Page 1

CS1 Series, C200HX/HG/HE, C200HS, C200H

C200HW-NC113, C200HW-NC213, and C200HW-NC413

Position Control Unit

Specification Sheets

Page 2

1

“Programmable Controller” is abbreviated as “PC” in these

Specification Sheets.

CS1 Series, C200HX/HG/HE, C200HS, C200H

Position Control Unit

C200HW-NC113, C200HW-NC213, and C200HW-NC413

C200H Special I/O Unit

One-axis, Two-axis, and Four-axis

Postion Control Units Capable of

Memory Operation or Direct Operation

The C200HW-NC113, C200HW-NC213, and

C200HW-NC413 are one-axis, two-axis, and

four-axis Position Control Units for the CS1-Series,

C200HX/HG/HE, C200HS, and C200H PCs. These

Units receive instructions from the CPU Unit and

output pulses to various motor drivers for

positioning.

Features

Memory Operation and Direct Operation

Operation can be controlled through memory operation, where data for positioning is transferred to the

Position Control Unit and then specified for position

control,

or through direct operation,

where target posi

tions and speeds are set each time from the CPU Unit.

Combining

these methods is also possible, allowing a

Position Control Unit to perform flexible positioning

operations ranging from easy to complicated.

Memory Operation

Position Control Unit

Position data

Speed data

CPU Unit

Data transfer bits

Start sequence No.

specification

Direct Operation

Data transfer bits

Position data

Speed data

Direct start

command

CPU Unit

Position Control Unit

Various Basis Functions

The C200HW-NC113, C200HW-MC213, and C200HW-413 support

various basic functions, such

as origin searches, interrupt feed

ing, speed controls, jogging, teaching, overrides (speed coefficients), backlash compensation, present position changes, zone

settings,

and deceleration stops.

Enhanced Functions

The C200HW-NC113, C200HW-MC213, and C200HW-413 support the following functions that the previous models (C200HNC211

and C200H-NC1

12) do not support.

•

Direct operation is possible.

• S-curve acceleration/declaration is possible in addition to

trapezoidal

acceleration/declaration.

•

Speed control is possible.

•

Backlash compensation speed can be specified.

• Forced intervention is possible (specified position data can be

forcibly

executed).

•

Flash memory operation is possible.

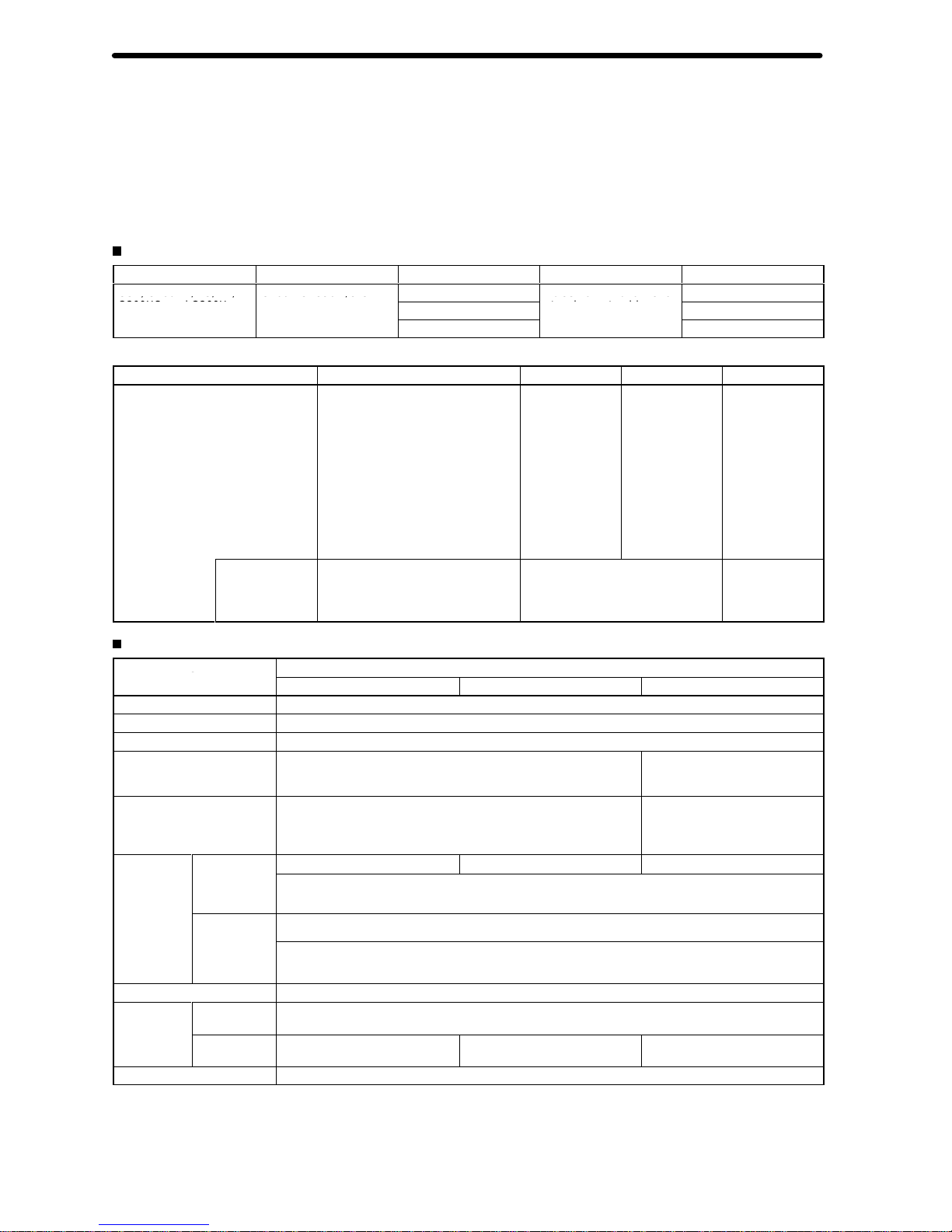

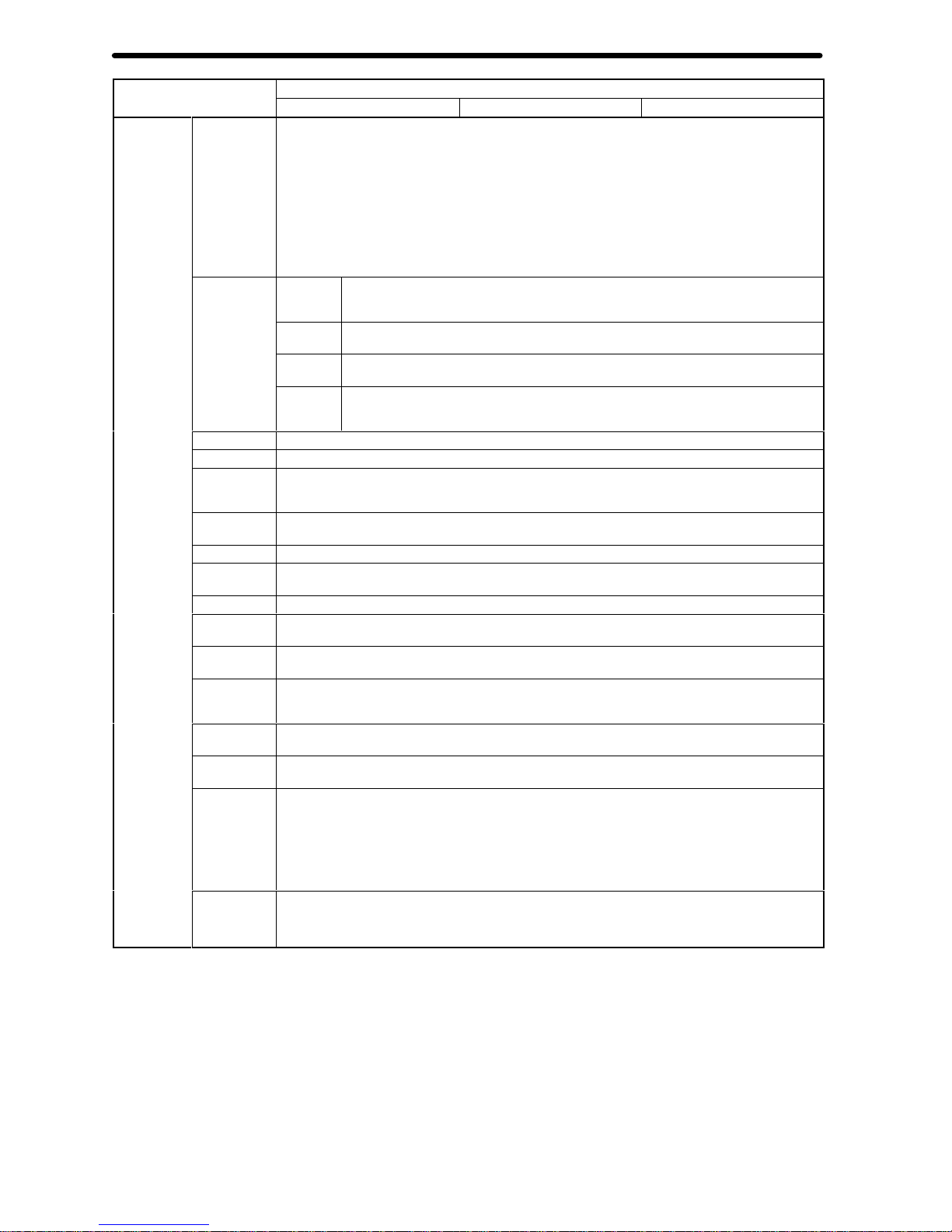

Product Specifications

C200HWNC113/NC213/NC413

Servo Relay Unit

Input

Pulse Input

Servodriver

Servomotor

J System

Configuration

Example

Position

Control

Unit

operations

Position

control

Speed control

Other operations

Memory operation

Direct operation

Interrupt feeding

Jogging

Teaching

Override

Present position change

Backlash compensation

Zone setting

Deceleration stop

Origin search

Independent

Automatic

Continuous

Page 3

Position Control Unit

Product Specifications

2

Compact Size

The

single-axis, two-axis, and four-axis models are all one compact

size.

Special Support Software for CS1-Series and

C200HX/HG/HE PCs)

Special

Support

Software, the SYSMAC-NCT

, which runs on Win

-

dows

95, allows the user to easily create

various data for the Posi

tion Control Unit. It can also be used for writing data to the PCU,

reading

data from the PCU, saving data, and printing data.

Easy Data Transfer

Position

data used for

memory operation can be transferred to the

Position Control Unit by using the NC Support Software (for

CS1-Series

and C200HX/HG/HE PCs only), data transfer bits, and

the

Intelligent I/O W

rite (IOWR) and Intelligent I/O Read (IORD)

in

-

structions (for CS1-Series and C200HX/HG/HE PCs only).

ROM Operation by Flash Memory

Position

data used for memory operation can be stored in the flash

memory in the Position Control Unit. It is retained even when the

power

is turned OFF

. So, there is no need

for battery maintenance.

Models

Applicable PCs

Unit classification

Number of control axes

Controlled driver

Model number

CS1, C200HX/HG/HE,

C200H Special I/O Unit

1 axis

Pulse-train input driver or

C200HW-NC113

CS , C 00 / G/ ,

C200HS, and C200H

C00 Seca /OU

2 axes

use a u d e o

stepping motor driver

C200HW-NC213

PC

s

4 axes C200HW-NC413

Support Software (Sold Separately)

Name System

requirements

Applicable PCs

Specifications Model

SYSMAC-NCT

Personal computer: IBM AT or

compatible

Operating system: Windows 95

Minimum memory: 16 MB

A

vailable disk space: 10 MB min.

CS1-Series and

C200HX/HG/HE

PCs only

(Cannot be used

with C200H or

C200HS PCs.)

Creating

positioning data

and parameter

data, transferring

data to the Unit,

writing data to

the flash

memory

, and

printing Unit

status monitor

data, positioning

data, and

parameter data

WS01-NCTF1-E

Connecting

Cable

For connecting the RS-232C port on

the CPU Unit

2.0 m, 5.0 m

XW2Z-jjjj

(For details, refer

to

j optional

parts.)

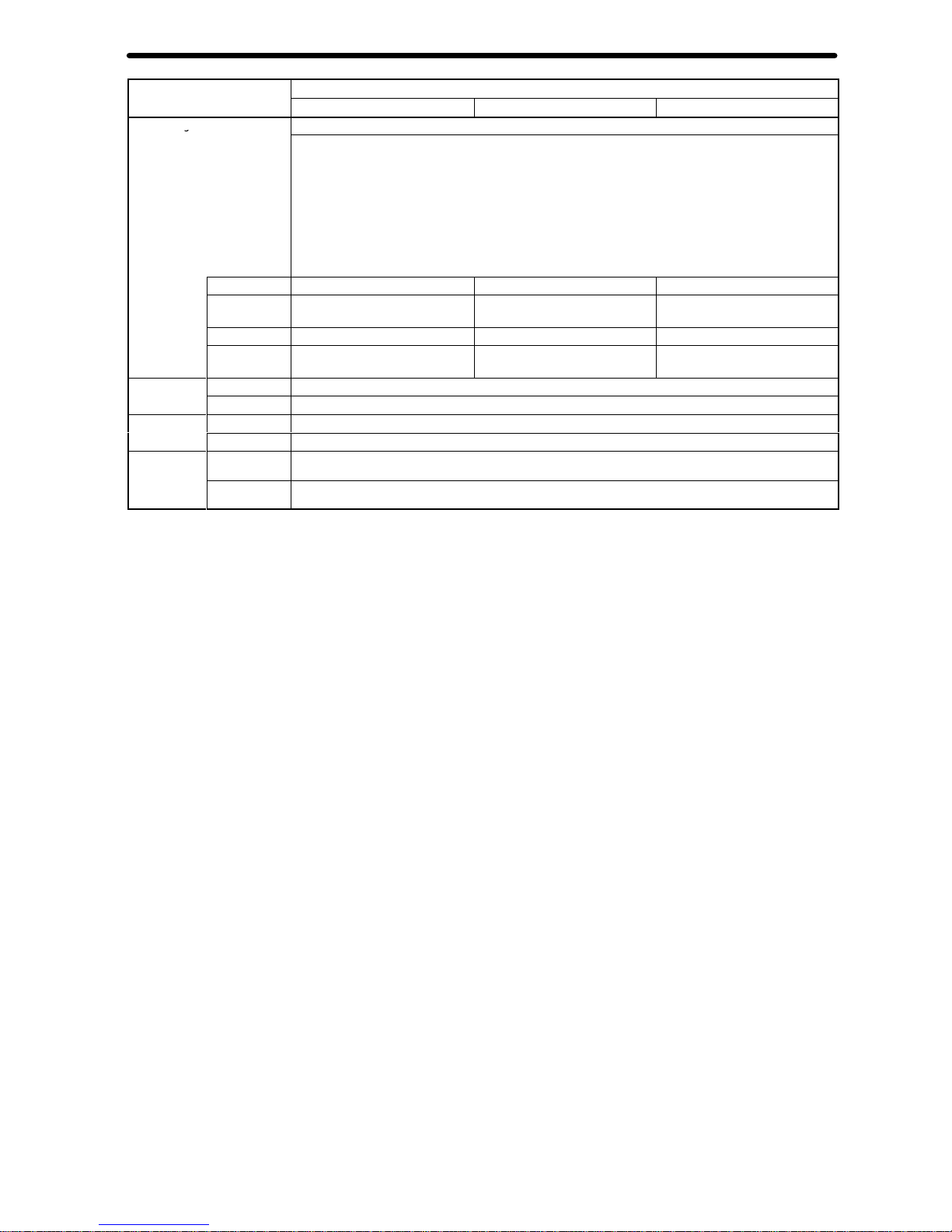

Specifications

Item

Specifications

e

C200HW-NC113 C200HW-NC213 C200HW-NC413

Applicable PCs CS1-Series, C200HX/HG/HE, C200HS, C200H

Unit classification

C200H Special I/O Unit

Mounting location

CPU Rack, C200H Expansion I/O Rack, CS1 Expansion Rack, SYSMAC BUS Remote I/O Slave Unit

Maximum number of Units

that can be mounted

16 or 10 Units depending on the CPU Unit model (refer to

Connectable CPU Unit Models

).

8 or 5 Units depending on the

CPU Unit model (refer to

Connectable CPU Unit Models

).

Unit numbers

0 to F or 0 to 9 depending on the CPU Unit model (refer to

Connectable CPU Unit Models

).

0 to 8, or 0 to 8 and A to E

depending on the CPU Unit

model (refer to

Connectable

CPU Unit Models

).

Data

Words

5 words/Unit

10 words/Unit 20 words/Unit

exchange

area with

CPU Unit

allocated in

the Special

I/O Unit Area

CPU Unit →

Position Control Unit: Operating commands (sequence numbers, start, origin search, etc.)

Position Control Unit → CPU Unit: Status (positioning completed, present position, etc.)

DM area

words

100 words/Unit

words

allocated to

Special I/O

Units

CPU Unit →

Position Control Unit: Common parameters and axis parameters (I/O selection, operation

mode selection, start speed, origin search speed, acceleration/deceleration time, etc.)

Controlled driver

Pulse-train input type Servodriver or stepping motor driver

Control

Control

system

Open-loop control by pulse train output (automatic trapezoidal or S-curve acceleration/deceleration)

Number of

control axes

1 axis 2 axes 4 axes

Control unit

Pulse

Page 4

Product Specifications

Position Control Unit

3

Item SpecificationsItem

C200HW-NC413C200HW-NC213C200HW-NC113

Positioning

operations

T

wo types: Memory operation and direct operation

os o g o e a o s

Memory operation: T

ransfers sequence data such as position data and speed data to the Position

Control Unit beforehand, and executes positioning in ascending order of sequence numbers by

specifying the start sequence number from the CPU Unit.

Completion code of each sequence for memory operation: Independent, automatic, continuous, bank

end, speed control (continuous output), or interrupt feeding (continuos output with positioning) can be

specified.

Direct operation: W

rites position data and speed data to the specified area in the CPU Unit and

executes positioning by outputting the data to the Position Control Unit through I/O refresh.

Speed control and interrupt feeding are also possible.

Independent 1 axis

2 independent axes 4 independent axes

Linear

interpolation

– 2 axes max. 4 axes max.

Speed control

1 axis

2 independent axes 4 independent axes

Interrupt

feeding

1 axis

2 independent axes 4 independent axes

Positions

Range

–9,999,999 to 9,999,999 pulses

os o s

Data items

100/axis

Speeds

Range

1 pps to 500 Kpps

S eeds

Data items

100/axis

Acceleration

and

Range

0 to 250 s, until maximum speed is reached.

and

deceleration

times

Data items

9/axis for acceleration and deceleration each.

Page 5

Position Control Unit

Product Specifications

4

Item SpecificationsItem

C200HW-NC413C200HW-NC213C200HW-NC113

Functions

Origin search

Origin proximity input signal: selectable (absent, N.O. or N.C. contact).

Origin input signal: selectable (N.O. or N.C. contact)

Origin compensation: –9,999,999 to 9,999,999 pulses

Origin search speed: High-speed or proximity-speed can be set.

Origin search method: May be set to stop upon origin input signal after proximity input signal has turned

ON, to stop upon origin input signal after proximity input signal has turned OFF

, to stop upon origin input

signal without using proximity input signal, or to stop upon origin input signal after limit input signal has

turned OFF

.

N.O. = Normally open

N.C. = Normally closed

Origin search

operation

mode

0

(Mode 0)

Stepping motors are used and external sensor signals are used as origin input signals. In

this case, error counter reset output and origin-adjustment command output can be used

as general-purpose outputs.

1

(Mode 1)

Servodrivers are used and encoder phase-Z signals are used as origin input signals. The

Servodriver’

s positioning completed signals are not used.

2

(Mode 2)

Servodrivers are used and encoder phase-Z signals are used as origin input signals. The

Servodriver’

s positioning completed signals are used.

3

(Mode 3)

Servodrivers such as OMRON H-Series and M-Series are used. The Servodriver’s

origin-adjustment command is used to complete origin search. The Servodriver

’s

positioning completed signals are used.

Jogging

Jogging can be executed at a specified speed.

Dwell times

19/axis can be set from 0 to 9.99 s (unit: 0.01 s).

Acceleration/

deceleration

curves

T

rapezoidal or S-curve (Can be set separately for each axis.)

Zones

Zone Flag turns ON when present position is within a specified zone. Three zones can be set for each

axis.

Software limit

Can be set within a range of –9,999,999 to 9,999,999 pulses.

Backlash

compensation

0 to 9,999 pulses. Compensation speed can also be set.

Teaching

With a command from the CPU Unit, the present position can be taken as the position data.

Forced

intervention

Stops the active sequence and executes the specified sequence No. (V

alid during memory operation

only)

Deceleration

stop

The ST

OP command causes positioning to decelerate to a stop according to the specified deceleration

time.

Present

position

change

The PRESENT POSITION CHANGE command can be used to change the present position to a

specified value.

Override

When the override enabling command is executed during positioning, the target speed is changed by

applying the override coef

ficient.

Pulse output

prohibited

Prohibits pulse output when emergency stop, CW limit, CCW limit, or CW/CCW software limit input

turns ON.

Data transfer

(data

read/write)

V

arious data can be transferred to the memory in the Position Control Unit, using either of the following

methods:

1) Data transfer bits

2) Intelligent I/O W

rite (IOWR) and Intelligent I/O Read (IORD) instructions (for CS1-Series and

C200HX/HG/HE PCs only)

3) SYSMAC-NCT Support Software (for CS1 Series and C200HX/HG/HE PCs only)

Data savingVarious data can be saved in the internal flash memory

.

If data is saved, the Position Control Unit can be operated using the saved data when it is turned ON or

restarted. There is no need to transfer data to the Unit each time.

Note: Flash memory life expectancy: 100,000 times (reads/writes)

Page 6

Product Specifications

Position Control Unit

5

Item SpecificationsItem

C200HW-NC413C200HW-NC213C200HW-NC113

External I/O Inputs

Prepare the following inputs for each axis:

CW and CCW limit input signals, origin proximity input signal, origin input signal (see note), emergency

stop input signal, positioning completed signal, interrupt input signal

V

oltage: 24 VDC

±10%

Current: 4.3 mA (at 24 V) typ.

ON voltage: 17.4 VDC min.

OFF voltage: 5.0 VDC max.

ON response time: 1 ms max. (0.1 ms max.: Interrupt input)

OFF response time: 1 ms. max.

The following information applies to origin input only

.

External signal is open-collector signal: Same as above, except for response time (N.O. contact: 0.1 ms

max.; N.C. contact: 1 ms max.)

External signal is line-driver signal: Corresponds to line driver signals equivalent to Am26LS31, except

for response time (N.O. contact: 0.1 ms max.; N.C. contact: 1 ms max.)

Outputs

Prepare the following outputs for each axis:

Pulse outputs (open collector outputs)

CW/CCW pulses, pulse outputs and direction outputs can be switched.

Either error counter reset or origin-adjustment command outputs can be selected depending on the

mode.

Maximum switching capacity: 30 mA at 4.75 to 26.4 VDC (NPN open collector)

(16 mA: T

erminals with 1.6-kΩ limit resistance)

Minimum switching capacity: 7 mA at 4.75 to 26.4 VDC (NPN open collector)

Leakage current: 0.1 mA max.

Residual voltage: 0.6 V max.

External power supply:

24 VDC ±10%

C200HW-NC1

13: 30 mA max.

C200HW

-NC213: 50 mA max.

C200HW

-NC413: 90 mA max.

Pulse output distribution

period

4 ms

Self-diagnostic function

Flash memory check, memory loss check, I/O bus check

Error detection function

Overtravel, CPU error

, software limit over

, emergency stop

Unit number setting switch

Rotary switch: Unit number (0 to F) (Dif

fers depending on the CPU Unit model. Refer to

Connectable

CPU Unit Models

.)

LED indicators

Number of indicators: 5 (NC113), 6 (NC213), 8 (NC413)

Show the PCU’

s status such as running state, error state, input signal state, data state, and each axis

state.

Connections on the front

panel

X-axis connector X/Y-axis connector X/Y-axis connector

,

Z/U-axis connector

Use the FCN-361J048-AU Connector (soldered) and the FCN-360C048-D Connector Cover provided.

Also, use OMRON’

s Servodriver Connecting Cables.

Internal current consumption

(provided from Power Supply

Unit)

300 mA max. at 5 VDC 300 mA max. at 5 VDC 500 mA max. at 5 VDC

Dimensions

130 x 34.5 x 100.5 mm (H x W x D)

The height including the Backplane is 230 mm when the attached connector or OMRON’

s Servodriver

Cable is used.

W

eight (excluding

connectors)

250 g max. 300 g max. 350 g max.

Standard accessories

Fujitsu FCN-361J048-AU Connector (soldered) and FCN-360C048-D Connector Cover: 1 set

Cat. No. W334 (W324 for SYSMAC-NCT Support Software)

Options (Sold Separately)

Item Specifications Model

number

Connectors for each axis Soldered

(provided as

Soldered connector

FCN-361J048-AU

( rovided as

standard on this

Unit)

Connector cover FCN-360C048-D

Crimp

Crimp-type housing

FCN-363J048

C

Contact FCN-363J-AU/S

Connector cover FCN-360C048-D

Page 7

Position Control Unit

Product Specifications

6

Item Model

number

Specifications

The following cables and Servo Relay Units can be used

to connect OMRON’s Servodrivers.

Applicable

Position Control

Unit

Applicable

OMRON

Servodriver

Cable length

---

1 axis Connecting

C200HW-NC113 U-Series,

50 cm

XW2Z-050J-A6

C

able H-Series,

M-Series

100 cm

XW2Z-100J-A6

UEP-Series only

50 cm

XW2Z-050J-A8

USeesoy

100 cm

XW2Z-100J-A8

Servo Relay Unit

Connects to the above cable.

XW2B-20J6-1B

2 axes Connecting

C200HW-NC213

U-Series,

50 cm XW2Z-050J-A7

C

able

an

d

C200HW-NC413

H-Series,

M-Series

100 cm XW2Z-100J-A7

(T

wo

cables are

required for

UEP-Series

only

50 cm

XW2Z-050J-A9

q

C200HW-NC413.)

USees

oy

100 cm

XW2Z-100J-A9

Servo Relay Unit

Connects to the above cable. (T

wo Units are required

for C200HW

-NC413.)

XW2B-40J6-2B

Item Connection port

Personal computer Cable length

Model

SYSMAC-NCT Support

Software Connecting

Connects to the

RS-232C port on the

IBM A

T or compatible

2.0 m

XW2Z-200S-V

Software Connecting

Cable

RS 232C ort on the

CPU Unit (in Host Link

Mode).

5.0 m

XW2Z-500S-V

Applicable CPU Units

PC CPU

Unit model

T

otal number of PCUs that can be mounted on

CPU Racks, Expansion Racks, and SYSMAC BUS

Remote I/O Slave Units (see note).

Unit mounting

restrictions

Position Control Unit C200HW-NC113/NC213 C200HW-NC413

CS1 Series CS1H-CPUjjj

CS1G-CPUjjj

16 (Unit No.: 0 to F) 8 (Unit No.: 0 to 8, A to E)

None

C200HX/HG/HE

C200HE-CPU1

1/32/42 (-ZE)

C200HG-CPU33/43 (-ZE)

C200HX-CPU34/44 (-ZE)

10 (Unit No.: 0 to 9) 5 (Unit No.: 0 to 8)

None

C200HG-CPU53/63 (-ZE)

C200HX-CPU54/64 (-ZE)

C200HX-CPU65-ZE/85-ZE

16 (Unit No.: 0 to F) 8 (Unit No.: 0 to 8, A to E)

None

C200HS C200HS-CPU01(-j)/21

(-j)/31/03/23/33

10 (Unit No.: 0 to 9) 5 (Unit No.: 0 to 8)

None

C200H C200H-CPU01/02/03/11/21/2

2/23/31

10 (Unit No.: 0 to 9) 5 (Unit No.: 0 to 8)

Cannot be mounted in

the two rightmost slots

on the CPU Rack.

Note: Restrictions in Using SYSMAC BUS Remote I/O Slave Units

The

maximum number of C200H Special I/O Units that can be mounted

on a SYSMAC BUS Remote I/O Slave Unit dif

fers according to

the

Units as shown below

. C200H Special I/O Units can be divided into the following four groups according to the maximum number of

Units

that can be mounted.

Group A B C D

Units

ASCII Unit,

High-speed Counter

Unit, Position Control

Unit

(NC111/112/113/213),

Analog I/O Unit, ID

Sensor Unit, Fuzzy

Logic Unit

High-density I/O Unit,

T

emperature Control

Unit, PID Control Unit,

Heating/Cooling

Control Unit, Cam

Positioner Unit

T

emperature Sensor

Unit, Voice Unit

Position Control Unit

(NC21

1/413), Motion

Control Unit

Maximum number of

Units that can be

mounted in each group

under one Master Unit

4 Units 8 Units 6 Units 2 Units

Maximum number of

Units that can be

mounted in all groups

3A + B + 2C + 6D x 12, AND A + B + C + D

x 8

Page 8

Product Specifications

Position Control Unit

7

System Configuration

Control System: Open-loop System

Position

Control Unit

Note: The

Position Control Unit does not in

-

put

position feedback signals.

Pulse output

Servodriver or stepping driver

Servomotor or stepping motor

Tachogenerator

Rotary encoder

Connection Configuration

Item 1-axis 2/4-axis

Connecting

cable

on PCU end

XW2Z-jjjJ-Aj XW2Z-jjjJ-Aj

Servo Relay Unit

XW2B-20J6-1B XW2B-40J6-2B

Item Connection

to U-Series

Connection

to M-Series

Connection

to H-Series

Connecting cable on

Servodriver end

XW2Z-jjj

J-B1

XW2Z-jjj

J-B2

XW2Z-jjj

J-B3

Servodriver U-Series M-Series H-Series

R88D-UPjjj R88D-MTjjj R88D-Hjjj

+

+

Position Control

Unit

CPU Unit

Power Supply

Unit

Host link

Connecting cable on PCU end

Servo Relay Unit

Connecting cable on Servodriver

end

Pulse output

CCW limit input, CW

limit input, origin

proximity input,

emergency stop input,

etc.

Servodriver

Servomotor

Stepping driver

Stepping motor

or

SYSMAC-NCT

Page 9

Position Control Unit

Product Specifications

8

Exchanging Data

CPU Unit

Ladder program

I/O memory

IR/CIO area (operating memory area)

Operation

commands

Status inputs

Position Control Unit (C200HW-NC413)

Command

interpretation

Status

such as

positioning completed

or present position

I/O refresh

DM area (parameter area)

Common

parameters

Axis

parameters

At power-up or restart

At power-up or restart

Common

parameters

DM or EM area

Operating data area

Data

transfer data,

operation data, etc.

Status inputs

I/O refresh

Settings analysis

and execution

Status such as

I/O signals and

error codes

Internal memory

Data transfer area

Data for memory

operation

Address

Data area

Axis parameters

Sequence data

Speed data

Position data

Acceleration time data

Deceleration time data

Dwell time data

Zone data

Data for

X axis

Data for Y

to U axes

Saving data Startup restart

Flash memory

When data transfer

commands are executed

When IOWR or IORD

is executed

When data transfer

commands are executed

MOV

, LD, etc.

SYSMAC-NCT

n+7

n+8

n+19

m+3

m+4

m+99

I+25

I+26

I+33

Page 10

Product Specifications

Position Control Unit

9

Components

C200HW-NC413

LED indicators

Show the PCU’s

operating status.

Unit number

setting switch

Set the unit number

for the PCU (0 to F).

X/Y axis connector

(see note)

Connects stepping

motor driver or

Servodriver. (2-axis

control)

Z/U axis connector

(see note)

Connects stepping

motor driver or

Servodriver. (2-axis

control)

X-,

Y-axis

connect

or

X-axis connector (see note)

Note: The Unit is provided with a Fujitsu

FCN-361J048-AU Connector (soldered) and

FCN-360C048-D Connector Cover.

C200HW-NC213 C200HW-NC113

LED Indicators

Name Color Status Explanation

RUN Green

Lit

Lit

during normal operation.

Not

lit

Hardware error, or PC notified of PCU error.

ERR Red

Lit

/ flashing

An error has occurred.

Not

lit

No error has occurred.

SENS Red

Lit

Either a CW/CCW limit signal or an emergency stop

input signal is being input. At this time the LED indicator

for the relevant axis (X to U) will flash.

Flashing

Either a parameter loss, a data loss, or an operating

data area designation error has occurred.

Not

lit

None of the above has occurred.

DATA Red

Flashing

The check of all data (parameters, positions, etc.)

following power up shows that data is lost or corrupted.

Lit

Data is incorrect (e.g., the parameters or positions

transferred are out of the permissible range). At this time

the LED indicator for the relevant axis (X to U) will flash.

Not

lit

None of the above has occurred.

X Orange

Lit

Pulses are being output to the X axis (either forward or

reverse).

Flashing

An error has occurred, such as incorrect cable type for

the X axis or faulty data.

Not

lit

None of the above has occurred.

Y Orange

Lit

Pulses are being output to the Y axis (either forward or

reverse).

Flashing

An error has occurred, such as incorrect cable type for

the Y axis or faulty data.

Not

lit

None of the above has occurred.

Z Orange

Lit

Pulses are being output to the Z axis (either forward or

reverse).

Flashing

An error has occurred, such as incorrect cable type for

the Z axis or faulty data.

Not

lit

None of the above has occurred.

U Orange

Lit

Pulses are being output to the U axis (either forward or

reverse).

Flashing

An error has occurred, such as incorrect cable type for

the U axis or faulty data.

Not

lit

None of the above has occurred.

Page 11

Position Control Unit

Product Specifications

10

External I/O Connectors

X/Y axis Z/U axis X/Y axis X axis

C200HW-NC413 C200HW-NC213 C200HW-NC113

Connector Pin Numbers

Outline of connector (rear

side)

Pin number marks

(Viewed from soldered side)

Connector

Pin Arrangement for X and Z Axes

Pin

No.

I/O Name

A1 IN

Output power supply

, 24 VDC

A2 IN

Output GND, 24 VDC

A3 --

Not used

A4 --

Not used

A5 OUT

CW pulse output

A6 OUT

CW pulse/pulse output with 1.6 KΩ resistance

A7 OUT

CCW pulse/direction output

A8 OUT

CCW pulse/direction output with 1.6 KΩ resistance

A9 --

Not used

A10 OUT

Error counter reset output Origin-adjustment

command output

A11 OUT

Error counter reset output with 1.6 KΩ resistance

Origin-adjustment command output with 1.6 K

Ω

resistance

A12 IN

Positioning completed input signal

A13 --

Not used

A14 IN

Origin common

A15 IN

Origin input signal (24 V)

A16 IN

Origin input signal (5 V)

A17 --

Not used

A18 --

Not used

A19 IN

Interrupt input signal

A20 IN

Emergency stop input signal

A21 IN

Origin proximity input signal

A22 IN

CW limit input signal

A23 IN

CCW limit input signal

A24 IN

Input common

Connector

Pin Arrangement for Y and U Axes

Pin

No.

I/O Name

B1 IN

Output power supply

, 24 VDC

B2 IN

Output GND, 24 VDC

B3 --

Not used.

B4 --

Not used.

B5 OUT

CW pulse output

B6 OUT

CW pulse/pulse output with 1.6 KΩ resistance

B7 OUT

CCW pulse/direction output

B8 OUT

CCW pulse/direction output with 1.6 KΩ resistance

B9 --

Not used.

B10 OUT

Error counter reset output Origin-adjustment

command output

B11 OUT

Error counter reset output with 1.6 KΩ resistance

Origin-adjustment command output with 1.6 K

Ω

resistance

B12 IN

Positioning completed input signal

B13 --

Not used.

B14 IN

Origin common

B15 IN

Origin input signal (24 V)

B16 IN

Origin input signal (5 V)

B17 --

Not used.

B18 --

Not used.

B19 IN

Interrupt input signal

B20 IN

Emergency stop input signal

B21 IN

Origin proximity input signal

B22 IN

CW limit input signal

B23 IN

CCW limit input signal

B24 IN

Input common

Page 12

Product Specifications

Position Control Unit

11

External Connection Diagram

This

example shows the use of a Servodriver

with encoder phase-Z

as

origin input signals.

Emergency stop input

Origin proximity input (see note)

CW limit input (see note)

CCW limit input (see note)

Input common

CW pulse output

CCW pulse output/

direction output with

1.6 KΩ resistance

24-V power supply

for output

24 V GND for output

Error counter reset output,

origin-adjustment command output

Origin input signal (5 V)

Origin common

N.C.

contact

OMRON R88D-UPjjj

Servodriver

R88M-U Servomotor

Note: N.O.

or N.C. contact can be selected

using axis parameters.

24 VDC

24 VDC

+

–

+

–

–

–

–

–

Page 13

Position Control Unit

Product Specifications

12

Combinations of Servo Relay Units, Servodrivers, and Position Control Units

Position Control Unit

Connecting cable on

PCU end

Servo Relay Unit

Single-axis Position

Control Unit for C200HS

Connecting cable

for C200H-NC113

Servo Relay Unit

for C200H-NC113

2/4-axis Position Control

Unit for C200HS

Connecting cable for

C200H-NC213/413

(see note 1)

Servo Relay Unit for

C200H-NC213/413

(see note 1)

Note: 1. Two

cables or Units are requIred for

4-axis PCUs.

Connecting cable on

Servodriver end

Servodriver

Connecting cable

for U-Series

U-Series Servodriver

Connecting cable

for M-Series

M-Series Servodriver

H-Series Servodriver

Connecting cable

for H-Series

2. When

the Servodriver is combined with the C200HW

-NC213 (2-axis), two

connecting

cables are required on the Servodriver end. When the Servo

driver is combined with the C200HW-NC413 (4-axis), four connecting

cables are required on the Servodriver end.

(See note 2)

(See note 2)

(See note 2)

C200HW-NC113

XW2Z-jjjJ-Aj

XW2B-20J6-1B

C200HW-NC213/413

XW2Z-jjjJ-Aj

XW2B-40J6-2B

XW2Z-jjjJ-B1

R88D-UPjjj

XW2Z-jjjJ-B2

R88D-MTjjj

XW2Z-jjjJ-B3

R88D-Hjjj

Page 14

Product Specifications

Position Control Unit

13

Connection Diagram for Position Control Unit

and Servo Relay Unit

XW2Z-jjjJ-A6/A8

Connecting

Cable:

For C200HW-NC113

1 axis, U/H/M-Series Servodriver 1 axis, UEP-Series Servodriver

Position Control

Unit NC113

Connecting cable

XW2Z-jjjJ-A6

Servo Relay Unit

XW2B

Power supply for output

24-V GND for output

CCW

pulse output/direction

output with 1.6 KΩ resistance

CW pulse output with

1.6 KΩ resistance

Error

counter reset output,

origin-adjustment command output

Origin input (5 V)

Origin common

Input common

Positioning completed input

Origin proximity input

CCW limit input

CW limit input

Interrupt input

Emergency stop input

Origin input (24 V)

Origin proximity

CCW limit

CW limit

External interrupt

FG

Origin input (24 V)

Origin common

Emergency stop input

– ECRST

+ ECRST

– CW

+ CW

– CCW

+ CCW

GND

24 V

+ Z

– Z

24 V

INP

Origin proximity

CCW limit

CW limit

External interrupt

Origin input (24 V)

Origin common

Emergency stop input

– ECRST

+ ECRST

– CW

+ CW

– CCW

+ CCW

GND

24 V

+ Z

– Z

24 V

INP

Position Control

Unit NC113

Connecting cable

XW2Z-jjjJ-A8

Servo Relay Unit

XW2B

F.G. (crimp terminal)

(Lead: 500 mm)

FG

XW2Z-jjjJ-A7/A9

Connecting

Cable:

For C200HW-NC213/NC413

2 axes, U/H/M-Series Servodriver

2 axes, UEP-Series Servodriver

24-V power supply for output

24-V GND for output

CCW pulse output/direction

output with 1.6 KΩ resistance

CW pulse output with

1.6 KΩ resistance

Error counter reset output,

origin-adjustment command

output

Origin input (5 V)

Origin common

Input common

Positioning completed input

CCW limit input

CW limit input

Interrupt input

F.G. (crimp terminal)

(Lead: 500 mm)

Origin proximity

CCW limit

CW limit

External interrupt

FG

Origin input (24 V)

Emergency stop input

– ECRST

+ ECRST

– CW

+ CW

– CCW

+ CCW

GND

+ Z

– Z

24 V

INP

Position Control Unit

NC213/NC413

Connecting cable

XW2Z-jjjJ-A7

Servo Relay Unit

XW2B

Origin proximity input

X-axis emergency stop input

CW limit input

CCW pulse output/direction

output with 1.6 KΩ resistance

CW pulse output with

1.6 KΩ resistance

Error counter reset

output, origin-adjustment

command output

Origin input (5 V)

Origin common

CCW limit input

CW limit input

Origin proximity input

Interrupt input

Positioning completed input

Y-axis emergency stop input

– CW

+ CW

– CCW

+ CCW

– ECRST

+ ECRST

HRET

+ Z

– Z

HRET

CCW limit

CW limit

Origin proximity

External interrupt

INP

Position Control Unit

NC213/NC413

Connecting cable

XW2Z-jjjJ-A9

Servo Relay Unit

XW2B

Origin proximity

CCW limit

CW limit

External interrupt

FG

Origin input (24 V)

Emergency stop input

– ECRST

+ ECRST

– CW

+ CW

– CCW

+ CCW

GND

24 V

+ Z

– Z

24 V

INP

– CW

+ CW

– CCW

+ CCW

– ECRST

+ ECRST

HRET

+ Z

– Z

HRET

CCW limit

CW limit

Origin proximity

External interrupt

INP

HRET

24 V

F.G. (crimp terminal)

(Lead: 500 mm)

F.G. (crimp terminal)

(Lead: 500 mm)

Page 15

Position Control Unit

Product Specifications

14

Dimensions (Unit: mm)

Mounted

Dimensions

Backplane

Connection

cable

Approx. 230

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To

convert millimeters into inches, multiply by 0.03937. T

o convert grams into ounces, multiply by 0.03527.

Page 16

OMRON Corporation

Systems Components Division

66 Matsumoto

Mishima-city

, Shizuoka 41

1-851

Japan

T

el: (81)559-77-9633

Fax: (81)559-77-9097

Regional Headquarters

OMRON EUROPE B.V.

W

egalaan 67-69, NL-2132 JD Hoofddorp

1

The Netherlands

T

el: (31)2356-81-300/Fax: (31)2356-81-388

OMRON ELECTRONICS, INC.

1 East Commerce Drive, Schaumburg, IL 60173

U.S.A.

T

el: (1)847-843-7900/Fax: (1)847-843-8568

OMRON ASIA PACIFIC PTE. LTD.

83 Clemenceau Avenue,

#1

1-01, UE Square,

Singapore 239920

T

el: (65)835-301

1/Fax: (65)835-271

Authorized Distributor:

Note:

Specifications subject to change without notice.

Cat.

No. R060-E1-1

1

Printed in Japan

0100-0.7M

Loading...

Loading...