Page 1

□□

□□

P068-E1-03

Programmable Controller CJ1

Replacement Guide

From CJ1M/CJ1G to CJ2M

CJ1M-CPU

CJ1G-CPU4□(H)

CJ2M-CPU

Page 2

About this document

This document provides the reference information for replacing CJ1M/CJ1G PLC systems with

CJ2M series PLC.

This document does not include precautions and reminders; please read and understand the

important precautions and reminders described on the manuals of PLCs (both of PLC used in the

existing system and PLC you will use to replace the existing PLC) before attempting to start

operation.

Page 3

Man.No. Manual

Related Manuals

W472 CJ2 CPU Unit Hardware USER'S MANUAL

W473 CJ2 CPU Unit Software USER'S MANUAL

W486 CJ2M Pulse I/O Module USER'S MANUAL

W393 CJ Series OPERATION MANUAL

W441 CJ series CJ1M CPU Units with Ethernet Functions OPERATION MANUAL

W395 CJ series Built-in I/O CJ1M CPU Units OPERATION MANUAL

W394 CS/CJ/NSJ PROGRAMMING MANUAL

W474 CS/CJ/NSJ Series INSTRUCTIONS REFERENCE MANUAL

W342 CS/CJ/CP/NSJ Series Communications Commands REFERENCE MANUAL

W345 CS/CJ Series Analog I/O Units AD/DA/MAD42 OPERATION MANUAL

W368 CS/CJ Series Analog I/0 Units OPERATION MANUAL

W466 CJ Series Universal Input Units OPERATION MANUAL

W396 CJ Series Temperature Control Units OPERATION MANUAL

W401 High-speed Counter Units OPERATION MANUAL

W465 EtherNet/IP Units OPERATION MANUAL

W420 CS and CJ Series Ethernet Units OPERATION MANUAL Construction of Networks

W343 CS/CJ Series Ethernet Units OPERATION MANUAL

W421 CS/CJ Series Ethernet Units OPERATION MANUAL Construction of Applications

Z174 CS/CJ Series ID SENSOR UNITS OPERATION MANUAL

W397 CJ Series Position Control Units CJ1W-NC□□3 OPERATION MANUAL

W477 CJ Series Position Control Units CJ1W-NC□□4 OPERATION MANUAL

W336 CS/CJ Series Serial Communications Boards Serial Communications Units OPERATION MANUAL

W426 CS/CJ Series Position Control Units CS1W-NC□□1/CJ1WNC□□1-MA OPERATION MANUAL

W435 CS/CJ series Motion Control Unit CS1W/CJ1W-MCH71OPERATION MANUAL

W467 Controller Link Support Boards for PCI Bus INSTALLATION GUIDE

W309 Controller Link Units OPERATION MANUAL

V237 SPU-Console Ver.2.1 OPERATION MANUAL

W406 CS/CJ Series Loop Control Boards/Process-control CPU Units /Loop-control CPU Units OPERATION MANUAL

W407

W463 CX-One FA Integrated Tool Package SETUP MANUAL

W446 CX-Programmer OPERATION MANUAL

W447 CX-Programmer OPERATION MANUAL:Function Blocks/Structured Text

W469 CX-Programmer OPERATION MANUAL SFC Programming

W366 CX-Simulator OPERATION MANUAL

W464 CX-Integrator OPERATION MANUAL

W433 CX-Position OPERATION MANUAL

W436 CX-Motion-NCF OPERATION MANUAL

W448 CX-Motion-MCH OPERATION MANUAL

CS/CJ Series Loop Control Boards/Process-control CPU Units /Loop-control CPU Units FUNCTION BLOCK

REFERENCE MANUAL

Page 4

Terms and Conditions Agreement

Read and understand this catalog.

Please read and understand this catalog before purchasing the products. Please consult your

OMRON representative if you have any questions or comments.

Warranties.

(a) Exclusive Warranty. Omron’s exclusive warranty is that the Products will be free from defects in

materials and workmanship for a period of twelve months from the date of sale by Omron (or such

other period expressed in writing by Omron). Omron disclaims all other warranties, express or

implied.

(b) Limitations. OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED,

ABOUT NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE OF THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED

THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based on

infringement by the Products or otherwise of any intellectual property right.

(c) Buyer Remedy. Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in

the form originally shipped with Buyer responsible for labor charges for removal or replacement

thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer

an amount equal to the purchase price of the non-complying Product; provided that in no event shall

Omron be responsible for warranty, repair, indemnity or any other claims or expenses regarding the

Products unless Omron’s analysis confirms that the Products were properly handled, stored, installed

and maintained and not subject to contamination, abuse, misuse or inappropriate modification.

Return of any Products by Buyer must be approved in writing by Omron before shipment. Omron

Companies shall not be liable for the suitability or unsuitability or the results from the use of Products

in combination with any electrical or electronic components, circuits, system assemblies or any other

materials or substances or environments. Any advice, recommendations or information given orally or

in writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc.

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS

IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN

CONTRACT, WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

Suitability of Use.

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings

Page 5

and limitations of use which apply to the Product. This information by itself is not sufficient for a

respective companies.

complete determination of the suitability of the Product in combination with the end product, machine,

system, or other application or use. Buyer shall be solely responsible for determining appropriateness

of the particular Product with respect to Buyer’s application, product or system. Buyer shall take

application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY OR IN LARGE QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE

HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL

EQUIPMENT OR SYSTEM.

Programmable Products.

Omron Companies shall not be responsible for the user’s programming of a programmable Product,

or any consequence thereof.

Performance Data.

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual

performance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications.

Product specifications and accessories may be changed at any time based on improvements and

other reasons. It is our practice to change part numbers when published ratings or features are

changed, or when significant construction changes are made. However, some specifications of the

Product may be changed without any notice. When in doubt, special part numbers may be assigned

to fix or establish key specifications for your application. Please consult with your Omron’s

representative at any time to confirm actual specifications of purchased Product.

Errors and Omissions.

Information presented by Omron Companies has been checked and is believed to be accurate;

however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

Microsoft products screen shot(s) reprinted with permission from Microsoft Corporation.

Other company names and product names in this document are the trademarks or registered trademarks of their

Page 6

MEMO

Page 7

Replacement guide from CJ1M/CJ1G to CJ2

Table of Contents

WORK FLOW ..................................................................................................................................... 2

1. PERFORMANCE SPECIFICATIONS .............................................................................................. 3

1.1 CJ1M/CJ2M SPECIFICATIONS COMPARISON .................................................................................................. 3

1.2 CJ1G/CJ2M SPECIFICATIONS COMPARISON ................................................................................................... 4

2. SYSTEM CONFIGURATIONS ........................................................................................................ 5

2.1 CJ1M/CJ1G/CJ2M SYSTEM COMFIGURATION COMPARISON ......................................................................... 5

3. MEMORY AREA ............................................................................................................................. 6

3.1 CJ1M/CJ1G/CJ2M MEMORY AREA COMPARISON .......................................................................................... 6

4. EXAMPLE OF CONVERTING LADDER PROGRAM BY CX-PROGRAMMER .............................. 8

APPENDIX 1. CJ1M/CJ2M APPEARANCE COMPARISON ............................................................ 10

APPENDIX 2. CJ1M/CJ2M PERIPHERAL FUNCTION COMPARISON ........................................... 13

APPENDIX 3. CJ1M/CJ2M BUILT IN I/O FUNCTION COMPARISON ............................................. 14

APPENDIX 4. CJ1M/CJ2M BUILT IN ETHERNET FUNCTION COMPARISON ............................... 16

1

Page 8

This replacement guide describes the procedure to rebuild the system which uses the CJ1-series PLC by

Work flow

Selecting the model

Reading PLC data

Description

Reference Pages

Select the unit, programming software, and connecting cable

to replace CJ1 with CJ2M.

Some CJ1 Units can be used with CJ2M. However, some

Units can not be used with CJ2M. Read the reference pages

(r

ecommended models and precautions) and select the

models.

Load the program, I/O Memory and other settings from the

CJ1M/CJ1G using the programming software and connecting

cable.

Converting and modifying data

Convert the data read from

CJ1 for CJ2M.

Most of the data can be automatically converted; however,

some instructions and some Unit data can not be converted.

Refer to the reference pages and modify the data and program

separately.

1. Performance specifications

2. System Configurations

4.Example of co

nverting

ladder program by

CX-Programmer

Preparing Units

Prepare the units, programming software, and connecting

cable.

Continue to actual replacement work

Start

4.Example of converting

ladder program by

CX-Programmer

Replacing the units

Writing data

D

escription

Reference pages

Replace the units.

*Refer to CJ-series

CJ2 CPU Unit Hardware User

’s

Manual (Cat. No.

W472)

and user’s manuals of each

Special Units for installation of the unit.

Write the data acquired and converted from

CJ1M/CJ1G (programs, IO memory, setting data) to

CJ2M.

Check the wirings by oper

ating

In/Out signals

Checking operation

Turn ON the power to the controller and check the

operation.

Refer to

the related

manuals.

Wiring

Perform wiring for the replacement unit.

*Refer to CJ-series CJ2 CPU Unit Hardware User’s

Manual (Cat. No. W472) and user’s manuals of each

Special Units for information of wiring

.

Replacement finished

Notes:

In some systems, cycle time needs to be adjusted because the cycle times in

CJ1M/CJ1G and CJ2M are different and it may affect the operation.

introducing the CJ2M-series PLC instead. The CJ2M-series has functions which can replace the functions and

operation of CJ1-series PLC. Take the below work flow to replace your system. Also, refer to the reference

pages for details.

1) Preparation: Before starting replacement, prepare according to the following steps.

2) Actual replacement work: Take the steps below to replace the CJ1M/CJ1G to CJ2M.

2

Page 9

Item

CJ1M-CPU**

CJ2M-CPU**

Number of I/O points

CPU*1: 160 points

CPU*3: 640 points

2,560 points

Program capacity

CPU*1: 5k step

CPU*1: 5k step

CPU*5: 60k step

Data memory

32k words

32k words

EM

CPU*4 to *5: 4 banks (32k x 4)

Built-in I/O

CJ2*: In:10 points/Out:6 points

CPU Unit funcitons will be available by

the CPU Unit of unit version 2.0 or later.

Length of instructions

1-7 steps/one instruction

1-30 steps/one instruction

Execution

time of

instruction

LD instruction

0.10us

0.04us

MOV instruction

0.30us

0.12us

Overhead processing time

CPU*1: 0.7ms

CPU*2/*3: 0.5ms

CPU3*: 270us

CPU1*: 160us

Maximum Number of

Connectable Units

CPU*1/CPU*2: 10 units

CPU*3: 20 units

40 units

Maximum Number of Expansion

Racks

CPU*1/CPU*2: No expansion

CPU*3: 1

3

Clock function

Equipped as a standard function

Equipped as a standard function

Dimensions (CPU Unit)

CPU*1: 90(H)x31(W)x65(D)

Programming software

CX-Programmer

CX-Programmer

Programmin

Programming

< Peripheral port connection >

CN118 +

< Peripheral (USB) port >

the unit)

Programming

Available

CQM1-PRO01

Not supported

1. Performance specifications

1.1 CJ1M/CJ2M specifications comparison

The table below lists the major difference in specifications of the CJ1M series and CJ2M series.

CPU*2: 320 points

CPU*2: 10k step

CPU*3: 20k step

CPU*2: 10k step

CPU*3: 20k step

CPU*4: 30k step

CPU*1 to *3: 1 bank (32k)

mounting CJ2M-MD211/CJ2M-MD212. Up

to two units can be mounted.

In:10 points/Out:6 points (when one unit is

used)

In:20 points/Out:12 points (when two units

are used)

Attention: It is possible to use the unit with

g device

connection

device for

personal

computer

console

CPU*2: 90(H)x49(W)x65(D)

Connection with PC requires cables:

CS1W-CN*** or CS1WXW2Z-***S-**

< RS232C port connection >

Connection with PC requires cables:

XW2Z-***S-CV or XW2Z-***S(-V).

C200H-PRO27

CPU*1: 90(H)x31(W)x75(D)

CPU*3: 90(H)x62(W)x75(D)

A direct connection can be made between

the USB port of the personal computer

and the PLC using the

commercially-available USB cable

< Serial (RS232C) port connection >

Use the serial cable

(XW2Z-200S-CV/500S-CV) to connect the

PC and serial port on the CPU Unit. (The

CPU3* does not have the RS232C port on

it. Mount the RS232C option board

(CP1W-CIF01) and connect the cable with

3

Page 10

Item

CJ2M-CPU**

Number of I/O points

CPU42H/43H: 960 points

CPU44/45/44H/45H: 1280 points

2,560 points

Program capacity

CPU42H: 10k step

CPU*1: 5k step

CPU*5: 60k step

Data memory

32k words

32k words

EM

CPU*4 to *5: 4 banks (32k x 4)

Built-in I/O

-

Built-in CPU funciton will be available by

the CPU Unit of unit version 2.0 or later.

Length of instructions

1-7 steps/one instruction

1-30 steps/one instruction

Execution

LD instruction

CPU4*H: 0.04us

CPU4*: 0.08us

0.04us

MOV instruction

CPU4*H: 0.20us

CPU4*: 0.29us

0.12us

Overhead processing time

CPU4*H : 0.3ms

CPU4*: 0.5ms

CPU3*: 270us

CPU1*: 160us

Maximum number of

connectable units

40 units

40 units

Maximum number of Expansion

Racks

3

3

Clock function

Equipped as a standard function

Equipped as a standard function

Dimensions (CPU Unit)

Programming software

CX-Programmer

CX-Programmer

Programmin

Programming

< Peripheral port connection >

CN118 +

< Peripheral (USB) port >

the unit)

Programming

Available

CQM1-PRO01

Not supported.

1.2 CJ1G/CJ2M specifications comparison

The table below lists the major difference in specifications of the CJ1G and CJ2M series.

CJ1G-CPU4*H/CPU4*

time of

instruction

CPU43H: 20k step

CPU44/44H: 30k step

CPU45/45H: 60k step

CPU*2: 10k step

CPU*3: 20k step

CPU*4: 30k step

CPU*1 to *3: 1 bank (32k)

adding the CJ2M-MD211/CJ2M-MD212.

Up to two units can be mounted.

In:10 points/Out:6 points (when one unit is

used)

In:20 points/Out:12 points (when two units

are used)

Attention: It is possible to use the unit with

g device

connection

4

device for

personal

computer

console

90(H)x62(W)x65(D) CPU1*: 90(H)x31(W)x75(D)

CPU3*: 90(H)x62(W)x75(D)

Connection with PC requires cables:

CS1W-CN*** or CS1WXW2Z-***S-**

< RS232C port connection >

Connection with PC requires cables:

XW2Z-***S-CV or XW2Z-***S(-V)

C200H-PRO27

A direct connection can be made between

the USB port of the personal computerand

the PLC using the commercially-available

USB cable

< Serial (RS232C) port connection >

Use the serial cable

(XW2Z-200S-CV/500S-CV) to connect the

PC and serial port on the CPU Unit. (The

CPU3* does not have the RS232C port on

it. Mount the RS232C option board

(CP1W-CIF01) and connect the cable with

Page 11

CJ1M

CJ2M

Built-in I/O function

Built-in I/O function

CPU funcitons will be available by adding the

2.0 or later

In:10 points/Out:6

only

-

In:10 points/Out:6 points (when one unit is used)

2. System Configurations

2.1 CJ1M/CJ1G/CJ2M system comfiguration comparison

Same Power Supply Unit, Special I/O Units, and Basic I/O Unit can be used for CJ1M/CJ1G Series and

CJ2M Series.

♦Built-in I/O

CJ1G

points

Supported by CPU2*

not supported

CJ2M-MD211/CJ2M-MD212

Up to two units can be mounted.

*It is possible to use the unit with the CPU Unit of unit version

In:20 points/Out:12 points (when two units are used)

5

Page 12

CJ1M-CPU2*

C

CPU4*H/4*

CJ2M-CPU**

0000

0000

0000

0039

0040

0159

0159

0160

Not used

0160

Not used

09

0999

0999

1000

1000

1000

1199

1199

1199

1200

1200

1200

1299

1300

1499

1499

1499

1500

1500

1500

1899

1899

1899

1900

1900

1900

1999

1999

1999

2000

2000

2000

2959

2959

2959

2960 2960 2960

2961

2962

Not used

2963

2964

3099 3099 3099

3100

3100

3100

3189

3189

3190

3190

3199

3199

3199

3200

3200

3200

3799

3799

3799

3800

3800

3800

6143

6143

6143

I/O Area

Data Link Area

Data Link Area

Data Link Area

I/O Area

Not used

I/O Area

I

Area

Internal I/O Area

Not used

Internal I/O Area

CPU Bus Unit Area

Not used

Not used

Not used

CPU Bus Unit Area

CPU Bus Unit Area

Special I/O Unit Area

Pulse I/O Area

Not used

Pulse I/O Area

Special I/O Unit Area

Special I/O Unit Area

Not used

Serial

Link Area

Not used

Not used

Serial

ea

Not used

DeviceNet Area

Internal I/O Area

Internal I/O Area

Internal I/O Area

DeviceNet Area

DeviceNet Area

3. Memory area

3.1 CJ1M/CJ1G/CJ2M memory area comparison

This section explains the difference of the memory area of the CJ1M series, CJ1G series and CJ2M

series, using an example of CJ1M-CPU2*, CJ1G-CPU4*H/4* and CJ2M-CPU**.

♦ CI/O area

J1G-

6

99

nternal I/O

PLC Link Ar

PLC

Page 13

♦ Area other than CIO Area

CJ1M-CPU2*

CJ1G-CPU4*H/4*

CJ2M

W000

W000

W000

W511

W511

W511

H000

H000

H000

H511

H511

H511

A000

A000

A000

A959

A959

A959

A960

A1471

A10000

A11535

T0000

T0000

T4095

T4095

C0000

C0000

C0000

C4095

C4095

C4095

D00000

D00000

D00000

D19999

D19999

D19999

D20000

D20000

D20000

D29599

D29599

D29599

D29600

D29600

D29600

D29999

D29

D29999

D30000

D300

D30000

D31599

D31599

D31599

D31600

D31600

D31600

D32767

D32767

D32767

E□_00000

□:

44H/44>

E□_00000

□:

□3>

□:

<CPU45H/45>

□:

□5>

E□_32767

E□_32767

IR00

IR00

IR00

IR15

IR15

IR15

DR00

DR00

DR00

DR15

DR15

DR15

TK00

TK00

TK00

TK31

TK31

TK127

Internal I/O Area

Internal I/O Area

EM Area

Internal I/O Area

EM Area

Counter

Completion Flags

Counter

Completion Flags

Counter

Completion Flags

DM Area

DM Area

DM Area

Auxiliary Area

Auxiliary Area

Timer Completion

Flags

DM Area for Special

I/O Unit

DM Area for CPU

Bus Unit

Data Registers

Data Registers

Data Registers

Index Registers

Index Registers

Index Registers

DM Area for CPU

Bus Unit

DM Area for CPU

Bus Unit

DM Area for Special

I/O Unit

DM Area for Special

I/O Unit

Timer Comp

on

Flags

Timer Completion

Flags Auxiliary Area

Auxiliary Area

Auxiliary Area

Holding Area

Holding Area

Holding Area

Internal I/O Area

Internal I/O Area

Internal I/O Area

-CPU**

T0000

T4095

leti

999

00

0 <CPU42H to

0 to 2

0 <CPU□1 to

0 to 3 <CPU□4/

7

Page 14

Timing of program check

Description

When PLC model is changed.

Program check for each PLC model

Check for all instructions and all operands.

Right-click and

4. Example of converting ladder program by CX-Programmer

This section explains the method of converting the ladder program using CX-Programmer Ver.9.1. Here,

convert the ladder program of CJ1M/CJ1G for CJ2M-CPU** as an example.

♦Changing model from CJ1M/CJ1G to CJ2M.

As shown on the below figure, select NewPLC1[CJ1M] and right-click or double click it to change the

PLC model. Please set the CPU model to the Device Type.

The error report might be displayed if there are instructions which cannot be converted.

Please correct and modify the program using support software function or manually, and execute

program check. If errors are detected by the program check, please correct them referring to the

error report.

select

“Change” or

double-click.

♦Checking program

Check whether there is problem in the ladder program which was converted from the CJ1M/CJ1G

series for CJ2M series.

Program check

There are 2 types of program check; automatic check on the CX-Programmer and check conducted

by users. CX-Programmer checks the program when “Change model” is executed and the ledder

program is converted.

• Automatic program checks on the CX-Programmer

You can see the check result on the "Compile (Program check)" tab of the Output Window.

The left bus-bar on the ladder section window turns red if there is an error in the rung.

• Program check conducted by users

This section describes the procedure of program check, an example of checking

result, and explanation of error levels.

<Program check for one program (task)>

1. Select the ladder section window or nimonic window to check.

2. Select Program – Compile (Program check).

The results of program check will be displayed on the Output Window. Refer to Results of

program check on the next page for details.

8

Page 15

• Checking the entire program

Menu

Functions

[Clear]

Clears the content of Output Window.

Same as selecting “Edit” – “Clear Compile Window”.

[Next Reference]

Jump to the error cell next to the error now selected.

Same as selecting “Edit” – “Next Reference”.

[Allow Docking]

Output Window is shown on the main window of the

. If unckeck the check box, Output

Window will be shown on the separate window.

[Hide]

Close the output window.

Same as selecting “View” – “Window” – “Output”.

[Float In Main Window]

Output window will be changed to other window

(ex. Ladder section window).

Select PLC – Compile All PLC Programs.

You can see the program check results on the Output Window.

Refer to Results of program check for details.

<Results of program check>

You can see the check result on the "Compile (Program check)" tab of the Output

Window.

There are three error levels; errors are divided and shown for each level.

When there is no error.

When there are errors.

Double-click an error on the Output Window to jump to the correposnding cell.

Numeric data in ( , ) shows the position of a cell with an error.

If you right-click on the Output Window, below menus are shown.

CX-Programmer

9

Page 16

CJ1M-CPU11/12/13

CJ2M-CPU11/12/13/14/15

(a) Battery : Common to all models (use CJ1W-BAT01)

(f) Depth dimension : CJ2M is about 10mm larger than CJ1M.

(d) Memory Card

(f) Depth

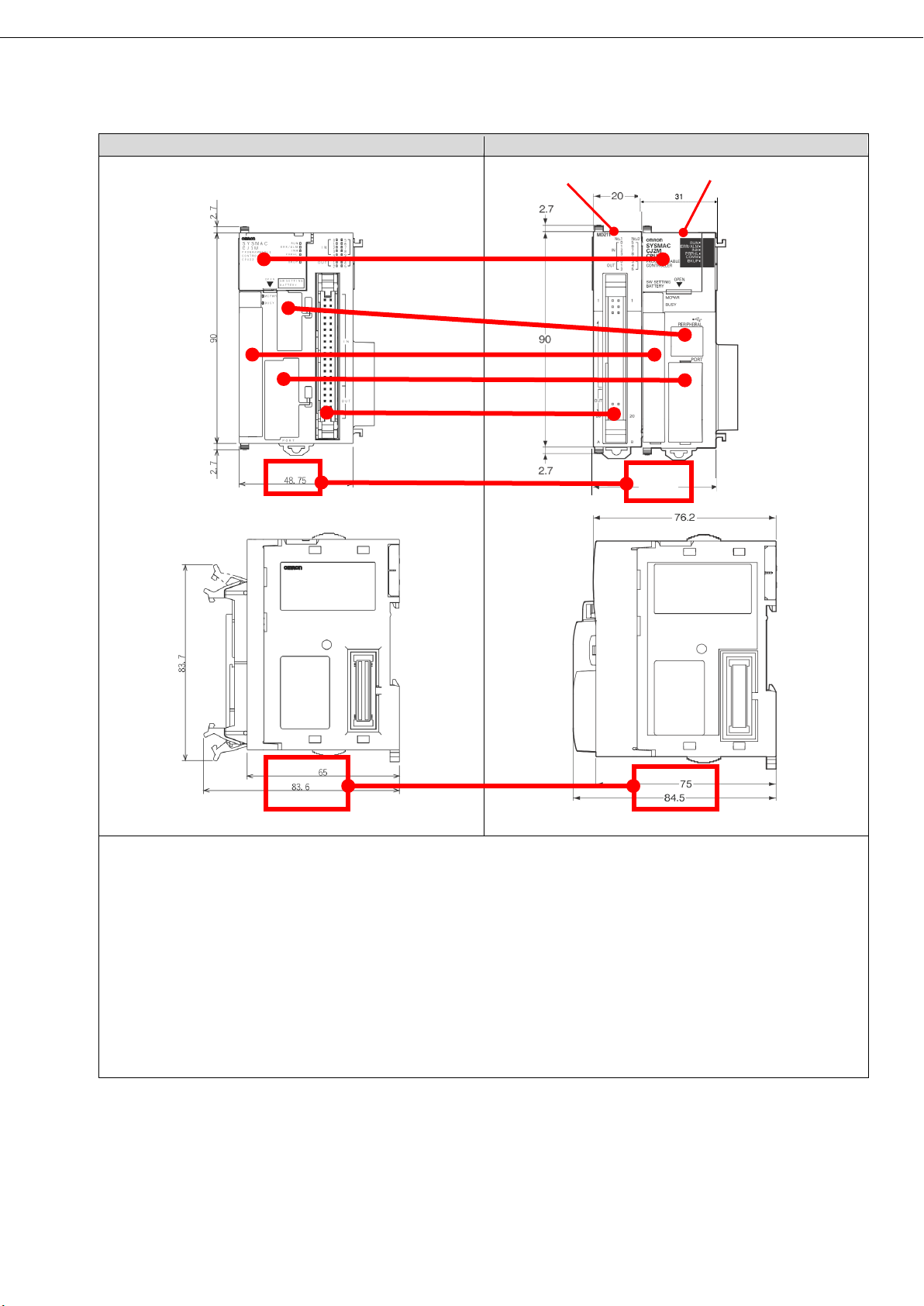

Appendix 1. CJ1M/CJ2M Appearance comparison

(a) Battery

(b) DIP switch

(c) Peripheral

(e) RS232C

dimension

(b) DIP switch : CJ2M does not use SW4 (Setting Peripheral port) (Other switches are common to all models)

(c) Peripheral : CJ2M uses USB communication (See Appendix 2 for functional difference)

(d) Memory Card : Common to all models (use HMC-EFxxx)

(e) RS232C : Pin assignment and functions are common to all models.

10

Page 17

CJ1M-CPU21/22/23

CJ2M-CPU11/12/13/14/15, CJ2M-MD211

CJ2M-MD211 CJ2M-CPU1x

(a) Battery : Common to all models (use CJ1W-BAT01)

(h) Depth dimension : CJ2M is about 10mm larger than CJ1M.

51

(d) Memory Card

(c) Peripheral

(f) Built in I/O

(h) Depth

dimension

(g) Width

dimension

(a) Battery

(b) DIP switch

(e) RS232C

(b) DIP switch : CJ2M does not use SW4 (Setting Peripheral port) (Other switches are common to all models)

(c) Peripheral : CJ2M uses USB communication (See Appendix 2 for functional difference)

(d) Memory Card : Common to all models (use HMC-EFxxx)

(e) RS232C : Pin assignment and functions are common to all models.

(f) Built in I/O :

[Position] CJ1M is located on the right side and CJ2M is located on the left side.

[Wiring] Same. However, do not connect any signal other than “Power supply input (+V) for output” to pin

38. (See Appendix 3 for pin assignment)

[Operation] There are some differences in the operation of the interrupt input. (See Appendix 3 for

functional differences)

(g) Width dimension : CJ2M is about 2mm larger than CJ1M.

11

Page 18

CJ1M-CPU11/12/13-ETN

CJ2M-CPU31/32/33/34/35

(a) Battery : Common to all models (use CJ1W -BAT01)

(g) Depth dimension : CJ2M is about 10mm larger than CJ1M.

(a) Battery

(b) DIP switch

(d) Memory Card

(c) Peripheral

(f) Built in Ethernet

(g) Depth

dimension

(e) RS232C

(b) DIP switch : CJ2M does not use SW 4 (Setting Peripheral port) (Other switches are common to all models)

(c) Peripheral : CJ2M uses USB communication (See Appendix 2 for functional difference)

(d) Memory Card : Common to all models (use HMC-EFxxx)

(e) RS232C : CJ2M requires an optional board (CP1W-CIF01) to be installed.

(f) Built in Ethernet : Some functions cannot be used with the built-in EtherNet/IP of CJ2M (See Appendix 4)

12

Page 19

Function

CJ1M

CJ2M

Description

Programming console

CJ2M cannot use the programming

console.

Tool Bus

Supported

Supported

Host Link

Supported

Not Supported

Use CJ1W-SCUxx, if you use this

function

NT Link (1: N)

Supported

Not Supported

Use CJ1W-SCUxx, if you use this

function

Serial Gateway

Supported

Not Supported

Use CJ1W-SCUxx, if you use this

function

Appendix 2. CJ1M/CJ2M Peripheral function comparison

Supported Not Supported

13

Page 20

Pin layout

Terminal symbol

Input signal type

Pin

No.

Terminal symbol

Input signal type

Pin

No. IN0

24 VDC

1

IN1

24 VDC

2 LD+ 3

LD+

4

0 V/LD-

5 0 V/LD-

6

IN2

24 VDC

7

IN3

24 VDC

8

LD+ 9

LD+

10

0 V/LD-

11 0 V/LD-

12

IN4

24 VDC

13

IN5

24 VDC

14 LD+

15 LD+

16 0 V/LD-

17 0 V/LD-

18

IN6

24 VDC

19

IN7

24 VDC

20

LD+

21 LD+

22 0 V/LD-

23 0 V/LD-

24

IN8

24 VDC

25

IN9

24 VDC

26 LD+

27 LD+

28

0 V/LD-

29 0 V/LD-

30

OUT0

---

31

OUT1

---

32

OUT2

---

33

OUT3

---

34

OUT4

---

35

OUT5

---

36

Power supply input

(+V) for output

---

37

Not used

---

38

Output COM

---

39

Output COM

---

40

Pin layout

Terminal symbol

Input signal type

Pin

No.

Terminal symbol

Input signal type

Pin

No. IN0/IN10

24 VDC

1

IN1/IN11

24 VDC

2

LD+ 3

LD+

4

0 V/LD-

5 0 V/LD-

6

IN2/IN12

24 VDC

7

IN3/IN13

24 VDC

8

LD+ 9

LD+

10 0 V/LD-

11 0 V/LD-

12

IN4/IN14

24 VDC

13

IN5/IN15

24 VDC

14 LD+

15 LD+

16

0 V/LD-

17 0 V/LD-

18

IN6/IN16

24 VDC

19

IN7/IN17

24 VDC

20 LD+

21 LD+

22 0 V/LD-

23 0 V/LD-

24

IN8/IN18

24 VDC

25

IN9/IN19

24 VDC

26

LD+

27 LD+

28

0 V/LD-

29 0 V/LD-

30

OUT0/OUT10

---

31

OUT1/OUT11

---

32

OUT2/OUT12

---

33

OUT3/OUT13

---

34

OUT4/OUT14

---

35

OUT5/OUT15

---

36

Power supply input

(+V) for output

---

37

Power supply input

(+V) for output

---

38

Output COM

---

39

Output COM

---

40

Appendix 3. CJ1M/CJ2M Built in I/O function comparison

(1) Pin assignment

Note. CJ1M does not use Pin No.38, but CJ2M use as “Power supply input +V for output”. CJ2M does not

affect operation if it is not connected. But remove the wiring if it is connecting to another signal.

[CJ1M-CPU21/22/23]

[CJ2M-MD211]

14

Page 21

Interrupt Inputs

CJ1M

CJ2M

Description

Update method for

Updating interrupt

counter SV in Auxiliary

Updating interrupt

counter SV in Auxiliary

and then executing

SKS again to enable

interrupts

Add MSKS instruction, if

Update method for

pdating interrupt

counter PV in Auxiliary

Area

Updating with INI

Change to INI instruction,

for

Updating timing for

nstruction is

count completion

hen PRV instruction is

executed

Make sure that it does

If it is affected, it is

necessary to change the

Operation of interrupt

Counter operation not

Counter operation

errupt

l not occur at count

Make sure that it does

If it is affected, it is

y to change the

program etc.

(2) Functional differences for Interrupt inputs

The following operation differences exist between CJ1M / CJ2M in the interrupt input function. If used,

check that the operation is not affected.

interrupt counter SV

(Counter Mode)

interrupt counter PV

(Counter Mode)

interrupt counter PV

(Counter Mode)

counter when interrupts

are disabled with DI

instruction

Area

・ Updating with INI

instruction

・ U

・Once per count

When PRV i

・

executed

countinued

Area

M

instruction

・Every cycle

When

・

interrupt occurs

・W

continued, but int

wil

completion

you use this operation.

if you use Auxiliary

updating.

not affect operation.

program etc.

not affect operation.

necessar

15

Page 22

Function

CJ1M

Built in Ethernet

CJ2M

Built in EtherNet/IP

Description

Tag data link

communications service

CIP message

communications service

FINS/UDP service

Supported

Supported

FINS/TCP service

Supported

Supported

File transfer (FTP)

Supported

Supported

Web functions

Use CJ1W-ETN21, if you

use this function

Automatic adjustment of

PLC’s internal clock

Simple backup function

Supported

Supported

Error log

Supported

Supported

Response to PING

command

SNMP/SNMP trap

Not supported

Supported

CIDR function for IP

addresses

Not supported

Online connection by

EtherNet/IP using CX-One

Online connection by

CX-One

Online connection by

Configurator

Appendix 4. CJ1M/CJ2M Built in Ethernet function comparison

Not supported Supported

Not supported Supported

Supported Not supported

Supported Supported

Supported Supported

Supported

Not supported Supported

Ethernet (FINS) using

EtherNet/IP using Network

Supported Supported

Not supported Supported

16

Page 23

MEMO

Page 24

2020

Note: Do not use this document to operate the Unit.

P068-E1-03

0320(1210)

Loading...

Loading...