Machine Automation Controller

CJ-series

Serial Communications Units

Operation Manual

for NJ-series CPU Unit

CJ1W-SCU22

CJ1W-SCU32

CJ1W-SCU42

Serial Communications Units

W494-E1-03

OMRON, 2011

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Introduction

Thank you for purchasing an CJ-series CJ1W-SCU@2 Serial Communications Units.

This manual contains information that is necessary to use with the NJ-series CPU Unit. Please read

this manual and make sure you understand the functionality and performance of the NJ-series CPU

Unit before you attempt to use it in a control system.

Keep this manual in a safe place where it will be available for reference during operation.

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and maintaining FA systems.

• Personnel in charge of managing FA systems and f acilities.

For programming, this manual is intended for personnel who understand the programming language

specifications in international standard IEC 61131-3 or Japanese standard JIS B3503.

Introduction

Applicable Products

This manual covers the following products.

CJ-series Serial Communications Units

• CJ1W-SCU22

• CJ1W-SCU32

• CJ1W-SCU42

CJ-series Serial Communications Units Operation Manual for NJ-series CPU Unit(W494)

1

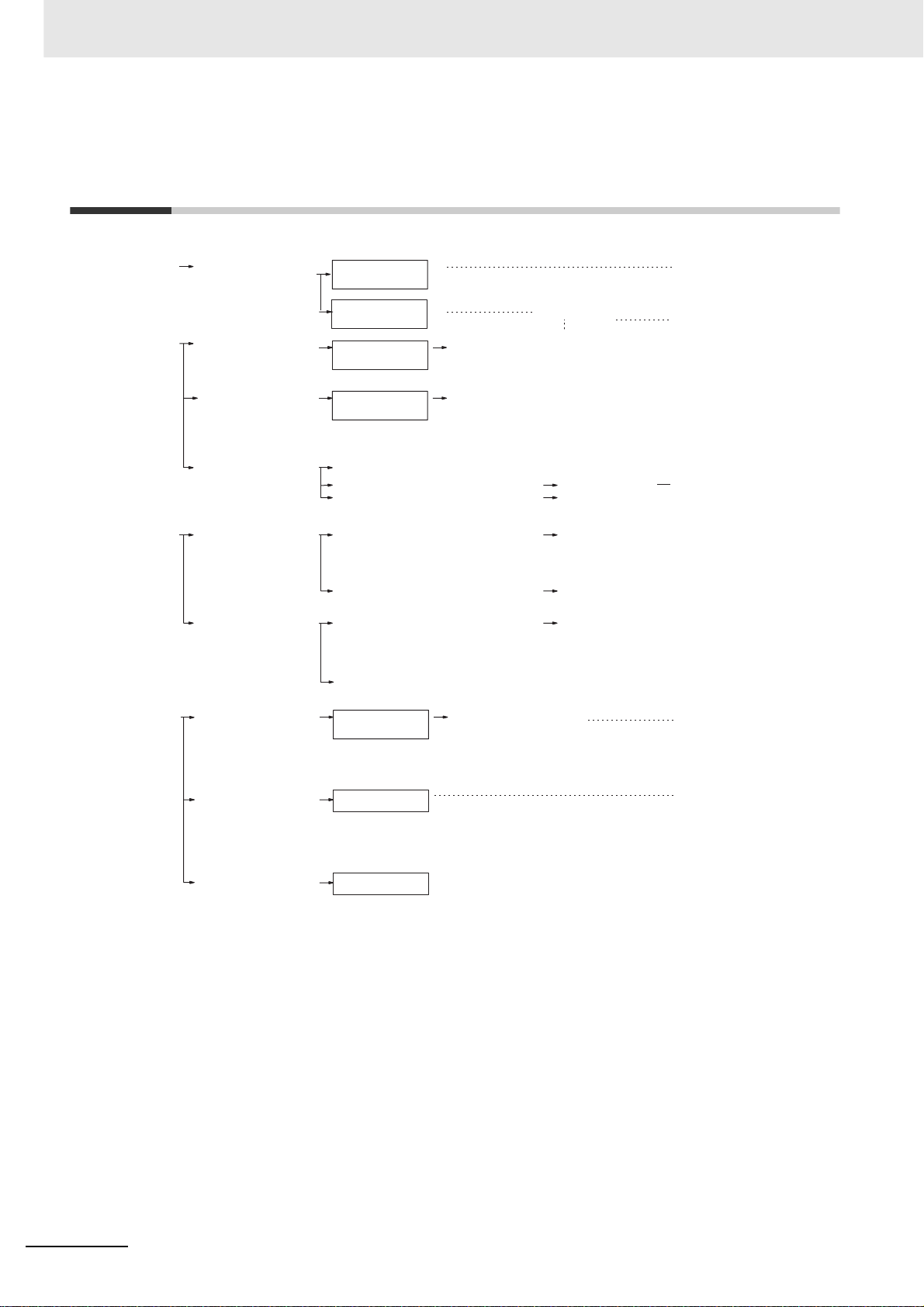

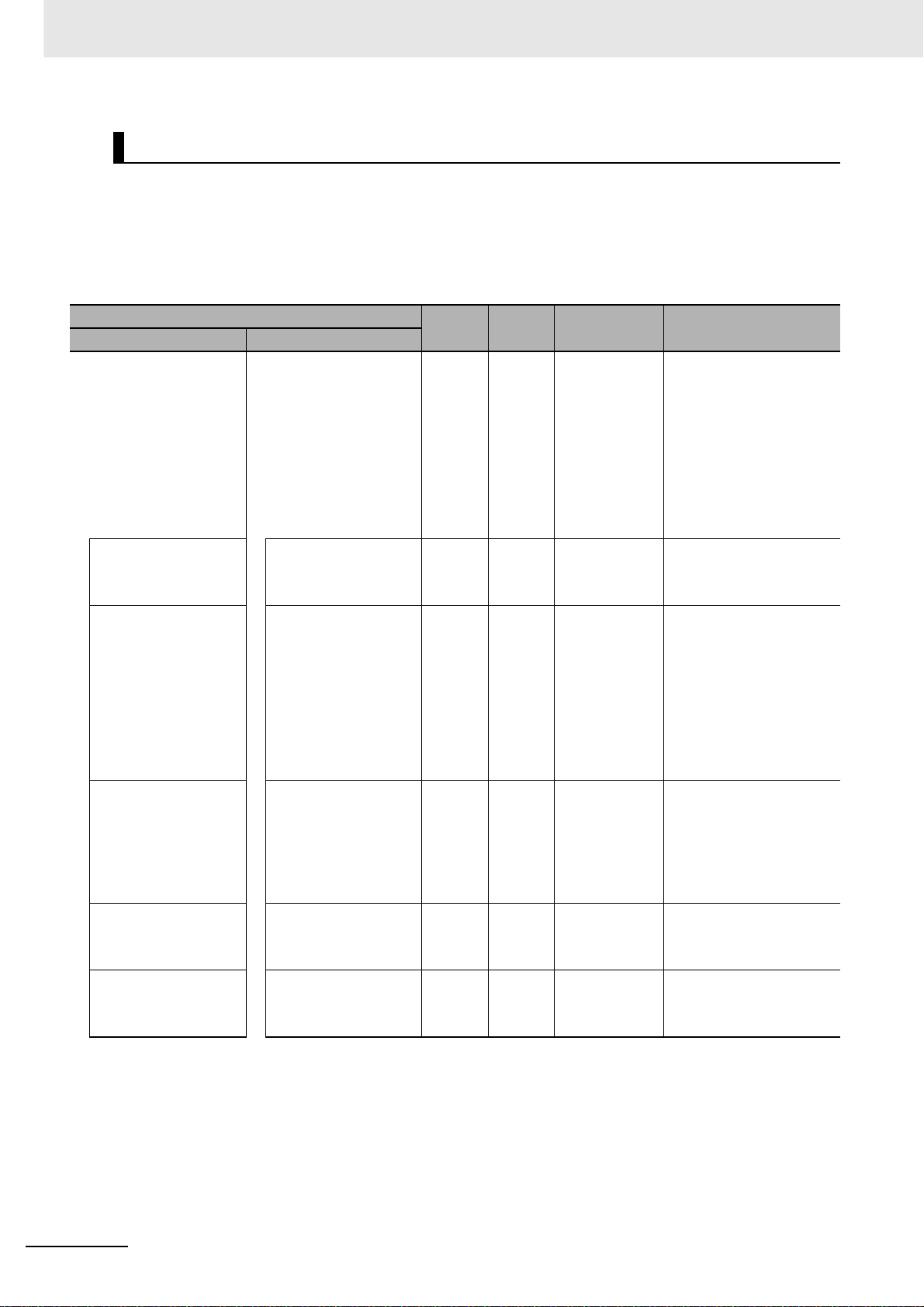

Relevant Man uals

Relevant Manuals

There are three manuals that pr o vide b asic information on the NJ-series CPU Units: the NJ-series CPU

Unit Hardware User's Manual, the NJ-series CPU Unit Software User's Manual, and the NJ-series

Instructions Reference Manual.

Most operations are perf ormed from the Sysmac Studio A ut omation Softw are . Ref er t o the Sysmac Studio Version 1 Operation Manual (Cat. No. W504) for information on the Sysmac Studio.

Other manuals are necessary for specific system configurations and applications.

Read all of the manuals that are relevant to your system configuration and application to make the most

of the NJ-series CPU Unit.

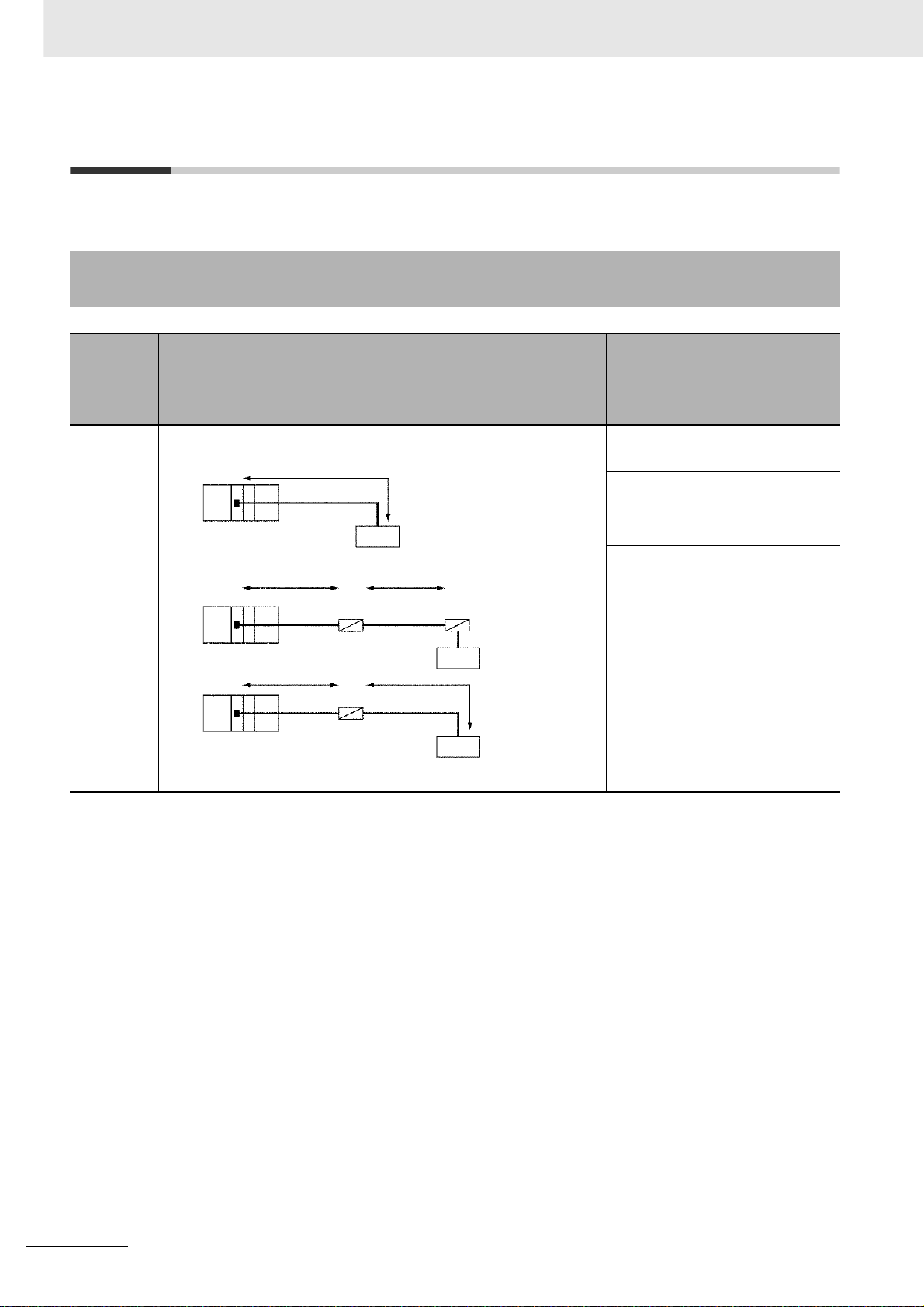

Basic information

NJ-series User’s Manuals

Introduction to NJ-series Controllers

Setting devices and hardware

Using motion control

Using EtherCAT

Using EtherNet/IP

Using CJ-series Units

Software settings

Using motion control

Using EtherCAT

Using EtherNet/IP

Programming

Using motion control

Using EtherCAT

Using CJ-series Units

Programming error processing

Testing operation and debugging

Using motion control

Using EtherCAT

Using EtherNet/IP

Troubleshooting and managing

errors in an NJ-series Controller

NJ-series CPU Unit

Hardware User´s Manual

Use the

relevant

manuals for

references

according to

any error that

occurs.

NJ-series CPU Unit

Software User´s Manual

NJ-series Instructions

Reference Manual

NJ-series CPU Unit Motion

Control User´s Manual

NJ-series CPU Unit Built-in

EtherCAT Port User´s Manual

NJ-series Motion Control

Instructions Reference Manual

NJ-series CPU Unit Built-in

EtherNet/IP Port User´s Manual

NJ-series Troubleshooting Manual

CJ-series Special Unit Operation

Manuals for NJ-series CPU Unit

Maintenance

Using EtherCAT

Using EtherNet/IP

Using CJ-series Units

2

CJ-series Serial Communications Units Operation Manual for NJ-series CPU Unit(W494)

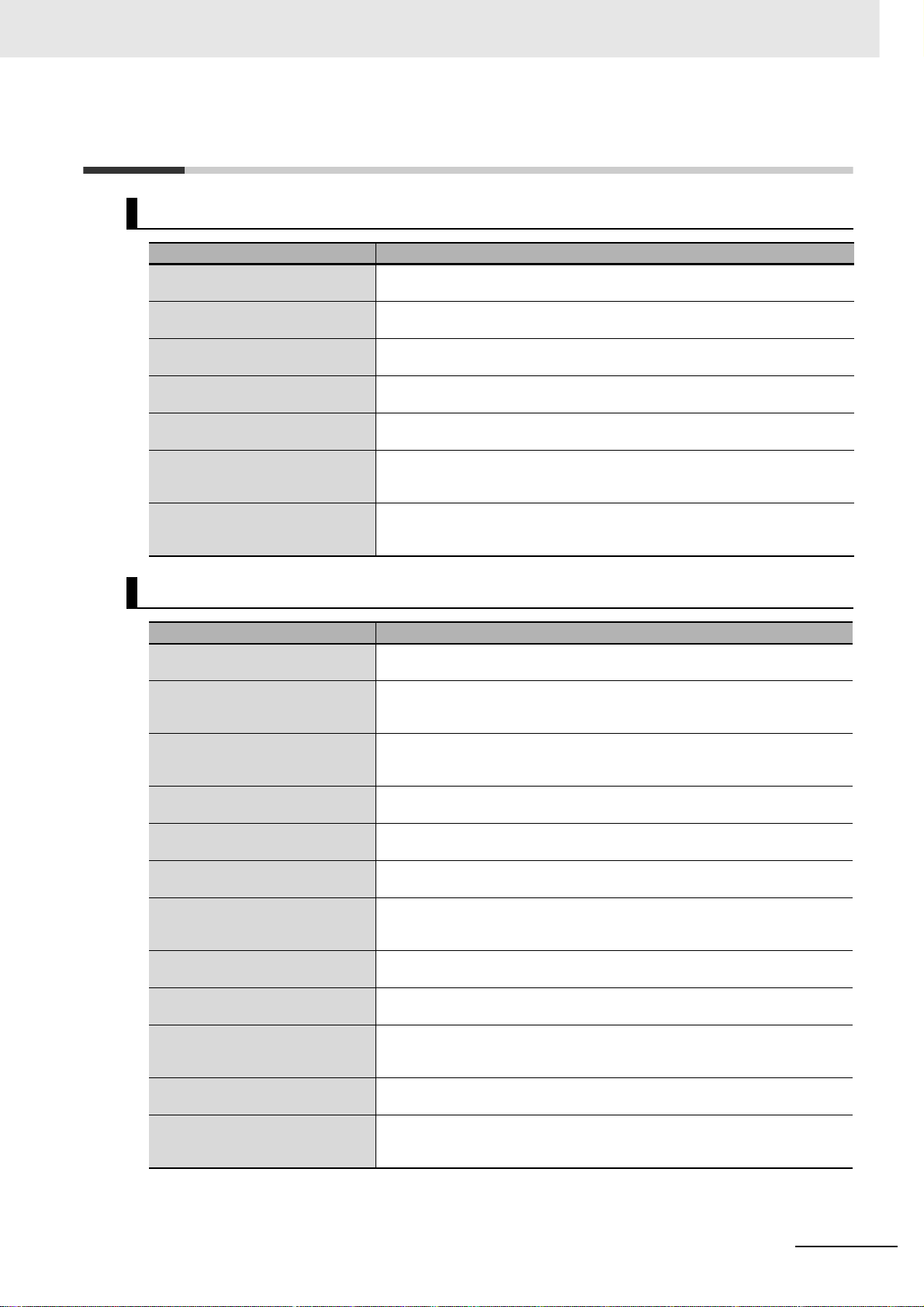

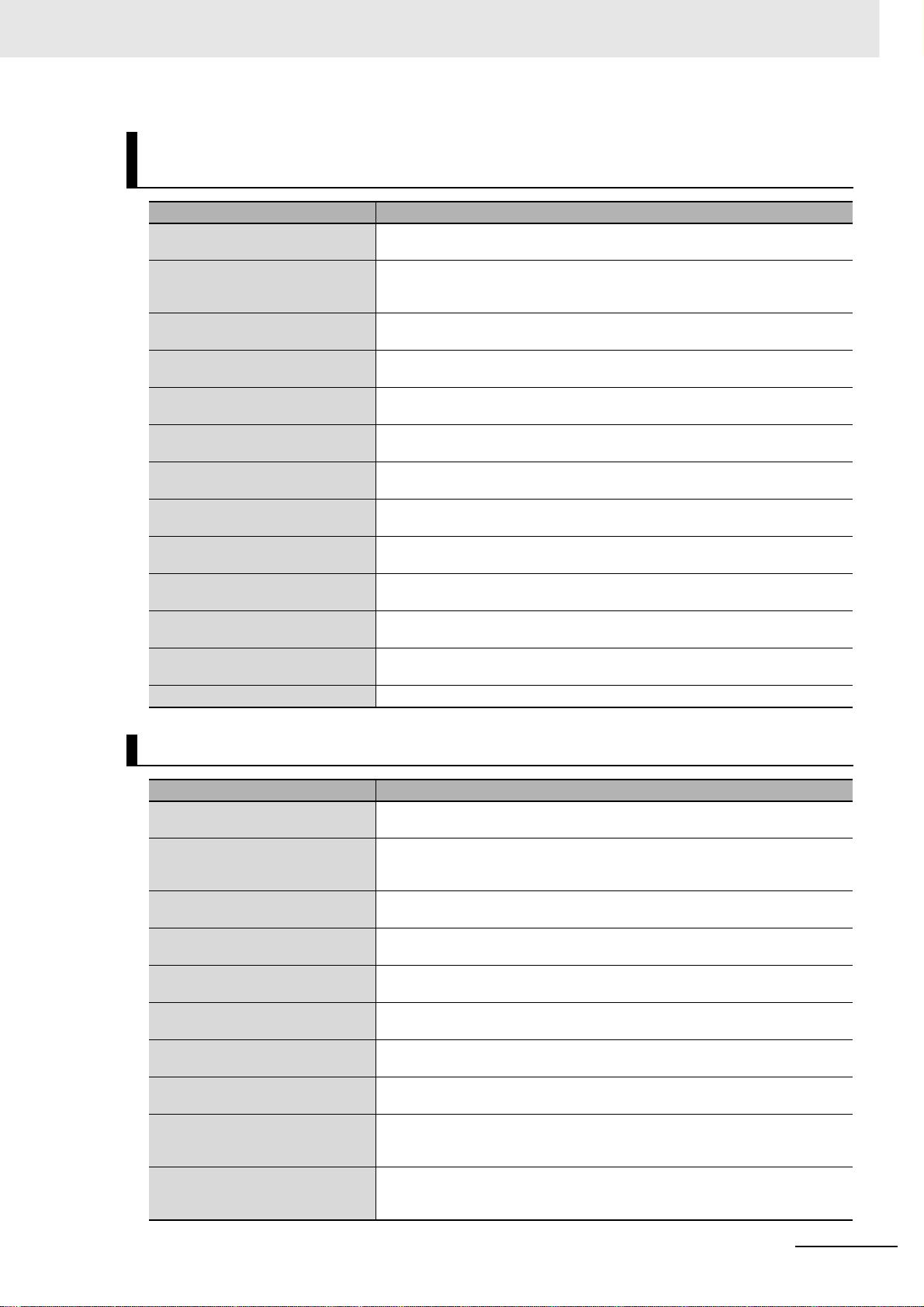

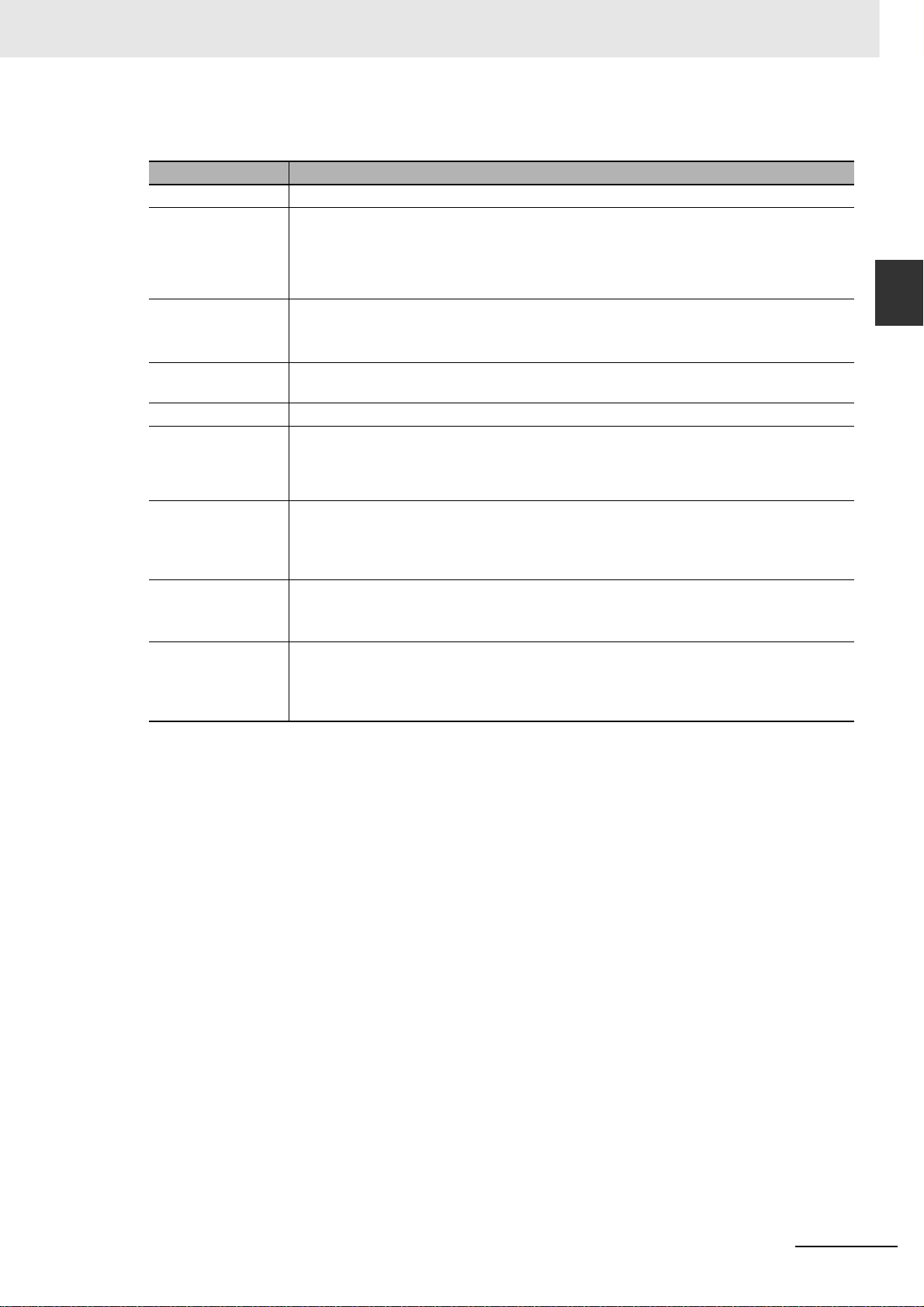

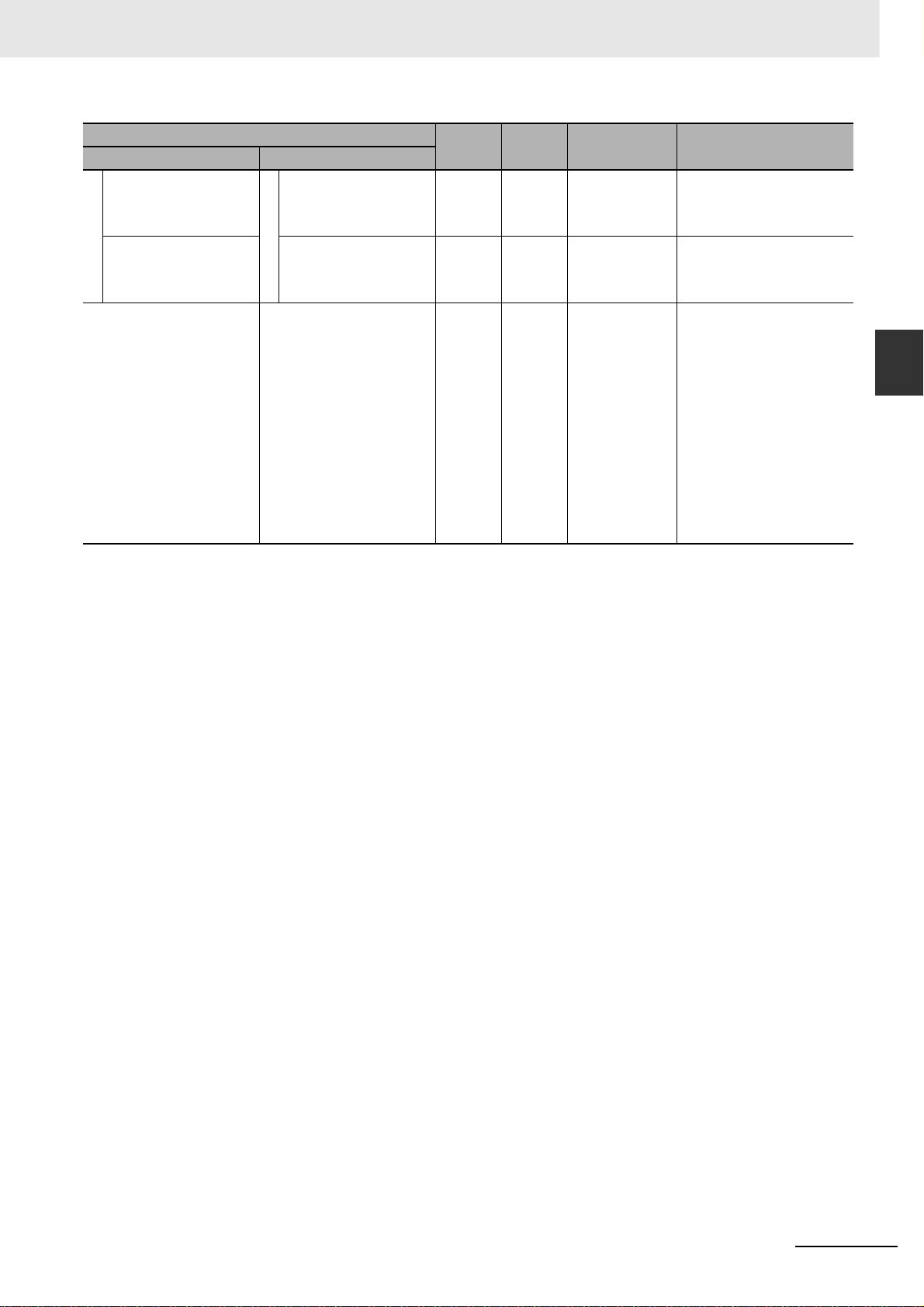

Manual Configuration

NJ-series CPU Unit Hardware User's Manual (Cat. No. W500)

Section Description

Section 1

Introduction

Section 2

System Configuration

Section 3

Configuration Units

Section 4

Installation and Wiring

Section 5

Troubleshooting

Section 6

Inspection and Maintenance

Appendices

This section provides an introduction to the NJ-series Controllers and their features,

and gives the NJ-series Controller specifications.

This section describes the system configuration used for NJ-series Controllers.

This section describes the parts and functions of the configuration devices in the NJseries Controller configuration, including the CPU Unit and Configuration Units.

This section describes where and how to install the CPU Unit and Configuration Units

and how to wire them.

This section describes the event codes, error confirmation methods, and corrections

for errors that can occur.

This section describes the contents of periodic inspections, the service life of the Battery and Power Supply Units, and replacement methods for the Battery and Power

Supply Units.

The appendices provide the specifications of the Basic I/O Units, Unit dimensions,

load short-circuit protection detection, line disconnection detection, and measures for

EMC Directives.

Manual Configuration

NJ-series CPU Unit Software User's Manual (Cat. No. W501)

Section Description

Section 1

Introduction

Section 2

CPU Unit Operation

Section 3

I/O Ports, Slave Configuration, and

Unit Configuration

Section 4

Controller Setup

Section 5

Designing Tasks

Section 6

Programming

Section 7

Checking Operation and Actual

Operation

Section 8

CPU Unit Functions

Section 9

Communications Setup

Section 10

Example of Actual Application Procedures

Section 11

Troubleshooting

Appendices

This section provides an introduction to the NJ-series Controllers and their features,

and gives the NJ-series Controller specifications.

This section provides information that is necessary to use the CPU Unit, including

how the CPU Unit works and the operations that it performs depending on the status

of the CPU Unit.

This section describes how to use I/O ports, how to create the slave configuration

and unit configuration and how to assign functions.

This section describes the initial settings of the function modules.

This section describes the task system and types of tasks.

This section describes programming, including the programming languages and the

variables and instructions that are used in programming.

This section describes the items and procedures for checking the operation of an NJseries Controller, including offline debugging procedures.

This section describes the functionality provided by the CPU Unit.

This section describes how to go online with the CPU Unit and how to connect to

other devices.

This section describes the procedures that are used to actually operate an NJ-series

Controller.

This section describes the event codes, error confirmation methods, and corrections

for errors that can occur.

The appendices provide the CPU Unit specifications, task execution times, specifications of individual system-defined variables, data attribute lists, CJ-series Unit memory information, CJ-series Unit memory allocation methods, and version information.

CJ-series Serial Communications Units Operation Manual for NJ-series CPU Unit(W494)

3

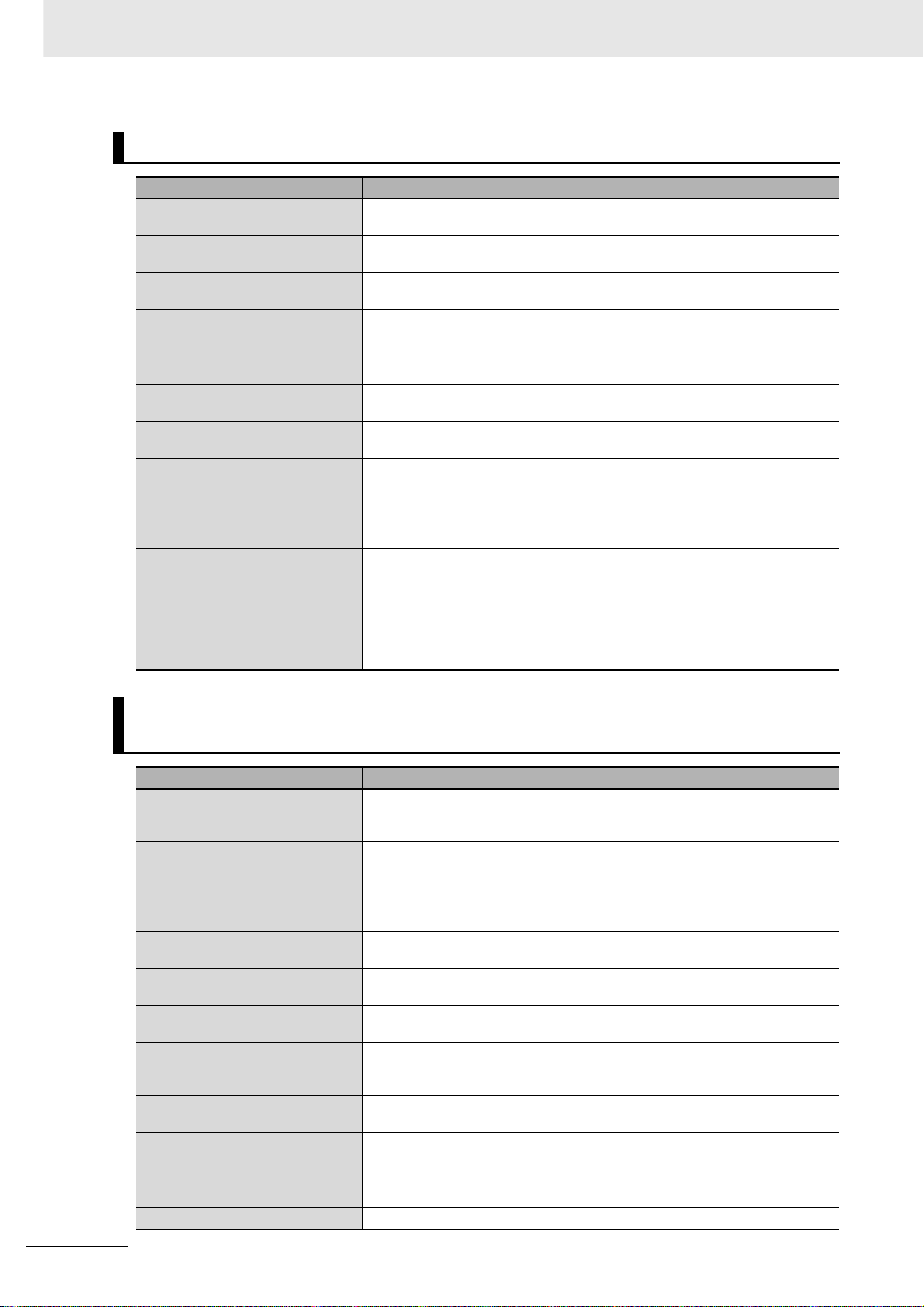

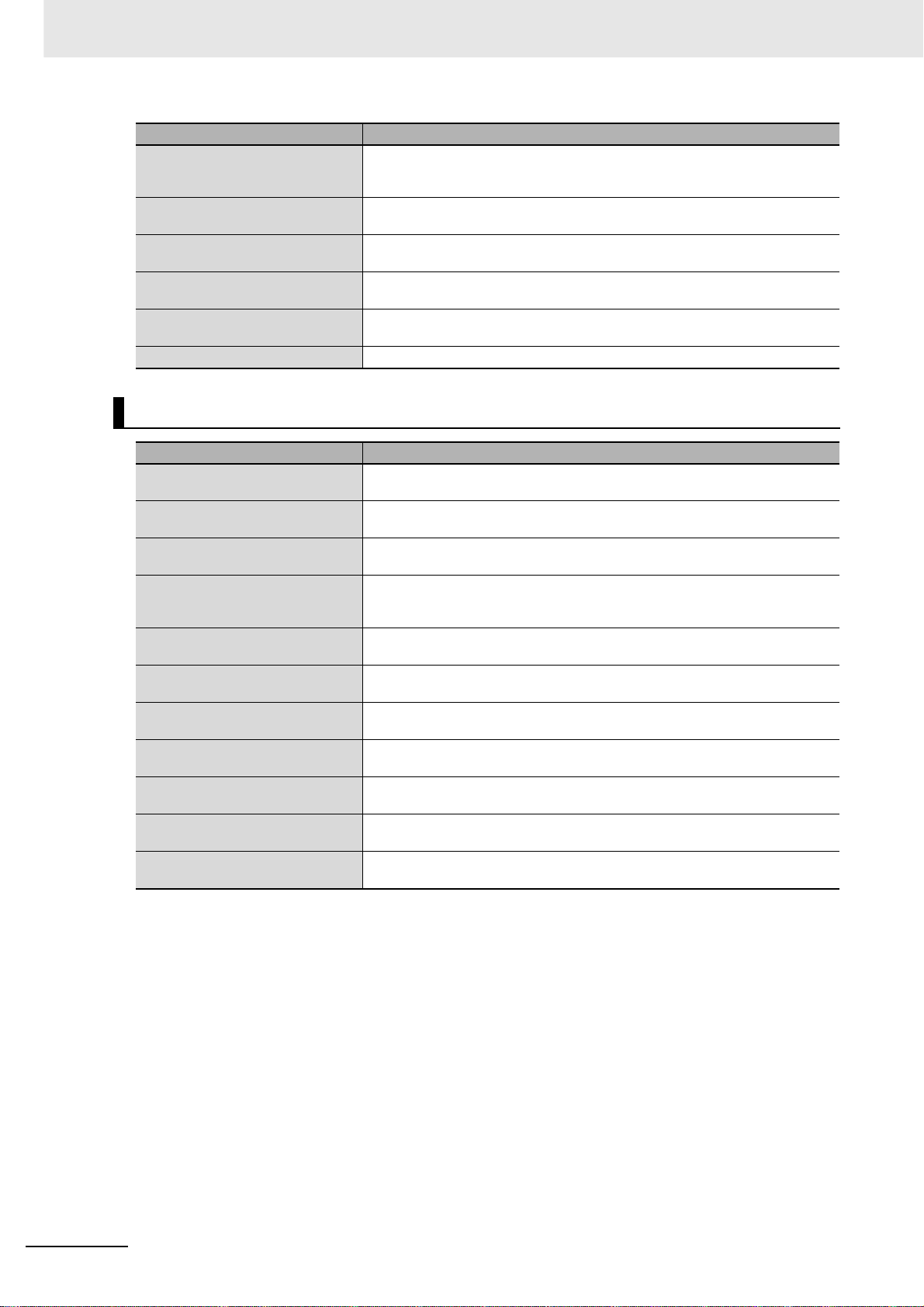

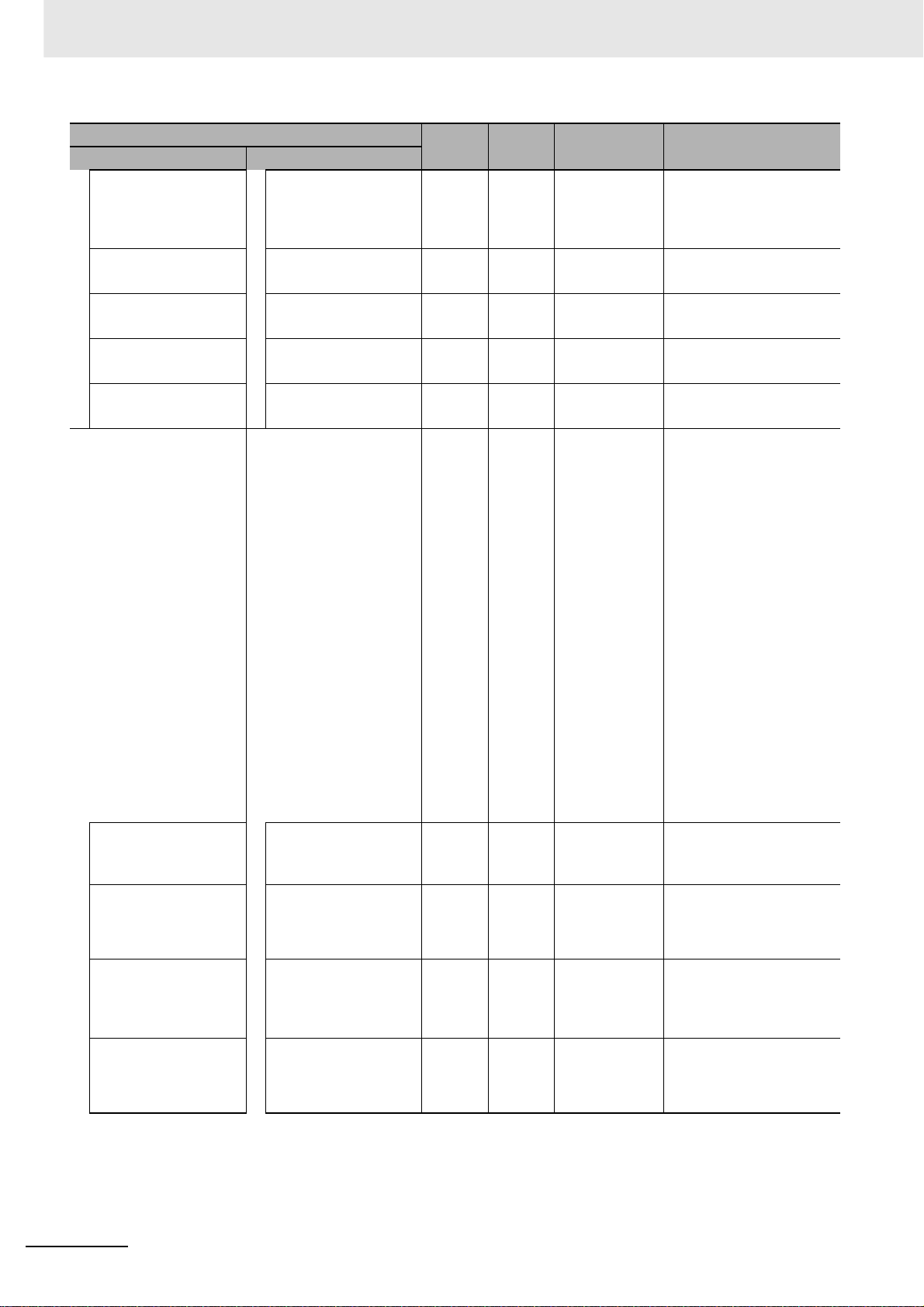

Manual Configuration

Sysmac Studio Version 1 Operation Manual (Cat. No. W504)

Section Description

Section 1

Introduction

Section 2

Installation and Uninstallation

Section 3

System Design

Section 4

Programming

Section 5

Online Connections to a Controller

Section 6

Debugging

Section 7

Other Functions

Section 8

Reusing Programming

Section 9

Support Software Provided with the

Sysmac Studio

Section 10

Troubleshooting

Appendices

This section provides an overview and lists the specifications of the Sysmac Studio

and describes its features and components.

This section describes how to install and uninstall the Sysmac Studio.

This section describes the basic concepts for designing an NJ-series System with the

Sysmac Studio and the basic operating procedures.

This section describes how to create programs with the Sysmac Studio.

This section describes how to go online with a Controller.

This section describes how to debug the programs online on the Controller or debug

it offline with the Simulator.

This section describes other functions that are supported by the Sysmac Studio,

including security functions and troubleshooting functions.

This section describes how to reuse the programs that you create with the Sysmac

Studio.

This section describes the Support Software that is provided with the Sysmac Studio.

This section describes the error messages that are displayed when you check a program on the Sysmac Studio and how to correct those errors.

The appendices describe the following:

Driver Installation for Direct USB Cable Connection

Specifying One of Multiple Ethernet Interface Cards

Online Help

Simulation Instructions

CJ-series Serial Communications Units Operation Manual for NJseries CPU Unit (Cat. No. W494) (this manual)

Section Description

Section 1

Introduction

Section 2

Initial Settings and Allocations of

Device Variables for CJ-series Unit

Section 3

Installation and Wiring

Section 4

Using Protocol Macros

Section 5

Serial Gateway

Section 6

No-protocol Mode

Section 7

Using Modbus-RTU Slave Mode

Section 8

Loopback Test

Section 9

Troubleshooting and Maintenance

Reference

Appendix ---

This section provides an introduction to the Serial Communications Units and their

features. It also describes the operating procedure and the specifications of the

Serial Communications Units.

This section describes the data exchange between the CPU Unit and Serial Communications Unit and the definitions of the device variables for CJ-series Unit.

This section describes where and how to install the Serial Communications Unit, and

how to connect and wire them.

This section describes the protocol macro function provided by the Serial Communications Unit and the procedure for using the function.

This section describes the Serial Gateway function provided by the Serial Communications Unit and the procedure for using the function.

This section describes the No-protocol Mode function provided by the Serial Communications Unit to send/receive data, and the procedure for using the function.

This section describes the Modbus-RTU Slave Mode function provided by the Serial

Communications Unit, the procedure for using the function and the details of the

command responses.

This section describes the loopback test function provided by the Serial Communications Unit and the procedure for using the function.

This section describes the troubleshooting procedure, event logs and maintenance

procedure for the Serial Communications Unit.

This section describes the details on the standard system protocols provided by the

CX-Protocol and the Serial Communications Unit.

4

CJ-series Serial Communications Units Operation Manual for NJ-series CPU Unit(W494)

Manual Configuration

SYSMAC CS/CJ Series Serial Communications Boards Serial

Communications Units OPERATION MANUAL (Cat. No. W336)

Section Description

Section 1

Introduction

Section 2

Initial Settings and I/O Memory

Allocations

Section 3

Installation and Wiring

Section 4

Using Host Link Communications

Section 5

Using Protocol Macros

Section 6

Serial Gateway

Section 7

No-protocol Mode

Section 8

Using 1:N NT Links

Section 9

Using Modbus-RTU Slave Mode

Section 10

Communications Performance

Section 11

Loopback Test

Section 12

Troubleshooting and Maintenance

Appendices ---

This section introduces the features, specifications, and procedures of the Serial

Communications Boards and the Serial Communications Units.

This section describes the data exchange between the CPU Unit and the Serial Communications Boards/Serial Communications Units, and the I/O memory allocation.

This section describes how to mounting the Serial Communications Board and Serial

Communications Units, and how to connect the ports to external devices.

This section describes the procedure and other information required to use Host Link

communications.

This section describes the procedure and other information required to use the protocol macros.

This section describes the procedure and other information required to use the Serial

Gateway.

This section describes the procedure and other information required to use the noprotocol mode.

This section describes the procedure and other information required to use the 1:N

NT Links to Programmable Terminals

This section describes the procedure and other information required to use the

Modbus-RTU slave mode.

This section describes the communications performance of the Serial Communications Boards and the Serial Communications Units.

This section describes the procedure and other information required to conduct loopback test.

This section describes the troubleshooting and maintenance procedures for the

Serial Communications Boards and the Serial Communications Unit.

CX-Protocol Ve r.1.9 OPERATION MANUAL (Cat. No. W344)

Section Description

Section 1

Introduction

Section 2

Installing/Uninstalling/Starting/

Ending

Section 3

Protocol Macro

Section 4

Using the Protocol Macro Function

Section 5

Object Creation

Section 6

Project and Protocol Editing

Section 7

Sequence Setting and Editing

Section 8

Step Setting and Editing

Section 9

Setting and Editing Messages and

Matrix Lists

Section 10

Communications PLC Setup and

Online Connections

This section introduces the Protocol Macro function, the features and specifications

of the CX-Protocol, and outline of the standard system protocol.

This section outlines the functions of the CX-Protocol and describes installation procedure, startup/shutdown, and the user interface for the CX-Protocol.

This section describes details of the protocol macro functions.

This section describes the communications sequence and settings for the protocol

macro function.

This section describes how to create objects, such as projects, protocols, sequences,

steps, messages, and matrices.

This section describes details of the editing of projects and protocols.

This section describes details of the creating, setting and editing of sequences.

This section describes details of the creating, setting and editing of steps.

This section describes details of the creating, setting and editing of messages and

matrix lists.

This section describes details of the communications settings and online connections.

CJ-series Serial Communications Units Operation Manual for NJ-series CPU Unit(W494)

5

Manual Configuration

Section Description

Section 11

Protocol Data Transferring and

Printing

Section 12

Tracing and Monitoring

Section 13

Error and Error Log Display

Section 14

Troubleshooting

Section 15

Help

Appendices ---

CX-Integrator Ver.2. Operation Manual (Cat. No. W464)

Section Description

Section 1

Overview

Section 2

Basic Operations

Section 3

Routing Tables

Section 4

Data Links for Controller Link and

SYSMAC LINK

Section 5

Ethernet

Section 6

DeviceNet

Section 7

CompoNet

Section 8

CompoWay/F

Section 9

NT Links

Section 10

Network Testing

Appendices

This section describes details of the transferring, converting, and printing of protocol

data.

This section describes details of PLC memory area monitoring and the transmission

line tracing.

This section describes details of the displaying of errors and the error log. This function cannot be used in NJ series.

This section lists the error messages and describes their causes and remedies.

This section describes the online help services.

This section provides an overview of the CX-Integrator and describes the CX-Integrator menus and connecitions.

This section describes the basic operations used for the CX-Integrator.

This section describes how to set the routing tables. For NJ-series, routing table is

created by using Sysmac Studio instead of CX-Integrator.

This section describes how to set data links for Controller Link and SYSMAC LINK

networks.

This section describes the operations specific to Ethernet.

This section describes the settings and operations unithe to DeviceNet networks

including registeing slaves in the master, I/O allocations, and devide monitoring.

This section describes the basic usage of CompoNet networks and how to set ConpoNet parameters.

This section describes the settings and operations specific to the CompoWay/F system.

This section describes the settings and operations specific to the NT Link system.

This section describes the operations of the network test tool.

This section describes the CPS files for Ethernet, Controller Link, CompoWay/F and

NT Link Networks, and EDS files for DeviceNet Networks.

6

CJ-series Serial Communications Units Operation Manual for NJ-series CPU Unit(W494)

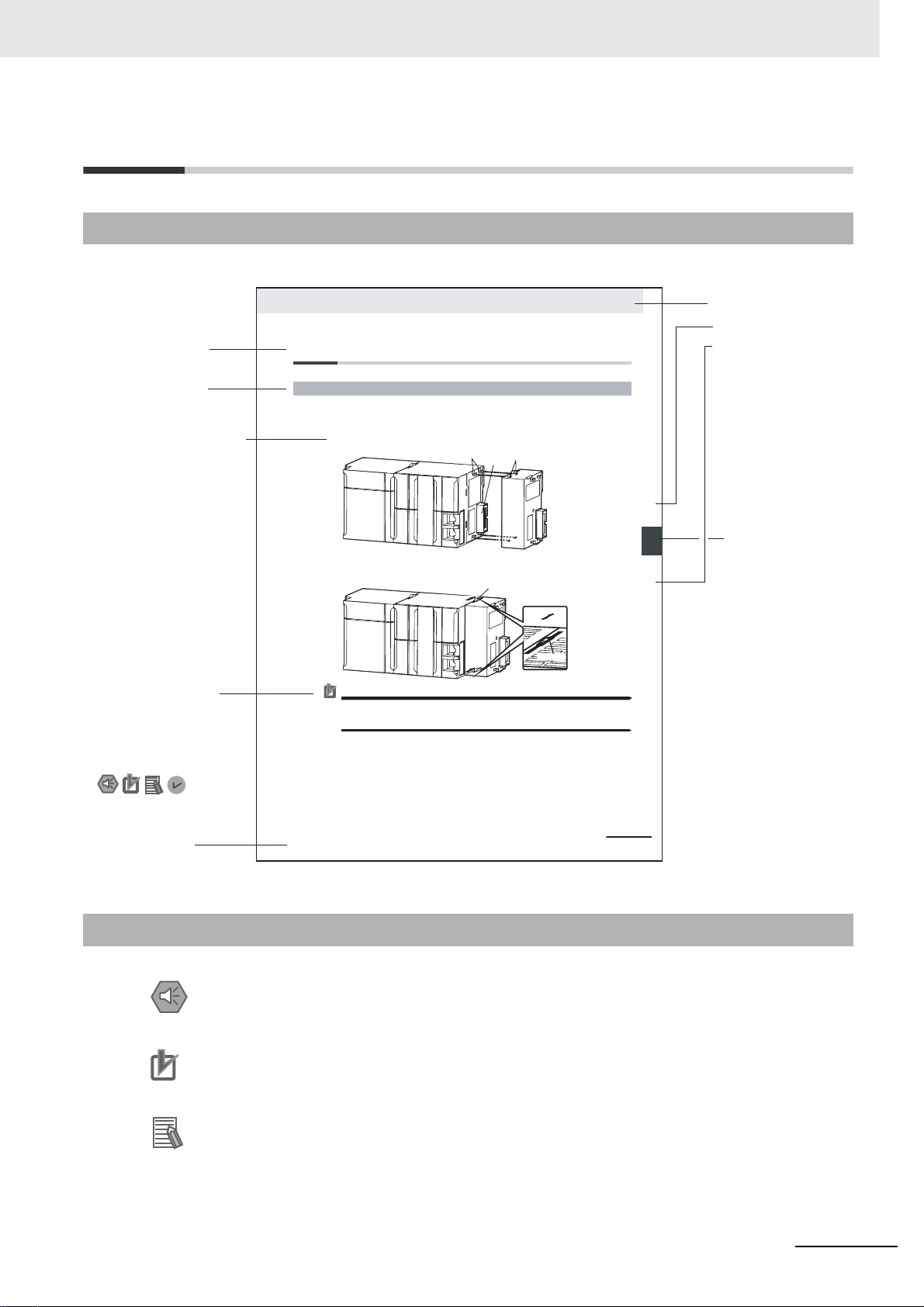

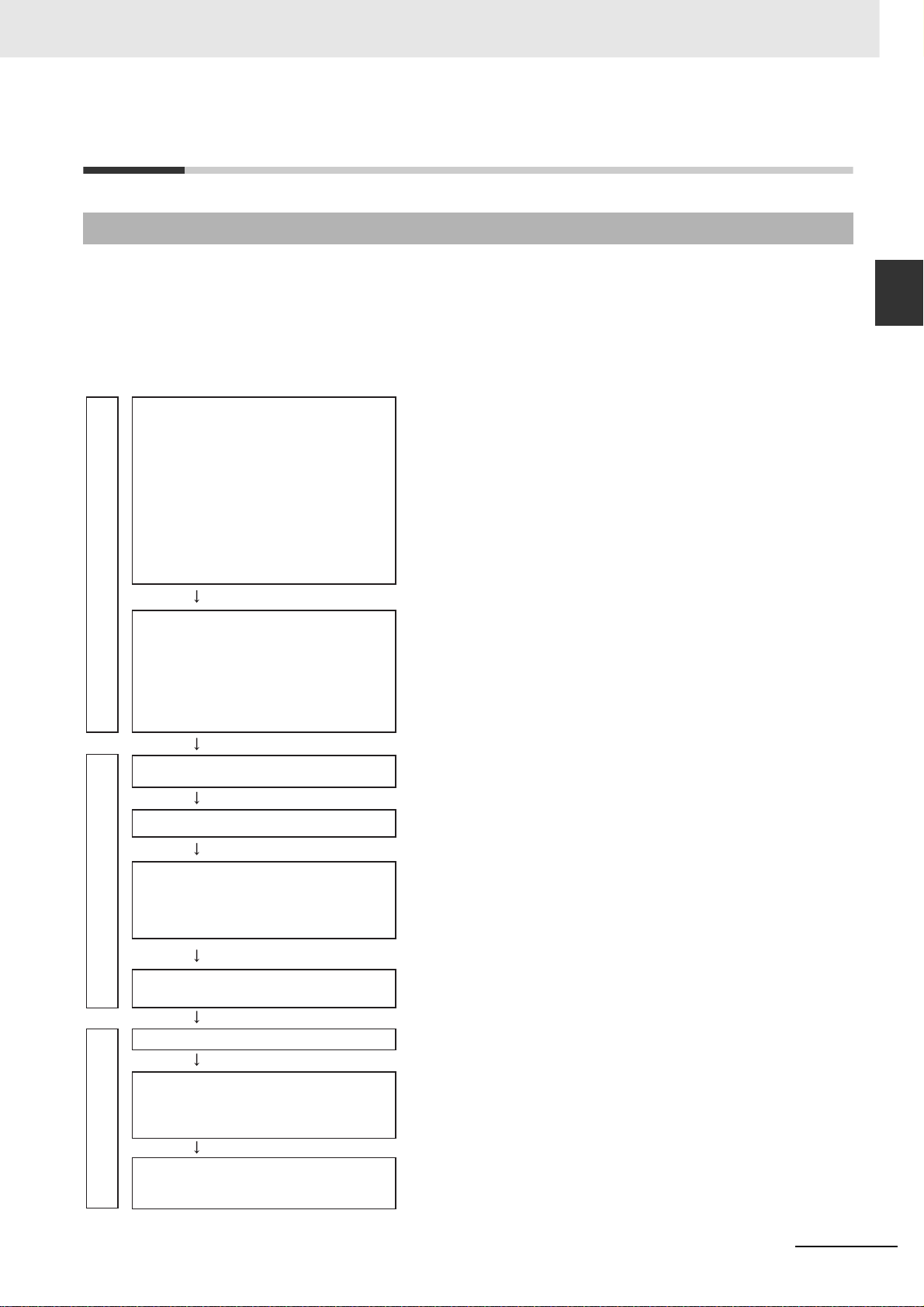

Manual Structure

Page Structure

The following page structure is used in this manual.

Manual Structure

Level 2 heading

Level 3 heading

A step in a procedure

Indicates a procedure.

Special information

Icons indicate

precautions, additional

information, or reference

information.

4 Installation and Wiring

4-3 Mounting Units

4-3-1 Connecting Controller Components

The Units that make up an NJ-series Controller ca n b e c o nn ec te d si m pl y b y p re s s in g th e Un i t s t o g e t h e r

and locking the sliders by moving them toward the bac k of th e Un its . Th e E nd Co ver is connecte d in t h e

same way to the Unit on the far right side of the Controller.

1 Join the Units so that the connectors fit exactly.

2 The yellow sliders at the top and bottom of each Unit lock the Units together. Move the sliders

toward the back of the Units as shown below until they click into place.

Precautions for Correct UsePrecautions for Correct Use

The sliders on the tops and bottoms of the Power Supply Unit, CPU Unit, I/O Units, Special I/O

Units, and CPU Bus Units must be completely locked (until they c l ick into place) after connecting

the adjacent Unit connectors.

Hook

Connector

Move the sliders toward the back

until they lock into place.

Hook holes

Release

Lock

Slider

Level 1 heading

Level 2 heading

Level 3 heading

Gives the current

headings.

stinU gnitnuoM 3-4

4

stnenopmoC rellortnoC gnitcennoC 1-3-4

Page tab

Gives the number

of the main section.

Manual name

NJ-series CPU Unit Hardware User’s Manual (W500)

This illustration is provided only as a sample. It may not literally appear in this manual.

Special Information

Special information in this manual is classified as follows:

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase unde rstanding or make operation easier.

CJ-series Serial Communications Units Operation Manual for NJ-series CPU Unit(W494)

4-9

7

Manual Structure

Version Information

Information on differences in specifications and functionality for CPU Units with different unit versions

and for different versions of the Sysmac Studio is given.

Note References are provided to more detailed or related information.

Precaution on Terminology

In this manual, "download" refers to transferring data from the Sysmac Studio to the physical Controller

and "upload" refers to transferring data from the physical Controller to the Sysmac Studio.

For the Sysmac Studio, synchronization is used to both upload and download data. Here , "synchron iz e"

means to automatically compare t he data for the Sysmac Studio on the comp uter with the data in the

physical Controller and tran sfer the data in the direction that is specified by the user .

8

CJ-series Serial Communications Units Operation Manual for NJ-series CPU Unit(W494)

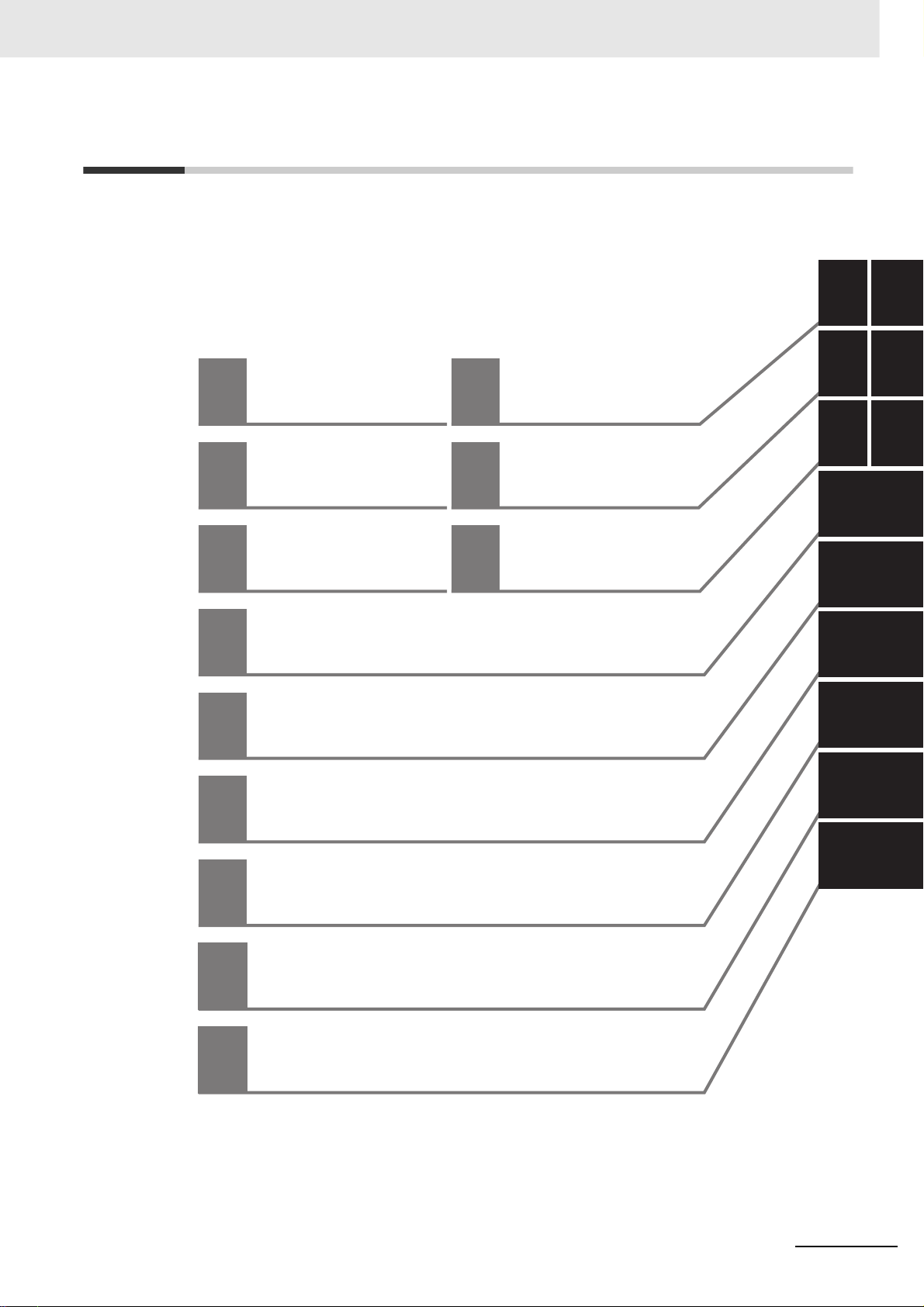

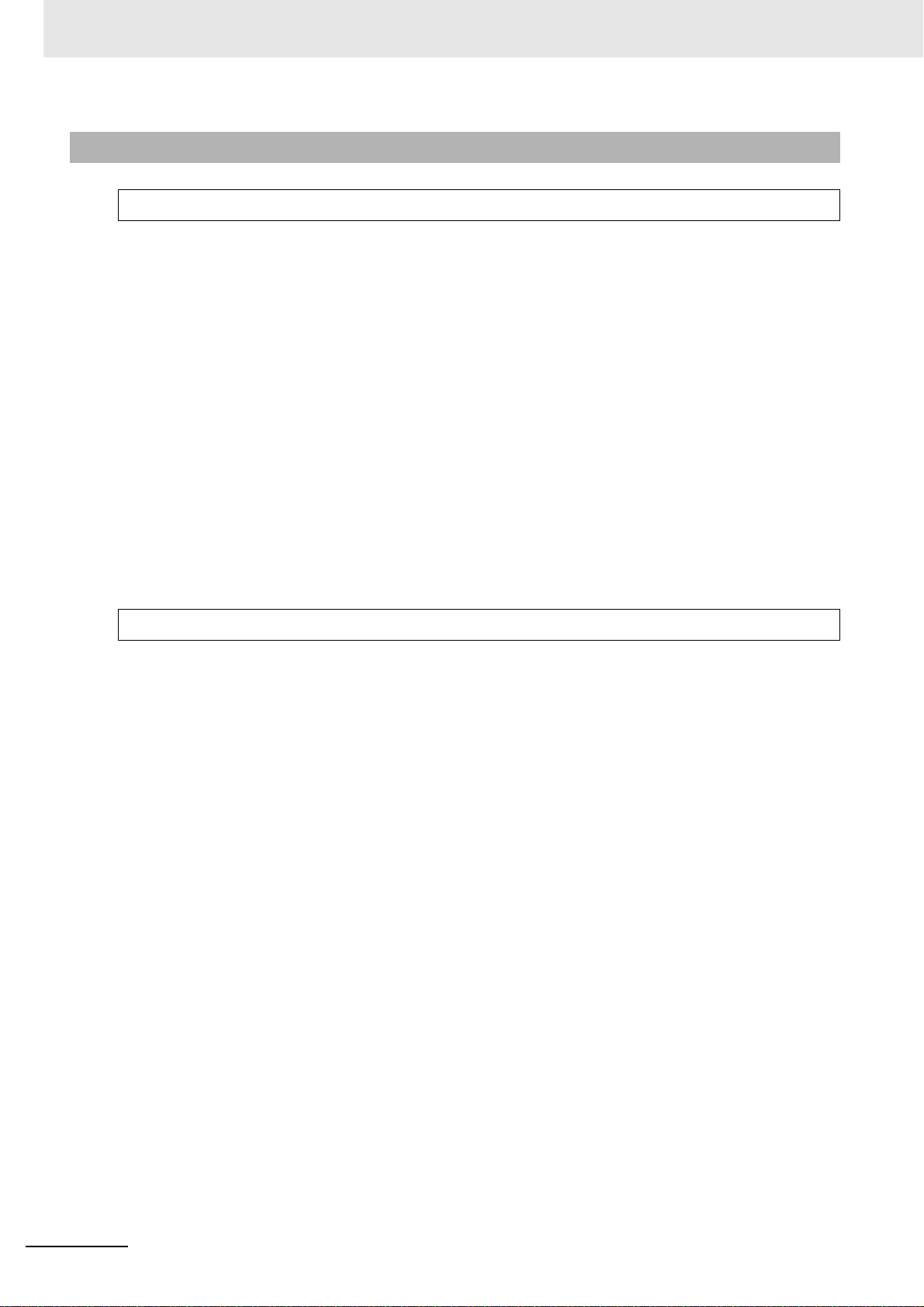

Sections in this Manual

Sections in this Manual

1R

1R

2A

3I

4

5

6

Introduction

Initial Settings and

Allocations of Device

Variable for CJ-series Unit

Installation and

Wiring

Using Protocol

Macros

Serial Gateway

No-protocol Mode

A Standard

System Protocol

Appendices

Index

2A

3I

4

5

6

7

8

Using Modbus-RTU Slave Mode

7

8

9

CJ-series Serial Communications Units Operation Manual for NJ-series CPU Unit(W494)

Loopback Test

Troubleshooting and Maintenance

9

9

CONTENTS

CONTENTS

Introduction ...............................................................................................................1

Relevant Manuals......................................................................................................2

Manual Configuration ...............................................................................................3

Manual Structure.......................................................................................................7

Sections in this Manual ............................................................................................9

CONTENTS...............................................................................................................10

Read and Understand this Manual ........................................................................15

Safety Precautions..................................................................................................18

Precautions for Safe Use........................................................................................23

Precautions for Correct Use...................................................................................29

Regulations and Standards....................................................................................32

Unit Versions ...........................................................................................................35

Related Manuals......................................................................................................37

Revision History......................................................................................................38

Section 1 Introduction

1-1 Using this Manual....................................................................................................................1-2

1-2 Overview................................................................................................................................... 1-3

1-3 Protocol Overview ................................................................................................................... 1-5

1-3-1 Protocol Macros..........................................................................................................................1-6

1-3-2 Loopback Test.............................................................................................................................1-6

1-3-3 Serial Gateway Mode.................................................................................................................. 1-6

1-3-4 No-protocol Mode........................................................................................................................ 1-7

1-3-5 Modbus-RTU Slave Mode...........................................................................................................1-7

1-4 Features.................................................................................................................................... 1-8

1-4-1 Serial Communications Units......................................................................................................1-8

1-4-2 Protocols.....................................................................................................................................1-8

1-5 System Configurations ......................................................... ... ... ... ... .................................... 1-10

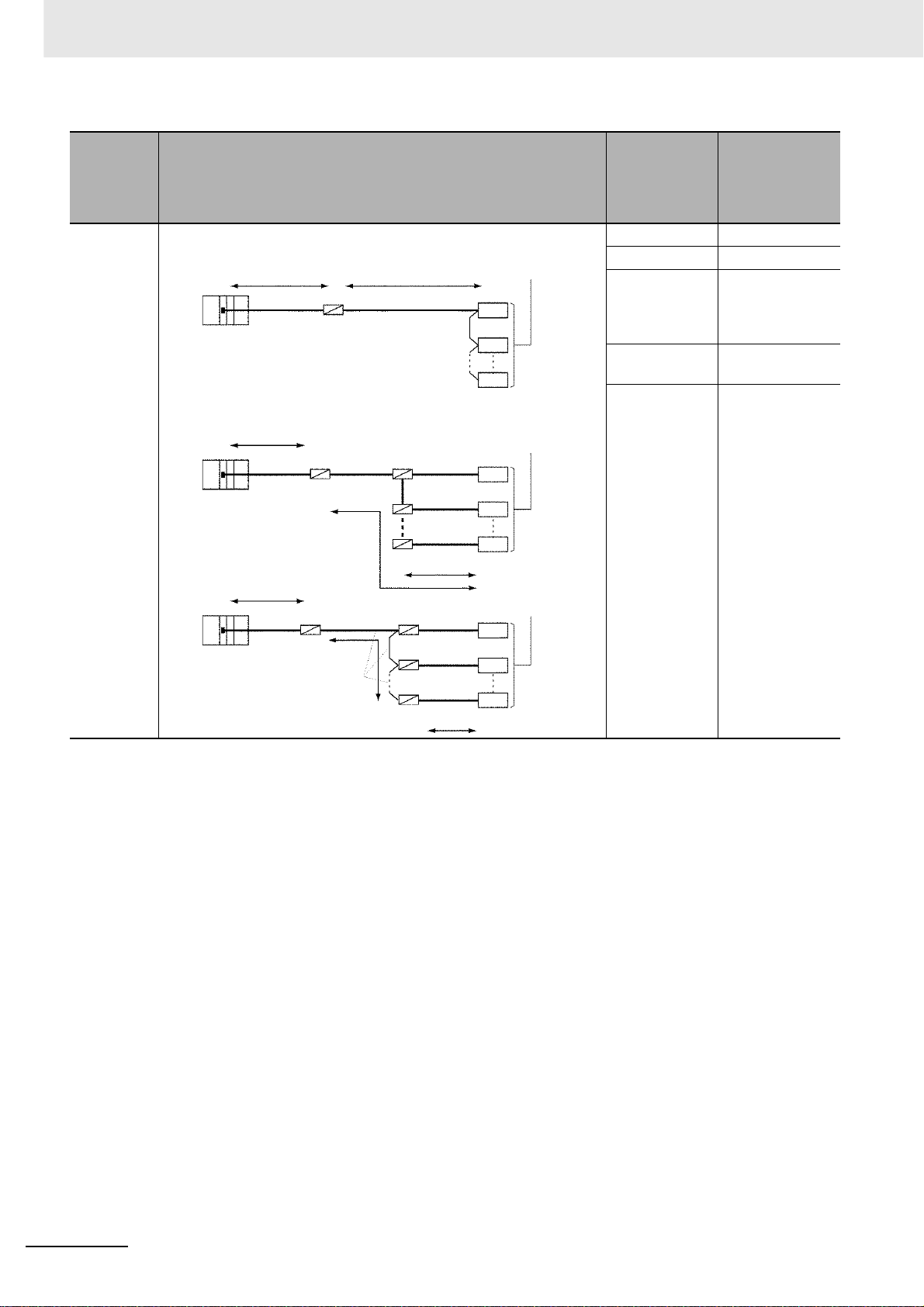

1-5-1 Protocol Macro, Serial Gateway, No-protocol, or Modbus-RTU Slave......................................1-10

1-6 Specifications ........................................................................................................................ 1-14

1-6-1 Serial Communications Unit......................................................................................................1-14

1-6-2 General Specifications.................................. ... .................................... ... ..................................1-15

1-7 Selecting the Serial Communications Mode....................................................................... 1-22

10

1-8 Basic Operating Procedure .................................................. ... ... .......................................... 1-23

1-8-1 Overview...................................................................................................................................1-23

1-8-2 Explanation of Procedure. .... .....................................................................................................1-24

CJ-series Serial Communications Units Operation Manual for NJ-series CPU Unit(W494)

CONTENTS

Section 2 Initial Settings and Allocations of Device V ariable f or CJ-

series Unit

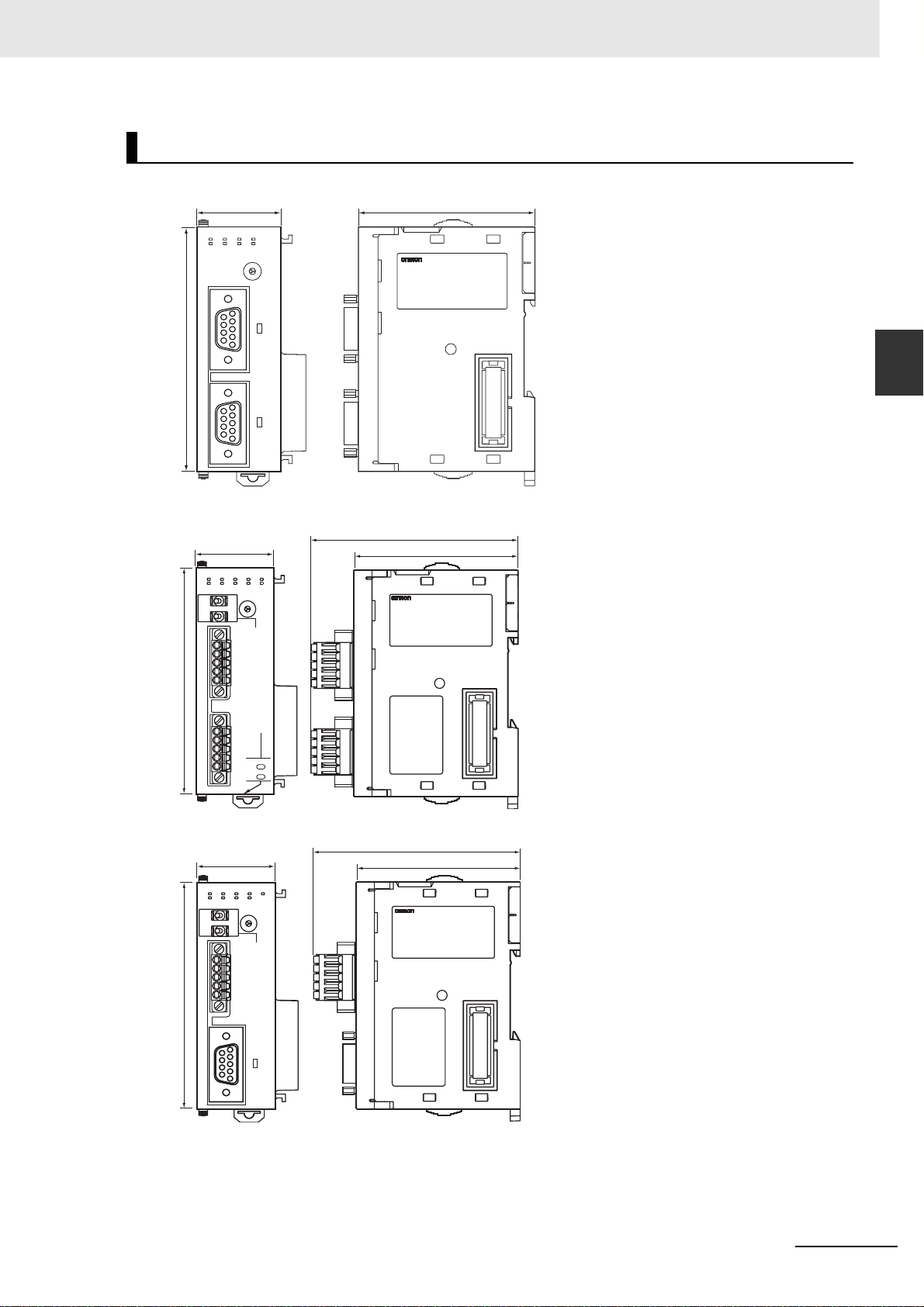

2-1 Component Names and Functions ........................................................................................ 2-2

2-2 Data Exchange with the CPU Unit .......................................................................................... 2-8

2-2-1 Data Flow.................................................................................................................................... 2-8

2-2-2 How to Specify and Create Variables ....................................................................................... 2-12

2-3 Device Variable for CJ-series Unit ....................................................................................... 2-14

2-3-1 Allocations of Device Variable for CJ-series Unit......................................................................2-14

2-3-2 Device Variable for CJ-series Unit for System Settings............................................................2-14

2-3-3 Device Variable for CJ-series Unit for Software Switches......................................................... 2-23

2-3-4 Device Variable for CJ-series Unit for Status............................................................................2-24

2-4 System-defined Variable....................................................................................................... 2-34

Section 3 Installation and Wiring

3-1 Installing Serial Communications Units................................................................................ 3-2

3-1-1 System Configuration Precautions ............................................................................................. 3-2

3-1-2 Serial Communications Unit Installation Procedure.................................................................... 3-2

3-1-3 Unit Handling Precautions.......................................................................................................... 3-3

3-2 Wiring ....................................................................................................................................... 3-4

3-2-1 Wiring Precautions ................... ... ... ... .................................... ... .................................... .............. 3-4

3-2-2 Port Types...................................................................................................................................3-4

3-2-3 Communications Modes and Ports.............................................................................................3-4

3-2-4 Connector Pin Layout................................................................................................................. 3-5

3-2-5 Mounting Height and Connector Cover Dimensions................................................................... 3-6

3-2-6 Reducing Electrical Noise for External Wiring............................................................................ 3-7

3-2-7 2-Wire and 4-Wire Connections..................................................................................................3-7

3-2-8 NT-AL001 Link Adapter Settings.................................................................................................3-8

3-2-9 Connections for Protocol Macro, Serial Gatewa y, No-protocol Mode,

and Modbus-RTU Slave Mode....................................................................................................3-9

3-2-10 Connections in Loopback Test...................................................................................... ... ......... 3-18

3-3 RS-232C and RS-422A/485 Wiring ....................................................................................... 3-19

3-3-1 Recommended RS-232C Wiring Examples ....................... ..................................... ... .............. 3-19

3-3-2 Recommended RS-422A/485 Wiring Examples......................................................... .............. 3-20

3-3-3 Wiring RS-232C Connectors on the CJ1W-SCU22/42............................................................. 3-22

3-3-4 Soldering .................................................................................................................................. 3-23

3-3-5 Assembling Connector Hood....................................................................................................3-24

3-3-6 Wiring RS-422A/485 Terminal-block Connectors on the CJ1W-SCU32/42..............................3-25

3-3-7 Connecting to Unit....................................................................... .. ... ........................................ 3-26

Section 4 Using Protocol Macros

4-1 Overview of the Protocol Macro Function............................................................................. 4-2

4-1-1 Protocol Macros..........................................................................................................................4-2

4-1-2 Using the Protocol Macros............................... .. ... ..................................... .. ............................... 4-2

4-1-3 Protocol Structure....................................................................................................................... 4-4

4-1-4 Data Exchange Method for Link Words.................................................................................... 4-10

4-2 Device Variables for CJ-series Unit and System-defined Variables

(Protocol Macro Mode) ... ... ... ................................................................................................. 4-13

4-2-1 Device Variable for CJ-series Unit for System Settings............................................................4-13

4-2-2 Area Descriptions .....................................................................................................................4-15

4-2-3 System-defined Variable............................................................................................... ... ......... 4-21

4-2-4 Devices Variable for CJ-series Unit for Software Switches.......................................................4-22

4-2-5 Device Variables for CJ-series Unit for Status.......................................................................... 4-24

4-2-6 Protocol Status .........................................................................................................................4-32

CJ-series Serial Communications Units Operation Manual for NJ-series CPU Unit(W494)

11

CONTENTS

4-3 Using Protocol Macros..........................................................................................................4-40

4-3-1 Executing Communications Sequences....................................................................................4-40

4-3-2 User Program Example.............................................................................................................4-42

Section 5 Serial Gateway

5-1 Serial Gateway Overview ........................................................................................................5-2

5-1-1 Overview.....................................................................................................................................5-2

5-1-2 Operating Conditions ................................................................ ..................................... .............5-2

5-1-3 Features......................................................................................................................................5-3

5-1-4 Serial Gateway Specifications.....................................................................................................5-4

5-2 Device Variables for CJ-series Unit and System-defined Variables

(During Serial Gateway Mode)................................................................................................5-5

5-2-1 Device Variables for CJ-series Unit f or System Settings......................... ... .................................5-5

5-2-2 System-defined Variable.............................................................................................................5-8

5-2-3 Device Variable for CJ-series Unit for Software Switches...........................................................5-9

5-2-4 Device Variable for CJ-series Unit f or Status..............................................................................5-9

5-3 Using the Serial Gateway...................................................................................................... 5-12

5-3-1 Setting Device Variable for CJ-series Unit for System Settings and Software Switches...........5-12

5-3-2 Sending Messages Using the SendCmd Instruction.................................................................5-14

5-3-3 Using the Serial Gateway Function When Protocol Macros Are Executed...............................5-15

5-4 Protocol Conversion.............................................................................................................. 5-22

5-4-1 Types of Protocol Conversion....................................................................................................5-22

5-4-2 Converting to CompoWay/F................................................... ... ..................................... .. .........5-23

5-4-3 CompoWay/F Connection Examples ........................................................................................5-25

5-4-4 Converting to Modbus-RTU.. ... .. ..................................... ... .. ..................................... ... ... ...........5-26

5-4-5 Converting to Modbus-ASCII .......................................................... .. ... ... ..................................5-28

5-5 Serial Gateway ....................................................................................................................... 5-29

5-5-1 Serial Gateway Execution Timing for Protocol Macros.............................................................5-29

5-5-2 Serial Gateway Timeout Monitoring..........................................................................................5-31

5-5-3 Other Functions.........................................................................................................................5-32

5-6 Communications Frames...................................................................................................... 5-33

5-6-1 CompoWay/F ............................................................................................................................5-33

5-6-2 Modbus-RTU.............................................................................................................................5-34

5-6-3 Modbus-ASCII...........................................................................................................................5-36

Section 6 No-protocol Mode

6-1 Overview................................................................................................................................... 6-2

6-1-1 Definition.....................................................................................................................................6-2

6-1-2 Specifications..............................................................................................................................6-3

6-1-3 Connections for No-protocol Mode .............................................................................................6-4

6-2 Device Variables for CJ-series Unit and System-defined Variables

(No-protocol Mode)6-5

6-2-1 Device Variables for CJ-Series Unit f or System Settings......................................... ... ... .............6-5

6-2-2 System-defined Variable.............................................................................................................6-8

6-2-3 Device Variable for CJ-series Unit for Software Switches...........................................................6-8

6-2-4 Device Variable for CJ-series Unit f or Status..............................................................................6-8

6-2-5 Device Variable for CJ-series Unit for Status (When Sending/Receiving Data

with SerialSend, SerialRcv, or SerialRcvNoClear Instruction) ..................................................6-11

6-3 Using Serial Port I/O Instructions ........................................................................................ 6-12

6-3-1 System Settings...................................................................................... ... ...............................6-12

6-3-2 Instruction Execution Methods.................................................. ... .................................... ... ......6-12

12

CJ-series Serial Communications Units Operation Manual for NJ-series CPU Unit(W494)

Section 7 Using Modbus-RTU Slave Mode

7-1 Modbus-RTU Slave System................. .... ... ... ......................................................................... 7-2

7-1-1 Modbus-RTU Slave System........................................................................................................7-2

7-1-2 Modbus-RTU Specifications....................................................................................................... 7-2

7-1-3 Communicating with NJ-series CPU Units Using Modbus ......................................................... 7-3

7-2 Device Variables for CJ-series Unit and System-defined Variables

(Modbus-RTU Slave Mode) ..................................................................................................... 7-5

7-2-1 Device Variable for CJ-series Unit for System Settings.............................................................. 7-5

7-2-2 System-defined Variable............................................................................................... ... ...........7-8

7-2-3 Device Variable for CJ-series Unit for Software Switches........................................................... 7-8

7-2-4 Device Variable for CJ-series Unit.............................................................................................. 7-9

7-3 Command and Response Details......................................................................................... 7-13

7-3-1 Supported Modbus-RTU Commands ....................................................................................... 7-13

7-3-2 Command and Response Details............................................................................................. 7-14

Section 8 Loopback Test

CONTENTS

8-1 Executing Loopback Tests .....................................................................................................8-2

8-1-1 Overview.....................................................................................................................................8-2

8-1-2 Connection Method.....................................................................................................................8-2

8-1-3 Procedure...................................................................................................................................8-2

8-1-4 Indicators Used for the Loopback Test......................................... .. ... ..................................... ..... 8-3

8-2 Device Variable for CJ-series Unit (Loopback Test)............................................................. 8-4

8-2-1 Device Variables for CJ-Series Unit for System Settings............................................................8-4

8-2-2 Device Variables for CJ-Series Unit for Status ...........................................................................8-5

Section 9 Troubleshooting and Maintenance

9-1 Indicator Error Displays.......................................................................................................... 9-2

9-2 Communications Status Error Notification........................................................................... 9-3

9-2-1 Status Area Error Information.....................................................................................................9-3

9-3 Troubleshooting....................................................................................................................... 9-4

9-3-1 Serial Gateway (Serial Gateway or Protocol Macro Mode)................................ ... ......................9-4

9-3-2 No-protocol Mode.....................................................................................................................9-10

9-3-3 Protocol Macros........................................................................................................................9-16

9-3-4 Modbus-RTU Slave Mode.........................................................................................................9-22

9-4 Error Logs .............................................................................................................................. 9-25

9-4-1 Error Log Data..........................................................................................................................9-25

9-4-2 Error Contents and Details .......................................................................................................9-26

9-4-3 Error Codes and Troubleshooting.............................................................................................9-28

9-5 Event Logs ............................................................................................................................. 9-30

9-5-1 Overview of the Event Logs......................................................................................................9-30

9-5-2 Error Table ................................................................................................................................ 9-30

9-5-3 Error Descriptions..................................................................................................................... 9-36

9-6 Cleaning and Inspection.......................................................................................................9-53

9-6-1 Cleaning....................................................................................................................................9-53

9-6-2 Inspection .................................................................................................................................9-53

9-7 Replacement Precautions . ... .... ............................................................................................. 9-55

9-7-1 Precautions when Replacing Unit............................................................................................. 9-55

9-7-2 Settings after Replacing Unit.................................................................................................... 9-55

9-7-3 Replacing the Unit....................................................................................................................9-56

CJ-series Serial Communications Units Operation Manual for NJ-series CPU Unit(W494)

13

CONTENTS

A Standard System Protocol

R-1 Reading Reference Documents..............................................................................................R-3

R-1-1 Using Standard System Protocols ............................................................. ... .............................R-3

R-1-2 Standard System Protocols........................................................................................................ R-6

R-2 CompoWay/F Master Protocol................................................................................................R-7

R-2-1 CompoWay/F ............................................................................................................................. R-7

R-2-2 Communications Specifications................................................................................................. R-8

R-2-3 Transmission Procedure.............................................................................................................R-8

R-2-4 Command and Response Formats............................................................................................ R-8

R-2-5 CompoWay/F Master Protocol Sequences.............................................................................. R-12

R-2-6 CompoWay/F Message Frames and PMCR(260) Operands...................................... ... .......... R-12

R-2-7 Send/Receive with ASCII Conversion and with Response......................................................R-13

R-2-8 Structure of the Protocol .............................................................. ... .. ....................................... R-13

R-2-9 Connections.............................................................................................................................R-38

R-3 Mitsubishi Computer Link Master

(A-compatible 1C Frame, Model 1)R-41

R-3-1 Communications Specifications............................................................................................... R-41

R-3-2 Command/Response Formats.................................................................................................R-42

R-3-3 Command Frame Contents......................................................................................................R-43

R-3-4 Mitsubishi Computer Link Master Protocol Sequences............................................................ R-43

R-3-5 Structure of the Protocol .............................................................. ... ......................................... R-43

R-4 V500/V520 Bar Code Reader Protocol .................................................................................R-65

R-4-1 Connections.............................................................................................................................R-65

R-4-2 System Setting.................................................................................. ... .................................... R-66

R-4-3 Protocol Configuration.............................................................................................................. R-67

R-5 3Z4L Laser Micrometer Protocol.......................................... ... ... ... ... .... ... ... ... .... ... ... ... ... .... ...R-78

R-5-1 Connections.............................................................................................................................R-78

R-5-2 List of Operations with Laser Micrometer (5000/6000 Series)................................................. R-81

R-5-3 Protocol Configuration.............................................................................................................. R-83

R-6 Hayes Modem AT Command Protocol ...............................................................................R-117

R-6-1 Protocol Configuration............................................................................................................ R-117

R-6-2 Connections...........................................................................................................................R-119

R-6-3 Compatible Modems.................................................................... .................................... ...... R-119

R-6-4 Modem Settings........................... ............................... ... ........................................................R-120

R-6-5 Communication Errors...........................................................................................................R-125

Appendices

A-1 Differences in Available Functions Depending on the CPU Unit (NJ or CJ Series) ..........A-2

A-1-1 Functional Differences ................................................................................................................A-2

A-1-2 Differences in Methods for Access from a User Program...........................................................A-3

A-2 Version Information...............................................................................................................A-12

Index

14

CJ-series Serial Communications Units Operation Manual for NJ-series CPU Unit(W494)

Read and Understand this Manual

Read and Understand this Manual

Please read and understand this manual before using the products. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the re sponsibility of OMRON f or any act e xceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINA TION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

CJ-series Serial Communications Units Operation Manual for NJ-series CPU Unit(W494)

15

Read and Understand this Manual

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to t he

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This info rmation by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an e xhaustive list of all possible uses of the products, nor is it intended to imp ly th at the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• S ystems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the produ cts.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

16

CJ-series Serial Communications Units Operation Manual for NJ-series CPU Unit(W494)

Read and Understand this Manual

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specificat ions of the products may be changed

without any notice. When in doubt, special model numbers may be assigned t o fix or establish key

specifications for y our application on your request. Ple ase consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not t o be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Perf ormance data given in this manual is provided as a guide fo r the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

CJ-series Serial Communications Units Operation Manual for NJ-series CPU Unit(W494)

17

Safety Precautions

Safety Precautions

Definition of Precautionary Information

The following notation is used in this manual to provide precautions required to ensure safe usage of a

CJ-series Serial Communications Unit. The safety precautions that are provided are extremely important to safety. Always read and heed the information provided in all safety precautions.

The following notation is used.

Indicates a potentially hazardous situation which, if not avoided,

WARNING

could result in death or serious injury . Additionally, there may be

severe property damage.

Caution

Precautions for Safe Use

Indicates precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Indicates precautions on what to do and what not to do to ensure proper operation and pe rformance.

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury, or property damage.

18

CJ-series Serial Communications Units Operation Manual for NJ-series CPU Unit(W494)

Symbols

Safety Precautions

The circle and slash symbol indicates operations that you must not do.

The specific operation is shown in the circle and explained in text.

This example indicates prohibiting disassembly.

The triangle symbol indicates precautions (including warnin gs).

The specific operation is shown in the triangle and explained in text.

This example indicates a precaution for electric shock.

The triangle symbol indicates precautions (including warnin gs).

The specific operation is shown in the triangle and explained in text.

This example indicates a general precaution.

The filled circle symbol indicates operations that you must do.

The specific operation is shown in the circle and explained in text.

This example shows a general precaution for something that you must do.

CJ-series Serial Communications Units Operation Manual for NJ-series CPU Unit(W494)

19

Safety Precautions

During Power Supply

Do not touch any of the terminals or terminal blocks while the power is being

supplied. Doing so may result in electric shock.

Do not attempt to take any Unit apart. In particular, high-voltage parts are

present in the Power Supply Unit while power is supplied or immediately after

power is turned OFF. Touching any of these parts may result in electric

shock. There are sharp parts inside the Unit that may cause injury.

WARNING

Fail-safe Measures

Provide safety measures in external circuits to ensure safety in the system if

an abnormality occurs due to malfunction of the CPU Unit, other Units, or

slaves or due to other external factors affecting operation. Not doing so may

result in serious accidents due to incorrect operation.

Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

The Controller outputs may remain ON or OFF due to deposition or burning

of the output relays or destruction of the output transistors. As a countermeasure for such problems, external safety measures must be provided to

ensure safe operation of the system.

The CPU Unit will turn OFF all outputs from Basic Output Units in the following cases. The remote I/O slaves will operate according to the settings in the

slaves.

• If an error occurs in the power supply

• If the power supply connection becomes faulty

• If a CPU watchdog timer error or CPU reset occurs

• If a major fault level Controller error occurs

• While the CPU Unit is on standby until RUN mode is entered after the

power is turned ON

External safety measures must be provided to ensure safe operation of the

system in such cases.

20

If external power supplies for slav es or other de vices are o v erloaded or shortcircuited, the voltage will drop, outputs will turn OFF, and the system may be

unable to read inputs. Provide external safety measures in controls with monitoring of external power supply voltage as required so that the system operates safely in such a case.

CJ-series Serial Communications Units Operation Manual for NJ-series CPU Unit(W494)

WARNING

Fail-safe Measures

Unintended outputs may occur when an error occurs in variable memory or

in memory used for CJ-series Units. As a countermeasure for such problems, external safety measures must be provided to ensure safe operation of

the system.

Provide measures in the communications system and user program to

ensure safety in the overall system even if errors or malfunctions occur in

data link communications or remote I/O communications.

Safety Precautions

If there is interference in remote I/O communications or if a major fault level

error occurs, output status will depend on the products that are used.

Confirm the operation that will occur when there is interference in communications or a major fault level error, and implement safety measures.

Correctly set all of the EtherCAT slaves.

The NJ-series Controller continues normal operation for a certain period of

time when a momentary power interruption occurs. This means that the NJseries Controller may receive incorrect signals from external devices that are

also affected by the power interruption. Accordingly, take suitable actions,

such as external fail-safe measures and interlock conditions, to monitor the

power supply voltage of the external device as required.

You must take fail-safe measures to ensure safety in the event of incorrect,

missing, or abnormal signals caused by broken signal lines, momentary

power interruptions, or other causes. Not doing so may result in serious accidents due to incorrect operation.

Voltage and Current Inputs

Make sure that the voltages and currents that are input to the Units and

slaves are within the specified ranges.

Inputting voltages or currents that are outside of the specified ranges may

cause accidents or fire.

Downloading

Always confirm safety at the destination before you transfer a user program,

configuration data, setup data, device variable s, or values in memory used

for CJ-series Units from the Sysmac Studio. The devices or machines may

perform unexpected operation regardless of the operating mode of the CPU

Unit.

CJ-series Serial Communications Units Operation Manual for NJ-series CPU Unit(W494)

21

Safety Precautions

Application

Do not touch any Unit when power is being supplied or immediately after the

power supply is turned OFF. Doing so may result in burn injury.

Wiring

Be sure that all terminal screws and cable connector screws are tightened to

the torque specified in the relevant manuals. The loose screws may result in

fire or malfunction.

Caution

Online Editing

Execute online editing only after confirming that no adverse effects will be

caused by deviations in the timing of I/O. If you perform online editing, the

task execution time may exceed the task period, I/O may not be refreshed

with external devices, input signals may not be read, and output timing may

change.

22

CJ-series Serial Communications Units Operation Manual for NJ-series CPU Unit(W494)

Precautions for Safe Use

Disassembly and Dropping

• Do not attempt to disassemble, repair, or modify any Units. Doing so may result in malfunction or fire.

• Do not drop any Unit or subject it to abno rmal vibration or shoc k. Doing so ma y r esult in Unit malfunction or burning.

Mounting

• The sliders on the tops and bottoms of the Power Supply Unit, CPU Unit, I/O Units, and other Units

must be completely locked (until they clic k into place) after connecting the adjacent Unit connectors.

Installation

Precautions for Safe Use

• Always conn ect to a ground of 100 Ω or less when installing the Units. A g round of 100 Ω or less must

be installed when shorting the GR and LG terminals on the Power Su pply Unit.

Wiring

• Follow the instructions in this manual to correctly perform wiring.

Double-check all wiring and switch settings before turning ON the power supply.

• Use crimp terminals for wiring.

Do not connect bare stranded wires directly to terminals.

• Do not pull on the cables or bend the cables beyond their natural limit.

Do not place heavy objects on top of the cables or other wiring lines. Doing so may break the cables.

• Mount terminal blocks and connectors only after checking the mou nting location carefully.

• Be sure that the terminal blocks, expansion cables, and other items with locking devices are properly

locked into place.

• Always remove any dustproof labels that are on the top of the Units when they are shipped before

you turn ON the power supply. If the labels are not removed, heat will accumulate and malfunctions

may occur.

• Before you connect a computer to the CPU Unit, disconnect the power supply plug of the computer

from the AC outlet. Also, if the computer has an FG terminal, make the connections so that the FG

terminal has the same electrical potential as the GR terminal on the Power Supply Unit. A difference

in electric potential between the computer and Controller may cause failure or malfunction.

• If the external power sup ply to an O utput Un it or sla ve has polarity, connect it with the corr ect pola rity.

If the polarity is reversed, current may flow in the reverse direction and damage the connected

devices regardless of the operation of the Controller.

Power Supply Design

• Do not exceed the rated supply capacity of the Power Supply Units in the NJ-series Controller. The

rated supply capacities are given in the NJ-series CPU Unit Hardware User's Manual

(Cat. No. W500).

If the capacity is exceeded, operation may stop, malfunctions may occur, or data may not be backed

up normally for power interruptions.

Use NJ-series Power Supply Units for both the NJ-series CPU Rack and Expansion Racks.

Operation is not possible if a CJ-series Power Supply Unit is used with an NJ-series CPU Unit or an

NJ-series Power Supply Unit is used with a CJ-series CPU Unit.

CJ-series Serial Communications Units Operation Manual for NJ-series CPU Unit(W494)

23

Precautions for Safe Use

• Do not apply voltages or connect loads to the Output Units or slaves in excess of the maximum ratings.

• Surge current occurs when the power supply is turned ON. When selecting fuses or breakers for

external circuits, consider the above precaution and allow sufficient margin in shut-off performance.

Refer to the relevant manuals for surge current specifications. Refer to the NJ-series CPU Unit Hard-

ware User 's Manual (Cat. No. W500) for surge current specifications.

• If the full dielectric strength voltage is applied or turned OFF using the s witch on the tester, the generated impulse voltage may damage the Power Supply Un it. Use the a djustmen t on the t est er t o gradually increase and decrease the voltage.

• Apply the voltage between the Power Supply Unit's L1 or L2 terminal and the GR terminal when testing insulation and dielectric strength.

• Do not supply AC power from an inverter or other device with a square-wave output. Int ernal temperature rise may result in smoking or burning. Always input a sinusoidal wave with the frequency that is

given in the NJ-series CPU Unit Hardware User's Manual (Cat. No. W500).

• Install external breakers and take other safety measures against short-circuiting in external wiring.

Turning ON the Power Supply

• It takes up to approximately 10 to 20 s to enter RUN mode after the power is turned ON. During that

time, outputs will be OFF or will be the values specified in the Unit or slave settings, and external

communications cannot be perf ormed. Use the R UN output on t he Power Supply Unit, for example , to

implement fail-safe circuits so that external devices do not operate incorrectly.

• Configure the external circuits so that the power supply to the control system turns ON only after the

power supply to the Cont roller h as turned ON. If the power supply to the Controll er is t urned ON after

the control power supply , temporary errors may result in incorrect control system signals because the

output terminals on Ou tput Units may momentarily turn ON when power supply is turned ON to the

Controller.

• If you transfer data from a backup file on an SD Memory Card to the Controller when the power supply is turned ON, proper ly select the da ta groups to transfer. If the data for an unintended data group

is transferred to the Controller, it may cause the equipment to operate unpredictably.

Actual Operation

• Check the user program, data, and parameter settings for proper execution before you use them for

actual operation.

Turning OFF the Power Supply

• Never turn OFF the power supply to the Controller whe n the BUSY indicator is flashing. While the

BUSY indicator is lit, the user program and settings in the CPU Unit are being backed up in the builtin non-volatile memory. This data will not be backed up correctly if the power supply is turned OFF.

Also, a major fault level Controller error will occur the next time you start operation, and operation will

stop.

• Do not turn OFF the power supply or remo ve the SD Memory Card while SD Memory Card access is

in progress (i.e., while the SD BUSY indicator flashes). Data ma y become corrupted, and the Controller will not operate correctly if it uses corrupted data. To remove the SD Memory Card from the CPU

Unit while the power supply is ON, press the SD Memory Card power supply switch and wait for the

SD BUSY indicator to turn OFF before you remove the SD Memory Card.

• Do not disconnect the cable or turn OFF the power supply to the Controller when downloading data

or the user program from Support Software.

• Always turn OFF the power supply to the Controller before you attempt any of the following.

• Mounting or removing I/O Units or the CPU Unit

• Assembling the Units

• Setting DIP switches or rotary switches

24

CJ-series Serial Communications Units Operation Manual for NJ-series CPU Unit(W494)

Precautions for Safe Use

• Connecting cables or wiring the system

• Connecting or disconnecting the connectors

The Power Supply Unit may continue to supply power to the rest of the Controller for a few seconds

after the power supply turns OFF. The PWR indicator is lit during this time. Confirm that the PWR

indicator is not lit before you perform any of the above.

Operation

• Confirm that no adverse effect will occur in the system before you attempt any of the following.

• Changing the operating mode of the CPU Unit (including changing the setting of the Operating

Mode at Startup)

• Changing the user program or settings

• Changing set values or present values

• Forced refreshing

• Always sufficiently check the safety at the connected devices before you change the settings of an

EtherCAT slave or Special Unit.

• If two different function modules are used together, such as when you use CJ-series Basic Output

Units and EtherCAT slave outputs, take suitable measures in the user program and external controls

to ensure that safety is maintained in the controlled system if on e of the fu nctio n mod ules stop s. The

relevant outputs will stop if a partial fault level error occurs in one of the function modules.

• Always confirm safety at the connected equipment before you reset Controller errors with an event

level of partial fault or higher for the EtherCAT Master Function Module.

When the error is reset, all slaves that were in any state other than Operational state due to a Controller error with an event le vel of partial fault or higher (in which outputs are disabled) will go to Operational state and the outputs will be enabled.

Before you reset all errors, confirm that no Controller errors with an event level of partial fault have

occurred for the EtherCAT Master Function Module.

• Always confirm safety at the connected equipment before you reset Controller errors for a CJ-series

Special Unit. When a Controller error is reset, the Unit where the Controller error with an event level

of observation or higher will be restarted.

Before you reset all errors, confirm that no Controller errors with an event level of observation or

higher have occurred for the CJ-series Special Unit. Observation level events do not appear on the

Controller Error Tab Page, so it is possible that you may restart the CJ-series Special Unit without

intending to do so.

You can check the status of the _CJB_UnitErrSta[0,0] to _CJB_UnitErrSta[3,9] error status variables

on a Watch Tab Page to see if an observation level Controller error has occurred.

Battery Backup

• The user program and initial values for the variables are stored in non-volatile memory in the CPU

Unit. The present values of variables with the Retain attribute and the values of the Holding, DM, and

EM Areas in the memory used for CJ-series Units are backed up by a Battery. If the Battery is not

connected or the Batter y is exhausted, the CPU Un it dete cts a Ba ttery-backup Memor y Check Error.

If that error is detected, variables with a Retain attribute are set to their initial values and the Holding,

DM, and EM Areas in memory used for CJ-series Units are cleared to all zeros. Perform thorough

verifications and provide sufficient measures to ensure that the devices perform safe operation for the

initial values of the variables with Retain attributes and the resulting operation.

Debugging

• Forced refreshing ignores the results of user program execution and refreshes I/O with the specified

values. If forced refreshing is used for inputs for which I/O refreshing is not supported, the inputs will

first take the specified values, but they will then be overwritten by the user program. This operation

differs from the force-set/reset functionality of the CJ-series PLCs.

CJ-series Serial Communications Units Operation Manual for NJ-series CPU Unit(W494)

25

Precautions for Safe Use

• You cannot upload or download information for forced refreshing with the Sysmac Studio.

After downloading data that contains forced refreshing, change to RUN mode and then use the Sysmac Studio to perform the operation for forced refreshing.

Depending on the difference in the forced status, the control system may operate unexpectedly.

• Do not specify the same address for the AT specification for more than one variab le.

Doing so would allow the same entity to be accessed with different variable names, which would

make the user program more difficult to understand and possibly cause programming mistakes.

General Communications

• When you use data link communications, check the error information that is given in ErrSta (Controller Error Status) to make sure that no error has occu rred in the source de vice . Write the user progr am

to use the received data only if there is no error. If there is an error in the source device, the data for

the data link may contain incorrect values.

• Unexpected operat ion may result if inappropriate data link tables are set. Even if appro priate data link

tables have been set, confirm that the controlled system will not be adversely affected before you

transfer the data link tables. The data links start automatically after the data link tables are transferred.

• All CPU Bus Units are restarted when routing tables are transferred from Support Software to the

CPU Unit. Confirm that the system will not be adversely affected by restarting before you transfer the

routing tables.

• Tag data links will stop between related nodes while tag data link parameters are transferred during