Page 1

C500-ASC04 ASCII Unit

Operation Manual

Revised February 2001

Page 2

No. 6182

OMRON Corporation

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

1

Page 3

No. 6182

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

2

Page 4

No. 6182

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

3

Page 5

iv

Page 6

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify warnings in this manual. Always heed the

information provided with them.

DANGER Indicates information that, if not heeded, is likely to result in loss of life or serious injury.

!

WARNING Indicates

!

Caution Indicates

!

age to the product, or faulty operation.

information that, if not heeded, could possibly result in loss of life or serious injury

information that, if not heeded, could result in relatively serious or

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Note Indicates

of the product.

information of particular interest for ef

minor injury

ficient and convenient operation

, dam

.

-

OMRON, 1991

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

1, 2, 3...

1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 7

vi

Page 8

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Back Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 ASCII Unit Internal Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

Data Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1 Bits and Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Data Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3

Programming and Communications . . . . . . . . . . . . . . . .

3-1 Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Program Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Running the BASIC Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Assembly Routines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4

BASIC Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1 Program Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Commands, Statements, and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5

Assembly Programming . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1 Assembly Language Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Terminology and Formatting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 Monitor Mode Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6

Program Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1 Timing Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2 Programs in Two-word Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3 Programs in Four-word Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4 Assembly Language Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendices

A Standard Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C PC Statements and Refresh Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D Formatting and Data Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E Memory Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G BASIC Commands, Statements, and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vii

Page 9

About this Manual:

This

manual describes the installation and operation of the C500-ASC04 ASCII Unit. The ASCII Unit can

be mounted to a C500, C1000H, C2000H, or CV-series PC to control ASCII data I/O through a BASIC

program

and I/O WRITE instructions (READ(88) and WRIT(87) or READ(190) and WRIT(191)).

It has been assumed in the writing of this manual that the reader is already familiar with the hardware,

programming,

should refer to the appropriate OMRON PC manuals for assistance.

stored in the ASCII Unit. The C500-ASC04

and terminology of OMRON PC’

must be used with a PC that supports the I/O READ

s. If a review of this information is necessary

, the

reader

manual contains the following sections. Please read this

This

stand the information provide before attempting to install and operation the ASCII Unit.

Section 7

Section

ASCII Unit and the PC exchange data.

Section

load, save, and run an BASIC program for the ASCII Unit.

Section

commands

ers already proficient in BASIC pay careful attention to this section.

Section 11

Unit’s

Section 12

ented

the PC work together in various applications. Also in this section are several examples used to illustrate

the execution sequence of the hardware during execution of the ASCII Unit and PC programs.

Detailed technical information not immediately necessary for the understanding of a particular section

has

of the appendices, see the table of contents.

Note In this manual, ladder diagram instructions are given by mnemonics with the function codes in

explains the external hardware of the ASCII Unit and how it connects to a PC system.

8

explains the format of the PC memory area accessed by the ASCII Unit. This area is where the

9

explains how the ASCII Unit program and the PC program communicate as well as how to write,

10

presents the BASIC programming language used by the ASCII Unit. Since many of the BASIC

are nonstandard and peculiar to an ASCII Unit-PC system, it

explains the

BASIC program. It also explains in detail how to write, edit, and run an assembly language program.

presents programming examples that are meant to bring together all of the concepts pres-

in this manual. Most of the programs deal with data transfer and illustrate

been put into one of the seven appendices and should be used for reference

parentheses

code is for CV-series PCs. For example, in MOV(21/030) (the MOVE instruction), the function

code for C-series PCs is 21; for CV-series PCs, 030.

assembly language programming environment and how it relates to the ASCII

following them. The first function code is for C-series PCs and the second function

manual completely and be sure you under

is recommended that even read

how the ASCII Unit and

when needed. For a list

-

-

!

WARNING Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section

and related sections before attempting any of the procedures or operations given.

in its entirety and be sure you understand the information provided

in the section

ix

Page 10

PRECAUTIONS

This section provides general precautions for using the Programmable Controller (PC) and related devices.

The

information contained in this section is important for the safe and r

this section and understand the information contained before attempting to set up or operate a PC system.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

eliable application of the PC. Y

ou must read

xi

Page 11

1 Intended Audience

This

manual is intended for the following personnel, who must also have knowl

edge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The

user must operate the product according to the performance specifications

described in the operation manuals.

Before

using the product under conditions which are

or applying the product to nuclear control systems, railroad systems, aviation

systems, vehicles, combustion systems, medical equipment, amusement

machines,

may

your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient

systems, machines, and equipment with double safety mechanisms.

This

Be

sure

manual close at hand for reference during operation.

safety equipment, and other systems, machines,

have a serious influence on lives and property if

for

manual provides

to read this manual before attempting to use the software and keep this

4Operating Environment Precautions

-

not described in the manual

and equipment that

used improperly

the systems, machines, and equipment, and be sure to provide the

information for programming and operating OMRON PCs.

, consult

WARNING It is extreme important that a PC and all PC Units be used for the specified

!

purpose

directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PC System to the abovementioned

applications.

and under the specified conditions, especially in applications that can

3 Safety Precautions

WARNING Do

!

WARNING Do not touch any of the terminals or terminal blocks while the power is being

!

WARNING Do

!

not attempt to take any Unit apart while the power is being supplied. Doing

may result in electric shock.

supplied. Doing so may result in electric shock.

not

attempt to disassemble, repair

may result in malfunction, fire, or electric shock.

, or modify any Units. Any attempt to do so

4 Operating Environment Precautions

Caution Do not operate the control system in the following locations:

!

so

xii

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified in

the specifications.

• Locations

ture.

subject to condensation as the result of severe changes in tempera

-

Page 12

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

5Application Precautions

Caution Take

!

Caution The

!

appropriate and suf

following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

operating environment of the PC system can

gevity

and reliability of the system. Improper operating environments can lead to

malfunction,

sure

that the operating environment is within the specified conditions at installa

tion and remains within the specified conditions during the life of the system.

failure,

5 Application Precautions

Observe the following precautions when using the PC system.

WARNING Always heed these precautions. Failure to abide by the following precautions

!

could lead to serious or possibly fatal injury.

• Always

necting to a ground of 100 Ω or less may result in electric shock.

• Always

lowing.

shock.

ground the system to 100 Ω or less when installing the Units. Not con

turn OFF the power supply to the PC before attempting any of the fol

Not turning OFF the power supply may result in malfunction or

• Mounting

ply Units, or any other Units.

• Assembling the Units.

• Setting DIP switches or rotary switches.

• Connecting cables or wiring the system.

• Connecting or disconnecting the connectors.

or dismounting I/O Units, CPU Units, Memory Units Power Sup

ficient countermeasures when installing systems in the

have a large ef

and other unforeseeable problems with the PC system. Be

fect on the lon

electric

-

-

-

-

-

Caution Failure

!

PC

cautions.

• Fail-safe measures must be taken by the customer to ensure safety in the

• Always use the power supply voltages specified in this manual. An incorrect

• Take

• Install

to abide by the following precautions could lead to faulty operation of the

or the system, or

of incorrect, missing, or abnormal signals caused by broken signal lines,

event

momentary power interruptions, or other causes.

voltage may result in malfunction or burning.

appropriate measures to ensure that the specified power with the rated

voltage

power

ing

result in burning.

and frequency is supplied. Be particularly careful in places where the

supply is unstable. An incorrect power supply may result in malfunction.

external breakers and take other safety measures against short-circuit

in external wiring. Insuf

could damage the PC or PC Units. Always heed these pre

ficient safety measures against short-circuiting may

-

-

xiii

Page 13

• Do not apply voltages to the Input Units in excess of the rated input voltage.

Excess voltages may result in burning.

• Do not apply voltages or connect loads to the Output Units in excess of the

maximum switching capacity. Excess voltage or loads may result in burning.

• Disconnect

tests.

• Be sure that all the mounting screws, terminal screws, and cable connector

screws

ing torque may result in malfunction.

• Leave

sult in malfunction if foreign matter enters the Unit.

• Remove

tion. Leaving the label attached may result in malfunction.

• Double-check

ply. Incorrect wiring may result in burning.

• Wire correctly. Incorrect wiring may result in burning.

• Mount Units only after checking terminal blocks and connectors completely.

• Be

sure that the terminal blocks, Memory

items with locking devices are properly locked into place. Improper locking

may result in malfunction.

• Check

Unit. Not checking the program may result in an unexpected operation.

• Confirm

the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Resume

the DM Area, HR Area, and other data required for resuming operation. Not

doing so may result in an unexpected operation.

• Do

not pull on the cables or bend the cables beyond their natural limit.

either of these may break the cables.

• Do

not place objects on top of the cables or other wiring lines. Doing so may

break the cables.

• Use

crimp terminals for wiring. Do not connect bare stranded wires directly to

terminals. Connection of bare stranded wires may result in burning.

• When

Not doing so may result in malfunction or burning.

• Before

to

discharge any

age.

the functional ground terminal when

Not disconnecting the functional ground terminal may result in burning.

are tightened to the torque specified

the label attached to

the label after the completion of wiring to ensure proper heat dissipa

all wiring and switch settings before turning ON the power sup

the user program for proper execution before actually running it on the

that no adverse ef

operation only after transferring to the new CPU Unit the contents of

replacing parts, be sure to confirm that the

touching a Unit, be sure to first touch a

static built-up. Not doing so may result in malfunction or dam

the Unit when wiring. Removing the label may re

fect will occur in the system before attempting any of

performing withstand voltage

in this manual. Incorrect tighten

Units, expansion cables, and other

Doing

rating of a new part is correct.

grounded metallic object in order

5Application Precautions

-

-

-

-

-

xiv

Page 14

SECTION 1

Hardware

This

section describes the external hardware of the ASCII Unit. The front and back panels of the ASCII Unit contain switches,

buttons,

Unit’s internal configuration as well as a typical system configuration are also illustrated.

connectors, and indicators which

1-1 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2

Back Panel

1-3 ASCII Unit Internal Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

enable the user to setup, control, and monitor ASCII Unit operations. The ASCII

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

Page 15

Front Panel Section 1-1

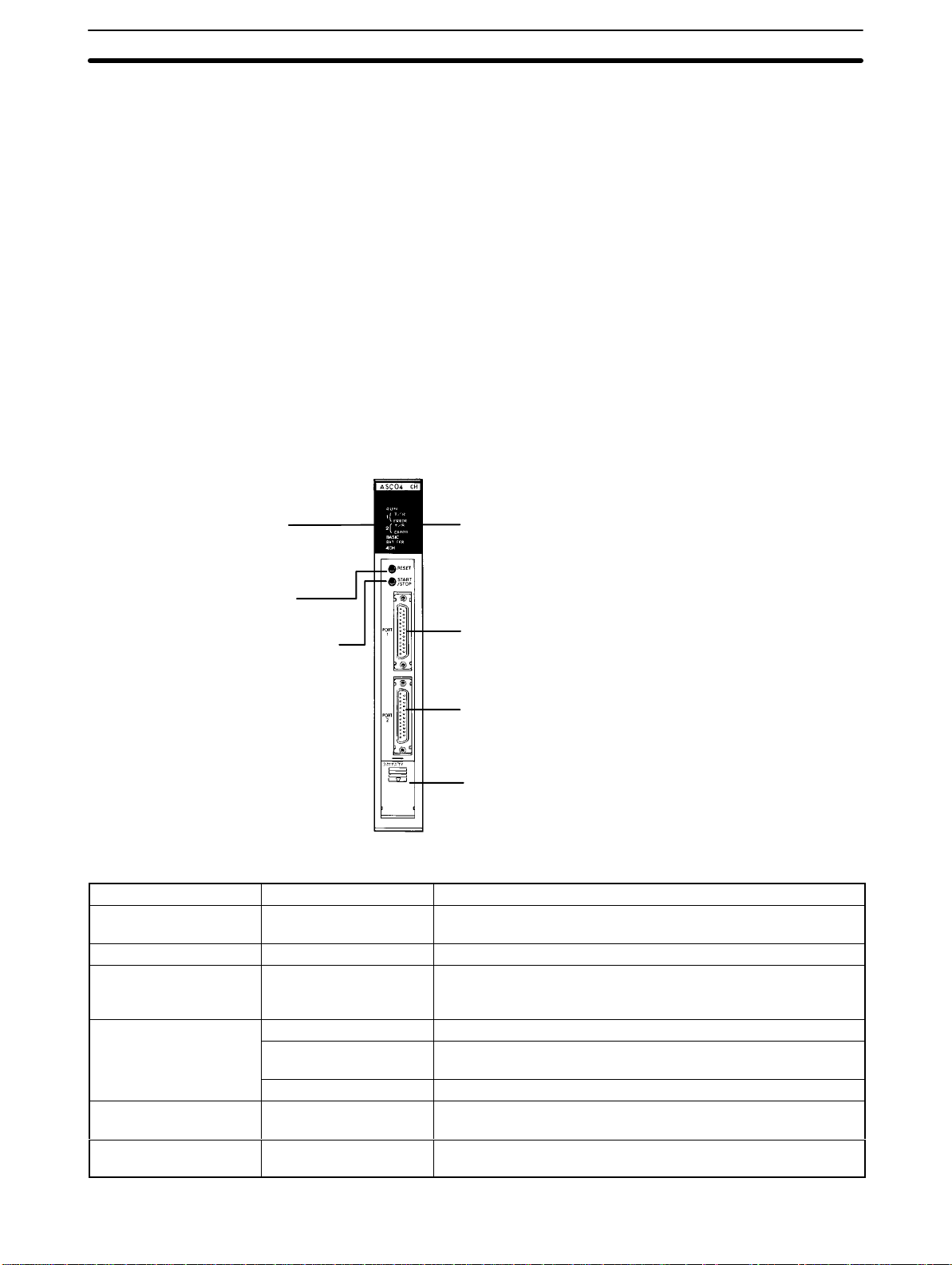

1-1 Front Panel

On the front panel of the ASCII Unit, there are six indicator lights, the reset

switch,

the ST

partment.

for setting various control parameters.

Ports The front panel of the ASCII Unit contains two RS-232C ports. These ports

are used for connecting peripheral I/O devices to the ASCII Unit. Both ports

can be used for communication devices such as printers, terminals, and modems. Only port 1 can be used for uploading or downloading a BASIC program. The standard configuration is a personal computer connected to port 1

and a printer or other I/O device connected to port 2.

Switches The START/STOP switch is a toggle switch and is used for initiating and halt-

ing execution of the ASCII Unit program.

RESET

The

Battery Compartment The battery compartment holds the C500-BAT08 Battery.

Front Panel

ART/ST

OP switch, two RS-232C

connectors, and a battery com

In addition, behind the LED Display Panel, is an 8-pin DIP switch used

switch is used for resetting the ASCII Unit.

-

LED display

Indicates the operating

status of the ASCII Unit.

RESET switch

Resets the ASCII Unit

START/STOP switch

Starts/stops BASIC

program execution.

Indicator LEDs

Name Indication Function

RUN Lit (green) Lit when the ASCII Unit is operating normally. Unlit if an error

T/R for ports 1 and 2 Blinking (green) Blinks during data transmission (port 1 and port 2).

ERROR 1 (port 1)

ERROR 2 (port 2)

BASIC

BAT ERR Blinking (red) Blinks when the battery voltage has fallen below the rated level or

4CH Lit (green) Lit when the ASCII Unit is set for 4-word mode. Unlit when the

Lit (red) Lit if a reception buffer overflows or an error such as parity error

Lit (green) Lit while the BASIC program is running.

Blinking (green) Blinks when the BASIC program stops, or when the ASCII Unit is

Unlit (green) Unlit when in monitor mode.

The following table describes the ASCII Unit’s indicators.

DIP switch

DIP switch is visible when the

indicator panel is removed.

RS-232C connector port 1

Connects peripheral devices. Is generally

used to input the BASIC program but can be

used for other peripheral devices as well.

RS-232C connector port 2

Connects peripheral devices. Cannot be

used to input a BASIC program. Is generally

used for a printer or other RS-232C devices.

Battery compartment

Holds the C500-BAT08 Battery.

occurs.

occurs (see note), or while the ASCII Unit is waiting for specific

transmission conditions to be satisfied.

waiting for input while the BASIC program is running.

if the battery is not inserted correctly.

ASCII Unit is set for 2-word mode.

2

Page 16

Front Panel Section 1-1

Front Panel DIP Switch

Note When

a reception buf

is

lit and will not be turned of

overflow

tor, execute the CLOSE instruction or stop the program.

In order to access the front panel DIP switch, the indicator cover must be removed

DIP

before

when mounting the ASCII Unit.

is corrected, because the error log must be kept. To turn of

with a standard screwdriver as shown in the illustration below

switch, the power

the ASCII Unit is mounted to the PC. Make sure the power to the PC is of

fer overflows or transmission error occurs, the red indicator

f even if the transmission error

to the ASCII Unit must be OFF

Standard

Screwdriver

. The DIP switch must be set

or reception buf

fer

f the indica

. T

o set the

-

f

3

Page 17

Front Panel Section 1-1

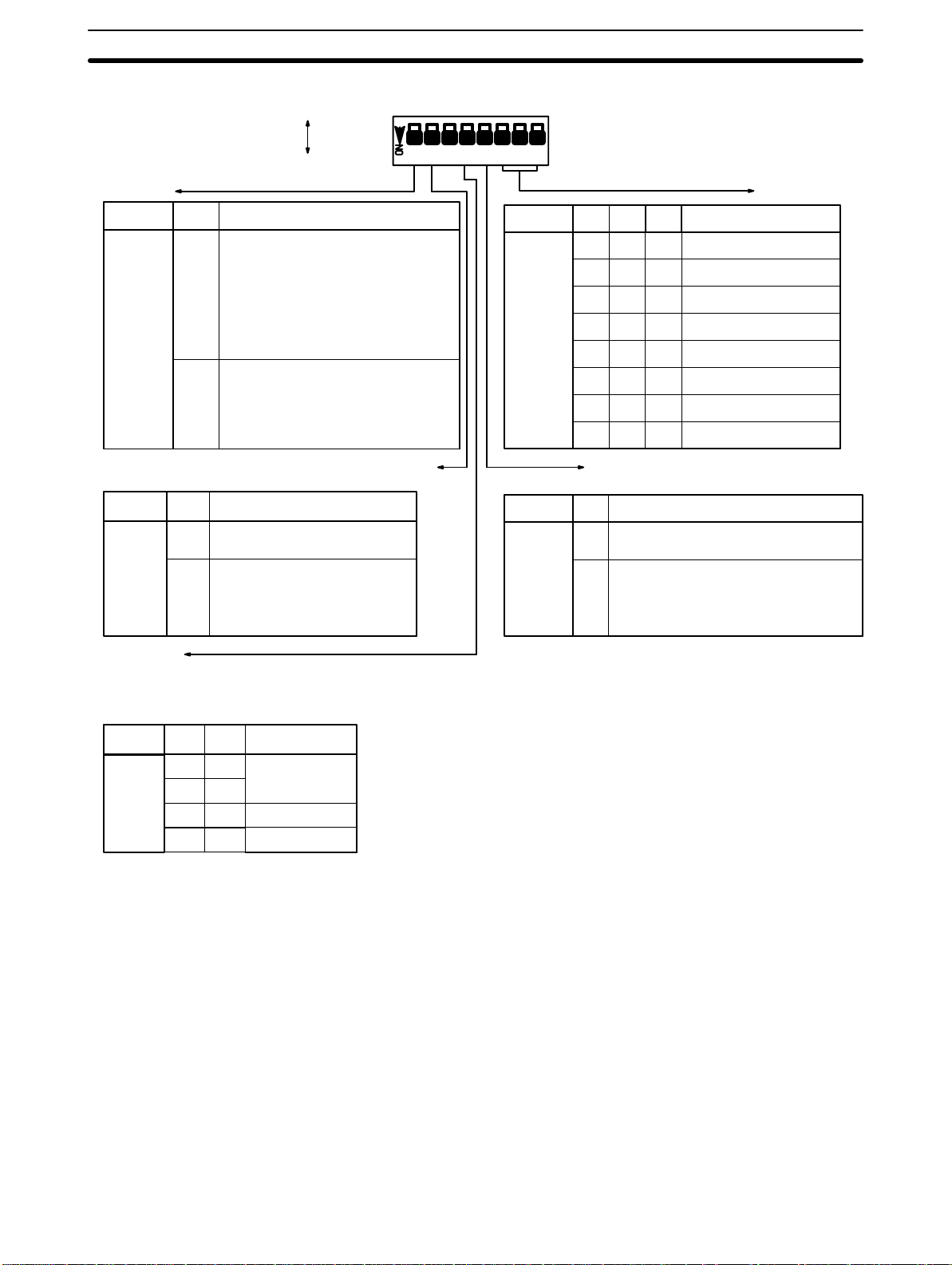

DIP Switch Settings

OFFON: 0

: 1

12345678

Start mode

Pin No. 1 Function

Setting

Automatic program transfer from EEPROM to RAM

Pin No. Function

Setting

0

1

Manual start mode

In this mode, the BASIC program is

not started upon power application.

0

To start the program, either press

the START/STOP switch or issue a

start command from the personal

computer connected to port 1.

Automatic start mode

In this mode, the BASIC program

1

is started automatically on power

application.

2

Set this pin to “0” if only the

RAM is to be used.

Set this pin to “1” to automatically transfer the program

from the EEPROM to RAM on

power application or reset.

Screen size

Pin No. Screen Size

Setting

Pin No. Function5

Setting

678

000

1

00

1

11

00

0

1

11

0

Specifies 2 or 4 word setting for

the Data Section.

Two word setting. Choose this setting

0

to use WRIT(87/191)/READ(88/190)

Four word setting. This setting is used

when the ASCII Unit is mounted to a

1

Slave Rack or when the PC does not

support WRIT(87/191)/READ(88/190).

40 columns x 7 lines

40 columns x 8 lines

40 columns x 15 lines

00

40 columns x 16 lines

0

80 columns x 15 lines

1

80 columns x 16 lines

1

80 columns x 24 lines

80 columns x 25 lines

111

Program No.

These pins select which program will be executed on power

application or reset. The program number can be changed

later with the PGEN command.

Pin No. Function34

Setting

00

10

01

11

No. 1

No. 2

No. 3

4

Page 18

Back Panel Section 1-2

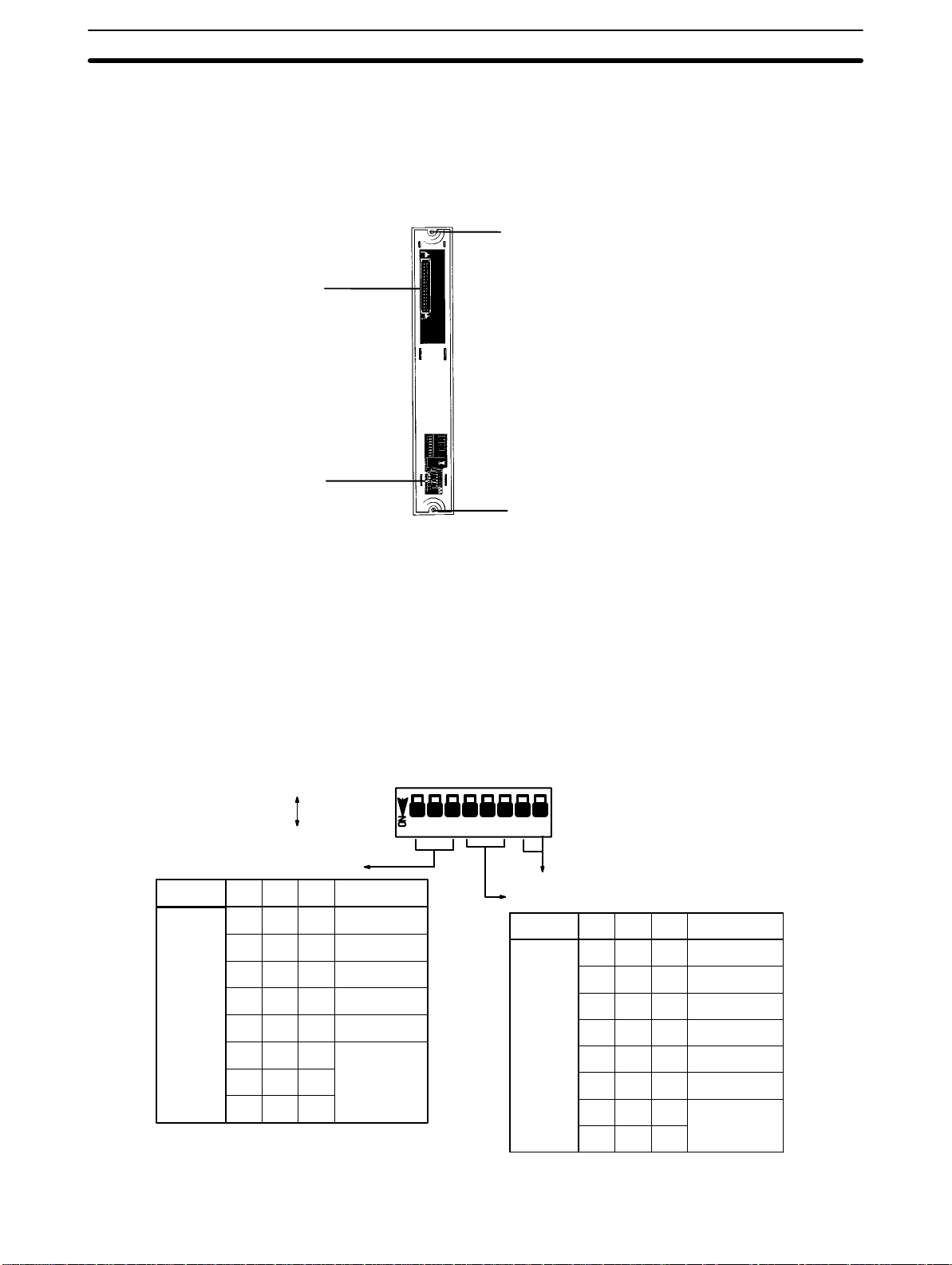

1-2 Back Panel

The back panel of the ASCII Unit houses the PC connector and an 8-pin DIP

switch used for setting the communication parameters.

Back Panel

Mounting Screw

For mounting the ASCII Unit

to the PC Rack

Connector

Connects the ASCII Unit

to the PC

DIP Switch

For setting the communication parameters

Mounting Screw

For mounting the ASCII Unit

to the PC Rack

Back Panel DIP Switch

Baud rate selection for port 1

Pin No.

Setting

123

000

1

1

0

• Pins 1, 2, and 3 are used for setting the baud rate of port 1.

• Pins 4, 5, and 6 are used for setting the baud rate of port 2.

• Pins

7 and 8 are not used but must be set to OFF

. If they are left ON, the Hard

ware Test program will be executed and all RAM data will be lost.

The DIP switch settings are described in more detail in the following diagram.

OFFON: 0

00

1

00

11

0

1

00

1

0

11

111

: 1

Baud Rate

300 bps

600 bps

1,200 bps

2,400 bps

4,800 bps

9,600 bps

12345678

Not used (Always set these pins to OFF.)

Baud rate selection for port 2

Pin No.

Setting

456

000

1

00

1

00

11

0

1

00

1

0

1

11

0

111

Baud Rate

300 bps

600 bps

1,200 bps

2,400 bps

4,800 bps

9,600 bps

19,200 bps

-

5

Page 19

ASCII Unit Internal Configuration Section 1-3

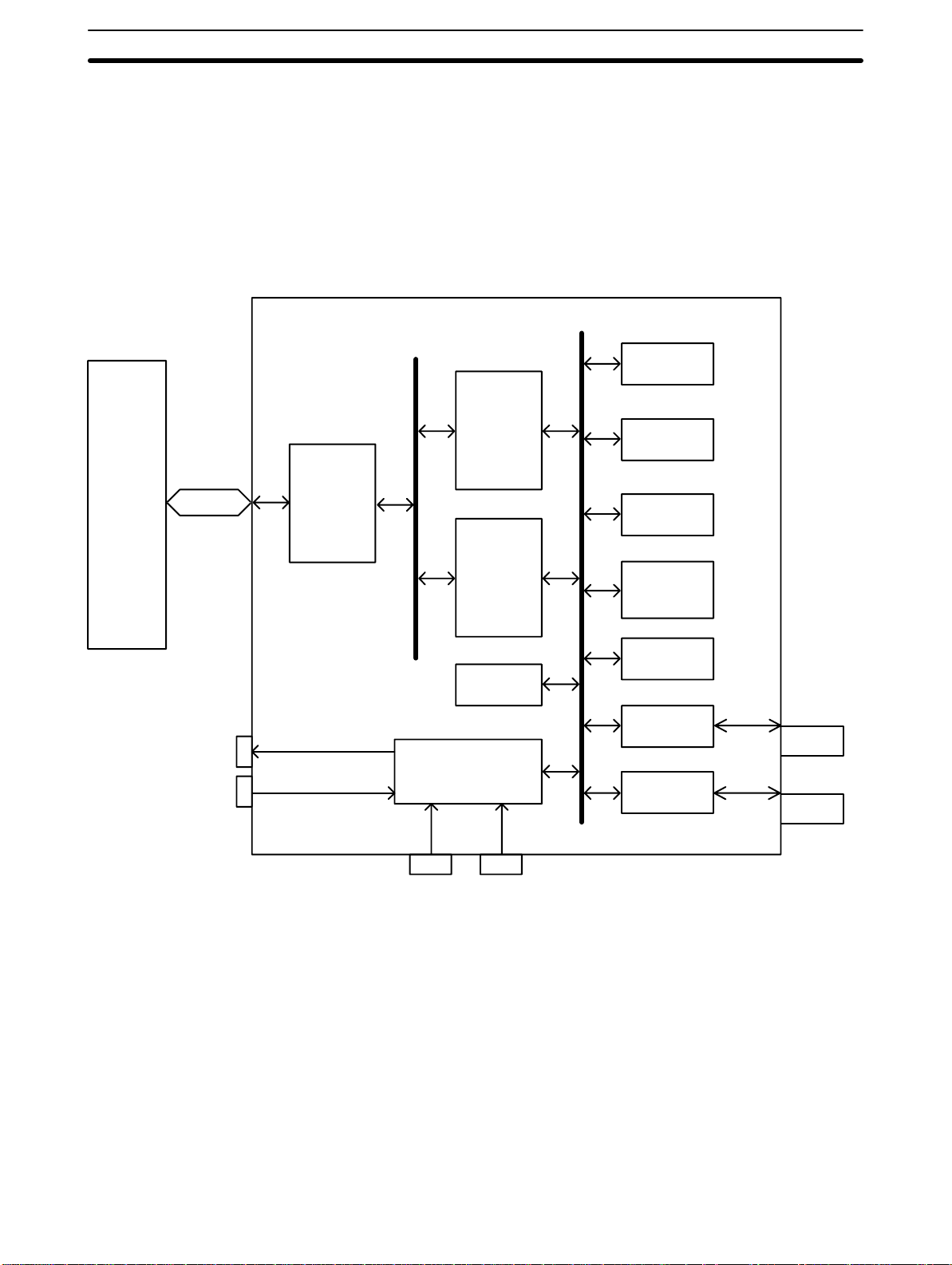

1-3 ASCII Unit Internal Configuration

The

Common Memory can be accessed using the ASCII Unit’

WRITE

READ(88/190)

statements. It can also be accessed using the PC’

instructions. I/O data can be accessed using the ASCII Unit’

GET, PC PUT, and ON PC statements. It can also be accessed using the

MOV(21/030) instruction.

The following figure illustrates these instructions and their relationship to the

Common Memory and the I/O data.

ASCII Unit

s PC READ or PC

s WRIT(87/191) and

s PC

PC

CPU

LED Indicators

DIP Switches

I/O Bus

Interface

Circuit

Common

Memory

Data

I/O

EEPROM

I/O

CPU

System

Memory

Work

Memory

BASIC

Program

Memory

BASIC Data

Memory

RS-232C

Interface

RS-232C

Interface

RS-232C

Port 1

Connectors

Port 2

RESET

START

/STOP

6

Page 20

Mounting Section 1-5

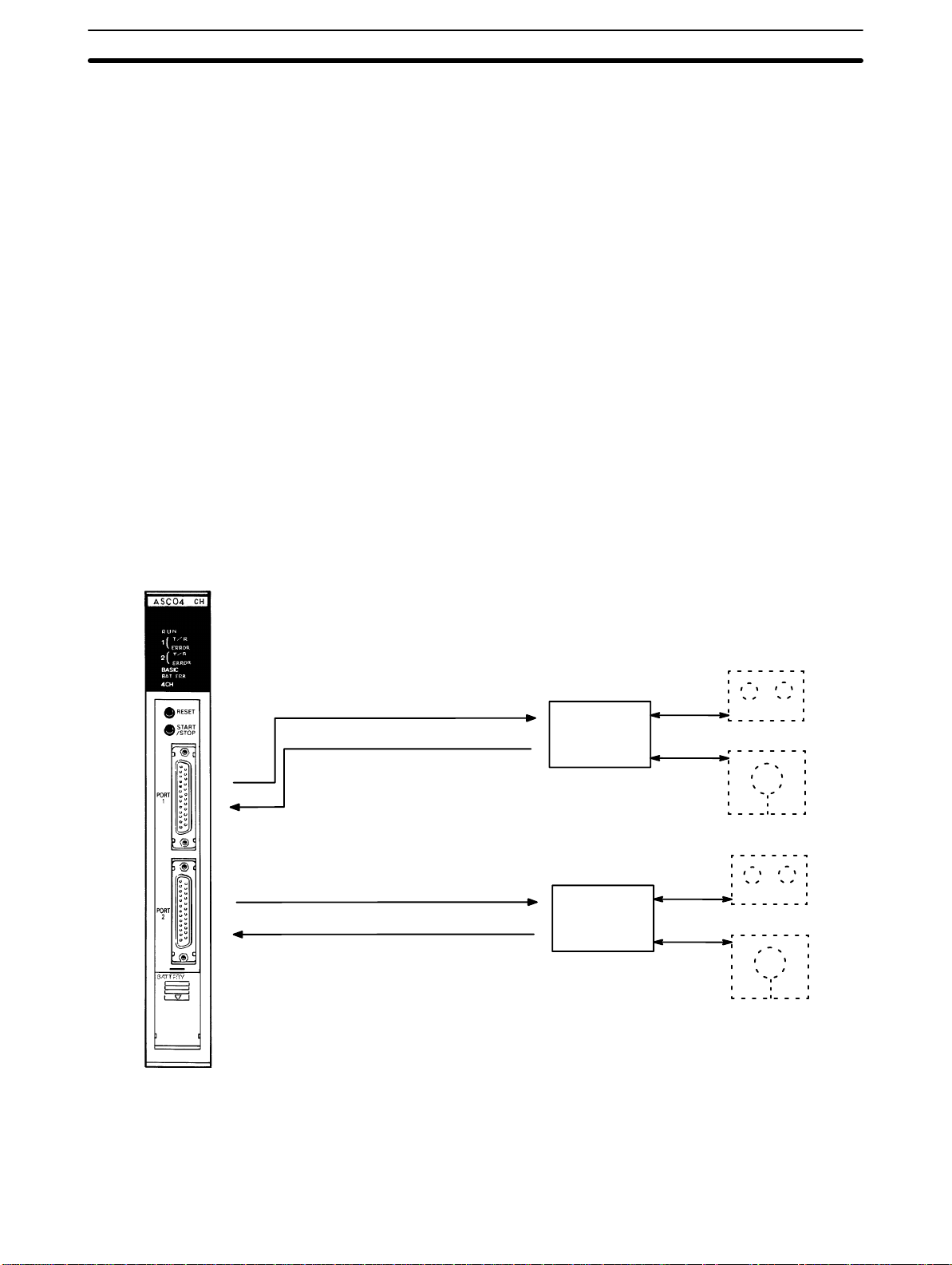

1-4 System Configuration

The ASCII Unit can be mounted to any slot on the CPU Backplane. Before

mounting

er

supply to the PC is turned OFF during installation of the ASCII Unit. A personal

computer

and

connected

tion on peripheral interface connections and timing, refer to

C500/C1000H/C2000H CV SeriesC120

the ASCII Unit, the DIP switches must be set. Make sure that the

used for entering the BASIC program should be connected to Port

other peripheral I/O devices such as a printer or a display terminal can be

to Port 2 (refer to the following diagram). For more detailed informa

Appendix B

C500

Expansion

I/O Rack

pow

.

-

1

-

1-5 Mounting

Personal Computer

The ASCII Unit can be mounted to any I/O slot. The control panel must allow

enough space for the connectors, as shown in the figure below.

Bar-code Reader

Plasma Display

*1. Height

*2. Height of the ASCII Unit with an RS-232C con-

of the ASCII Unit including the base (100

mm)

nector attached (approximately 160 to 180 mm)

Printer

7

Page 21

This section explains the words of the PC used to communicate with the ASCII Unit.

2-1

Bits and W

2-2 Data Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-1 Two-word Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-2 Four-Word Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

Data Allocations

9

Page 22

Data Configuration Section 2-2

2-1 Bits and Words

The

PC’

s memory is divided up into many sections, each of which has its own

unique name and purpose. The ASCII Unit can access any of these memory

using

areas

detail

IR data area that are uniquely assigned to each ASCII Unit.

The PC’s memory is organized into units called

stored in word or multiple word units. Each word has a unique address in the

computer memory and can be accessed by specifying its address.

Each

stored

one (OFF or ON). Certain bits can be accessed individually and are used as

flags.

computer or to enable or disable certain operations. Bits can also be set or

cleared

the

CPU.

For

example, when the ASCII Unit program requests data to be sent from the PC

using

that

the ASCII Unit must wait while the PC prepares the data. When the PC has

collected

proceed to read the data.

the BASIC READ and WRITE statements (this is explained in more

in

Section

word contains 16 bits. A bit is the smallest piece of information that can be

or accessed by a computer

A

flag

by the programmer to communicate certain parameters or conditions to

the BASIC GET statement, the PC’

the data,

4 BASIC Programming

is turned ON and OFF by the hardware to indicate some state of the

it turns ON the W

). However

. A bit is always

s W

rite Flag, signaling the ASCII Unit that it may

, there

are words in the PC’

words

. Information is usually

in one of two states: zero or

rite Flag is turned OFF

, indicating

s

2-2 Data Configuration

Each

ASCII Unit is assigned a section of memory in the PC. The data has two

configurations,

pin 5 of the front panel

setting

Unit.

The

basic dif

in

two-word mode the WRIT(87/191)/READ(88/190) instructions are supported

for

data transfer while in four-word mode they are not supported. The structure

and application of the words in each of the two modes is explained next.

2-2-1 Two-word Configuration

WRIT(87/191)

WRIT(87/191) is the PC’

I/O READ instruction.

When

the PC uses

can be transferred at one time. In order to transfer multiple data words at the

same

time, however

or PC WRITE statements. In addition the A or S formats

Appendix D

The following PCs support WRIT(87/191)/READ(88/190):

C500: 3G2C3-CPU11-EV1

C120: 3G2C4-SC024-EV1

All C1000H, C2000H, CV-series PCs.

When WRIT(87/191)/READ(88/190) are not supported or not used, data is

transferred

used, only one word of data is transferred at a time.

To output (word n) data using the MOV(21/030), set bits 00, 01, 02 and 03 to

zero.

for more information on formats.

using the PC’

two-word

ference between the two-word

and READ(88/190) are supported in the two-word configuration.

and

four-word

DIP switch before power is applied to the ASCII

s I/O WRITE instruction and READ(88/190)

these instructions for data transfer

, the ASCII

Unit must be programmed to use the PC READ

s MOV(21/030) instruction. When

. The data configuration is selected by

and four-word configurations is that

, up to 255 words of data

must be used. Refer to

is the PC’

the MOV(21/030) is

s

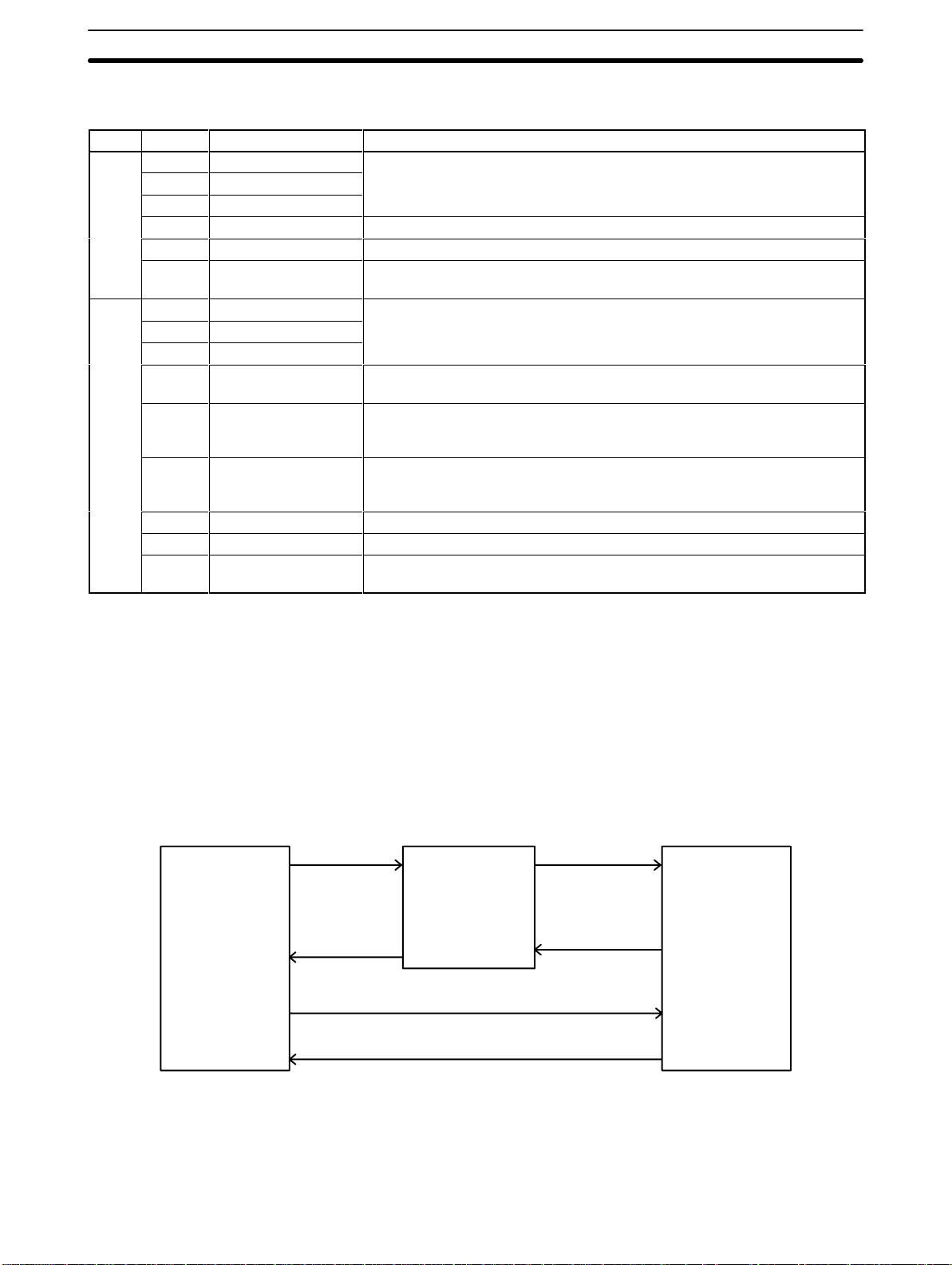

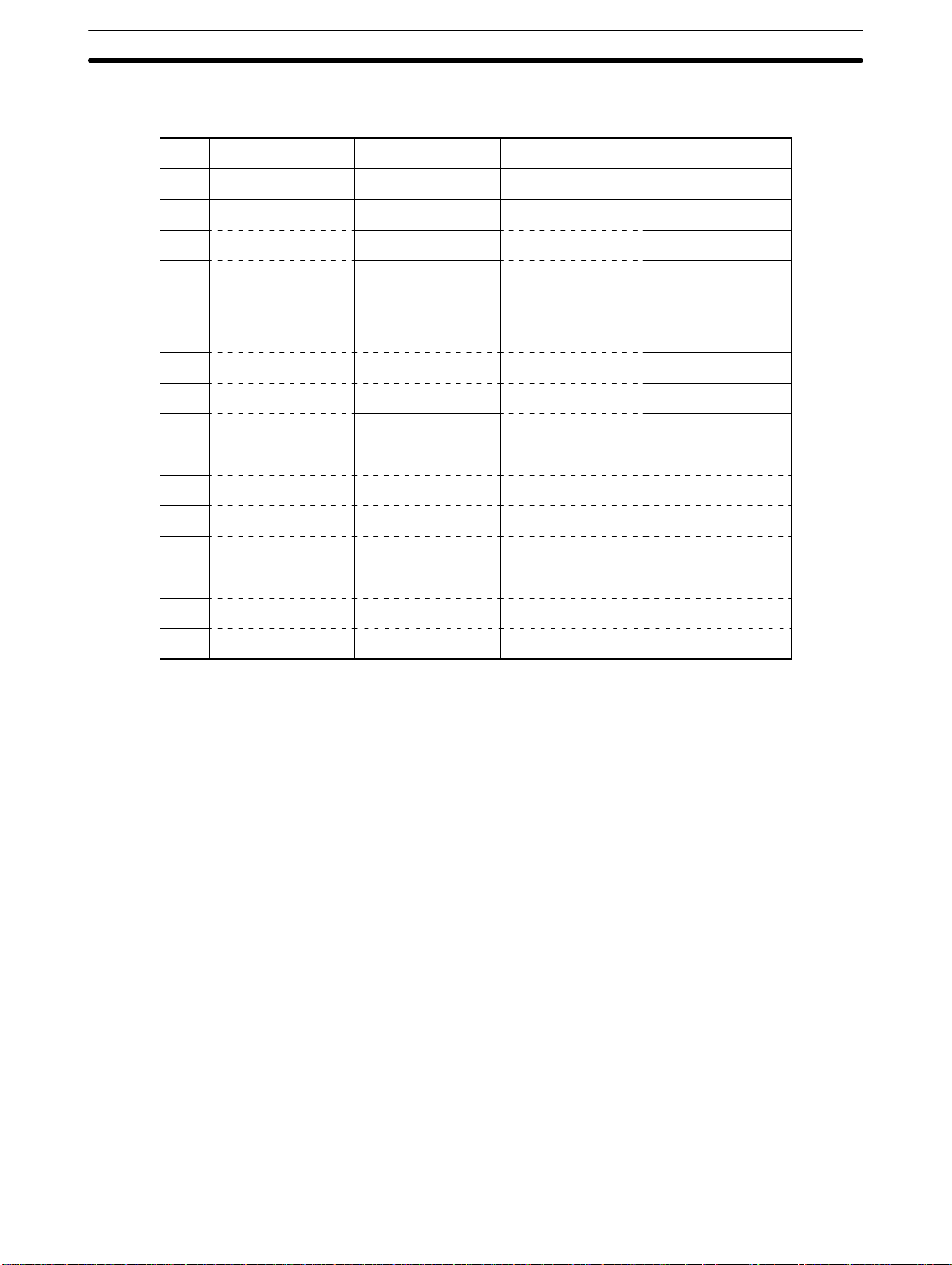

Data Bit Definitions

10

The

following table identifies the individual bits in the two words allocated to the

ASCII

Unit. In the following Bit Definition table, entries in the

Bit

column enclosed

Page 23

Data Configuration Section 2-2

in parentheses are reserved for use by WRIT(87/191)/READ(88/190) and are

not available for general programming application.

Word Bit Function Description

n (00) PC busy Reserved for WRIT(87/191)/READ(88/190)

(01) PC WRITE complete

(02) PC READ complete

03 Restart The ASCII Unit is activated when this bit goes OFF

04 to 07

08 to 15

n+1 (00) ASCII busy Reserved for WRIT(87/191)/READ(88/190)

(01) PC READ complete

(02) PC WRITE complete

03 ASCII error Turns ON when an error occurs in the ASCII Unit, when the RESET

04 Port 1 error Turns ON when a buffer overflows or transmission error occurs in Port 1.

05 Port 2 error Turns ON when a reception buffer overflows or transmission error occurs in

06 Battery error Turns ON when the battery is low or removed

07 BASIC RUN Turns ON when a BASIC program is running

08 to 15

--- Not Used

Output data bits 0 to7Data output from the PC to the ASCII Unit. Read by the PC GET statement.

activates, or when the ASCII Unit restarts.

Turns OFF when the CLOSE statement is executed or the program is

stopped.

Port 2. Turns OFF when the CLOSE statement is executed or the program is

stopped.

Input data bits 0 to 7 Data output from the ASCII Unit to the PC. Written by the PC PUT

statement.

Program Execution

PC

Application

Program

Note When

the reset switch is turned ON, the data in word n+1 will be $FFF9. Restart

ing can be checked using bit 03 of word n+1.

When the ASCII Unit is restarted, the data of word n+1 will be 0000.

following diagram illustrates how the words and bits allocated to the ASCII

The

Unit relate to program execution.

WRIT(87/191) is executed when the data communication condition for

WRIT(87/191)

is

satisfied and the ASCII busy flag is cleared. If these conditions

are not met, the WRIT(87/191) is treated as a NOP.

READ(88/190)

and

the ASCII busy flag and ASCII write

is executed when the data communication condition is

tions are not met, the READ(88/190) is treated as a NOP.

WRIT(87/191)

(n)

Common

Memory

READ(88/190)

(n+1)

MOV(21/030)/OUT Output Data

(n) 08 to 15

MOV(21/030)/LD/OR

(n+1) 08 to 15

Write Data in n

PC READ

Read data in n+1

PC WRITE

PC GET

Input Data PC PUT

complete flag are OFF

ASCII Unit

BASIC

Program

satisfied

. If these condi

-

-

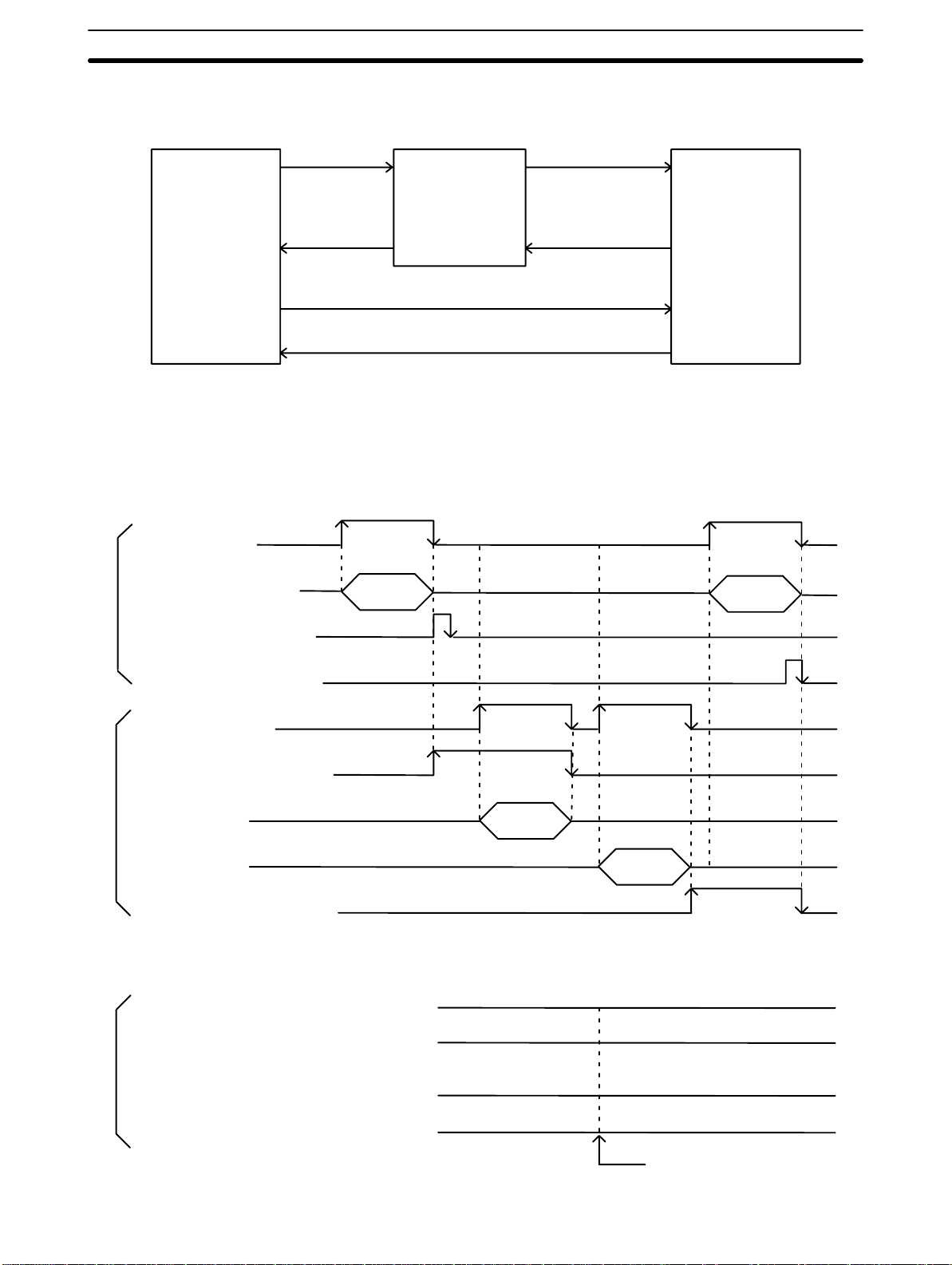

Timing

The WRIT(87/191) and READ(88/190) instructions are executed

and the com

mon memory is refreshed every time the PC completes one cycle of the program. I/O data, however, does not use the common memory (see above diagram) and is refreshed when the PC refreshes all the I/O data. Consequently

11

-

Page 24

Data Configuration Section 2-2

there

is a time dif

I/O

data is set. This time dif

paring both the ASCII Unit and PC programs.

ference between when common memory data is set and when

ference must be taken into consideration when pre

-

1 cycle

MOV(21/030) WRIT(87/191)

With WRIT(87/191)

Data set in common

memory

The following diagram illustrates the various timing relationships between the

PC and ASCII Unit during data transfer.

Relationship between READ and WRITE Timing

Application Program

PC busy: n (00)

Write/Read data: n or n+1

PC Unit

PC write complete: n (01)

PC read complete: n (02)

BASIC Program

ASCII busy n+1 (00)

↔ common memory

PC WRITE PC READ

PC

→ ASCII

I/O refresh

Output data set

ASCII

→ PC

time

ASCII read complete: n+1 (01)

Read data

common memory

data

Write

ASCII → common memory

ASCII write complete: n+1 (02)

→ ASCII

Relationship between Output and Input Timing

Output

data

PC → ASCII: n (08 to 15)

Input data

ASCII → PC: n+1 (08 to 15)

2-2-2 Four-Word Configuration

In four-word mode, WRIT(87/191) and READ(88/190) instructions cannot be

used.

The ASCII Unit can be

panel DIP switch to ON.

Bit Allocation The

following two tables identify the individual bits in the four words allocated to

the

ASCII Unit. Notice that words n and n+1 are used for output and words n+2

PC READ

PC → ASCII

ASCII → PC

set to four-word mode by setting pin 5 of the front

PC WRITE

PC → ASCII

ASCII → PC

I/O refresh

12

Page 25

Data Configuration Section 2-2

and n+3 are used for input. In this case, input and output are from the point of

view of the PC.

Bit Word n (OUT) Word n+1 (OUT) Word n+2 (IN) Word n+3 (IN)

00

Write Data 00 Read Data 00PC busy

01

Write Data 01

02

Write Data 02

Write Data 03

03

Write Data 04

04

Write Data 05

05

Write Data 06

06

Write Data 07

07

Write Data 08

08

Write Data 09

09

Write Data 10

10

Write Data 11

11

Write Data 12

12

Write Data 13

13

Write Data 14

14

Write Data 15

15

PC write complete

PC read complete

Restart

Interrupt No. 00

Interrupt No. 01

Interrupt No. 02

Interrupt No. 03

Output Data 00

Output Data 01

Output Data 02

Output Data 03

Output Data 04

Output Data 05

Output Data 06

Output Data 07

Read Data 01

Read Data 02

Read Data 03

Read Data 04

Read Data 05

Read Data 06

Read Data 07

Read Data 08

Read Data 09

Read Data 10

Read Data 11

Read Data 12

Read Data 13

Read Data 14

Read Data 15

ASCII busy

ASCII read complete

ASCII write complete

ASCII error

Port 1 error

Port 2 error

Battery error

BASIC RUN

Input Data 00

Input Data 01

Input Data 02

Input Data 03

Input Data 04

Input Data 05

Input Data 06

Input Data 07

13

Page 26

Data Configuration Section 2-2

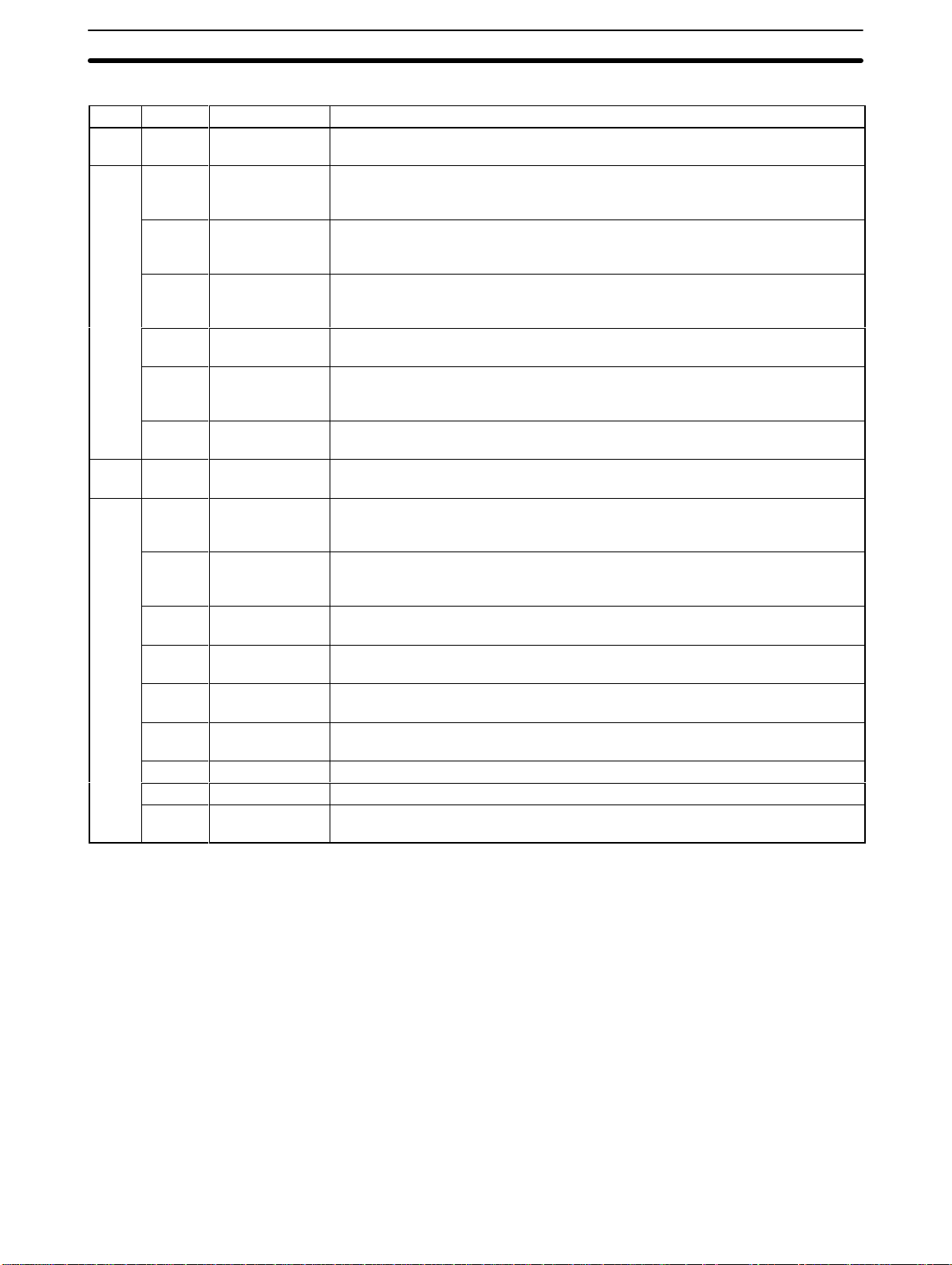

Bit Definitions

Word Bit Function Description

n 00

n+1 00 PC busy Set by the PC program when the PC accesses common memory, and cleared

n+2

n+3 00 ASCII busy Set when the ASCII Unit accesses the common memory and cleared when

to 15

01 PC write

02 PC read

03 Restart The ASCII Unit is activated at the trailing edge of this flag (when the flag goes

04 to 07

08 to 15

00 to 15

01 ASCII read

02 ASCII write

03 ASCII error Set when an ASCII Unit error occurs, when RESET is activated, or when the

04 Port 1 error Set when a reception buffer overflows or transmission error occurs at Port 1.

05 Port 2 error Set when a reception buffer overflows or transmission error occurs at Port 2.

06 Battery error Set when the battery is low or removed.

07 BASIC RUN Set when the BASIC program is running.

08 to 15

Write data bits

00 to 15

complete

complete

Interrupt number

bits 00 to 03

Output data bits

00 to 07

Read data bits

00 to 15

complete

complete

Input data bits

00 to 07

Data that will be written to the common memory from the PC by the MOV(21/030)

and read with the PC READ statement.

when memory access is terminated. The ASCII Unit cannot access the common

memory while this bit is set.

Momentarily set by the PC program when the PC has completed writing data to

the common memory. When this bit goes ON, the ASCII Unit read complete flag

n+3 (01) goes ON as well.

Momentarily set by the PC program when the PC has completed reading data

from the common memory. When this bit goes ON, the ASCII Unit write complete

flag n+3 (02) goes OFF as well.

OFF). A differentiated signal must be used for the Restart signal.

Serves as an interrupt number when the ON PC statement is used.When bits 00

to 03 are converted into hexadecimal 00 to 15, 00 is ignored and 01 to 15 are

used as valid interrupt numbers.

Data output from the PC to the ASCII Unit, written by the MOV and read with the

PC GET statement.

Data that will be written to the common memory from the ASCII Unit with the PC

WRITE statement and read with the MOV.

memory access is terminated. The PC cannot access common memory while this

bit is set.

Momentarily set when the PC write complete flag goes ON enabling the ASCII

Unit to read from common memory. This flag is cleared when the ASCII Unit

terminates the read operation.

Set at the time the ASCII Unit terminates a write operation to the common

memory and cleared when the PC read complete flag goes ON.

ASCII Unit restarts.

Turns OFF when the CLOSE statement is executed or the program is stopped.

Turns OFF when the CLOSE statement is executed or the program is stopped.

Data written with the PC PUT statement and read with the MOV.

14

Note 1. Apart

08

to 15 of word n+2 can be used for program control

ting the 8-bit data to the PC.

2. When

starting can be checked using bit 03 of word n+1.

When the ASCII Unit is restarted, the data of word n+1 will be 0000.

from the data used to

read bit 00 to 15 of word n+2, the input data of bit

of the PC by transmit

the reset switch is turned ON, the data in word n+1 will

be $FFF9. Re

-

-

Page 27

Data Configuration Section 2-2

The

Program Execution

following diagram illustrates how the words and bits allocated to the ASCII

Unit relate to program execution.

rite data in n

W

PC READ

Read data in n+2

PC WRITE

PC GET

ASCII Unit

BASIC

Program

PC

Application

Program

MOV(21/030)

MOV(21/030)

MOV/OUT Output Data

MOV/LD/OR

Common

Memory

n+1 08 to 15

Input Data PC PUT

n+3 08 to 15

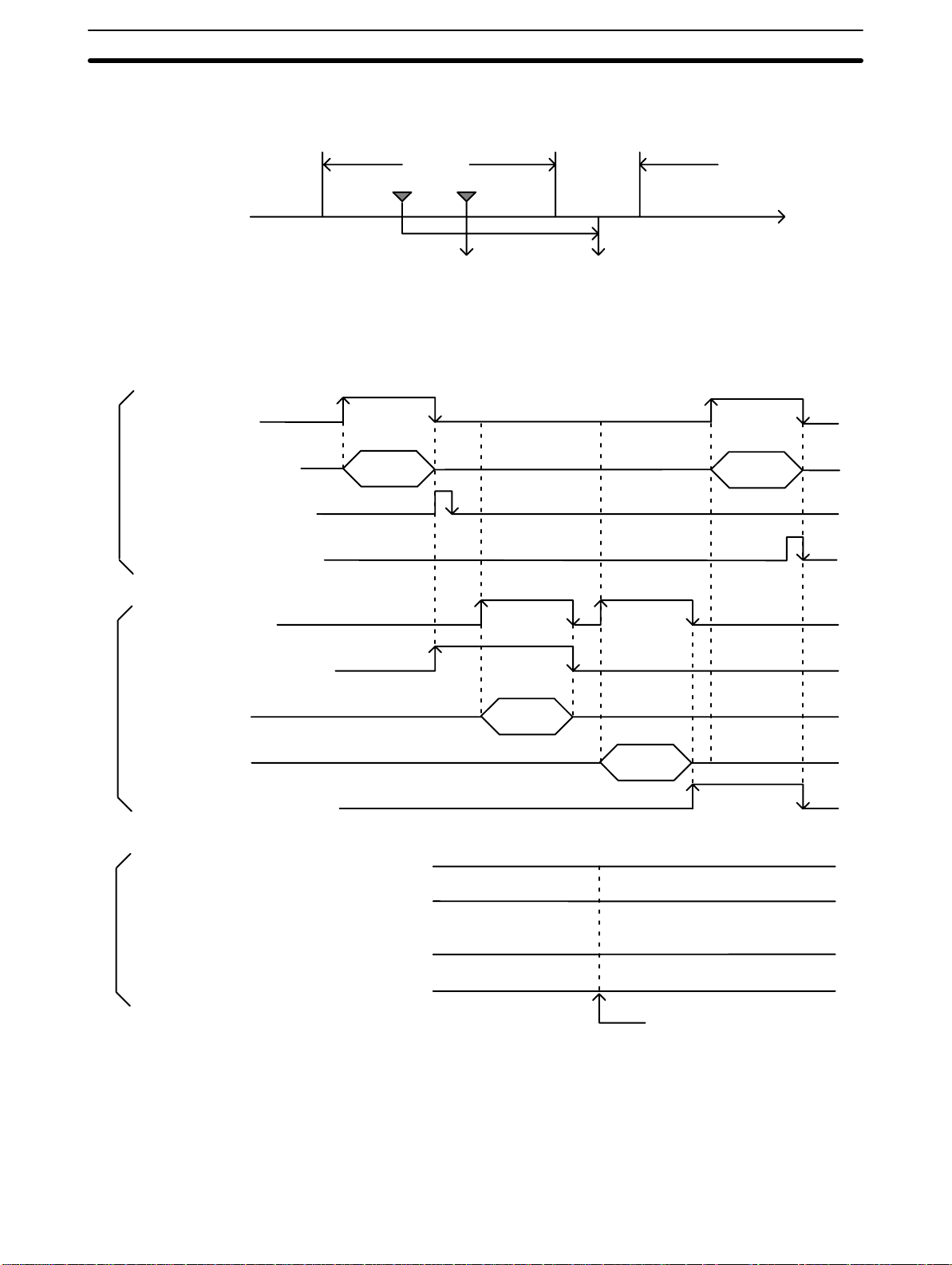

Timing The following diagram illustrates the various timing relationships between the

PC and ASCII Unit during data transfer.

Relationship between READ and WRITE Timing

Application program

PC busy: n+1 (00)

Write/Read data: n or n+2

PC Unit

PC write complete: n+1 (01)

↔ common memory

PC WRITE PC READ

PC

→ ASCII ASCII → PC

PC read complete: n+1 (02)

BASIC Program

ASCII busy n+3 (00)

ASCII read complete: n+3 (01)

Read data: n

common memory

Write data: n+2

→ common memory

ASCII

ASCII write complete: n+3 (02)

→ ASCII

Relationship between Output and Input Timing

Output

data

PC → ASCII: n+1 (08 to 15)

Input data

ASCII → PC: n+3 (08 to 15)

ASCII READ

PC READ

PC → ASCII

ASCII

→ PC

ASCII WRITE

PC WRITE

→ ASCII

PC

ASCII

→ PC

I/O refresh

15

Page 28

SECTION 3

Programming and Communications

The first part of this section explains how the ASCII Unit and the PC exchange information.

The

second part of this section explains how to transfer programs from one device to another

is written on a personal computer

gram

Unit

program can be permanently stored in the ASCII Unit’

also be transferred back to the personal computer or other storage device.

The last part of this section explains how to run a BASIC program once it has been transferred to the ASCII Unit.

3-1 Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Program Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Running the BASIC Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4

Assembly Routines

. T

o run the program, it must be transferred to the RAM of the ASCII Unit. The ASCII

s EEPROM and also loaded from the EEPROM. The program can

. The ASCII Unit’

s BASIC pro

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

17

Page 29

Program Transfer Section 3-2

3-1 Programs

To

use the ASCII

in

BASIC is needed. A data exchange routine must also be incorporated into the

PC program. The PC data exchange routine must set the number of words to be

transferred,

using the PC’s MOV(21/030) instruction.

There are two ways the ASCII Unit can communicate with the PC. In the first

method,

the PC controls the timing of the data transfer between

The ASCII Unit “requests” access to the PC data memory area using the PC

READ,

respond

performs

PC WRITE, PC GET

by setting either the read or write flag. The PC data exchange routine

the designated operations. When the PC is ready

is set and the ASCII Unit proceeds with the data transfer.

In the second method, the WRIT(87/191) and READ(88/190) instructions are

used

in conjunction with the PC READ, PC WRITE, PC GET

ments to transfer data.

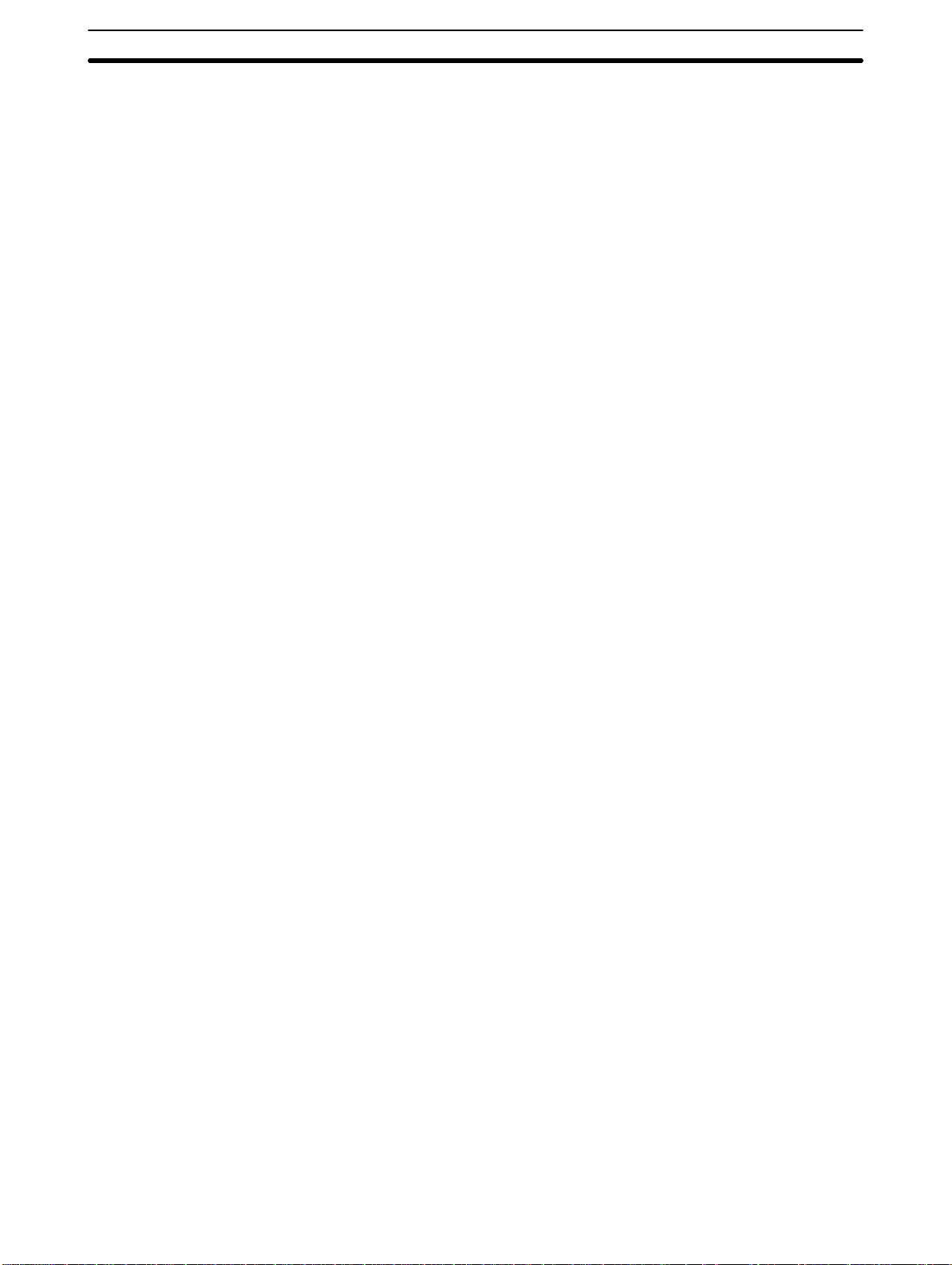

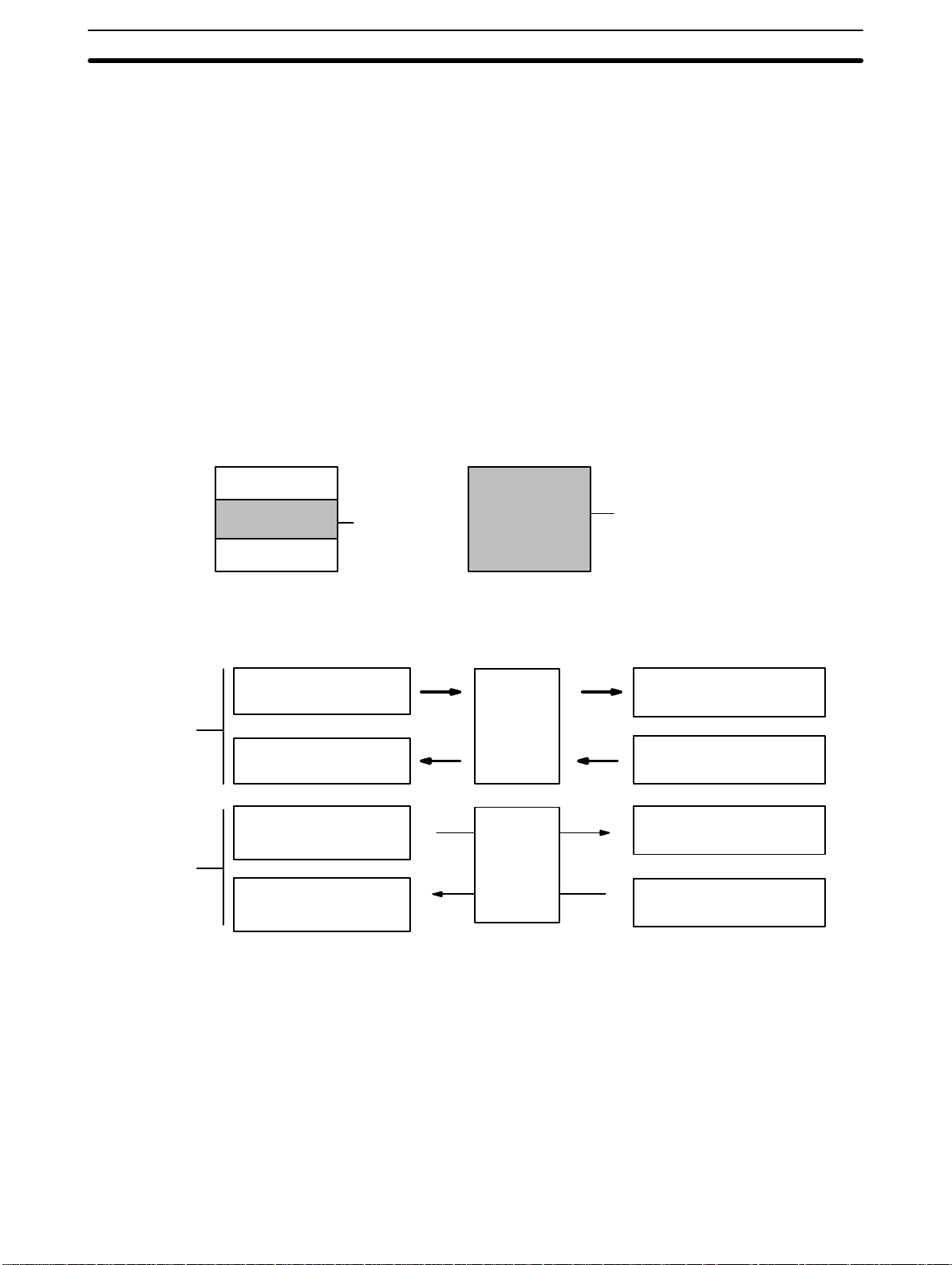

This diagram illustrates the PC and ASCII Unit programs.

Unit in conjunction with the PC, an ASCII Unit program written

the base address, and the specific memory area. This can be done

the two devices.

, or PC

PUT statements, and then waits for the PC to

, the appropriate flag

, and PC PUT

state

-

Write/read

data

exchange

I/O data

exchange

PC program

General Program

General Program

This diagram illustrates the relationship between the PC data exchange code

and the ASCII Unit program.

PC program

MOV(21/030)

MOV(21/030)

MOV(21/030), OUT, etc.

MOV(21/030), OUT, etc.

Data exchange

code

ASCII Unit program

Data exchange

processing or I/O

program

ASCII Unit program

PC READ command

Common

memory

PC WRITE command

PC GET command

I/O

memory

PC PUT command

3-2 Program Transfer

Preparation For

18

the personal computer to communicate with the ASCII Unit, set the comput

er communication software as follows:

Baud rate: same as ASCII Unit

Data length: 8 bits

Parity: none

No. stop bits: 2

Full duplex, no echo, no XON/XOFF buf

Also:

Set

the ASCII Unit DIP

Hardware

-

fer busy control, no auto line

switches to the desired configuration (refer to

feed.

Section

1

).

Page 30

Program Transfer Section 3-2

Transfer

The ASCII Unit’s BASIC or assembly language program must be written on a

personal computer which is connected to port 1 of the ASCII Unit through an

RS-232C

sonal

interface. A program can be transferred to the ASCII Unit from the per

computer or any other storage device connected to one of the communi

cation ports with the BASIC LOAD command or the S and L commands. Programs can also be transferred from the ASCII Unit’s EEPROM to the ASCII

Unit’s RAM using the LOAD command.

Programs

personal

can be transferred

computer or other storage device connected to one of the communica

from the ASCII Unit’

s RAM to the EEPROM or to a

tion ports using the BASIC SAVE command.

ASCII Unit can be booted on

The

power up by a program stored in the EEPROM.

To do this set pin 2 of the front panel DIP switch on the ASCII Unit to ON.

Note 1. During

data transfer

baud

rate settings of the computer and the

overflow

error does occur

, an overflow may occur if

, set either a slower baud rate or specify XON with

the buf

fering capacity of the

ASCII Unit are not matched. If an

the OPEN command.

2. Programs

executing

The

FIT or LSS can be used to back up BASIC programs onto

named with PNAME cannot be transferred. Delete the name

PNAME “ ” if necessary before attempting to transfer a program.

floppy disks, con

sult the FIT or LSS Operation Manual.

The following figure illustrates the direction of data transfer when using the

SAVE and LOAD commands.

-

-

-

by

-

SAVE #1, “COMU:”

LOAD #1, “COMU:”

SAVE #2, “COMU:”

LOAD #2, “COMU:”

Note 1. The

Refer to the explanation of the OPEN statement for details on

2.

COMU.

EEPROM’

(1)

Computer or

other peripheral device

(2)

Computer or

other peripheral device

sn lifetime is limited to 5,000 write operations.

19

Page 31

Assembly Routines Section 3-4

3-3 Running the BASIC Program

The ASCII Unit can store and access three separate BASIC programs. Each

program

gram

be done before the Unit is activated.

There are three ways to execute the specified BASIC program:

• Enter

• Press the START/STOP switch. Press it again to stop the program.

• If

has an associated program number

is to be used by setting pins 3 and 4 of the front panel DIP switch. This must

the RUN

in CTRL+X will abort the program.)

pin 1 of the front panel DIP switch is set

gram will be executed automatically when the Unit is turned ON or reset.

command from the keyboard of the personal computer

. The user can specify which pro

. (Keying

to the ON position, the specified pro

3-4 Assembly Routines

Use

the

monitor mode of the ASCII Unit for writing assembly language routines

to execute operations that cannot be processed with BASIC programs. The

ASCII Unit incorporates the Hitachi HD6303 CPU.

Assembly language routines can be written for the ASCII Unit and called from

the BASIC program with the USR statement. An assembly program can be

saved

to the

personal computer with the S command and loaded from the per

sonal computer with the L command. Assembly programs are stored in the S

format.

-

-

-

20

Page 32

SECTION 4

BASIC Programming

This

section contains an explanation of the terminology

on

the ASCII Unit. Even those familiar with BASIC should study this section carefully as many of the ASCII Unit BASIC

commands,

attention to the explanations of statements

cial

statements, and functions are non-standard, especially those that control I/O operations. Readers should pay spe

that are prefixed with “PC.” Also pay special attention to the OPEN statement.

4-1 Program Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2

Commands, Statements, and Functions

4-2-1 BASIC Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2-2 Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2-3

4-2-4

4-2-5 Arithmetic Operation Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2-6 Character String Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2-7

General Statements

Device Control Statements

Special Functions

, components, structure, and use of the BASIC programming language

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

21

Page 33

Program Configuration Section 4-1

4-1 Program Configuration

A BASIC program consists of commands, statements, and functions.

General statement

Statement

Device control statement

BASIC

Language

Command

Arithmetic operation function

Lines and Statements

Function

Basic

Statements

used

in

program lines within a program. Statements are usually created as pro

grams and executed by the RUN command. Statements can be directly input

and executed from the keyboard.

Commands

Basic

ations

external to the program such as printing and listing. Commands must be

directly

into programs and executed

into programs and executed, the commands may not work properly.

Examples: print, list, run

Functions are self-contained programs which accept one or more arguments,

perform predefined calculations, and return a result(s). There are predefined

BASIC functions for arithmetic and string operations as well as user defined

functions.

Examples: INT(x), LOG(x), SQR(x)

A

more

separated

quote marks (’) to separate comments.

Example of four statements on a line:

10 FOR L=1 TO 100: J=L*I: PRINT J: NEXT L

input and executed from the keyboard. Commands cannot be inserted

program written in BASIC is a series of lines, each of which consists of one or

statements. If several statement are written on the same line, they must be

with colons(:). A line can be no longer than 255

designate and control

are

Character string function

Special function

the flow of programs and are generally

usually entered from the command line and control oper

by

the RUN command. If commands are inserted

characters. Use single

-

-

Line Numbers Every

Character Set The

BASIC program line begins with

order

in which the program

erences for branching and editing. Line numbers must be in the range of 0 to

63999.

refer to the current line.

Examples: LIST. EDIT. AUTO DEL 100–

acters, and special characters.

The

the alphabet. The numeric characters in BASIC are the digits 0 through 9.

The following special characters are recognized by BASIC:

SP (space) ! ” # $ & ’ ( ) * + , – . / : ; < = > ? [ \ } ^ _

A period may be used in AUT

BASIC character set is comprised

alphabetic characters in BASIC are the upper case and lower case letters of

lines are stored in memory and are also used as ref

a line number

O, DELETE, EDIT

of alphabetical characters, numeric char

Constants The following can be used as constants:

22

. Line numbers indicate the

-

, and LIST commands to

-

Page 34

Program Configuration Section 4-1

Constants Character

A

Character Constants

Integers Constants

character constant is a

(”).

It can be up to 255 characters long. If it has no character

character string” or a null string.

Example: “CF-BASIC”

Whole

sign (%) can be added to specifically indicate an integer constant. Integer con

stants do not have decimal points.

Examples: 1234 –1234 12

Octal Constants Octal

to &177777 can be used.

Examples: &0127 &7777

Hexadecimal

Constants

Hexadecimal

in the range &H0000 to &HFFFF can be used.

Examples:

Numeric Integer

Real Number

character string enclosed by double quotation marks

numbers between –32768 and 32767 can be used.

numbers from 0 to 7 beginning with the prefix “&” and within the range of &0

numbers with the prefix “&H”, from

&H5E &HBF4

Decimal

Octal

Hexadecimal

Single-precision

Double-precision

, it is called an “empty

An optional percent

-

0 to F (0 to 9,A,B,C,D,E,F) and

Floating Point

Constants

1, 2, 3...

1, 2, 3...

precision: This type of constant is stored with seven-digit

output as a six-digit constant with

by one of the following methods:

1. As a number with seven or less digits: 1234.5

2. As a number in exponential form using E: 1.2E+3

3. As a number with the character “!” at the end: 2.34!

Double precision: This type of constant is stored with 16-digit precision and is

output as 16 digits or less. It is represented by one of the following methods:

1. As a number with 8 or more valid digits: 1.23456789

2. As a number in exponential form using D: –1.2D–3

3. As a number with the character “#” at the end: 2.34#

the

seventh digit rounded of

precision and is

f. It is represented

Single

Variables Variables are names used to represent values that are used in a BASIC pro-

gram. The value of a variable may be assigned as the result of calculations or

explicitly by the programmer with an assignment statement. If no value is assigned

Variable Name A

Note A

to a numeric variable, it is assumed to

character variable, it is assumed to be a null string.

variable may be up to 255 alphanumeric characters long, but only the first 16

characters are actually valid. No variable can start with “FN” or a valid BASIC

command name.

syntax error will occur if a variable begins with a reserved word (i.e., in the case

of TOT

AL or ABSOL, a syntax error will occur because T

words).

be zero. If no value is assigned to a

O and ABS are reserved

Type Declarator The

is placed after the variable name. Even if two variables have the same name,

they

Integer: Uses 2 bytes per variable.

variable TYPE must be declared. This is done using a type declarator

will be treated dif

ferently if they are declared as dif

ferent types of variables.

which

23

Page 35

Program Configuration Section 4-1

! Single-precision real: Uses 4 bytes per variable.

# Double-precision real: Uses 8 bytes per variable.

$ Character: Uses a maximum of 255 characters.

There is a second way to declare variable types. The BASIC statements DE-

FINT, DEFSTR, DEFSNG, and DEFDBL may be used to declare the types for

certain variable names.

Variable Array An

array is a group of values of the same TYPE that is

unit

by the same variable name. Each element in an array has

and

is referenced by the name of the array subscripted with an integer or

expression.

There

can be many dimensions to an array

two,

and three dimensional

sion in the array.

For example, T(4) would reference the fourth element in the one-dimensional

array T. R(2,3) would reference the value located in the second row and third

column of the two-dimensional array R.

maximum number of

The

of

elements per dimension is 32767. The array

must be declared with

of the first element

tion

TYPE.

arrays. An array has one subscript for each dimen

dimensions of an array is 255. The maximum number

the

DIM statement. The subscript value zero is the posi

in an array

. All elements of an array must be of the same

. The most common types are one,

stored and referenced as a

a unique position

integer

size and number of dimensions

Type Conversion When necessary, BASIC will convert a numeric constant from one TYPE to

another. The following rules and examples apply:

1, 2, 3...

1. If

the numeric data on

the

type of data on the

However,

sa.

Example: A = 12.3: if A is an integer then, “12” is assigned to A.

2. Double-precision

to a single-precision variable.

Example:

IF “A” is a single-precision variable and the statement:

LET

verted to a single-precision number and then assigned to “A.”

3. When

double-precision values, the single-precision value is converted to

double-precision first, and then the operation is performed. Therefore, the

result is a double-precision value.

Example: 0#/3 (double-precision)

4. In

logic operations, all numeric data is first converted into integer data. If any

value cannot be converted into an integer within the range of –32768 to

32767, an error will occur.

Example: LET A = NOT 12.34, –13 is assigned as A.

5. When

the decimal point is rounded off.

Example: A = 12.3: “12” is assigned to A.

character data cannot be converted to numerical data, or vice ver

A = 12.3456789# occurs in a program, then 12.3456789# will be con

an arithmetic operation is performed using both single-precision

a real number is converted into an integer

the right side of an assignment statement dif

left side, the right side is converted to match the left.

data is converted to single-precision data when assigned

, everything to the right of

fers from

and

-

-

-

-

Expressions Expressions refer to constants, variables, and functions that have been com-

bined by operators. Numeric values, variables, or characters alone can also

form expressions. There are four types of expressions:

• Arithmetic

24

Page 36

Program Configuration Section 4-1

• Relational

• Logical

• Character

Of

these,

the first three produce numeric values as a result, and are thus called,

“numeric expressions.” The last type is called a “character expression.”

An

Arithmetic Operators

Arithmetic Operator Example Operation

arithmetic expression is made up of constants, variables, and functions com

using arithmetic operators. A list of valid arithmetic operators is shown

bined

the following table.

in

-

+

–

*

/

\

MOD

^

Relational Operators

Relational Operator Example Operation

=

<>,><

A + B

A – B, –A

A * B

A / B

A \ B

A MOD B

A ^ B

Note If A or B is a real number in an expression using the \ or MOD operator

mal

part is first rounded up to convert the real number into an integer, and then

Addition

Subtraction or negation

Multiplication

Real number division

Integer division

Remainder after integer division

Exponentiation

, the deci

the operation is performed.

Relational

operators

compare two values. The output is “–1” (&HFFFF) if the two

values are equal and “0” if they are not.

A = B

A <> B

Equal

Not equal

-

<

>

≤

≥

Character Operator A

character expression is made up of character constants and variables that are

linked with the character operator

“+” operator links the characters together to form one character value.

Input: A$=“CF” B$=“BASIC” PRINT A$+“–”+B$

Output: “CF–BASIC” is displayed.

Logical Operators Logical

ean

operations. The logical operator returns a bit result which is either “true”

0)

or

“false” (0). In an expression, logical operations are performed after arithme

and relational operations. The outcome of a logical operation is determined

tic

A < B

A > B

A

≤ B

A

≥ B

Less than

Greater than

Less than or equal to

Greater than or equal to

“+”. Instead of adding characters together

, the

Operators perform tests on multiple relations, bit manipulation, or bool

(not

25

-

-

Page 37

Program Configuration Section 4-1

as shown in the following table. The operators are listed in the order of precedence.

Logical Operator Description, Example, and Result

NOT (negation)

AND (logical product)

OR (logical sum)

XOR (exclusive-OR)

A

1

0

A B A AND B

1 1

1 0

0 1

0 0

A B A OR B

1 1

1 0

0 1

0 0

A B A XOR B

1 1

1 0

0 1

0 0

NOT A

0

1

1

0

0

0

1

1

1

0

0

1

1

0

IMP (implication)

EQV (equivalence)

A B A IMP B

1 1

1 0

0 1

0 0

A B A EQV B

1 1

1 0

0 1

0 0

1

0

1

1

1

0

0

1

Operator Priority Arithmetic and logical operations are performed in the following order. Note,

however, that an expression or function enclosed by parentheses is executed

first, irrespective of operator priority.

1. ^ (exponentiation) 8. NOT

2. – (negation) 9. AND

3.

4. \ 11. XOR

5. MOD 12. EQV

6. +. – 13. IMP

7. Relational operators

*, /

10. OR

26

Page 38

Commands, Statements, and Functions Section 4-2

Calculation Examples of Logical Expressions

NOT (negation)

A =1= 0000000000000001

NOT 1 = 1111111111111110 = –2

NOT A = –2

AND (logical product)

A = 5 = 0000000000000101

B = 6 = 0000000000000110

A AND B = 0000000000000100 = 4

OR (logical sum)

A = 4 = 0000000000000100

B = 3 = 0000000000000011

A OR B = 0000000000000111 = 7

XOR (exclusive OR)

A = –4 = 1111111111111100

B = 5 = 0000000000000101

A XOR B = 1

EQV (equivalent)

A = –4 =1111111111111100

B = 5 = 0000000000000101

A EQV B = 0000000000000110 = 6

IMP (implication)

A = –4 = 1111111111111100

B = 5 = 0000000000000101

A IMP B = 0000000000000111 = 7

111111111111001 = –7

4-2 Commands, Statements, and Functions

This section explains, in detail, the BASIC commands, statements and functions.

They are presented in alphabetical order by section. Each description is

formatted as described below.

4-2-1 BASIC Format

Purpose: Explains the purpose or use of the instruction

Format: Shows the correct format for the instruction

The following rules apply to the format descriptions of all commands, instructions, and functions:

• Items in CAPITAL LETTERS must be input as shown.

• Items

• Items in square brackets ([ ]) are optional.

• All punctuation marks except angle and square brackets (i.e., comas, hy-

• Arguments to functions are always enclosed in parentheses. In the formats

in lower case letters enclosed in angle brackets (< >) are to be supplied

by the user.

phens, semicolons, parentheses, and equal signs) must be included where

shown.

for the functions in this chapter

given

follows: