Page 1

Programmable Multi-Axis Controller

Startup Guide

for DirectPWM Interface

CK3W-AX1313

CK3W-AX2323

O047-E1-01

Page 2

NOTE

• All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

• No patent liability is assumed with respect to the use of the information contained herein.

Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained

in this manual is subject to change without notice.

• Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions.

Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Trademarks

• Microsoft, Windows, Windows Vista, Excel, and Visual Basic are either registered trademarks or trademarks of

Microsoft Corporation in the United States and other countries.

• EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

Other company names and product names in this document are the trademarks or registered trademarks of their

respective companies.

Copyrights

• Microsoft product screen shots reprinted with permission from Microsoft Corporation.

• This product incorporates certain third party software. The license and copyright information associated with this

software is available at http://www.fa.omron.co.jp/nj_info_e/.

Page 3

Sections in this Manual

1

2

3

Summary of Materials

Target Equipment and Device Configuration

DirectPWM Interface Connection Procedure

1

2

3

Sections in this Manual

CK3M-series Startup Guide DirectPWM Interface (O047)

3

Page 4

CONTENTS

CONTENTS

Sections in this Manual ........................................................................................... 3

Related Manuals....................................................................................................... 5

Revision History

....................................................................................................... 6

Terms and Definitions.............................................................................................. 7

Precautions .............................................................................................................. 8

Section 1 Summary of Materials

1-1 Summary of Materials............................................................................................................1-2

1-1-1 Intended Audience

......................................................................................................................1-2

Section 2 Target Equipment and Device Configuration

2-1 Device Configuration.............................................................................................................2-2

Section 3 DirectPWM Interface Connection Procedure

3-1 Work Flow...............................................................................................................................3-2

3-2 Controller Setting Preparations

3-2-1 Creation of a New Project ...........................................................................................................3-3

3-2-2 Controller Initial Setting ...............................................................................................................3-4

3-3 Various Equipment Connection............................................................................................3-6

3-4 Various Controller Settings...................................................................................................3-8

3-4-1 Notes List ..................................................................................................................................3-13

3-5 Confirmation of Settings ..................................................................................................... 3-17

3-6 Motor Tuning ........................................................................................................................3-19

3-6-1 Open Loop Test.........................................................................................................................3-19

3-6-2 Current Loop Gain Setting ........................................................................................................3-20

3-6-3 Bandwidth Automatic Setting ....................................................................................................3-21

3-6-4 Manual Setting of Bandwidth ....................................................................................................3-23

3-6-5 Feed-Forward Value Setting......................................................................................................3-25

3-6-6 Checking of Operation and Creation of Tuning Parameter Project...........................................3-27

............................................................................................3-3

4

CK3M-series Startup Guide DirectPWM Interface (O047)

Page 5

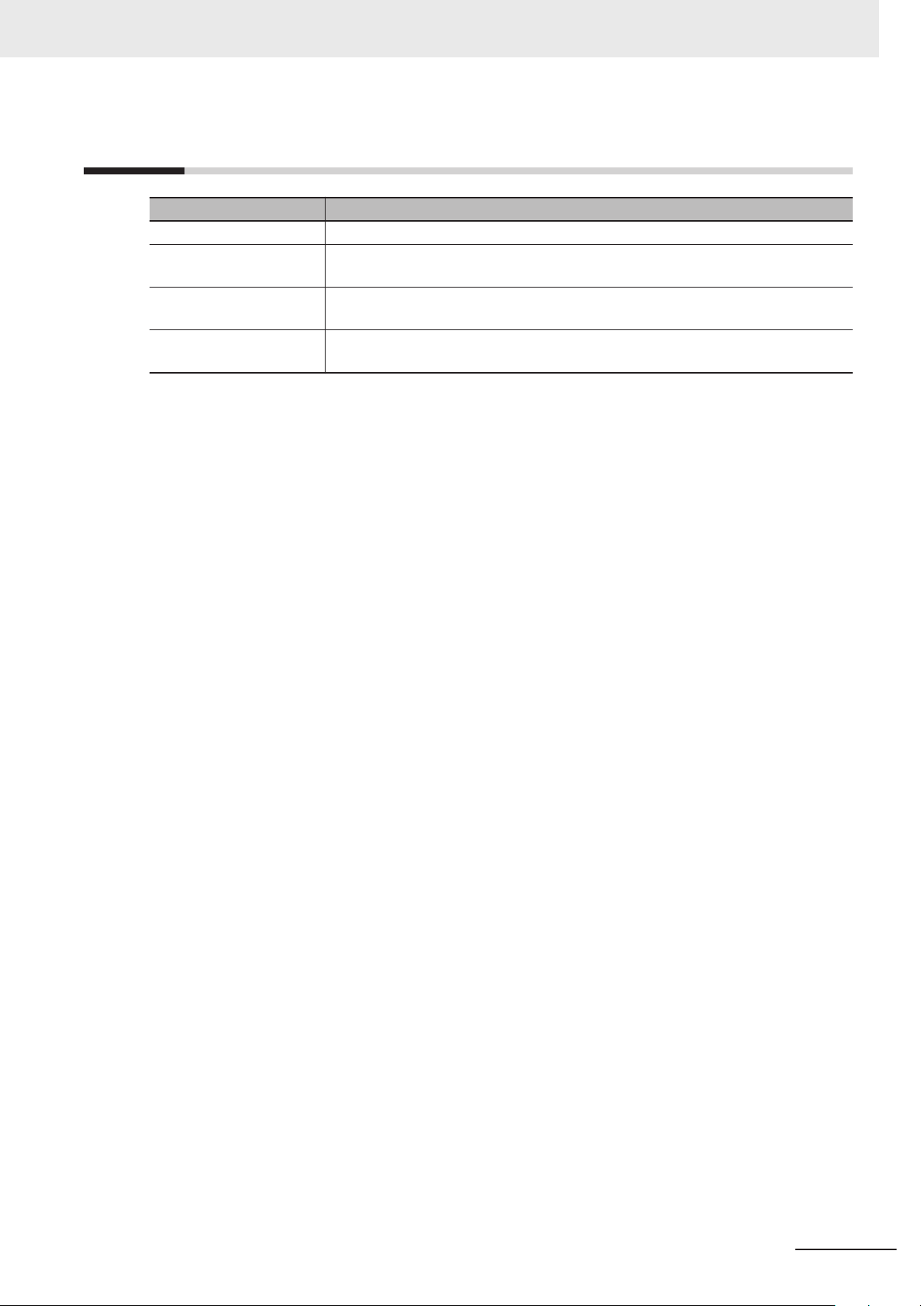

Related Manuals

To safely utilize the system, obtain a manual or user's guide for each device and piece of equipment,

confirm their content, including “Safety Precautions”, “Precautions for Safe Use”, and other precautions related to safety, and then proceed with use.

The manuals for OMRON Corporation (hereafter, “OMRON”) and Delta Tau Data Systems Inc. (hereafter “DT”) are as shown below.

Related Manuals

Manufac-

turer

OMRON O036

DT O014 --- Power PMAC User's Manual

DT O015 --- Power PMAC Software Reference Manual

DT O016 --- Power PMAC IDE User's Manual

Cat. No. Model Manual Name

CK3M-£

-

CK3W

£

Programmable Multi-Axis Controller Hardware User's Manual

CK3M-series Startup Guide DirectPWM Interface (O047)

5

Page 6

O047-E1-01

Revision code

Revision History

Revision History

A manual revision code appears as a suffix to the catalog number on the front and back covers.

Revision

code

01 July 2019 Original production

Revision date Revised content

6

CK3M-series Startup Guide DirectPWM Interface (O047)

Page 7

Terms and Definitions

Terms Descriptions and Definitions

PMAC This is the acronym for Programmable Multi-Axis Controller.

Power PMAC IDE This is computer software that is used to configure the Motion Controller, create

user programs, and perform monitoring.

DirectPWM This is a proprietary interface method developed by Delta Tau Data Systems, Inc.

for connecting Servo Drives.

Digital Quadrature Encod-erThis is a type of encoder that outputs pulse signals.

Terms and Definitions

CK3M-series Startup Guide DirectPWM Interface (O047)

7

Page 8

Precautions

Precautions

• For actual system construction, check the specifications for each device and piece of equipment that

makes up the system, use a method with sufficient margin for ratings and performance, and adopt

safety circuits and other safety measures to minimize risks even if a breakdown occurs.

• To safely utilize the system, obtain a manual or user's guide for each device and piece of equipment

that makes up the system, confirm and understand their content, including “Safety Precautions”,

“Precautions for Safe Use”, and other precautions related to safety, and then proceed with use.

• The customer must check all regulations, laws, and rules that are applicable to the system themselves.

• Copying, duplication, or redistribution of part or all of these materials without the permission of OMRON Corporation is prohibited.

• The content listed in these materials is valid as of July 2019.

The content listed in these materials may be changed without notice for purposes of improvement.

The marks used in these materials are defined as follows.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure correct operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding and make operation easier.

8

CK3M-series Startup Guide DirectPWM Interface (O047)

Page 9

Summary of Materials

This section lists a summary of these materials.

1

1

1-1 Summary of Materials

1-1-1 Intended Audience.......................................................................................... 1-2

.................................................................................... 1-2

CK3M-series Startup Guide DirectPWM Interface (O047)

1-1

Page 10

1 Summary of Materials

1-1

1-1-1

Summary of Materials

This document summarizes the procedures and confirmation methods for connecting a Servo Drive

that is compatible with the DirectPWM interface method to the OMRON Programmable Multi-Axis Controller CK3M-££££ (hereinafter called “Controller”).

By understanding the setting content and setting procedure points described in Section 3 DirectPWM

Interface Connection Procedure on page 3-1, you can configure the Controller to send commands

to the DirectPWM interface-capable Servo Drive and control Servomotors.

The connection procedure in this document describes an example when a digital quadrature encoder

is used to perform position and velocity feedback for CK3W-AX1313£.

*1.

If CK3W-AX2323£ is used, the same DirectPWM interface as CK3W-AX1313£

setting needs to be changed because a different type of encoder needs to be connected. Refer to the following documents for encoder settings.

• Startup Guide Sinusoidal Encoder

• Startup Guide for SSI/Mitutoyo/EnDat 2.1/2.2 Serial Encoder

Intended Audience

This guide is intended for the following personnel, who must also have knowledge of electrical systems (electrical or the equivalent).

• Personnel in charge of introducing F

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and maintaining FA systems.

• Personnel in charge of managing FA systems and facilities.

A systems.

*1

is available but the encoder

Also, this guide is intended for personnel who understand the contents described in the DT manual.

1-2

CK3M-series Startup Guide DirectPWM Interface (O047)

Page 11

2

Target Equipment and Device

Configuration

This section lists the target equipment and system configurations for connections in

these materials.

2-1 Device Configuration

..................................................................................... 2-2

2

CK3M-series Startup Guide DirectPWM Interface (O047)

2-1

Page 12

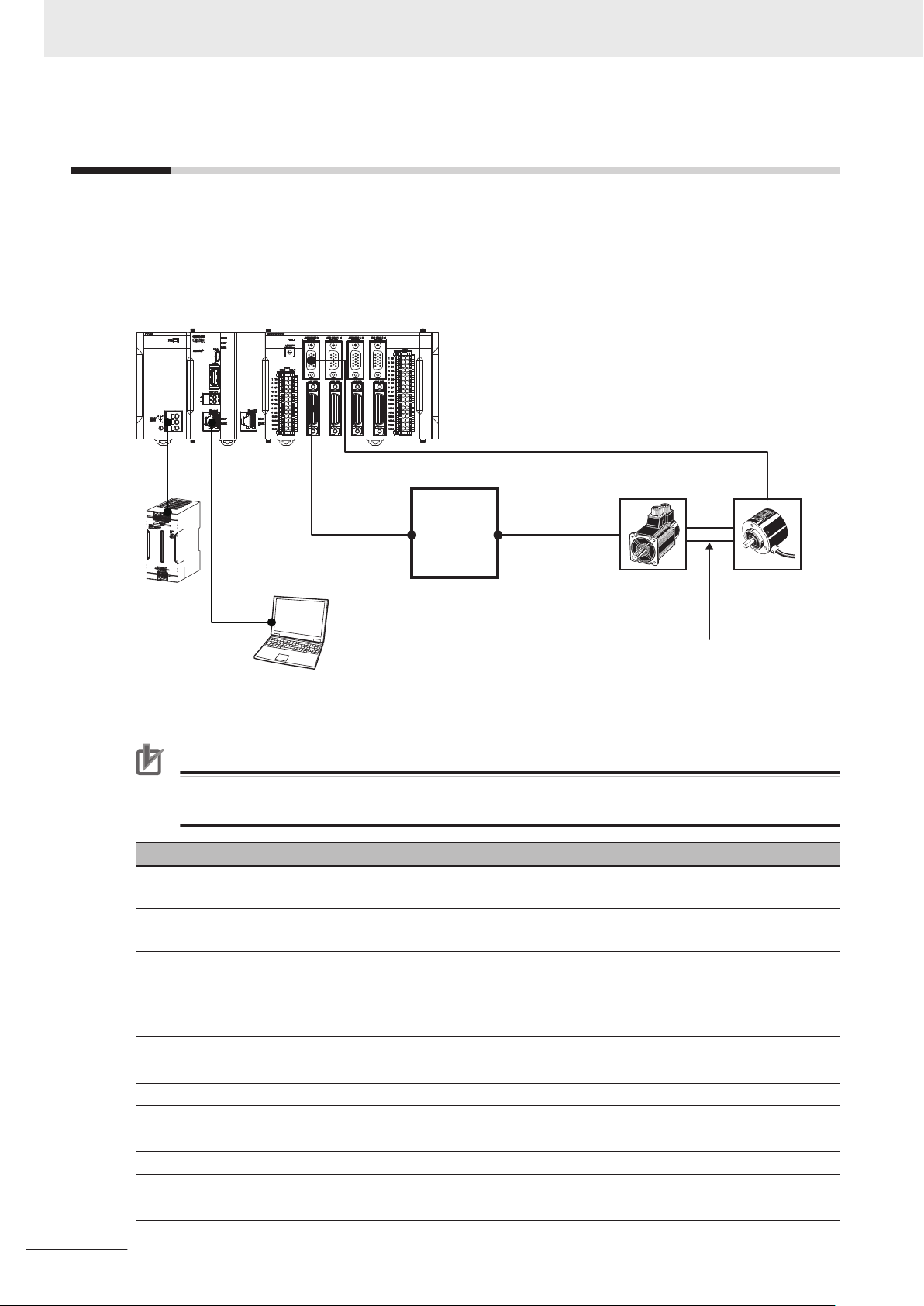

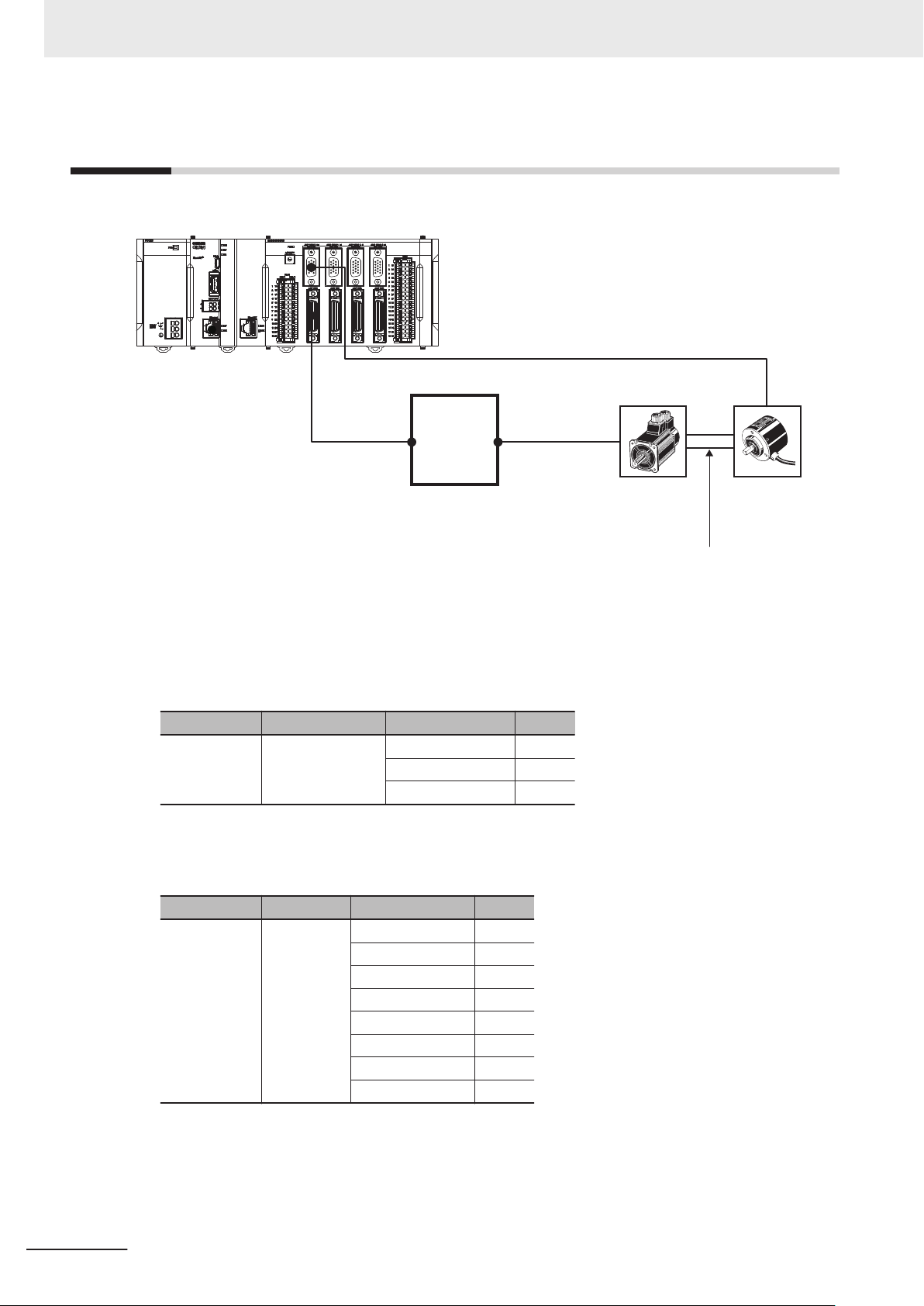

Programmable Multi-Axis Controller

CK3M-CPU1£1

CK3W-AX1313£

CK3W-PD048

CK3W-TER11

CK3W-CAED03A

CK3W-CAAD0££A

R88ACAKA0££S

Servo Drive

Servomotor

Coupling

Digital

Quadrature

Encoder

S8VK-£

Ethernet

cable

Windows PC

Power PMAC IDE

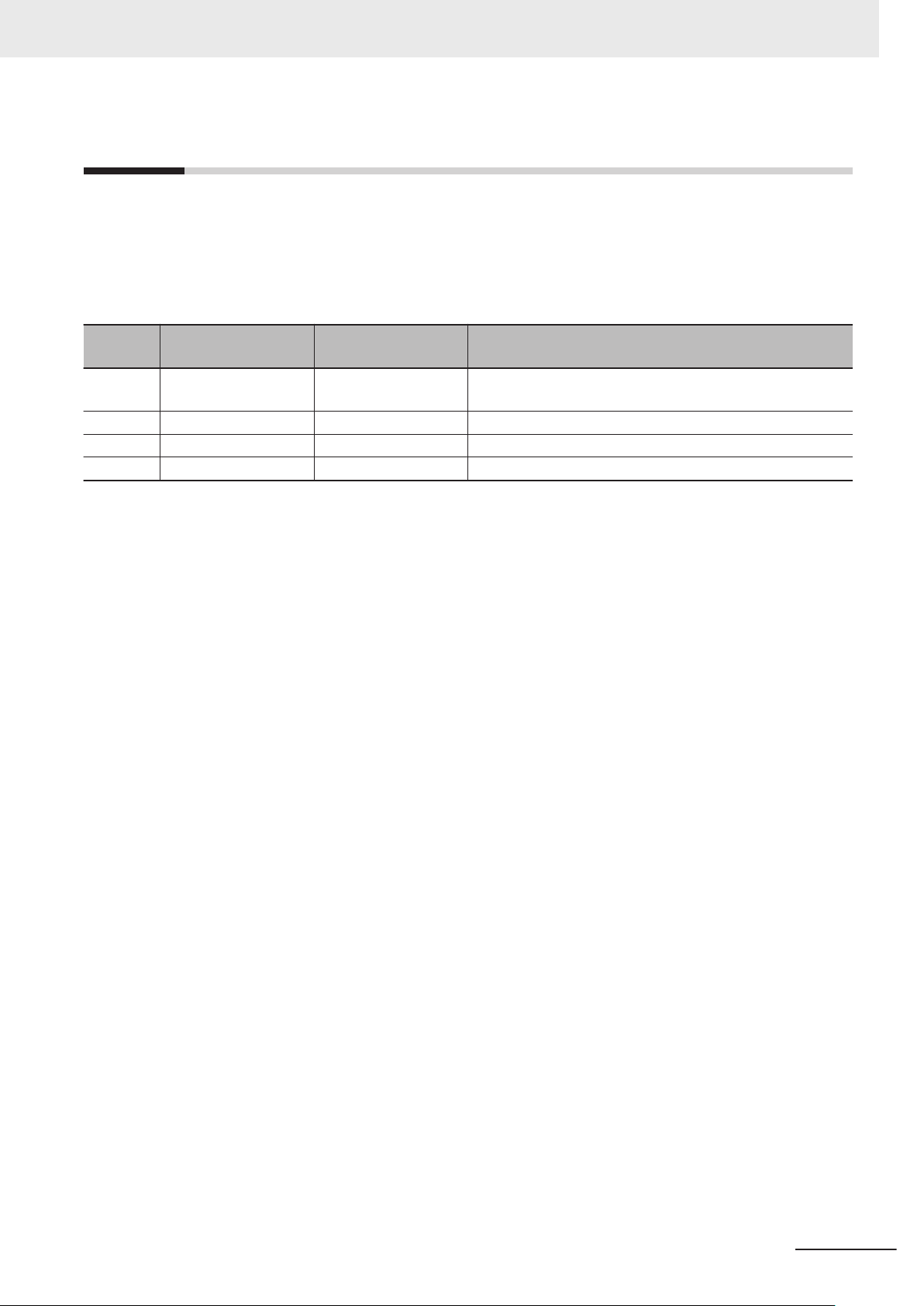

2 Target Equipment and Device Configuration

2-1

Device Configuration

The configuration devices for reproducing the connection procedures in this document are shown below.

This example shows a DirectPWM interface setting using the configuration where the digital quadrature encoder is connected to the output axis of a motor. This configuration is used only to show a setting example and is not a standard configuration.

Precautions for Correct Use

Always secure a Servomotor and encoder. Starting the motor that is not secured leads to a failure.

Manufacturer Name Model Version

OMRON Programmable Multi-Axis Controller

CPU Unit

OMRON Programmable Multi-Axis Controller

Axis Interface Unit

OMRON Programmable Multi-Axis Controller

Power Supply Unit

OMRON Programmable Multi-Axis Controller

End Cover

OMRON DirectPWM Cable

OMRON Motor Cable

OMRON Encoder Cable CK3W-CAES03A --Servotronix Servo Drive CDHD-0032APB0 --OMRON Servomotor R88M-K05030T --OMRON Digital Quadrature Encoder E6B2-CWZ1X --OMRON Coupling E69-C68B

OMRON Switching Power Supply

CK3M-CPU1£1

CK3W-AX1313£

CK3W-PD048 ---

CK3W-TER11 ---

CK3W-CAAD0££A

R88A-CAKA0££S

S8VK-£

Version 2.5.2 or

later

---

---

---

---

2-2

CK3M-series Startup Guide DirectPWM Interface (O047)

Page 13

2 Target Equipment and Device Configuration

Manufacturer Name Model Version

--- Windows PC --- --DT Power PMAC Setting Tool Power PMAC IDE Version 4.3 or

later

2-1 Device Configuration

2

CK3M-series Startup Guide DirectPWM Interface (O047)

2-3

Page 14

2 Target Equipment and Device Configuration

2-4

CK3M-series Startup Guide DirectPWM Interface (O047)

Page 15

3

DirectPWM Interface Connection

Procedure

3

This section describes the procedures for connecting the Controller and Servo Drive,

and operating the motion control equipment with the DirectPWM interface. The de-

scription assumes that the Controller is set to factory default.

3-1 W

3-2 Controller Setting Preparations.................................................................... 3-3

3-3 Various Equipment Connection.................................................................... 3-6

3-4 Various Controller Settings........................................................................... 3-8

3-5 Confirmation of Settings .............................................................................3-17

3-6 Motor Tuning................................................................................................. 3-19

ork Flow ....................................................................................................... 3-2

3-2-1 Creation of a New Project............................................................................... 3-3

3-2-2 Controller Initial Setting................................................................................... 3-4

3-4-1 Notes List...................................................................................................... 3-13

3-6-1 Open Loop Test ............................................................................................ 3-19

3-6-2 Current Loop Gain Setting ............................................................................ 3-20

3-6-3 Bandwidth Automatic Setting........................................................................ 3-21

3-6-4 Manual Setting of Bandwidth ........................................................................ 3-23

3-6-5 Feed-Forward Value Setting ......................................................................... 3-25

3-6-6 Checking of Operation and Creation of Tuning Parameter Project............... 3-27

CK3M-series Startup Guide DirectPWM Interface (O047)

3-1

Page 16

3 DirectPWM Interface Connection Procedure

3-1

Work Flow

The procedures for connecting the Controller and Servo Drive, and operating the motion control equipment with the DirectPWM interface, are shown below.

3-2 Controller Setting Preparations on page

3-3

▼

Creation of a New Project on page 3-3

3-2-1

▼

3-2-2 Controller Initial Setting on page 3-

▽

4

3-3 Various Equipment Connection on page

3-6

▽

3-4 Various Controller Settings on page 3-8

▽

3-5 Confirmation of Settings on page 3-17

▽

▼

▼

▼

▼

▼

on page

▼

3-19

3-20

3-25

3-6 Motor T

3-6-1 Open Loop Test on page 3-19

3-6-2 Current Loop Gain Setting on page

3-6-3 Bandwidth Automatic Setting on page 3-21

3-6-4 Manual Setting of Bandwidth on page 3-23

3-6-5 Feed-Forward V

3-6-6 Checking of Operation and Creation of Tuning Parameter

Project on page 3-27

uning on page

alue Setting

Perform the Controller setting preparations.

Perform connection and wiring for each device.

Perform the Controller settings.

Check that the settings up to here are correct.

Use Power PMAC IDE tuning tools to tune

the motor.

3-2

CK3M-series Startup Guide DirectPWM Interface (O047)

Page 17

3 DirectPWM Interface Connection Procedure

3-2

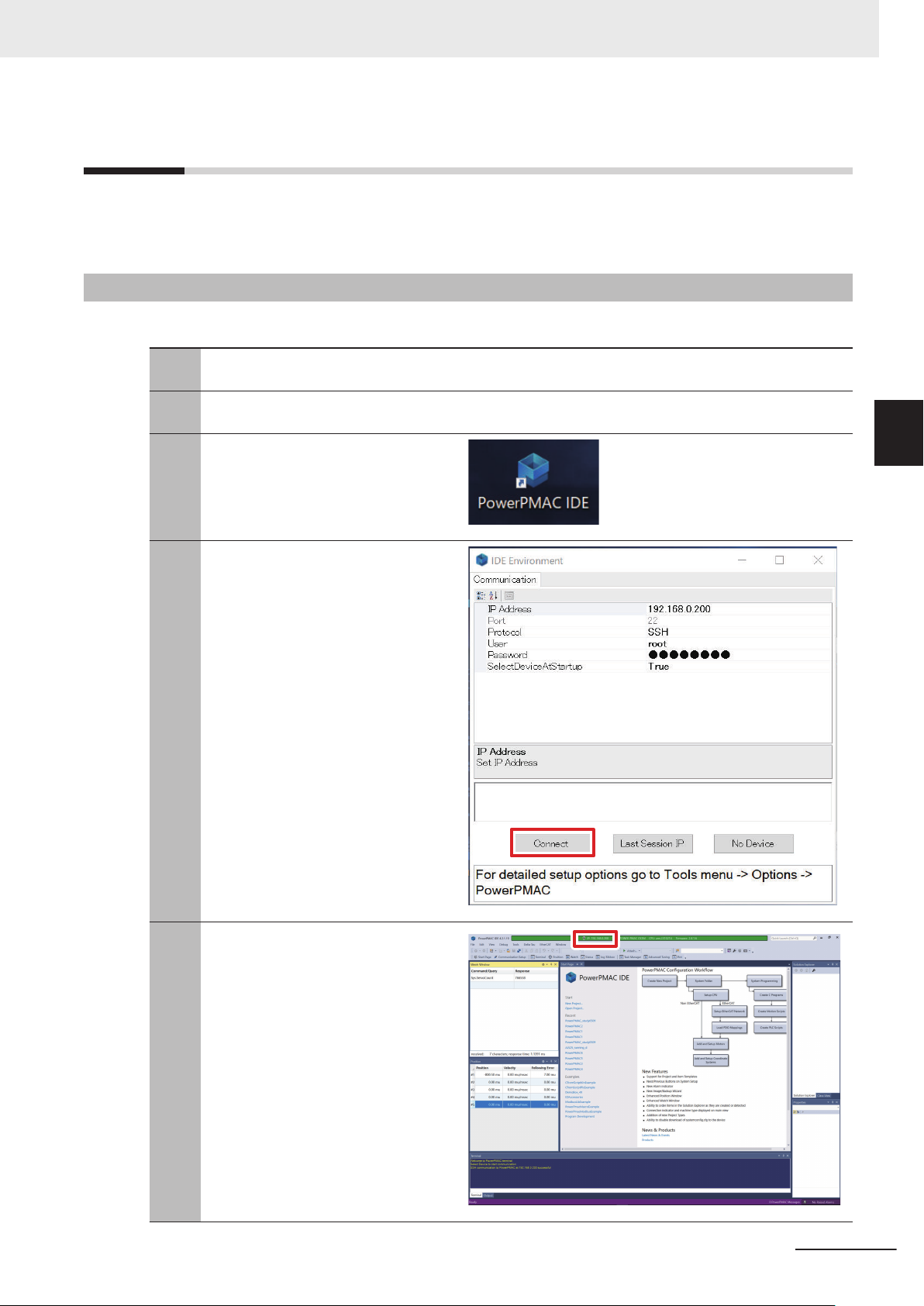

3-2-1

Controller Setting Preparations

Perform the Controller setting preparations.

Install the Power PMAC IDE on the PC beforehand.

Creation of a New Project

Follow the procedure below to create a new project.

Connect the Controller and computer

1

with an Ethernet cable.

Turn ON the power supply to the Con-

2

troller

.

Start up Power PMAC IDE.

3

• If a dialog for checking access rights

is displayed at the time of startup, select the option for starting up.

The Communication screen is dis-

4

played, so specify the IP address of the

Controller to be connected to, and click

the Connect button.

• The default IP address for the Con-

troller is "192.168.0.200".

• If necessary

address to "192.168.0.X".

, change the Windows IP

3-2 Controller Setting Preparations

3

3-2-1 Creation of a New Project

Power PMAC IDE starts up, and the

5

Controller will come online.

CK3M-series Startup Guide DirectPWM Interface (O047)

3-3

Page 18

3 DirectPWM Interface Connection Procedure

From the File menu, select New ‒

6

Project.

3-2-2

Input a project name and save destina-

7

tion, and select the OK button.

Controller Initial Setting

Follow the procedure below to perform the initial settings for the Controller.

Precautions for Correct Use

Since all memory is cleared by the initial settings, be sure to save any data remaining in the

Controller that you may need.

3-4

Type the $$$*** command from the T

1

minal, and set the Controller to the factory default state.

er-

CK3M-series Startup Guide DirectPWM Interface (O047)

Page 19

Type the save command in the Power

2

PMAC IDE T

• When the save is completed,

Completed" is displayed in the Terminal.

Type the $$$ command in the Power

3

PMAC IDE Terminal.

• When the reset is completed,

"PowerPMAC Reset complete

played in the Terminal.

erminal.

"Save

" is dis-

3 DirectPWM Interface Connection Procedure

3-2 Controller Setting Preparations

3

3-2-2 Controller Initial Setting

CK3M-series Startup Guide DirectPWM Interface (O047)

3-5

Page 20

CK3W-AX1313£

CK3W-CAED03A

CK3W-CAAD0££A

R88ACAKA0££S

Servo Drive

CDHD-0032APB0

Servomotor

Coupling

Digital

Quadrature

Encoder

d

a

b

c

3 DirectPWM Interface Connection Procedure

3-3

Various Equipment Connection

The following diagram shows the connection between the axis interface unit and various equipment.

Follow the instructions below to connect a, b, c, and d shown in the diagram above.

3-6

a. Connection between the Controller and Servo Drive

Use the following dedicated cables to connect the CK3W-AX1313£

amplifier connector to the Ser-

vo Drive C2 connector.

Manufacturer Name Model Length

OMRON DirectPWM Cable CK3W-CAAD009A 0.9 m

CK3W-CAAD018A 1.8 m

CK3W-CAAD036A 3.6 m

b. Connection between the Servo Drive and Servomotor

Use the following dedicated cables to connect the Servo Drive P2 connector to the Servomotor

connector.

Manufacturer Name Model Length

OMRON Motor Cable R88A-CAKA003S 3 m

R88A-CAKA005S 5 m

R88A-CAKA010S 10 m

R88A-CAKA015S 15 m

R88A-CAKA020S 20 m

R88A-CAKA030S 30 m

R88A-CAKA040S 40 m

R88A-CAKA050S 50 m

c. Connection between the Servomotor and Encoder

Use the following coupling to connect the rotary axes of the Servomotor and digital quadrature encoder

Coupling: E69-C68B

.

CK3M-series Startup Guide DirectPWM Interface (O047)

Page 21

CK3W-CAES03A

Encoder Cable

E6B2-CWZ1X

Pulse Encoder

Black

Red

Black

Red

Black

Red

Black

Red

Brown

Blue

Black

Black/red stripes

White

White/red stripes

Orange

Orange/red stripes

Power supply (+Vcc)

0 V (common)

Output phase A

Output phase AOutput phase B

Output phase BOutput phase Z

Output phase Z-

11

13

1

6

2

7

3

8

Blue

Blue

Pink

Pink

Green

Green

Orange

Orange

Encoder Power Supply (+5VDC)

Encoder Power Supply (GND)

Encoder A+

Encoder AEncoder B+

Encoder BEncoder C+

Encoder C-

Signal SignalColor

Pin

No.

Cable

color

Mark

3 DirectPWM Interface Connection Procedure

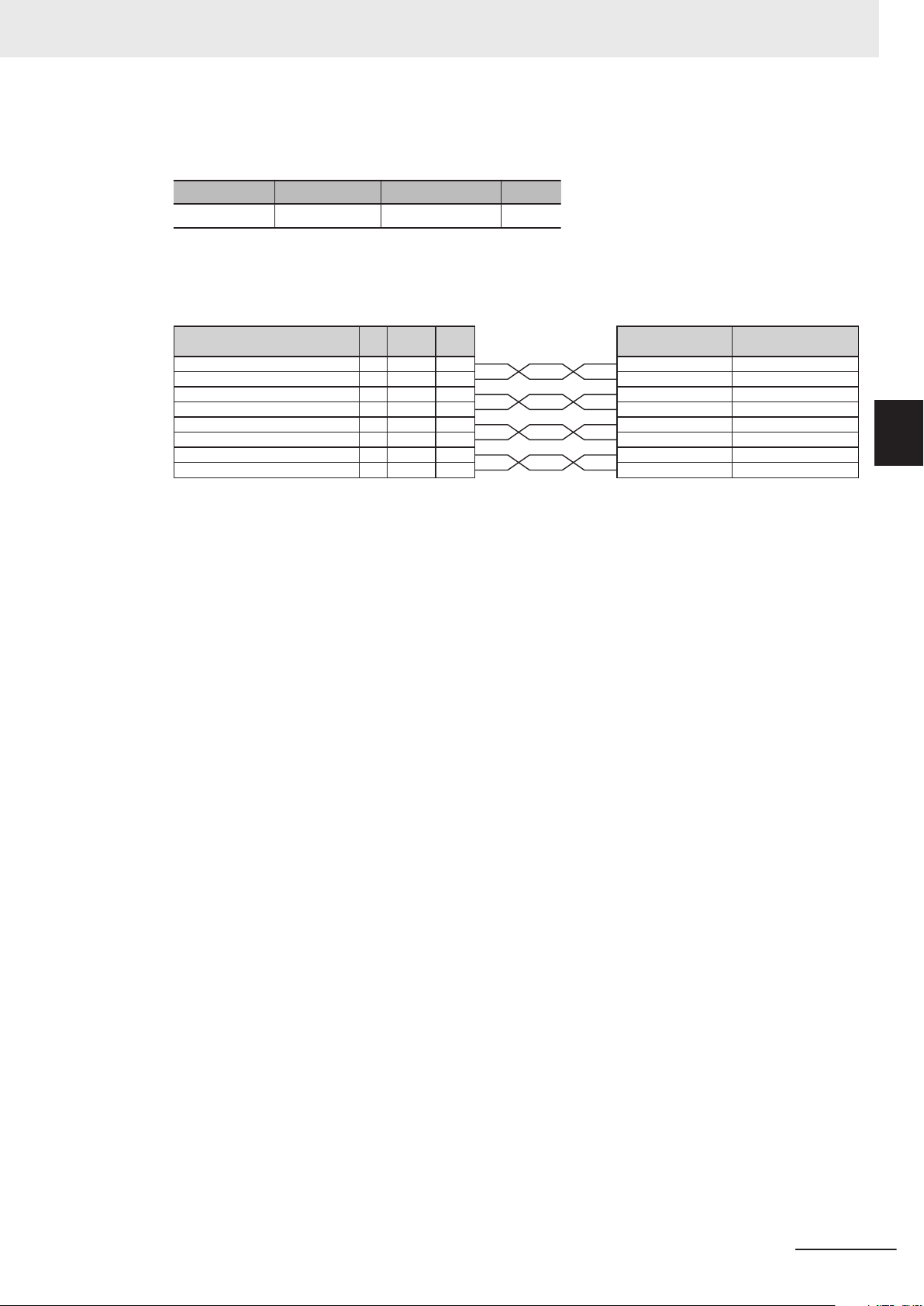

d. Wiring between the Controller and Encoder

Use the following dedicated cable to connect CK3W-AX1313£

Manufacturer Name Model Length

OMRON Encoder Cable CK3W-CAES03A 3 m

Follow the wiring diagram below to connect the dedicated cable (CK3W-CAES03A) to the digital

quadrature encoder.

to the digital quadrature encoder.

3-3 Various Equipment Connection

3

CK3M-series Startup Guide DirectPWM Interface (O047)

3-7

Page 22

3 DirectPWM Interface Connection Procedure

3-4

Various Controller Settings

Follow the procedure below to perform the settings for the Controller when a Servomotor is controlled

by the DirectPWM interface and digital quadrature encoder.

Precautions for Correct Use

• For items to be written in the global definitions.pmh in step 2 in the following procedure, set

appropriate values depending on the motor and Servo Drive used. If the set value is not appropriate, an excessive current flows, which may cause the equipment to fail.

Refer to Notes *24 through *26 in 3-4-1 Notes List on page 3-13 for the settings.

• If Motor[1].IaBias and Motor[1].IbBias are set to other than 0 in the following step 9 and 11,

the motor may rotate. Make sure that no problem occurs and the equipment is safe if the motor rotates before the setting.

Open the global definitions.pmh under

1

PMAC Script Language ‒ Global

Includes in the Solution Explorer

.

3-8

CK3M-series Startup Guide DirectPWM Interface (O047)

Page 23

3 DirectPWM Interface Connection Procedure

Write the text on the right to the global

2

definitions.pmh.

• Refer to 3-4-1 Notes List on page

3-13 for details on setting items with

Notes *1 through *30 shown in the

text on the right.

Sys.WpKey = $AAAAAAAA

//global setting

Gate3[0].PhaseServoDir = 0;

Gate3[0].PhaseFreq = 10000; //10kHz

Gate3[0].ServoClockDiv = 9; //1kHz

Sys.PhaseOverServoPeriod = 0.1;

Sys.ServoPeriod = 1;

//Encoder Setting

EncTable[1].Type = 1; //*1

EncTable[1].pEnc = Gate3[0].Chan[0].ServoCapt

.a; //*2

EncTable[1].ScaleFactor = 1/exp2(8); //*3

Gate3[0].EncClockDiv = 5; //3.125MHz

Gate3[0].Chan[0].EncCtrl = 7; //*4

//DirectPWM AD Convertor setting

Gate3[0].AdcAmpStrobe = $fffffc; //*5

Gate3[0].AdcAmpHeaderBits = 2; //*6

Gate3[0].AdcAmpClockDiv = 5; //3.125MHz

//DirectPWM PWM output setting

Gate3[0].Chan[0].PwmFreqMult = 2; //*7

Gate3[0].Chan[0].PwmDeadTime = 15; //*8

Gate3[0].Chan[0].PackInData = 2; //*9

Gate3[0].Chan[0].PackOutData = 1; //*10

3-4 Various Controller Settings

3

3-4-1 Notes List

CK3M-series Startup Guide DirectPWM Interface (O047)

3-9

Page 24

3 DirectPWM Interface Connection Procedure

Sys.WpKey=$0

//Motor setting

Motor[1].ServoCtrl = 1; //Enable the Motor[1]

.

Motor[1].PhaseCtrl = 1; //Enable the commutat

ion task.

Motor[1].pPhaseEnc = Gate3[0].Chan[0].PhaseCa

pt.a; //*11

Motor[1].PhasePosSf = 2048/(256*2000*4/5); //

*12

Motor[1].PwmSf = 13458; //*13

Motor[1].PhaseOffset = 683; //*14

Motor[1].AmpFaultLevel = 1; //*15

Motor[1].pLimits = 0; //Disable the Overtrave

l limit.

Motor[1].WarnFeLimit = 4000; //*16

Motor[1].FatalFeLimit = 8000; //*17

Motor[1].pAmpEnable = Gate3[0].Chan[0].OutCtr

l.a;

Motor[1].pAmpFault = Gate3[0].Chan[0].Status.

a;

Motor[1].pCaptFlag = Gate3[0].Chan[0].Status.

a;

Motor[1].pCaptPos = Gate3[0].Chan[0].HomeCapt

.a;

Motor[1].pEncCtrl = Gate3[0].Chan[0].OutCtrl.

a;

Motor[1].pEncStatus = Gate3[0].Chan[0].Status

.a;

Motor[1].pMasterEnc = EncTable[1].a;

Motor[1].CurrentNullPeriod = 1; //*18

Motor[1].pEnc = EncTable[1].a //*19

Motor[1].pEnc2 = EncTable[1].a //*20

Motor[1].pDac = Gate3[0].Chan[0].Pwm[0].a; //

*21

Motor[1].pAdc = Gate3[0].Chan[0].AdcAmp[0].a;

//*22

Motor[1].AdcMask = $FFFC0000; //*23

Motor[1].MaxDac = 28377 * 3.33 / 11.25; //*24

Motor[1].I2tSet = 28377 * 1.1 / 11.25; //*25

Motor[1].I2tTrip = (Motor[1].MaxDac * Motor[1

].MaxDac -Motor[1].I2tSet * Motor[1].I2tSet)

* 3; //*26

Motor[1].AbsPhasePosOffset = 400; //*27

Motor[1].PhaseFindingDac = 4000; //*28

Motor[1].PhaseFindingTime = 1000; //*29

Motor[1].PowerOnMode = 1; //*30

Motor[1].InPosBand = 100;

3-10

// Setting Coordinate System

&1

#1->x

&1%100;

CK3M-series Startup Guide DirectPWM Interface (O047)

Page 25

Right click on the Solution Explorer

$$$

3

project name at the upper right of the

Power PMAC IDE screen, select Build

and Download All Programs, and execute Build and Download.

3 DirectPWM Interface Connection Procedure

3-4 Various Controller Settings

3

Make sure that there are no errors in

4

the Output Window.

• If the transfer failed, check the con-

tent of the error in the Output Window

. If there is a program error, fix

the program.

Type the save command in the Power

5

PMAC IDE T

• When the save is completed,

Completed" is displayed in the Terminal.

Type the $$$ command in the T

6

erminal.

3-4-1 Notes List

"Save

erminal.

To determine a sign for

7

Motor[1].PhaseOffset, paste

Motor[1].PhasePos, Motor[1].IaBias,

and Motor[1].IbBias in the Watch window

.

CK3M-series Startup Guide DirectPWM Interface (O047)

3-11

Page 26

3 DirectPWM Interface Connection Procedure

8

9

10

Type the #1out0 command in the T

minal.

Set Motor[1].IaBias=200 and

Motor[1].IbBias=0 in the Terminal.

Check the Motor[1].PhasePos value in

the W

atch window

.

er-

11

12

Set Motor[1].IbBias=200 in the Terminal.

• Motor[1].IaBias

Check the Motor[1].PhasePos value in

the W

atch window

remains 200.

.

3-12

CK3M-series Startup Guide DirectPWM Interface (O047)

Page 27

3 DirectPWM Interface Connection Procedure

13

14

15

Type Motor[1].IaBias=0

Motor[1].IbBias=0

return the phase A and B bias currents

to 0.

If the Motor[1].PhasePos value decreases when values in step 10 and 12

are compared, set the sign of

Motor[1].PhaseOffset to + (addition); if

the value increases, set the sign to −

(subtraction).

and

in the Terminal to

• Since the value decreases in this ex-

ample, set

Motor[1].PhaseOffset=683 in the

global definitions.pmh.

If a sign of Motor[1].PhaseOffset

needs to be changed, change the

sign in the global definitions.pmh and

perform download again following the

procedure in step 3 through 6.

Manually rotate the coupling that connects the motor to encoder and check

that the desired scale is applied to the

current position in the Position window

• The

EncTable[1].ScaleFactor value

is set to 8000 counts per rotation in

this example, so 8000 mu is added to

the current position per rotation.

3-4 Various Controller Settings

3

3-4-1 Notes List

.

Precautions for Correct Use

If the save command is not successfully completed, the transferred project is not saved in the

Controller. If the power to the Controller is switched OFF without the project being saved, the

transferred project is destroyed.

Additional Information

To change the counting direction of the digital quadrature encoder (clockwise/counterclockwise), change the sign of the following set values to write in the global definitions.pmh in step 2

to − (subtraction).

• EncT

able[1].ScaleFactor

• Motor[1].PhasePosSf

3-4-1

Notes List

The following table shows details on notes (description of set items) in step 2.

CK3M-series Startup Guide DirectPWM Interface (O047)

3-13

Page 28

Set value :

1

2

(32 bits -24 bits )

f

PWM

=

Gate3[0].Chan[0].PwmFreqMult+1

2

× f

IntPhase

f

IntPhase

: Internal phase clock frequency

Sf =

2048 × Number of motor pole pairs

256 × Encoder resolution × Encoder multiplication setting

3 DirectPWM Interface Connection Procedure

No. Set item Set value Description

*1 EncTable[1].Type 1 Enable EncTable[1] as single-word (32 bits) read.

*2 EncTable[1].pEnc Gate3[0].Chan[0].S

ervoCapt.a

*3 EncTable[1].Scale-

1/exp2(8) Calculate a scale factor set value in accordance with the following for-

Factor

Assign the digital quadrature encoder data to EncTable[1].

mula because EncT

able[1] is 32 bits and Gate3[0].Chan[0].ServoCapt

(digital quadrature encoder data) is 24 bits.

*4 Gate3[0].Chan[0].E

ncCtrl

*5 Gate3[0].Ad-

cAmpStrobe

*6

Gate3[0].AdcAmpHeaderBits

*7 Gate3[0].Chan[0].P

wmFreqMult

*8 Gate3[0].Chan[0].P

wmDeadTime

*9 Gate3[0].Chan[0].P

ackInData

*10 Gate3[0].Chan[0].P

ackOutData

*11 Motor[1].pPha-

seEnc

*12 Motor[1].Phase-

PosSf

7 Set the digital quadrature encoder conversion method to four multipli-

cation, counterclockwise.

$fffffc Specify AMP Strobe Word. If $fffffc is set, the Controller is compatible

with all AD converters.

2 Set the header length of analog to digital conversion data to 2 bits.

Set it depending on the Servo Drive specifications.

2 Set the PWM frequency to 15 kHz. Calculate the PWM frequency in

accordance with the formula below.

Make sure that the value is 40 kHz or less and the same as the Servo

Drive maximum input frequency or less.

15 Set the PWM signal dead time to 800 ns. Calculate the dead time in

accordance with the formula below.

Dead time = 0.0533 μs × Gate3[0].Chan[0].PwmDeadTime

Set it depending on the Servo Drive specifications.

2 AdcAmp compression: Enabled

If the digital current loop is implemented, enable data compression that

improves algorithm efficiency

.

1 Enable PWM/DAC compression. If the commutation and digital current

loop are calculated, enable data compression that improves algorithm

.

Gate3[0].Chan[0].P

efficiency

Use the digital quadrature encoder for commutation position feedback.

haseCapt.a

2048/

(256*2000*4/5)

Set a scale factor (Sf) of the commutation position (angle). Use the following formula to calculate the scale factor if 24 bits digital quadrature

encoder (Gate3[0].Chan[0].ServoCapt) is assigned to 32 bits EncTable[1] as this example.

3-14

Set it depending on the specifications of equipment used.

The following shows parameters for equipment used in this example.

(32 bits - 24 bits)

256: 2

= 256

Encoder resolution: 2000 pulses per rotation

Encoder multiplication: 4 multiplication

Number of motor pole pairs: 5 pairs (10 poles)

CK3M-series Startup Guide DirectPWM Interface (O047)

Page 29

MaxDac =

Cos (30°) × 32767 × Maximum instantaneous current

Servo driver ADC full-range current

3 DirectPWM Interface Connection Procedure

No. Set item Set value Description

*13 Motor[1].PwmSf 13458 Set a scale factor for PWM output. The full range is 16384.

The scale factor is normally set to less than 95% of the full range so

that PWM waveform cannot reach the duty cycle of 0% or 100%. It is

set to approximately 82% in this example.

Set it depending on the Servo Drive specifications.

*14 Motor[1].PhaseOff-

set

*15 Motor[1].AmpFault-

Level

*16 Motor[1].WarnFeLi-

mit

*17 Motor[1].FatalFeLi-

mit

*18 Motor[1].Current-

NullPeriod

*19 Motor[1].pEnc EncTable[1].a Specify the digital quadrature encoder as an address used for loop

*20

*21 Motor[1].pDac Gate3[0].Chan[0].P

*22 Motor[1].pAdc Gate3[0].Chan[0].A

*23 Motor[1].AdcMask $FFFC0000 Specify which bit of 32 bits current feedback word is used as the actual

*24 Motor[1].MaxDac 28377*3.33/11.25 Set an instantaneous current limit value (root mean square: RMS).

Motor[1].pEnc2 EncTable[1].a Specify the digital quadrature encoder as the address used for loop

683 For a three-phase motor, set to 683 or −683.

1 Specify a logic of AMP Fault detection. Set it depending on the Servo

Drive specifications.

0: Negative logic is used to detect AMP Fault.

1: Positive logic is used to detect AMP Fault.

4000 The status bit Motor[1].AmpWarn is set when the positional deviation

exceeds this value.

The value for a half-rotation of the motor is set in this example. Set it

depending on applications used.

8000 The motor is killed and the status bit Motor[1].FeFatal is set when the

positional deviation exceeds this value.

The value for a half-rotation of the motor is set in this example. Set it

depending on applications used.

1 Motor[1].IaBias and Motor[1].IbBias are set in

Motor[1].PhaseFindingStep=1 during phase search.

feedback to control the motor position.

able[1] in Notes *2

able[1] in Notes *2

, and use a smaller

wm[0].a

dcAmp[0].a

The digital quadrature encoder is assigned to EncT

in this example.

feedback to control the motor velocity.

The digital quadrature encoder is assigned to EncT

in this example.

Assign DirectPWM to the motor command output register.

Specify the DirectPWM interface AD converter as an AD converter

used for digital current feedback.

current value.

The 14 bits AD converter is set in this example. Set it depending on the

Servo Drive specifications.

Compare those of the Servo Drive and the motor

value. The motor has a smaller value in this example.

Use the following formula for calculation.

3-4 Various Controller Settings

3

3-4-1 Notes List

CK3M-series Startup Guide DirectPWM Interface (O047)

Determine parameters depending on the equipment used.

The following shows parameters for equipment used in this example.

Maximum instantaneous current for R88M-K05030T: 4.7 A (p-p)/

3.33 A (RMS)

ADC full range current for CDHD-0032APB0: 11.25 A (RMS)

√2 =

3-15

Page 30

I2tSet =

Cos (30°) × 32767 × Rated current

Servo driver ADC full-range current

3 DirectPWM Interface Connection Procedure

No. Set item Set value Description

*25 Motor[1].I2tSet 28377*1.1/11.25 Set a rated current limit value (RMS). Compare those of the Servo

Drive and the motor, and use a smaller value. The motor has a smaller

value in this example.

Use the following formula for calculation.

Determine parameters depending on the equipment used.

The following shows parameters for equipment used in this example.

Rated current for R88M-K05030T: 1.1 A (RMS)

1.25 A (RMS)

*26 Motor[1].I2tTrip (Motor[1].Max-

Dac*Motor[1].MaxDac − Motor[1].I2tSet*Motor[1].I2tSet)*3

*27 Motor[1].AbsPha-

sePosOf

*28 Motor[1].PhaseFin-

dingDac

*29 Motor[1].PhaseFin-

dingTime

Motor[1].PowerOn-

*30

Mode

fset

400 Specify the minimum operation that is considered to be an ef

4000 Set the size of phase-sequence current that is output to each motor

1000 Set duration of each step during phase search. Adjust it depending on

1 1: Enables the motor after phase search.

ADC full range current for CDHD-0032APB0: 1

Set a motor integrated current limit. Use the following formula for cal-

culation.

I2tTrip = (MaxDAC2 + IdCmd2 − I2tSet2) × allowable time (second)

Allowable time for R88M-K05030T

phase search. Although the commutation cycle (2048) 1/4 = 512 (90°)

is ideal, it is set to approximately 80% in this example considering that

problems such as friction can prevent the operation.

If Motor[1].PhaseFindingStep=1 displacement is smaller than this

value during phase search, the phase search is considered to be failed

by Power PMAC.

phase in phase search. Adjust it depending on the equipment used.

the equipment used.

The following duration is used in this example.

Duration = Servo cycle × Motor[1].PhaseFindingTime = 1 ms × 1000 =

1000 ms

0: Kills the motor after phase search.

: 3 seconds

ficient

3-16

CK3M-series Startup Guide DirectPWM Interface (O047)

Page 31

3 DirectPWM Interface Connection Procedure

3-5

Confirmation of Settings

Follow the procedure below to check that the settings up to here are correct.

Type the

1

Motor[1].PhaseFindingStep=1 com-

mand from the T

phase search.

• The Motor[1].PhaseFindingStep

value changes to 1, 6, 7, and 0.

When the phase search succeeds,

the Motor[1].ClosedLoop and

Motor[1].PhaseFound

change from 0 to 1.

In addition, the Motor[1].New[0].Pos

value becomes larger than the

Motor[1].AbsPhasePosOffset set

value. The AMP ENAB 0 LED is

turned on at that time.

erminal to perform a

values

*1

3-5 Confirmation of Settings

3

Type the #1 out1 command from the

2

T

erminal.

Make sure that the motor is rotating. In

3

addition, check that the Position window Position value is increasing in the

positive direction.

• If the motor does not rotate even af-

ter typing the #1 out1 command, increase the value gradually as #1

out2, #1 out3.

Type the kill command from the Termi-

4

nal to stop the motor.

*1. If Motor[1].PhaseFound does not indicate 1, the phase search has failed. Check if the set value is appro-

priate.

The following shows some examples of set value adjustment when a phase search fails.

CK3M-series Startup Guide DirectPWM Interface (O047)

3-17

Page 32

3 DirectPWM Interface Connection Procedure

• If the Motor[1].New[0].Pos value is smaller than the Motor[1].AbsPhasePosOffset set value after

phase search, increase the Motor[1].PhaseFindingDac value. In addition, check that the

Motor[1].PhasePosSf set value is appropriate.

• If an error occurs in I2tFault status during phase search, decrease the value of

Motor[1].PhaseFindingDac or

• If the Motor[1].New[0].Pos value indicates − (subtraction) after phase search, change signs of

Motor[1].PhasePosSf and EncTable[1].ScaleFactor.

Motor[1].PhaseFindingTime.

3-18

CK3M-series Startup Guide DirectPWM Interface (O047)

Page 33

3 DirectPWM Interface Connection Procedure

3-6

3-6-1

Motor Tuning

Follow the procedure below to use Power PMAC IDE tuning tools for tuning the motor.

Open Loop Test

Follow the procedure below to operate the motor in an open loop, and check that each setting is correct.

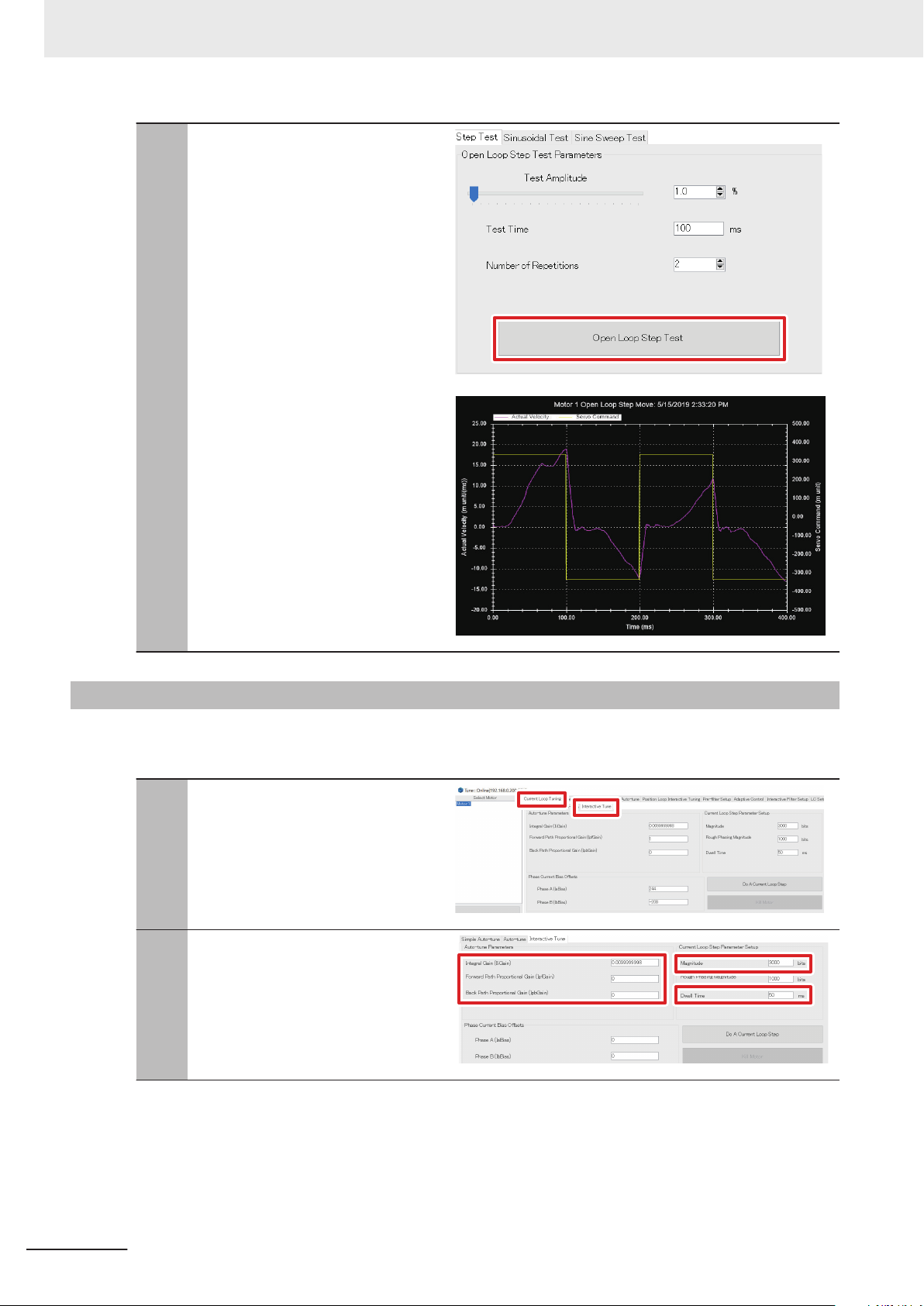

From the T

1

lect

Tune screen, and then select Open

LoopTest ‒ Step Test.

ools menu in Delta Tau, se-

Advanced Tuning to open the

3-6 Motor Tuning

3

3-6-1 Open Loop Test

Set the following tuning parameters.

2

T

est Amplitude: 1.0%

est Time: 100 ms

T

Number of Repetitions: 2

*1. If the motor does not rotate, set a

large value.

*1

CK3M-series Startup Guide DirectPWM Interface (O047)

3-19

Page 34

3 DirectPWM Interface Connection Procedure

Click the Open Loop Step T

3

• The motor is performing reciprocating

operation and the test result on the

right is displayed.

• If the motor does not rotate, change

the T

est Amplitude

large value.

• The test result is when the Test

Amplitude parameter is set to 8.0%.

parameter to a

est

button.

3-6-2

Current Loop Gain Setting

Follow the procedure below to perform current loop gain settings and adjust them to achieve desired

response characteristics.

In the Tune screen, select Current

1

Loop Tuning ‒

Set the following parameters.

2

IliGain: 0.0099999998 (Default)

IpfGain: 0

IpbGain: 0

Magnitude: 3000 bits

Dwell T

ime: 50 ms

Interactive Tune.

3-20

CK3M-series Startup Guide DirectPWM Interface (O047)

Page 35

Click the Do A Current Loop Step but-

3

ton.

3 DirectPWM Interface Connection Procedure

• The current step response is dis-

played.

Adjust the IliGain, IpfGain, and

4

IpbGain parameters to achieve the de-

sired response characteristics.

3-6 Motor Tuning

3

3-6-3 Bandwidth Automatic Setting

3-6-3

• If the startup response is slow, in-

crease the IliGain parameter

• If the overshooting or vibration is

large, increase the IpfGain or

IpbGain parameter.

• Increase each gain parameter gradu-

ally starting from a small value.

.

Bandwidth Automatic Setting

Follow the procedure below to use the auto-tuning function for setting the servo loop bandwidth automatically.

CK3M-series Startup Guide DirectPWM Interface (O047)

3-21

Page 36

3 DirectPWM Interface Connection Procedure

In the Tune screen, select Position

1

Loop Auto-tune ‒ Advance Autotune.

Set the following parameters.

2

Amplifier Type: Direct PWM

Auto Select Bandwidth: Select the

check box.

Encoder Resolution: 8000 cts/rev

Excitation Magnitude: 8.0%

Iteration No.: 2

*1.

Select the value rotated in the open

loop in step 3 in 3-6-1 Open Loop

T

on page 3-19.

est

*1

• For Encoder Resolution, set the

pulse counts per one motor rotation.

In this example, 2000 pulses per rotation of the digital quadrature encoder is set to be multiplied by four, so

Encoder Resolution indicates 8000.

Click the Auto-tune Motor button.

3

If the message on the right appears,

4

click the Y

button.

es

3-22

CK3M-series Startup Guide DirectPWM Interface (O047)

Page 37

If the screen on the right appears, click

5

the Implement button.

Check that the Recommended Gains

6

values are applied to Current Gains,

and then click the OK button.

3 DirectPWM Interface Connection Procedure

3-6 Motor Tuning

3

3-6-4 Manual Setting of Bandwidth

3-6-4

Manual Setting of Bandwidth

Follow the procedure below to set a more appropriate bandwidth, while monitoring the step response

characteristic.

Select Position Loop Interactive

1

T

Set the following parameters.

2

Step Size: 2500 mu

‒ Step in the Tune screen.

uning

CK3M-series Startup Guide DirectPWM Interface (O047)

3-23

Page 38

3 DirectPWM Interface Connection Procedure

Click the Step Move button.

3

Check the step response characteristic.

4

If the target position has not been

5

reached, return to the Advance Autotune screen, and set an even larger

value for

Click the Recalculate button.

6

If the screen on the right appears, click

7

the Implement button.

Bandwidth.

3-24

CK3M-series Startup Guide DirectPWM Interface (O047)

Page 39

Check that the Recommended Gains

8

values are applied to Current Gains,

and then click the OK button.

Return to step 1 and repeat the proce-

9

dure until the desired responsiveness is

obtained.

3 DirectPWM Interface Connection Procedure

3-6 Motor Tuning

3

3-6-5 Feed-Forward Value Setting

3-6-5

Feed-Forward Value Setting

Follow the procedure below to set a more appropriate bandwidth, while monitoring the step response

characteristic.

In the Tune screen, select Position

1

Loop Auto-tune ‒ Advance Autotune, and insert checks into Velocity

FF and Acceleration FF

Click the Recalculate button.

2

.

CK3M-series Startup Guide DirectPWM Interface (O047)

3-25

Page 40

3 DirectPWM Interface Connection Procedure

If the screen on the right appears, click

3

the Implement button.

Check that the Recommended Gains

4

values are applied to Current Gains,

and then click the OK button.

Select Position Loop

5

InteractiveT

and set the following parameters.

Move Size: 2500 mu

Move Time: 500 ms

Left Axis: Velocity

Right Axis: Following Error

Click the Parabolic V

6

ton.

Check the parabolic response charac-

7

teristic of velocity

uning ‒

Parabolic Vel.

elocity Move

.

but-

3-26

CK3M-series Startup Guide DirectPWM Interface (O047)

Page 41

If Following Error has a positive corre-

8

lation to the velocity

If it has a reverse correlation, make

Kvff smaller.

, make

3 DirectPWM Interface Connection Procedure

Kvff larger.

3-6 Motor Tuning

9

10

Click the Parabolic Velocity Move

ton again.

• Repeat this until the correlation of

Following Error to the velocity disappears.

In the same way, if Following Error

has a correlation to Acceleration,

Position, etc., increase or decrease the

Kaff and Kfff values.

but-

3

3-6-6 Checking of Operation and Creation of Tuning Parameter Project

3-6-6

CK3M-series Startup Guide DirectPWM Interface (O047)

Checking of Operation and Creation of Tuning Parameter Project

Follow the procedure below to check operations and create a tuned parameter project.

3-27

Page 42

3 DirectPWM Interface Connection Procedure

Type the

1

Motor[1].PhaseFindingStep=1 com-

mand from the T

phase search.

• The Motor[1].PhaseFindingStep

value changes to 1, 6, 7, and 0.

• When the phase search succeeds,

the Motor[1].ClosedLoop and

Motor[1].PhaseFound values

change from 0 to 1. In addition, the

Motor[1].New[0].Pos value becomes larger than the

Motor[1].AbsPhasePosOffset set

value. The AMP ENAB 0 LED is

turned on at that time.

erminal to perform a

Type the #1 j+ command from the Ter-

2

minal.

Make sure that the motor is rotating. In

3

addition, confirm that the #1 V

value is around 32 in the Position win-

.

dow

• Velocity depends on

Motor[1].JogSpeed (32 by default).

Type the kill command from the T

4

nal to stop the motor

.

elocity

ermi-

3-28

CK3M-series Startup Guide DirectPWM Interface (O047)

Page 43

Open the global definitions.pmh under

5

PMAC Script Language ‒ Global

Includes in the Solution Explorer

3 DirectPWM Interface Connection Procedure

.

3-6 Motor Tuning

3

3-6-6 Checking of Operation and Creation of Tuning Parameter Project

Add the gain values obtained from tun-

6

ing to the global definitions.pmh.

Open the pp_startup.txt under

7

Configuration in the Solution Explorer.

Motor[1].IiGain = ***

Motor[1].IpfGain = ***

Motor[1].IpbGain = ***

Motor[1].Servo.Kp = ***

Motor[1].Servo.Kvfb = ***

Motor[1].Servo.Kaff = ***

Motor[1].Servo.Kvff = ***

Write the phase search implementation

8

command shown on the right.

CK3M-series Startup Guide DirectPWM Interface (O047)

Motor[1].PhaseFindingStep = 1

3-29

Page 44

3 DirectPWM Interface Connection Procedure

Select the project and execute Build

9

and Download.

• Refer to step 3 through 6 in 3-4 V

ous Controller Settings on page

for the Build and Download method.

• As shown in step 5 and 6, gains can

be downloaded on PMAC as a program if you write gains in the global

definitions.pmh.

• As shown in step 7 and 8, the phase

search is automatically performed after the power is turned ON or reset to

enable Motor[1] if you write the

phase search implementation command in the pp_startup.txt.

ari-

3-8

3-30

CK3M-series Startup Guide DirectPWM Interface (O047)

Page 45

Page 46

OMRON Corporation Industrial Automation Company

Kyoto, JAPAN

Contact: www.ia.omron.com

Regional Headquarters

OMRON EUROPE B.V.

Wegalaan 67-69, 2132 JD Hoofddorp

The Netherlands

Tel: (31)2356-81-300/Fax: (31)2356-81-388

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08 (Lobby 2),

Alexandra Technopark,

Singapore 119967

Tel: (65) 6835-3011/Fax: (65) 6835-2711

OMRON ELECTRONICS LLC

2895 Greenspoint Parkway, Suite 200

Hoffman Estates, IL 60169 U.S.A.

Tel: (1) 847-843-7900/Fax: (1) 847-843-7787

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120, China

Tel: (86) 21-5037-2222/Fax: (86) 21-5037-2200

Authorized Distributor:

© OMRON Corporation 2019 All Rights Reserved.

In the interest of product improvement,

specifications are subject to change without notice.

Cat. No. O047-E1-01

0719

Loading...

Loading...