Page 1

VS mini J7

Compact General Purpose Inverter

Model: CIMR-J7AZ

200V Class 3-phase 0.1 to 4.0kW

200V Class Single-phase 0.1 to 1.5kW

400V Class 3-phase 0.37 to 4.0kW

QUICK MANUAL

Manual No.

I39E-EN-01

EnglishDeutschEspañolFrançaisItalianoPortuguês

Pyccкий

Page 2

Page 3

General Precautions

z Some drawings in this manual are shown with protective covers or shields removed in

order to show detail with more clarity. Make sure all covers and shields are replaced

before operating the product.

z This manual may be modified when necessary because of improvements to the product,

modifications, or changes in specifications.

z To order a copy of this manual, or if your copy has been damaged or lost , contact your

OMRON YASKAWA Motion Control B. V. (Hereinafter called the OYMC) representatives.

z OYMC is not responsible for any modification of the product made by the user, since that

will void the guarantee.

Safety Information

The following conventions are used to indicate precautions in this document. Failure to heed precautions provided in this document can result in serious or possibly even fatal injury or damage to the

products or to related equipment and systems.

WARNING

CAUTION

Failure to heed a precaution classified as a caution can result in serious consequences depending on

the situation.

Indicates precautions that, if not heeded,

could possibly result in loss of life or serious injury.

Indicates precautions that, if not heeded,

could result in relatively serious or minor injury,

damage to the product, or faulty operation.

Precautions for UL/cUL Marking

· Do not connect or disconnect wiring, or perform signal checks while the power supply is turned ON.

· The Inverter internal capacitor is still charged even after the power supply is turned OFF. To prevent

electric shock, disconnect all power before servicing the Inverter, and then wait at least one minute

after the power supply is disconnected. Confirm that all indicators are OFF before proceeding.

· Do not perform a withstand voltage test on any part of the Inverter. The Inverter is an electronic

device that uses semiconductors, and is thus vulnerable to high voltage.

· Do not remove the Digital Operator or the blank cover unless the power supply is turned OFF.

Never touch the printed circuit board (PCB) while the power supply is turned ON.

· This Inverter is not suitable for use on a circuit capable of delivering more than 18,000RMS

symmetrical amperes, 250 volts maximum (200V class Inverters) or 480 volts maximum (400 V class

Inverters).

CAUTION

Use 75 °C copper wires or equivalent.

Low voltage wires shall be wired with Class I Wiring.

Page 4

Precautions for CE Markings

· Only basic insulation to meet the requirements of protection class I and overvoltage category II is

provided with control circuit terminals.

Additional insulation may be necessary in the end product to conform to CE requirements.

· For 400 V class Inverters, make sure to ground the supply neutral to conform to CE requirements.

· For conformance to EMC directives, refer to section 3 in this document.

For details, refer to the following document.

Document No. EZZ008390 for English version.

· Our products are tested by authorized bodies using the standards listed below.

Product standard: EN61800-3 : 1996

EN61800-3 ; A11 : 2000

Receiving

CAUTION

Do not install or operate any Inverter that is damaged or has missing parts.

Failure to observe this caution may result in injury or equipment damage.

· Verify that the part numbers match your purchase order or packing slip.

· Check the unit for physical damage that may have occurred during shipping.

Page 5

Warning Display

Japanese/French Warning Display

An English warning display is on the front panel of the inverter.

If you need Japanese or French warning display, use the stickers at the back of this manual.

Place it over the English warning display.

Page 6

Checking the Name Plate

Example of 3-phase, 200VAC, 0.1kW (0.13HP)

Mounting

CAUTION

· Lift the cabinet by the heatsink. When moving the Inverter,

never lift it by the plastic case or the terminal covers.

Otherwise, the main unit may fall and be damaged.

· Mount the Inverter on nonflammable material (i.e., metal).

Failure to observe this caution may result in a fire.

· When mounting Inverters in an enclosure, install a fan or other cooling

device to keep the intake air temperature below 122°F (50°C)

for IP20 (open chassis type), or below 105°F(40°C) for NEMA1 (TYPE1).

Overheating may cause a fire or damage the Inverter.

· The VS mini generates heat. For effective cooling, mount it vertically.

Refer to the figure in Mounting Dimensions on section 3.

Page 7

Wiring

WARNING

· Only begin wiring after verifying that the power supply is turned OFF.

Failure to observe this warning may result in an electric shock or a fire.

· Wiring should be performed only by qualified personnel.

Failure to observe this warning may result in an electric shock or a fire.

· When wiring the emergency stop circuit, check the wiring thoroughly before operation.

Failure to observe this warning may result in injury.

· Always ground the ground terminal according to the local grounding code.

Failure to observe this warning may result in an electric shock or a fire.

· For 400V class, make sure to ground the supply neutral.

Failure to observe this warning may result in an electric shock or a fire.

· If the power supply is turned ON during the FWD(or REV) RUN command is given,

the motor will start automatically.

Turn the power supply ON after verifying that the RUN signal is OFF.

Failure to observe this warning may result in injury.

· When the 3-wire sequence is set, do not make the wiring unless the multi-function input

terminal parameter is set.

Failure to observe this warning may result in injury.

CAUTION

· Verify that the Inverter rated voltage coincides with the AC power supply voltage.

Failure to observe this caution may result in personal injury or a fire.

· Do not perform a withstand voltage test on the Inverter.

Performing withstand voltage tests may damage semiconductor elements.

· To connect a Braking Resistor, Braking Resistor Unit, or Braking Unit, follow the

Procedure described in this manual.

Improper connection may cause a fire.

· Always tighten terminal screws of the main circuit and the control circuits.

Failure to observe this caution may result in a malfunction, damage or a fire.

· Never connect the AC main circuit power supply to output ter minals U/T1, V/T2 or W/T3.

The Inverter will be damaged and the guarantee will be voided.

· Do not connect or disconnect wires or connectors while power is applied to the circuits.

Failure to observe this caution may result in injury.

· Do not perform signal checks during operation.

The machine or the Inverter may be damaged.

Page 8

Preautions for wiring

Wiring the control circuit terminals Screwdriver blade width

Insert the wire into the lower part of the terminal block

and connect it tightly with a screwdriver.

Wire sheath strip length must be 5.5mm (0.22in).

Page 9

Operation

WARNING

· Only turn ON the input power supply after confirming the Digital Operator

or blank cover(optional) are in place. Do not remove the Digital Operator or

the covers while current is flowing.

Failure to observe this warning may result in an electric shock.

· Never operate the Digital Operator or DIP the switches with wet hands.

Failure to observe this warning may result in an electric shock.

· Never touch the terminals while current is flowing, even if the Inverter is stopping.

Failure to observe this warning may result in an electric shock.

· When the fault retry function is selected, stand clear of the Inverter or the load.

The Inverter may restart suddenly after stopping.

(Construct the system to ensure safety, even if the Inverter should restart.)

Failure to observe this warning may result in injury.

· When continuous operation after power recovery is selected, stand clear of the

Inverter or the load. The Inverter may restart suddenly after stopping.

(Construct the system to ensure safety, even if the Inverter should restart.)

Failure to observe this warning may result in injury.

· The Digital Operator stop button can be disabled by a setting in the Inverter.

Install a separate emergency stop switch.

Failure to observe this warning may result in injury.

Page 10

WARNING

· If an alarm is reset with the operation signal ON, the Inverter will restart automatically.

Reset an alarm only after verifying that the operation signal is OFF.

Failure to observe this warning may result in injury.

· When the 3-wire sequence is set, do not make the wiring unless the multi-function input

terminal parameter is set.

Failure to observe this warning may result in injury.

CAUTION

· Never touch the heatsinks, which can be extremely hot.

Failure to observe this caution may result in harmful burns to the body.

· It is easy to change operation speed from low to high. Verify the safe working

range of the motor and machine before operation.

Failure to observe this caution may result in injury and machine damage.

· Install a holding brake separately if necessary.

Failure to observe this caution may result in injury.

· If using an Inverter with an elevator, take safety measures on the elevator

to prevent the elevator from dropping.

Failure to observe this caution may result in injury.

· Do not perform signal checks during operation.

The machine or the Inver ter may be damaged.

· All the constants set in the Inverter have been preset at the factory.

Do not change the settings unnecessarily.

The Inverter may be damaged.

Page 11

Maintenance and Inspection

WARNING

· Never touch high-voltage terminals on the Inverter.

Failure to observe this warning may result in an electrical shock.

· Disconnect all power before performing maintenance or inspection, and then wait at

least one minute after the power supply is disconnected. Confirm that all indicators are

OFF before proceeding.

If the indicators are not OFF, the capacitors are still charged and can be dangerous.

· Do not perform withstand voltage test on any part of the VS mini.

The Inverter is an electronic device that uses semiconductors, and is thus vulnerable to

high voltage.

· Only authorized personnel should be permitted to perform maintenance, inspections, or

parts replacement.

(Remove all metal objects (watches, bracelets, etc.) before starting work.)

Failure to observe these warnings may result in an electric shock.

CAUTION

· The control PCB board employs CMOS ICs. Do not touch the CMOS elements.

They are easily damaged by static electricity.

· Do not connect or disconnect wires, connectors, or the cooling fan while

power is applied to the circuit.

Failure to observe this caution may result in injury.

Page 12

Periodical Inspection

Periodically inspect the inverter as described the following table to prevent accidents and to ensure

high performance with high-reliability.

Location to check Check for Solution

Terminals, unit mounting screws,

etc.

Heatsink Built up durst, and debris

Printed circuit board

Power elements and

smoothing capacitor

Cooling fan

Connection hardware is proper ly

seated and securely tightened.

Accumulation of conductive

material or oil mist

Abnormal odor or discoloration Replace the inverter unit.

Abnormal noise or vibration

Cumulative operation time

Properly seat and tighten

hardware.

Blow with dry compressed air:

4

to 58.8 x 104 Pa,

39.2 x 10

57 to 85 psi (4 to 6kg / cm

pressure.

Blow with dry compressed air:

39.2 x 104 to 58.8 x 104 Pa,

57 to 85 psi (4 to 6kg / cm

pressure

If dust or oil cannot be removed,

replace the inverter unit.

Replace the cooling fan.

2

)

2

)

Part Replacement

Inverter’s maintenance periods are noted below. Keep them as reference.

Part Replacement Guidelines

Part Standard Replacement Period Replacement Method

Cooling fan 2 to 3 years Replace with new part.

Smoothing capacitor 5 years

Breaker relays – Determine need by inspection.

Replace with new part.

(Determine need by inspection.)

Fuses 10 years Replace with new part.

Aluminium capacitors on PCBs 5 years

Note: Usage conditions are as follows:

· Ambient temperature: Yearly average of 30°C

· Load factor: 80% max.

· Operating rate: 12 hours max. per day

Replace with new part.

(Determine need by inspection.)

Page 13

Others

WARNING

· Never modify the product.

Failure to observe this warning can result in an electric shock or injury

and will invalidate the guarantee.

CAUTION

· Do not subject the Inverter to halogen gases, such as fluorine, chlorine, bromine,

and iodine, at any time even during transportation or installation.

Otherwise, the Inverter can be damaged or interior parts burnt.

Page 14

Page 15

VS MINI J7

Quick Start Guide

1. Wiring

2. Control Circuit Terminals

3. Installation

4. Start up and Trial run

5. Quick Parameter List

6. Monitors

7. Faults and Alarms

ENGLISH

Page 16

1. Wiring

3G3JV PFI @

Noise Filter

L1i

L1

L2

L3

3-phase 200 V AC

single-phase 200 V AC

(see note 1)

Forward/Stop

Multi-function input 1 (S2)

Multi-function input 2 (S3)

Multi-function input 3 (S4)

Multi-function input 4 (S5)

Sequence input common

Frequency reference power

External frequency

adjuster

(2 kΩ 1/4 W min.)

Note 1: Connect single-phase 200 V AC to terminals R/L1 and S/L2 of the J7AZB

Note 2: The braking resistor cannot be connected because no braking transistor is incorporated.

Ground terminal

Main circuit

output terminals

supply 20mA at +12V

Frequency reference input

Frequency reference common

R/L1

L2i

S/L2

L3i

T/L3

S1

S2

S3

S4

S5

SC

FS

FR

FC

Main circuit input

terminals

Control circuit

terminals

Ground

terminal

SHORT BAR

+1 +2 -

U/T1

V/T2

W/T3

Multi-function contact output

MA

NO

MB

NC

MC

Common

AM

Analog monitor output

AC

Analogue monitor output

common

Arrangement of Control Circuit Terminals

M

Page 17

2. Control Circuit Terminals

Symbol Name Function Signal Level

Input S1 Forward/Stop Forward at ON/Stops at OFF Photocoupler 8 mA

S2 Multi-function Input 1 Set by parameter n36 (Reverse/Stop)

S3 Multi-function Input 2 Set by parameter n37 (External Fault: NO)

S4 Multi-function Input 3 Set by parameter n38 (Fault Reset)

S5 Multi-function Input 4 Set by parameter n39

SC Sequence Input Common Common for S1 through S5

FS Frequency Reference Power Supply DC power supply for frequency reference use 20 mA at 12 V DC

FR Frequency Reference Input Input terminal for frequency reference use 0 to 10 V DC (20 kΩ)

FC Frequency Reference Common Common for frequency reference use 4 to 20 mA

Output MA MBMulti-function output: NO

*1 NPN is the setting for these terminals. No external power supply is required. Refer to connections shown below

*2 Functions in parentheses are default settings.

Multi-function output: NC

MC Multi-function output Common Com mon for MA an d MB use

AM Analogue Monitor output Set by parameter n44 (Output frequency)

AC Analogue Monitor output Common Common for AM use

(Multi-step reference 1)

Set by parameter n40 (during running)

*2

*2

*2

*2

*2

*2

*1

at 24 V DC

0 to 20 mA

Relay output 1 A

max. at 30 V DC and

250 V AC

12 mA max. at 0 to

10 V DC

Selecting Input Method

Switches SW7and SW8, both of

which are located above the control circuit terminals, are used for input method selection.

Remove the front cover and optional cover to use these switches.

PNP

NPN

SW7

SW7

V

OFF

Selecting Sequence Input Method

By using SW7, NPN or PNP input can be selected as shown below

NPN

(Default setting)

S1 to 5

24V

SW7

GND

0.1µ

360

3.3k

SC

GND

PNP

24 V DC

(±10%)

SW8

S1 to 5

I

SW8

Control circuit

terminal block

Control circuit

terminal block

24V

SW7

GND

0.1µ

360

3.3k

SC

GND

Page 18

3. Installation

Two 5 dia holes

Rated

Vol ta ge

Three Phase

200 V AC

Single Phase

200 V AC

Three Phase

400 V AC

Dimensions (mm) Supply Recommendations

Model

J7AZ

W H D W1 H1 MCCB (A) Wire (mm²)

20P1 68 128 70 56 118 5 2

20P2 68 128 70 56 118 5 2

20P4 68 128 102 56 118 5 2

20P7 68 128 122 56 118 10 2

21P5 108 128 129 96 118 20 2

22P2 108 128 154 96 118 20 3.5

24P0 140 128 161 128 118 30 5.5

B0P1 68 128 70 56 118 5 2

B0P2 68 128 70 56 118 5 2

B0P4 68 128 112 56 118 10 2

B0P7 108 128 129 96 118 20 3.5

B1P5 108 128 154 96 118 20 5.5

40P2 108 128 81 96 118 5 2

40P4 108 128 99 96 118 5 2

40P7 108 128 129 96 118 5 2

41P5 108 128 154 96 118 10 2

42P2 108 128 154 96 118 10 2

43P0 140 128 161 128 118 20 2

44P0 140 128 161 128 118 20 2

Noise Filter Specifications

Model

Filter

J7AZ

3G3JV-

20P1 PFI2010-SE 82 194 50 92 181 5.3

20P2

20P4

20P7

21P5 PFI2020-SE 111 169 50 91 156 5.3

22P2

24P0 PFI2030-SE 144 174 50 120 161 5.3

B0P1 PFI1010-SE 71 169 45 51 156 5.3

B0P2

B0P4

B0P7 PFI1020-SE 111 169 50 91 156 5.3

B1P5

Dimensions

W L H Y X d

Page 19

Model

Filter

J7AZ

3G3JV-

40P2 PFI3005-SE 111 169 50 91 156 5.3

40P4

40P7 PFI3010-SE 111 169 50 91 156 5.3

41P5

42P2

43P0 PFI3020-SE 144 174 50 120 161 5.3

44P0

Dimensions

W L H Y X d

Installation of noise filter and J7

Shield

Control Panel Control Panel

Schaffner

RFI Filter

3 Phase

Cable

Metal Mounting

Plate

Ground

Bonds

(remove

any paint)

Schaffner

RFI Filter

3 Phase

Shield

Cable

Metal Mounting

Plate

Ground

Bonds

(remove

any paint)

Ground Bonds

(remove any paint)

J7Series

Inverter

Shield

Cable

Max. 20m

Motor Cable

Ground Bonds

(remove any paint)

J7Series

Inverter

Shield

Cable

Max. 20m

Motor Cable

CIMR-J7@@@@20P1 to 24P0 CIMR-J7@@@@B0P1 to B4P0

CIMR-J7@@@@40P2 to 44P0

Page 20

Mounting Dimensions

30mm

(1.18 in.)

OR MORE

30mm

(1.18 in.)

OR MORE

OR MORE

100mm (3.94 in.)

OR MORE

100mm (3.94 in.)

4. Start up and Trial run

Data display

AIR

AIR

Indicators

(Setting/Monitor

item indicators)

Keys

Appearance Name Function

Data display Displays relevant data items, such as frequency reference,

FREQ adjuster Sets the frequency reference within a range between OHz

FREF indicator The frequency reference can b& monitored or set while

FOUT indicator The output frequency of the Inverter can be monitored

IOUT indicator The output current of the inverter this indicator is lit.

MNTR indicator The values set in U01 through U10 are monitored

F/R idicator The direction of rotation can be selected while this indicator

output frequency and parameter set values.

and the maximum frequency.

this indicator is lit.

or set while this indicator is lit.

while this indicator is lit.

is lit when operating the Inverter with the RUN Key.

FREQ adjuster

Page 21

Appearance Name Function

LO/RE indicator The operation of the Inverter through the Digital Operator or

PRGM indicator The parameter in n01 through to n79 can be set or monitored while this

Mode Key Switches the setting and monitor item indicators in sequence.

Increment Key Increases multi-function monitor numbers, parameter

Decrement Key Decreases multi-function monitor numbers, parametei

Enter Key Enters multi-function monitor numbers, parameter numl and

RUN Key Starts the Inverter running when the 3G3JV is in operation

STP/RESET Key Stops the Inverter unless parameter nO6 is not set to

according to the sot parameteres is selectable while this

indicator is lit.

Note: The status of this indicator can be only monitored

while the Inverter is in operation. Any RUN command

input is ignored while this indicator is lit.

indicator is lit.

Note:

While the Inverter is in operation, the paramete can be

only monitored and only some parameti can be

changed. Any RUN command input is ignored while

this indicator is lit.

Parameter being set will be cancelled if this key is pressed

before entering the setting.

num-bers and parameter set values.

numbers and parameter sel values.

internal data values after they are set or changed.

with the Digital Operator.

disable the STOP Key.

The following seven steps describe the recommended minimum operations

to allow the J7 to control a connected motor in typical configuration, to allow

simple operation in the quickest time:

Step 1 – initial checks

1-1 Checkpoints before connecting the power supply.

Check that the power supply is as of the correct voltage.

CIMR-J7AZ2@@@: Three phase 200 to 230VAC

CIMR-J7AZB@@@: Single phase 200 to 240VAC (Wire R/L1 and S/L2)

CIMR-J7AZ4@@@: Three phase 380 to 460VAC

1-2 Make sure that the motor output terminals (U/T1, V/T2, W/T3) are connected to the motor.

1-3 Ensure that the control circuit terminals and the control device are wired correctly.

1-4 Make sure that all control terminals are turned off.

1-5 Set the motor to no-load status (i.e. not connected to the mechanical system)

Step 2 – Connecting the power supply and check the display status

2-1 After conducting the checks in step-1, connect the power supply.

2-2 If the display is normal when the power is connected it will read as follows;

Page 22

RUN indicator: flashes

ALARM indicator: off

Setting/monitor indicators: FREF, FOUT or IOUT is lit.

Data display: displays the corresponding data for the indicator that is lit.

When fault has occurred, the details of the fault will be displayed. In that case, refer to user’s

manual and take necessary action.

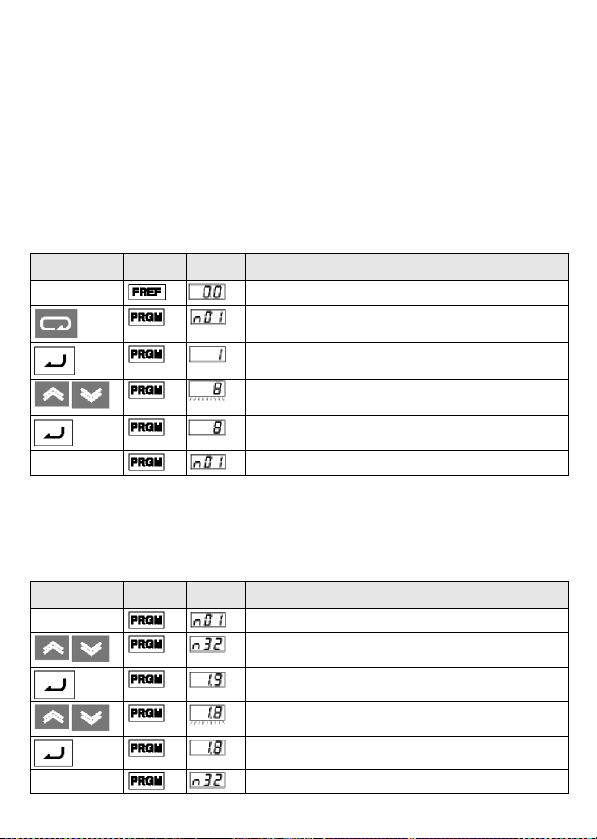

Step 3 – Initializing parameters

To initialize the drive parameters to factory defaults, set parameter n01 = 8. This will set the J7 to

accept start/stop commands in what in termed “2-wire control”, i.e. 1 wire for a motor forward/stop

command, and 1 wire for a motor reverse/stop command.

Key

Sequence

In approximately

1s.

Indicator

Display

Explanation

example

Power On

Press the Mode Key repeatedly until the PRGM indicator is lit.

Press the Enter Key. The data of n01 will be displayed.

Use the Increment or Decrement Key to set n01 to 8. The display will

flash.

Press the Enter Key so that the set value will be entered and the data

display will be lit.

The parameter number will be displayed.

Step 4 – Set the motor rated current

This parameter is used for the electronic thermal function for motor overload detection (OL1). By correctly setting this, the J7 will protect an overloaded motor from burning out.

Read the rated current (in amps) on the motor nameplate, and enter this into parameter n32. The

example to the below shows entering a value of 1.8Amps.

Key

Sequence

Indicator

Display

Explanation

example

Displays the parameter number

Use the Increment or Decrement Key until n32 is displayed.

Press the Enter Key. The data of n32 will be displayed.

Use the Increment or Decrement Key to set the rated motor current. The

display will flash.

Press the Enter Key so that the set value will be entered and the data

display will be lit.

In approximately1s. The parameter number will be displayed.

Page 23

Step 5 – Set the motor rated frequency

This is the maximum frequency the motor can run and allows the J7 to properly control the motor.

Read the rated frequency (in Hz) on the motor nameplate, and enter this into parameters n09 and n11

Step 6 – Set the operation command

This is the method for motor run and stop commands (i.e. how the inverter will start and stop the

motor). The two basic operations are for the RUN and STOP/RESET keys on the Digital Operator, or

for one of multi-function inputs through the control circuit terminals.

To set the operation command, enter the appropriate value into parameter n02:

0 = RUN and STOP/RESET keys on the Digital Operator are enabled.

1 = Multi-function inputs through the control circuit terminals.

The diagram to the below shows how to connect a switch to start/stop the motor in the forward direction in “2-wire control”. Set parameter n02=1. To enable a separate switch for reverse rotation on control terminal S2, set parameter n36=2 (this is actually the factory default setting for n36).

FWD RUN/STOP

REV RUN/STOP

Step 7 – Set the frequency reference

This is the method for selecting the source for the motor speed command. The factory default is for the

potentiometer on the digital Operator (FREF adjuster), in which case no setting is required.

Frequency reference can also come from an external potentiometer, an analog output from a PLC, or

up to 8 pre-programmed speeds held in the inverter and selected via the multi-function inputs.

For example, to accept frequency reference from an external potentiometer, or a 0-10V analog out

from a PLC, set parameter n03=2.

FS

( )

FREQUENCY

SETTING

MASTER SPEED

FREQUENCY

REFERENCE

(0 TO +10V)

POWER

+12V, 20mA

FR

FC(0V)

.

Page 24

5. Quick Parameter List

Parameter No. Description Range Default

n01 Parameter access:

n02 Run command selection:

n03 Frequency reference selection:

n09 Maximum output frequency 50 to 400Hz

n10 Maximum output voltage 1 to 255V (200V class)

N11 Maximum voltage output frequency 50 to 400Hz

n16 Acceleration time 1 0.0 to 999sec 10sec

n17 Deceleration time 2 0.0 to 999sec 10sec

n21 Frequency reference 1 0.0 to 400Hz 50Hz

n22 - n28 Frequency reference 2 - 8 0.0 to 400Hz 0Hz

n32 Motor rated current Depending on model 0 to 120% of inverter rated

n36 - n39 Multi-function input (S2 -S5) 0 to 35 -n40 Multi-function output (MA-MB-MC) 0 to 18 1

n44 Multi-function analog output (AM-AC):

n46 Carrier frequency 1 to 4 (2.5 - 10kHz)

n52 DC injection braking current 0 to 100% 50%

n53 DC injection braking at stop 0 to 100% 50%

n54 DC injection braking at start 0 to 100% 50%

n55 Stall prevention during deceleration:

Multi-function Inputs Multi-function Outputs

Val ue*1Function Val ue*1Function

2 Reverse/Stop 0 Fault Output

3 External Fault (NO) 1 During Run

4 External Fault (NC) 2 Frequency agree

5 Faul reset 6 Overtorque being monitored (NO)

6 Multi-step speed reference 1 12 RUN mode

7 Multi-step speed reference 2 13 Inverter ready

0: Limited parameter access

1: Full parameter access

8: Factory parameter initialise

0: Digital operator

1: Control circuit terminal

2: Communication (option)

0: Digital operator (potentiometer)

1: Frequency reference 1 (n21)

2: Control circuit terminal (0 to 10V)

3: Control circuit terminal (4 to 20mA)

4: Control circuit terminal (0 to 20mA)

6: Communication (option)

0: Output frequency (10V/Max, freq.)

1: Output current (10V/Inverter rated current)

0: Enabled

1: Disabled

*1

0 to 9 1

0 to 2 0

0 to 4, 6 0

1 to 510V (400V class)

0,1 0

7 to 9 (Proportional to

output freq.)

0,1 0

200 (200V class)

400 (400V class)

output current

Depending on model

*1 Refer to user’s manual for complete list

Page 25

Multi-function Inputs Multi-function Outputs

Valu e*1Function Val ue*1Function

8 Multi-step speed reference 3 15 Undervoltage in progress

10 Inching Command

12 External base block (NO)

13 External Base block (NC) 0 Otput frequency

17 Local/Remote selection 1 Output current

*1 Refer to user’s manual for full set value

Analogue Output Functionsts

Val ue*1Function

Example of Parameter Settings

Cancels

Set Data

Key

Sequence

In approximately

1s.

Note 1: To cancel the set value, press the Mode Key instead, The parameter number will be

displayed.

2: There are parameters that cannot be changed while the Inverter is in operation. Refer to the

list of parameters. When attempting to change such parameters, the data display will not

change by pressing the Increment or Decrement Key.

In approximately 1s.

Indicator Display example Explanation

Power On

Press the Mode Key repeatedly until the PRGM indicator

is lit.

Use the Increment or Decrement Key to set the parameter

number.

Press the Enter Key. The data of the selected parameter

number will be displayed.

Use the Increment or Decrement Key to set the data.

At that time, the display will flash.

Press the Enter Key so that the set value will be entered and the

data display will be lit (see note 1)

The parameter number will be displayed.

Page 26

6. Monitors

The Vs mini J7 allows you to monitor various conditions, such as output current and status of multifunction inputs.

This monitoring is performed via the “U” parameters.

Key Secuence Indicator Display example Explanation

Constant No. Name Description

U01 Frequency Reference

U02 Output frequency

U03 Output Current

U04 Output Voltage V Output voltage can be monitored

U05 DC Voltage V Main circuit DC voltage can be monitored

U06 Input Terminal Status -- Input terminal status of control circuit terminals can be monitored

U07 Output Terminal Status -- Output terminal status of control circuit terminals can be monitored

U09 Fault History -- Last four fault history is displayed

U10 Software No. -- Software No. can be checked

U15 Data Reception Error -- Contents of MEMOBUS communication data reception error can be

(FREF)

(FOUT)

(IOUT)

Power On

Press the Mode Key repeatedly until the MNTR indicator

is lit. U01 will be displayed.

Use the Increment or Decrement Key to select the monitor

item to be displayed..

Press the Enter Key so that the data of the selected

monitor item will be displayed.

The monitor number display will appear again by

pressing the mode key.

Hz Frequency reference can be moitored. (Same as FREF)

Hz Output frequency can be monitored. (Same as FOUT)

A Output current can be monitored. (Same as IOUT)

checked. (contents of transmission register No. 003DH are the same)

Page 27

Input/Output terminal status

Input Terminal Status

1: Terminal S1 is “closed”

1: Terminal S2 is “closed”

1: Terminal S3 is “closed”

1: Terminal S4 is “closed”

1: Terminal S5 is “closed”

Output Terminal Status

Not Used

1: Terminal MA-MC is “closed”

Not Used

7. Faults and Alarms

Fault Display Fault name and meaning Possible cause and remedy

OC Overcurrent

OV O ver volta ge

uV1 Main circuit undervoltage

OH Unit overheated

OL1 Motor overload

EF

SER

(flashing)

bb

(flashing)

EF

(flashing)

*1 Refer to user’s manual for full fault code listings

Output current is higher than 250% of

inverter rated current.

DC bus voltage has exceeded

detection level.

DC bus voltage is below detection

level.

Temperature inside the inverter has

exceeded 110°C.

The inverter is protecting the motor

from overload based on an internal IT

calculation using n036 setting.

*1

External fault

An external fault has been input.

Sequence error

Sequence input when inverter

running.

External baseblock

An external baseblock command has

been input.

Sequence error has occured Forward and reverse run signal have been applied simultaneously.

Check output for short circuit or ground fault.

The Load is too large, reduce it ore use larger Inverter.

Check motor FLA rating compared to inverter and V/F setting.

Load inertia is too large and the motor is regenerating.

Increase deceleration time (n020 or n022).

Connect an external braking resistor and set n092 to 1.

Check braking resistor and wiring.

Check mains power supply voltage and connections.

Check correct supply for Inverter being used.

Monitor for mains dips or interruptions.

Refer to manual for installation guidelines and recommendations.

Check cooling fan (if fitted).

Check V/F characteristic ore reduce Carrier frequency.

Check and reduce the load.

Check V/F characteristic (V

Increase the running speed of the motor.

Increase acceleration/decelleration times.

Check your control terminal wiring.

A multi-functional digital input has been set to 3 or 4.

Run signal must be removed before this can be reset.

Inverter must be stopped when Local/Remote switching attempted.

Inverter must be stopped when Comms/Remote switching

attempted

Check your control terminal wiring.

A multi-functional digital input has been set to 12 or 13.

and F

).

max

max

Page 28

Page 29

VS MINI J7

Kurzanleitung

1. Anschlussplan

2. Steuerklemmen

3. Installation

4. Inbetriebnahme und Testlauf

5. Parameterübersicht

6. Überwachungsanzeige

7. Fehler und Alarme

DEUTSCH

Page 30

1. Anschlussplan

3G3JV PFI @

Entstörfilter

L1

L2

L3

200 V AC (Drehstrom

oder Wechselstrom,

siehe Hinweis 1)

Vorwärts/Stopp

Multifunktionseingang 1 (S2)

Multifunktionseingang 2 (S3)

Multifunktionseingang 3 (S4)

Multifunktionseingang 4 (S5)

Bezugspotenzial

Frequenzsollwert-Spannungsversorgung

Externer

Frequenzeinsteller

(Potentiometer)

(2 kΩ min. 1/4 W)

Hinweis 1: 200 V Wechselspannung: Anschluss an die Klemmen R/L1 und S/L2.

Hinweis 2: Der Frequenzumrichter verfügt über keinen Bremstransistor, daher kann kein Bremswiderstand

Erdungsklemme

(20 mA bei 12 V DC)

Frequenzsollwerteingang

Frequenzsollwert-Bezugspotenzial

angeschlossen werden.

L1i

L2i

L3i

+1 +2 -

R/L1

S/L2

T/L3

S1

S2

S3

S4

S5

SC

FS

FR

FC

Brücke

U/T1

V/T2

W/T3

Multifunktionskontaktausgang

MA

Schließer

MB

Öffner

MC

Bezugspunkt

Analoger

AM

Überwachungsausgang

AC

Bezugspotenzial analoger

Überwachungsausgang

Versorgungsspannungseingangsklemmen

M

Motorausgangsklemmen

Steuerklemmen

Erdungsklemme

Anordnung der Steuerklemmen

Page 31

2. Steuerklemmen

Symbol Bezeichnung Funktion Signalspezifikation

Ein-

S1 Vorwärts/Stopp EIN: Vorwärtslauf / AUS: Stopp Optokoppler (8 mA

gänge

S2 Multifunktionseingang 1 Bestimmt durch Parameter n36 (Rückwärtslauf/Stopp)

S3 Multifunkt ionseingang 2 Bestimmt durch Parameter n37 (Externer Fehler,

S4 Multifunkt ionseingang 3 Bestimmt durch Parameter n38 (Fehlerrücksetzung)

S5 Multifunkt ionseingang 4 Bestimmt durch Parameter n39 (Multistep-Sollwert 1)

SC Bezugspotenzial

Multifunktionseingänge

FS Frequenzsollwert-

Spannungsversorgung

FR Frequenzsollwert-Eingang Eingangsklemme für die Einstellung des

FC Bezugspotenzial Frequenzsollwert Bezugspotenzial für die Einstellung des

Aus-

MA MBMultifunktionsausgang: Schließer

gänge

Multifunktionsausgang: Öffner

MC Multifunktionsausgan g-Bezugspunkt Bezugspu nkt für MA und MB

AM Analoger Überwachungsausgang Bestimmt durch Parameter n44 (Ausgangsfrequ enz)

AC Bezugspotenzial analoger

Überwachungsausgang

*1 Werkseinstellung: NPN-Spannungseingänge. Keine externe Spannungsversorgung erforderlich (siehe nachstehende

Anschlussdiagramme)

*2 Bei den Funktionsangaben in Klammern handelt es sich um die Standardeinstellungen.

*2

Schließer)

Gemeinsames Bezugspotenzial für die Eingänge S1

bis S5

DC-Spannungsversorgung für die Einstellung des

Frequenzsollwerts

Frequenzsollwerts

Frequenzsollwerts

Bestimmt durch Parameter n40 (während des Betriebs)

Bezugspotenzial für die Klemme AM

*2

*2

*2

*2

*1

bei 24 V DC

20 mA bei 12 V DC

0 bis 10 V DC (20 kΩ)

4 bis 20 mA

0 bis 20 mA

*2

Relaisausgang

(max. 1 A bei 30 V DC

bzw. 250 VAC)

0 bis 10 V DC,

max. 12 mA

)

Auswahl der Eingangspolarität

Mithilfe der Schalter SW7 und SW8

oberhalb des Steuerklemmenblocks

kann die Eingangspolarität und die Art

des Eingangs (Strom- oder Spannungseingang) umgeschaltet werden.

Diese Schalter befinden sich hinter der

Frontabdeckung.

SW7

PNP

NPN

SW7

Auswahl der Eingangspolarität

Mithilfe des Schalters SW7 kann die Eingangspolarität wie dargestellt

zwischen NPN und PNP umgeschaltet werden.

NPN

(Standardeinstellung)

S1 bis S5

SC

GND

3,3 k

SW7

0,1µ

360

GND

24 V

PNP

24 V DC

(±10 %)

SW8

OFF

I

SW8

S1 bis S5

Steuerklemmenblock

Steuerklemmenblock

24 V

SW7

GND

0,1µ

360

3,3 k

SC

GND

U

Page 32

3. Installation

Zwei Bohrungen Ø 5

,

Nennspannung

Drehstrom

200 V AC

Wechselstrom

200 V AC

Drehstrom

400 V AC

Entstörfilter

Modell

Filter

J7AZ

3G3JV-

20P1 PFI2010-SE 82 194 50 92 18 1 5,3

20P2

20P4

20P7

21P5 PFI2020-SE 111 169 50 91 156 5,3

22P2

24P0 PFI2030-SE 144 174 50 120 161 5,3

B0P1 PFI1010-SE 71 169 45 51 156 5,3

B0P2

B0P4

B0P7 PFI1020-SE 111 169 50 91 156 5,3

B1P5

Abmessungen (mm) Zuleitungen

Modell

J7AZ

B H T B1 H1

20P1 68 128 70 56 118 5 2

20P2 68 128 70 56 118 5 2

20P4 68 128 102 56 118 5 2

20P7 68 128 122 56 118 10 2

21P5 108 128 129 96 118 20 2

22P2 108 128 154 96 118 20 3,5

24P0 140 128 161 128 118 30 5,5

B0P1 68 128 70 56 118 5 2

B0P2 68 128 70 56 118 5 2

B0P4 68 128 112 56 118 10 2

B0P7 108 128 129 96 118 2 0 3,5

B1P5 108 128 154 96 118 2 0 5,5

40P2 108 128 81 96 118 5 2

40P4 108 128 99 96 118 5 2

40P7 108 128 129 96 118 5 2

41P5 108 128 154 96 118 10 2

42P2 108 128 154 96 118 10 2

43P0 140 128 161 128 118 20 2

44P0 140 128 161 128 118 20 2

Abmessungen

B L H Y X d

Leistungsschalter (A)

Draht (mm²)

Page 33

Modell

Filter

J7AZ

3G3JV-

40P2 PFI3005-SE 111 169 50 91 156 5,3

40P4

40P7 PFI3010-SE 111 169 50 91 156 5,3

41P5

42P2

43P0 PFI3020-SE 144 174 50 120 161 5,3

44P0

Abmessungen

B L H Y X d

Installation von Entstörfilter und Frequenzumrichter

Schaltschrank Schaltschrank

Schaffner

DrehstromEntstörfilter

Frequenzumrichter

der

J7-Serie

Montageplatte

(Metall)

Erdungs-

flächen

(sämtliche

Farbe vor

der

Montage

entfernen)

Schaffner

DrehstromEntstörfilter

Frequenzumrichter

der

J7-Serie

KabelschirmKabelschirm

Montageplatte

(Metall)

Erdungs-

flächen

(sämtliche

Farbe vor

der

Montage

entfernen)

Erdungsflächen (sämtliche

Farbe vor der Montage entfernen)

Kabelschirm

Motorzuleitung

(max. 20 m)

Erdungsflächen (sämtliche

Farbe vor der Montage entfernen)

Kabelschirm

Motorzuleitung

(max. 20 m)

CIMR-J7@@@@20P1 bis 24P0 CIMR-J7@@@@B0P1 bis B4P0

CIMR-J7@@@@40P2 bis 44P0

Page 34

Einbauabmessungen

min. 30 mmmin. 30 mm

Luft

Luft

min. 100 mm min. 100 mm

4. Inbetriebnahme und Testlauf

Datenanzeige

Anzeigen

(Einstellung/

Anzeige)

Tasten

Anzeige Bezeichnung Funktion

Datenanzeige Anzeige relevanter Daten wie Frequenzsollwert, Ausgangsfrequenz und

FREQ-Einsteller Einstellung des Frequenzsollwerts auf einen zwischen 0 Hz und der

FREF-Anzeige Wenn diese Anzeige leuchtet, wird der Frequenzsollwert angezeigt und

FOUT-Anzeige Wenn diese Anzeige leuchtet, wird die Ausgangsfrequenz des

IOUT-Anzeige Wenn diese Anzeige leuchtet, wird der Ausgangsstrom des

MNTR-Anzeige Wenn diese Anzeige leuchtet, können die durch U01 bis U10 bestimmten

F/R-Anzeige Wenn diese Anzeige leuchtet, kann die Drehrichtung au sgewählt werden,

eingestellte Parameterwerte.

Maximalfrequenz liegenden Wert.

kann eingestellt werden.

Frequenzumrichters angezeigt und kann eingestellt werden.

Frequenzumrichters angezeigt.

Betriebsparameterwerte angezeigt werden.

die bei Aktivierung des Frequenzumrichters mit der RUN-Taste verwendet

wird.

FREQ-Einsteller

Page 35

Anzeige Bezeichnung Funktion

LO/RE-Anzeige Wenn diese Anzeige leuchtet, kann ausgewählt werden, ob der Betrieb

PRGM-Anzeige Wenn diese Anzeige leuchtet, können die Parameter n01 bis n79 ange-

Betriebs arten-Taste Wechselt der Reihe nach durch die o. a. Anzeige- und Einstellungsanzeigen.

Erhöhen-Taste Erhöhen von Parameternummern (Anzeige und Einstellung) und

Verringern-Taste Verringern von Parameternummer n (Anzeige und Einstellung) und

Eingabetaste Übernahme von Parameternummern (Anzeige und Einstellung),

RUN-Taste Starten des Frequenzumrichters, sofern diese Taste nicht durch eine

STOP/RESET-Taste Stoppen des Frequenzumrichters, sofern die STOP-Taste nicht durch eine

des Frequenzumrichters über die digitale Bedienkonsole oder gemäß der

eingestellten Parameter erfolgt.

Hinweis: Der Status dieser Einstellung kann nur bei laufendem

Frequenzumrichterbetrieb ange zeigt werden. RUN-Befehle werden

ignoriert, sol ange diese Anzeige leuchtet.

zeigt und eingestellt werden.

Hinweis: Während des Frequenzumrichterbetriebs können die Parameter

lediglich angezeigt werden. Nicht alle Parameter können eingestellt

werden. RUN-Befehle werden ignoriert, solange diese Anzeige

leuchtet.

Ungespeicherte Änderungen an Parametereinstellungen werden

verworfen, wenn diese Taste gedrückt wird.

Parameter-Einstellungen.

Parameter-Einstellungen.

Übernahme geänderter Parametereinstellungen.

entsprechende Parametereinstellung gesperrt ist.

entsprechende Einstellung des Parameters n06 deaktivier t wurde.

Die folgenden sieben Schritte beschreiben die Vorgehensweise zur Inbetriebnahme des Frequenzumrichters, um in kürzester Zeit den einfachen

Betrieb eines Motors in einer typischen Konfiguration zu ermöglichen:

Schritt 1 – Grundüberprüfungen

1-1 Vor dem Anschluss der Versorgungsspannung durchzuführende Überprüfungen.

Kontrollieren Sie die Versorgungsspannung:

CIMR-J7AZ2@@@: Drehstrom 200 bis 230 V AC

CIMR-J7AZB@@@: Wechselstrom 200 bis 240 V AC (Anschluss an R/L1 und S/L2)

CIMR-J7AZ4@@@: Drehstrom 380 bis 460 V AC

1-2 Kontrollieren Sie den korrekten Anschluss des Motors an die Motorausgangsklemmen (U/T1,

V/T2, W/T3).

1-3 Kontrollieren Sie den korrekten Anschluss des Steuerschaltkreises an die Steuerklemmen.

1-4 Stellen Sie sicher, dass alle Steuerklemmen auf AUS geschaltet sind.

1-5 Trennen Sie den Motor von der Last.

Schritt 2 – Anschließen der Spannungsversorgung und Überprüfen des

Anzeigestatus

2-1 Schließen Sie nach Durchführen der Überprüfungen in Schritt 1 die Spannungsversorgung an

den Frequenzumrichter an.

2-2 Treten beim Anschließen und Einschalten der Spannungsversorgung keine Fehler auf, zeigt die

Anzeige das folgende Verhalten:

Page 36

RUN-Anzeige: blinkt.

ALARM-Anzeige: aus

Sonstige Anzeigen (Einstellung/Anzeige): FREF, FOUT oder IOUT leuchtet.

Datenanzeige: zeigt die entsprechenden Daten (Frequenzsollwert, Ausgangsfrequenz oder

Ausgangsstrom) an.

Trat beim Einschalten der Versorgungsspannung ein Fehler auf, werden die Details des Fehlers

angezeigt. Konsultieren Sie in diesem Fall die Bedienungsanleitung, und ergreifen Sie die erfor-

derlichen Maßnahmen.

Schritt 3 – Initialisieren der Parameter

Zum Zurücksetzen der Frequenzumrichter-Parameter auf die Werkseinstellungen setzen Sie den

Parameter n01 auf 8. In dieser Einstellung erfolgt die Ansteuerung des Frequenzumrichters im so

genannten Zweidrahtbetrieb, d. h. ein Multifunktionseingang („Draht“) fungiert als Vorwärts/StoppBefehl, ein weiterer als Rückwärts/Stopp-Befehl.

Tastenfolge

Nach etwa einer

Sekunde

Anzeige

Datenanzeige

(Beispiel)

Erläuterung

Spannung EIN

Drücken Sie wiederholt die Mode Key, bis die PRGM-Anzeige

leuchtet.

Drücken Sie die Eingabetaste. Nun wird die aktuelle Einstellung des

Parameters n01 angezeigt.

Stellen Sie mithilfe der Erhöhen- oder Verringern-Taste den Wert 8

ein. Dabei blinkt die Datenanzeige.

Drücken Sie die Eingabetaste, damit der geänderte Wert

übernommen wird. Anschließend wird der Wer t nicht mehr blinkend,

sondern konstant leuchtend angezeigt.

Die Parameternummer wird wieder angezeigt.

Schritt 4 – Einstellung des Motornennstroms

Dieser Parameter regelt das Verhalten des elektronischen Thermorelais für den Motorüberlastschutz

(OL1). Bei korrekter Einstellung dieses Parameters verhindert der Frequenzumrichter das Durchbrennen des Motors bei Überlastung.

Lesen Sie den auf dem Typenschild des Motors angegebenen Nennstrom (A) ab, und stellen Sie den

Parameter n32 auf diesen Wert. Das folgende Beispiel zeigt die Einstellung des Werts 1,8 A.

Tastenfolge

Nach etwa einer

Sekunde

Anzeige

Datenanzeige

(Beispiel)

Erläuterung

Anzeige der Parameternummer.

Stellen Sie mithilfe der Erhöhen- oder Verringern-Taste den

Parameter n32 ein.

Drücken Sie die Eingabetaste. Nun wird die aktuelle Einstellung des

Parameters n32 angezeigt.

Stellen Sie mithilfe der Erhöhen- oder Verringern-Taste den

Motornennstrom ein. Dabei blinkt die Datenanzeige.

Drücken Sie die Eingabetaste, damit der geänderte Wert übernommen wird. Anschließend wird der Wert nicht mehr blinkend, sondern

konstant leuchtend angezeigt.

Die Parameternummer wird wieder angezeigt.

Page 37

Schritt 5 – Einstellung der Motornennfrequenz

Die Motornennfrequenz gibt die maximale Betriebsfrequenz des Motors an. Der Frequenzumrichter

benötigt diese Angabe, um den Motor ordnungsgemäß ansteuern zu können. Lesen Sie die auf dem

Typenschild des Motors angegebene Nennfrequenz (Hz) ab, und stellen Sie die Parameter n09 und

n11 auf diesen Wert.

Schritt 6 – Einstellen der Befehlsquelle

Legen Sie fest, wie die Start- und Stoppbefehle gegeben werden. Dies kann wahlweise über die RUNund die STOP/RESET-Taste oder über entsprechende Signale an Multifunktionseingängen erfolgen.

Die Einstellung der Befehlsquelle erfolgt durch Setzen des Parameters n02 auf den entsprechenden

Wert :

0: Die RUN- und die STOP/RESET-Taste sind aktiviert.

1: Start- und Stoppbefehle werden über Steuerklemmen gegeben.

Das nachstehende Diagramm zeigt den Anschluss eines Schalters zum Starten/Stoppen des Motors

im Vorwärtslauf im so genannten Zweidrahtbetrieb. Dazu muss der Parameter n02 auf 1 gesetzt sein.

Um mit einem weiteren Schalter an Steuerklemme S2 den Rückwärtslauf zu aktivieren, muss zusätzlich der Parameter n36 auf 2 gesetzt sein (Standardeinstellung).

Vorwärts

Start/Stopp

Rückwärts

Start/Stopp

Schritt 7 – Einstellen des Frequenzsollwerts

Legen Sie fest, wie die Drehzahl des Motors eingestellt wird. Standardmäßig erfolgt dies mithilfe des

FREQ-Einstellers, bei dessen Verwendung keine weiteren Einstellungen erforderlich sind.

Der Frequenzsollwert kann auch mittels eines externen Potenziometers oder eines analogen SPSAusgangs geregelt oder auf einen von acht im Frequenzumrichter vorprogrammierten und vermittels

der Multifunktionseingänge ausgewählten Werten gesetzt werden.

Um beispielsweise den Frequenzsollwert mittels eines externen Potenziometers oder eines analogen

SPS-Ausgangs zu regeln, muss der Parameter n03 auf 2 gesetzt werden.

Frequenz-

( )

einstellungsSpannungs-

Drehzahlsollwert

(0 bis +10 V)

versorgung

+12 V, 20 mA

FR

FC (0 V)

Page 38

5. Parameterübersicht

Parame ter-Nr. Beschreibung Bereich Standardeinstellung

n01 Parameterschutz:

n02 Befehlsquelle:

n03 Frequenzsollwertquelle:

n09 Maximale Ausgangsfrequenz 50 bis 400 Hz

n10 Maximale Ausgangsspannung 1 bis 255V (200-V-Klasse)

n11 Maximale Ausgangsfrequenz 50 bis 400 Hz

n16 Beschleunigungszeit 1 0,0 bis 999 s 10 s

n17 Verzögerungszeit 2 0,0 bis 999 s 10 s

n21 Frequenzsollwert 1 0,0 bis 400 Hz 50 Hz

n22 bis n28 Frequenzsollwert 2 bis 8 0,0 bis 400 Hz 0 Hz

n32 Motornennstrom Modellabhängig 0 bis 120 % des Frequenz-

n36 bis n39 Multifunktionseingänge S2 bis S5 0 bis 35 -n40 Multifunktionsausgänge (MA/MB) 0 bis 18 1

n44 Analoger Multifunktionsausgang (AM):

n46 Trägerfrequenz 1 bis 4 (2,5 bis 10 kHz)

n52 DC-Bremsstrom 0 bis 100 % 50 %

n53 DC-Bremsstrom beim Stopp 0 bis 100 % 50 %

n54 DC-Bremsstrom beim Start 0 bis 100 % 50 %

n55 Blockierschutz bei Verzögerung:

0: Beschränkter Zugriff auf die Parameter

1: Vollständiger Zugriff auf die Parameter

8: Zurücksetzen der Parameter auf die

Werkseinstellungen

0: Bedientasten

1: Steuerklemmen

2: Kommunikation (Option)

0: FREQ-Einsteller

1: Frequenzsollwert 1 (n21)

2: Steuerklemme (0 bis 10 V)

3: Steuerklemme (4 bis 20 mA)

4: Steuerklemme (0 bis 20 mA)

6: Kommunikation (Option)

0: Ausgangsfrequenz (10 V = Maximalfrequenz)

1: Ausgangsstrom (10 V = Frequenzumrichternennstrom)

0: Aktiviert

1: Deaktiviert

*1

0 bis 9 1

0 bis 2 0

0 bis 4, 6 0

1 bis 510V (400-V-Klasse)

0,1 0

7 bis 9 (proportional zur

Ausgangsfrequenz)

0,1 0

200 V (200-V-Klasse)

400 V (400-V-Klasse)

umrichternennstroms

Modellabhängig

Multifunktionseingänge Multifunktionsausgänge

Einstellung*1Funktion Einstellung*1Funktion

2 Rückwärts/Stopp 0 Fehlerausgang

3 Externer Fehler (Schließer) 1 In Betr ieb

4 Externer Fehler (Öffner) 2 Frequenzübereinstimmung

5 Fehlerrücksetzung 6 Drehmomentüberschreitung wird überwacht

6 Multistep-Drehzahlsollwert 1 12 RUN-Betriebsar t

(Schließer)

*1 Eine vollständige Liste finden Sie in der Bedienungsanleitung.

Page 39

Multifunktionseingänge Multifunktionsausgänge

Einstellung*1Funktion Einstellung*1Funktion

7 Multistep-Drehzahlsollwert 2 13 Frequenzumrichter bereit

8 Multistep-Drehzahlsollwert 3 15 Unterspannung

10 Tippbetrieb

12 Externe Endstufensperre (Schließer)

13 Externe Endstufensperre (Öffner) 0 Ausgangsfrequenz

17 Umschaltung Lokal / Dezentral 1 Ausgangsstrom

*1 Eine vollständige Liste finden Sie in der Bedienungsanleitung.

Analoger Überwachungsausgang

Einstellung*1Funktion

Parametereinstellungen (Beispiel)

Änderungen

verwerfen

TastenFolge

Nach etwa einer

Sekunde

Hinweis1: Wenn Sie die geänderte Parametereinstellung nicht übernehmen, sondern verwerfen

Anzeige

möchten, drücken Sie einfach stattdessen die Betriebsar tentaste. Anschließend wird

wieder die Parameternummer angezeigt.

2: Bestimmte Parameter können während des laufenden Frequenzumrichterbetriebs nicht

geändert werden (siehe Parameterliste). Wenn Sie versuchen, einen dieser Parameter zu

ändern, zeigt die Datenanzeige beim Drücken der Erhöhen- oder Verringern-Taste keine

Änderung.

Datenanzeige

(Beispiel)

Erläuterung

Spannung EIN

Drücken Sie wiederholt die Mode Key, bis die PRGM-Anzeige

leuchtet.

Stellen Sie mithilfe der Erhöhen- oder Verringern-Taste die

Parameternummer ein.

Drücken Sie die Eingabetaste. Nun wird die aktuelle Einstellung

des ausgewählten Parameters angezeigt.

Stellen Sie mithilfe der Erhöhen- oder Verringern-Taste den

gewünschten Wert ein.

Dabei blinkt die Datenanzeige.

Drücken Sie die Eingabetaste, um den geänderten Wert zu

übernehmen. Anschließend wird der Wer t nicht mehr blinkend,

sondern konstant leuchtend angezeigt (siehe Hinweis 1).

Die Parameternummer wird wieder angezeigt.

Nach etwa einer Sekunde

Page 40

6. Überwachungsanzeige

Der Frequenzumrichter VS Mini J7 ermöglicht die kontinuierliche Anzeige bestimmter Betriebsparameter (z. B. Ausgangsstrom oder Status der Multifunktionseingänge).

Diese Überwachung erfolgt mithilfe der „U“-Parameter.

Tastenfolge Anzeige

Einstellung Bezeichnung Beschreibung

U01 Frequenzsollwert

U02 Ausgangsfrequenz

U03 Ausgangsstrom

U04 Ausgangsspannung V Anzeige der Ausgangsspannung

U05 Zwischenkreisspannung V Anzeige der Zwischenkreisspannung

U06 Eingangsklemmenstatus -- Anzeige des Status der Steuerklemmen

U07 Ausgangsklemmenstatus -- Anzeige des Status der Ausgangsklemmen

U09 Fehlerspeicher -- Anzeige der letzten vier Fehler

U10 Software-Nummer -- Anzeige der Software-Nummer

U15 Datenempfangsfehler -- Anzeige des Inhalt des M EMOBUS-Kommunika tions-Datenempfangs-

(FREF)

(FOUT)

(IOUT)

Datenanzeige

(Beispiel)

Erläuterung

Spannung EIN

Drücken Sie wiederholt die Betriebsartentaste, bis die MNTRAnzeige leuchtet. Nun wird U01 angezeigt.

Stellen Sie mithilfe der Erhöhen- oder Verringern-Taste den

anzuzeigenden/zu überwachenden Betriebsparameter ein.

Drücken Sie die Eingabetaste. Nun wird der Wert des

ausgewählten Betriebsparameters kontinuierlich angezeigt.

Durch erneutes Drücken der Betriebsartentaste wird wieder die

Nummer des angezeigten Betriebsparameters angezeigt.

Hz Anzeige des Frequenzsollwerts (entspricht FREF)

Hz Anzeige der Ausgangsfrequenz (entspricht FOUT)

A Anzeige des Ausgangsstroms (entspricht IOUT)

fehler-Registers (entspricht dem Übertragungsregisters 003Dh)

Page 41

Eingangs-/Ausgangsklemmenstatus

Eingangsklemmenstatus

1: Klemme S1 ist auf EIN gesetzt

1: Klemme S2 ist auf EIN gesetzt

1: Klemme S3 ist auf EIN gesetzt

1: Klemme S4 ist auf EIN gesetzt

1: Klemme S5 ist auf EIN gesetzt

Ausgangsklemmenstatus

Nicht verwendet

1: Kontakt MA-MC ist geschlossen

Nicht verwendet

7. Fehler und Alarme

Fehleranzeige Bezeichnung und Bedeutung Mögliche Ursachen und Abhilfemaßnahmen

OC Überstrom

OV Überspannung

UV1 Zwischenkreisunterspannung

OH Überhitzung

OL1 Motorüberlastung

*1

EF

SER

(blinkend)

bb

(blinkend)

EF

(blinkend)

*1 Eine vollständige Fehlercode-Liste finden Sie in der Bedienungsanleitung.

Der Ausgangsstrom beträgt mehr

als 250 % des Frequenzumrichternennstroms.

Die Zwischenkreisspannung

übersteigt den ÜberspannungsErkennungspegel.

Die Zwischenkreisspannung

unterschreitet den UnterspannungsErkennungspegel.

Die Temperatur im Inneren des Frequenzumrichters hat 110 °C überschritten.

Der Frequenzumrichter schützt den

Motor mittels interner, auf dem Wert

des Parameters n036 basierender

Berechnungen vor Überlastung.

Externer Fehler

Dem Frequenzumrichter wurde ein

externer Fehler signalisiert.

Sequenzfehler

Sequenzeingabe bei laufendem

Frequenzumrichter.

Externe Endstufensperre

Ein externer Endstufensperrbefehl

wurde gegeben.

Sequenzfehler Vorwärts- und Rückwärtslaufsignal wurden gleichzeitig angelegt.

Ausgang auf Kurz- oder Erdschluss überprüfen.

Die Last ist zu groß. Last reduzieren oder leistungsfähigeren Frequenzumrichter einsetzen.

Maximalen Motorstrom in Hinsicht auf maximalen Frequenzumrichterausgangsstrom und U/f-Einstellung überprüfen.

Beim generatorischen Betrieb des Motors ist die Massenträgheit

der Last zu groß. Verzögerungszeit (n020 oder n022) vergrößern.

Externe Bremseinheit anschließen und n092 auf 1 setzen.

Bremswiderstand und Verdrahtung überprüfen.

Versorgungsspannung und Anschlüsse überprüfen.

Eignung der Versorgungsspannung für den Frequenzumrichter

überprüfen. Versorgungsspannung auf Spannungseinbrüche und unterbrechungen überwachen.

Richtlinien und Empfehlungen der Bedienungsanleitung beachte n.

Kühllüfter (sofern vorhanden) überprüfen.

U/f-Kennlinie überprüfen oder Trägerfrequenz reduzieren.

Last überprüfen und ggf. reduzieren.

U/f-Kennlinie (U

Motordrehzahl erhöhen.

Beschleunigungs-/Verzögerungszeiten erhöhen.

Verdrahtung des Steuerschaltkreises überprüfen.

Einer der Parameter für die Funktion der Multifunktionseingänge

wurde auf 3 oder 4 gesetzt. Dieser Fehlerzustand kann erst nach

Aufheben des RUN-Signals gelöscht werden.

Umschaltung zwischen lokaler und dezentraler Steuerung kann nur

bei angehaltenem Frequenzumrichter erfolgen.

Umschaltung zwischen Kommunikations- und dezentraler Steuerung kann nur bei angehaltenem Frequenzumrichter erfolgen.

Verdrahtung des Steuerschaltkreises überprüfen.

Einer der Parameter für die Funktion der Multifunktionseingänge

wurde auf 12 oder 13 gesetzt.

und f

) überprüfen.

max

max

Page 42

Page 43

VARIADOR DE VELOCIDAD J7

Guía rápida

1. Cableado

2. Terminales del circuito de control

3. Instalación

4. Inicio y prueba de funcionamiento

5. Lista rápida de parámetros

6. Monitorización

7. Fallos y alarmas

ESPAÑOL

Page 44

1. Cableado

3G3JV PFI @

Filtro de ruido

L1

L2

L3

Trifásica de 200 V c.a.;

monofásica de 200 V

c.a. (ver nota 1)

Marcha directa/parada

Entrada multifuncional 1 (S2)

Entrada multifuncional 2 (S3)

Entrada multifuncional 3 (S4)

Entrada multifuncional 4 (S5)

Común de entrada de secuencia

Alimentación de referencia de

Potenciómetro

externo de ajuste

de frecuencia

Nota 1: Conecte la alimentación monofásica de 200 V c.a. a los terminales R/L1 y S/L2 del J7AZB

Nota 2: La resistencia de freno no puede conectarse porque no hay incorporado un transistor de freno.

Terminal

de masa

Terminales de

salida del

circuito principal

frecuencia 20 mA a +12 V

Entrada de referencia de frecuencia

Común de referencia de frecuencia

+1 +2 -

L1i

R/L1

L2i

S/L2

L3i

T/L3

S1

S2

S3

S4

S5

SC

FS

FR

FC

Terminales de entrada

del circuito principal

Terminales del

circuito de

control

Terminal

de masa

PUENTE

U/T1

V/T2

W/T3

Salida de contacto multifuncional

MA

NA

MB

NC

MC

Común

AM

Salida de monitorización analógica

AC

Común de salida de

monitorización analógica

Disposición de los terminales del circuito

de control

M

Page 45

2. Terminales del circuito de control

Símbolo Nombre Función Nivel de la señal

Entrada S1 Marcha directa/Parada Marcha directa: ON, Parada: OFF Fotoacoplador de

S2 Entrada multifuncional 1 Configurada mediante el parámetro n36

S3 Entrada multifuncional 2 Configurada mediante el parámetro n37

S4 Entrada multifuncional 3 Configurada mediante el parámetro n38

S5 Entrada multifuncional 4 Configurada mediante el parámetro n39

SC Común de entrada de secuencia Común para S1 hasta S5

FS Alimentación eléctrica de referencia

de frecuencia

FR Entrada de referencia de frecuencia Terminal de entrada para uso de referencia de

FC Común de referencia de frecuencia Común para uso de referencia de frecuencia 4 a 20 mA

Salida MA MBSalida multifuncional: NA

*1 La configuración de estos terminales es NPN. No se requiere una fuente de alimentación externa. Consulte las

*2 Las funciones entre paréntesis indican la configuración predeterminada.

Salida multifuncional: NC

MC Común de salida multifuncional Común para uso de MA y MB

AM Salida de monitorización analógica Configurada mediante el parámetro n44

AC Común de salida de monitorización

analógica

conexiones que se indican a continuación

(Inversa/Parada)

(Fallo externo: NA)

(Reset de fallo)

(Referencia de multivelocidad 1)

Alimentación eléctrica de c.c. para uso de

referencia de frecuencia

frecuencia

Configurada por el parámetro n40 (durante el

funcionamiento)

(Frecuencia de salida)

Común para uso de AM

*2

*2

*2

*2

*2

*2

8mA a 24Vc.c.

20 mA a 12 V c.c.

0 a 10 V c.c. (20 kΩ)

0 a 20 mA

Salida de relé 1 A

máx. a 30 V c.c. y

250 V c.a.

12 mA máx. a 0

hasta 10 V c.c.

*1

Selección del método de entrada

Los interruptores SW7 y SW8, ambos situados sobre los terminales

del circuito de control, se utilizan

para la selección del método de

entrada.

Para utilizar estos interruptores, retire la cubierta delantera y la cubierta opcional.

PNP

NPN

SW7

SW7

SW8

OFF

I

SW8

Bloque de

terminales del

circuito de control

Bloque de

terminales del

circuito de control

V

Selección de entrada de secuencia

La entrada puede seleccionarse empleando SW7, NPN o PNP, tal y como se indica a continuación

NPN

(Configuración

predeterminada)

S1 a 5

24 V

SW7

GND

0,1 µ

360

3,3 k

SC

GND

PNP

24 V c.c.

(± 10%)

S1 a 5

SW7

GND

0,1 µ

360

3,3 k

SC

GND

24 V

Page 46

3. Instalación

Dos orificios de 5 de diá.

,

Tensión

nominal

Trifásica de

200 V c.a.

Monofásica de

200 V c.a.

Trifásica de

400 V c.a.

Especificaciones del filtro de ruido

Modelo

Filtro

J7AZ

3G3JV-

20P1 PFI2010-SE 82 194 50 92 18 1 5,3

20P2

20P4

20P7

21P5 PFI2020-SE 111 169 50 91 156 5,3

22P2

24P0 PFI2030-SE 144 174 50 120 161 5,3

B0P1 PFI1010-SE 71 169 45 51 156 5,3

B0P2

B0P4

B0P7 PFI1020-SE 111 169 50 91 156 5,3

B1P5

Dimensiones (mm)

Modelo

J7AZ

A H F A1 H1 MCCB (A) Hilo (mm²)

20P1 68 128 70 56 118 5 2

20P2 68 128 70 56 118 5 2

20P4 68 128 102 56 118 5 2

20P7 68 128 122 56 118 10 2

21P5 108 128 129 96 118 20 2

22P2 108 128 154 96 118 20 3.5

24P0 140 128 161 128 118 30 5.5

B0P1 68 128 70 56 118 5 2

B0P2 68 128 70 56 118 5 2

B0P4 68 128 112 56 118 10 2

B0P7 108 128 129 96 118 2 0 3.5

B1P5 108 128 154 96 118 2 0 5.5

40P2 108 128 81 96 118 5 2

40P4 108 128 99 96 118 5 2

40P7 108 128 129 96 118 5 2

41P5 108 128 154 96 118 10 2

42P2 108 128 154 96 118 10 2

43P0 140 128 161 128 118 20 2

44P0 140 128 161 128 118 20 2

Dimensiones

A L H Y X f

Línea y protección

recomendada

Page 47

Modelo

Filtro

J7AZ

3G3JV-

40P2 PFI3005-SE 111 169 50 91 156 5,3

40P4

40P7 PFI3010-SE 111 169 50 91 156 5,3

41P5

42P2

43P0 PFI3020-SE 144 174 50 120 161 5,3

44P0

Dimensiones

A L H Y X f

Instalación del filtro de ruido y J7

Cable

Panel de control Panel de control

Filtro trifásico

Schaffner

RFI

apantallado

Placa de mon-

taje metálica

Conexiones a masa (quite

la pintura)

Filtro trifásico

Schaffner

RFI

Cable

apantallado

Placa de mon-

taje metálica

Conexiones a masa (quite

la pintura)

Conexiones a masa (quite la pintura)

Variador

serie J7

Cable

apantallado

Cable del motor:

máx. 20 m

Conexiones a masa (quite la pintura)

Variador

serie J7

Cable

apantallado

Cable del motor:

máx. 20 m

CIMR-J7@@@@20P1 hasta 24P0 CIMR-J7@@@@B0P1 hasta B4P0

CIMR-J7@@@@40P2 hasta 44P0

Page 48

Dimensiones de instalación

30 mm

(1,18 pulg.)

O MÁS

30 mm

(1,18 pulg.)

O MÁS

100 mm (3,94

pulg.) O MÁS

100 mm (3,94

pulg.) O MÁS

AIRE

AIRE

4. Inicio y prueba de funcionamiento

Indicadores (indicadores

Display de datos

Teclas

Aspecto Nombre Función

Display de datos Muestra los elementos de datos pertinentes, como referencia de

Potenciómetro de

ajuste de frecuencia

(FREQ)

Indicador de

referencia de

frecuencia (FREF)

Indicador de salida

de frecuencia (FOUT)

Indicador de salida

del variador (IOUT)

Indicador de

monitorización

(MNTR)

Indicador de directa/

inversa (F/R)

frecuencia, frecuencia de salida y valores seleccionados de parámetro.

Selecciona la referencia de frecuencia en un intervalo entre 0 Hz

y la frecuencia máxima.

La referencia de frecuencia se puede monitorizar o seleccionar mientras

este indicador esté iluminado.

La frecuencia de salida del variador se puede monitorizar

o seleccionar mientras este indicador esté iluminado.

La corriente de salida del variador se puede monitorizar mientras este

indicador esté iluminado.

Mientras este indicador esté iluminado,

se monitorizan los valores seleccionados en U01 h asta U10.

La dirección de rotación se puede seleccionar mientras este indicador

esté iluminado, cuando el variador esté funcionando con la tecla RUN

de elemento de

selección/monitorización)

Potenciómetro de ajuste

de frecuencia (FREQ)

Page 49

Aspecto Nombre Función

Indicador de local/

remota (LO/RE)

Indicador PRGM Los parámetros de n01 hasta n79 pueden seleccionarse o monitorizarse

Tecla Modo Alterna secuencialmente los indicadores de elemento de selección y

Tecla Más Aumenta los números de monitorización multifuncional, los números de

Tecla Menos Disminuye los números de monitorización multifunci onal, los números de

Tecla Enter Permite introducir números de monitorización multifuncional, números de

Tecla RUN Pone en marcha el variador cuando el 3G3JV está funcionando

Tecla STOP/RESET Detiene el funcionamiento del variador, siempre y cuando el parámetro

Mientras este indicador e sté iluminado, se puede seleccionar la operación d el

variador a través del operador digital o según los parámetros seleccionados.

Nota: El estado de este indicador sólo puede monitorizarse mientras el

variador esté en funcionamiento. Cualquier entrada de comando

RUN será ignorada mientras este indicador esté iluminado.

mientras este indicador esté iluminado.

Nota

: Mientras el variador esté en funcionamiento, los parámetros sólo podrán

ser monitorizados, y sólo algunos modificados. Cualquier entrada de

comando RUN será ignorada mientras este indicador esté iluminado.

monitorización.

El parámetro que se esté configurando quedará cancelado

si se pulsa esta tecla antes de introducir la selección.

parámetros y los valores seleccionados de parámetro.

parámetros y los valores seleccionados de parámetro.

parámetro y valores de datos internos después de ha ber sido

seleccionados o modificados.

con el operador digital

nO6 no esté configurado para inhabilitar la tecla STOP.

Los siete pasos siguiente describen las operaciones mínimas recomendadas

que permiten que el J7 controle un motor conectado en una configuración

típica, con el objeto de permitir un funcionamiento sencillo en el menor tiempo:

Paso 1 – Comprobaciones iniciales

1-1 Comprobaciones a realizar antes de conectar la fuente de alimentación.

Compruebe que la tensión de la fuente de alimentación es la correcta.

CIMR-J7AZ2@@@: Trifásica de 200 a 230 Vc.a.

CIMR-J7AZB@@@: Monofásica de 200 a 240 Vc.a. (hilo R/L1 y S/L2)

CIMR-J7AZ4@@@: Trifásica de 380 a 460 Vc.a.

1-2 Asegúrese de que los terminales de salida del motor (U/T1, V/T2, W/T3) estén conectados al

motor.

1-3 Asegúrese de que los terminales del circuito de control y el dispositivo de control estén

cableados correctamente.

1-4 Asegúrese de que todos los terminales de control estén desconectados.

1-5 Ajuste el motor para funcionar en vacío (es decir, no conectado al sistema mecánico)

Paso 2 – Conexión de la fuente de alimentación y comprobación del

estado del display

2-1 Una vez realizadas las comprobaciones del paso 1, conecte la fuente de alimentación.

Page 50

2-2 Si el display es normal al conectar la alimentación, presentará la siguiente información:

indicador RUN: parpadea

indicador ALARM: apagado

Indicadores de selección/monitorización: FREF, FOUT o IOUT iluminado.

Display de datos: muestra los datos correspondientes al indicador iluminado.

En caso de haberse producido un fallo, presentará los detalles del mismo. En tal caso, consulte

el manual del usuario y adopte las medidas pertinentes.

Paso 3 – Inicialización de parámetros

Para inicializar los parámetros a los valores predeterminados de fábrica, configure el parámetro n01 = 8.

De este modo, el J7 quedará configurado para aceptar comandos de inicio/parada en lo que se denomina

“control de 2 hilos”. Es decir, un hilo para el comando de marcha directa/parada y el otro para un comando

de marcha inversa/parada de un motor.

Secuencia

de teclas

En aproximadamente 1 s.

Paso 4 – Configuración de la corriente nominal del motor

Este parámetro se utiliza para la función termolectrónica de detección de sobrecarga del motor (OL1).

Si lo configura correctamente, el J7 impedirá que un motor sobrecargado se queme.

Lea la corriente nominal (en amperios) en la placa de referencia del motor, y especifique este valor en

el parámetro n32. En el siguiente ejemplo se ha especificado un valor de 1,8 amperios.

Secuencia

de teclas

Indicador

Indicador

Display

Explicación

ejemplo

Alimentación ON

Pulse varias veces la tecla Modo hasta que se ilumine el indicador

PRGM.

Pulse la tecla Enter. De este modo se visualizarán los datos del

parámetro n01.

Utilice las teclas Más o Menos para configurar el parámetro n01 con el

valor 8. El display parpadeará.

Pulse la tecla Enter para introducir el valor seleccionado, tras lo cual se

iluminará el display de datos.

Se mostrará número de parámetro.

Display

Explicación

ejemplo

Muestra el número del parámetro

Pulse las teclas Más o Menos hasta que aparezca n32.

En aproximadamente 1 s.

Pulse la tecla Enter. De este modo se visualizarán los datos del

parámetro n32.

Utilice las teclas Más o Menos para selecciona r la corriente nominal del

motor. El display parpadeará.

Pulse la tecla Enter para introducir el valor seleccionado, tras lo cual se

iluminará el display de datos.

Se mostrará número de parámetro.

Page 51

Paso 5 – Configuración de la frecuencia nominal del motor

Es la frecuencia máxima a la que puede funcionar el motor, y permite al J7 controlarlo correctamente.

Lea la frecuencia nominal (en Hz) en la placa de referencia del motor, y especifique este valor en los

parámetros n09 y n11

.

Paso 6 – Configuración del comando de operación

Es el método correspondiente a los comandos de funcionamiento y parada del motor (es decir, el

modo en que el variador pondrá en marcha y parará el motor). Las dos operaciones básicas

corresponden a las teclas RUN y STOP/RESET del operador digital, o bien a una de las entradas

multifuncionales de los terminales del circuito de control.

Para seleccionar el comando de operación, especifique el valor adecuado en el parámetro n02:

0 = las teclas RUN y STOP/RESET del operador digital están habilitadas.

1 = Entradas multifuncionales a través de los terminales del circuito de control.

El siguiente diagrama muestra cómo conectar un interruptor para poner en marcha directa/parar el

motor, con el “control de 2 hilos”. Configure el parámetro n02=1. Para habilitar un interruptor

independiente para la rotación inversa en el terminal de control S2, configure el parámetro n36=2

(que es la configuración predeterminada de fábrica del parámetro n36).

MARCHA

DIRECTA/PARADA

MARCHA

INVERSA/PARADA

Paso 7 – Configuración de la referencia de frecuencia

Es el método para seleccionar el origen del comando de velocidad del motor. La configuración

predeterminada de fábrica es para el potenciómetro del operador digital (potenciómetro de ajuste de

frecuencia, FREF), en cuyo caso no será necesaria ninguna configuración.

La referencia de frecuencia también puede proceder de un potenciómetro externo, de la salida

analógica de un autómata programable o de hasta 8 velocidades preprogramadas guardadas en el

variador y seleccionadas a través de las entradas multifuncionales.

Por ejemplo, para aceptar la referencia de frecuencia de un potenciómetro externo, o bien de la salida

analógica de 0-10 V de un autómata programable, configure el parámetro n03=2.

REFERENCIA

PRINCIPAL DE

FRECUENCIA DE

VELOCIDAD

AJUSTE DE

( )

FRECUENCIA FS

(0 a +10 V)

+12 V, 20 mA

FR

FC (0 V)

Page 52

5. Lista rápida de parámetros

Nº de

parámetro

n01 Acceso al parámetro: