Page 1

Profinet Quick Start Guide

Object of this guide

This quick start guide is to allow a new user to PROFINET to attach PROFINET I/O to an Omron PLC

and configure it to work.

PROFINET products supported in this guide

CJ1W-PNT21 PROFINET I/O Controller for CJx series PLC’s

CS1W-PNT21 PROFINET I/O Controller for CJ1 series PLC’s

GRT1-PNT PROFINET I/O Device – Smart Slice Bus coupler.

Prerequisites

A PC computer with both Serial/USB and Ethernet (via PROFINET) connection to Omron

PLC.

Omron Cx-One V3.x or V4.x installed and up to date using Cx-One Auto Update utility. Cx-

One suite contains the utility application ‘Cx-Configurator FDT’ for configuring and setting

PROFINET devices.

PLC & I/O Controller and IO Devices (at least one) for configuration.

I/O table on PLC should be created using Cx-Programmer.

Network

It is recommended that the PROFINET network is ‘stand alone’. This means not part of a

larger network.

The network speed must be 100MBaud. Using a 10BaseT hub will not allow the network to

operate correctly.

If you wish to use switching hubs as part of the network, we recommend that these are

managed switches and of an industrial nature (e.g. Hirschmann).

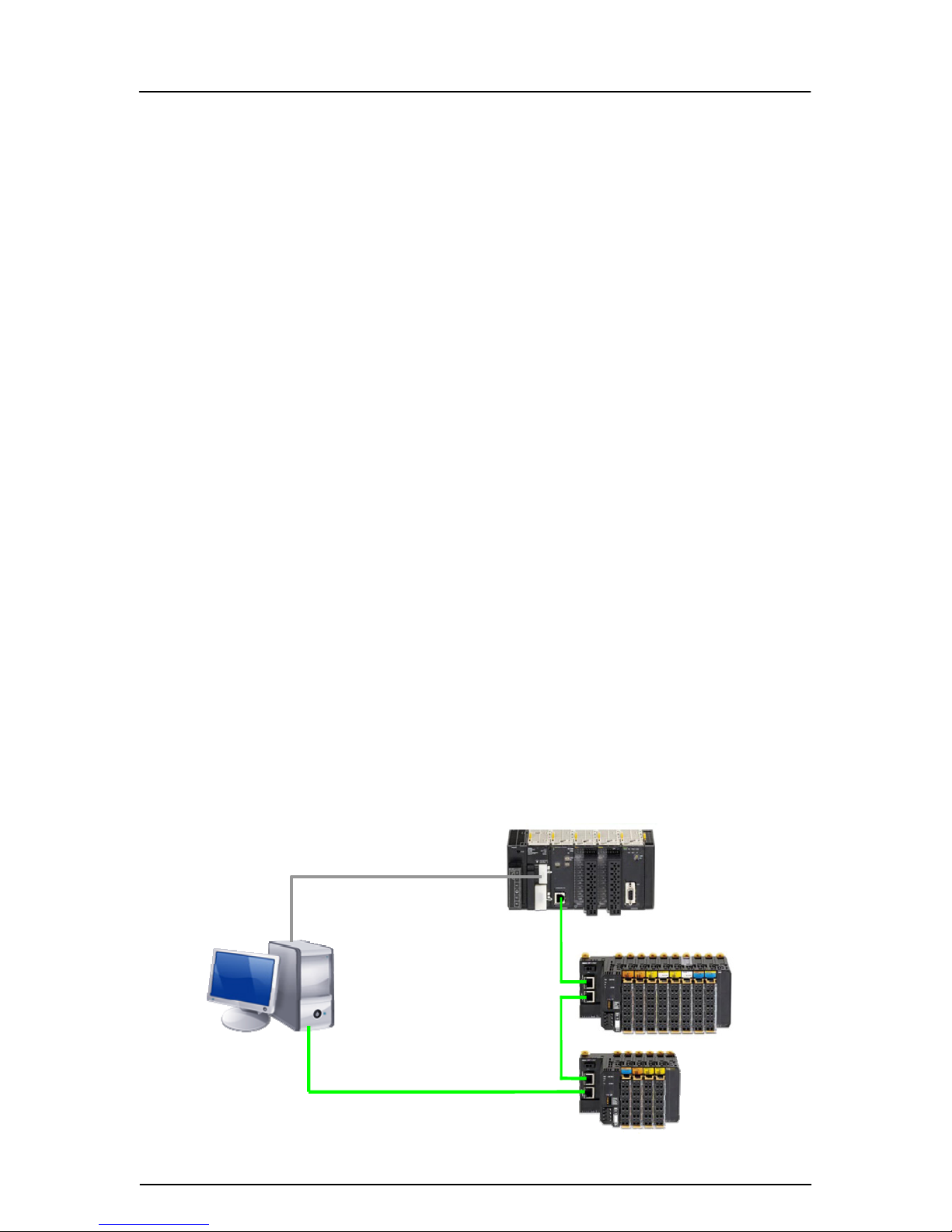

Connection of devices for configuration

To configure the I/O controller – use a serial or USB connection from PLC to PC.

To configure the I/O devices – connect a network cable to the last I/O device (in case of

GRT1-PNT).

Typical Initial Connection diagram

Serial for config

uration of IO Controller

Ethernet for configuration of IO Devices

Rev 1.01 1 of 8

Page 2

Profinet Quick Start Guide

Configuration outline

1. Create IO Table in Cx-Programmer (fo r new Cx1W-PNT21)

2. Create the network topology in Cx-Configurator FDT

3. Set ‘names’ in real IO Devices using Ethernet connection (Search Devices)

4. Set same names of IO Devices to IO Controller in network topolo gy

5. Download Configuration of IO Devices to IO Controller (via Serial connection)

6. Restart system to finish configuration (IO Controller connects to IO Devices)

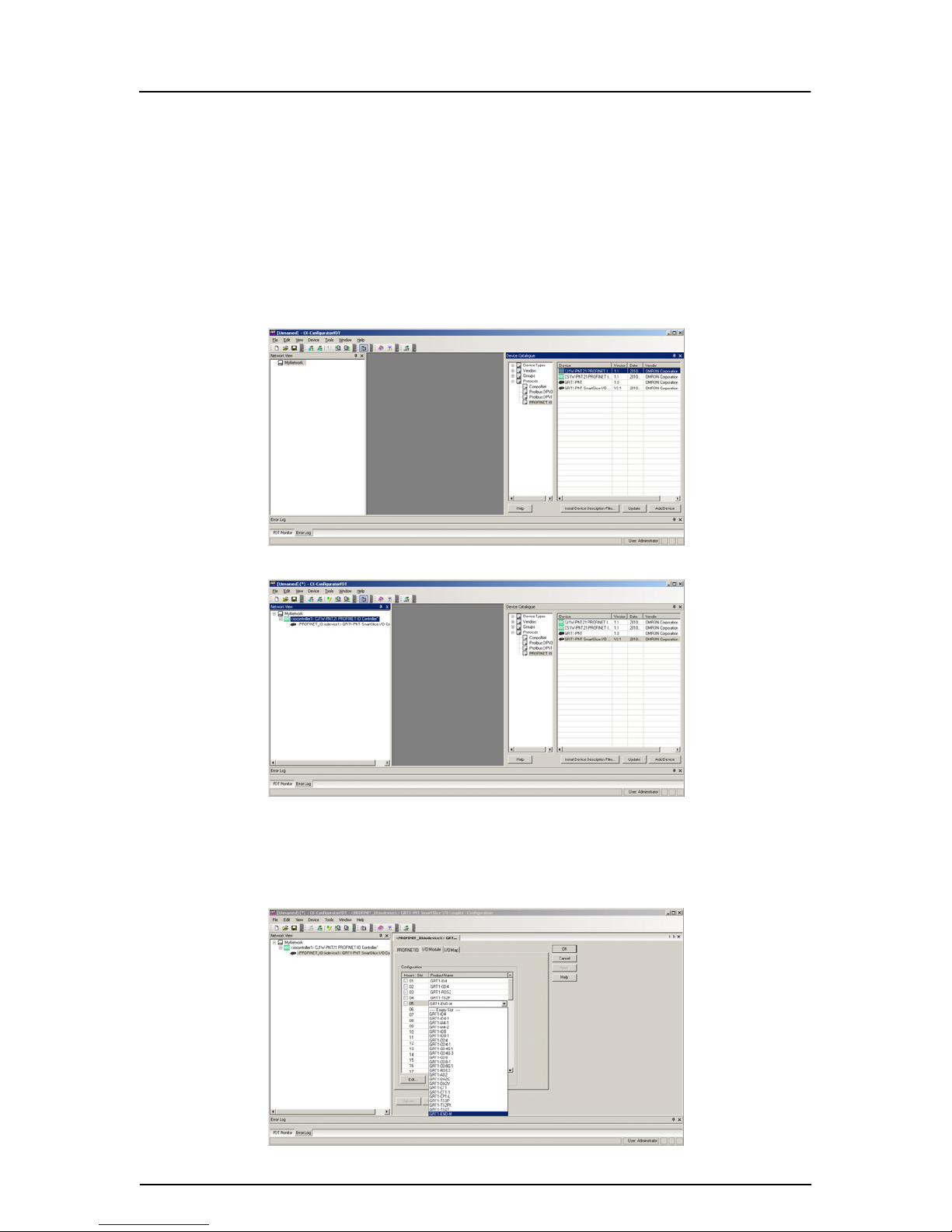

Create a network using Cx-Configurator FDT

Using Cx-Configurator FDT, open the Device Catalogue and show PROFINET IO. Highlight

PROFINET IO Controller (e.g. CJ1W-PNT21) and click ‘Add Device’.

Now add any IO Devices to the Controller (Controller must be highlighted in ‘MyNetwork’ tree).

Device Catalogue can be closed now.

Configure IO Device with correct set of IO Modules (Slices)

Double click on ‘iodevice1’ to configure the correct slices used in real system.

If GRT1-END-M is used, then this must be added as last slice – configuration error will occur if not.

Rev 1.01 2 of 8

Page 3

Profinet Quick Start Guide

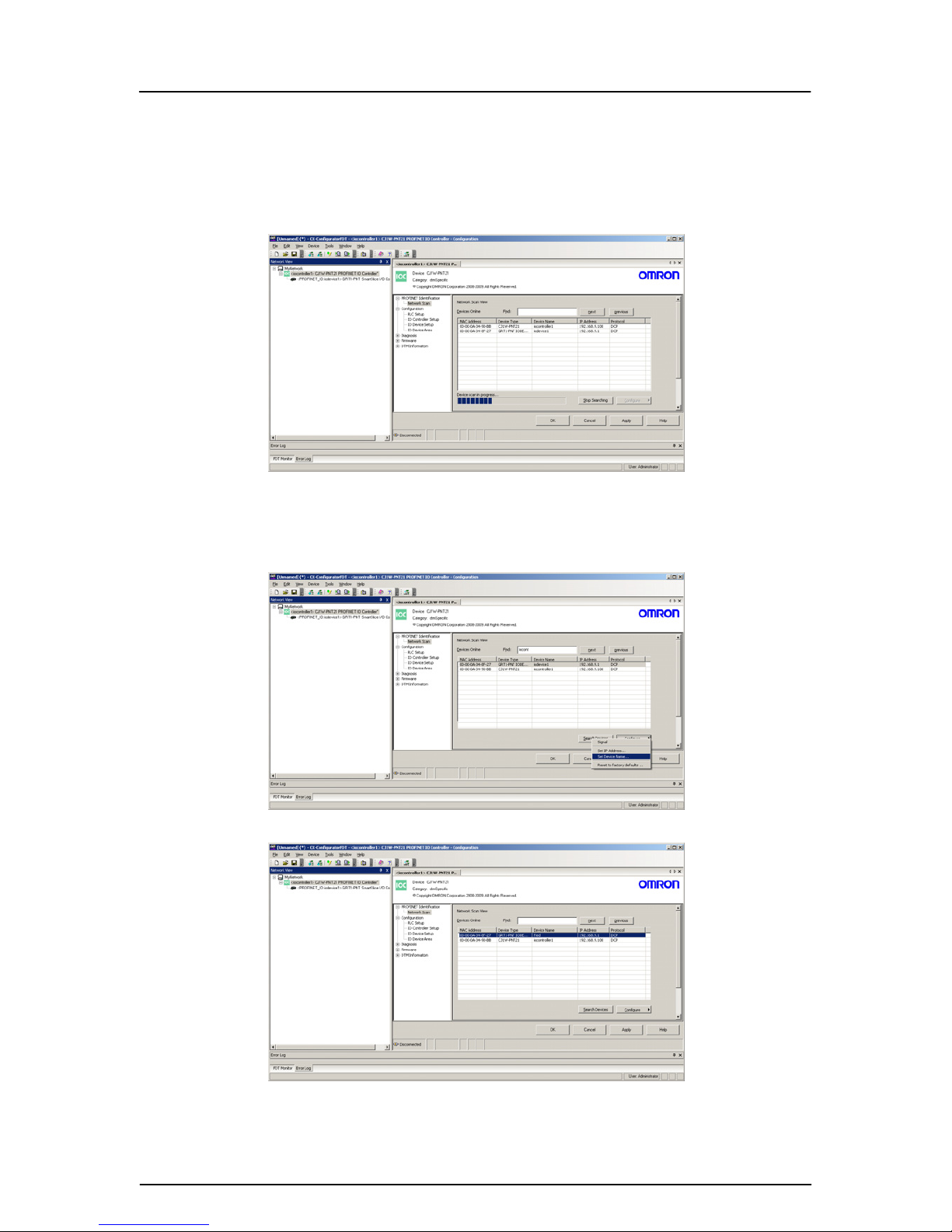

Configure IO Controller and IO Device ‘names’

Open the IO Controller in the ‘tree’ (double click) and initial screen will be ‘PROFINET Identification’.

First operation is to use ‘Network Scan’ to ‘find’ devices on the Ethernet network. This is done by

searching for MAC addresses (so IP does not need to be configured at this point).

Once all devices have been recognised, the IO devices now require unique ‘Device names’ set. Use

the ‘Configure’ button and ‘Set Device Name’ option to give each IO device a name. The name is

used by the IO Controller at boot time to confirm existence and then allow configuration by the IO

Controller (setting IP address, etc.).

For example the IO Device now has the name ‘fred’

Rev 1.01 3 of 8

Page 4

Profinet Quick Start Guide

Set up communication to PLC CPU by way of Serial/USB connection

Enter PLC type and communication settings using ‘Configure’. Enter the PROFINET unit number (set

on front of unit) and press ‘Test’.

The IO Controller will respond with data in ‘Unit Information’

The IO Controller Setup allows user to specify name and IP address for network (leave as defaults if

unsure).

IO Device Setup

The IO Device names must be changed to those set in the ‘Network Scan’. This allows the IO

Controller to make initial communication by ‘name’ (using ARP) and thereafter set the IP Address

(using DCP). Therefore change from….

Rev 1.01 4 of 8

Page 5

Profinet Quick Start Guide

to…

Saving configuration before download to IO Controller

When there is an ‘*’ displayed in Windows title or in network ‘tree’, then the configuration on the

‘screen’ does not match that stored on Disk. Before downloading Configuration changes to the IO

Controller, please make sure the project is saved (‘*’ disappear).

Download Configuration

Now the project (configuration) can be sent to the IO Controller.

Right Click on the IO Controller and select ‘Download Parameters to device’.

Rev 1.01 5 of 8

Page 6

Profinet Quick Start Guide

Once Parameters Downloaded, system requires restart. This is easily achieved by turning power off

and then on. Please make sure the IO Devices are powered on before the IO Controller (or at least at

the same time).

This should result in communication between IO Device(s) and IO Controller and hence cyclic IO

exchange.

Where is my data?

Data is mapped to/from PLC where IO Device configuration was set.

In this example, the input data from the Input devices will start at CIO 3300. Note that the PROFINET

Smart Slice bus coupler (GRT1-PNT) has IO allocated – to allow user to read Slice ‘status’.

Select the ‘Output Allocation’ tab for output IO.

Rev 1.01 6 of 8

Page 7

Profinet Quick Start Guide

Configuring individual Smart Slice parameters

To configure/setup parameters on individual Smart Slices (e.g. changing range on an Analogue input

from 0V-5V to 4mA-20mA), Cx-Configurator FDT must be connected to the Profinet using an Ethernet

connection (same connection to set ‘names’). It is not currently possible to use another

communication option (e.g. via USB on PLC CPU).

Once ‘on-line’, configuration data for Individual Smart Slices can be modified, compared and

uploaded.

Connection diagram for Smart Slice Parameter configuration

Ethernet to configure Smart Slices of IO Devices

The P

C running Cx-Configurator FDT must have a unique IP address set on the same network as the

Profinet. For example, if the PROFINET IO Controller is 192.168.9.100, PROFINET IO Device is

192.168.9.90, then set PC IP address to 192.168.9.20 (say).

Messages sent from Cx-Configurator FDT to the Smart Slice coupler are sent as FINS packets over

PROFINET/Ethernet.

In the project tree ‘open’ the Smart Slice component. Also right click on the same component in the

tree and ‘Work Online’. When connected, the buttons along the component will no longer be greyed

out.

Italic = online

Online = not greyed out

Rev 1.01 7 of 8

Page 8

Profinet Quick Start Guide

Rev 1.01 8 of 8

Use ‘Edit’ button to modify settings.

For example, to change the input range on ‘Smart Slice AD2’ from 0V-5V to 4mA-20mA

Once changes have been made, click ‘OK’ to close the Edit window. Use the ‘Download’ button to

transfer the new settings to the Smart Slice Coupler. The unit will usually require a ‘restart’ for the new

settings to take effect.

Hint – make a backup

Please keep a backup copy of the Cx-Co nfigurato r FDT file ( *.cpr). O nce config uration is downloaded

to the IO Controller, it is not possible to upload configuration ‘layout’ details. It is not possible to

connect with a ‘blank’ Cx-Configurator FDT network and upload devices that are connected to

resurrect Cx-Configurator FDT configuration.

Further Information

For more detailed information about PROFINET IO setup, configuration and operation please refer to

the relevant Omron manuals and support information:-

W12E-EN-xx CJ1W-PNT21 Operation Manual

W16E-EN-xx CS1W-PNT21 Operation Manual

W13E-EN-xx GRT1-PNT Operation Manual

Please use myOMRON.com to search for more PROFINET articles:For example …

http://www.myomron.com/modules/KB/file_d.php?id=109

Technote_Profinet

PROFINET Quick Start Guide

Revision 1.00 November 2010 Original document

Revision 1.01 December 2010 Addition of Smart Slice parameter setup via Ethernet

Loading...

Loading...