Omron CJ1W-AD041-V1, CS1W-DA08C, CJ1W-AD081-V1, CJ1W-DA021, CJ1W-DA041 Operation Manual

...Page 1

Cat. No. W345-E1-08

SYSMAC CS/CJ Series

CS1W-AD041-V1/AD081-V1/AD161

CS1W-DA041/DA08V/DA08C

CS1W-MAD44

CJ1W-AD041-V1/AD081-V1

CJ1W-DA021/DA041/DA08V/DA08C

CJ1W-MAD42

Analog I/O Units

OPERATION MANUAL

Page 2

SYSMAC CS/CJ Series

CS1W-AD041-V1/AD081-V1/AD161

CS1W-DA041/DA08V/DA08C

CS1W-MAD44

CJ1W-AD041-V1/AD081-V1

CJ1W-DA021/DA041/DA08V/DA08C

CJ1W-MAD42

Analog I/O Units

Operation Manual

Revised July 2005

Page 3

iv

Page 4

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 1999

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3...

1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 5

vi

Page 6

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

1 Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

2 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

5 Application Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

6 EC Directives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

7 Other Applicable Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

8 Precautions for the C200H-AD003, C200H-DA003/004, and C200H-MAD01. . xxii

9 Changes to the CJ1W-DA08V/08C and CJ1W-MAD42 . . . . . . . . . . . . . . . . . . . . xxiii

SECTION 1

System Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Features and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Basic Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-3 Function Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

SECTION 2

CS-series Analog Input Units . . . . . . . . . . . . . . . . . . . . . . 13

2-1 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-2 Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2-3 Components and Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2-4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2-5 Exchanging Data with the CPU Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2-6 Analog Input Functions and Operating Procedures. . . . . . . . . . . . . . . . . . . . . . . . 52

2-7 Adjusting Offset and Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

2-8 Handling Errors and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

SECTION 3

CJ-series Analog Input Units . . . . . . . . . . . . . . . . . . . . . . 77

3-1 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

3-2 Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

3-3 Components and Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

3-4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

3-5 Exchanging Data with the CPU Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

3-6 Analog Input Functions and Operating Procedures. . . . . . . . . . . . . . . . . . . . . . . . 104

3-7 Adjusting Offset and Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

3-8 Handling Errors and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

vii

Page 7

TABLE OF CONTENTS

SECTION 4

CS-series Analog Output Units . . . . . . . . . . . . . . . . . . . . 125

4-1 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

4-2 Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

4-3 Components and Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

4-4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

4-5 Exchanging Data with the CPU Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

4-6 Analog Output Functions and Operating Procedures . . . . . . . . . . . . . . . . . . . . . . 149

4-7 Adjusting Offset and Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

4-8 Handling Errors and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

SECTION 5

CJ-series Analog Output Unit . . . . . . . . . . . . . . . . . . . . . 169

5-1 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

5-2 Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

5-3 Components and Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

5-4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

5-5 Exchanging Data with the CPU Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

5-6 Analog Output Functions and Operating Procedures . . . . . . . . . . . . . . . . . . . . . . 197

5-7 Adjusting Offset and Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

5-8 Handling Errors and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

SECTION 6

CS-series Analog I/O Unit . . . . . . . . . . . . . . . . . . . . . . . . 221

6-1 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

6-2 Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

6-3 Components and Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

6-4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

6-5 Exchanging Data with the CPU Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

6-6 Analog Input Functions and Operating Procedures. . . . . . . . . . . . . . . . . . . . . . . . 252

6-7 Analog Output Functions and Operating Procedures . . . . . . . . . . . . . . . . . . . . . . 259

6-8 Ratio Conversion Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

6-9 Adjusting Offset and Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

6-10 Handling Errors and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

viii

Page 8

TABLE OF CONTENTS

SECTION 7

CJ-series Analog I/O Unit. . . . . . . . . . . . . . . . . . . . . . . . . 287

7-1 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

7-2 Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

7-3 Components and Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

7-4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

7-5 Exchanging Data with the CPU Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

7-6 Analog Input Functions and Operating Procedures. . . . . . . . . . . . . . . . . . . . . . . . 318

7-7 Analog Output Functions and Operating Procedures . . . . . . . . . . . . . . . . . . . . . . 327

7-8 Ratio Conversion Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

7-9 Adjusting Offset and Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

7-10 Handling Errors and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 352

Appendices

A Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

B Sample Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

C Data Memory Coding Sheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 395

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 401

ix

Page 9

TABLE OF CONTENTS

x

Page 10

About this Manual:

This manual describes the installation and operation of the CS1W-AD041-V1, CS1W-AD081-V1,

CS1W-AD161, CJ1W-AD041-V1, and CJ1W-AD081-V1 Analog Input Units; the CS1W-DA041, CS1WDA08V, CS1W-DA08C, CJ1W-DA021, CJ1W-DA041, CJ1W-DA08V, and CJ1W-DA08C Analog Output

Units; and the CS1W-MAD44 and CJ1W-MAD42 Analog I/O Units. This manual includes the sections

described below.

The input function of CS/CJ-series Analog I/O Units converts analog sensor output to the digital format

and transmits it to CS/CJ-series PLCs. The output function converts digital data from the PLC to the

analog format for output.

Please read this manual and the other manuals related to the CS/CJ-series Analog I/O Units carefully

and be sure you understand the information provided before attempting to install and operate the

Units. The manuals used with the CS/CJ-series Analog I/O Units are listed in the following table. The

suffixes have been omitted from the catalog numbers. Be sure you are using the most recent version

for your area.

Name Cat. No. Contents

SYSMAC CS-series

CS1G/H-CPU@@-EV1, CS1G/H-CPU@@H

Programmable Controllers Operation Manual

SYSMAC CS Series

CS1D-CPU@@H CPU Units, CS1D-CPU@@S CPU Units,

CS1D-DPL01 Duplex Unit, CS1D-PA/PD@@@ Power

Supply Unit

CS1D Duplex System Operation Manual

SYSMAC CJ-series

CJ1G-CPU@@, CJ1G/H-CPU@@H, CJ1M-CPU@@

Programmable Controllers Operation Manual

SYSMAC CS/CJ-series

CS1G/H-CPU@@-EV1, CS1G/H-CPU@@H, CJ1GCPU@@, CJ1G/H-CPU@@H, CJ1M-CPU@@

Programmable Controllers Programming Manual

SYSMAC CS/CJ-series

CS1G/H-CPU@@-EV1, CS1G/H-CPU@@H, CJ1GCPU@@, CJ1G/H-CPU@@H, CJ1M-CPU@@

Programmable Controllers Instructions Reference Manual

SYSMAC WS02-CXPC1-EV50

CX-Programmer Ver. 5.0 Operation Manual

SYSMAC CS/CJ-series

CQM1H-PRO01-E, CQM1-PRO01-E, C200H-PRO27-E

Programming Consoles Operation Manual

W339 Describes the installation and operation

of the CS-series PLCs.

W405 Provides an outline of and describes the

design, installation, maintenance, and

other basic operations for a Duplex System based on CS1D CPU Units.

W393 Describes the installation and operation

of the CJ-series PLCs.

W394 Describes the programming methods

required to use the functions of the CS/

CJ-series PLCs.

W340 Describes the ladder diagram program-

ming instructions supported by CS/CJseries PLCs.

W437 Provides information on how to use the

CX-Programmer, a programming device

that supports the CS/CJ-series PLCs.

W341 Provides information on how to program

and operate CS/CJ-series PLCs using a

Programming Console.

xi

Page 11

Section 1 describes the features and system configurations of the CS/CJ-series Analog I/O Unit.

Section 2 explains how to use the CS1W-AD041-V1/081-V1/161 Analog Input Units.

Section 3 explains how to use the CJ1W-AD041-V1/081-V1 Analog Input Units.

Section 4 explains how to use the CS1W-DA041/08V/08C Analog Output Units.

Section 5 explains how to use the CJ1W-DA021/041/08V/08C Analog Output Units.

Section 6 explains how to use the CS1W-MAD44 Analog I/O Unit.

Section 7 explains how to use the CJ1W-MAD42 Analog I/O Unit.

Appendix A provides details on dimensions.

Appendix B gives programming examples.

Appendix C provides data memory coding sheets.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

xii

Page 12

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xiii

Page 13

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xiv

Page 14

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xv

Page 15

xvi

Page 16

PRECAUTIONS

This section provides general precautions for using the Programmable Controller (PLC) and Analog I/O Units.

The information contained in this section is important for the safe and reliable application of the Analog I/O Unit.

You must read this section and understand the information contained before attempting to set up or operate a PLC

system and Analog I/O Unit.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

6 EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

7 Other Applicable Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

8 Precautions for the C200H-AD003, C200H-DA003/004, and C200H-MAD01 xxii

9 Changes to the CJ1W-DA08V/08C and CJ1W-MAD42 . . . . . . . . . . . . . . . . xxiii

xvii

Page 17

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems

• Personnel in charge of designing FA systems

• Personnel in charge of managing FA systems and facilities

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating OMRON

Analog I/O Units. Be sure to read this manual before attempting to use the

software and keep this manual close at hand for reference during operation.

!WARNING It is extremely important that a PLC and all PLC Units be used for the speci-

fied purpose and under the specified conditions, especially in applications that

can directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PLC System to the above-mentioned applications.

3 Safety Precautions

!WARNING Do not attempt to take any Unit apart while power is being supplied. Doing so

may result in electric shock.

!WARNING Do not touch any of the terminals or terminal blocks while power is being sup-

plied. Doing so may result in electric shock.

!WARNING Provide safety measures in external circuits (i.e., not in the Programmable

Controller), including the following items, in order to ensure safety in the system if an abnormality occurs due to malfunction of the PLC or another external factor affecting the PLC operation. Not doing so may result in serious

accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PLC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instruction is executed.

As a countermeasure for such errors, external safety measures must be

provided to ensure safety in the system.

xviii

Page 18

Operating Environment Precautions 4

• The PLC outputs may remain ON or OFF due to deposition or burning of

the output relays or destruction of the output transistors. As a countermeasure for such problems, external safety measures must be provided

to ensure safety in the system.

!WARNING When the 24-VDC output (service power supply to the PLC) is overloaded or

short-circuited, the voltage may drop and result in the outputs being turned

OFF. As a countermeasure for such problems, external safety measures must

be provided to ensure safety in the system.

!Caution When wiring crossovers between terminals, the total current for both terminals

will flow in the line. Check the current capacities of all wires before wiring

crossovers.

!Caution Tighten the screws on the terminal block of the AC Power Supply Unit to the

torque specified in the operation manual. The loose screws may result in

burning or malfunction.

!Caution Execute online edit only after confirming that no adverse effects will be

caused by extending the cycle time. Otherwise, the input signals may not be

readable.

4 Operating Environment Precautions

!Caution Do not operate the control system in the following places:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

!Caution Take appropriate and sufficient countermeasures when installing systems in

the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

!Caution The operating environment of the PLC System can have a large effect on the

longevity and reliability of the system. Improper operating environments can

lead to malfunction, failure, and other unforeseeable problems with the PLC

System. Be sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life

of the system.

xix

Page 19

Application Precautions 5

5 Application Precautions

Observe the following precautions when using the PLC.

!WARNING Always heed these precautions. Failure to abide by the following precautions

could lead to serious or possibly fatal injury.

• Always connect to a class-3 ground (to 100

Units. Not connecting to a class-3 ground may result in electric shock.

• Always turn OFF the power supply to the PLC before attempting any of

the following. Not turning off the power supply may result in malfunction or

electric shock.

• Mounting or dismounting I/O Units, CPU Units, Memory Cassettes, or

any other Units.

• Assembling the Units.

• Setting DIP switch or rotary switches.

• Connecting or wiring the cables.

• Connecting or disconnecting the connectors.

!Caution Failure to abide by the following precautions could lead to faulty operation of

the PLC or the system, or could damage the PLC or PLC Units. Always heed

these precautions.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal

lines, momentary power interruptions, or other causes.

• Always use the power supply voltage specified in this manual. An incorrect voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied. Be particularly careful in places

where the power supply is unstable. An incorrect power supply may result

in malfunction.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may result in burning.

• Do not apply voltages to input sections in excess of the rated input voltage. Excess voltages may result in burning.

• Do not apply voltages or connect loads in excess of the maximum switching capacity to output sections. Excess voltage or loads may result in

burning.

• Be sure that all the mounting screws, terminal screws, and cable connector screws are tightened to the torque specified in the relevant manuals.

Incorrect tightening torque may result in malfunction.

• Wiring correctly, as indicated in this manual.

• Do not attempt to disassemble, repair, or modify any Units.

• Be sure to confirm that the DIP switch and the data memory (DM) are

properly set.

• Leave the label attached to the Unit when wiring. Removing the label may

result in malfunction.

Ω or less) when installing the

xx

Page 20

EC Directives 6

• Remove the labels after the completion of wiring to ensure proper heat

dissipation. Leaving the label attached may result in malfunction.

• Do not pull on cables and cords and do not bend them past their natural

bending radius.

• Do not place any heavy objects on cables or cords.

• Mount the Unit only after checking the terminal block completely.

• Be sure that the terminal blocks, Memory Units, expansion cables, and

other items with locking devices are properly locked into place. Improper

locking may result in malfunction.

• Check the user program for proper execution before actually running it on

the Unit. Not checking the program may result in an unexpected operation.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals. Connection of bare stranded wires may result in

burning.

• Double-check all the wiring before turning on the power supply. Incorrect

wiring may result in burning.

• Confirm that no adverse effect will occur in the system before attempting

any of the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PLC (including the setting of the

startup operating mode).

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Touch a grounded metal object to discharge static electricity from your

body before touching any Unit.

6 EC Directives

CS/CJ-series Units conform to EC Directives. For the system to conform to

EC Directives, however, the following precautions must be adhered to.

• CS/CJ-series Units must be installed within control panels.

• Use reinforced insulation or double insulation for the DC power supplies

used for the I/O power supplies.

• CS/CJ-series Units that meet EC Directives also meet the Common Emission Standard (EN61000-6-4). The measure necessary to ensure that

standards, such as the radiated emission standard (10 m), are met, however, will vary depending on the overall configuration of the control panel,

the other devices connected to the control panel, and wiring. You must

therefore confirm that EC Directives are met for the overall machine or

device.

xxi

Page 21

Other Applicable Directives 7

7 Other Applicable Directives

Applicable Directives

•EMC Directive

• Low Voltage Directive

EMC and Low Voltage Directives

EMC Directive

In order that OMRON products can be used with any machinery and in combination with other manufacturer’s equipment, the products themselves are

designed to comply with EMC standards (see note 1.), so that the assembled

machinery or device can then also easily comply with EMC standards.

Even if machinery and equipment complies with EMC standards before

assembly, this compliance may change depending on the device, the configuration of the control panel, and wiring, so OMRON cannot guarantee that particular system complies with the directive. You must therefore confirm that

EMC Directives are met for the overall machine or device.

Note EMC: One directive relating to Electro-Magnetic Compatibility

EMS: Electro-Magnetic Susceptibility Standard

CS Series: EN61131-2

CJ Series: EN61000-6-2

EMI: Electro-Magnetic Interference Standard EN61000-6-4

Common Emission Standard EN61000-6-4, radiated emission standard

(10 m)

Low Voltage Directive

The Low Voltage Directive provides that necessary safety standards are guaranteed for devices operating at voltages of 50 to 1,000 VAC or 75 to

1,500 VDC.

Conditions for

Conforming to EMC

Directive for CS/CJ-series

PLCs

The immunity test conditions for CJ-series Analog I/O Units are as follows:

Tot al Ac c u r a c y

CS1W-AD161: +4%/

CJ1W-DA021/DA041: +4%/

CJ1W-AD041-V1/AD081-V1: +3%/

CJ1W-DA08V/DA08C/MAD42: +4%/

−6%

−1%

−6%

−4%

8 Precautions for the C200H-AD003, C200H-DA003/004, and

C200H-MAD01

Note the following important differences between the CS-series Analog I/O

Units and the C200H Analog I/O Units.

Current Input Wiring

The CS1W-AD041-V1/081-V1 Analog Input Units and the CS1W-MAD44

Analog I/O Unit do not have a current input terminal. To switch analog conversion input from voltage input to current input, the voltage/current switch must

be turned ON. Refer to 2-3-4 or 6-3-4 Voltage/Current Switch.

Mean Value Processing

The default setting for mean value processing in the CS1W-AD041-V1/081-V1

Analog Input Units and the CS1W-MAD44 Analog I/O Unit is mean value processing with 2 buffers. By changing the setting in data memory, no mean processing can be selected. Refer to 2-6-3 or 6-6-2 Mean Value Processing.

Operation Mode Switch

To change from normal mode to adjustment mode, or vice versa, with the

C200H-AD003, C200H-DA003/004, or C200H-MAD01 Analog I/O Units, it is

xxii

Page 22

Changes to the CJ1W-DA08V/08C and CJ1W-MAD42 9

necessary to create an I/O table. With the CS-series Analog I/O Units, the

operation mode switch can be used to make this change. Therefore the I/O

table is no longer necessary. Refer to 2-7-1, 4-7-1 or 6-9-1 Adjustment Mode

Operational Flow.

Error Flags

The C200H-AD003, C200H-DA003/004, and C200H-MAD01 use error codes,

whereas the CS-series Analog I/O Units use error flags. When the ERC indicator is lit due to a setting error in the DM area or an operating error, a bit flag

will be stored in the CIO Area. Refer to 2-8-2 Alarms Occurring at the Analog

Input Unit, 4-8-2 Alarms Occurring at the Analog Output Unit,

Alarms Occurring at the Analog I/O Unit.

or 6-10-2

9 Changes to the CJ1W-DA08V/08C and CJ1W-MAD42

The following additions and changes have been made for the CJ1W-DA08V/

08C Analog Output Unit and the CJ1W-MAD42 Analog I/O Unit in relation to

earlier CS/CJ-series Analog I/O Units.

Added Functions

Conversion Time/

Resolution Setting

(CJ1W-DA08V/DA08C/

MAD42)

Scaling Function

(CJ1W-DA08V/DA08C/

MAD42)

Voltage/Current Signal

Range Setting

(CJ1W-MAD42 only)

Changed Functions

Operation Mode

Switching

(CJ1W-DA08V/DA08C/

MAD42)

It is now possible to set A/D and D/A conversion times and resolution. The

settings are made in D(m+18) in the DM Area allocated for Special I/O Units.

Either a conversion time of 1 ms and a resolution of 4,000 or a conversion

time of 250

set. For details, refer to 5-6-2 Conversion Time/Resolution Setting (CJ1W-

DA08V/08C Only) and 7-6-2 Conversion Time and Resolution Setting.

With the scaling function, values within a range of ±32,000 can be set in the

DM Area words allocated for Special I/O Units, in user-specified units, as

upper and lower limits. A/D and D/A conversion are then executed with these

upper and lower limits taken as full scale. The scaling function is only enabled

when a conversion time of 1 ms and a resolution of 4,000 are set. For details,

refer to 5-6-5 Output Scaling Function (CJ1W-DA08V/08C Only), 7-6-5 Input

Scaling Function, and 7-7-4 Output Scaling Function.

When “1 to 5 V, 4 to 20 mA” is set for the I/O signal range, either the “1 to 5 V”

or “4 to 20 mA” range can then be selected by means of the D(m+35) setting.

Adjusting the factory-set voltage and current can improve the accuracy of current output specifications in comparison to earlier models. For details, refer to

Voltage/Current Range Setting in 7-6-1 Input Settings and Conversion Values

and 7-7-1 Output Settings and Conversions.

With earlier models, the operation mode (normal mode and adjustment mode)

was changed by means of a DIP switch setting on the rear panel of the Unit.

(With CJ1W/CS1W-AD041-V1/08-V1 Units, the operation mode can be

changed by means of either a rear-panel switch or a DM Area setting.)

With the CJ1W-DA08V/DA08C/MAD42, it is possible only by means of a setting in D(m+18) in the Special I/O Unit DM Area. For details, refer to 5-6-2

Conversion Time/Resolution Setting (CJ1W-DA08V/08C Only), 7-6-2 Conversion Time and Resolution Setting, and 7-7-2 Conversion Time and Resolution

Setting.

µs (500 µs for the CJ1W-MAD42) and a resolution of 8,000 can be

xxiii

Page 23

Changes to the CJ1W-DA08V/08C and CJ1W-MAD42 9

External Maximum

Output Current during

Voltage Output

(CJ1W-DA08V/MAD42)

Maximum Allowable

Load during Current

Output (CJ1W-DA08C)

For earlier models, the maximum value was 12 mA (for 1 kΩ of external load

resistance). For the CJ1W-DA08V/MAD42, the maximum value is 2.4 mA (for

5 k

Ω of external load resistance).

For earlier models, the maximum value was 600 Ω. For the CJ1W-DA08C, the

maximum value is 350

Ω.

xxiv

Page 24

System Design

This section describes the features and system configurations of CS/CJ-series Analog I/O Units.

1-1 Features and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Basic Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-2-1 Mounting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-2-2 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-3 Function Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

SECTION 1

1

Page 25

Features and Functions Section 1-1

t

1-1 Features and Functions

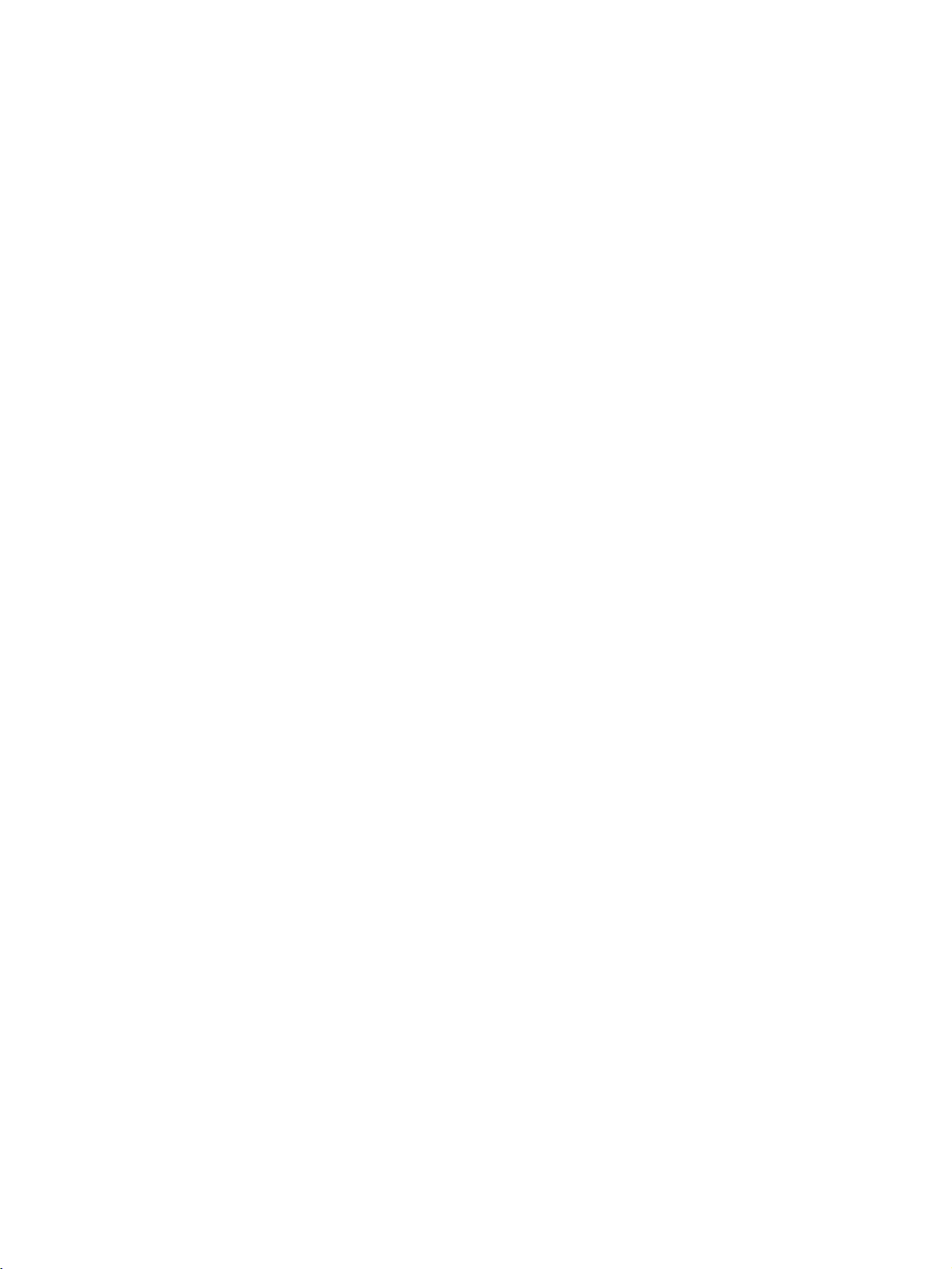

CS-series Analog I/O Units

Analog Input Units Analog Output Units

Analog I/O Uni

CS1W-AD041-V1 CS1W-AD081-V1 CS1W-DA041 CS1W-DA08V CS1W-DA08C

CS1W-AD161

The SYSMAC CS Series includes CS1W-AD041-V1, CS1W-AD081-V1, and

CS1W-AD161 Analog Input Units that convert analog signals to digital signals

and transfer them to CS-series CPU Units, and CS1W-DA041, CS1W-DA08V,

and CS1W-DA08C Analog Output Units for converting digital data in CSseries CPU Units into analog signals for output, and CS1W-MAD44 Analog I/

O Units that have both analog input and output functions.

CS1W-MAD44

Analog Input

Units

Analog Output Units

Analog I/O

Units

Unit Analog input Analog output

Maximum input

points

CS1W-AD041-V1 4 –10 to 10 V

CS1W-AD081-V1 8

CS1W-AD161 16

CS1W-DA041 --- --- 4 –10 to 10 V

CS1W-DA08V 8 –10 to 10 V

CS1W-DA08C 8 4 to 20 mA

CS1W-MAD44 4 –10 to 10 V

Input signal range Maximum

output points

--- --0 to 10 V

0 to 5 V

1 to 5 V

4 to 20 mA

4 –10 to 10 V

0 to 10 V

0 to 5 V

1 to 5 V

4 to 20 mA

Output signal range

0 to 10 V

0 to 5 V

1 to 5 V

4 to 20 mA

0 to 10 V

0 to 5 V

1 to 5 V

0 to 10 V

0 to 5 V

1 to 5 V

2

Page 26

Features and Functions Section 1-1

CJ-series Analog I/O Units

Analog Input Unit

CJ1W-AD041-V1

CJ1W-AD081-V1

AD081

RUN

ERC

B1 A1

ERH

ADJ

MACH

No.

1

x10

0

x10

Analog Output Unit

CJ1W-DA021

CJ1W-DA041

DA041

RUN

ERC

B1 A1

ERH

ADJ

MACH

No.

1

x10

0

x10

CJ1W-DA08V

CJ1W-DA08C

DA08V

RUN

ERC

B1 A1

ERH

ADJ

MACH

No.

1

x10

0

x10

Analog I/O Unit

CJ1W-MAD42

MAD42

RUN

ERC

B1 A1

ERH

ADJ

MACH

No.

1

x10

0

x10

Analog Input

Units

Analog Output Units

Analog I/O

Units

12

MODE

12

MODE

The SYSMAC CJ Series includes CJ1W-AD041-V1 and CS1W-AD081-V1

Analog Input Units that convert analog signals to digital signals and transfer

them to CJ-series CPU Units, and CJ1W-DA041 and CS1W-DA021 Analog

Output Units for converting digital data from CJ-series CPU Units into analog

signals for output. CJ1W-MAD42 Analog I/O Units and CJ1W-DA08V and

CJ1W-DA08C Analog Output Units that enable use of conversion time/resolution settings and scaling functions are also available.

Unit Analog input Analog output

Maximum input

points

CJ1W-AD041-V1 4 –10 to 10 V

CJ1W-AD081-V1 8

CJ1W-DA041 --- --- 4 –10 to 10 V

CJ1W-DA021 2

CJ1W-DA08V 8 –10 to 10 V

CJ1W-DA08C --- --- 8 4 to 20 mA

CJ1W-MAD42 4 –10 to 10 V

Input signal range Maximum

output points

--- --0 to 10 V

0 to 5 V

1 to 5 V

4 to 20 mA

2 –10 to 10 V

0 to 10 V

0 to 5 V

1 to 5 V

4 to 20 mA

Output signal range

0 to 10 V

0 to 5 V

1 to 5 V

4 to 20 mA

0 to 10 V

0 to 5 V

1 to 5 V

0 to 10 V

0 to 5 V

1 to 5 V

4 to 20 mA

High-speed Conversion The Analog Input Units (CS1W-AD041-V1/081-V1/161 and CJ1W-AD041-V1/

081-V1) and the CJ1W-DA08V/08C Analog Output Unit provide high-speed

data conversion at 250

provides data conversion at 500

µs per I/O point. The CJ1W-MAD42 Analog I/O Unit

µs per I/O point. The sampling period can be

further shortened by setting unused inputs and outputs so that their use is

prohibited.

3

Page 27

Features and Functions Section 1-1

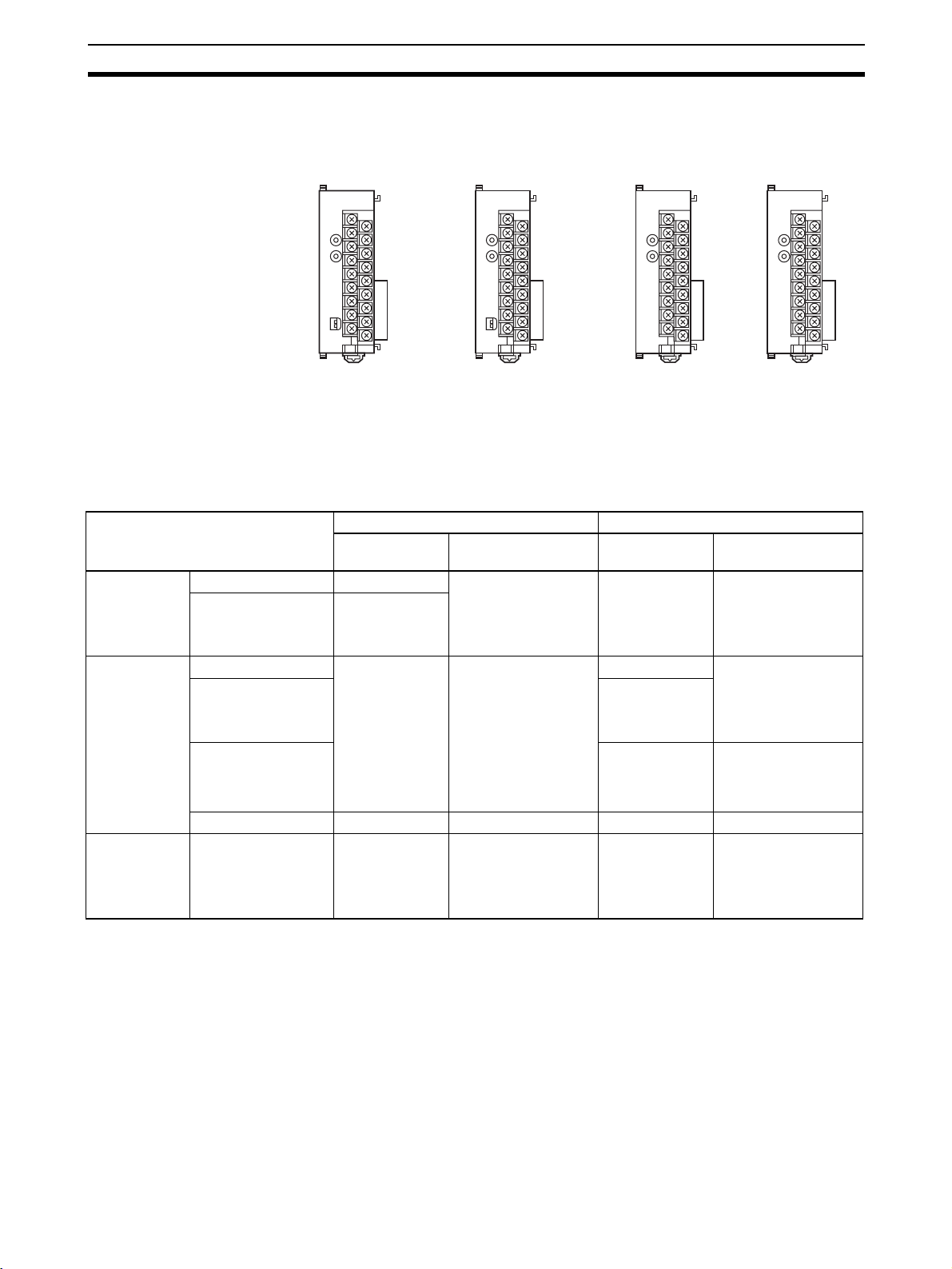

Input Disconnection

Detection Function

The input disconnection detection function can be used for analog inputs

within an input signal range of 1 to 5 V (4 to 20 mA). Any input under 0.3 V will

be regarded as a disconnection. For details, refer to 2-4-3, 2-6-5, or 6-6-4

Input Disconnection Detection Function.

Analog Input Unit CPU Unit

Disconnection

Detection Flag

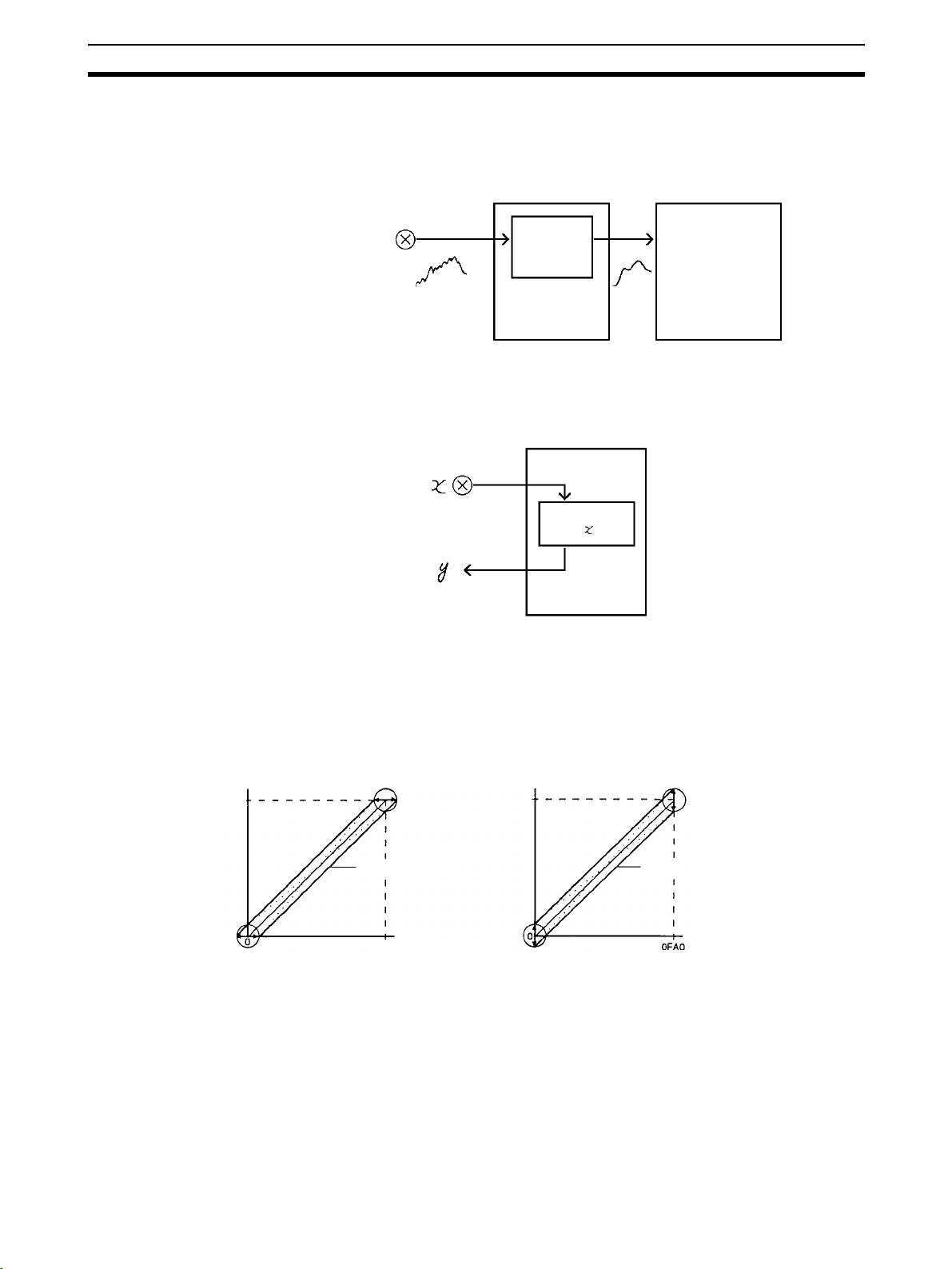

Peak Value Hold Function The peak value hold function holds the maximum digital conversion value for

every input (including mean value processing). This function can be used with

analog input. The following diagram shows how digital conversion values are

affected when the peak value hold function is used. For details, refer to 2-6-4

or 6-6-3 Peak Value Hold Function.

Peak hold bit

Output Hold Function The output hold function can be used to hold the analog output value at any

preset value when there is a fatal error at the CPU Unit or when specified by

the CPU Unit. When output is stopped, CLR, HOLD, or MAX can be selected

for output. For details, refer to 4-6-3 or 6-7-2 Output Hold Function.

Analog Output Unit CPU Unit

Output Enable

Flag OFF

CLR/HOLD/MAX

4

Page 28

Features and Functions Section 1-1

g

j

Mean Value Function The mean value function can be used to remove erroneous values that occur

due to factors such as noise that is included in analog inputs. The operating

mean is taken without affecting the data refresh cycle. For details, refer to 2-6-

3 or 6-6-2 Mean Value Processing.

Analog Input Unit CPU Unit

Mean value

of "n" history buffers

Ratio Conversion

Function

Offset and Gain

Adjustment Function

(Input signal range: 0 to 10 V)

0FA0/(1F40)

The CS1W-MAD44 and CJ1W-MAD42 Analog I/O Unit can output in analog

format the results of analog inputs calculated for ratio and bias. For details,

refer to 6-8 Ratio Conversion Function.

The A/D and D/A converter offset deviation and gain deviation can be

adjusted for each input and output. The offset and gain adjustments are made

with the Unit set for the adjustment mode, and the adjustment values are

stored in the Unit’s built-in EEPROM. For details, refer to 2-7, 4-7 or 6-9

Adjusting Offset and Gain.

Analog Input Function

Adjustable range Adjustable range

Gain

adjustment

Ratio and bias setting device

Analog Output Function

(Output signal range: 0 to 10 V)

10 V

Analog

output

Ratio and biasA x + B

Gain

adjustment

Offset ad

ustment Offset adjustment

Analo

10 V

input

Scaling Function With CS1W-AD161 Analog Input Units, CJ1W-DA08V/08C Analog Output

Units (See note 1.), and CJ1W-MAD42 Analog I/O Units, input analog values

and output analog set values can be automatically converted into user-specified units. This scaling function eliminates the previous need to provide programs (e.g., scaling using the SCL instruction) for numeric conversion to

different units.

When upper and lower limits have been preset in 16-bit binary data in the

CPU Unit’s DM Area, within a decimal range of

−32,000 to +32,000, input

analog values and output analog set values can be automatically converted

5

Page 29

Features and Functions Section 1-1

into user-specified units. (See note 2.) When input values are negative, they

are set using two’s complement.

Note 1. Only output scaling is supported by CJ1W-DA08V/08C Analog Output

Units.

2. This is possible only for a conversion time of 1 ms and a resolution of

4,000. The scaling function is not enabled for a conversion time of 250

(500 µs for the CJ1W-MAD42) and a resolution of 8,000.

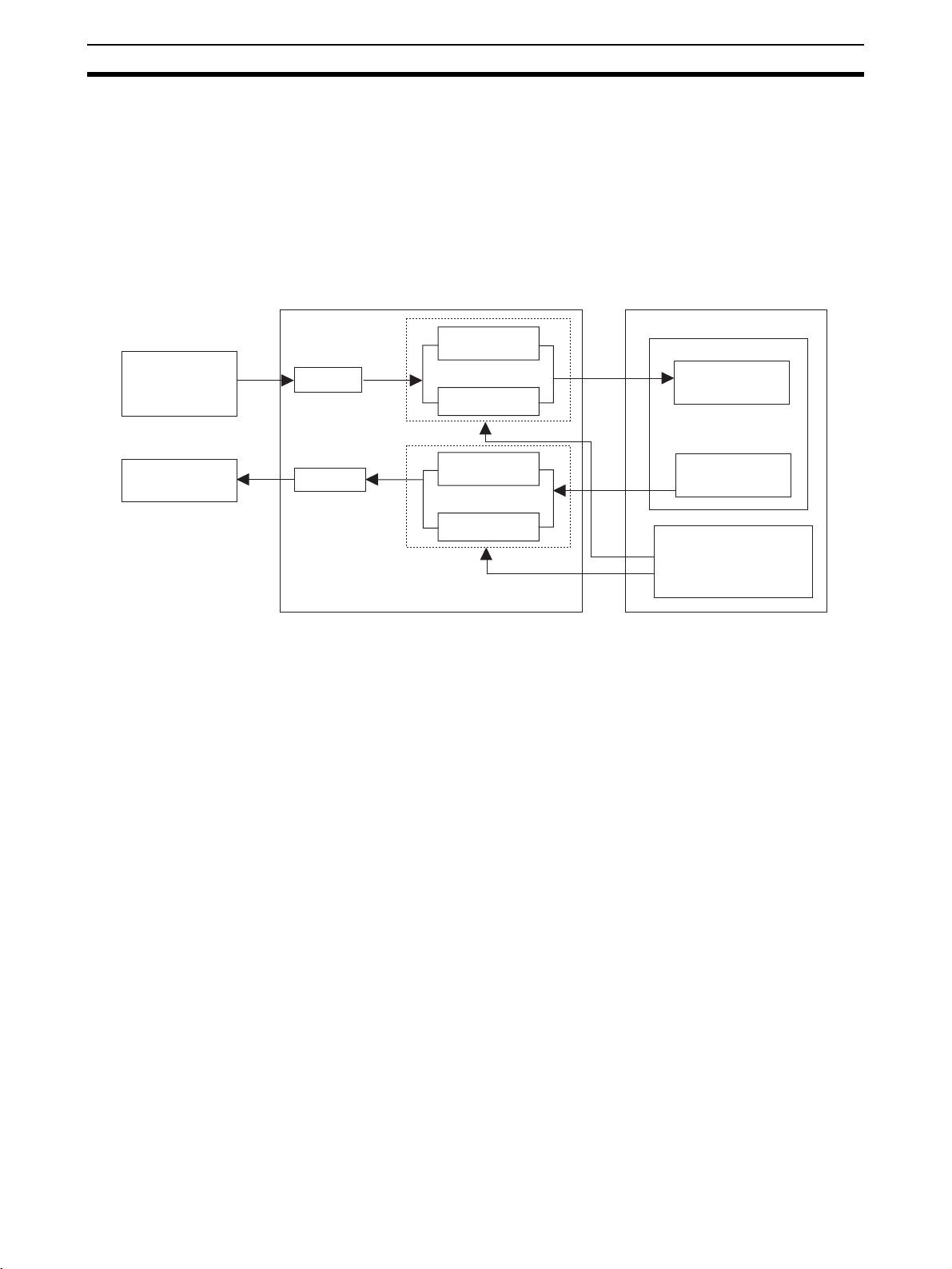

Conceptual Diagram of Scaling (CJ1M-MAD42 Only)

µs

Input analog value

(temperature,

flowrate, etc.)

Output analog

value

A/D conversion

D/A conversion

Analog I/O Unit

Power turned ON or

Unit restarted.

No scaling

Scaling

No scaling

Scaling

CPU Unit

Special I/O Unit Area

Converted analog

input value

(in engineering units)

Set analog output

value

(in engineering units)

DM Area

Scaling settings

Input scaling: D(m+27) to

D(m+34)

Output scaling: D(m+19) to

D(m+22)

6

Page 30

Basic Configuration Section 1-2

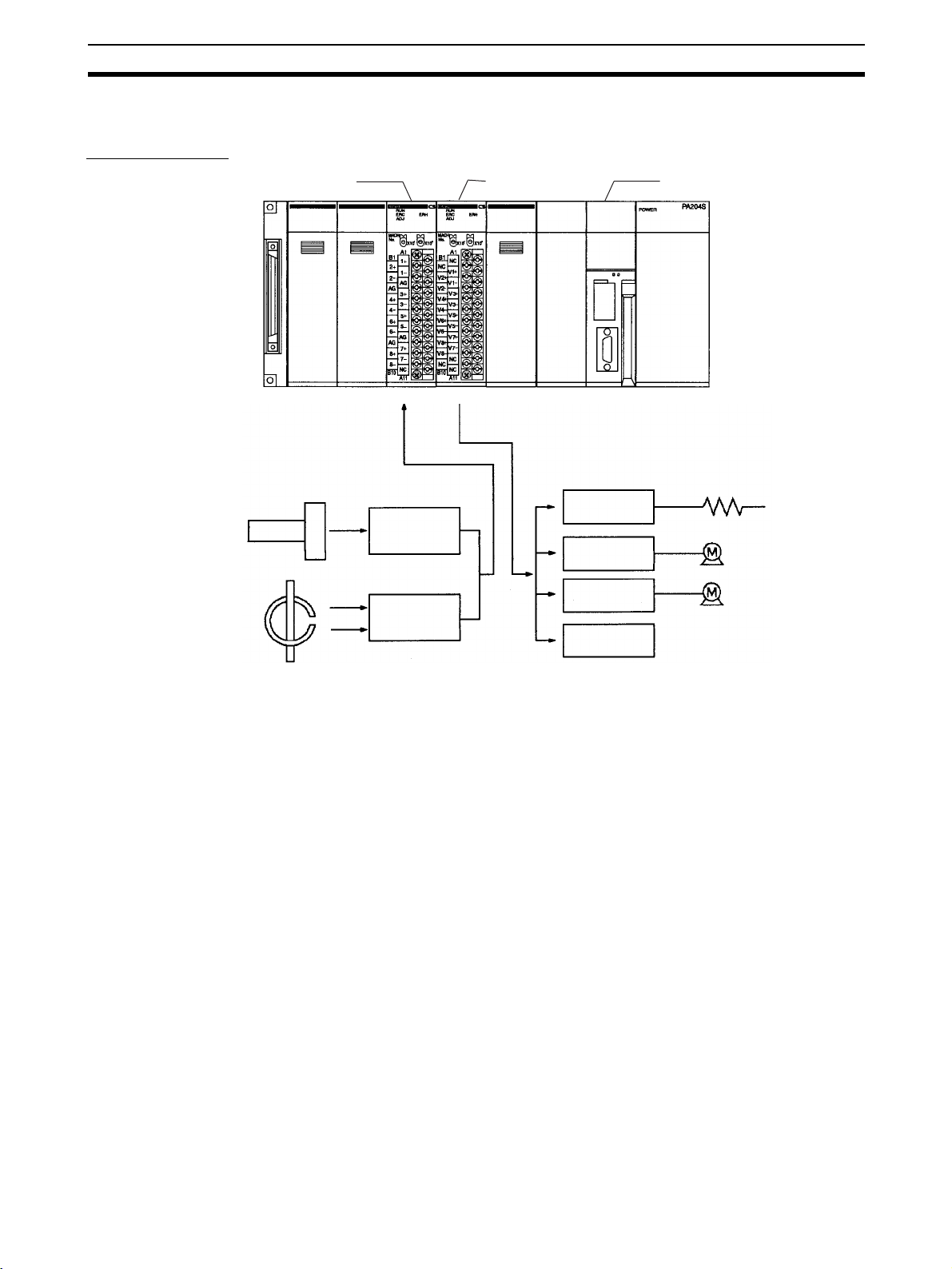

1-2 Basic Configuration

CS-series PLCs

Temperature

Pressure

Speed

Flow rate

Voltage

Current

Powe r

Power factor

Analog Input Unit

Sensor

Preamp

Transducer

Analog Output Unit

Regulator

Servocontroller

Variable speed

controller

Chart recorder

CPU Unit

(Temperature control)

(Position control)

(Speed control)

Sensor

Note The above diagram is an installation example for the CS1W-AD081-V1 Ana-

log Input Unit and CS1W-DA08V Analog Output Unit.

7

Page 31

Basic Configuration Section 1-2

CJ-series PLCs

CPU Unit

SYSMAC

CJ1G-CPU44

PROGRAMMABLE

CONTROLLER

RUN

ERR/ALM

INH

PRPHL

COMM

OPEN

MCPWR

BUSY

PERIHERAL

AD081

MACH

No.

x10

x10

DA041

RUN

ERC

ERH

ADJ

1

0

B1 A1

RUN

ERC

ERH

ADJ

MACH

No.

1

x10

0

x10

Analog Input Unit

Analog Output Unit

B1 A1

12

PORT

MODE

12

MODE

Sensor

Temperature

Pressure

Speed

Flow rate

Voltage

Current

Power

Power factor

Sensor

Preamp

Transducer

Regulator

Servocontroller

Variable speed

controller

Chart

recorder

(Temperature control)

M

(Position control)

M

(Speed control)

Note The above diagram is an installation example for the CJ1W-AD041-V1/081-V1

Analog Input Unit and CJ1W-DA021/041 Analog Output Unit.

Mounting Restrictions

CS-series PLCs The CS1W-MAD44 Analog I/O Unit is a Special I/O Unit of the CS Series.

CS1W-MAD44 Analog I/O Units can be mounted to either CS-series CPU

Racks or CS-series Expansion Racks. These Analog I/O Units cannot be

mounted to C200H Expansion I/O Racks or SYSMAC BUS Slave Racks.

The number of Analog I/O Units that can be mounted to one Rack (i.e., a CPU

Rack or Expansion Rack) depends on the maximum supply current of the

Power Supply Unit and the current consumption of other Units. If a Rack is to

be mounted with Analog Input, Output, or I/O Units only, the following restrictions will apply.

Power Supply Unit Rack CS1W-

AD041-V1

CS1W-

AD081-V1

(5 VDC

120 mA)

C200HW-PA204

C200HW-PA204S

C200HW-PA204R

CPU Rack63328

Expansion Rack63329

C200HW-PA204C

C200HW-PD024

(4.6 A at 5 VDC)

C200HW-PA209R

(9 A at 5 VDC)

CS1D-PA207R

(7 A at 5 VDC)

CS1D-PD024

(4.3 A at 5 VDC)

CPU Rack1076510

Expansion Rack1076510

CPU Rack85448

Expansion Rack96549

CPU Rack63227

Expansion Rack63228

8

CS1W-DA041

CS1W-DA08V

(5 VDC

130 mA)

CS1WMAD44

(5 VDC

200 mA)

CS1W-DA08C

(5 VDC

130 mA)

CS1W-AD161

(5 VDC

150 mA)

Page 32

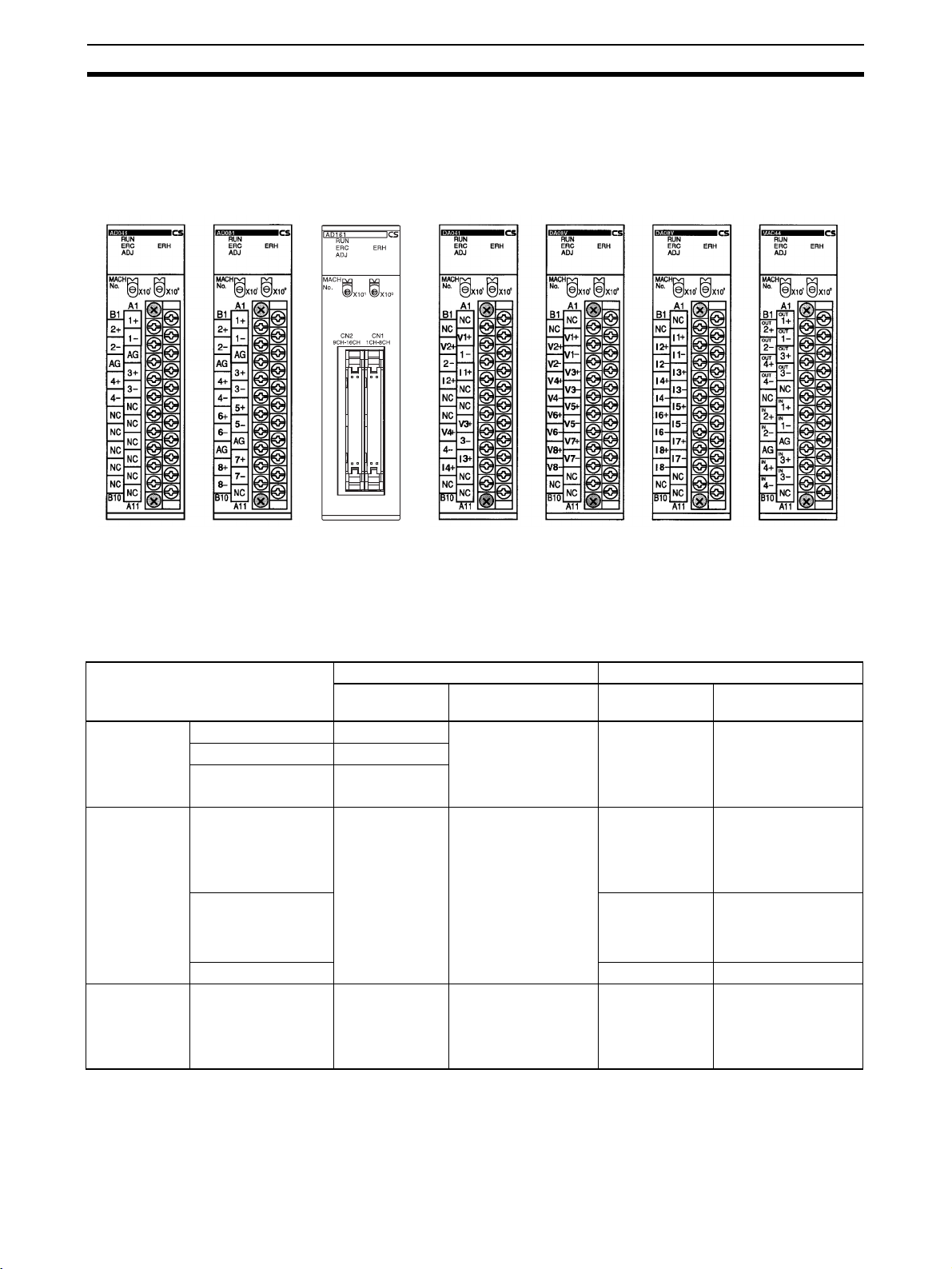

Basic Configuration Section 1-2

Note The I/O bits of the Special I/O Unit are allocated according to the setting of the

unit number switch on the front panel of the Unit, and not the slot number

where the Unit is mounted.

CJ-series PLCs CJ-series Analog I/O Units are Special I/O Unit of the CJ-series PLCs.

These Units can be connected in the CJ-series CPU Rack or Expansion

Racks. The number of Analog I/O Units that can be connected in each Rack

will depend on the current consumption of the other Units in the Rack. The following table shows the maximum number of Analog I/O Units that can be connected in one Rack if no other I/O Units are connected.

Power Supply Unit Rack CJ1W-DA021

CJ1W-DA041

(5 VDC 120 mA)

CJ1W-DA08V

CJ1W-DA08C

(5 VDC 140 mA)

CJ1W-PA205R

CJ1W-PA205C

CJ1W-PD025

(5.0 A at 5 VDC)

CJ1W-PA202

(2.8 A at 5 VDC)

CJ1W-PD022

(2.0 A at 5 VDC)

CPU Rack 10 9 7

Expansion Rack 10 10 8

CPU Rack 10 4 3

Expansion Rack 10 6 4

CPU Rack 7 2 1

Expansion Rack 10 4 3

Note The I/O bits of the Special I/O Unit are allocated according to the setting of the

unit number switch on the front panel of the Unit, and not the order in which it

is connected.

1-2-1 Mounting Procedure

CS-series PLCs

Use the following procedure to mount Analog I/O Units to the Backplane.

1,2,3... 1. Lock the top of the Analog I/O Unit into the slot on the Backplane and rotate

the Unit downwards as shown in the following diagram.

CS1W-AD041-V1

CJ1W-AD081-V1

(5 VDC 420 mA)

CJ1W-MAD42

(5 VDC 580 mA)

Hook

Backplane

2. While making sure to align the Unit properly with the connectors, tighten

the mounting screws securely to the tightening torque of 0.4 N·m.

9

Page 33

Basic Configuration Section 1-2

3. To remove the Unit, first loosen the mounting screws using a Phillips

screwdriver.

Mounting screw

Leave enough space below each Rack, as shown in the following diagram for

mounting and removing the Units.

20 mm min.

Backplane

CJ-series PLCs

20 mm min.

Phillips screwdriver

Analog I/O Units are connected as I/O Units in the system configuration, as

shown below.

CPU Rack

SYSMAC

CJ1G-CPU44

PROGRAMMABLE

CONTROLLER

MCPWR

BUSY

OPEN

ERR/ALM

PERIHERAL

PORT

RUN

INH

PRPHL

COMM

AD081

MACH

No.

x

x

RUN

ERC

ERH

ADJ

1

10

0

10

12

MODE

Power Supply Unit CPU Unit I/O Units (10 max.)

DA041

RUN

ERC

B1 A1

ERH

B1 A1

ADJ

MACH

No.

1

x

10

0

x

10

12

MODE

End Cover

(included with CPU Unit)

10

Use the following procedure to connect Analog I/O Units to a CJ-series Rack.

Page 34

Basic Configuration Section 1-2

1,2,3... 1. Align the connectors and press in firmly on the Units to connect them com-

pletely.

Hooks

Connector

2. Move the sliders on the top and bottom of the Unit to the lock position to

secure the Units. The sliders should click into place.

Move the sliders to the back

until they click into place.

Hook holes

Note The CJ-series PLC may not operate properly if the sliders are not locked

1-2-2 Precautions

Lock

Slider

Release

3. Attach an End Cover to the Unit on the right end of the Rack.

firmly into place.

Be sure to turn OFF the power supply to the PLC before installing or disconnecting Units or connecting lines.

To reduce the risk of malfunctioning due to electrical noise, wire input and output lines in separate ducts from high-voltage and power lines.

When wiring a Unit, place a label over the top of the Unit to prevent wire clippings or other materials from getting inside the Unit. When the wiring has

been completed, the label must be removed to prevent heat radiation.

CS-series PLCs

Remove the label after the

wiring has been completed.

11

Page 35

Function Applications Section 1-3

CJ-series PLCs

Remove the label after the

wiring has been completed.

AD081

AD081

UN

UN

R

R

RC

RC

E

E

RH

RH

E

E

DJ

DJ

A

A

H

H

C

C

A

A

M

M

.

.

1

1

No

No

0

0

1

1

x

x

0

0

0

0

1

1

x

x

12

12

E

E

OD

OD

M

M

1-3 Function Applications

Function Application Page

Mean value processing Performs a smooth conversion when the input fluctuation is too extreme.

Example: Removes noise interference from data such as flow/pressure.

Peak value hold Holds the maximum value that has been read.

Holds the data that is less than the maximum value.

Disconnection detection Detects disconnection of input signals. 59, 258

Output hold Holds the output signal at the previous value for certain conditions, such as

errors.

Holds the output signal in the lower-limit value or 0 V for certain conditions,

such as errors.

Holds the output signal in the upper-limit value for certain conditions, such

as errors.

Ratio conversion Uses the Analog I/O Unit as a gradient setting device for setting ratio and

bias.

Offset gain adjustment Adjusts the offset and gain, and uses the I/O functions. 60, 153, 265

55, 254

58, 257

152, 261

262

12

Page 36

CS-series Analog Input Units

This section explains how to use the CS1W-AD041-V1/081-V1/161 Analog Input Units.

2-1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-1-1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-1-2 Input Function Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2-1-3 Input Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2-2 Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2-2-1 Procedure Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2-3 Components and Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2-3-1 Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2-3-2 Unit Number Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2-3-3 Operation Mode Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2-3-4 Voltage/Current Switch (CS1W-AD041-V1/AD081-V1) . . . . . . . . 31

2-4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2-4-1 Terminal Arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2-4-2 Internal Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2-4-3 Voltage Input Disconnection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2-4-4 Input Wiring Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2-4-5 Input Wiring Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2-5 Exchanging Data with the CPU Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2-5-1 Outline of Data Exchange. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2-5-2 Unit Number Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2-5-3 Special I/O Unit Restart Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2-5-4 Fixed Data Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2-5-5 I/O Refresh Data Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

2-6 Analog Input Functions and Operating Procedures . . . . . . . . . . . . . . . . . . . . 52

2-6-1 Input Settings and Conversion Values . . . . . . . . . . . . . . . . . . . . . . . 52

2-6-2 Conversion Time/Resolution Setting . . . . . . . . . . . . . . . . . . . . . . . . 54

2-6-3 Mean Value Processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

2-6-4 Peak Value Hold Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

2-6-5 Input Disconnection Detection Function . . . . . . . . . . . . . . . . . . . . . 59

2-6-6 Scaling Function (CS1W-AD161 Only) . . . . . . . . . . . . . . . . . . . . . . 60

2-7 Adjusting Offset and Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

2-7-1 Adjustment Mode Operational Flow . . . . . . . . . . . . . . . . . . . . . . . . 60

2-7-2 Input Offset and Gain Adjustment Procedures. . . . . . . . . . . . . . . . . 62

2-8 Handling Errors and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

2-8-1 Indicators and Error Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

2-8-2 Alarms Occurring at the Analog Input Unit . . . . . . . . . . . . . . . . . . . 70

2-8-3 Errors in the CPU Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

2-8-4 Restarting Special I/O Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

2-8-5 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

SECTION 2

13

Page 37

Specifications Section 2-1

2-1 Specifications

2-1-1 Specifications

Item CS1W-AD041-V1 CS1W-AD081-V1 CS1W-AD161

Unit type CS-series Special I/O Unit

Isolation (See note 1.) Between I/O and PLC signals: Photocoupler

External terminals 21-point detachable terminal block (M3 screws) Two 34-pin MIL connectors

Affect on CPU Unit cycle time 0.2 ms

Power consumption 120 mA max. at 5 VDC, 90 mA max. at 26 VDC 150 mA max. at 5 VDC,

Dimensions (mm) (See note 2.) 35 x 130 x 126 (W x H x D) 35 x 130 x 119 (W x H x D)

Weight 450 g max.

General specifications Conforms to general specifications for SYSMAC CS Series.

Mounting position CS-series CPU Rack or CS-series Expansion Rack

Maximum number of Units

(See note 3.)

Data exchange with CPU Units

(See note 4.)

Input

specifications

Number of analog inputs 4 8 16

Input signal range

(See note 5.)

Maximum rated input (for

1 point) (See note 7.)

Input impedance Voltage Input: 1 MΩ min.

Resolution 4,000/8,000 (See note 8.)

Converted output data 16-bit binary data

Accuracy

(See note

9.)

A/D conversion time

(See note 10.)

23±2°C Voltage Input: ±0.2% of full scale

0°C to 55°C Voltage Input:±0.4% of full scale

(No isolation between individual I/O signals.)

55 mA max. at 26 VDC

(Cannot be mounted to a C200H Expansion I/O Rack or a SYSMAC BUS Slave

Rack.)

Refer to the table on page 15.

Special I/O Unit Area in CIO Area (CIO 2000 to CIO

2959): 10 words per Unit

Special I/O Unit Area in DM Area (D20000 to D29599):

100 words per Unit

1 to 5 V

0 to 5 V

0 to 10 V

–10 to 10 V

4 to 20 mA

(See note 6.)

Voltage Input: ±15 V

Current Input: ±30 mA

Current Input: 250 Ω (rated value)

Current Input: ±0.4% of full scale

Current Input: ±0.6% of full scale

1.0 ms or 250 µs per point max. (See note 8.)

Special I/O Unit Area in

CIO Area (CIO 2000 to

CIO 2959): 20 words per

Unit

Special I/O Unit Area in

DM Area (D20000 to

D29599): 200 words per

Unit

Voltage Input: ±0.2% of full

scale

Current Input: ±0.2% of full

scale

Voltage Input:±0.4% of full

scale

Current Input: ±0.4% of full

scale

14

Page 38

Specifications Section 2-1

Item CS1W-AD041-V1 CS1W-AD081-V1 CS1W-AD161

Input

functions

Mean value processing Stores the last “n” data conversions in the buffer, and stores the mean value of the

Peak value holding Stores the maximum conversion value while the Peak Value Hold Bit is ON.

Input disconnection

detection

Scaling function None None Enabled only for conver-

conversion values.

Buffer number: n = 2, 4, 8, 16, 32, 64

Detects the disconnection and turns ON the Disconnection Detection Flag. (See note

11.)

sion time of 1 ms and resolution of 4,000. Setting any

values within a range of

±32,000 as the upper and

lower limits allows the A/D

conversion result to be output with these values as

full scale.

Note 1. Do not apply a voltage higher than 600 V to the terminal block when per-

forming withstand voltage test on this Unit. Otherwise, internal elements

may deteriorate.

2. Refer to Dimensions on page 359 for details on the Unit’s dimensions.

3. The maximum number of Analog Input Units that can be mounted to one

Rack depends on the Power Supply Unit mounted to the Rack.

Power Supply Unit Rack CS1W-

AD041-V1

CS1W-

AD081-V1

(5 VDC

120 mA)

C200HW-PA204

C200HW-PA204S

C200HW-PA204R

C200HW-PA204C

C200HW-PD024

(4.6 A at 5 VDC)

C200HW-PA209R

(9 A at 5 VDC)

CS1D-PA207R

(7 A at 5 VDC)

CS1D-PD024

(4.3 A at 5 VDC)

CPU Rack63328

Expansion Rack63329

CPU Rack1076510

Expansion Rack1076510

CPU Rack85448

Expansion Rack96549

CPU Rack63227

Expansion Rack63228

The above limits may be reduced depending on the power consumed by

other Units on the same Rack.

CS1W-DA041

CS1W-DA08V

(5 VDC

130 mA)

CS1WMAD44

(5 VDC

200 mA)

CS1W-DA08C

(5 VDC

130 mA)

CS1W-AD161

(5 VDC

150 mA)

15

Page 39

Specifications Section 2-1

4. Data Exchange with the CPU Unit

Area Number of words Data transfer

Special I/O Unit Area

in CIO Area

(CIO 2000 to

CIO 2959,

CIO 2000.00 to

CIO 2959.15)

Special I/O Unit Area

in DM Area

(D20000 to D26959)

• CS1W-AD041-V1/

081-V1: 10 words per

Unit

• CS1W-AD161: 20

words per Unit

• CS1W-AD041-V1/

081-V1: 100 words

per Unit

• CS1W-AD161: 200

words per Unit

Note The resolution/conversion time setting and operation mode setting

5. Input signal ranges can be set for each input.

6. Voltage input or current input is selected for the CS1W-AD041-V1 and

CS1W-AD081-V1 by using the voltage/current switch at the back of the terminal block. Voltage input or current input is selected for the CS1W-AD161

by wiring the connector terminals. Voltage/current selection for input ranges 1 to 5 V or 4 to 20 mA can be set in DM word m+52.

7. Use the analog input voltage/current value within the specified input signal

range. Exceeding the specified range may result in malfunction.

8. With Analog Input Units, the resolution can be changed from 4,000 to

8,000 and the conversion time changed from 1 ms to 250

m+18 for CS1W-AD041-V1 and CS1W-AD081-V1 or in DM word m+19 for

CS1W-AD161.

9. The following are adjusted at the factory.

CS1W-AD041-V1/081-V1: Voltage inputs

CS1W-AD161: Voltage inputs and current inputs

To use current inputs with the CS1W-AD041-V1/081-V1 or to use the

CS1W-AD161 with products other than the recommended ones, adjust the

offset and gain as required.

10. A/D conversion time is the time it takes for an analog signal to be stored in

memory as converted data after it has been input. It takes at least one cycle before the converted data is read by the CPU Unit.

11. Input disconnection detection is valid only when the 1 to 5-V or 4 to 20-mA

range is set. If there is no input signal for when the 1 to 5-V or 4 to 20-mA

range is set, the Disconnection Detection Flag will turn ON.

Transfer direction Data contents

timing

Constantly CPU Unit to Ana-

When power is

turned ON or

Unit is

restarted

log Input Unit

Analog Input Unit

to CPU Unit

CPU Unit to Analog Input Unit

Peak hold indicators

Analog input values

Line disconnection detection

Alarm flags

Etc.

Input signal conversion ON/OFF

Signal range specifications

Averaging specifications

Resolution/conversion time setting

Operation mode setting

Scaling setting (CS1W-AD161 only)

are supported only by version-1 Analog Input Units.

Calibration conditions: Recommended Terminal BlockConnector Conversion Unit used. (The factory calibration

for a current input can be made effective by setting DM

word m+52.)

µs in DM word

16

Page 40

Specifications Section 2-1

g

2-1-2 Input Function Block Diagram

Analog Input Unit CPU Unit

Analog input 1

Analog input 2

Analog input 3

Analog input 4

Analog input 5

Analog input 6

Analog input 7

Analog input 8

A/D

Same as above.

Same as above.

Same as above.

Same as above. (See note.)

Same as above. (See note.)

Same as above. (See note.)

Same as above. (See note.)

Input disconnection

detection

Note There are only four analog inputs for the CS1W-AD041-V1, and 16 analog

inputs for the CS1W-AD161.

2-1-3 Input Specifications

If signals that are outside the specified range provided below are input, the

conversion values (16-bit binary data) used will be either the maximum or

minimum value.

Mean value

processing

disabled

Mean value

processing

enabled

Peak value

hold function

disabled

Peak value

hold function

enabled

I/O

refresh

Special I/O

Unit Area

Analog

input 1

conversion

value

Range: 1 to 5 V (4 to 20 mA)

Conversion value

1068 (20D0)

0FA0 (1F40)

0000 (0000)

FF38 (FE70)

1 V/4 mA

0.8 V/3.2 mA

5 V/20 mA

5.2 V/20.8 mA

input signal

Analo

Resolution: 4,000

(Resolution: 8,000)

17

Page 41

Specifications Section 2-1

g

Range: 0 to 10 V

Conversion value

1068 (20D0)

0FA0 (1F40)

Resolution: 4,000

(Resolution: 8,000)

0000 (0000)

FF38 (FE70)

0 V 10 V

–0.5 V 10.5 V

input signal

Analo

Range: 0 to 5 V

Conversion value

1068 (20D0)

0FA0 (1F40)

0000 (0000)

FF38 (FE70)

Resolution: 4,000

(Resolution: 8,000)

0 V 5 V

–0.25 V 5.25 V

Analog input signal

18

Page 42

Specifications Section 2-1

g

Range: –10 to 10 V

Conversion value

0898 (1130)

07D0 (0FA0)

Resolution: 4,000

0000 (0000)

F830 (F060)

F768 (EED0)

(Resolution: 8,000)

–10 V

–11 V

0 V 10 V

Analo

11 V

input signal

Note The conversion values for a range of –10 to 10 V will be as follows (for a reso-

lution of 4,000):

16-bit binary data BCD

F768 –2200

::

FFFF –1

0000 0

0001 1

::

0898 2200

19

Page 43

Operating Procedure Section 2-2

2-2 Operating Procedure

Follow the procedure outlined below when using Analog Input Units.

Installation and Settings

1,2,3... 1. Set the operation mode to normal mode. (See note 1.)

2. Select voltage/current input using the switch at the back of the terminal

block. (See note 2.)

3. Wire the Unit.

4. Use the unit number switch on the front panel of the Unit to set the unit

number. (See note 3.)

5. Turn ON the power to the PLC.

6. Create the Input tables.

7. Make the Special Input Unit DM Area settings.

• Set the input numbers to be used.

• Set the input signal ranges.

• Set the number of mean processing samplings.

• Conversion time and resolution

8. Turn the power to the PLC OFF and ON, or turn ON the Special I/O Unit

Restart Bit to ON.

When the input for the connected devices needs to be calibrated, follow the

procedures in Offset Gain Adjustment below. Otherwise, skip to Operation

below.

Offset and Gain Adjustment

Operation

1,2,3... 1. Set the operation mode to adjustment mode. (See note 1.)

2. Select voltage or current input. (See note 2.)

3. Turn ON the power to the PLC.

4. Adjust the offset and gain.

5. Turn OFF the power to the PLC.

6. Set the operation mode to normal mode. (See note 1.)

1,2,3... 1. Turn ON the power to the PLC.

2. Ladder program

• Read conversion values or write set values by means of MOV(021)

and XFER(070).

• Specify the peak hold function.

• Obtain disconnection notifications and error codes.

Note 1. Setting the Operation Mode

The operation mode can be changed either by setting the DIP switch on

the rear panel of the Unit or changing the DM Area settings. When normal

mode is set both in the DIP switch and in the DM Area settings, the Unit

operates in normal mode. If adjustment mode is set in either or both of the

settings, the Unit operates in adjustment mode. The operation mode selection setting is allocated in DM word m+18 for CS1W-AD041-V1 and CS1WAD081-V1 and in DM word m+19 for CS1W-AD161.

2. Selecting Voltage/Current Input

With the CS1W-AD041-V1 and CS1W-AD081-V1, remove the terminal

block and set the DIP switch located at the back. With the CS1W-AD161,

20

Page 44

Operating Procedure Section 2-2

select either voltage input or current input by wiring the connector terminals. Use DM word m+52 to select 1 to 5 V or 4 to 20 mA as the voltage or

current input range, respectively.

3. Setting the Unit Number

Set the unit number for the Special I/O Unit using the rotary switches on

the front panel of the Unit.

Set the CS1W-AD041-V1 and CS1W-AD081-V1 between 0 and 95. A single CS1W-AD161 is allocated words in the CIO Area and DM Area for two

Units. Set the unit number between 0 and 94. To set a CS1W-AD161 to unit

number "n," the unit number setting "n+1" is not possible.

2-2-1 Procedure Examples

The procedure for using Analog Input Units is provided here using the CS1WAD081-V1 as an example. The method used to set CS1W-AD161 Analog

Input Units is different. Be sure to use the correct procedure.

CS1W-AD081-V1 CS-series CPU Unit

IN1: 1 to 5 V

IN2: 1 to 5 V

IN3: 4 to 20 mA

Analog input

IN4: 4 to 20 mA

IN5: 0 to 10 V

IN6: 0 to 10 V

IN7: –10 to 10 V

IN8: Not used

Ladder Program

Setting the Analog Input Unit

1,2,3... 1. Set the operation mode. Refer to 2-3-3 Operation Mode Switch for further

Unit No.: 1

details.

Turn OFF SW1 for normal mode

The operation mode can be changed by setting DM word m+18 (DM word

m+19 for CS1W-AD161).

21

Page 45

Operating Procedure Section 2-2

2. Set the voltage/current switch. Refer to 2-3-4 Voltage/Current Switch

(CS1W-AD041-V1/AD081-V1) for further details.

Pins IN1 to IN8 correspond to analog inputs 1 to 8.

E.g., To use voltage input for analog inputs 1 and 2,

turn OFF IN1 and IN2.

To use current input for analog inputs 3 and 4, turn

ON IN3 and IN4.

Note With CS1W-AD161, select voltage/current input by wiring the connector termi-

nals.

3. Mount and wire the Analog Input Unit. Refer to 1-2-1 Mounting Procedure,

2-4 Wiring or 2-4-4 Input Wiring Example for further details.

4. Set the unit number switch. Refer to 2-3-2 Unit Number Switch for further

details.

22

Page 46

Operating Procedure Section 2-2

If the unit number is set to 1, words will be allocated to the Special I/O Unit

Area CIO 2010 to CIO 2019 and to the Special I/O Unit Area D20100 to

D20199.

Note A single CS1W-AD161 is allocated CIO Area words and DM Area words for

two Units. For example, if the unit number is set to 1, the CS1W-AD161 will be

allocated CIO Area words CIO 2010 to CIO 2029 and DM Area words D20100

to D20299.