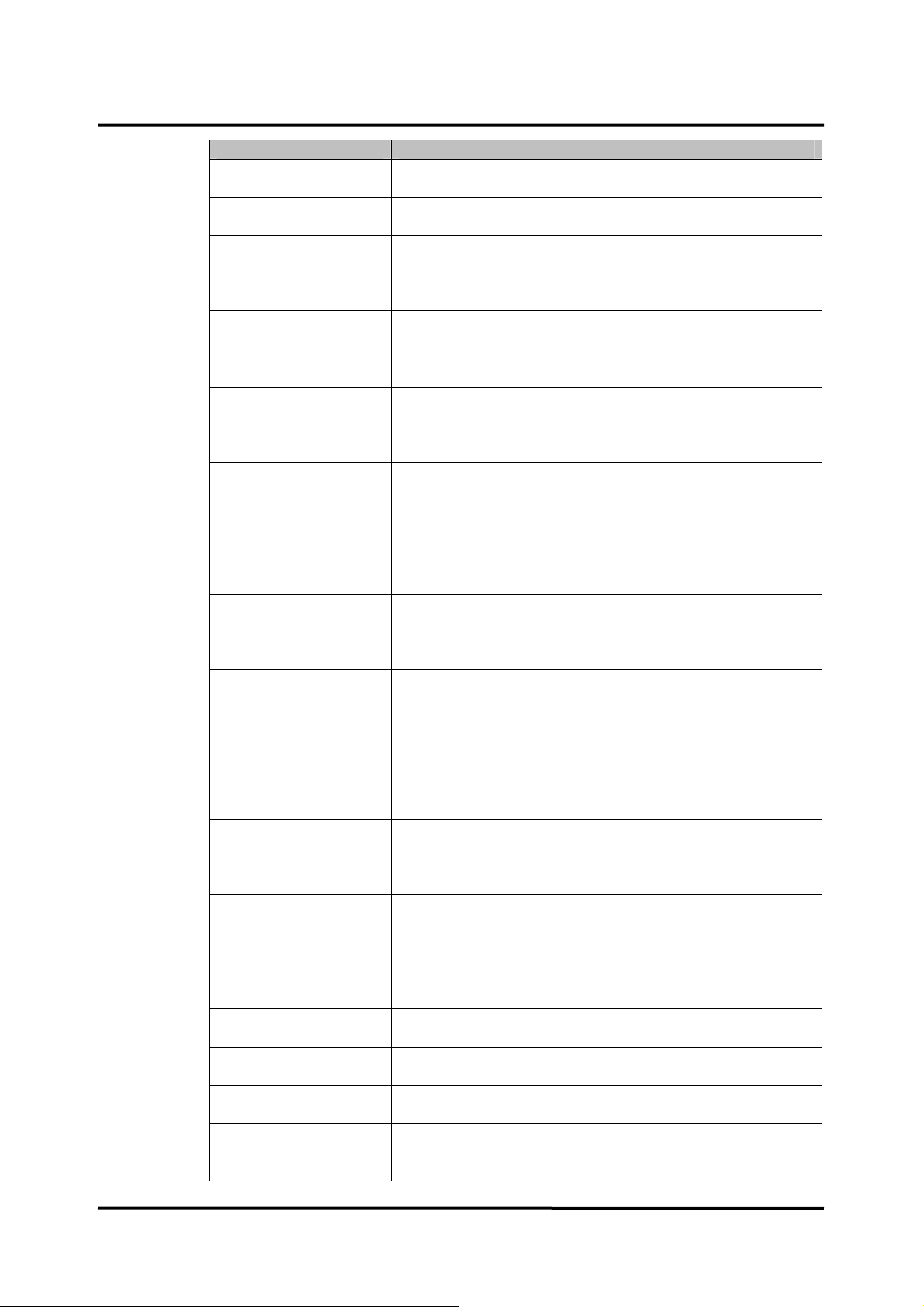

Safety Tests

The monitor safety tests meet the standards of, and are performed in accordance with,

IEC 60601-1, Clause 19 (Second Edition, 1988; Amendment 1, 1991-11, Amendment 2,

1995-03), EN60601-1 for instruments classified as Class I and Type CF.

Protective Earth Continuity

This test checks the integrity of the power cord ground wire from the AC plug to the

instrument chassis ground. The current used for this test is less than or equal to 4 Volts

RMS, 50 to 60 Hz, and 25 Amperes.

1. Connect the monitor AC mains plug to the analyzer recommended by the analyzer

operating instructions.

2. Connect the analyzer resistance input lead to the equipotential terminal (ground lug) on

the rear of the instrument. Verify that the analyzer indicates 100 milliohms or less.

Electrical Leakage

Earth Leakage Current

This test is in compliance with IEC60601-1 earth leakage current. The applied voltage for

IEC60601-1 the voltage is 264 Volts AC, 50 to 60 Hz. All measurements shall be made

with the power switch in both “On” and “Off” positions.

1. Connect the monitor AC plug to the electrical safety analyzer as recommended by the

analyzer operating instructions.

2. Perform the test as recommended by analyzer operating instructions.

Normal Condition (NC) 500

SFC Open Supply (SFC OS) 1000

Normal Condition RM (NCRM) 500

SFC Open Supply RM (SFC OSRM) 1000

SFC: Single Fault Condition / RM: Reverse Mains/Lines Voltage

Note: Earth leakage current is measured under various conditions of the AC mains and

protective earth conductor. For each condition, the measured leakage current must

not exceed that indicated in Table 3.

Enclosure Leakage Current

This test is in compliance with IEC60601-1 enclosure leakage current. This test is for

ungrounded enclosure current, measured between enclosure parts and earth. The applied

voltage for IEC60601-1 the applied voltage is 264 Volts AC at 50 to 60 Hz.

1. Connect the monitor AC plug to the electrical safety analyzer as recommended by the

analyzer operating instructions.

2. Place a 200cm

contact with any metal parts of the enclosure that may be grounded.

Table 3. Earth Leakage Current Values