Page 1

Cobra 350 ePLC Robot

Quick Setup Guide

I592-E-01

Page 2

Copyright Notice

The information contained herein is the property of Omron Adept Technologies, Inc., and shall

not be reproduced in whole or in part without prior written approval of Omron Adept Technologies, Inc. The information herein is subject to change without notice and should not be construed as a commitment by Omron Adept Technologies, Inc. This manual is periodically

reviewed and revised.

Omron Adept Technologies, Inc., assumes no responsibility for any errors or omissions in this

document. Critical evaluation of this manual by the user is welcomed. Your comments assist

us in preparation of future documentation. Please email your comments to: techpubs@adept.com.

Copyright© 2013, 2016 by Omron Adept Technologies, Inc. All rights reserved.

Any trademarks from other companies used in this publication

are the property of those respective companies.

Printed in the United States of America

Cobra ePLC350 Quick Setup Guide, 13590-000 Rev D

Page 2 of 14

Page 3

Chapter 1: Cobra ePLC350 Robot Quick Setup

1.1 Introduction

Process Overview

This Quick Setup Guide steps you through the installation and start-up of your Cobra ePLC350

robot. The major steps are:

l

Preparation, including workcell layout and safety

l

Hardware Installation, including mounting the robot and system cable connections

l

System Start-Up, including system configuration and turning on the robot

NOTE:This guide does not apply to robot systems that include a SmartController

motion controller. Refer to the Cobra s350 Robot User's Guide for those systems.

During this process, refer also to your PLC user’s guide. The Cobra 350 Robot User's Guide is

available on the support disk.

Resources on the Support Disk

l

This guide

Resources on Omron Web Sites

On the Omron Industrial Automation web site:

On the Omron Adept web site:

1.2 Safety

l

The Cobra 350 Robot User's Guide

ia.omron.com

l

The ePLCConnect 3 Software User's Guide

l

EtherNet/IP Connection Guide (P649-E1-01)

This covers ePLC for the Omron NJ controller with Omron Adept Robots.

l

EtherNet/IP Connection Guide (P650-E1-01)

This covers ePLCIO for the Omron NJ controller with Omron Adept robots.

adept.com

l

Legacy systems communication structure pdfs

l

Legacy systems code examples

WARNING:We strictly prohibit installation or operation of

our robots without adequate safeguards according to applicable local and national standards. See Typical Workcell Layout on page 4 for a simple workcell layout.

Cobra ePLC350 Quick Setup Guide, 13590-000 Rev D

Page 3 of 14

Page 4

You must read the Robot Installation and Operation chapters in the Cobra 350 Robot User's

DC

IN

24V

GND

AC

200 240V

Ø

1

XBELTIO

XIO

Servo

ENETENET

XSYSTEM

Front Panel

T20 Pendant -

Optional

PC running

PLC Programming

Software

Safety Barrier

Restricted Area

Inside Safety

Barrier

200-240 VAC

Cobra

ePLC350 Robot

24 VDC

XUSR

eMB-40R Amplifier

Programmable

Logic

Controller (PLC)

User-Supplied

Components

STOP

R

Guide for information on safe operation of your robot system, and the Robot Safety Guide.

Refer to Installing User-Supplied Safety Equipment in the System Installation chapter of the

Cobra 350 Robot User's Guide, which provides details on connecting a user-designed E-Stop system to the XUSR connector on the robot.

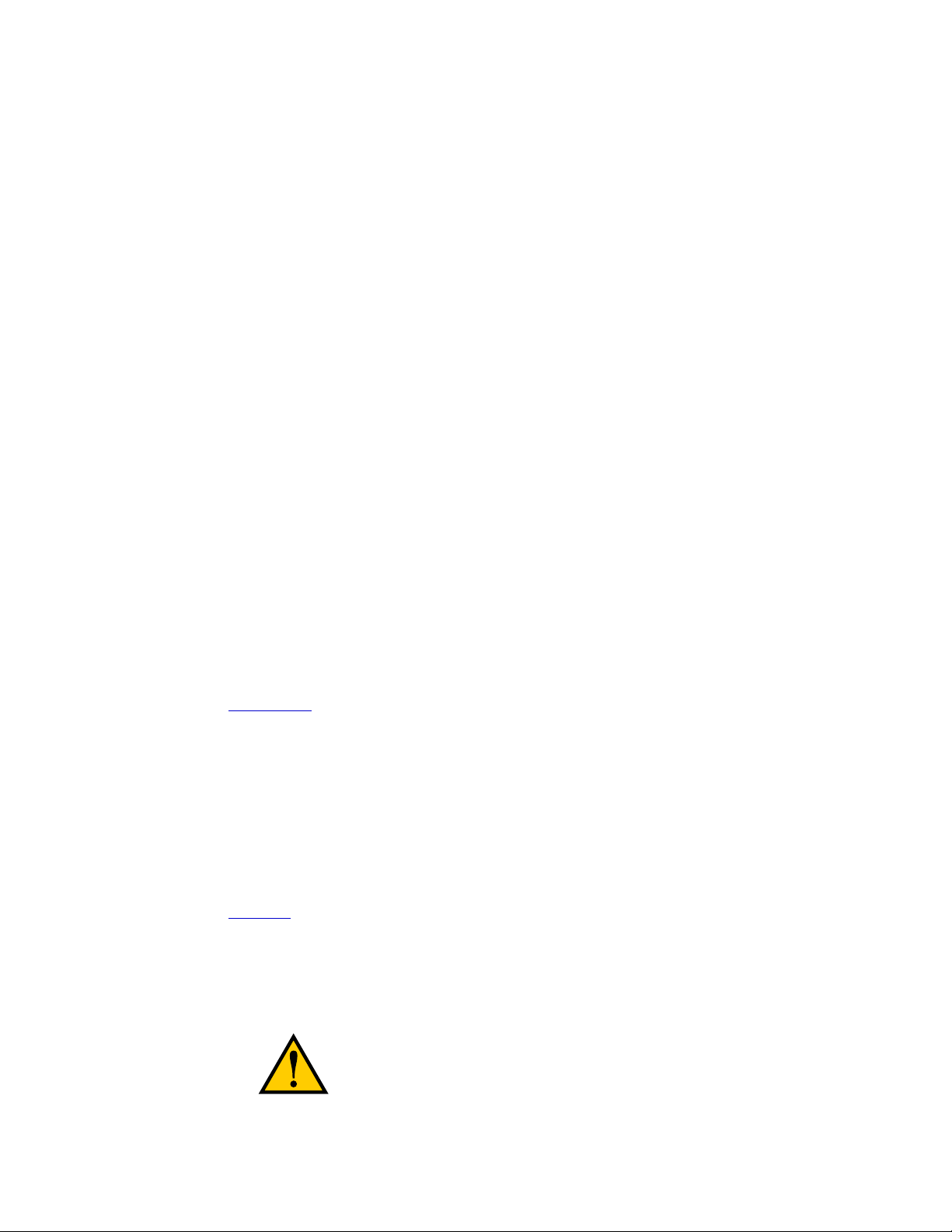

1.3 Workcell Layout

The following figure shows a simple workcell layout with a user-supplied safety barrier and

E-Stops provided by the Front Panel and optional T20 pendant.

1.3 Workcell Layout

Figure 1-1. Typical Workcell Layout

Cobra ePLC350 Quick Setup Guide, 13590-000 Rev D

Page 4 of 14

Page 5

Chapter 1: Cobra ePLC350 Robot Quick Setup

Bolts

Pallet

Bolts

Turn until it comes

into contact with

the mechanical end.

Worker B

Worker A

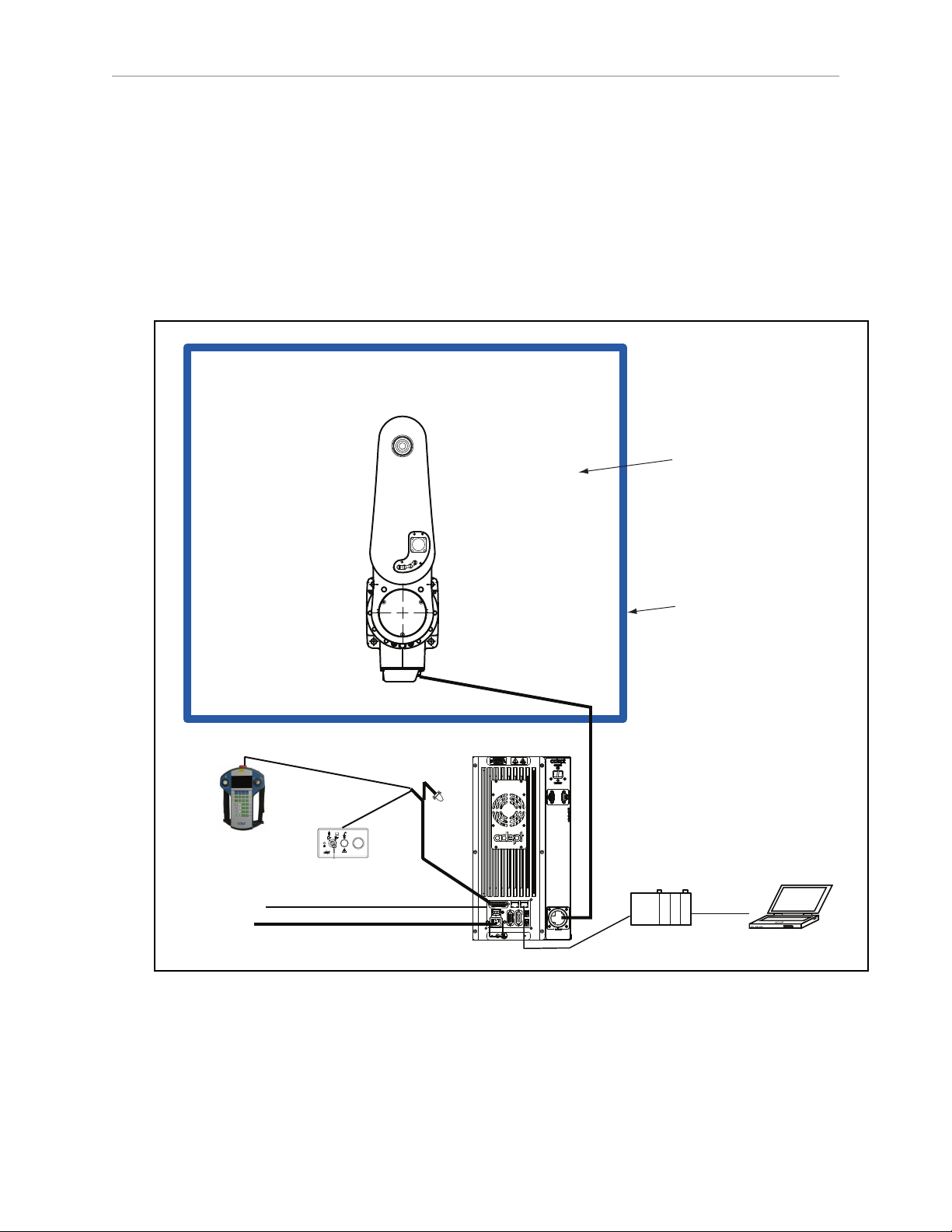

1.4 Installing the Robot

Rotate the robot outer arm before removing the shipping bolts from the pallet. This will help

prevent the robot from tipping over. Use two people to lift the robot. See the following figure.

Figure 1-2. Rotate Outer Arm, Remove Bolts, then Lift the Robot

Mounting the Robot

Mount the robot to a rigid surface that will prevent vibration and flexing during operation. We

recommend a 25 mm (1 in.) thick steel plate, mounted to a rigid steel tube frame. See the following figure for the mounting hole dimensions.

Cobra ePLC350 Quick Setup Guide, 13590-000 Rev D

Page 5 of 14

Page 6

1.4 Installing the Robot

120

120

7

17

R 1500

R 1500

144

(291 for Cabling)

4x Ø 12 Thru

2x Ø 6 H7

+0.012

0

134 ± 0.005

Units are mm

2nd axis (J2)

1st axis (J1)

3rd axis (J3)

4th axis (J4)

(-)

(+)

(+)

(+)

(+)

(-)

(-)

(-)

Figure 1-3. Mounting Hole Dimensions

Figure 1-4. Robot Movements

Cobra ePLC350 Quick Setup Guide, 13590-000 Rev D

Page 6 of 14

Page 7

Chapter 1: Cobra ePLC350 Robot Quick Setup

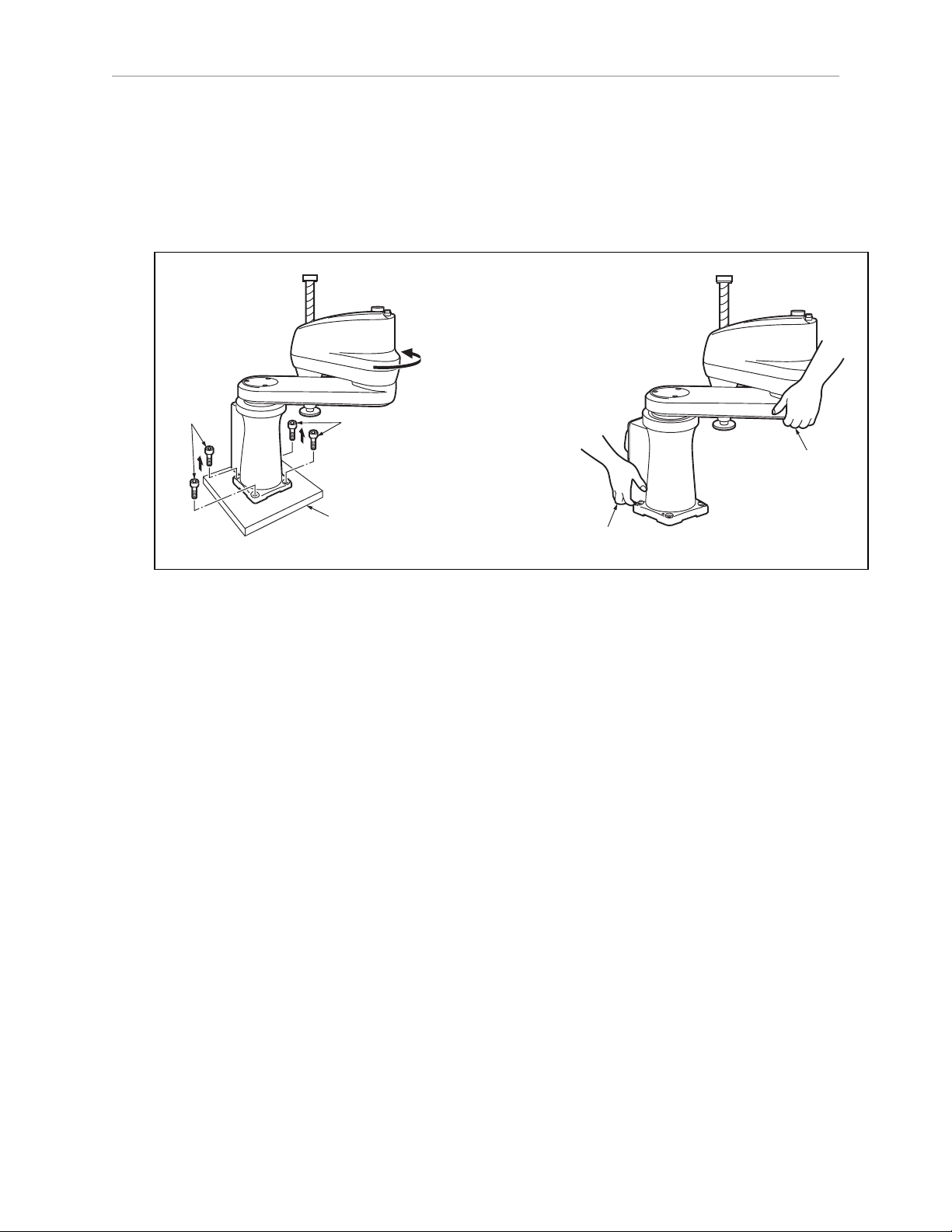

1.5 System Cable Connections

Open the Accessory box and locate the eAIB XSYSTEM cable. Connect the cables and peripherals as shown in the following figure. Parts and steps are covered in the following two

tables. Refer to the System Installation chapter in the Cobra 350 User’s Guide for AC specifications and wiring instructions.

Part Cable and Parts List Part # Part of: Notes

A eAIB XSYSTEM Cable Assembly 13323-000 standard, eMB-40R

B User E-Stop, Safety Gate n/a n/a user-supplied

C XUSR Jumper Plug 04736-000 13323-000 standard, eMB-40R

D Front Panel 90356-10358 standard

E Front Panel Cable 10356-10500 90356-

10358

F Front Panel Jumper Plug 10053-000 13323-000 standard, eMB-40R

G XMCP Jumper Plug 04737-000 13323-000 standard, eMB-40R

H T20 Bypass Plug 10048-000 10055-000 standard, T20

J T20 Adapter Cable 10051-003 10055-000 standard, T20

K T20 Pendant (option) 10055-000 option

L AC Power Cable (option) 04118-000 90565-010 user-supplied

M 24 VDC Power Cable (option) 04120-000 90565-010 user-supplied

N 24 VDC, 6 A Power Supply

(option)

P Ethernet Cable - PC -> PLC

(Only while programming PLC)

Q Ethernet Cable - PLC -> switch n/a n/a user-supplied

R Ethernet Cable - switch ->

SmartVisionMX

S Ethernet switch, cable n/a n/a user-supplied

04536-000 90565-010 user-supplied

n/a n/a user-supplied

n/a n/a user-supplied

standard

T Camera and cable n/a n/a option

Power Requirements

The power requirements for the SmartVision MX and the Cobra robot are covered in their

respective user guides. For 24 VDC, both can be powered by the same power supply.

NOTE:The resistance of all ground conductors must be ≤ 10 Ω.

Cobra ePLC350 Quick Setup Guide, 13590-000 Rev D

Page 7 of 14

Page 8

1.5 System Cable Connections

Step Connection Part

1 Connect eAIB XSYSTEM cable to XSYSTEM on eMB-40R. A

2 Connect a user E-Stop or Muted Safety Gate to the eAIB XSYSTEM cable XUSR

B

connector or

2a verify XUSR jumper plug is installed in eAIB XSYSTEM cable XUSR connector. C

3 Connect Front Panel cable to Front Panel and eAIB XSYSTEM cable XFP con-

D, E

nector or

3a if no Front Panel, install FP jumper on eAIB XSYSTEM cable XFP connector.

F

See NOTE after table.

4 Connect T20 adapter cable to eAIB XSYSTEM cable XMCP connector or J, K

4a if no T20, install XMCP jumper or T20 Adapter Cable with T20 bypass plug. G or

H

5 Connect user-supplied ground to robot. See robot user's guide for location. n/a

5a Connect user-supplied ground to SmartVision MX, if used. See SmartVision

n/a

MX user's guide for location.

6 Connect 200-240 VAC to AC input on eMB-40R Interface Panel; secure with

L

clamp.

7 Connect 24 VDC to DC input on Interface Panel. N,

M

7a Connect 24 VDC to SmartVision MX, if used. N,

M

8 Connect Ethernet cable from PC to PLC. P

9 Connect Ethernet cable from PLC to switch. S

9a Connect Ethernet cable from switch to eMB-40R. Q, S

9b Connect Ethernet cable from SmartVision MX, if used, to switch. R, S

10 Connect optional camera and cable to SmartVision MX, if used. T

NOTE:A front panel ships with each Cobra ePLC system, but you can choose not

to use it if you replace its functionality with equivalent circuits. That is beyond the

scope of this guide.

Cobra ePLC350 Quick Setup Guide, 13590-000 Rev D

Page 8 of 14

Page 9

Chapter 1: Cobra ePLC350 Robot Quick Setup

DC

IN

24 V

GND

AC

200 -

240 V

Ø

1

XBELTIO

XIO

Servo

ENETENET

XSYSTEM

eMB-40R for

Cobra ePLC350

Robot

24 VDC, 6 A

Power Supply

200-240 VAC

10 A

single-phase

AC Power

Cable

DC Power

Cable

Front Panel

Cable

Front Panel

User-Supplied PC

running PLC

Programming Software

T20 Adapter

Cable

XMCP Jumper Plug

XMCP

XFP

XUSR

XUSR Jumper Plug

eAIB

XSYSTEM

Cable

Robot Interface

Panel

XUSR for:

- User E-Stop/Safety Gate

- Muted Safety Gate

The Jumper Plug is required if

neither of these is used

Ethernet from

PC to PLC

T20 Bypass Plug

User-Supplied

Ground Wire

T20 Pendant (option)

Either T20 Pendant,T20 Bypass Plug, or

XMCP Jumper Plug must be used

2

3

4a

A

B

G

H

J

4a

4

4

1

5

6

7

9

8

L

M

Q

P

E

K

D

N

3

85 - 264 VAC

Universal

Input

Ethernet from

PLC to eMB-40R

FP Jumper Plug

F

Either Front Panel or

FP plug must be used

3a

2a

C

Ethernet from eMB-40R

to SmartVision MX

R

9b

9a

User-supplied

Switch

SmartVision MX (option)

Camera

(option)

User-Supplied

Ground Wire

5a

7a

M

T

10

DC Power

Cable

S

PLC

DC

IN

24V

GND

AC

200 240V

Ø

1

XBELTIO

XIO

Servo

ENETENET

XSYSTEM

1.6 Configuration

The user-supplied PLC and the Cobra ePLC350 robot are connected either through a shared

network or via a user-supplied Ethernet cable.

When the Cobra ePLC350 robot is powered on and waiting for a PLC connection, the eMB-40R

status panel will display its IP address, two digits at a time.

The format will be:

IP xxx-xxx-xxx-xxx OK

Figure 1-5. Configuration with Vision

Cobra ePLC350 Quick Setup Guide, 13590-000 Rev D

Page 9 of 14

Page 10

1.6 Configuration

NOTE:If you can use the eMB-40R’s default IP address, then you can skip the ACE

software installation completely.

Installing ACE Software

ACE is used to change the IP address of the robot and for troubleshooting. You install the ACE

software onto your PC from the ACE disk.

NOTE:You will have to restart the PC after installing ACE software.

Setting the Robot IP Address

Configure the IP address of the Cobra ePLC350 robot using ACE software.

1.

Connect the PC and the eMB-40R, either through a shared network or with an Ethernet

cable between them.

2.

Start the ACE software.

3.

Click the Detect and Configure button, circled in the following figure.

Figure 1-6. Detect and Configure Button

The IP address detection and configuration window will open. The ACE software will show

the IP address of any controllers it detects. See the following figure.

Cobra ePLC350 Quick Setup Guide, 13590-000 Rev D

Page 10 of 14

Page 11

Chapter 1: Cobra ePLC350 Robot Quick Setup

Figure 1-7. IP Addresses Detected

4.

You can change the IP address and subnet mask in the Desired Address and Desired

Subnet fields, if needed.

5.

Click OK. The ACE software will ask you to wait for the controller to reboot.

Configuring the Omron PLC

Refer to the EtherNet/IP Connection Guide (P649-E1-01) for configuring the Omron PLC to

work with Omron Adept robots. Refer to Resources on Omron Web Sites on page 3.

Using your PLC software, set the IP address for the PLC to connect to on the robot.

Enabling High Power

The details of enabling high power to the robot are covered in the EtherNet/IP Connection

Guide (P649-E1-01).

Once high power is enabled, the Robot Status Panel displays ON, and the Robot Status LED is

green, with a fast blink.

1.7 Finding Additional Information

Installing Optional Equipment

For details on installing optional equipment, see the following topics in the Optional Equipment Installation chapter of the Cobra 350 Robot User’s Guide:

l

Installing end-effectors

l

Connecting user air and electrical lines to user connection panel

l

Mounting external equipment on the robot

l

Mounting the robot solenoid option kit

Cobra ePLC350 Quick Setup Guide, 13590-000 Rev D

Page 11 of 14

Page 12

1.7 Finding Additional Information

NOTE:For dimensions and specifications, see Technical Specifications in the Cobra

350 Robot User’s Guide.

System Operation

For details on system operation, see the following topics in the System Operation chapter of the

Cobra 350 Robot User’s Guide:

l

Robot Status LED Indicator

l

Status panel fault codes

l

Brake Release button (located above the diagnostic panel). To move Joint 3 manually,

press the Brake Release button.

l

Connecting digital I/O on the XIO connector at the robot interface panel

l

Connecting a user-designed E-Stop System

Cobra ePLC350 Quick Setup Guide, 13590-000 Rev D

Page 12 of 14

Page 13

Page 14

OMRON Corporation Industrial Automation Company

Kyoto, JAPAN

Regional Headquarters

OMRON EUROPE B.V.

Wegalaan 67-69, 2132 JD Hoofddorp

The Netherlands

Tel: (31)2356-81-300/Fax: (31)2356-81-388

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08 (Lobby 2),

Alexandra Technopark,

Singapore 119967

Tel: (65) 6835-3011/Fax: (65) 6835-2711

Contact: www.ia.omron.com

OMRON ELECTRONICS LLC

2895 Greenspoint Parkway, Suite 200 Hoffman Estates,

IL 60169 U.S.A.

Tel: (1) 847-843-7900/Fax: (1) 847-843-7787

OMRON ADEPT TECHNOLOGIES, INC.

4550 Norris Canyon Road, Suite 150, San Ramon, CA 94583 U.S.A.

Tel: (1) 925-245-3400/Fax: (1) 925-960-0590

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower, 200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120, China

Tel: (86) 21-5037-2222/Fax: (86) 21-5037-2200

Authorized Distributor:

© OMRON Corporation 2016 All Rights Reserved.

In the interest of product improvement,

specifications are subject to change without notice.

Cat. No. I592-E-01

Printed in USA

0416

Loading...

Loading...