Page 1

Cat. No. W235-E1-5

SYSMAC

C200HS

Programmable Controllers

Page 2

C200HS Programmable Controllers

Operation Manual

Revised February 2002

Page 3

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

!

serious injury.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

!

serious injury.

Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

!

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 1994

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Note Indicates information of particular interest for efficient and convenient operation

of the product.

1, 2, 3...

1. Indicates lists of one sort or another, such as procedures, checklists, etc.

ii

Page 4

About this Manual:

This manual describes the operation of the C200HS C-series Programmable Controllers, and it includes

the sections described below. Installation information is provided in the

ler Installation Guide

Section 1 Introduction

in

ences between the older CPUs and the new CPUs described in this manual.

Please read this manual completely and be sure you understand the information provided before attempting to operate the C200HS. Be sure to read the precautions in the following section.

. A table of other manuals that can be used in conjunction with this manual is provided

. Provided in

C200HS Programmable Control-

Section 2 Hardware Considerations

is a description of the differ-

Section 1 Introduction

programming. It also provides an overview of the process of programming and operating a PC and explains basic terminology used with OMRON PCs. Descriptions of Peripheral Devices used with the

C200HS PCs and a table of other manuals available to use with this manual for special PC applications

are also provided.

Section 2 Hardware Considerations

scribes the indicators that are referred to in other sections of this manual.

Section 3 Memory Areas

mation provided there to aid in programming. It explains how I/O is managed in memory and how bits in

memory correspond to specific I/O points. It also provides information on System DM, a special area in

C200HS PCs that provides the user with flexible control of PC operating parameters.

Section 4 Writing and Entering Programs

at the elements that make up the parts of a ladder-diagram program and explaining how execution of this

program is controlled. It also explains how to convert ladder diagrams into mnemonic code so that the

programs can be entered using a Programming Console.

ection 5 Instruction Set

S

Section 6 Program Execution Timing

tells how to coordinate inputs and outputs so that they occur at the proper times.

Section 7 Program Debugging and Execution

input and debug the program and to monitor and control operation.

Section 8 Communications

C200HS.

Section 9 Memory Cassette Operations

Memory Cassettes. mounted in the CPU.

Section 10 T roubleshooting

time. Information in this section is also useful when debugging programs.

Section 11 Host Link Commands

which can be used for host link communications via the C200HS ports.

The

Appendices

tables of instructions and Programming Console operations, coding sheet to help in programming and

parameter input, and other information helpful in PC operation.

explains the background and some of the basic terms used in ladder-diagram

explains basic aspects of the overall PC configuration and de-

takes a look at the way memory is divided and allocated and explains the infor-

explains the basics of ladder-diagram programming, looking

describes all of the instructions used in programming.

explains the cycling process used to execute the program and

explains the Programming Console procedures used to

provides an overview of the communications features provided by the

describes how to manage both UM Area and IOM data via

provides information on error indications and other means of reducing down-

explains the methods and procedures for using host link commands,

provide tables of standard OMRON products available for the C200HS PCs, reference

!

WARNING Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section in its entirety and be sure you understand the information provided in the section

and related sections before attempting any of the procedures or operations given.

iii

Page 5

TABLE OF CONTENTS

PRECAUTIONS xiii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Intended Audience xiv . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xiv . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xiv . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions xiv . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions xv . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Conformance to EC Directives xvi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1 – Introduction 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 Overview 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 The Origins of PC Logic 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 PC Terminology 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 OMRON Product Terminology 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5 Overview of PC Operation 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-6 Peripheral Devices 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-7 Available Manuals 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8 New C200HS Features 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8-1 Improved Memory Capabilities 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8-2 Faster Execution Times 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8-3 Larger Instruction Set 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8-4 Wide Selection of Special I/O Units 9 . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8-5 Improved Interrupt Functions 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8-6 SYSMAC NET Link and SYSMAC LINK Capabilities 9 . . . . . . . . . . .

1-8-7 Built-in RS-232C Connector 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8-8 More Flexible PC Settings 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8-9 Debugging and Maintenance 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8-10 New Programming Console Operations 10 . . . . . . . . . . . . . . . . . . . . . . .

1-8-11 Peripheral Devices 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8-12 Using C200H Programs 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2 – Hardware Considerations 15 . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1 CPU Components 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-1 CPU Indicators 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-2 Peripheral Device Connection 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 PC Configuration 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 CPU Capabilities 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 Memory Cassettes 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5 Installing Memory Cassettes 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6 CPU DIP Switch 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3 – Memory Areas 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1 Introduction 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Data Area Structure 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 IR (Internal Relay) Area 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 SR (Special Relay) Area 33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-1 SYSMAC NET/SYSMAC LINK System 37 . . . . . . . . . . . . . . . . . . . . . .

3-4-2 Remote I/O Systems 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-3 Link System Flags and Control Bits 39 . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-4 Forced Status Hold Bit 41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-5 I/O Status Hold Bit 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-6 Output OFF Bit 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-7 FAL (Failure Alarm) Area 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-8 Low Battery Flag 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-9 Cycle Time Error Flag 43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

v

Page 6

Table of contents

3-4-10 I/O Verification Error Flag 43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-11 First Cycle Flag 43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-12 Clock Pulse Bits 43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-13 Step Flag 44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-14 Group-2 Error Flag 44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-15 Special Unit Error Flag 44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-16 Instruction Execution Error Flag, ER 44 . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-17 Arithmetic Flags 44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-18 Interrupt Subroutine Areas 45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-19 RS-232C Port Communications Areas 45 . . . . . . . . . . . . . . . . . . . . . . . .

3-4-20 Peripheral Port Communications Areas 46 . . . . . . . . . . . . . . . . . . . . . . .

3-4-21 Memory Cassette Areas 46 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-22 Data Transfer Error Bits 47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-23 Ladder Diagram Memory Areas 47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-24 Memory Error Flags 47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-25 Data Save Flags 47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-26 Transfer Error Flags 48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-27 PC Setup Error Flags 48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5 AR (Auxiliary Relay) Area 48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-1 Restarting Special I/O Units 50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-2 Slave Rack Error Flags 50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-3 Group-2 Error Flags 50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-4 Optical I/O Unit and I/O Terminal Error Flags 50 . . . . . . . . . . . . . . . . . .

3-5-5 SYSMAC LINK System Data Link Settings 51 . . . . . . . . . . . . . . . . . . . .

3-5-6 Error History Bits 51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-7 Active Node Flags 52 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-8 SYSMAC LINK/SYSMAC NET Link System Service Time 52 . . . . . .

3-5-9 Calendar/Clock Area and Bits 52 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-10 TERMINAL Mode Key Bits 53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-11 Power OFF Counter 54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-12 Cycle Time Flag 54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-13 Link Unit Mounted Flags 54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-14 CPU-mounting Device Mounted Flag 54 . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-15 FPD Trigger Bit 54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-16 Data Tracing Flags and Control Bits 54 . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-17 Cycle Time Indicators 54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6 DM (Data Memory) Area 55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6-1 Expansion DM Area 56 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6-2 Special I/O Unit Data 56 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6-3 Error History Area 57 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6-4 PC Setup 58 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-7 HR (Holding Relay) Area 60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8 TC (Timer/Counter) Area 60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-9 LR (Link Relay) Area 61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-10 UM Area 61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-11 TR (Temporary Relay) Area 61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

SECTION 4 – Writing and Inputting the Program 63 . . . . . . . . . . . . . . . . . .

4-1 Basic Procedure 64 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Instruction Terminology 64 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Program Capacity 65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4 Basic Ladder Diagrams 65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4-1 Basic Terms 66 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4-2 Mnemonic Code 66 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4-3 Ladder Instructions 67 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4-4 OUTPUT and OUTPUT NOT 70 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4-5 The END Instruction 70 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4-6 Logic Block Instructions 71 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4-7 Coding Multiple Right-hand Instructions 78 . . . . . . . . . . . . . . . . . . . . . .

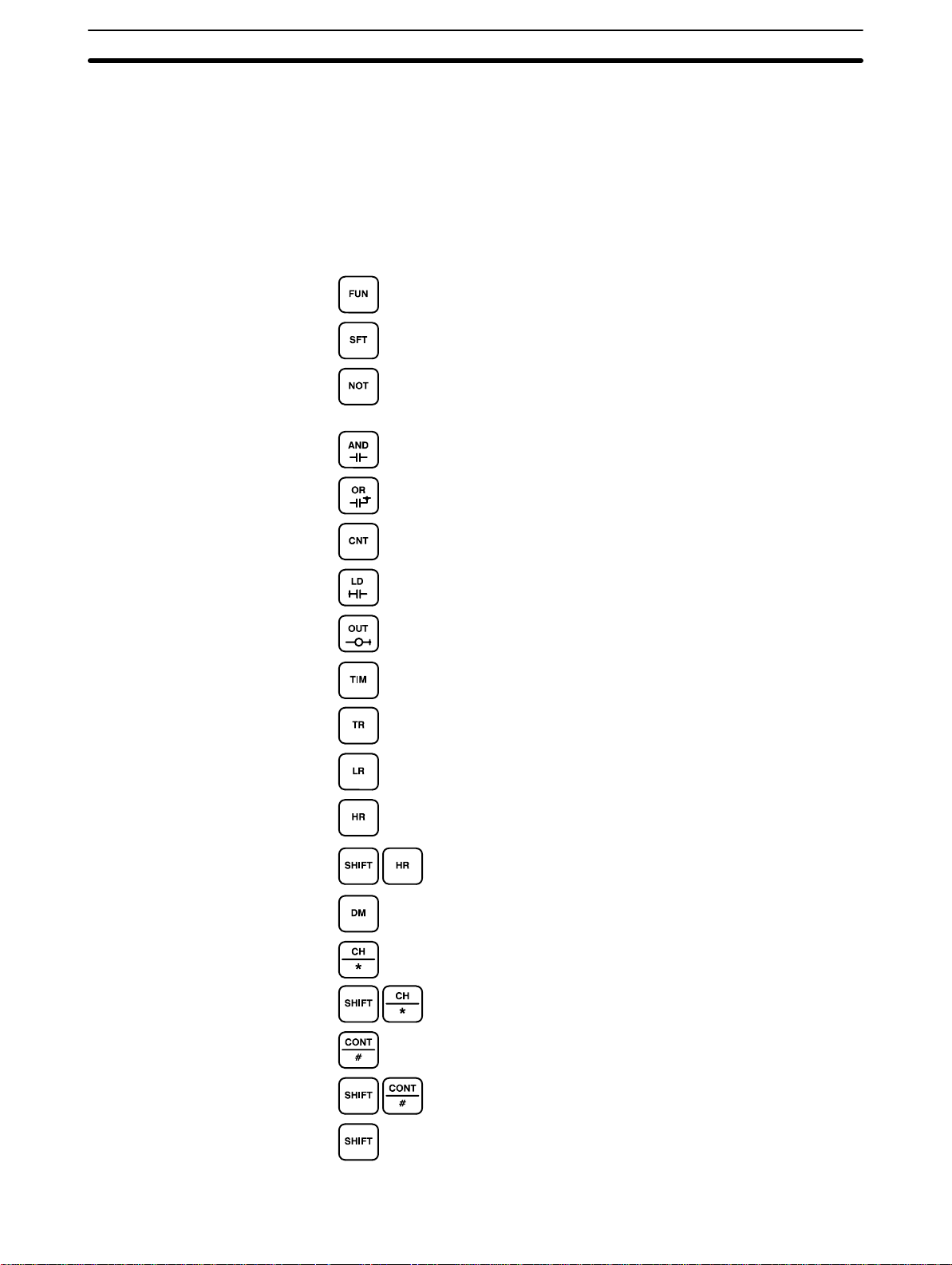

4-5 The Programming Console 78 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 7

Table of contents

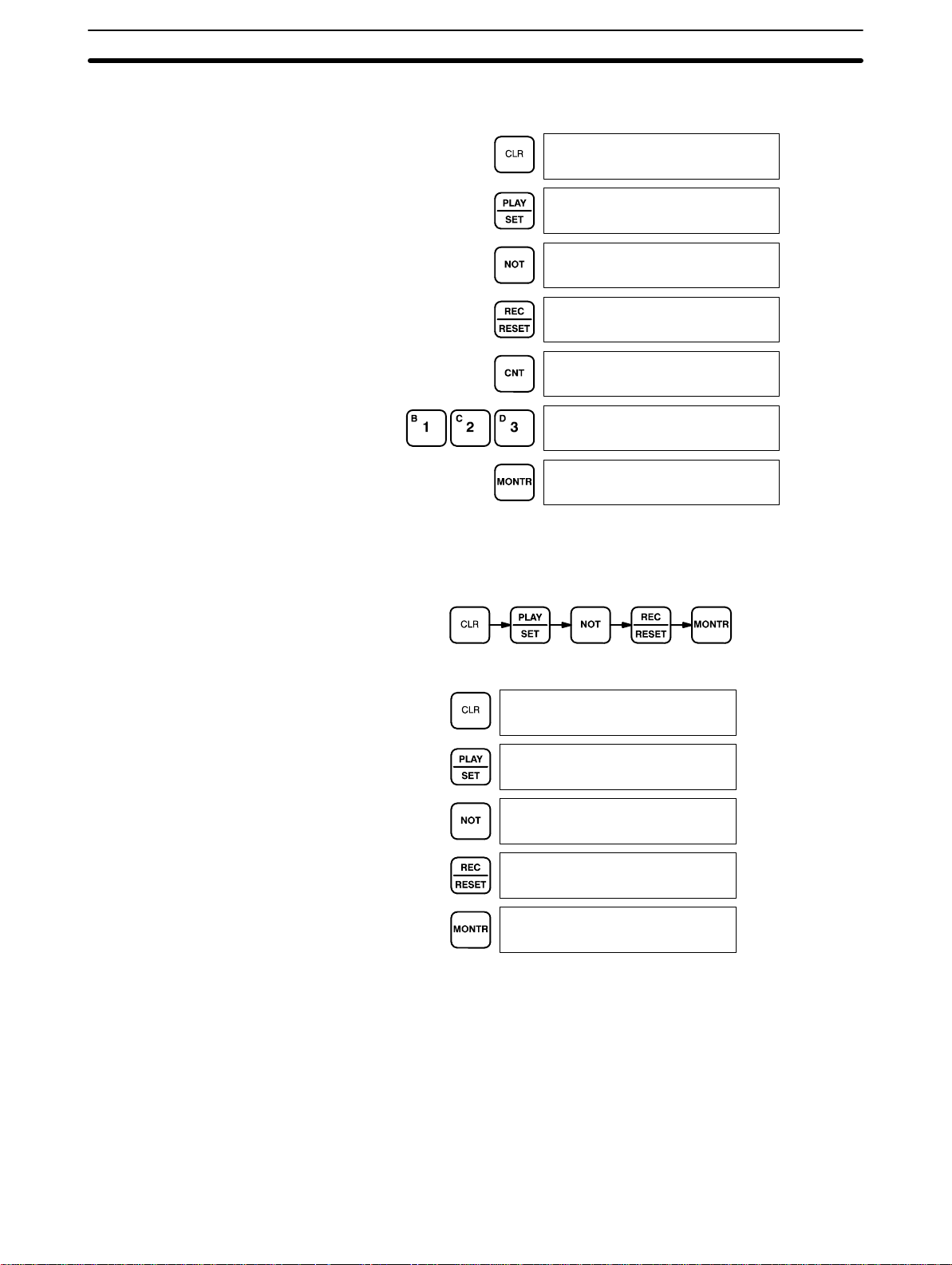

4-5-1 The Keyboard 78 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-5-2 PC Modes 80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-5-3 The Display Message Switch 80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-6 Preparation for Operation 80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-6-1 Entering the Password 81 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-6-2 Buzzer 81 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

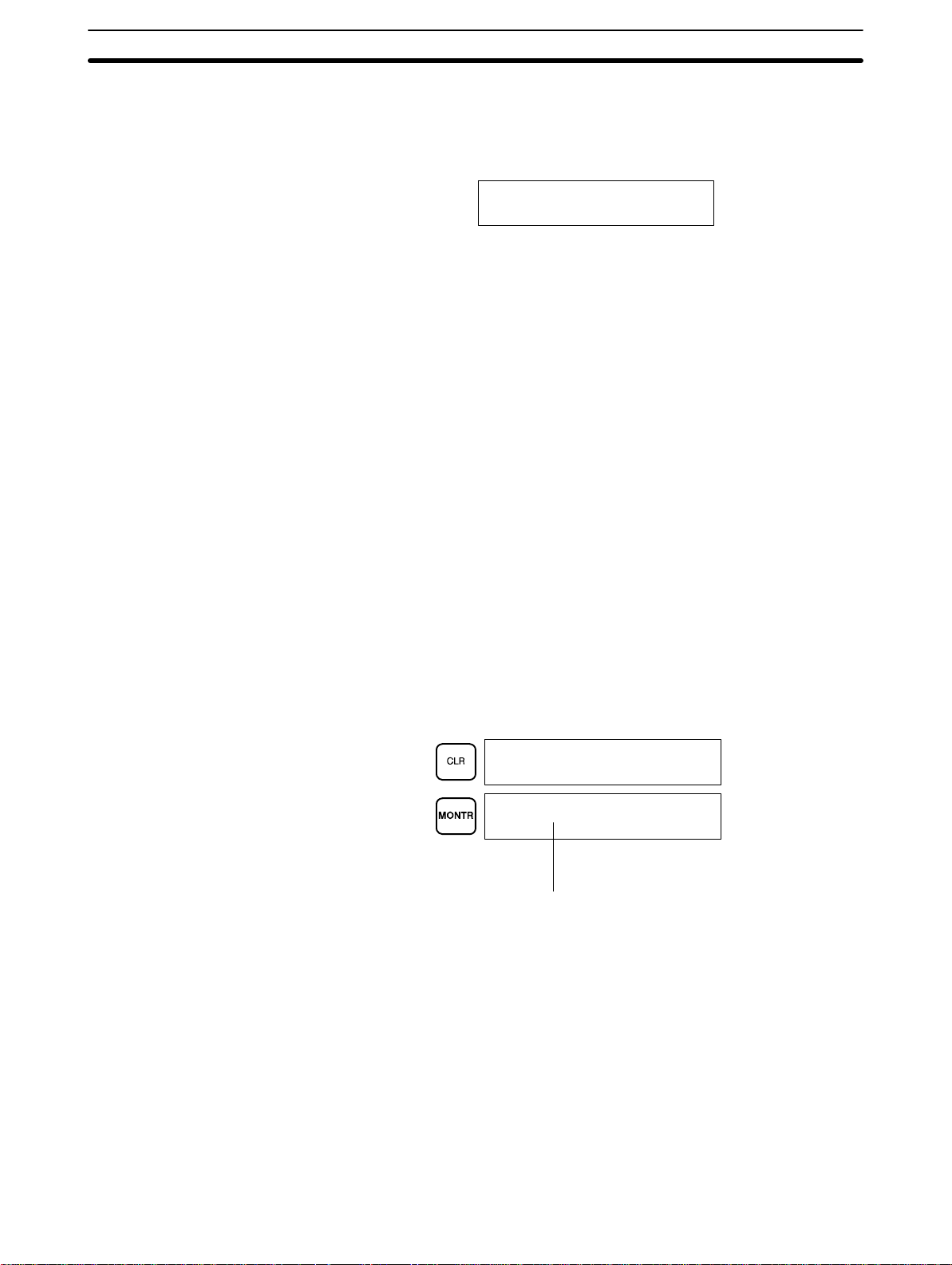

4-6-3 Clearing Memory 82 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-6-4 Registering the I/O Table 84 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-6-5 Clearing Error Messages 85 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-6-6 Verifying the I/O Table 86 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-6-7 Reading the I/O Table 87 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-6-8 Clearing the I/O Table 89 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-6-9 SYSMAC NET Link Table Transfer (CPU31/33-E Only) 90 . . . . . . . . .

4-7 Inputting, Modifying, and Checking the Program 92 . . . . . . . . . . . . . . . . . . . . . . . .

4-7-1 Setting and Reading from Program Memory Address 92 . . . . . . . . . . . .

4-7-2 Entering and Editing Programs 93 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-7-3 Checking the Program 96 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-7-4 Displaying the Cycle Time 98 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-7-5 Program Searches 99 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-7-6 Inserting and Deleting Instructions 100 . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-7-7 Branching Instruction Lines 103 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-7-8 Jumps 107 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-8 Controlling Bit Status 108 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-8-1 DIFFERENTIATE UP and DIFFERENTIATE DOWN 109 . . . . . . . . . . .

4-8-2 KEEP 109 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-8-3 Self-maintaining Bits (Seal) 109 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-9 Work Bits (Internal Relays) 110 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-10 Programming Precautions 112 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-11 Program Execution 114 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5 – Instruction Set 115 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1 Notation 118 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Instruction Format 118 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 Data Areas, Definer Values, and Flags 118 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-4 Differentiated Instructions 119 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5 Expansion Instructions 120 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-6 Coding Right-hand Instructions 122 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-7 Instruction Set Lists 125 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-7-1 Function Codes 125 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-7-2 Alphabetic List by Mnemonic 125 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-8 Ladder Diagram Instructions 129 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-8-1 LOAD, LOAD NOT, AND, AND NOT, OR, and OR NOT 129 . . . . . . . .

5-8-2 AND LOAD and OR LOAD 130 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-9 Bit Control Instructions 130 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-9-1 OUTPUT and OUTPUT NOT – OUT and OUT NOT 130 . . . . . . . . . . . .

5-9-2 DIFFERENTIATE UP and DOWN – DIFU(13) and DIFD(14) 131 . . . . .

5-9-3 SET and RESET – SET and RSET 133 . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-9-4 KEEP – KEEP(11) 133 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-10 INTERLOCK and INTERLOCK CLEAR – IL(02) and ILC(03) 135 . . . . . . . . . . . .

5-11 JUMP and JUMP END – JMP(04) and JME(05) 137 . . . . . . . . . . . . . . . . . . . . . . . . .

5-12 END – END(01) 138 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-13 NO OPERATION – NOP(00) 138 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-14 Timer and Counter Instructions 138 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-14-1 TIMER – TIM 139 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-14-2 HIGH-SPEED TIMER – TIMH(15) 143 . . . . . . . . . . . . . . . . . . . . . . . . . .

5-14-3 TOTALIZING TIMER – TTIM(87) 144 . . . . . . . . . . . . . . . . . . . . . . . . . .

5-14-4 COUNTER – CNT 145 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-14-5 REVERSIBLE COUNTER – CNTR(12) 148 . . . . . . . . . . . . . . . . . . . . . .

vii

Page 8

Table of contents

5-15 Data Shifting 150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-15-1 SHIFT REGISTER – SFT(10) 150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-15-2 REVERSIBLE SHIFT REGISTER – SFTR(84) 152 . . . . . . . . . . . . . . . . .

5-15-3 ARITHMETIC SHIFT LEFT – ASL(25) 154 . . . . . . . . . . . . . . . . . . . . . .

5-15-4 ARITHMETIC SHIFT RIGHT – ASR(26) 154 . . . . . . . . . . . . . . . . . . . . .

5-15-5 ROTATE LEFT – ROL(27) 155 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-15-6 ROTATE RIGHT – ROR(28) 155 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-15-7 ONE DIGIT SHIFT LEFT – SLD(74) 156 . . . . . . . . . . . . . . . . . . . . . . . .

5-15-8 ONE DIGIT SHIFT RIGHT – SRD(75) 156 . . . . . . . . . . . . . . . . . . . . . . .

5-15-9 WORD SHIFT – WSFT(16) 157 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-15-10 ASYNCHRONOUS SHIFT REGISTER – ASFT(17) 157 . . . . . . . . . . . .

5-16 Data Movement 158 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-16-1 MOVE – MOV(21) 159 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-16-2 MOVE NOT – MVN(22) 159 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-16-3 BLOCK SET – BSET(71) 160 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-16-4 BLOCK TRANSFER – XFER(70) 161 . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-16-5 DATA EXCHANGE – XCHG(73) 162 . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-16-6 SINGLE WORD DISTRIBUTE – DIST(80) 162 . . . . . . . . . . . . . . . . . . .

5-16-7 DATA COLLECT – COLL(81) 164 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-16-8 MOVE BIT – MOVB(82) 166 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-16-9 MOVE DIGIT – MOVD(83) 167 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-16-10 TRANSFER BITS – XFRB(62) 168 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-17 Data Comparison 169 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-17-1 MULTI-WORD COMPARE – MCMP(19) 169 . . . . . . . . . . . . . . . . . . . . .

5-17-2 COMPARE – CMP(20) 170 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-17-3 DOUBLE COMPARE – CMPL(60) 172 . . . . . . . . . . . . . . . . . . . . . . . . . .

5-17-4 BLOCK COMPARE – BCMP(68) 174 . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-17-5 TABLE COMPARE – TCMP(85) 175 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-17-6 AREA RANGE COMPARE – ZCP(88) 176 . . . . . . . . . . . . . . . . . . . . . . .

5-17-7 DOUBLE AREA RANGE COMPARE – ZCPL(––) 177 . . . . . . . . . . . . .

5-17-8 SIGNED BINARY COMPARE – CPS(––) 178 . . . . . . . . . . . . . . . . . . . . .

5-17-9 DOUBLE SIGNED BINARY COMPARE – CPSL(––) 179 . . . . . . . . . . .

5-18 Data Conversion 180 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-18-1 BCD-TO-BINARY – BIN(23) 180 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-18-2 DOUBLE BCD-TO-DOUBLE BINARY – BINL(58) 181 . . . . . . . . . . . .

5-18-3 BINARY-TO-BCD – BCD(24) 181 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-18-4 DOUBLE BINARY-TO-DOUBLE BCD – BCDL(59) 182 . . . . . . . . . . . .

5-18-5 HOURS-TO-SECONDS – SEC(65) 183 . . . . . . . . . . . . . . . . . . . . . . . . . .

5-18-6 SECONDS-TO-HOURS – HMS(66) 184 . . . . . . . . . . . . . . . . . . . . . . . . . .

5-18-7 4-TO-16 DECODER – MLPX(76) 185 . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-18-8 16-TO-4 ENCODER – DMPX(77) 188 . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-18-9 7-SEGMENT DECODER – SDEC(78) 191 . . . . . . . . . . . . . . . . . . . . . . . .

5-18-10 ASCII CONVERT – ASC(86) 194 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-18-11 ASCII-TO-HEXADECIMAL – HEX(––) 195 . . . . . . . . . . . . . . . . . . . . . .

5-18-12 SCALING – SCL(––) 198 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-18-13 COLUMN TO LINE – LINE(63) 200 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-18-14 LINE TO COLUMN – COLM(64) 201 . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-18-15 2’S COMPLEMENT – NEG(––) 202 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-18-16 DOUBLE 2’S COMPLEMENT – NEGL(––) 203 . . . . . . . . . . . . . . . . . . .

5-19 BCD Calculations 204 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-19-1 INCREMENT – INC(38) 204 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-19-2 DECREMENT – DEC(39) 204 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-19-3 SET CARRY – STC(40) 205 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-19-4 CLEAR CARRY – CLC(41) 205 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-19-5 BCD ADD – ADD(30) 205 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-19-6 DOUBLE BCD ADD – ADDL(54) 206 . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-19-7 BCD SUBTRACT – SUB(31) 207 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-19-8 DOUBLE BCD SUBTRACT – SUBL(55) 209 . . . . . . . . . . . . . . . . . . . . .

5-19-9 BCD MULTIPLY – MUL(32) 211 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-19-10 DOUBLE BCD MULTIPLY – MULL(56) 212 . . . . . . . . . . . . . . . . . . . . .

viii

Page 9

Table of contents

5-19-11 BCD DIVIDE – DIV(33) 212 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-19-12 DOUBLE BCD DIVIDE – DIVL(57) 213 . . . . . . . . . . . . . . . . . . . . . . . . .

5-19-13 FLOATING POINT DIVIDE – FDIV(79) 214 . . . . . . . . . . . . . . . . . . . . . .

5-19-14 SQUARE ROOT – ROOT(72) 217 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-20 Binary Calculations 219 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-20-1 BINARY ADD – ADB(50) 219 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-20-2 BINARY SUBTRACT – SBB(51) 221 . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-20-3 BINARY MULTIPLY – MLB(52) 224 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-20-4 BINARY DIVIDE – DVB(53) 224 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-20-5 DOUBLE BINARY ADD – ADBL(––) 225 . . . . . . . . . . . . . . . . . . . . . . .

5-20-6 DOUBLE BINARY SUBTRACT – SBBL(––) 227 . . . . . . . . . . . . . . . . . .

5-20-7 SIGNED BINARY MULTIPLY – MBS(––) 229 . . . . . . . . . . . . . . . . . . . .

5-20-8 DOUBLE SIGNED BINARY MULTIPLY – MBSL(––) 230 . . . . . . . . . .

5-20-9 SIGNED BINARY DIVIDE – DBS(––) 231 . . . . . . . . . . . . . . . . . . . . . . .

5-20-10 DOUBLE SIGNED BINARY DIVIDE – DBSL(––) 232 . . . . . . . . . . . . .

5-21 Special Math Instructions 233 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-21-1 FIND MAXIMUM – MAX(––) 233 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-21-2 FIND MINIMUM – MIN(––) 234 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-21-3 AVERAGE VALUE – AVG(––) 235 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-21-4 SUM – SUM(––) 237 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-21-5 ARITHMETIC PROCESS – APR(69) 239 . . . . . . . . . . . . . . . . . . . . . . . .

5-21-6 PID CONTROL – PID(––) 242 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-22 Logic Instructions 249 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-22-1 COMPLEMENT – COM(29) 249 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-22-2 LOGICAL AND – ANDW(34) 250 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-22-3 LOGICAL OR – ORW(35) 251 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-22-4 EXCLUSIVE OR – XORW(36) 252 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-22-5 EXCLUSIVE NOR – XNRW(37) 253 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-23 Subroutines and Interrupt Control 253 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-23-1 Subroutines 253 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-23-2 Interrupts 254 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-23-3 SUBROUTINE ENTER – SBS(91) 257 . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-23-4 SUBROUTINE DEFINE and RETURN – SBN(92)/RET(93) 259 . . . . . .

5-23-5 MACRO – MCRO(99) 260 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-23-6 INTERRUPT CONTROL – INT(89) 262 . . . . . . . . . . . . . . . . . . . . . . . . .

5-24 Step Instructions 266 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-24-1 STEP DEFINE and STEP START–STEP(08)/SNXT(09) 266 . . . . . . . . .

5-25 Special Instructions 275 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-25-1 FAILURE ALARM – FAL(06) and

5-25-2 CYCLE TIME – SCAN(18) 276 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-25-3 TRACE MEMORY SAMPLING – TRSM(45) 277 . . . . . . . . . . . . . . . . . .

5-25-4 MESSAGE DISPLAY – MSG(46) 278 . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-25-5 LONG MESSAGE – LMSG(47) 279 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-25-6 TERMINAL MODE – TERM(48) 280 . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-25-7 WATCHDOG TIMER REFRESH – WDT(94) 281 . . . . . . . . . . . . . . . . . .

5-25-8 I/O REFRESH – IORF(97) 281 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-25-9 GROUP-2 HIGH-DENSITY I/O REFRESH – MPRF(61) 282 . . . . . . . . .

5-25-10 BIT COUNTER – BCNT(67) 283 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-25-11 FRAME CHECKSUM – FCS(––) 283 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-25-12 FAILURE POINT DETECTION – FPD(––) 285 . . . . . . . . . . . . . . . . . . . .

5-25-13 DATA SEARCH – SRCH(––) 289 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-25-14 EXPANSION DM READ – XDMR(––) 290 . . . . . . . . . . . . . . . . . . . . . . .

5-26 Network Instructions 291 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-26-1 NETWORK SEND – SEND(90) 291 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-26-2 NETWORK RECEIVE – RECV(98) 293 . . . . . . . . . . . . . . . . . . . . . . . . .

5-26-3 About Network Communications 295 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-27 Serial Communications Instructions 297 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-27-1 RECEIVE – RXD(––) 297 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-27-2 TRANSMIT – TXD(––) 299 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SEVERE FAILURE ALARM – FALS(07) 275 . . . . . . . . . . . . . . . . . . . . .

ix

Page 10

Table of contents

5-28 Advanced I/O Instructions 301 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-28-1 7-SEGMENT DISPLAY OUTPUT – 7SEG(––) 301 . . . . . . . . . . . . . . . . .

5-28-2 DIGITAL SWITCH INPUT – DSW(––) 304 . . . . . . . . . . . . . . . . . . . . . . .

5-28-3 HEXADECIMAL KEY INPUT – HKY(––) 308 . . . . . . . . . . . . . . . . . . . .

5-28-4 TEN KEY INPUT – TKY(––) 311 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-28-5 MATRIX INPUT – MTR(––) 313 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6 – Program Execution Timing 317 . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1 Cycle Time 318 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2 Calculating Cycle Time 322 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-1 PC with I/O Units Only 322 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-2 PC with Link Units 323 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3 Instruction Execution Times 324 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4 I/O Response Time 333 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4-1 Basic Systems 333 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4-2 Remote I/O Systems 334 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4-3 Host Link Systems 336 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4-4 PC Link Systems 337 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4-5 One-to-one Link I/O Response Time 339 . . . . . . . . . . . . . . . . . . . . . . . . .

6-4-6 Interrupt Response Times 341 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 7 – Program Monitoring and Execution 345 . . . . . . . . . . . . . . . . . .

7-1 Monitoring Operation and Modifying Data 346 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1-1 Bit/Word Monitor 346 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1-2 Forced Set/Reset 349 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1-3 Forced Set/Reset Cancel 351 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1-4 Hexadecimal/BCD Data Modification 352 . . . . . . . . . . . . . . . . . . . . . . . .

7-1-5 Hex/ASCII Display Change 354 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1-6 4-digit Hex/Decimal Display Change 355 . . . . . . . . . . . . . . . . . . . . . . . . .

7-1-7 8-digit Hex/Decimal Display Change 356 . . . . . . . . . . . . . . . . . . . . . . . . .

7-1-8 Differentiation Monitor 357 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1-9 3-word Monitor 358 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1-10 3-word Data Modification 358 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1-11 Binary Monitor 359 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1-12 Binary Data Modification 361 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1-13 Changing Timer/Counter SV 362 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1-14 Expansion Instruction Function Code Assignments 365 . . . . . . . . . . . . . .

7-1-15 UM Area Allocation 366 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1-16 Reading and Setting the Clock 367 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1-17 Expansion Keyboard Mapping 367 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1-18 Keyboard Mapping 368 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 8 – Communications 373 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-1 Introduction 374 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-2 Parameters for Host Link and RS-232C Communications 374 . . . . . . . . . . . . . . . . .

8-2-1 Standard Communications Parameters 375 . . . . . . . . . . . . . . . . . . . . . . . .

8-2-2 Specific Communications Parameters 376 . . . . . . . . . . . . . . . . . . . . . . . . .

8-2-3 Wiring Ports 377 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-2-4 Host Link Communications 377 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-2-5 RS-232C Communications 379 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-2-6 One-to-one Link Communications 382 . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-2-7 NT Links 384 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 9 – Memory Cassette Operations 385 . . . . . . . . . . . . . . . . . . . . . . . .

9-1 Memory Cassettes 386 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-2 Memory Cassette Settings and Flags 386 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-3 UM Area Data 387 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-4 IOM Area Data 388 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

x

Page 11

Table of contents

SECTION 10 – Troubleshooting 391 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-1 Alarm Indicators 392 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-2 Programmed Alarms and Error Messages 392 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-3 Reading and Clearing Errors and Messages 392 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-4 Error Messages 392 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-5 Error Flags 397 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-6 Host Link Errors 399 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 11 – Host Link Commands 401 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-1 Communications Procedure 402 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-2 Command and Response Formats 404 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-2-1 Commands from the Host Computer 404 . . . . . . . . . . . . . . . . . . . . . . . . . .

11-2-2 Commands from the PC 406 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3 Host Link Commands 407 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-1 IR/SR AREA READ –– RR 407 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-2 LR AREA READ –– RL 407 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-3 HR AREA READ –– RH 408 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-4 PV READ –– RC 408 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-5 TC STATUS READ –– RG 409 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-6 DM AREA READ –– RD 409 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-7 AR AREA READ –– RJ 410 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-8 IR/SR AREA WRITE –– WR 410 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-9 LR AREA WRITE –– WL 411 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-10 HR AREA WRITE –– WH 411 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-11 PV WRITE –– WC 412 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-12 TC STATUS WRITE –– WG 412 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-13 DM AREA WRITE –– WD 413 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-14 AR AREA WRITE –– WJ 413 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-15 SV READ 1 –– R# 414 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-16 SV READ 2 –– R$ 415 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-17 SV READ 3 –– R% 416 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-18 SV CHANGE 1 –– W# 417 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-19 SV CHANGE 2 –– W$ 417 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-20 SV CHANGE 3 –– W% 418 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-21 STATUS READ –– MS 419 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-22 STATUS WRITE –– SC 420 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-23 ERROR READ –– MF 421 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-24 FORCED SET –– KS 422 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-25 FORCED RESET –– KR 423 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-26 MULTIPLE FORCED SET/RESET –– FK 424 . . . . . . . . . . . . . . . . . . . . .

11-3-27 FORCED SET/RESET CANCEL –– KC 425 . . . . . . . . . . . . . . . . . . . . . .

11-3-28 PC MODEL READ –– MM 425 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-29 TEST–– TS 426 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-30 PROGRAM READ –– RP 426 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-31 PROGRAM WRITE –– WP 427 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-32 I/O TABLE GENERATE –– MI 427 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-33 COMPOUND COMMAND –– QQ 427 . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-34 ABORT –– XZ 429 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-35 INITIALIZE –– :: 430 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3-36 Undefined Command –– IC 430 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-4 Host Link Errors 431 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xi

Page 12

Table of contents

Appendix 433 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A – Standard Models 433 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B – Programming Instructions 443 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C – Error and Arithmetic Flag Operation 449 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D – Memory Areas 453 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E – PC Setup 461 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F – Word Assignment Recording Sheets 465 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

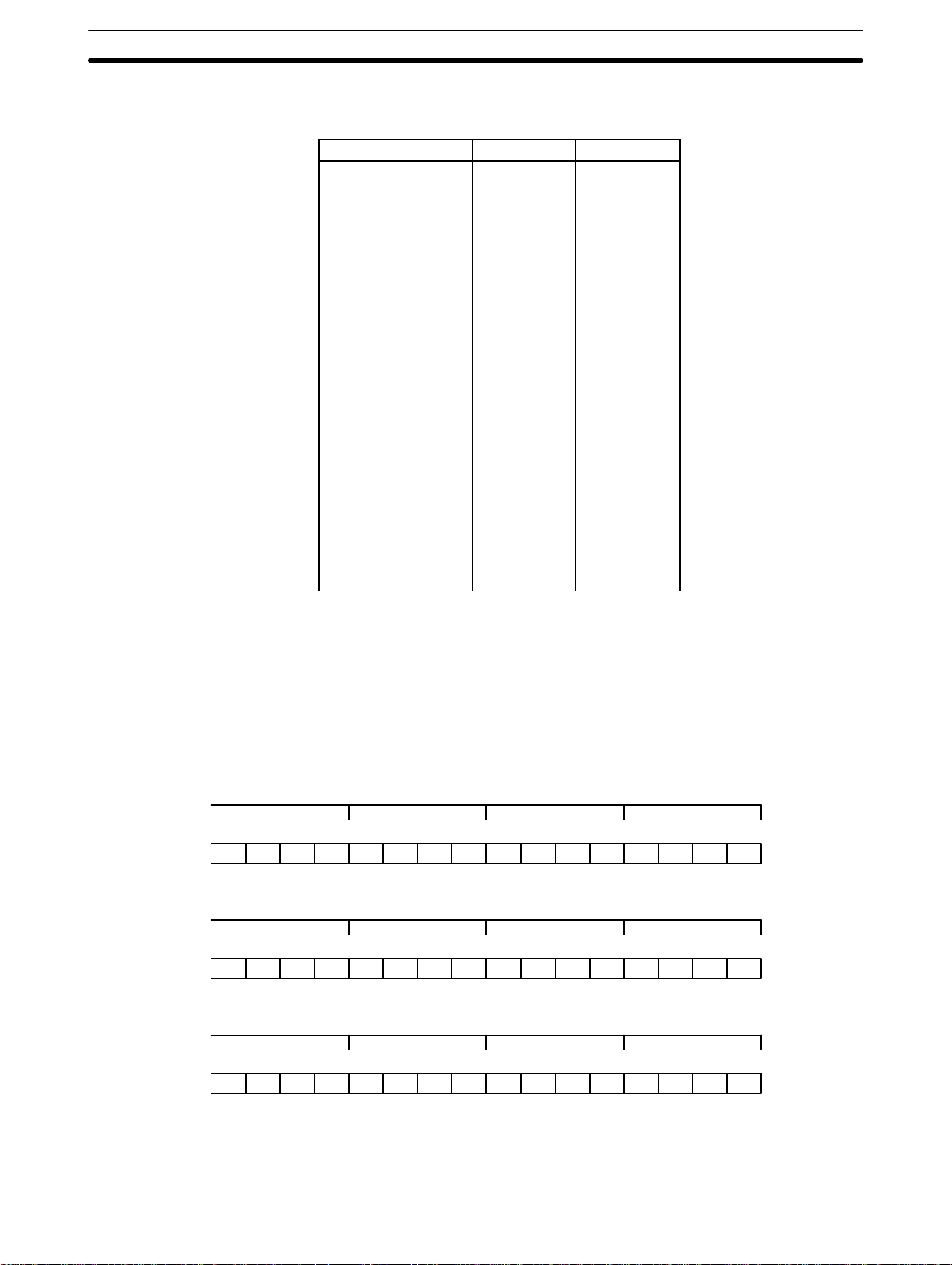

G – Program Coding Sheet 471 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

H – Data Conversion Tables 473 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I – Extended ASCII 475 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary 477 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History 493 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 497 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xii

Page 13

PRECAUTIONS

This section provides general precautions for using the Programmable Controller (PC) and related devices.

The information contained in this section is important for the safe and reliable application of the PC. You must read

this section and understand the information contained before attempting to set up or operate a PC system.

1 Intended Audience xiv . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xiv . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xiv . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions xiv . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions xv . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Conformance to EC Directives xvi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xiii

Page 14

Operating Environment Precautions

1 Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications

described in the operation manuals.

Before using the product under conditions which are not described in the manual

or applying the product to nuclear control systems, railroad systems, aviation

systems, vehicles, combustion systems, medical equipment, amusement

machines, safety equipment, and other systems, machines, and equipment that

may have a serious influence on lives and property if used improperly, consult

your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide the

systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating OMRON PCs.

Be sure to read this manual before attempting to use the software and keep this

manual close at hand for reference during operation.

4

WARNING It is extremely important that a PC and all PC Units be used for the specified

!

purpose and under the specified conditions, especially in applications that can

directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PC System to the abovementioned

applications.

3 Safety Precautions

WARNING Never attempt to disassemble any Units while power is being supplied. Doing so

!

may result in serious electrical shock or electrocution.

WARNING Never touch any of the terminals while power is being supplied. Doing so may

!

result in serious electrical shock or electrocution.

4 Operating Environment Precautions

Do not operate the control system in the following places.

• Where the PC is exposed to direct sunlight.

• Where the ambient temperature is below 0°C or over 55°C.

• Where the PC may be affected by condensation due to radical temperature

changes.

• Where the ambient humidity is below 10% or over 90%.

• Where there is any corrosive or inflammable gas.

• Where there is excessive dust, saline air, or metal powder.

• Where the PC is affected by vibration or shock.

• Where any water, oil, or chemical may splash on the PC.

xiv

Page 15

Application Precautions

Caution The operating environment of the PC System can have a large ef fect on the lon-

!

gevity and reliability of the system. Improper operating environments can lead to

malfunction, failure, and other unforeseeable problems with the PC System. Be

sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life of the system.

5 Application Precautions

Observe the following precautions when using the PC.

WARNING Failure to abide by the following precautions could lead to serious or possibly

!

fatal injury. Always heed these precautions.

• Always ground the system to 100 Ω or less when installing the system to pro-

tect against electrical shock.

• Always turn off the power supply to the PC before attempting any of the following. Performing any of the following with the power supply turned on may lead

to electrical shock:

• Mounting or dismounting Power Supply Units, I/O Units, CPU Units,

Memory Units, or any other Units.

• Assembling any devices or racks.

• Connecting or disconnecting any cables or wiring.

5

Caution Failure to abide by the following precautions could lead to faulty operation or the

!

PC or the system or could damage the PC or PC Units. Always heed these precautions.

• Use the Units only with the power supplies and voltages specified in the operation manuals. Other power supplies and voltages may damage the Units.

• Take measures to stabilize the power supply to conform to the rated supply if it

is not stable.

• Provide circuit breakers and other safety measures to provide protection

against shorts in external wiring.

• Do not apply voltages exceeding the rated input voltage to Input Units. The

Input Units may be destroyed.

• Do not apply voltages exceeding the maximum switching capacity to Output

Units. The Output Units may be destroyed.

• Always disconnect the LG terminal when performing withstand voltage tests.

• Install all Units according to instructions in the operation manuals. Improper

installation may cause faulty operation.

• Provide proper shielding when installing in the following locations:

• Locations subject to static electricity or other sources of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radiation.

• Locations near to power supply lines.

• Be sure to tighten Backplane screws, terminal screws, and cable connector

screws securely.

• Do not attempt to take any Units apart, to repair any Units, or to modify any

Units in any way.

Caution The following precautions are necessary to ensure the general safety of the sys-

!

tem. Always heed these precautions.

• Provide double safety mechanisms to handle incorrect signals that can be

generated by broken signal lines or momentary power interruptions.

• Provide external interlock circuits, limit circuits, and other safety circuits in

addition to any provided within the PC to ensure safety.

xv

Page 16

Conformance to EC Directives

6 Conformance to EC Directives

Observe the following precautions when installing the C200HS-CPU01-EC and

C200HS-CPU21-EC that conform to the EC Directives.

Provide reinforced insulation or double insulation for the DC power source connected to the DC I/O Unit and for the Power Supply Unit.

Use a separate power source for the DC I/O Unit from the external power supply

for the Relay Output Unit.

Section 6

xvi

Page 17

SECTION 1

Introduction

This section gives a brief overview of the history of Programmable Controllers and explains terms commonly used in ladderdiagram programming. It also provides an overview of the process of programming and operating a PC and explains basic

terminology used with OMRON PCs. Descriptions of peripheral devices used with the C200HS, a table of other manuals

available to use with this manual for special PC applications, and a description of the new features of the C200HS are also

provided.

1-1 Overview 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 The Origins of PC Logic 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 PC Terminology 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 OMRON Product Terminology 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5 Overview of PC Operation 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-6 Peripheral Devices 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-7 Available Manuals 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8 New C200HS Features 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8-1 Improved Memory Capabilities 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8-2 Faster Execution Times 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8-3 Larger Instruction Set 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8-4 Wide Selection of Special I/O Units 9 . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8-5 Improved Interrupt Functions 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8-6 SYSMAC NET Link and SYSMAC LINK Capabilities 9 . . . . . . . . . . .

1-8-7 Built-in RS-232C Connector 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8-8 More Flexible PC Settings 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8-9 Debugging and Maintenance 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8-10 New Programming Console Operations 10 . . . . . . . . . . . . . . . . . . . . . . . .

1-8-11 Peripheral Devices 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8-12 Using C200H Programs 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

Page 18

The Origins of PC Logic Section 1-2

1-1 Overview

A PC (Programmable Controller) is basically a CPU (Central Processing Unit)

containing a program and connected to input and output (I/O) devices. The program controls the PC so that when an input signal from an input device turns ON,

the appropriate response is made. The response normally involves turning ON

an output signal to some sort of output device. The input devices could be photoelectric sensors, pushbuttons on control panels, limit switches, or any other device that can produce a signal that can be input into the PC. The output devices

could be solenoids, switches activating indicator lamps, relays turning on motors, or any other devices that can be activated by signals output from the PC.

For example, a sensor detecting a passing product turns ON an input to the PC.

The PC responds by turning ON an output that activates a pusher that pushes

the product onto another conveyor for further processing. Another sensor, positioned higher than the first, turns ON a different input to indicate that the product

is too tall. The PC responds by turning on another pusher positioned before the

pusher mentioned above to push the too-tall product into a rejection box.

Although this example involves only two inputs and two outputs, it is typical of the

type of control operation that PCs can achieve. Actually even this example is

much more complex than it may at first appear because of the timing that would

be required, i.e., “How does the PC know when to activate each pusher?” Much

more complicated operations, however, are also possible. The problem is how

to get the desired control signals from available inputs at appropriate times.

To achieve proper control, the C200HS uses a form of PC logic called ladder-diagram programming. This manual is written to explain ladder-diagram programming and to prepare the reader to program and operate the C200HS.

1-2 The Origins of PC Logic

PCs historically originate in relay-based control systems. And although the integrated circuits and internal logic of the PC have taken the place of the discrete

relays, timers, counters, and other such devices, actual PC operation proceeds

as if those discrete devices were still in place. PC control, however, also provides computer capabilities and accuracy to achieve a great deal more flexibility

and reliability than is possible with relays.

The symbols and other control concepts used to describe PC operation also

come from relay-based control and form the basis of the ladder-diagram programming method. Most of the terms used to describe these symbols and concepts, however, have come in from computer terminology.

Relay vs. PC Terminology The terminology used throughout this manual is somewhat different from relay

terminology, but the concepts are the same.

The following table shows the relationship between relay terms and the PC

terms used for OMRON PCs.

Relay term PC equivalent

contact input or condition

coil output or work bit

NO relay normally open condition

NC relay normally closed condition

Actually there is not a total equivalence between these terms. The term condition is only used to describe ladder diagram programs in general and is specifically equivalent to one of certain set of basic instructions. The terms input and

output are not used in programming per se, except in reference to I/O bits that

are assigned to input and output signals coming into and leaving the PC. Normally open conditions and normally closed conditions are explained in

Ladder Diagrams

.

4-4 Basic

2

Page 19

OMRON Product Terminology Section 1-4

1-3 PC Terminology

Although also provided in the

terms are crucial to understanding PC operation and are thus explained here.

PC Because the C200HS is a Rack PC, there is no one product that is a C200HS

PC. That is why we talk about the configuration of the PC, because a PC is a

configuration of smaller Units.

To have a functional PC, you would need to have a CPU Rack with at least one

Unit mounted to it that provides I/O points. When we refer to the PC, however , we

are generally talking about the CPU and all of the Units directly controlled by it

through the program. This does not include the I/O devices connected to P C i n puts and outputs.

If you are not familiar with the terms used above to describe a PC, refer to

tion 2 Hardware Considerations

Inputs and Outputs A device connected to the PC that sends a signal to the PC is called an input

device; the signal it sends is called an input signal. A signal enters the PC

through terminals or through pins on a connector on a Unit. The place where a

signal enters the PC is called an input point. This input point is allocated a location in memory that reflects its status, i.e., either ON or OFF. This memory location is called an input bit. The CPU, in its normal processing cycle, monitors the

status of all input points and turns ON or OFF corresponding input bits accordingly.

There are also output bits in memory that are allocated to output points on

Units through which output signals are sent to output devices, i.e., an output

bit is turned ON to send a signal to an output device through an output point. The

CPU periodically turns output points ON or OFF according to the status of the

output bits.

These terms are used when describing different aspects of PC operation. When

programming, one is concerned with what information is held in memory , and so

I/O bits are referred to. When talking about the Units that connect the PC to the

controlled system and the places on these Units where signals enter and leave

the PC, I/O points are referred to. When wiring these I/O points, the physical

counterparts of the I/O points, either terminals or connector pins, are referred to.

When talking about the signals that enter or leave the PC, one refers to input

signals and output signals, or sometimes just inputs and outputs. It all depends

on what aspect of PC operation is being talked about.

Glossary

at the back of this manual, the following

for explanations.

Sec-

Controlled System and

Control System

The Control System includes the PC and all I/O devices it uses to control an external system. A sensor that provides information to achieve control is an input

device that is clearly part of the Control System. The controlled system is the

external system that is being controlled by the PC program through these I/O

devices. I/O devices can sometimes be considered part of the controlled system, e.g., a motor used to drive a conveyor belt.

1-4 OMRON Product Terminology

OMRON products are divided into several functional groups that have generic

names.

The term Unit is used to refer to all of the OMRON PC products. Although a Unit

is any one of the building blocks that goes together to form a C200HS PC, its

meaning is generally, but not always, limited in context to refer to the Units that

are mounted to a Rack. Most, but not all, of these products have names that end

with the word Unit.

The largest group of OMRON products is the I/O Units. These include all of the

Rack-mounting Units that provide non-dedicated input or output points for general use. I/O Units come with a variety of point connections and specifications.

Appendix A Standard Models

list products according to these groups.

3

Page 20

Overview of PC Operation Section 1-5

High-density I/O Units are designed to provide high-density I/O capability and

include Group 2 High-density I/O Units and Special I/O High-density I/O Units.

Special I/O Units are dedicated Units that are designed to meet specific needs.

These include some of the High-density I/O Units, Position Control Units, Highspeed Counter Units, and Analog I/O Units.

Link Units are used to create Link Systems that link more than one PC or link a

single PC to remote I/O points. Link Units include Remote I/O Units, PC Link

Units, Host Link Units, SYSMAC NET Link Units, and SYSMAC LINK Units.

SYSMAC NET Link and SYSMAC LINK Units can be used with the CPU11 only.

Other product groups include Programming Devices, Peripheral Devices,

and DIN Rail Products.

1-5 Overview of PC Operation

The following are the basic steps involved in programming and operating a

C200HS. Assuming you have already purchased one or more of these PCs, you

must have a reasonable idea of the required information for steps one and two,

which are discussed briefly below. This manual is written t o explain steps three

through six, eight, and nine. The relevant sections of this manual that provide

more information are listed with each of these steps.

1, 2, 3...

Control System Design Designing the Control System is the first step in automating any process. A PC

1. Determine what the controlled system must do, in what order, and at what

times.

2. Determine what Racks and what Units will be required. Refer to the

Installation Guide

tem Manual

3. On paper, assign all input and output devices to I/O points on Units and determine which I/O bits will be allocated to each. If the PC includes Special I/O

Units or Link Systems, refer to the individual

Manuals

4. Using relay ladder symbols, write a program that represents the sequence

of required operations and their inter-relationships. Be sure to also program

appropriate responses for all possible emergency situations. (

for details on I/O bit allocation. (

. If a Link System is required, refer to the appropriate

.

Operation Manuals

Section 3 Memory Areas)

C200HS

Sys-

or

System

Section 4

Writing and Inputting the Program, Section 5 Instruction Set, Section 6 Program Execution Timing)

5. Input the program and all required operating parameters into the PC. (

tion 4-7 Inputting, Modifying, and Checking the Program.

6. Debug the program, first to eliminate any syntax errors, and then to find execution errors. (

Section 4-7 Inputting, Modifying, and Checking the Program, Section 7 Program Monitoring and Execution,

Troubleshooting

7. Wire the PC to the controlled system. This step can actually be started as

soon as step 3 has been completed. Refer t o the

and to

Units.

8. Test the program in an actual control situation and carry out fine tuning as

required. (

Operation Manuals

Troubleshooting

9. Record two copies of the finished program on masters and store them safely

in different locations. (

Program

can be programmed and operated only after the overall Control System is fully

understood. Designing the Control System requires, first of all, a thorough understanding of the system that is to be controlled. The first step in designing a

Control System is thus determining the requirements of the controlled system.

)

)

C200HS Installation Guide

and

System Manuals

for details on individual

Section 7 Program Monitoring and Execution

)

Section 4-7 Inputting, Modifying, and Checking the

)

and

and

Sec-

Section 10

Section 10

4

Page 21

Available Manuals Section 1-7

Input/Output Requirements The first thing that must be assessed is the number of input and output points

that the controlled system will require. This is done by identifying each device

that is to send an input signal to the PC or which is to receive an output signal

from the PC. Keep in mind that the number of I/O points available depends on

the configuration of the PC. Refer to

the allocation of I/O bits to I/O points.

Sequence, Timing, and

Relationships

Unit Requirements The actual Units that will be mounted or connected to PC Racks must be deter-

Next, determine the sequence in which control operations are to occur and the

relative timing of the operations. Identify the physical relationships between the

I/O devices as well as the kinds of responses that should occur between them.

For instance, a photoelectric switch might be functionally tied to a motor by way

of a counter within the PC. When the PC receives an input from a start switch, it

could start the motor. The PC could then stop the motor when the counter has

received a specified number of input signals from the photoelectric switch.

Each of the related tasks must be similarly determined, from the beginning of the

control operation to the end.

mined according to the requirements of the I/O devices. Actual hardware specifications, such as voltage and current levels, as well as functional considerations,

such as those that require Special I/O Units or Link Systems will need to be considered. In many cases, Special I/O Units, Intelligent I/O Units, or Link Systems

can greatly reduce the programming burden. Details on these Units and Link

Systems are available in appropriate

Once the entire Control System has been designed, the task of programming,

debugging, and operation as described in the remaining sections of this manual

can begin.

3-3 IR Area

Operation Manuals

for details on I/O capacity and

and

System Manuals.

1-6 Peripheral Devices

The following peripheral devices can be used in programming, either to input/

debug/monitor the PC program or to interface the PC to external devices to output the program or memory area data. Model numbers for all devices listed below are provided in

been placed in bold when introduced in the following descriptions.

Programming Console A Programming Console is the simplest form of programming device for OM-

RON PCs. All Programming Consoles are connected directly to the CPU without

requiring a separate interface.

Ladder Support Software:

LSS

LSS is designed to run on IBM AT/XT compatibles and allows you to perform all

the operations of the Programming Console as well as many additional ones. PC

programs can be written on-screen in ladder-diagram form as well as in mnemonic form. As the program is written, it is displayed on a display, making confirmation and modification quick and easy . Syntax checks may also be performed

on the programs before they are downloaded to the PC.

The LSS is available on either 5” or 3.5” disks.

A computer running the LSS is connected to the C200HS via the Peripheral Port

on the CPU using the CQM1-CIF02 cable.

Appendix A Standard Models

. OMRON product names have

1-7 Available Manuals

The following table lists other manuals that may be required to program and/or

operate the C200HS.

vided with individual Units and are required for wiring and other specifications.

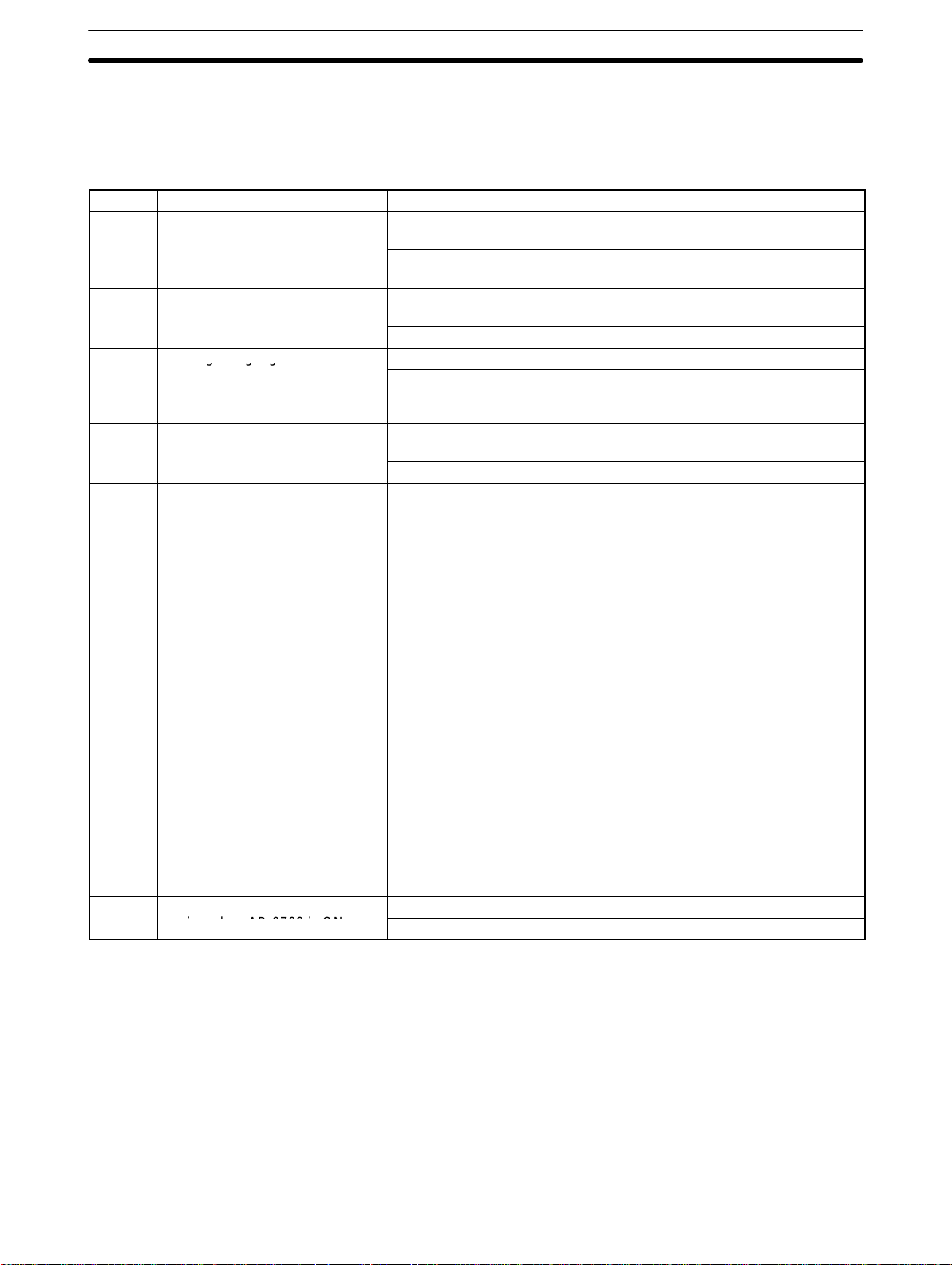

Name Cat. No. Contents

GPC Operation Manual W84 Programming procedures for the GPC

FIT Operation Manual W150 Programming procedures for using the FIT

Operation Manuals

(Graphics Programming Console)

(Factory Intelligent Terminal

and/or

Operation Guides

are also pro-

5

Page 22

New C200HS Features Section 1-8

Name ContentsCat. No.

SYSMAC Support Software Operation Manuals W247/W248 Programming procedures for using the SSS

Data Access Console Operation Guide W173 Data area monitoring and data modification

procedures for the Data Access Console

Printer Interface Unit Operation Guide W107 Procedures for interfacing a PC to a printer

PROM Writer Operation Guide W155 Procedures for writing programs to EPROM chips

Floppy Disk Interface Unit Operation Guide W119 Procedures for interfacing PCs to floppy disk drives

Wired Remote I/O System Manual

(SYSMAC BUS)

Optical Remote I/O System Manual

(SYSMAC BUS)

PC Link System Manual W135 Information on building a PC Link System to

Host Link System Manual

(SYSMAC WAY)

SYSMAC NET Link Unit Operation Manual W114 Information on building a SYSMAC NET Link

SYSMAC LINK System Manual W174 Information on building a SYSMAC LINK System to

High-speed Counter Unit Operation Manual W141 Information on High-speed Counter Unit

Position Control Unit Operation Manuals NC111: W137

Analog I/O Units Operation Guide W127 Information on the C200H-AD001, C200H-DA001

Analog Input Unit Operation Manual W229 Information on the C200H-AD002 Analog Input Unit

Temperature Sensor Unit Operation Guide W124 Information on Temperature Sensor Unit

ASCII Unit Operation Manual W165 Information on ASCII Unit

ID Sensor Unit Operation Guide W153 Information on ID Sensor Unit

Voice Unit Operation Manual W172 Information on Voice Unit

Fuzzy Logic Unit Operation Manual W208 Information on Fuzzy Logic Unit

Fuzzy Support Software Operation Manual W210 Information on the Fuzzy Support Software which

Temperature Control Unit Operation Manual W225 Information on Temperature Control Unit

Heat/Cool Temperature Control Unit Operation

Manual

PID Control Unit Operation Manual W241 Information on PID Control Unit

Cam Positioner Unit Operation Manual W224 Information on Cam Positioner Unit

W120 Information on building a Wired Remote I/O System

to enable remote I/O capability

W136 Information on building an Optical Remote I/O

System to enable remote I/O capability

automatically transfer data between PCs

W143 Information on building a Host Link System to