Page 1

Cat. No. W408-E2-02-X

CJ1W-PRT21

PROFIBUS-DP Slave Unit

OPERATION MANUAL

Page 2

CJ1W-PRT21

PROFIBUS-DP Slave Unit

Operation Manual

Produced January 2005

Page 3

ii

Page 4

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch”, which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 2004

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of the information contained in this publication.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3...

Indicates lists of one sort or another, such as procedures, checklists, etc.

iii

Page 5

iv

Page 6

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiii

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

SECTION 1

PROFIBUS-DP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Protocol architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-3 Device types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-4 PROFIBUS-DP characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-5 Device Data Base files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-6 Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SECTION 2

Features and System Configuration . . . . . . . . . . . . . . . . . . . 9

2-1 Overall Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-3 Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

SECTION 3

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3-1 Physical layout of the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3-2 Connecting PC Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3-3 Setting up a network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

SECTION 4

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4-1 Input and Output Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4-2 I/O Data Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4-3 I/O Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4-4 Data Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4-5 Control and status area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4-6 Configuration information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

4-7 PLC status information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4-8 LEDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

v

Page 7

TABLE OF CONTENTS

SECTION 5

Troubleshooting and Maintenance . . . . . . . . . . . . . . . . . . . . 49

5-1 Error Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5-2 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5-3 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5-4 Addition/Replacement of Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Appendices

A GSD file for CJ1W-PRT21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

B Device specific parameters and diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

C PLC Status information words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

vi

Page 8

About this Manual

This manual describes the installation and operation of the CJ1W-PRT21 PROFIBUS-DP Slave Unit

and includes the sections described below.

Please read this manual carefully and be sure you understand the information provided before

attempting to install or operate the PROFIBUS-DP Slave Unit. Be sure to read the precautions pro-

vided in the following section.

Precautions

related devices.

Section 1

Section 2

Section 3

Section 4

Section 5

provides general precautions for using the MC Unit, Programmable Controller (PC), and

gives a brief description of PROFIBUS-DP.

explains the installation of the PROFIBUS-DP.

provides the overall specification and the communication performance of the Unit.

describes interface with the user.

describes the troubleshooting procedures and maintenance operations.

!WARNING

Failure to read and understand the information provided in this manual may result in personal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

vii

Page 9

Page 10

PRECAUTIONS

This section provides general precautions for using the CJ-series Programmable Controllers (PCs) and related devices.

The information contained in this section is important for the safe and reliable application of Programmable

Controllers. You must read this section and understand the information contained before attempting to set up or

operate a PC system.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

6-1 Applicable Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

6-2 Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

6-3 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

6-4 Relay Output Noise Reduction Methods . . . . . . . . . . . . . . . . . . . . . xv

ix

Page 11

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual close at hand for reference during operation.

!WARNING It is extremely important that a PC and all PC Units be used for the specified

purpose and under the specified conditions, especially in applications that can

directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PC System to the above-mentioned applications.

3 Safety Precautions

!WARNING The CPU Unit refreshes I/O even when the program is stopped (i.e., even in

PROGRAM mode). Confirm safety thoroughly in advance before changing the

status of any part of memory allocated to I/O Units, Special I/O Units, or CPU

Bus Units. Any changes to the data allocated to any Unit may result in unexpected operation of the loads connected to the Unit. Any of the following operation may result in changes to memory status.

• Transferring I/O memory data to the CPU Unit from a Programming

Device.

• Changing present values in memory from a Programming Device.

• Force-setting/-resetting bits from a Programming Device.

• Transferring I/O memory files from a Memory Card or EM file memory to

the CPU Unit.

• Transferring I/O memory from a host computer or from another PC on a

network.

!WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing

so may result in electric shock.

x

Page 12

Safety Precautions 3

!WARNING Do not touch any of the terminals or terminal blocks while the power is being

supplied. Doing so may result in electric shock.

!WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do

so may result in malfunction, fire, or electric shock.

!WARNING Do not touch the Power Supply Unit while power is being supplied or immedi-

ately after power has been turned OFF. Doing so may result in electric shock.

!WARNING Provide safety measures in external circuits (i.e., not in the Programmable

Controller), including the following items, to ensure safety in the system if an

abnormality occurs due to malfunction of the PC or another external factor

affecting the PC operation. Not doing so may result in serious accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instruction is executed.

As a countermeasure for such errors, external safety measures must be

provided to ensure safety in the system.

• The PC outputs may remain ON or OFF due to deposition or burning of

the output relays or destruction of the output transistors. As a countermeasure for such problems, external safety measures must be provided

to ensure safety in the system.

• When the 24-V DC output (service power supply to the PC) is overloaded

or short-circuited, the voltage may drop and result in the outputs being

turned OFF. As a countermeasure for such problems, external safety

measures must be provided to ensure safety in the system.

!Caution Confirm safety before transferring data files stored in the file memory (Mem-

ory Card or EM file memory) to the I/O area (CIO) of the CPU Unit using a

peripheral tool. Otherwise, the devices connected to the output unit may malfunction regardless of the operation mode of the CPU Unit.

!Caution Execute online edit only after confirming that no adverse effects will be

caused by extending the cycle time. Otherwise, the input signals may not be

readable.

!Caution Confirm safety at the destination node before transferring a program to

another node or changing contents of the I/O memory area. Doing either of

these without confirming safety may result in injury.

!Caution Tighten the screws on the terminal block of the AC Power Supply Unit to the

torque specified in the operation manual. The loose screws may result in

burning or malfunction.

xi

Page 13

Operating Environment Precautions 4

4 Operating Environment Precautions

!Caution Do not operate the control system in the following locations:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

!Caution Take appropriate and sufficient countermeasures when installing systems in

the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

!Caution The operating environment of the PC System can have a large effect on the

longevity and reliability of the system. Improper operating environments can

lead to malfunction, failure, and other unforeseeable problems with the PC

System. Be sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life

of the system.

xii

Page 14

Application Precautions 5

5 Application Precautions

Observe the following precautions when using the PROFIBUS-DP Slave

Units or the PLC.

!WARNING Failure to abide by the following precautions could lead to serious or possibly

fatal injury. Always heed these precautions.

• Always ground the system to 100 Ω or less when installing the system to

protect against electrical shock.

• Always turn off the power supply to the PLC before attempting any of the

following. Performing any of the following with the power supply turned on

may lead to electrical shock:

• Mounting or removing any Units (e.g., I/O Units, CPU Units, etc.) or

memory cassettes.

• Assembling any devices or racks.

• Connecting or disconnecting any connectors, cables or wiring.

• Setting DIP switches or rotary switches.

!Caution Failure to abide by the following precautions could lead to faulty operation of

the PLC or the system, or could damage the PLC or PLC Units. Always heed

these precautions.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing or abnormal signals caused by broken signal

lines, momentary power interruptions, or other causes.

• Interlock circuits, limit circuits and similar safety measures in external circuits (i.e., not in the Programmable Controller) must be provided by the

customer.

• If the I/O Hold Bit is turned ON, the outputs from the PLC will not be

turned OFF, and will maintain their previous status when the PLC is

switched from RUN or MONITOR mode to PROGRAM mode. Make sure

that the external loads will not procedure dangerous conditions when this

occurs (When operation stops for a fatal error, including those produced

with the FALS instruction, all outputs from Output Unit will be turned OFF,

and only the internal output status will be remained.)

• Use the Units only with the power supplies and voltages specified in the

operation manuals. Other power supplies and voltages may damage the

Units.

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied. Be particularly careful in places

where the power supply is unstable. An incorrect power supply may result

in malfunction.

• Install external breakers and take other safety measures against shortcircuiting in external wiring. Insufficient safety measures against shortcircuiting may result in burning.

• Do not apply voltages exceeding the rated input voltages to Input Units.

The Input Units may be destroyed.

• Do not apply voltages exceeding the maximum switching capacity to Output Units. The Output Units may be destroyed.

• Always disconnect the LG terminal when performing withstand voltages

tests.

• Install the Units properly as specified in the operation manuals. Improper

installation of the Units may result in malfunction.

xiii

Page 15

Application Precautions 5

!Caution • Be sure that all mounting screws, terminal screws, and cable connector

screws are tightened to the torque specified in the relevant manuals.

Incorrect tightening may result in malfunction.

• Leave the label attached to the Unit when wiring. Removing the label may

result in malfunction if foreign matter enters the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals. Connection of bare stranded wires may result in

burning.

• Wire all connections correctly. Double-check all wiring and switch settings

before turning on the power supply. Incorrect wiring may result in burning.

• Mount Units only after checking terminal blocks and connectors completely.

• Be sure that the terminal blocks, Memory Units, expansion cables, and

other items with locking devices are properly locked into place. Improper

locking may result in malfunction.

• Check switch settings, the contents of the DM Area, and other preparations before starting operation. Starting operation without the proper settings or data may result in an unexpected operation.

• Check the user program for proper execution before actually running it on

the Unit. Not checking the program may result in an unexpected operation.

• Confirm that no adverse effect will occur in the system before attempting

any of the following. Not doing so may result in unexpected operation.

• Changing the operating mode of the PC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Resume operation with a new CPU Unit only after transferring the contents of the DM Area, H Area, and other data required for resuming operation to the new Unit. Not doing so may result in an unexpected

operation.

• Do not pull on the cables or bend the cables beyond their natural limit.

Doing either of these may break the cables.

• Do not place object on top of the cables or other wiring lines. Doing so

may break the cables.

• When replacing parts, be sure to confirm that the rating of a new part is

correct. Not doing so may result in malfunction or burning.

• Before touching a Unit, be sure to first touch a grounded metallic object in

order to discharge any static built-up. Not doing so may result in malfunction or damage.

• Do not touch circuit boards or the components mounted to them with your

bare hands. There are sharp leads and other parts on the boards that

may cause injury if handed improperly.

• Provide proper shielding when installing in the following locations:

• Locations subject to static electricity or other sources of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to exposure to radiation.

• Locations near power supply lines.

• Do not attempt to take any Units apart, to repair any Units, or to modify

any Units in any way.

xiv

Page 16

Conformance to EC Directives 6

6 Conformance to EC Directives

6-1 Applicable Directives

•EMC Directives

• Low Voltage Directive

6-2 Concepts

EMC Directives

OMRON devices that comply with EC Directives also conform to the related

EMC standards so that they can be more easily built into other devices or the

overall machine. The actual products have been checked for conformity to

EMC standards (see the following note). Whether the products conform to the

standards in the system used by the customer, however, must be checked by

the customer.

EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions of

the equipment or control panel on which the OMRON devices are installed.

The customer must, therefore, perform the final check to confirm that devices

and the overall machine conform to EMC standards.

Note Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN61000-6-2

EMI (Electromagnetic Interference): EN50081-2

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 V AC and 75

to 1,500 V DC meet the required safety standards for the PC (EN61131-2).

6-3 Conformance to EC Directives

The CJ-series PCs comply with EC Directives. To ensure that the machine or

device in which the CJ-series PC is used complies with EC Directives, the PC

must be installed as follows:

1,2,3...

1. The CJ-series PC must be installed within a control panel.

2. You must use reinforced insulation or double insulation for the DC power

supplies used for the communications power supply and I/O power supplies.

3. CJ-series PCs complying with EC Directives also conform to the Common

Emission Standard (EN50081-2). Radiated emission characteristics (10-m

regulations) may vary depending on the configuration of the control panel

used, other devices connected to the control panel, wiring, and other conditions. You must therefore confirm that the overall machine or equipment

complies with EC Directives.

(Radiated emission: 10-m regulations)

6-4 Relay Output Noise Reduction Methods

The CJ-series PCs conform to the Common Emission Standards (EN50081-

2) of the EMC Directives. However, noise generated by relay output switching

may not satisfy these Standards. In such a case, a noise filter must be connected to the load side or other appropriate countermeasures must be provided external to the PC.

xv

Page 17

Conformance to EC Directives 6

Countermeasures taken to satisfy the standards vary depending on the

devices on the load side, wiring, configuration of machines, etc. Following are

examples of countermeasures for reducing the generated noise.

Countermeasures

(Refer to EN50081-2 for more details.)

Countermeasures are not required if the frequency of load switching for the

whole system with the PC included is less than 5 times per minute.

Countermeasures are required if the frequency of load switching for the whole

system with the PC included is more than 5 times per minute.

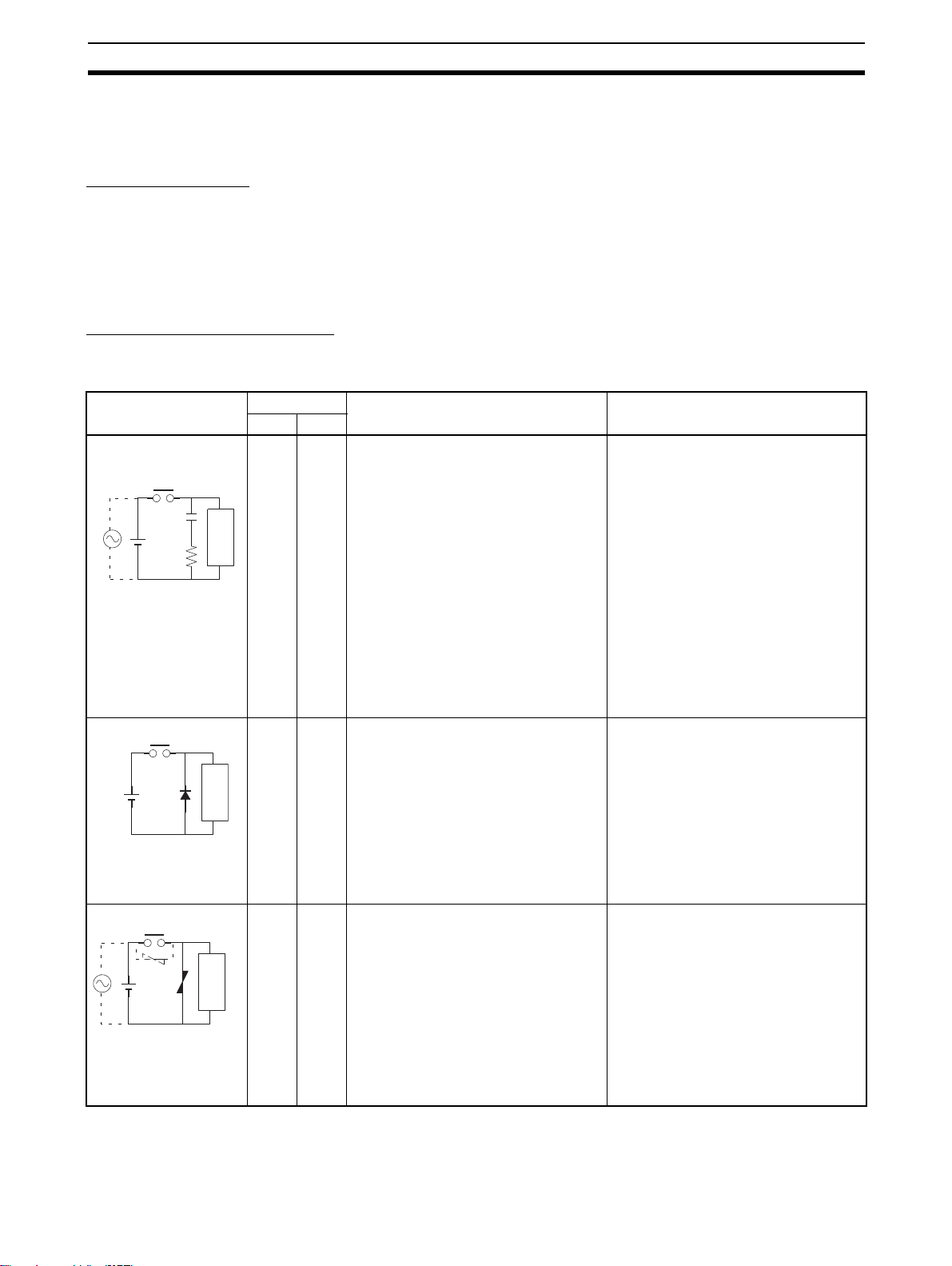

Countermeasure Examples

When switching an inductive load, connect an surge protector, diodes, etc., in

parallel with the load or contact as shown below.

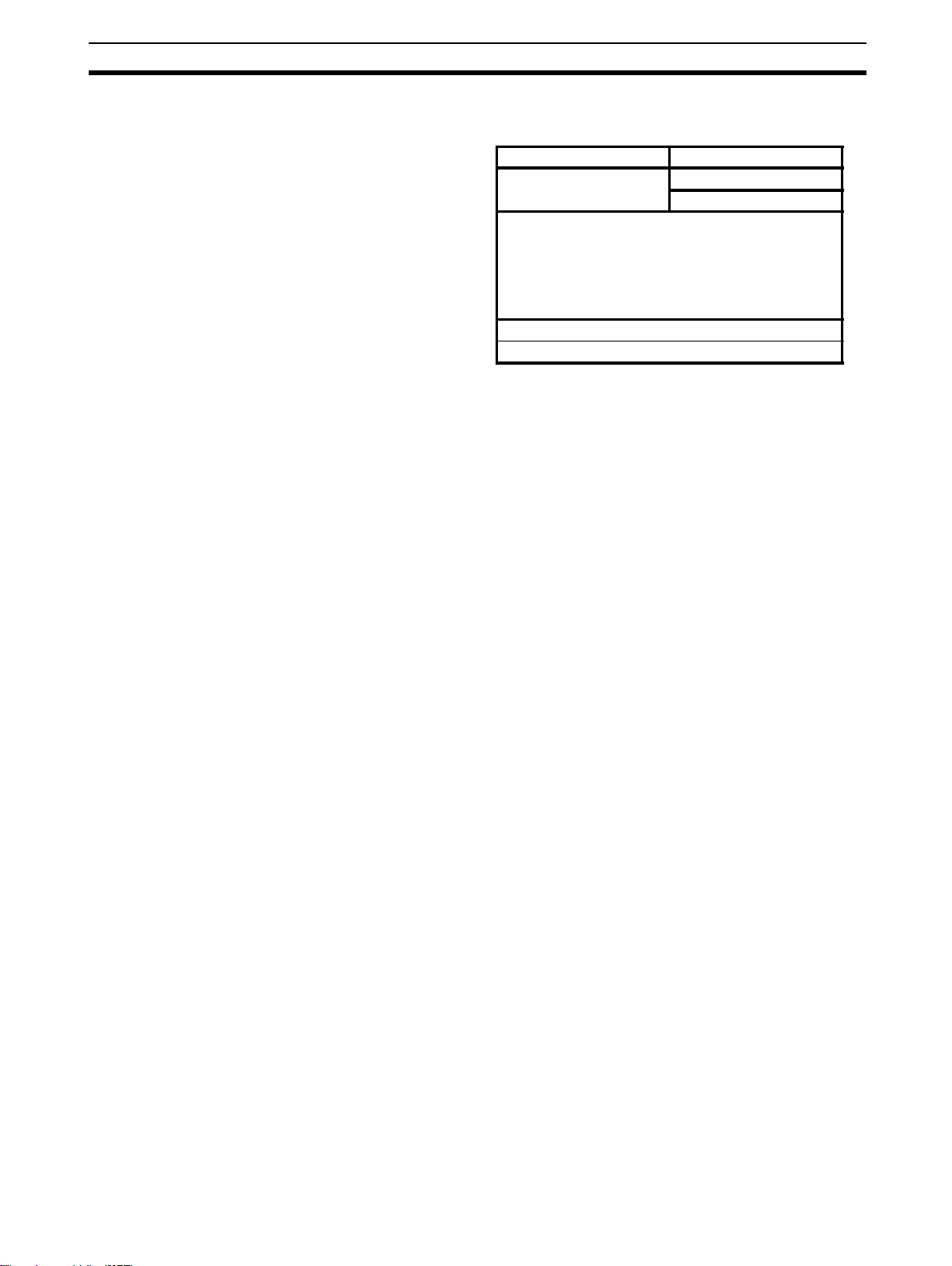

Circuit Current Characteristic Required element

AC DC

The capacitance of the capacitor must

be 1 to 0.5 µF per contact current of

1 A and resistance of the resistor must

be 0.5 to 1 Ω per contact voltage of

1 V. These values, however, vary with

the load and the characteristics of the

relay. Decide these values from experiments, and take into consideration that

the capacitance suppresses spark discharge when the contacts are separated and the resistance limits the

current that flows into the load when

the circuit is closed again.

The dielectric strength of the capacitor

must be 200 to 300 V. If the circuit is an

AC circuit, use a capacitor with no

polarity.

The reversed dielectric strength value

of the diode must be at least 10 times

as large as the circuit voltage value.

The forward current of the diode must

be the same as or larger than the load

current.

The reversed dielectric strength value

of the diode may be two to three times

larger than the supply voltage if the

surge protector is applied to electronic

circuits with low circuit voltages.

---

CR method

C

Power

supply

R

Diode method

Power

supply

Varistor method

Powe r

supply

Yes Yes If the load is a relay or solenoid, there is

a time lag between the moment the circuit is opened and the moment the load

is reset.

If the supply voltage is 24 or 48 V,

insert the surge protector in parallel

Inductive

load

No Yes The diode connected in parallel with

Inductive

load

Yes Yes The varistor method prevents the impo-

Inductive

load

with the load. If the supply voltage is

100 to 200 V, insert the surge protector

between the contacts.

the load changes energy accumulated

by the coil into a current, which then

flows into the coil so that the current will

be converted into Joule heat by the

resistance of the inductive load.

This time lag, between the moment the

circuit is opened and the moment the

load is reset, caused by this method is

longer than that caused by the CR

method.

sition of high voltage between the contacts by using the constant voltage

characteristic of the varistor. There is

time lag between the moment the circuit is opened and the moment the load

is reset.

If the supply voltage is 24 or 48 V,

insert the varistor in parallel with the

load. If the supply voltage is 100 to 200

V, insert the varistor between the contacts.

xvi

Page 18

Conformance to EC Directives 6

When switching a load with a high inrush current such as an incandescent

lamp, suppress the inrush current as shown below.

Countermeasure 1

OUT

R

COM

Providing a dark current of

approx. one-third of the rated

value through an incandescent

lamp

Countermeasure 2

R

OUT

COM

Providing a limiting resistor

xvii

Page 19

Conformance to EC Directives 6

xviii

Page 20

This section provides a brief description of PROFIBUS-DP

1-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Protocol architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-3 Device types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-4 PROFIBUS-DP characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-4-1 Bus Access Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-4-2 Data throughput . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-4-3 Diagnostic functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-4-4 Protection mechanisms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-4-5 Network states . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-5 Device Data Base files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-6 Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SECTION 1

PROFIBUS-DP

1

Page 21

Introduction Section 1-1

1-1 Introduction

PROFIBUS is a vendor-independent, open fieldbus standard for a wide range

of applications in manufacturing, process and building automation. Vendor

independence and openness are guaranteed by the PROFIBUS standard

EN 50170. With PROFIBUS, devices of different manufacturers can commu-

Standard EN50170

High speed PROFIBUS-DP

Process Automation PROFIBUS-PA

nicate without special interface adjustments.The PROFIBUS family consists

of three compatible versions:

DP stands for Decentralised Periphery. It is optimised for high speed and lowcost interfacing, especially designed for communication between automation

control systems and distributed I/O at the device level.

PA stands for Process Automation. It permits sensors and actuators to be

connected on one common bus line even in intrinsically-safe areas. It permits

data communication and power supply over the bus using 2-wire technology

according the international standard IEC 1158-2.

Higher level PROFIBUS-FMS

FMS stands for Fieldbus Message Specification. This version is the general-

purpose solution for communication tasks at a higher level. Powerful services

open up a wide range of applications and provide great flexibility. It can also

be used for extensive and complex communications tasks.

Uniform bus access

protocol

!Caution It is not possible to exchange one of these family members by another family

PROFIBUS-DP and PROFIBUS-FMS use the same transmission technology

and a uniform bus access protocol. Thus, both versions can be operated

simultaneously on the same cable. However, FMS field devices cannot be

controlled by DP masters or vice versa.

member. This will cause faulty operation.

The rest of this section only describes PROFIBUS-DP.Protocol architecture

1-2 Protocol architecture

OSI The PROFIBUS protocol architecture is oriented on the OSI (Open System

Interconnection) reference model in accordance with the international standard ISO 7498. Layer 1 (physical layer) of this model defines the physical

transmission characteristics. Layer 2 (data link layer) defines the bus access

protocol. Layer 7 (application layer) defines the application functions

2

Page 22

Protocol architecture Section 1-2

DP-Profiles

DP-Extensions

User Interface Layer DP Basic Functions

(7) Application Layer

(6) Presentation Layer

(5) Session Layer NOT DEFINED

(4) Transport Layer

(3) Network Layer

(2) Data Link Layer Fieldbus Data Link (FDL)

(1) Physical Layer RS-485 / Fibre Optics

Layer 1, 2 and user

interface

PROFIBUS-DP uses layers 1 and 2, and the user interface. Layers 3 to 7 are

not defined. This streamlined architecture ensures fast and efficient data

transmission. The application functions which are available to the user, as

well as the system and device behaviour of the various PROFIBUS-DP device

types, are specified in the user interface.

Transmission medium

RS-485 transmission technology or fibre optics are available for transmission.

RS-485 transmission is the most frequently used transmission technology. Its

application area includes all areas in which high transmission speed and sim-

High-speed, inexpensive

ple inexpensive installation are required. Twisted pair shielded copper cable

with one conductor pair is used.

Easy installation The RS-485 transmission technology is very easy to handle. Installation of the

twisted pair cable does not require expert knowledge. The bus structure permits addition and removal of stations or step-by-step commissioning of the

system without influencing the other stations. Later expansions have no effect

on stations which are already in operation. Transmission speeds between 9.6

kbit/s and 12 Mbit/s can be selected. One unique transmission speed is

selected for all devices on the bus when the system is commissioned.

Cable length The maximum cable length depends on the transmission speed (see

Fieldbus cabling

3-3-1 Fieldbus cabling

). The specified cable lengths are based on type-A cable (see

). The length can be increased by the use of repeaters.

3-3-1

The use of more than 3 repeaters in series is not recommended.

3

Page 23

Device types Section 1-3

1-3 Device types

PROFIBUS distinguishes between master devices and slave devices.

Master devices Master devices determine the data communication on the bus. A master can

send messages without an external request, as long as it holds the bus

access right (the token). Masters are also called active stations in the PROFIBUS standard.

DPM1, DPM2 There are two types of master devices: DP master class 1 (DPM1) and DP

master class 2 (DPM2).

A DPM1 is a central controller which exchanges information with the decen-

tralised stations (i.e. DP slaves) within a specified message cycle.

DPM2 devices are programmers, configuration devices or operator panels.

They are used during commissioning, for configuration of the DP system, or

for operation and monitoring purposes.

Slave devices Slave devices are peripheral devices. Typical slave devices include input/out-

put devices, valves, drives, and measuring transmitters. They do not have bus

access rights and they can only acknowledge received messages or send

messages to the master when requested to do so. Slaves are also called passive stations.

The CJ1W-PRT21 is a PROFIBUS-DP slave device.

4

Page 24

PROFIBUS-DP characteristics Section 1-4

1-4 PROFIBUS-DP characteristics

1-4-1 Bus Access Protocol

Layer 2 The bus access protocol is implemented by layer 2. This protocol also

includes data security and the handling of the transmission protocols and

messages.

Medium Access Control The Medium Access Control (MAC) specifies the procedures which determine

when a station is permitted to transmit data. A token passing procedure is

used to handle the bus access between master devices, and a polling procedure is used to handle the communication between a master device and its

assigned slave device(s).

Token passing The token passing procedure guarantees that the bus access right (the token)

is assigned to each master within a precisely defined time frame. The token

message, a special message for passing access rights from one master to the

next master, must be passed around the logical token ring - once to each

master - within a specified target rotation time. Each master executes this procedure automatically. A user can only change the target rotation time, but is

not recommended.

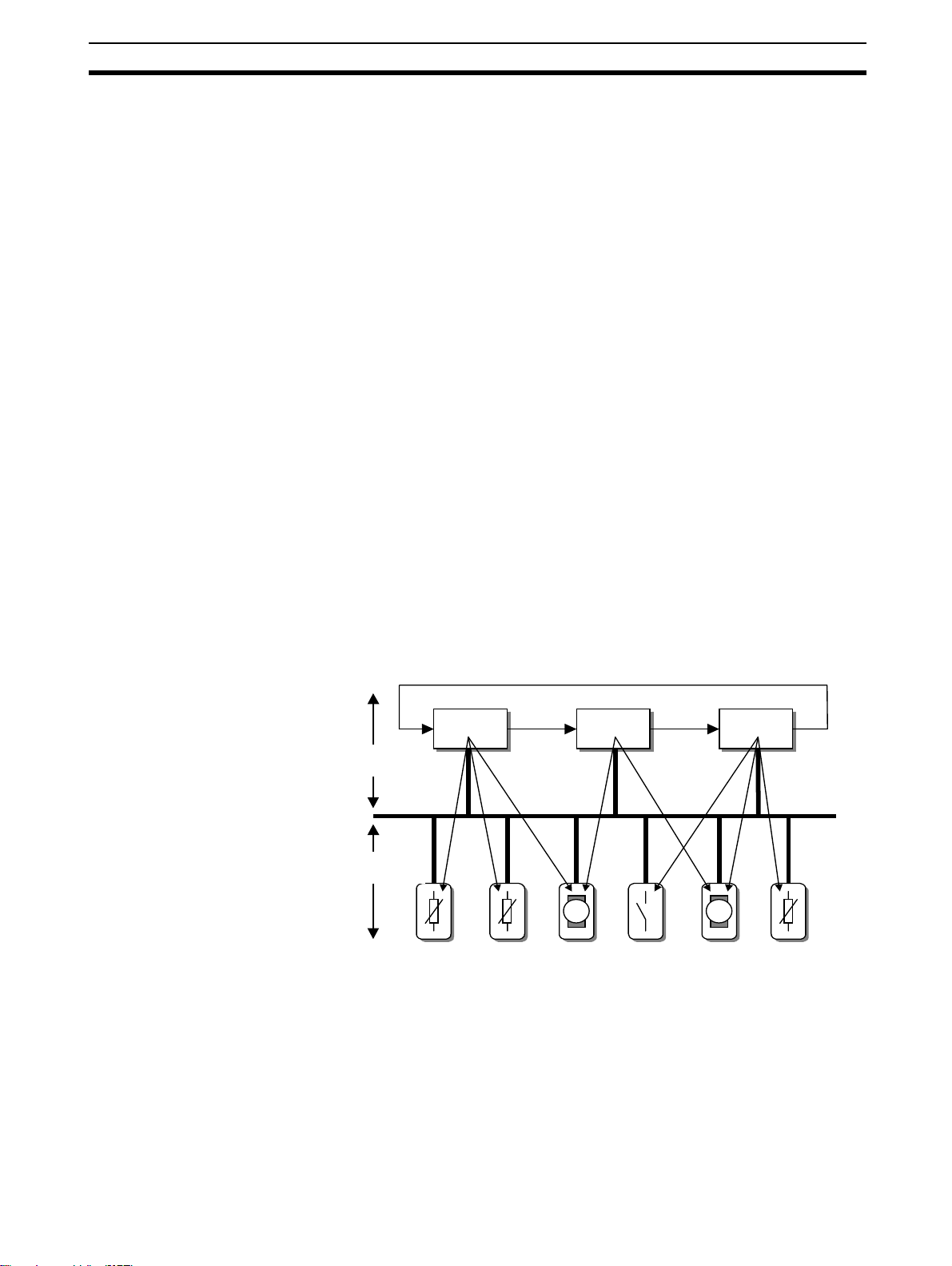

Polling procedure The polling or master-slave procedure permits the master, which currently

owns the token, to access its assigned slaves. The picture below shows a

possible configuration The configuration shows three active stations (masters) and six passive stations (slaves).

.

Token Passing

DPM1 DPM2 DPM1

Active stations

Master devices

Passive stations

Slave devices

The three masters form a logical token ring. When an active station receives

the token message, it can perform its master role for a certain period of time.

During this time it can communicate with all assigned slave stations in a master-slave communication relationship, and a DPM2 master can take the initiative to communicate with DPM1 master stations in a master-master

communication relationship.

Polling

PROFIBUS

5

Page 25

PROFIBUS-DP characteristics Section 1-4

Multi-peer communication In addition to logical peer-to-peer data transmission, PROFIBUS-DP provides

multi-peer communication (broadcast and multicast).

Broadcast communication: an active station sends an unacknowledged

message to all other stations (masters and

slaves).

Multicast communication: an active station sends an unacknowledged

message to a predetermined group of stations

(masters and slaves).

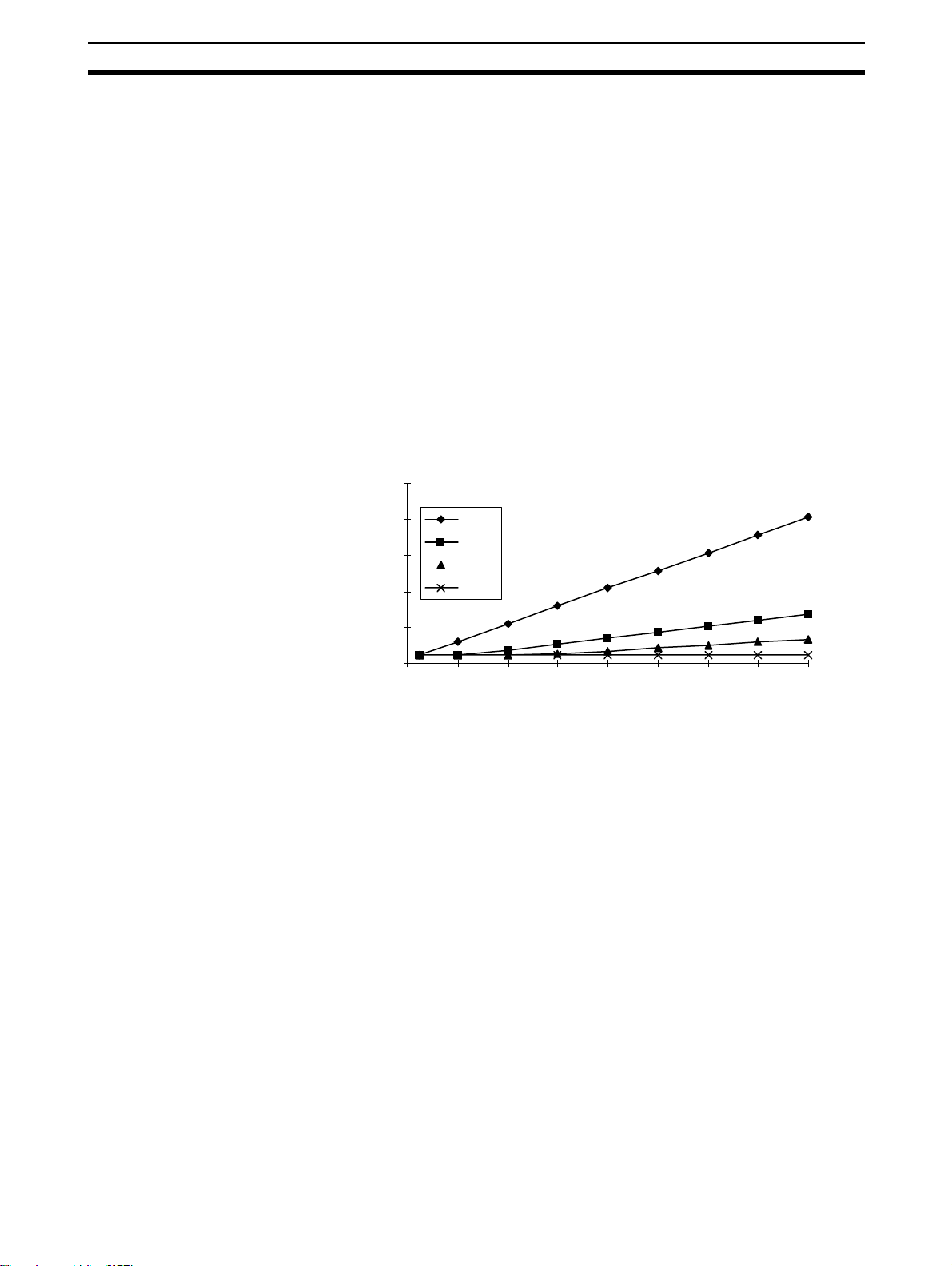

1-4-2 Data throughput

Transmission time At 12 Mbit/s, PROFIBUS-DP requires only about 1 ms for the transmission of

512 bits of input data and 512 bits of output data distributed over 32 stations.

The figure below shows the typical PROFIBUS-DP transmission time depending on the number of stations and the transmission speed. The data throughput will decrease when more than one master is used.

Baud Rate

(kbit/s)

500

1500

3000

12000

0 4 8 12 16 20 24 28 32

Slaves

Bus cycle time [ms]

25.0

20.0

15.0

10.0

5.0

0.0

1-4-3 Diagnostic functions

Extensive diagnostics The extensive diagnostic functions of PROFIBUS-DP enable fast location of

faults. The diagnostic messages are transmitted over the bus and collected at

the master. These messages are divided into three levels:

Device related diagnostics • Device related diagnostics

These messages concern the general operational status of the whole device

(e.g. overtemperature or low voltage).

Module related

diagnostics

• Module related diagnostics

These messages indicate that a fault is present in a specific I/O range (e.g. an

8-bit output module) of a station.

Channel related

diagnostics

6

• Channel related diagnostics

These messages indicate an error at an individual input or output (e.g. short

circuit on output 5).

Page 26

PROFIBUS-DP characteristics Section 1-4

1-4-4 Protection mechanisms

Time monitoring PROFIBUS-DP provides effective protection functions against parameterisa-

tion errors or failure of the transmission equipment. Time monitoring is provided at the DP master and at the DP slaves. The monitoring interval is specified during the configuration.

At the master • Protection mechanism at the master.

The DPM1 master monitors data transmission of its active slaves with the

Data_Control_Timer. A separate control timer is used for each slave. This

timer expires when correct data transmission does not occur within the monitoring interval.

If the master’s Auto_Clear mode is enabled, the DPM1 exits the ’Operate’

state, switches the outputs of all assigned slaves to fail-safe status, and

changes to its ’Clear’ state (see also

At the slave • Protection mechanisms at the slave.

The slave uses the watchdog control to detect failures of the master or the

transmission line. If no data communication with the master occurs within the

watchdog control interval, the slave automatically switches its outputs to the

fail-safe status. This mechanism can be enabled or disabled for each individual slave.

Also, access protection is available for the inputs and outputs of the DP

slaves operating in multi-master systems. This ensures that direct access can

only be performed by the authorised master. For other masters, the slaves

offer an image of their inputs and outputs, which can be read by any master,

even without access rights.

1-4-5 Network states

).

1-4-5 Network states

PROFIBUS-DP distinguishes four different network states.

Off-line • Off-line

Communication between all DP participants is stopped.

Stop • Stop

Communication between DPM1 and DP slaves is stopped. Only communication between DPM1 and DPM2 is possible.

Clear • Clear

DPM1 master attempts to set parameters, check the configuration, and subsequently perform data exchange with its associated DP-slaves. The data

exchange comprises reading the inputs of the DP-slaves and writing zero’s to

the outputs of the DP-slaves.

Operate • Operate

DPM1 master exchanges data with its assigned slaves, inputs are read and

outputs are written. Beside this, the DPM1 cyclically sends its local status to

all assigned DP slaves (with a multicast message) at a configurable time

interval.

Auto_Clear When an error occurs during the data transfer phase of the DPM1, the

‘Auto_Clear’ configuration setting determines the subsequent actions. If this

parameter is set to false, the DPM1 remains in the 'Operate' state. If set to

true, the DPM1 switches the outputs of all assigned DP slaves to the fail-safe

state and the network state changes to the 'Clear' state.

7

Page 27

Device Data Base files Section 1-5

1-5 Device Data Base files

GSD-file To achieve straightforward configuration of a PROFIBUS-DP network, the

characteristic features of a device are specified in a file. This file is called a

GSD-file (Gerätestammdaten file). The language of the GSD file is expressed

with the last letter from the extension, *.GS?:

Default: =GSD

English =GSE

Deutsch =GSG

Italian =GSI

Portuguese =GSP

Spanish =GSS

The GSD files are prepared individually by the vendor for each type of device,

according to a fixed format. Some parameters are mandatory, some have a

default value and some are optional. The device data base file is divided into

three parts:

General section • General specifications

This section contains the vendor name, the device name, hardware- and software release versions, station type and identification number, protocol specification and supported baud rates.

DP-master section • DP master-related specifications

This section contains all parameters which only apply to DP master devices

(e.g. maximum memory size for the master parameter set, maximum number

of entries in the list of active stations, or the maximum number of slaves the

master can handle).

DP-slave section • DP slave-related specifications

This section contains all specification related to slaves (e.g. minimum time

between two slave poll cycles, specification of the inputs and outputs, and

consistency of the I/O data).

Configurator The device data base file of each device is loaded in the configurator and

downloaded to the master device. Refer to the Operation Manual of the

PROFIBUS-DP Master Unit for usage of the GSD file in the master's configuration software.

GSD files are usually supplied with each unit. Alternatively, GSD files can be

downloaded from the Internet, either from the manufacturer's site, or from the

GSD library of the PROFIBUS Nutzerorganisation at http://www.profibus.com.

1-6 Profiles

Exchanging devices To enable the exchange of devices from different vendors, the user data has

to have the same format. The PROFIBUS-DP protocol does not define the

format of user data, it is only responsible for the transmission of this data. The

format of user data may be defined in so called profiles. Profiles can reduce

engineering costs since the meaning of application-related parameters is

specified precisely. Profiles have been defined for specific areas like drive

technology, encoders, and for sensors / actuators.

8

Page 28

SECTION 2

Features and System Configuration

This section describes the overall specification and the communication performance of the PROFIBUS-DP CJ1W-PRT21

Slave Unit

2-1 Overall Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-3 Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

9

Page 29

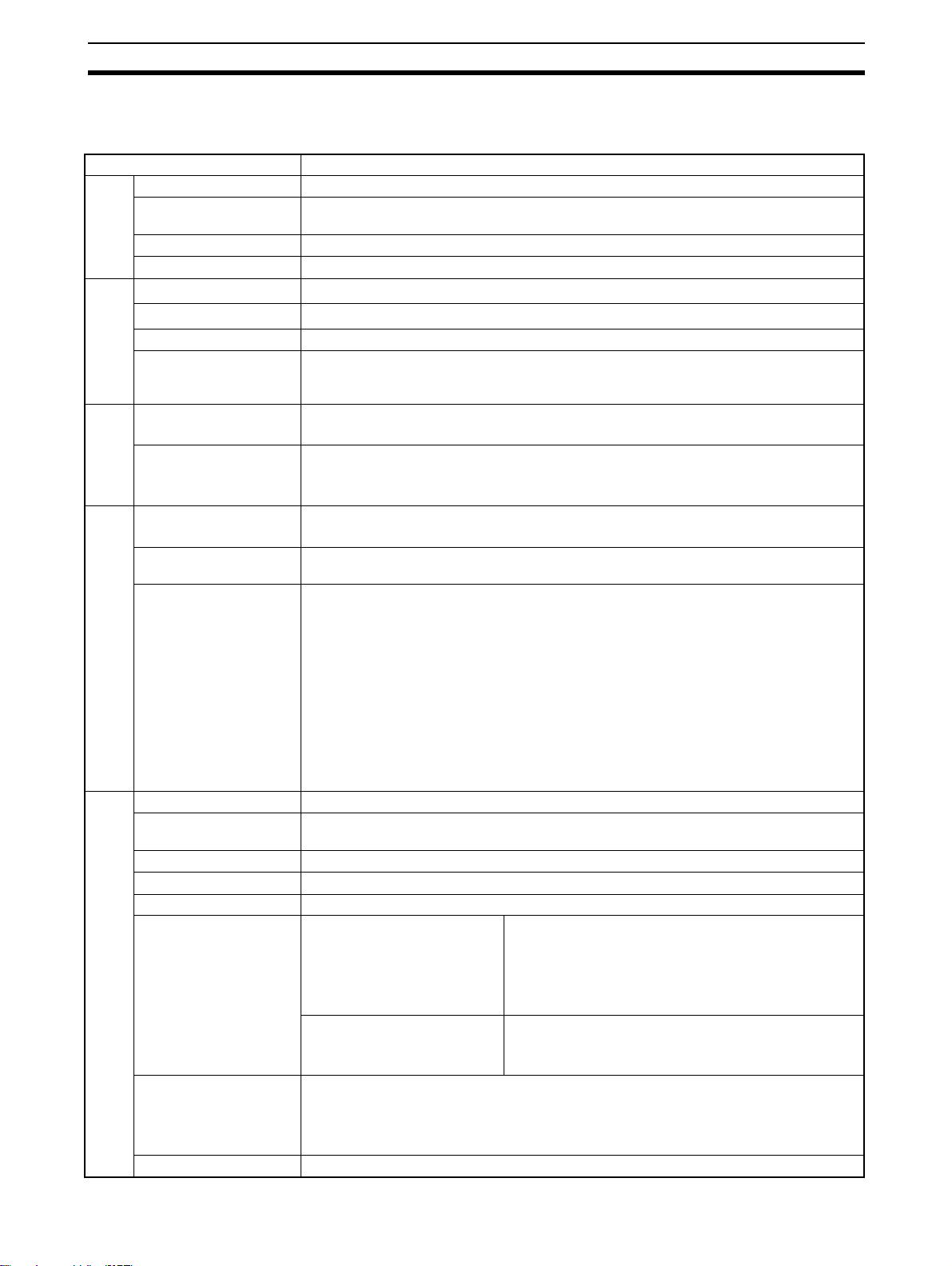

Overall Specification

2-1 Overall Specification

Modal code CJ1W-PRT21

Host PLC System CJ1

Maximum number of

Units per PLC system

Current consumption 400 mA (maximum) at 5V DC from PLC power supply

Weight 90 g (typical)

Installation

Storage temperature

Operating temperature

Operating humidity 10 to 90% (non-condensing)

Conformance to EMCand environmental

standards

Environment

Switch settings Special I/O Machine number (00-95) by 2 rotary switch

LED Indicators Unit status: RUN (green LED), ERC (red LED)

User

Interface

No. of CIO words allocated

No. of DM words allocated

Amount of I/O data per

Unit

PLC Interface

Applicable standard EN50170 Vol. 2

Conformance to

PROFIBUS standard

Bus connector 9-pin female sub-D connector (RS-485 PROFIBUS connector)

Bus address 0 to 99, Remote setting

Baud rate (auto-detect) 9.6k, 19.2k, 45.45k, 93.75k, 187.5k, 500k, 1.5M, 3M, 6M, 12M bit/s

Supported functions

(as responder)

Station type Modular station, max. 32 modules

GSD file OC_0602.GSD, supplied with the unit

Profibus Interface

40

o

C to +70oC

-20

o

0

C to +55oC

EN50081-2

EN61131-2

PROFIBUS-DP node address (00-99) by 2 rotary switches

Network status: COMM (green LED), BF (red LED)

CPU status: ERH (red LED)

PLC -> Unit: 1 word control data

Unit -> PLC: 1 word status data

Unit -> PLC: 8 words of Unit setup information

Fixed:

2 words CIO area (one in, one out) for Unit status + control bits.

2 words status information from the host PLC, containing operation status and error

code (read from location A400). This information will be sent to the PROFIBUS master:

• as extended diagnostics, only at a change of data content.

• optionally, attached to the I/O data, each PROFIBUS cycle.

Variable :

2 user-defined areas for PROFIBUS I/O data, with the following restrictions:

• Up to 100 words input in one PLC area (CIO, H, D, EM).

• Up to 100 words output in one PLC area (CIO, H, D, EM).

• Inputs+outputs must be 180 words or less

Certificate No. Z01033

to DPM1 + DPM2 masters Data_Exchange

to DPM2 master only RD_Inp

Configurable with In-, Out-, and I/O-modules of 1, 2, 4, 8, and 16 words

Total of 0~100 words in + 0~100 words.

Sum of Input and Output size can be up to 180 words

Section 2-1

not supported

Slave_Diag

Set_Prm

Chk_cfg

Global_Control (SYNC/FREEZE/CLEAR)

RD_outp

Get_cfg

10

Page 30

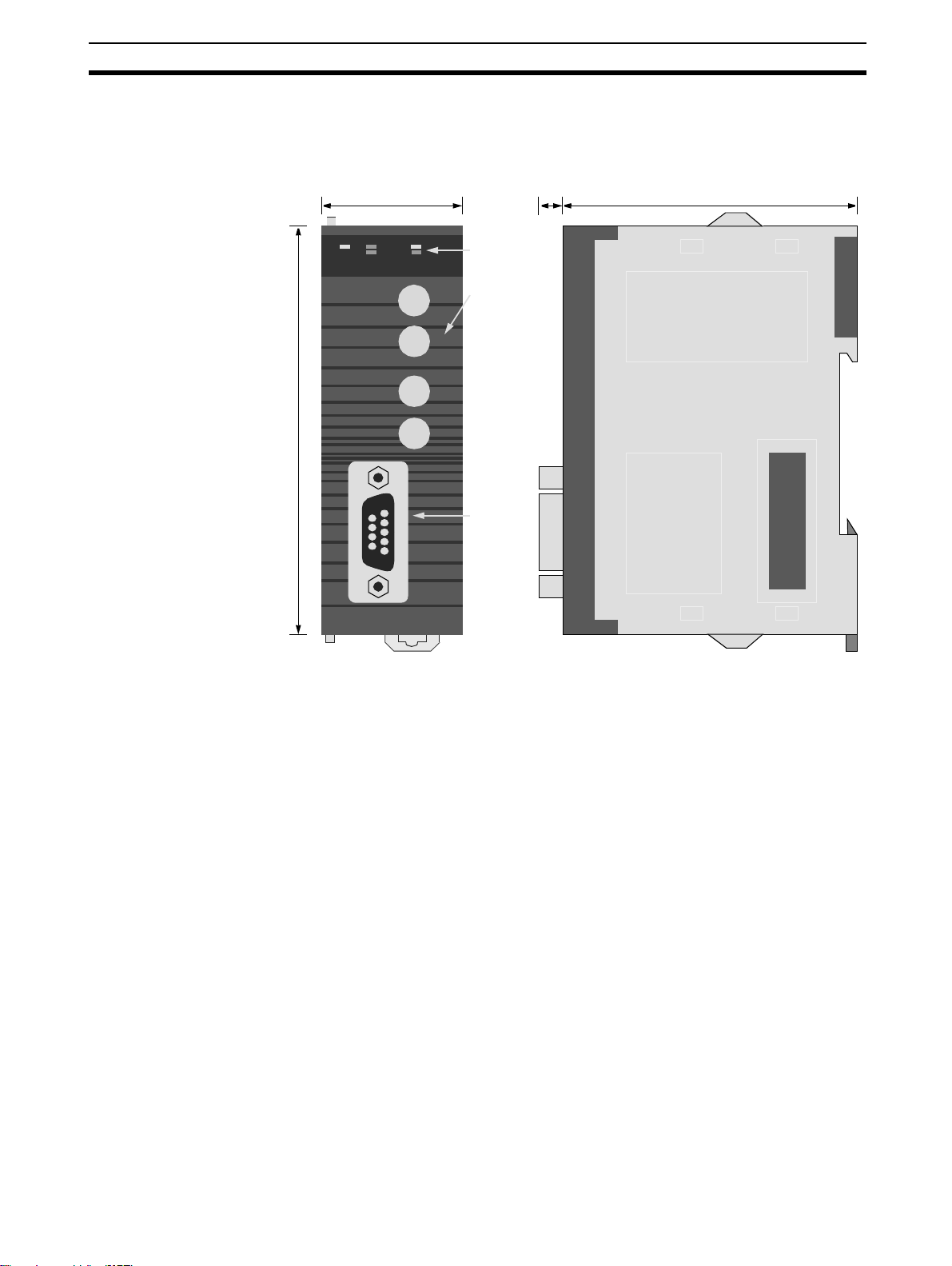

Dimensions

2-2 Dimensions

Section 2-2

The following figure shows the dimensions of the Unit. (All dimensions are in

mm.)

90 mm

PRT21

RUN ERC

31 mm

COMM

ERH BF

Bus

MACH

No.

x10

x10

NODE

No.

x10

x10

1

0

1

0

Indicator

LEDs

Rotar y

switches

D-SUB 9

connector

5 mm

65 mm

11

Page 31

Performance

2-3 Performance

The CJ1W-PRT21’s task is to exchange predetermined amounts of data

between the host PLC system and a PROFIBUS-DP master unit. Its performance in terms of data transfer rate is therefore mainly governed by two factors

external to the Unit: the PROFIBUS-DP cycle time and the host PLC’s cycle

time.

The PLC cycle and the PROFIBUS-DP cycle will generally be:

• independent,

• of unequal length,

• more or less variable,

Asynchronous and therefore fundamentally asynchronous.

In case the PROFIBUS-DP cycle time is longer than the host PLC cycle time,

it may occur that slave input data, sent by the Unit’s host PLC only during a

single PLC cycle, cannot be read in time by the PROFIBUS master.

Section 2-3

Data sent by host PLC

I/O refresh

Data in slave input buffer

Master-Slave polling

PROFIBUS master input data

Data read by host PLC

I/O refresh

Data in slave output buffer

Master-Slave polling

PROFIBUS master output data

1

2 3 4

1 2 3 4

1

3 4

In case the PROFIBUS-DP cycle time is shorter than the host PLC cycle time,

it may occur that slave output data, sent by the PROFIBUS master only during

a single fieldbus cycle, cannot be read in time by the Unit’s host PLC.

ADFC

AB

A

B C D

CDE

E F

F

If it is necessary that each different set of transmitted data is acknowledged

by the receiving side, the user will have to implement a verification mechanism in the PLC programs on both the master and the slave PLC. An example

is to reserve one byte/word in the master’s data block for a transmission counter, which is copied back by the slave in its reply. The master may only transmit the next data if the received counter value equals the sent value,

indicating that the previous data was received by the slave.

Consistency The CJ1W-PRT21 guarantees consistency over the full length of the PROFI-

BUS data message, i.e. all I/O data in one PROFIBUS message is transferred

to the host PLC in one I/O refresh, and vice versa. There are added modules

without consistency which simplify communication with Siemens S7 masters.

12

Page 32

Performance

PROFIBUS-DP cycle time The overall PROFIBUS-DP communication cycle time will depend on the

number and types of PROFIBUS-DP master(s) and other slaves connected to

the network, and the overall bus parameters defined in the configuration of

the master unit(s).

The time required to exchange I/O data between the CJ1W-PRT21 and its

master will depend on the number of input and output words defined in the

master’s configuration, the selected baud rate, and on the performance of the

master unit itself.

The minimum time interval between subsequent I/O data exchanges with the

CJ1W-PRT21 (minimum slave interval) is 0.5 ms as defined in the Unit’s GSD

file.

PLC cycle time The host PLC’s cycle time mainly depends on the size of the PLC program

and the I/O refresh times of all I/O Units on its backplanes. The size of the

PLC program is application specific. Besides optimising the PLC program, the

program execution time can only be decreased by using a faster CPU Unit.

I/O Refresh Time The total I/O refresh time depends on the types of Units that are mounted. Not

all Units refresh the same amount of data. The I/O refresh time of the CJ1WPRT21 depends on the number of I/O data words that have been mapped.

Section 2-3

For the CJ1G CPU45:

I/O Refresh Time = n x 1 µs.

n = number of I/O data words

Maximum words = 184, so maximum I/O refresh time becomes 184 x 1 µs =

0.184 ms

13

Page 33

Page 34

This section describes the installation of the PROFIBUS-DP CJ1W-PRT21 Slave Unit

3-1 Physical layout of the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3-1-1 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3-1-2 Rotary Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3-1-3 BUS Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3-2 Connecting PC Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3-3 Setting up a network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3-3-1 Fieldbus cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3-3-2 Configuring PROFIBUS-DP systems . . . . . . . . . . . . . . . . . . . . . . . . 23

SECTION 3

Installation

15

Page 35

Physical layout of the Unit Section 3-1

3-1 Physical layout of the Unit

PRT21

RUN ERC

COMM

ERH BF

Bus

MACH

No.

x10

x10

NODE

No.

x10

x10

1

0

1

0

Indicator

LEDs

Rotar y

switches

D-SUB 9

connector

The front view shows the indicator LEDs, the rotary switches, and the 9-pin

female sub-D PROFIBUS-DP connector.

3-1-1 LEDs

The CJ1W-PRT21 has 5 indicator LEDs.

Three LEDs (RUN, ERC

and ERH) give a status

indication of the Unit in

general.

During normal operation, the RUN and COMM LEDs (green) should be ON,

while the ERC, ERH and BF LEDs (red) should be OFF. Refer to

for a detailed description of the LED functions.

3-1-2 Rotary Switches

The CJ1W-PRT21 has 4 rotary switches to:

Note Always turn off the power to the PLC before changing a rotary switch setting.

The Unit only reads the settings during the initialisation after power-on.

Use a small flat-blade screwdriver to turn the rotary switches; be careful not to

damage the switches.

PRT21

RUN ERC

COMM

ERH BF

Two LEDs (COMM and

BF) are related to the

status of the PROFIBUSDP network.

• set its Special I/O Unit number or Machine No. (00-95)

• set the PROFIBUS-DP node address (00-99)

4-8 LEDS

16

Page 36

Physical layout of the Unit Section 3-1

MACH No. The MACH No. rotary switches are used to select the CJ1 Special I/O Unit

number or so called “Machine No.”.

The Special I/O number setting determines which words in the CIO Area and

Data Memory Area are allocated to the CJ1W-PRT21.

Any Machine number in the setting range is allowed as long as it has not been

set on another Special I/O Unit connected to the PLC. If the same number is

used for the CJ1W-PRT21 and another Special I/O Unit, an Unit/Rack Number Duplication error (FALS 80E9) will occur in the PLC, and it will not be possible to start up the PROFIBUS-DP Slave communication see (

Device specific parameters and diagnostics

).

Appendix B

NODE ADDRESS Two switches, marked Node No. x10

1

and x100, are used to set the PROFI-

BUS-DP node address of the Unit. Addresses in the range of 00 through 99

are valid. Be sure the node address on the unit is equal to the station address

in the masters configuration.

3-1-3 BUS Connector

The fieldbus connector is a 9-pin female sub-D connector, as recommended

in the PROFIBUS standard EN50170 Vol.2.

Table 1 Profibus Connector

Pin No. Signal Description

1 Shield Shield / functional ground

2- -

3 B-line Data signal

4 RTS Direction control signal for repeaters (TTL)

5 DGND Data ground

6 VP Supply voltage for terminator resistance (+5V)

7- -

8 A-line Data signal

9- -

Data Signal The PROFIBUS User Group recommends the following colour coding for the

data signal lines:

A-line = Green B-line = Red

These data signal lines must be connected to the corresponding signal terminals or pins at the master unit and other stations (i.e. A to A, B to B). For

detailed PROFIBUS-DP cable requirements, see

3-3-1 Fieldbus cabling

.

RTS The signal RTS (TTL signal relative to DGND) is meant for the direction con-

trol of repeaters in case repeaters without self control capability are used

17

Page 37

Connecting PC Components Section 3-2

VP, DGND The signals VP and DGND are meant to

power an externally mounted bus terminator.

The powering of the 220 Ω termination

resistor ensures a defined idle state

potential on the data lines. To ensure

proper functioning up to the highest

baud rate, each bus segment has to be

terminated at both ends of the cable.

3-2 Connecting PC Components

The Units that make up a CJ-series PC can be connected simply by pressing

the Units together and locking the sliders by moving them toward the back of

the Units. The End Cover is connected in the same way to the Unit on the far

right side of the PLC. Follow the procedure listed below to connect PLC components.

1,2,3...

1. The following diagram shows the connection of two Units that make up a

CJ-series PLC. Join the Units so that the connectors fit exactly.

VP

390Ω

B-line

220Ω

A-line

390Ω

DGND

18

Page 38

Connecting PC Components Section 3-2

2. The yellow sliders at the top and bottom of each Unit lock the Units

together. Move the sliders toward the back of the Units as shown below until they click into place.

Note If the locking tabs are not secured properly, the CJ-series PLC may not func-

tion properly. Be sure to slide the locking tabs until they are securely in place.

3. Attach the End Cover to the Unit on the far right side of the Rack.

CPU Rack

Note Connect the I/O Control Unit directly to the CPU Unit to enable connecting

Expansion Racks.

Expansion Rack

Note Connect the I/O Interface Unit directly to the Power Supply Unit.

There is no Backplane for the CJ-series. The PC is constructed by connecting

Units together using the connectors on the sides.

19

Page 39

Connecting PC Components Section 3-2

!Caution Attach the End Cover to the Unit on the far right side of the Rack. An I/O bus

error will occur and the PC will not operate in either RUN or MONITOR mode

if the End Cover is not connected. If this occurs, the following information will

be set in memory.

Name Address Status

I/O Bus Error Flag A 40114 ON

I/O Bus Error Slot Number A40400 to A40407 0E Hex

I/O Bus Error Rack Number A40408 to A40415 0E Hex

Note 1. Always turn OFF the power supply before connecting Units to each other.

2. Always turn OFF the power supply to the entire system before replacing a

Unit.

A maximum of 10 I/O Units can be connected to a CPU Rack or an Expansion

Rack. If 11 or more I/O Units are connected, and I/O overflow error will occur

and the PC will not operate in either RUN or MONITOR mode. If this occurs,

FALS(80E9) occurs, the Too Many I/O Points error flag (A40111) will turn ON

and A40713 to A40715 (I/O Overflow Details) will turn ON (see

Device specific parameters and diagnostics

).

Appendix B

20

Page 40

Setting up a network Section 3-3

3-3 Setting up a network

3-3-1 Fieldbus cabling

Bus structure All PROFIBUS-DP devices are connected in a line structure. Each RS-485

bus segment may contain up to 32 stations (masters, slaves, repeaters).

When more than 32 stations are required, repeaters must be used to link the

individual bus segments. The bus must be terminated at the beginning and at

the end of each segment.

Cable type The standard EN50170 Vol.2 specifies to use shielded twisted pair cables

with the following parameters (PROFIBUS line type A):

Table 2 PROFIBUS Cable parameters

Parameter Value

Impedance 135 to 165 Ω (3 to20 MHz)

Capacitance per unit length < 30 pF/m

Loop resistance < 110 W/km

Core diameter > 0.64 mm

Core cross section > 0.34 mm (22 AWG)

Maximum length The maximum length of the cable depends on the transmission speed. The

cable lengths specified in the table below are based on the above cable specifications.

Table 3 Maximum cable lengths

Baud rate (kbit/s) Length/segment (m)

9.6, 19.2, 45.45, 93.75 1200

187.5 1000

500 400

1500 200

3000, 6000, 12000 100

Repeaters The maximum communication distance as specified in

increased by the use of repeaters. The repeater must be included in the count

of the number of stations on the segment. Even though repeaters do not have

a node address, they represent an electrical load on the bus segment like any

master or slave station.

If a repeater is located at the end of a bus segment, it should provide bus termination as well.

It is recommended to limit the number of repeaters in series between any two

stations in the system to a maximum of three units, as shown in the following

example (3 repeaters are encountered in communication between segment 6

and segments 1, 2 and 4).

Tab le 3

can be

21

Page 41

Setting up a network Section 3-3

Segment 1

Max. 31 Stations

M/S

REP REP

REP

Segment 4

Segment 5

Max. 31 Stations

Max. 31 Stations

M/S

M/S

Master or slave station

Repeater

REP

Te r m i na t io n

Max. total number of stations = 126

Segment 2

Max. 31 Stations

M/S

Segment 3

Max. 31 Stations

M/S

REP

M/S

REP

Segment 6

Max. 31 Stations

M/S

Stub lines Stub lines (branches from the main line) should be avoided for data transmis-

sion speeds of more than 500 kbit/s. Except at end stations with termination, it

is recommended to always use plug connectors that permit two data cables to

be connected directly to the plug. This method allows the bus connector to be

plugged and unplugged at all times without interrupting data communication

between other stations.

22

Page 42

Setting up a network Section 3-3

Fieldbus connector The connector plug to be used on the CJ1W-PRT21 is a 9-pin male sub-D

connector, preferably with a metal case, and a facility to connect the shield of

the cable to the case. The cable should at least be connected to pin 3 (B-line)

and pin 8 (A-line) of the connector.

At baud rates of 1.5 Mbit/s or higher, always use special PROFIBUS-DP connectors with built-in series inductances, to ensure that cable reflections

caused by the capacitive the load of each unit are minimised.

Connectors with built-in inductors and termination resistors, as shown here

schematically, are available from various manufacturers.

To ensure electromagnetic compatibility (EMC), the shield of the cable should

be connected to the metal case of the connector. If this is impossible, use pin

1.

When the Unit is installed within a control cabinet, the cable shield of the bus

cable should be electrically connected to a grounding rail as close as possible

to the cable lead-through using a shield grounding clamp or similar. The cable

shield should continue within the cabinet to the fieldbus device. Ensure that

the PLC and the control cabinet in which the device is mounted have the

same ground potential by providing a large-area metallic contact to ground

(use e.g. galvanised steel to ensure a good connection). Grounding rails

should not be attached to painted surfaces.

You may find further information about:

• Commissioning of PROFIBUS equipment

• Testing the PROFIBUS cable and bus connectors

• Determining the loop resistance

• Testing for correct bus termination

• Determining the segment length and cable route

• Other test methods

• Example of an equipment report

in the PROFIBUS guideline "Installation Guideline for PROFIBUS-DP/FMS"

(PNO Order No- 2.112), which is available at every regional PROFIBUS user

organisation.

3-3-2 Configuring PROFIBUS-DP systems

After making the physical connections of the network, the PROFIBUS-DP

system needs to be configured. For each master and its assigned slaves, a

configuration has to be defined using a dedicated configuration program.

Configurator The configurator provides the master with information about:

• The slaves that are connected to the master.

• The assignment of slaves to groups for broadcast / multicast messages.

• The mapping of the slaves into the memory of the master.

• The bus parameters (e.g. baud rate, target rotation time etc.).

23

Page 43

Setting up a network Section 3-3

C200HW-PRM21 For more details about the configurator for the C200HW-PRM21 Master Unit,

refer to OMRON Catalog No. W349-E1.

GSD file To configure a master unit to communicate with the CJ1W-PRT21, the Unit’s

device database file OC_0602.GSD is required. Based on the contents of this

file, the configuration program for the master unit will allow the user to specify

the amount of input- and output data to be exchanged. The sizes of the inand the output block can both be set in 1-word increments from 0 to 100

words.

Modular slave The CJ1W-PRT21 is characterised as a modular slave. The following types of

data exchange modules are pre-defined:

IN modules of 1, 2, 4, 8, and 16 words

OUT modules of 1, 2, 4, 8, and 16 words

IN/OUT modules of 1+1, 2+2, 4+4, 8+8, and 16+16 words

By concatenating up to 32 modules, any desired size of input and output block

can be created (multiple selections of any module type are allowed). The

sequence in which the modules are entered is irrelevant. Only the resulting

total lengths of the input and output areas are of significance.

Check configuration Upon startup of the PROFIBUS-DP communication, the master unit will send

a Chk_Cfg message so that the slave can verify that the master’s expected

I/O configuration for the slave is correct.

The CJ1W-PRT21 Slave Unit will accept any in/ out words up to 100 input,

100 output words. The maximum of input + outputs must be 180 words or

less.

Parameter data The Set_Prm telegram will provide the following information at system star-

tup, after a restart and in data exchange mode:

• Start address of the area in the host PLC where to read and to send to the

master.

• Format (Motorola/Intel) of the data to be sent to the master.

• Actions to be taken in case of PLC status change or fatal errors.

• Inclusion of 2 words PLC status information or not.

24

Page 44

Setting up a network Section 3-3

Fail safe support:

Off: After the master sends a global control command ‘CLEAR’, the slave

requires data telegramcontaining 0000 as data, in order to remain in

data exchange mode.

On: After the master sends a global control command ‘CLEAR’, the slave

can accept data telegrams containing no data, while still remaining in

data exchange mode

Watchdog Base:

The slave uses the watchdog control to detect failures of the master or the

transmission line. If no data communication with the master occurs within the

watchdog control interval, the slave automatically switches its outputs to the

fail-safe status. The watchdog control time can be specified in intervals of 1

ms or 10 ms.

Output data on PROFIBUS fail:

The user can select how the slave will behave on the host PLC’s I/O bus in

case the PROFIBUS data exchange communications fails:

• Clear data to Host PLC

• Hold data to Host PLC

Output data format:

The user can select how the data bytes of a PROFIBUS data exchange telegram are mapped to the host PLC data words.

• Motorola

•Intel

4-3 I/O Data Format

See

for details:

Output to slave PLC area:

The user can select the area to which the unit will write PROFIBUS output

data received from its master. See

4-2 I/O Data Mapping

for details.

Output area start address:

Sets the start address in the host PLC to which the PROFIBUS output data,

received from the master, will be written.

Action on slave PLC PROGRAM mode:

Defines how the slave will behave on PROFIBUS in case the host PLC is in

PROGRAM mode (as opposed to RUN or MONITOR mode).

Action on slave PLC I/O bus fail:

Defines how the slave will behave on PROFIBUS in case (the communication

with) the host PLC has a fatal error (CPU ERC LED ON) e.g. I/O refresh timeout.

Input data format:

Defines how Host PLC data words are mapped to a PROFIBUS data

exchange telegram. See

4-3 I/O Data Format

for details.

Input from slave PLC area:

Selects the area from which the unit will read PROFIBUS input data to be sent

to its master.

25

Page 45

Setting up a network Section 3-3

Input area start address:

Sets the start address in the host PLC, from which the PROFIBUS input data,

to be sent to the master, will be read.

Slave PLC status indication:

Selects if the PLC status information should occupy the first two words of

input data to the PROFIBUS master.

Example The example below shows a slave configuration screen. The CJ1W-PRT21 is

configured as a slave with 2 words input for status information and

(16+16+4=) 36 words input data and (16+16+8=) 40 words output data. The

terms input and output are to be interpreted as seen from the PROFIBUS-DP

master unit.

List of available

module types,

defined in GSD file

I/O data limits,

defined in GSD file

Total I/O sizes,

calculated by

Configurator

List of modules,

selected by user

26

Page 46

Setting up a network Section 3-3

Slave PLC status indication configured as

Cyclic by first 2 input words

If the Slave PLC status indication is configured as Cyclic by first 2 input words

then the connections between master and slave are as follows:

Master Slave

st

IN word 1st Slave PLC status word

1

nd

IN word 2nd Slave PLC status word

2

rd

3

IN word

th

IN word

4

CIO 50

CIO 51

...

th

IN word

38

st

1

OUT word

nd

OUT word

2

CIO 85

CIO 350

CIO 351

...

th

OUT word

40

CIO 389

27

Page 47

Page 48

SECTION 4

User Interface

This section describes the Interface between the CJ1-series PLC CPU and the PROFIBUS-DP CJ1W-PRT21 Slave Unit.

4-1 Input and Output Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4-2 I/O Data Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4-3 I/O Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4-4 Data Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4-5 Control and status area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4-5-2 Control bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4-5-1 Allocated CIO words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4-5-3 Status Flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4-6 Configuration information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4-6-1 Allocated DM words. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4-6-2 Slave Parameter Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4-6-3 Slave Output Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4-6-4 Slave Input Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4-7 PLC status information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4-8 LEDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Page 49

Input and Output Data Section 4-1

4-1 Input and Output Data

The CJ1W-PRT21 forms a link between two bus systems: the host PLC’s I/O

bus on one side, and PROFIBUS-DP on the other. The Unit can be considered as a slave to both systems: the I/O bus communication is controlled by

the CPU Unit of the host PLC, the PROFIBUS-DP communication is controlled by a PROFIBUS-DP master.

Definitions Being a slave of two systems may cause confusion as to which data should

be considered ’input data’ and which is ’output data’. In this manual all I/O

data communication is defined from the point of view of the PROFIBUS-DP

system:

Slave INPUT Data Slave INPUT Data is process data which the CJ1W-PRT21 reads from the

assigned areas on demand of the host PLC. The CJ1W-PRT21 sends this

data to the PROFIBUS-DP master unit.

CJ1W-PRT21Host PLC PROFIBUS

I/O Bus

PROFIBUS

Master

Figure 1 Slave INPUT data direction

Slave OUTPUT Data Slave OUTPUT Data is process data which the CJ1W-PRT21 receives from

the PROFIBUS-DP master unit. The CJ1W-PRT21 writes this data to the

assigned areas on demand of the host PLC.

CJ1W-PRT21Host PLC PROFIBUS

I/O Bus

Figure 2 Slave OUTPUT data direction

PROFIBUS

Master

30

Page 50

I/O Data Mapping Section 4-2

4-2 I/O Data Mapping

Data flow The figure below shows the flow of remote I/O data in the PLC system. It is

possible to map the PROFIBUS-DP I/O data to the CIO, D, EM, H or W areas