Omron C200H-PID01, SYSMAC C200H-PID0, C200H-PID02, C200H-PID03, SYSMAC C200H-PID01 Operation Manual

...Page 1

Cat. No. W241-E1-2

SYSMAC

C200H–PID0_

PID Control Unit

Page 2

C200H-PID0j

PID Control Unit

Operation Manual

Revised March 2000

Page 3

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

!

serious injury.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

!

serious injury.

Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

!

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 1993

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Note Indicates information of particular interest for efficient and convenient operation

of the product.

1, 2, 3...

1. Indicates lists of one sort or another, such as procedures, checklists, etc.

ii

Page 4

About this Manual:

This manual describes the installation and operation of the C200H-PID0j PID Control Unit and includes

the sections described below. Also briefly described is the basic operation and installation of the

C200H-DSC01 Data Setting Console.

Please read this manual carefully and be sure you understand the information provided before attempting

to install and operate the C200H-PID0j PID Control Unit and Data Setting Console.

Section 1

Section 2

Section 3

tings and displays.

Section 4

cedures and examples are also provided.

Section 5

The three Appendices provide references dealing with specifications, dimensions, and key operations.

provides PID Control Unit features and describes its basic system configuration.

provides information on the connections and settings of the PID Control Unit.

provides the basic operating procedures of the Data Setting Console including parameter set-

provides the C200H PC’s memory allocation for the PID Control Unit. Basic programming pro-

describes possible errors and provides measures for dealing with them.

!

WARNING Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section in its entirety and be sure you understand the information provided in the section

and related sections before attempting any of the procedures or operations given.

iii

Page 5

TABLE OF CONTENTS

PRECAUTIONS vii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Intended Audience viii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions viii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions viii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions ix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions ix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1 – System Configuration and Features 1 . . . . . . . . . . . . . . . . . . .

1-1 Features 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Basic System Configuration 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2 – Connections and Settings 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1 Nomenclature 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Switch Settings 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 Wiring 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-1 Input Wiring 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-2 Output Wiring 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-3 Data Setting Console Cables 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3 – Data Setting Console Operation 19 . . . . . . . . . . . . . . . . . . . . . .

3-1 Operating Procedure 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Data Flow 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Nomenclature and Features 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3-1 Nomenclature 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3-2 Features 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Parameter Displays and Settings 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-1 Table of Parameters 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-2 How to Display and Set Parameter Data 25 . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4 – PC Memory Allocation and Programming 33 . . . . . . . . . . . . .

4-1 Memory Allocation 34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1-1 Memory Allocation Table 35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1-2 Memory Contents 36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1-3 Table of Commands 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Data Flow 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Programming 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3-1 Example with SW2-1 in the Fixed Position 42 . . . . . . . . . . . . . . . . . . . .

4-3-2 Example 1: Write with SW2-1 in the Normal Position 43 . . . . . . . . . . . .

4-3-3 Example 2: Read with SW2-1 in the Normal Position 46 . . . . . . . . . . . .

4-3-4 Operation Timing 49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5 – Troubleshooting 51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error Detection 52 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix 55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A – Specifications 55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B – Dimensions 57 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C – Parameters and Key Operations 59 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

v

Page 6

PRECAUTIONS

This section provides general precautions for using the C200H-PID0j PID Control Unit and related devices.

The information contained in this section is important for the safe and reliable application of the C200H-PID0j PID

Control Unit. You must read this section and understand the information contained before attempting to set up or

operate the C200H-PID0j PID Control Unit.

1 Intended Audience viii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions viii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions viii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions ix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions ix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vii

Page 7

1 Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications

described in the relevant manuals.

Before using the product under conditions which are not described in the manual

or applying the product to nuclear control systems, railroad systems, aviation

systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that

may have a serious influence on lives and property if used improperly, consult

your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide the

systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual

close at hand for reference during operation.

3Safety Precautions

WARNING It is extremely important that a PC and all PC Units be used for the specified

!

purpose and under the specified conditions, especially in applications that can

directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PC system to the above-mentioned

applications.

3 Safety Precautions

WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing so

!

may result in electric shock.

WARNING Do not touch any of the terminals or terminal blocks while the power is being

!

supplied. Doing so may result in electric shock.

WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do so

!

may result in malfunction, fire, or electric shock.

WARNING Provide safety measures in external circuits (i.e., not in the Programmable

!

Controller), inclu d i n g t h e f o l l o w i n g i tems, in order to ensure safety in the system

if an abnormality occurs due to malfunction of the PC or another external factor

affecting the PC operation. Not doing so may result in serious accidents.

viii

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PC will turn OFF all outputs when its self-diagnosis function detects any

error or when a severe failure alarm (FALS) instruction is executed. As a countermeasure for such errors, external safety measures must be provided to ensure safety in the system.

Page 8

• The PC outputs may remain ON or OFF due to deposition or burning of the

output relays or destruction of the output transistors. As a countermeasure for

such problems, external safety measures must be provided to ensure safety in

the system.

• When the 24-VDC output (service power supply to the PC) is overloaded or

short-circuited, the voltage may drop and result in the outputs being turned

OFF . As a countermeasure for such problems, external safety measures must

be provided to ensure safety in the system.

4 Operating Environment Precautions

Caution Do not operate the control system in the following locations:

!

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified in

the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

5Application Precautions

Caution Take appropriate and sufficient countermeasures when installing systems in the

!

following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

Caution The operating environment of the PC system can have a large effect on the lon-

!

gevity and reliability of the system. Improper operating environments can lead to

malfunction, failure, and other unforeseeable problems with the PC system. Be

sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life of the system.

5 Application Precautions

Observe the following precautions when using the PC system.

WARNING Always heed these precautions. Failure to abide by the following precautions

!

could lead to serious or possibly fatal injury.

• Always ground the system to 100 Ω or less when installing the Units. Not con-

necting to a ground of 100 Ω or less may result in electric shock.

• Always turn OFF the power supply to the PC before attempting any of the following. Not turning OFF the power supply may result in malfunction or electric

shock.

• Mounting or dismounting I/O Units, CPU Units, Memory Units, or any other

Units.

• Assembling the Units.

• Setting DIP switches or rotary switches.

• Connecting cables or wiring the system.

• Connecting or disconnecting the connectors.

ix

Page 9

Caution Failure to abide by the following precautions could lead to faulty operation of the

!

PC or the system, or could damage the PC or PC Units. Always heed these precautions.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal lines,

momentary power interruptions, or other causes.

• Always use the power supply voltages specified in this manual. An incorrect

voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the rated

voltage and frequency is supplied. Be particularly careful in places where the

power supply is unstable. An incorrect power supply may result in malfunction.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may

result in burning.

• Do not apply voltages to the Input Units in excess of the rated input voltage.

Excess voltages may result in burning.

• Do not apply voltages or connect loads to the Output Units in excess of the

maximum switching capacity. Excess voltage or loads may result in burning.

• Disconnect the functional ground terminal when performing withstand voltage

tests. Not disconnecting the functional ground terminal may result in burning.

• Be sure that all the mounting screws, terminal screws, and cable connector

screws are tightened to the torque specified in this manual. Incorrect tightening torque may result in malfunction.

• Leave the label attached to the Unit when wiring. Removing the label may result in malfunction if foreign matter enters the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Double-check all wiring and switch settings before turning ON the power supply. Incorrect wiring may result in burning.

• Wire correctly. Incorrect wiring may result in burning.

• Mount Units only after checking terminal blocks and connectors completely.

• Be sure that the terminal blocks, Memory Units, expansion cables, and other

items with locking devices are properly locked into place. Improper locking

may result in malfunction.

• Check the user program for proper execution before actually running it on the

Unit. Not checking the program may result in an unexpected operation.

• Confirm that no adverse ef fect will occur in the system before attempting any of

the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Resume operation only after transferring to the new CPU Unit the contents of

the DM Area, HR Area, and other data required for resuming operation. Not

doing so may result in an unexpected operation.

• Do not pull on the cables or bend the cables beyond their natural limit. Doing

either of these may break the cables.

• Do not place objects on top of the cables or other wiring lines. Doing so may

break the cables.

• Use crimp terminals for wiring. Do not connect bare stranded wires directly to

terminals. Connection of bare stranded wires may result in burning.

• When replacing parts, be sure to confirm that the rating of a new part is correct.

Not doing so may result in malfunction or burning.

5Application Precautions

x

Page 10

• Before touching a Unit, be sure to first touch a grounded metallic object in order

to discharge any static built-up. Not doing so may result in malfunction or damage.

5Application Precautions

xi

Page 11

System Configuration and Features

This section provides PID Control Unit features and the basic system configuration.

1-1 Features 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Basic System Configuration 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1

1

Page 12

Features Section 1-1

1-1 Features

The PID Control Unit scales inputs from connected sensors and then carries out

PID control according to preset parameters.

Advanced PID Control

Stable PID control is achieved using advanced PID control and an auto-tuning

feature. ON/OFF control can also be selected.

Two PID Control Loops with a Single Unit

Two PID control loops are possible with one Unit.

High-speed Sampling Period of 100 ms

A sampling period of 100 ms is achieved with two loops, enabling high-speed

PID control.

Input Noise Reduction with Digital Filter

Mitigation of sudden input fluctuations makes the PID Control Unit effective in

quick-response systems.

Comprehensive Output Specifications

Three types of output specification versions are available: C200H-PID01 for

transistor output, C200H-PID02 for voltage output, and C200H-PID03 for current output.

Eight Banks of Data Settings

Eight data values such as set point (SP) and alarm set values can be preset in

eight data banks for easy selection.

Data Input and Display

The C200H-DSC01 Data Setting Console (sold separately) is used to input data

and display present values (PV) and set values (SV). The easy-to-read display

can be panel-mounted.

User Programs Allows Reading and Writing of Data

Data can be set and retrieved by means of C200H user programs.

2

Page 13

Basic System Configuration

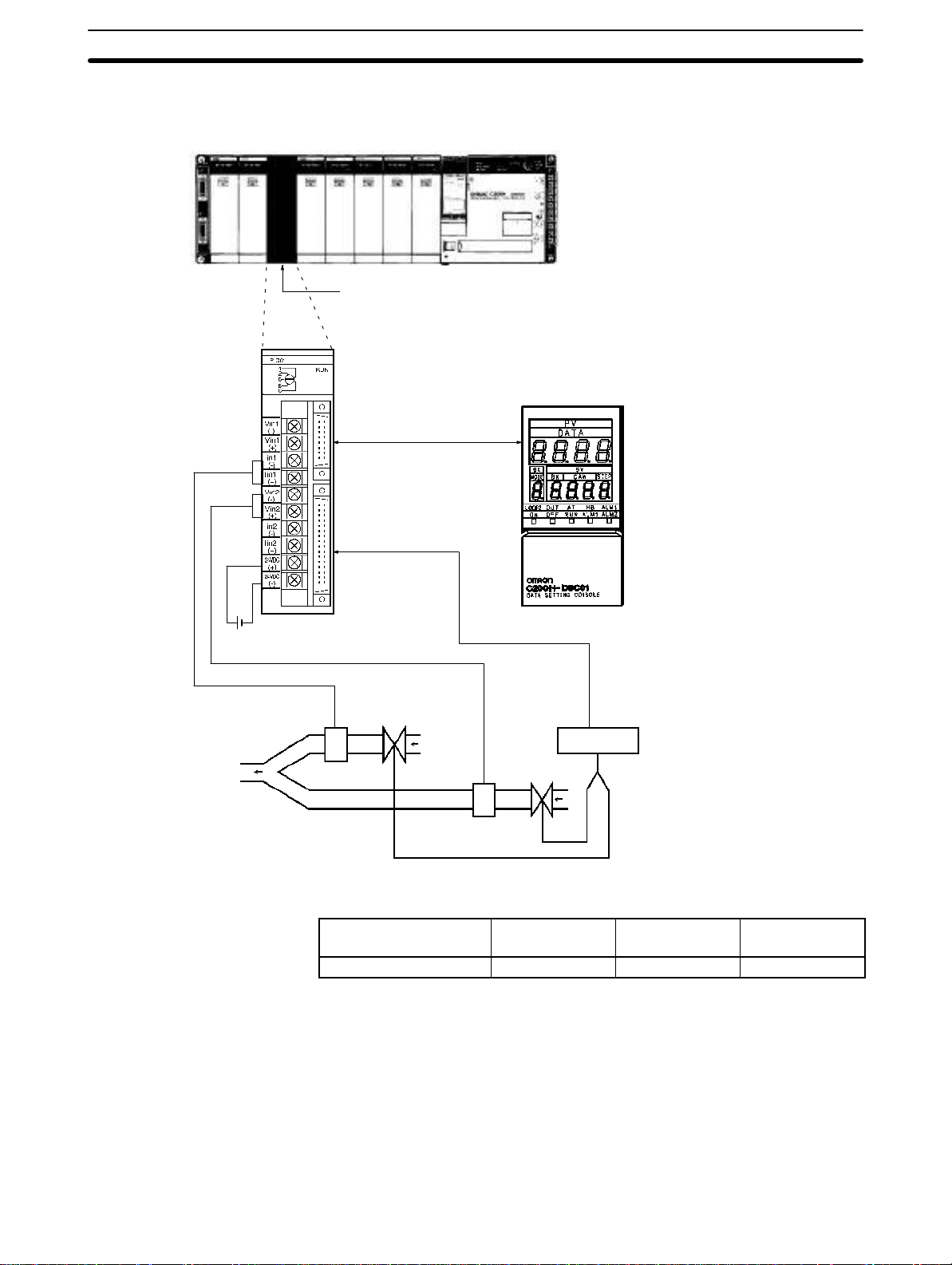

1-2 Basic System Configuration

SYSMAC C200H/C200HS PC

C200H-PID0j

PID Control Unit

Connecting cables:

C200H-CN225 (2 m)

C200H-CN425 (4 m)

Recommended cable:

ES1000-CA021-051 (0.5 m)

ES1000-CA021-102 (1 m)

ES1000-CA021-202 (2 m)

Section 1-2

Data Setting Console

C200H-DSC01

24 VDC

Remote I/O Terminal or

Connector Terminal

Block Converter Unit

(Refer to page 15)

Relay box

Gas

Mixture

Loop 1 Loop 2

Air

Flow sensor

Valve

Flow sensor Valve

PID Control Unit Models

Output type Transistor

output

Model C200H-PID01 C200H-PID02 C200H-PID03

Voltage output Current output

Number of Units The PID Control Unit belongs to the C200H Special I/O Unit group. A maximum

of ten Special I/O Units (including PC Link Units) can be mounted on the CPU

Rack, Expansion I/O Rack, and Slave Rack.

Note Configure the Units such that the maximum current supplied for each Rack is

greater than or equal to the total current consumption for the Units.

Refer to the

C200H PC Operation Manuals

for details on configuring systems.

Number of Units Mountable

on Slave Rack

The number of Special I/O Units used with a Slave Rack is limited by data transmission considerations, as shown in the table below. The numbers in the table

3

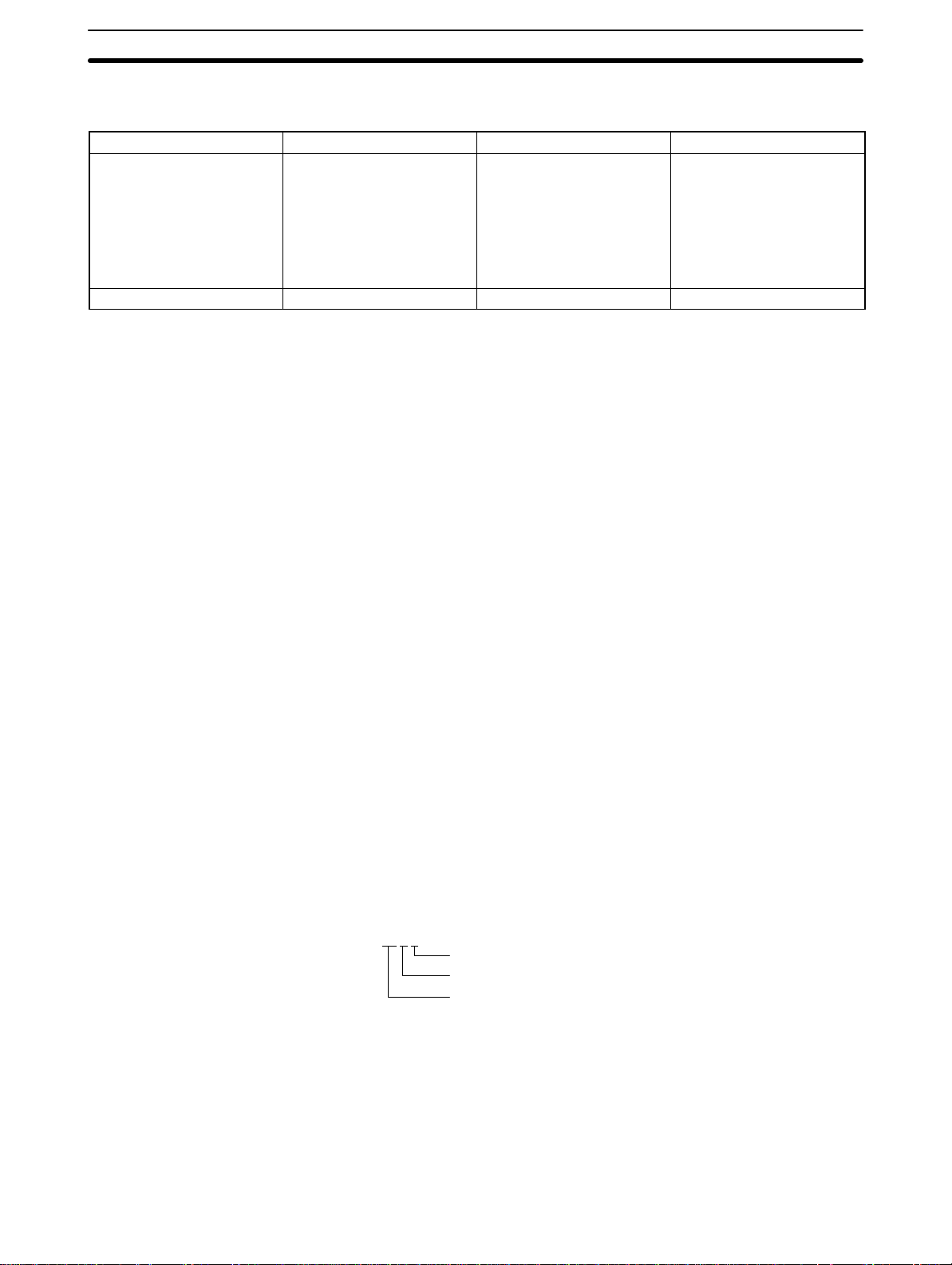

Page 14

Basic System Configuration

Section 1-2

indicate the maximum number of Units of groups A, B, C, or D which can be used

with a single Slave Rack.

A B C D

High-speed Counter Units

Position Control Units

(NC111/112)

ASCII Unit

Analog I/O Units

ID Sensor Units

Fuzzy Logic Unit

4 units max. 8 units max. 6 units max. 2 units max.

High-density and Mixed I/O

Units

Temperature Control Units

Heat/Cool Temperature

Control Units

PID Control Units

Cam Positioner Unit

Temperature Sensor Units

Voice Unit

Position Control Unit

(NC211)

Note 1. When a combination of Units from groups A, B, C, and D is used, the number

from each group must satisfy both the following equations:

3A + B + 2C + 6D ≤ 12

A + B + C + D ≤ 8

2. Other Units can be added until the total number of units reaches ten. If PC

Link Units are used, the number of Units including the PC Link Units must

not exceed ten.

Precautions The IR area of the C200H Special I/O Unit is allocated according to the setting of

not

the unit number switch on the front panel,

unit is mounted. Refer to

4-1 Memory Allocation

the address of the slot where the

for the allocation of the memory

area.

With the C200 H, leave the two slots next to the CPU free. It is not possible to use

devices connected to the CPU (such as the Programming Console) if these slots

are occupied.

If the C200H Slave Rack is connected to another SYSMAC model Remote I/O

Master Unit, such as the C120, C500, C1000H, or C2000H, it is not possible to

use a Special I/O Unit with the C200H Slave Rack.

WARNING Always turn the C200H power off before connecting or disconnecting a Unit,

Caution Connect thermocouples with the appropriate compensating conductor.

Additional Function

Description of Function

terminal block, or output connector.

Wire I/O leads in separate ducts from power leads to prevent noise problems.

The function described below has been added to products with the following lot

number and later ones.

07 Z 4 O

1994 (last digit of the year)

December (X: October, Y: November, Z: December)

07 (7th day of the month)

RAM Write Commands

• Previous commands allowed reading and writing to the EEPROM only. These

new commands allow writing to the RAM.

• When various settings require frequent rewriting, write to the RAM and, after

confirming the setting values, save the data by writing it to the EEPROM. The

data written to the RAM is deleted when the power is turned off.

4

Page 15

Basic System Configuration

Section 1-2

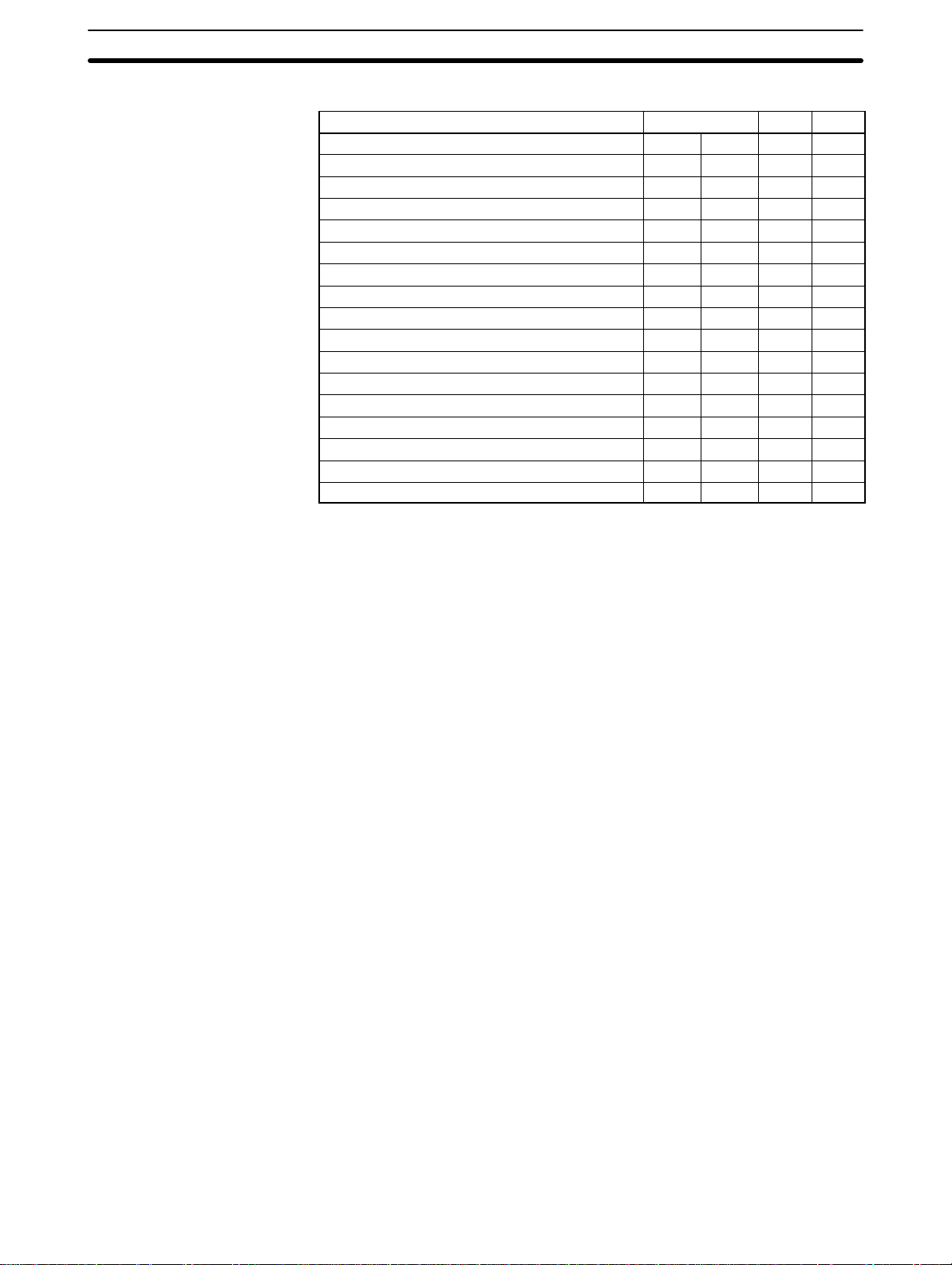

• List of RAM Write Commands

Parameter Command Write Read

Set point 4 0 Yes No

Execution bank number 4 2 Yes No

Alarm SV 1 4 3 Yes No

Alarm SV 2 4 4 Yes No

Input shift value 4 5 Yes No

Proportional band 4 6 Yes No

Integral (reset) time 4 7 Yes No

Derivative (rate) time 4 8 Yes No

Decimal point position 5 2 Yes No

Scaling lower limit 5 3 Yes No

Scaling upper limit 5 4 Yes No

Control period 5 7 Yes No

Hysteresis 5 8 Yes No

Alarm hysteresis 5 9 Yes No

Digital filter 5 E Yes No

Alarm 1 mode 6 4 Yes No

Alarm 2 mode 6 5 Yes No

5

Page 16

Connections and Settings

This section provides information on the connections and settings of the PID Control Unit.

2-1 Nomenclature 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Switch Settings 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 Wiring 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-1 Input Wiring 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-2 Output Wiring 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-3 Data Setting Console Cables 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

7

Page 17

Switch Settings

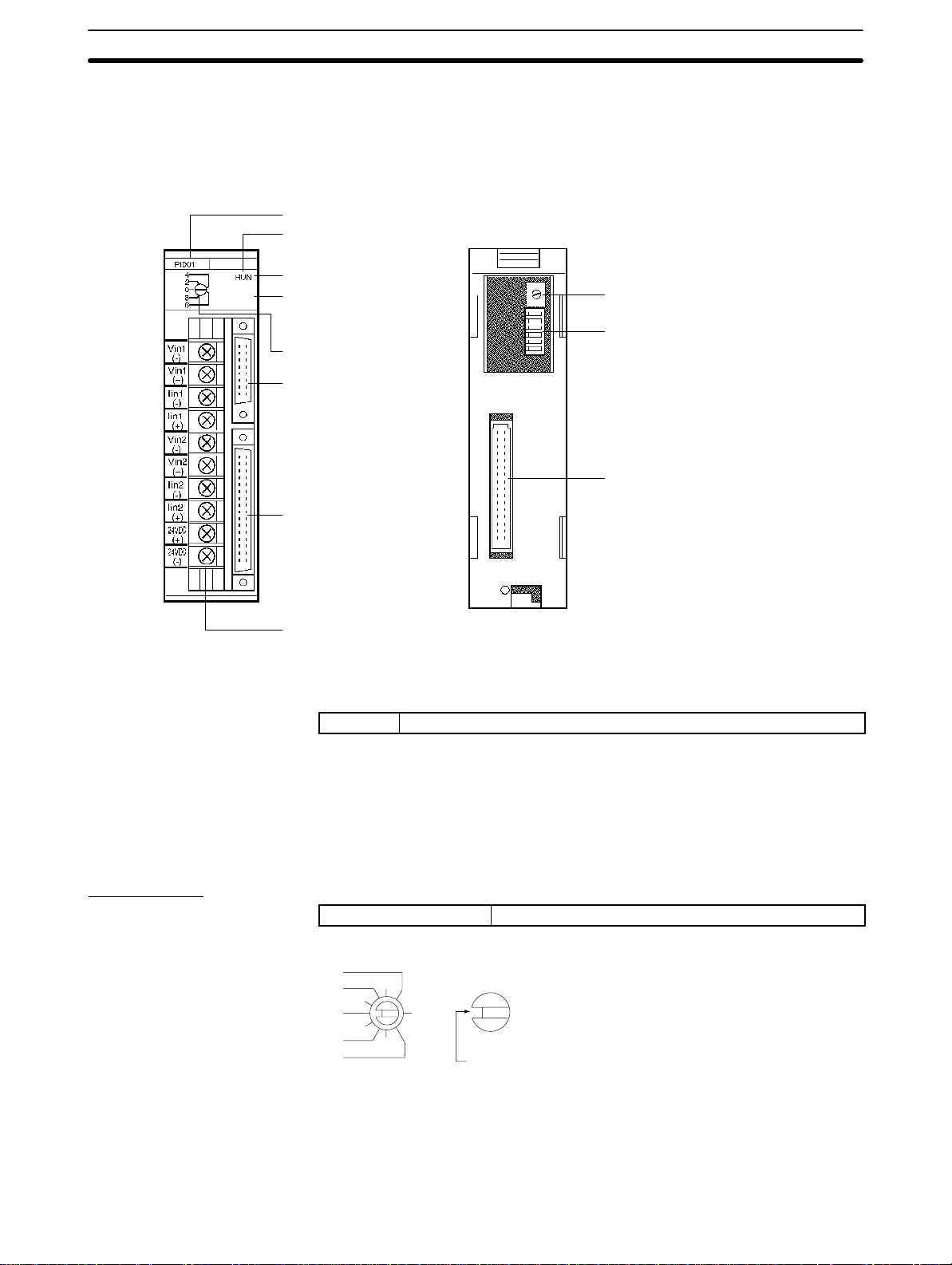

2-1 Nomenclature

C200H-PID0j

Section 2-2

Front Panel

Model label

Cover

RUN indicator

SW2

(Switching memory contents

and setting direction under

the cover)

SW1

(Unit number setting)

Data Setting Console

connector

Output connector

Input terminal block

Rear Panel

SW202

(Input type setting)

SW203

(Operation and function settings)

Rack connector

Indicators

RUN Lit when the PID Control Unit is operating normally.

2-2 Switch Settings

The function and setting of switches are identical for all models, except for

SW202.

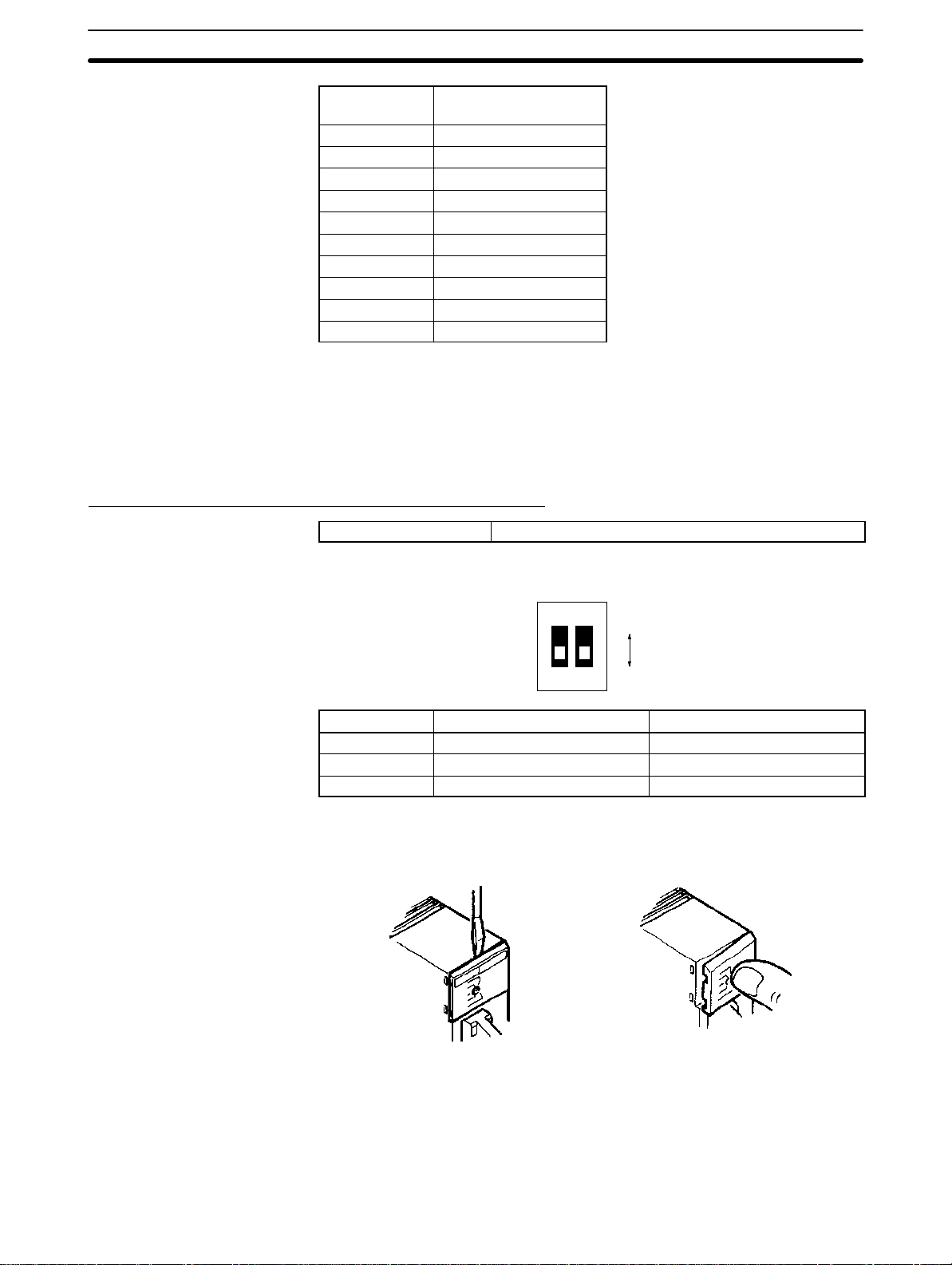

Unit Number

SW1 Unit number setting

4

2

0

8

6

The addresses are allocated as shown in the following table according to the

Unit number setting.

(3)

(1)

(9)

(5)

(7)

The cut-out indicates the selected position. Negative numbers

are not indicated. Turn the switch with a flat-blade screwdriver.

Turn the switch until it clicks in position. Do not leave the switch

between two settings.

8

Page 18

Switch Settings

Section 2-2

Unit no.

setting

0 Wd 100 to 109

1 Wd 1 10 to 119

2 Wd 120 to 129

3 Wd 130 to 139

4 Wd 140 to 149

5 Wd 150 to 159

6 Wd 160 to 169

7 Wd 170 to 179

8 Wd 180 to 189

9 Wd 190 to 199

Allocated address

The switch is factory-set to 0.

Note If the Unit number is set to an existing Unit number, an alarm occurs and the

C200H does not operate.

Turn the C200H power off before setting the Unit number. If the setting is

changed with the power on, the new setting is not valid until the power is turned

off and back on again.

Switching Memory Contents and Setting Direction

SW2 Switching memory contents and setting direction

Remove the cover and set the switch with the tip of a ballpoint pen or similar object.

Switch no. Pin 1 Pin 2

Function Switching memory contents Setting direction

ON Normal C200H PC

OFF Fixed Data Setting Console

The new setting is valid immediately after the switch setting is changed.

Removing and Attaching the Cover

1

2

ON

OFF

Removing the Cover Attaching the Cover

OFF

Insert a small flat-blade screwdriver between the case and

the cover at the top of the Unit

and lever off the cover.

Place the right edge of the

cover against the case and

press into position.

Switching Memory Contents The contents of the allocated memory differ according to the Unit number set-

ting.

9

Page 19

Switch Settings

Section 2-2

Normal Parameters can be designated as required using

Fixed Parameters are allocated in advance.

Refer to

4-1 Memory Allocation

commands (Refer to

for details of the memory contents.

4-1 Memory Allocation

).

Setting Direction Selects whether the data settings are made from the Data Setting Console or

from the C200H PC, using a user program or Programming Console.

Executed Bank Number

The setting of the executed bank number is made from the C200H PC, regardless of the ON/OFF setting of this switch.

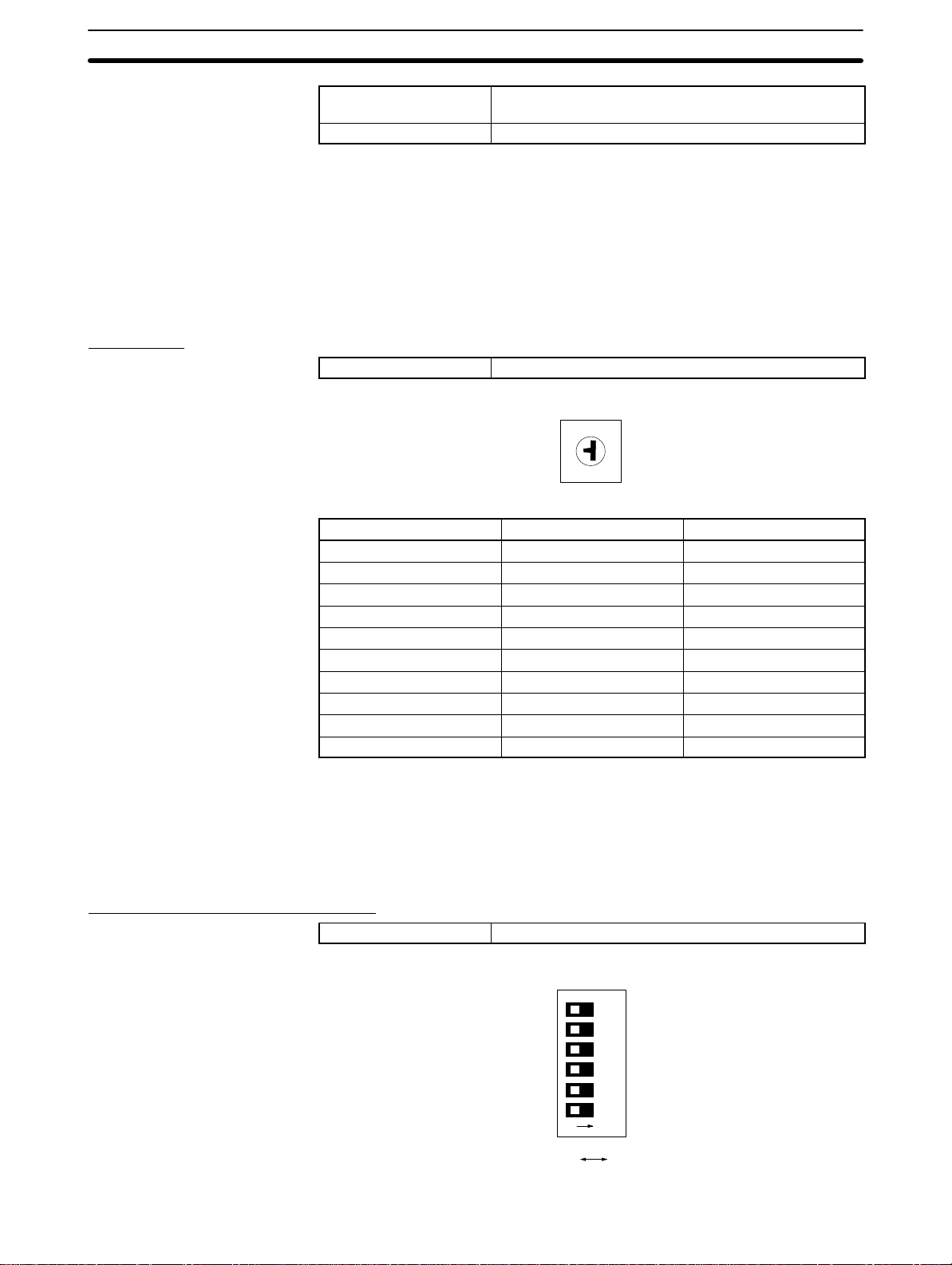

Input Type

SW202 Input type setting

3

2

4

1

0

5

9

6

7

8

Switch number Loop 1 Loop 2

0 4 to 20 mA 4 to 20 mA

1 1 to 5 V 1 to 5 V

2 0 to 5 V 0 to 5 V

3 0 to 10 V 0 to 10 V

4 4 to 20 mA 1 to 5 V

5 4 to 20 mA 0 to 5 V

6 4 to 20 mA 0 to 10 V

7 1 to 5 V 0 to 5 V

8 1 to 5 V 0 to 10 V

9 0 to 5 V 0 to 10 V

The switch is factory-set to 0.

The selected position is shown by the arrow. Turn the switch with a small flat-

blade screwdriver.

The permissible setting range for measurement is –999 to 9999 (EU).

Operation and Function Setting

SW203 Operation and Function Setting

10

134562

NO

OFF ON

Page 20

Switch Settings

Pin no. Function OFF ON

6 Loop 2

Input approximation

5 Loop 1

Input approximation

4 Loop 2 Enabled Disabled or not used

3 SP write mode EEPROM and RAM RAM

2 Control action Reverse Normal

1 Control method PID control ON/OFF control

Straight line Square root

Straight line Square root

Section 2-2

approximation

approximation

The switch is factory-set to OFF.

Input Approximation Set each loop to either straight line (no approximation) or square root approxi-

mation.

Loop 2 Set to “enabled” to use input loop 2, or to “disabled” to use only input loop 1. It is

not possible to use only input loop 2.

Note Always set this switch to the ON (disabled) position when input loop 2 is not

used. A sensor error occurs if this switch is set to the OFF (enabled) position

when no temperature sensor is connected to loop 2.

SP Write Mode This setting selects the SP storage memory. Set it to ON or use RAM Write com-

mands if the writing is to be frequently changed.

Display Units Selects whether setting and SVs displayed on the Data Setting Console are in

Celsius or Fahrenheit.

Control Action Reverse:

The output is increased when the measured temperature is below the SP (i.e., a

negative temperature difference).

Normal:

The output is increased when the measured temperature is above the SP (i.e., a

positive temperature difference).

Control Method Selects the method of control.

11

Page 21

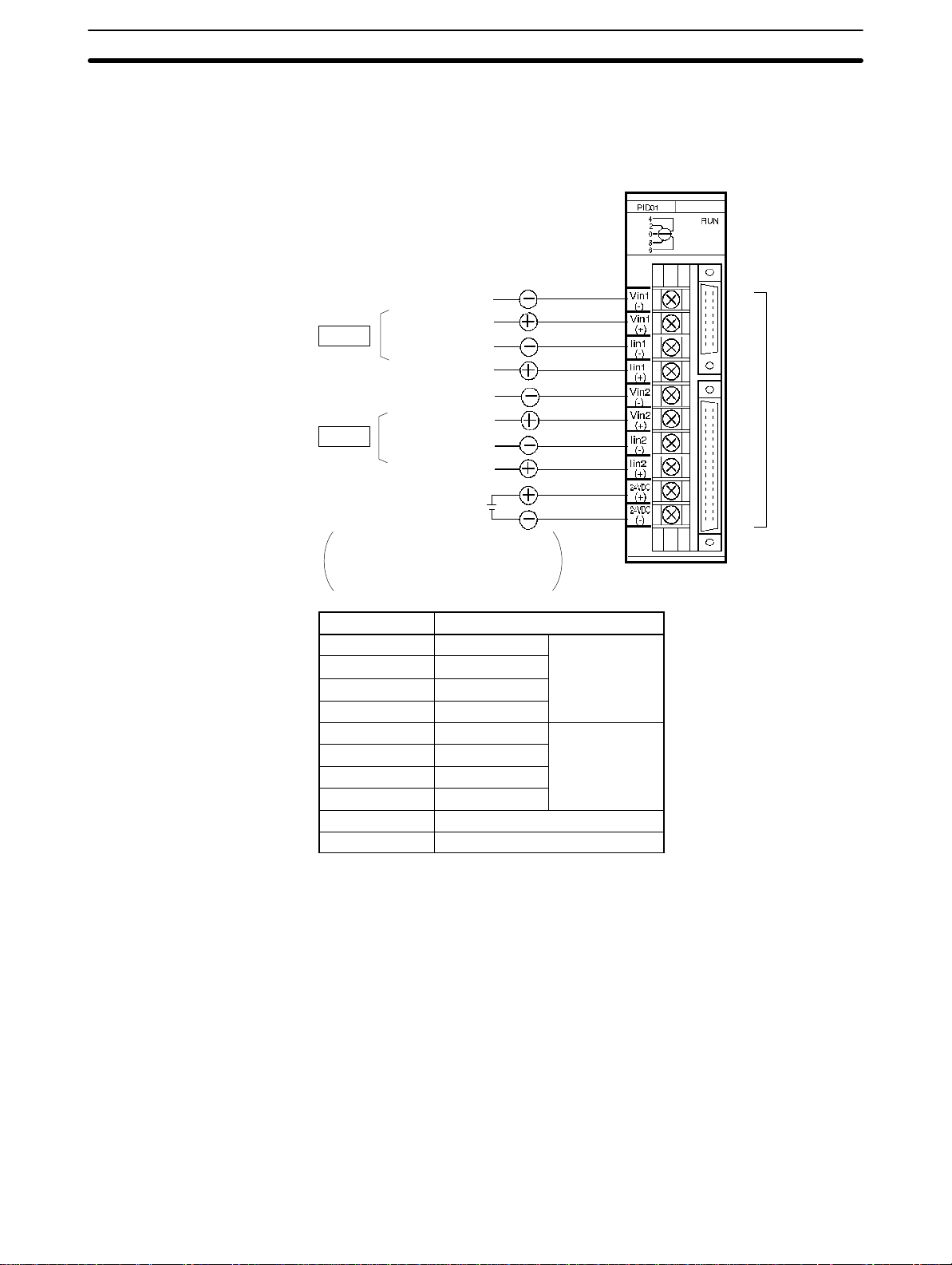

Wiring

2-3 Wiring

2-3-1 Input Wiring

C200H-PID0j

Section 2-3

Voltage input

Loop 1

Current input

Voltage input

Loop 2

Current input

24 VDC

0.2 A

The 24-VDC output from the C200H

CPU or the Power Supply Units is

convenient.

Terminal no. T erminal name

A0 Vin (–) Loop 1

A1 Vin (+)

A2 lin (–)

A3 lin (+)

A4 Vin (–) Loop 2

A5 Vin (+)

A6 lin (–)

A7 lin (+)

A8 24 VDC

A9 GND

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

Refer to the

table below.

Input Wiring Precautions

1, 2, 3...

12

1. The PID Control Unit will not operate correctly if the SW202 setting does not

match the type of inputs that are connected. In addition, each loop can be

connected to either voltage inputs or current inputs, but not to both. For example, if Loop 1 is set for voltage input, then current input will not work.

2. If no input lead is connected to Loop 2, turn SW203-4 on the rear of the Unit

ON to disable Loop 2. A sensor error occurs if this switch is set to the OFF

(enabled) position when no sensor is connected to Loop 2.

3. Be sure to wire the polarity correctly for each input.

4. Wire I/O leads in separate ducts from power leads to prevent noise problems.

5. A voltage of 24 VDC is used for the voltage output, current output and Data

Setting Console power supply.

6. The terminal block is removable. Make sure that it is attached correctly after

the input wiring connections are completed.

Page 22

Wiring

Section 2-3

Terminal Block

Connections

Use crimp terminals for wiring. T ake care not to overtighten the terminal screws.

Tighten the screws to a torque of 0.8 N S m.

Crimp Terminals

The screws on the terminal block are M3.5 self-rising terminal screws. Use the

following types of M3.5 crimp terminals.

7 mm max.

7 mm max.

Soldered Lead

Strip insulation from 7 to 10 mm at the end of the wire and carefully solder the

lead.

2-3-2 Output Wiring

Connection Diagrams

C200H-PID01 Transistor Output

7 to 10 mm

+

10

24 VDC 24 VDC

NC: Not connected

The pairs of terminals B2 to A2 and B1 to A1 are shorted internally. Always supply power to the 24-VDC terminal (B1) as this drives the internal circuits.

13

Page 23

Wiring

C200H-PID02/PID03 Voltage/Current Output

Circuit Diagrams

C200H-PID01 Transistor Output

Section 2-3

C200H-PID02 Voltage Output

C200H-PID03 Current Output

24 VDC

OUT

Internal circuits

COM

OUT (+)

OUT (–)

Internal circuits

14

Internal circuits

OUT (+)

OUT (–)

Page 24

Wiring

Section 2-3

Applicable Connectors The following connector set manufactured by Fujitsu is included with the Unit:

FCN-361J032-AU (soldering connector)

FCN-360C032-B (cover)

Connector Wiring

Precautions

Connection Precautions

After soldering the lead to each pin, insulate with heat-shrink tube to prevent

shorting with the adjacent terminal.

Tighten the screws after inserting the connector into the Unit. Push the connector firmly into the Remote I/O Terminal or Connector Terminal Block Converter

Unit until it fully locks.

Output Cable The output cables in the table below are recommended.

Model Cable length (L)

ES1000-CA021-051 50 cm

ES1000-CA021-102 1 m

ES1000-CA021-202 2 m

32-pin connector

(manufactured by Fujitsu)

FCN-361J032-AU

63

L

20-pin connector

(manufactured by OMRON)

XG4M-2030

30

Wiring Diagrams

Pin no. Wire no. Pin no. Wire no.

B16

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

28

46

32-pin connector 20-pin connector

Pin no. Wire no. Pin no. Wire no.

1

2

3

4

5

6

7

8

9

10

Note The pin numbers of the 20-pin con-

nector are marked for convenience.

Refer to them from the ∆ mark.

#1

#2

#3

#4

#5

#6

#7

#8

#9

#10

A16

A15

A14

A13

A12

A11

A10

A9

A8

A7

A6

A5

A4

A3

A2

A1

#11

#12

#13

#14

#15

#16

#17

#18

#19

#20

16.1

#1

#2

#3

#4

#5

#6

#7

#8

#9

#10

11

12

13

14

15

16

17

18

19

20

#11

#12

#13

#14

#15

#16

#17

#18

#19

#20

Note Pins A11 through A16 and B11

through B16 are not connected.

15

Page 25

Wiring

Section 2-3

Remote I/O Terminal The Remote I/O Terminal in the table below is recommended for transistor out-

put.

Model Specification Relays used

G7TC-OC08 Common (+) 8 x G7T-1112S (max. resistive load: 220 VAC, 2A)

Note One P7TF-OS08 I/O Terminal and two G7T-1112S Relays may be

purchased separately and used.

Wiring Diagram External View

24 VDC

Connector Terminal Block

Converter Unit

The Connector Terminal Block Converter Units in the table below are recommended for voltage output and current output type.

Model Terminal screw size

XW2B-20G4 M 2.4

XW2B-20G5 M 3.5

External View

2-3-3 Data Setting Console Cables

Connecting Cable Use the connecting cables in the table below (sold separately) to connect the

Unit to the Data Setting Console.

16

Model Cable length (L)

C200H-CN225 2 m

C200H-CN425 4 m

L

39

17.5

10

17.3

16.1

Page 26

Wiring

Connection Precautions

1, 2, 3...

Section 2-3

1. Tighten the lock screws after inserting the connector into the Unit.

2. Push the connector firmly into the Data Setting Console until the clips fully

lock.

3. The Data Setting Console uses power from input terminals A8 and A9 of the

PID Control Unit, supplied through the connecting cable.

4. Install the supplied connector cover when the Data Setting Console is not

used.

17

Page 27

SECTION 3

Data Setting Console Operation

This section provides the basic operating procedures of the Data Setting Console including parameter settings and displays.

3-1 Operating Procedure 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Data Flow 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Nomenclature and Features 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3-1 Nomenclature 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3-2 Features 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Parameter Displays and Settings 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-1 Table of Parameters 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-2 How to Display and Set Parameter Data 25 . . . . . . . . . . . . . . . . . . . . . . . .

19

Page 28

Operating Procedure Section 3-1

3-1 Operating Procedure

After preparing the C200H PC, follow the procedure below to use the PID Control Unit.

1, 2, 3...

1. Set the switches on the front and rear panels according to the operating conditions. (Refer to

Set SW2-2 under the display cover to the OFF position to enable data setting from the Data Setting Console.

2. Mount to Rack.

Turn off the C200H power supply before mounting or dismounting the

C200H on the Rack.

3. Connect the input wiring. (Refer to

The 24-VDC power supply must be connected. The Data Setting Console

will not operate unless the 24-VDC power supply is connected. The sensors

can be connected immediately before the system is tested.

4. Connect the Data Setting Console. (Refer to

Cables

5. Turn on the 24-VDC and the C200H power supplies.

Set the C200H to PROGRAM mode.

6. Use the Data Setting Console to make the settings for the parameters that

need to be changed. (Refer to the rest of this section.)

7. Test operation and adjust data. (Refer to the rest of this section.)

Connect the output wiring and turn on the heater power . To start the test op-

eration, turn ON the RUN bit of the loop that is to be controlled with a device

such as the Programming Console. Monitor the control conditions and adjust the data until the required control is achieved. During operation, the

“bank no.” is switched to “executed bank no.” and cannot be changed from

the Data Setting Console. To change it, use a device such as the Programming Console, or else use the user program.

8. Create the user programs. (Refer to

Programming.

Arrange the data for the test operation, and create the user programs for

data setting, monitoring, switching the bank number, and so on. Set SW2-2

under the display cover to the ON position to enable data setting from the

C200H PC.

9. Start operation.

.)

2-2 Switch Settings.

)

)

2-3 Wiring.

Section 4 PC Memory Allocation and

)

2-3-3 Data Setting Console

20

Page 29

Data Flow

3-2 Data Flow

Section 3-2

The data flow in the PID Control Unit is shown in the diagram below.

Read

PID Control Unit

Write executed bank no.

Write

Read

ON

SW2-2

OFF

C200H PC

Data Setting Console

The read operation and setting the executed bank number are possible from a

user program or from a device, such as the Programming Console, regardless of

the ON/OFF setting of SW2-2.

Data written from the Data Setting Console and data written with the EEPROM

write commands when SW2-1 (switching memory contents) is set to Normal are

written to the PID Control Unit EEPROM and are consequently retained when

the power supply is turned OFF.

Data written with RAM write commands when SW2-1 (switching memory contents) is set to Normal, the SP value set when SW2-1 is set to Fixed, and

executed bank number settings made from the C200H PC are written directly to

RAM and are not saved to EEPROM. This data is lost when the power supply is

turned OFF.

Data Settings from Data

Setting Console

Set SW2-2 under the display cover to the OFF position to enable data setting

from the Data Setting Console.

The “bank no.” can be set when operation is stopped (i.e., when the RUN bit is

OFF). During operation it is switched to “executed bank no.” and cannot be

changed from the Data Setting Console. To change the executed bank number,

use a user program or a device such as the Programming Console.

Operation begins when the RUN bit of the output relay turns ON. (For information on output relays, refer to

.

ming

Section 4 PC Memory Allocation and Program-

21

Page 30

Nomenclature and Features

3-3 Nomenclature and Features

3-3-1 Nomenclature

Section 3-3

Display Key

Front View

(With cover open)

Data display

Operation indicators

Display for Cam

Positioner

Cover

Down Key

Up Key

Operation keys

Select parameters

Set data

Switch Loops

Side View

Panel mounting bracket

(Refer to

panel mounting.)

Appendix B Dimensions

Rear View

for details about

Level Key Loop Key

PID Control Unit connector

Connecting cable (sold separately)

C200H-CN225 (2 m)

C200H-CN425 (4 m)

The bottom row of the operation keys have upper and lower labels. The upper

labels apply to PID Control Unit operation. The lower labels are for the Cam Positioner Unit.

Two display sheets are supplied: one for the PID Control Unit and one for the

Cam Positioner Unit. If the Data Setting Console is to be used with the PID Control Unit only, attach the display sheet for the PID Control Unit.

Note The Data Setting Console will not operate unless a 24-VDC power supply is con-

nected to the PID Control Unit input terminals.

22

Page 31

Nomenclature and Features

3-3-2 Features

Data Display

Note Operation begins when the RUN bit of the output relay turns ON.

Operation Indicators

Section 3-3

Name Function

PV (Process

Value)

SV (Set Value) The display is as follows, according to the PV display contents.

BK (Bank

Number)

Name Function

LOOP2 Indicates whether the displayed settings relate to Loop 1 or Loop

OUT (Output) Turns ON when the output is ON for

AT

(Auto-tuning)

HB (Heater

Burnout)

ALM1 (Alarm) Turns ON to indicate the temperature is in

Displays the PV or the parameter symbol selected with the Level

or Display Key (Refer to next page).

PV (process value): SV (set value) is displayed.

Parameter symbol: Setting/monitor data is displayed.

Displays the bank number of the data presently being displayed.

During operation, the executed bank number is displayed. (See

note)

2. Press the Loop Key and hold down for approximately 2

seconds to switch between Loop 1 and Loop 2.

Indicator OFF: Loop 1

Indicator ON: Loop 2

These indicators

transistor output or voltage output types.

Blinks at approximately 1 second intervals

during auto-tuning.

relate to the

currently displayed

loop.

Turns ON to indicate a heater burnout

alarm.

the alarm range set with Alarm SV 1

(upper- and lower-limit alarm). Refer to the

following page.

Display Patterns

Executed bank number or displayed

bank number

Display Pattern 1 Display Pattern 2

Process

value

Set point

Executed

bank number

or displayed

Indicator OFF: Loop 1

Indicator ON: Loop 2

bank number

Indicator OFF: Loop 1

Indicator ON: Loop 2

Parameter symbol

SV (Set value)

Monitored value

Execution status

23

Page 32

Parameter Displays and Settings

Operation Keys

Level Key The parameter items are divided into three display groups (Refer

Display Key Press this key to select the required parameter from the selected

Section 3-4

Name Function

to display levels 0 to 2 in the table below). Press this key to

switch from one group to another. The display levels

automatically cycle in the sequence 0 –> 1 –> 2 –> 0 when the

key is held down for approximately 2 seconds.

display level 0 to 2 (Refer to table below).

The parameters cycle automatically when the key is held down.

Loop Key Press this key for approximately two seconds to switch between

Up Key Press this key to increment SV.

Down Key Press this key to decrement an SV.

Loop 1 and Loop 2.

The SV increment continuously while the key is held down. The

SV display blinks when the value reaches its upper limit.

The SV decreases continuously while the key is held down. The

SV display blinks when the value reaches its lower limit.

3-4 Parameter Displays and Settings

3-4-1 Table of Parameters

Display

level

0

Parameter Display

PV monitor

(see note 3)

Manual output

volume

(see note 6)

Set point (see

note 3)

Bank number

Alarm SV 1 (see

notes 3, 4)

Alarm SV 2 (see

notes 3, 4)

Input shift value

(see note 3)

Proportional band

(see note 1)

Integral (reset)

time (see note 1)

Derivative (rate)

time (see note 1)

symbol

---

---

bk

al–1

al–2

in–5

Write Read Loop

no.

No Yes Yes No Scaling lower

Yes Yes Yes No -5 to 105% 0% 26

o

Yes Yes Yes Yes Scaling lower

See

note 5

Yes Yes Yes Yes

Yes Yes Yes Yes

Yes Yes Yes Yes –999 to 9999 0 EU 27

Yes Yes Yes Yes 0.0 to 999.9% FS 10.0% FS

p

Yes Yes Yes Yes 0 to 9999 s 240 s

i

Yes Yes Yes Yes 0 to 9999 s 40 s

d

Yes Yes No 1 to 8 1 26

Bank

no.

Data range Default value Page

(Unit: EU) 26

limit –10% to

scaling upper

limit +10%

0 EU 26

limit to scaling

upper limit

Alarm mode

1, 4, 5:

0 to 9999

Other:

–999 to 9999

0 EU 27

27

24

Page 33

Parameter Displays and Settings

Section 3-4

Display

level

1

2 Control output

Parameter

Decimal point

position

Scaling lower limit

Scaling upper limit

Digital filter

Control period

(see note 1)

Hysteresis (see

note 2)

Alarm hysteresis

(see note 4)

variable monitor

Auto-tuning start/

stop (see note 1)

Copy bank

Input-type monitor

Alarm 1 mode

Alarm 2 mode

symbol

dp

inl

inh

df

cp

hys

hysa

bcpy

in-t

alt1

alt2

ReadWriteDisplay

Yes Yes Yes No 0 to 3 1 28

Yes Yes Yes No -999 to (scaling

Yes Yes Yes No (Scaling lower

Yes Yes Yes No 0 to 100 s 0 s 28

Yes Yes Yes No 1 to 99 s 20 s 29

Yes Yes Yes Yes 0.0 to 100.0% FS 0.2% FS 29

Yes Yes Yes No 0.0 to 100.0% FS 0.1% FS 29

No Yes Yes No 0.0 to 100.0% 0.0% 30

o

Yes Yes Yes No --- --- 30

at

Yes Yes Yes No --- --- 30

No Yes No No 0 to 9 Setting for

Yes Yes Yes No 0 to 9 2 31

Loop

no.

no.

0 28

upper limit – 1

digit)

1000 28

limit + 1) to 9999

SW202

PageDefault valueData rangeBank

31

Yes: Possible.

No: Not possible or not required.

Note 1. Only when advanced PID control is selected. (Switch 203-1 = OFF)

2. Only when ON/OFF control is selected. (Switch 203-1 = ON)

3. The decimal point position is set by the “decimal point position” parameter.

4. Does not apply when Alarm Mode = 0.

5. Writing is not possible during operation (i.e., when RUN is ON).

6. Only when the output relay “MAN” bit = 1.

3-4-2 How to Display and Set Parameter Data

Basic Operation

When not specifically explained, use the keys as described below.

Changing the Display Level

When the Level Key is pressed, the leading parameter for each level is displayed.

Changing Parameters

When the Display Key is pressed, the parameters are displayed in order. There

may be skips depending on the model and DIP switch settings.

Changing the SV

Pressing the Up Key or the Down Key changes the SV. The SV is retrieved automatically.

Changing the Loop

The loop is changed each time the Loop Key is pressed. It can be confirmed by

means of the LOOP 2 indicator.

25

Page 34

Parameter Displays and Settings

Manual Output Volume (Display Level 0)

Section 3-4

PV and SV (Display Level 0)

PV

SV

Process value (monitored every 100 ms)

Manual output volume of currently selected loop (Unit: %)

Parameter signal of manual output volume

Settings

• This is used to manually manipulate the output volume. It is valid when the output relay “MAN” bit is ON.

• The “MAN” bit can be turned ON and OFF by means of a device such as the

Programming Console, or by means of the user program. For details, refer to

Section 4 PC Memory Allocation and Programming

PV

SV

Process value (monitored every 100 ms)

Set point of currently selected bank and loop (unit:EU)

.

Bank Number (Display Level 0)

PV

SV

Valid SV Range

Set the set point in the range between the scaling lower limit and the scaling upper limit.

Error Display

When a sensor error occurs, one of the codes below and the detected temperature blink alternately in the PV display.

ser1

ser2

Bank number parameter symbol

Currently set bank number.

During control operation: Executed bank number

Control operation interrupted: Currently displayed bank number

The analog input is out of the range: (input measurement range +

10%FS). That is, 10%FS below the lower limit or 10%FS above

pp

the upper limit. Includes broken or incorrect input wiring.

ser1 : Loop1 or Loop1 and Loop2 simultaneously.

ser2 : Loop2

p

Settings

• The bank number can be changed.

• The changed SV is reflected in the bank number display (BK).

Bank Number and Executed Bank Number

The executed bank number cannot be changed from the Data Setting Console.

When changing these parameters from the Data Setting Console, stop operation. While operation is stopped, the bank number setting can be changed.

26

Page 35

Parameter Displays and Settings

Alarm SV 1 (Display Level 0)

Section 3-4

Alarm SV 2 (Display Level 0)

Input Shift Value (Display Level 0)

If the displayed value differs from the actual value due to the sensor position or

some other conditions, set the input shift value such that the correct value is displayed.

PV

SV

Invalid if ALARM mode = 0.

PV

SV

Invalid if ALARM mode = 0.

PV

SV

Alarm 1 parameter symbol

Alarm SV of currently selected bank and loop (unit: EU)

Alarm 2 parameter symbol

Alarm SV of currently selected bank and loop (unit: EU)

Input shift value parameter symbol

Input shift value of currently selected bank and loop (unit:

EU)

Proportional Band (Display Level 0)

PV

SV

• This sets the proportional band. It is valid only when SW203-1 is set to OFF

(i.e., PID control).

• This value is reflected even when auto-tuning (AT) is executed.

• If this value is set to “0.0,” ON/OFF control is executed with PID control se-

lected.

Integral (Reset) Time (Display Level 0)

PV

SV

• This sets the integral time. It is valid only when SW203-1 is set to OFF (i.e., PID

control).

• This value is reflected even when auto-tuning (AT) is executed.

Derivative (Rate) Time (Display Level 0)

Proportional Band parameter symbol

Proportional band of currently selected bank and loop

(unit: %FS)

Integral time parameter symbol

Integral time of currently selected bank and loop

(unit: second)

PV

SV

Derivative time parameter symbol

Derivative time of currently selected bank and loop

(unit: second)

27

Page 36

Parameter Displays and Settings

• This sets the integral time. It is valid only when SW203-1 is set to OFF (i.e., PID

control).

• This value is reflected even when auto-tuning (AT) is executed.

Decimal Point Position (Display Level 1)

Section 3-4

PV

SV

The decimal point position setting applies to the following parameters:

PV monitor, SV, alarm SV, and input shift value.

Scaling Lower Limit (Display Level 1)

PV

SV

This sets the scaling lower limit. The default value is 0%.

Scaling Upper Limit (Display Level 1)

PV

SV

Decimal point position parameter symbol

Decimal point position of currently selected loop

Scaling lower limit parameter symbol

Scaling lower limit of currently selected loop

Scaling upper limit parameter symbol

Scaling upper limit of currently selected loop

Digital Filter (Display Level 1)

This sets the scaling upper limit. The default value is 1000%.

PV

SV

Digital filter parameter symbol

Time constant of currently selected loop (unit: seconds)

This delays the response to sudden input changes. The SV is designated by “T”

in the illustration below.

Input

After Passing Through the Filter of Set Value “T”

100%

63%

0

T0

(s)

→

28

Page 37

Parameter Displays and Settings

Control Period (Display Level 1)

Section 3-4

Hysteresis (Display Level 1)

PV

SV

Control period parameter symbol

Control period of currently selected loop

(Unit: seconds)

• This sets the control period. It is valid when SW203-1 is OFF (PID control).

• The control period is the time required to complete one transistor output or volt-

age output ON/OFF cycle.

ON

OFF

ON time

Control period

PV

SV

Hysteresis parameter symbol

Hysteresis of currently selected bank and loop

(Unit: %FS)

• Hysteresis prevents control output chattering and eliminates noise influences.

• When switching from ON to OFF, operation proceeds at the set point. When

switching from OFF to ON, operation proceeds at a lower point determined by

the hysteresis SV, as shown in the illustration below.

Hysteresis is applied in the following situations.

• When ON/OFF control is selected (i.e., when SW203-1 is ON).

• When advanced PID control is selected (i.e., when SW203-1 is OFF) and P

(proportional band) is 0.

Alarm Hysteresis (Display Level 1)

PV

SV

Hysteresis

ON

OFF

Set point

Alarm hysteresis parameter symbol

Alarm hysteresis of currently selected loop

(Unit: %FS)

• Alarm hysteresis prevents alarm output chattering and eliminates noise influences. It is invalid when both ALARM mode 1 and ALARM mode 2 are set to

“0.”

• When switching from OFF to ON, operation proceeds at the set point. When

switching from ON to OFF, a hysteresis SV operating band is provided which

29

Page 38

Parameter Displays and Settings

may be either higher or lower than the set point, depending on the ALARM

mode.

Section 3-4

Upper Limit Mode Lower Limit Mode

Hysteresis

OFF

Alarm SV Alarm SV

The alarm output is OFF if the present value lies within the hysteresis band when

the Unit is turned on.

Control Output Variable Monitor (Display Level 2)

PV

SV

The relationship between the control output variable and control period is defined by the formula below:

Control output variable (%) = x 100

The control output variable during ON/OFF control (when SW203-1 on the rear

panel is ON) is ON = 100% and OFF = 0%.

Auto-tuning Start/Stop (Display Level 2)

ON

Hysteresis

ON

OFF

Control output variable monitor parameter symbol

Control output variable of currently selected loop

(Unit: %) Monitored every 100 ms.

ON time

Control period

PV

SV

AT start/stop parameter symbol

Copy Bank (Display Level 2)

PV

SV

Copy bank parameter symbol

Process value

Set point

AT indicator blinks

• The auto-tuning operation begins when the Up Key is pressed. The PV and SV

return to the respective present value and set point displays. While auto-tuning

is in progress the AT indicator blinks.

• To interrupt, press the Level and Display Keys again to display at. When at

appears, press the Up Key. When the interrupt is executed, the A T display disappears and the process value is displayed.

• When auto-tuning is completed, the AT indicator stops blinking and the P, I, a nd

D data is written to EEPROM.

Execute bank copy

Bank being copied

Bank copy completed

• When the Up Key is pressed, the data other than the set point is copied from

bank number 1 to banks 2 through 8.

• Use this method to create data in banks 2 through 8 by slightly modifying the

data in bank number 1.

30

Page 39

Parameter Displays and Settings

Input-type Monitor (Display Level 2)

Section 3-4

PV

SV

Note Cannot be set.

Alarm 1 and Alarm 2 Modes (Display Level 2)

PV

SV

PV

SV

Select the desired alarm type from the following chart and set the number (X: set

value)

ALARM

mode

0No alarm

Input-type monitor parameter symbol

SW202 set value

Alarm 1 Mode parameter symbol

Alarm 1 Mode of currently selected loop

Alarm 2 Mode parameter symbol

Alarm 2 Mode of currently selected loop

Alarm Type Alarm Range

0SP

1 Upper- and lower-limit alarm

2 Upper-limit alarm

3 Lower-limit alarm

4 Upper- and lower-limit range alarm

5 Upper- and lower-limit alarm with

standby sequence

6 Upper-limit alarm with standby

sequence

7 Lower-limit alarm with standby

sequence

8 Absolute-value upper-limit alarm

9 Absolute-value lower-limit alarm

x x

x

x

x x

x x

x

x

x

x

Standby Sequence

When the power is turned on, the value is below the set point, so alarm output

status occurs with regard to the lower limit alarm. In this situation, if “lower limit

31

Page 40

Parameter Displays and Settings

alarm with standby sequence” is selected, the standby sequence recognizes

that the value is out of the alarm range and then outputs an alarm when the value

enters the alarm range once more.

Lower Limit Alarm with Standby Sequence

The standby sequence is restarted in the following situations.

• When the power is turned on.

• When the set point is changed.

• When the executed bank number is changed.

• When the ALARM mode is changed.

• When changing from stop to run.

Hysteresis

OFF point

Alarm SV

0°C

Alarm output

Standby sequence

cancel point

Section 3-4

32

Page 41

SECTION 4

PC Memory Allocation and Programming

This section provides the C200H PC’s memory allocation for the PID Control Unit. Basic programming procedures and

examples are also provided.

4-1 Memory Allocation 34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1-1 Memory Allocation Table 35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1-2 Memory Contents 36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1-3 Table of Commands 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Data Flow 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Programming 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3-1 Example with SW2-1 in the Fixed Position 42 . . . . . . . . . . . . . . . . . . . . .

4-3-2 Example 1: Write with SW2-1 in the Normal Position 43 . . . . . . . . . . . . .

4-3-3 Example 2: Read with SW2-1 in the Normal Position 46 . . . . . . . . . . . . .

4-3-4 Operation Timing 49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

33

Page 42

Memory Allocation Section 4-1

4-1 Memory Allocation

Memory Allocation According to the Unit number switch setting on the front of the C200H PID Con-

trol Unit, 10 words are allocated for each Unit number in the Special I/O Unit IR

area between IR100 to IR199, which is used as the I/O refresh data area. The IR

area used by the C200H PID Control Unit is refreshed on each C200H PC I/O

refresh scan.

C200H PC

IR area

Unit#0 IR100 to IR109

Unit#1 IR110 to IR119

Unit#2 IR120 to IR129

Unit#3 IR130 to IR139

Unit#4 IR140 to IR149

Unit#5

Unit#6 IR160 to IR169

Unit#7 IR170 to IR179

Unit#8 IR180 to IR189

Unit#9 IR190 to IR199

IR150 to IR159

OUT

IN

During PC I/O refresh, each

scan is executed for the outputs (PC to PID Control Unit)

followed by the inputs (PID

Control Unit to PC).

PID Control Unit

I/O refresh data area

Wd (n)

to

Wd (n+2)

Wd (n+3)

to

Wd (n+9)

(n=100 + 10 x Unit number)

The terms “output” and “input” are defined from the C200H PC side.

Output

refresh

Input

refresh

Note A Duplicate I/O Unit error occurs if the set Unit number corresponds to the num-

ber of an existing Special I/O Unit.

Selecting Allocated Data The data allocated to each IR word due to the Unit number setting is determined

by the setting of SW2-1 on the front of the Unit.

ON Normal All data can be set using commands.

OFF Fixed Parameters are fixed for the set point (SV).

This setting becomes valid immediately when the switch is set.

34

Page 43

number

number

re

Memory Allocation Section 4-1

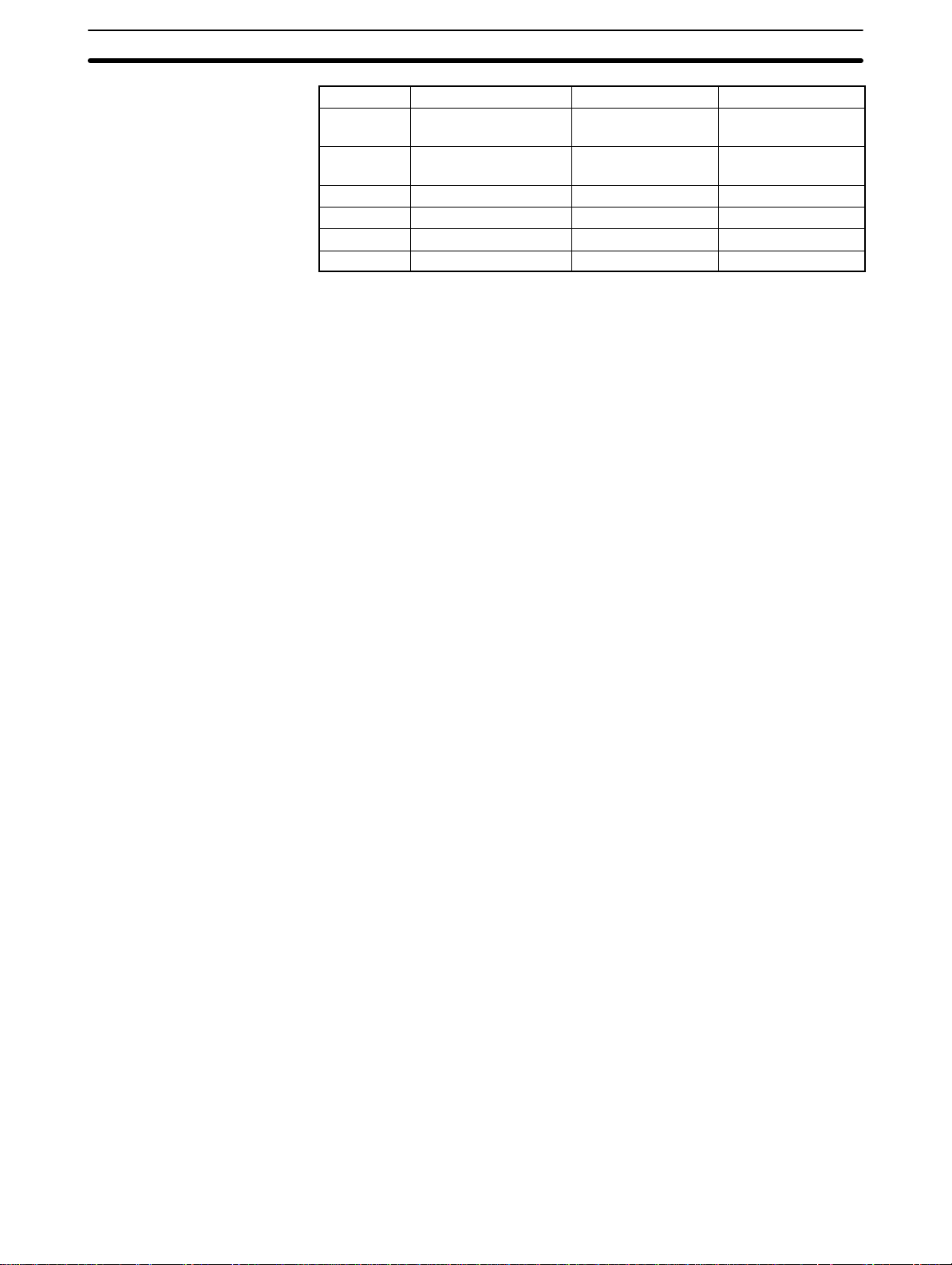

4-1-1 Memory Allocation Table

SW2-1 in Fixed Position

(n=100 + 10 x Unit number)

I/O Word

Output n

n+1

n+2 Loop 1 executed bank

Input n+3

n+4

n+5

n+6

n+7

n+8 Loop 1 status data

n+9 Loop 2 status data

Bit

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Loop 1 SP (see note)

0 to 9, F 0 to 9 0 to 9 0 to 9

Loop 2 SP (see note)

0 to 9, F 0 to 9 0 to 9 0 to 9

Loop 2 executed bank

number number

Loop 1 PV (see note)

0 to 9, F 0 to 9 0 to 9 0 to 9

Loop 2 PV (see note)

0 to 9, F 0 to 9 0 to 9 0 to 9

Loop 1 SP (see note)

0 to 9, F 0 to 9 0 to 9 0 to 9

Loop 2 SP (see note)

0 to 9, F 0 to 9 0 to 9 0 to 9

Loop 1 executed bank

number number

0 Sen-

0 Sen-

0 0 0 MAN

sor

error

0 0 0 MAN

sor

error

Loop 2 executed bank

Loop 1 Loop 2

MAN RUN MAN RUN

0 0 0

RUN

0 0 0 Con-

RUN

0 0 0 Con-

0

SW 2

2 1

AT 0 AL1 AL2

trol

output

AT 0 AL1 AL2

trol

output

SW2-1 in Normal Position

I/O Word

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Output

Input n+3

n Read/write instruction

Read/write Loop no. Bank no. Instruction

n+1

n+2 Loop 1 executed bank

Write data (see note)

0 to 9, F 0 to 9 0 to 9 0 to 9

Loop 1 PV (see note)

0 to 9, F 0 to 9 0 to 9 0 to 9

Note Four digits BCD and the decimal point position are designated by the “decimal

point position” parameter. The most significant digit (F) = minus (–).

(n=100 + 10 x Unit number)

Bit

Loop 2 executed bank

Loop 1 Loop 2

MAN RUN MAN RUN

0 0 Write

-

-

quest

35

Page 44

N

ified

Wd

aue

Memory Allocation Section 4-1

I/O BitWordI/O

Word

00010203040506070809101112131415

Input n+4

n+5

n+6 0 Write

n+7

n+8 Loop 1 status data

n+9 Loop 2 status data

Loop 2 PV (see note)

0 to 9, F 0 to 9 0 to 9 0 to 9

Read data (see note)

0 to 9, F 0 to 9 0 to 9 0 to 9

error

Loop 1 executed bank

number number

0 Sen-

0 Sen-

0 0 0 MAN

sor

error

0 0 0 MAN

sor

error

Loop 2 executed bank

0 0 Write

0 0 0 0 Read

complete

0 0 0

RUN

0 0 0 Con-

RUN

0 0 0 Con-

AT 0 AL1 AL2

trol

output

AT 0 AL1 AL2

trol

output

com-

plete

SW2

2 1

Note Four digits BCD and the decimal point position are designated by the “decimal

point position” parameter. The most significant digit (F) = minus (–).

4-1-2 Memory Contents

SW2-1 in Fixed Position

I/O Address Data item Data contents

Word Bit

Output n 15 to 00 Loop 1 SP

n+1 15 to 00 Loop 2 SP

n+2 15 to 12 Loop 1

executed

bank

number

11 to 08 Loop 2

executed

bank

number

07 Loop 1

MAN

06 Loop 1

RUN

05 Loop 2

MAN

04 Loop 2

RUN

03 to 00 --- Not used. Set to 0.

Sets the Loop 1 and Loop 2 SP (set point) as 4-digit BCD data.

Set the most significant digit to F for minus (–).

oteThese spec

(n+2) and can are written directly to RAM. (Refer to

gramming.

Sets the bank number executed for Loop 1 and Loop 2 as 1-digit

BCD data. Set executed bank numbers from 1 to 8. If the value is

set out of this range, the bank number reverts to the previous

value.

This is the Loop 1 Manual Output Mode bit. When it is set to 1,

the Unit goes into Manual Output Mode.

This is the Loop 1 Run/Stop bit. When it is set to 1, operation

starts; when it is set to 0, operation stops.

This is the Loop 2 Manual Output Mode bit. When it is set to 1,

the Unit goes into Manual Output Mode.

This is the Loop 2 Run/Stop bit. When it is set to 1, operation

starts; when it is set to 0, operation stops.

p

values apply to the bank number set with

)

(n=100 + 10 x Unit number)

pp

4-3 Pro-

36

Page 45

gg ()

()g

Memory Allocation Section 4-1

I/O Data contentsData itemAddress

BitWord

Input n+3 15 to 00 Loop 1 PV

n+4 15 to 00 Loop 2 PV

n+5 15 to 00 Loop 1 SP

n+6 15 to 00 Loop 2 SP

n+7 15 to 12 Loop 1

executed

bank

number

11 to 08 Loop 2

executed

bank

number

07 to 02 --- Not used. Each bit is set to 0.

01 SW2-2 Outputs the ON/OFF status of SW2-2 (setting direction).

00 SW2-1 Outputs the ON/OFF status of SW2-1 (switching memory

n+8 Loop 1

n+9 Loop 2

15 --- Not used. Set to 0.

14 Sensor

error

13 to 10 --- Not used. Each bit is set to 0.

09 MAN ON (set to 1) for Manual Output Mode.

08 RUN ON (set to 1) during operation.

07 to 05 --- Not used. Each bit is set to 0.

04 Control

output

03 AT Bit set to 1 during auto-tuning (AT).

02 --- Not used. Set to 0.

01 AL1

00 AL2

Outputs the Loop 1 and Loop 2 PV (process value) as 4-digit

BCD data. The most significant digit is F for minus (–).

Outputs the Loop 1 and Loop 2 SP (set point) as 4-digit BCD

data. The most significant digit is F for minus (–).

Outputs the bank number currently executed for Loop 1 and Loop

2 as 1-digit BCD data.

0: Data Setting Console

1: C200H PC

contents).

0: Fixed

1: Normal

Loop 1/2

status data

Bit set to 1 if the sensor is not connected, a sensor

wire is broken, or the input data exceeds the

operational temperature range.

Bit set to 1 when the control output (transistor or

voltage output) is ON.

Bit set to 1 when the value enters the set alarm

range. (Refer to page 23.)

SW2-1 in Normal Position

(n=100 + 10 x Unit number)

I/O Address Data item Data contents

Word Bit

Output n 15 and 14 Read/Write The data bit sets operation to read or write.

Write = 01 Read = 00

13 and 12 Loop no. The data bit sets the Loop Number to which the

read or write operation applies.

Loop 1 = 01, Loop 2 = 10

11 to 08 Bank no. Sets the bank number to which the read or write

operation applies as 1-digit BCD data. Set executed

bank numbers from 1 to 8.

07 to 00 Command Sets the command code (Refer to page 40) for the

read or write operation as 2-digit BCD data.

Read/Write

command

37

Page 46

e ous a ue

BCD data. The decimal oint osition is designated by the

Memory Allocation Section 4-1

I/O Data contentsData itemAddress

BitWord

Output n+1 15 to 00 Write data Set the SP for a write operation as 4-digit BCD data. The least

significant digit of the actual data matches the least significant

digit of the set value. Set the most significant digit to F for minus

(–) values. The write operation commences when the write

request flag (Wd (n+2), bit 00 ) turns ON.

n+2 15 to 12 Loop 1

executed

bank

number

11 to 08 Loop 2

executed

bank

number

07 Loop 1

MAN

06 Loop 1

RUN

05 Loop 2

MAN

04 Loop 2

RUN

03 to 01 --- Not used. Set to 0.

00 Write

request

Input n+3 15 to 00 Loop 1 PV

n+4 15 to 00 Loop 2 PV

n+5 15 to 00 Read data Outputs the data read with the commands set with Wd (n). The

n+6 15 to 12 --- Not used. Each bit is set to 0.

11 Write error Bit set to 1 when the write data exceeds the set permissible

10 and 09 --- Not used. Each bit is set to 0.

08 Write

complete

07 to 01 --- Not used. Each bit is set to 0.

00 Read

complete

Set the bank number currently executed for Loop 1 and Loop 2 as

1-digit BCD data. Executed bank numbers are from 1 to 8. If the

value is set out of this range, the bank number reverts to the

previous value.

This is the Loop 1 Manual Output Mode bit. When it is set to 1,

the Unit goes into Manual Output Mode.

This the Loop 1 Run/Stop bit. When it is set to 1, operation starts;

when it is set to 0, operation stops.

This is the Loop 2 Manual Output Mode bit. When it is set to 1,

the Unit goes into Manual Output Mode.

This the Loop 2 Run/Stop bit. When it is set to 1, operation starts;

when it is set to 0, operation stops.

Turn this bit ON to write the data in Wd (n+1), by means of this

command.

Turn this bit OFF after the Write Complete Flag (Wd (n+6), bit 08)

turns ON.

Outputs the Loop 1 and Loop 2 PV (process value) as 4-digit

BCD data. The decimal point position is designated by the

“decimal point position” parameter. Set the most significant digit

to F for minus (–) values.

decimal point position is designated by the “decimal point position

” parameter. Set the most significant digit to F for minus (–)

values.

range. The bit is automatically set to 0 when the Write Request

Flag (Wd (n+2), bit 00) turns OFF.

Bit set to 1 when the write operation executed by means of the

command set with Wd (n) ends normally. The bit is automatically

set to 0 when the Write Request Flag (Wd (n+2), bit 00) turns

OFF.

Bit set to 1 when the read operation executed by means of the

command set with Wd (n) ends normally. The bit is automatically

set to 0 when the next command is set.

38

Page 47

Memory Allocation Section 4-1

I/O Data contentsData itemAddress

BitWord

Input n+7

n+8 Loop 1

n+9 Loop 2

15 to 12 Loop 1

executed

bank

number

11 to 08 Loop 2

executed

bank

number

07 to 02 --- Not used. Each bit is set to 0.

01 SW2-2 Outputs the ON/OFF status of SW2-2 (setting direction).